Patents

Literature

149results about How to "Simplify the optimization process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

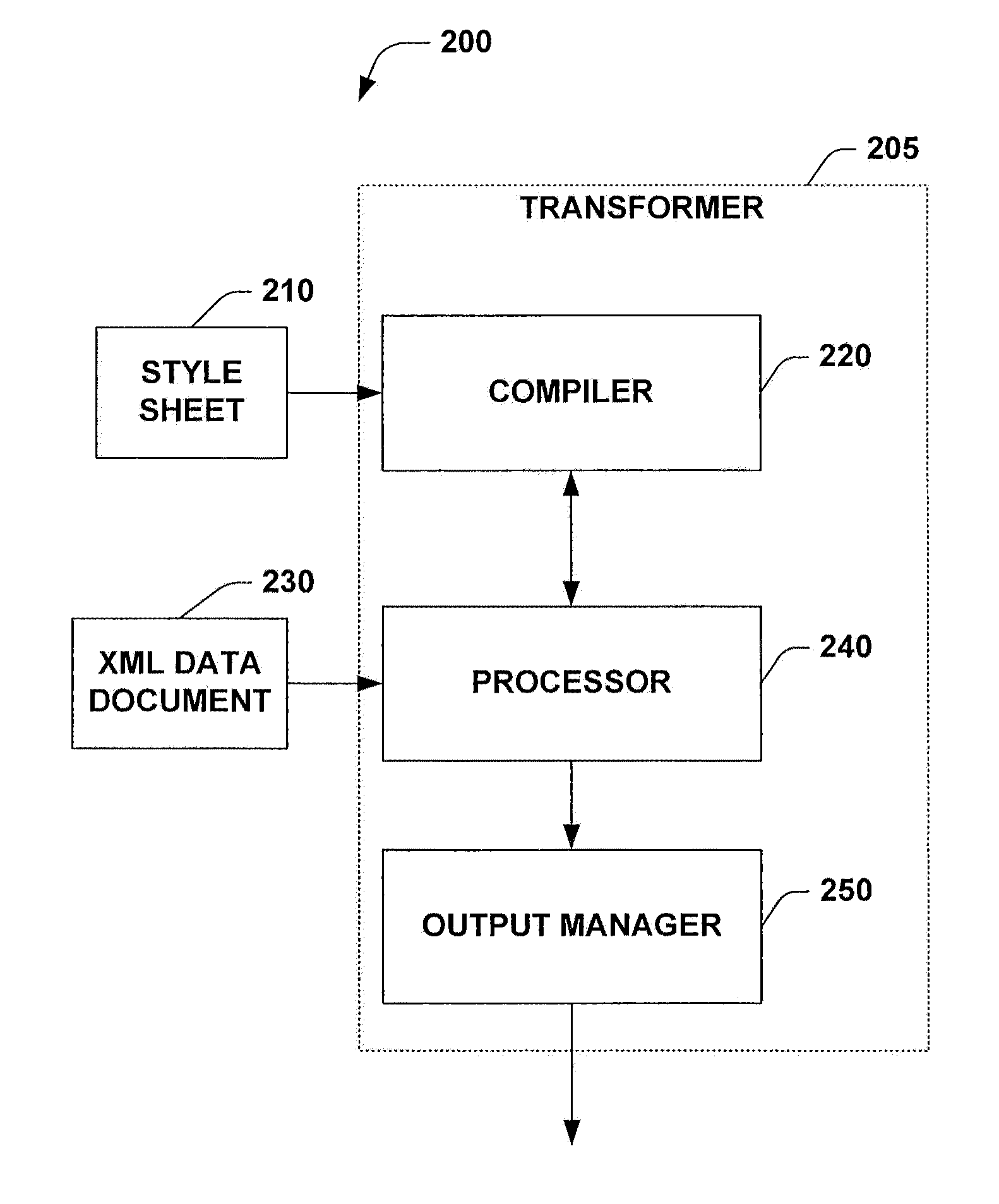

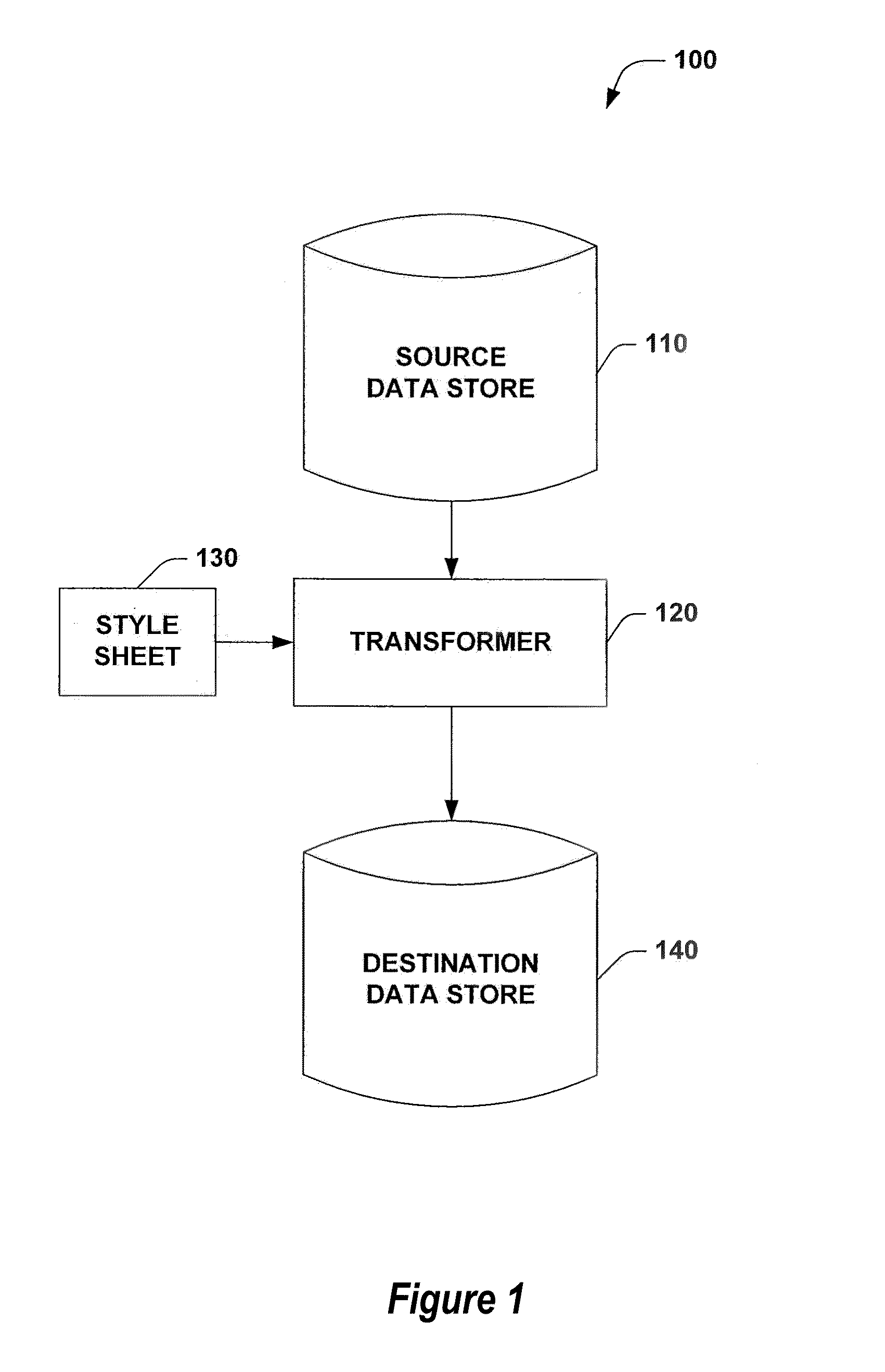

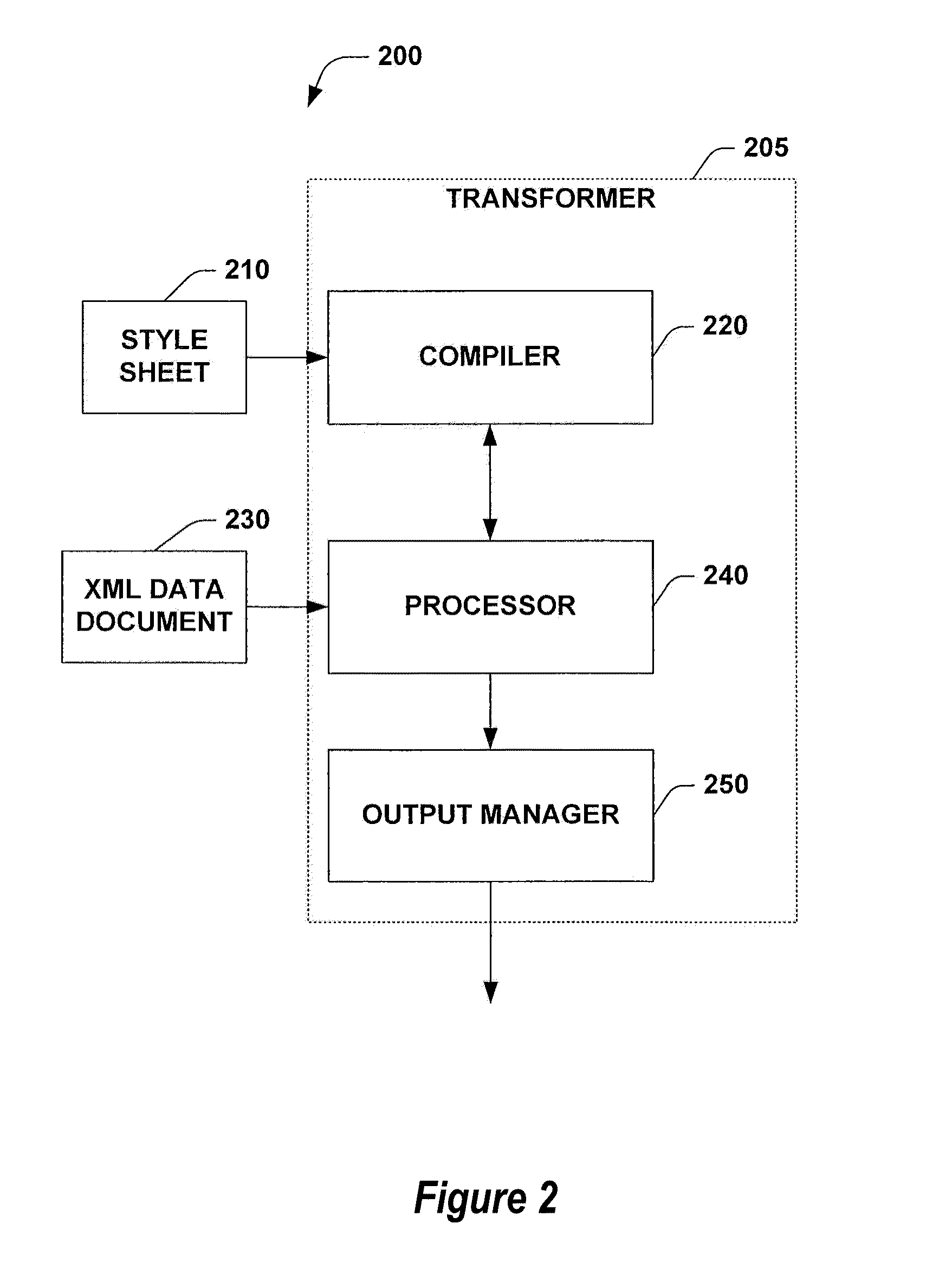

XSL transform

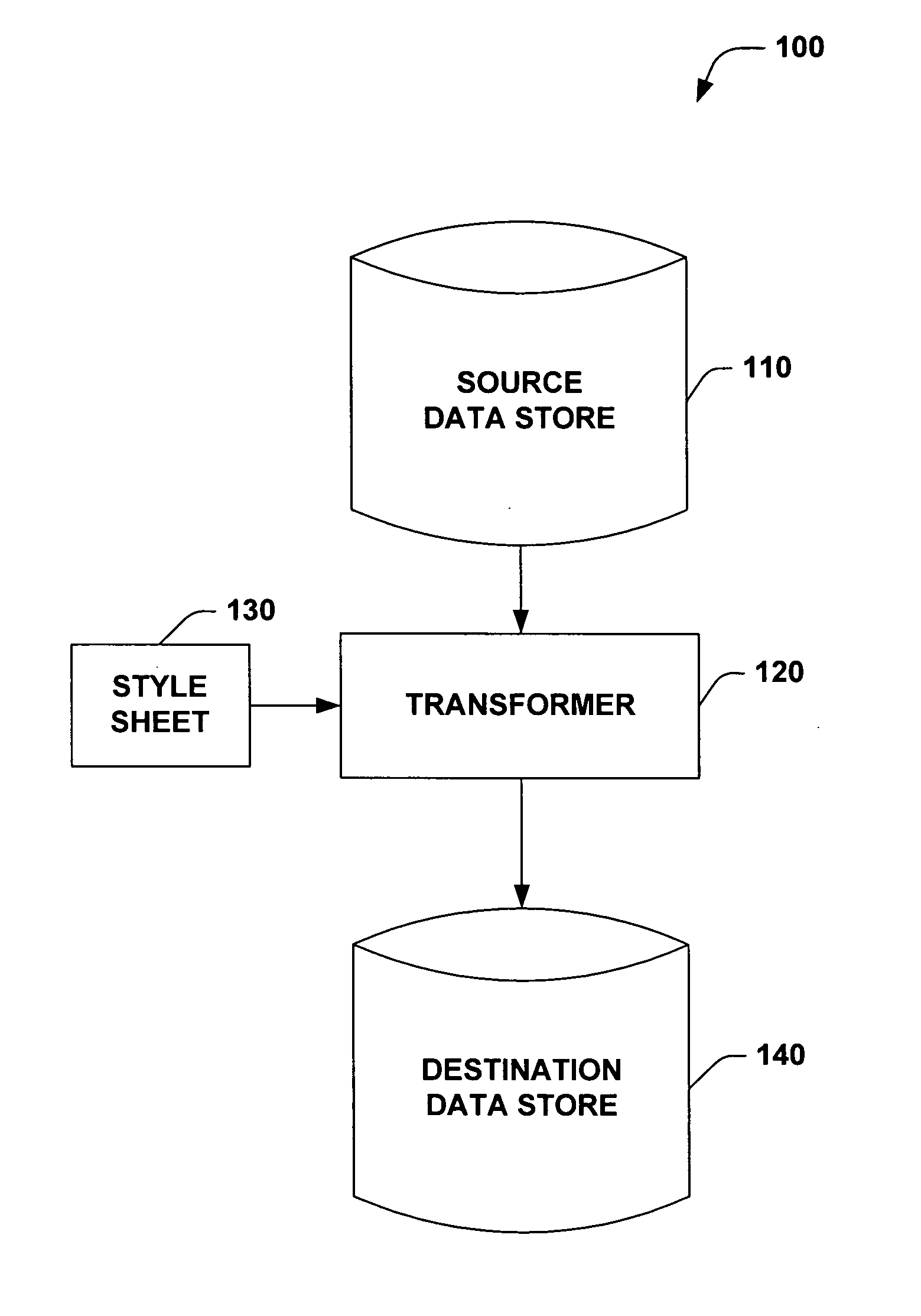

