Patents

Literature

42results about How to "Reduced risk of stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

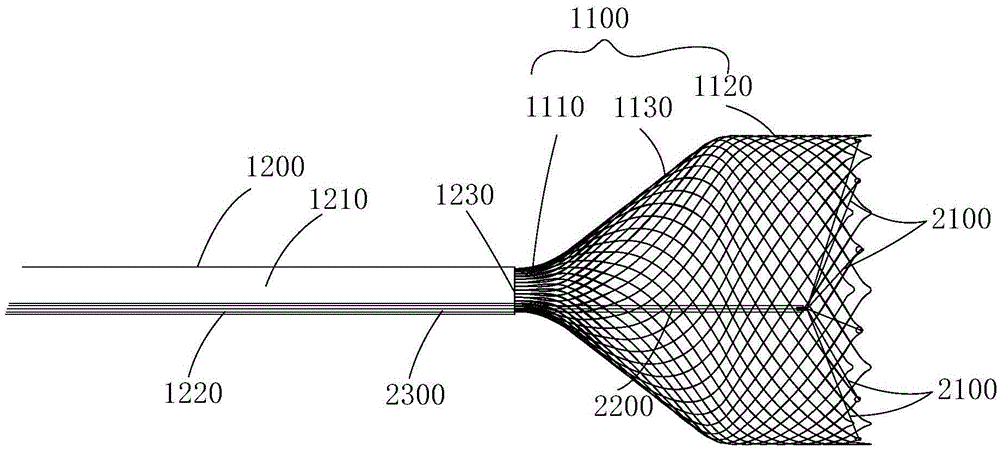

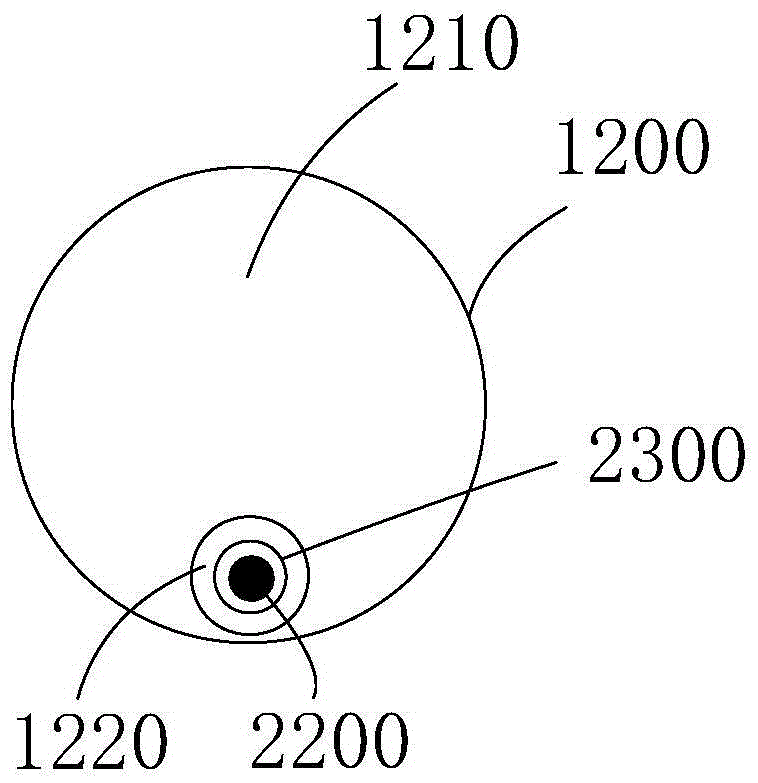

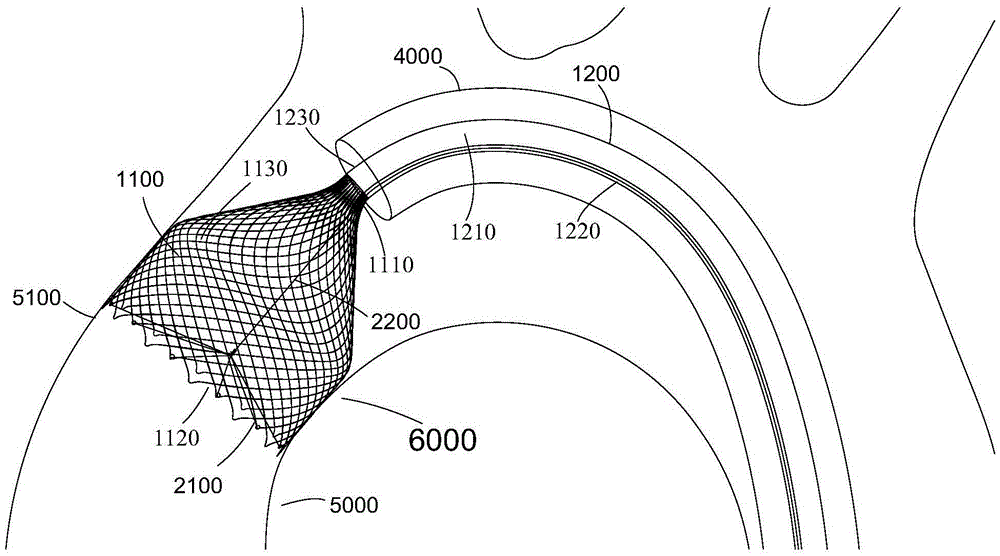

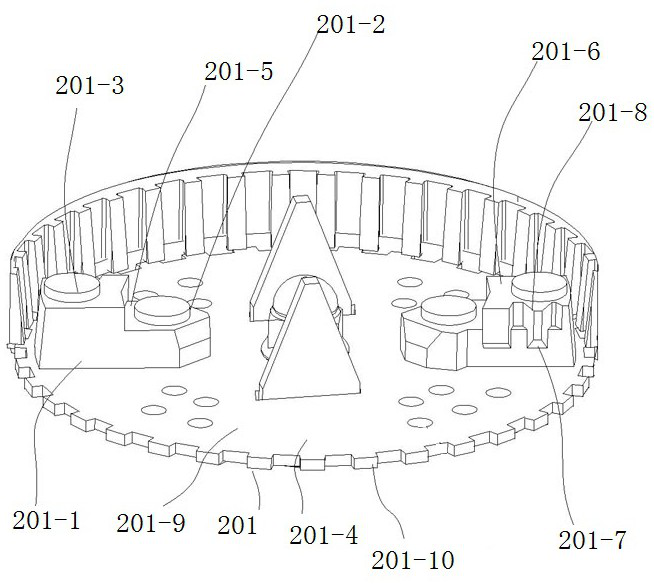

Thrombus filter

The invention discloses a thrombus filter which comprises a handle, a filter umbrella for capturing thrombi, a push catheter, and a folding device for shrinking and folding the filter umbrella, wherein the filter umbrella adopts a meshy elastically-recoverable funnel-shaped structure; a neck part of the filter umbrella is fixedly connected with the push catheter; an inner cavity is axially formed in the push catheter; a cavity enclosed by the filter umbrella is communicated with the inner cavity of the push catheter; the folding device comprises a take-up unit and a drawing mechanism for drawing the take-up action; the take-up unit is connected with an opening part of the filter umbrella and draws the opening part to be folded, so that the filter umbrella becomes a closed space; the drawing mechanism penetrates the inner cavity of the push catheter, extends towards the opening part of the filter umbrella and is connected with the take-up unit; the push catheter and the drawing mechanism are connected with the handle; the actions of the push catheter and the drawing mechanism are controlled by the handle. The thrombus filter can effectively block exfoliated plaques or emboli, and is simple in structure, small in push resistance and smooth in operation.

Owner:VENUS MEDTECH (HANGZHOU) INC

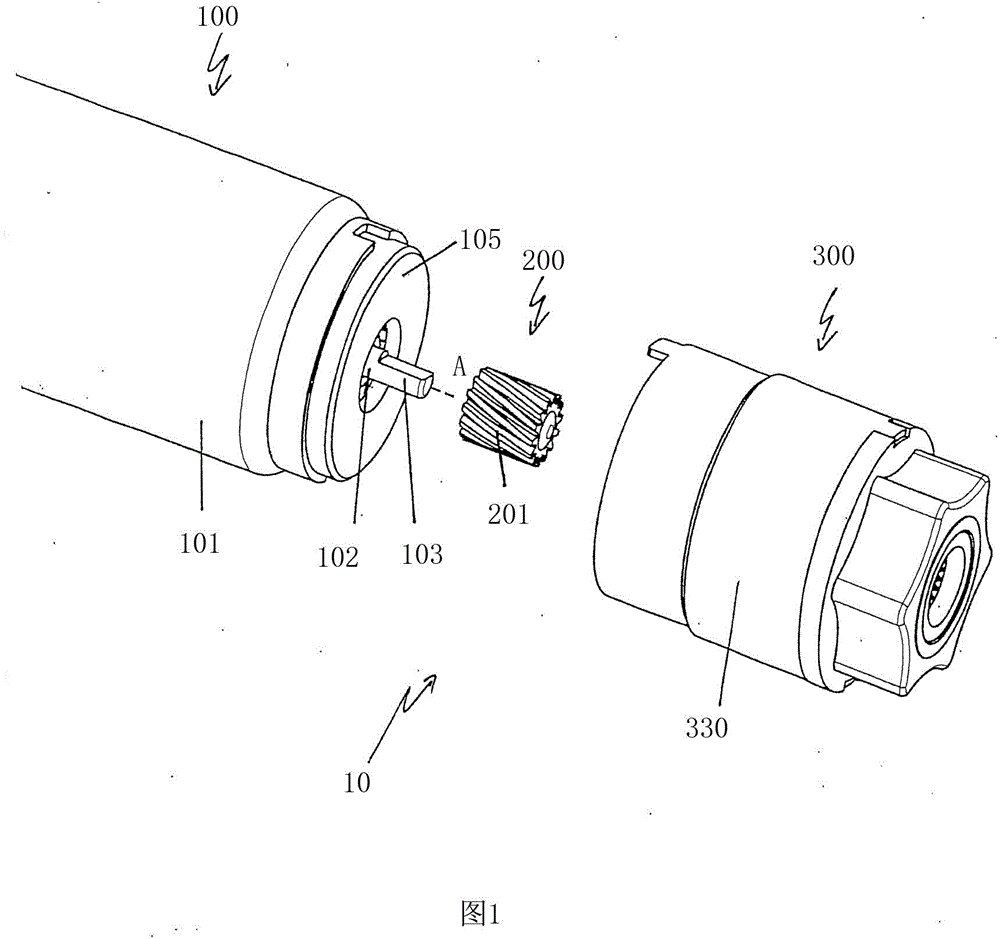

Driven hatch arrangement for a motor vehicle

InactiveCN104565330APrevent stuck phenomenonAffects operating characteristicsToothed gearingsPower-operated mechanismMobile vehicleDrive shaft

A driven hatch arrangement is provided, particularly a rear hatch arrangement, for a motor vehicle with a hatch and with a hatch drive for opening and / or closing the hatch, with the hatch drive comprising a motor with a motor shaft and a motor pinion and at least one planetary gear with a sun gear, planetary carriers with planetary rolling elements arranged on bearing pins, and an annulus, with the sun wheel of the planetary gear being formed by the motor pinion and a driven shaft being driven via the planetary gear, in which the bearing pins of the planetary gear projecting beyond the planetary rolling elements arranged on the bearing pins in the direction towards the motor.

