Method for controlling a leak detector, and leak detector

A leak detector and energy supply technology, which is applied in the testing of machines/structural components, instruments, pump control, etc., and can solve problems such as inability to comply with waiting time, user miscalculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

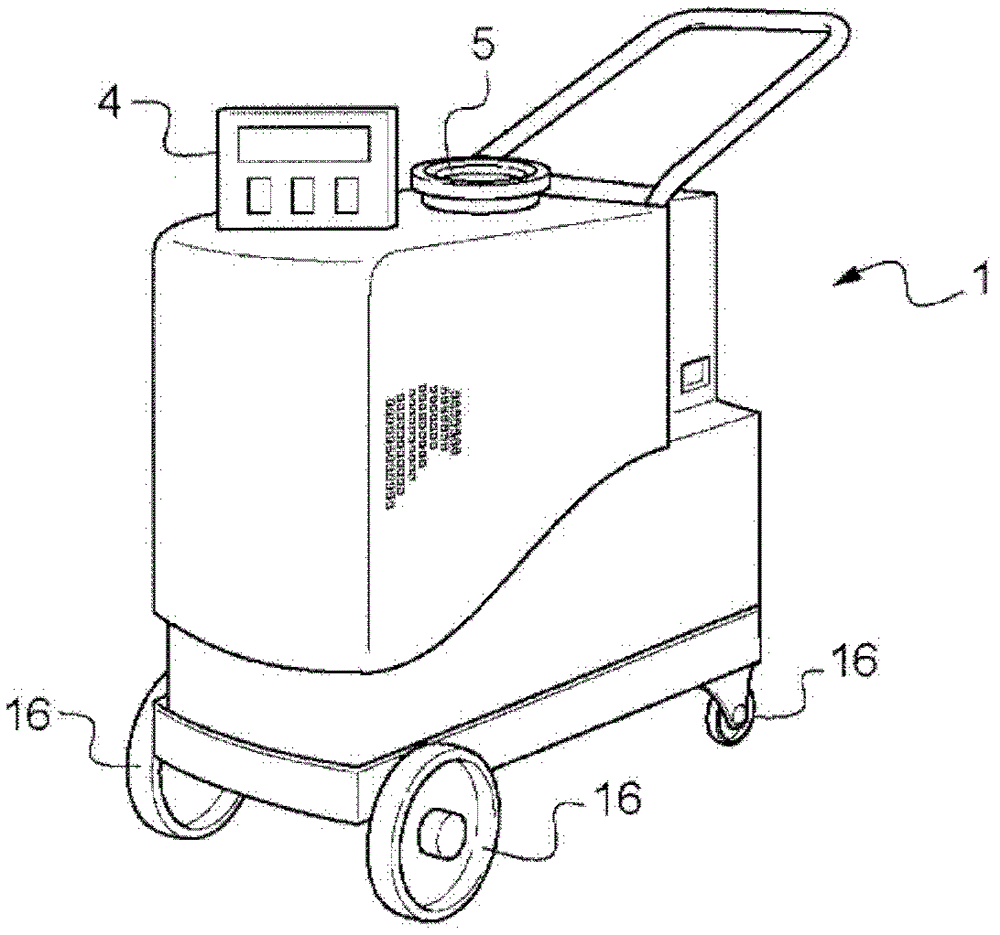

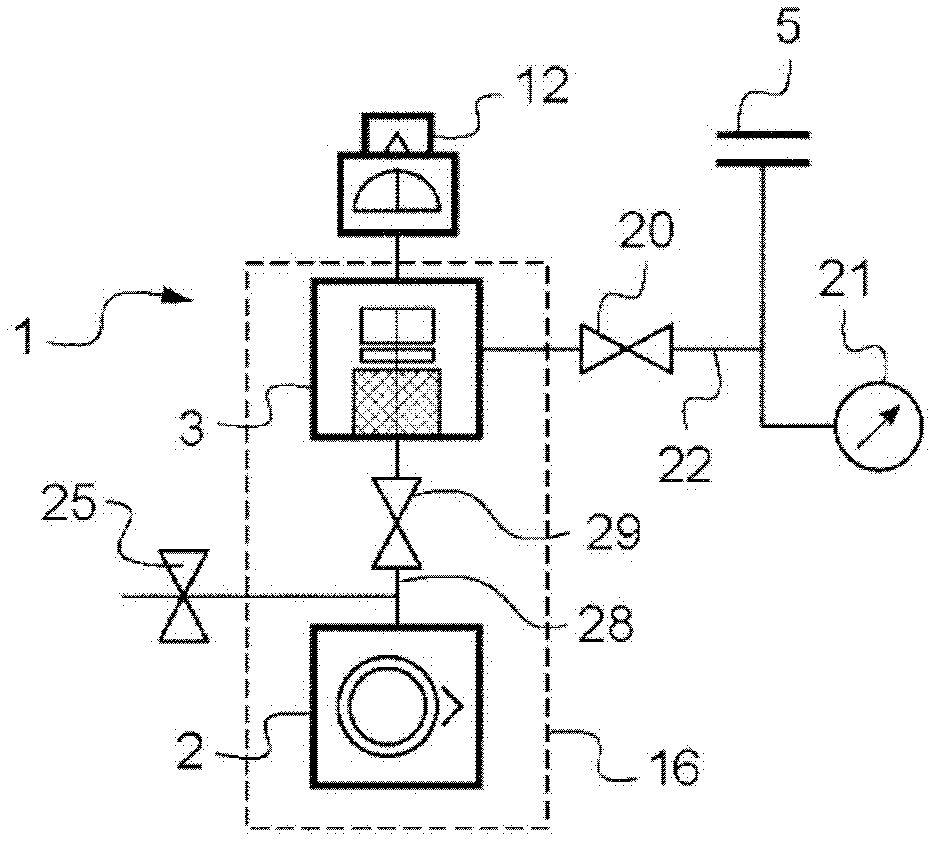

[0035] figure 1 and 2 An example of a leak detector 1 is depicted.

[0036] The leak detector 1 comprises a main vacuum pump 2, a secondary vacuum pump 3 connected to the main vacuum pump 2, a mass spectrometer 12 connected to the suction side of the secondary vacuum pump 3, and at least one notification device for notifying the user of the operating state of the leak detector 1 4.

[0037] The secondary vacuum pump 3 includes a rotor, a stator and a motor. The rotor is rotated by the motor in the stator when the motor is energized. figure 1 The gas inlet 5 of the leak detector 1 is shown.

[0038] The discharge side of the secondary vacuum pump 3 is connected to the suction side of the main vacuum pump 2 via a pumping pipe 28 provided with a first isolating solenoid valve 29 of the leak detector 1 .

[0039] According to another example not shown, the leak detector does not comprise a main vacuum pump: the outlet of the secondary vacuum pump 2 is designed to be connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com