Patents

Literature

58 results about "Shock testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shock testing can accurately measure the impact fragility of products. Shock tests are also commonly used to evaluate how components or complete systems respond to specific shock energy inputs.

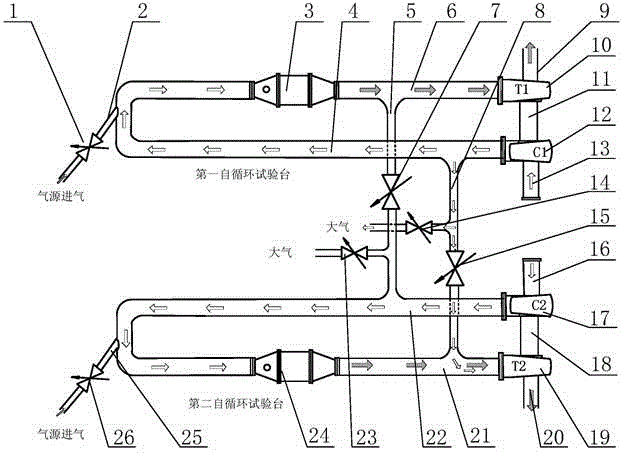

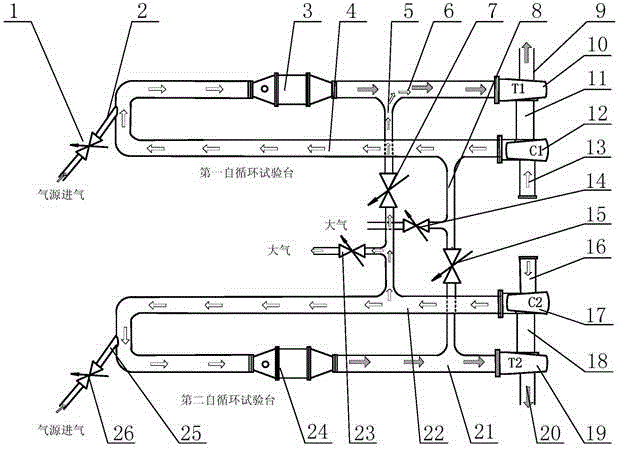

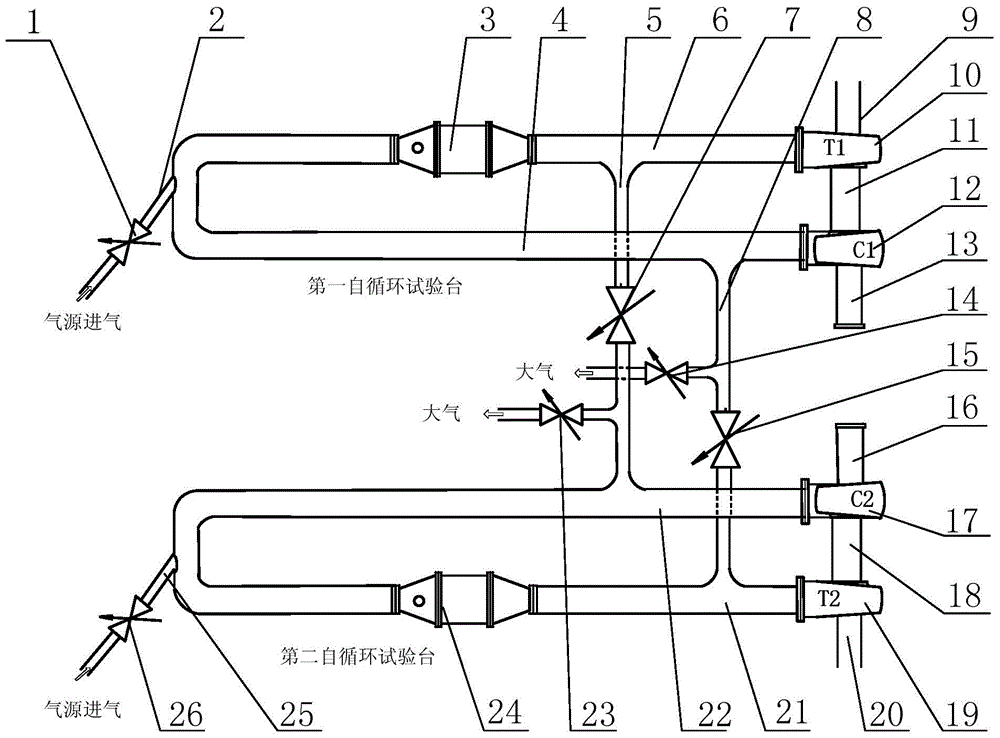

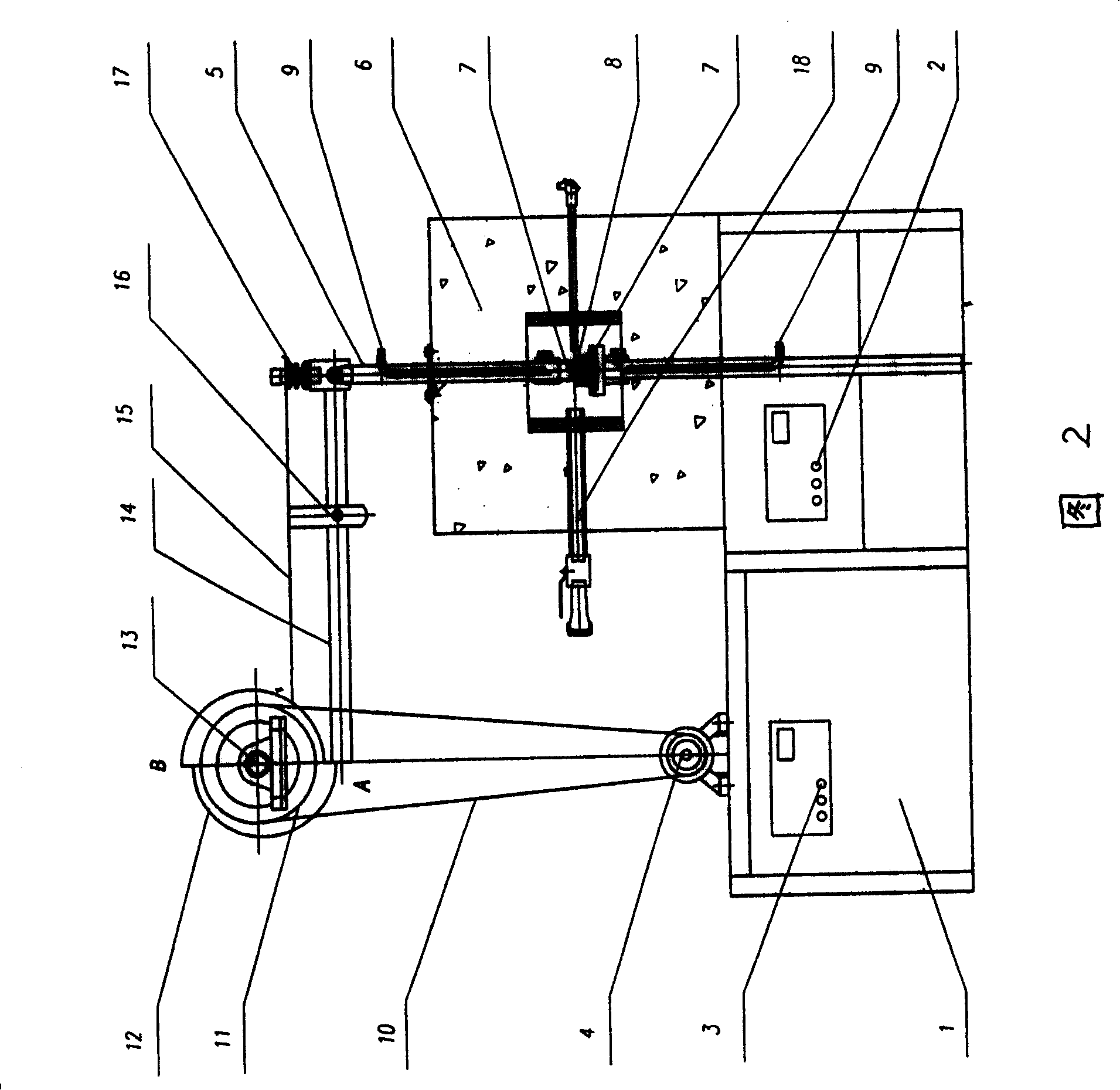

Self-circulating type test bed for turbocharger high-low temperature cycling thermal shock testing

InactiveCN104458238AWide temperature rangeReduce testing costsMachine part testingShock testingTurbochargerEngineering

The invention relates to a device for testing the reliability of a turbocharger and belongs to the technical field of power machines. The device comprises two independent turbocharger self-circulating test beds, a connecting pipeline between the two test beds, a valve used for adjusting the gas flow between the two test beds, and a valve used for adjusting a turbocharger to be tested so as to enable the turbocharger to discharge air to the atmosphere. The invention further discloses an adjustment method for high-low temperature cycling thermal shock testing. According to the device and method, turbocharger high-low temperature cycling thermal shock testing is achieved based on self circulation of the turbochargers, an external source does not need to supply compressed air to the test beds, thermal shock testing of two turbochargers can be achieved at the same time, and testing cost is reduced. Compared with the method for conducting thermal shock testing on an engine, the test bed has the advantages that the test bed is not limited by the exhaust temperature of the engine, high-low temperature cycling thermal shock testing within a wider temperature range can be achieved, and the test bed has high application value in improving the reliability of the turbochargers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

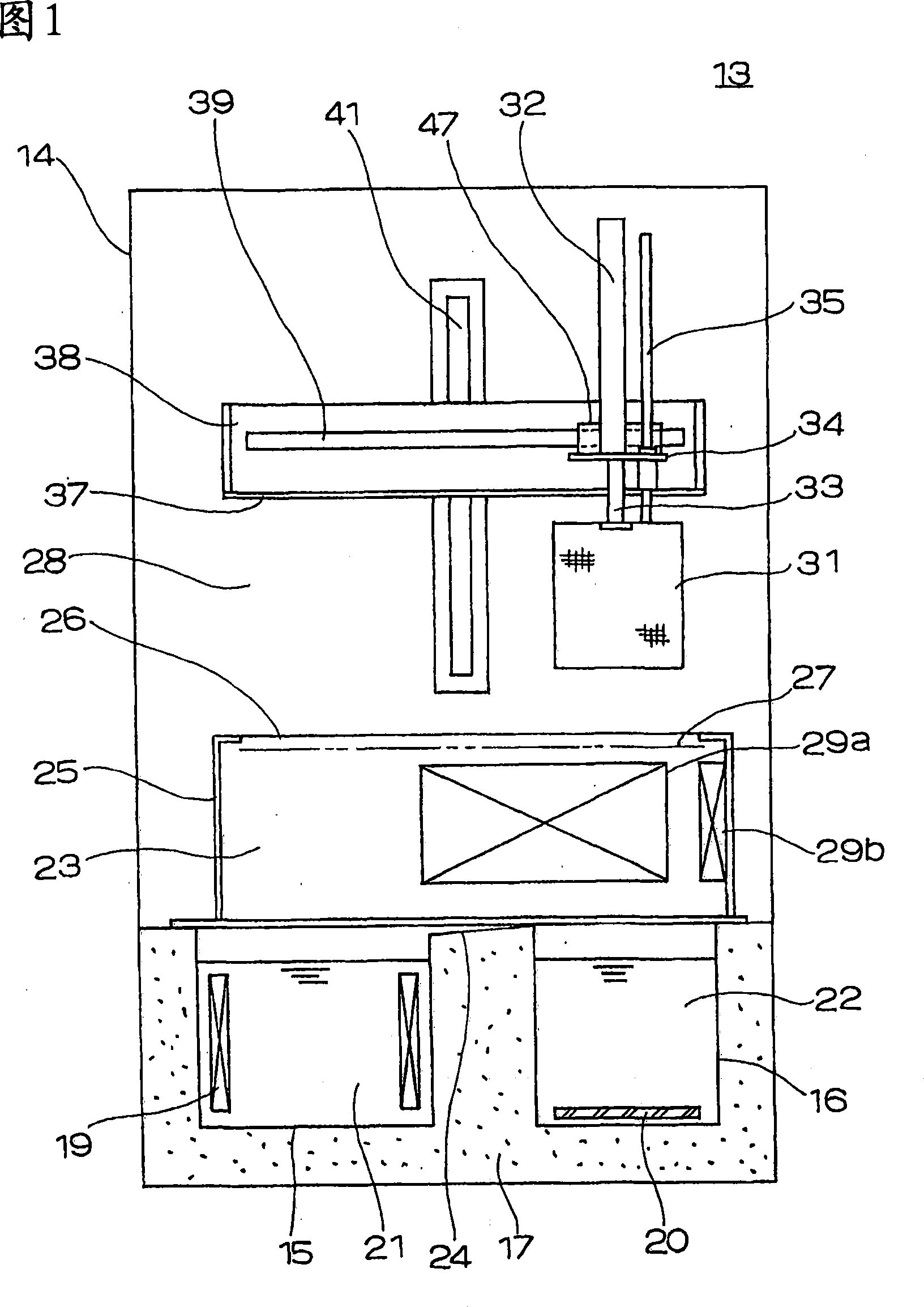

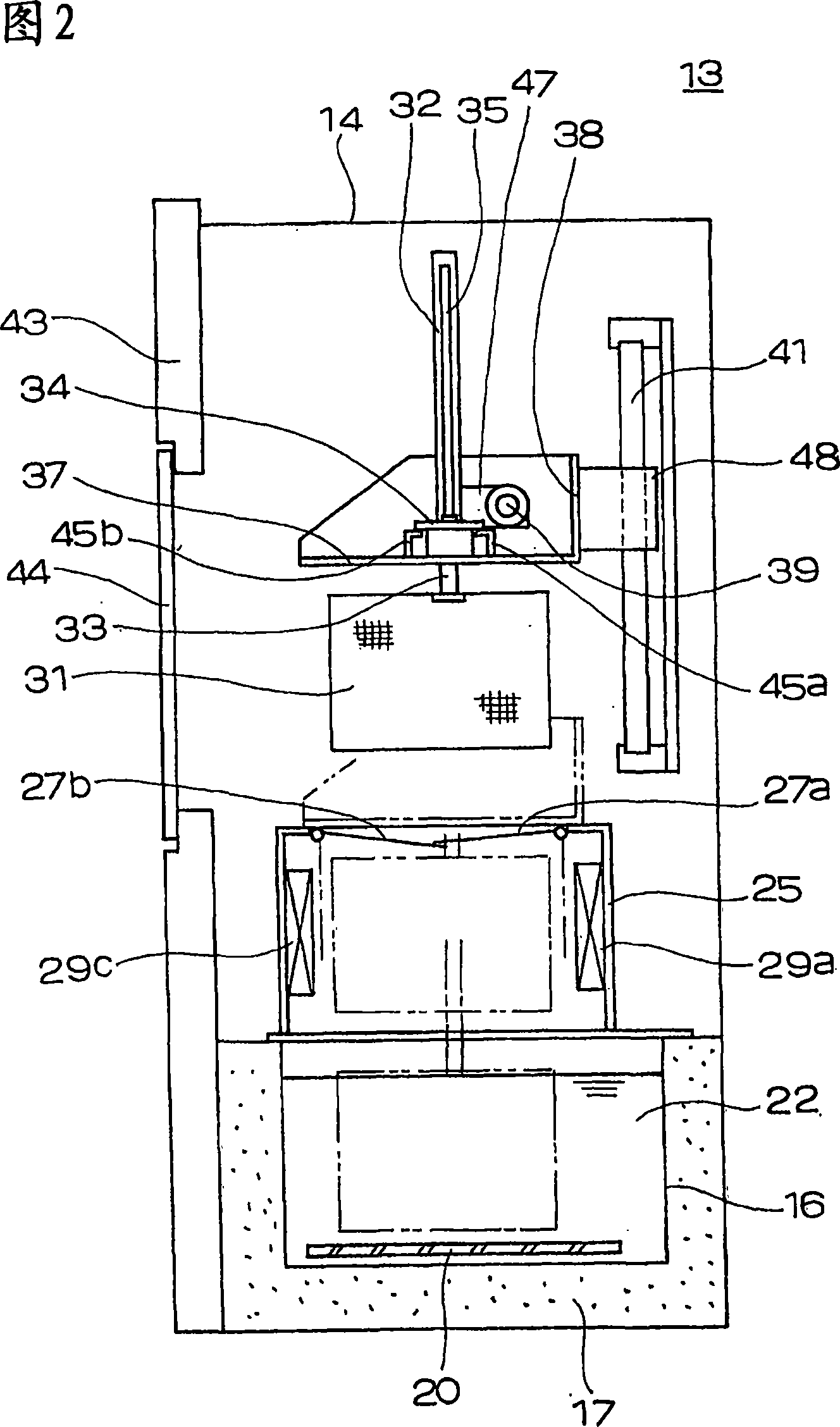

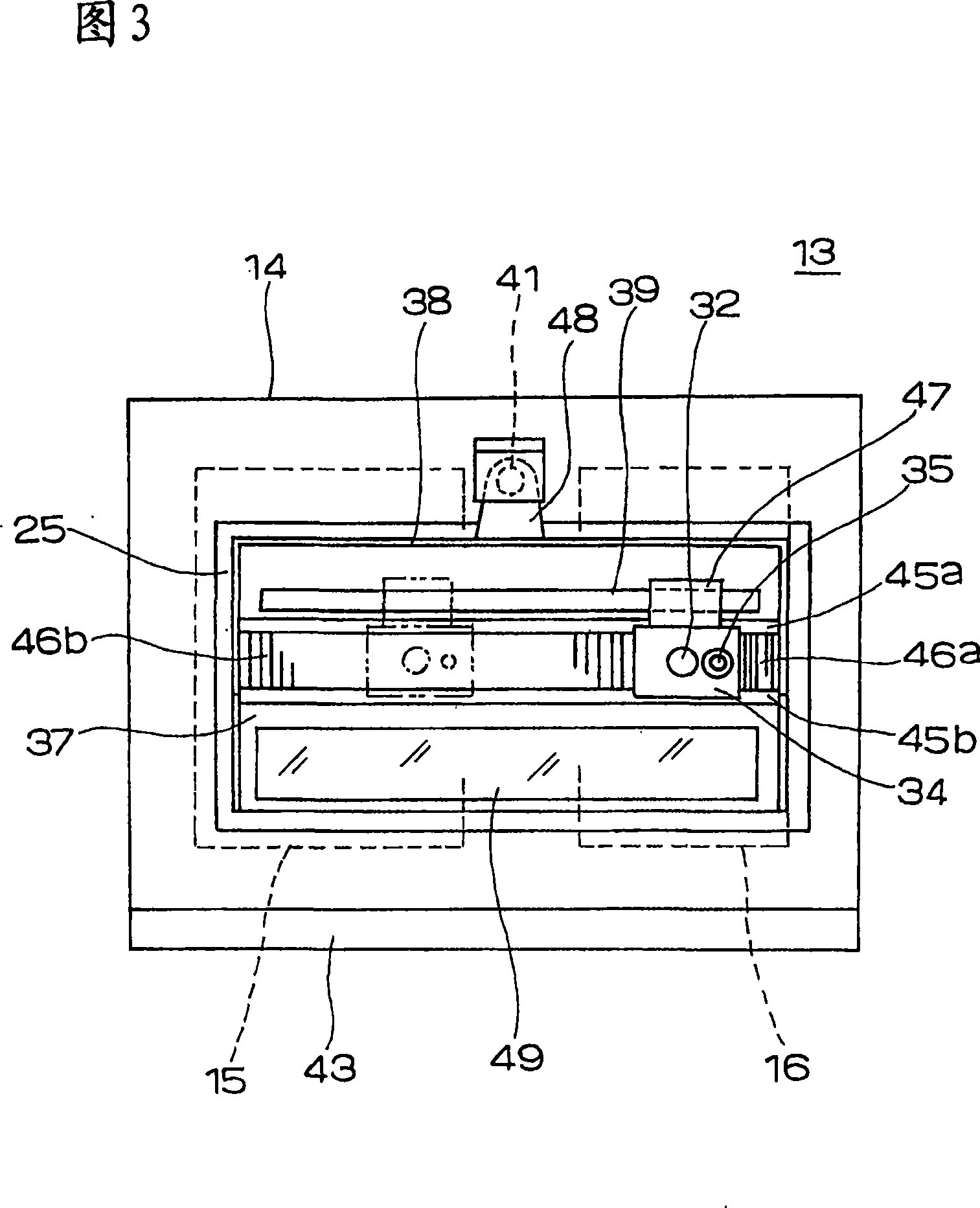

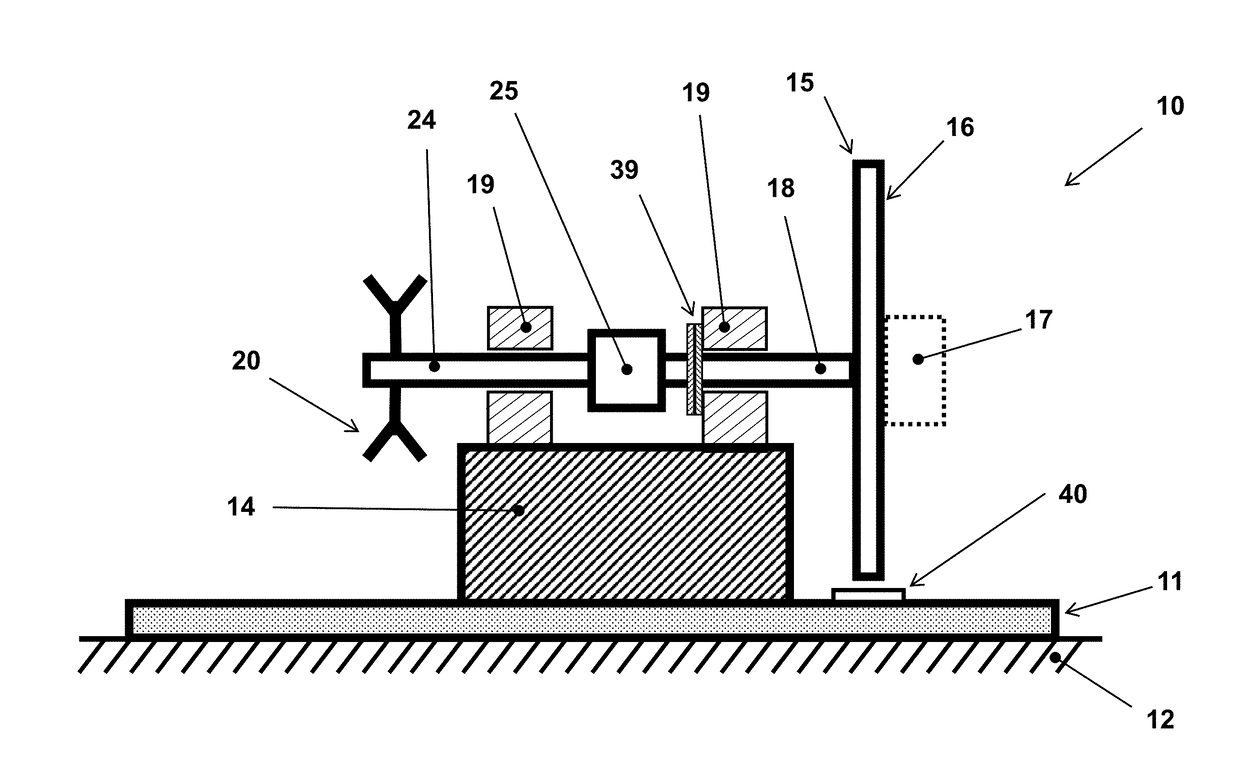

Liquid tank type cold shock testing device

Under the device main body (14) of the liquid tank type thermal shock test device (13), a low temperature tank (15) and a high temperature tank (16) are arranged side by side with a heat insulating layer (17). Above the low-temperature tank (15) and the high-temperature tank (16), a sealed box (25) is provided, and an opening (26) is formed on the upper surface thereof. Above the box body (25), a sealing cover (37) capable of covering the opening (26) is arranged in a sealed state, and is driven up and down by the cover driving mechanism (41). On the sealing cover (37), a horizontal driving mechanism (39) is arranged, which can drive the fixing plate (34) left and right. On the fixed plate (34), a vertical drive mechanism (32) is installed to freely move the sample cage (31) downward. Accordingly, the sample cage (31) can be repeatedly immersed in the low-temperature tank (15) and the high-temperature tank (16) while the box (25) is sealed by the sealing cover (37).