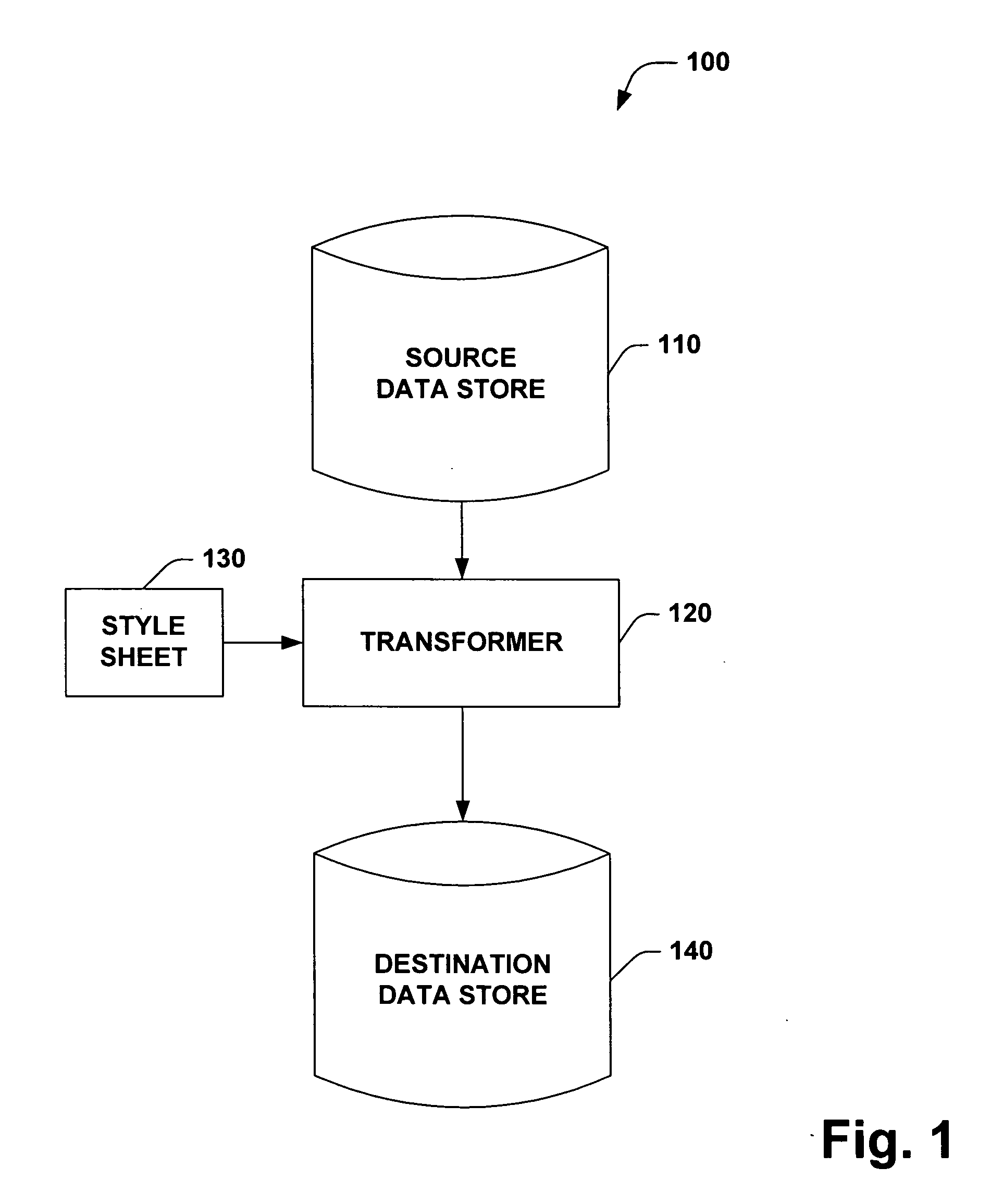

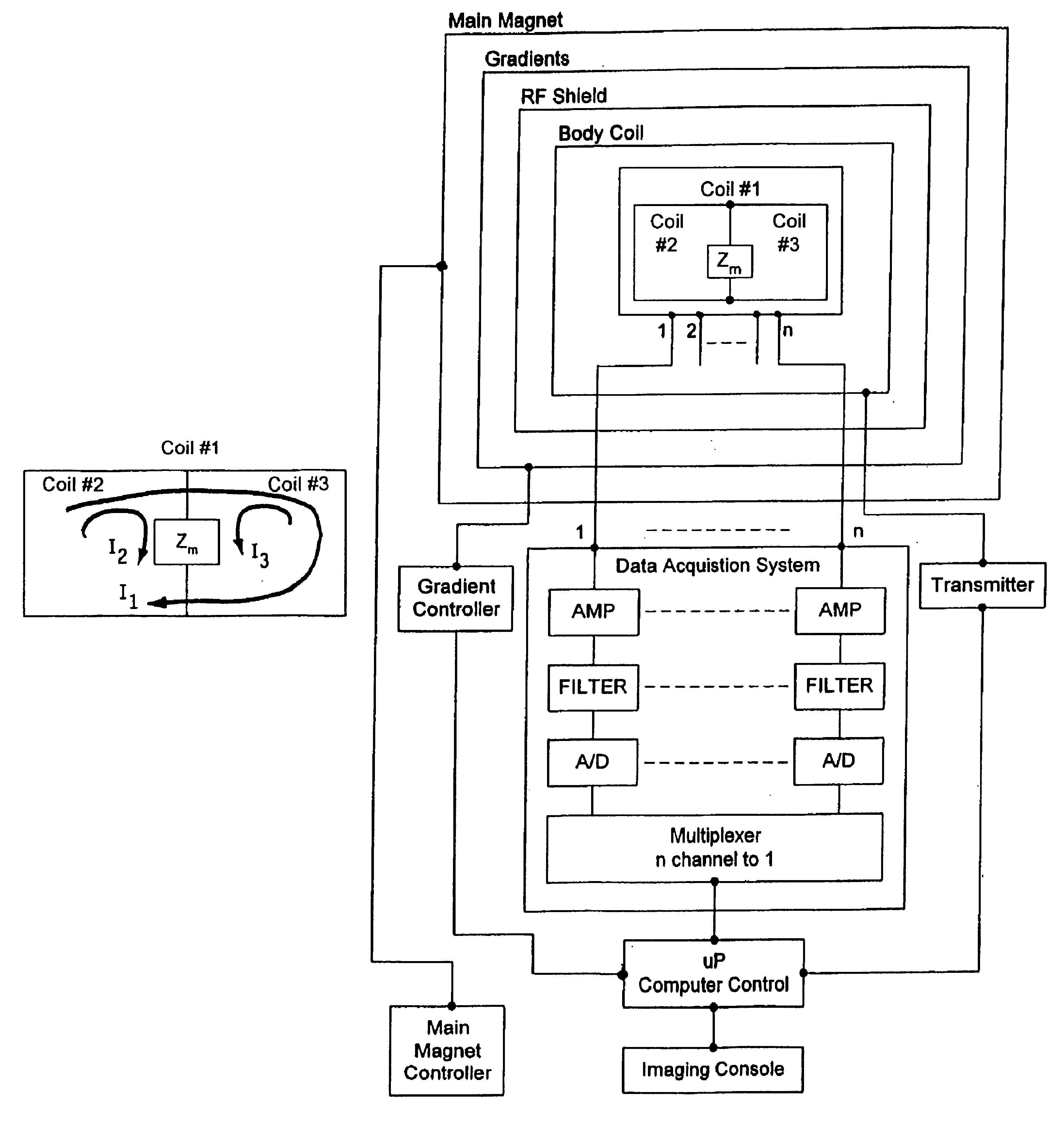

InactiveUS20050086584A1High outputEnhanced interactionDigital data information retrievalSoftware engineeringTransformerData storing

A system and method for transforming XML items is provided. The system includes a transformer that can selectively input XML items in a first format and selectively transform the input XML items to one or more transformed XML items in one or more second formats. The system also include an output manager that can be employed to facilitate selectively pulling and / or pushing a subset of the transformed XML items from the transformer to a variety of output destinations. The system provides an input abstractor that exposes data stored in data stores that implement the input abstractor as a data model and infoset, which facilitates navigating such exposed data.

