A Design Method of Gas Distribution Cam Profile

A gas distribution cam and design method technology, applied in calculation, valve details, instruments, etc., can solve the problems of accelerated cam wear and damage, discontinuous function curve, and difficult optimization design, etc., to achieve easy solution, less design parameters, Effect of improving work stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

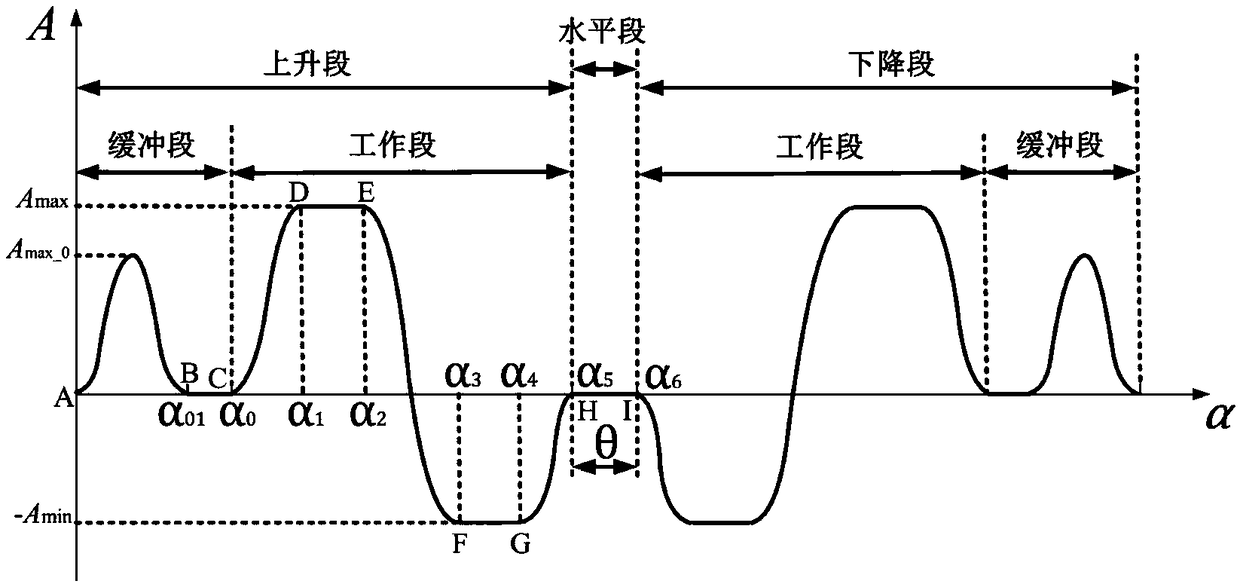

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] The present invention provides a method for designing a gas distribution cam profile, and the specific design steps are as follows:

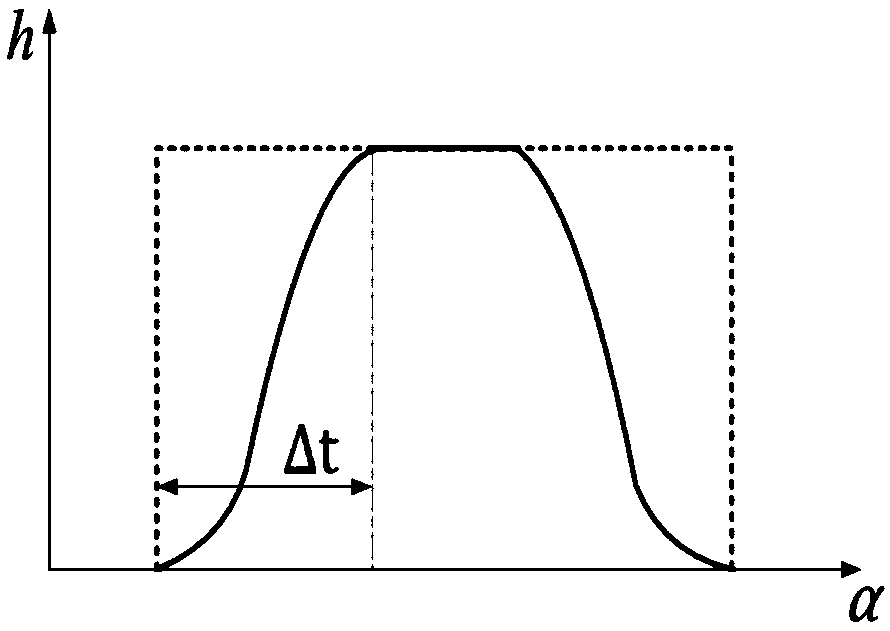

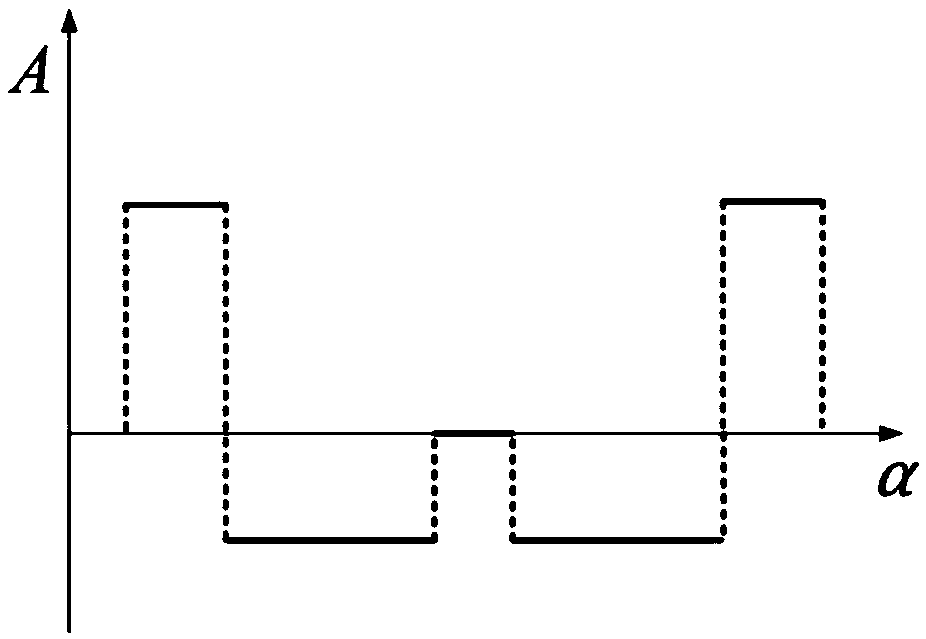

[0032] Step 1: Determine a symmetrical and continuous cam acceleration curve;

[0033] The effect of the gas distribution cam profile depends on the movement law of the tappet of its follower, so the design of the tappet profile is carried out first.

[0034] The design principle of the objective function of the tappet profile is that the total flow area of the airflow is as large as possible during the opening of the valve. Because the goal pursued by the valve train is sufficient exhaust and thorough intake. When other parameters of the valve train such as valve timing, maximum valve lift, etc. are under certain conditions, in order to obtain the maximum charge coefficient, it is required that the valve allows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com