Owner:FUTEC

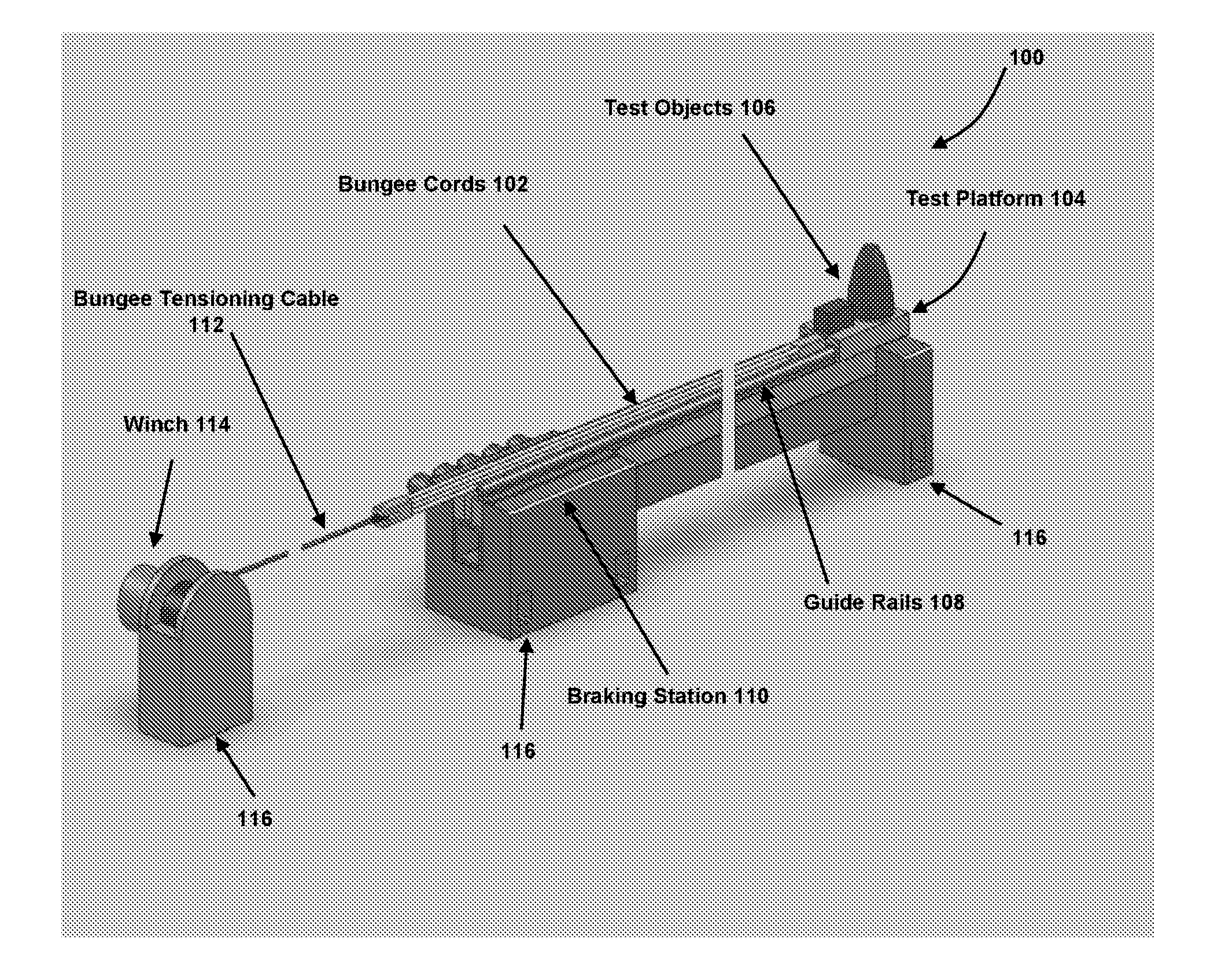

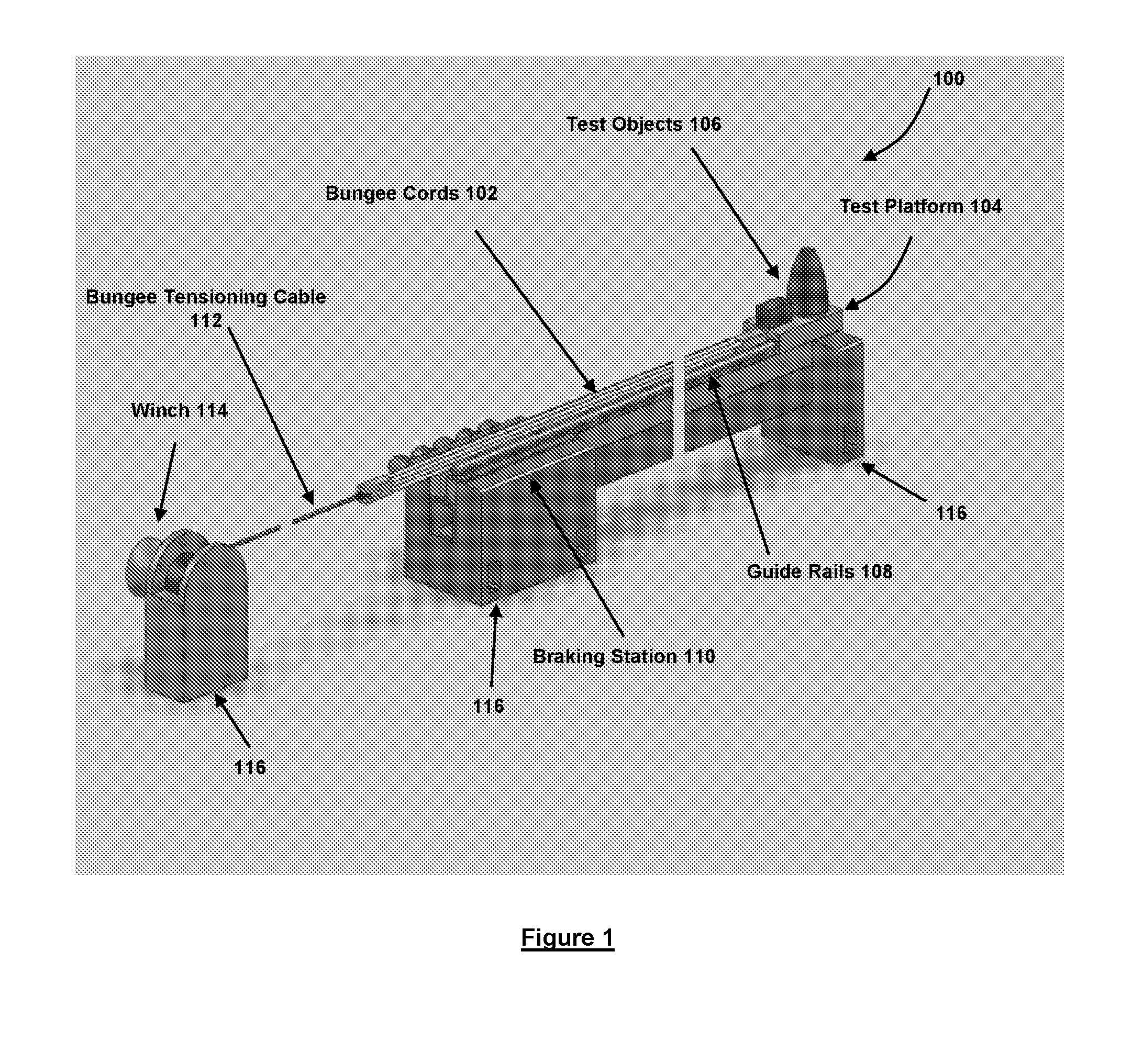

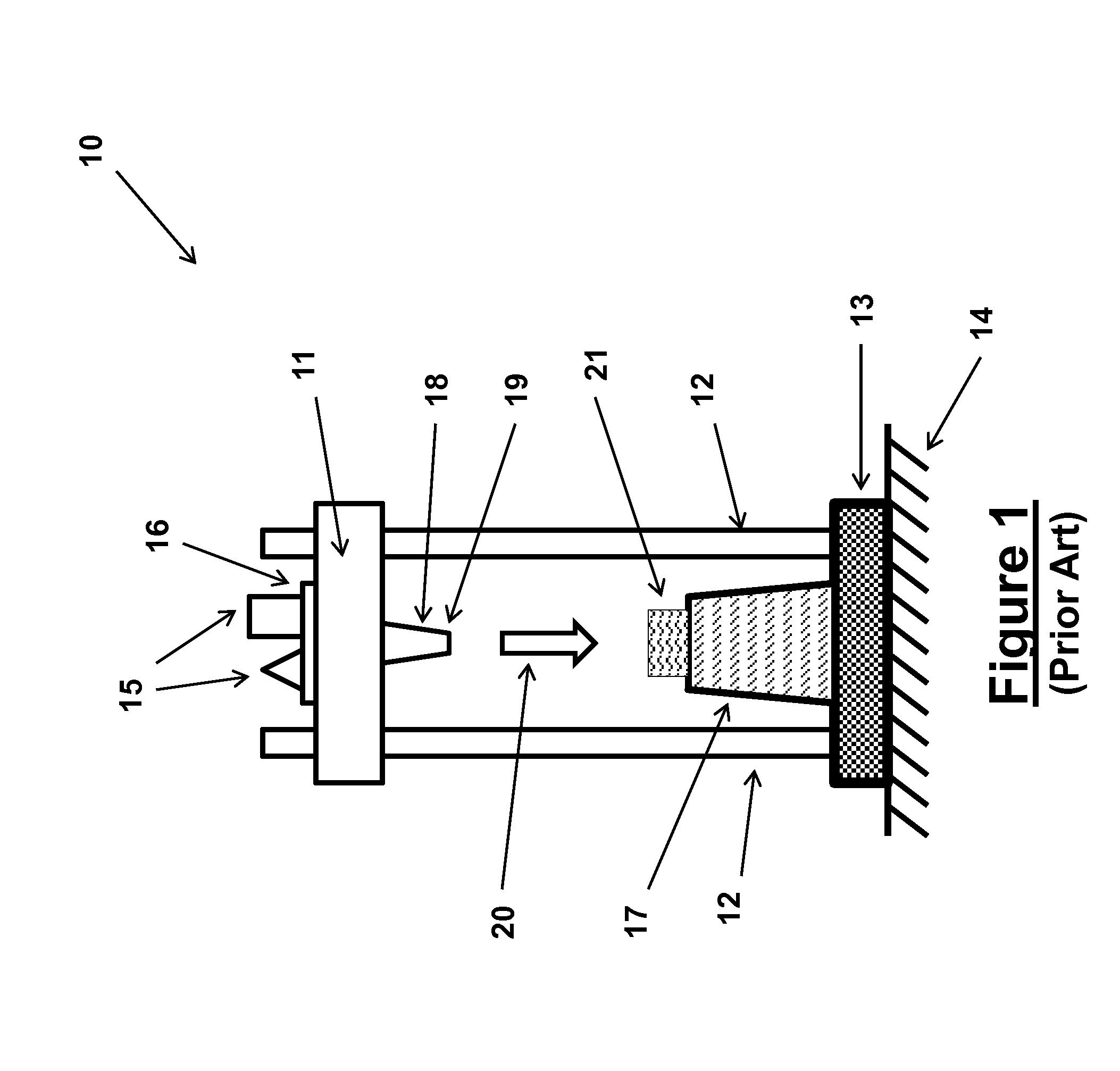

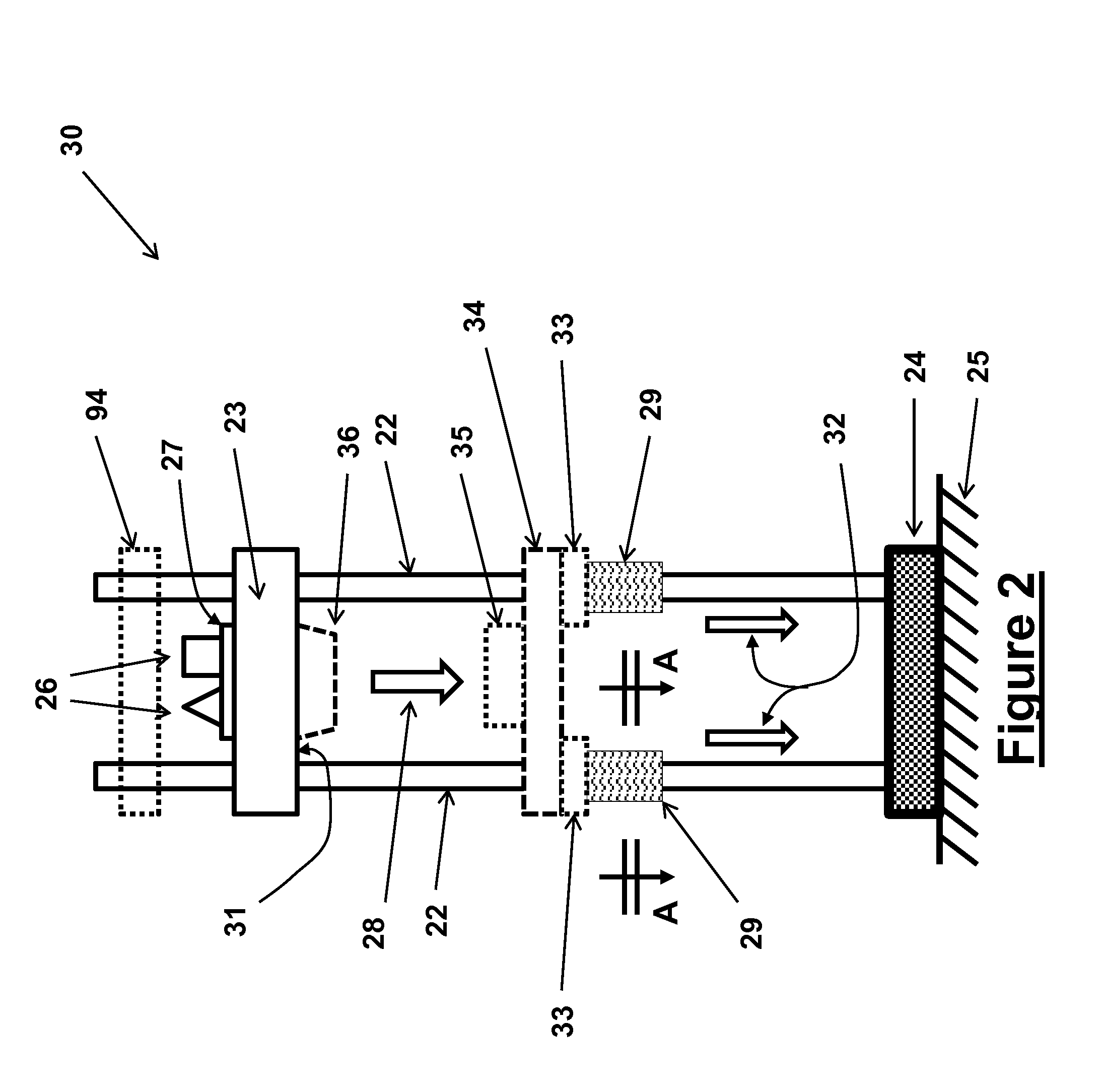

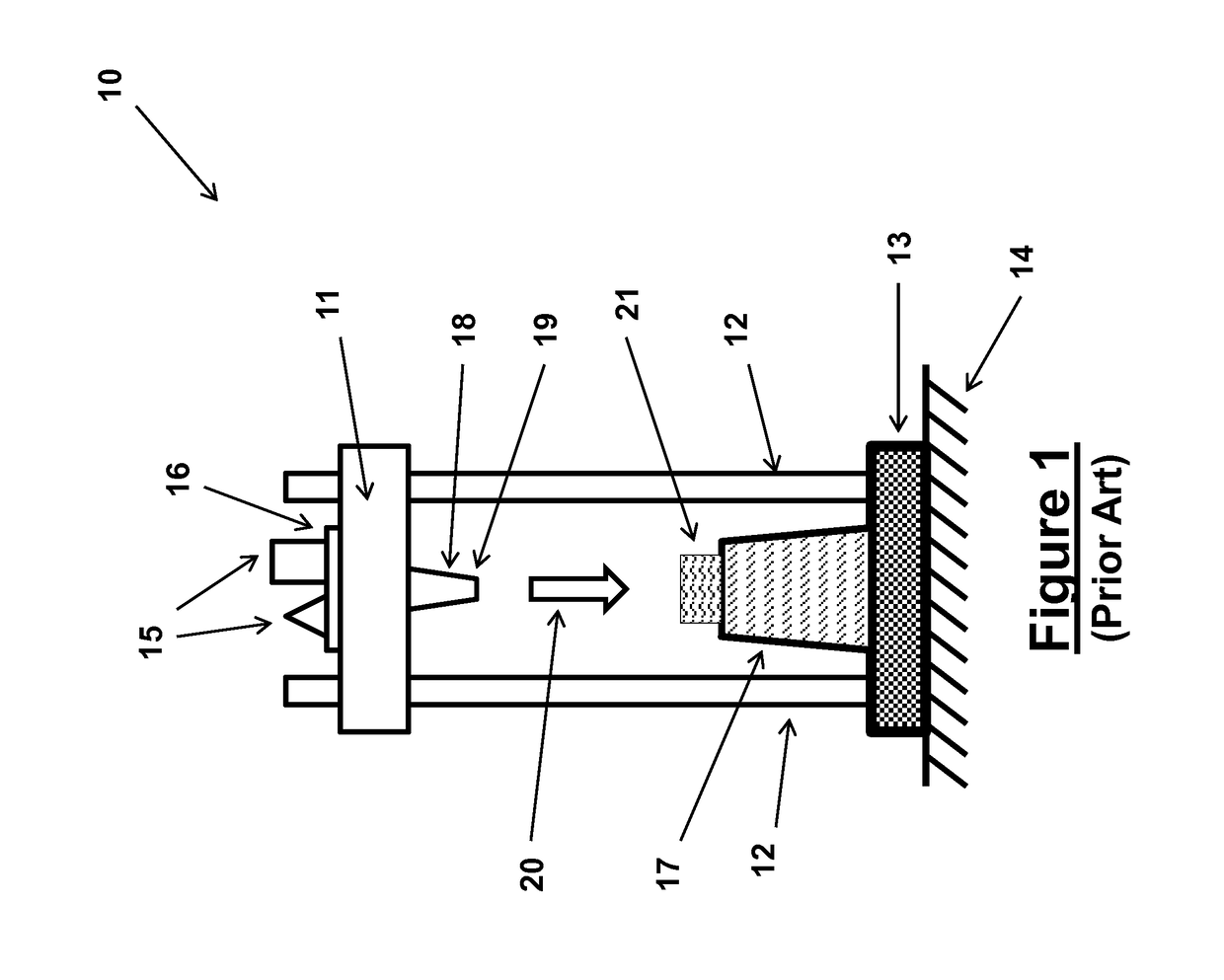

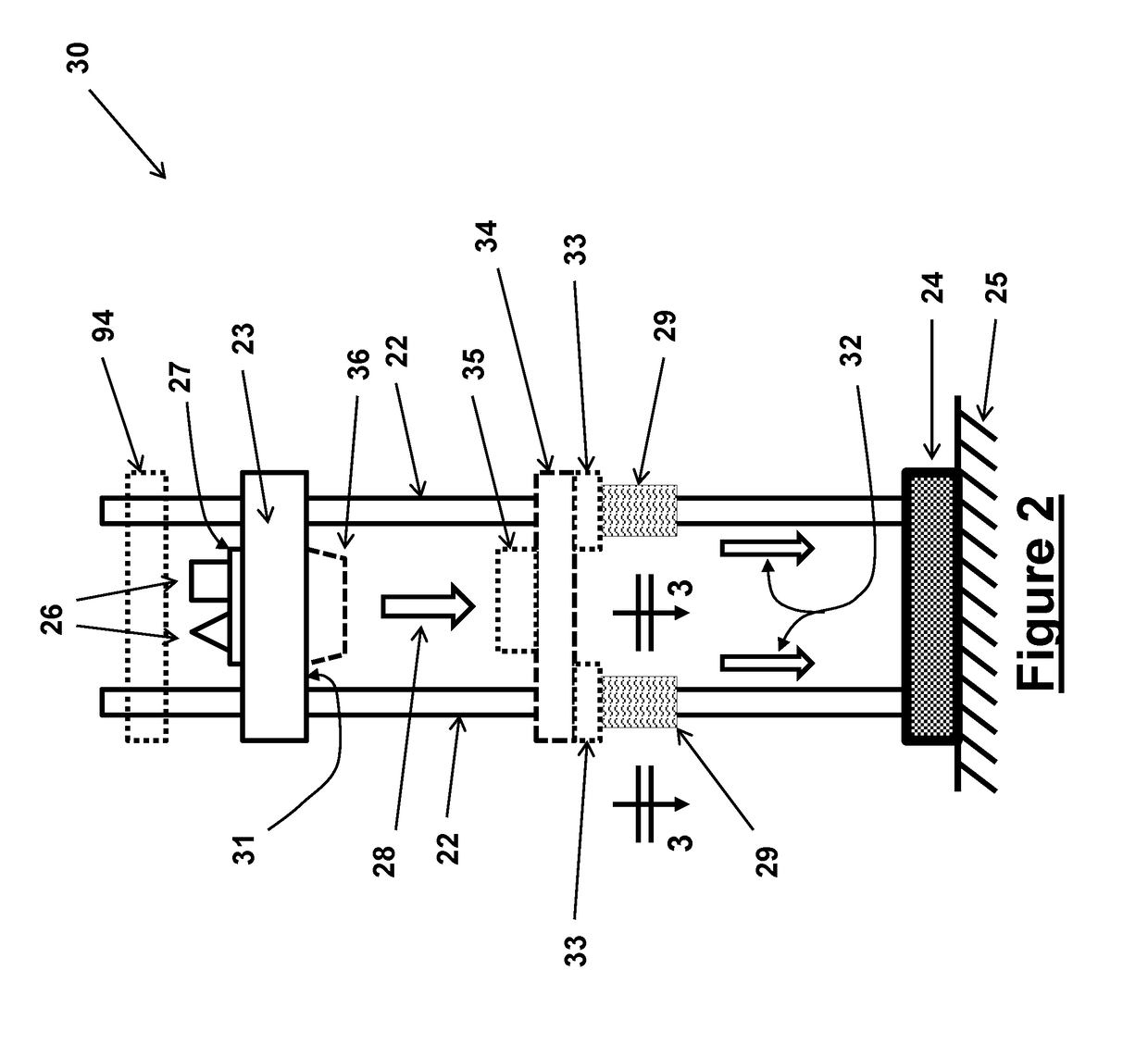

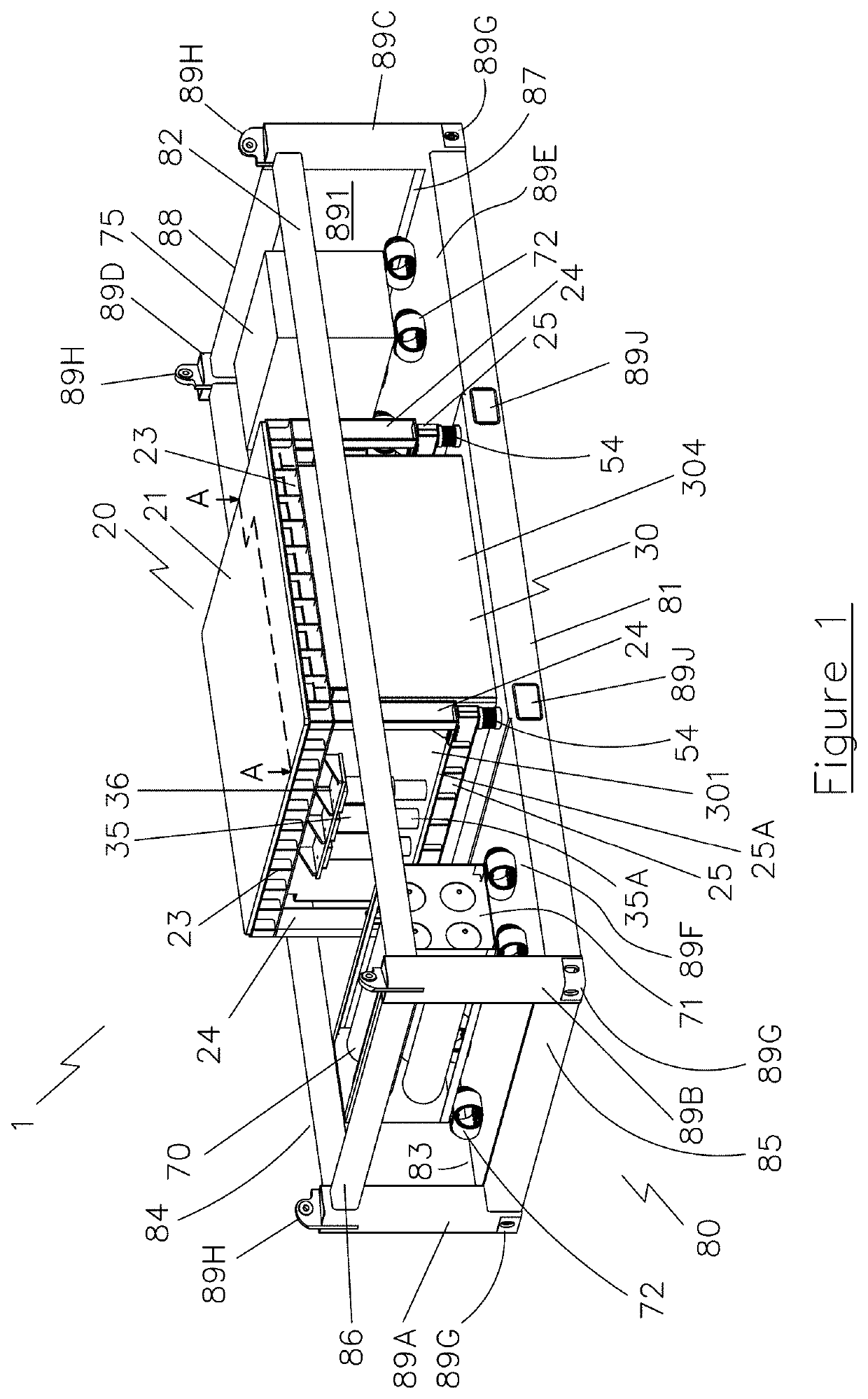

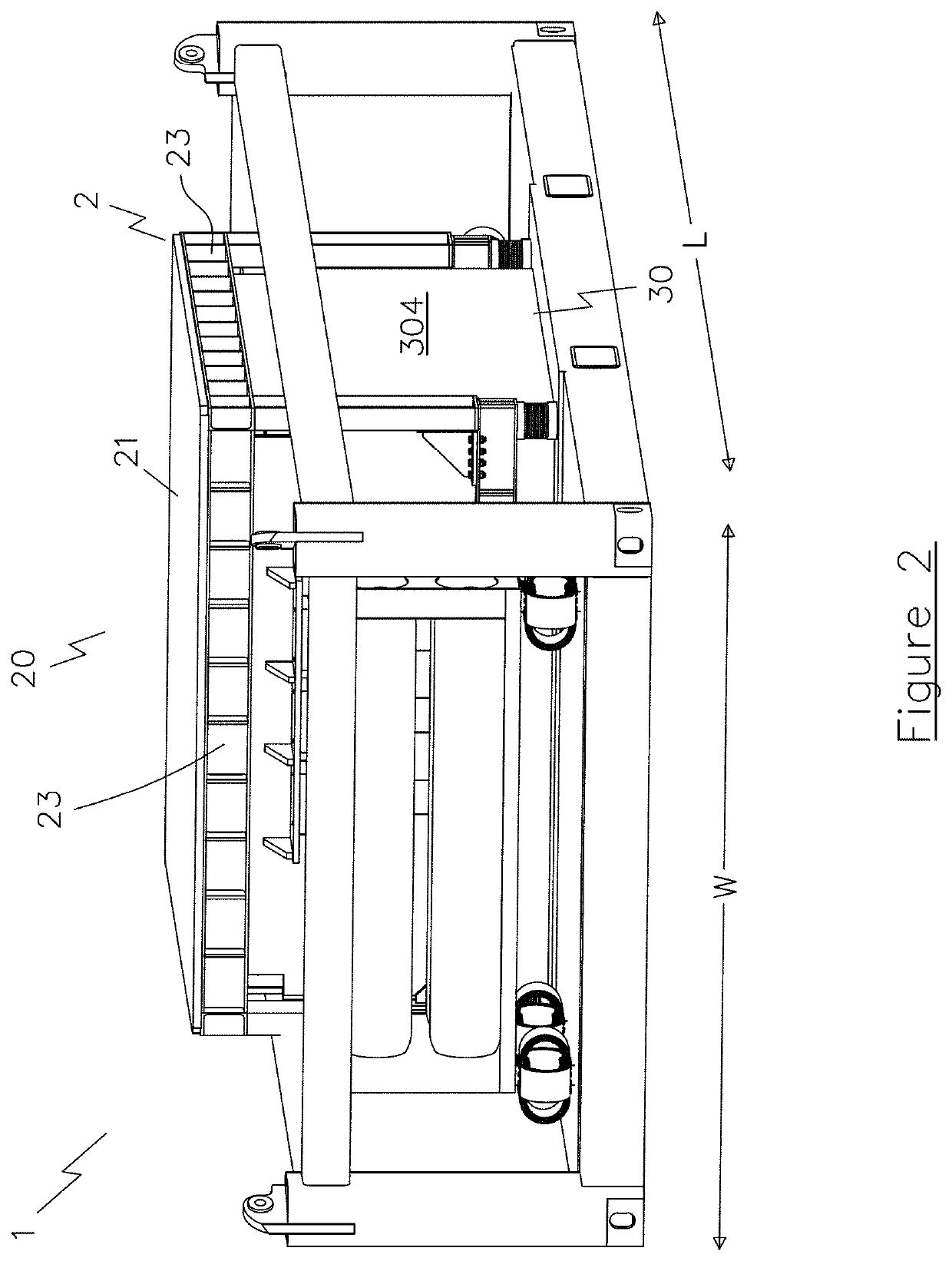

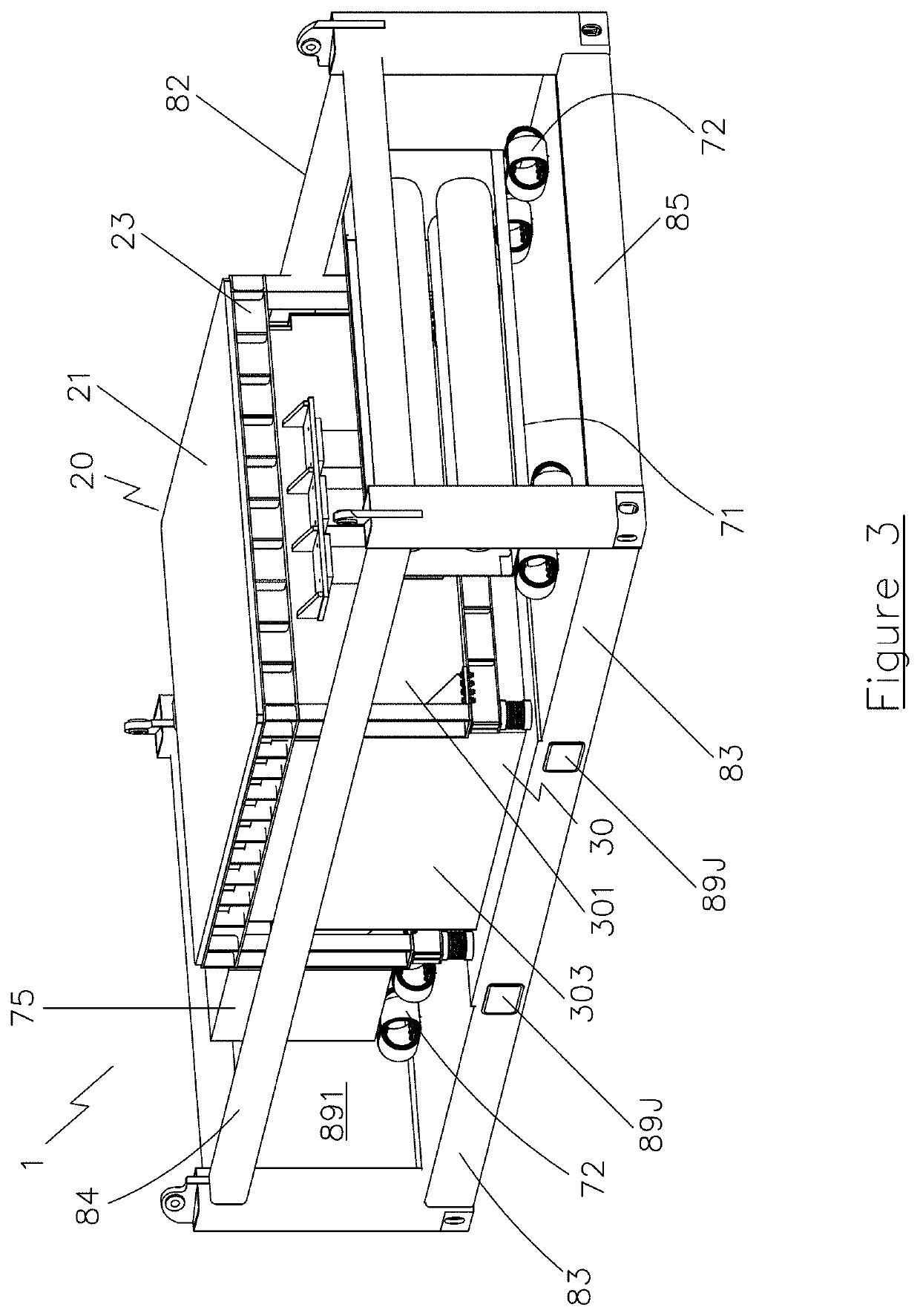

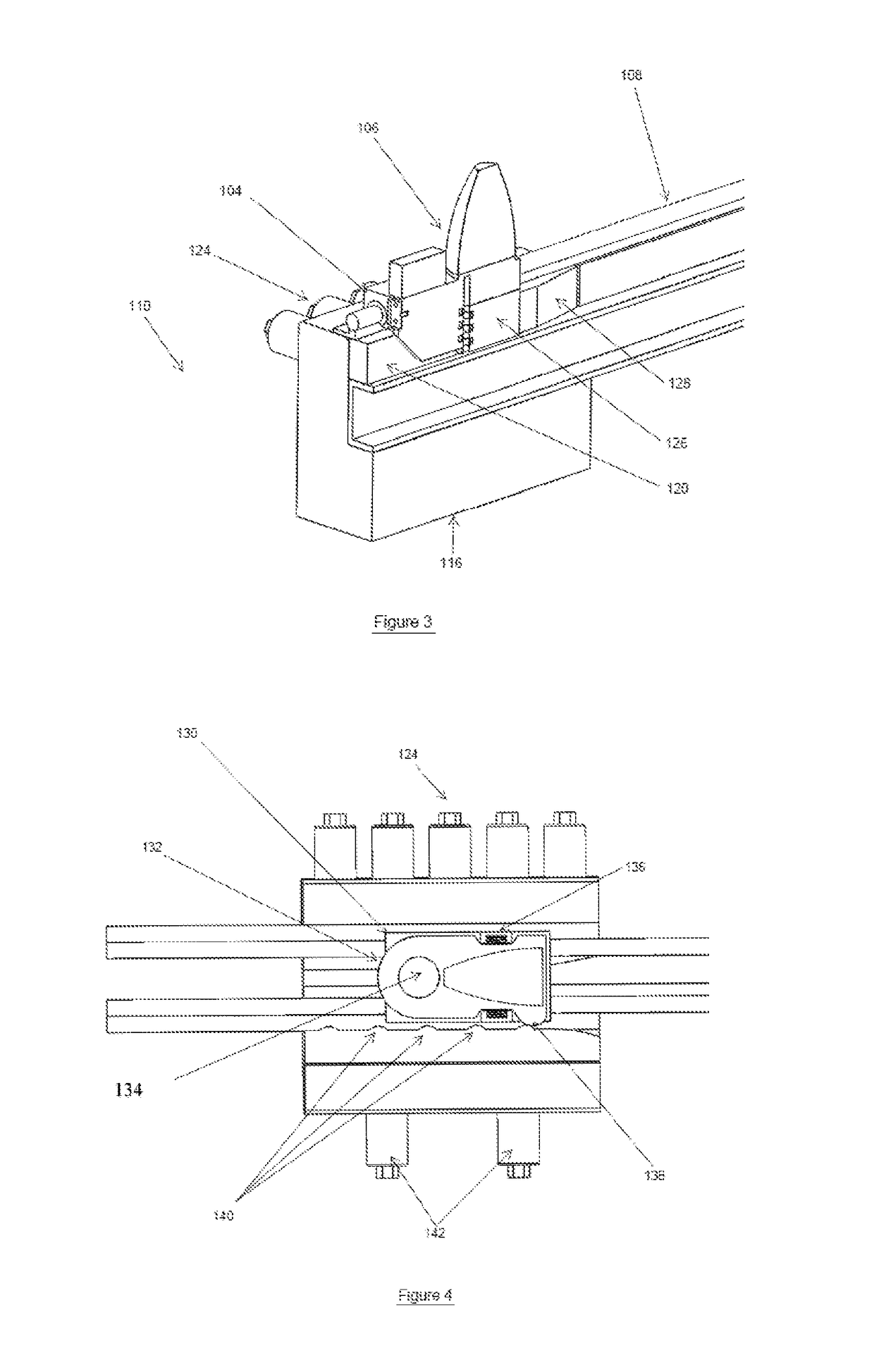

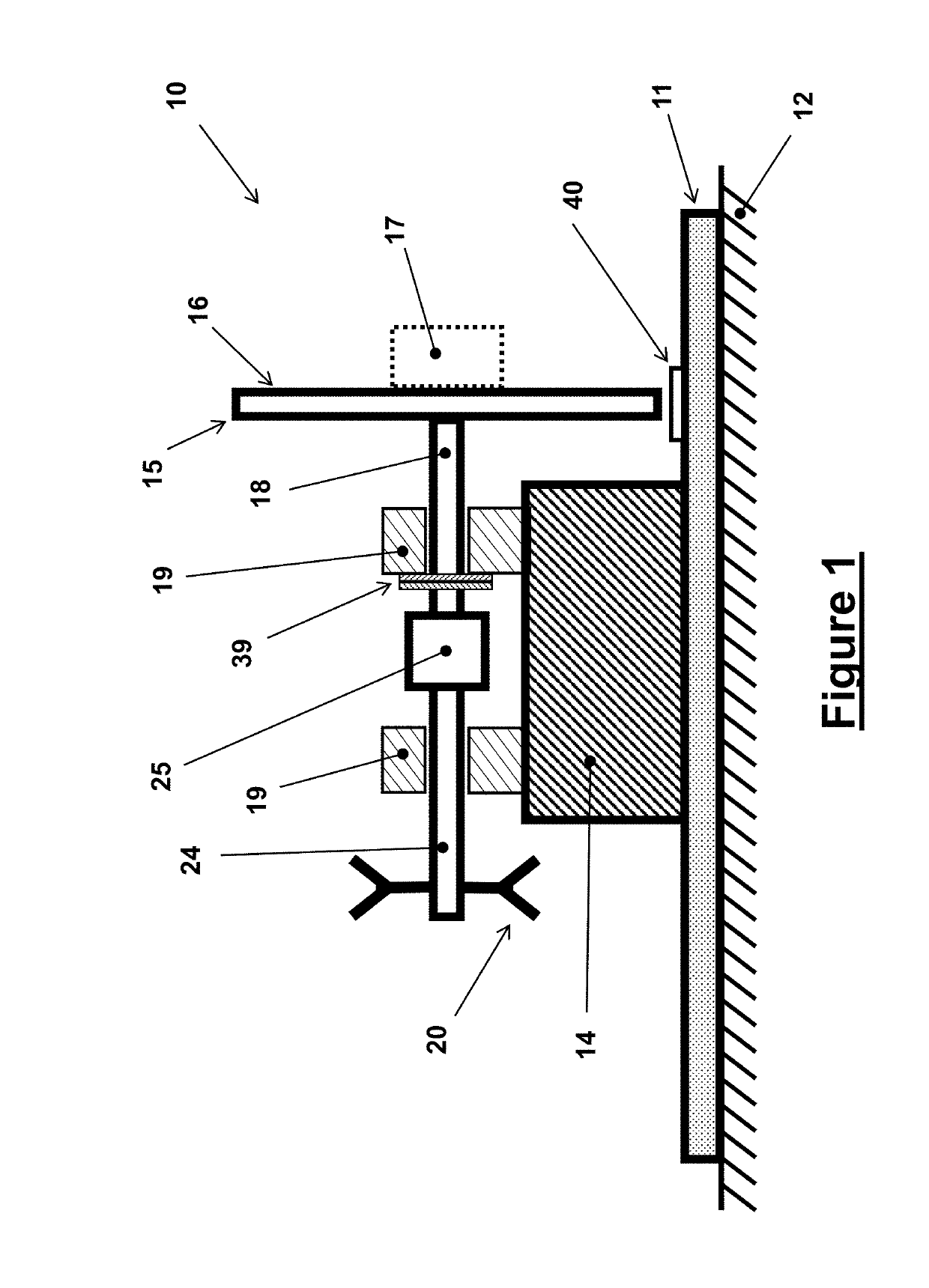

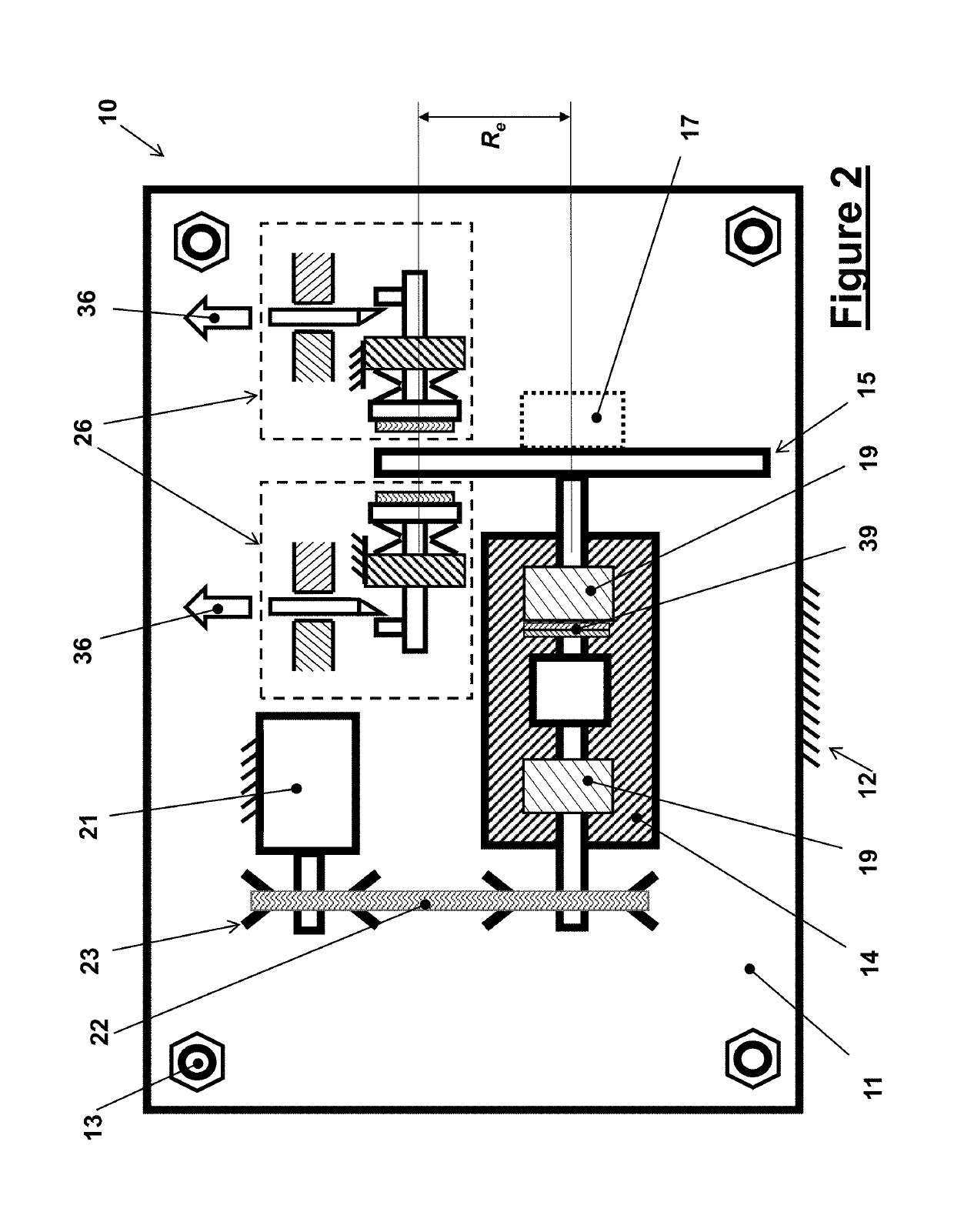

High-G Shock Testing Machine

ActiveUS20160258837A1High precisionHigh rateMaterial strength using single impulsive forceShock testingRelative motionEngineering

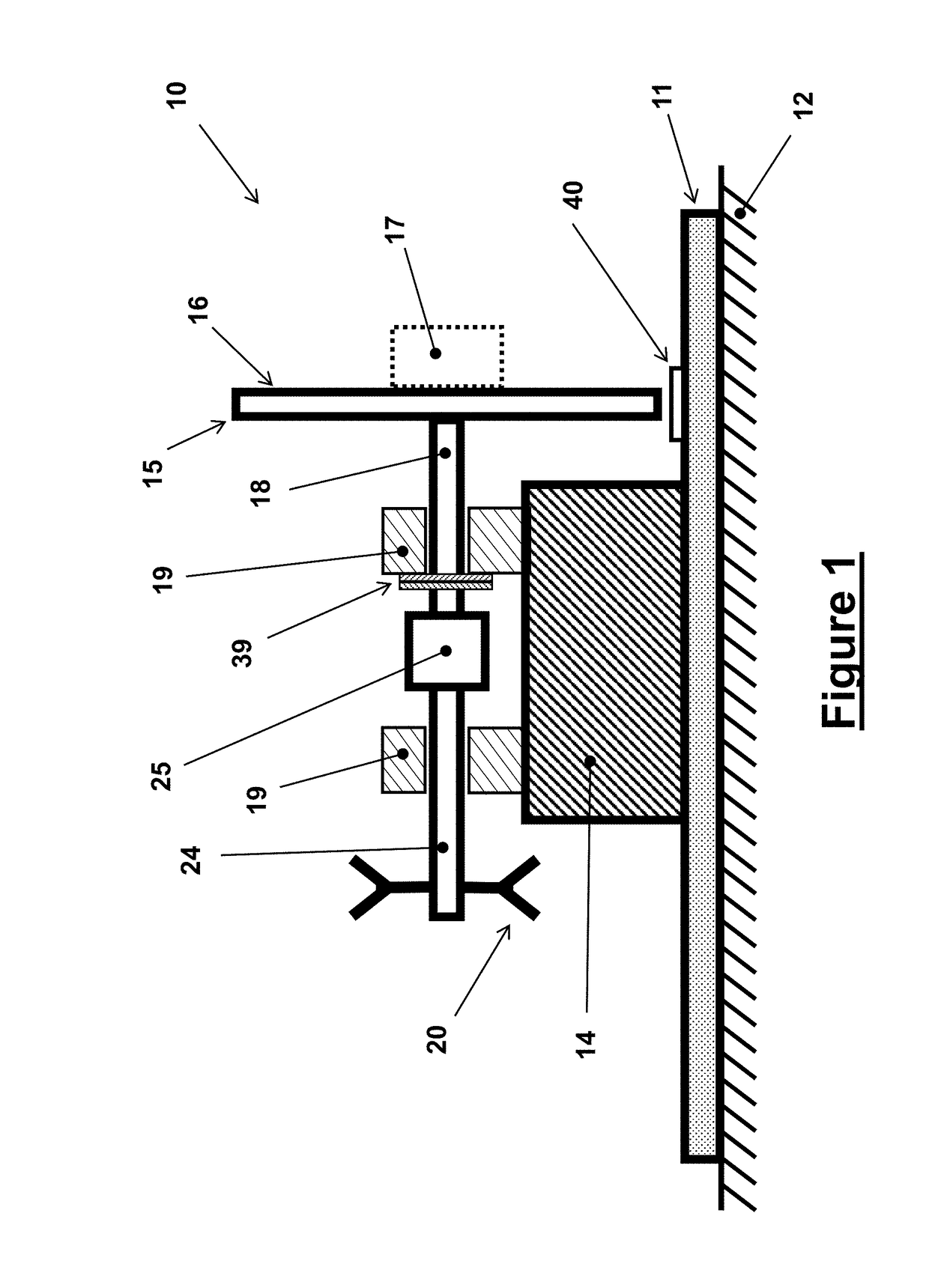

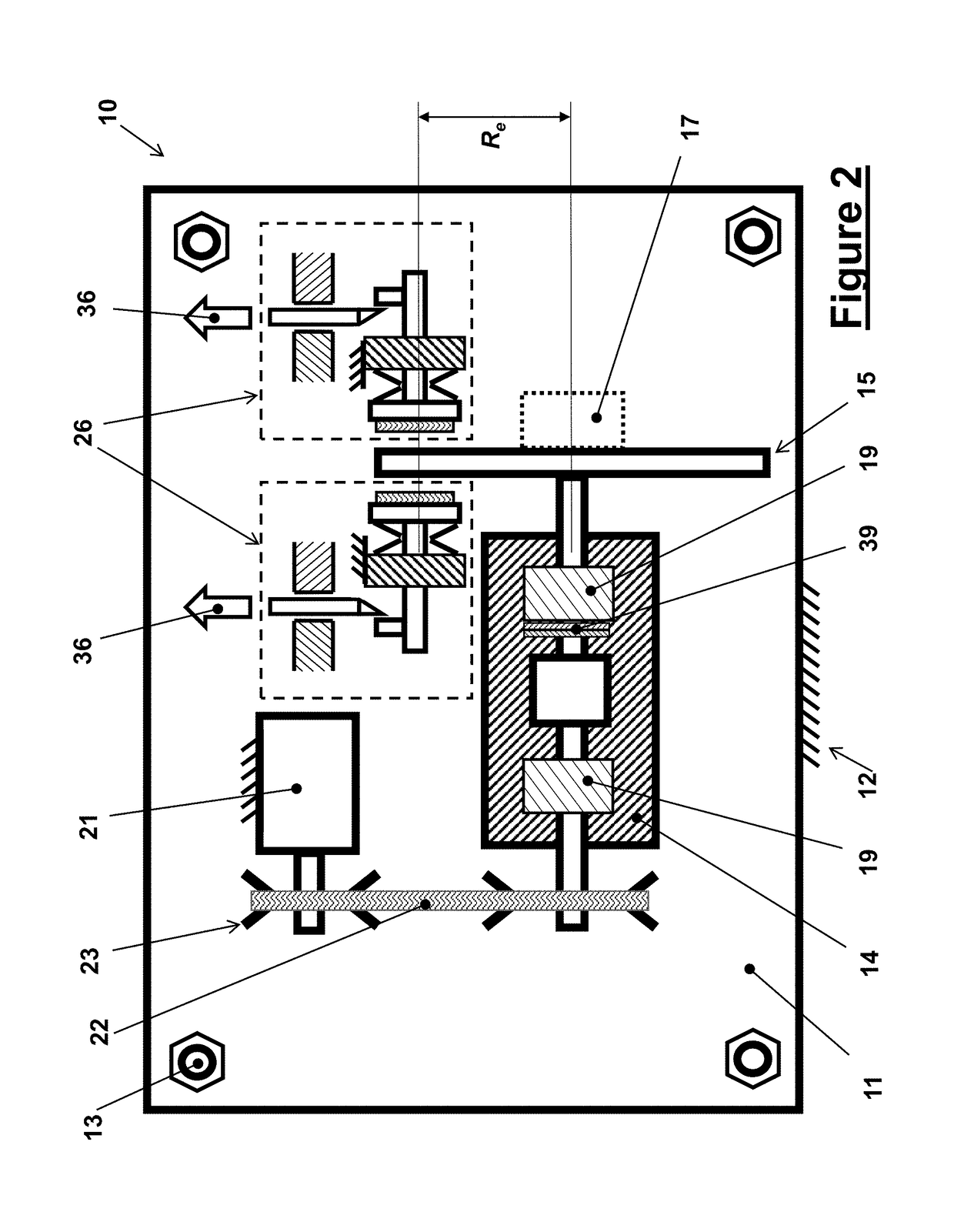

A shock testing machine including: a test platform upon which one or more objects to be tested are mounted; one or more rails upon which the test platform is movable in a longitudinal direction; and a braking station for retarding a relative motion between the test platform and the braking station, wherein the test platform and the braking station include at least one portion interfering with the relative motion of the test platform and the braking station such that relative movement of the test platform and the braking station past the at least one portion produces a shock lateral to the longitudinal direction.

Owner:OMNITEK PARTNERS LLC

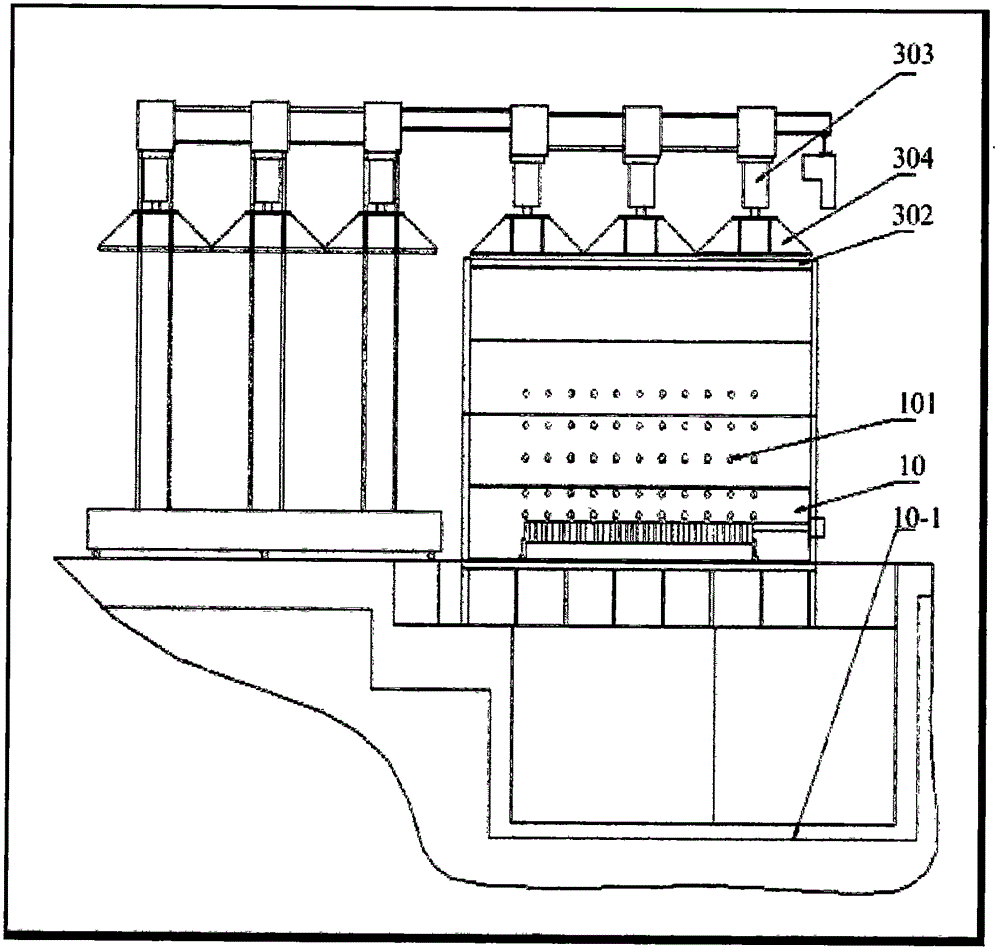

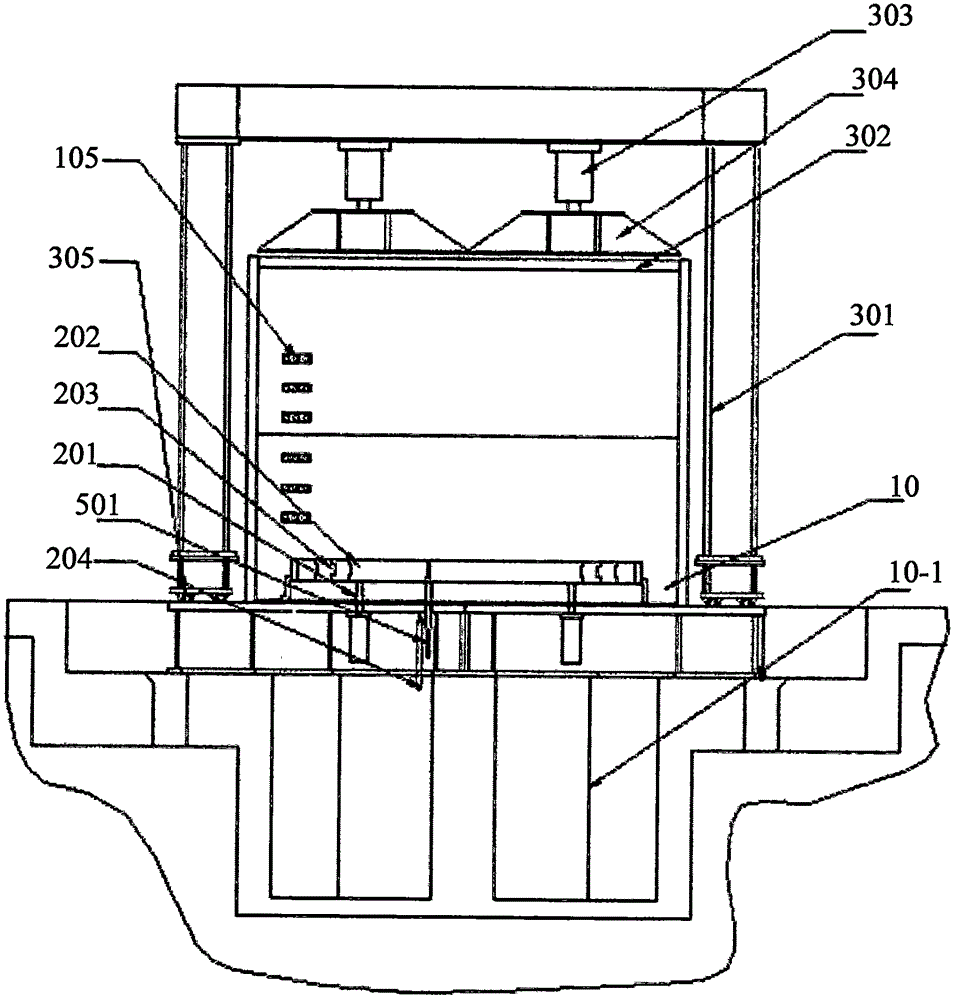