Owner:MICROSOFT TECH LICENSING LLC

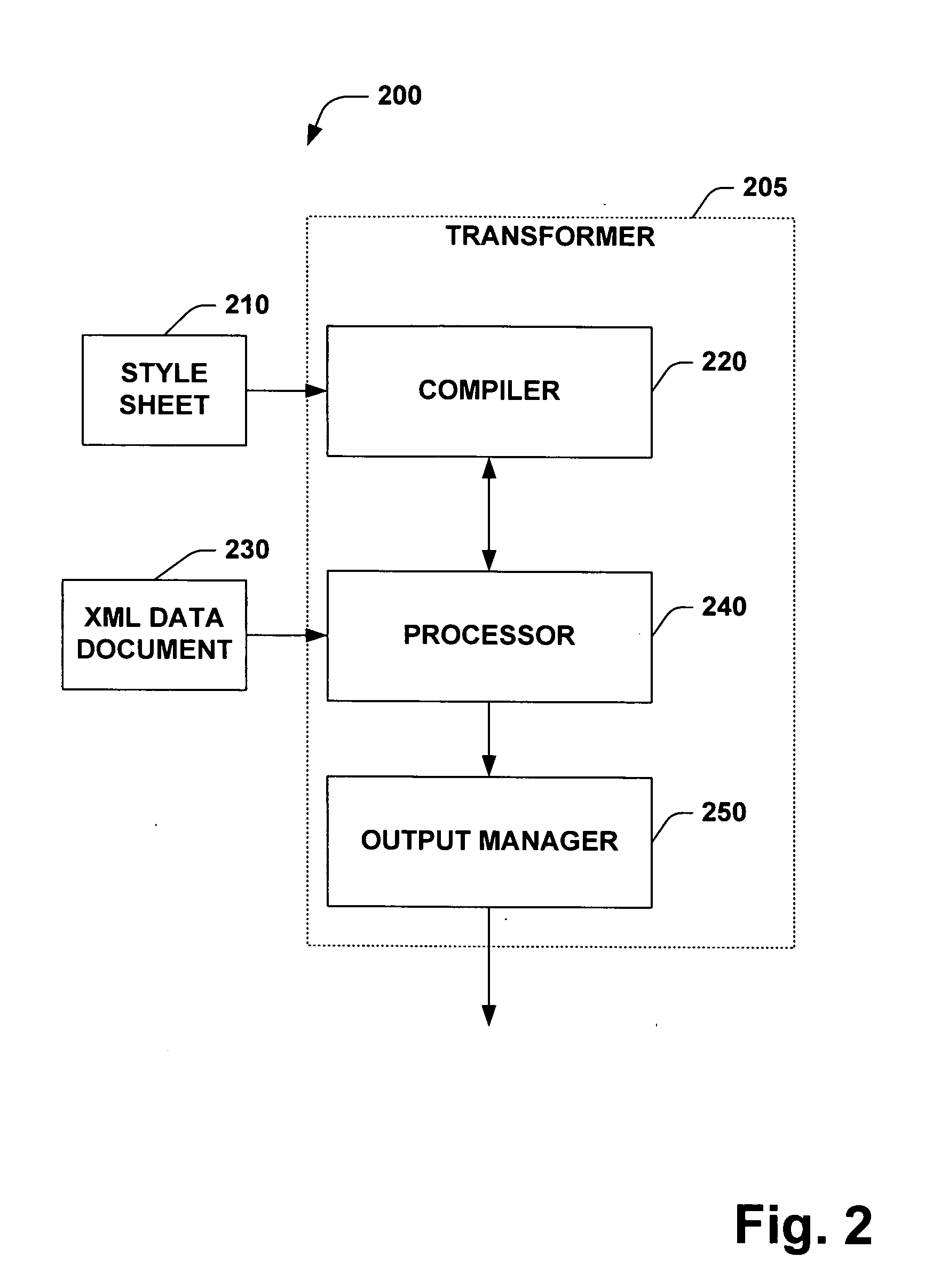

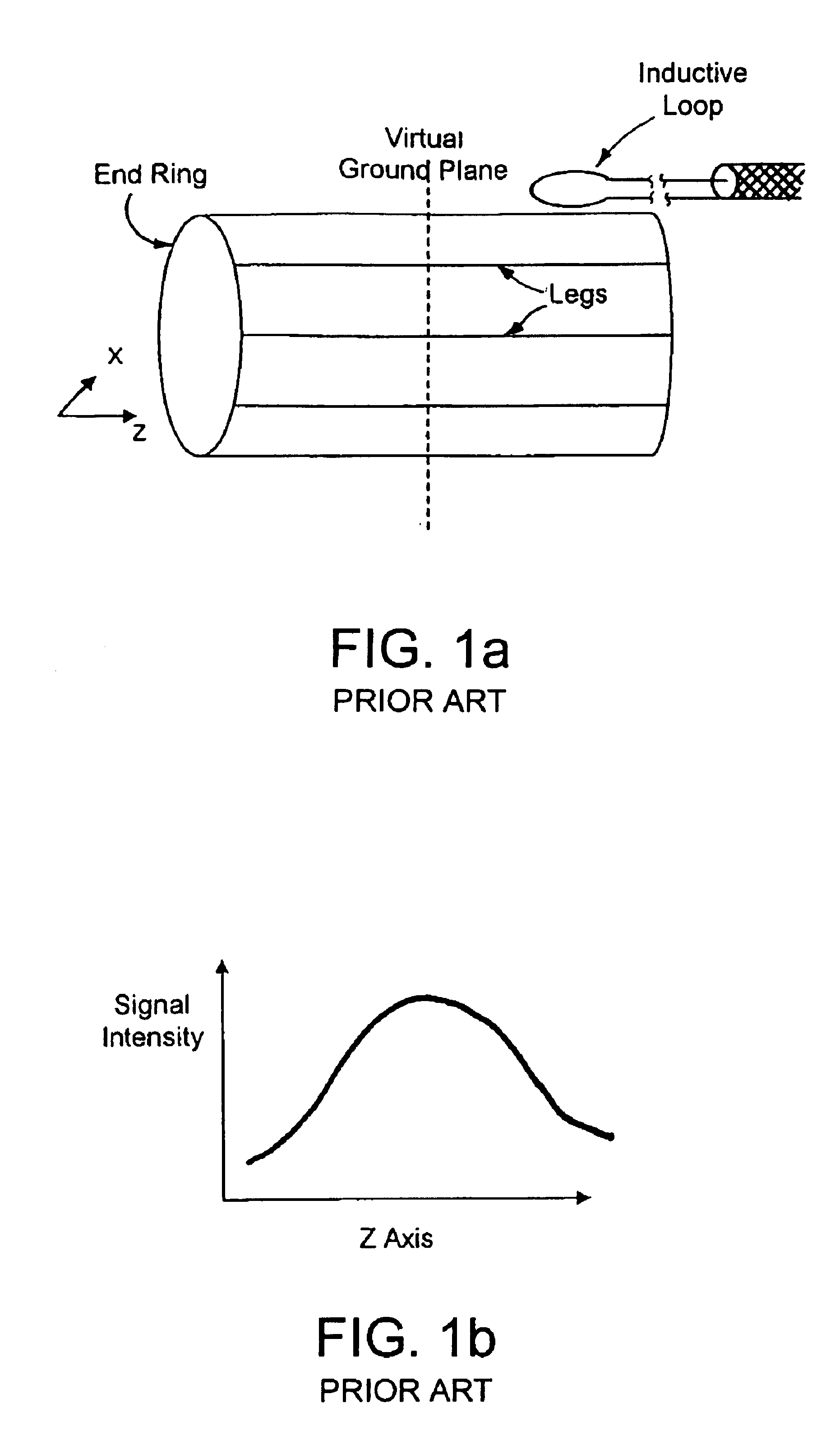

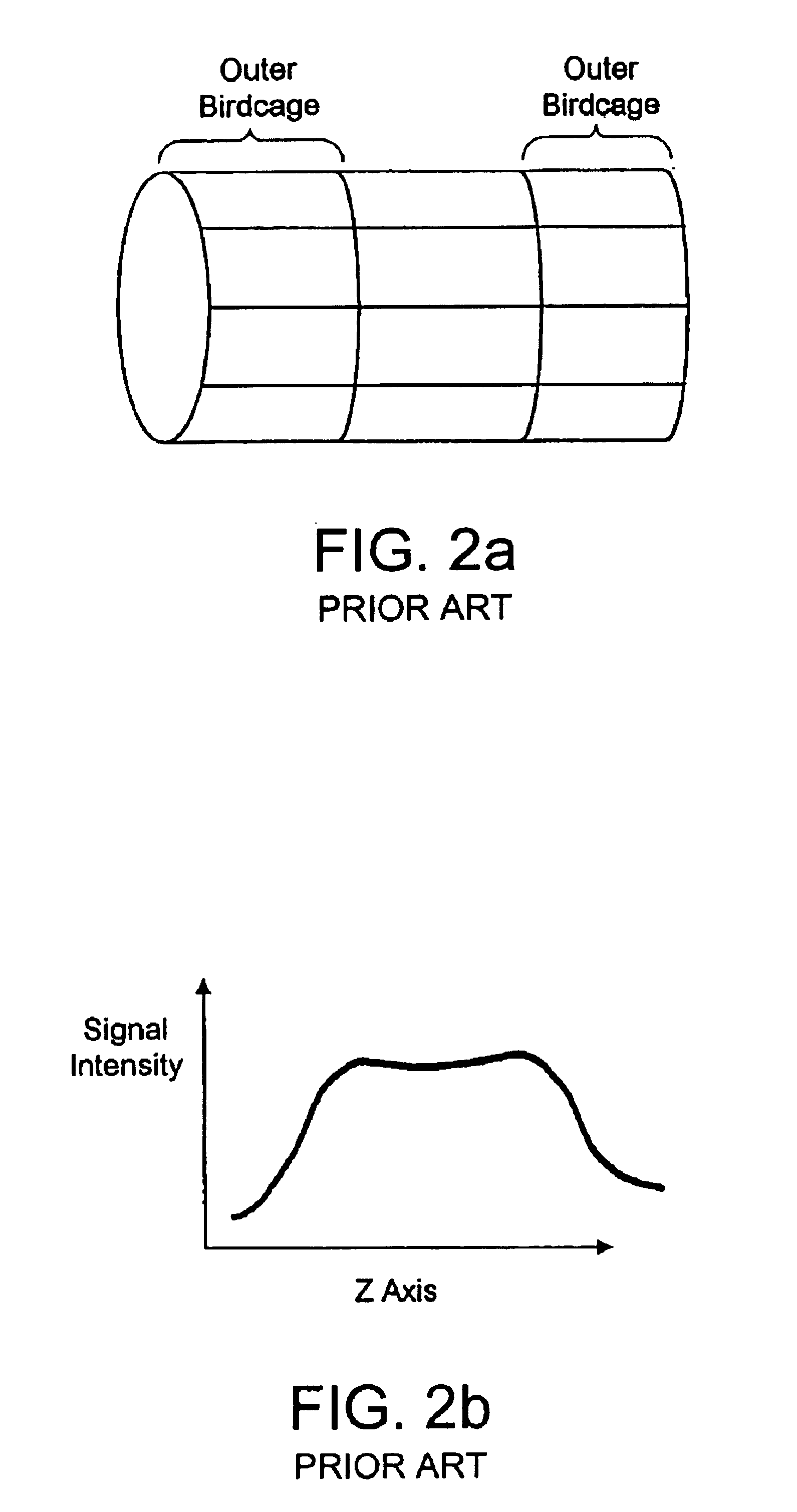

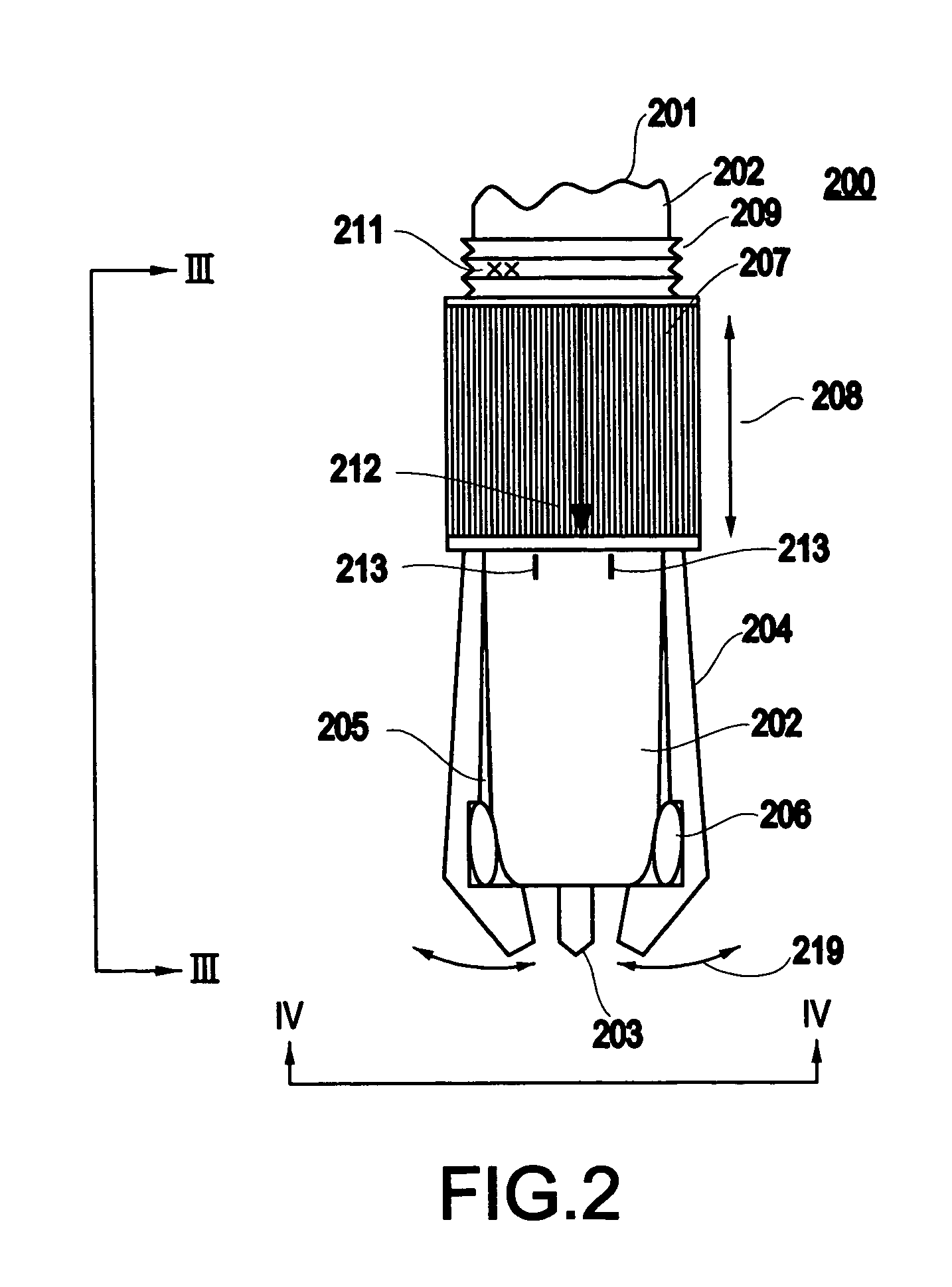

Radio-frequency coil array for resonance imaging analysis

InactiveUS6850064B1Improve signal-to-noise ratioHigh resolutionElectric/magnetic detectionMeasurements using magnetic resonanceCoil arrayImaging analysis

An RF coil array is provided with increased S / N over the entire imaging FOV. The array design includes a first RF coil spanning the entire FOV, second and third RF coils which together span the entire FOV such that the entire system provides improved S / N over the imaging FOV. An aspect of the invention is the unusual combination of coils in one integrated structure, that are well isolated from one another and maintain preferred current distributions and mode orientations.

