Patents

Literature

109results about How to "Meet the design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

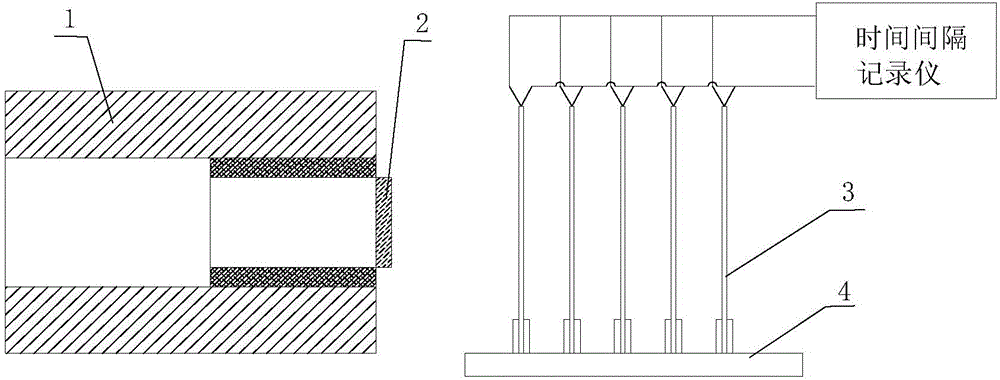

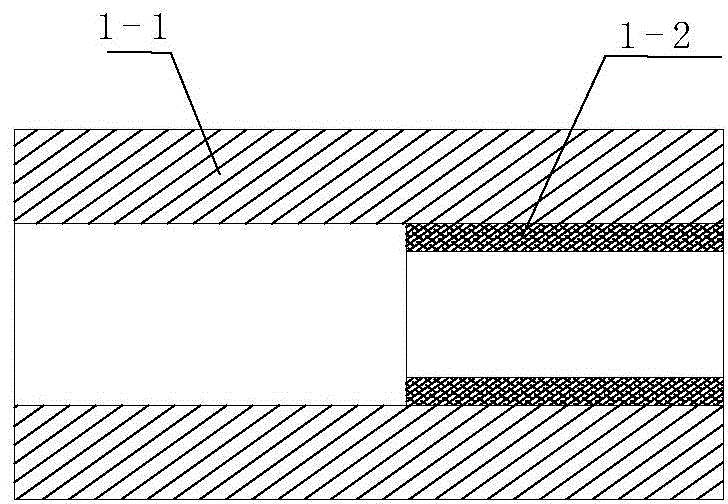

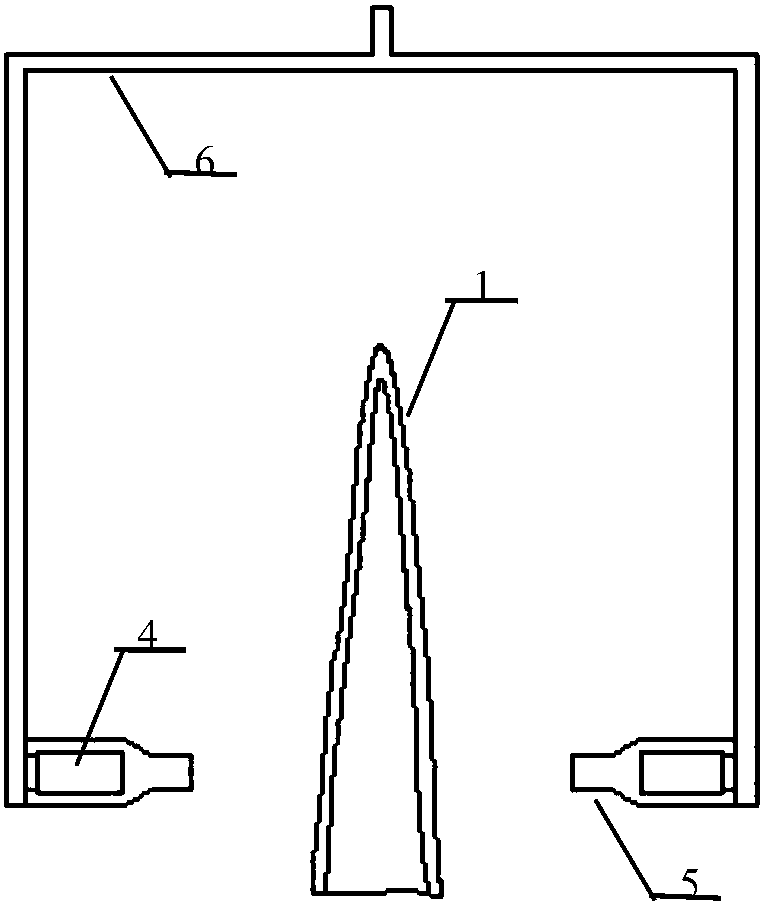

Measuring apparatus for capability of explosive explosion in driving of metal

InactiveCN104034859AMeet the designFulfil requirementsFuel testingMeasurement deviceExplosion protection

The invention discloses a measuring apparatus for capability of explosive explosion in driving of metal. The measuring apparatus is mainly composed of an explosion chamber, a metal flyer plate, velocity measurement targets, velocity measurement target supports, etc. The measuring apparatus is designed on the basis of velocity measuring principles; the explosion chamber composed of a charging sleeve and an explosion protection body is filled with a to-be-measured explosive column, the metal flyer plate is adhered on the end surface of the explosive column aligned with the charging sleeve and the explosion protection body, the explosive is fired from the other end surface of the explosive column so as to accelerate motion of the metal flyer plate, a time interval recorder is employed to acquire time when the metal flyer plate generates pulse current when passing through the velocity measurement targets at different distances, the relation curve of the distance and time of motion of the metal flyer plate is acquired through data processing, and first derivation is carried out on the curve so as to obtain the speed of the metal flyer plate at different times or distances so as to measure capacity of explosive explosion in accelerating metal.

Owner:XIAN MODERN CHEM RES INST

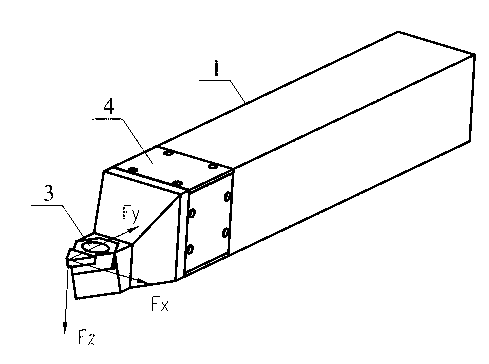

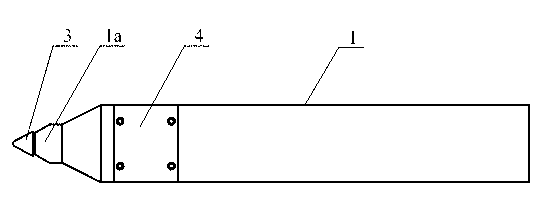

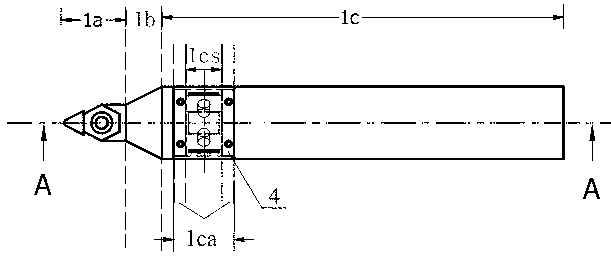

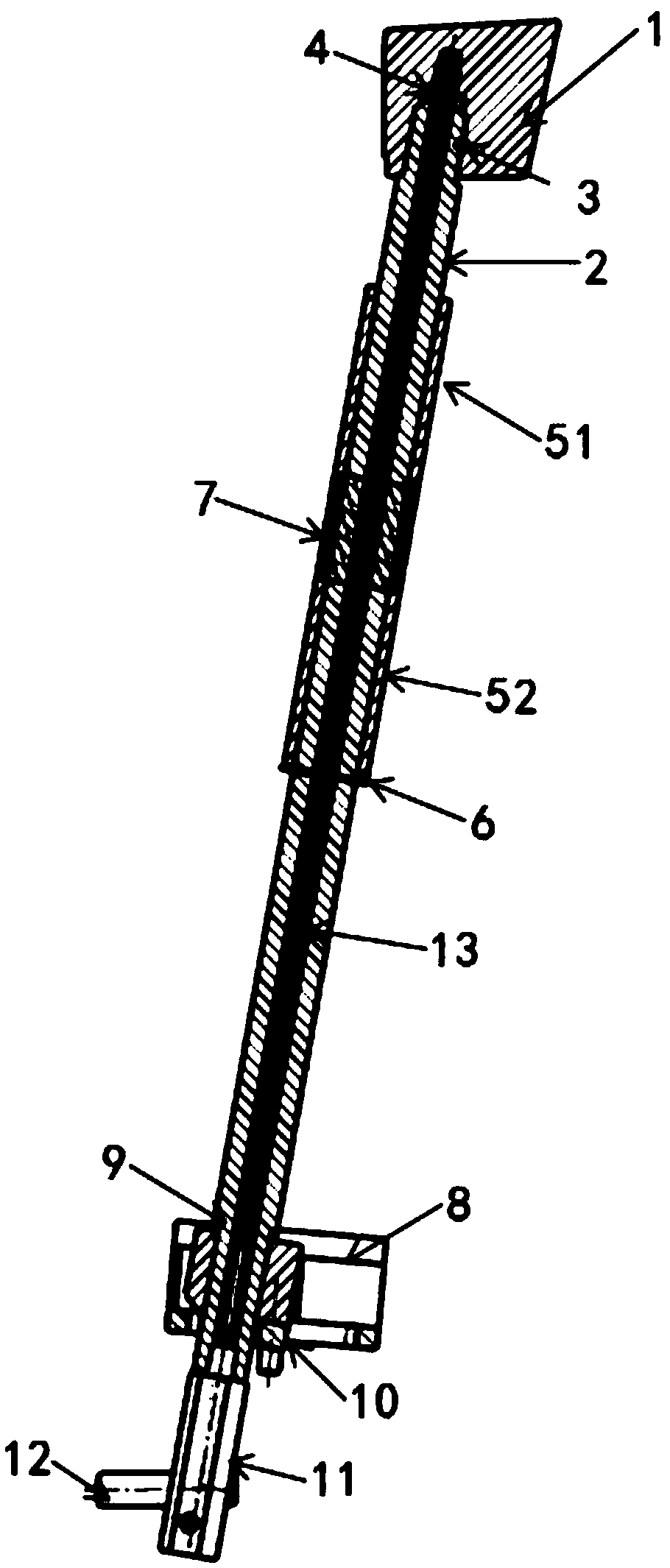

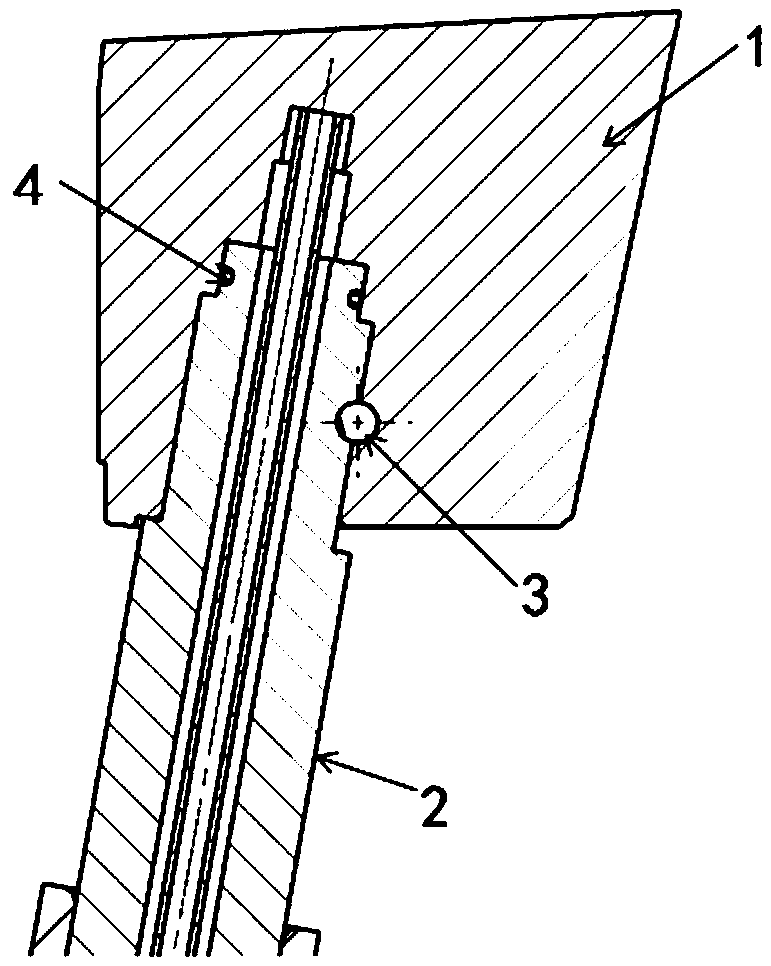

Intelligent cutter of integrated small three-way cutting force measurement system

InactiveCN102847961ARealize autonomous real-time monitoringAccurate solutionMeasurement/indication equipmentsTurning toolsEngineeringCutting force

The invention relates to an intelligent cutter of an integrated small three-way cutting force measurement system, belonging to the fields of ultraprecise cutting machining and cutting force measurement and real-time monitoring. The intelligent cutter can realize the real-time sensing measurement of small three-way cutting force in the ultraprecise machining process. The intelligent cutter mainly comprises a cutter bar, a cutting blade, a cutting force measurement system, a sealing cover and a signal interface end, wherein the upper surface of the cutting blade coincides with the central surface of the main body of the cutter bar; the cutter tip is positioned in the center of the main body of the cutter bar; the front end of the main body of the cutter bar is provided with a sensing measurement section; the small three-way cutting force measurement system is fixedly connected in a force measurement cavity of the sensing measurement section; the signal interface end is arranged at the back end of the cutter bar and is used for realizing signal output; and in the cutting machining process, a sensing unit senses the strain and displacement generated under the effect of the three-way cutting force to acquire a corresponding signal, and the small three-way cutting force is accurately computed through calibration and decoupling. The invention is used for related scientific researches in the field of ultraprecise machining and real-time monitoring and self-adaptive machining in the cutting process.

Owner:HARBIN INST OF TECH

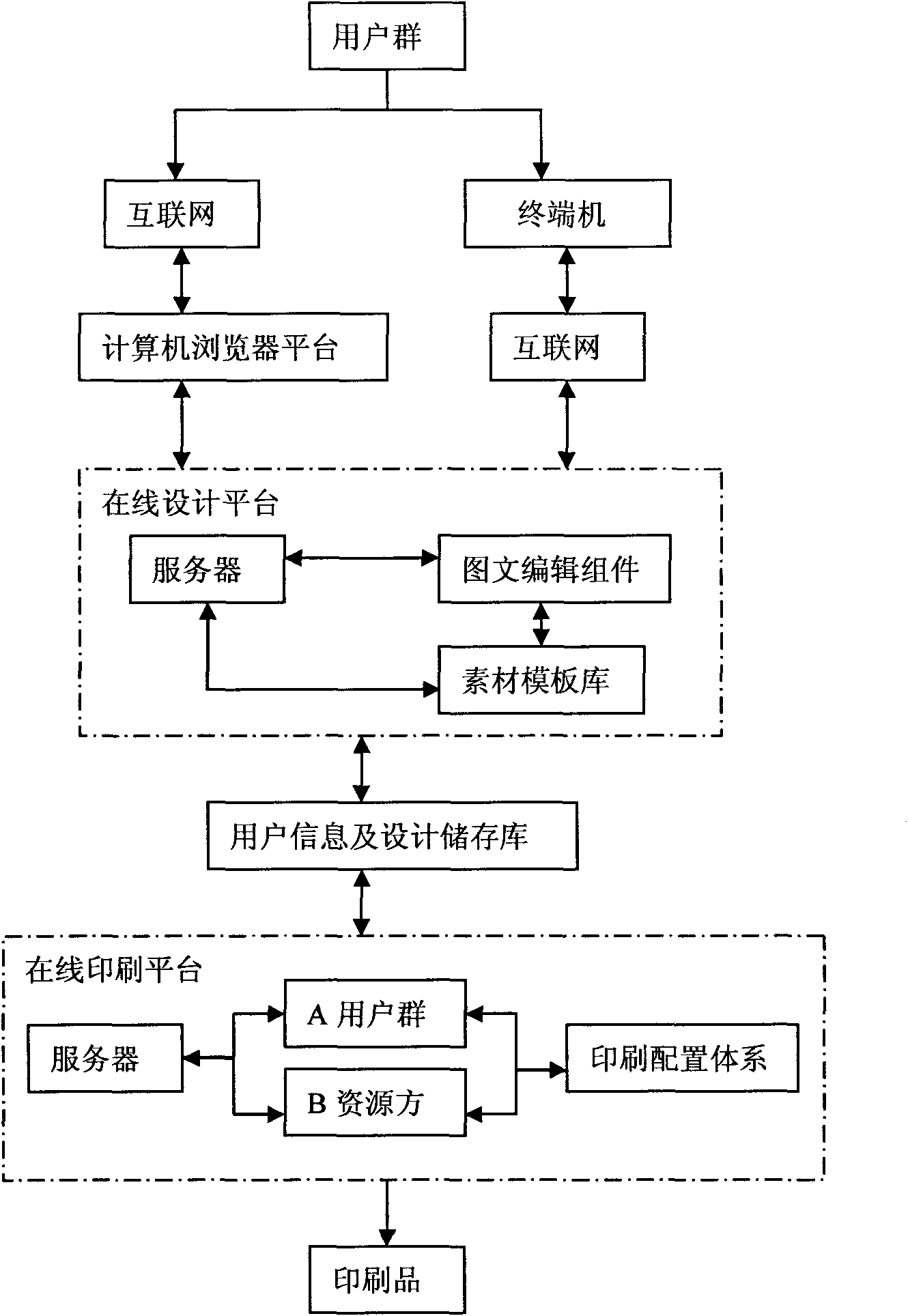

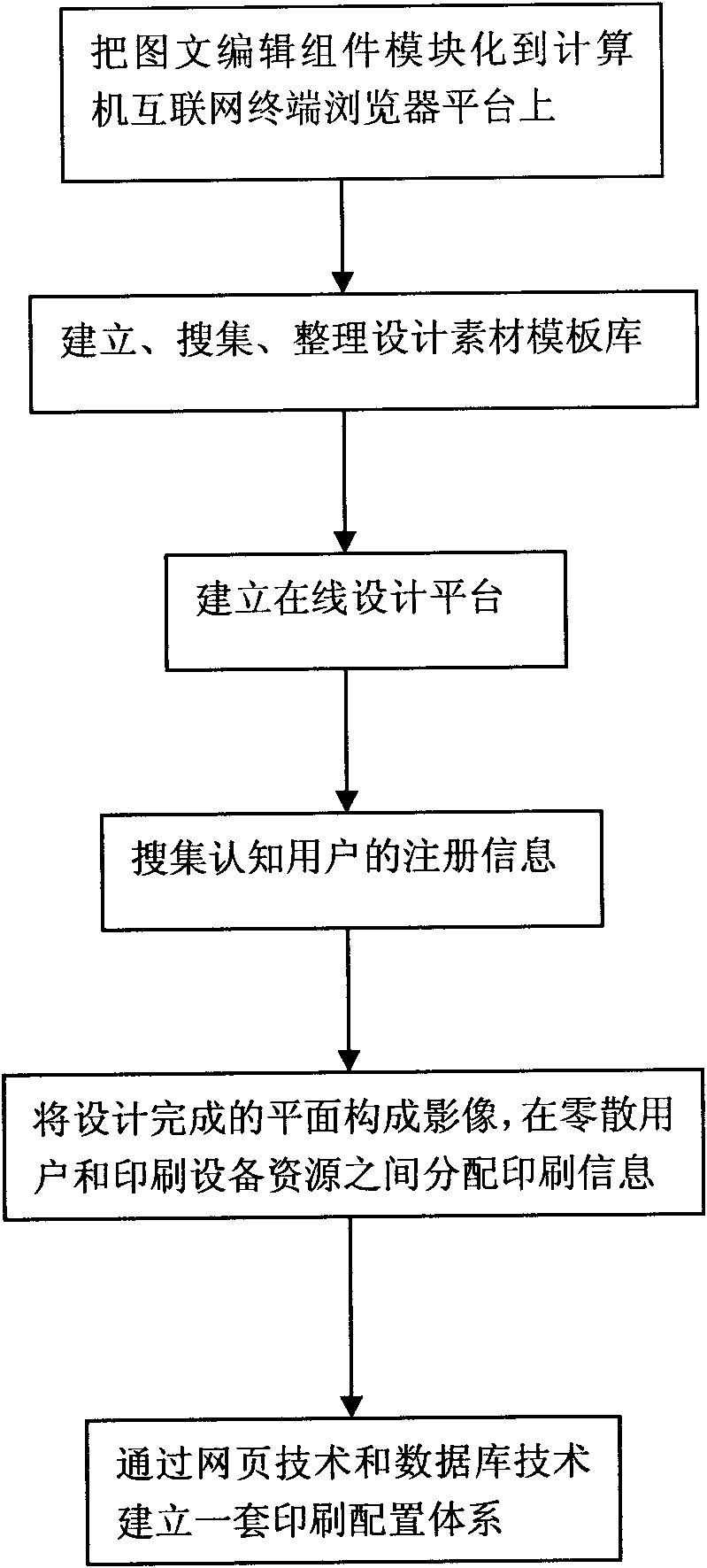

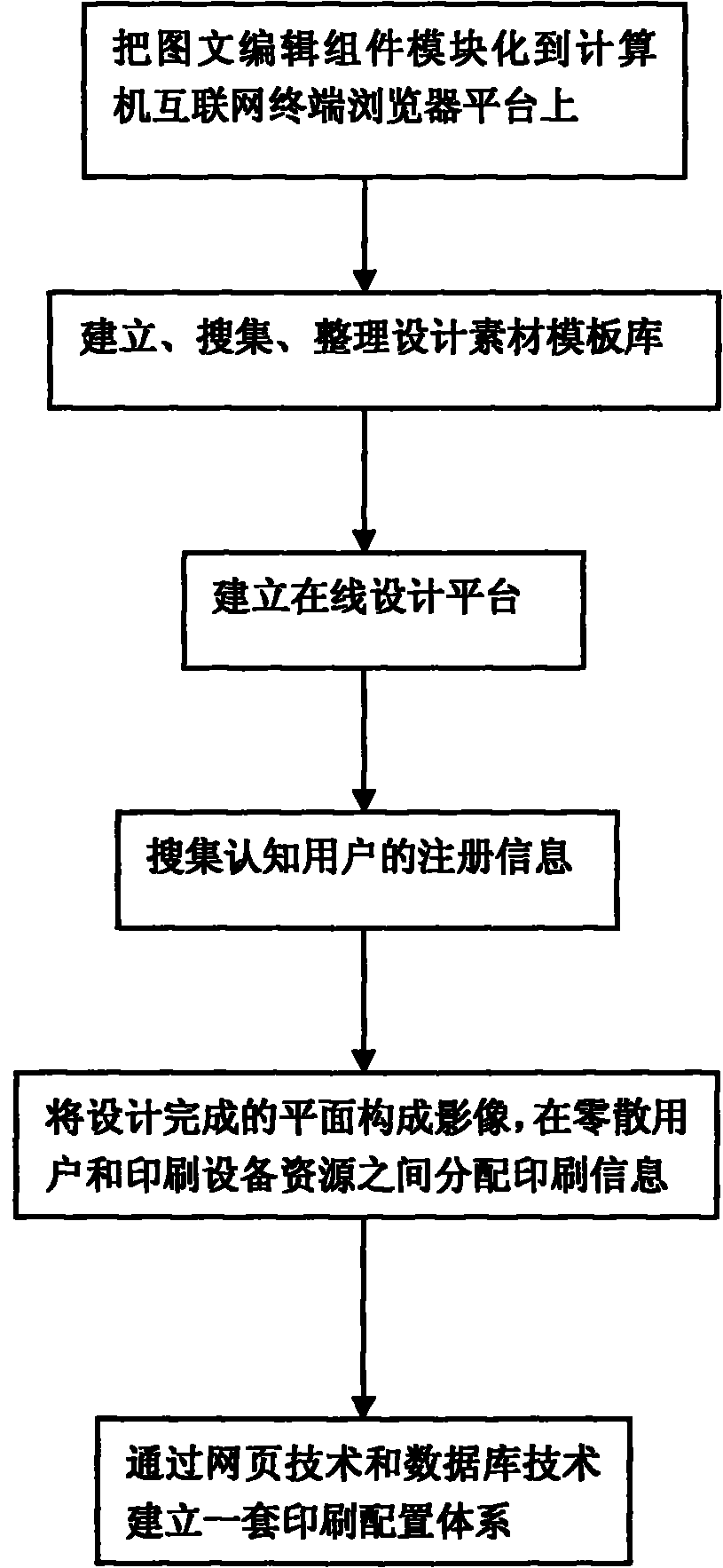

Method and system for integrating online modularized design and printing

InactiveCN101833674AEasy to buyMeet the designVisual presentationEditing/combining figures or textLogistics managementText editing

The invention provides method and system for integrating online modularized design and printing, wherein the method comprises the following steps of: modularizing a picture and text editing assembly onto an internet terminal browser platform; establishing, collecting, arranging and designing a material template base; establishing a blank template by a user and freely selecting an image element combination and a plane generated through type setting from the material template base to form an image, or selecting a template by the user to carry out the replacement, the addition, the detachment and the deletion of designed elements and the type setting of image elements, and combining into a new plane to form the image; searching and cognizing the registration information of the user; forming the image from the designed plane, and assigning printing information among scattered users and printing equipment resources; and establishing a set of assigning system integrating storage and logistics through a web page technology and a database technology. Through the invention, the design process is simple and rapid, the printing procedure is simplified, the printing cost is lowered, the automation and the intelligentization are high, and a rapid online design and printing solution can be supplied for medium and small enterprises and individual users.

Owner:赵德勇

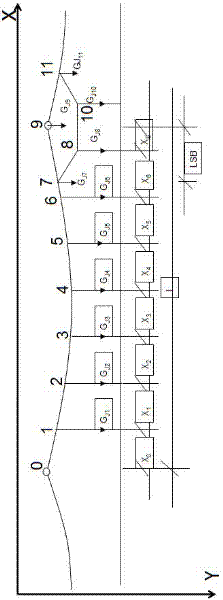

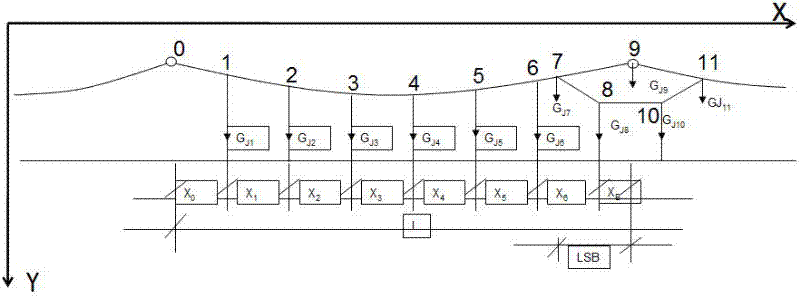

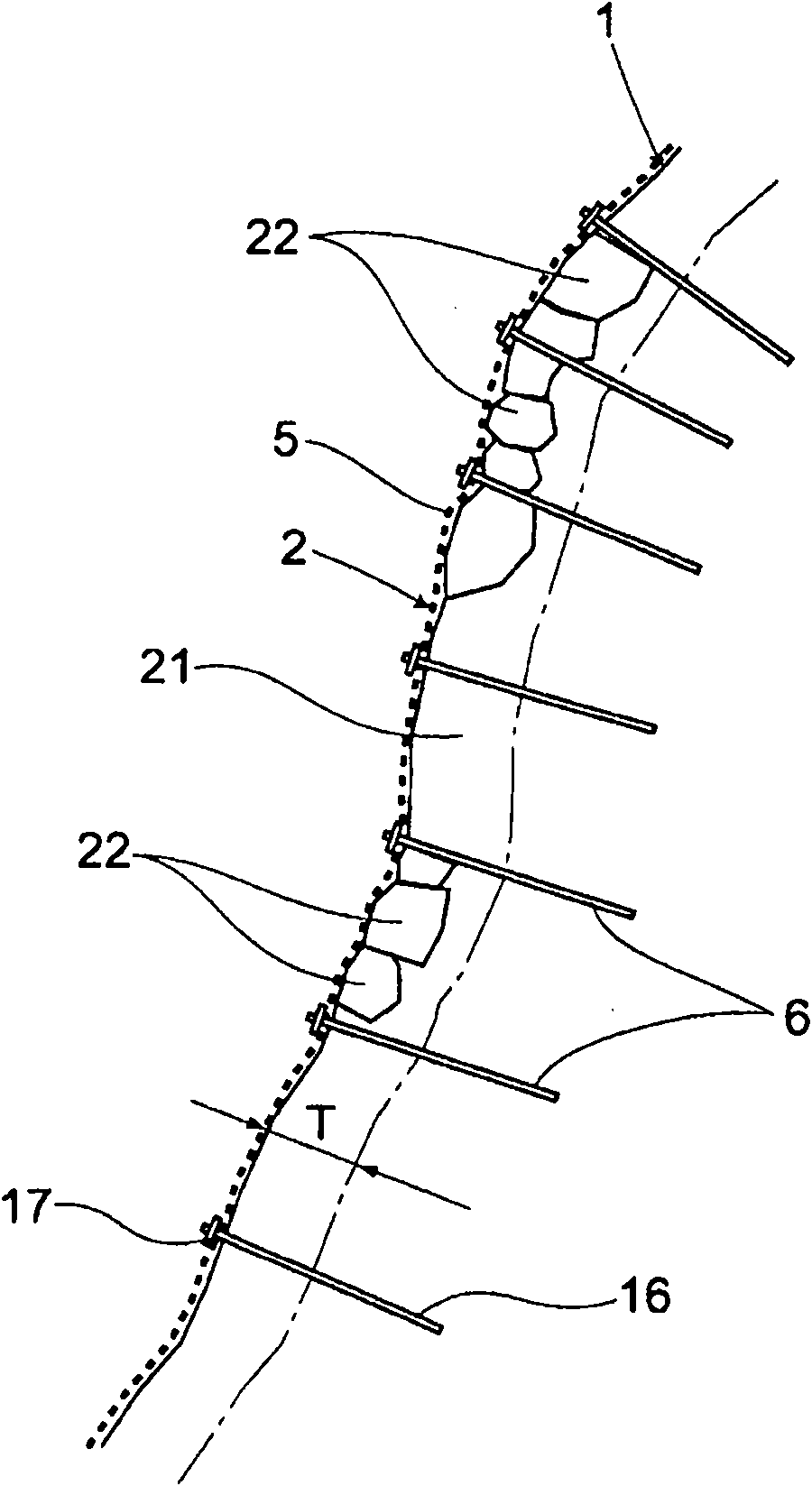

Full-compensation elastic chain hanging construction method for high-speed rail contact network

InactiveCN102381212AGuaranteed accuracyGuaranteed installation qualityTrolley linesContact networkArchitectural engineering

A full-compensation elastic chain hanging construction method for high-speed rail contact network, which comprises a construction preparing process, a construction measuring process, a software calculating process, a precasting process for sling and dropper, a mounting adjusting process for sling and dropper, and an ending process; each process is equipped with uniform and high-quality construction standards, and is assisted by modern construction meanses for satisfying with technical requirements for construction of high-speed rail contact network of 350 km / h; the software calculating process especially can obtain more accurate pre-stowage data of dropper length via a brand new calculating method finding form based on sling net, and then improve elastic chain hanging construction accuracy for high-speed rail contact net of 350 km / h. So the construction method does not only benefit for improving accuracy of sling and droppser calculation, and the construction method but also has high-quality construction standards and modern construction meanses, and is capable of improving quality and speed of construction of high-speed rail contact net of 350 km / h.