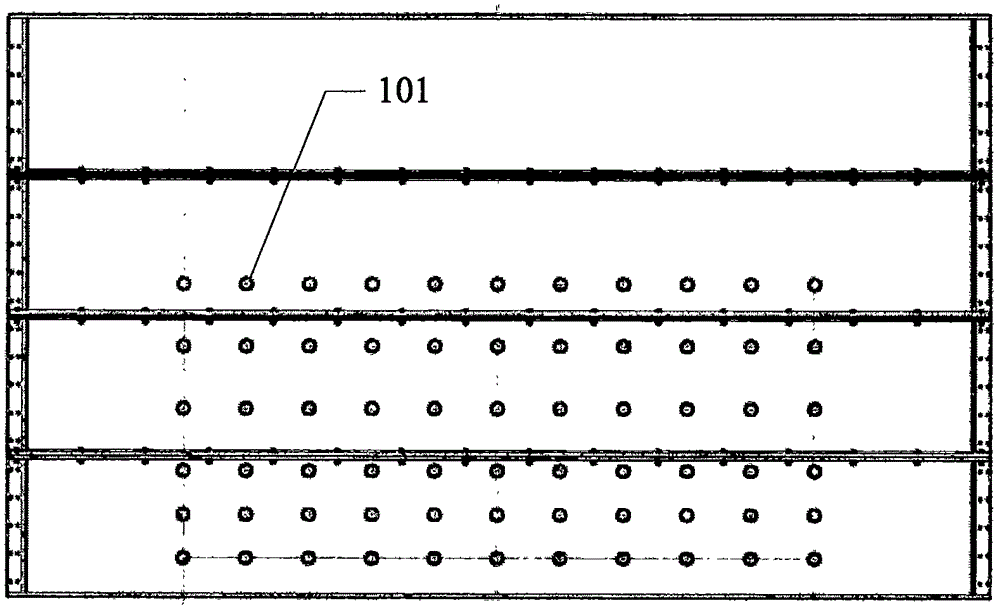

Coal and gas co-mining three-dimensional physical simulation comprehensive experiment system

The invention discloses a coal and gas co-mining three-dimensional physical simulation comprehensive experiment system, and belongs to the technical field of coal and gas safe co-mining. The system comprises a box, a hydraulic mining unit, a hydraulic loading unit, a ventilation roadway unit, a gas injection control unit, and a test unit. The first surface and third surface, which is opposite to the first surface, of the box are both provided with a gas testing hole. The second surface of the box is provided with an air inlet hole and an air return hole. The fourth surface of the box is provided with a wire outlet hole. The hydraulic mining unit comprises parallelly arranged hydraulic cylinders and support steel bars, and two hydraulic cylinders and the bottom of the box connect and support one steel bar. The hydraulic loading unit comprises a loading frame, which is arranged on the guide rails of the box. The guide rails are arranged on two sides of the box. The ventilation roadway comprises a roadway and a ventilating machine. A high pressure steel bottle in the gas injection control unit is communicated with a multi-way air distribution cabinet through an air distribution pipe, the air distribution pipe is communicated with a sub-pipeline; and the test unit comprises a gas testing unit, a stress testing unit, and a slight shock testing unit.