Owner:ADVANCED IMAGING

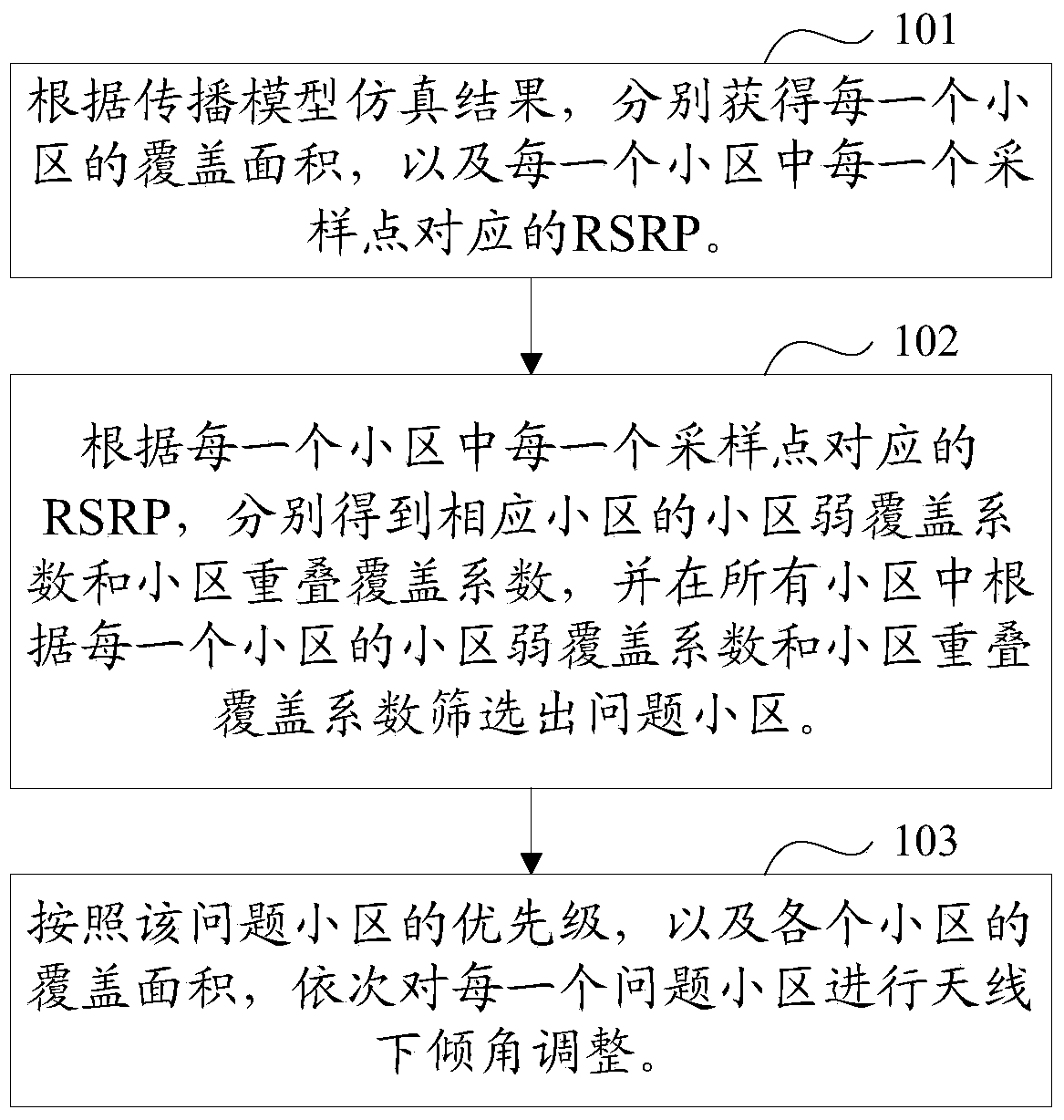

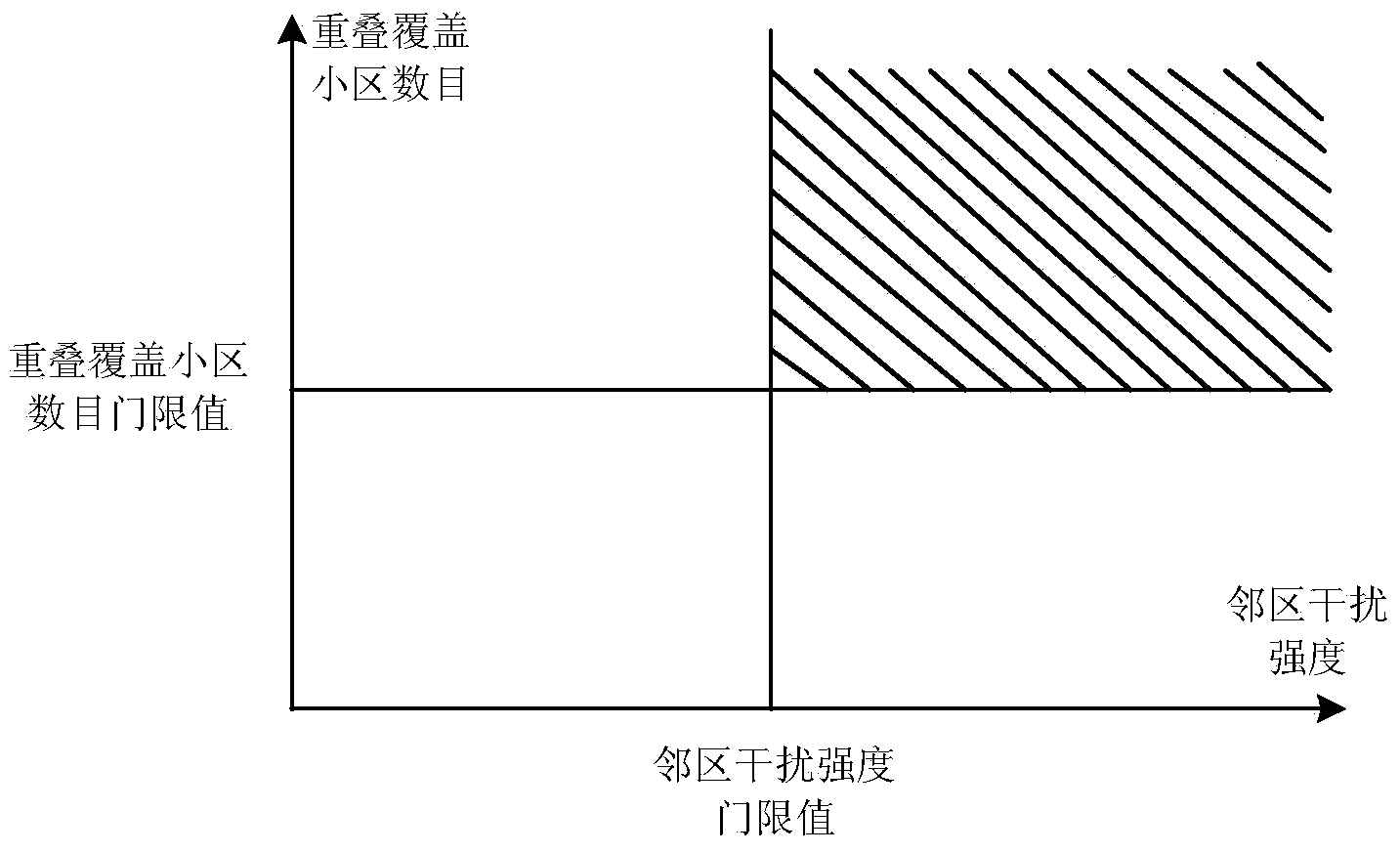

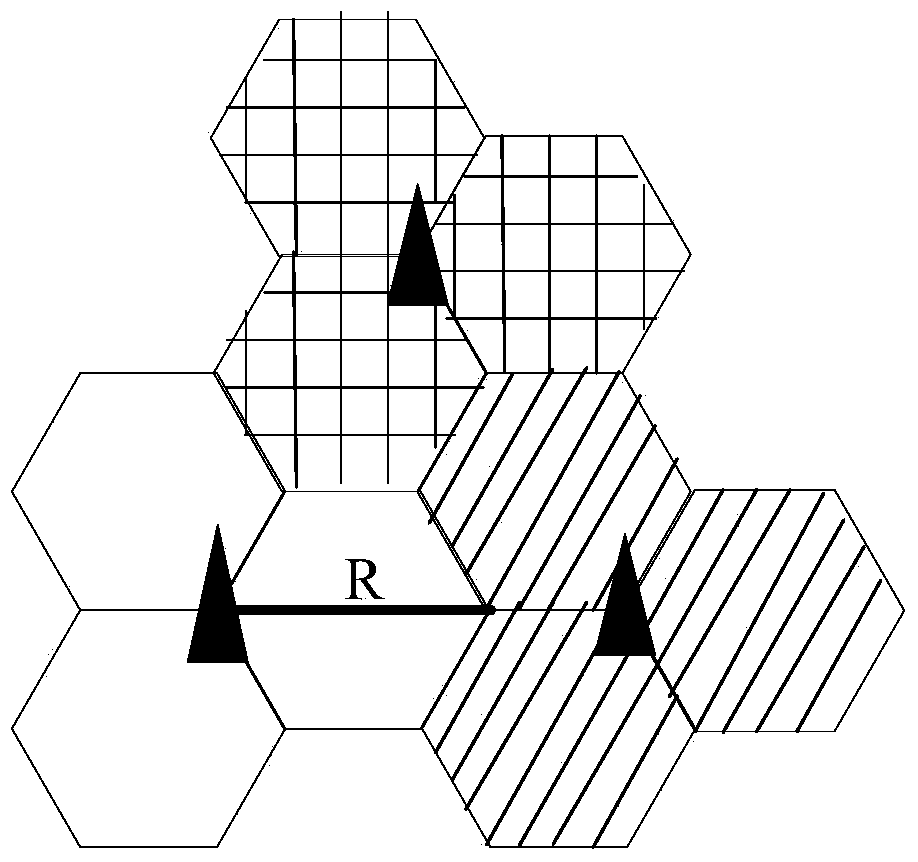

Antenna downward inclination angle adjusting method and device based on LTE network

ActiveCN103686767AAvoid wastingImprove accuracyNetwork planningWireless transmissionComputer science

The invention discloses an antenna downward inclination angle adjusting method and device based on an LTE network. The antenna downward inclination angle adjusting method and device based on the LTE network are used for solving the problems that in the prior art, due to manual intervention, resources are wasted, data are inaccurate, antenna downward inclination angles are arranged unreasonably, and the reliability of wireless transmission cannot be ensued. The method comprises the steps that a cell weak coverage coefficient and a