Owner:中铁建电气化局集团南方工程有限公司

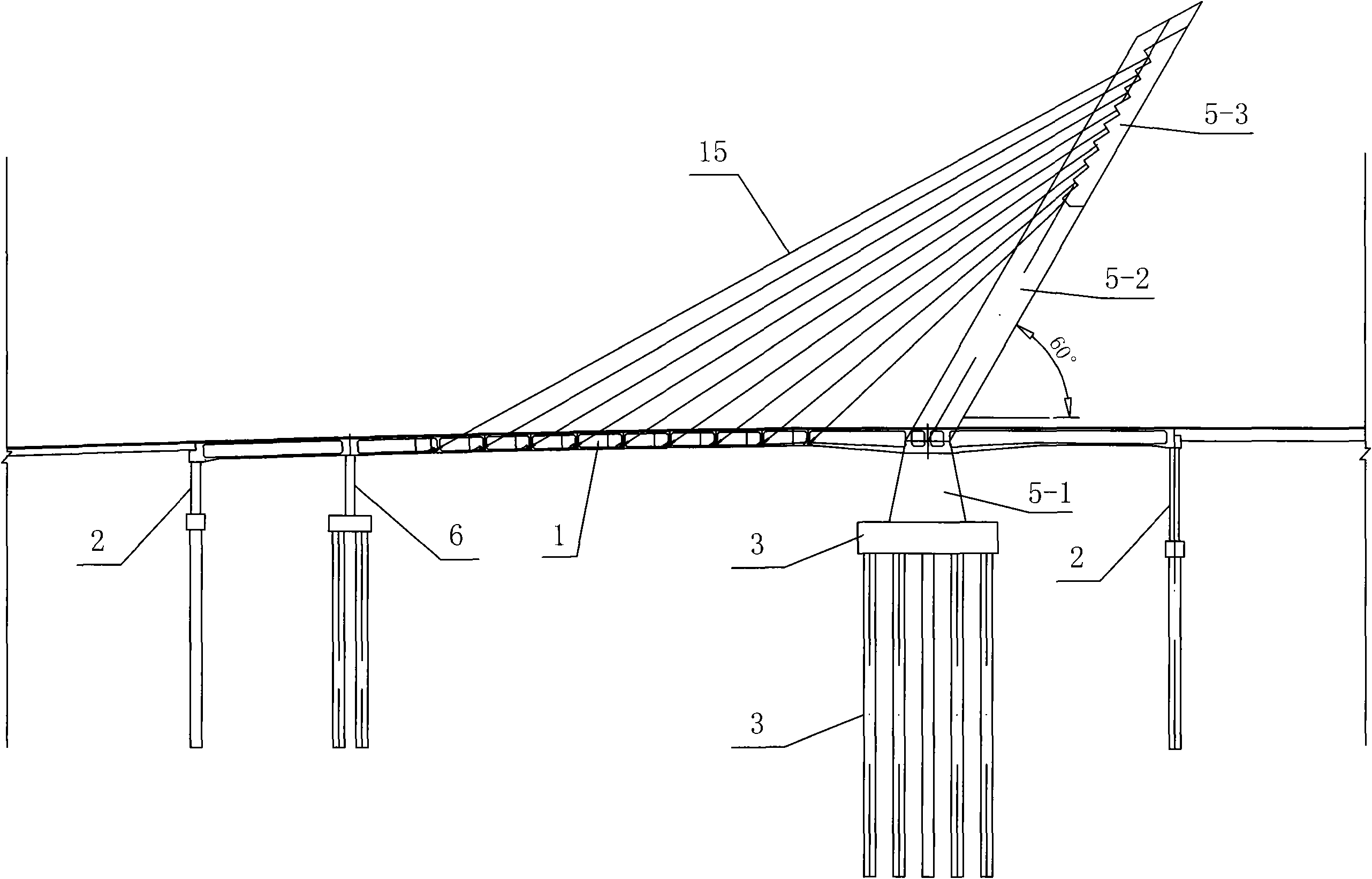

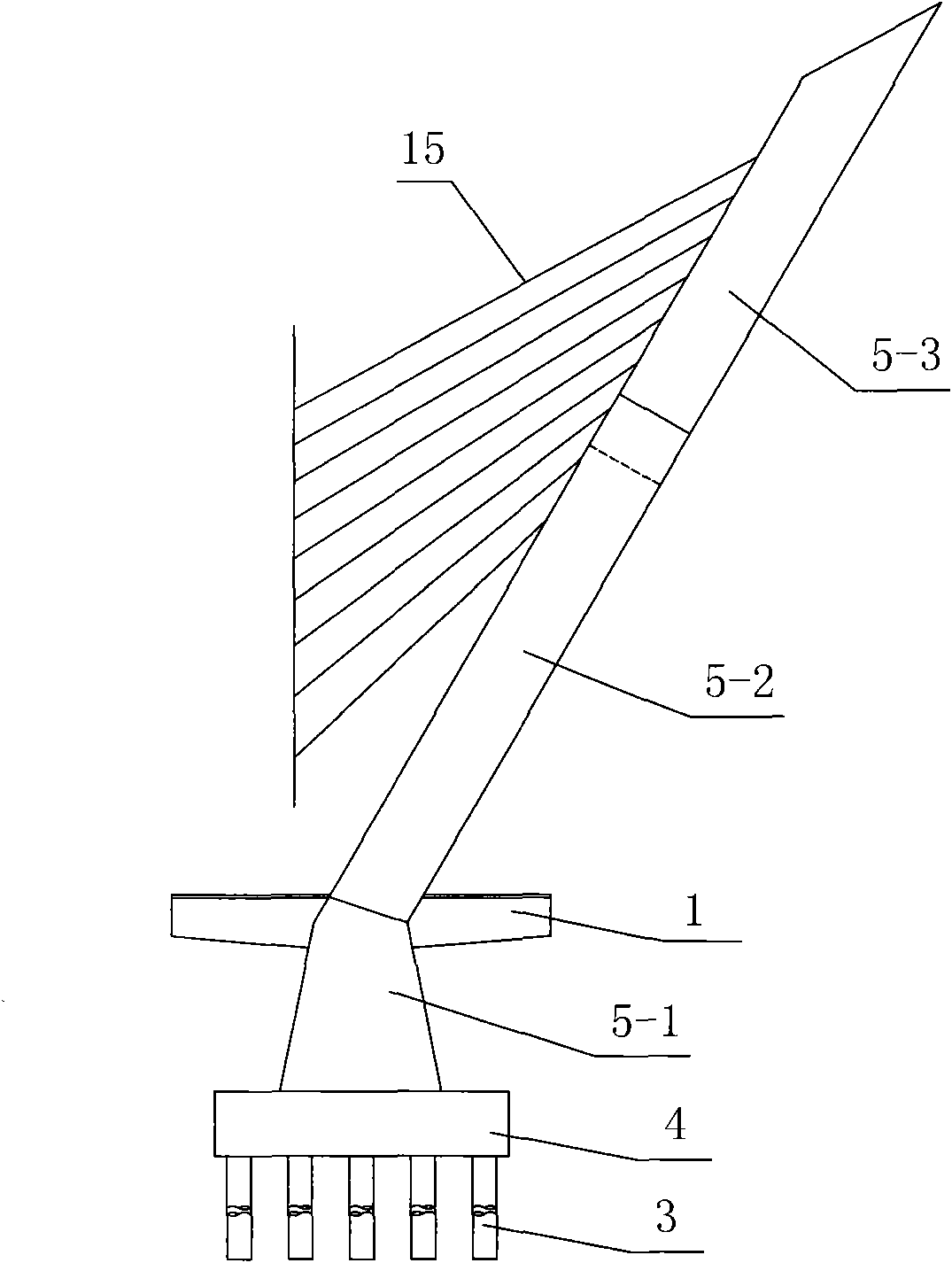

Integral lifting template of main pylon of single-pylon cable-stayed bridge without dorsal cables and lifting construction method thereof

ActiveCN101781878AReasonable structural designEasy to processCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses an integral lifting template of a main pylon of a single-pylon cable-stayed bridge without dorsal cables and a lifting construction method thereof. The method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction comprising the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The integral lifting template has reasonable structural design, convenient processing, manufacture, mounting and arrangement, low investment cost, simple construction method and steps and high construction speed and can quickly and safely complete the construction task of the main pylon of the cable-stayed bridge by utilizing simple construction tools and investing less labor, and various technical indexes of the main pylon of the constructed and molded cable-stayed bridge meet the requirements of the design and a construction specification.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

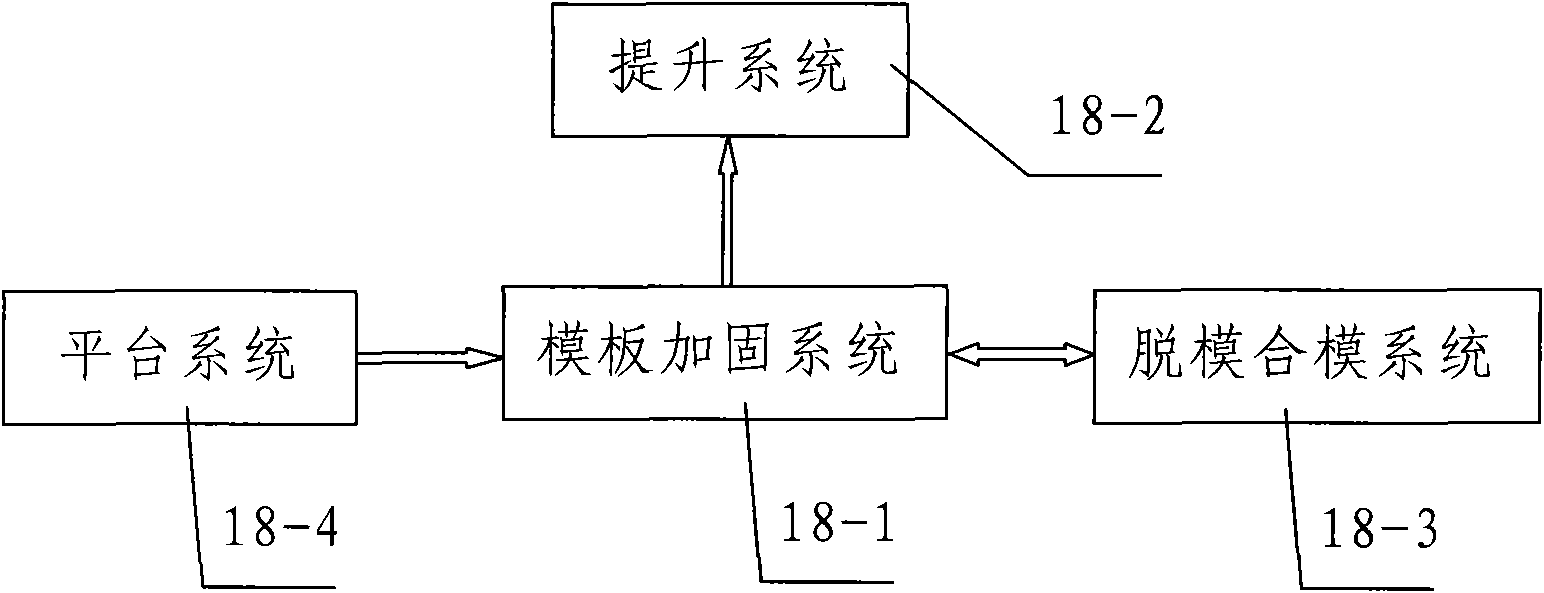

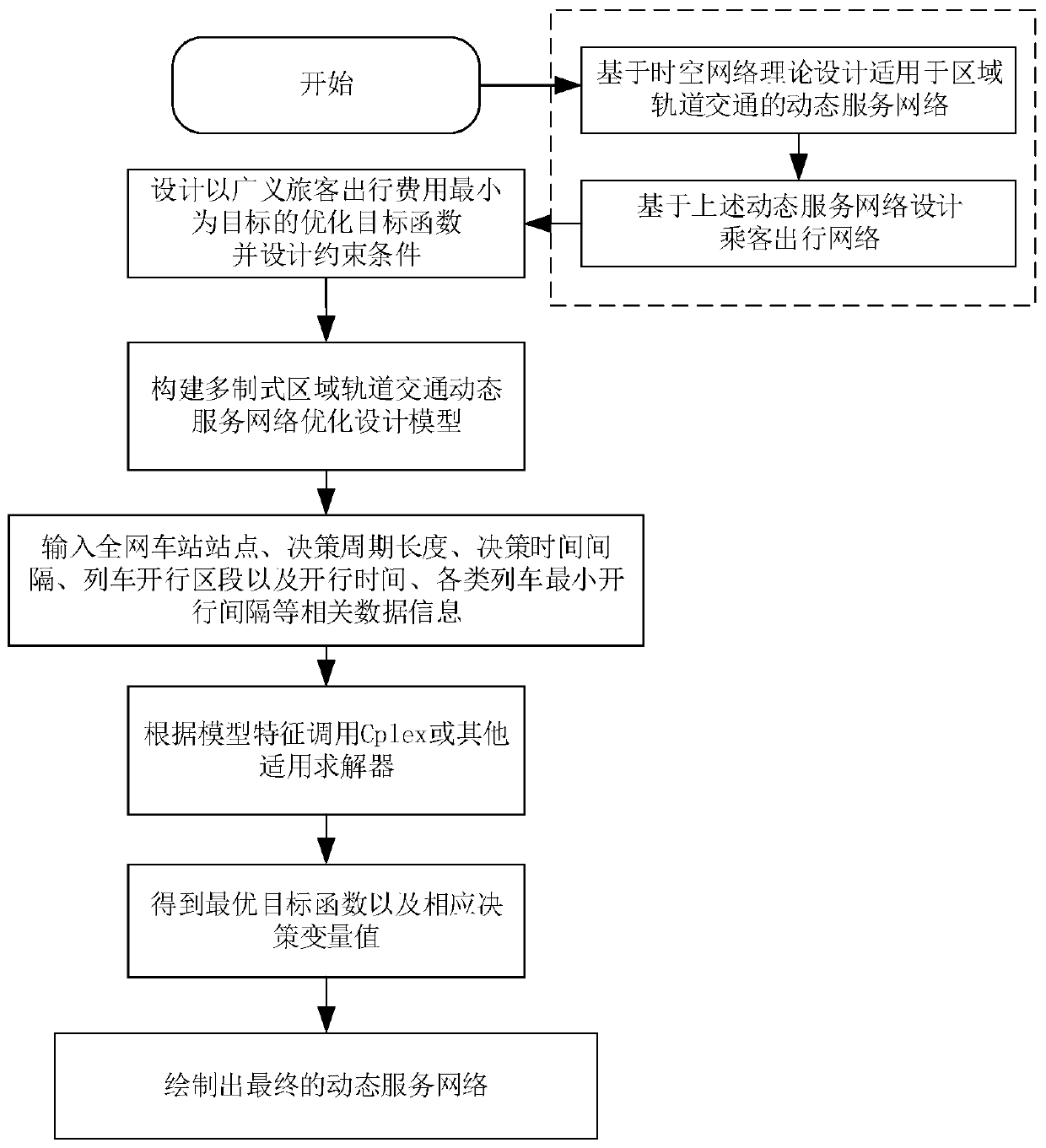

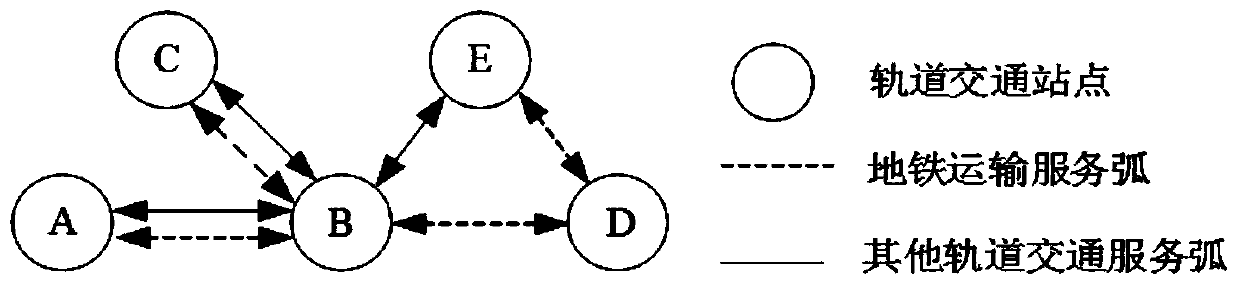

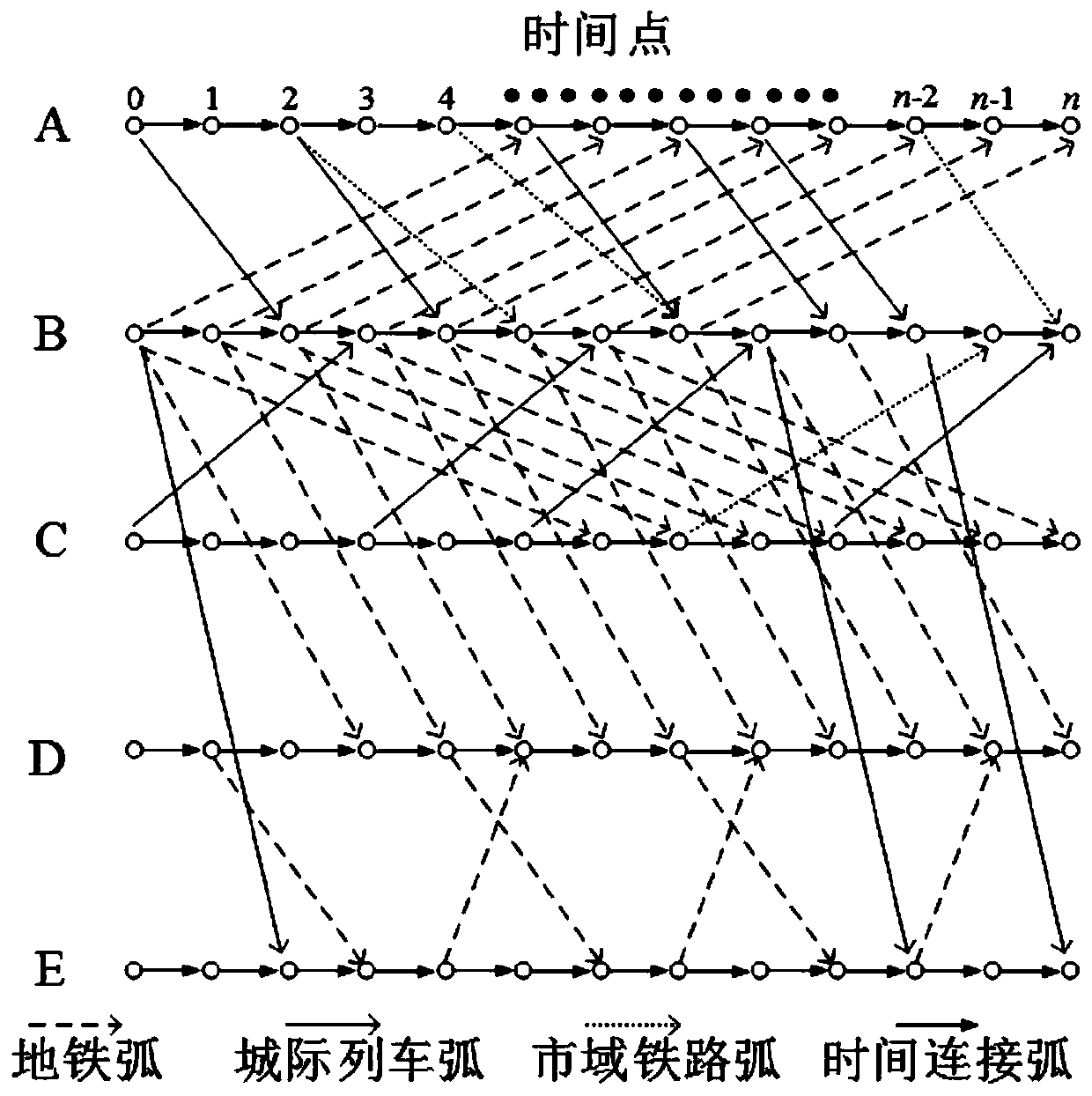

Dynamic service network optimization design method for multi-standard regional rail transit

InactiveCN110070218AAdapt to real-time operational needsMeet the designForecastingResourcesTraffic capacityMode of transport

The invention discloses a dynamic service network optimization design method for multi-standard regional rail transit. The method comprises the steps of constructing a regional rail transit dynamic service network in a peak period and constructing a regional rail transit dynamic service network model: step 1, establishing an objective function taking passenger generalized travel cost minimizationas an objective; and step 2, determining the following constraint conditions: capacity constraint, flow conservation constraint, minimum departure interval constraint and decision variable logic constraint. Compared with the prior art, the method has the positive effects that at the peak transportation moment, the real-time passenger transportation requirement can be met as much as possible, the passenger on-way time is shortened, the passenger travel track is accurately described, and urban congestion is properly relieved; various transportation modes can be compatible, collaborative optimization is achieved, and inter-regional train running is more reasonable; the nonlinear departure is represented through linear constraint, so that the solving difficulty of the method is reduced; and algorithm programming is not needed, and the solving speed is higher by using corresponding solving software.