Owner:XIAN UNIV OF SCI & TECH

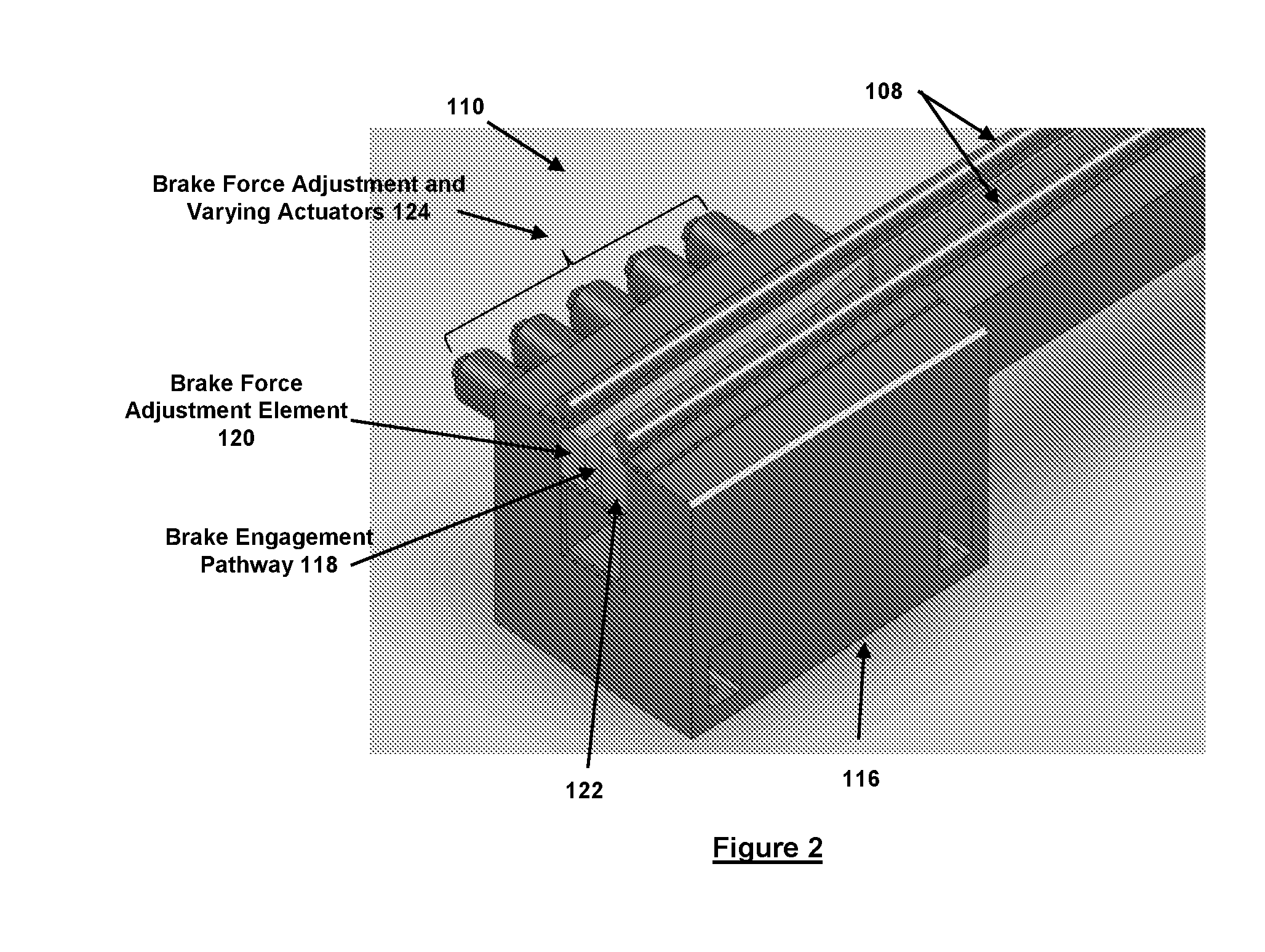

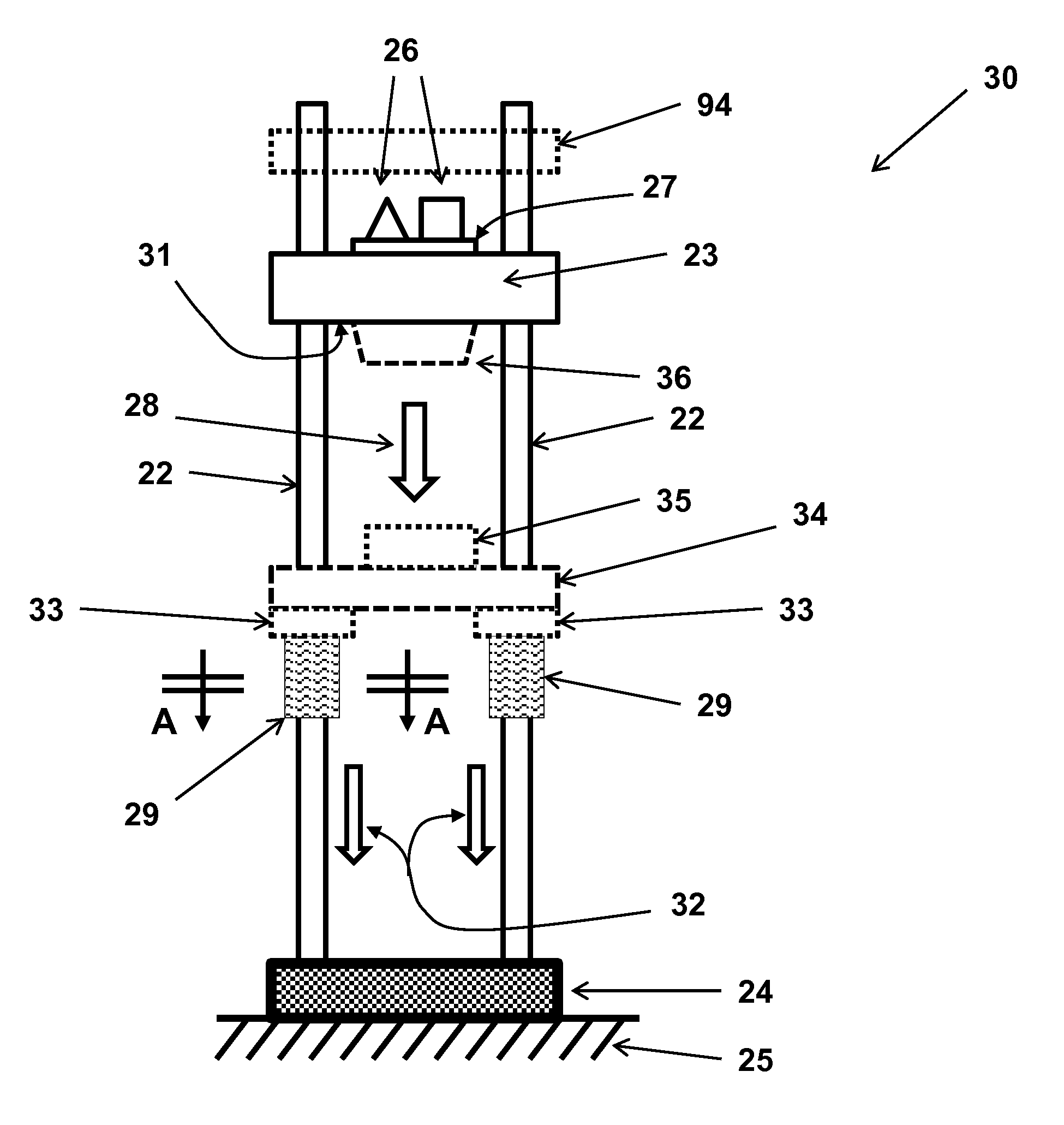

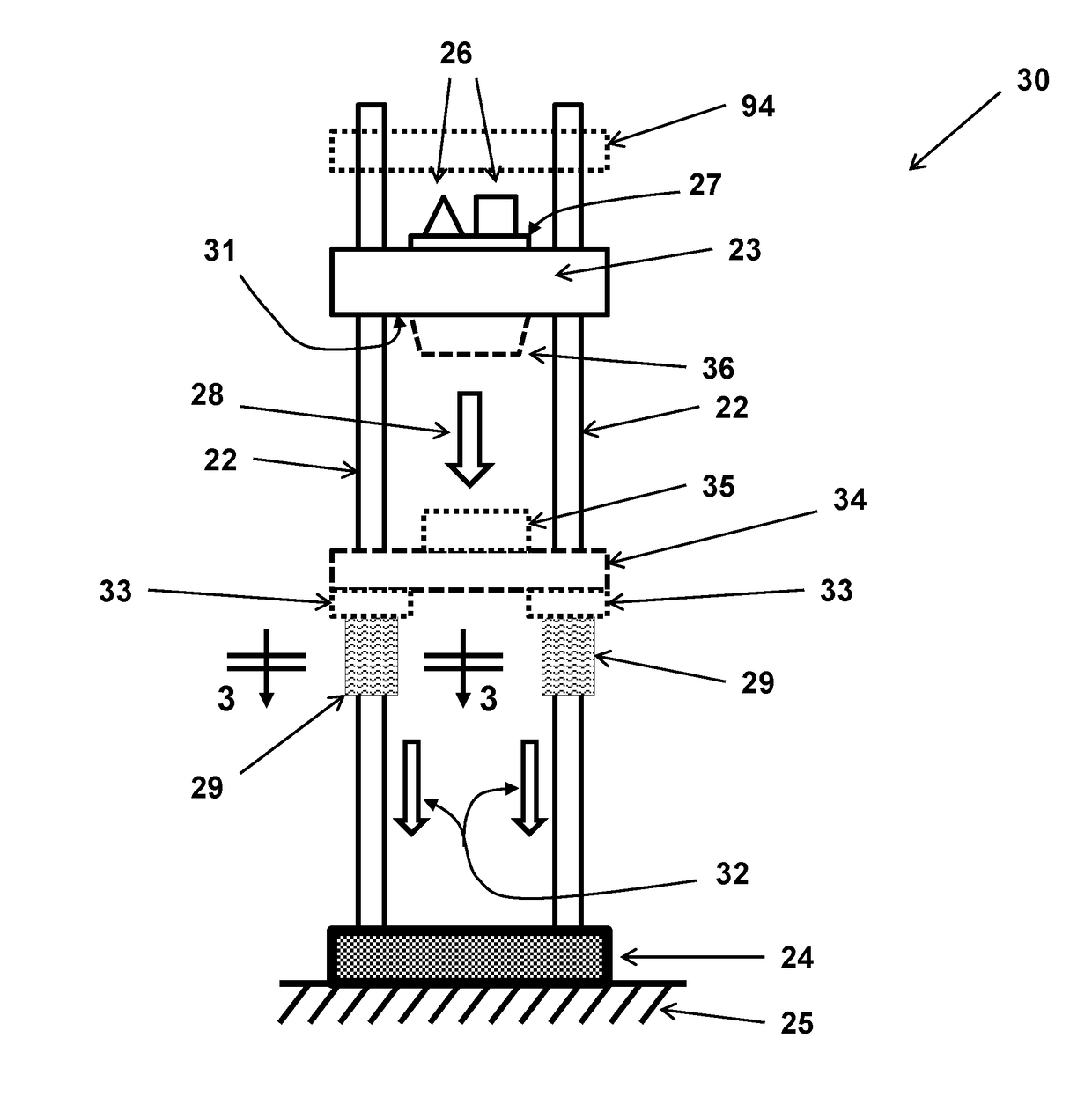

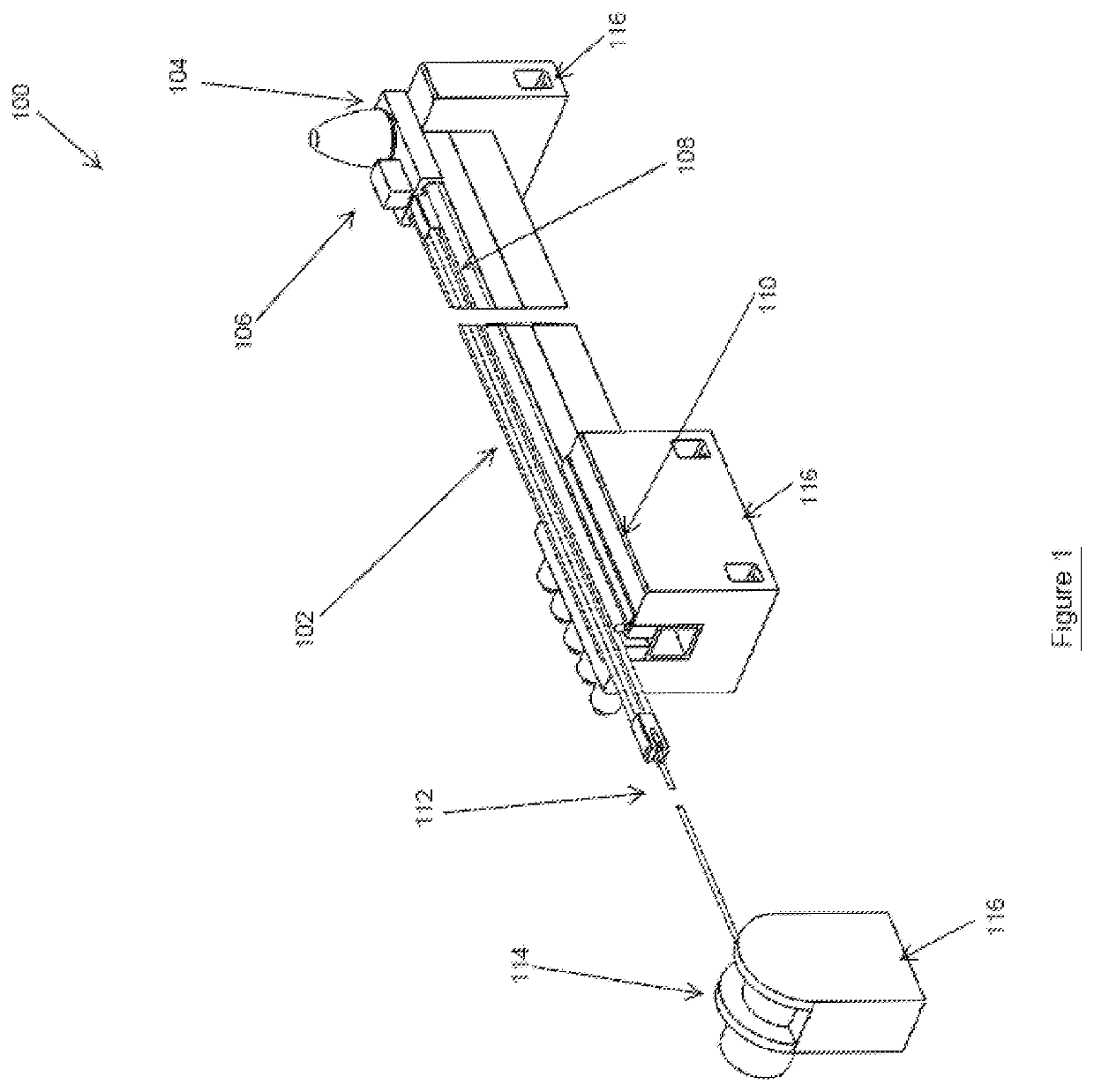

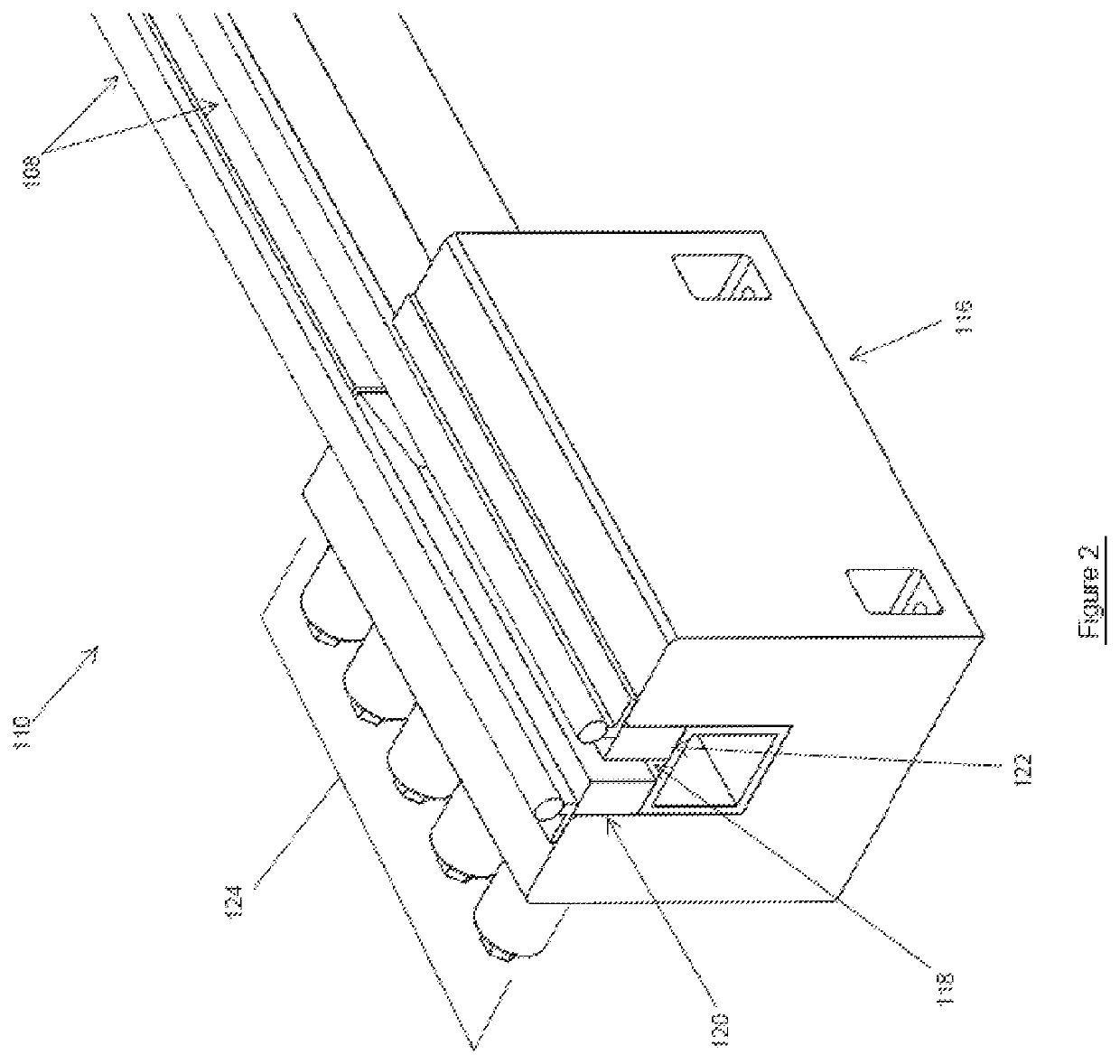

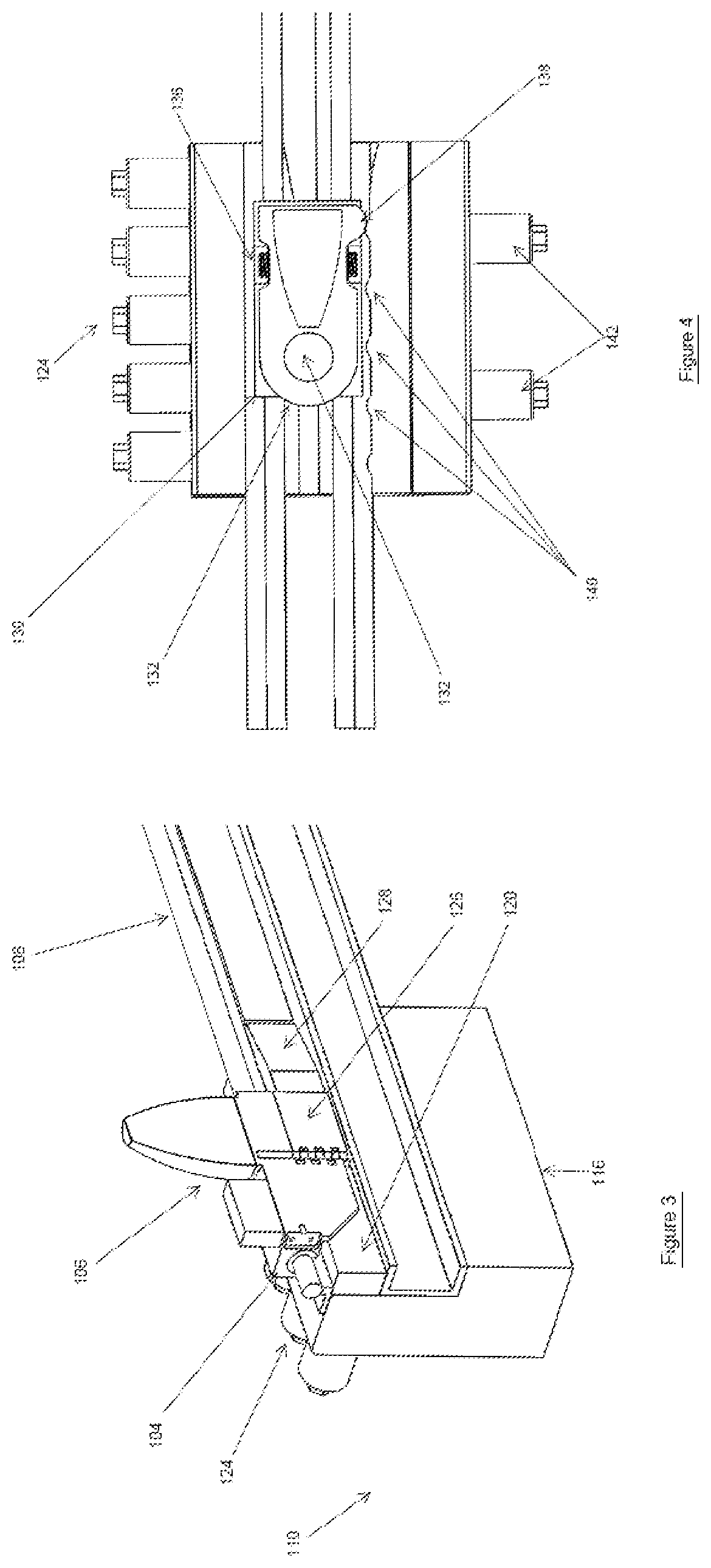

Mechanical High-G Shock Testing Machines

ActiveUS20160161362A1Quick installationShort timeMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceEngineeringShock testing

A shock testing machine including: a movable impact mass upon which one or more components to test are mounted; one or more rails upon which the impact mass is movable; and a brake operatively engageable with the movable impact mass after the movable impact mass has moved a predetermined distance to retard the movement of the movable impact mass such that the components to be tested experience a deceleration profile.

Owner:OMNITEK PARTNERS LLC

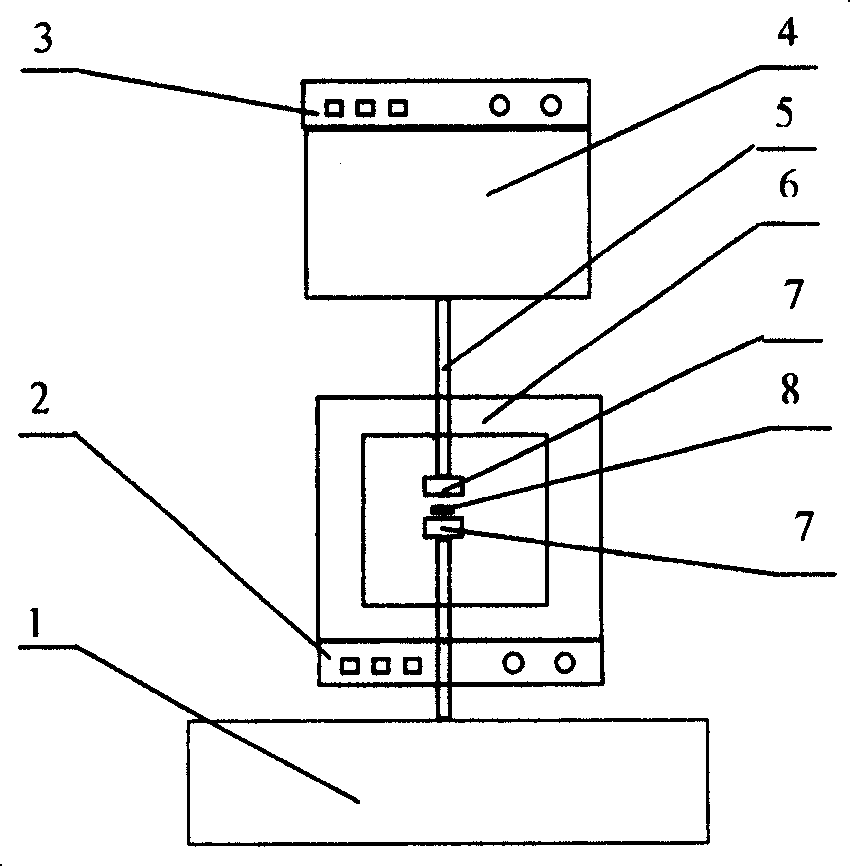

Shock testing machine and shock testing method

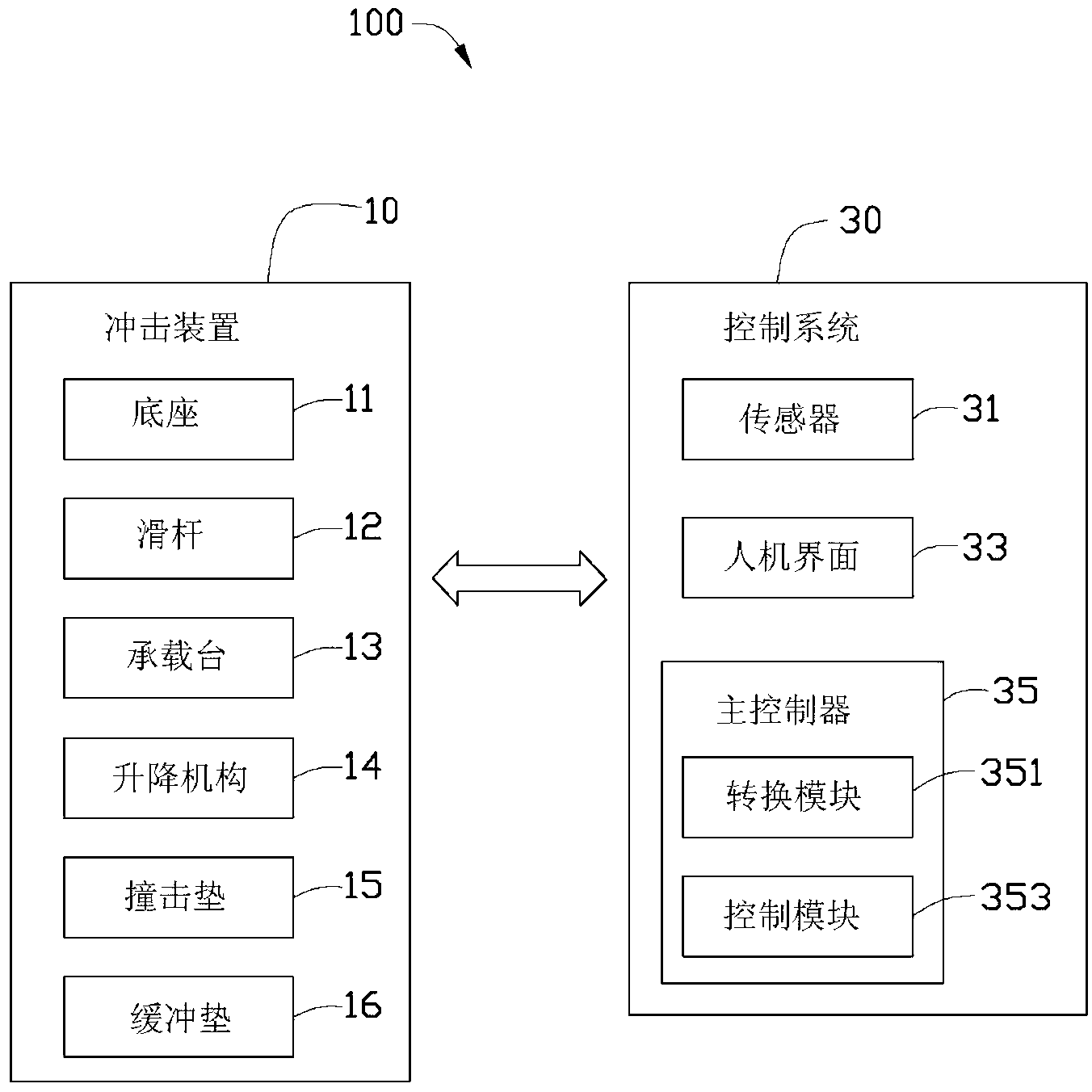

InactiveCN102879163AImprove work efficiencyExtended service lifeShock testingControl systemEngineering

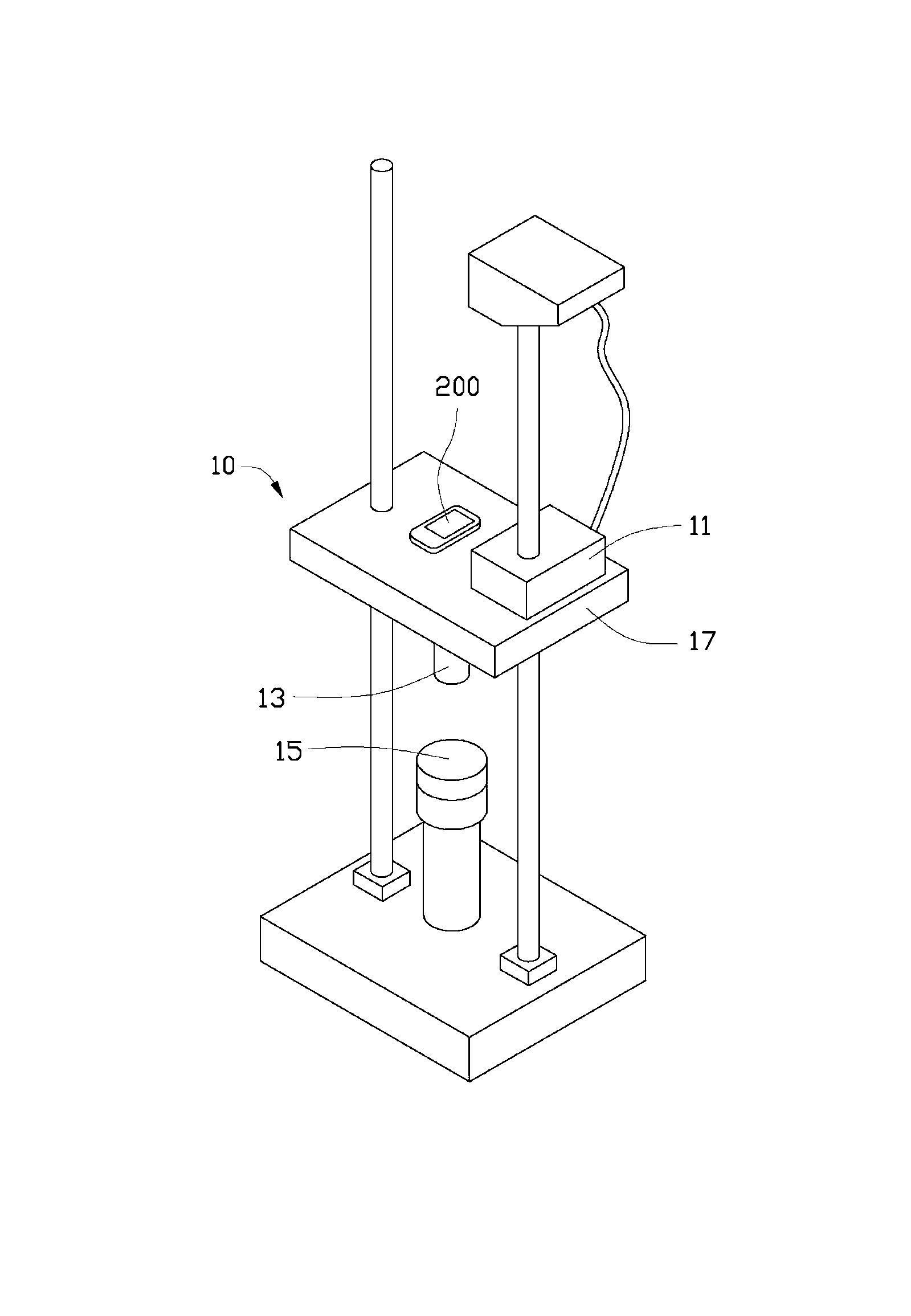

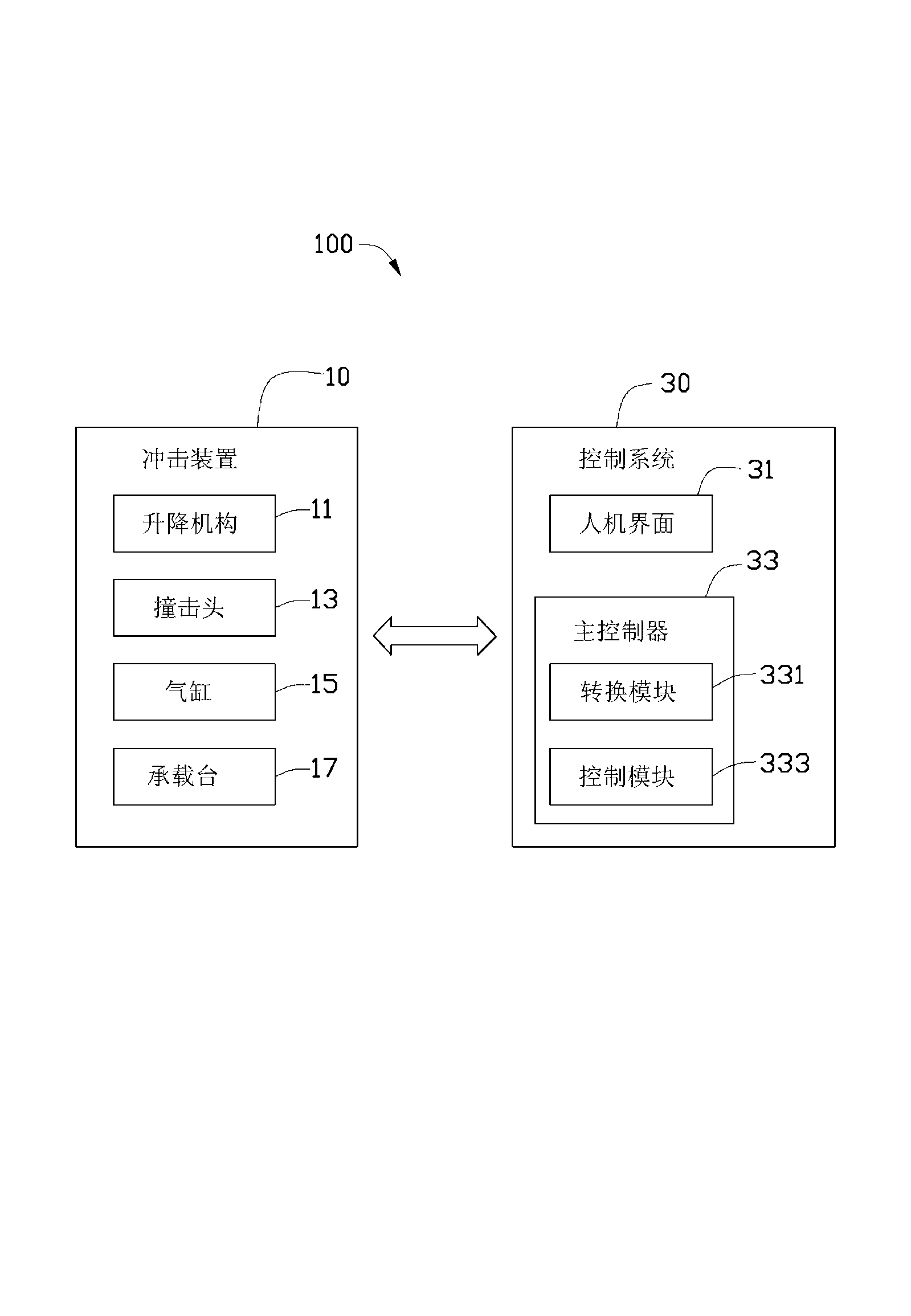

The invention discloses a shock testing machine. The shock testing machine comprises a shock device and a control system, wherein the shock device comprises a bearing table, an impact pad, a buffering pad and a lifting mechanism; the impact pad is arranged on the bearing table and faces to the buffering pad; the lifting mechanism is connected with the bearing table; the control system comprises a main controller; the main controller comprises a conversion module and a control module; the conversion module is used for calculating the numerical value of the parameter of the impact device needing to be set according to the numerical value of the impact parameter measured due to the requirement of the shock testing machine; and the lifting mechanism is controlled by the control module according to the numerical value of the parameter which needs to be set and is calculated by the conversion module, so as to drive the bearing table to move up and down by the lifting mechanism. The invention further provides a shock testing method; and the shock testing method has high work efficiency and provides the service life of the shock testing machine.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

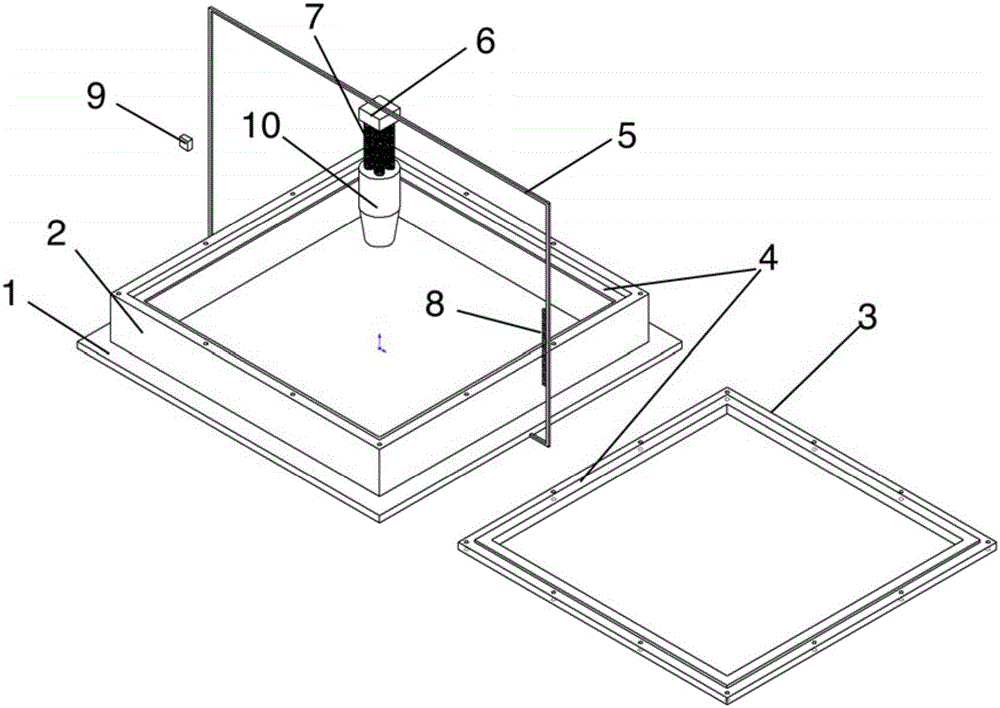

Shock testing device of large-scale protecting glass

InactiveCN105004622AGuaranteed accuracyMeasure bounce speedInvestigating material hardnessExperimental testingEngineering

The invention relates to the technical field of experimental testing, and aims at providing a shock testing device of large-scale protecting glass. The shock testing device comprises a clamping component and a suspending component. The clamping component comprises a base, a supporting steel box, an upper frame and a rubber gasket. The supporting steel box is used for placing the large-scale flat-panel protecting glass. The upper frame is capable of connecting with the supporting steel box tightly and enables the rubber gasket to be arranged between the upper frame and the supporting steel box. The suspending component comprises a suspending frame, an electromagnet, a spring, laser pens and a DV. The electromagnet is installed at the center of a top beam of the suspending frame, the spring is fixed on the electromagnet, a shocking piece is absorbed at the lower end of the spring through the electromagnet, the four faces of one frame column of the suspending frame are provided with scales, and a row of laser pens are tied on the other frame column of the suspending frame. The DV is arranged on the suspending component. According to the shock testing device of the large-scale protecting glass, the large-scale protecting glass is difficult to vibrate and deviate, the veracity of testing is guaranteed, the bouncing speed of the shocking piece can be measured, and a more completed analysis is conducted on the shock testing.