Owner:IMS GEAR GMBH

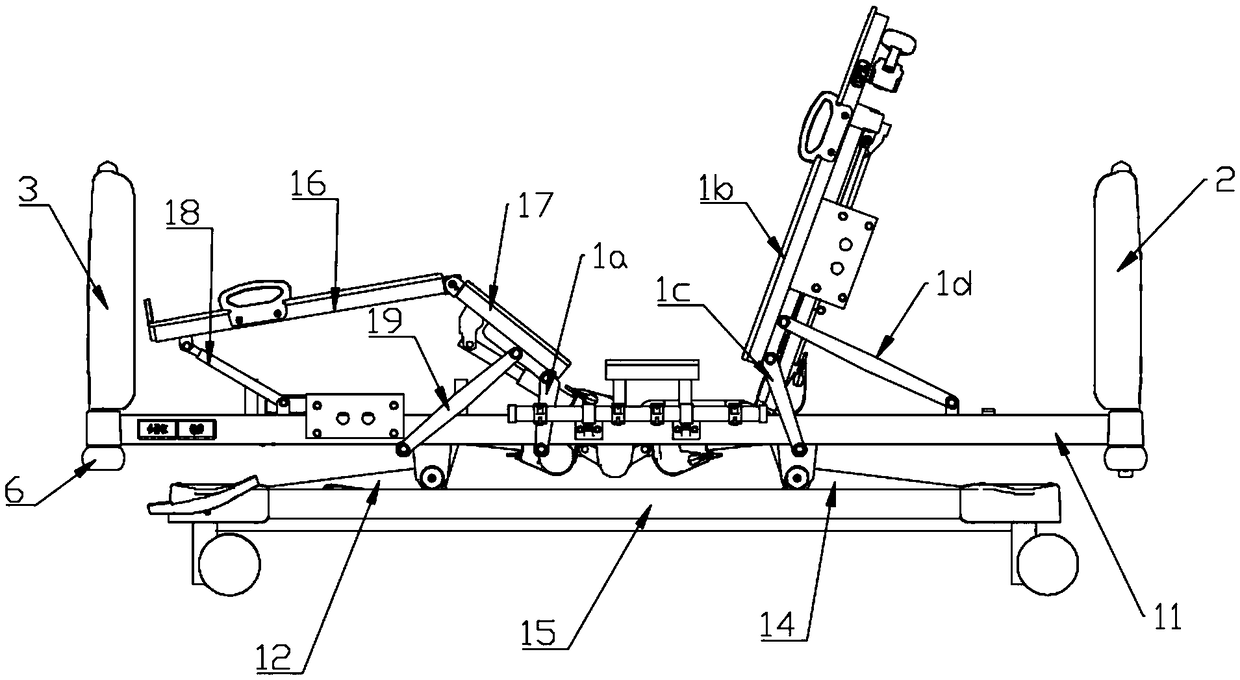

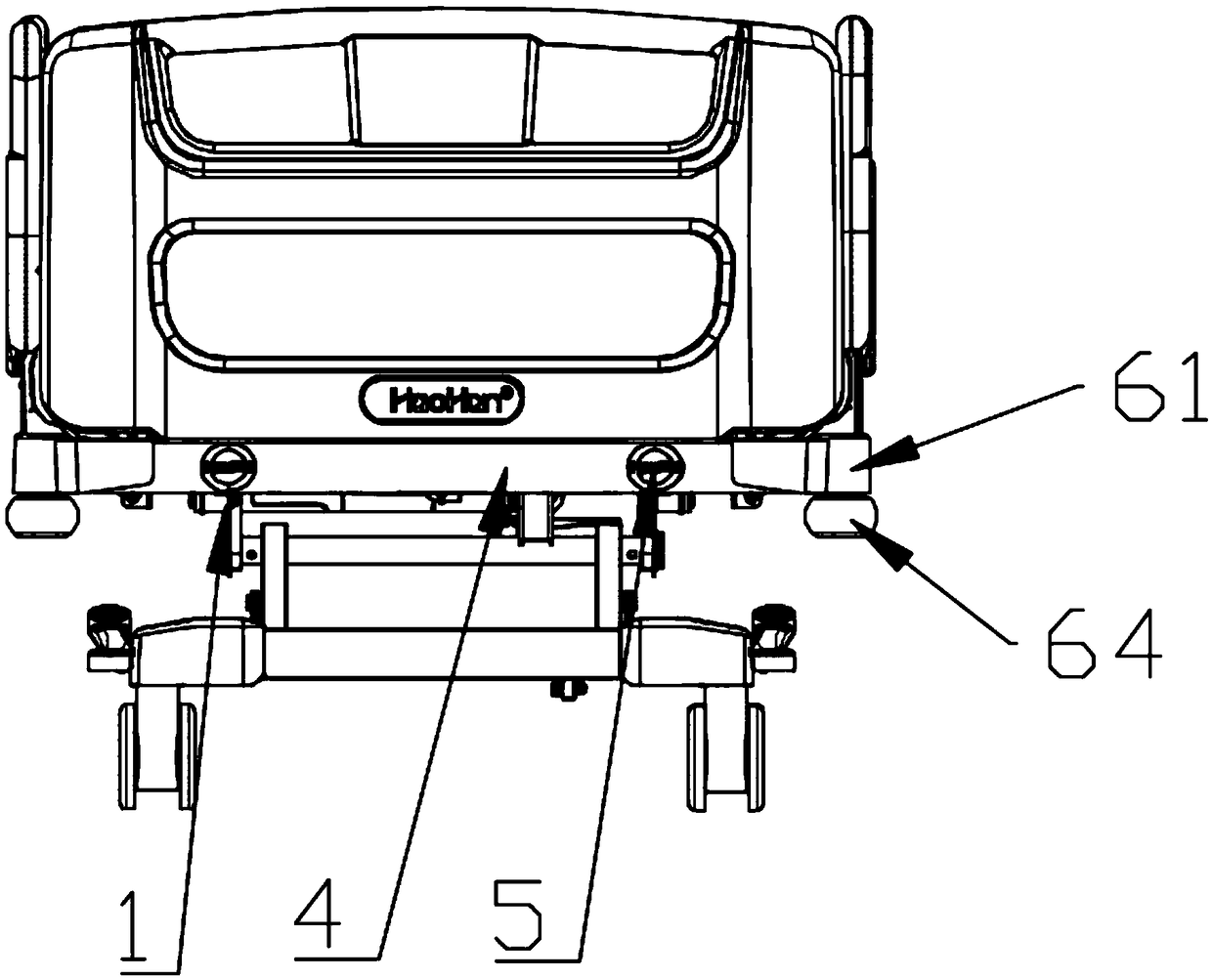

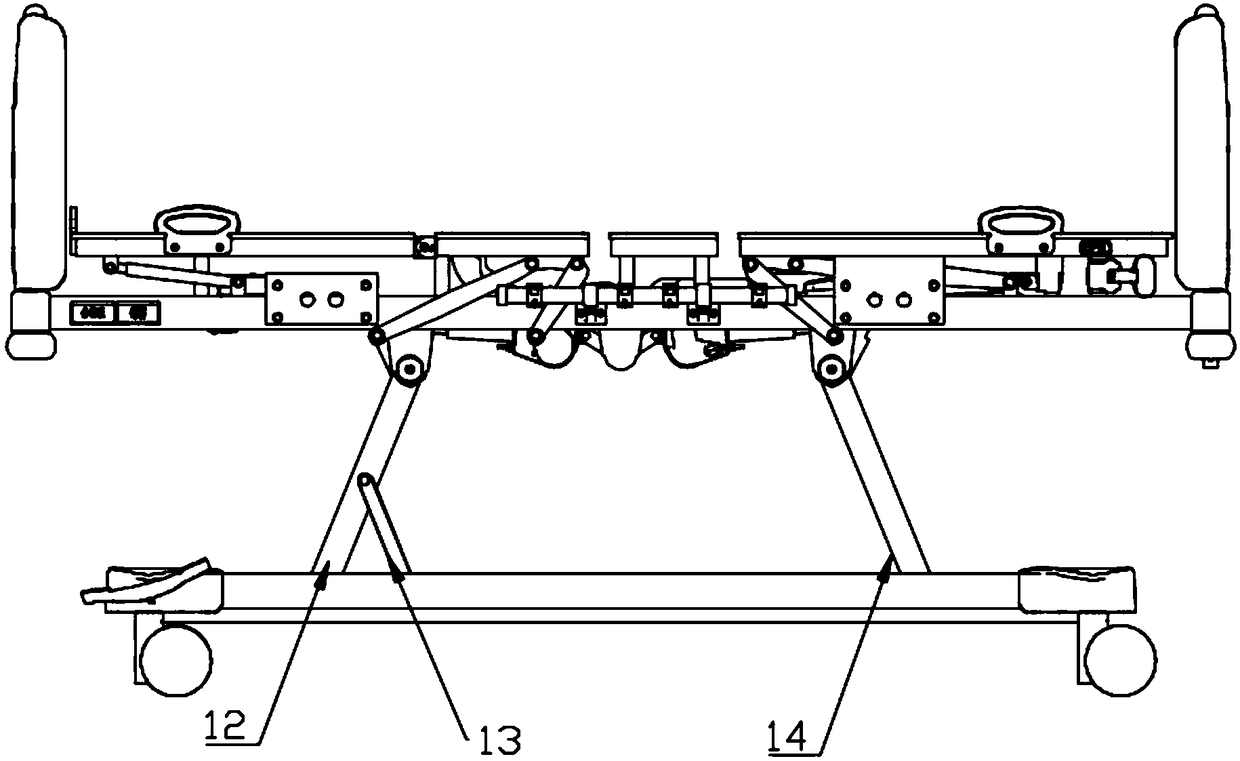

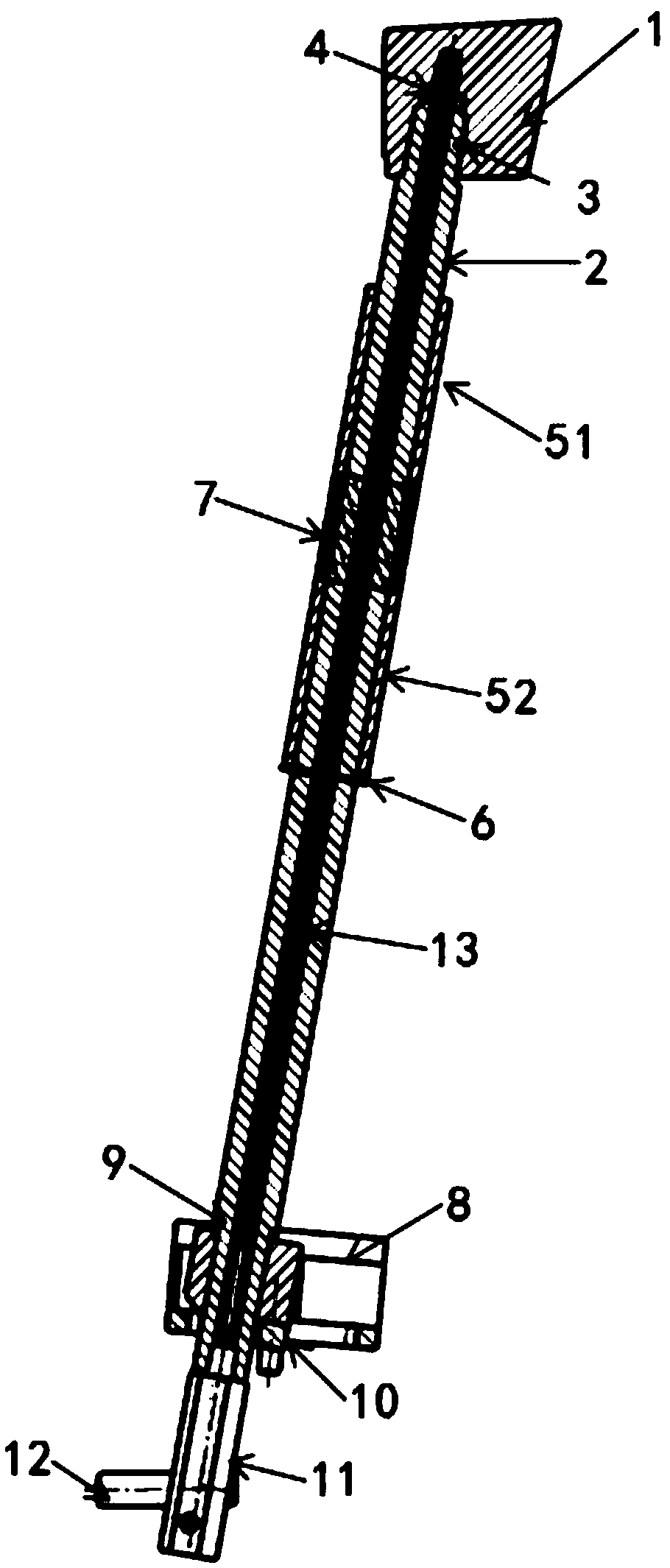

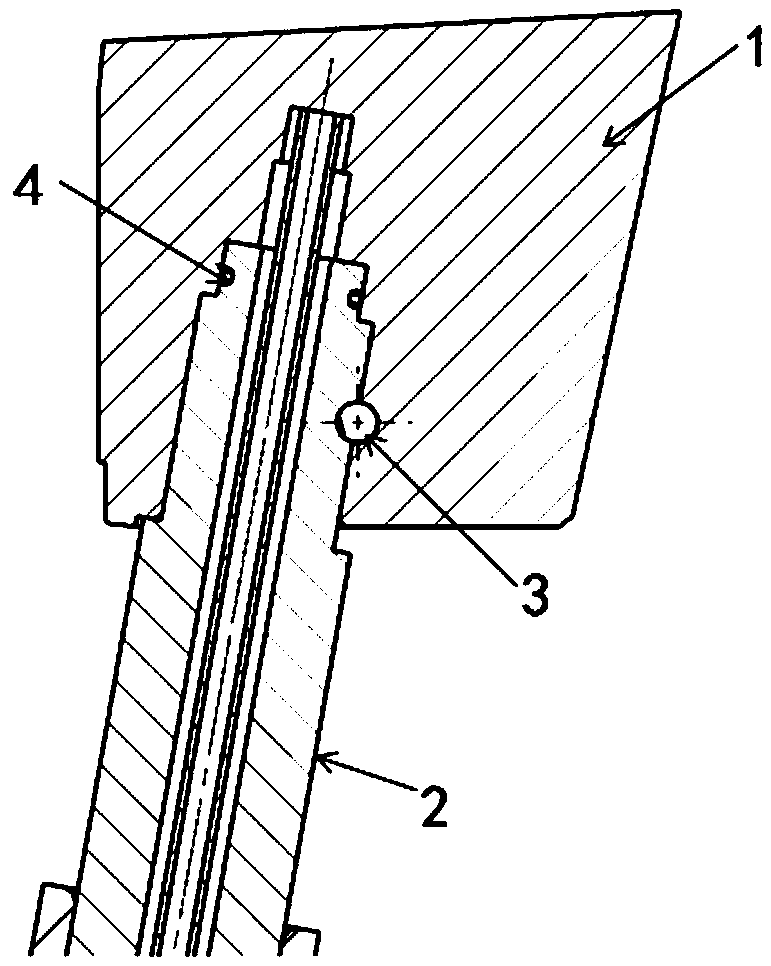

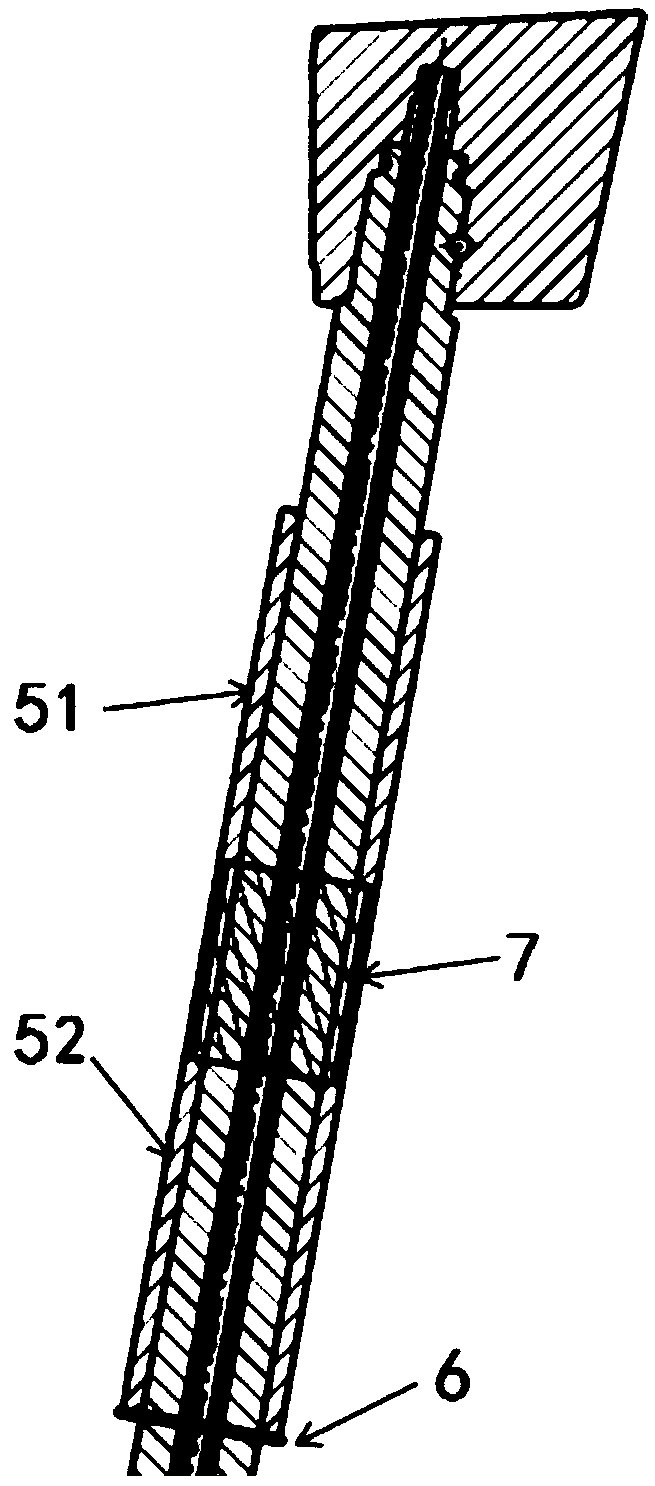

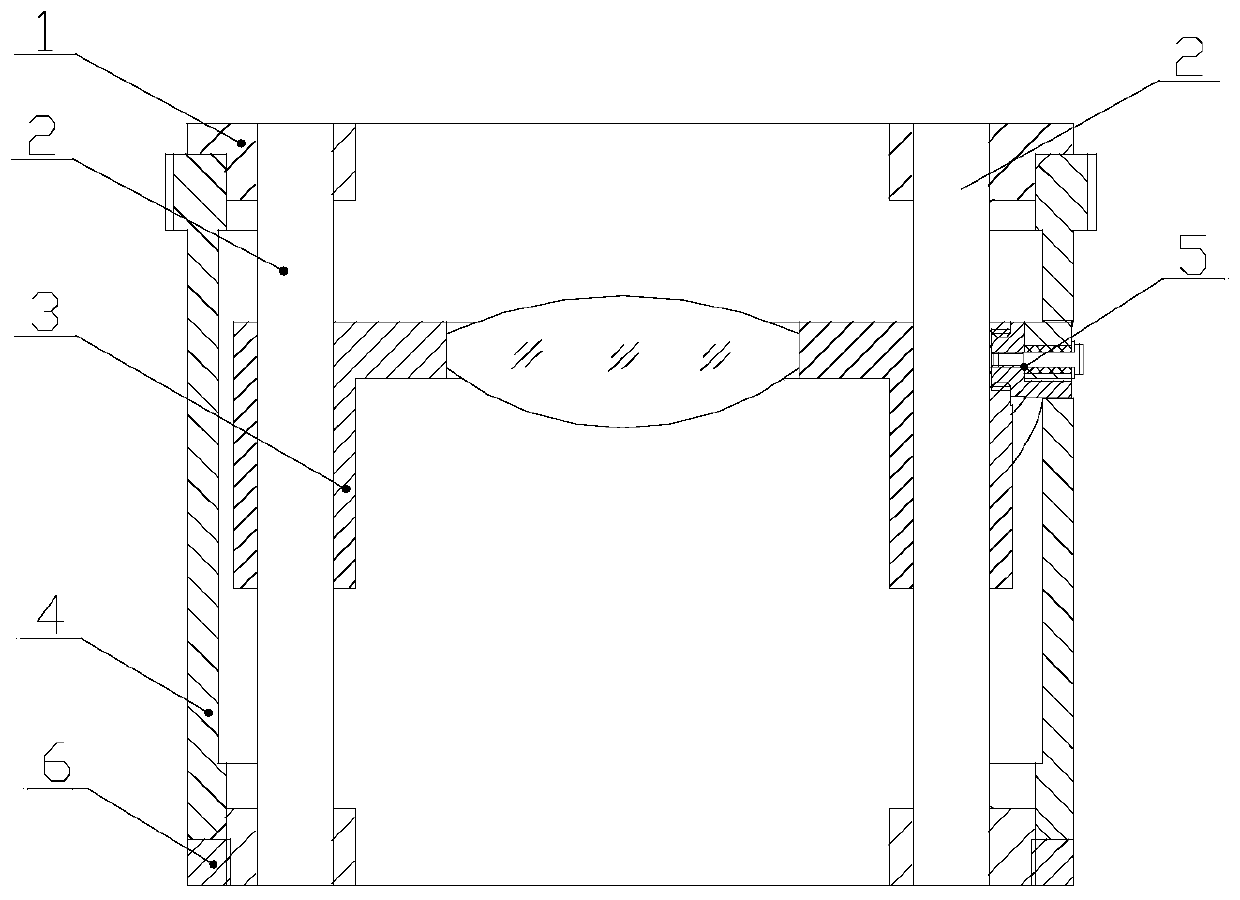

Multifunctional medical bed

PendingCN109223368AReduce usageRealize multi-directional adjustment functionNursing bedsAmbulance serviceEngineeringMedical treatment

The invention discloses a multifunctional medical bed, relating to the technical field of medical instruments, and comprising a bed body structure adjustable in multiple directions, a headboard, a tailboard, a bed frame crossbar, a locking structure of a bed frame and a bed body anti-collision assembly, wherein the bed head board and the bed tail board are installed on the bed frame cross bar through the bed frame locking structure, the bed frame cross bar is connected with the bed body structure for multi-orientation adjustment, and the bed body anti-collision assembly is installed at the endof the bed frame cross bar. The invention can realize the multi-orientation adjustment function and reduce the risk of locking, and simultaneously has the anti-collision and storage functions.

Owner:CHENGDU HAOHAN MEDICAL EQUIP

Mold angle ejector rod structure capable of adding cooling water

The invention discloses a mold angle ejector rod structure capable of adding cooling water, and belongs to the field of automobile injection molds. The mold angle ejector rod structure comprises an angle ejector block, an inclined ejector rod, an angle ejector sliding seat and an angle ejector change-over block, wherein the angle ejector block is connected with the head part of the hollow; the tail part of the inclined ejector rod is connected with the angle ejector sliding seat; the angle ejector sliding seat is capable of adjusting the relative height between the angle ejector sliding seat and the angle ejector rod through an O-shaped cushion block and is in clamping connection with the angle ejector rod through a U-shaped clamping block; the angle ejector rod is sequentially provided with a first self-lubricating copper guide sleeve, a hollow aluminum pipe and a second self-lubricating copper guide sleeve; an annular pipe is arranged in a cavity in the angle ejector rod along a longitudinal direction; the tail part of the angle ejector rod is connected with the angle ejector change-over block; the angle ejector change-over block is provided with a water pipe joint; the tail partof the annular pipe is communicated with the water pipe joint through the angle ejector change-over block; the head part of the annular pipe stretches out of the angle ejector rod. According to the mold angle ejector rod structure disclosed by the invention, addition of the cooling water to a single-rod angle ejector rod structure of a precision mold is realized, and meanwhile, an occlusion action process of an angle ejector rod can be avoided.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

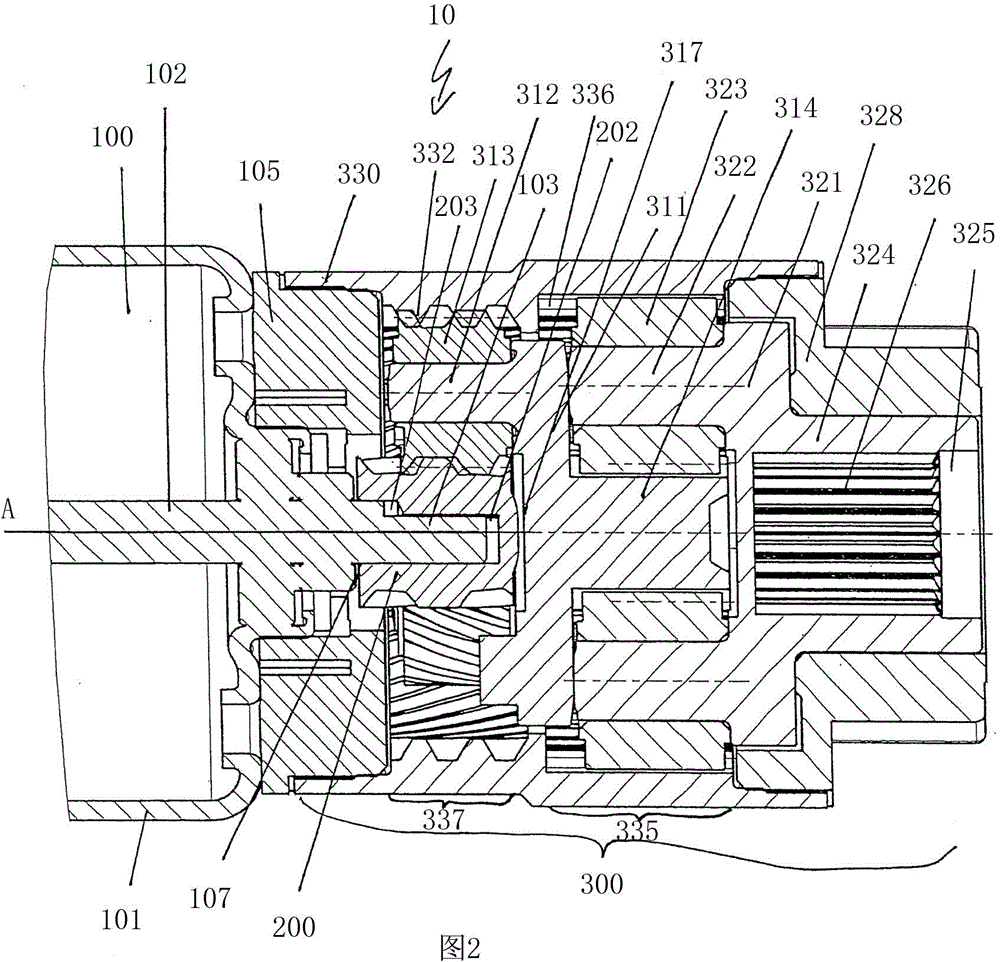

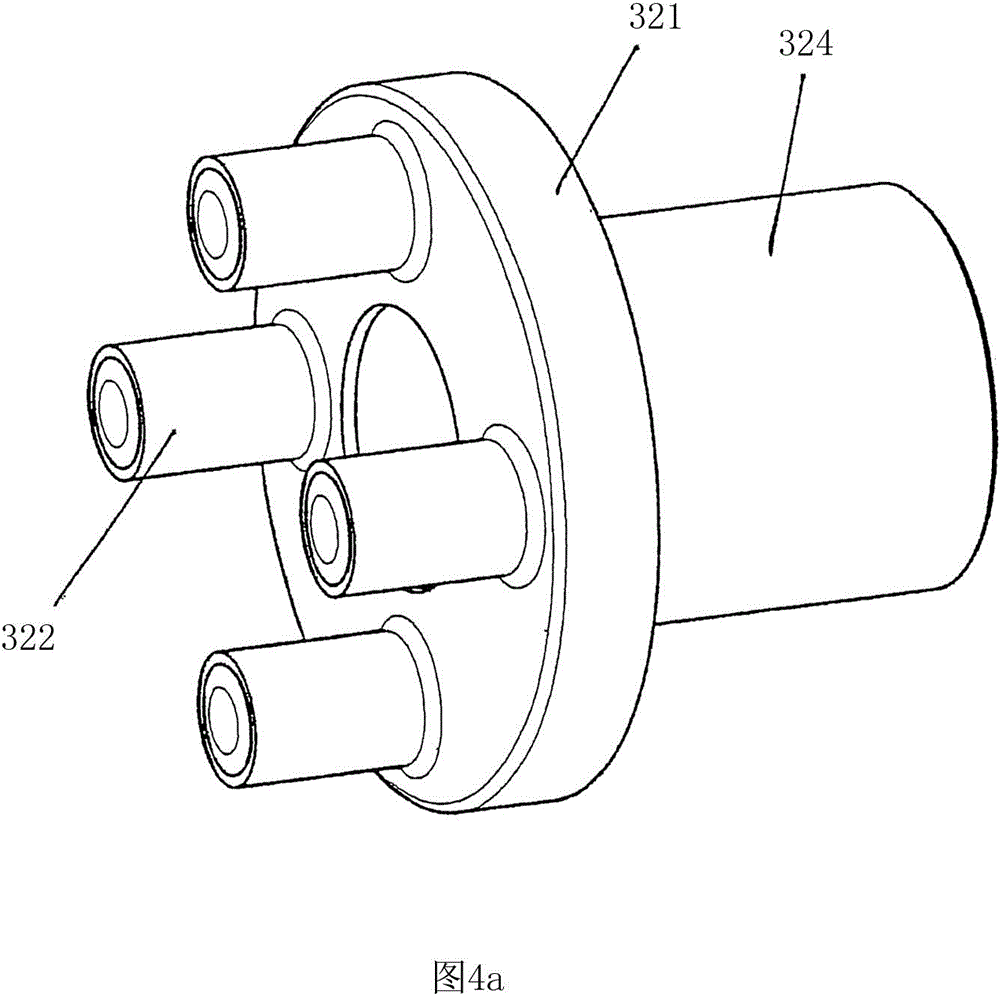

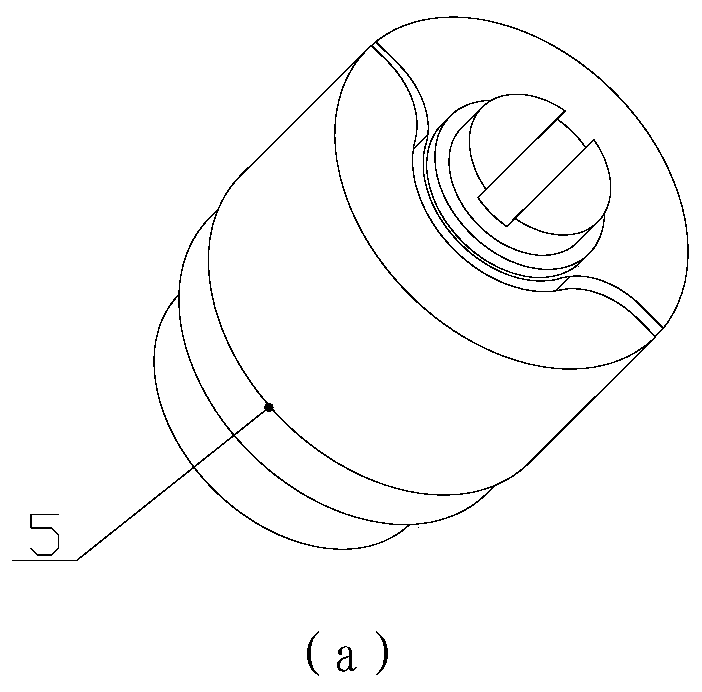

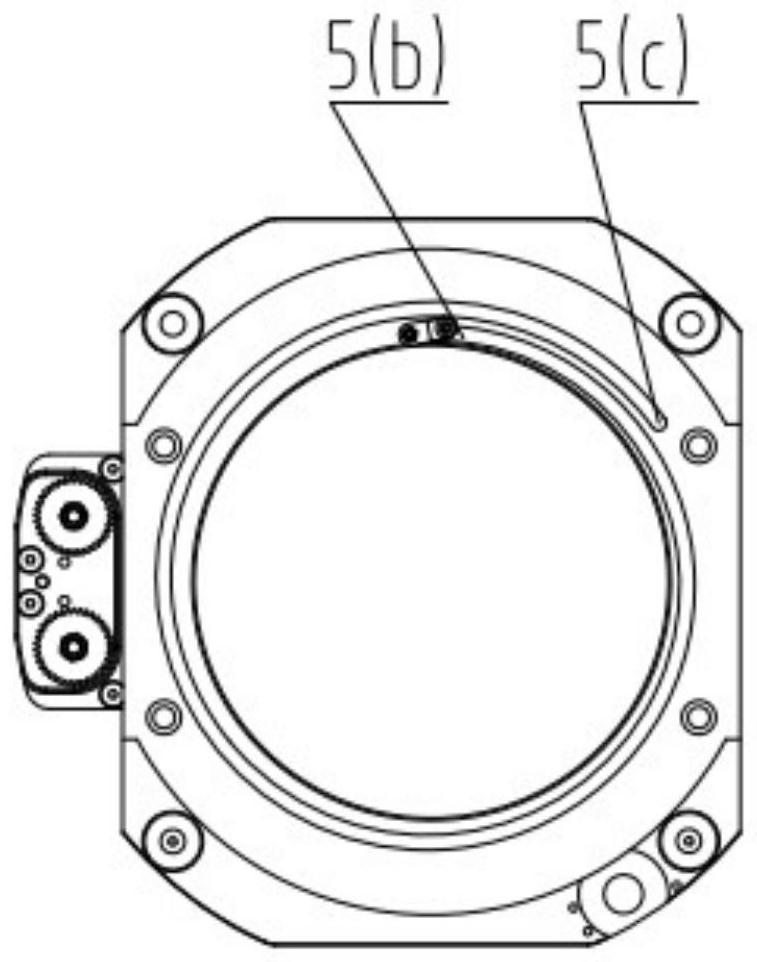

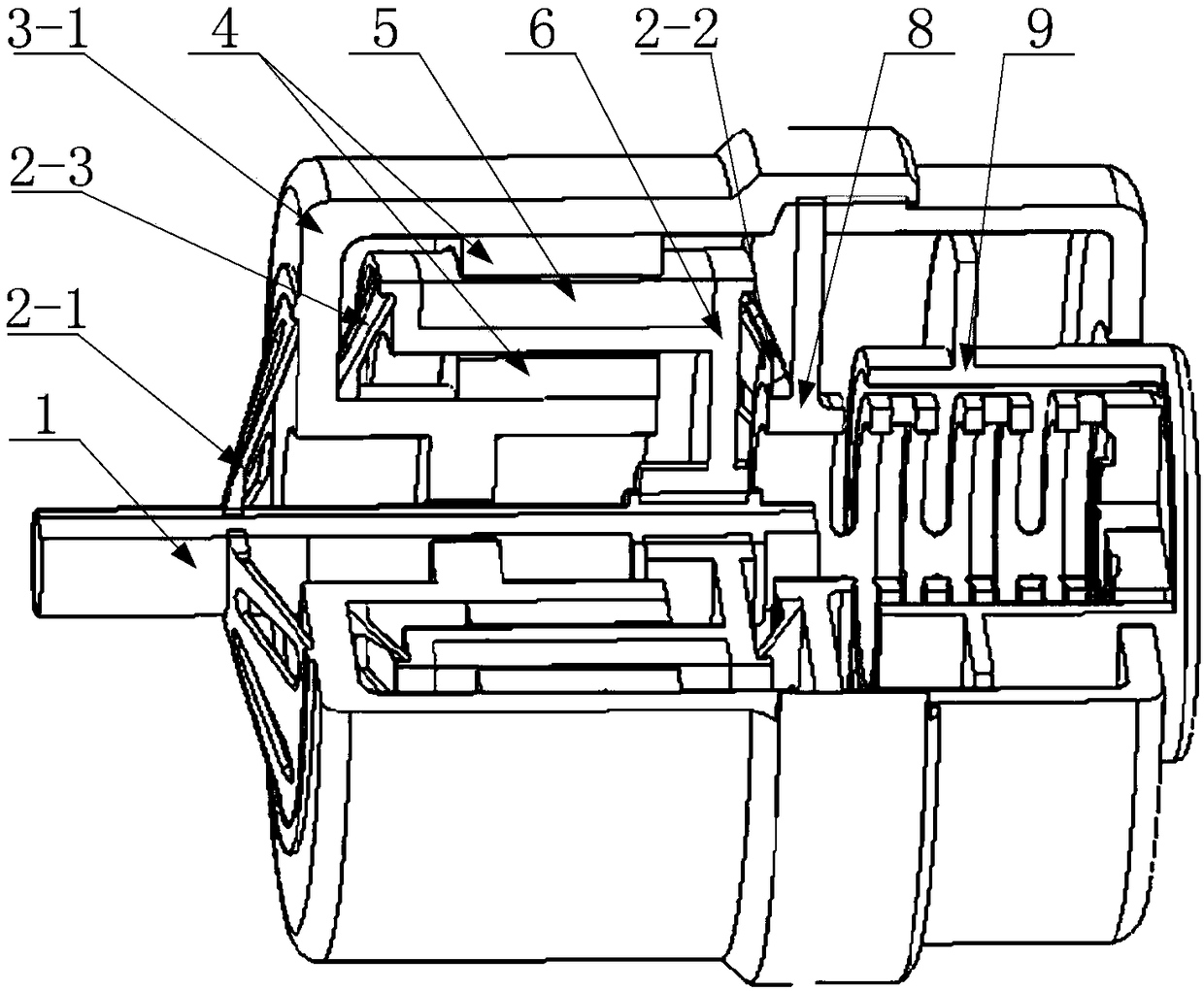

Unilateral positioning cam driving mechanism for continuous zoom lens

The invention discloses a unilateral positioning cam driving mechanism for a continuous zoom lens. The unilateral positioning cam driving mechanism comprises a main support, a sliding rod, an optical sliding assembly, a unilateral positioning curve sleeve, a semi-flexible pin assembly and a locking pressing ring; the optical sliding assembly is connected with the main support through the sliding rod; the sliding rod is fixed to the main support; the optical sliding assembly performs rotation-free linear movement relative to the main support along the sliding rod; the unilateral positioning curve sleeve is coaxially connected with the main support through the locking pressing ring; the unilateral positioning curve sleeve can rotate along a central axis relative to the main support; and the semi-flexible pin assembly penetrates through the curve groove of the unilateral positioning curve sleeve along a radial direction and is fixed to the optical sliding assembly. According to the unilateral positioning cam driving mechanism for the continuous zoom lens of the invention, the unilateral positioning curve sleeve rotates around the central axis, so as to drive the optical sliding assembly to perform linear movement along the sliding rod, and therefore, the axial movement of an optical element in the continuous zoom lens is realized; the semi-flexible pin assembly and the unilateral positioning curve sleeve are adopted, and therefore, the machining and assembling difficulty of a system are reduced, and the precision of the system and the temperature applicability of the system in use are improved.

Owner:西安应用光学研究所

Stratum settlement-preventing shield shell filling material and preparation method thereof

ActiveCN107459324AReduced risk of stuckReduce construction costsFilling materialsUltimate tensile strength

The invention discloses a stratum settlement-preventing shield shell filling material and a preparation method thereof. The stratum settlement-preventing shield shell filling material is prepared by mixing comprises a material A and a material B, wherein the material A comprises the following components: 25-30% of bentonite, 3-5% of a thickener, 3-5% of a colloidal stabilizer, 1-6% of a water-proofing agent and the balance of water; the material B comprises the following components: 45-55% of water glass and the balance of water; the volume ratio of the material A to the material B is 1:(0.8-1.2). In the filling material, the material A and the material B can be pumped according to equal volume, and after the material A and the material B meet each other and are mixed, a mixture can be quickly viscosified and has high viscosity and certain supporting strength, so that even if the material A and the material B are pumped out of a shield shell, the stratum settlement-preventing shield shell filling material can still effectively fill a gap above the shield shell and can effectively prevent the stratum settlement.