Owner:SOUTHWEST JIAOTONG UNIV

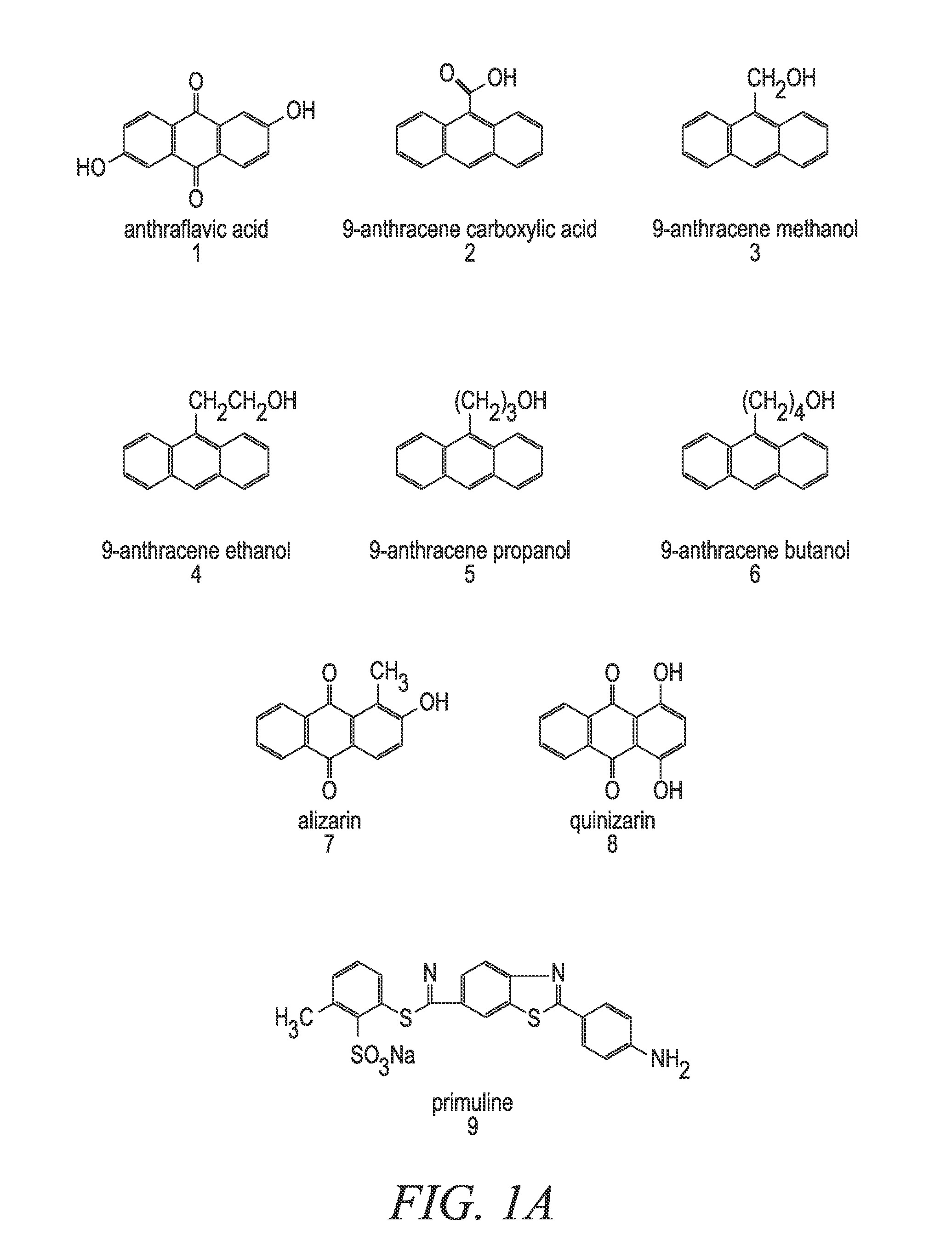

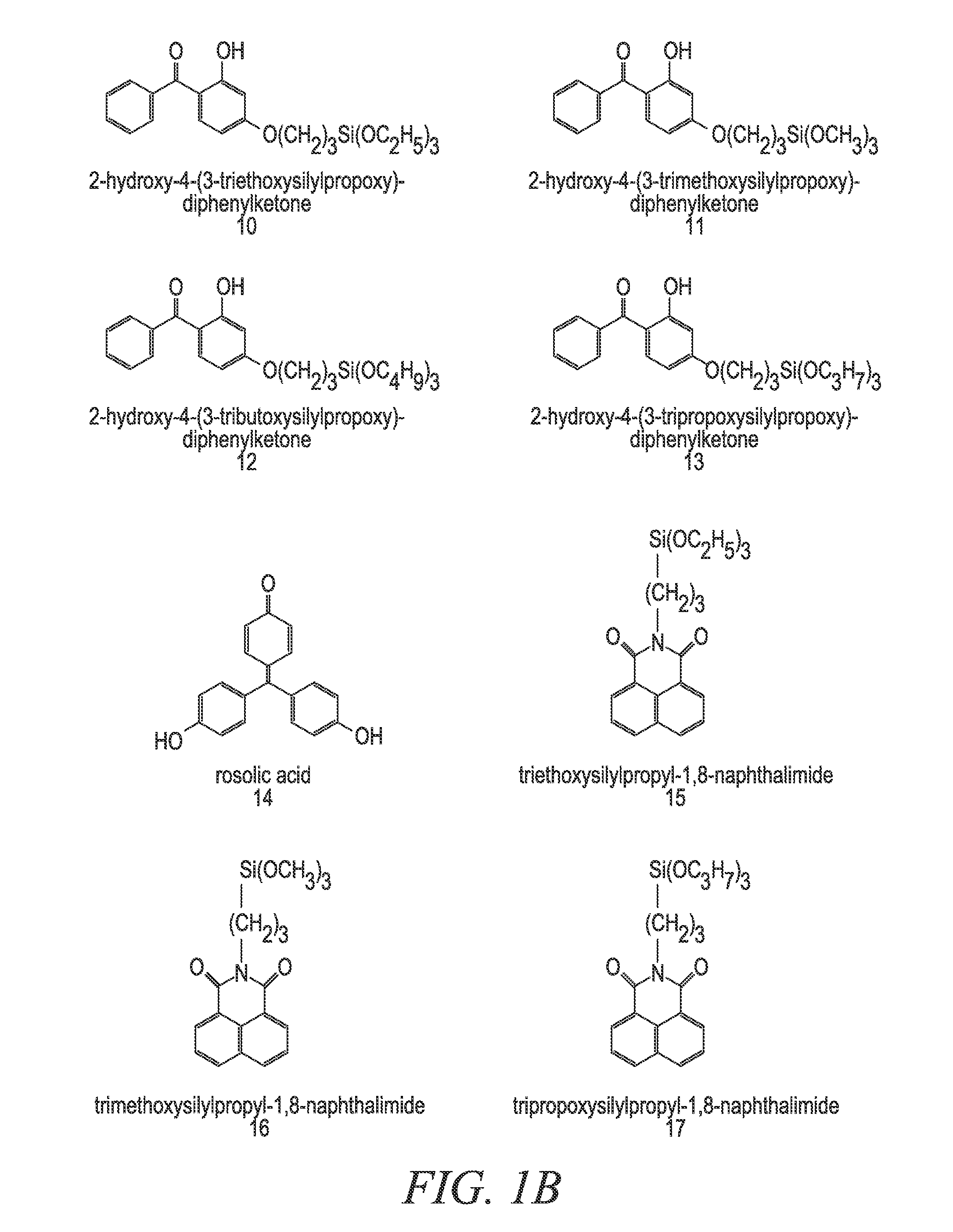

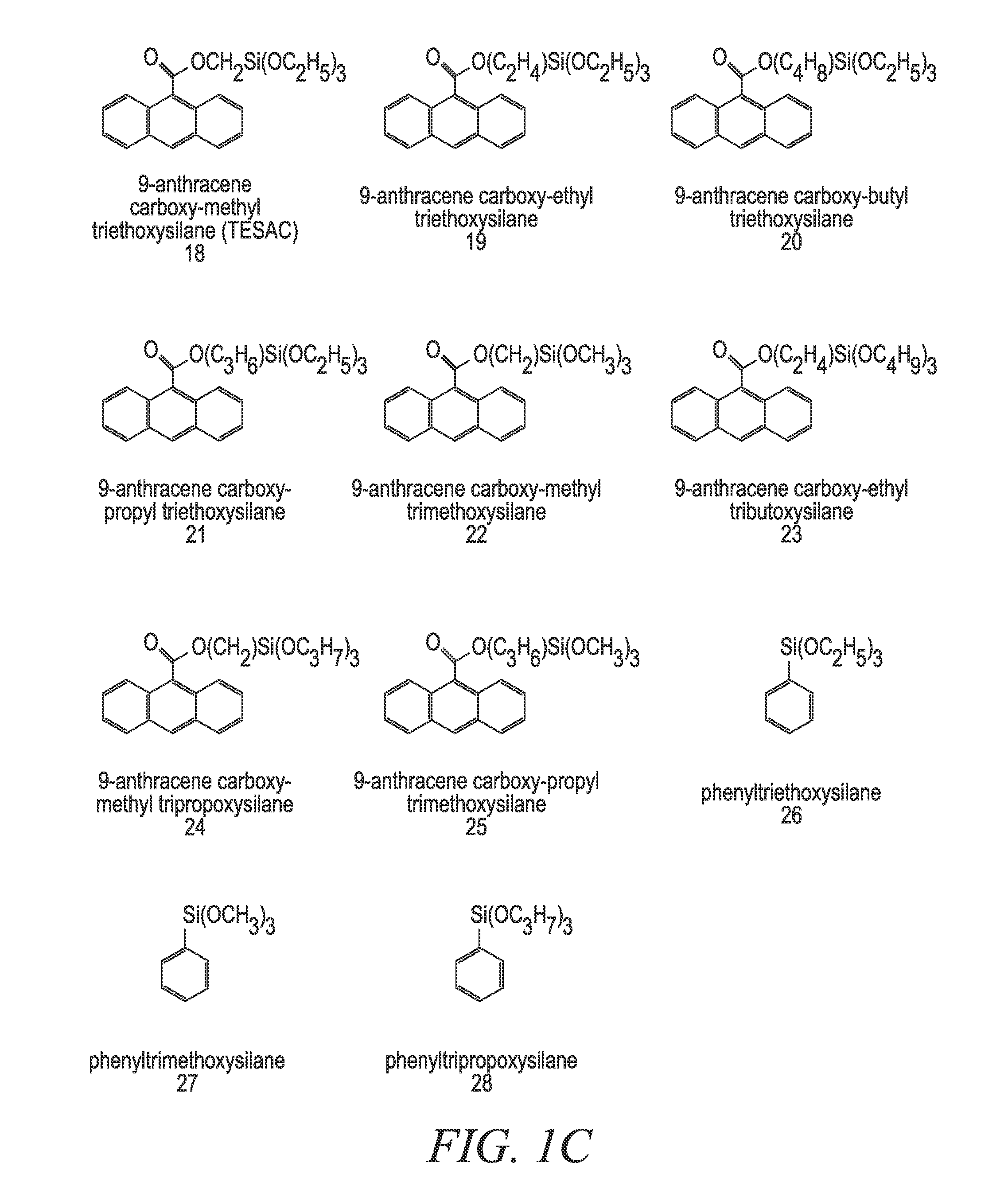

Anti-reflective coating for photolithography and methods of preparation thereof

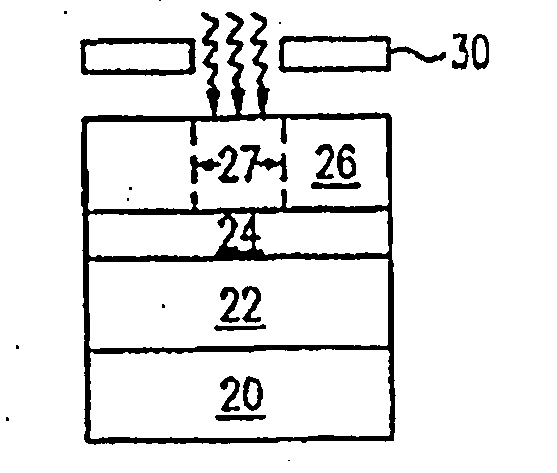

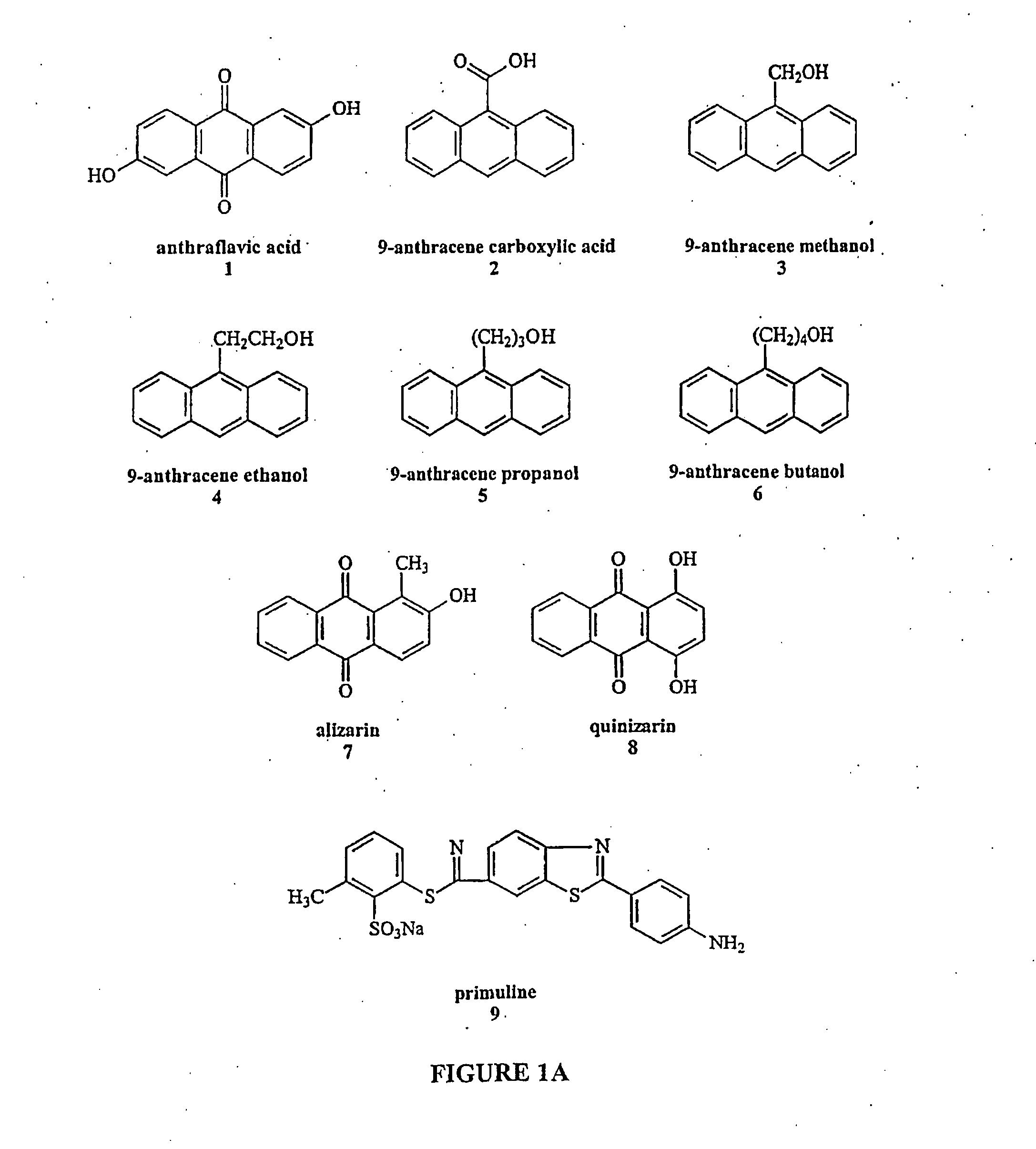

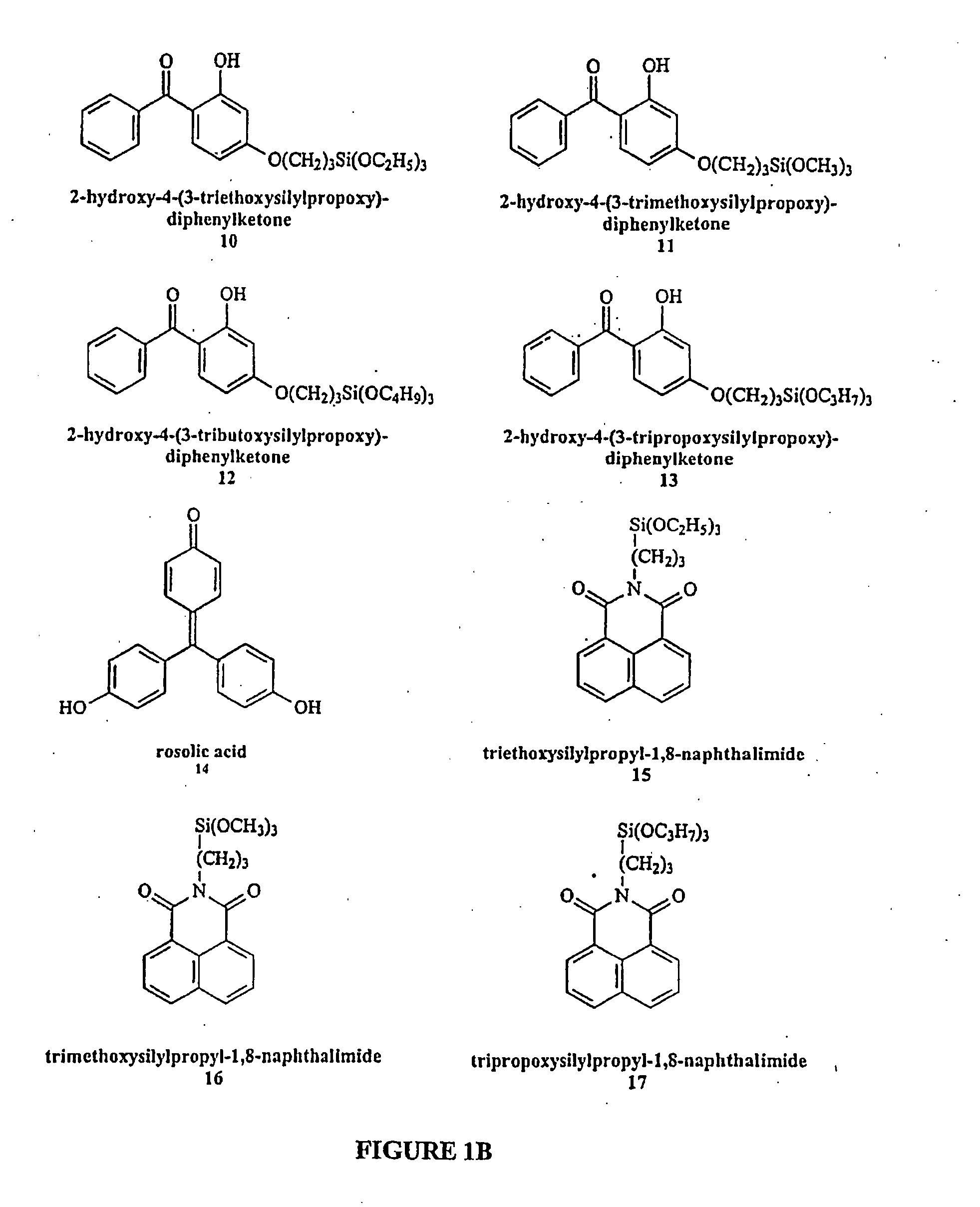

ActiveUS9069133B2Improve photolithographic and compatibility and physical qualityImprove etch selectivityGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingAnti-reflective coatingBoiling point

Owner:HONEYWELL INT INC

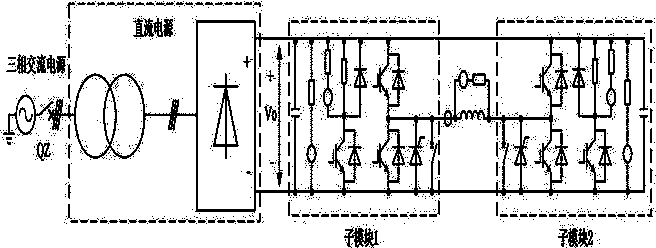

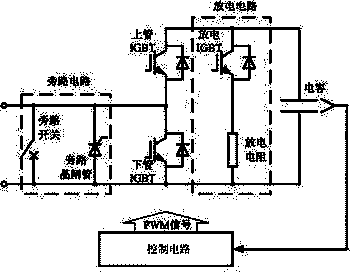

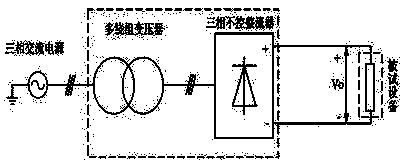

Testing circuit of half-bridge-structure voltage source current converter and modulation method thereof

ActiveCN103954866AThe structure of the test device is simpleThe test method is simple and reliableElectrical testingCapacitanceCell controller

The invention relates to a testing circuit of a half-bridge-structure voltage source current converter and a modulation method of the testing circuit. The testing circuit comprises a testing power source circuit, a direct current power source, a half-bridge-structure voltage source current converter sub-module 1, an impedance load and a half-bridge-structure voltage source current converter sub-module 2. According to the modulation method, by setting the output voltage of the direct current power source, the voltage of a direct current bus meets the requirement, and a direct current side capacitor of the half-bridge-structure voltage source current converter is charged; after charging is stable, a circuit controller is controlled to output PWM pulse signals, and the half-bridge-structure voltage source current converter operates under different work conditions; by measuring the current and the voltage of the impedance load and simulating various faults of the half-bridge-structure voltage source current converter, the performance and stability of the half-bridge-structure voltage source current converter are checked. By constructing the various work conditions of the half-bridge-structure voltage source current converter, the experimental verification requirements of the design of the half-bridge-structure voltage source current converter and a unit controller control strategy are met.

Owner:STATE GRID CORP OF CHINA +1

Anti-Reflective Coating for Photolithography and Methods of Preparation Thereof

ActiveUS20140227538A1Improve photolithographicGood compatibilityGroup 4/14 element organic compoundsLayered productsAnti-reflective coatingInorganic composition

Anti-reflective coating materials for ultraviolet photolithography include at least one absorbing compound and at least one material modification agent, such as at least one porogen, at least one high-boiling solvent, at least one capping agent, at least one leveling agent, at least one catalyst, at least one replacement solvent, at least one pH tuning agent, and / or a combination thereof that are incorporated into inorganic-based materials or inorganic compositions and / or compounds. Suitable absorbing compounds

Owner:HONEYWELL INT INC

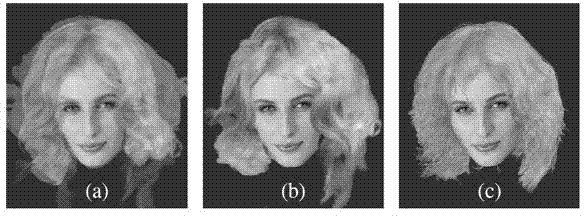

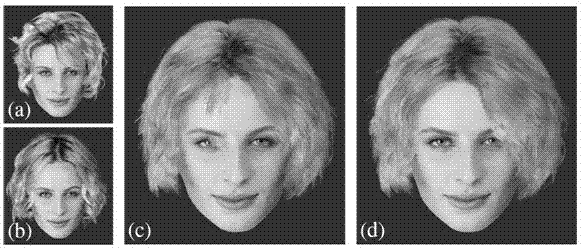

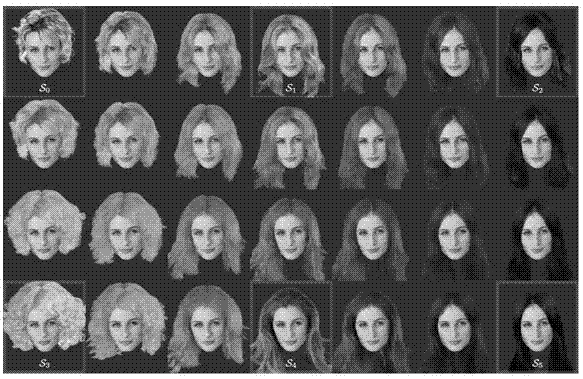

Virtual haircut interpolation and tweening animation producing method

The invention discloses a virtual haircut interpolation and tweening animation producing method. The method includes a first step of inputting and pre-processing haircut model data, a second step of obtaining many-to-many hair corresponding relationshipsamong multiple haircut models and corresponding weights by inputting haircut model hair quality transmission problem, a third step of obtaining hair cluster and representative hair from top to bottom by clustering the input haircut model and constructing hierarchical structure, and a fourth step of obtaining a new haircut model result after interpolation by expanding the binary haircut tweening to multiple input haircut models and ensuring high efficiency. The method is applied to a virtual haircut geometry object which is constructed by taking a three-dimensional hairline curve as a basic unit and widely applied in the industry, the method can conduct the interpolation on a plurality of different input haircut objects so as to combine a new haircut at the middle moment, and can be applied to aspects such as auxiliary design combination of virtual role haircuts and production of tweening role animation in the fields such as digital media.

Owner:ZHEJIANG UNIV

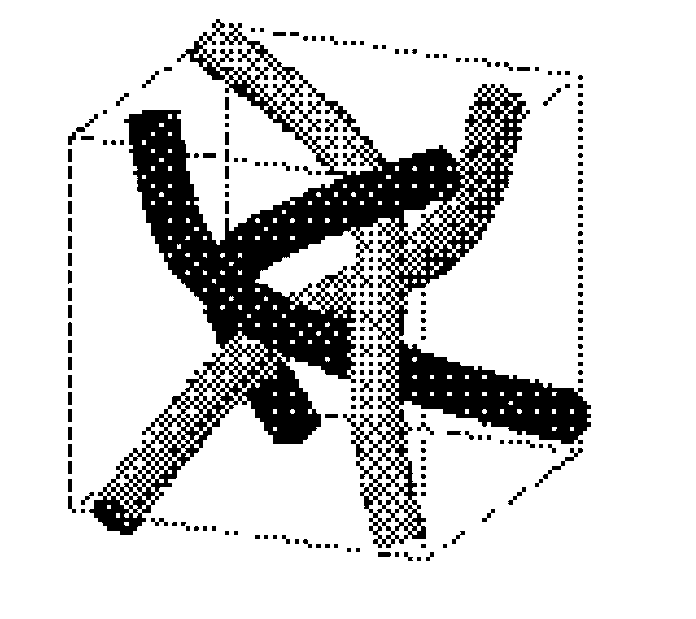

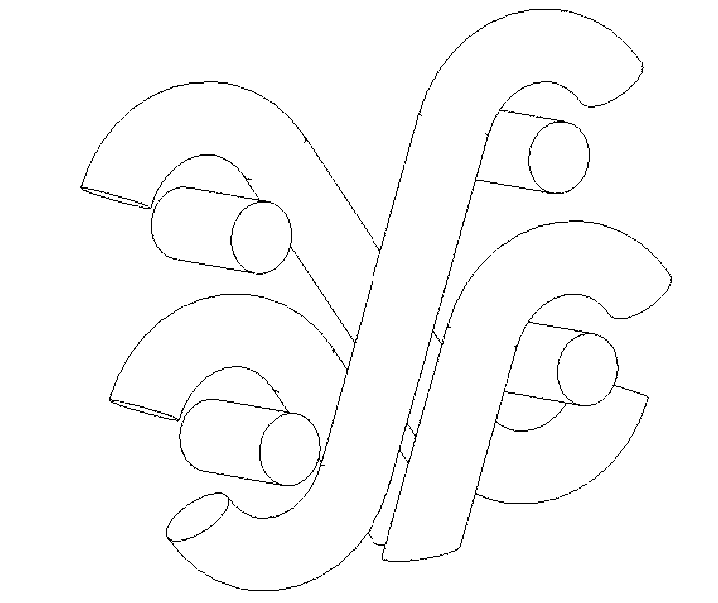

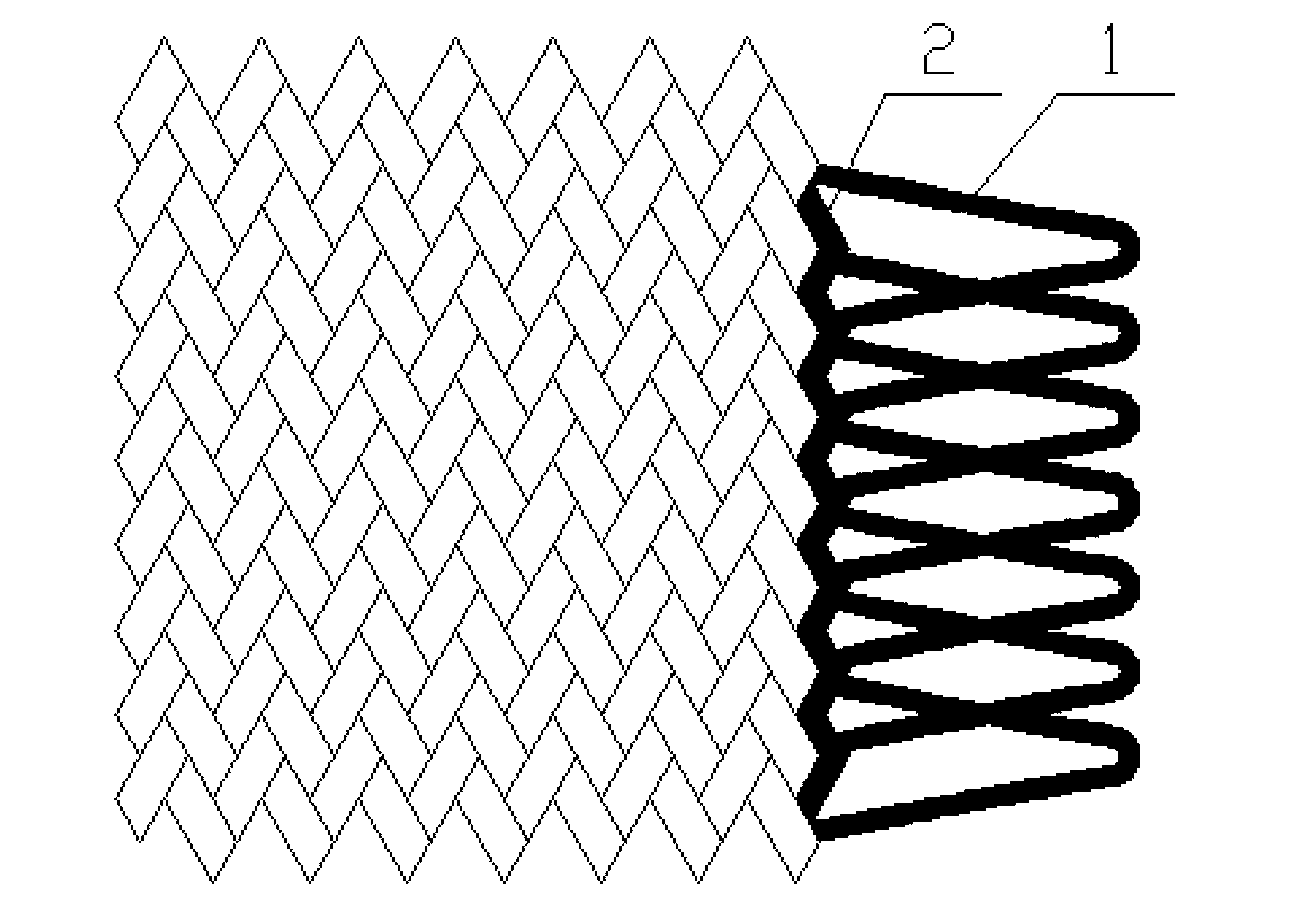

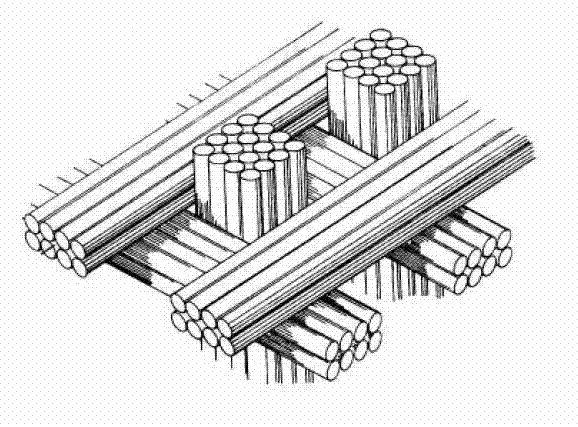

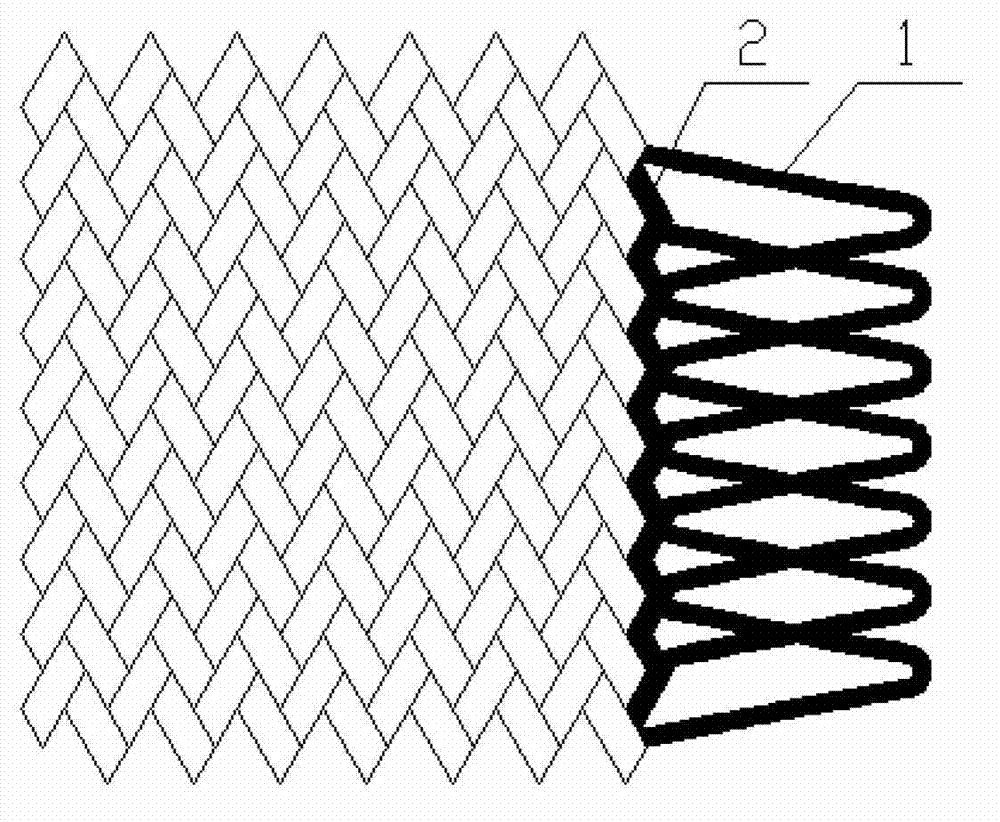

Novel structure three-dimensional woolen fabric and weaving method thereof

ActiveCN103061003AMeet the designGuaranteed continuityWoven fabricsBraidEngineeringFiber orientation

The utility model relates to a new structure three-dimensional woolen fabric and weaving method thereof. The novel structure three-dimensional fabric comprises a three-dimensional and multi-directional structure and a 2.5D shallow bending structure. The three-dimensional and multi-directional structure is in a structure with three dimensions and more than four directions. The key technique of the novel structure three-dimensional woolen fabric is that fabric between the two structures winds with each other so that continual weaving of fabric within the woolen fabric can be achieved. The novel structure three-dimensional woolen fabric can not only firstly weave from the three-dimensional structure and then weave from the 2.5D structure, but also firstly weave from the 2.5D structure and then weave from the three-dimensional structure. The novel structure three-dimensional woolen fabric has the advantages of being high in forming process reliability, being convenient and easy to operate, being complex in fiber orientation, being high in design of fiber volume content, and being numerous in the continuation of fabric. A novel method of utilizing three-dimensional woolen fabric as reinforcement material for manufacturing composite material of complex bearing components is provided.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

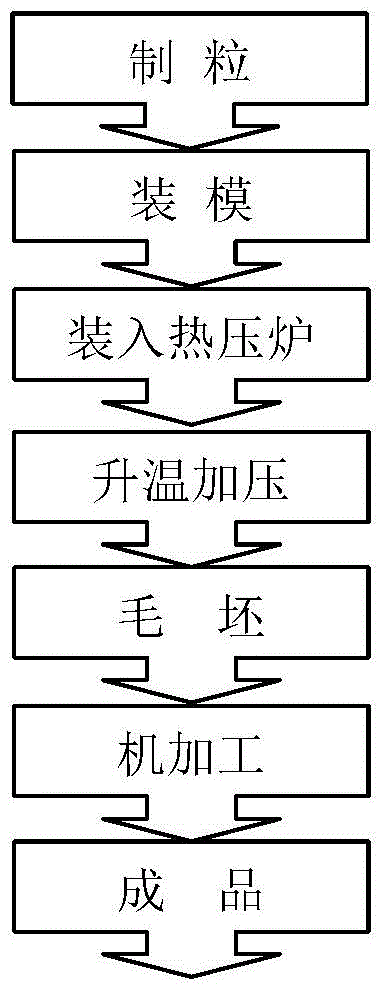

Hot-pressing technology for preparing boride sputtering target material

ActiveCN105693252AGood sputtering performanceMeet the needs of useVacuum evaporation coatingSputtering coatingBorideHigh pressure

The invention relates to a hot-pressing technology for preparing a boride sputtering target material. A preparation method sequentially comprises the following process steps of pulverizing boride with the purity being larger than or equal to 99.9 percent and the particle size being less than or equal to 5mum to be boride particles with the diameter being 1 to 3mm; filling in a graphite jig; loading in a hot-pressing furnace; warming and pressurizing; after keeping warm for 5 to 10h, cooling to form a workblank; obtaining a finished product through machining, wherein the relative density is 85 percent to 90 percent, and the electrical resistivity is 1.0 to 3.5 ohm.cm; the boride powder forms compact blocks at high temperature and high pressure, so that the compact blocks are high in relative density, low in electrical resistivity, good in uniformity, high in stability and favorable in sputtering performance, and meets the usage requirements of the target material. The preparation method is simple and easy to implement, the complicated mold design required by adopting a traditional powder metallurgy pressing method is avoided, the molding efficiency is greatly improved, and the obtained target material is excellent in sputtering performance, less in impurities, and suitable for sputtering coatings.

