PVDF piezoelectric film impact monitoring sensor

A piezoelectric film and impact monitoring technology, applied in the field of sensors, can solve the problems of not being able to directly measure the impact load stress value of the impact point, and not being able to stick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

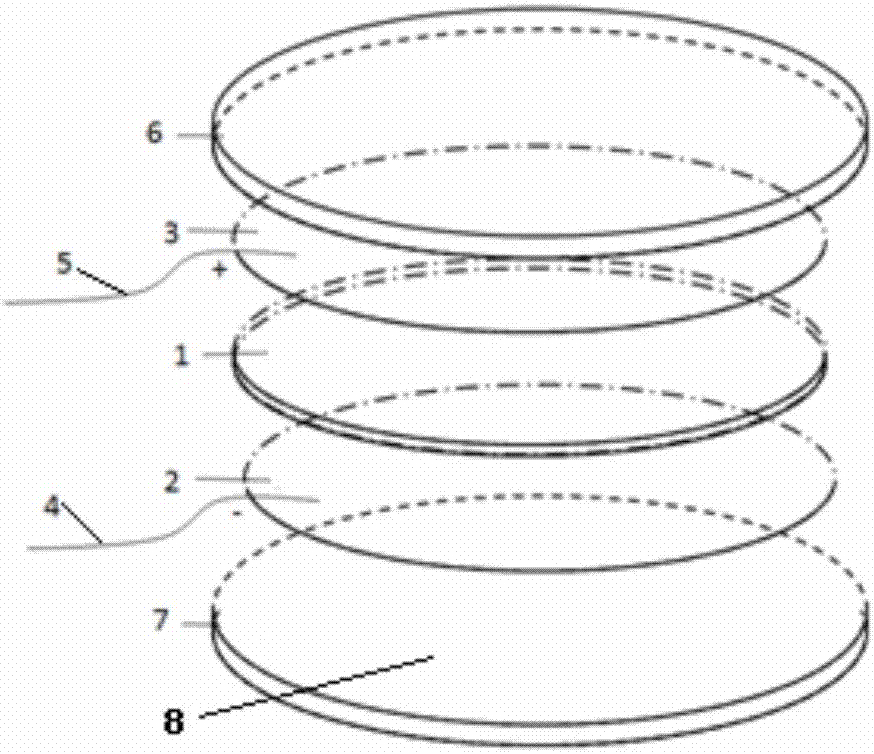

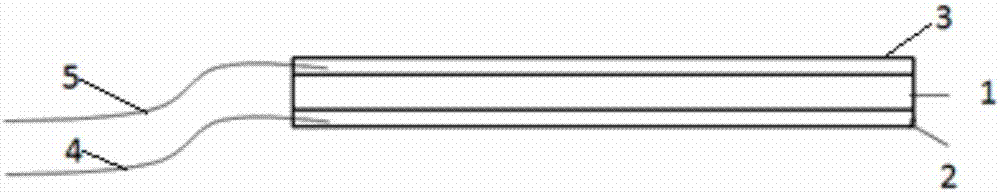

[0018] Such as Figure 1-Figure 2 A PVDF piezoelectric film impact monitoring sensor is shown, including a PVDF piezoelectric film 1, a positive electrode layer 2, a negative electrode layer 3, an upper protective layer 6 and a lower protective layer 7;

[0019] The upper and lower surfaces of the PVDF piezoelectric film 1 cover the positive electrode layer 2 and the negative electrode layer 3 respectively;

[0020] The positive electrode wire 4 and the negative electrode wire 5 are connected to the positive electrode layer 2 and the negative electrode layer 3 by double-sided pressure welding;

[0021] The positive electrode layer 2 and the negative electrode layer 3 are covered with an insulating layer;

[0022] The surface of the lower protective layer 7 is provided with a groove 8, and the PVDF piezoelectric film 1 covered with the positive electrode layer 2, the negative electrode layer 3 and the insulating layer is placed in the groove 8 of the lower protective layer 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com