Owner:ZHEJIANG UNIV

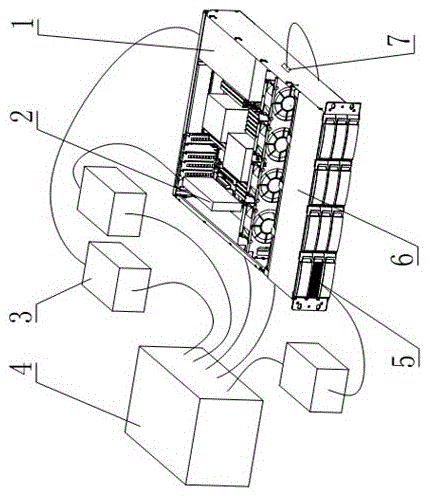

Vibration and impact test method of server chassis internal and external parameters and vibration and impact test device of server chassis internal and external parameters

InactiveCN105043699AWith test informationIncrease flexibilityVibration testingShock testingInformatizationEmbedded system

The present invention discloses a vibration and impact test method of server chassis internal and external parameters and a vibration and impact test device of the server chassis internal and external parameters. The vibration and impact test method of the server chassis internal and external parameters is characterized in that during a server vibration and impact test process, the equivalent counter weight blocks in which the acceleration sensors are arranged are arranged inside a server chassis to substitute for a real hard disk, a power supply and an expansion video card, and the built-in acceleration sensors acquire the linear stress and torsion situations of the real hard disk, the power supply and the expansion video card; the acceleration sensors are pasted on the external surface of the chassis to measure the linear acceleration of the pasting points; and the numerical values of the acceleration sensors inside and outside the chassis are utilized to quantize and describe the states of parts during the server vibration and impact test process. The method and device of the present invention help the anti-vibration and anti-impact structure design of the server chassis a lot, provide more determination bases for the reliability test result analysis, and have the characteristics of being test informatization, being high in flexibility, and being easy to operate.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

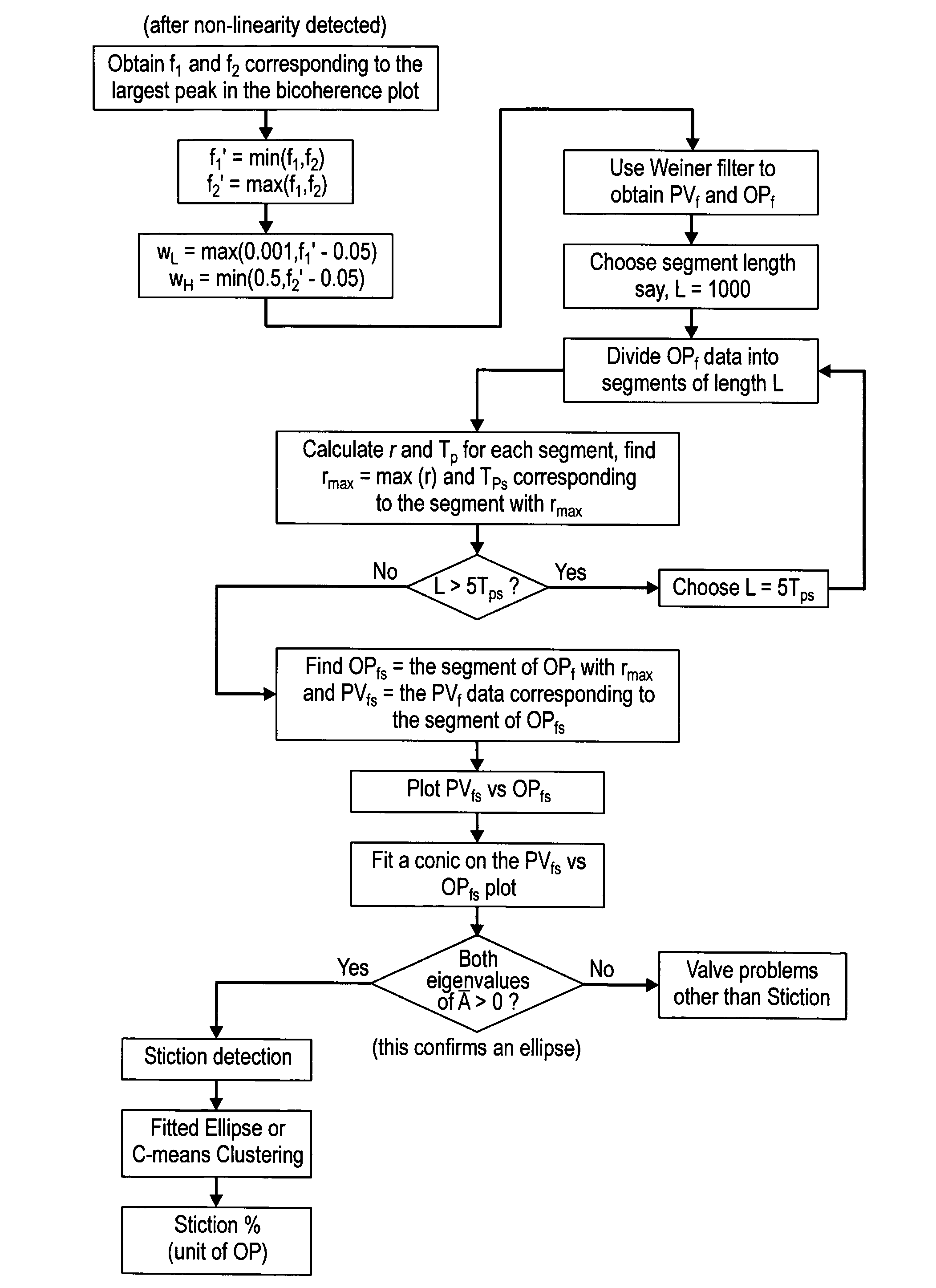

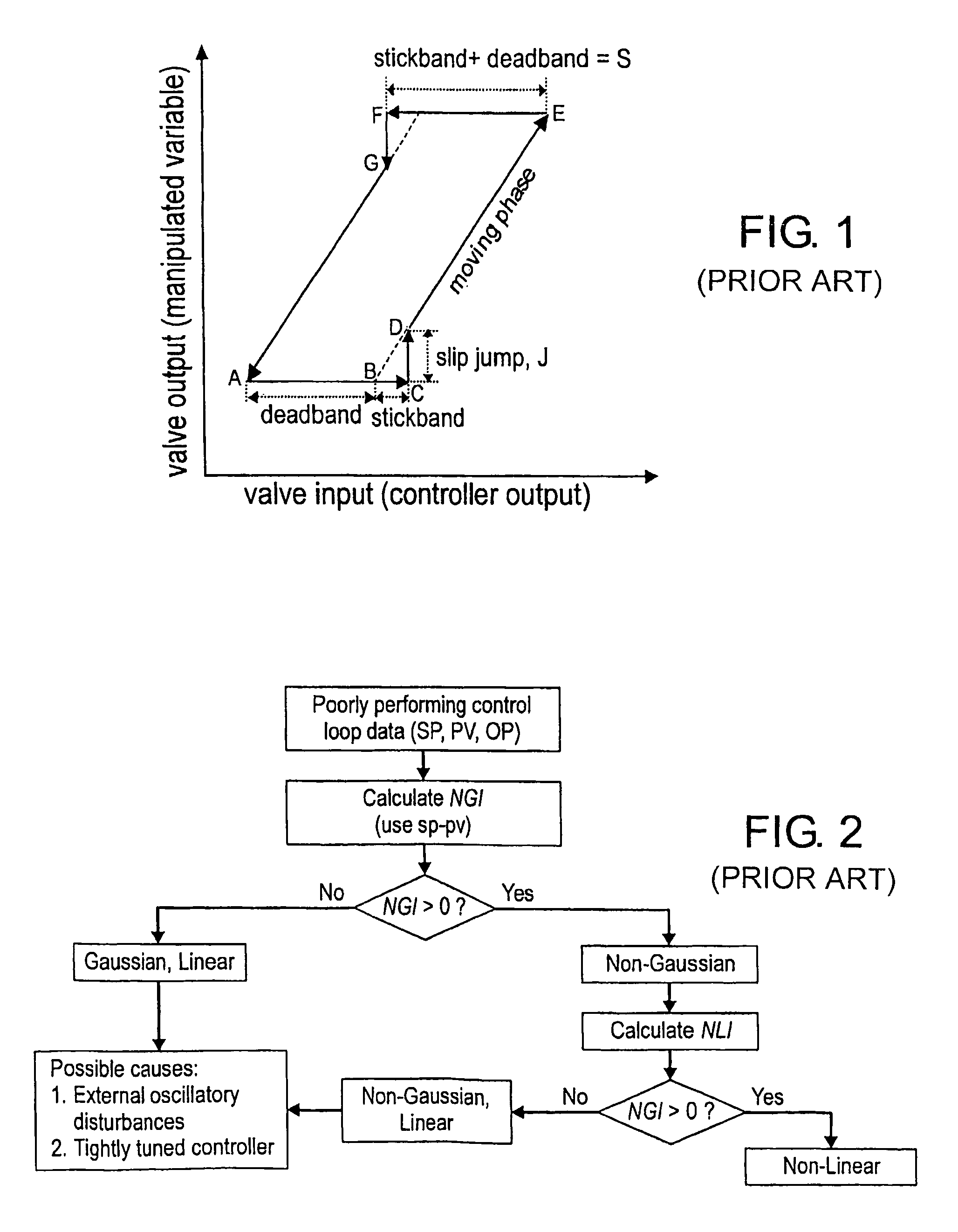

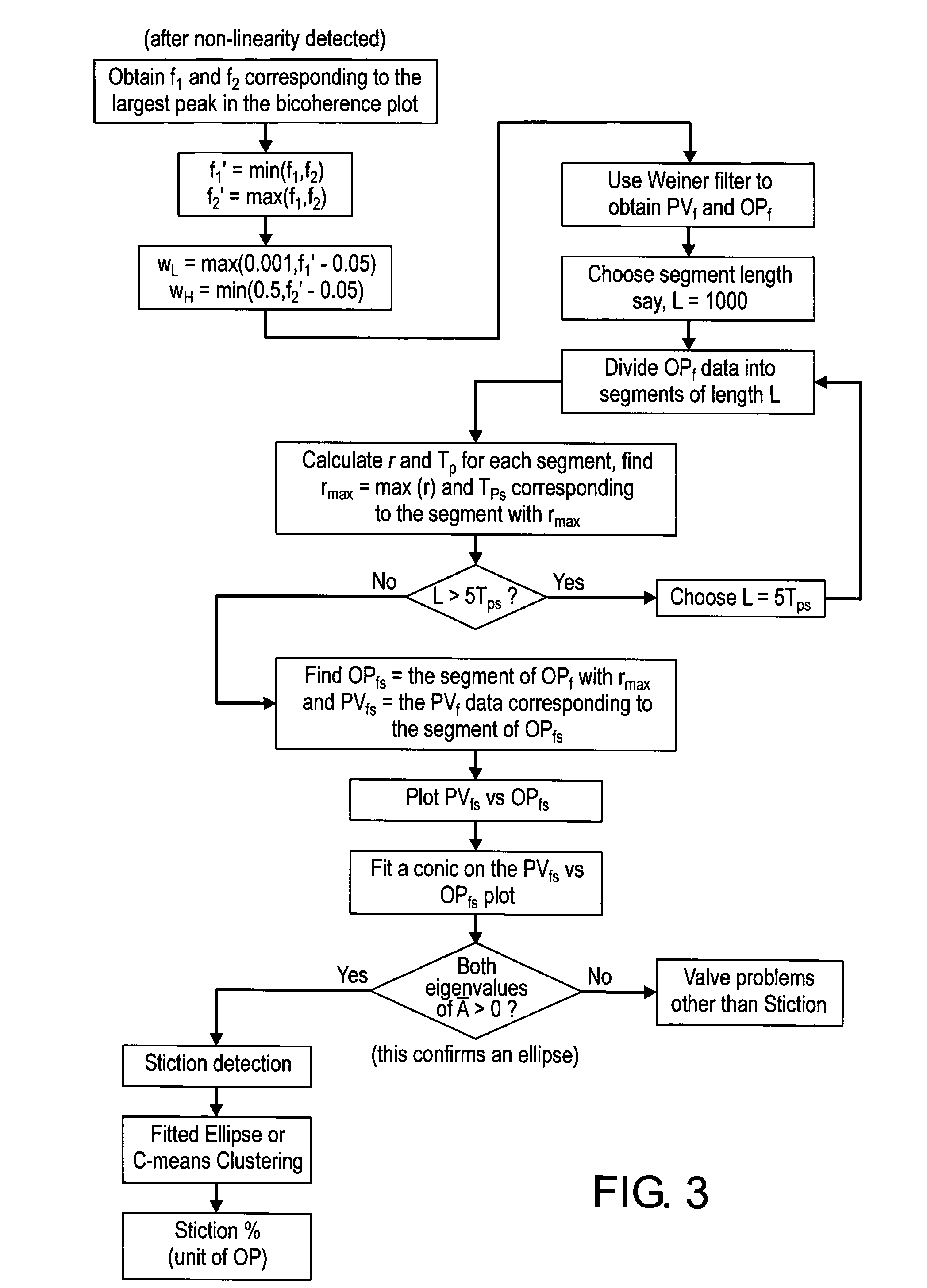

Detection and quantification of stiction

An effective non-intrusive data-based monitoring method may reduce the cost of control loop performance maintenance by screening and short-listing those control loops or valves that need maintenance. The invention comprises a data-based, model-free, non-invasive method that can automatically detect and quantify stiction present in control valves. The method does not require the implementation of any additional valve travel test or, as commonly known, bump test of the control loop. The method may detect and quantify stiction using controlled variable (pv), controller output (op) and set point (sp) data. It does not require valve positioner (mv) data.

Owner:THE UNIV OF ALBERTA +1

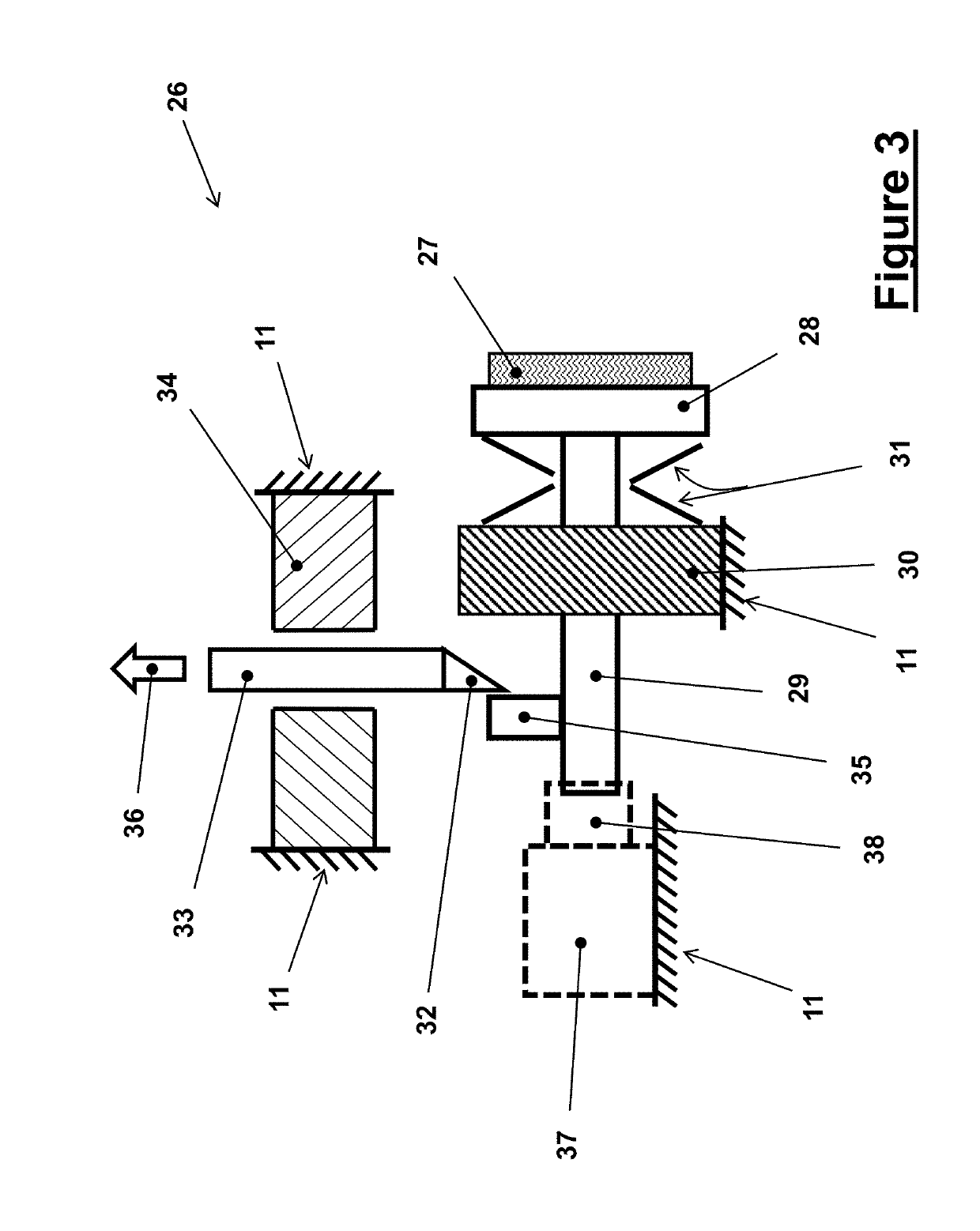

Mechanical High Spin-Shock Testing Machines

ActiveUS20180067029A1Short timeQuick installationAmmunition projectilesAmmunition testingSpinsEngineering

A rotary shock testing machine including: a base; a shaft rotatable relative to the base; a test disc for holding one or more specimens to be tested, the test disc being rotatable with the shaft; an actuator for applying a rotation to the shaft and test disc; and a brake for applying a braking force to the test disc to subject the one or more specimens to a rotary shock.

Owner:OMNITEK PARTNERS LLC

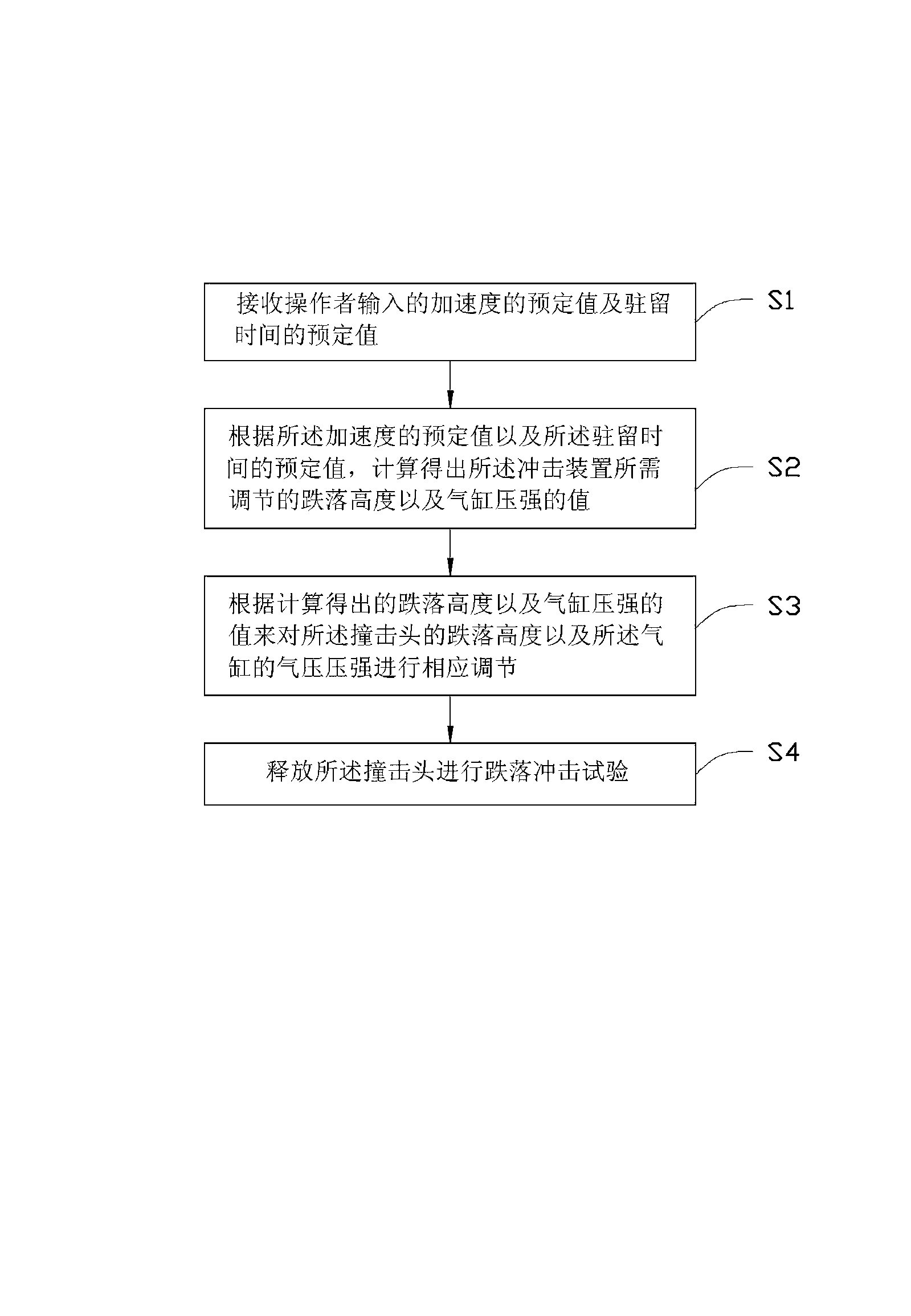

Shock testing machine and method for carrying out shock test by same

InactiveCN102865988AImprove work efficiencyExtended service lifeShock testingControl systemMaster controller

The invention relates to a shock test machine which comprises a shock device and a control system. The control system comprises a master controller, and the shock device comprises a lifting mechanism, an impact head driven by the lifting mechanism and an air cylinder arranged opposite to the impact head. The lifting mechanism under control of the master controller adjusts the falling height of the impact head automatically. The master controller further comprises a conversion module and a control module. The conversion module is used to calculate the falling height needed to be adjusted for the impact device and a value of the pressure of the air cylinder according to a predetermined value of acceleration and a predetermined time of residence. The control module is used to control the lifting mechanism to adjust the falling height of the impact head according to the value of the falling height obtained through calculation and adjust the pressure of the air cylinder according to the value of the pressure of the air cylinder. The shock test machine has higher work efficiency and a longer service life. The invention further relates to a method for carrying out the shock test by the shock test machine.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

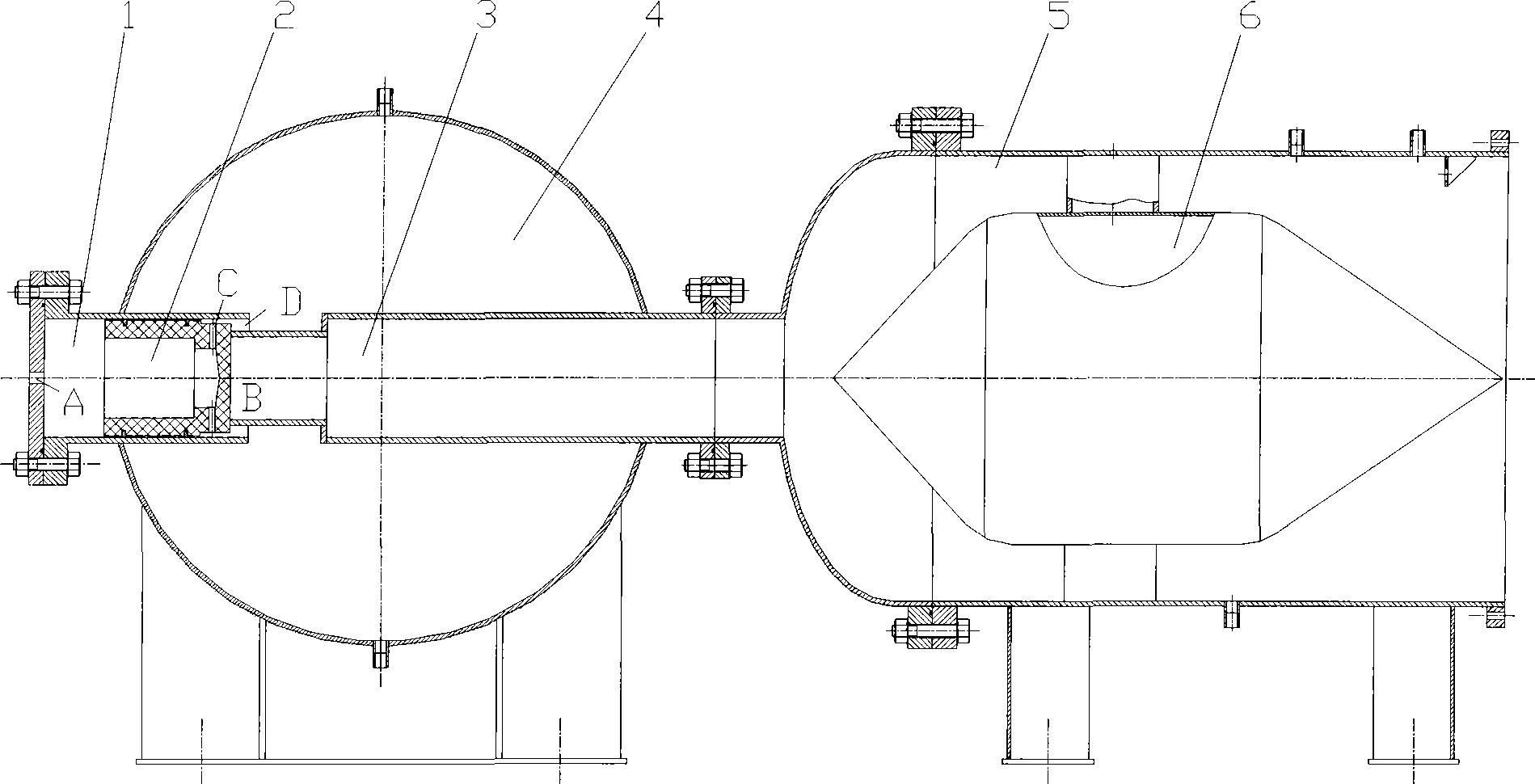

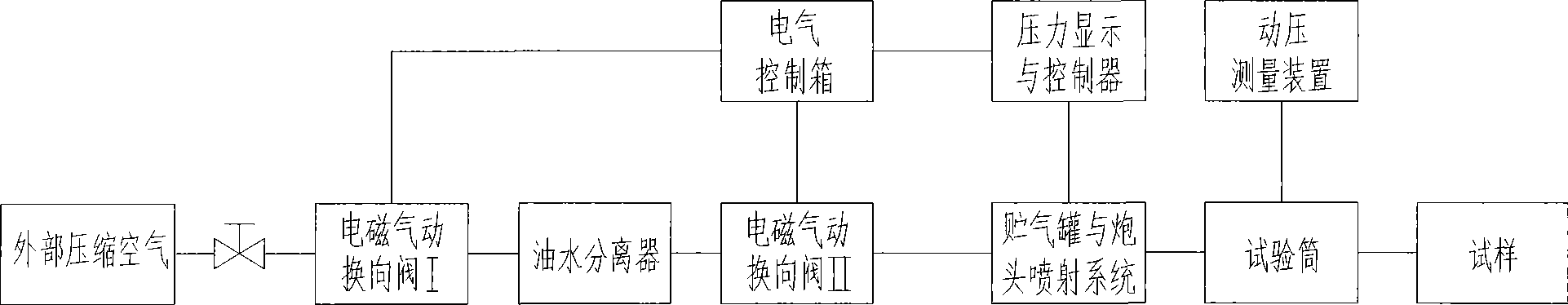

Gas shock testing machine for detecting fragile cover of projectile storage and transportation launching tube

ActiveCN101487781AGuaranteed pressure distributionEasy to operateStrength propertiesControl systemStressed state