Owner:GEMCH MATERIAL TECH SUZHOU

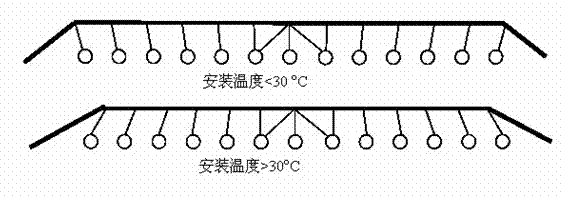

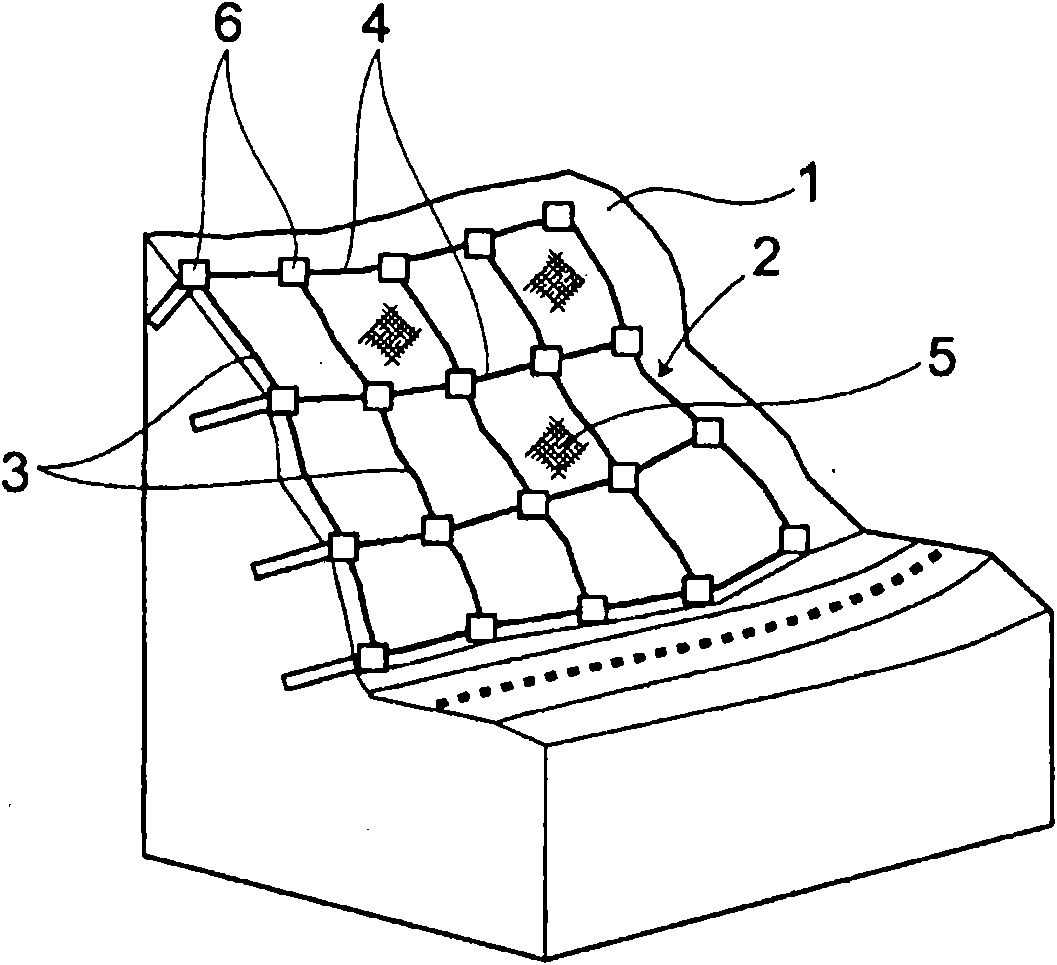

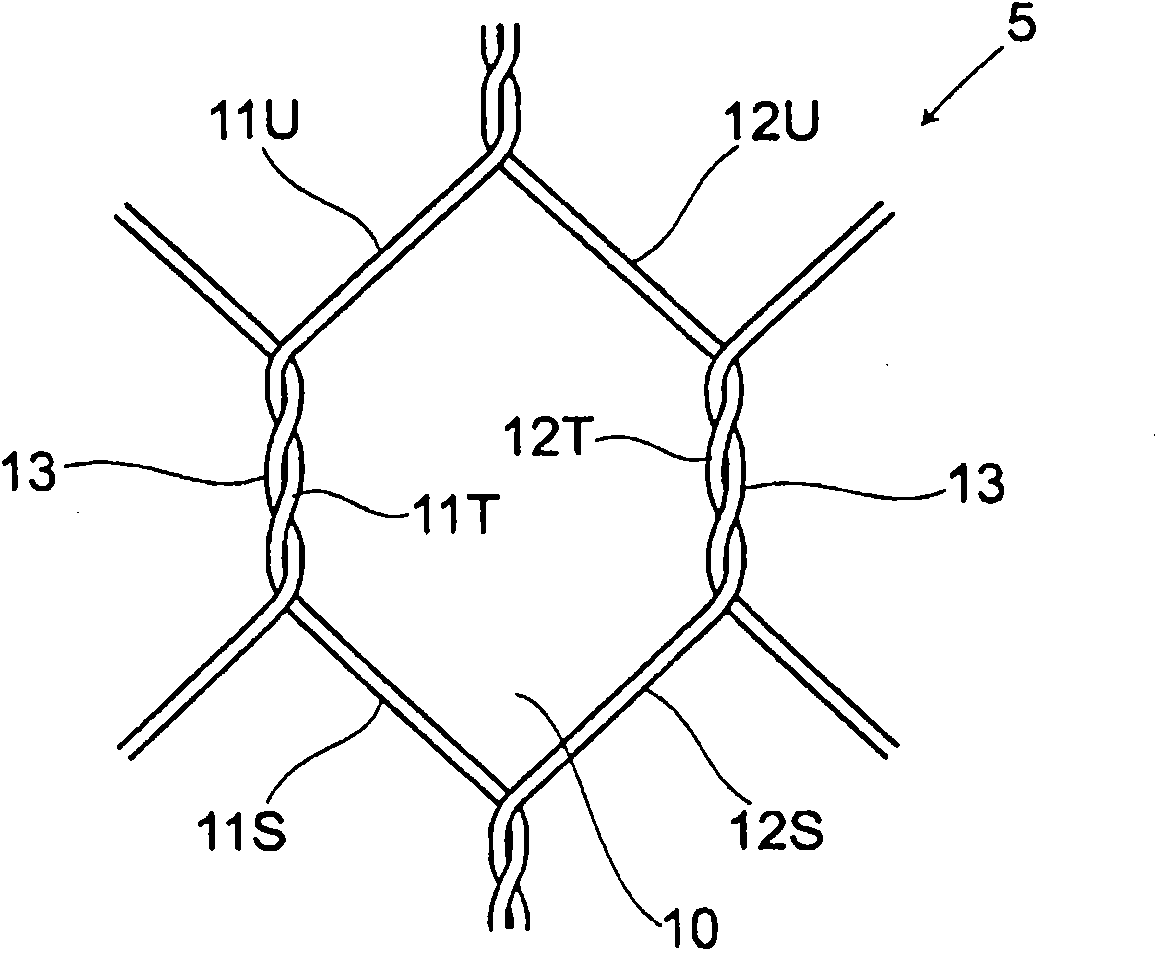

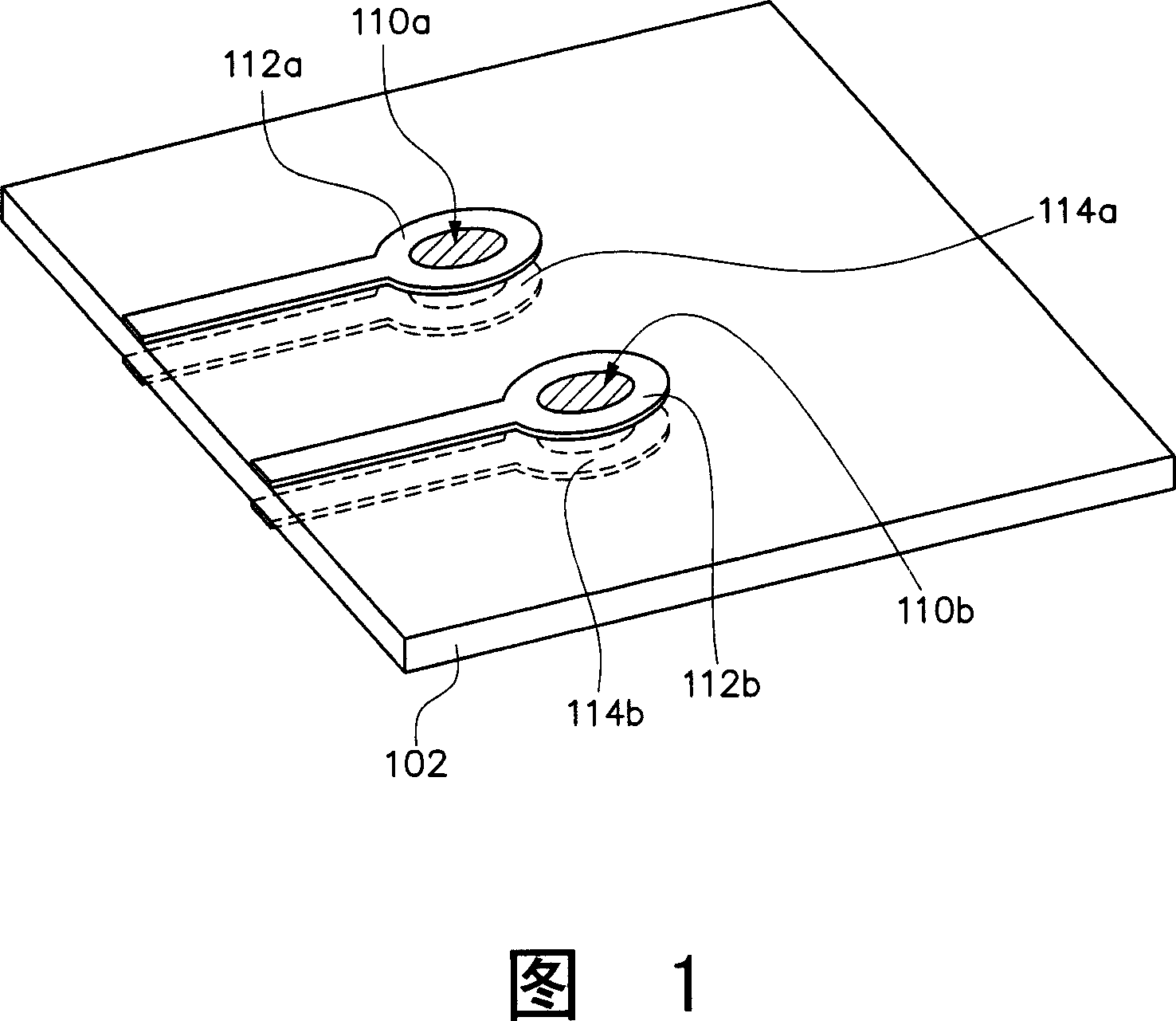

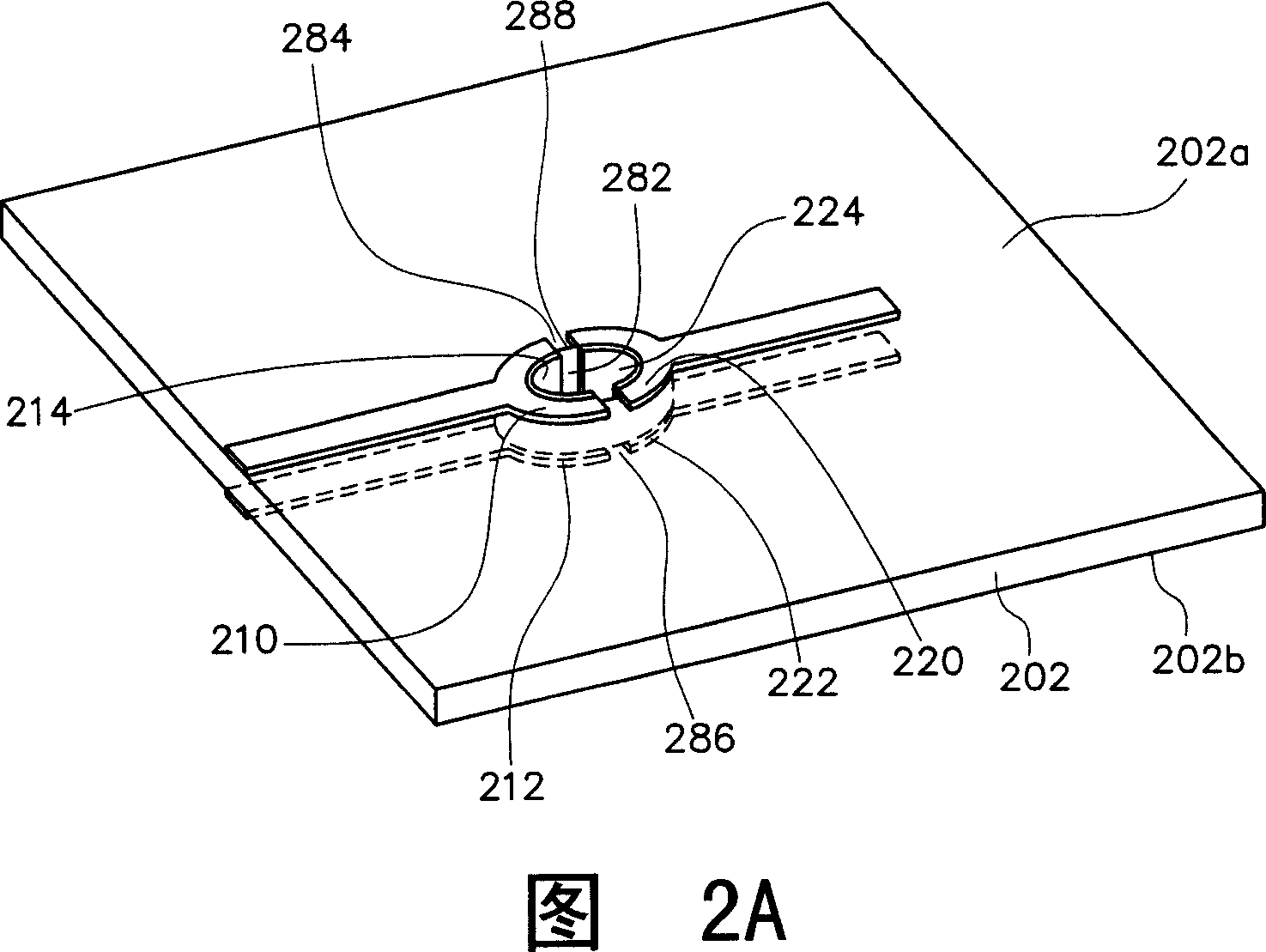

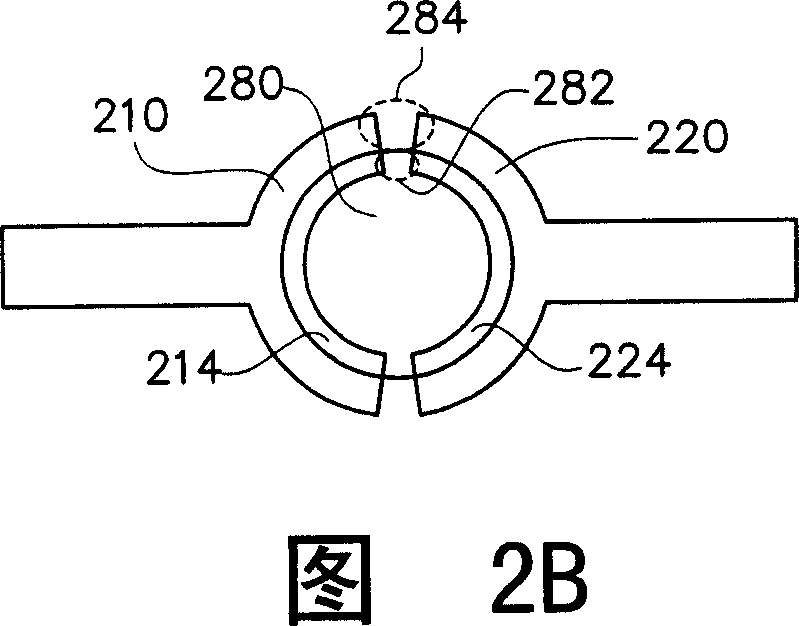

A structure for preventing rockfall, a rockfall prevention method, and a method for designing said structure

InactiveCN101970761APrevent collapsePrevent movementProtective constructionExcavationsSurface layerEngineering

To provide rock fall prevention structure and rock fall prevention method capable of preventing the collapse of surface layer and preventing the falling of identified rock masses. Slope (1) is covered with a net assembly (2) constructed of rope materials (3) and (4) combined in intersectional directions and a wire net connected thereto. The rope materials (3) and (4) of the net assembly (2) are anchored into slope (1) using anchors (6). The anchors (6) are inserted into slope (1) to stabilize a surface layer of the slope (1), giving the anchors (6) and the net assembly (2) a strength able to suppress the movement of identified rock masses (22) at slope (1). Using the anchors (6) will be able to prevent the surface layer of slope (1) from collapsing and at the same time, using the anchors (6) and the net assembly (2) will be able to suppress the movement and falling of the identified rock masses (22) at slope (1).

Owner:OFFICINE MACCAFERRI SPA

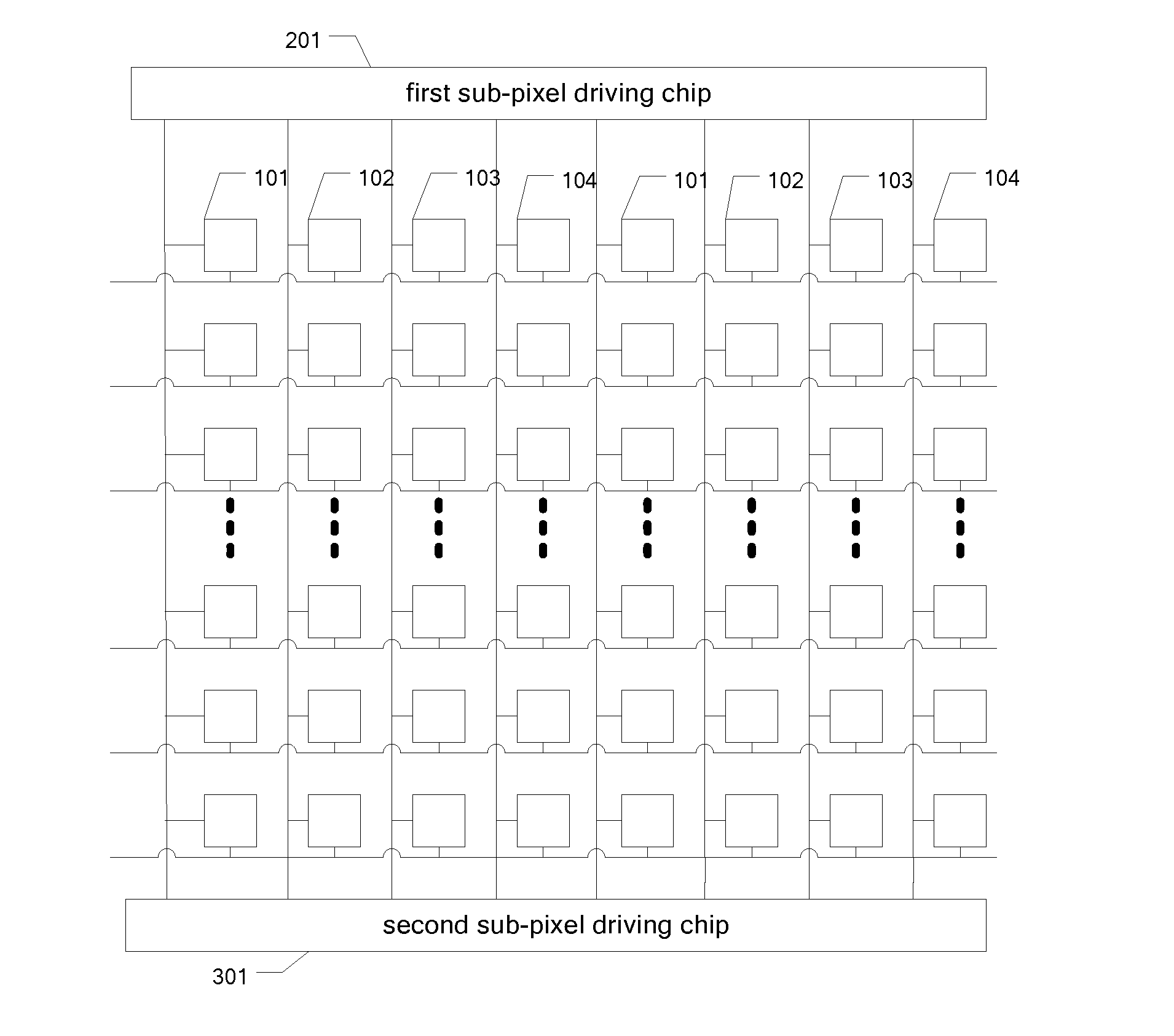

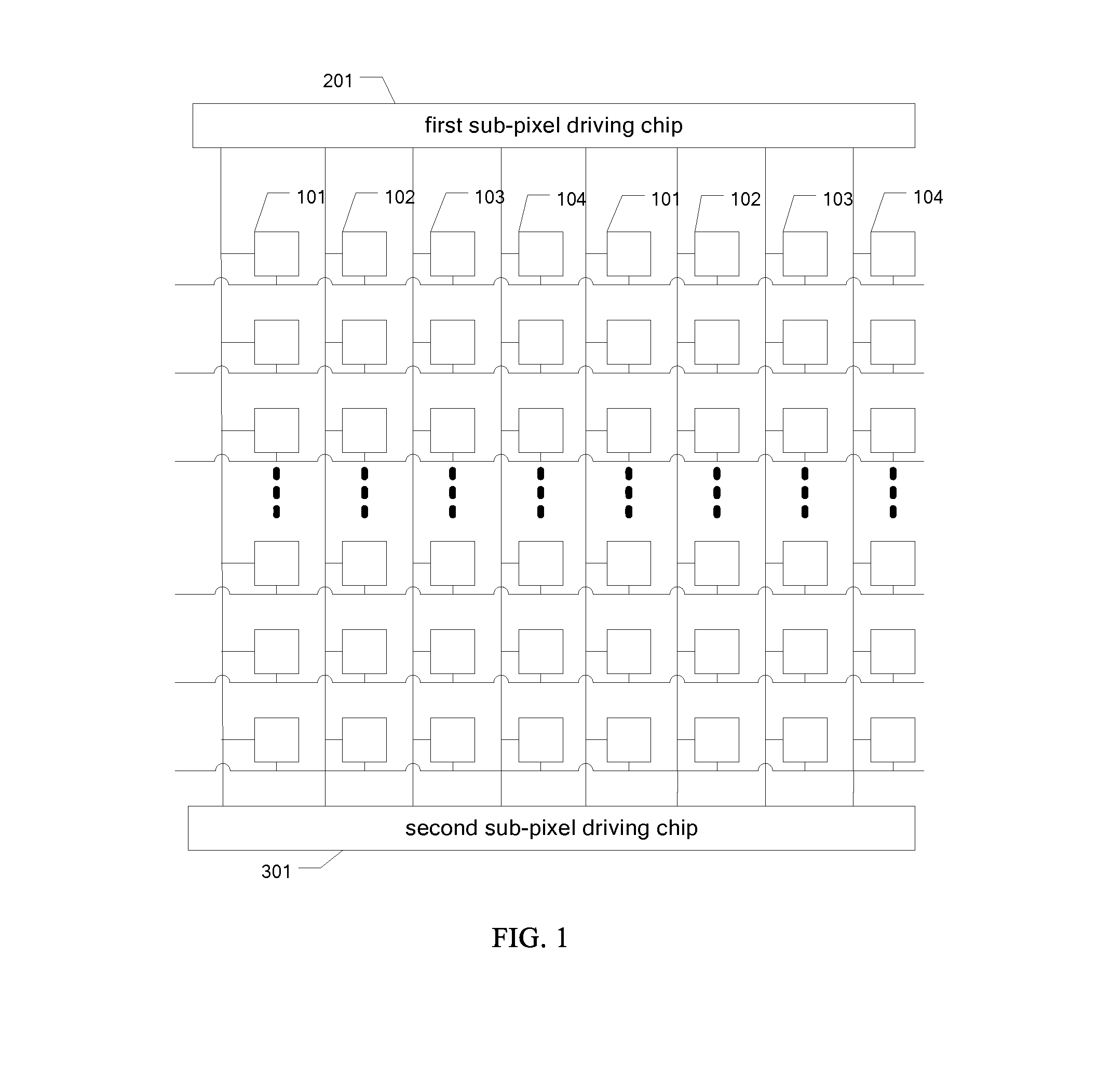

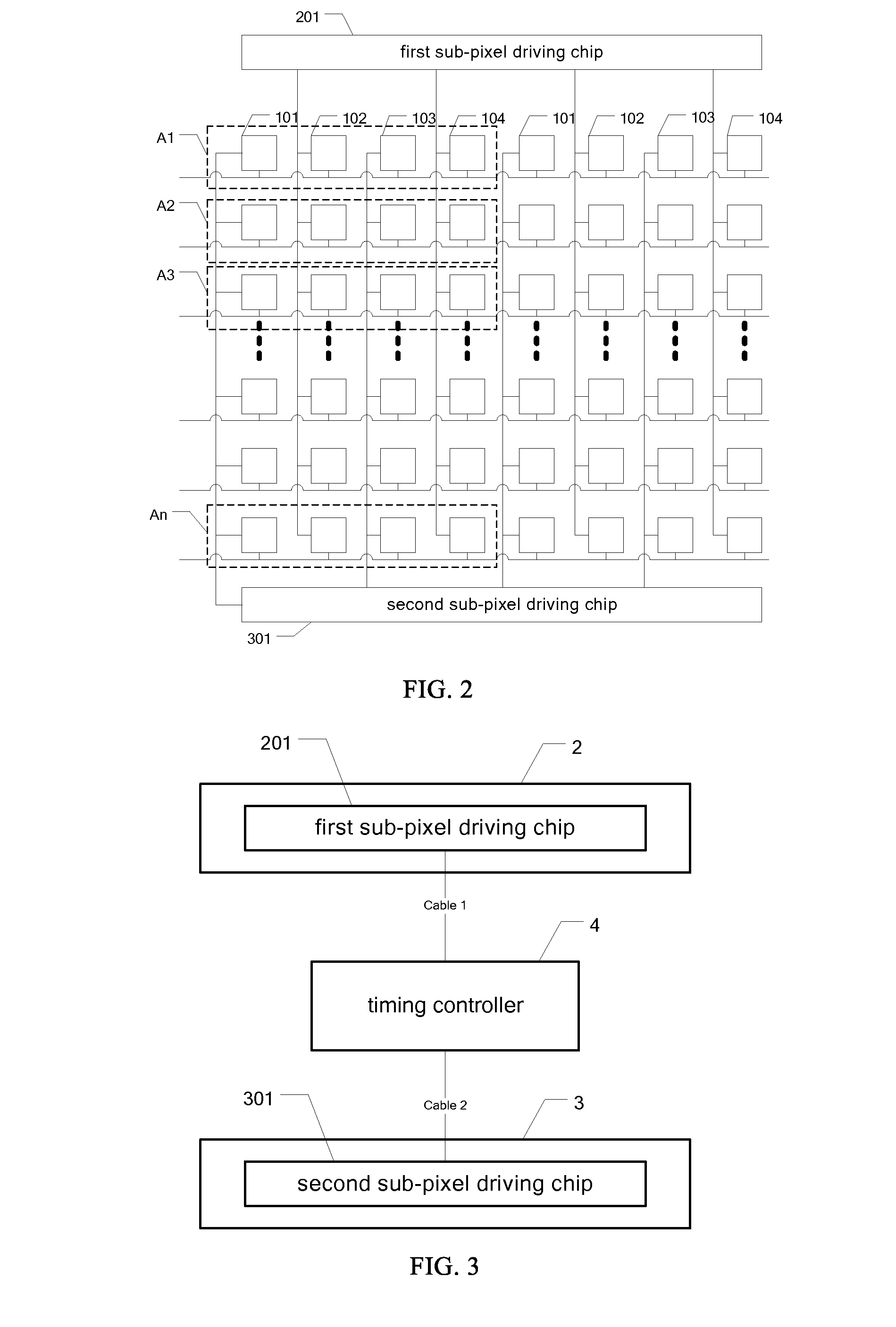

Pixel driving circuit and driving method thereof, and display device

ActiveUS20150356928A1Reduce usageReduce in quantityCathode-ray tube indicatorsInput/output processes for data processingComputer hardwareDisplay device

The present invention provides a pixel driving circuit and a driving method thereof, and a display device. The pixel driving circuit is used for driving a pixel array, wherein each pixel in the pixel array comprises four sub-pixels with different colors, and wherein the pixel driving circuit comprises: at least one first sub-pixel driving chip and at least one second sub-pixel driving chip, wherein the at least one first sub-pixel driving chip each is connected to a part of sub-pixels corresponding thereto in corresponding pixels to drive them, and the at least one second sub-pixel driving chip each is connected to the other part of sub-pixels corresponding thereto in the corresponding pixels to drive them. In the invention, noise interference can be avoided, and the display quality is improved; the cost is reduced; signal transmitting efficiency is increased and the EMI characteristic of products is improved.

