Mold angle ejector rod structure capable of adding cooling water

A technology of inclined ejector pin and cooling water, which is applied in the field of automotive injection molds, can solve the problems of unobtained design technology and processing technology, achieve the effects of improving mold output and product quality, simplifying production injection molding process, and reducing the risk of skin texture and color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

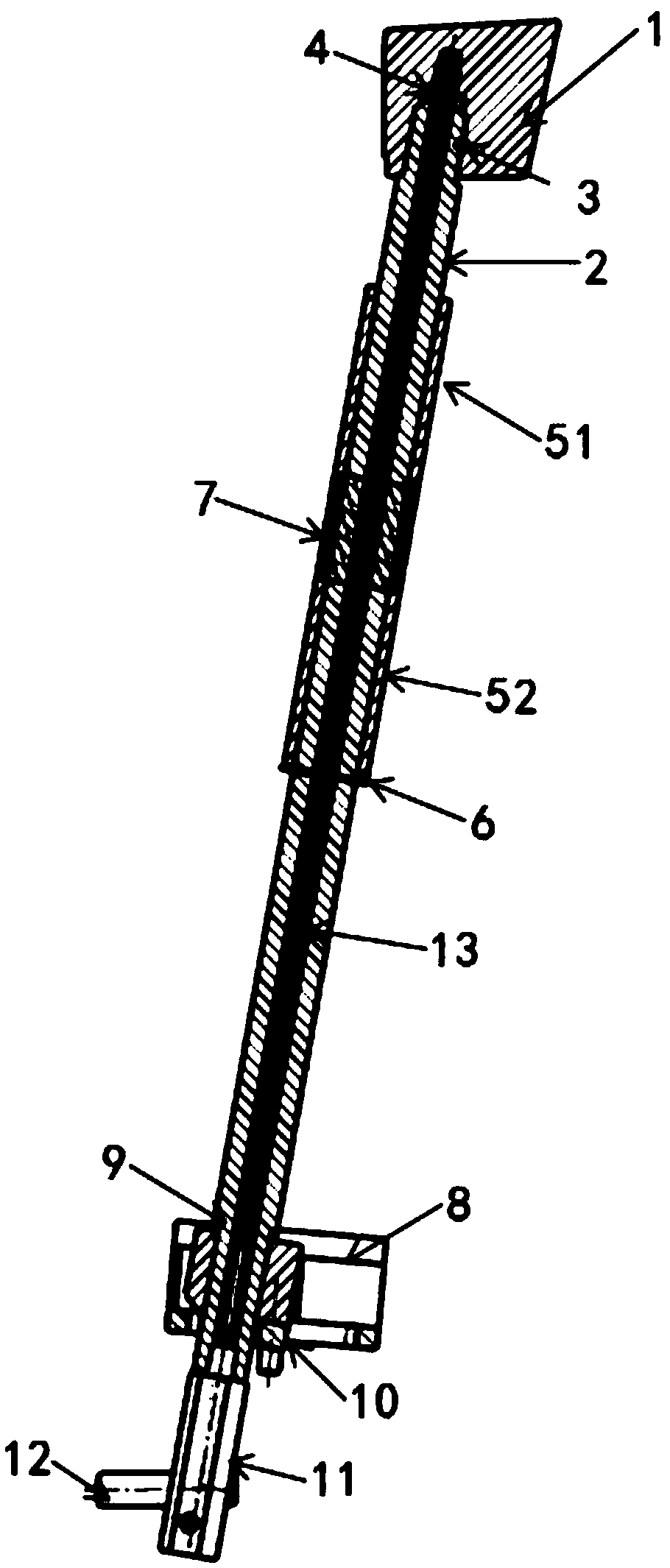

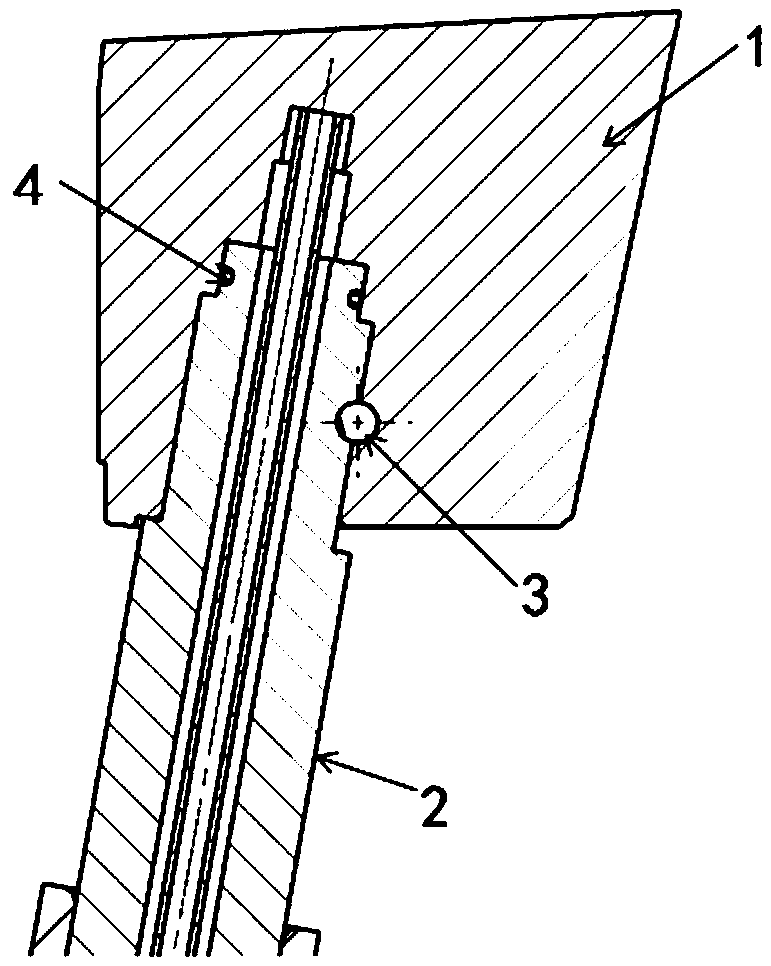

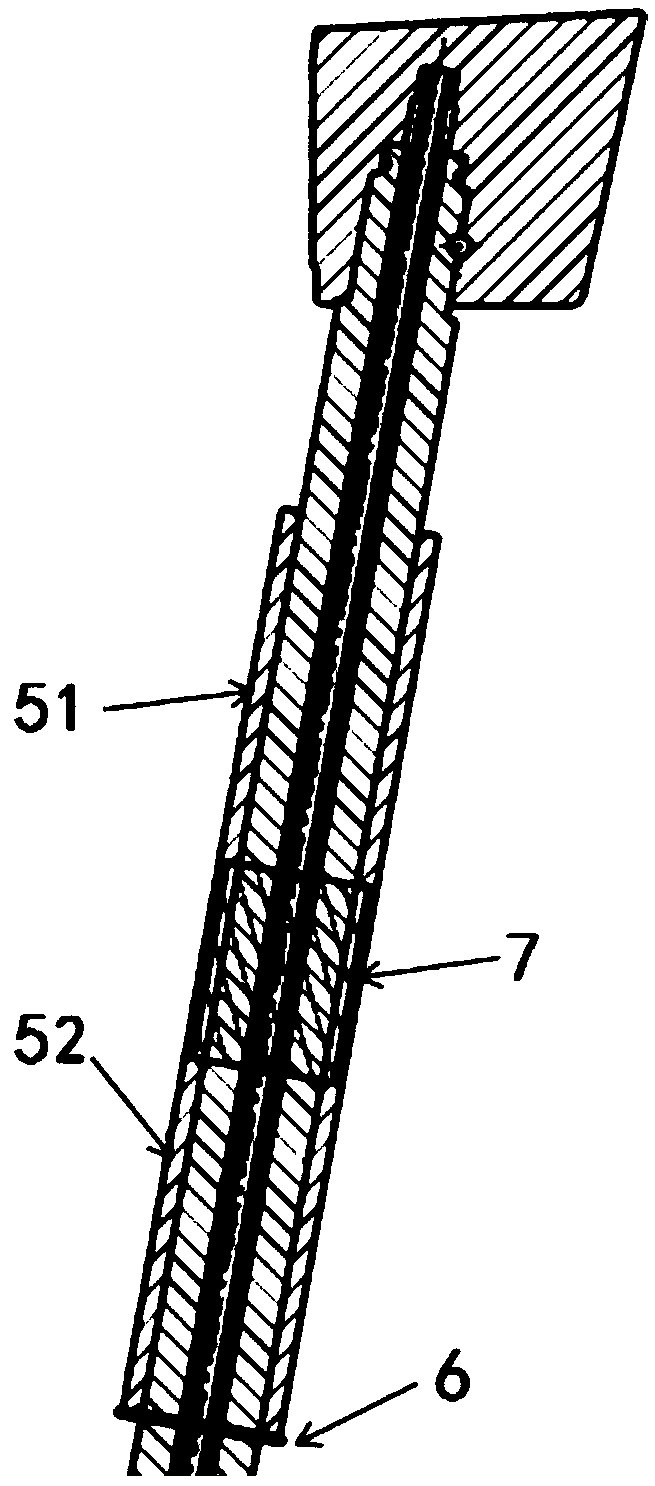

[0024] A kind of mold inclined ejector structure of the present invention that increases cooling water, such as figure 1 As shown, it includes inclined ejector block 1, inclined ejector rod 2, inclined ejector pin 3, O-ring 4, first self-lubricating copper guide bush 51, second self-lubricating copper guide bush 52, retaining spring 6, hollow aluminum Pipe 7, inclined top sliding seat 8, O-shaped cushion block 9, U-shaped block 10, inclined top adapter block 11, water pipe joint 12 and annular pipe 13, the head of inclined ejector rod 2 is sealed with O-shaped sealing ring 4 , the inclined jacking block 1 is connected with the head of the hollow jacking rod 2 and locked by the jacking pin 3; the tail of the jacking rod 2 is connected with the jacking sliding seat 8; The cushion block 9 is movably connected with the jack rod 2, and the relative height b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com