Bag for flowable materials

a flowable material and bag technology, applied in the direction of flexible container closure, closure using stoppers, liquid handling, etc., can solve the problems of inability to fully engage, the top of the bag is often not properly refolded, and the integrity of the closure seal is compromised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

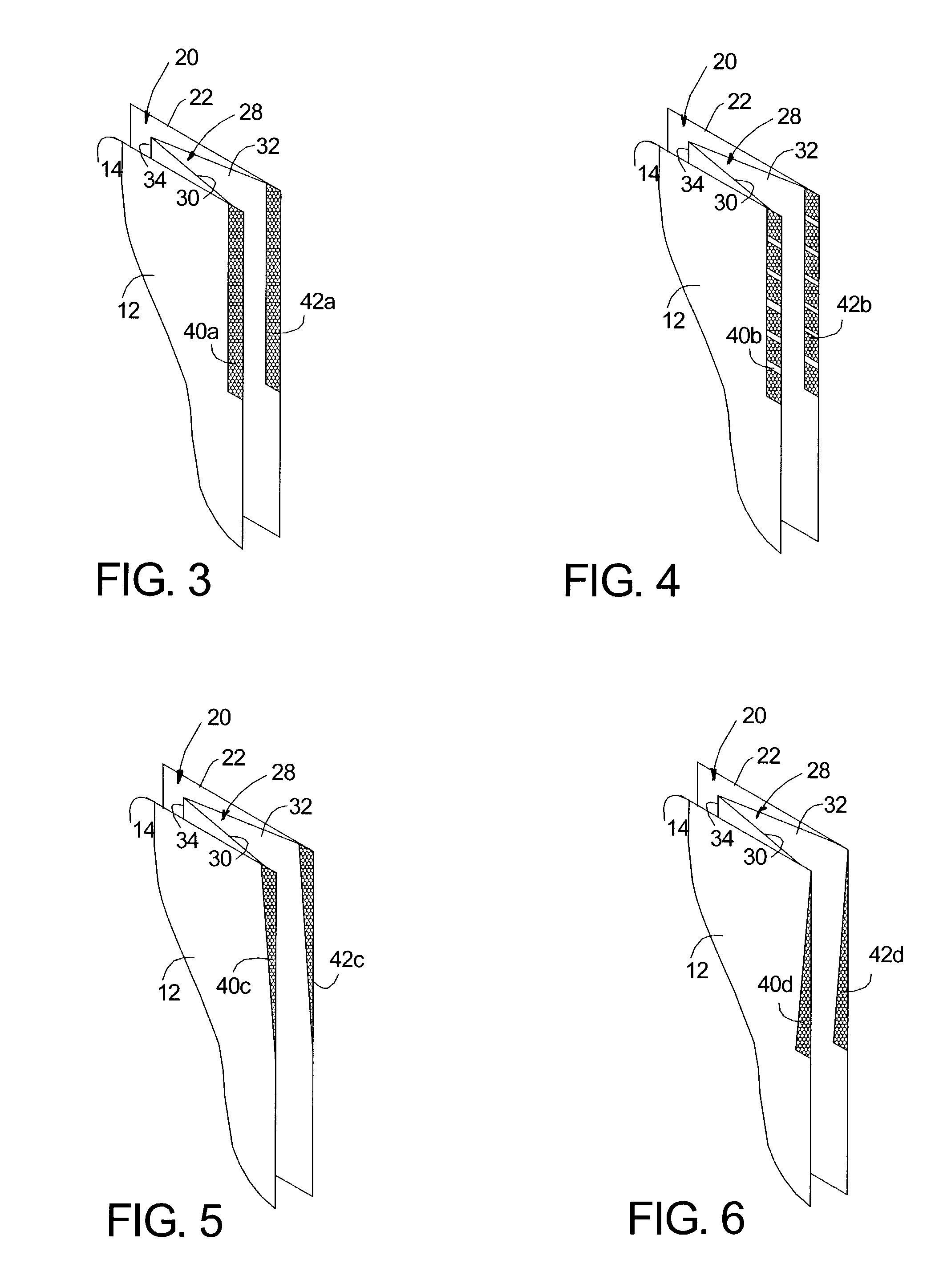

[0017] Reference will now be made in detail to the present embodiments of the invention, examples of which is illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to designate the same or like parts.