Owner:SHANDONG UNIV

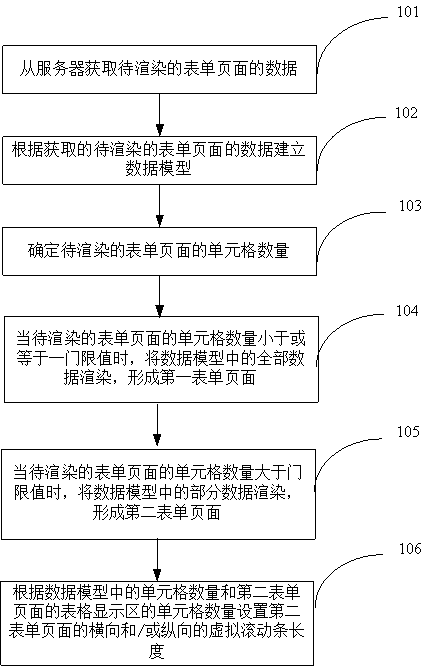

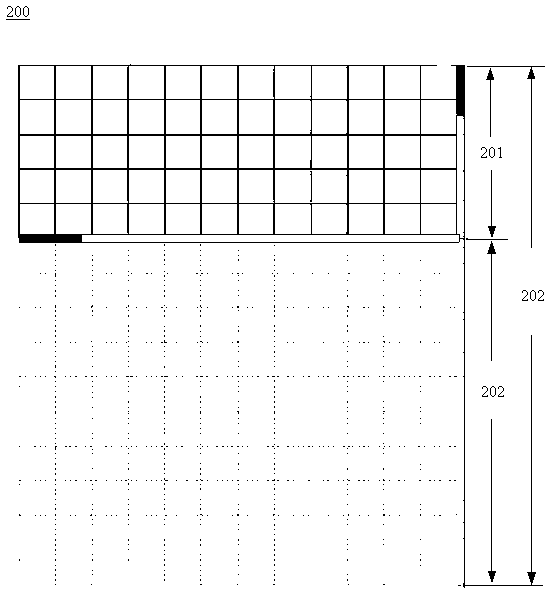

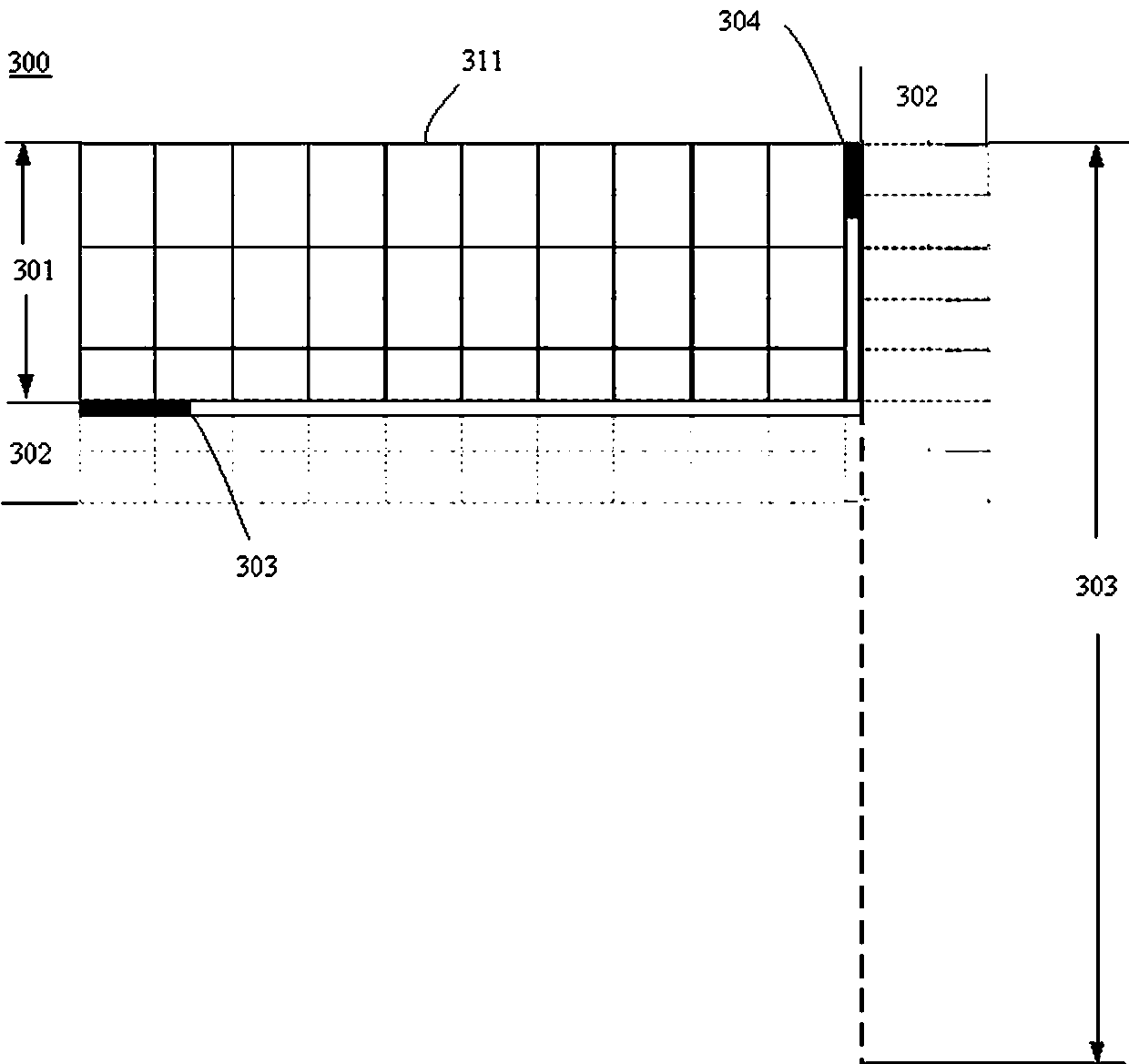

Form page rendering method, device and system, and readable medium

ActiveCN111459488AImprove interactivityReduce time overheadMedical data miningSoftware engineeringComputer graphics (images)Algorithm

The invention provides a form page rendering method. The method comprises the following steps: obtaining data of a to-be-rendered form page from a server; establishing a data model according to the acquired data of the to-be-rendered form page; determining the number of cells of the to-be-rendered form page; when the number of cells of the to-be-rendered form page is smaller than or equal to a threshold value, rendering all the data to form a first form page; when the number of cells of the to-be-rendered form page is greater than the threshold value, rendering part of the data to form a second form page; setting a transverse and / or longitudinal virtual scroll bar length of the second form page according to the number of cells in the data model and the number of visible cells in the user visible region; when it is monitored that a transverse or longitudinal virtual scroll bar of the second form page rolls, determining data in the data model which should be displayed in a user visible area of the second form page; and updating the data to the corresponding cells of the second form page.

Owner:浙江太美医疗科技股份有限公司

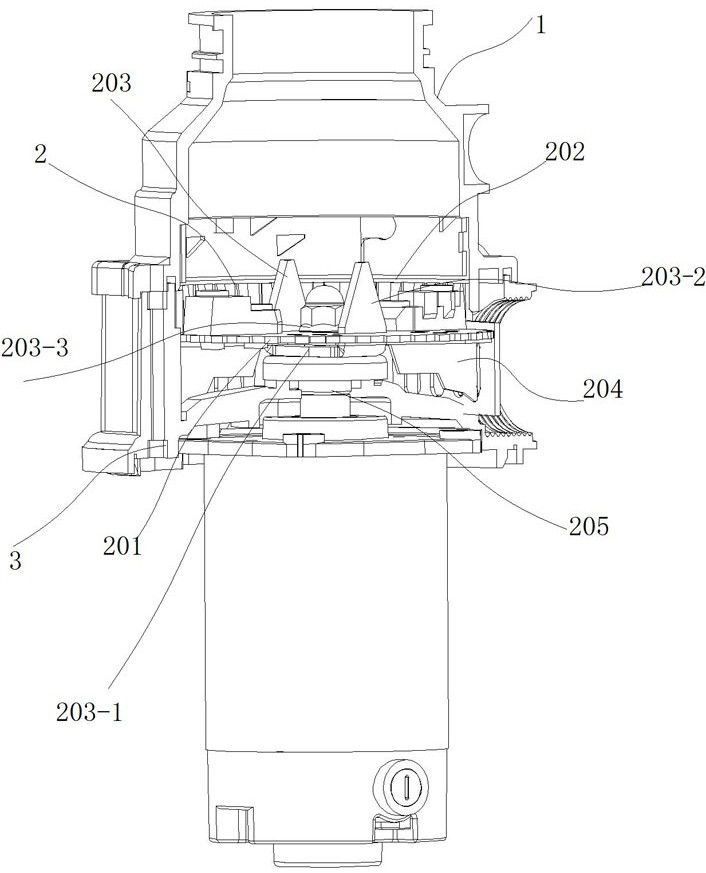

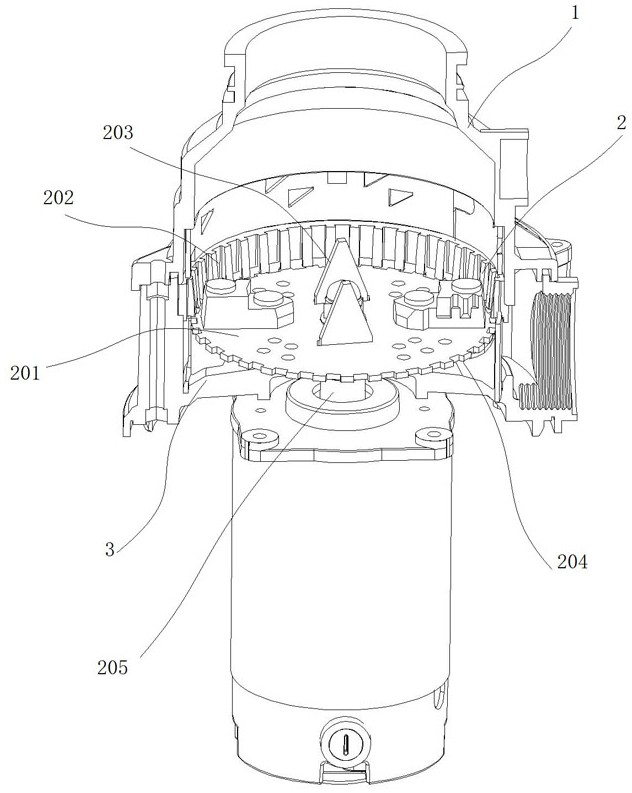

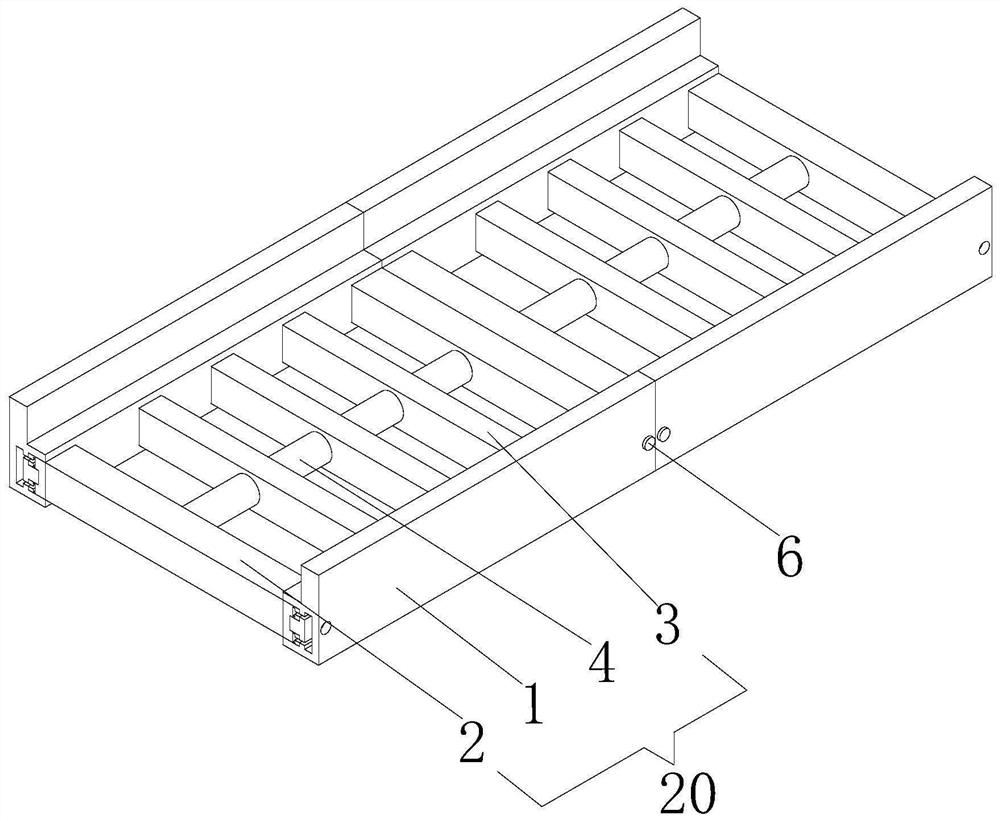

Triple grinding mechanism of garbage disposer

PendingCN112892843ANo breakageNo loosenessDomestic plumbingGrain treatmentsStructural engineeringKnife blades

The invention discloses a triple grinding mechanism of a of garbage disposer. The triple grinding mechanism comprises an upper grinding cavity, a grinding and cutting unit and a lower grinding cavity, wherein the upper grinding cavity is arranged at the upper end of the lower grinding cavity and fixedly connected to the lower grinding cavity through a connecting bolt, and the upper end of the grinding and cutting unit is connected to the inner end of the upper grinding cavity in a sleeved mode; the bottom end of the grinding cutting unit is clamped to the inner end of the lower grinding cavity; the grinding cutting unit comprises a triple grinding cutter head assembly, a triple grinding gear ring assembly, a crushing cutter assembly and a cutting knife, wherein the triple grinding cutter head assembly is arranged at the inner end of the triple grinding gear ring assembly, and blades of the crushing cutter assembly are inserted into the upper end of the triple grinding cutter head assembly through inserting grooves in the bottom end of the triple grinding cutter head assembly. The fixing performance of the crushing cutter assembly and the cutter head assembly can be effectively improved, so that a phenomenon that the crushing cutter assembly is very prone to loosening after long-time use is avoided, the crushing cutter assembly does not shake for a long time in the use process, and the crushing cutter can be ensured to be not damaged after being ground by many times.

Owner:江苏厨房宝电器有限公司

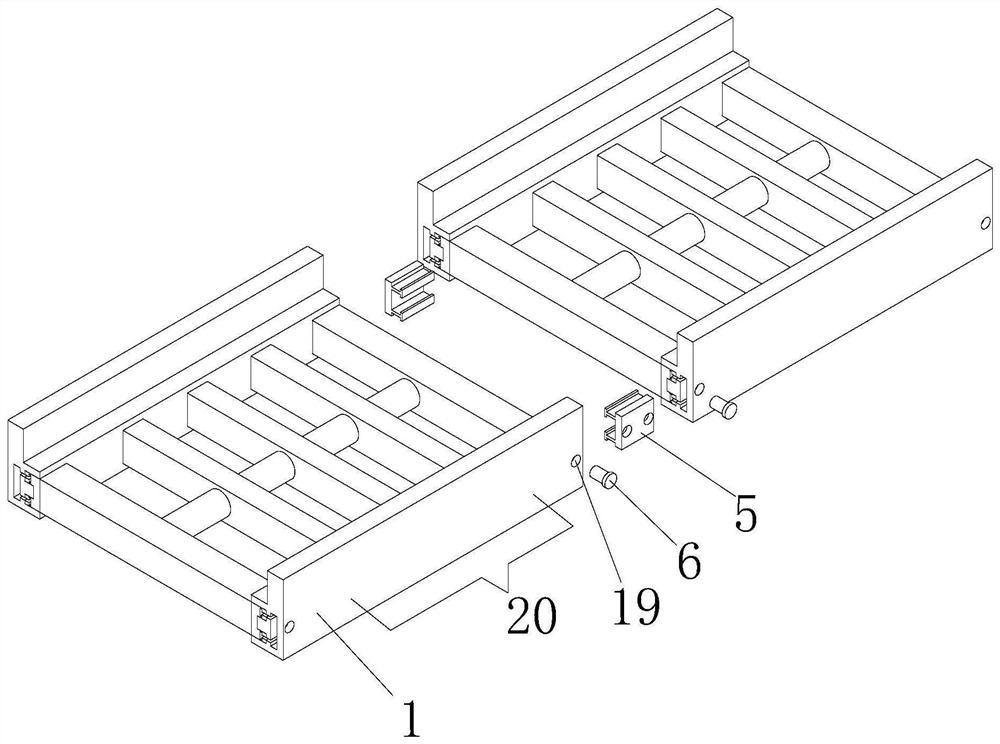

Mortise and tenon joint structure facilitating splicing and inserting of welded steel plates

The invention relates to the technical field of auxiliary equipment of laser cutting machines, and discloses a mortise and tenon joint structure facilitating splicing and inserting of welded steel plates. The mortise and tenon joint structure comprises a lathe bed body, and the lathe bed body comprises supporting bottom plates, butt joint plates, connecting plates and connecting rods. The butt joint plates are correspondingly arranged on the front side and the rear side between the two supporting bottom plates, the connecting plates are arranged between the two supporting bottom plates, connecting grooves are correspondingly formed in the connecting plates, the connecting grooves of the connecting plates movably sleeve the connecting rods, mortise and tenon joint mechanisms are arranged on the butt joint plates, and a splicing mechanism is arranged between the lathe bed body. According to the mortise and tenon joint structure facilitating splicing and inserting of the welded steel plates, when the lathe bed body is welded and fixed, only the positions where pins are installed need to be welded, in this way, the lathe bed body can be fixed, the working intensity of workers during welding is reduced, stress deformation during welding is reduced, the strength of the lathe bed body is improved, and then the stability of the lathe bed body is improved.

Owner:山东标度智能装备有限公司

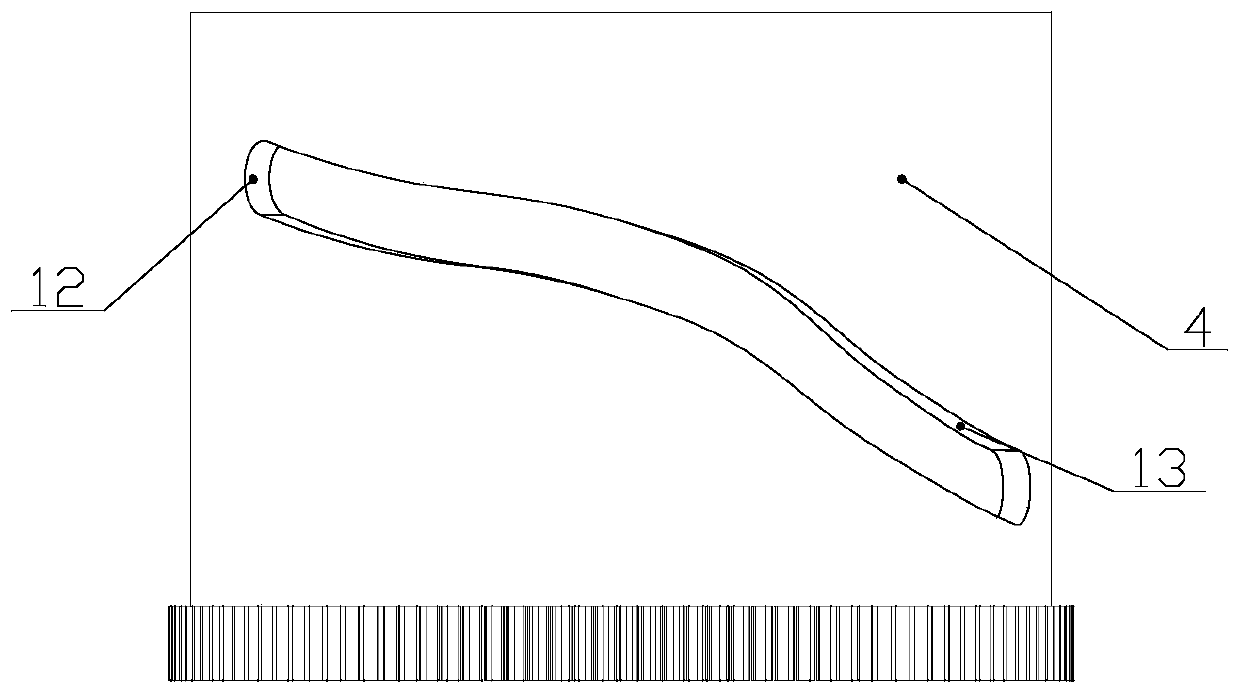

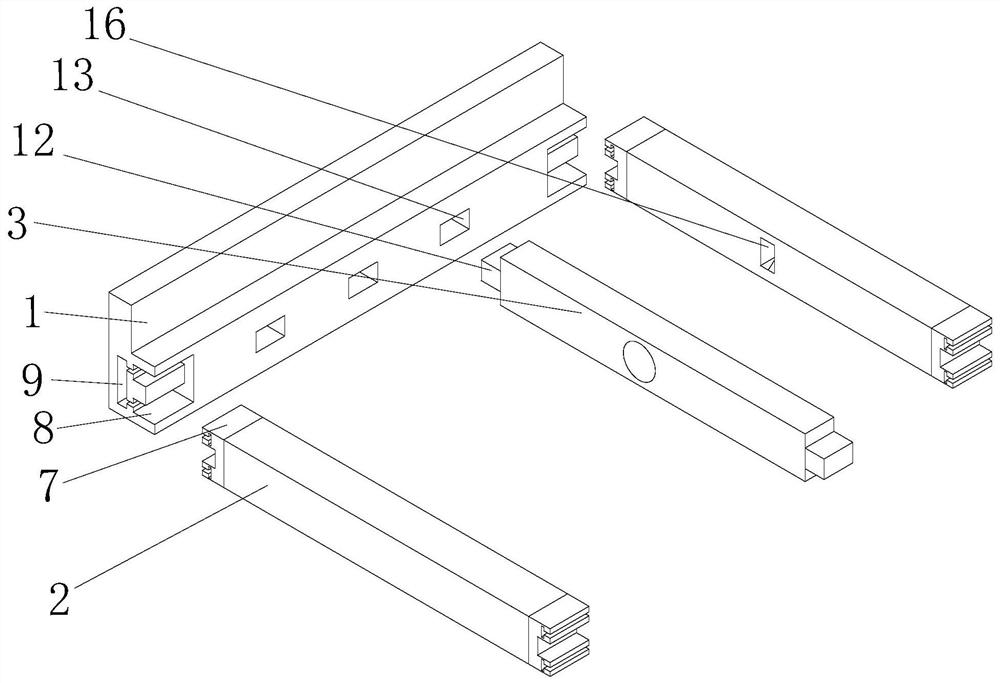

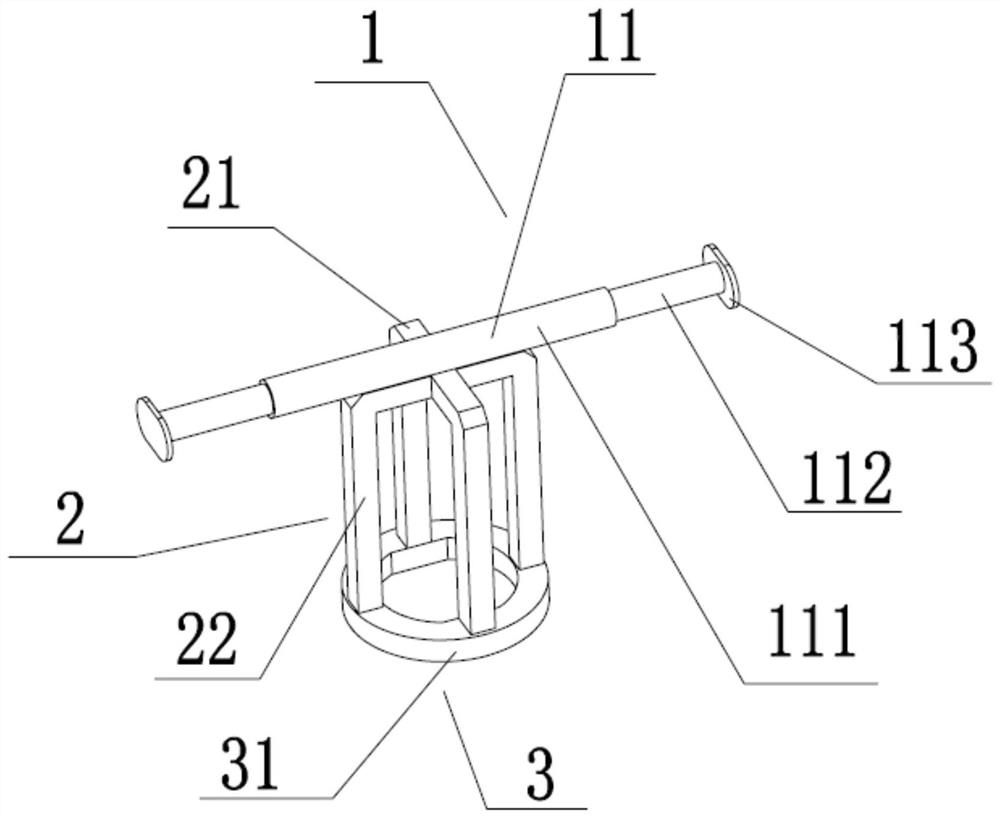

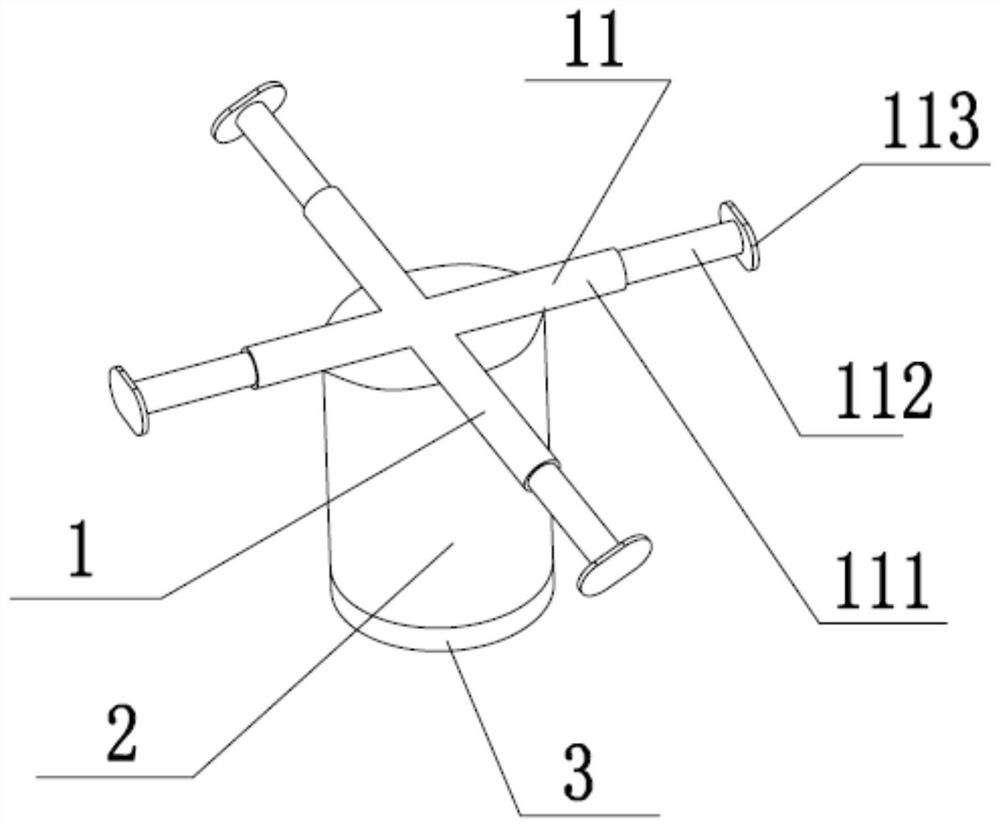

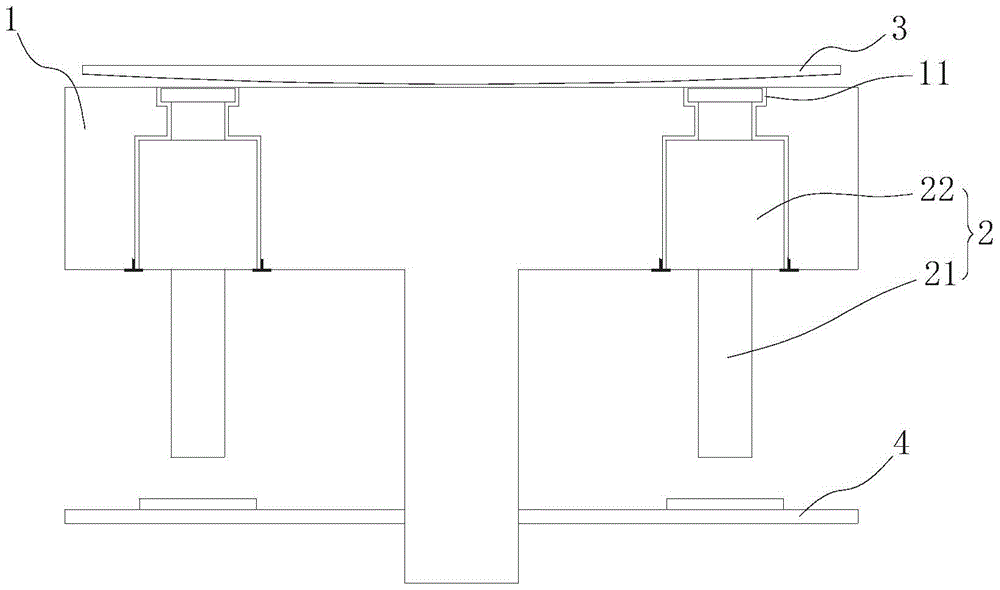

Supporting arm

ActiveCN113464805AReduce contact areaReduced risk of stuckStands/trestlesPivotal connectionsMedicineApparatus instruments

The invention provides a supporting arm. The supporting arm is used for connecting a control host and a medical instrument, and comprises a body, an arm body, a spherical hinge, an adjusting assembly and a locking piece, wherein the body is used for being connected with the control host. The arm body is connected with the body. The spherical hinge comprises a ball seat arranged at the far end, away from the body, of the arm body and a ball head rotationally arranged on the ball seat, and the ball head is used for being connected with the medical instrument. The adjusting assembly is arranged in the body and has a locking state and a loosening state. The locking piece is movably arranged in the arm body and is matched with the spherical hinge. The locking piece is configured to press or release the ball head in response to the change of the adjusting assembly between the loose state and the locking state. A non-metal stopping block is arranged on the inner wall, matched with the ball head, of the ball seat, and the non-metal stopping block abuts against the ball head when the locking piece responds to the change of the adjusting assembly from the loose state to the locking state. The adjusting assembly comprises a triggering piece which is movably arranged in the body and abuts against the locking piece and an executing piece which is arranged on the body and used for driving the triggering piece to move, and the triggering piece and the locking piece are in surface-surface contact.