Owner:BOE TECH GRP CO LTD

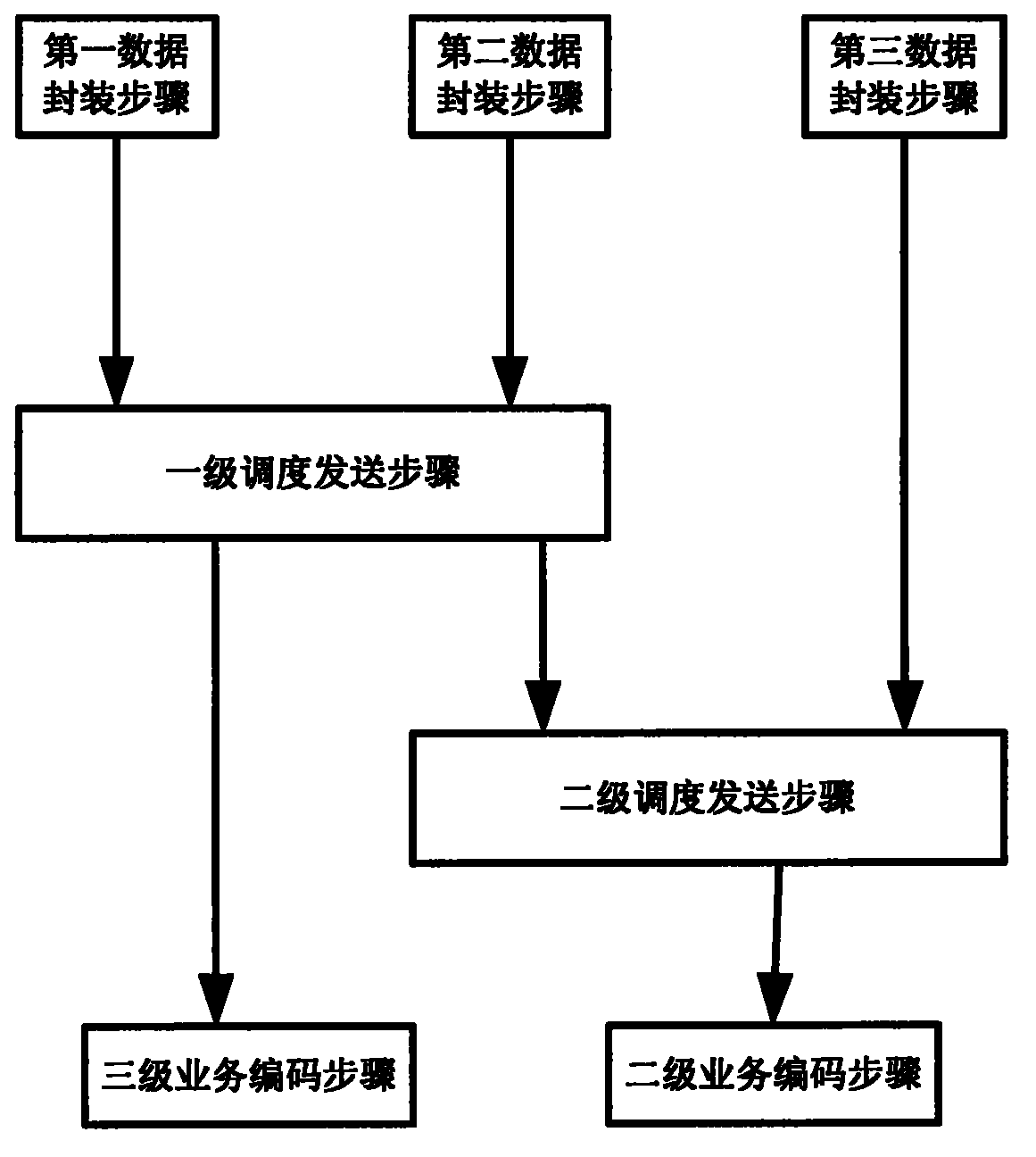

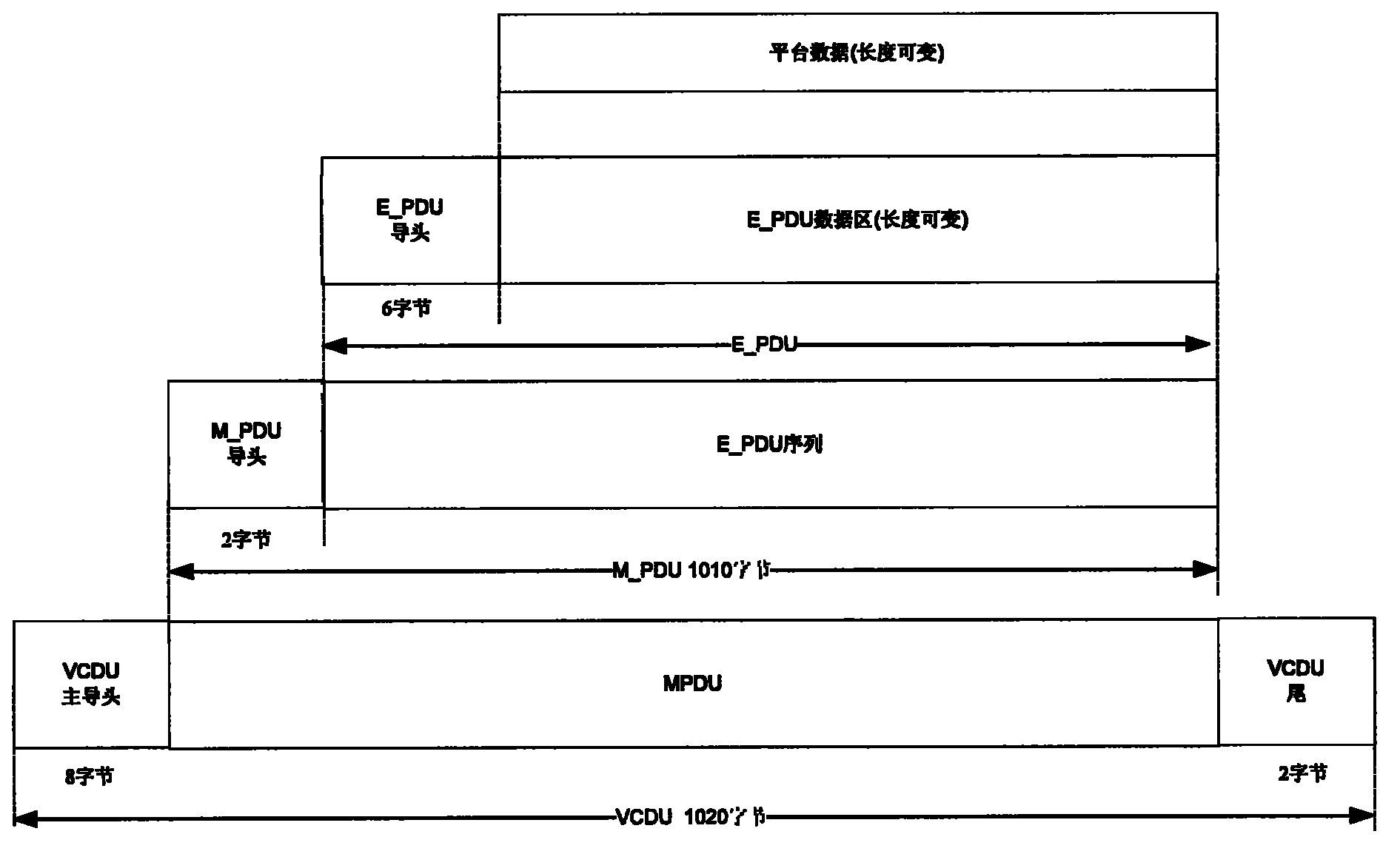

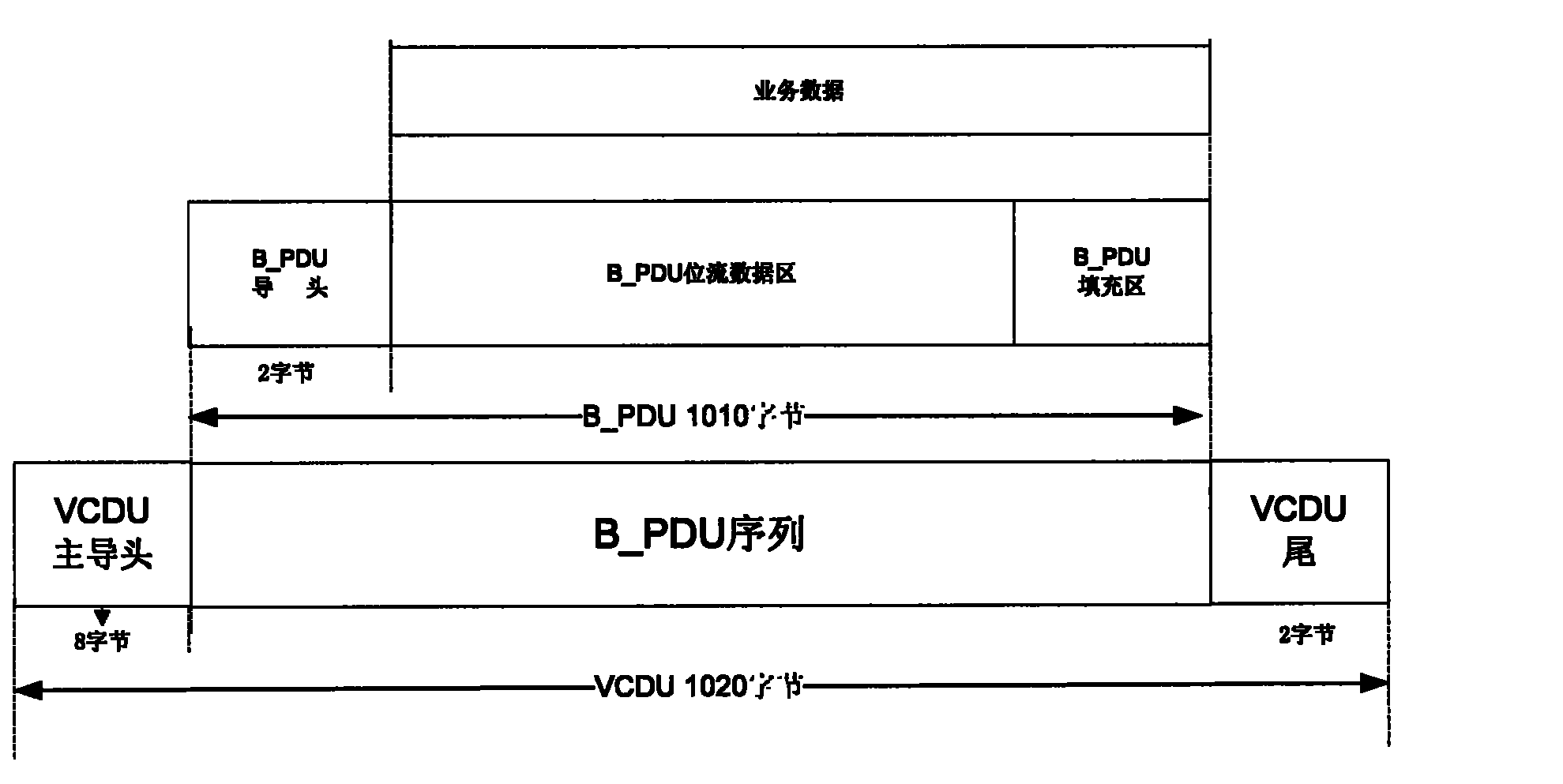

Satellite-borne data management method and device based on AOS standard

ActiveCN102801626AMeet the needs of data processingFlexible designError preventionRadio transmissionThree levelData management

The invention discloses a satellite-borne data management method based on an AOS standard, which comprises the data packaging step and the scheduling and sending step. In the data packaging step, service packages are carried out respectively for platform data, service data and experimental data. In the scheduling and sending step, VCDU (Virtual Channel Data Unit) data generated by the data packaging step is scheduled and sent in priority. The invention further discloses a satellite-borne data management device based on the AOS standard. The device comprises a data packaging unit, a data scheduling unit, a three-level service coding unit and a second-level service coding unit. The data packaging unit comprises a first data packaging unit, a second data packaging unit and a third data packaging unit. The data scheduling unit comprises a first-level scheduling unit and a second-level scheduling unit. The method and device provided by the invention can be used to package and schedule various data formats generated by satellites, and accordingly, the data transmission efficiency and the channel utilization ratio of satellites are improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

New-structure three-dimensional fabric and its knitting method

The invention relates to a new-structure three-dimensional fabric and its knitting method. The three-dimensional fabric is formed through the combination of a three-dimensional multi-way structure and a quadrature three-way structure, and the continuous knitting of fibers in the fabric is realized through the mutual fiber interknitting between the two structures. The knitting method comprises the following steps: carrying out three-dimensional four-way structure knitting, and simultaneously reserving a plurality of fibers on a side surface; and carrying out quadrature three-way structure knitting to reserve one-way fibers in the quadrature three-way structure to complete the knitting of the multi-structure three-dimensional fabric. The molding technology of the three-dimensional fabric has the advantages of high reliability, convenience, easy implementation, complex fiber orientation, strong fiber volume content designability, and continuous fibers, and is a way for solving three-dimensional fabric reinforcement materials for complex bearing member composite materials.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

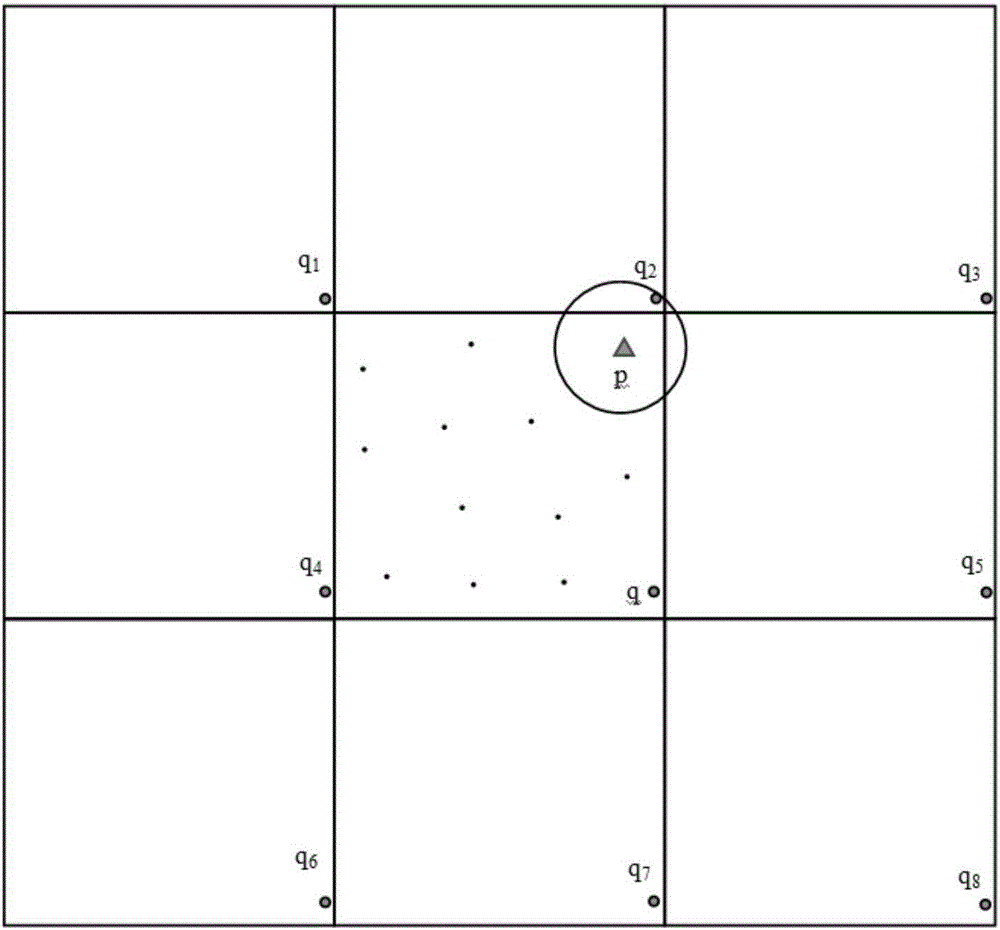

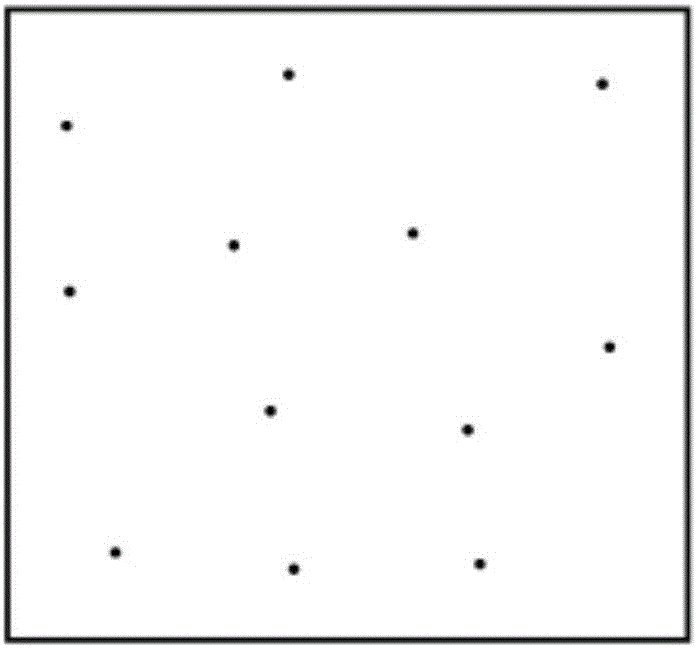

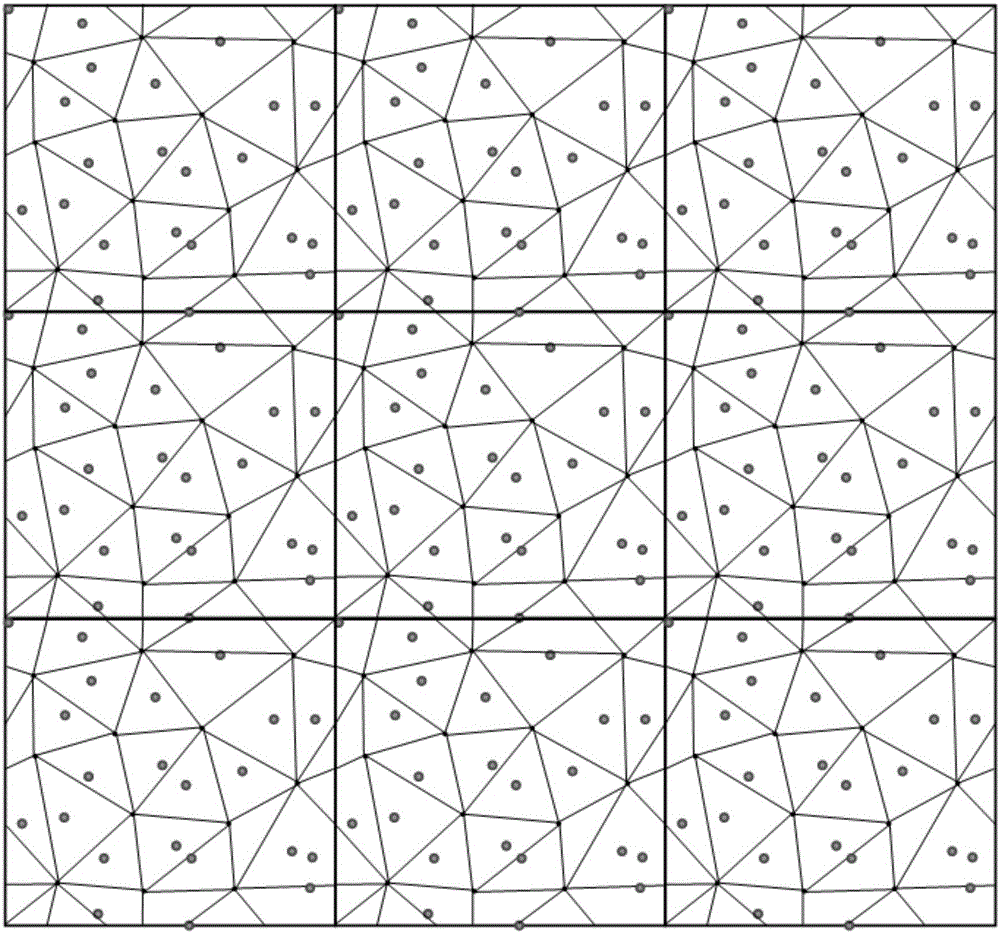

Weighted Voronoi diagram generation method used for big data test

The invention discloses a weighted Voronoi diagram generation method used for a big data test. The method comprises the following steps of constructing a group of randomly and uniformly distributed points in a set region as sites, ensuring a shortest distance between the two sites not to be smaller than a set threshold, and calculating a Voronoi diagram of a set consisting of all the sites; constructing a large-scale data point set in the set region according to the Voronoi diagram of the site set, traversing all Voronoi points, and connecting the Voronoi points to form a Voronoi diagram of the large-scale data point set; randomly selecting any site, modifying all Voronoi edges around the selected site according to a weighted distance function between the sites, and constructing a weighted Voronoi diagram based on an appointed weight set W; and applying the generated weighted Voronoi diagram to the big data test. According to the method, the overall site distribution has randomness and the distribution is relatively uniform, so that the correctness during the big data test is ensured.

Owner:SHANDONG UNIV

Via architecture of printed circuit board

InactiveCN1993017ASolve the problem of excessive demand areaSatisfy the layoutPrinted circuit aspectsPrinted element electric connection formationEngineeringPrinted circuit board

The invention relates to a through hole of printed circuit board, wherein it comprises one insulated layer with first and second faces, one exposed through hole and several internal connecting layers; the exposed through hole is through the first and second faces of insulated layer; the internal connecting layers connected on the hole walls of exposed through hole are separated from each other and insulated electrically; therefore, the invention has use one through hole to transmit different signals between base board layers.