The invention relates to an air impact testing machine for detecting a fragile / fissile cover of a missile storage / transportation launcher. The testing machine comprises a cannon head, an air tank, a testing cylinder, an electromagnetic pneumatic reversing valve and a central control system. The cannon head is transversely arranged in the middle of the air tank; the back end of the cannon head is connected with the front end of the testing cylinder; the back end of the testing cylinder is used for arranging the fragile / fissile cover of the missile storage / transportation launcher for testing; the electromagnetic pneumatic reversing valve is arranged at the front end of the cannon head; and the central control system is connected with a control coil of the electromagnetic pneumatic reversing valve. The invention has the advantages that the pressure distribution on the inner wall of the fragile / fissile cover from the high-speed flowing compressed air during the test is guaranteed to be completely equal to the action force distribution on the inner wall of the fragile / fissile cover from the fuel under the actual use condition, and the stress state of the specimen under the analogue test condition guaranteed to be consistent to the actual use condition; and the air impact testing machine uses the compressed air as power and has the advantages of simple operation, low labor and low cost. The air impact testing machine is suitable to tests in large quantities.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

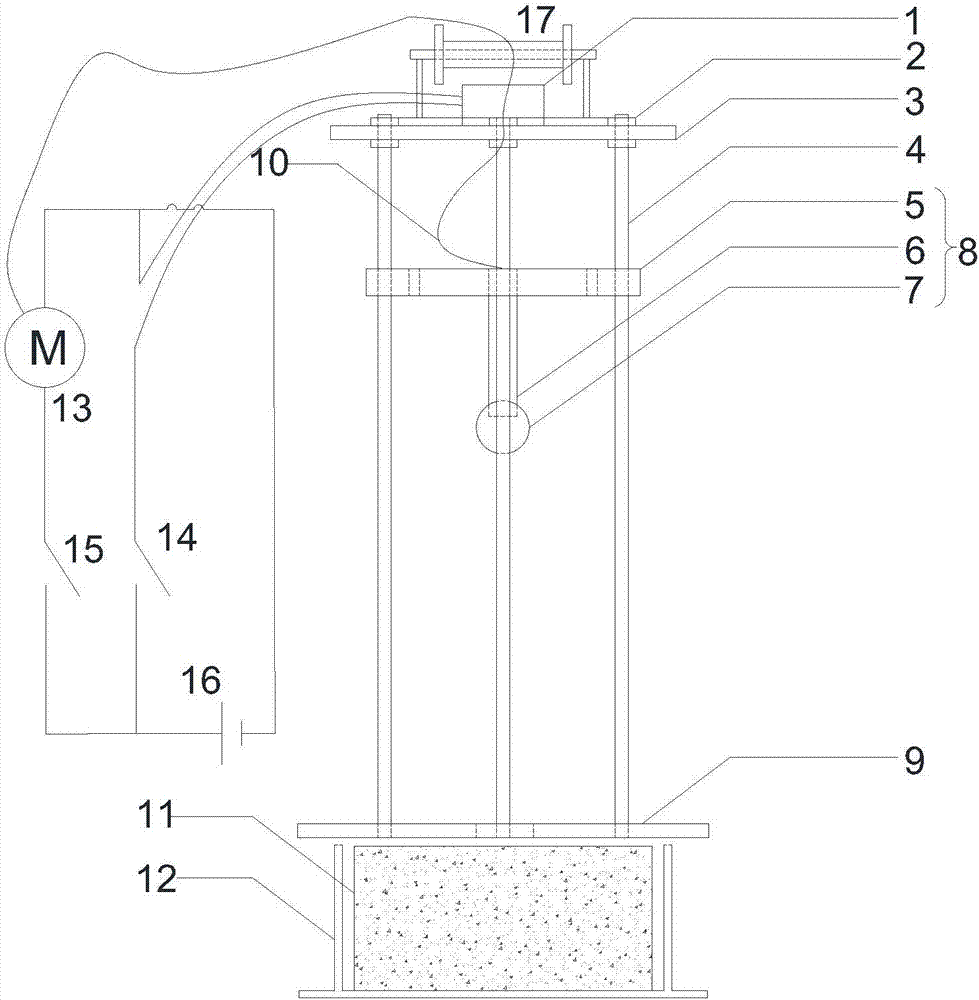

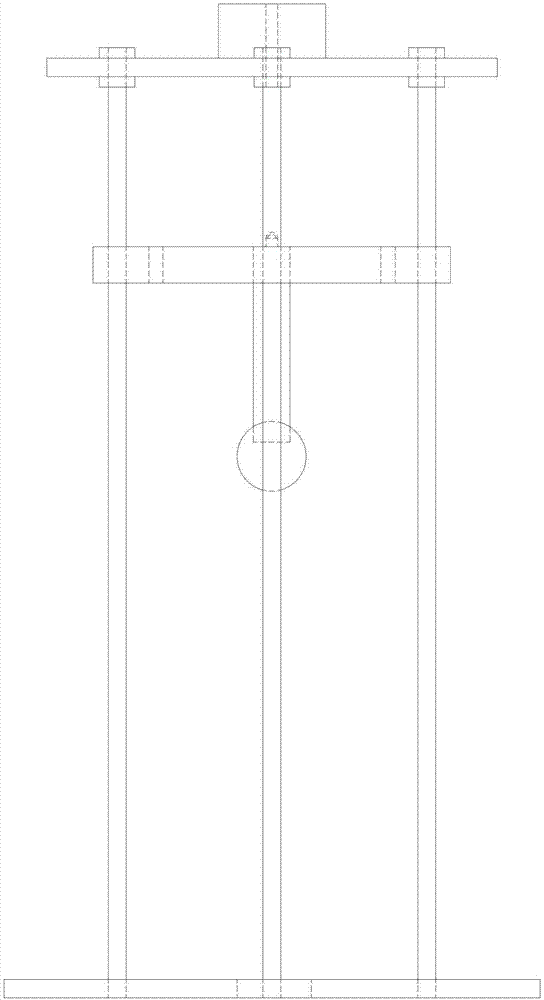

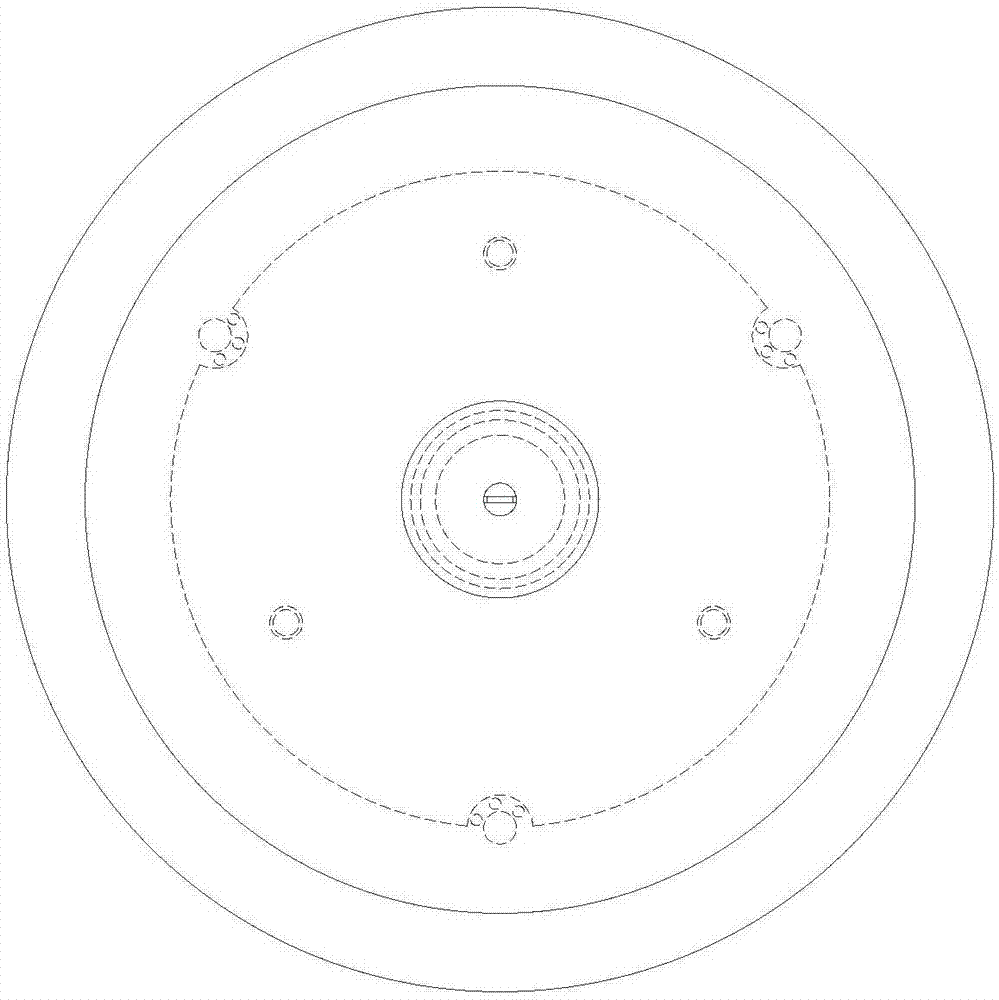

Temperature-regulating load-regulating frequency-regulating impact test machine

InactiveCN101191762AEasy to manufactureShock frequency continuously adjustableMaterial strength using repeated/pulsating forcesAlloyEngineering

The invention discloses an impact tester and belongs to the test device of impact performance and life estimation of materials such as hard alloy, ceramics and so on. The invention comprises a circulating load power generator, a power control device, a mechanical transmission device, a sample clamp, a heating and temperature regulating device, a support base and so on. The invention fixes the test sample on an impact test clamp and places the test sample in a heating device together with the clamp; the power generated by the circulating load power generator is converted into the impact force and acts on the test sample through the mechanical transmission device; the temperature, the load and the frequency of the impact test are changed by adjusting the temperature regulating device and the power control device. The invention has the functions of temperature regulation, load regulation and frequency regulation, and can evaluate the anti-impact performance and the service life of the sample according to the generation and extension of the cracks and failure condition of the tested sample.

Owner:CENT SOUTH UNIV

Mechanical high-G shock testing machines

ActiveUS9970844B2Quick installationShort timeShock testingStrength propertiesEngineeringShock testing

A shock testing machine including: a movable impact mass upon which one or more components to test are mounted; one or more rails upon which the impact mass is movable; and a brake operatively engageable with the movable impact mass after the movable impact mass has moved a predetermined distance to retard the movement of the movable impact mass such that the components to be tested experience a deceleration profile.

Owner:OMNITEK PARTNERS LLC

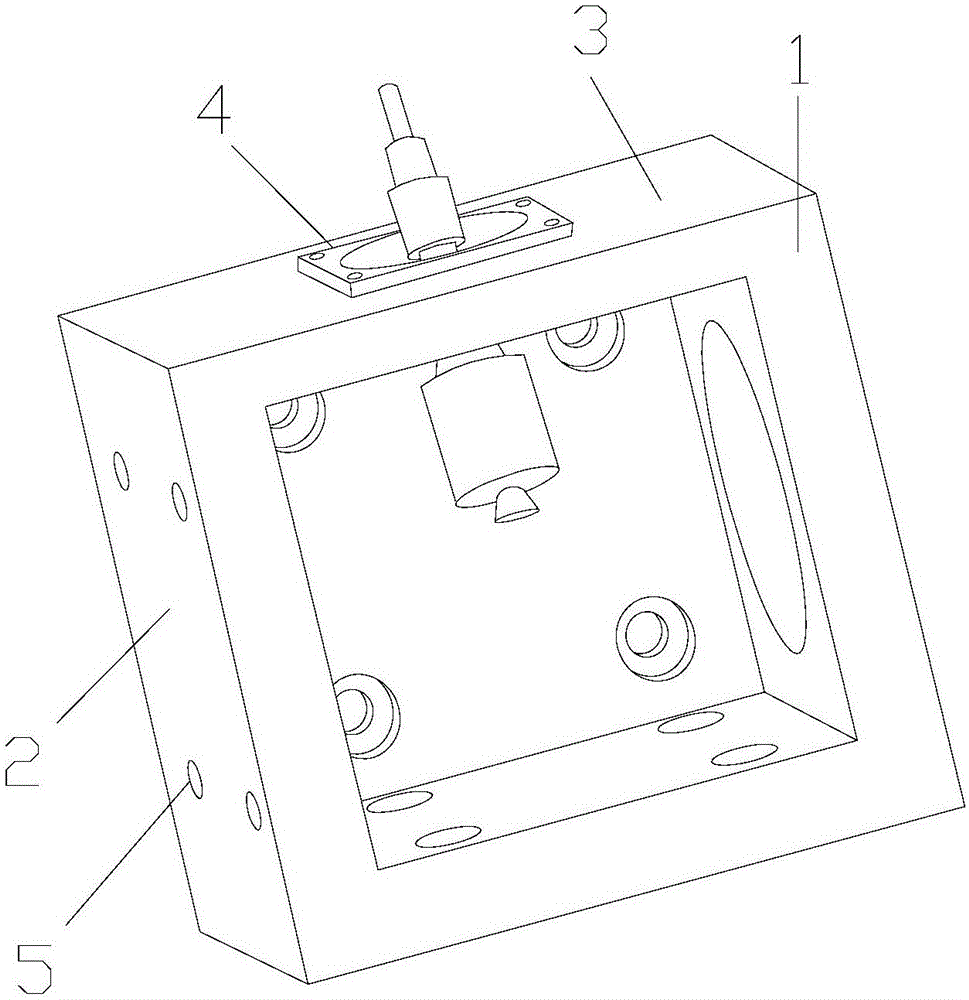

Vibration impact test fixture

InactiveCN106338374AReasonable transmission of vibration forceImprove efficiencyVibration testingEngineeringTested time

The present invention relates to the technical field of vibration impact test equipment and provides a vibration impact test fixture which comprises a fixture body which comprises at least two fixture mounting surfaces and two production installation surfaces. The production installation surfaces are provided with connection pieces for fixing a product, and the two production installation surfaces are fixed to a vibration test platform through fasteners. Since the device is provided with multiple installation surfaces, the installation and test of multiple products can be carried out through replacing different connection pieces. Through arranging the multiple fixture installation surfaces, each direction of the product can be tested, and the vibration impact tests of multiple products can be carried out at the same time. The test time and cost are greatly saved, and the efficiency is improved. About 10 minutes are needed in one time of changing a direction. The vibration force transfer of the vibration fixture is reasonable, and the quality of the vibration test is improved. The removal of the test product is not needed in changing a direction, and thus the probability of the man-made damage of the product is greatly reduced.

Owner:TIANJIN AEROSPACE RELIA TECH +2

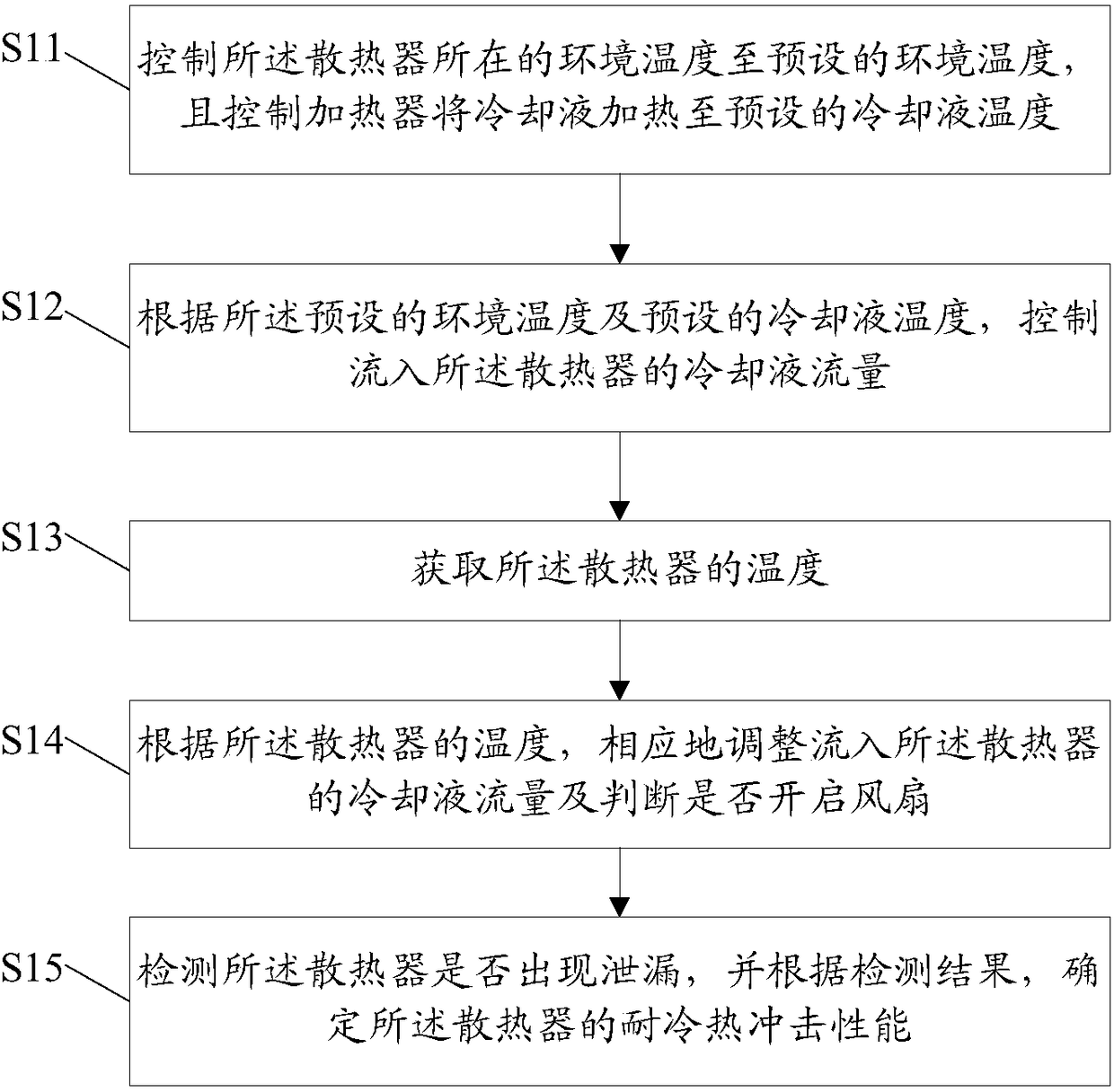

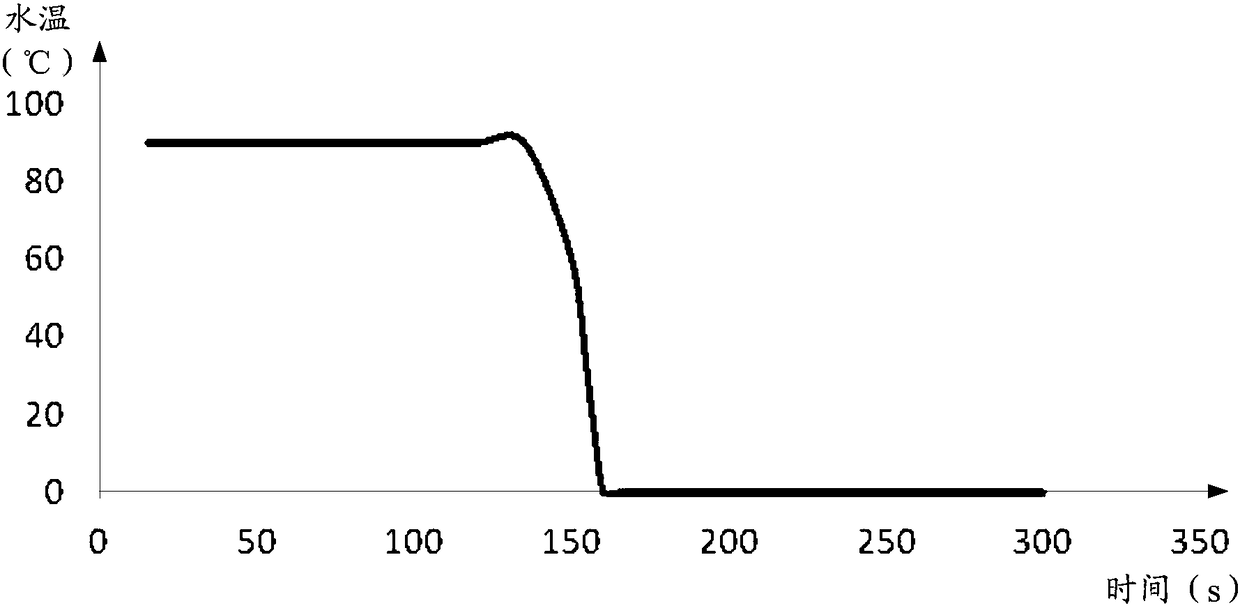

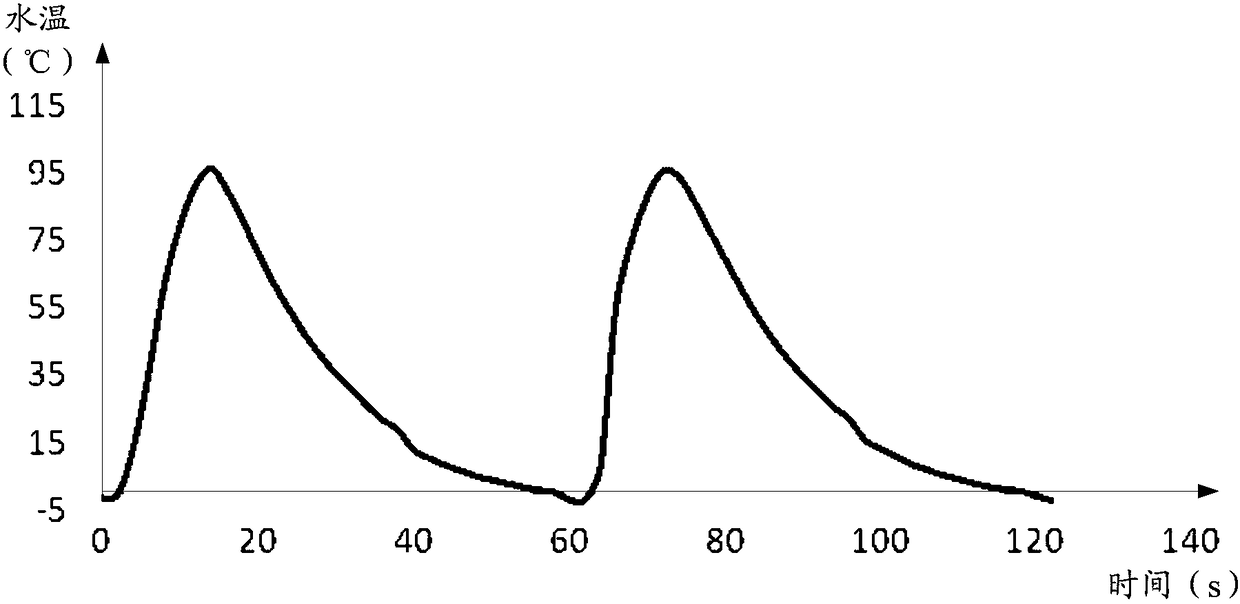

Radiator hot and cold shock-testing method, device and system

ActiveCN108088692AImprove accuracyImprove securityStructural/machines measurementLiquid temperatureEngineering

A radiator hot and cold shock-testing method, device and system are provided; the method comprises the following steps: controlling the ambient temperature, to where the radiator is located, to be ata preset ambient temperature, and controlling a heater to heat a cooling liquid up to a preset cooling liquid temperature; controlling the cooling liquid flow entering the radiator according to the preset ambient temperature and the preset cooling liquid temperature; obtaining the temperature of the radiator; correspondingly adjusting the cooling liquid flow entering the radiator according to theradiator temperature and determining whether to open a fan or not, wherein the relative relation between the fan and the radiator is same with the mounting relative positions on a vehicle, and the fanis used for diffusing the heat of the cooling liquid entering the radiator; detecting whether the radiator is leaking or not, and determining the hot and cold shock resistance property of the radiator according to the detection result. The method and device can improve the radiator hot and cold shock-testing accuracy.

Owner:SAIC MOTOR

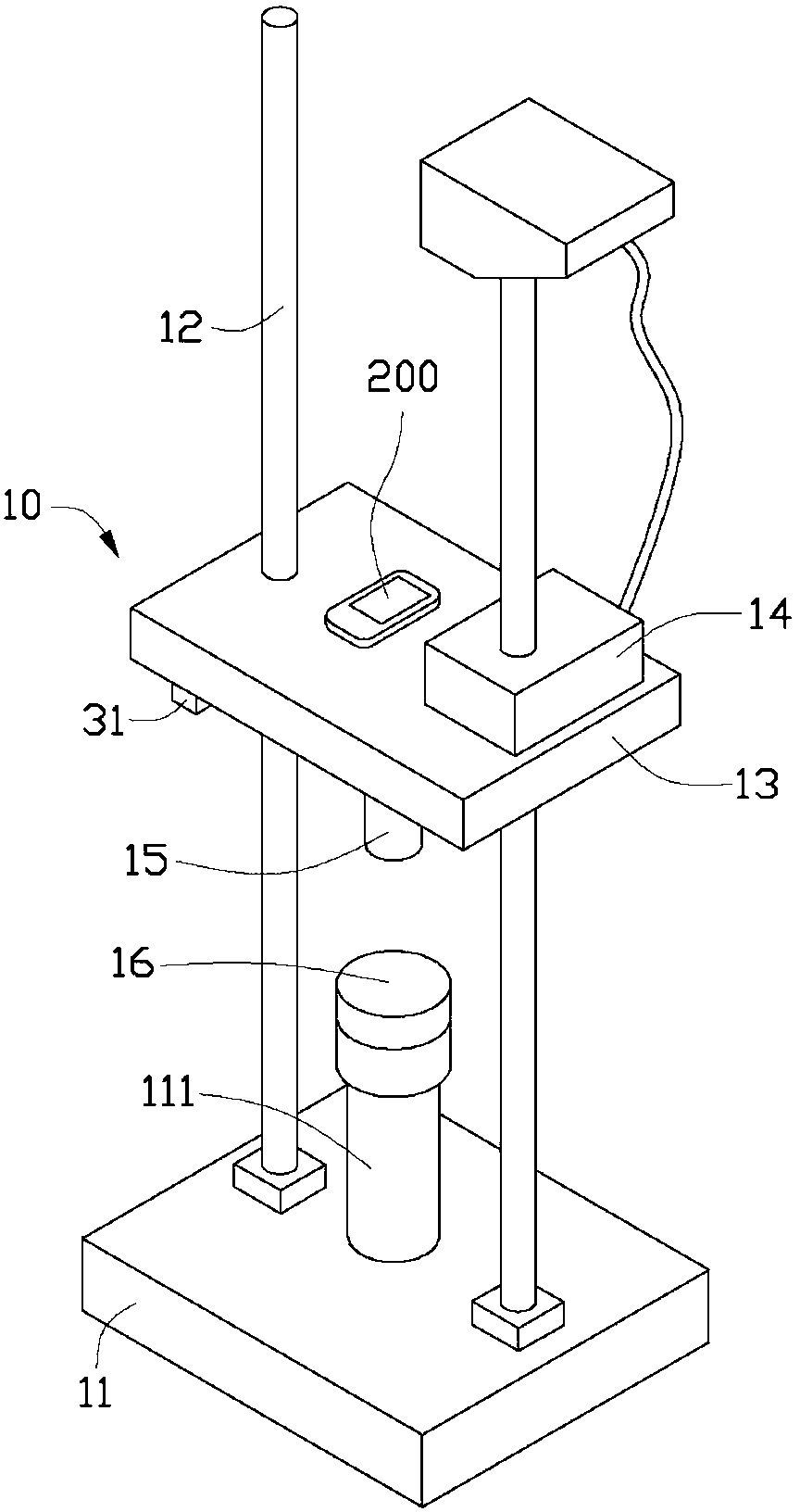

Apparatus and method for detecting shock resistance of concrete

ActiveCN107966375AEasy to installImprove assembly effectStrength propertiesShock resistancePetroleum engineering

The invention discloses an apparatus and a method for detecting shock resistance of concrete. The apparatus for detecting shock resistance of concrete comprises a chassis and an impact device; the chassis is placed over a concrete test block, the center of the chassis is provided with an impact hole in breakthrough, and the chassis is vertically provided with several guide rail rods; the impact device can climb on the guide rail rods and freely fall off, and the impact device can freely fall off from the guide rail rods and transverses the impact hole and impacts on the concrete test block. The method for detecting shock resistance of concrete comprises the following steps: a step 1, at least five concrete test blocks are poured; a step 2: the apparatus for detecting shock resistance of concrete is installed; a step 3: a motor with forward or reverse rotation is provided; a step 4: shock-testing is carried out; a step 5: the step 4 is repeated till the concrete test block appears cracking or penetrated cracks; a step 6: site clearing is carried out. The apparatus has small volume and is easy to carry, and shock resistance detection of the concrete can be rapidly completed.

