Shock testing device of large-scale protecting glass

A technology of impact testing and protective glass, applied in the field of experimental testing, can solve problems such as difficult impact resistance, inability to directly obtain data, smashed samples, etc., and achieve the effect of easy processing, reducing complexity, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

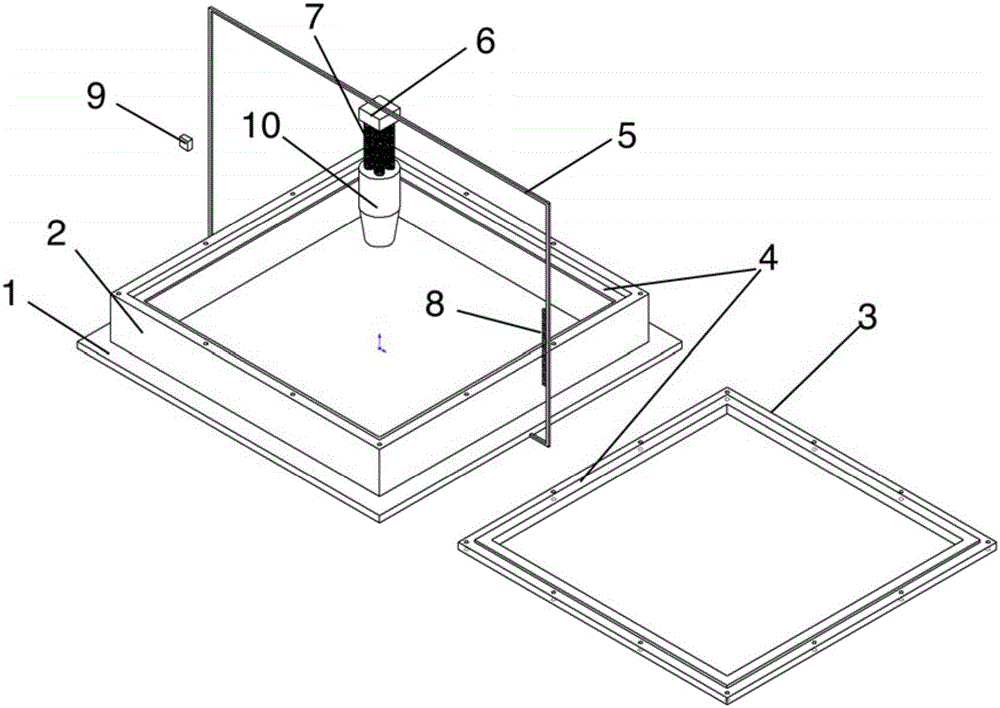

[0020] Such as figure 1 The shown impact test device for a large-scale protective glass includes a clamping assembly, a suspension assembly and an impact piece 10, and can perform an impact test on a large-scale flat protective glass.

[0021] The clamping assembly includes a base 1 , a supporting steel box 2 , an upper frame 3 , and a rubber gasket 4 . The base 1 is made of a steel plate with a certain thickness, and the supporting steel box 2 is a steel box formed by welding 4 steel plates, and one end of each steel plate is processed with a same step, which is used to place a large flat protective glass that needs to be impact tested , the other end of each steel plate is welded and fixed on the base 1 respectively. The upper frame 3 is a frame composed of 4 steel bars, which is used to tightly connect with the supporting steel box 2 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com