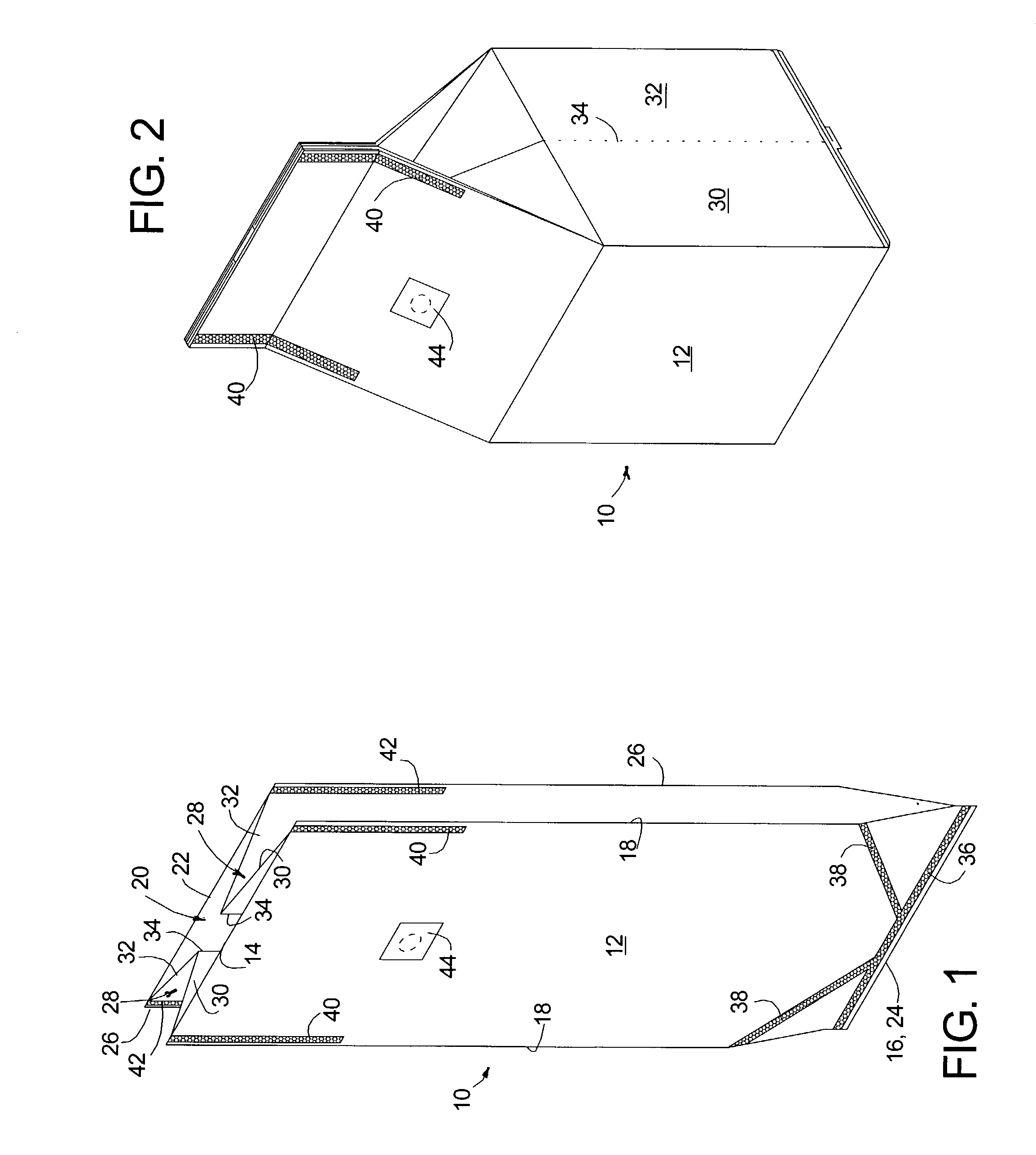

[0018] In accordance with the present invention, a bag is provided with a front panel, a rear panel coextensive with the front panel, and a pair of folded gussets. Each of the gussets has front and rear gusset layers joined at a central crease and a pair of outer gusset edges joined continuously along and to the side edges of the front and rear panels.