Owner:HTC CORP

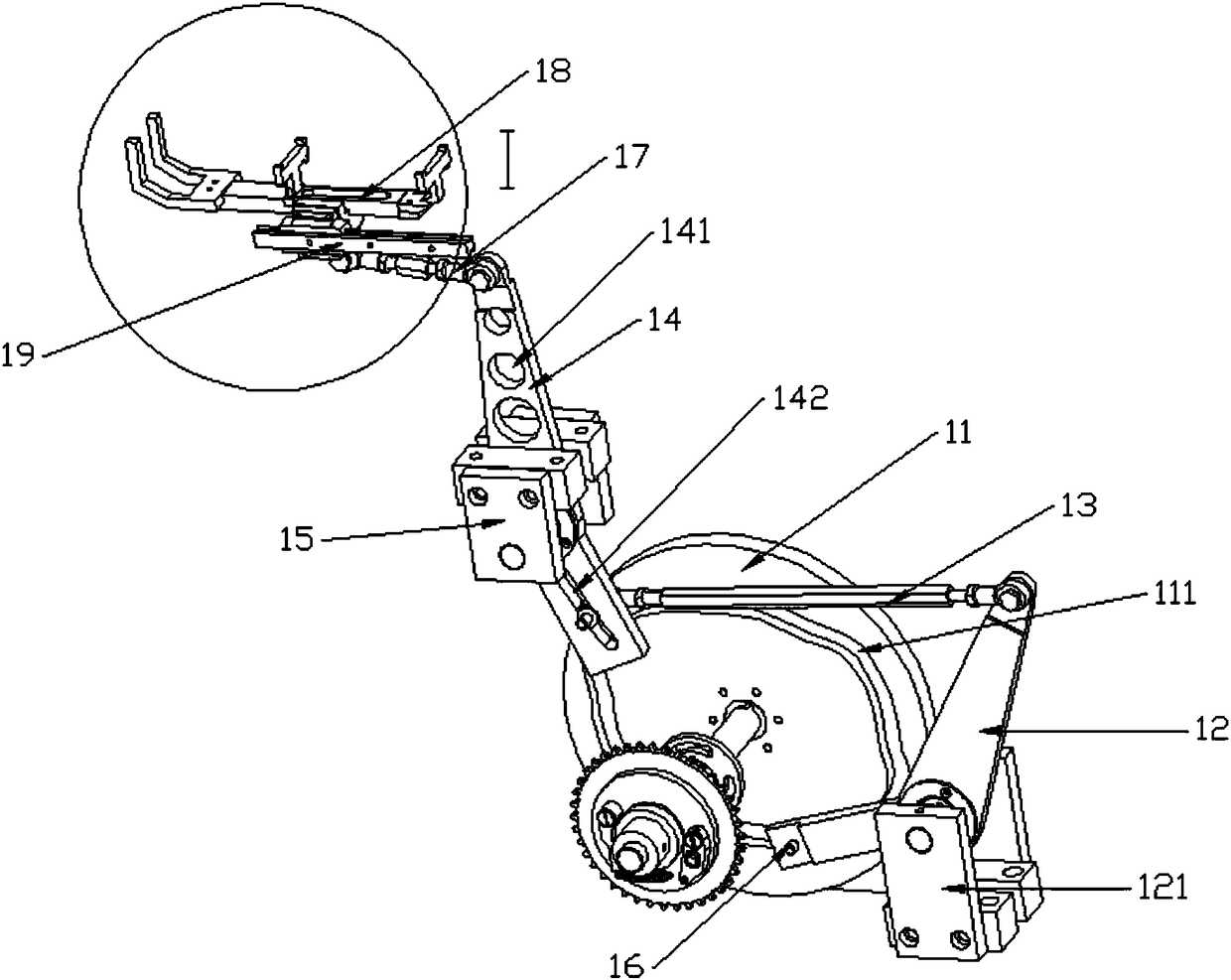

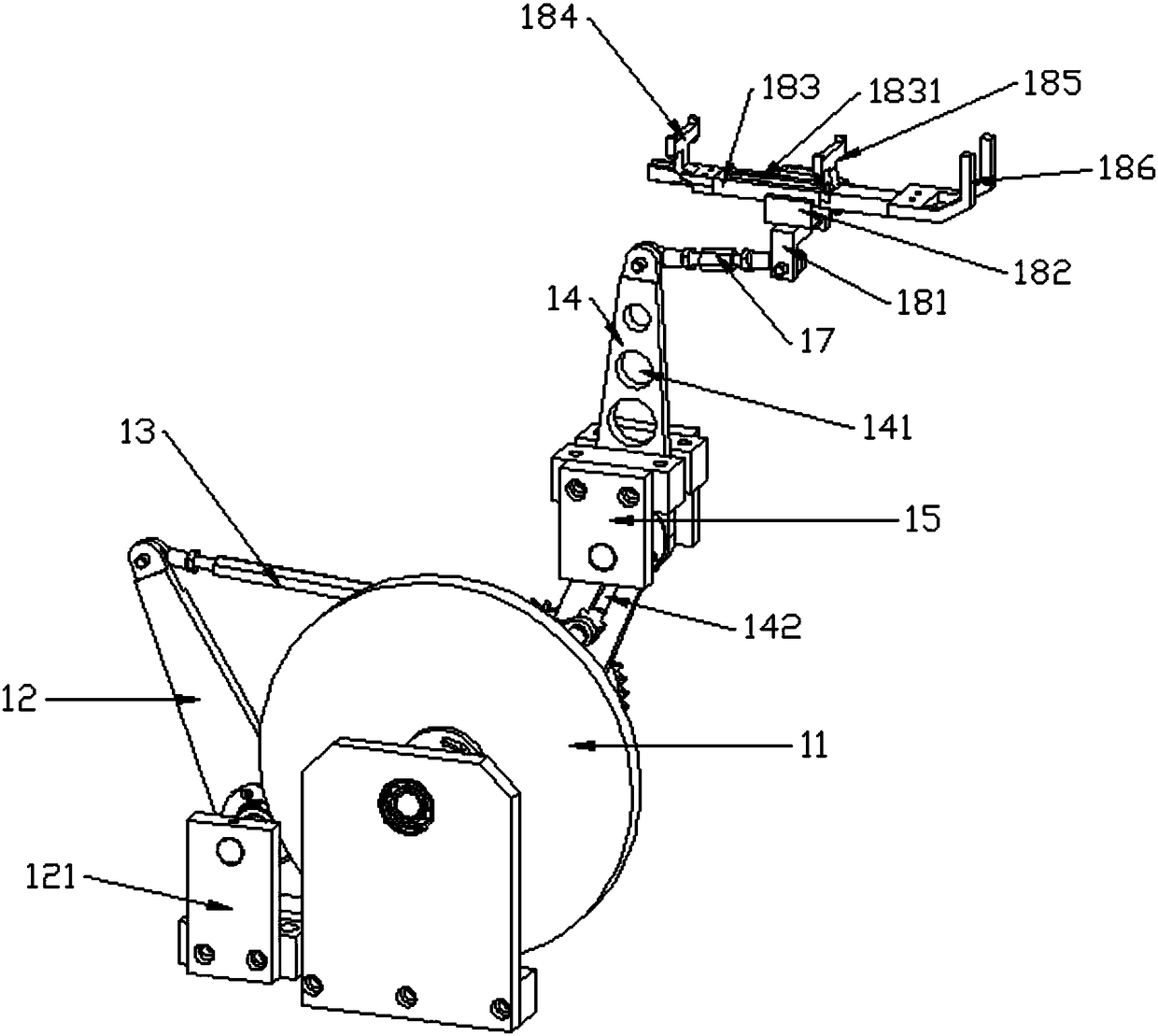

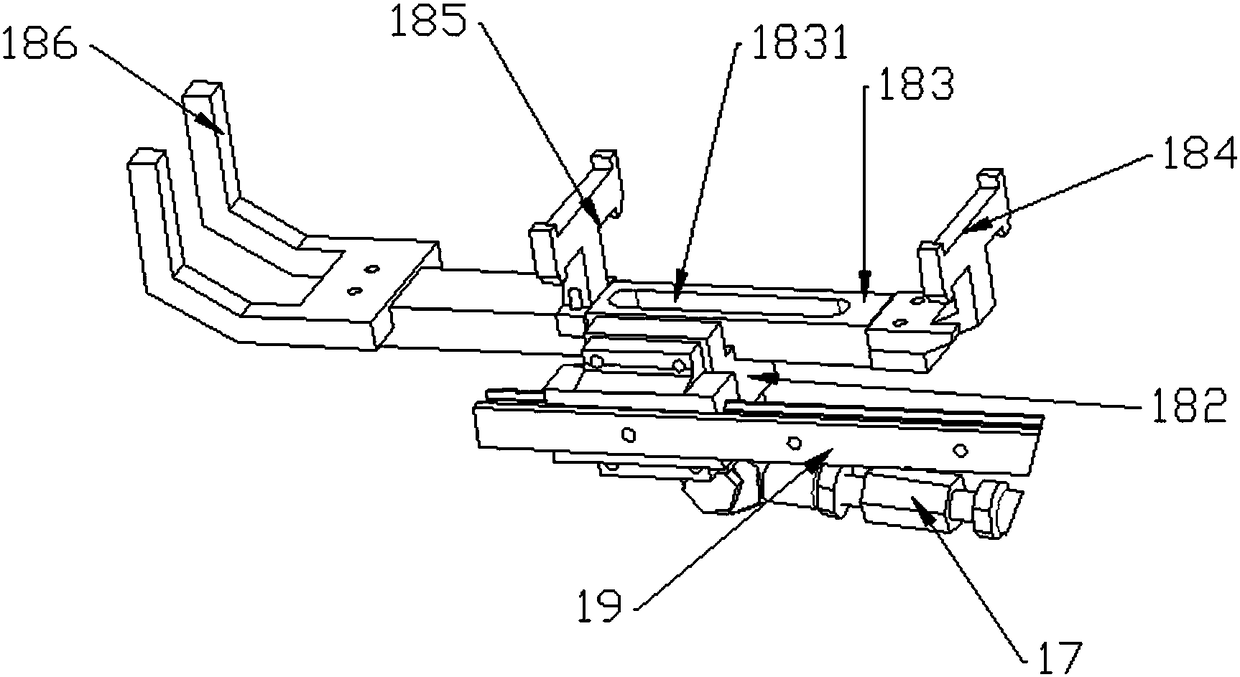

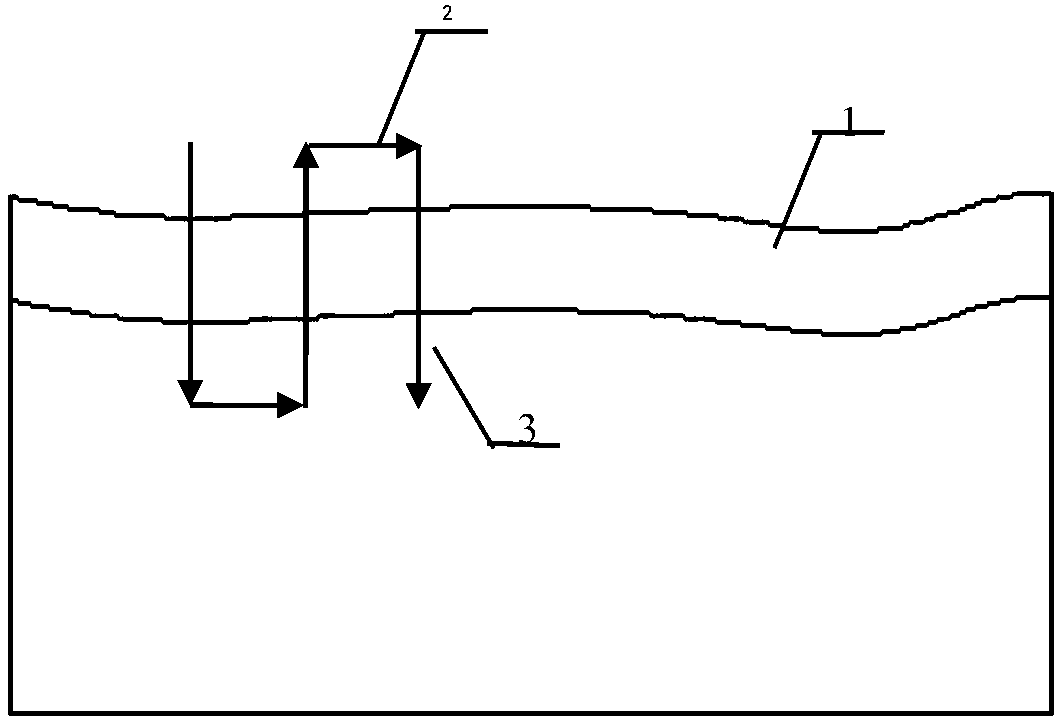

Material pushing device capable of moving bi-directionally and simultaneously

The invention provides a material pushing device capable of moving bi-directionally and simultaneously, and belongs to the field of card packaging equipment. The material pushing device comprises a bottom frame, a horizontal moving assembly and an up-down moving assembly. The horizontal moving assembly further comprises a lower swing arm, an upper swing arm and a pushing assembly. A driving grooveis formed in the side face of a horizontal cam, a guiding wheel is arranged in the driving groove, the guiding wheel is fixedly locked at one end of the lower swing arm, the middle of the lower swingarm is hinged to a first fixed seat, the end, away from the guiding wheel, of the lower swing arm is hinged to the lower end of the upper swing arm through a large connection rod, the middle of the upper swing arm is hinged to a second fixed seat, the second fixed seat is arranged above the horizontal cam, the upper end of the upper swing arm is hinged to the lower end of the pushing assembly through a hinged small connection rod, and a guiding linear rail which is horizontally arranged is arranged on the side face of the pushing assembly. The material pushing device is driven by adopting thehorizontal cam and a vertical cam, moving in the horizontal direction and vertical direction can be achieved simultaneously, and moving is stable and reliable.

Owner:TIANJIN JINSHUDA MACHINERY

Ultrasonic detection method for bonding quality

ActiveCN109115872AHigh sensitivityResolve indistinguishableAnalysing solids using sonic/ultrasonic/infrasonic wavesAir interfaceEngineering

The invention provides an ultrasonic detection method for bonding quality. The ultrasonic detection method comprises: 1, before the front edge of a composite material blade is not bonded to a metal overlap, detecting the front edge position by using an ultrasonic water spraying penetration C scanning method, and eliminating the composite material blade with the defect at the front edge position; 2, after the composite material blade with the defect-free front edge is bonded to a metal overlap, detecting the blade overlapping position by using the ultrasonic water spraying penetration C scanning method, determining the horizontal position of the debonding defect, and marking; and 3, respectively detecting the front surface and the back surface of the marking position by using a high-resolution retarding block probe, and through the height of the reflected ultrasonic wave pulse formed by the composite material / metal / air interface wave of the surface, determining the surface at which thedebonding defect is generated. With the method of the present invention, the debonding defect with the diameter of not more than 5 mm can be rapidly and accurately detected, the surface at which the debonding is generated can be accurately determined, and the design and rework requirements of the product can be met.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Mold angle ejector rod structure capable of adding cooling water

The invention discloses a mold angle ejector rod structure capable of adding cooling water, and belongs to the field of automobile injection molds. The mold angle ejector rod structure comprises an angle ejector block, an inclined ejector rod, an angle ejector sliding seat and an angle ejector change-over block, wherein the angle ejector block is connected with the head part of the hollow; the tail part of the inclined ejector rod is connected with the angle ejector sliding seat; the angle ejector sliding seat is capable of adjusting the relative height between the angle ejector sliding seat and the angle ejector rod through an O-shaped cushion block and is in clamping connection with the angle ejector rod through a U-shaped clamping block; the angle ejector rod is sequentially provided with a first self-lubricating copper guide sleeve, a hollow aluminum pipe and a second self-lubricating copper guide sleeve; an annular pipe is arranged in a cavity in the angle ejector rod along a longitudinal direction; the tail part of the angle ejector rod is connected with the angle ejector change-over block; the angle ejector change-over block is provided with a water pipe joint; the tail partof the annular pipe is communicated with the water pipe joint through the angle ejector change-over block; the head part of the annular pipe stretches out of the angle ejector rod. According to the mold angle ejector rod structure disclosed by the invention, addition of the cooling water to a single-rod angle ejector rod structure of a precision mold is realized, and meanwhile, an occlusion action process of an angle ejector rod can be avoided.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

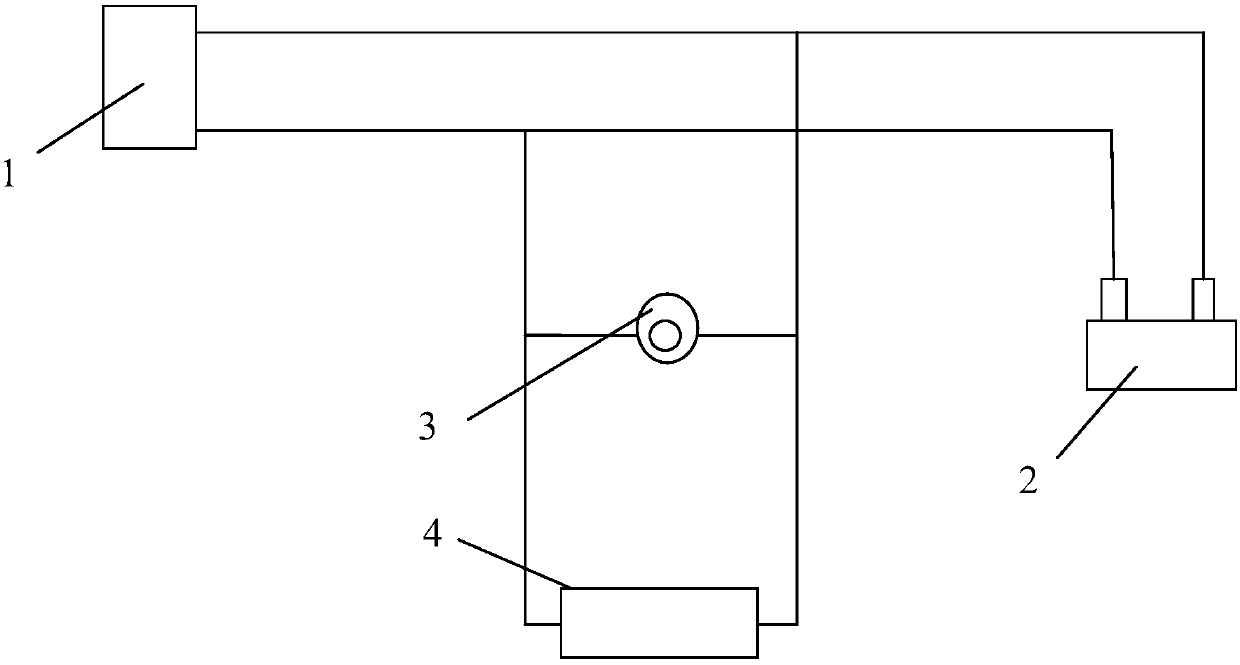

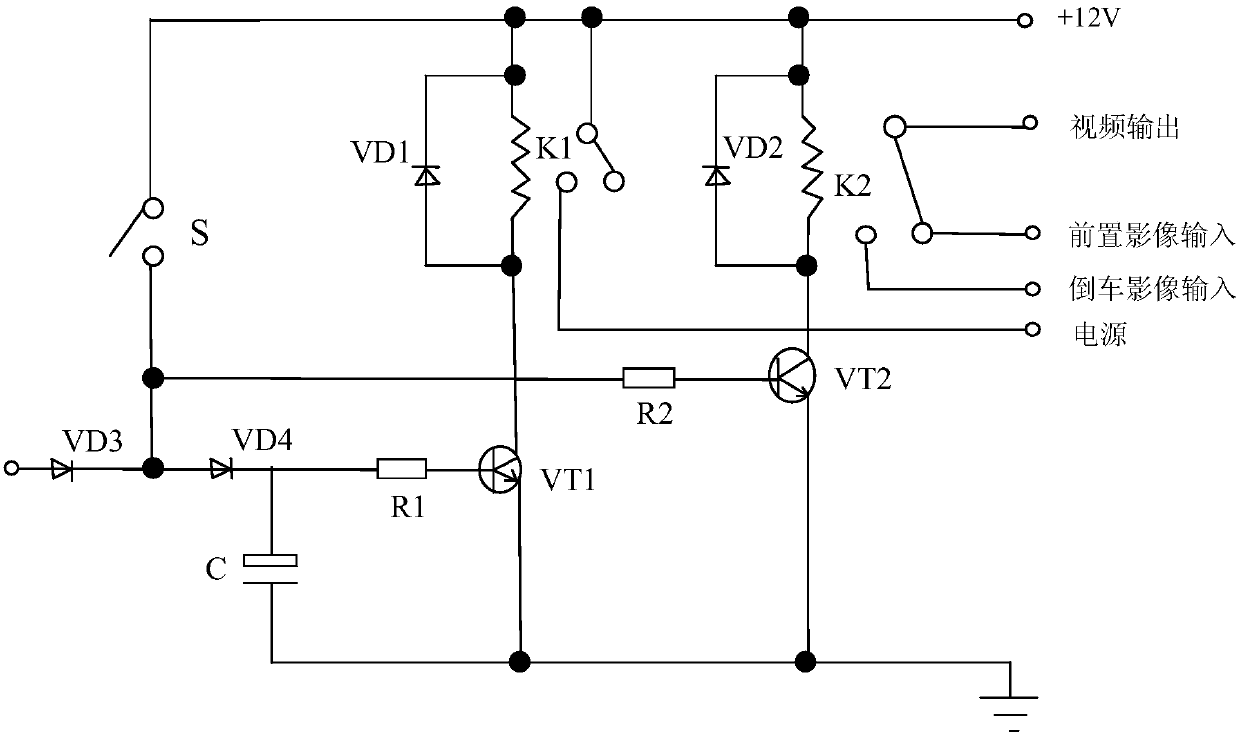

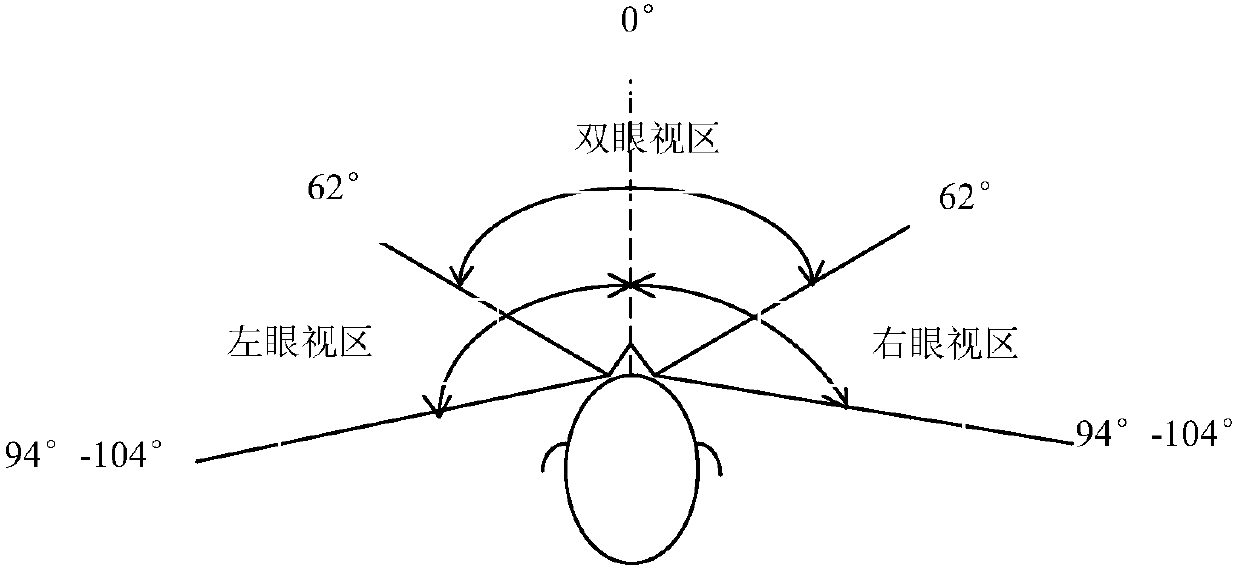

Front-loaded image system of automobile

InactiveCN105946720AEasy to moveExpand field of viewClosed circuit television systemsOptical viewingVisual field lossTraffic accident

The invention discloses a front-loaded image system of an automobile, and belongs to the technical field of automotive parts. The invention provides the front-loaded image system of the automobile with low cost and easiness for installation. The front-loaded image system of the automobile can reduce a driver blind area in driving and expand a visual area, so that the driver can have a better understanding for the front visual field so as to realize position movement of the automobile in driving conveniently, and therefore the occurrence of traffic accidents caused by cart blocking is reduced. The front-loaded image system of the automobile comprises a forward looking camera, wherein the forward looking camera is arranged on a middle segment of a wheel fender behind a left outside of the automobile or is arranged on a rearview mirror at the left side, and the forward looking camera is connected with a power supply and a screen respectively.

Owner:LIAONING TECHNICAL UNIVERSITY

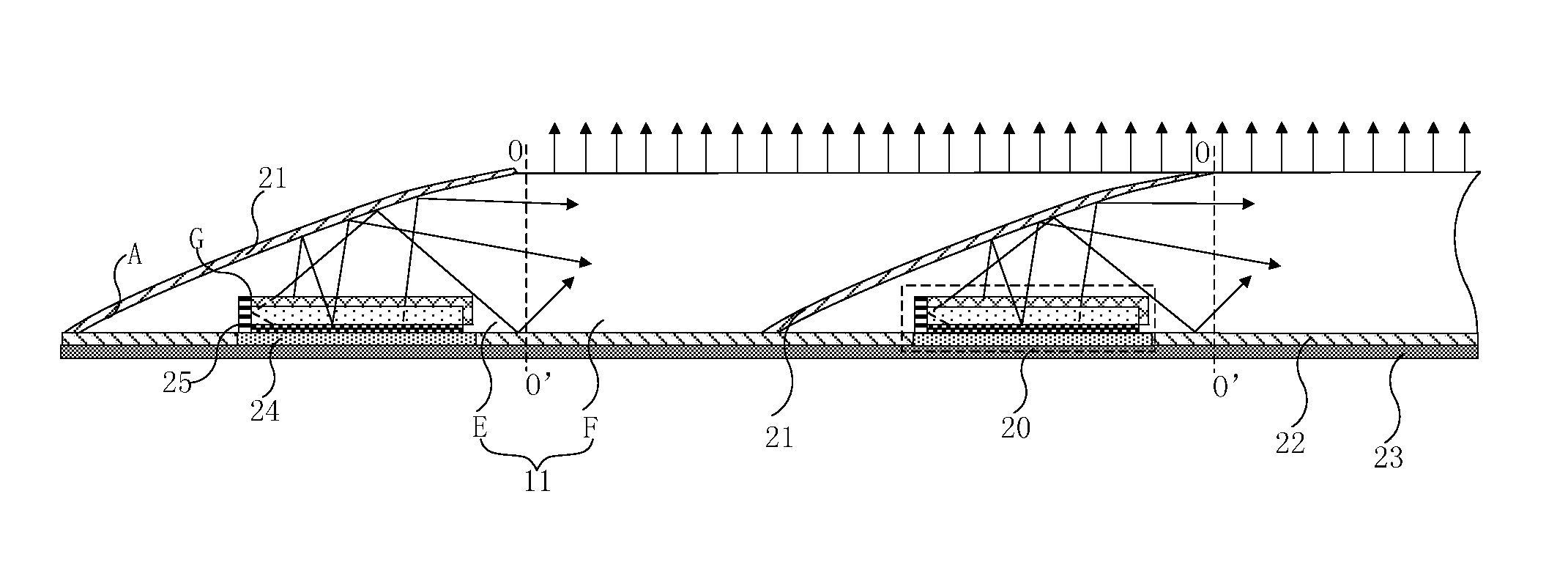

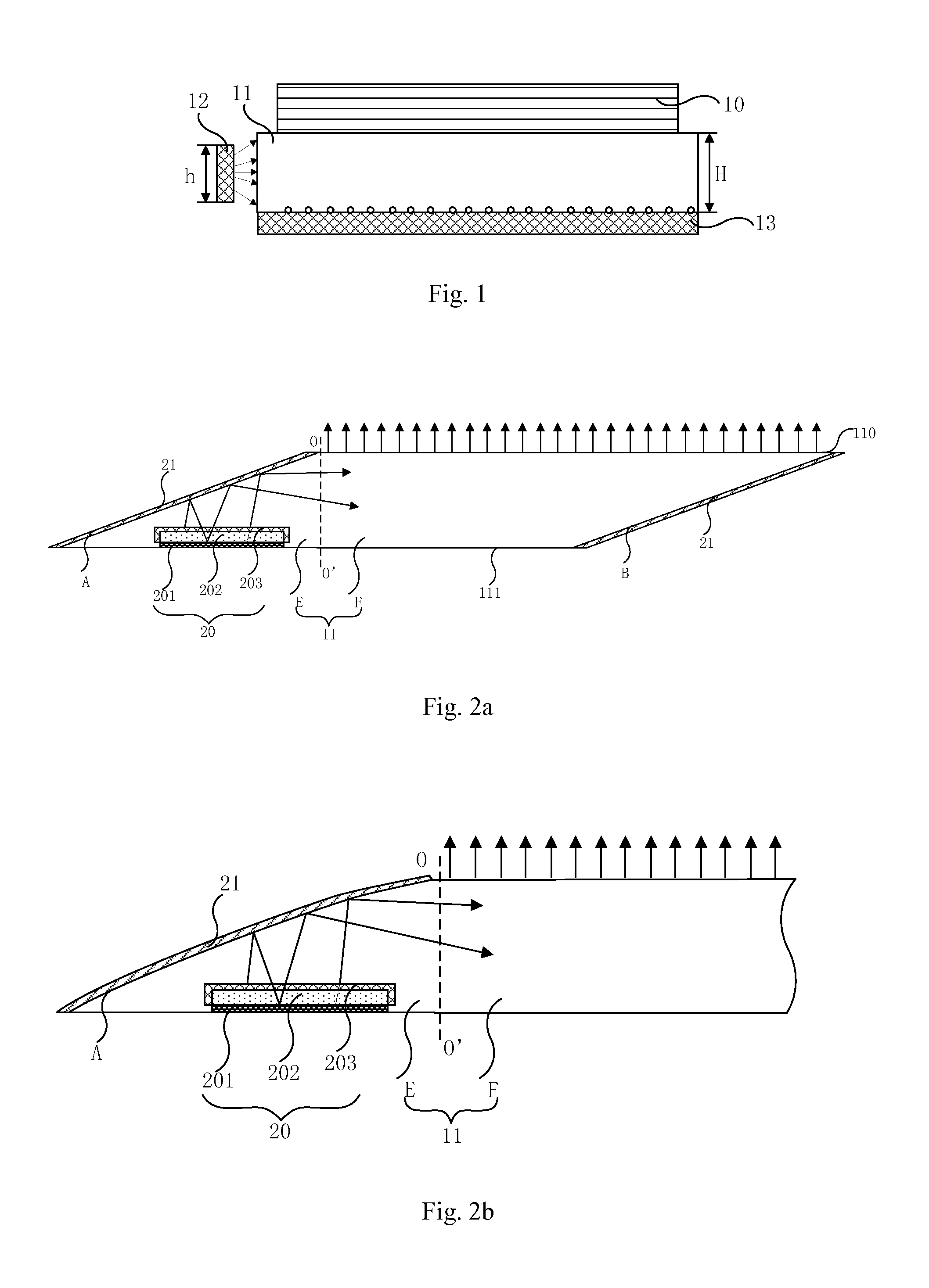

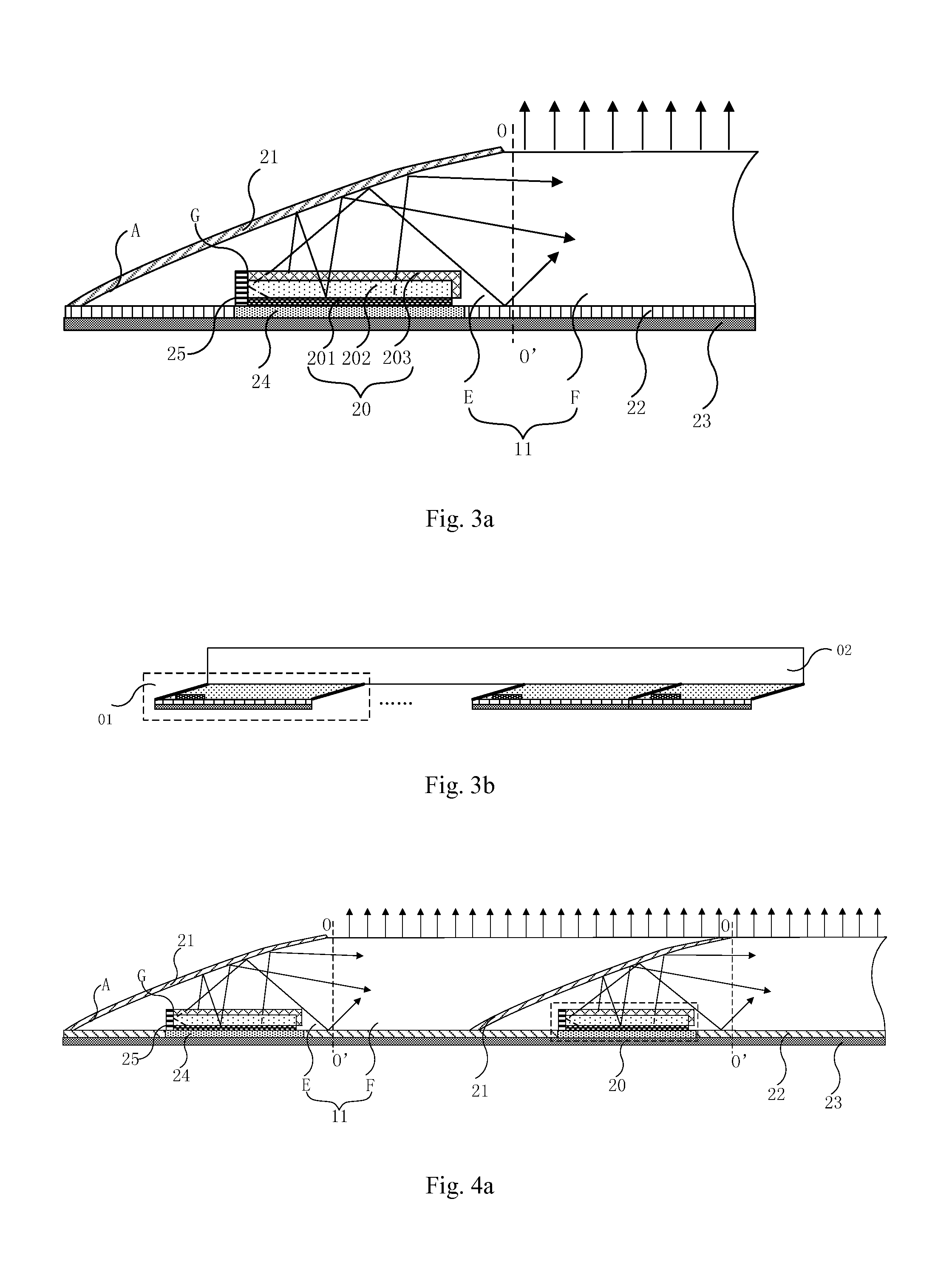

A backlight unit and a display device

ActiveUS20160356939A1Reduce thicknessConducive to thin designMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayLight guide

The present invention relates to the field of display technology, particularly to a backlight unit and a display device. The backlight unit according to the present invention comprises: a light guide plate, the light guide plate comprising a first inclined side and an upper bottom surface and a lower bottom surface parallel with each other, wherein the angle between the first inclined side and the lower bottom surface is a sharp angle; a light emitting element arranged below the first inclined side; and a first reflector arranged on a surface of the first inclined side of the light guide plate. Compared with the prior art, the thickness of such a backlight unit can be kept relatively small, which facilitates lighter and thinner design of the liquid crystal display.

