Vibration impact test fixture

A technology of impact test and vibration test bench, which is applied in the direction of vibration test, machine/structural component test, measuring device, etc. It can solve the problems of high cost, easy man-made damage, time-consuming and other problems, so as to improve the quality and the probability of man-made damage The effect of reducing and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

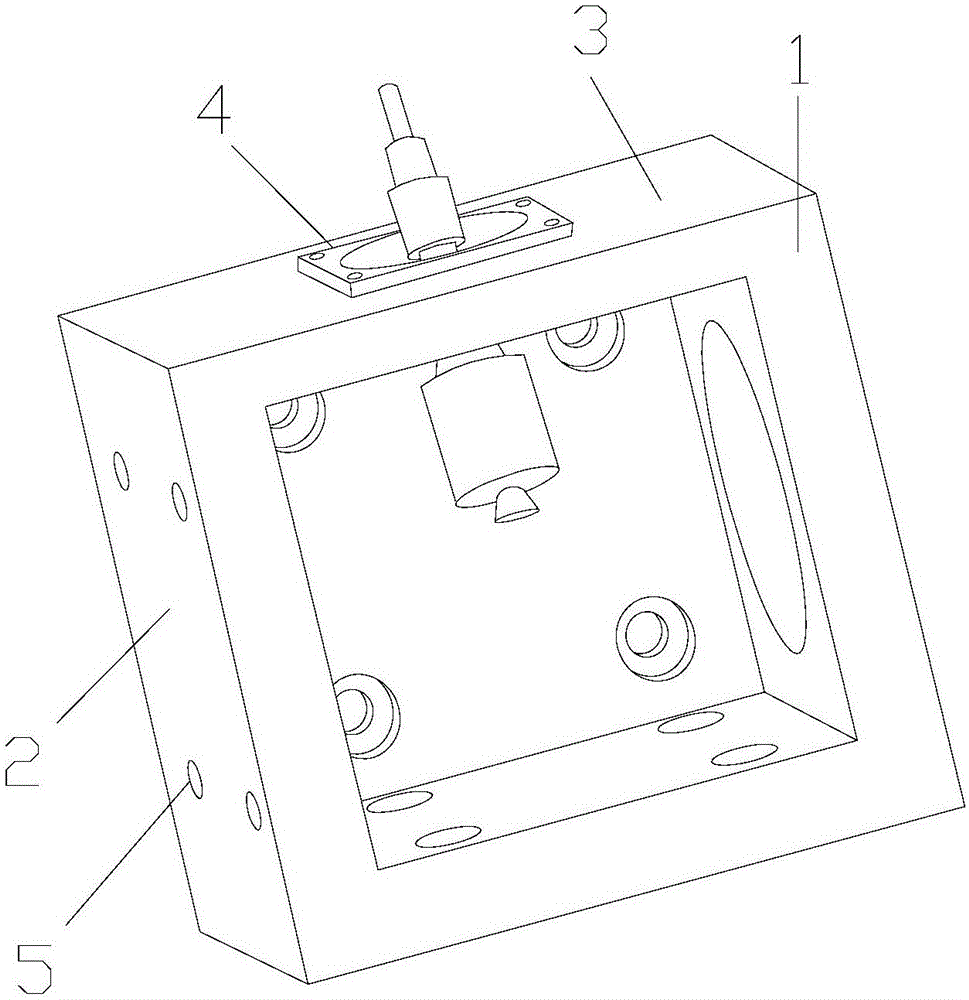

[0015] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. as attached figure 1 As shown, a vibration shock test fixture includes a fixture main body 1, and the fixture main body includes at least two fixture installation surfaces 2 and two product installation surfaces 3, and the two product installation surfaces are provided with connections for fixing products Part 4, the two fixture installation surfaces are fixed to the vibration test bench by fasteners. The fasteners can be fixed by bolts and nuts, or other fast fixing structures can also be selected. The main body of the fixture is a hollow cube. In the present invention, the main body of the fixture has three fixture installation surfaces, two of which are perpendicular to each other, and each fixture installation surface can be detachably fixed on the vibration test table superior. There are two produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com