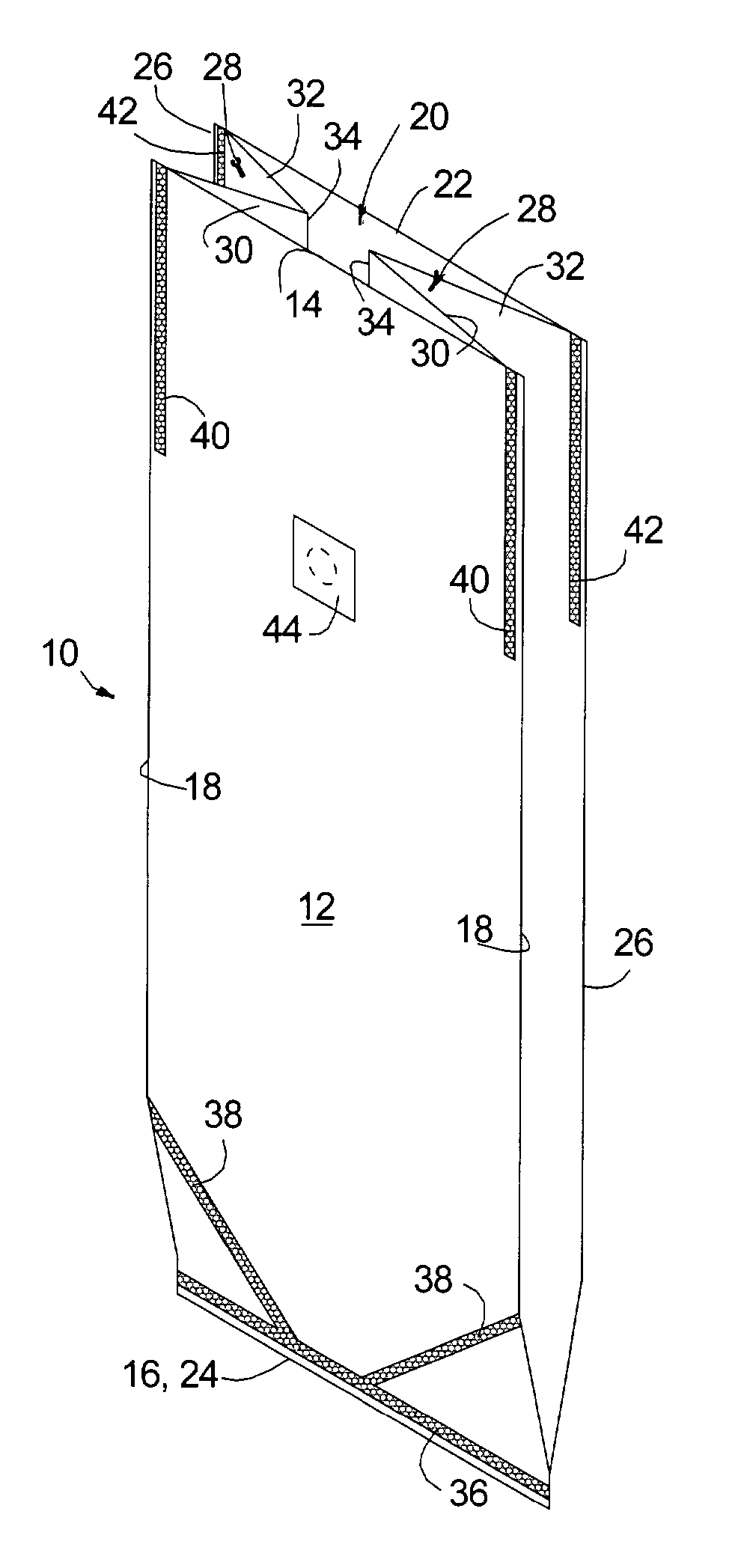

[0019] In the illustrated embodiments, as shown in FIG. 1, the bag, generally designated by the reference number 10, is formed by a folded tubular web to include a front panel 12 having top and bottom edges 14 and 16 and side edges 18, thus defining a front panel width and height. A rear panel 20 having top and bottom edges 22 and 24 and side edges 26 is coextensive wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com