Liquid tank type cold shock testing device

A technology of thermal shock and test device, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of bad environment, increased consumption, unfavorable cost, etc., to provide reliability, reduce consumption, and prevent icing phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

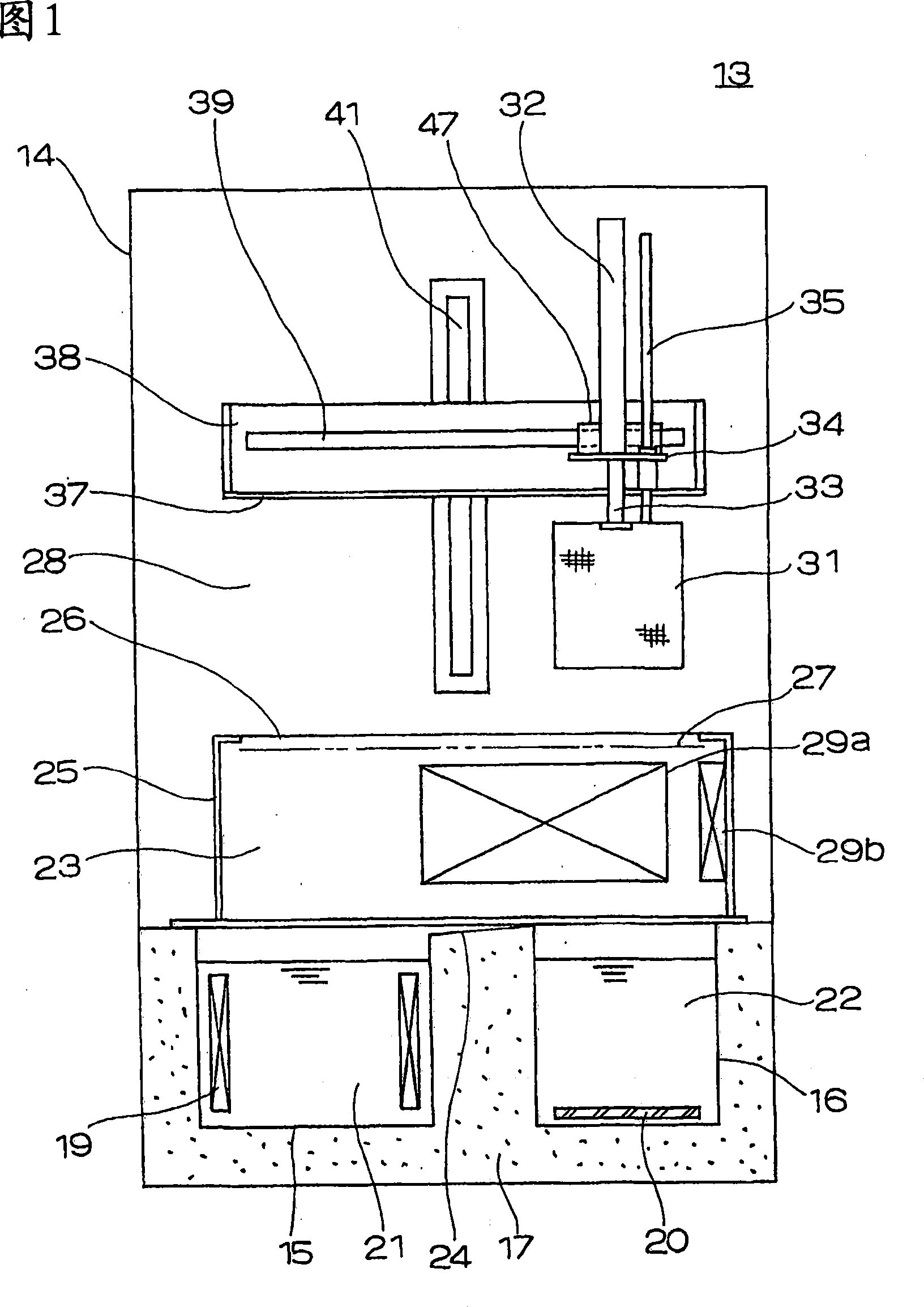

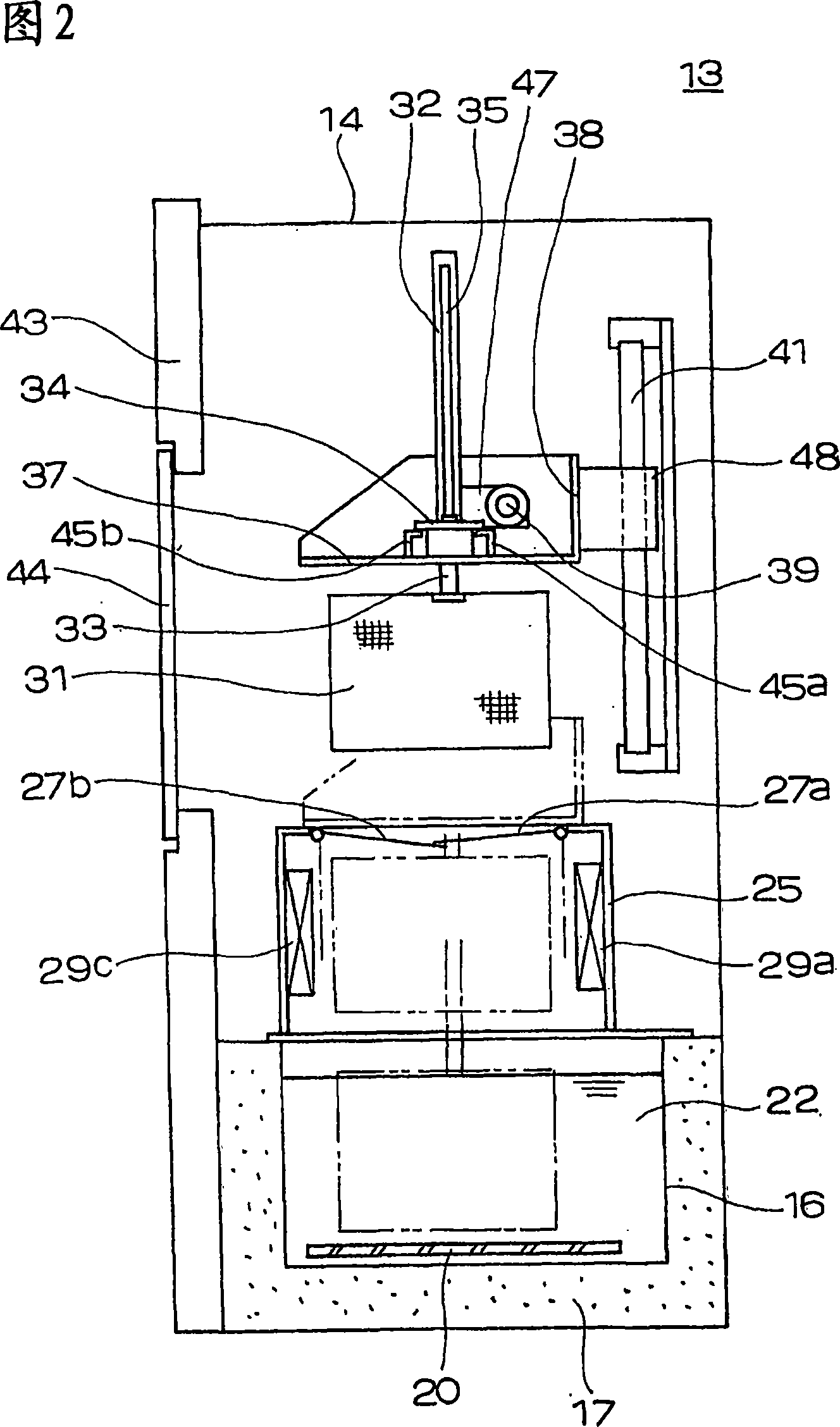

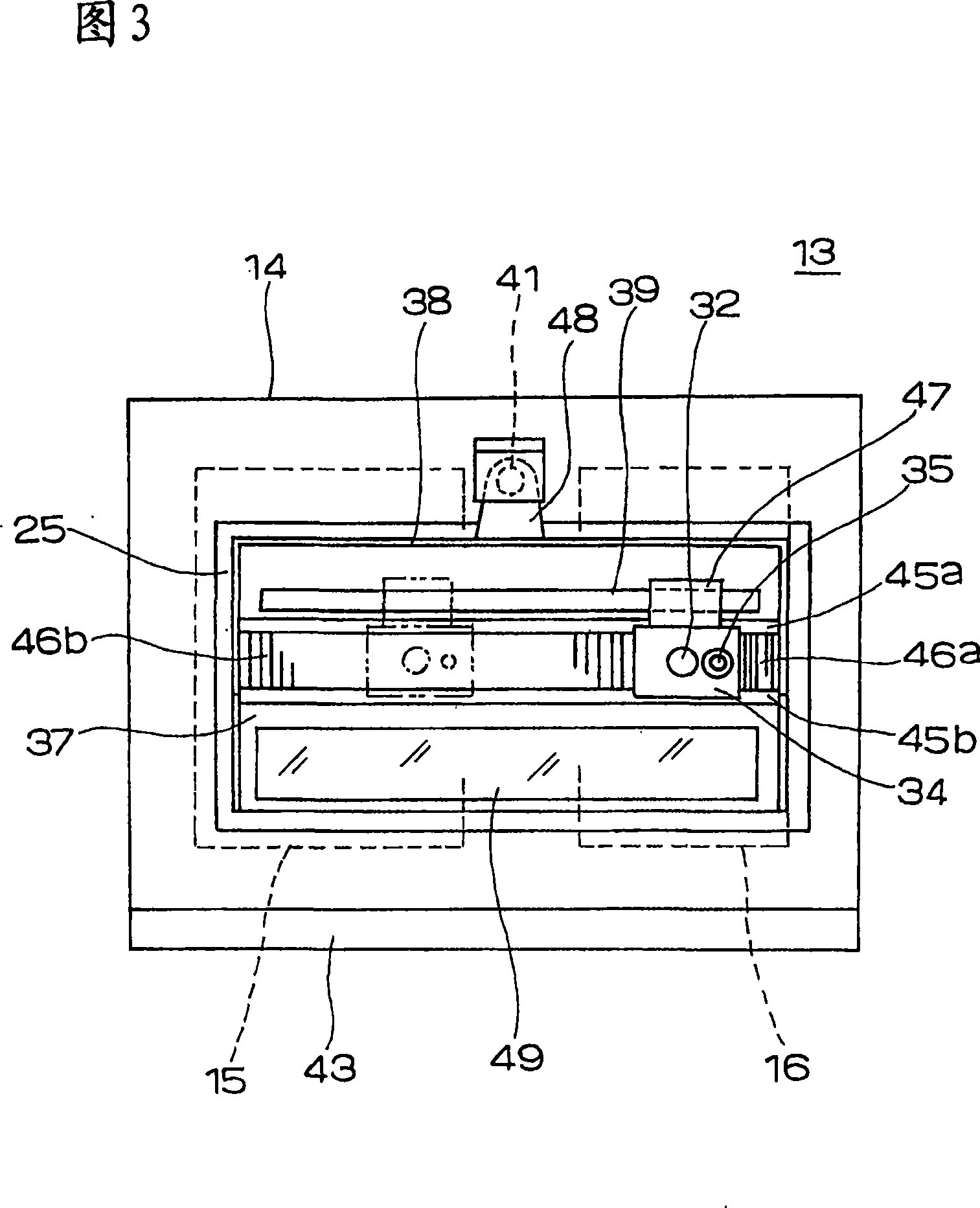

[0041] Fig. 1 is a front view showing a schematic structure of a liquid tank type thermal shock test device according to the first embodiment of the present invention, Fig. 2 is a schematic side view of the test device shown in Fig. 1 , and Fig. 3 is a schematic side view of the test device shown in Fig. 1 . A schematic top view of the test setup.

[0042] Referring to these figures, the liquid tank type thermal shock test device 13 is mainly composed of a rectangular parallelepiped-shaped device main body 14, and the outside of the device main body 14 is substantially sealed. In the lower part of the inside of the device main body 14, a low-temperature tank 15 holding a low-temperature liquid 21 as a first bath liquid and a high-temperature tank 16 holding a high-temperature liquid 22 as a second bath liquid are arranged in a parallel state. The thermal layer 17 is filled and divided. A cooling coil 19 is provided on the side wall of the low-temperature tank 15 , and a heater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com