Owner:BOE TECH GRP CO LTD

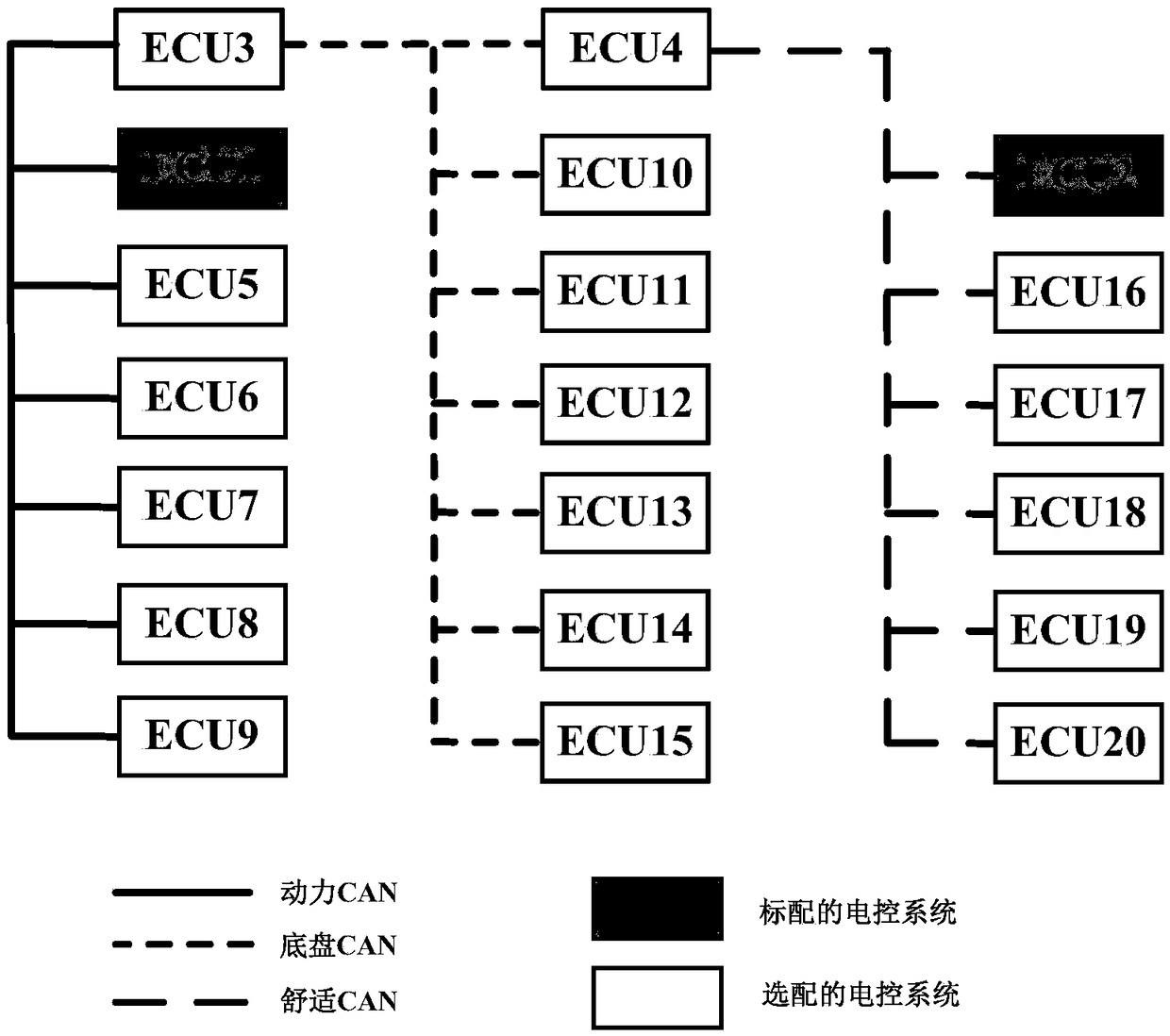

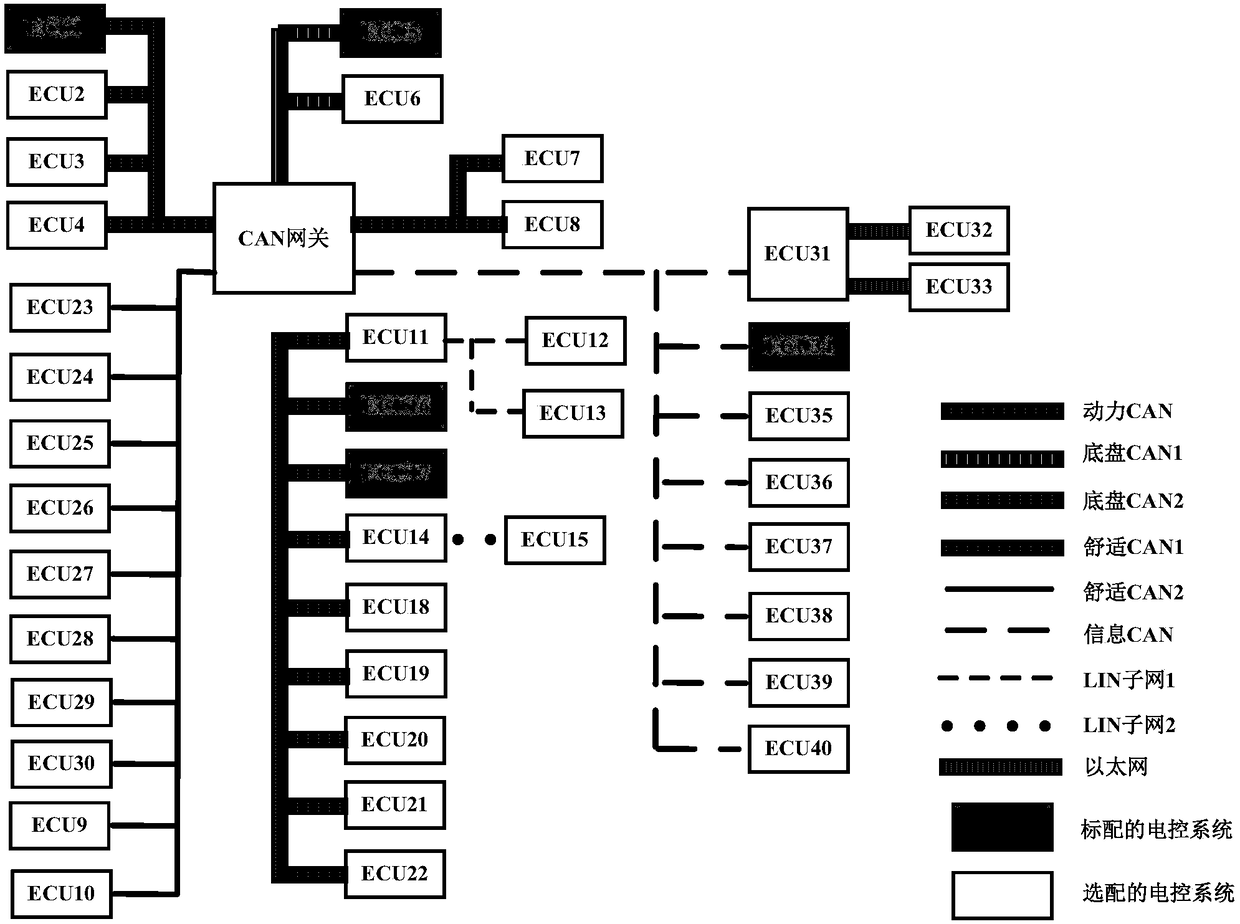

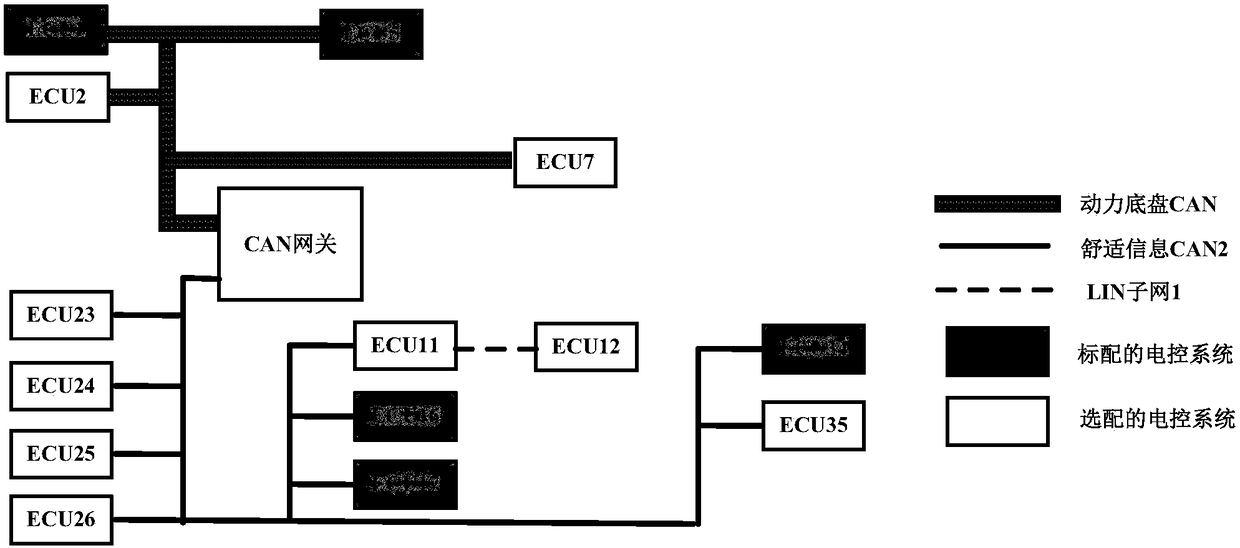

Design method of full vehicle network topology

The invention belongs to the technical field of vehicle network communication, and specifically relates to a design method of full vehicle network topology. The method comprises the following steps: step 1, analyzing the communication requirements of the entire vehicle network; step 2, designing platform-based full vehicle network topology that selects all electronic control system configurations;and step 3, designing full vehicle network topology of specific vehicle models that select a part of electronic control system configurations. According to the design method of full vehicle network topology, the design concept of flexible development of a full vehicle network is imported, so that only software matching needs to be performed on the electronic control systems when the full vehicleis removed from the production line while keeping the hardware unchanged, and the network communication requirements of the specific vehicle models can be met, the problem of network topology design when the number of the electronic control systems is large, the variation is complex and the option difference is large is solved, the compatibility of the full vehicle network is improved, and the categories of the components and parts of the electronic control systems are reduced, therefore the individual costs, the management costs and the development costs of the components and parts are reduced.

Owner:CHINA FIRST AUTOMOBILE

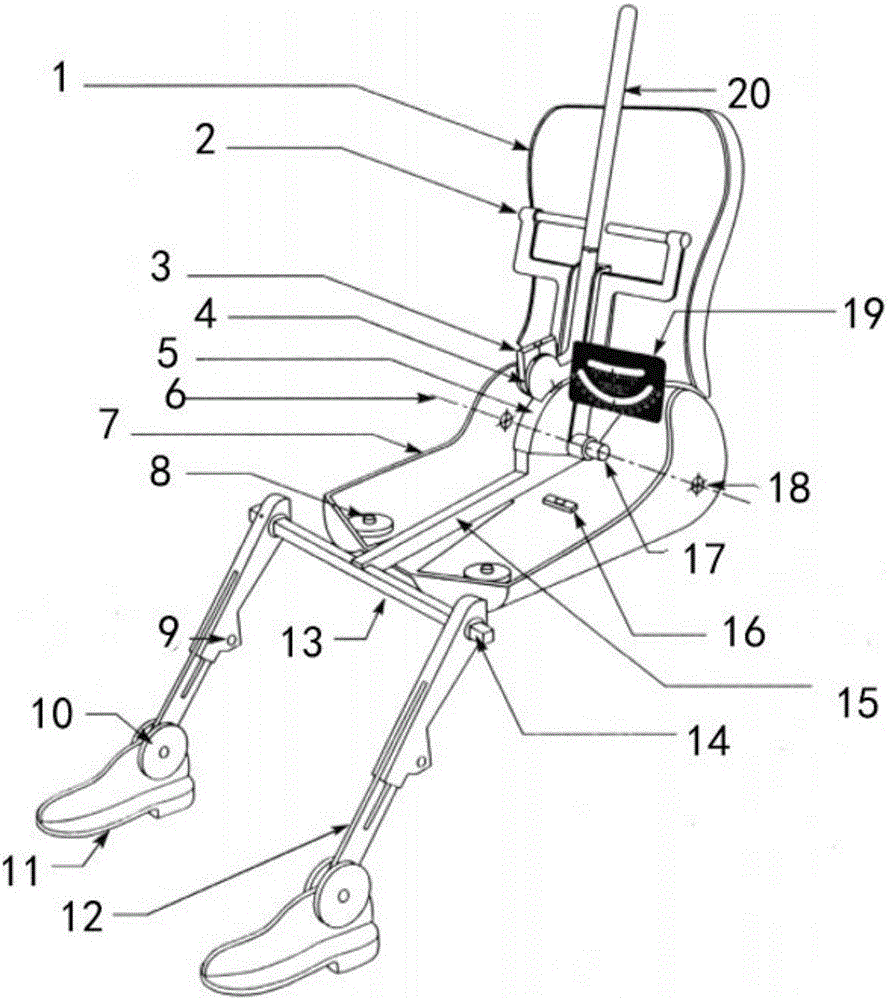

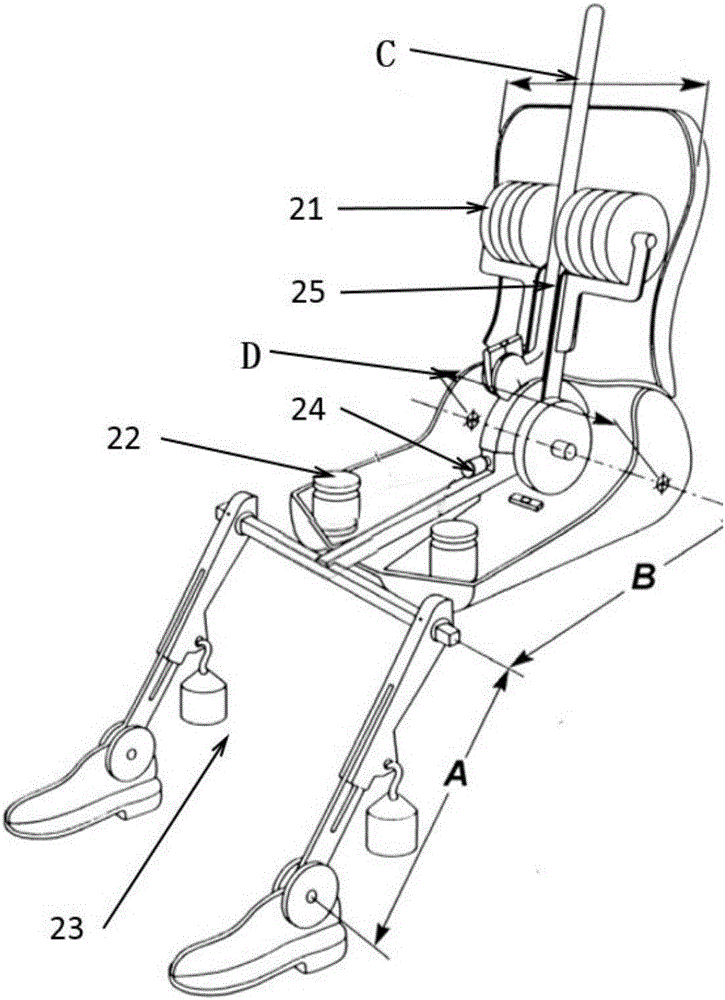

Loading method for measuring H points of seat simulation model

InactiveCN105956224APrediction is simpleShorten the timeGeometric CADDesign optimisation/simulationEngineeringThigh musculature

The invention discloses a loading method for measuring H points of a seat simulation model and aims to overcome the problems that the seat H points can be measured only after seat trial-production and the H points cannot be measured accurately in the seat simulation model. The method comprises the steps of (1) loading of own gravity, (2) applying of a horizontal load, (3) applying of a thigh load, (4) second-time applying of the thigh load, (5) applying of a load for hips and a trunk, (6) third-time applying of the horizontal load, (7) applying of a chest load, (8) fourth-time applying of the horizontal load and (9) extraction of the seat H point data. During the loading of the own gravity, an H point measurement instrument equipped with shank balance weights only is loaded in the gravity direction, the H point measurement instrument can then stably fall onto the seat model under the gravity effect, and a loading time interval is 0-1.2 s. During the applying of the horizontal load, the horizontal load of 56-76 N is applied at a horizontal load position (24) of the H point measurement instrument on the lower position along the direction of a T-shaped frame (13). During the applying of the thigh load, the load is applied on two thigh balance weight bases (8), and a time interval is 0.3-1.2 s.