Owner:MAGASSIST CO LTD

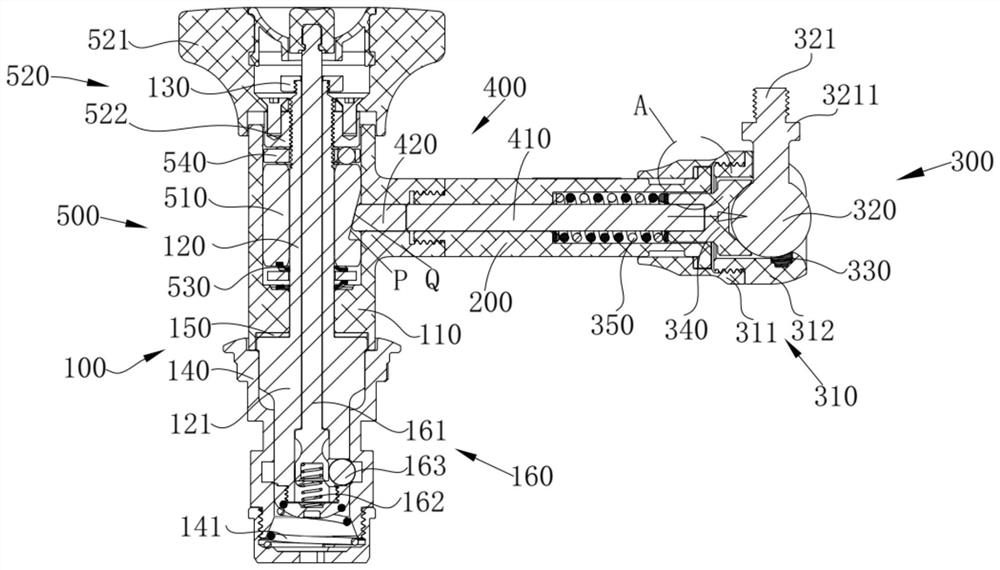

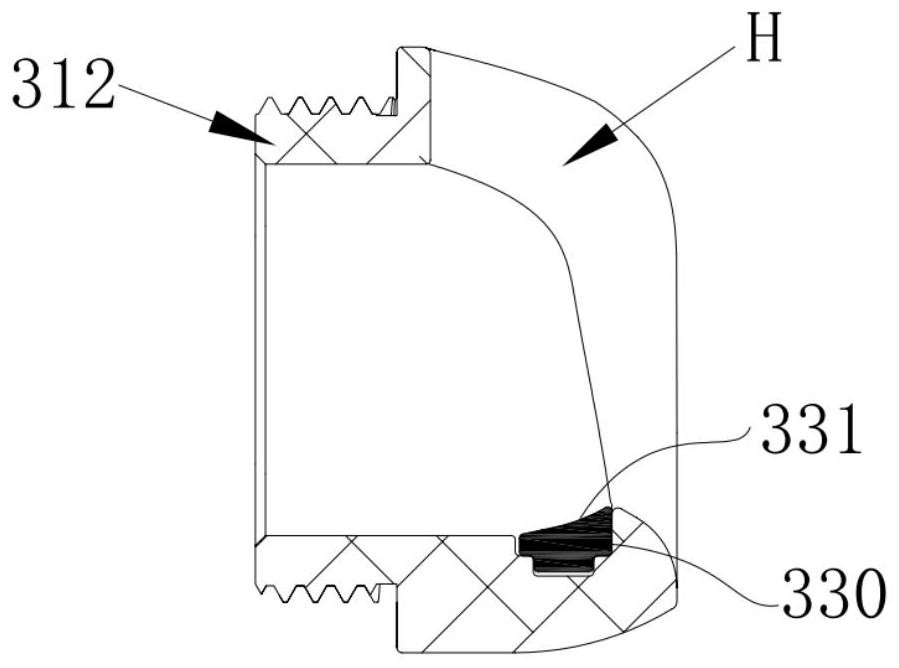

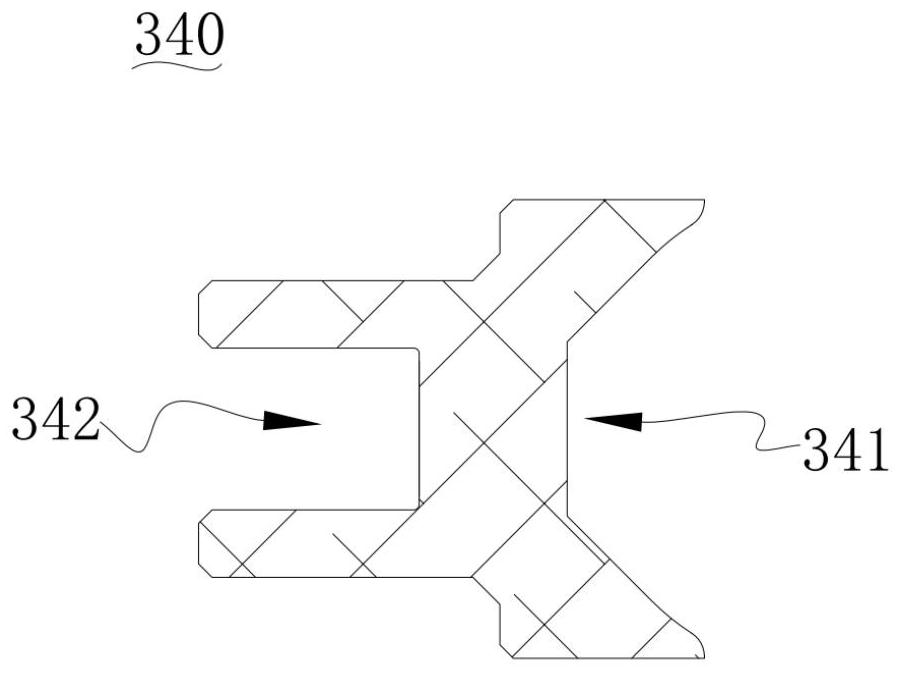

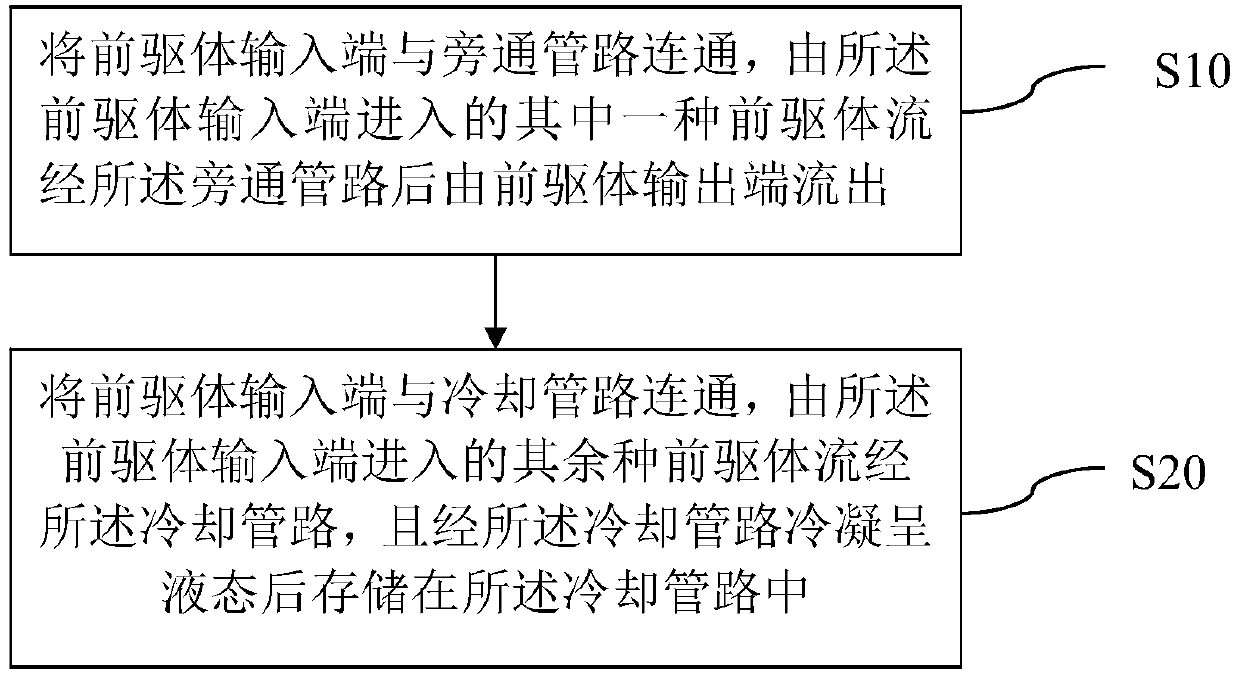

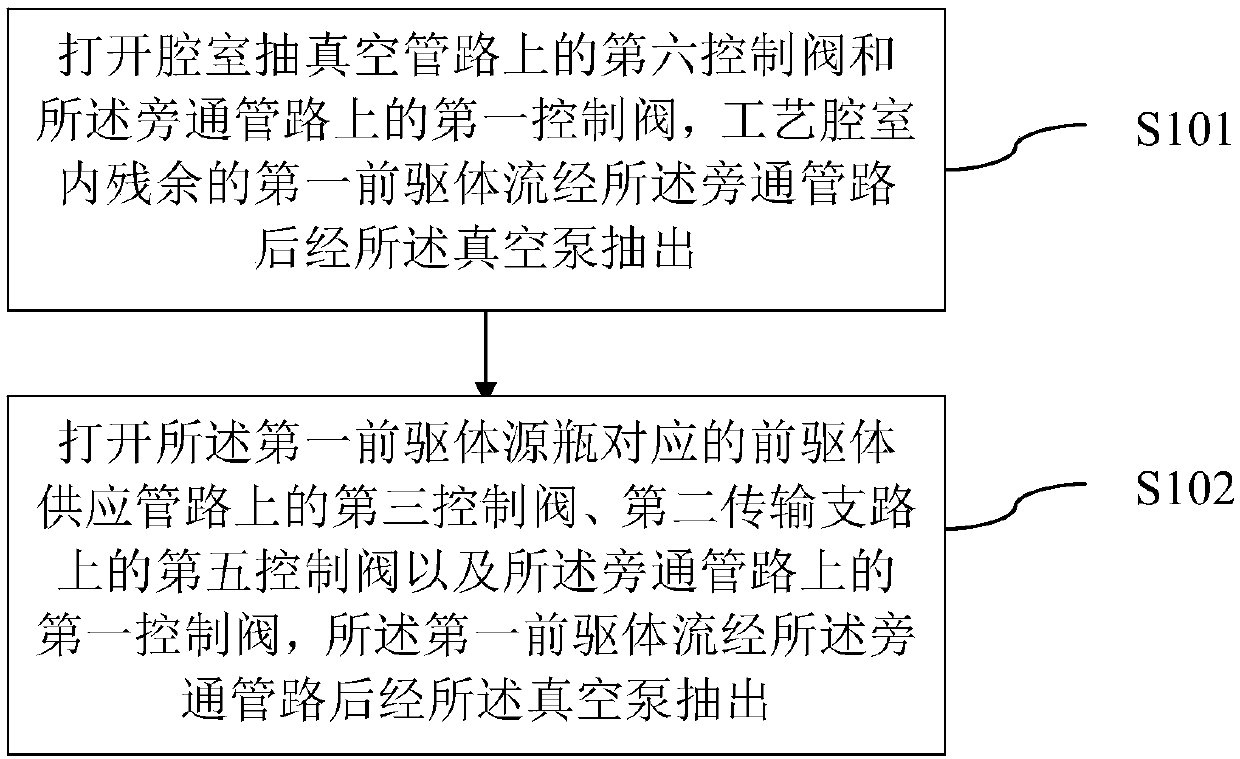

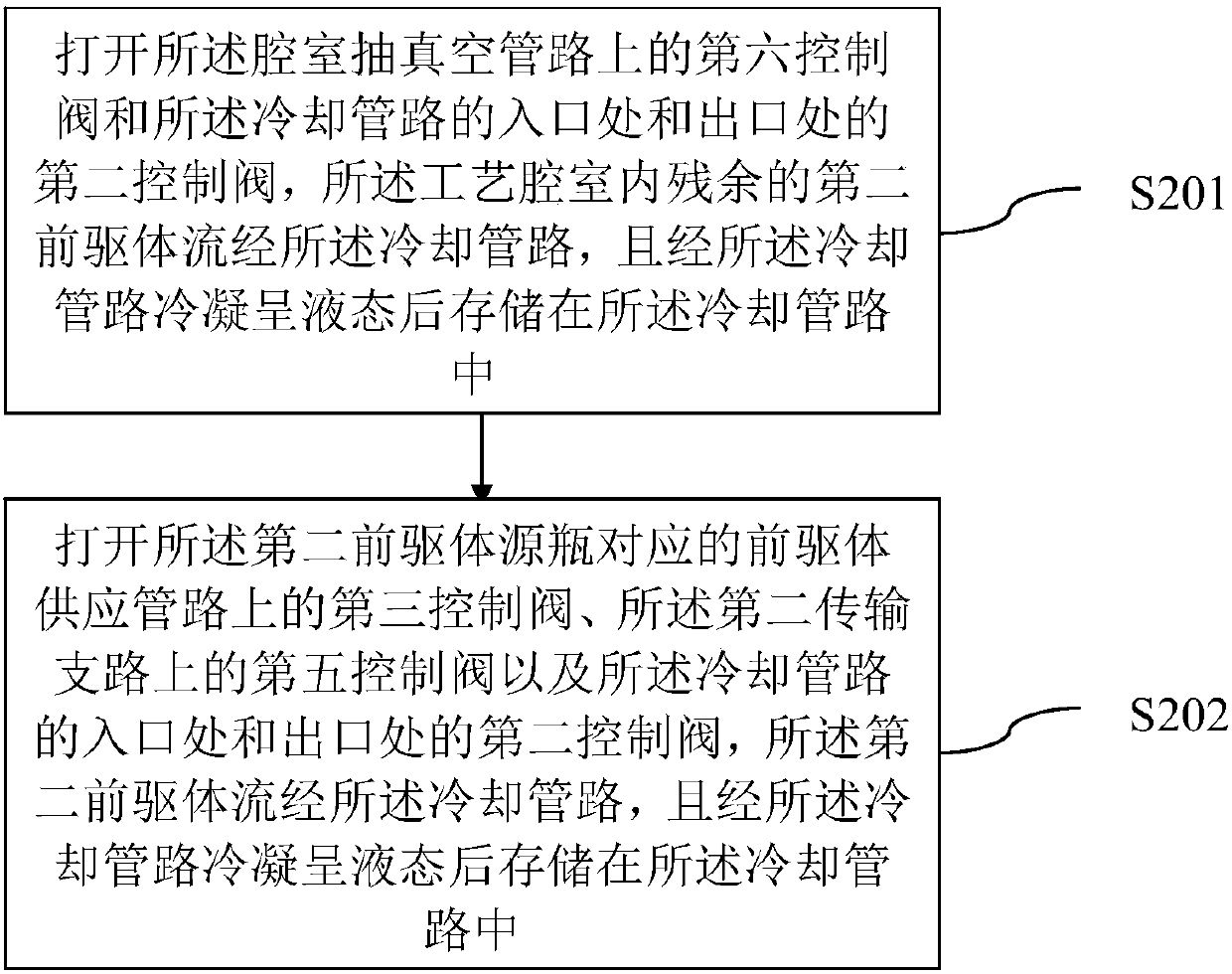

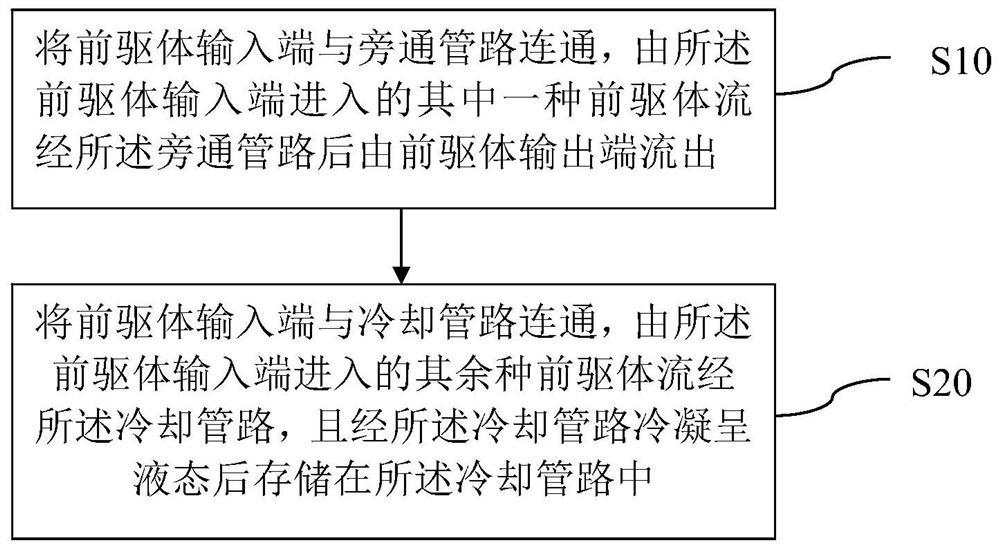

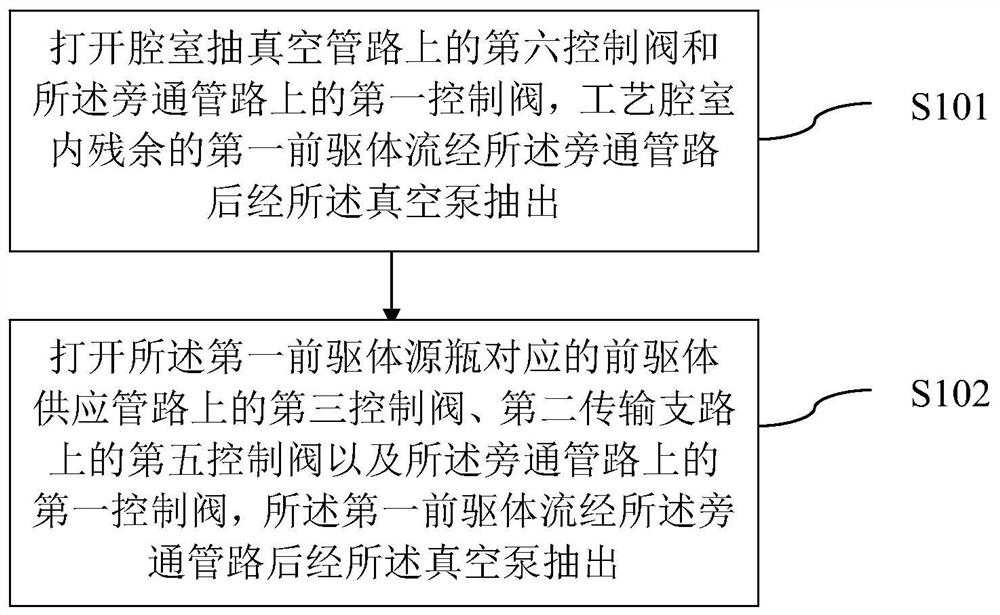

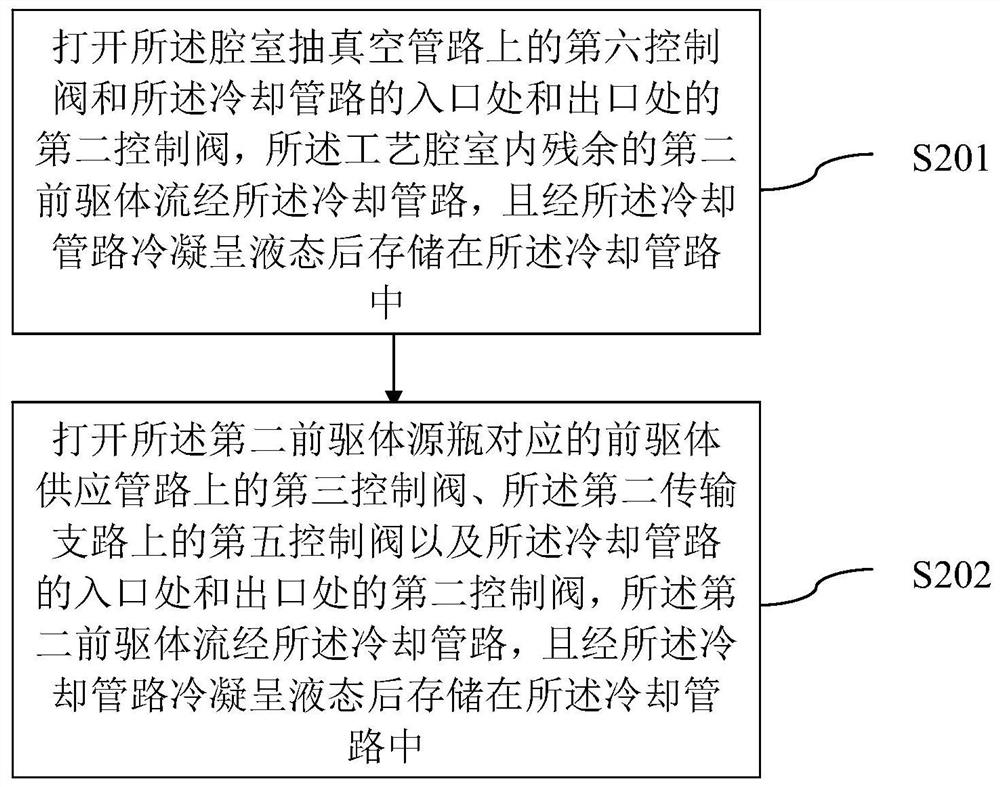

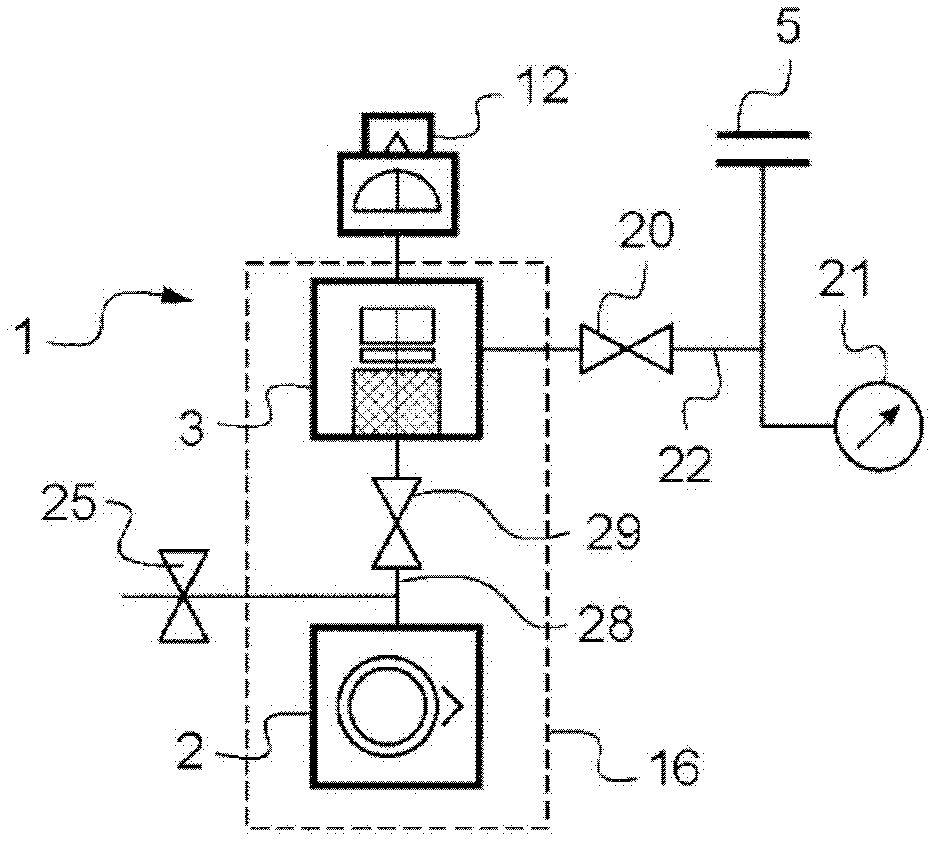

Atomic layer deposition equipment and gas transmission method

ActiveCN110387537AAvoid enteringReduced risk of stuckChemical vapor deposition coatingEngineeringVacuum pump

The invention discloses atomic layer deposition equipment and a gas transmission method. The equipment comprises a bypass pipeline and a cooling pipeline, wherein the cooling pipeline is used for condensing and storing at least one precursor, the bypass pipeline and the cooling pipeline are connected in parallel and then are connected between precursor input ends and precursor output ends, and theprecursor input ends selectively communicates with the bypass pipeline or the cooling pipeline. According to the atomic layer deposition equipment, the cooling pipeline is arranged to condense the precursor flowing through the pipeline, and the precursor is stored in the pipeline, so that a plurality of precursors are prevented from entering a vacuum pump at the same time, powder caused by reaction of multiple precursors in the vacuum pump is reduced, the risk that the vacuum pump is stuck due to powder accumulation is reduced, and the operation reliability and the service life of the vacuumpump are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

