Unilateral positioning cam driving mechanism for continuous zoom lens

A unilateral positioning and driving mechanism technology, which is applied in installation, optics, instruments, etc., can solve the problems of reduced consistency of the drive positioning groove wall, complex mechanism and control circuit, and low consistency of the image plane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

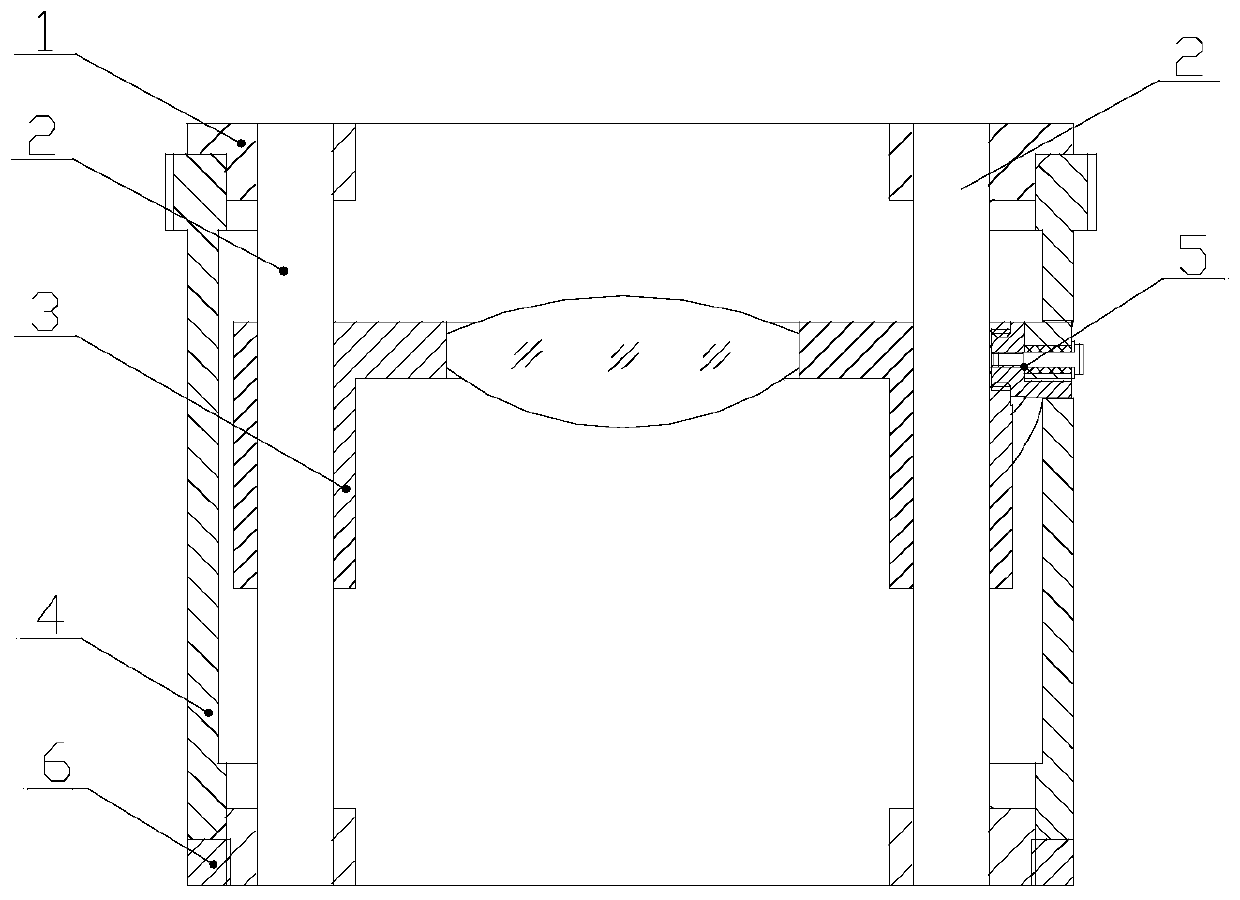

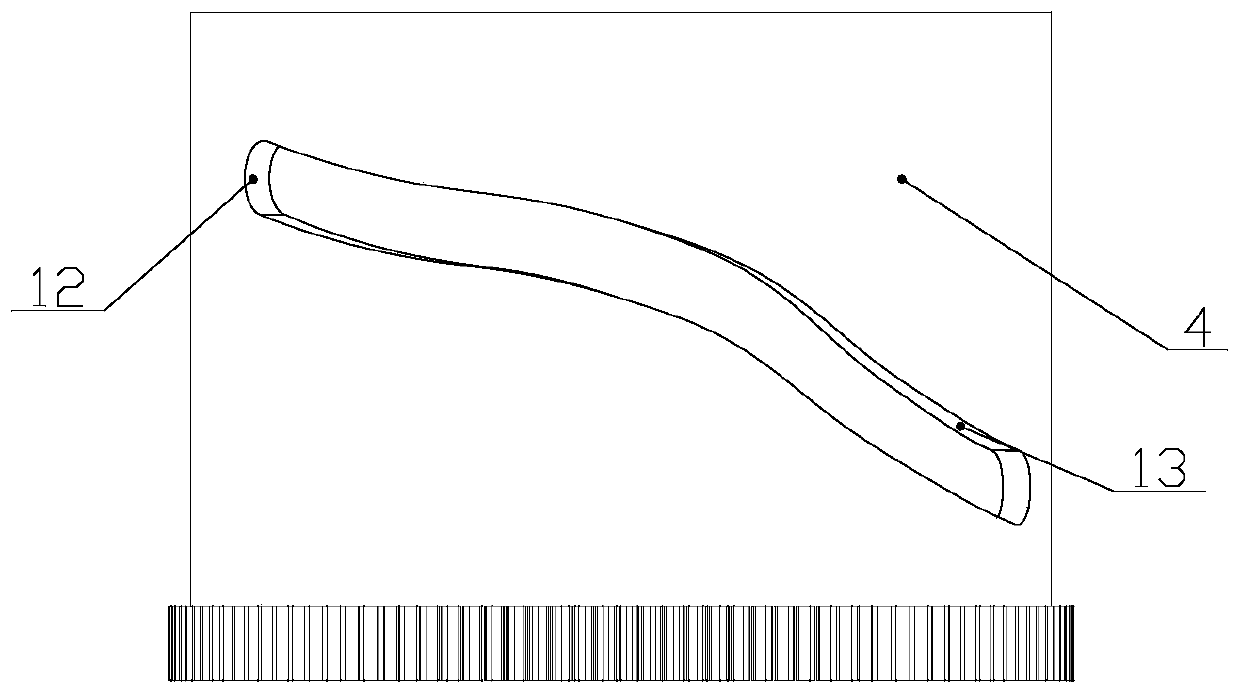

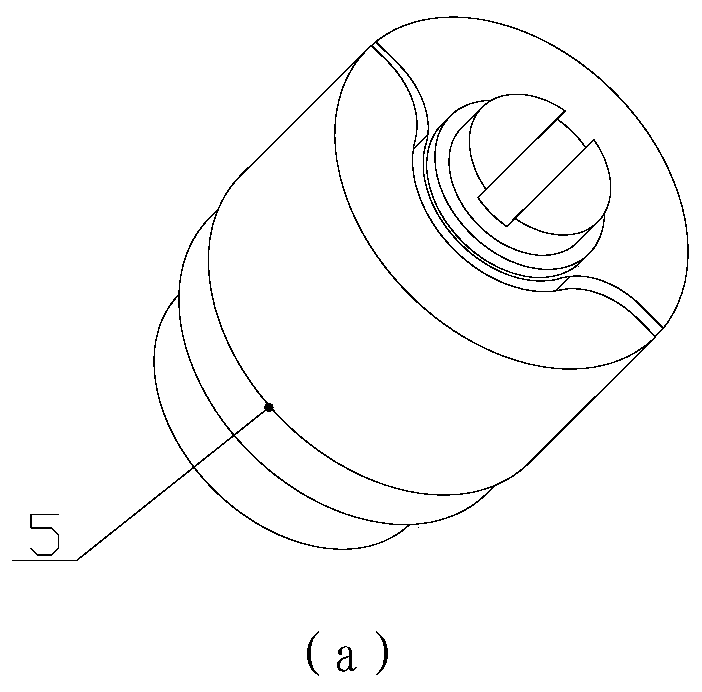

[0033] Such as figure 1 , a sectional view of a single-side positioning cam drive mechanism for a continuous zoom lens, including a main bracket 1, a sliding rod 2, an optical sliding assembly 3, a single-side positioning curve sleeve 4, a semi-flexible pin assembly 5, a locking pressure ring 6, Unilateral positioning pin 7, elastic column sleeve 8, pressing pin 9, pressing sheet 10, fixing nail 11.

[0034] Wherein, the optical sliding assembly 3 is connected with the main bracket 1 through the sliding rod 2, and the sliding rod 2 is fixed with the main bracket 1. Under the constraint of the sliding rod 2, the optical sliding assembly 3 does not rotate relative to the main bracket 1 along the sliding rod 2. linear sliding; the unilateral positioning curve sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com