Owner:JILIN UNIV

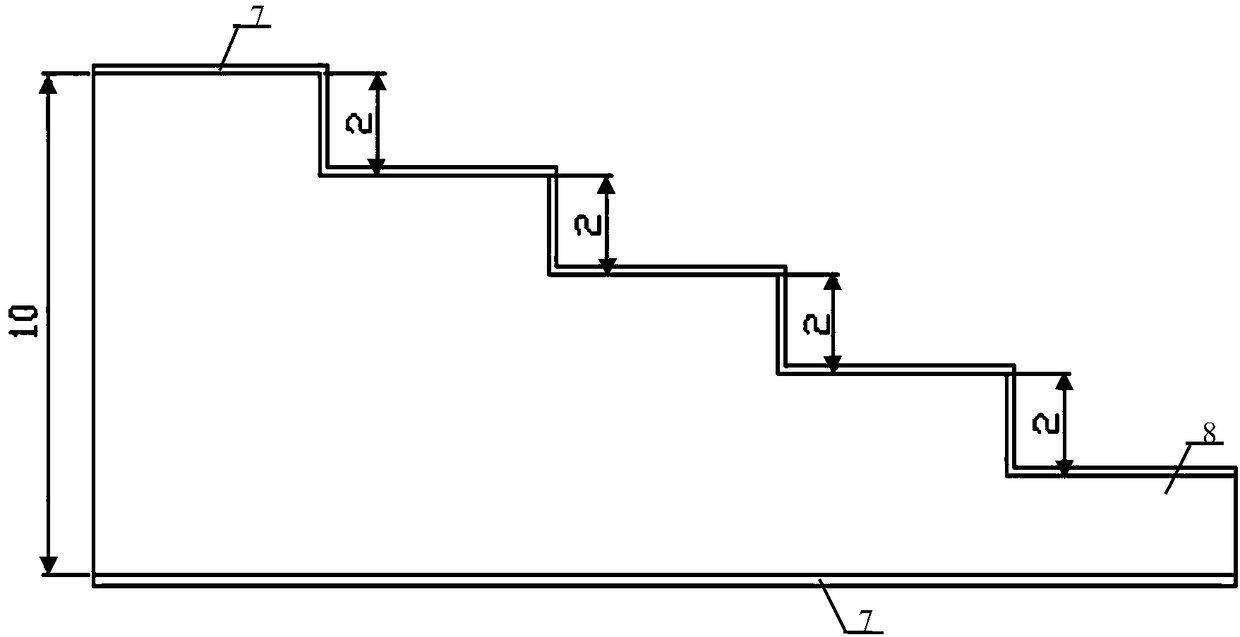

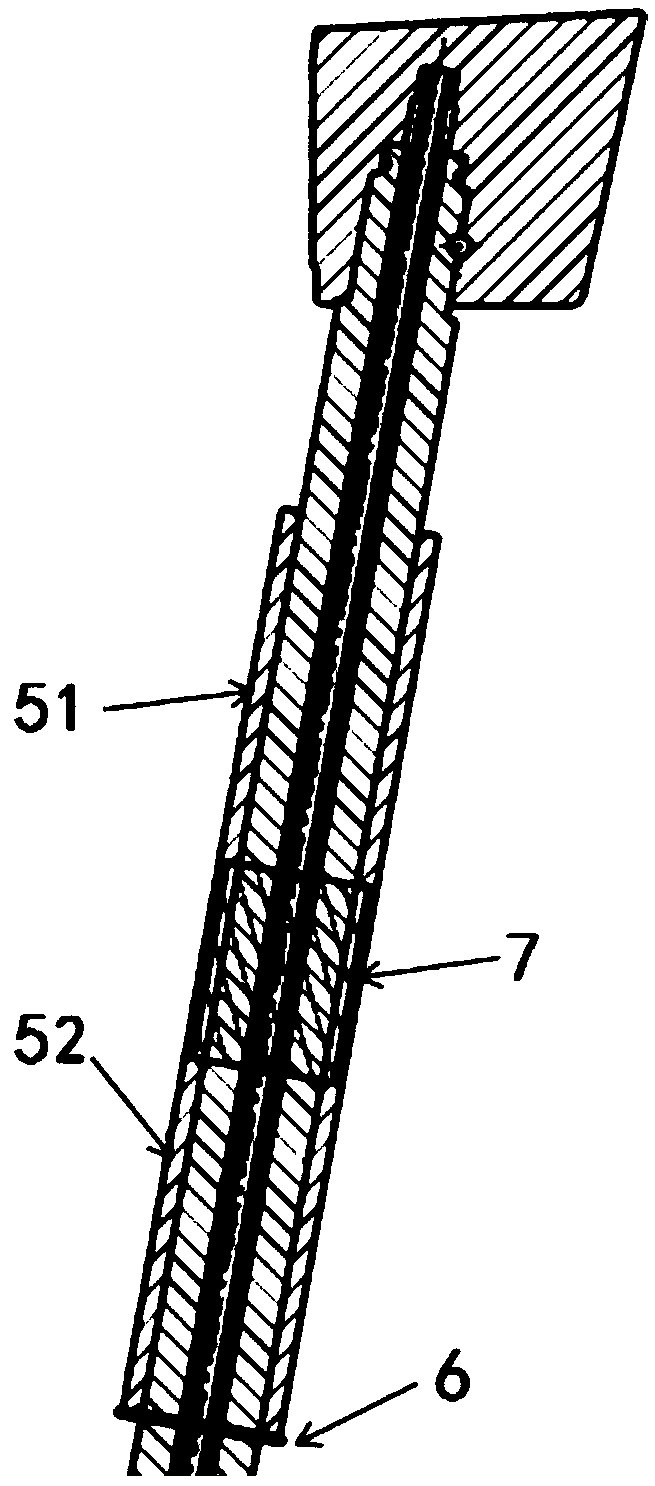

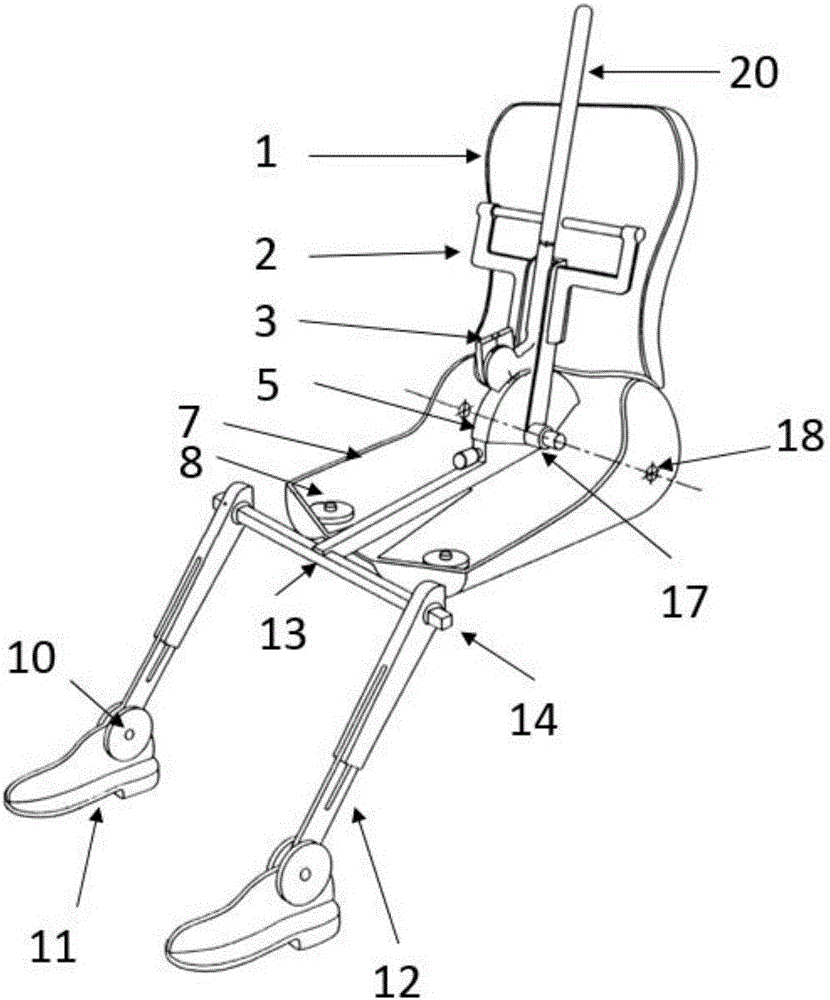

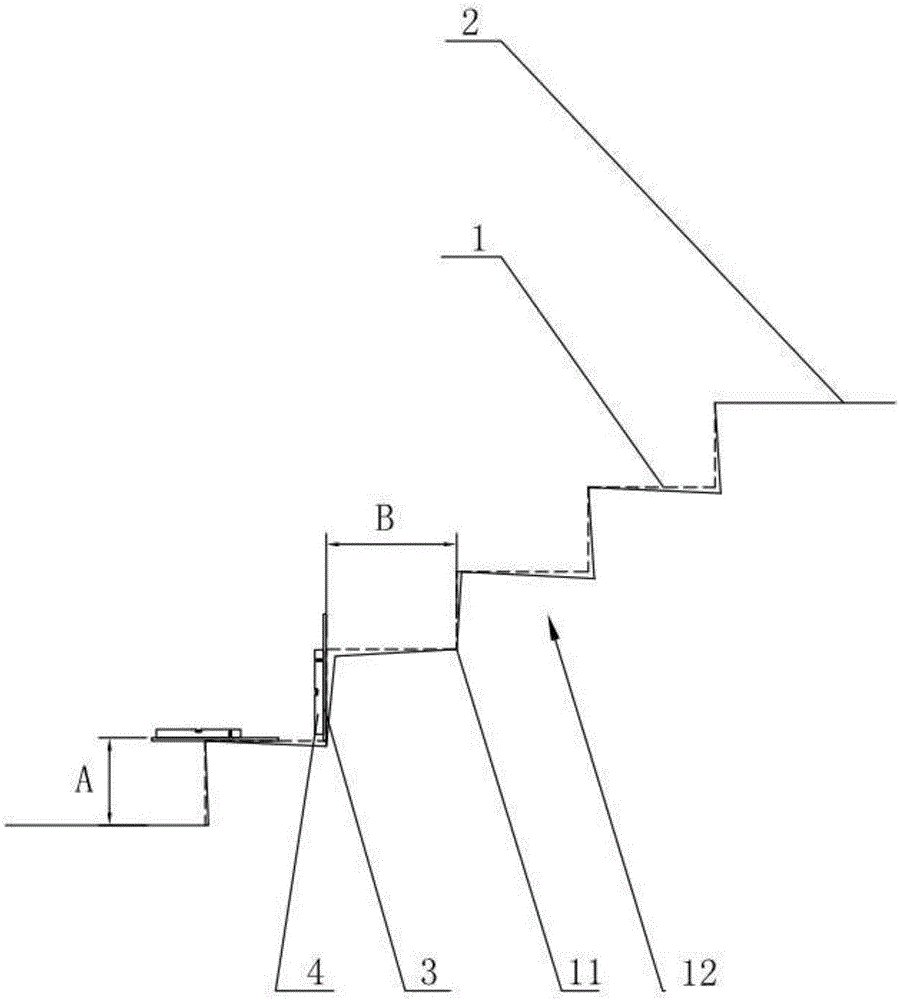

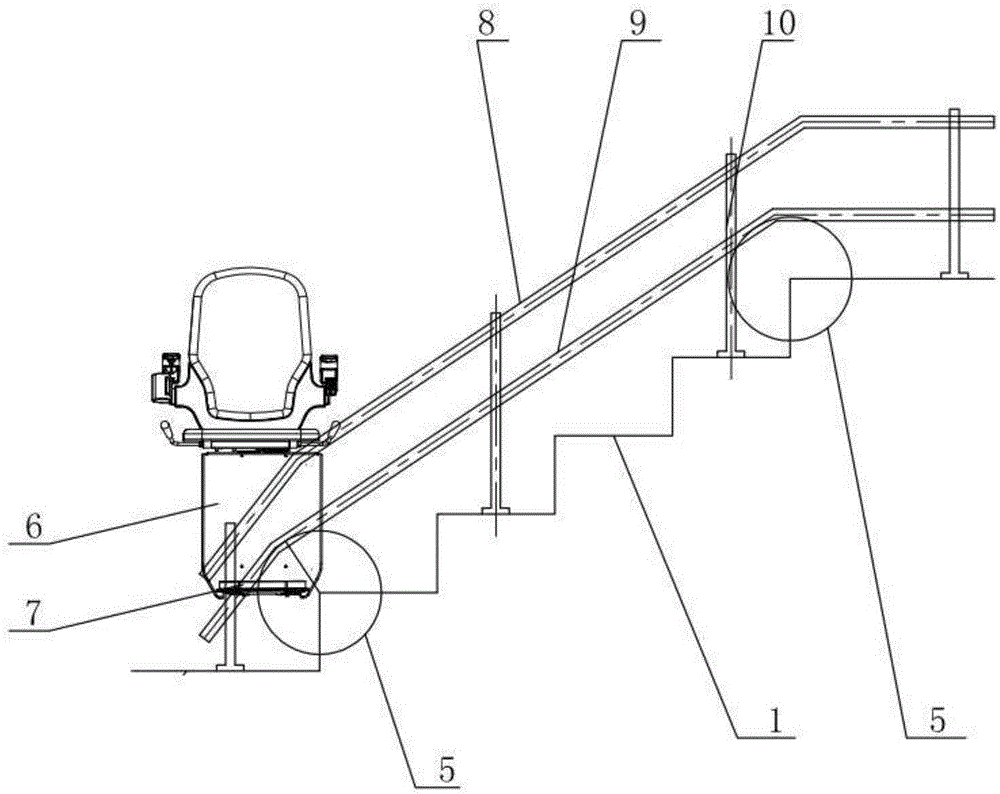

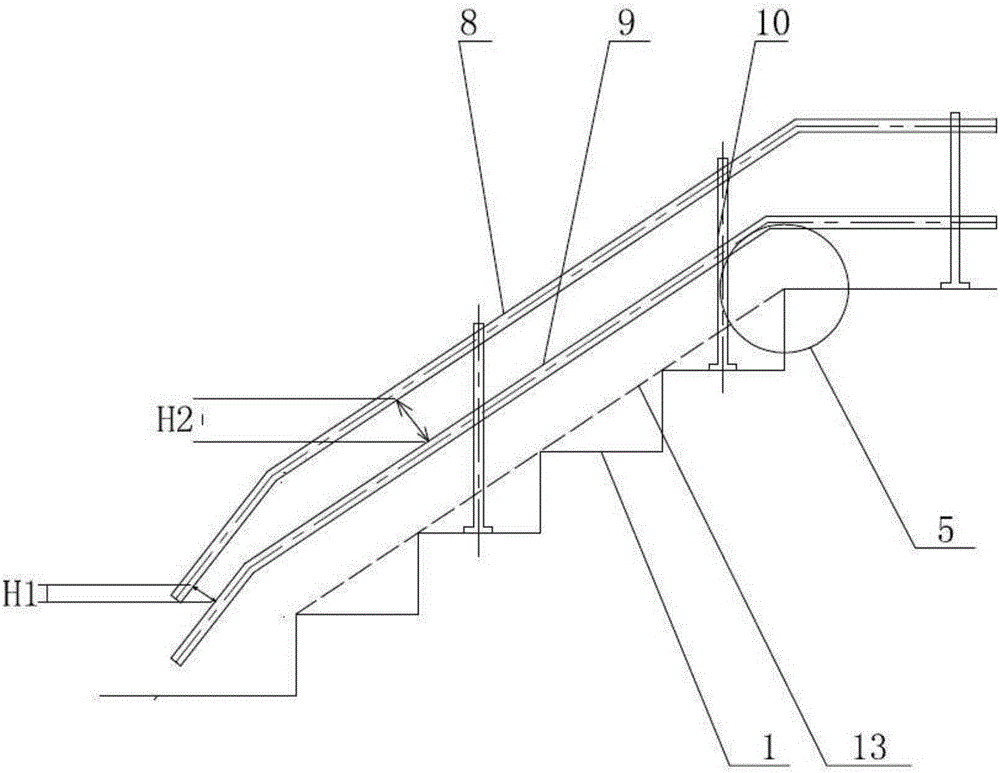

Stairway measurement and guide rail design method applicable to mounting of seat lift

ActiveCN106354939AEasy up and downMeet the designGeometric CADSurveying instrumentsEngineeringMeasurement precision

The invention relates to a stairway measurement and guide rail design method applicable to mounting of a seat lift. The method mainly includes standard measurement stairway design, seat lift lower guide rail design and seat lift upper guide rail design. Structural simplicity and convenience in use are realized, operating interference in mounting of the seat lift can be avoided, measurement precision is guaranteed, seat lift guide rail design is effectively satisfied, the seat lift can be designed to operate according to a mounting site stairway design, and clients can easily get on and get off the seat lift.

Owner:SYMAX ELEVATOR CHINA

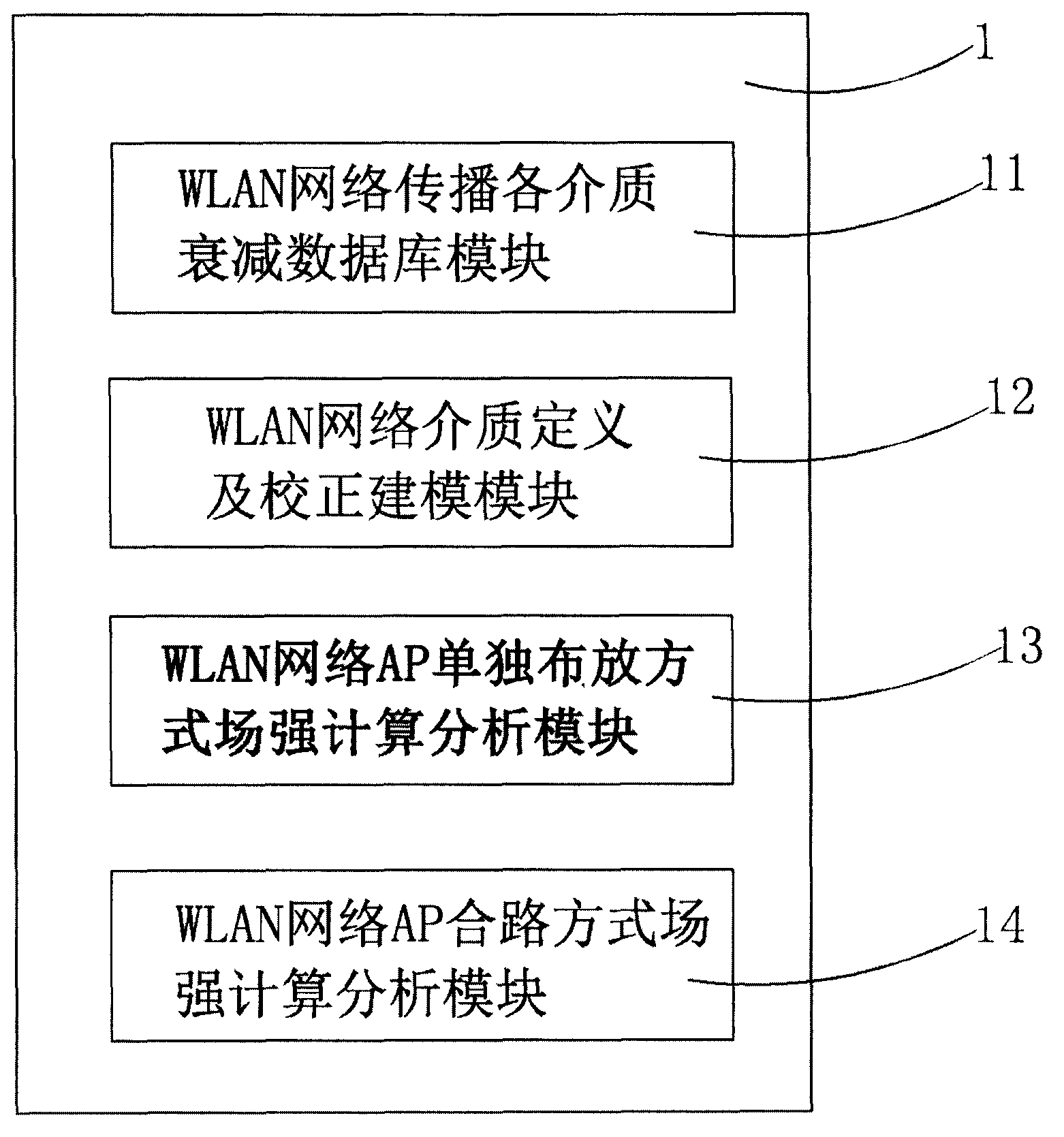

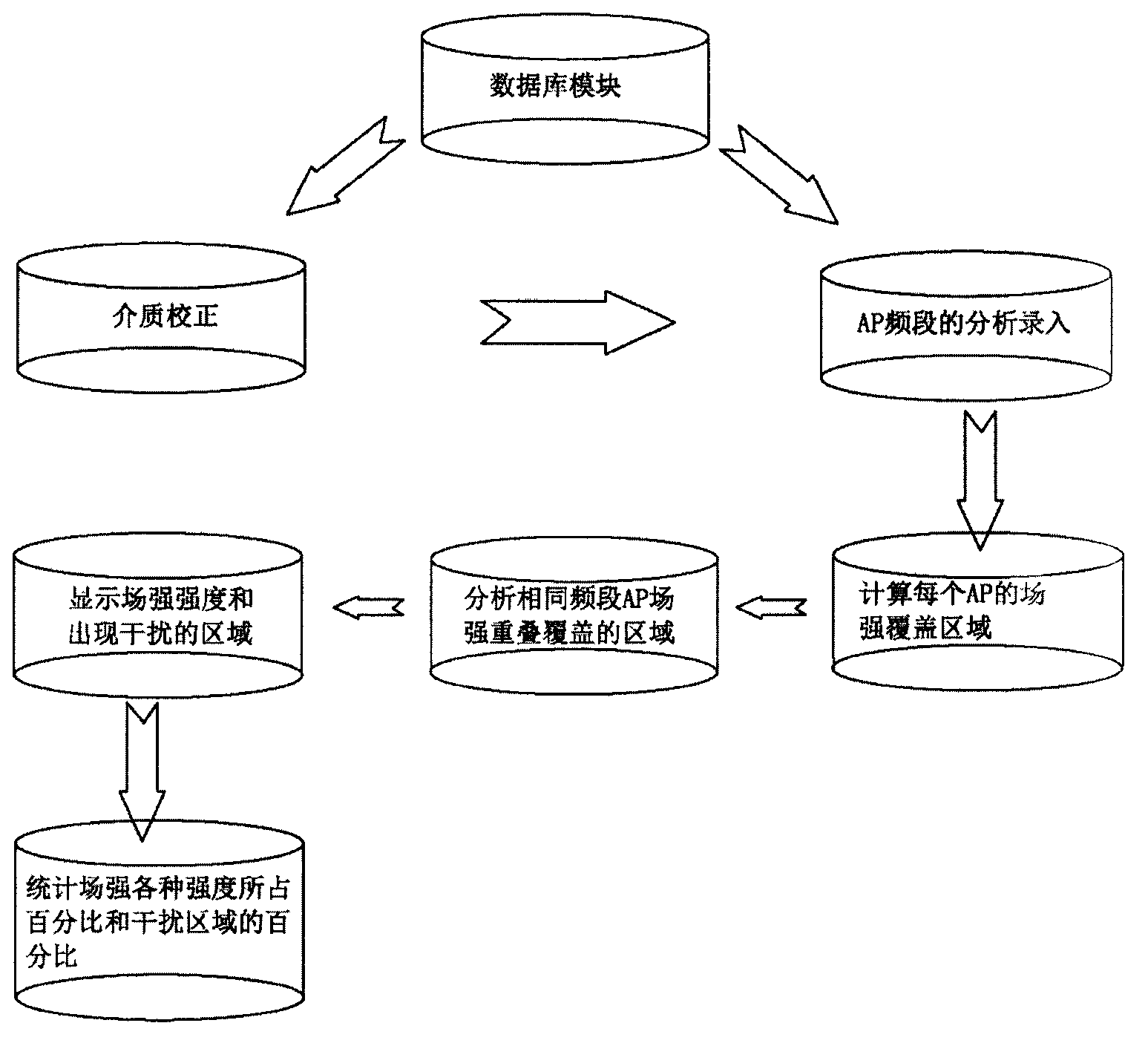

WLAN (Wireless Local Area Network) network field strength coverage simulation system and method based on CAD (Computer-Aided Design) platform

InactiveCN102802165AAvoid being able to meet the planAvoid being able to meet the designNetwork planningUltrasound attenuationComputer Aided Design

The invention discloses a WLAN (Wireless Local Area Network) network field strength coverage simulation system based on a CAD (Computer-Aided Design) platform, which can finish indoor field strength simulation design automatically and fast on the CAD (Computer-Aided Design) platform, and is characterized by comprising a dielectric attenuation WLAN (Wireless Local Area Network) network transmission data base module, a WLAN (Wireless Local Area Network) network media definition and correction modeling module, a WLAN (Wireless Local Area Network) network AP (Access Point) independent laying-type field strength computational analysis module and a WLAN (Wireless Local Area Network) network AP (Access Point) combining-type field strength computational analysis module. The invention also comprises a WLAN (Wireless Local Area Network) network field strength coverage simulation method based on the CAD (Computer-Aided Design) platform and the system. Due to the technical scheme, the WLAN (Wireless Local Area Network) network field strength coverage simulation system and method based on the CAD (Computer-Aided Design) platform have the advantages of being strong in practicability and easy in use, being concise and visual, having wide application and the like.

Owner:GUANGZHOU TIANYUE ELECTRONICS TECH

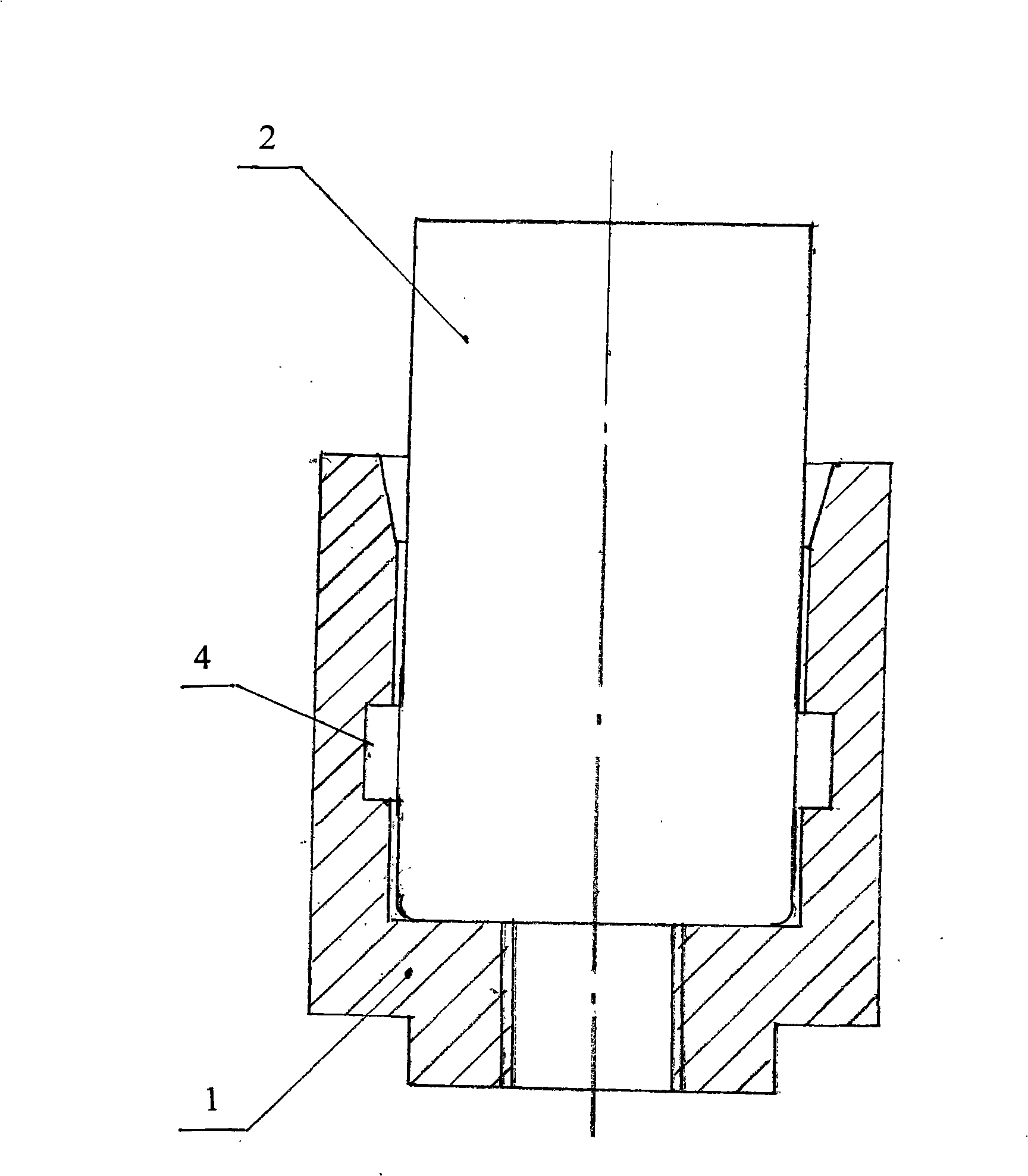

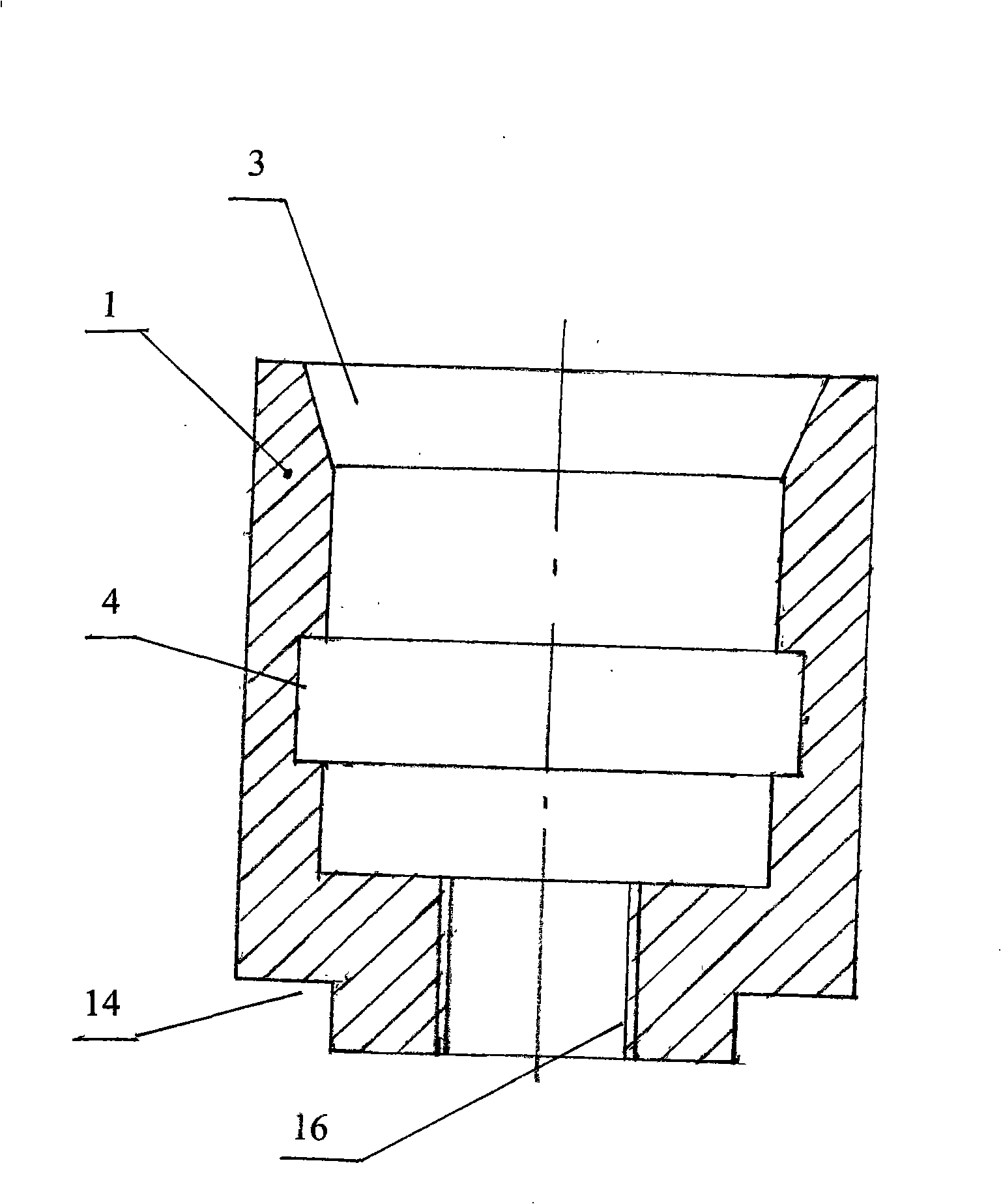

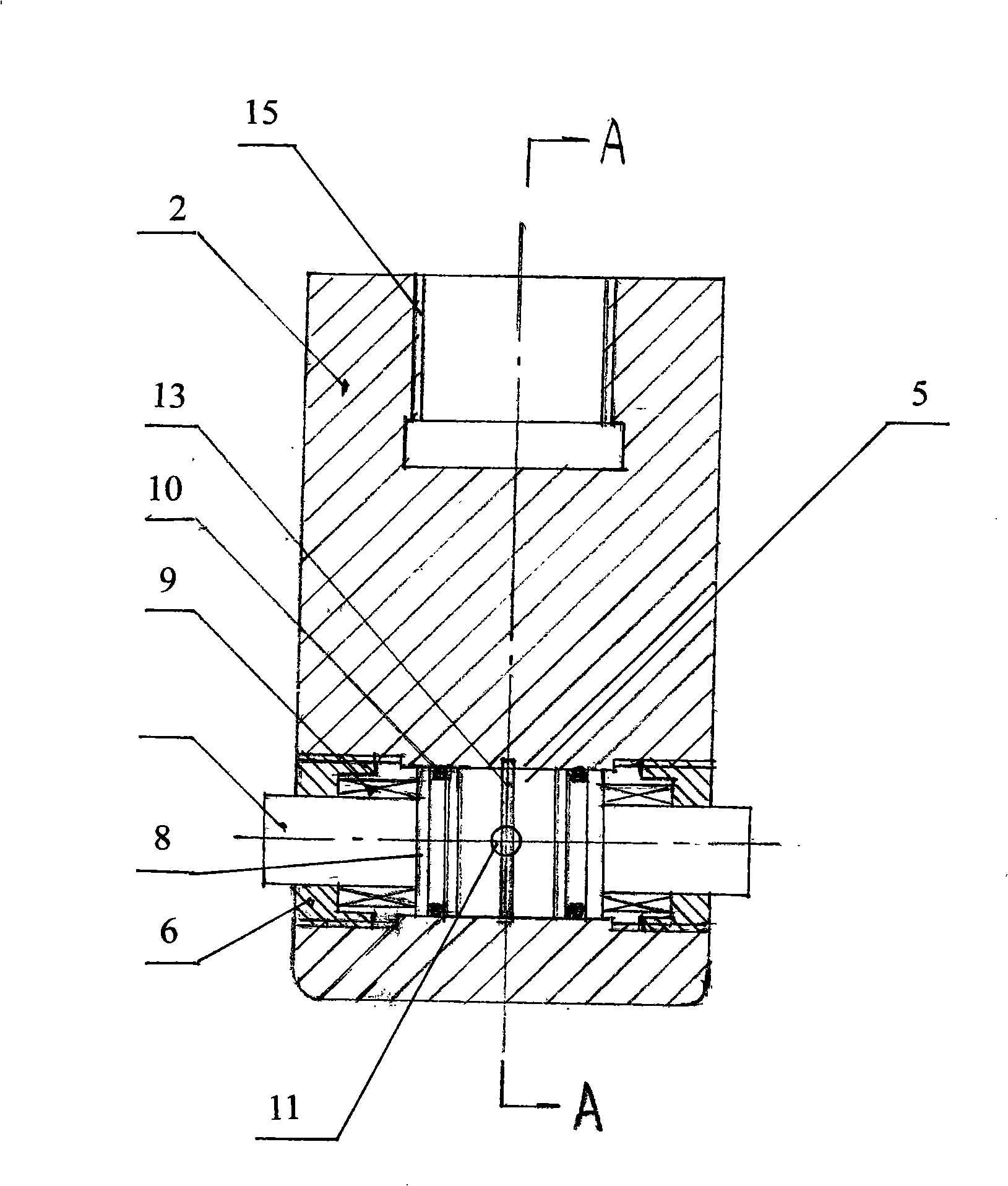

Hydraulic expanding type movable joint

InactiveCN101324249AConnections detach quicklyEasy to operateRefuse receptaclesRefuse transferringOil drillingEngineering

A hydro-bulging movable joint is characterized in that the movable joint comprises a concave joint with a central hole; a ring-shaped concave slot is formed at the inner peripheral surface of the central hole; the movable joint further comprises a convex joint; a section of the convex joint is disposed in the central hole of the concave joint; a radial perforation is formed at the lower section of the convex joint; inner screw threads are formed at the two ends of the radial perforation, and the two ends thereof are connected with locking helicoids; a small movable shaft provided with a ring-shaped lug boss at the inner end thereof is movably sleeved in each locking helicoid; a spring and a sealing ring are sleeved on the small movable shaft in the radial perforation; an oil intake and discharge hole is arranged in the convex joint, wherein one end of the oil intake and discharge hole communicates with the radial perforation, and the other end thereof passes out of the radial perforation. By adopting the movable joint, connection and detachment are rapid and convenient. The movable joint can be widely used for movable connection between hydraulically controlled carriages of automobiles or trains, and between drill stems in geological or oil drilling, and can also be used in equipment for disposing urban refuse.

Owner:贾林

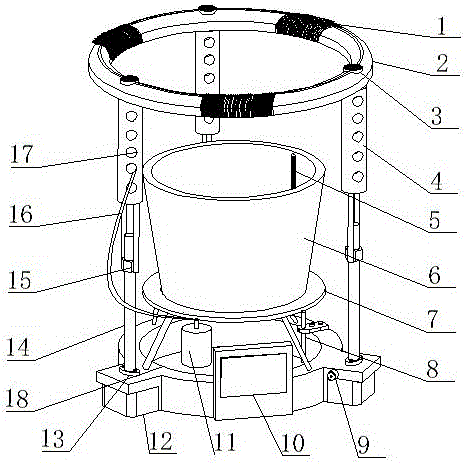

Height-adjustable dual-layer potting holder with early warning function

InactiveCN106416786AMeet the mechanicalMeet the designSelf-acting watering devicesReceptacle cultivationGyroscopeDisplay device

The invention provides a height-adjustable dual-layer potting holder with an early warning function. The height-adjustable dual-layer potting holder comprises a base, a tray, three upper supports, a supporting frame, a plurality of hose fixers, a stepping motor, adjusting screws, adjusting nuts, a bearing, gyroscopes, circular ropes, a pot, a soil humidity sensor, a display, a buzzer, an injection pump, a hose and a liquid-level sensor. The stepping motor actuates to drive the adjusting screws and the adjusting nuts to do relative movement to further drive the upper supports to move vertically; the hose fixers are arranged on the supporting frame; the three upper supports are connected through the circular ropes to form a circular structure; the gyroscopes are mounted on the upper supports, the display and the buzzer are arranged on the base; the liquid-level sensor and the injection pump are mounted inside the base; the soil humidity sensor is mounted in the pot; the display can display humidity value and liquid level. The height-adjustable dual-layer potting holder has the advantages of simple structure, smart design, high practicability and good market prospect.

Owner:朱树彪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com