Owner:SOUTHEAST UNIV

Thermal energy equipment anti-shock testing device

The invention aims to provide a thermal energy equipment anti-shock testing device; the middle of the bottom of the interior of a testing box is provided with a slide rail, the slide rail is providedwith a mounting fixed seat, and the left side of the mounting fixed seat is provided with a first drive motor; the left side and the right side of the interior of the testing box are each provided with a side slide rail, the inner side of each side slide rail is provided with a shock cylinder, the right side of each shock cylinder is connected with a shock push plate, and the bottom of each shockcylinder is provided with a second drive motor. A to-be-tested part is fixed on the mounting fixed seat and can have the position adjusted in the horizontal direction, then the shock cylinders are started, the surface of the to-be-tested part is shocked by the shock push plates, the positions of the shock cylinders can be adjusted according to the actual situation, a removable shock block is arranged for shocking, the to-be-tested part is clamped to push and pull by the shock push plates, an illuminating lamp and an observation camera arranged in the testing box are used for observation of thedetection process, a hot air inlet pipe and a cold air inlet pipe are arranged for adjusting the temperature in the testing box, and an shock test can be fast and efficiently carried out.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

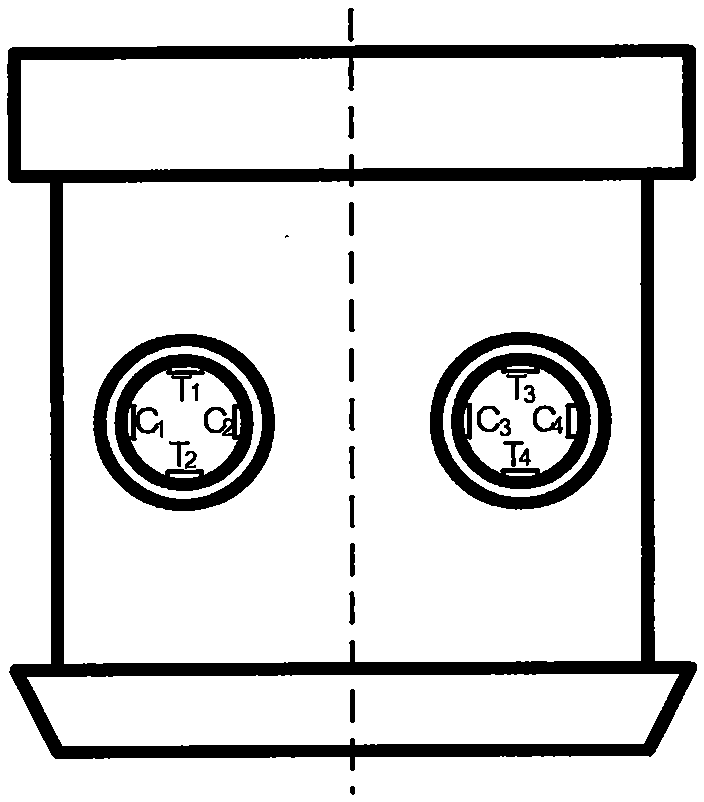

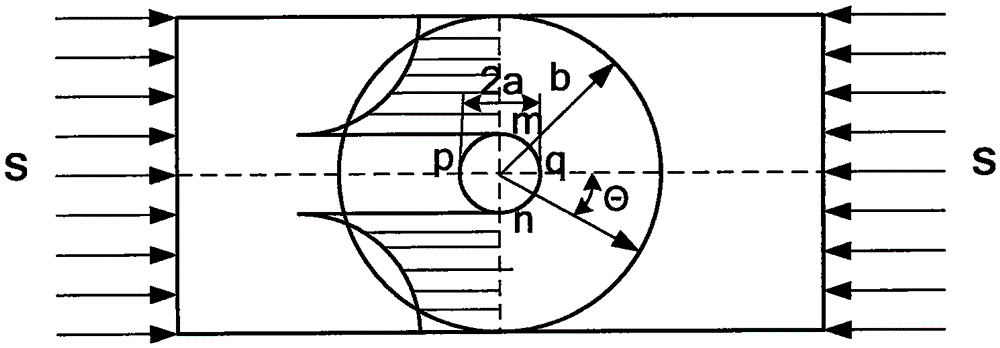

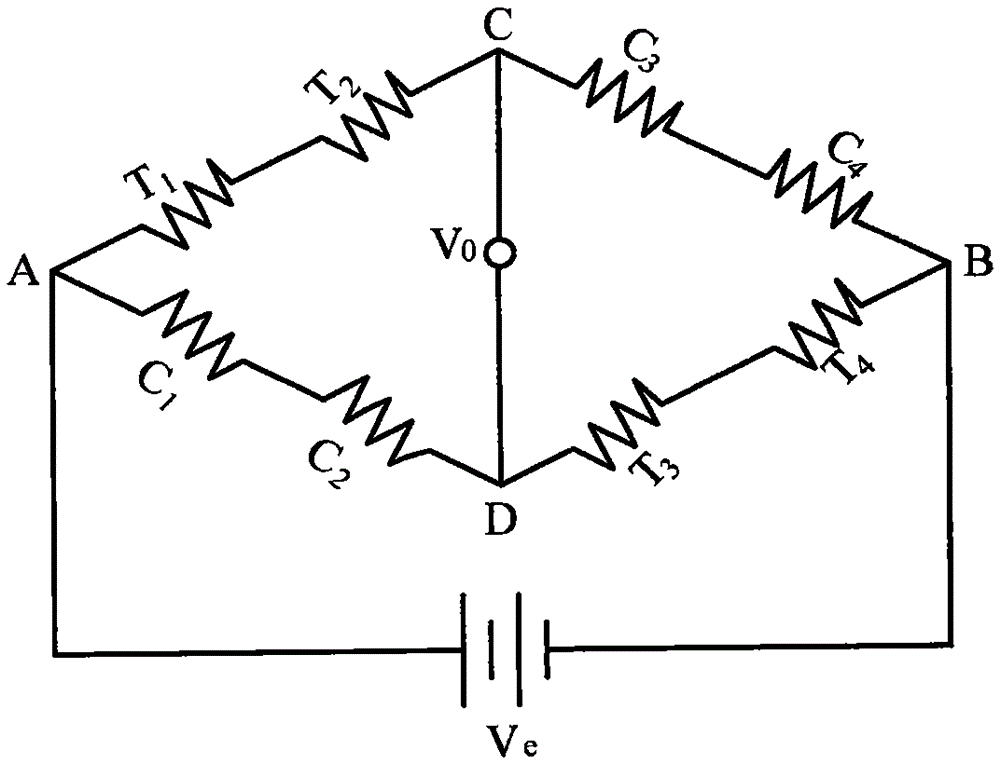

Drop hammer structural design based on stress concentration principle and test method thereof

InactiveCN105547868ASimple test methodReduce distractionsMaterial strength using repeated/pulsating forcesStress concentrationFull bridge

The invention belongs to the technical field of impact tests, and in particular relates to drop hammer structural design based on a stress concentration principle and a method adopting a Wheatstone full bridge circuit for testing impact force. Due to the fact that the elastic strain of a drop hammer is relatively small, in order to improve the test sensitivity, and improve the capacity of resisting disturbance, the drop hammer is made into a thin plate structure, holes are drilled in the middle of the plate, and the strain around the hole is improved through the stress concentration principle. The Wheatstone full bridge mode connecting circuit is adopted, so as to obtain the whole average strain of the drop hammer, to improve a temperature error and a non-linear error. Static load is adopted for calibrating the drop hammer, and a result shows that the output voltage has a linear relation with load. The method is different from a common drop hammer structure and test method, the drop hammer adopts the thin plate structure with two circular holes, each hole is internally and uniformly provided with 4 resistance strain gages, the eight resistance strain gages are connected to be the Wheatstone full bridge circuit, the output voltage is measured, and tested impact force is obtained according to calibration.

Owner:ZHONGBEI UNIV

Shock testing apparatus and method

PendingUS20200278270A1Avoid elevationReduce displacementHydrodynamic testingShock testingShock testMechanics

A shock testing apparatus comprising:an impact table for supporting an object to be tested;a tank;at least one float;one or more airguns;wherein the at least one float is arranged to float upon a fluid held within the tank and is movable within the tank to impact the impact table in response to the firing of the one or more airguns.

Owner:THORNTON TOMASETTI DEFENCE LTD

Impact resistance testing device for production of wooden packaging box

PendingCN108896417AMeet testing needsAvoid affecting test resultsStrength propertiesHydraulic cylinderButt joint

The invention discloses an impact resistance testing device for production of a wooden packaging box. The device comprises a U-shaped rack and a base, mounting cavities are formed in the two ends of the base, and a first electric hydraulic cylinder is arranged at the top in each mounting cavity through a mounting plate; a supporting cushion block is installed on the output shaft of each first electric hydraulic cylinder through screws, the U-shaped rack is installed at the top of the base through bolts, and a gravity sensing switch is arranged at one side of the bottom of the U-shaped rack through a mounting groove; electric sliding rails are mounted at the two sides of the inner wall of the U-shaped rack through screws, first sliding blocks are arranged in the electric sliding rails, anda connection rod is arranged between the first sliding blocks through a butt joint sheet; a first electromagnetic suction cup is installed on the connection rod through a mounting groove, and electricpush rods are connected to the two ends of the bottom of the connection rod through supporting rods. According to the impact resistance testing device, packaging box boards different in size are conveniently limited and subjected to impact resistance testing, second impact is effectively prevented, and the device is high in practicability and suitable for wide popularization.

Owner:江苏佳诚包装材料有限公司

Large aircraft temperature shock test device and test method

ActiveCN114537707AImprove reliabilityShort construction periodAir-pressure/air-lock chambersWater/sand/air bathsTemperature controlShock test

The invention provides a large aircraft temperature shock testing device and testing method, and belongs to the technical field of aircraft testing. Comprising a climate laboratory large chamber used for simulating a low-temperature environment, an environment compartment arranged in the climate laboratory large chamber and used for simulating a high-temperature environment, a hydraulic lifting assembly arranged in the environment compartment, a low-temperature control assembly communicated with the climate laboratory large chamber and a high-temperature control assembly communicated with the environment compartment. The test airplane is converted between two environments in a vertical movement mode, temperature shock environment simulation is achieved, the high-temperature environment is simulated in the environment chamber so that test equipment can be protected, the advantages of energy conservation and emission reduction are achieved, the construction period is short, cost is low, and implementation is easy.

Owner:CHINA AIRPLANT STRENGTH RES INST

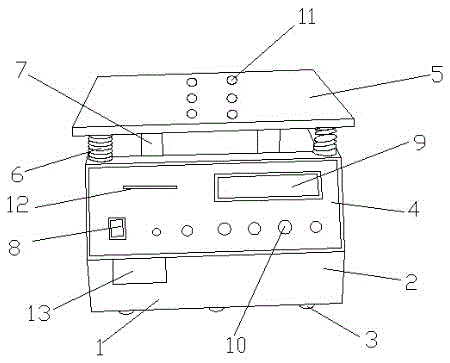

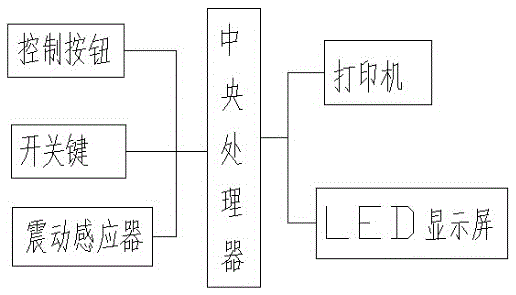

Fan shock testing apparatus

InactiveCN105466551AGuaranteed not to moveGuaranteed intelligenceSubsonic/sonic/ultrasonic wave measurementLED displayShock testing

The invention belongs to the shock test equipment technology field, and discloses a fan shock testing apparatus, which comprises a vibration testing apparatus body; the vibration testing apparatus body comprises a casing, an antiskid wheel and an objective table; the antiskid wheel is arranged on the bottom of the casing; a control panel is arranged at one side of the casing; a printer exit, a switching key, a control button and an LED display screen are arranged on the control panel; a central processor is arranged inside the control panel; a shock induction connecting piece and a printer are arranged inside the casing; a support spring is arranged on the top of the casing; the objective table is arranged on the top of the support spring; and a fixing threaded hole is arranged in the objective table. By using the support spring as the support apparatus of the objective table, the accuracy of the fan shock test is guaranteed; by arranging the fixing threaded hole, the fan is fixed on the objective table and can't move; and by arranging the central processor and the printer, the intelligence of the vibration testing apparatus is guaranteed; and the usage is convenient.

Owner:CHONGQING SHENGJIN AUTOMOBILE

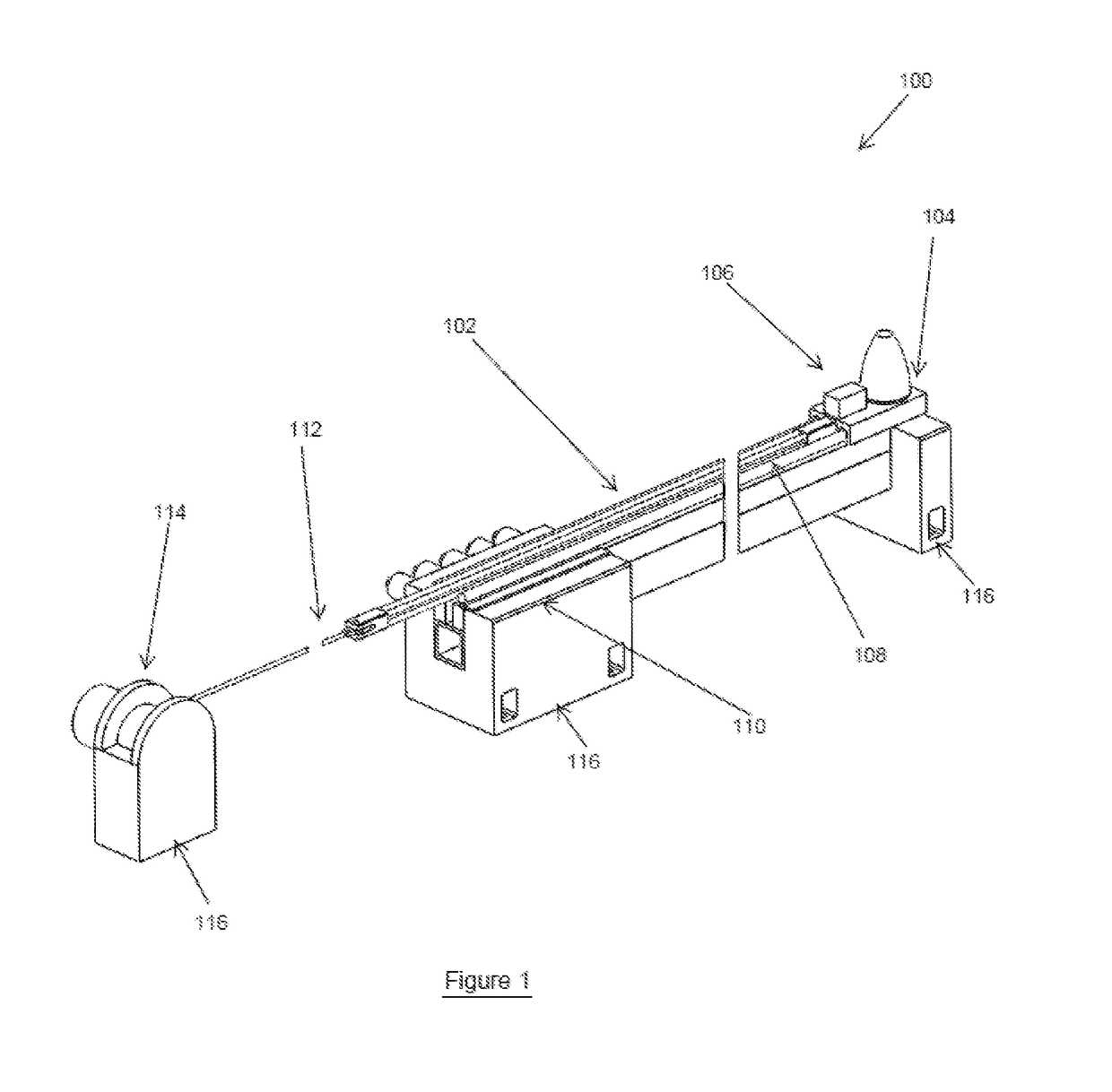

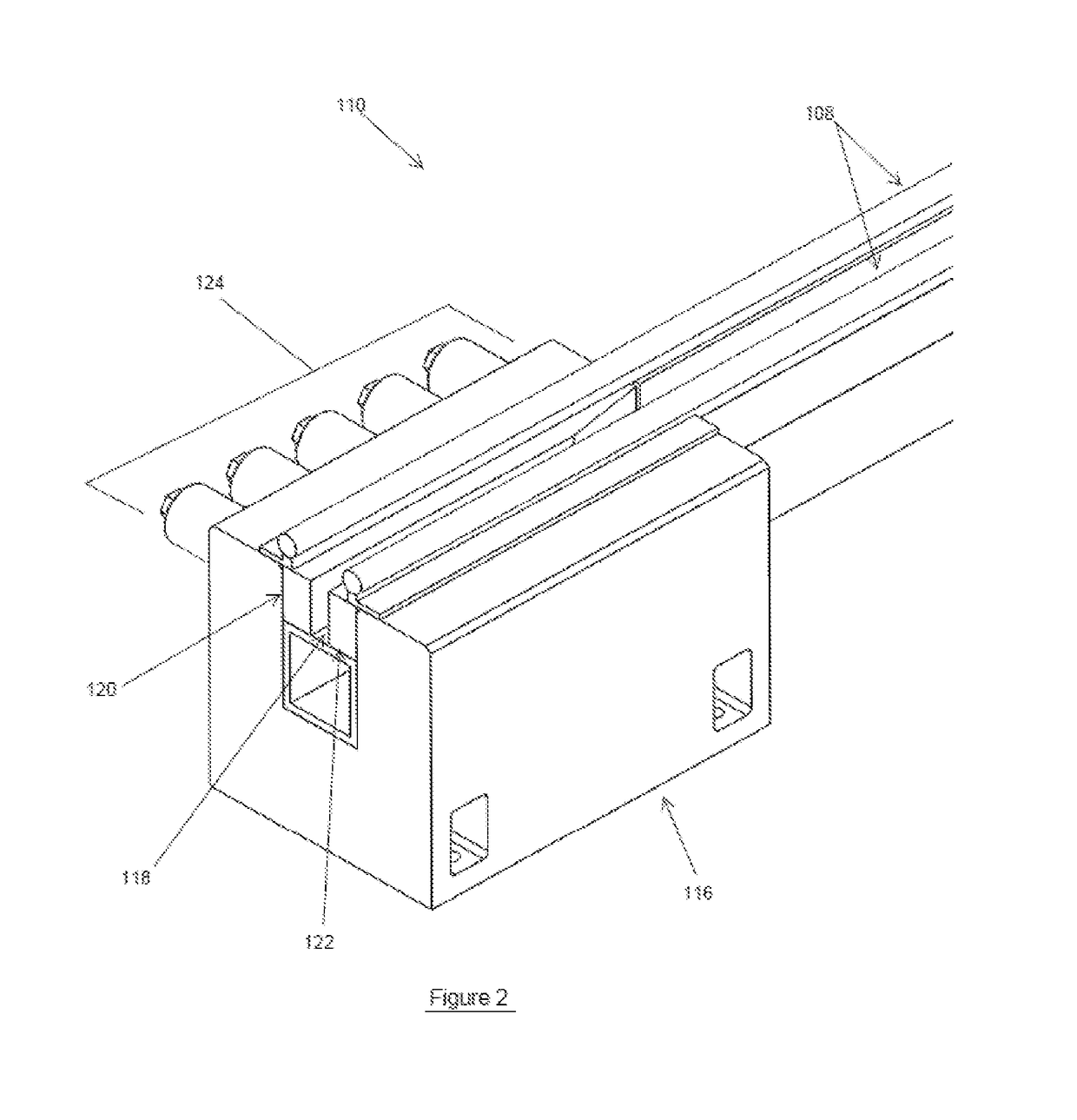

High-G shock testing machine

ActiveUS10190937B2High precisionHigh rateMaterial strength using single impulsive forceShock testingEngineeringRelative motion

A shock testing machine including: a test platform upon which one or more objects to be tested are mounted; one or more rails upon which the test platform is movable in a longitudinal direction; and a braking station for retarding a relative motion between the test platform and the braking station, wherein the test platform and the braking station include at least one portion interfering with the relative motion of the test platform and the braking station such that relative movement of the test platform and the braking station past the at least one portion produces a shock lateral to the longitudinal direction.

Owner:OMNITEK PARTNERS LLC

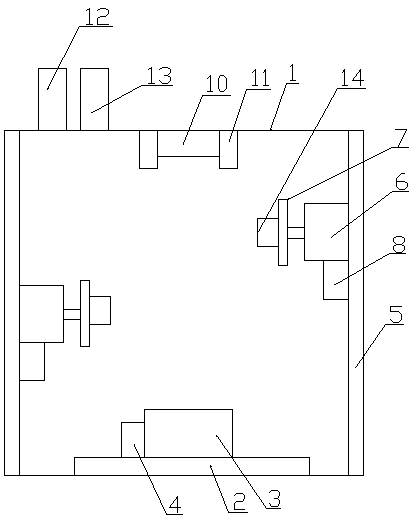

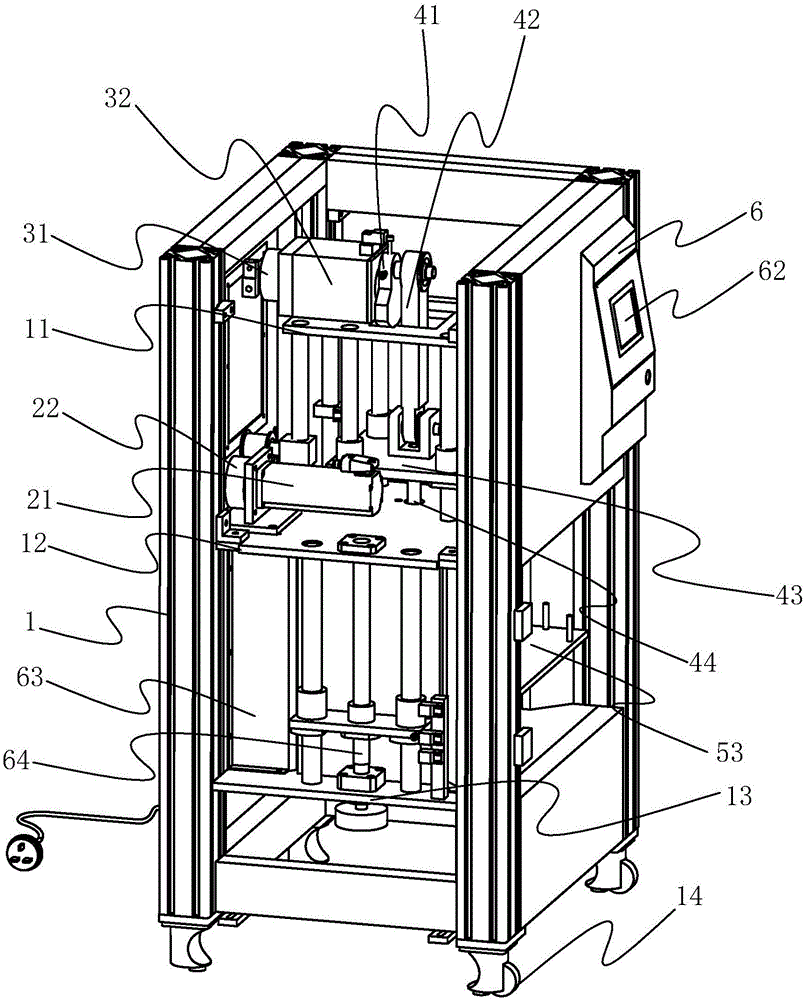

Elastic material repeated impact tester

InactiveCN106769559ARealize closed-loop controlReduce labor costsMaterial strength using repeated/pulsating forcesEngineeringShock testing

The invention relates to the field of test machines, and in particular relates to an elastic material repeated impact tester which is accurate in testing, saves cost and can accurately monitor and control an impact load in real time. The elastic material repeated impact tester comprises a machine body, a driving device, a transmission device, an eccentric device, a test device and a load adjusting device, wherein the machine body comprises a top plate arranged at the top of the machine body, a middle plate arranged at the middle part of the machine body and a bottom plate arranged at the bottom of the machine body, a test area is arranged between the middle plate and the bottom plate, the driving device is arranged on the middle plate and is in transmission connection with the transmission device arranged on the top plate, the transmission device is in transmission connection with the eccentric device which penetrates through the top plate and can extend to the test area, the eccentric device is connected with a test device arranged in the test area, the driving device drives the transmission device, the transmission device drives the eccentric device, so as to drive the test device to do vertical movement, and the test device is electrically connected with the load adjusting device arranged at the side edge of the machine body.

Owner:TST INSTR FUJIAN

High-G Shock Testing Machine

ActiveUS20200025660A1High precisionHigh rateBraking element arrangementsBrake actuating mechanismsBrakeRelative motion

A brake for use with a shock testing machine, the brake including: a brake material for generating a frictional force to stop a test platform when the brake material is urged against an opposed braking surface; links for rotatably connecting the brake material to the test platform; a biasing spring to bias the brake material towards the braking surface; a restraint mechanism for restraining the braking material, against a biasing force of the biasing spring, in a retracted position where the braking material is separated from the braking surface; and a release mechanism for releasing the restraint of the release mechanism to bias the brake material against the braking surface; wherein the links are configured such that relative movement between the brake material and braking surface while the brake material and braking surface are engaged causes a frictional force between the brake material and braking material to increase.

