Accounting and predicting method of a series of temperature impact energy of steel materials

A technology for steel materials and prediction methods, which is applied in the fields of analysis of materials, chemical statistics, computer materials science, etc. to achieve accurate prediction results and avoid material loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0029] The invention provides a statistical and predictive method for series temperature impact energy of iron and steel materials.

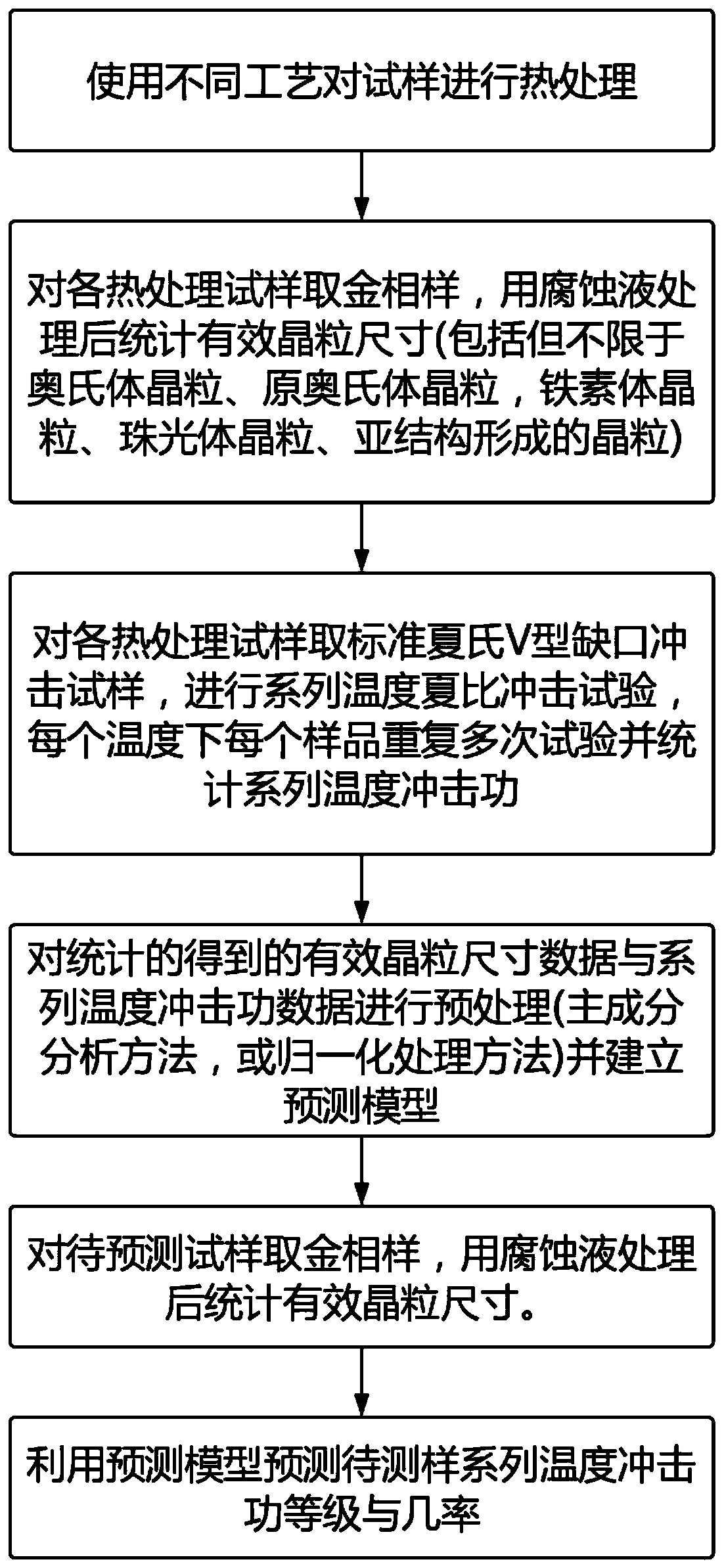

[0030] like figure 1 As shown, the method includes the following steps:

[0031] (1) Carry out heat treatment to the steel plate sample;

[0032] (2) For the heat-treated steel plate sample, take samples at different positions along the thickness direction of the steel plate. Among them, take the impact sample with a size of 10mm*10mm*55mm along the rolling direction, and the standard Charpy V-notch impact sample along the thickness direction Take metallographic samples perpendicular to the rolling direction;

[0033] (3) After inlaying, grinding and polishing the metallographic sample, it is eroded with corrosive solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com