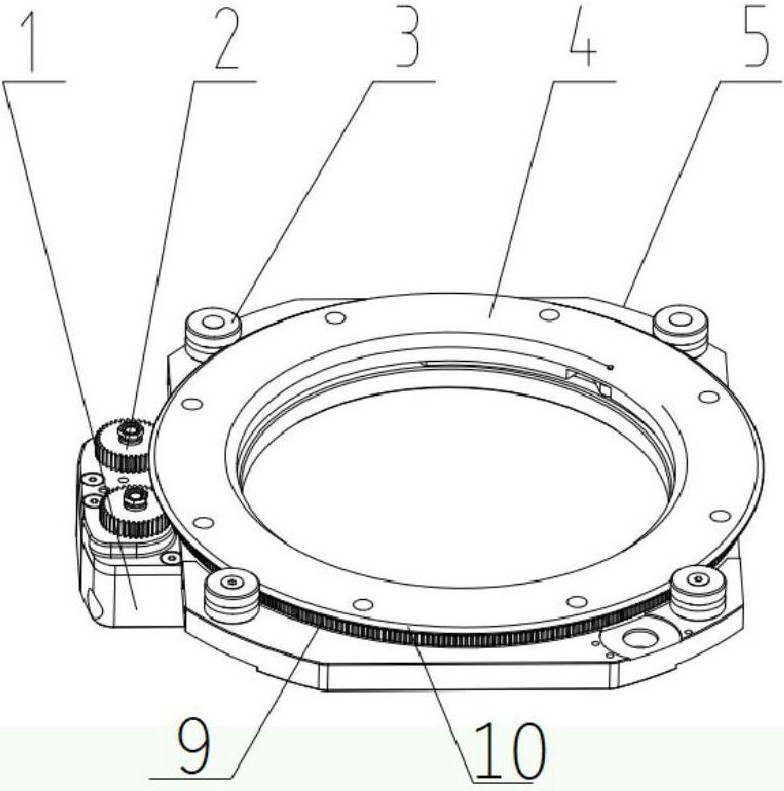

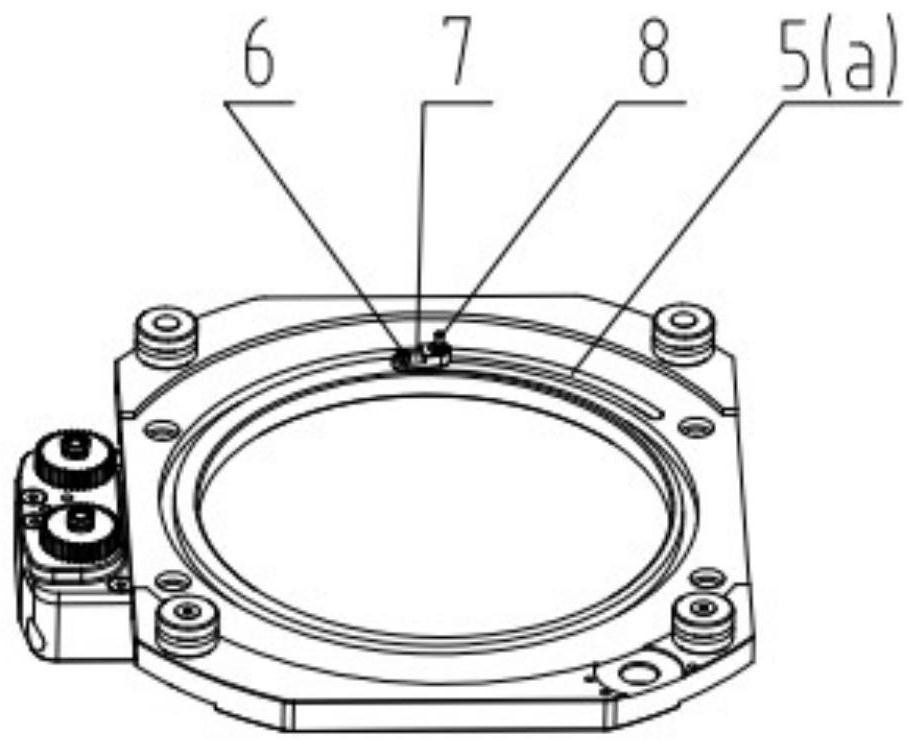

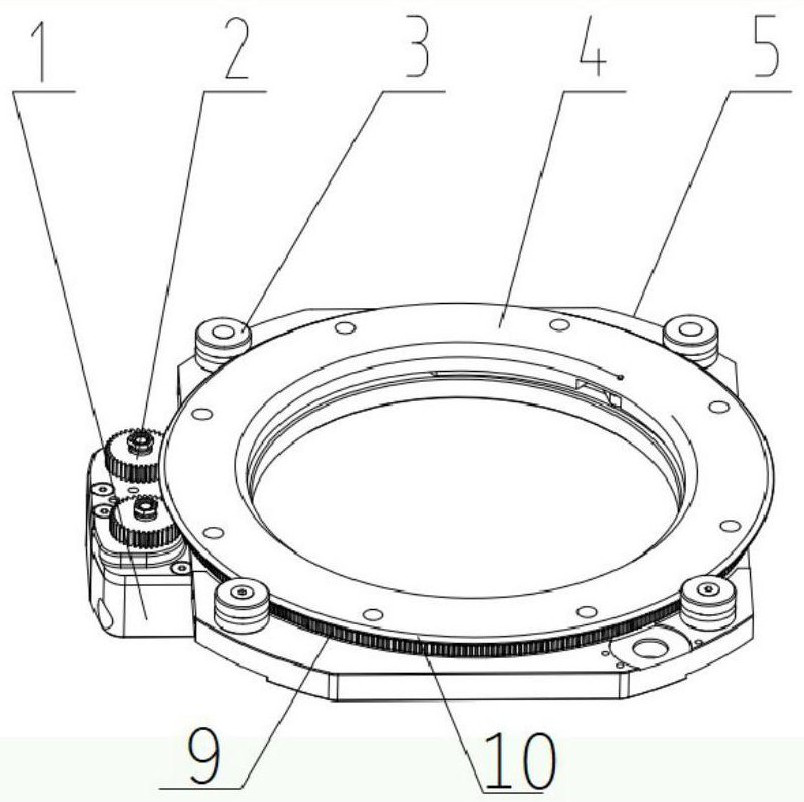

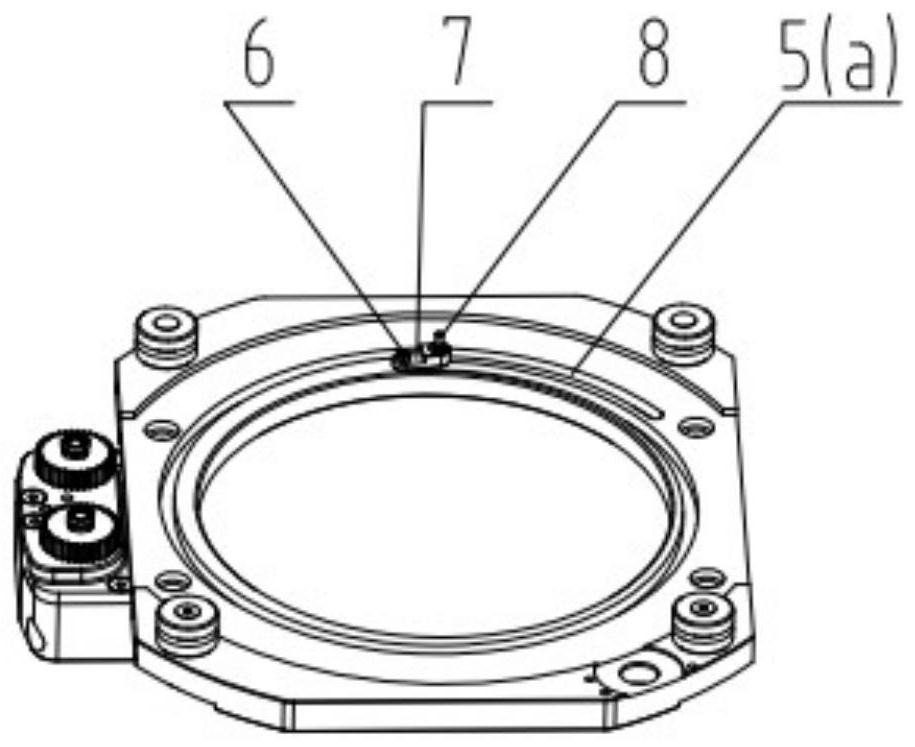

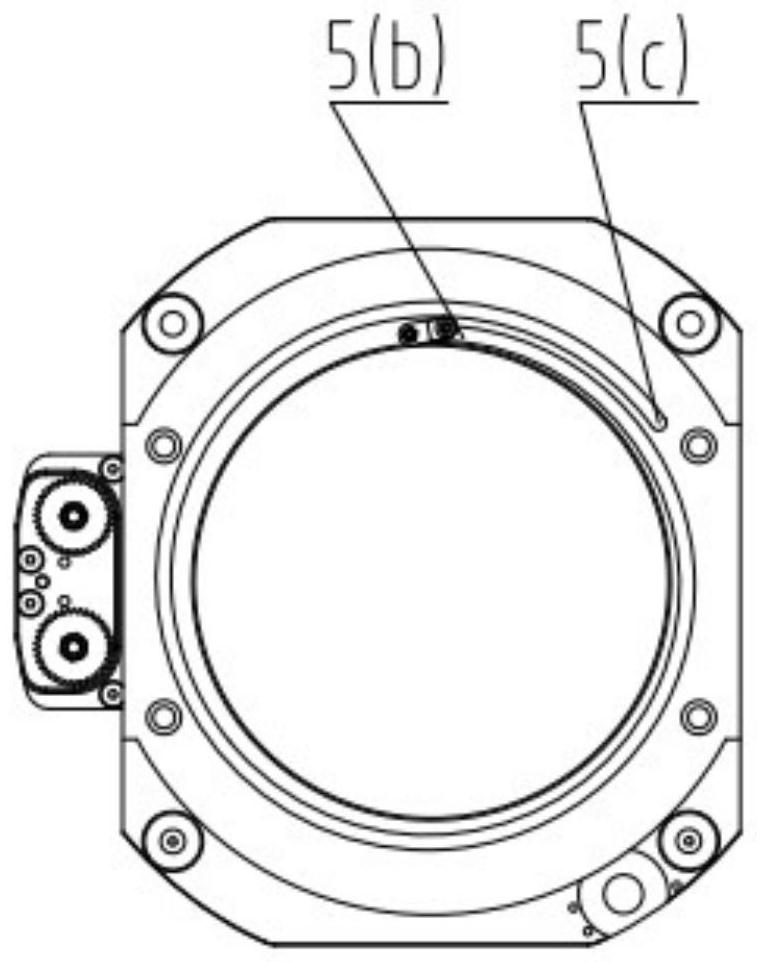

Circumferential rotation limiting mechanism

ActiveCN112413320AReduce volumeGood for NDTMeasurement apparatus componentsStands/trestlesEngineeringIdler-wheel

The invention discloses a circumferential rotation limiting mechanism. The limiting mechanism comprises a fixed disc, a rotating disc rotationally connected to the fixed disc, a rotating assembly enabling the rotating disc to be rotationally connected with the fixed disc, and a driving assembly used for driving the rotating disc to rotate, and a spiral limiting groove is formed in the fixed disc or the rotating disc. The limiting mechanism further comprises an idler wheel connected into the limiting groove in a rolling manner in the spiral extending direction of the limiting groove, a swing base located above the limiting groove and coaxially and fixedly connected with the idler wheel, and a rotating pin with two ends rotationally connected with the swing base and the rotating disc respectively. Physical limiting is achieved, transmission is smoother, the jamming risk is greatly reduced, the overall size of the mechanism can be reduced, and nondestructive testing in a small space is facilitated.

Owner:CGNPC INSPECTION TECH +3

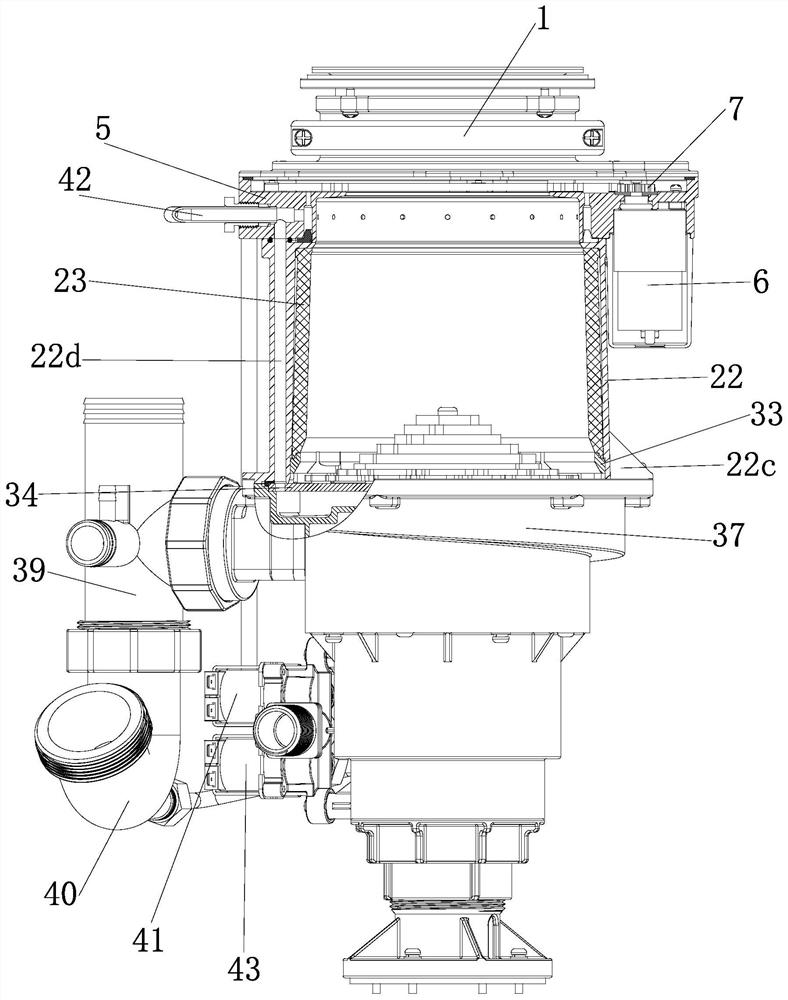

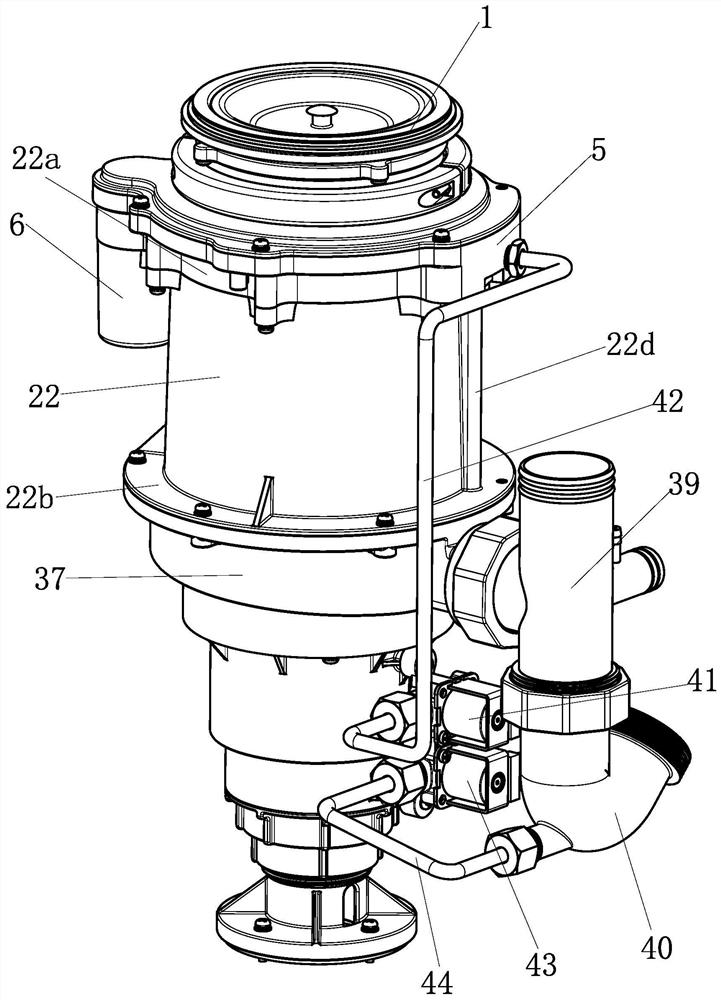

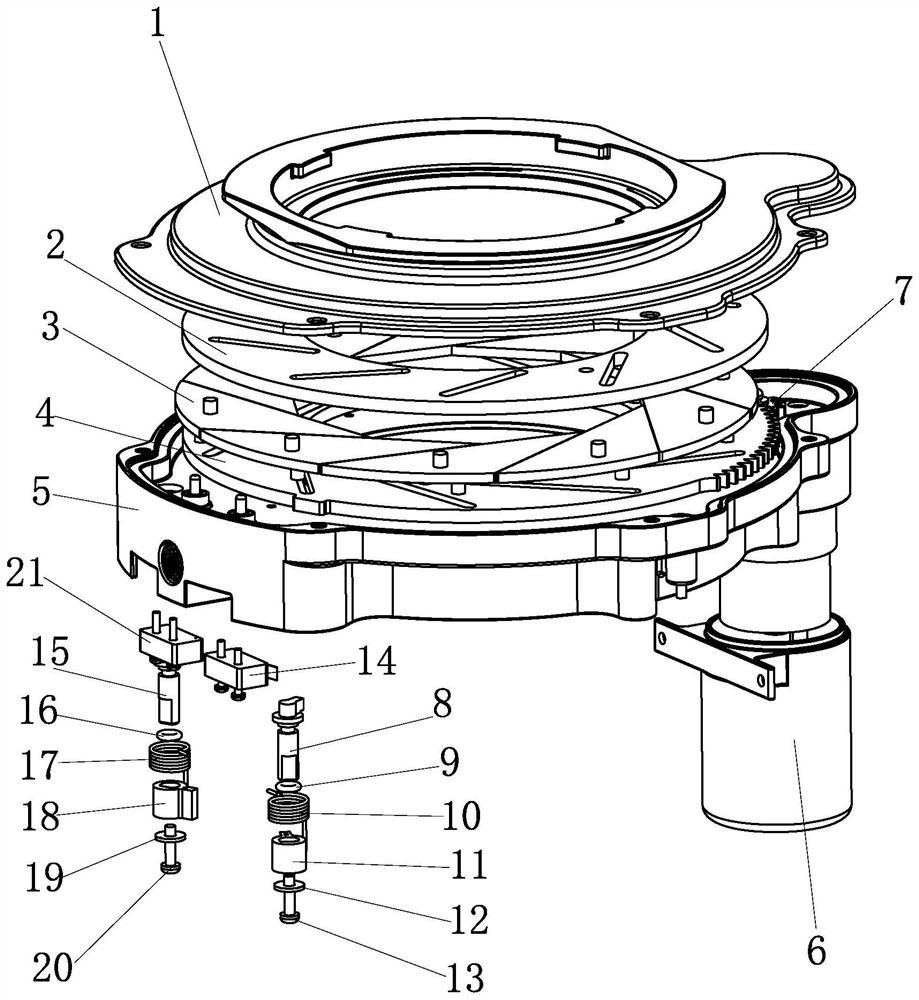

Multifunctional garbage processor and operation method thereof

The invention provides a multifunctional garbage disposer and an operation method thereof. The multifunctional garbage disposer comprises an opening and closing mechanism, a smashing cylinder and a drainage cylinder and further comprises a water inlet mechanism, wherein a silent smashing mechanism is arranged in the smashing cylinder; the opening and closing mechanism comprises an opening and closing cover and a fixing base; an opening and closing motor driving gear is meshed with an arc-shaped rack of a rotating disk; a plurality of opening and closing sheets are clamped between a fixed disk and the rotating disk; a full-open touch assembly is arranged on the fixing base and is in touch connection with a full-open microswitch; a full-closed touch assembly is in touch connection with a full-closed microswitch; the silent smashing mechanism comprises a lining cylinder and a smashing gear ring which are arranged in the smashing cylinder, and a smashing motor is fixedly arranged at the bottom of the drainage cylinder; a rotating shaft of the smashing motor is in driving connection with a first-stage cutter, a second-stage cutter assembly, a third-stage cutter and a fourth-stage cutter assembly from top to bottom; and the water inlet mechanism comprises a water inlet valve and a flushing valve, the water inlet valve communicates with a water guide passage of the fixing base through a water inlet pipe, the water guide passage is provided with an ascending through hole, a middle through hole and a descending through hole, and the flushing valve communicates with a V-shaped pipe through a flushing pipe.

