Impact resistance testing device for production of wooden packaging box

A testing device and packaging box technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems such as affecting the test results, not being able to limit the position of the packaging boxes of different sizes, and not being able to effectively prevent secondary impacts, etc., to achieve practicability Strong, easy-to-fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

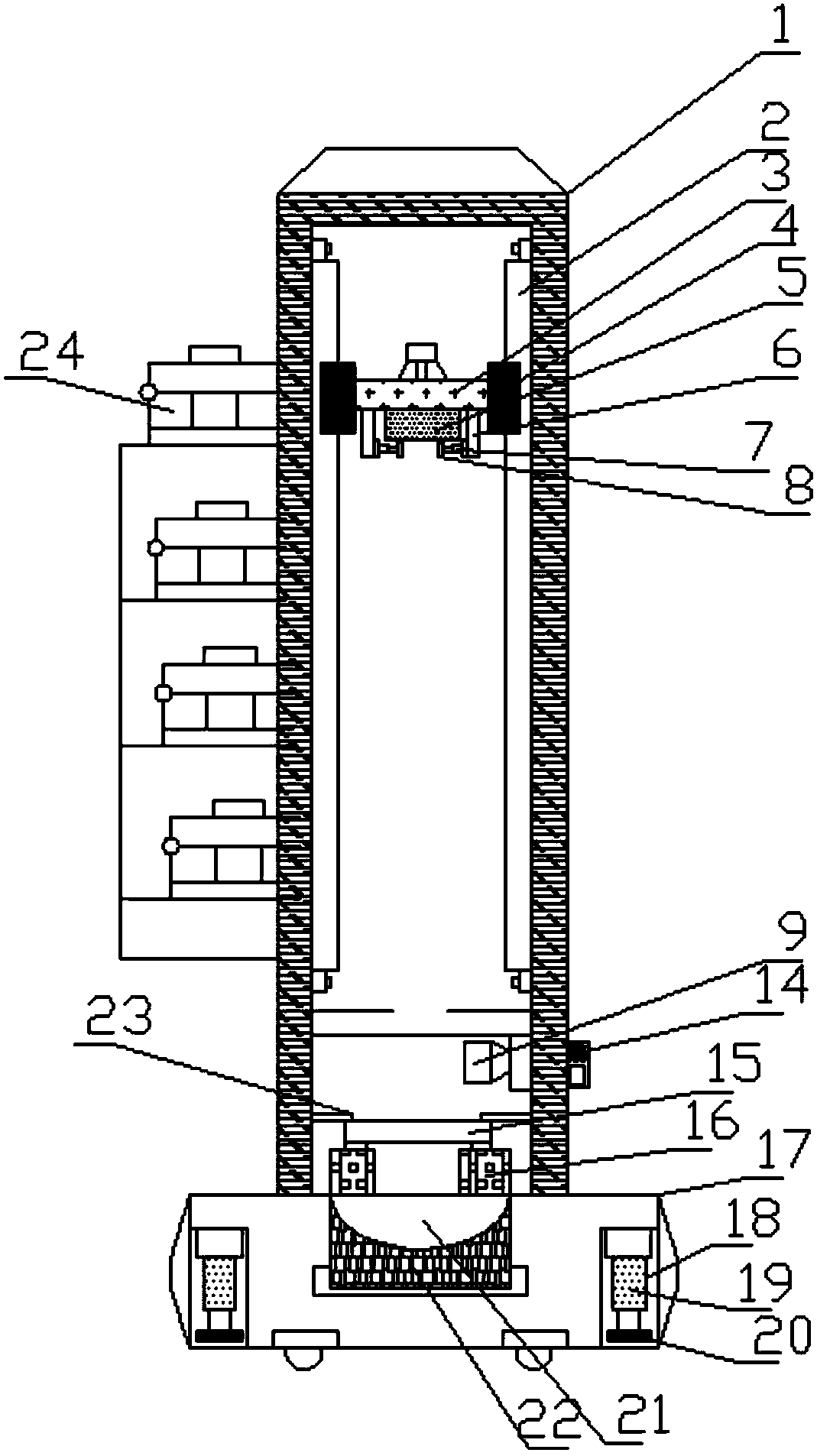

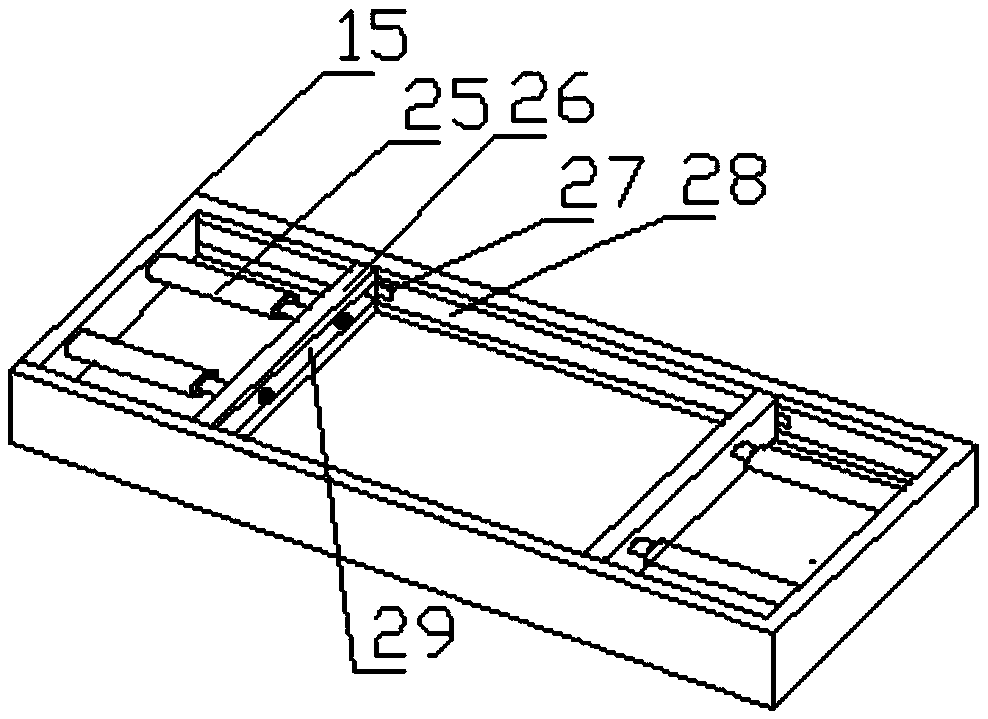

[0024] Such as Figure 1-2 As shown, a kind of impact resistance test device for the production of wooden packaging boxes includes a U-shaped bracket 1 and a base 17. The two ends of the base 17 are provided with installation cavities 18, and the top of the installation cavity 18 is provided with a No. Electric hydraulic cylinder 19, the output shaft of the No. 1 electric hydraulic cylinder 19 is equipped with a support pad 20 through a screw, the top of the base 17 is equipped with a U-shaped support 1 through a bolt, and the bottom end of the U-shaped support 1 is a The side is provided with a gravity sensor switch 14 through the installation groove, and the two sides of the inner wall of the U-shaped bracket 1 are installed with electric slide rails 2 through screws, and a No. A connecting rod 3 is arranged on the butt joint, and a No. 1 electromagnetic chuck 5 is installed on the connecting rod 3 through a mounting groove. The two ends of the bottom of the connecting rod 3...

Embodiment 2

[0033] Such as Figure 1-2 As shown, a kind of impact resistance test device for the production of wooden packaging boxes includes a U-shaped bracket 1 and a base 17. The two ends of the base 17 are provided with installation cavities 18, and the top of the installation cavity 18 is provided with a No. Electric hydraulic cylinder 19, the output shaft of the No. 1 electric hydraulic cylinder 19 is equipped with a support pad 20 through a screw, the top of the base 17 is equipped with a U-shaped support 1 through a bolt, and the bottom end of the U-shaped support 1 is a The side is provided with a gravity sensor switch 14 through the installation groove, and the two sides of the inner wall of the U-shaped bracket 1 are installed with electric slide rails 2 through screws, and a No. A connecting rod 3 is arranged on the butt joint, and a No. 1 electromagnetic chuck 5 is installed on the connecting rod 3 through a mounting groove. The two ends of the bottom of the connecting rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com