Owner:OMNITEK PARTNERS LLC

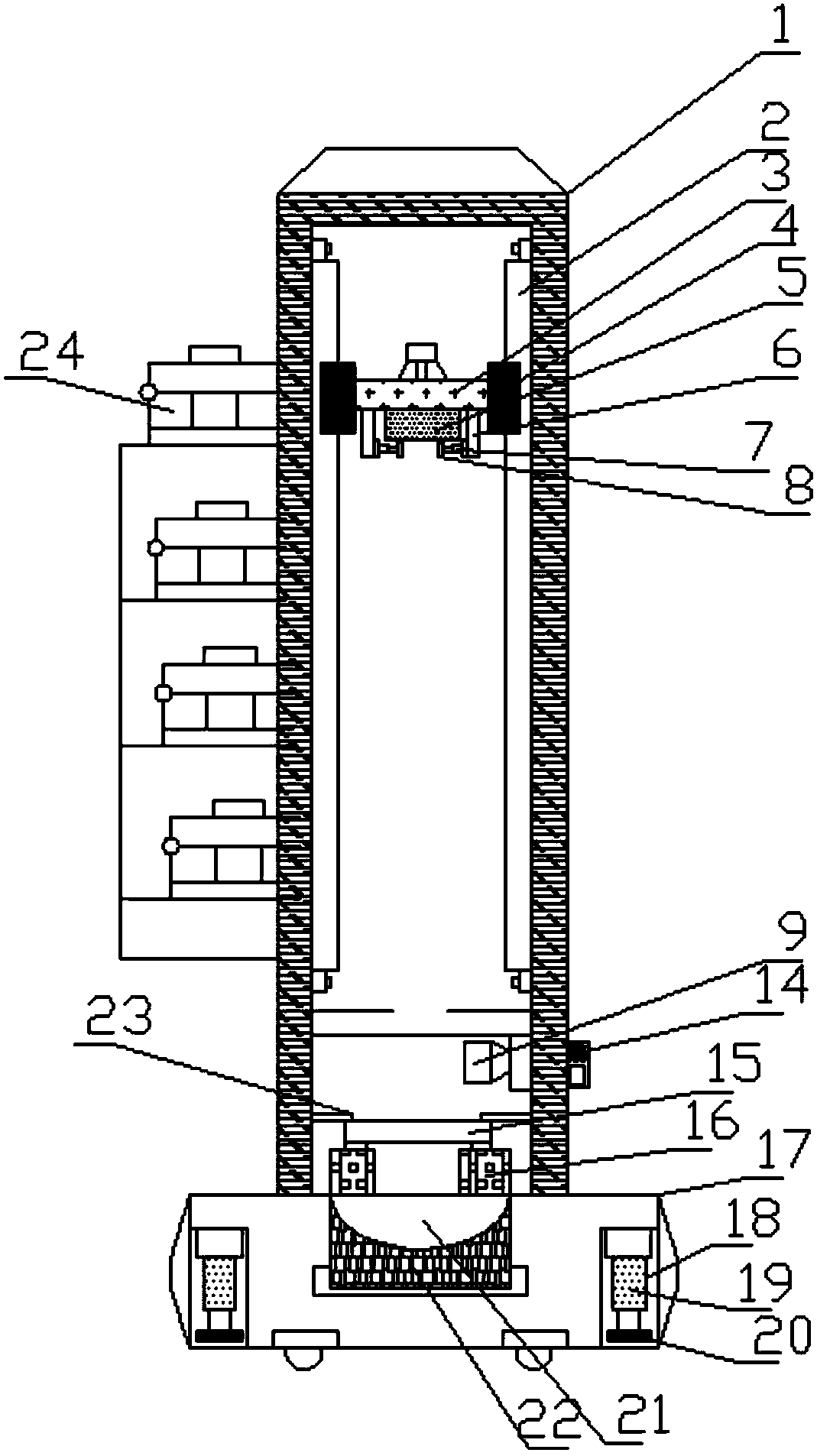

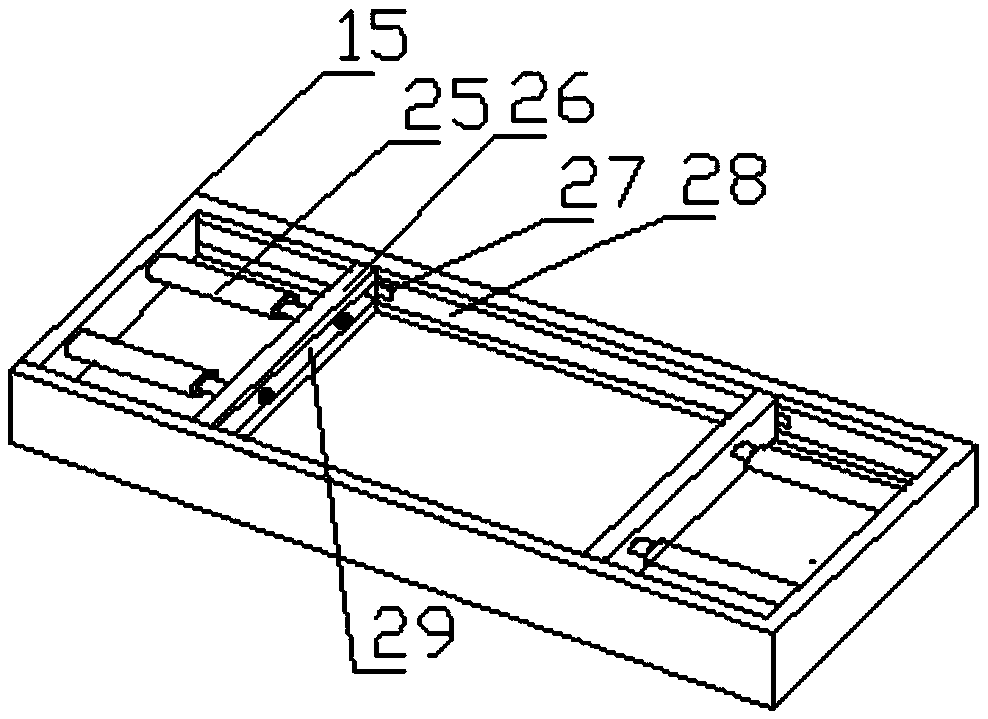

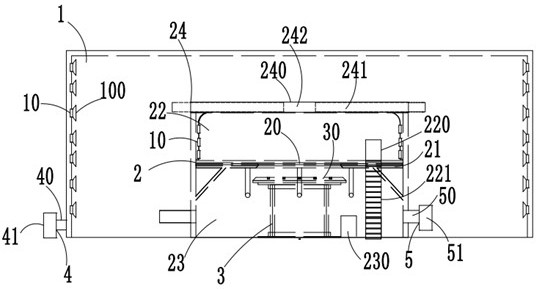

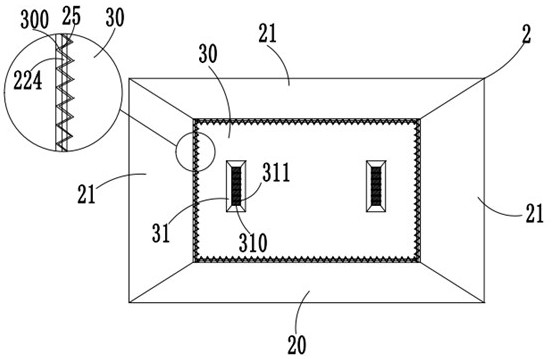

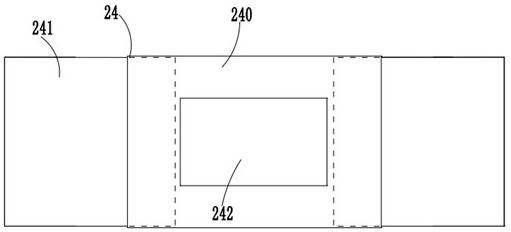

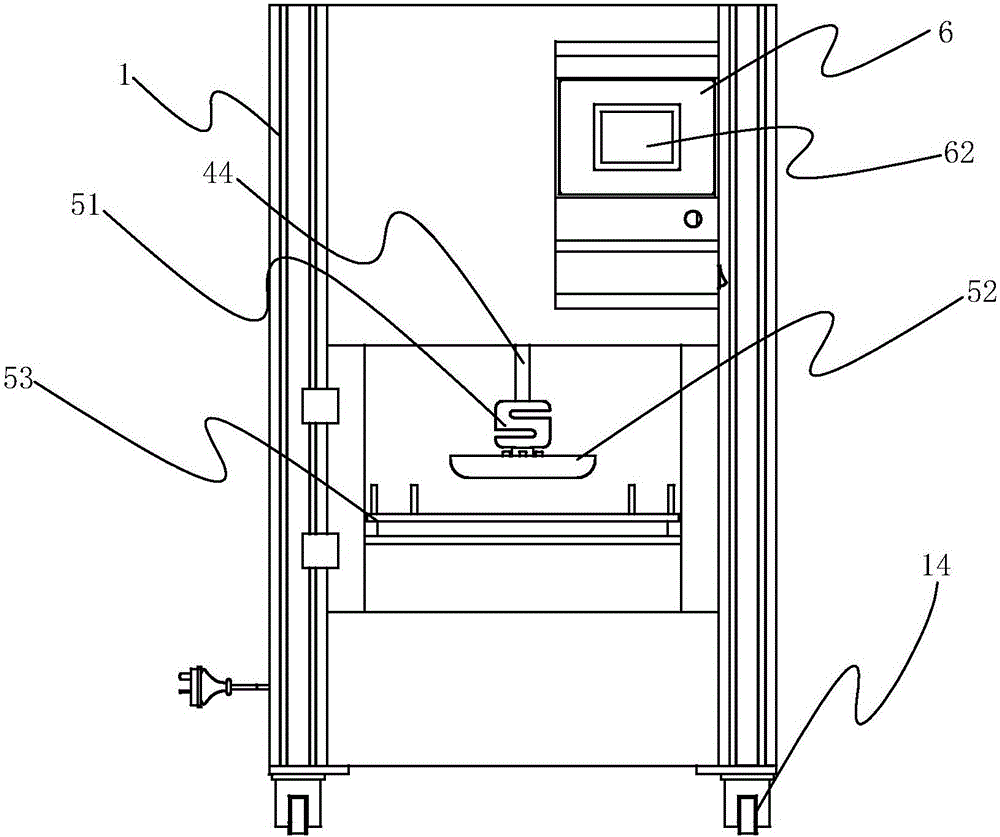

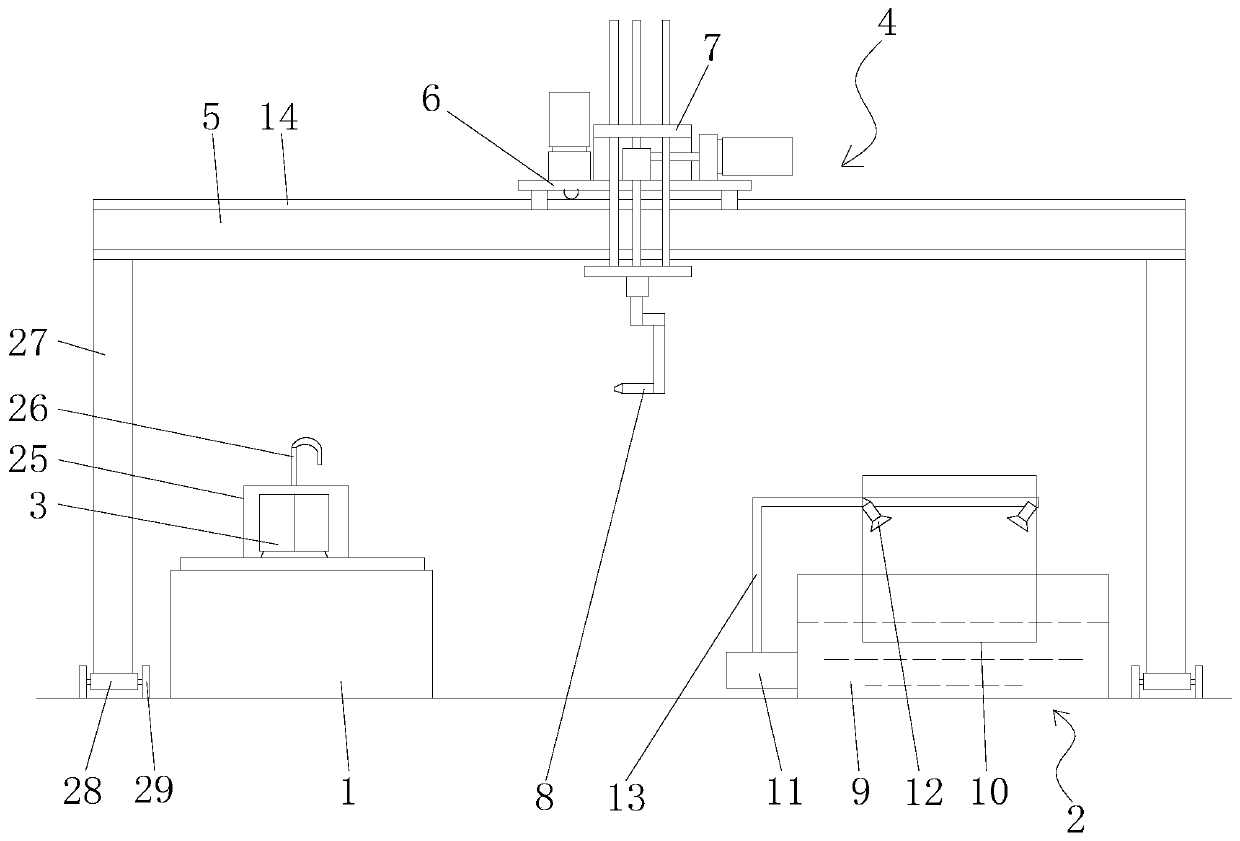

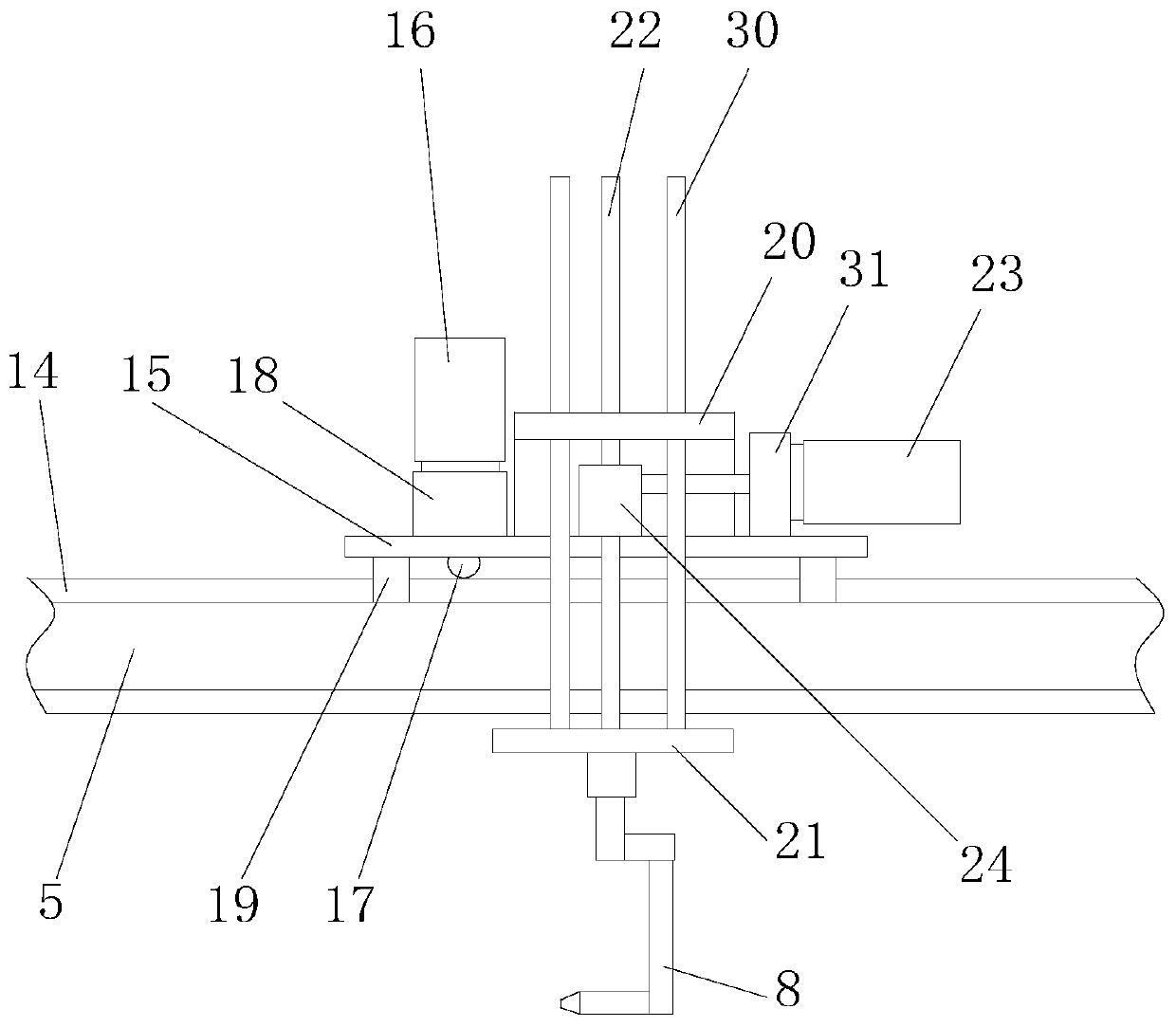

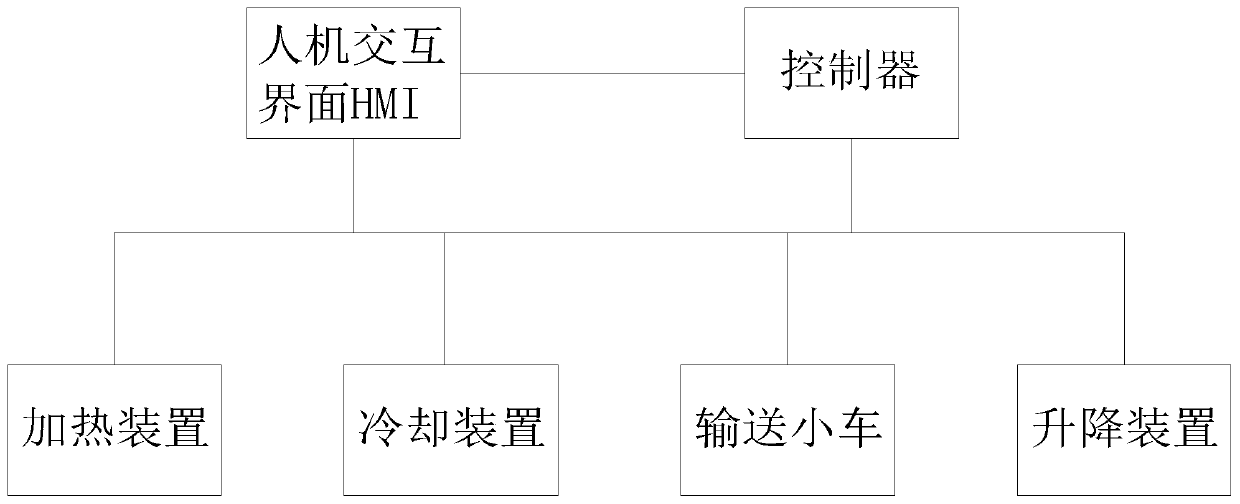

Automatic control system of engine heavy-cylinder-head cycle testing

PendingCN110608965AReduce labor intensityImprove efficiencyStorage devicesStrength propertiesAutomatic controlAutomatic train control

The invention discloses an automatic control system of engine heavy-cylinder-head cycle testing, and belongs to the technical field of cylinder head cycle cold and hot shock testing. The system mainlysolves the technical problems of high labor intensity, low efficiency and poor safety of existing cycle testing methods, and includes a heating device, a cooling device and a conveying mechanism usedfor cylinder head reciprocating conveying between the heating device and the cooling device. The conveying mechanism includes a cross beam located above the heating device and the cooling device. A transport trolley capable of reciprocating is arranged on the cross beam. A lifting device is arranged on the transport trolley. A spreader is arranged on the lifting device. The system also includes acontroller electrically connected with the heating device, the cooling device, the transport trolley and the lifting device respectively. According to the system, labor intensity can be reduced, efficiency is high, and safety is high.

Owner:GUANGXI YUCHAI MASCH CO LTD

Mechanical high spin-shock testing machines

ActiveUS10352838B2Short timeQuick installationAmmunition projectilesAmmunition testingSpinsEngineering

A rotary shock testing machine including: a base; a shaft rotatable relative to the base; a test disc for holding one or more specimens to be tested, the test disc being rotatable with the shaft; an actuator for applying a rotation to the shaft and test disc; and a brake for applying a braking force to the test disc to subject the one or more specimens to a rotary shock.

Owner:OMNITEK PARTNERS LLC

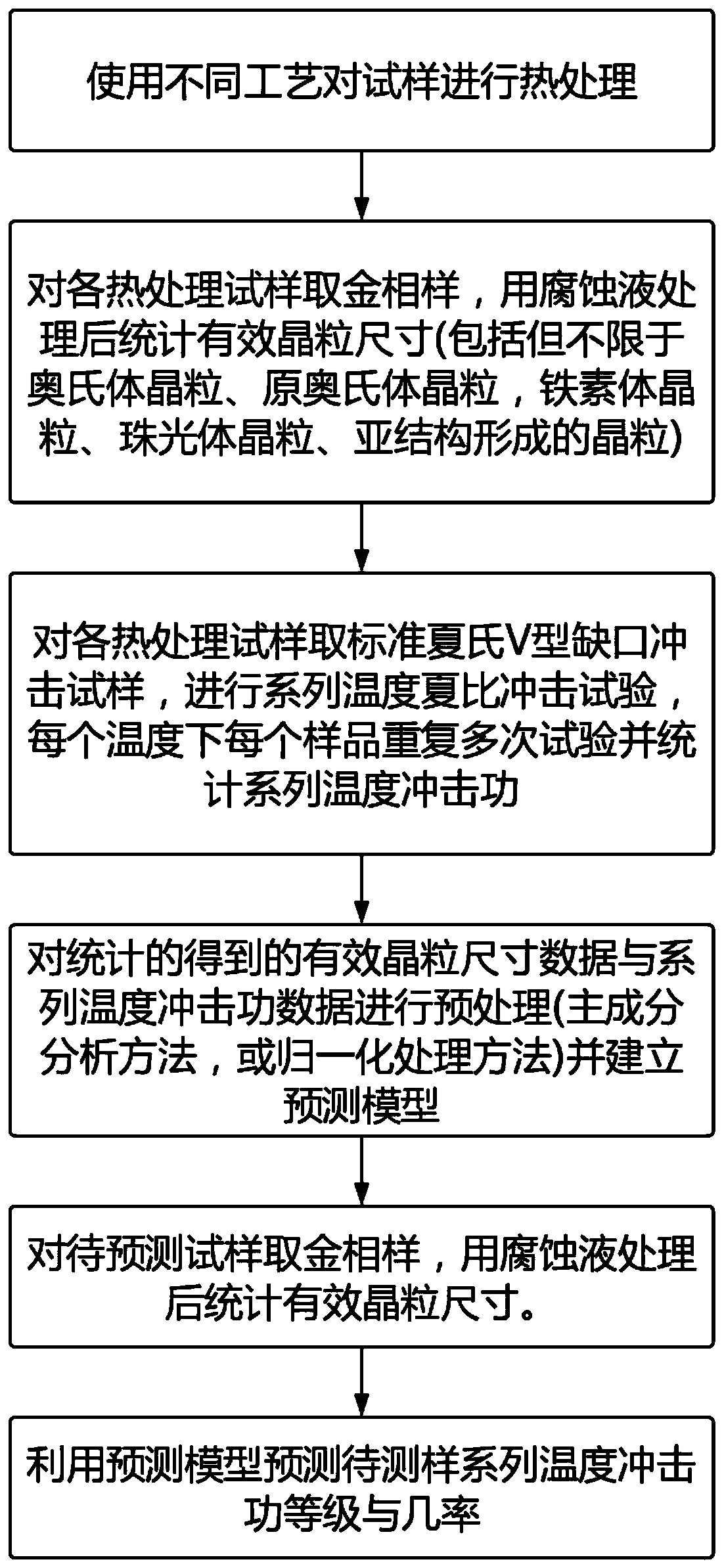

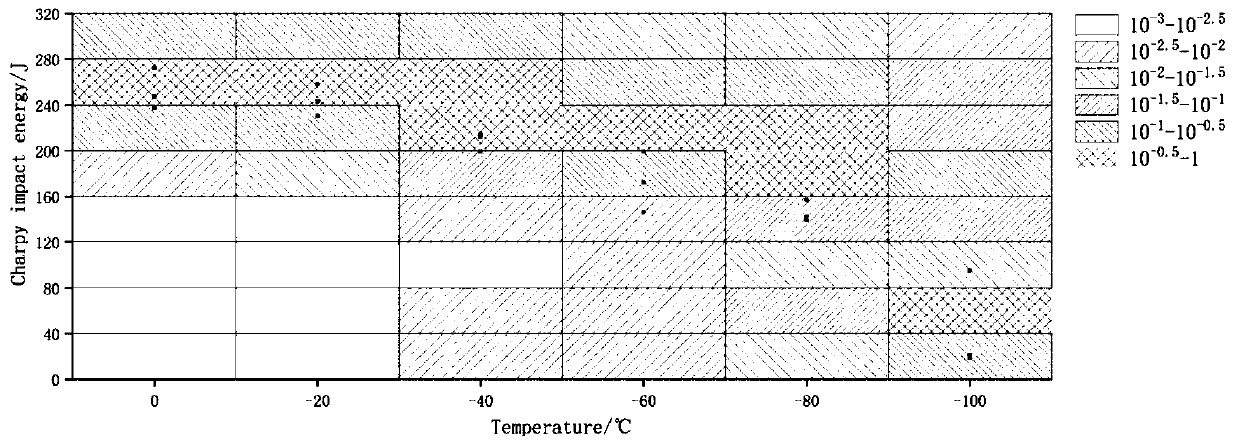

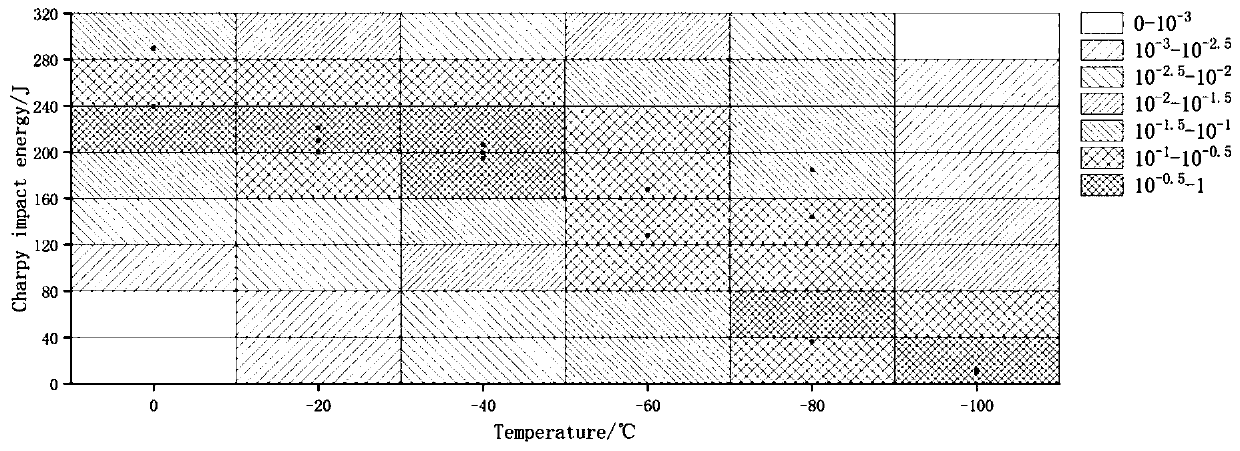

Accounting and predicting method of a series of temperature impact energy of steel materials

InactiveCN110018065AAvoid lossIncrease relative volatilityPreparing sample for investigationChemical machine learningMaterials scienceSoftware

The invention provides an accounting and predicting method of a series of temperature impact energy of steel materials, and belongs to the technical field of prediction of the series of temperature impact energy of the steel material. The method comprises the following steps: firstly, selecting gold phase test samples and impact test samples; then eroding the gold phase test samples by utilizing corrosion liquid to obtain gold phase images, processing the gold phase images by using image processing software and accounting effective crystal grain sizes; then testing the series of temperature impact on the impact test samples, and accounting impact energy; further pre-processing the effective crystal grain size data and the impact energy data and building a prediction model; accounting the effective crystal grain size data of to-be-tested samples and carrying out pre-processing; and finally, predicting the to-be-tested samples by using a prediction model to obtain impact energy level prediction results and distribution situations of different impact energy level probability. Compared with a conventional Cottrell-Petch relation, the method disclosed by the invention has the characteristics of being more in accuracy and scientificity.

Owner:UNIV OF SCI & TECH BEIJING

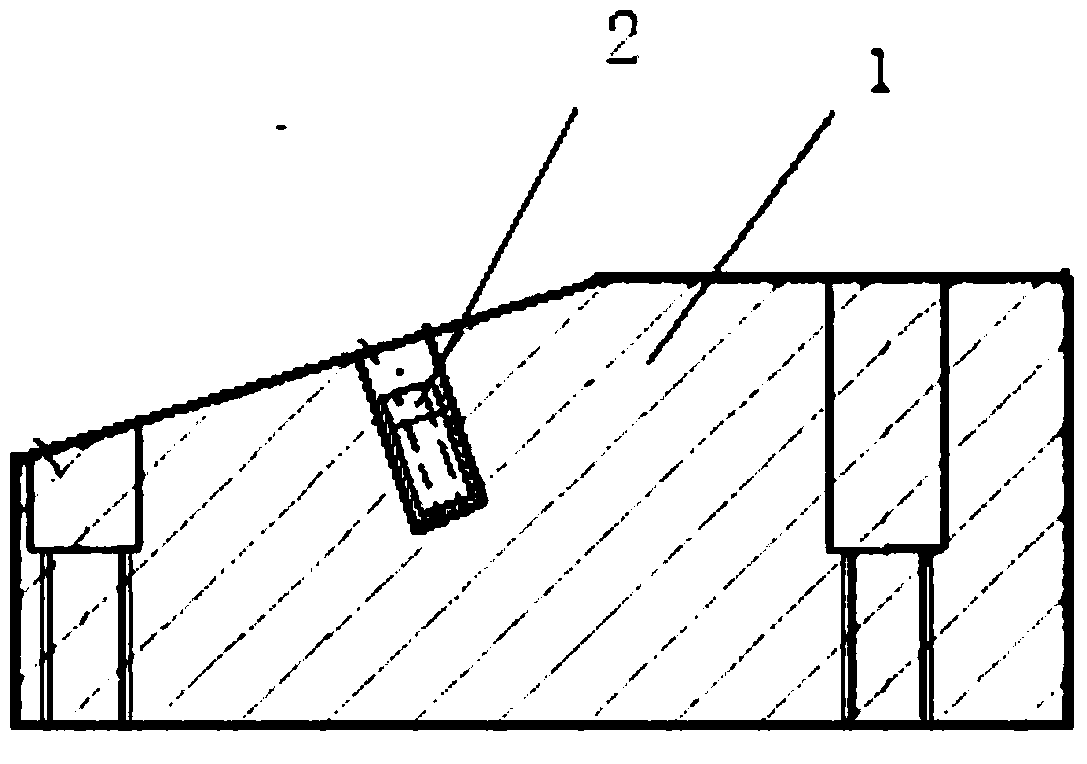

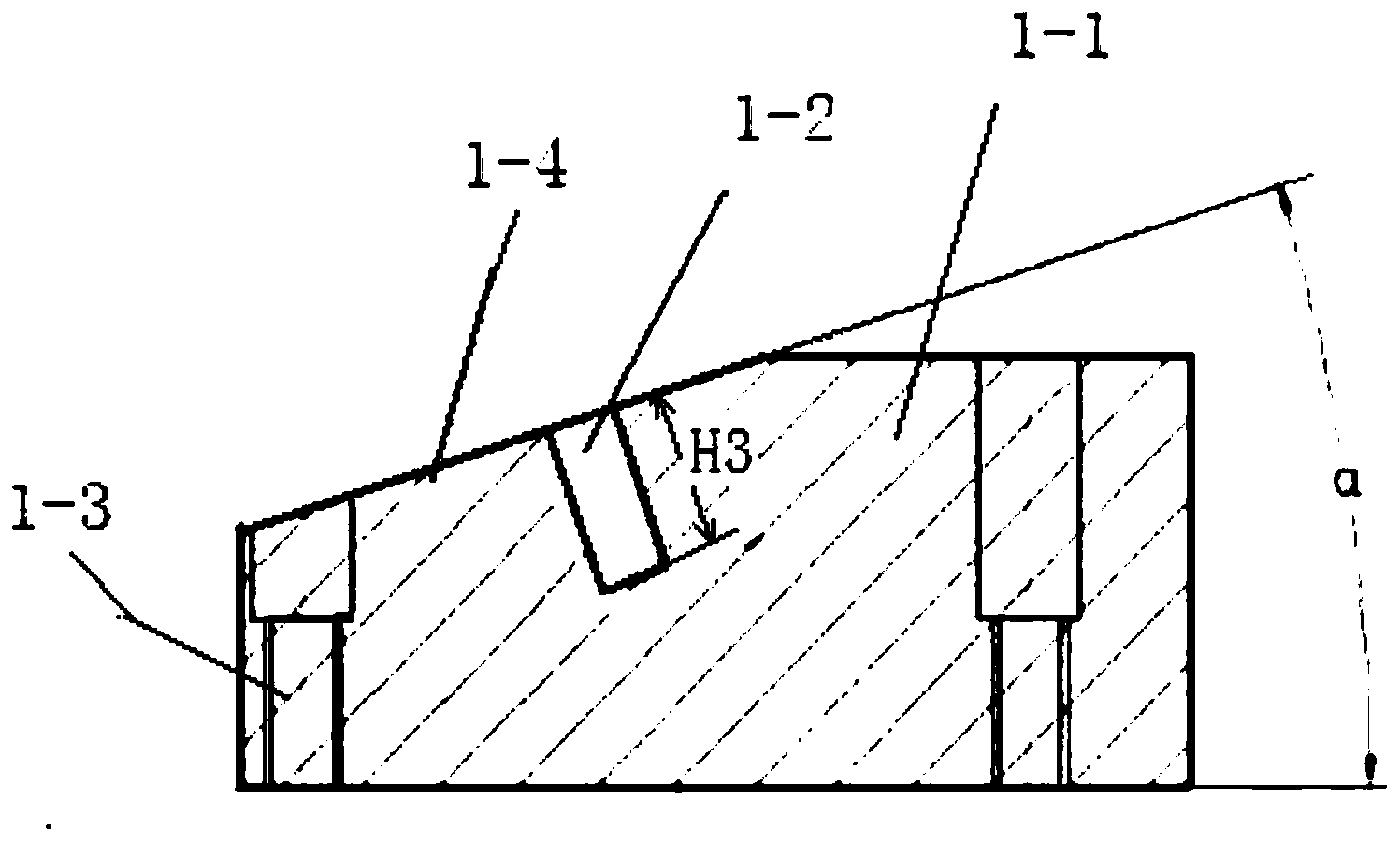

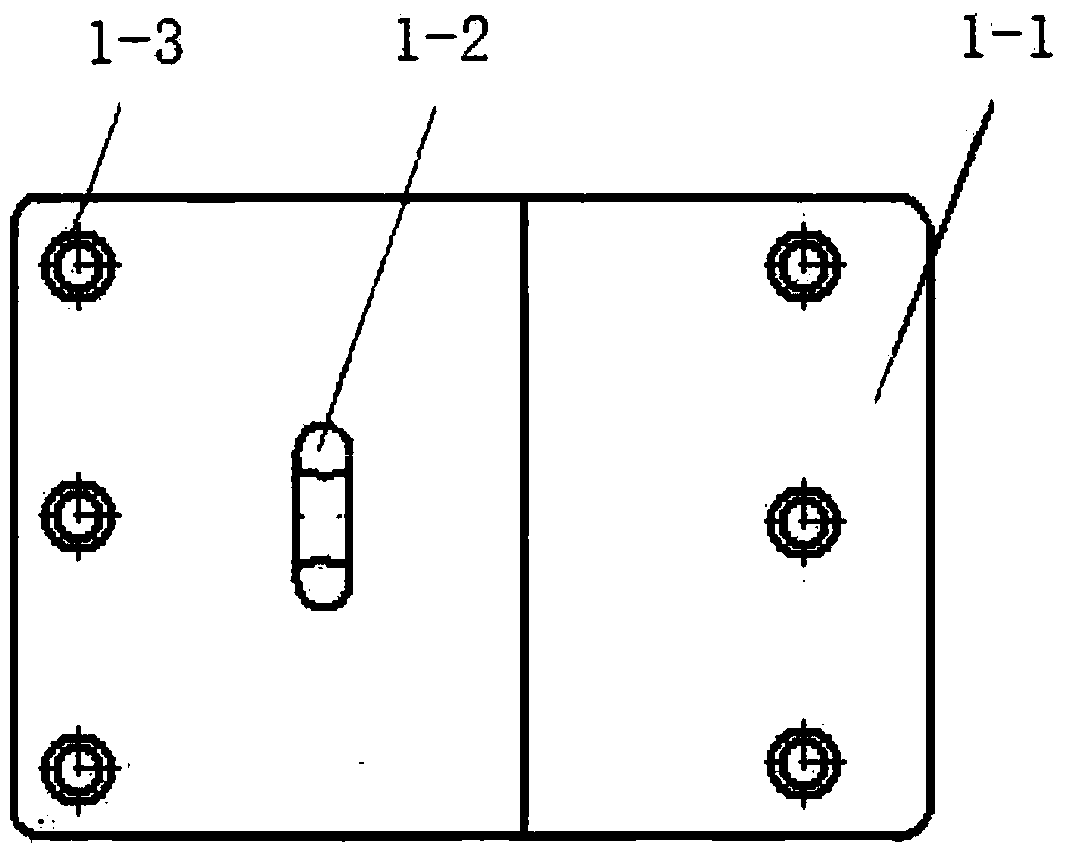

Fracture test sample mounting and clamping device matched with shock testing machine

InactiveCN103645090ASimple structureEasy to locate and installStrength propertiesEngineeringFracture test

The invention discloses a fracture test sample mounting and clamping device matched with a shock testing machine. The fracture test sample mounting and clamping device comprises a clamping apparatus and a cushion block, wherein the cushion block is a bar-shaped block body, a V-shaped groove for holding a sample is arranged on the top surface of the cushion block, the clamping apparatus is a cuboid which is provided with an inclined surface on the top surface, a cushion mounting groove is arranged on the inclined surface, in a formula of an included angle of the inclined surface and a horizontal plane, L1 is a length of a pendulum bob arm of the shock testing machine, and L2 is a distance between the center line of the cushion block mounting groove on the clamping apparatus and an anvil block of the shock testing machine after the sample mounting and clamping device is arranged on a fixed position on the shock testing machine; and the cushion block is arranged in the cushion block mounting groove arranged on the inclined surface of the clamping apparatus.

Owner:CHENGDU ENGINE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com