Owner:MARSSENGER KITCHENWARE CO LTD

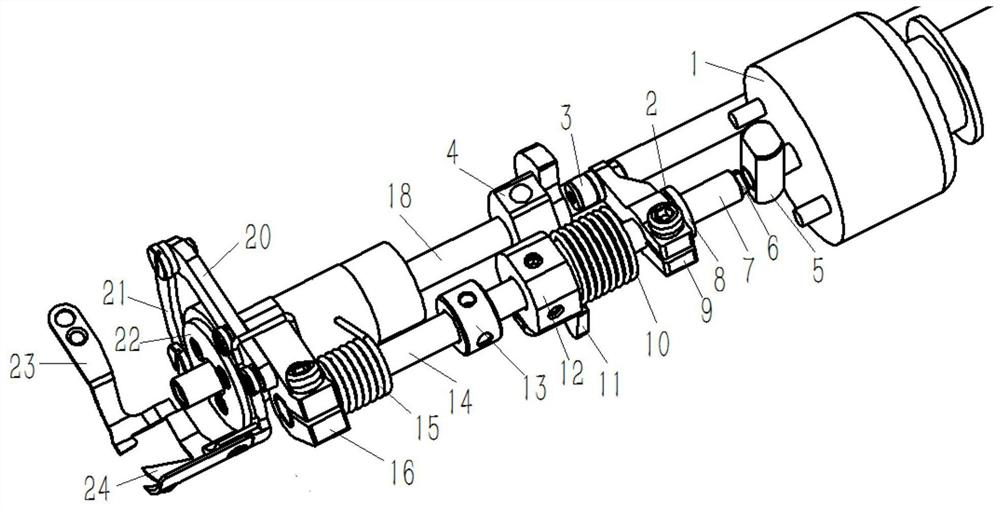

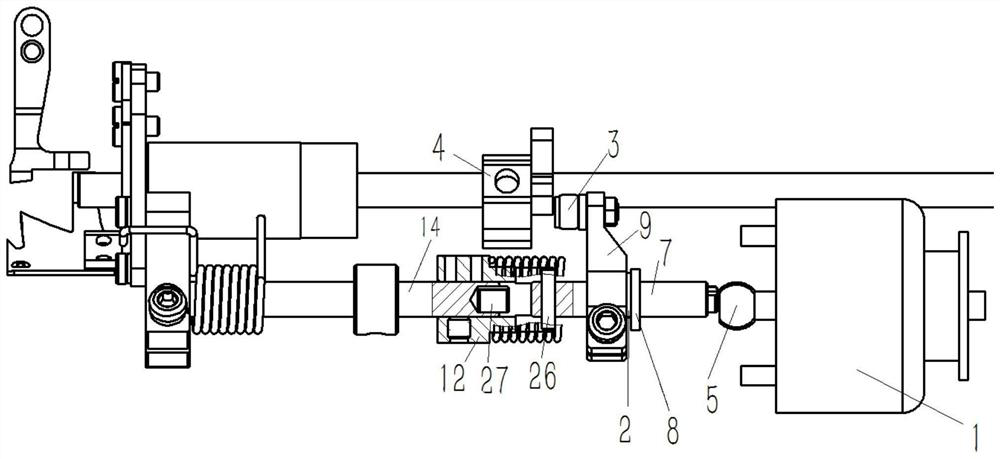

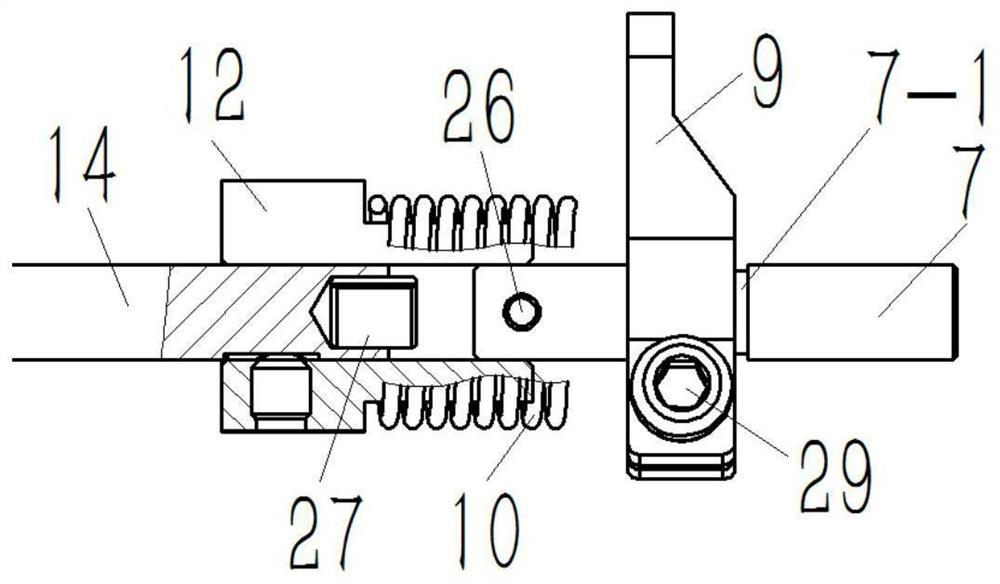

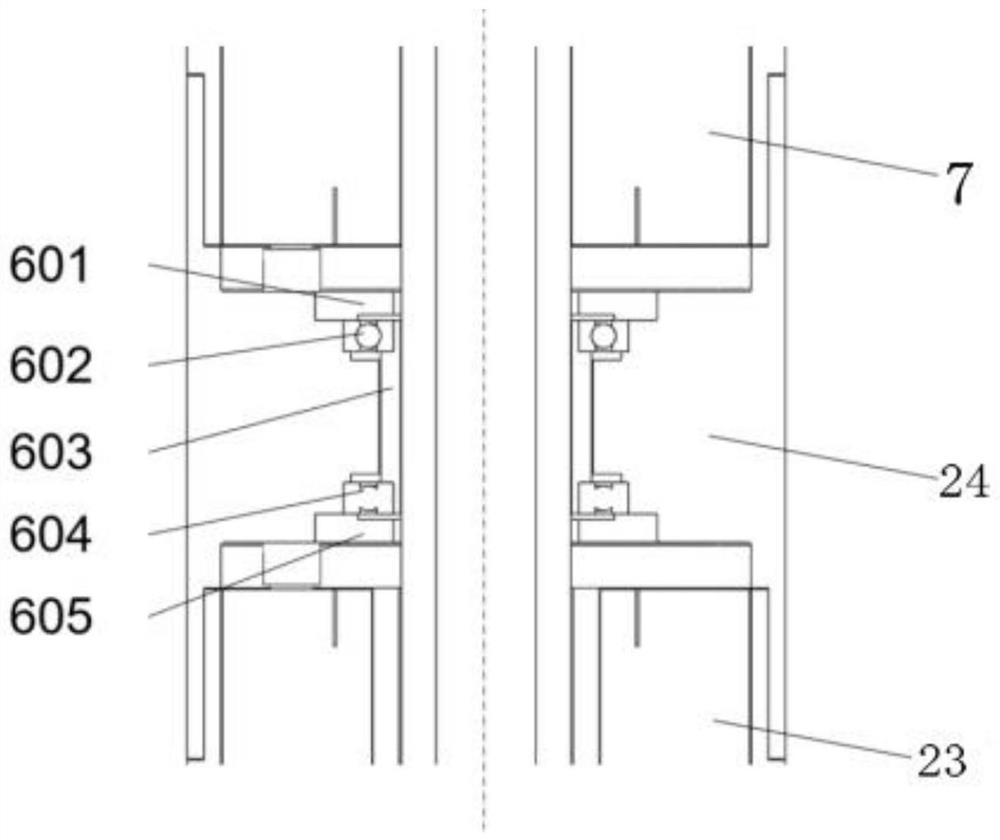

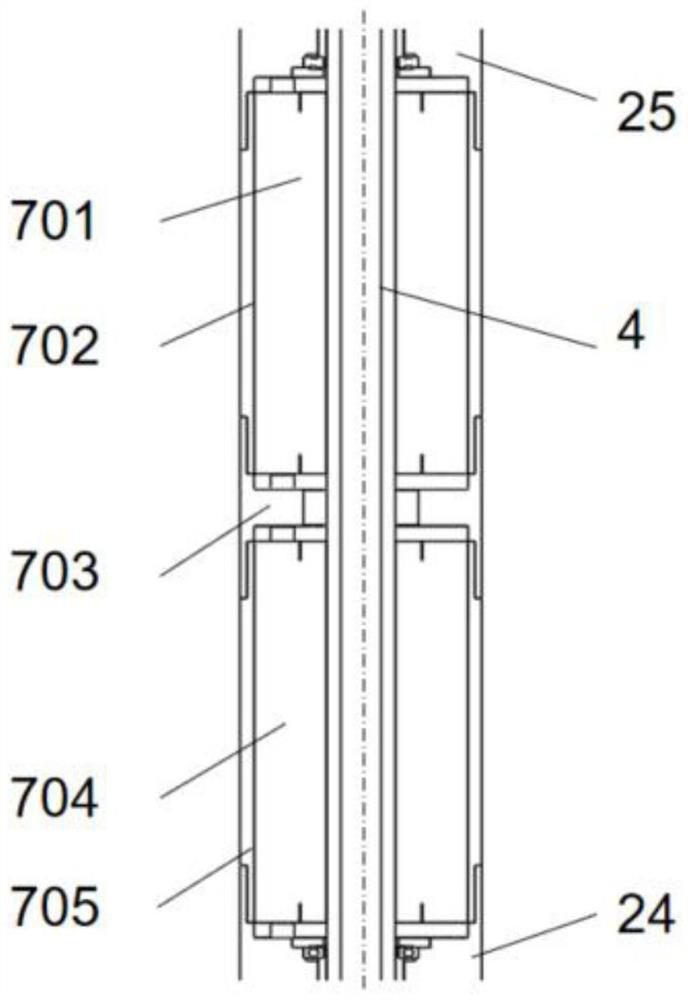

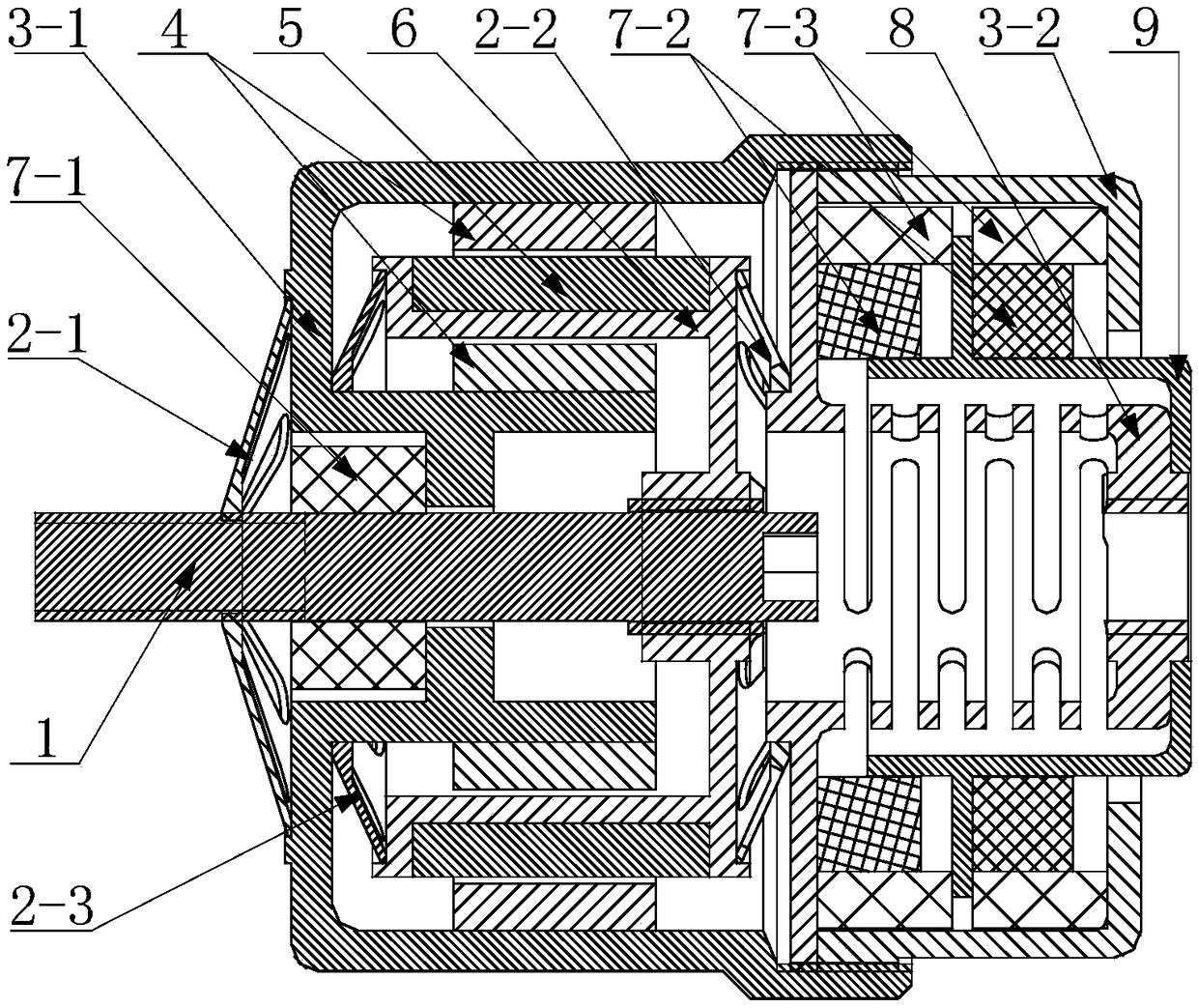

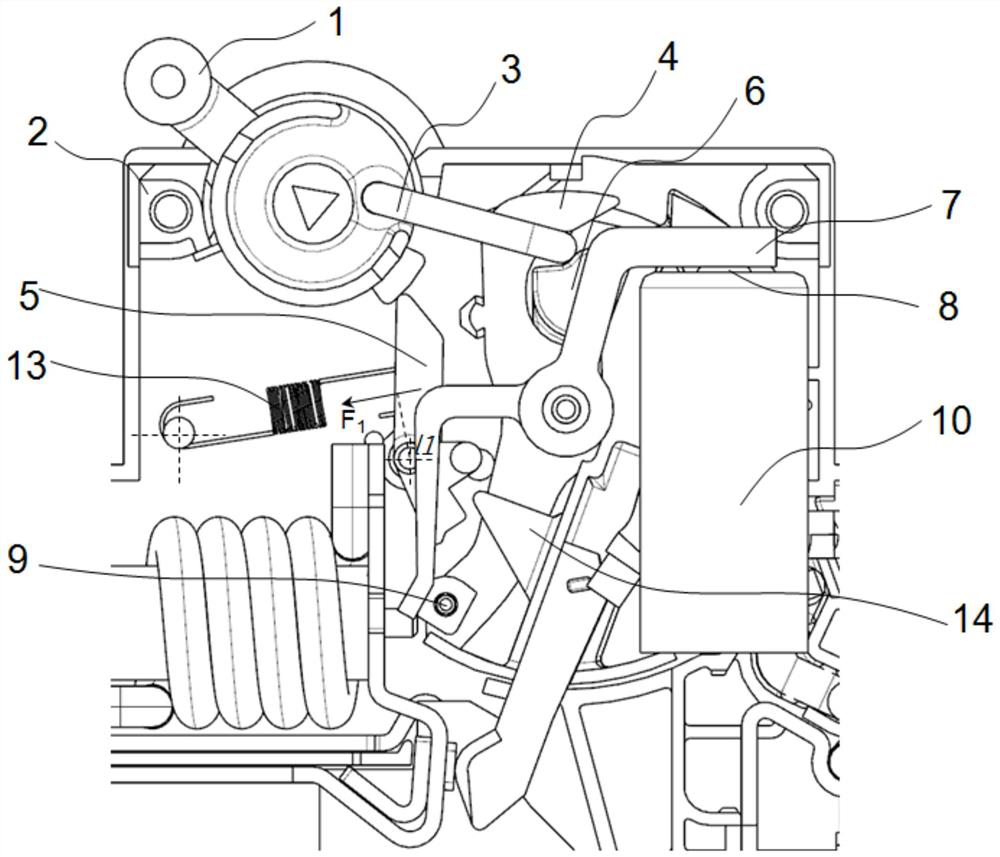

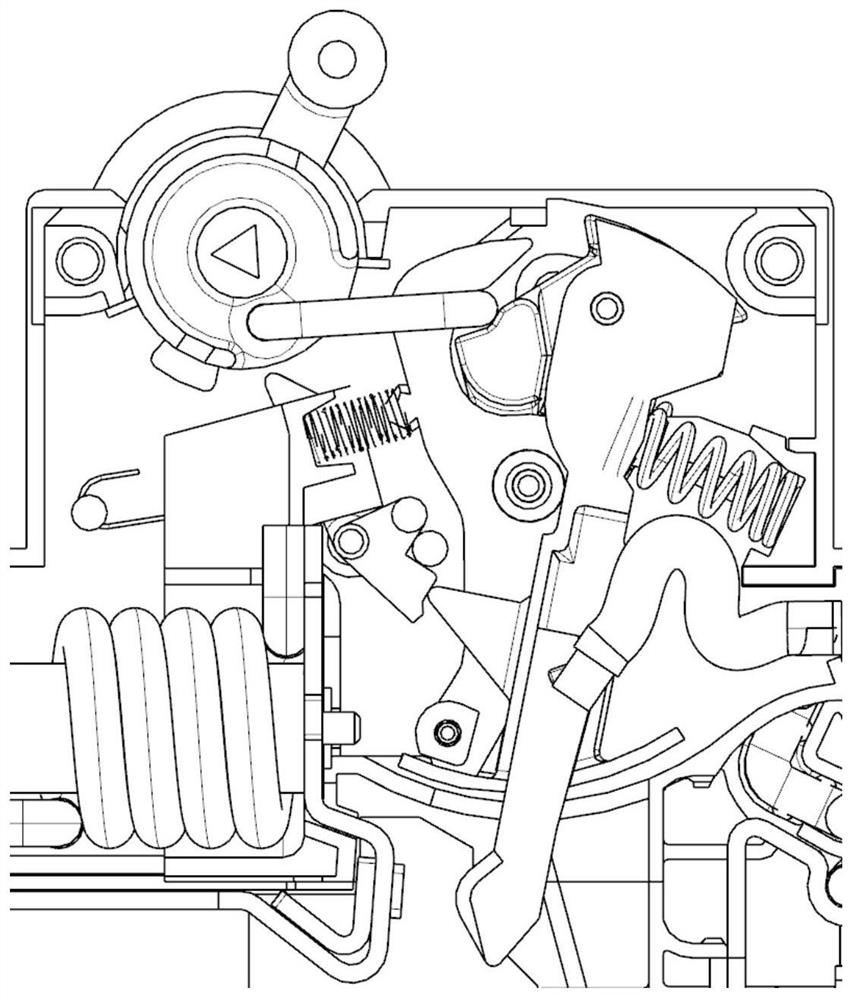

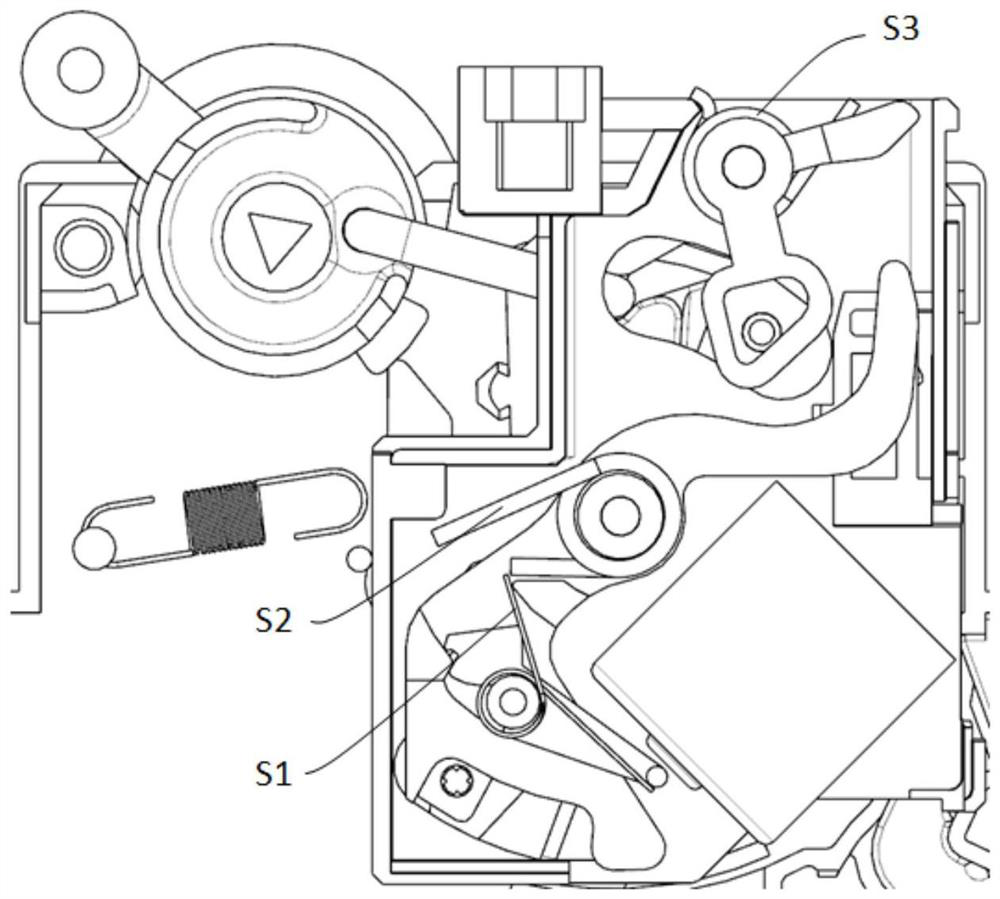

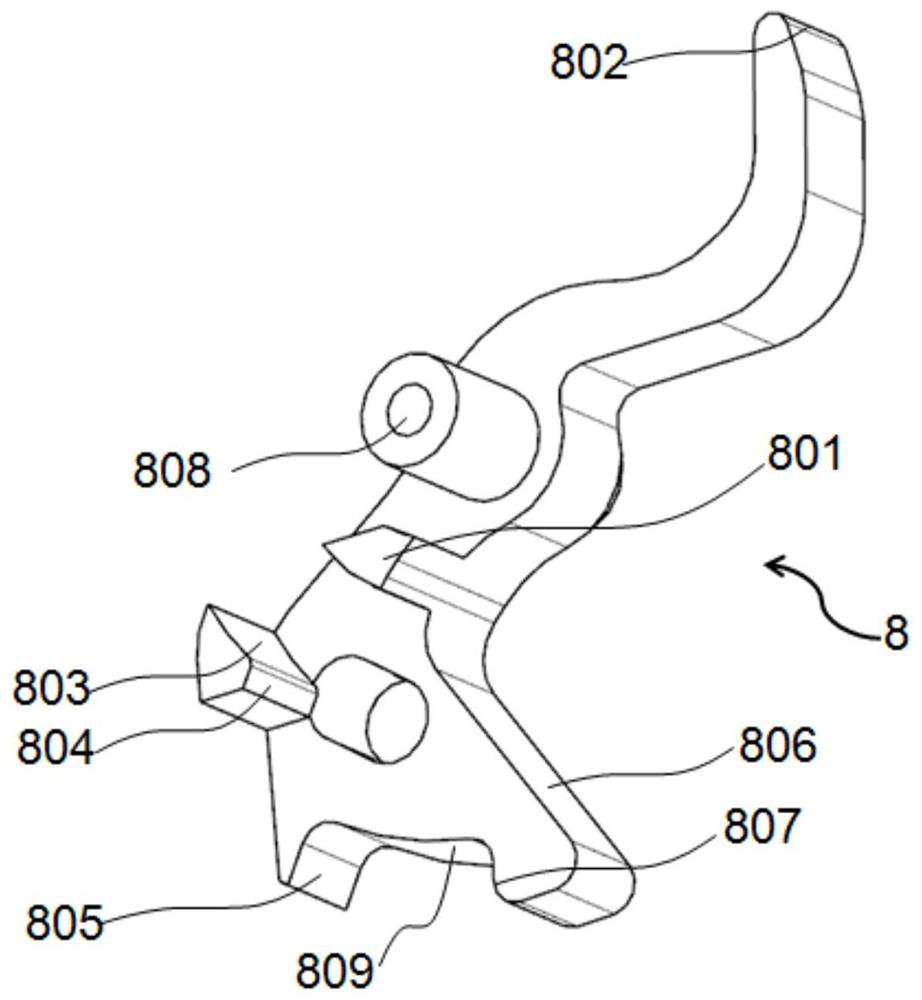

Thread trimming drive assembly, thread trimming mechanism and sewing machine

ActiveCN108193390BReduce the numberSimple structureNeedle severing devicesSewing-machine control devicesDrive shaftCrank

The invention relates to a thread shearing drive component, a thread shearing mechanism comprising the thread shearing drive component and a sewing machine comprising the thread shearing mechanism. The thread shearing drive component comprises a thread shearing shaft, a thread shearing drive crank, a drive shaft and drive cam and is characterized in that the thread shearing shaft comprises a thread shearing executing shaft and a torque transmission shaft, and the thread shearing drive crank is fixed on the torque transmission shaft; a fixed sleeve is fixed to the right end of the thread shearing executing shaft or the left end of the torque transmission shaft, the fixed sleeve is provided with an axial inner hole, and the left end of the torque transmission shaft or the right end of the thread shearing executing shaft can be slidably inserted into the axial inner hole; the torque transmission shaft or the thread shearing executing shaft is connected with the fixed sleeve through a slide connection structure. The thread shearing drive component and the thread shearing mechanism are few in parts, simple in part structure, convenient to mount, capable of effectively lowering production cost, capable of increasing assembling production efficiency and capable of greatly lowering the risk of getting stuck due to the fact that slide drive force can be allowed to act on the axis of thethread shearing shaft.

Owner:JACK SEWING MASCH CO LTD

A kind of ground subsidence shell filling material for shield tunneling and its preparation method

ActiveCN107459324BReduced risk of stuckReduce construction costsFilling materialsUltimate tensile strength

The invention discloses a stratum settlement-preventing shield shell filling material and a preparation method thereof. The stratum settlement-preventing shield shell filling material is prepared by mixing comprises a material A and a material B, wherein the material A comprises the following components: 25-30% of bentonite, 3-5% of a thickener, 3-5% of a colloidal stabilizer, 1-6% of a water-proofing agent and the balance of water; the material B comprises the following components: 45-55% of water glass and the balance of water; the volume ratio of the material A to the material B is 1:(0.8-1.2). In the filling material, the material A and the material B can be pumped according to equal volume, and after the material A and the material B meet each other and are mixed, a mixture can be quickly viscosified and has high viscosity and certain supporting strength, so that even if the material A and the material B are pumped out of a shield shell, the stratum settlement-preventing shield shell filling material can still effectively fill a gap above the shield shell and can effectively prevent the stratum settlement.

Owner:SHANDONG UNIV

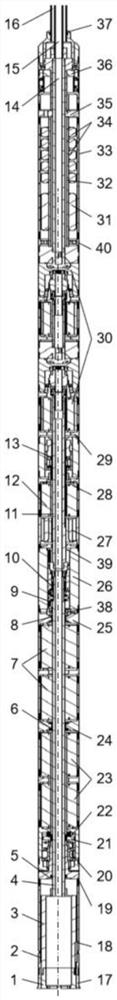

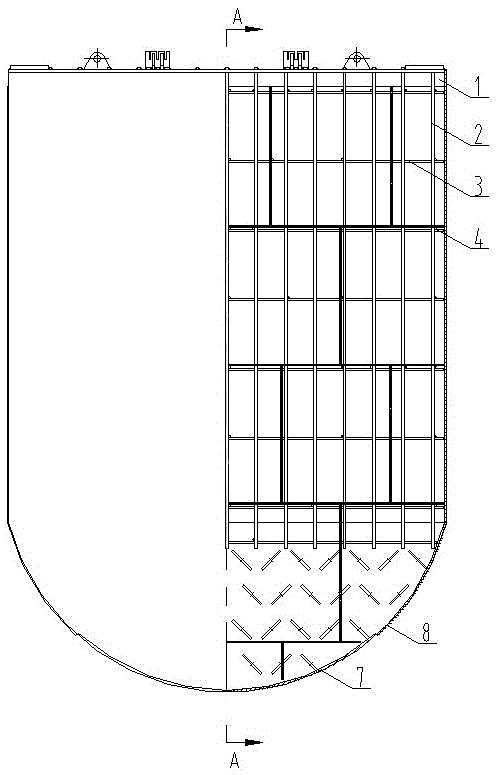

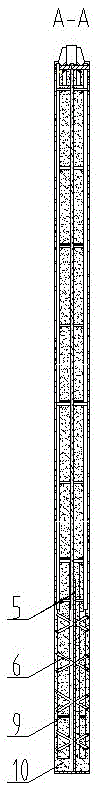

Drilling machine-free self-balancing rotary vibration coupling rock crushing drilling system

A drilling-machine-free self-balancing rotation vibration coupling rock crushing drilling system comprises an inner drill bit driving system, an outer drill bit driving system, a bit pressure distribution system and the like, an inner drill bit and an outer drill bit are driven by two motors to achieve self-balancing single rotation and self-balancing double rotation of the inner drill bit and the outer drill bit respectively, and the problem of control over self-balancing torque is solved; the drilling efficiency of the drilling system is improved by assisting double drill bits in rotary rock crushing through ultrasonic vibration, the risk that a back reaming grinding head is stuck is reduced by amplifying the output torque of a motor by multiple times through a reduction gear mechanism, and the problem that the transmission efficiency of strong current and weak current is low is solved by canceling a conductive slip ring. The back reaming drill bit has the following advantages that the vibration and rotation drilling efficiency is high, the inner drill bit and the outer drill bit rotate at the same time, self-balancing control is easy, the back reaming grinding head is not prone to being stuck due to large rotation torsion, the transmission efficiency of strong and weak electricity in a drilling system is high and stable, and the drilling reliability and efficiency are improved.

Owner:JILIN UNIV

Transformer tap screw tightening and loosening tool

InactiveCN112589732AEven by forceReduced risk of stuckMetal-working hand toolsTransformerEngineering

The invention relates to the technical field of tap auxiliary tools of transformers, in particular to a transformer tap screw tightening and loosening tool which comprises a force application part, aconnecting part and a fixing part which are sequentially connected from top to bottom and used for enabling the whole tool to rotate. The force application part is a handle symmetrically arranged about the central axis of the connecting part; and the handle is of a telescopic structure. The invention aims to overcome the defects of the prior art, and provides the tool for simultaneously applying force to the handle by two hands to enable the device to drive a screw to rotate so as to fasten the screw, so that on one hand, the screw can be stressed uniformly in the fastening process and is noteasy to block, and on the other hand, the screw can be rotated in a more labor-saving manner.

