Automatic ultrasonic impact device for straight welding line in pipeline

A technology of ultrasonic impact and straight welding seam, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult removal of welding slag on the inner wall of the pipeline, defect stress of weld toe, and difficulty in eliminating, so as to improve the post-weld The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

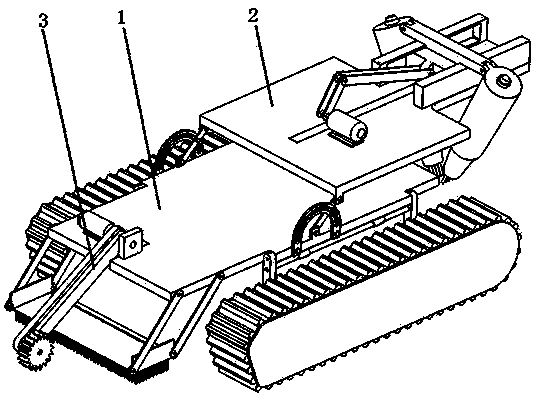

[0019] Such as figure 1 As shown, the automatic ultrasonic impact device for straight welds in pipelines includes a traveling mechanism 1, a stress relief mechanism 2 and a slag cleaning mechanism 3; the traveling mechanism 1 is the main body of the automatic ultrasonic impact device for straight welds in pipelines, and the traveling mechanism 1 serves as a load-bearing structure At the same time, it can crawl inside the pipeline; the stress relief mechanism 2 is set at the rear of the running mechanism 1, which can perform ultrasonic stress relief treatment on the straight welds inside the pipeline; the slag cleaning mechanism 3 is set at the front of the running mechanism Weld slag from straight welds inside pipes.

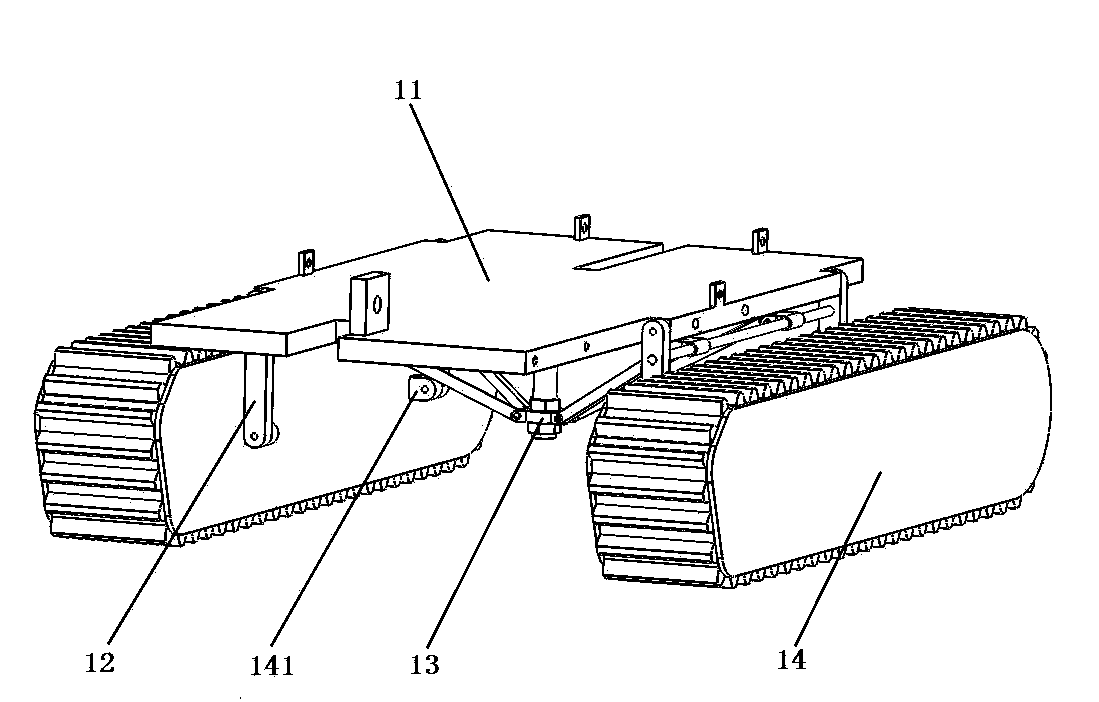

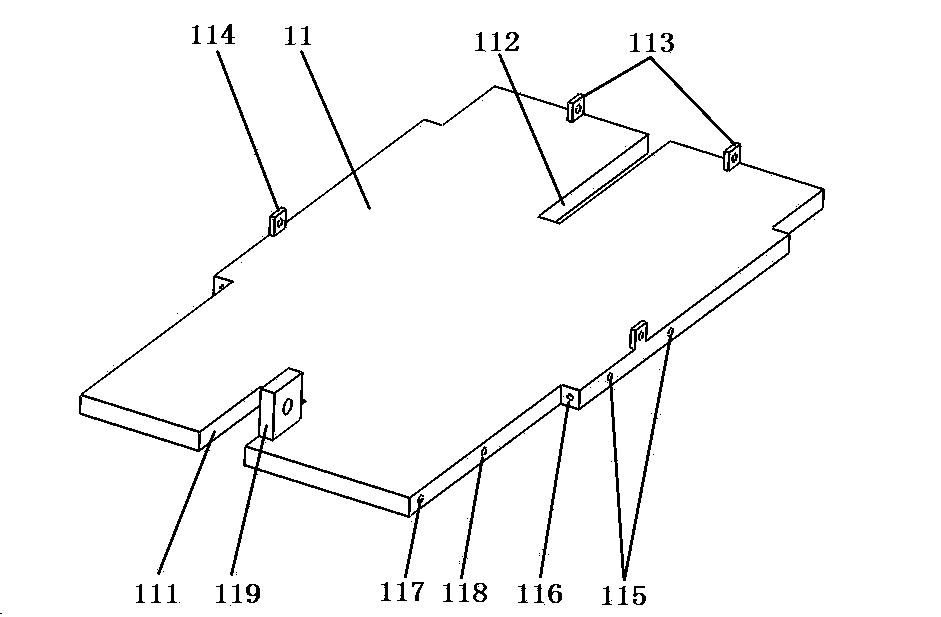

[0020] Such as figure 2 , image 3 As shown, the running mechanism 1 includes: a chassis 11, a swing leg 12, an angle adjustment mechanism 13 and a crawler foot 14; the crawler foot 14 is connected to the chassis 11 through the swing leg 12; the angle adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com