Concrete stress sensor by piezoelectric properties of PVDF (polyvinylidene fluoride) film

A technology of stress sensor and piezoelectric characteristics, applied in the field of stress sensor and concrete stress sensor using piezoelectric characteristics of PVDF (vinylidene fluoride) film, it can solve the problem that the sensor cannot be effectively captured, and achieve light weight and ensure testing. High precision and high piezoelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

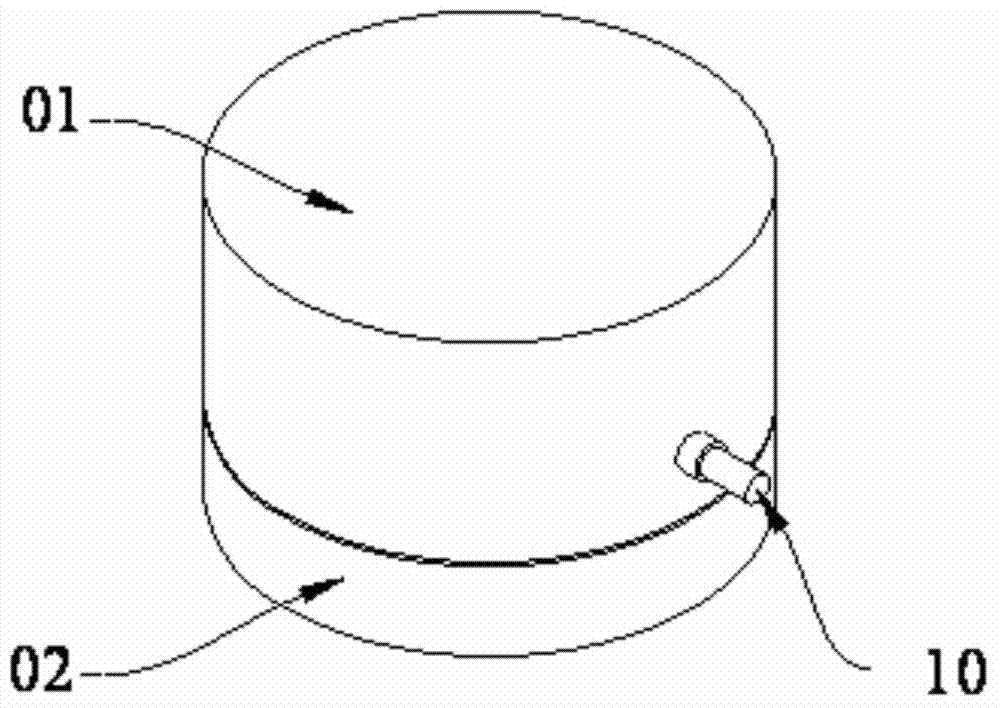

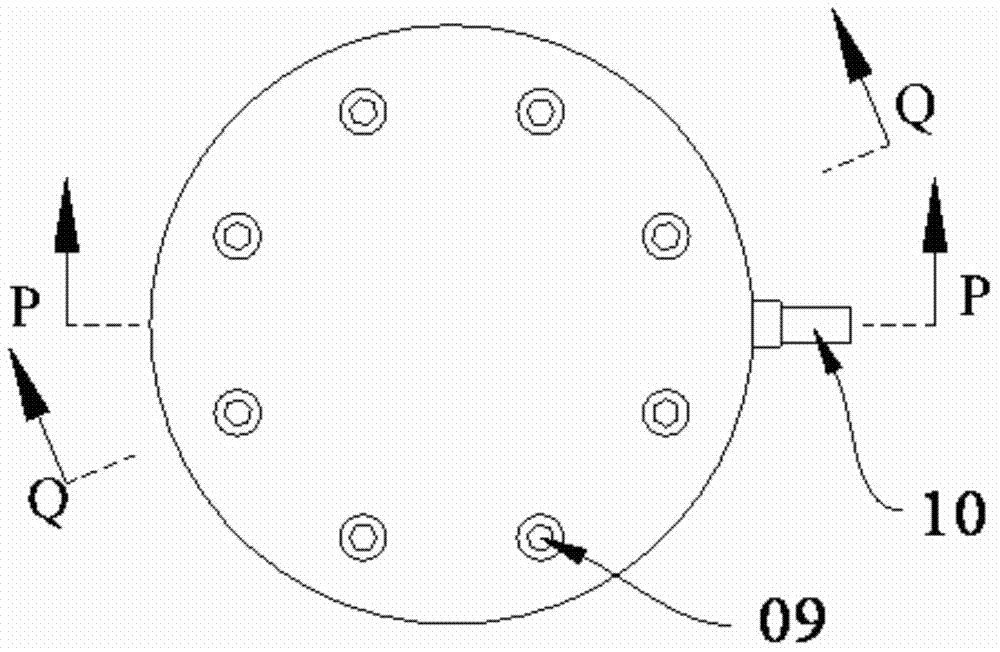

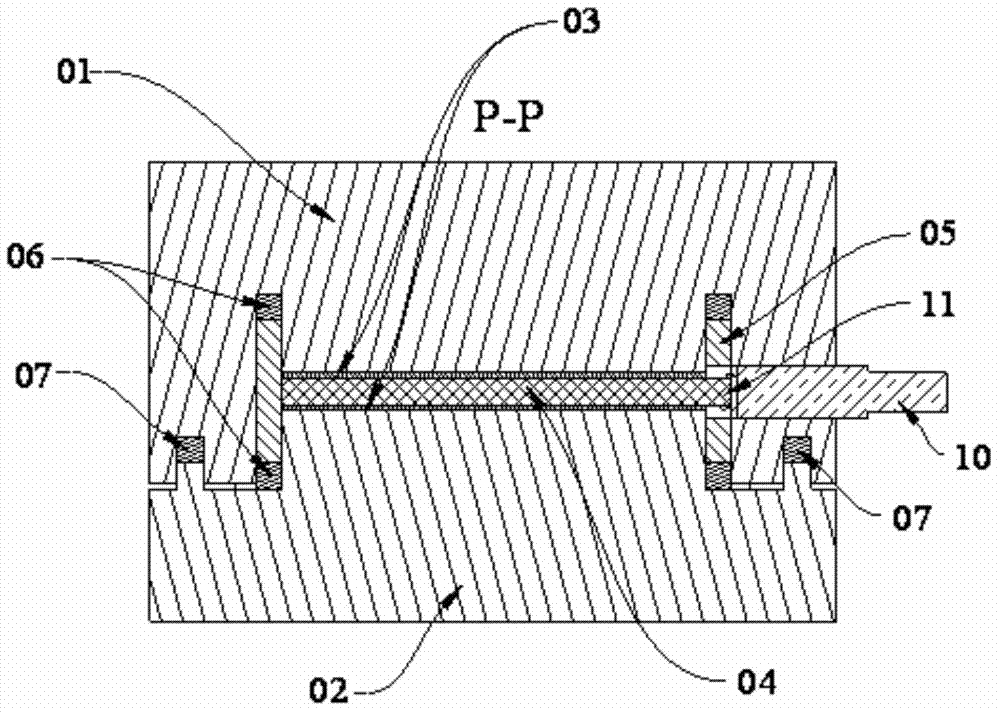

[0032] see Figure 1 to Figure 6 , the concrete stress sensor in the illustration utilizes the piezoelectric properties of PVDF (polyvinylidene fluoride) film, which includes PVDF piezoelectric film 04 plated with silver on both sides as the sensitive element of the sensor, which is used to protect the sensitive element and remove the The impact load is transmitted to the metal sensor case of the sensitive element, used for the output terminal 10 connected with the test circuit, the insulation layer 03 and the nylon sleeve 05 used for insulation between the PVDF piezoelectric film 04 and the sensor case, used for waterproof and The sealed flexible gasket 06 and the flexible waterproof sealing ring 07 are used for wiring electrodes 11 for electrical connection between the PVDF piezoelectric film 04 and the output terminal 10, and are used for encapsulating and fixing the screw 09 of the sensor shell.

[0033] For details, see Figure 3 to Figure 6 , the specific structure of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com