Owner:GUANGDONG POWER GRID CO LTD +1

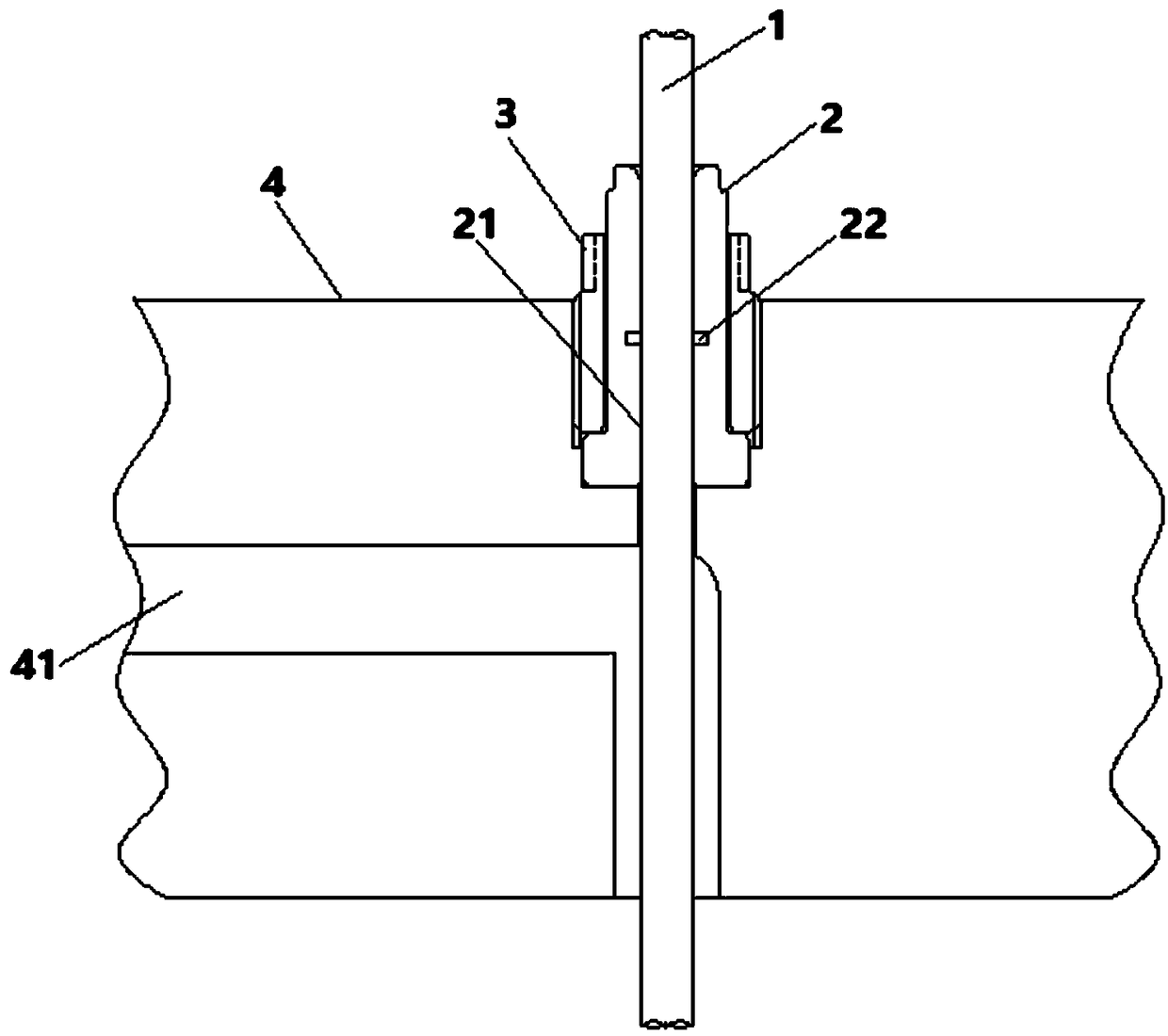

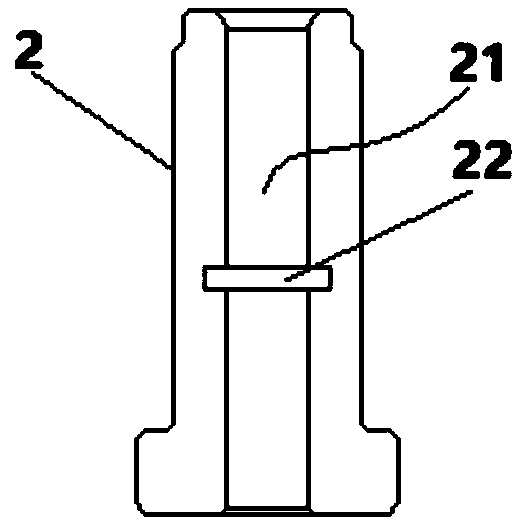

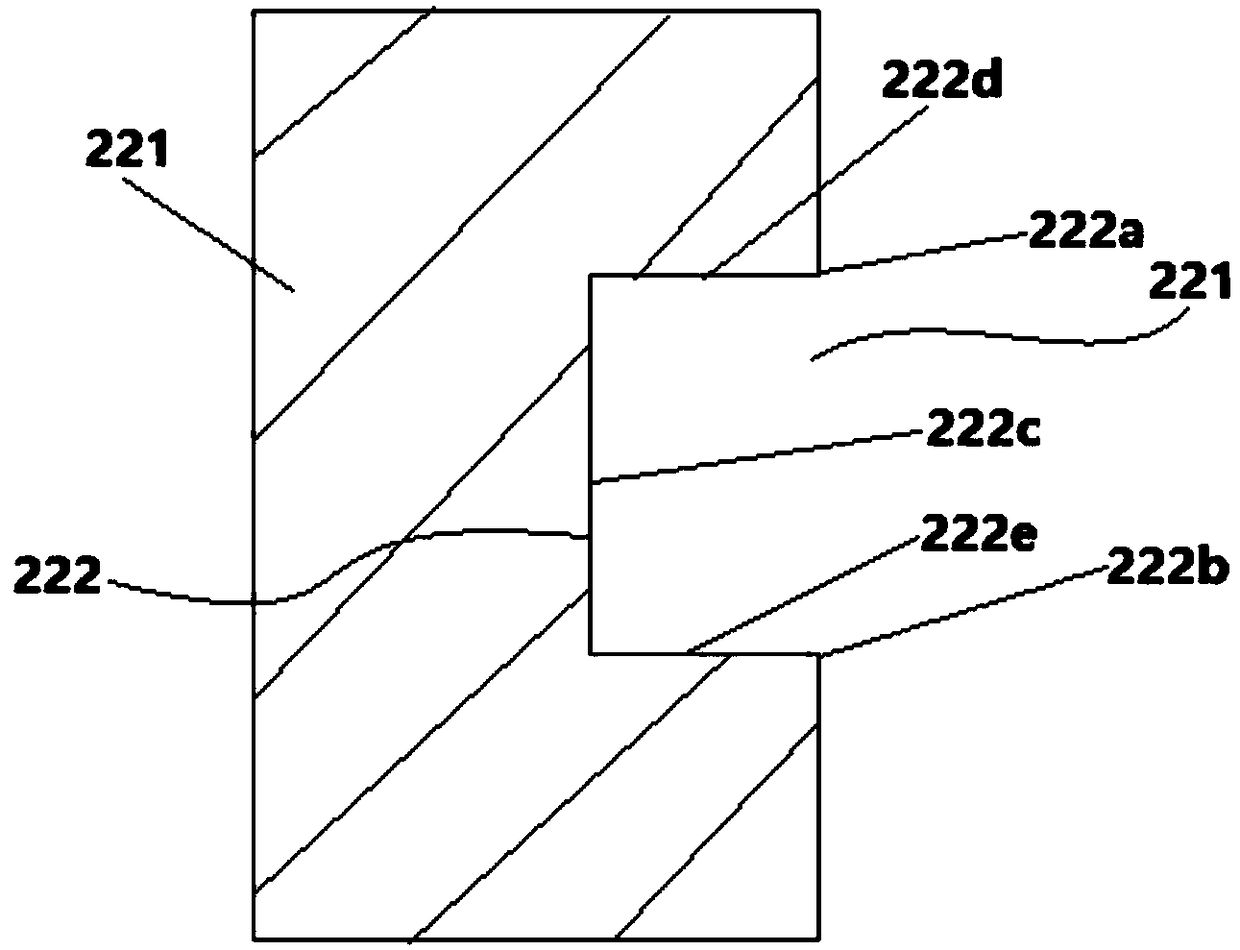

Valve needle guiding sleeve assembly and hot channel system therewith

InactiveCN109366902AReduce fit precision requirementsReduced risk of stuckHot runnerThermal expansion

The invention discloses a valve needle guiding sleeve assembly. The valve needle guiding sleeve assembly comprises a valve needle and a guiding sleeve, wherein the guiding sleeve includes a lengthwaysthrough hole and an inner wall, and the through hole is defined by the inner wall; the valve needle is movably penetrates through the through hole in the longitudinal direction; the guiding sleeve isalso includes a flashing groove which is concavely formed in the inner wall; the flashing groove encircles the through hole and is in a closing ring structure; and the flashing groove includes an opening end which communicates with the through hole and a closing end is relatively away from the through hole. According to the valve needle guiding sleeve assembly, the flashing groove is concavely formed in the inner wall of the through of the guiding sleeve, the molten plastic cement can be stored in the flashing groove, and a plastic cement sealing layer can be formed after the cooling and curing of the plastic cement, so that the requirement of fitting accuracy between the valve needle and the guiding sleeve an be reduced, the problem of plastic cement leaking in the fitting clearance between the valve needle and the guiding sleeve can be solved, the tightness of the fitting clearance can be enhanced, and meanwhile the risk of the valve needle seized by the thermal expansion is reduced.

Owner:YUDO SUZHOU HOT RUNNER SYST

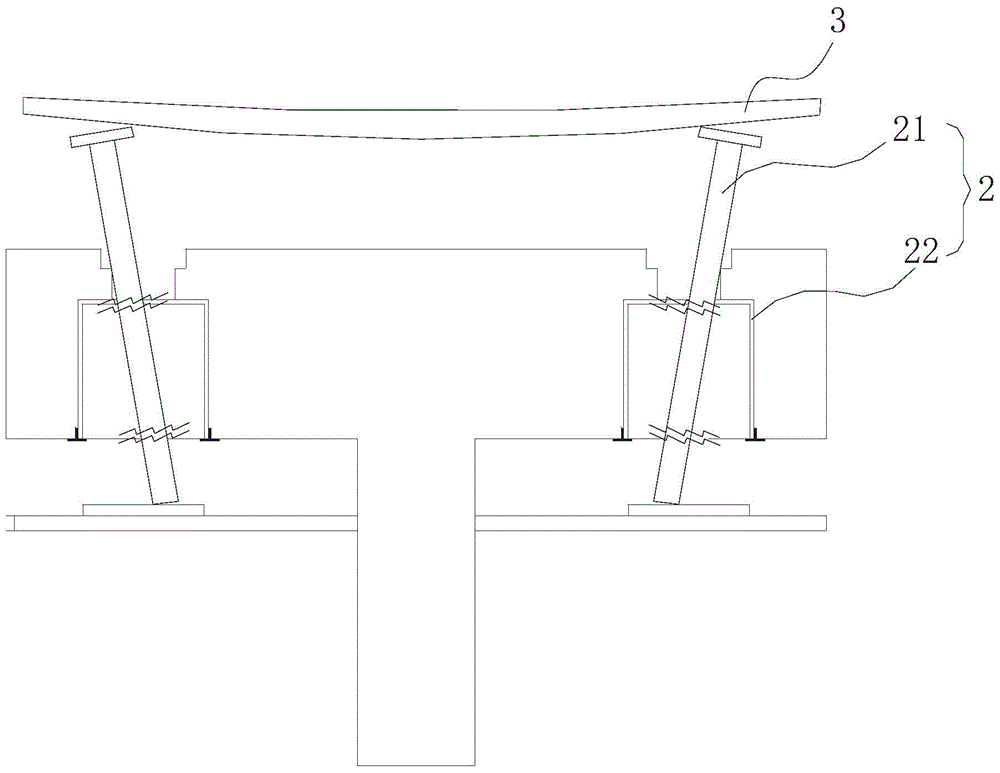

An active-passive integrated all-metal micro-vibration control device

ActiveCN106763474BLong-term working performance is stableReduced risk of stuckVibration suppression adjustmentsVibration controlMetal rubber

The invention discloses an active and passive integrated all-metal micro-vibration control device which comprises a supporting rod, diaphragm springs and the like. The supporting rod penetrates in a first shell inner cylinder, and a coil support is fixedly installed at the other end of the supporting rod through a supporting plate. A voice coil motor rotor is installed on the coil support and moves transversely between an inner ring permanent magnet and an outer ring permanent magnet of a voice coil motor stator in the axial direction. One end of a metal spring is fixedly installed at the connecting opening position of a second shell and a first shell through an end cover, and the other end of the metal spring is matched with the end portion of a limiting sleeve. The limiting sleeve is supported in the second shell through a metal rubber gasket. The metal spring is connected with external equipment through an inner thread at the end portion and presses the limiting sleeve. The diaphragm springs are installed between the supporting rod and an end cover of the first shell, between the coil support and the inner wall of the end cover of the first shell and between the supporting plate of the coil support and the end cover of the metal spring. According to the active and passive integrated all-metal micro-vibration control device, wide-frequency-band micro-vibration control can be achieved, the vibration isolation effect of a vibration isolator is improved, and adaptability to various complex environments is improved.

Owner:BEIJING INST OF CONTROL ENG

A Circumferential Rotation Limiting Mechanism

ActiveCN112413320BReduce volumeGood for NDTMeasurement apparatus componentsStands/trestlesDestructive testingRotating disc

The invention discloses a circumferential rotation limiting mechanism, which comprises a fixed plate, a rotating plate rotatably connected to the fixed plate, a rotating assembly for rotating the rotating plate and the fixed plate, and a driving assembly for driving the rotating plate to rotate. A helical limiting groove is provided on the fixed disk or the rotating disk, the roller connected to the limiting groove that rolls along the helical extension direction of the limiting groove, and the swinging wheel that is located above the limiting groove and coaxially fixedly connected with the roller The seat, the two ends are respectively rotatably connected with the swing seat and the rotating disk. The physical limit is realized, the transmission is smoother, the risk of jamming is greatly reduced, and the overall volume of the mechanism can be reduced, which is beneficial to non-destructive testing in a small space.

Owner:CGNPC INSPECTION TECH +3

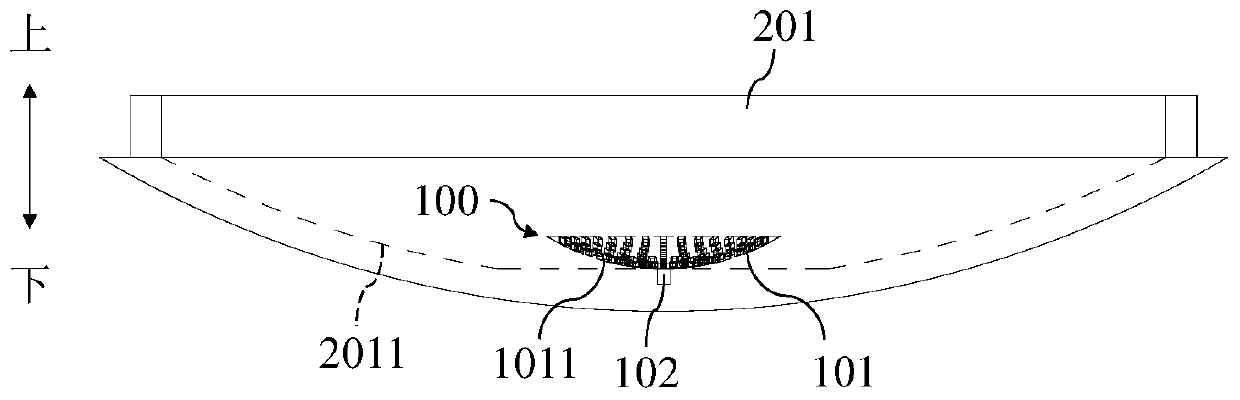

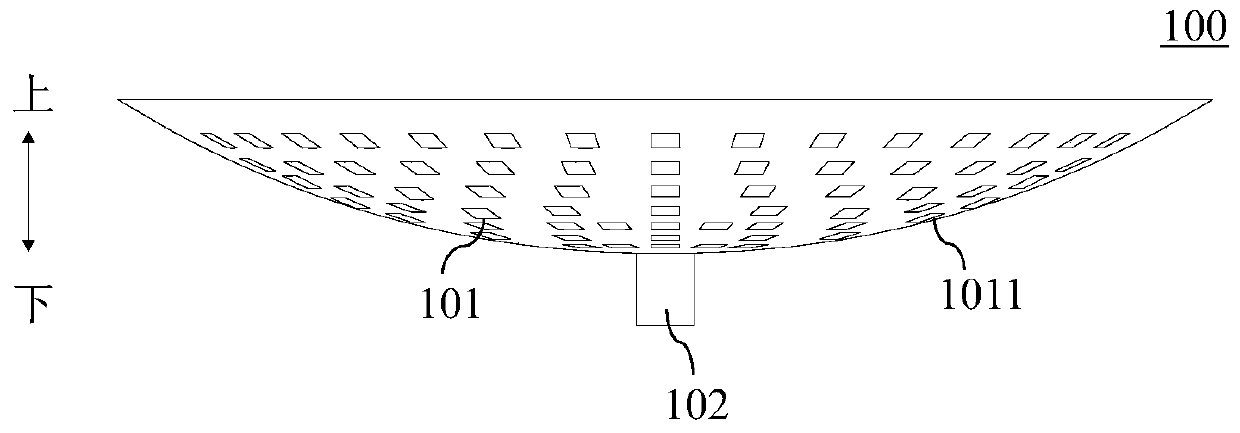

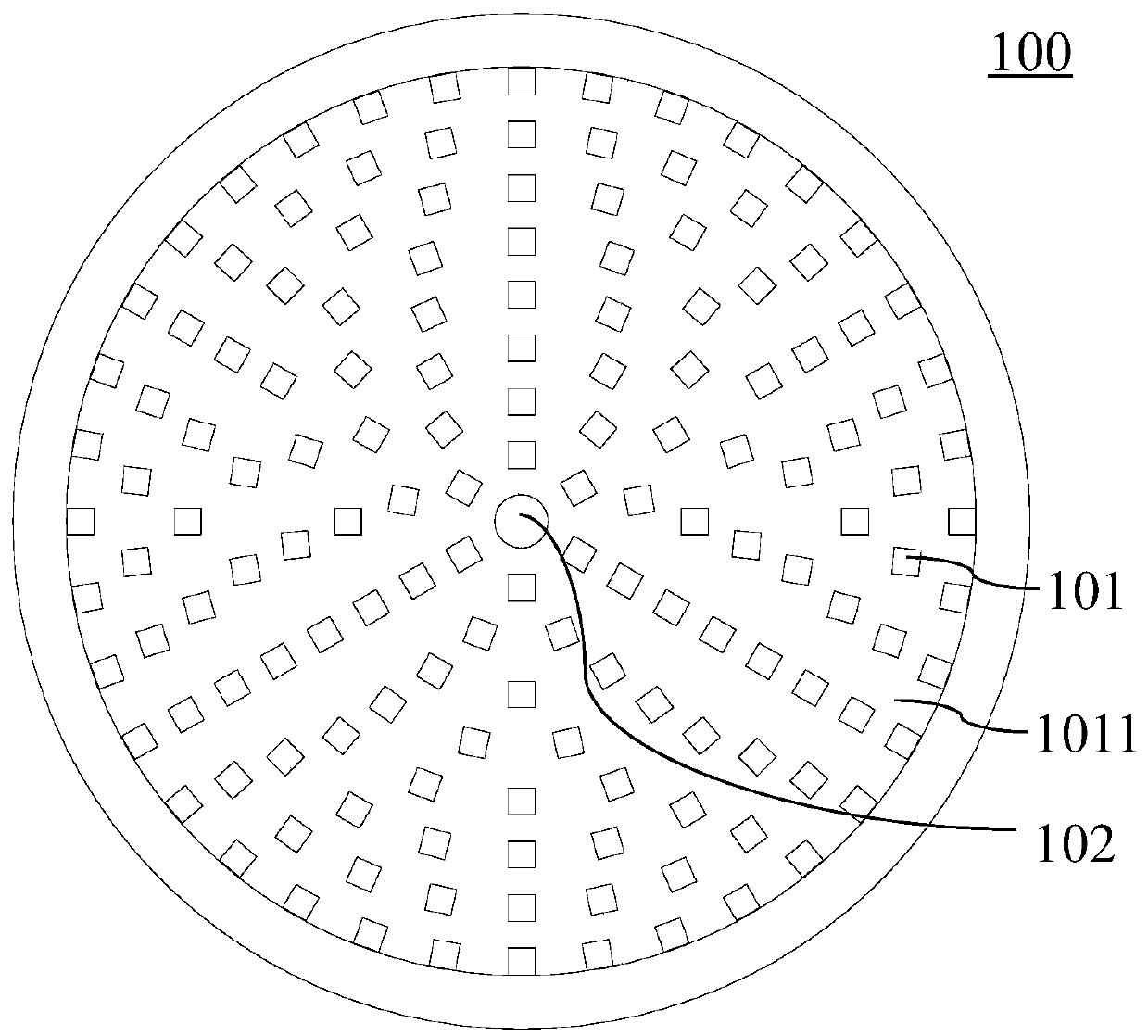

Filter part of vertical compressor and vertical compressor

PendingCN111456942ASimple structureEasy to manufactureRotary/oscillating piston pump componentsLiquid fuel engine componentsControl theoryMechanical engineering

