Reel base assembly

a technology of spool and base plate, which is applied in the field of reels, can solve the problems of vibration and impact force originating from the support surface and/or the spool traveling through the base plate,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

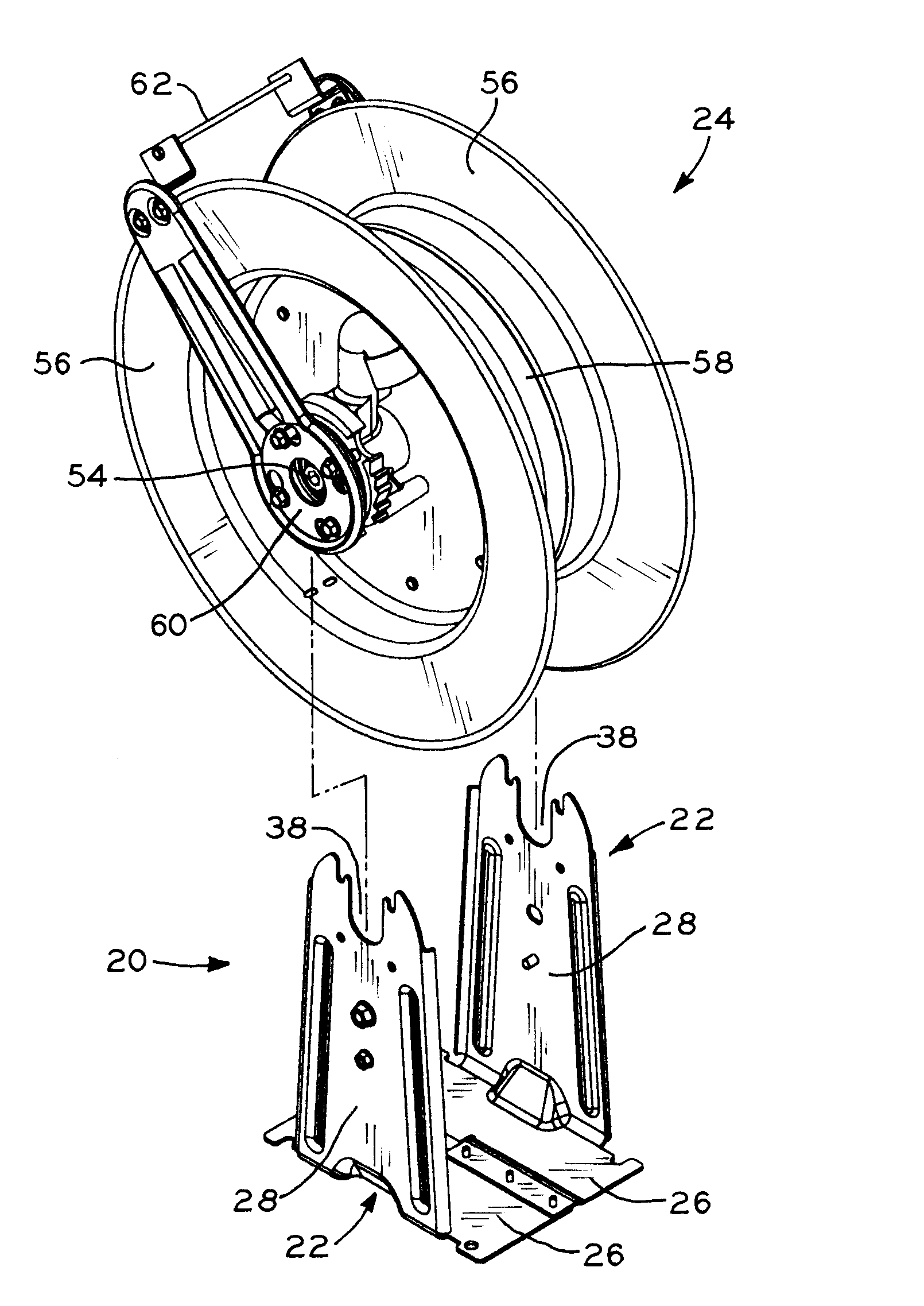

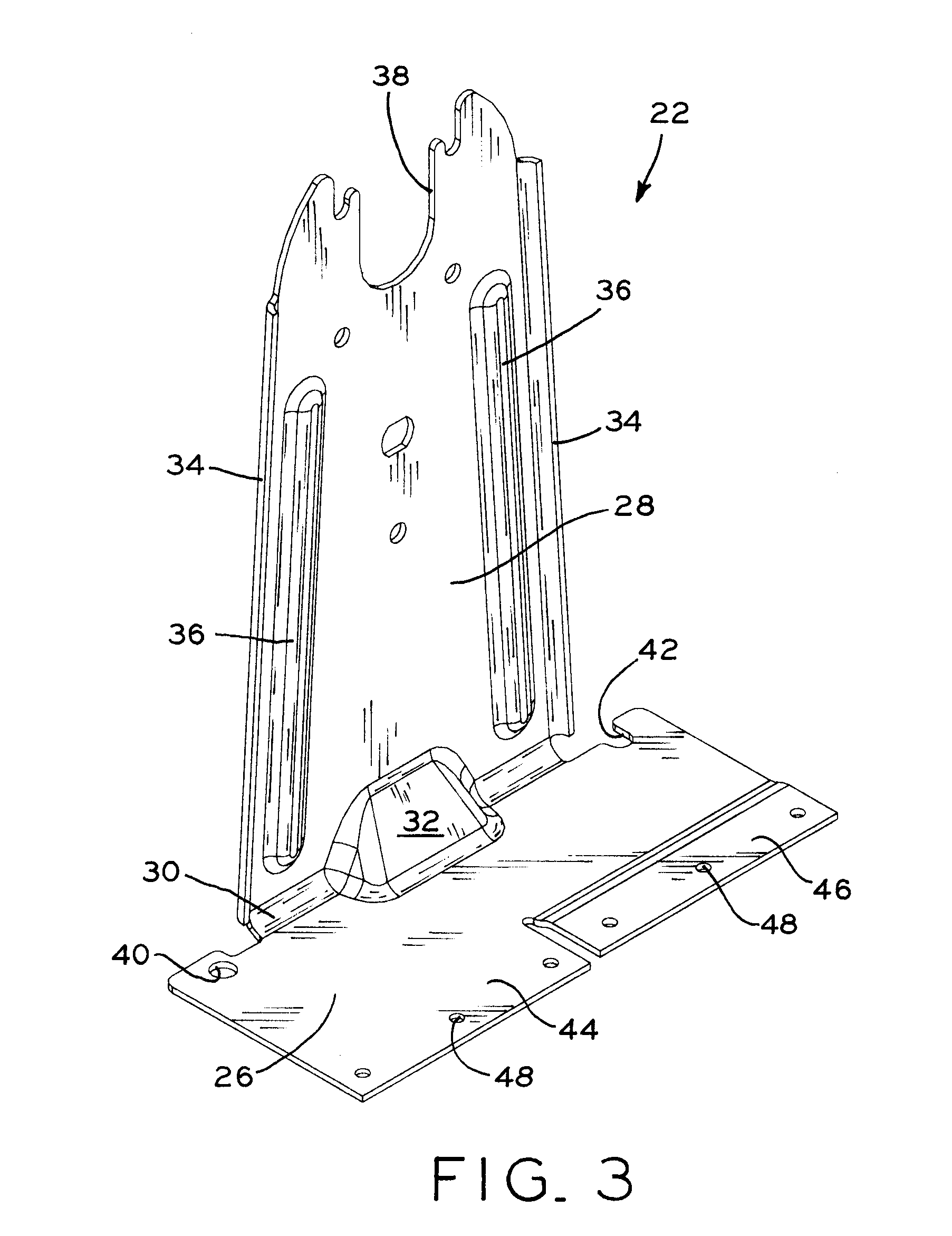

[0029] Referring to FIG. 3, one of the two base components 22 of base assembly 20 (FIG. 4) of a reel in accordance with the present invention is shown. As described below and shown in FIGS. 4-7, two identical base components 22 are connected to one another to form base assembly 20, which supports spool assembly 24 (FIGS. 6 and 7) to store and to facilitate the use of a hose, cord, rope, cable, or other flexible elongate item. Although base components 22 are described herein as identical, base components 22 need not be identical, wherein one or both of the base components 22 may include one or more structural features which are different from the other.

[0030] Each base component 22 may be formed monolithically from a single piece of metal, such as steel or aluminum, by stamping, punching, and / or bending operations, and generally includes base portion 26 and upright portion 28 oriented approximately 90° with respect to one another. Base portion 26 and upright portion 28 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com