Owner:GREE ELECTRICHEFEI +1

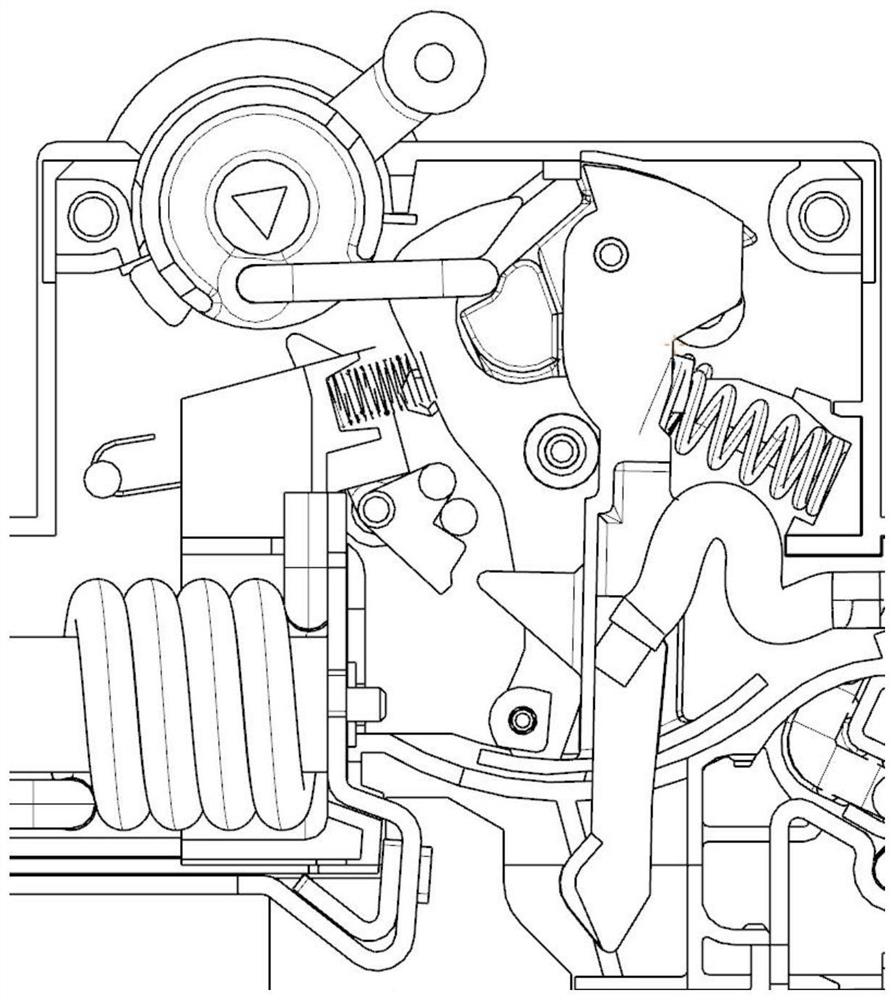

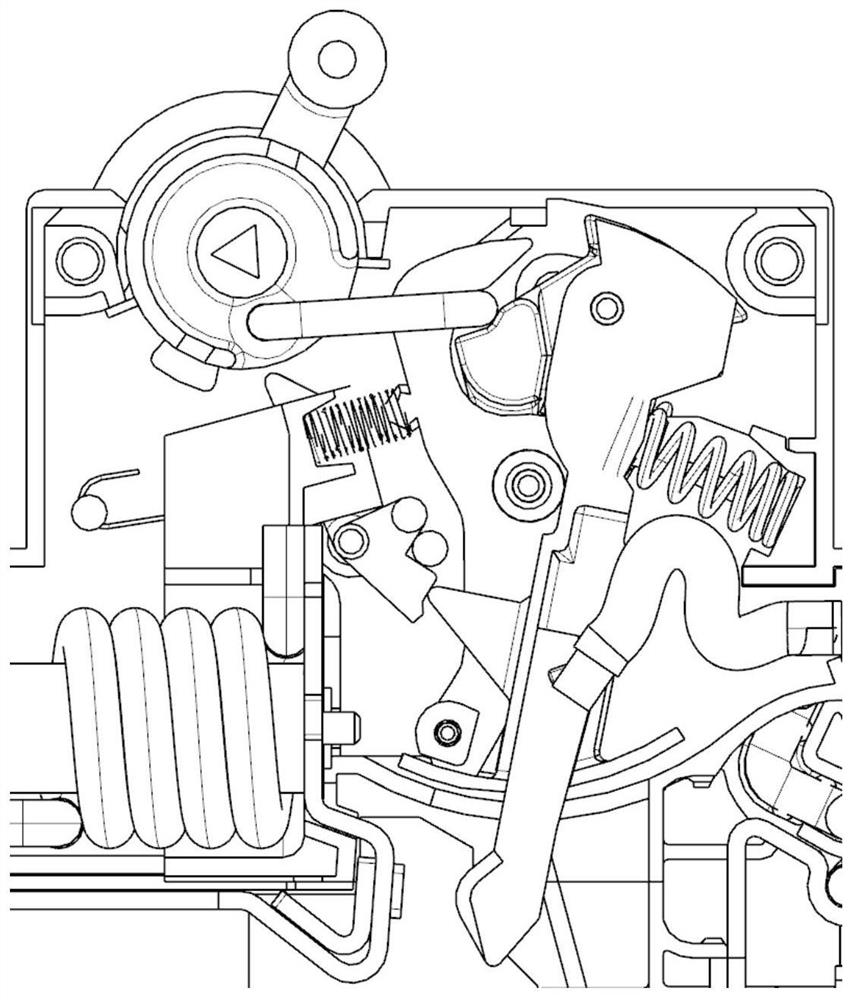

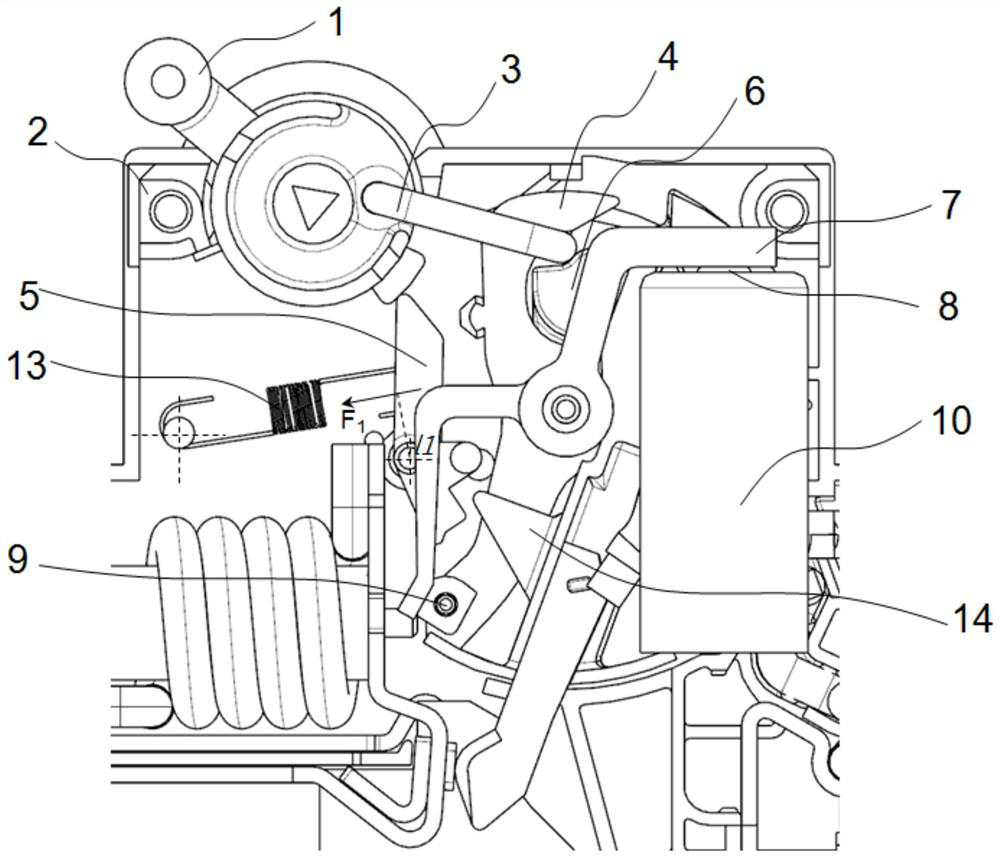

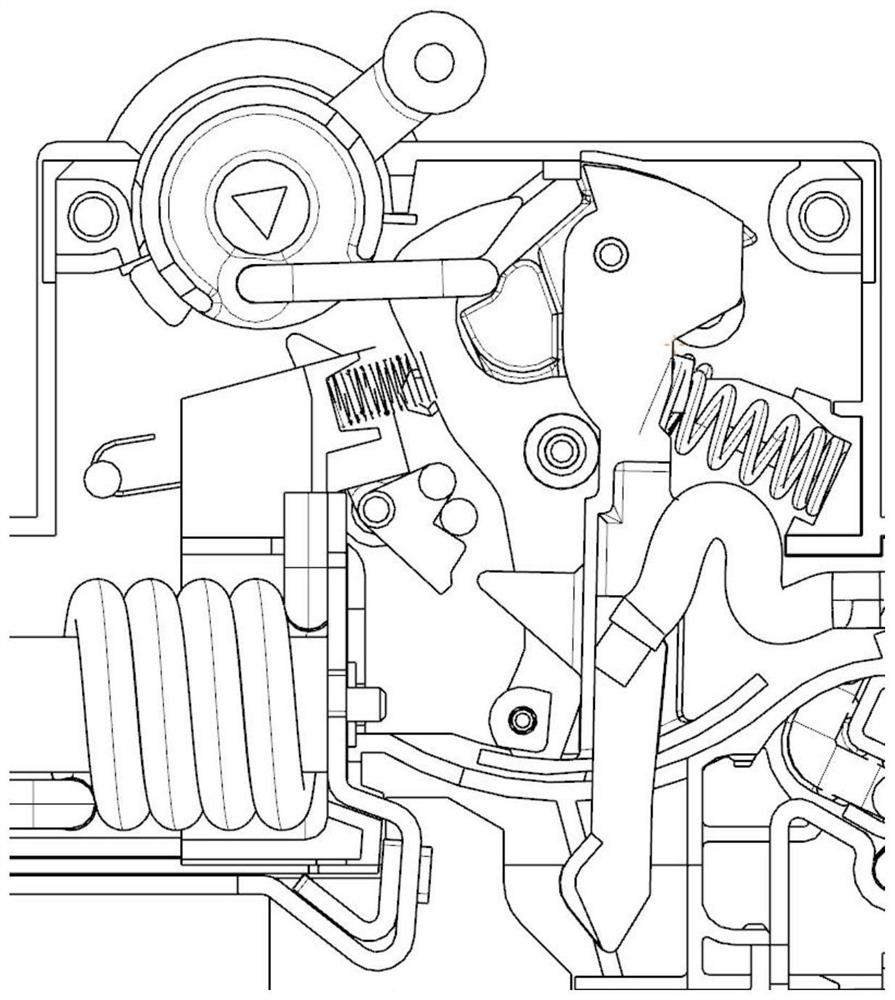

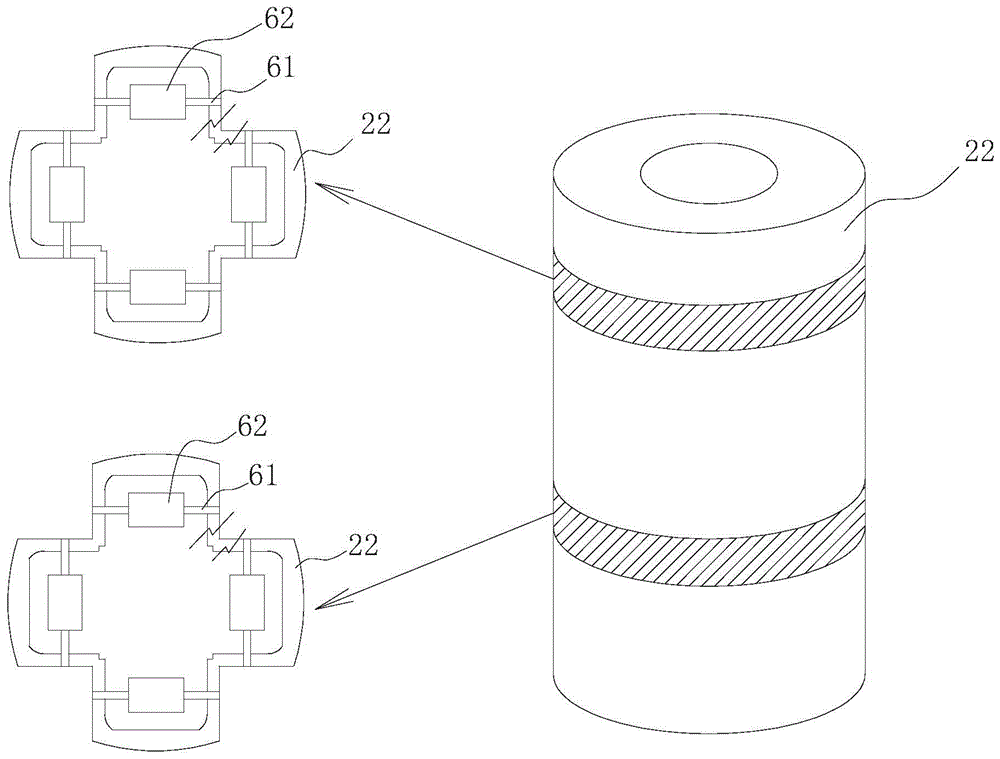

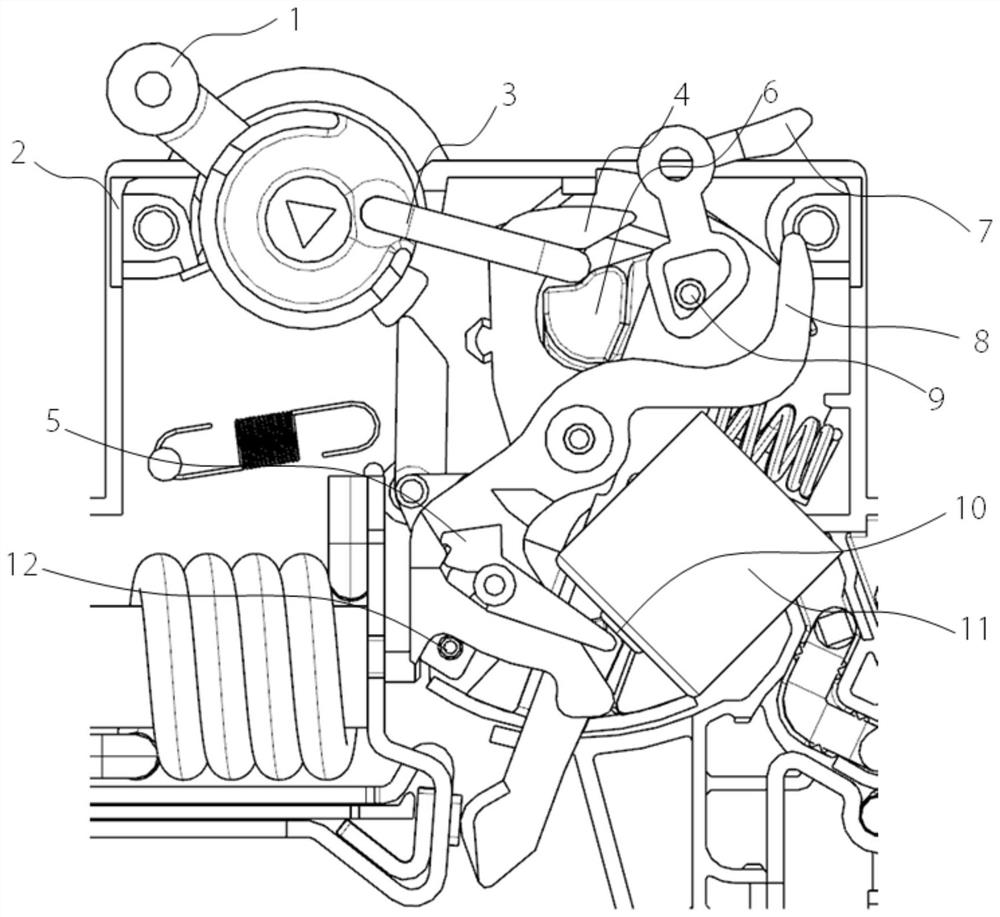

Reset mechanism of magnetic flux release

ActiveCN111883396ALarge outputReduced risk of stuckProtective switch operating/release mechanismsControl engineeringControl theory

The invention relates to a reset mechanism of a magnetic flux release, and belongs to the technical field of miniature circuit breakers. The reset mechanism comprises a handle, a convex block arrangedon the outer side of the circumference of the handle, a quick closing piece corresponding to the convex block of the handle, a tripping lever, a magnetic flux tripper and an ejector rod, the trippinglever is provided with one end acting with the ejector rod arranged on the magnetic flux tripper; the tripping lever is connected with a circuit breaker tripping pin shaft; and the tripping lever rotates through the quick closing piece and acts on the ejector rod of the magnetic flux tripper to reset the ejector rod. According to the invention, the electronic magnetic flux tripping system is reset through the existing handle without transmission of the main body mechanism, so the influence on the performance of the main body mechanism is avoided; the reset function is achieved through fewer parts, so the reliability of product manufacturing is improved. Meanwhile, a reset transmission space is reserved, so the number of turns of a winding of the magnetic flux release is increased, and themagnetic flux release can have larger output force; manual reset is not needed, and the risk that the reset button is stuck is reduced.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

A reset mechanism of a magnetic flux release

ActiveCN111883396BLarge outputReduced risk of stuckProtective switch operating/release mechanismsEngineeringMagnetic flux

The invention relates to a reset mechanism of a magnetic flux release, belonging to the technical field of small circuit breakers. the release lever and the ejector rod; the release lever is provided with one end that acts with the ejector rod provided with the magnetic flux release device; the release lever is connected with the tripping pin of the circuit breaker; the release lever is released through the quick-release part The lever rotates and acts on the ejector rod of the magnetic flux release to reset the ejector rod. The present invention resets the electronic magnetic flux tripping system through the existing handle, and does not transmit through the main body mechanism, thereby avoiding the influence on the performance of the main body mechanism; using fewer parts to realize the reset function and improving the reliability of product manufacturing. At the same time, the space for reset transmission is freed to increase the number of winding turns of the magnetic flux release, so that the magnetic flux release can have a larger output force; no manual reset is required, which reduces the risk of the reset button being stuck.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

substrate support

ActiveCN104051315BIncrease the lengthAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

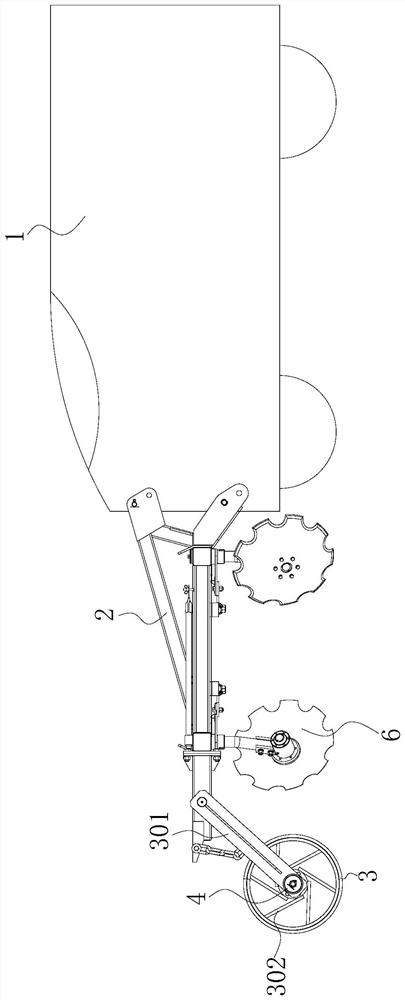

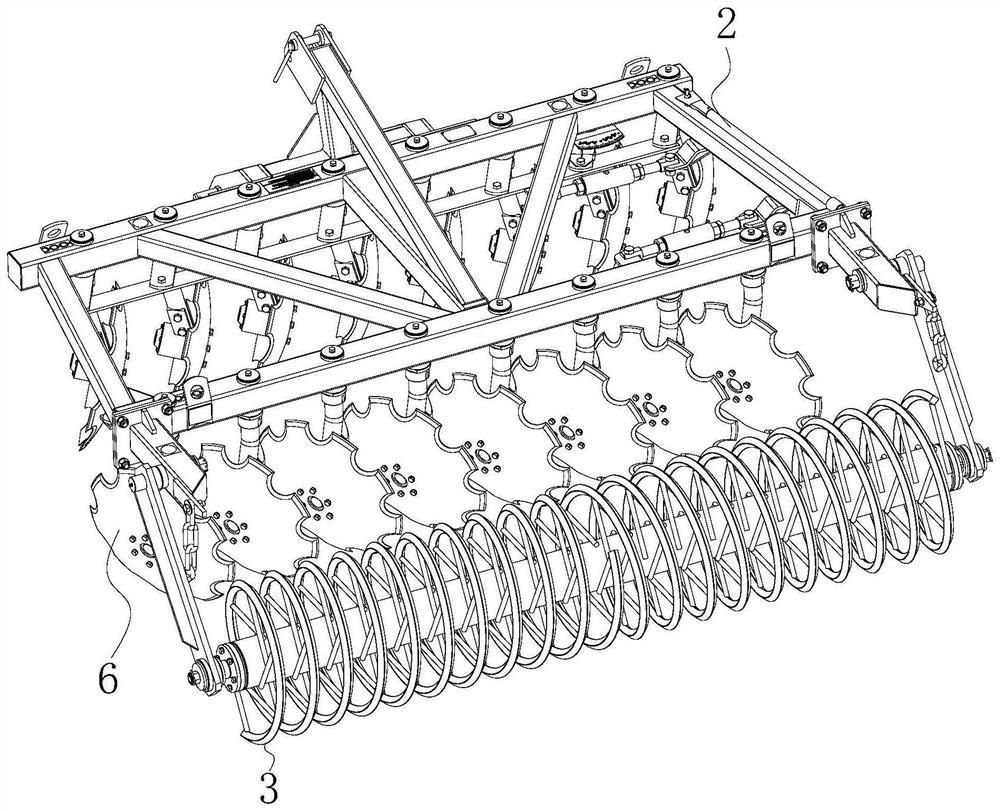

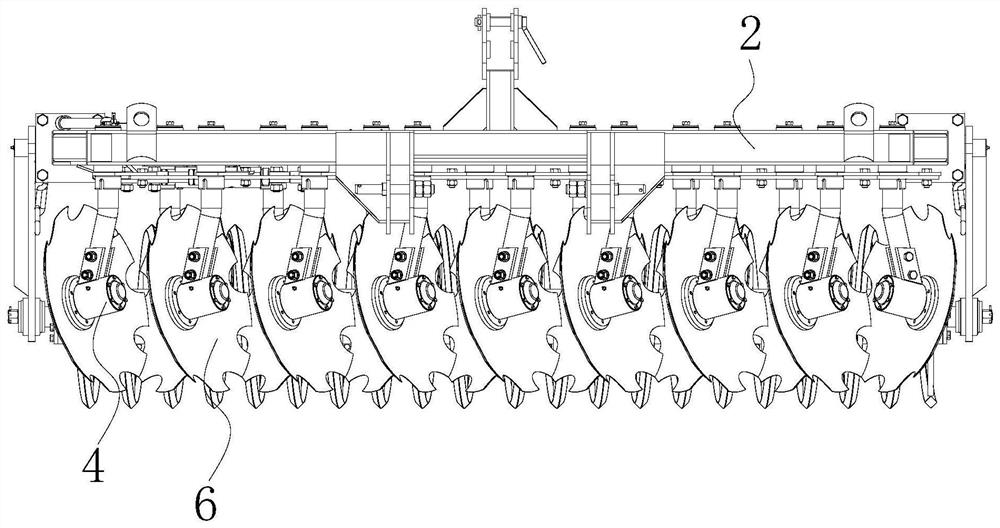

Environment-friendly shoveling device for removing toxic grassland grass

PendingCN113180028AImplementationEasy plantingSpadesPloughsAgricultural engineeringEnvironmental geology

The invention provides an environment-friendly shoveling device for removing toxic grassland grass, and relates to the technical field of agricultural machinery. The environment-friendly shoveling device for removing the toxic grassland grass comprises a vehicle body and further comprises a grass removing mechanism connected with the vehicle body, the grass removing mechanism comprises a mounting frame, a twisting-off assembly connected with the mounting frame and a plowing assembly connected with the mounting frame, the twisting-off assembly comprises a rotating motor, an auger and a supporting piece, and a plurality of cutting blades connected with a cutter head of the auger are assembled on the cutter head at the edge of the auger. According to the environment-friendly shoveling device, efficient toxic grass removing operation can be achieved through the twisting-off assembly and the plowing assembly at the same time, stems and leaves of toxic are cut off through the twisting-off assembly, and rhizomes of the toxic grass in soil are broken through the plowing assembly to avoid regeneration of the rhizomes. By means of the design, the device has the efficient toxic grass cleaning efficiency and can ensure that the soil environment is not damaged, so that forage grass can be normally planted, and the survival rate of the forage grass is not reduced.

Owner:库来夏哈孜依 +2

Auxiliary tripping unit of circuit breaker

ActiveCN111863556AAmplified outputIncrease tripping forceProtective switch operating/release mechanismsControl engineeringControl theory

The invention relates to an auxiliary tripping unit of a circuit breaker and belongs to the technical field of miniature circuit breakers. The auxiliary tripping unit and an operating mechanism part of the circuit breaker are connected and mutually driven to play a role in auxiliary tripping and self-resetting, a magnetic flux converter and an auxiliary tripping mechanism are arranged on a modulebase, the auxiliary tripping mechanism comprises a reset lever, a module tripping rod and a module lock catch, the magnetic flux converter assists completion of tripping action through the action of the movable ejector rod and the auxiliary tripping mechanism, and meanwhile, the tripping mechanism is assisted to complete the reset action. Through the technical scheme of a secondary lock catch, theoutput of the release type electromagnet is amplified, the tripping force is increased, and the magnetic flux tripper can be reliably tripped under the condition of limited energy input, the magneticflux tripper is reset while tripping is carried out, so tripping and resetting functions are realized, manual reset is not needed, and the risk that the reset button is stuck is reduced, the output requirement of the electronic circuit board on the release is reduced, and reliability of the product tripping action is improved.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

A new ultra-high temperature cage type ram and its processing technology

ActiveCN104121380BReduce overall loadImprove deformation resistanceSlide valveThermal deformationStructural engineering

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

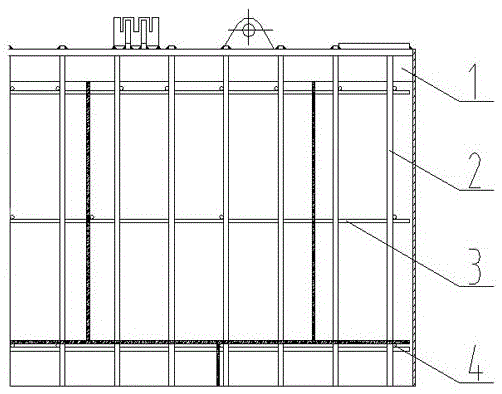

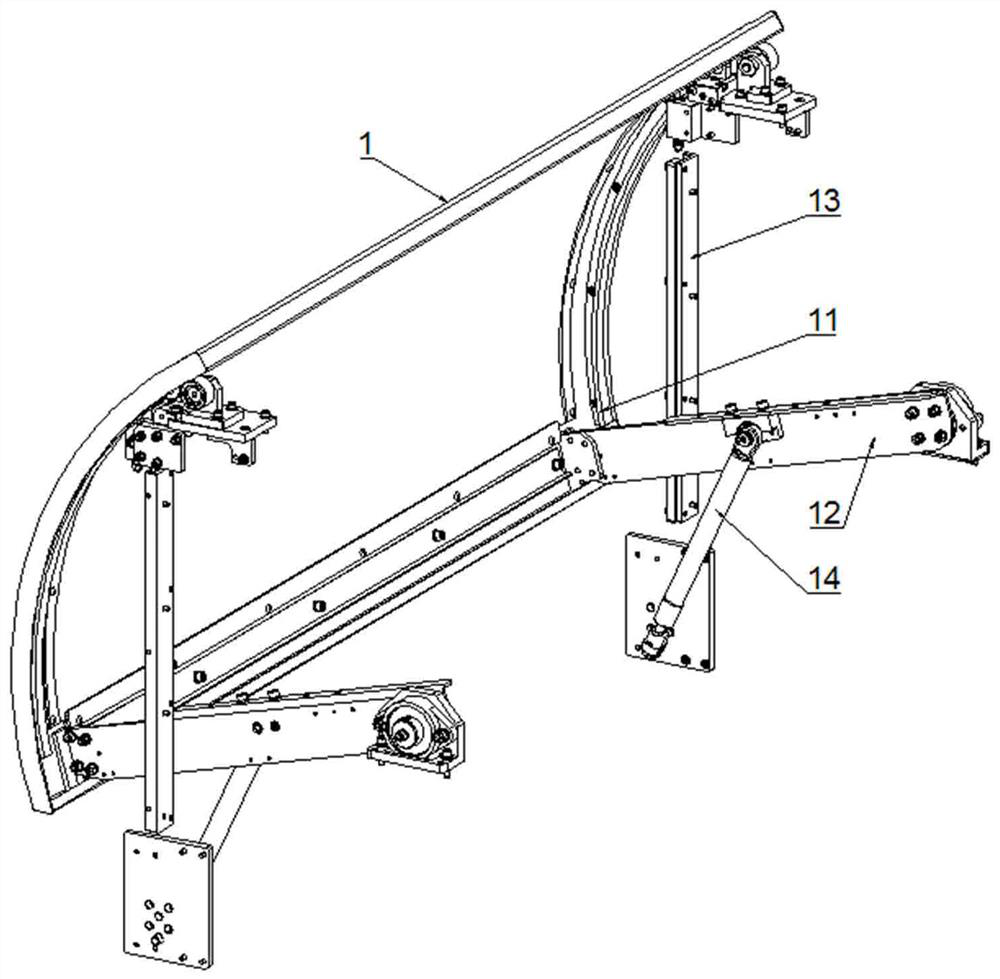

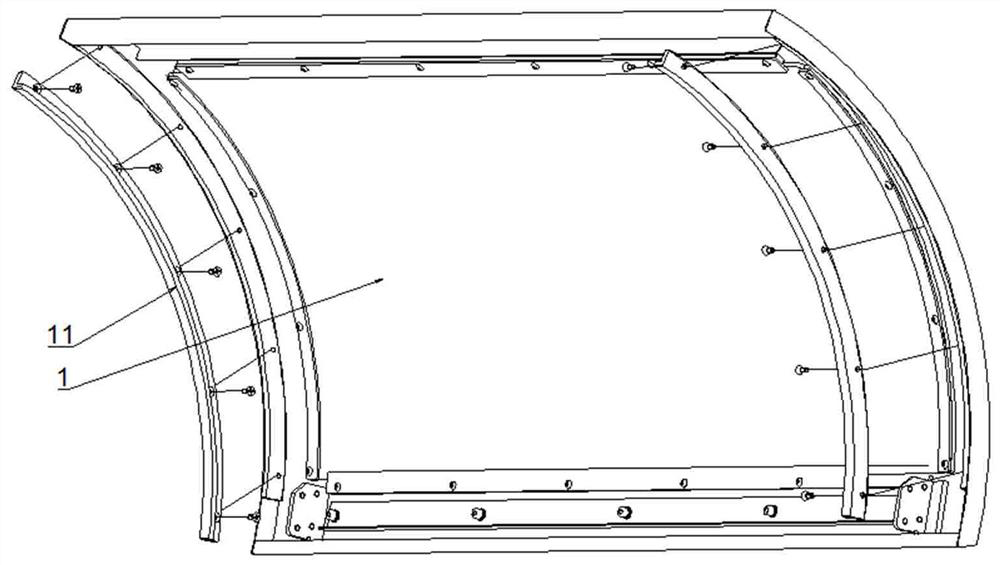

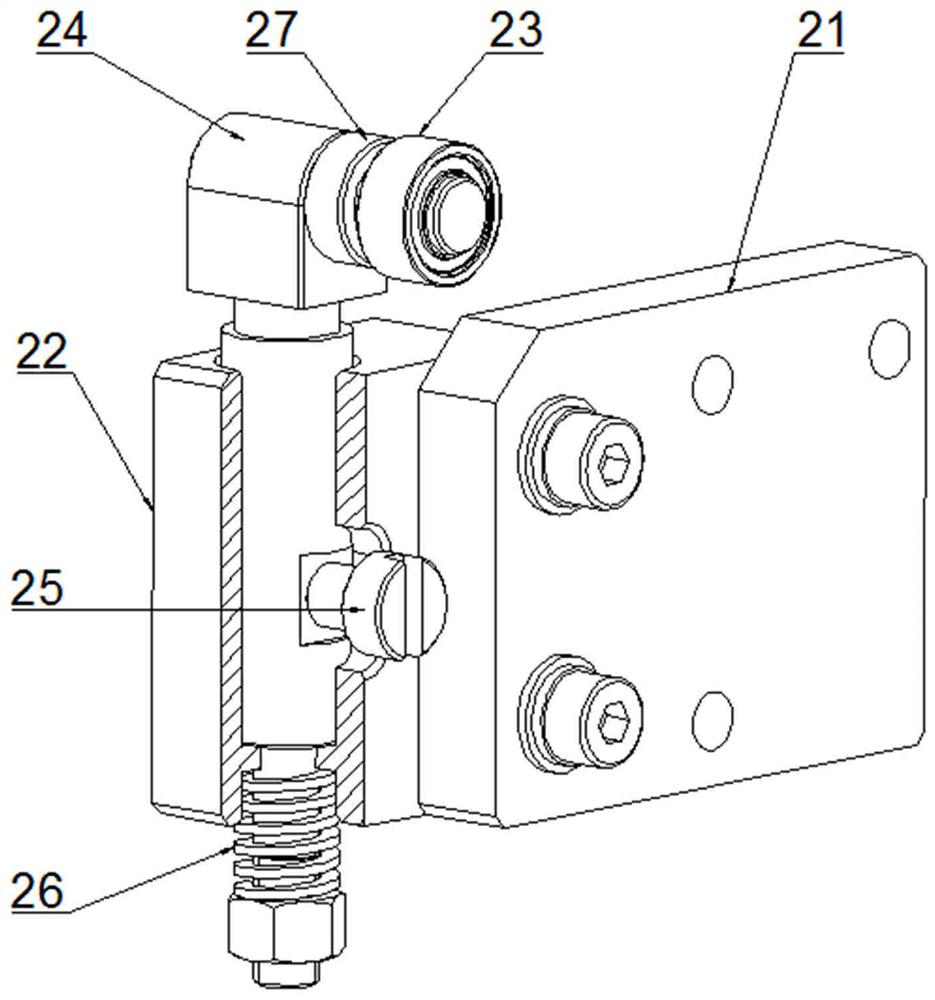

Arc-shaped sliding door

PendingCN114046122ALarge margin of errorSmall footprintWing openersWing arrangementsStructural engineeringMechanical engineering

Owner:AUTOBIO LABTEC INSTR CO LTD

A kind of atomic layer deposition equipment and gas transmission method

ActiveCN110387537BAvoid enteringReduced risk of stuckChemical vapor deposition coatingThermodynamicsEngineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com