cell overlapping coverage coefficient of each cell are obtained through simulation results of a propagation model, problem cells are screened out according to the cell weak coverage coefficients and the cell overlapping coverage coefficients of all cells, and lastly, the antenna downward inclination angles of all the problem cells are adjusted in sequence according to priorities of all the problem cells and the coverage areas of all the cells. In this way, the manual intervention is reduced, the resources are saved, the data are obtained through simulation calculation instead of experience values, the optimization process is simplified, optimization efficiency is improved, the accuracy of the antenna downward inclination angle is improved, and transmission reliability is ensured.

Owner:SHANGHAI DATANG MOBILE COMM EQUIP +1

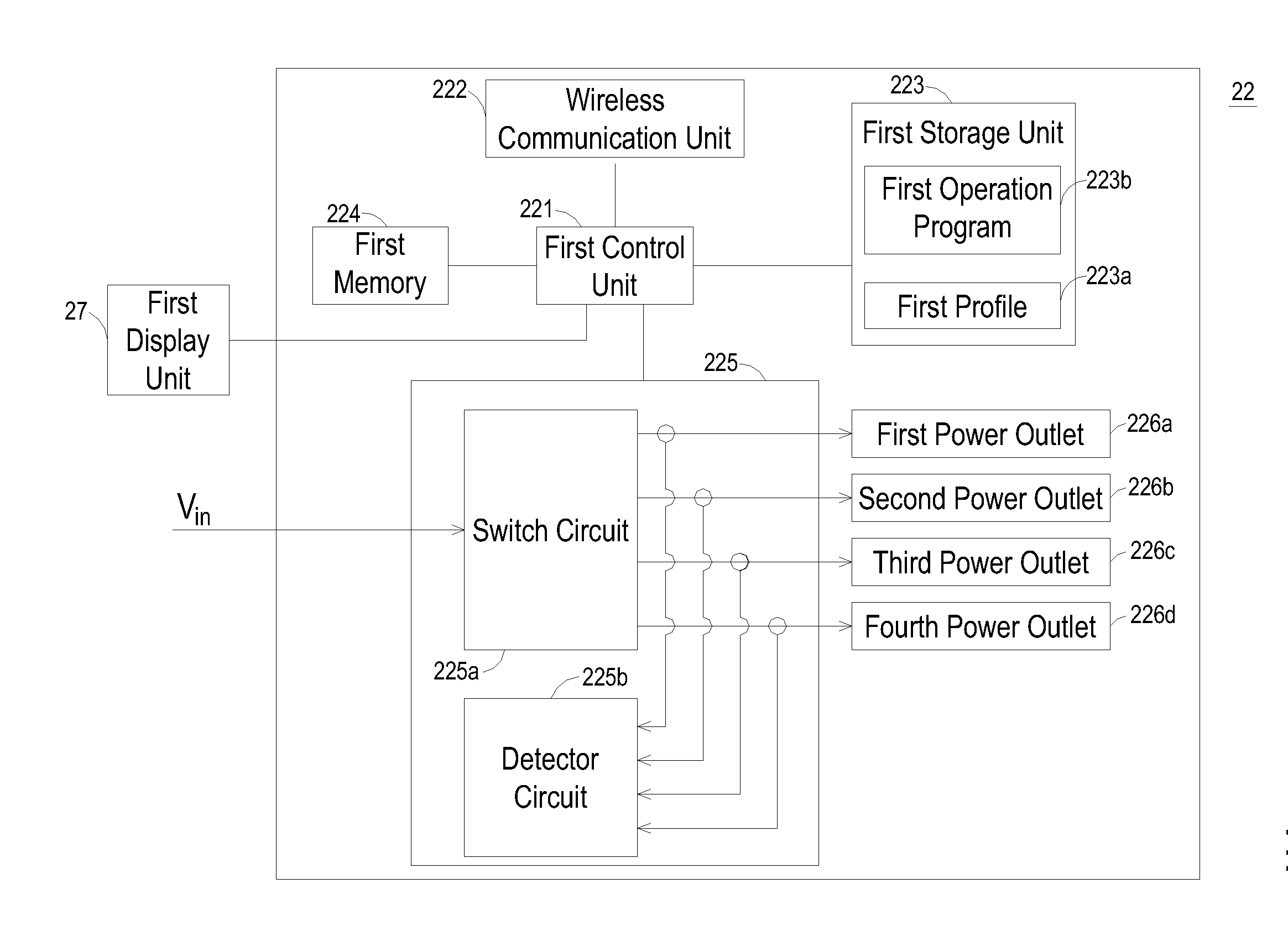

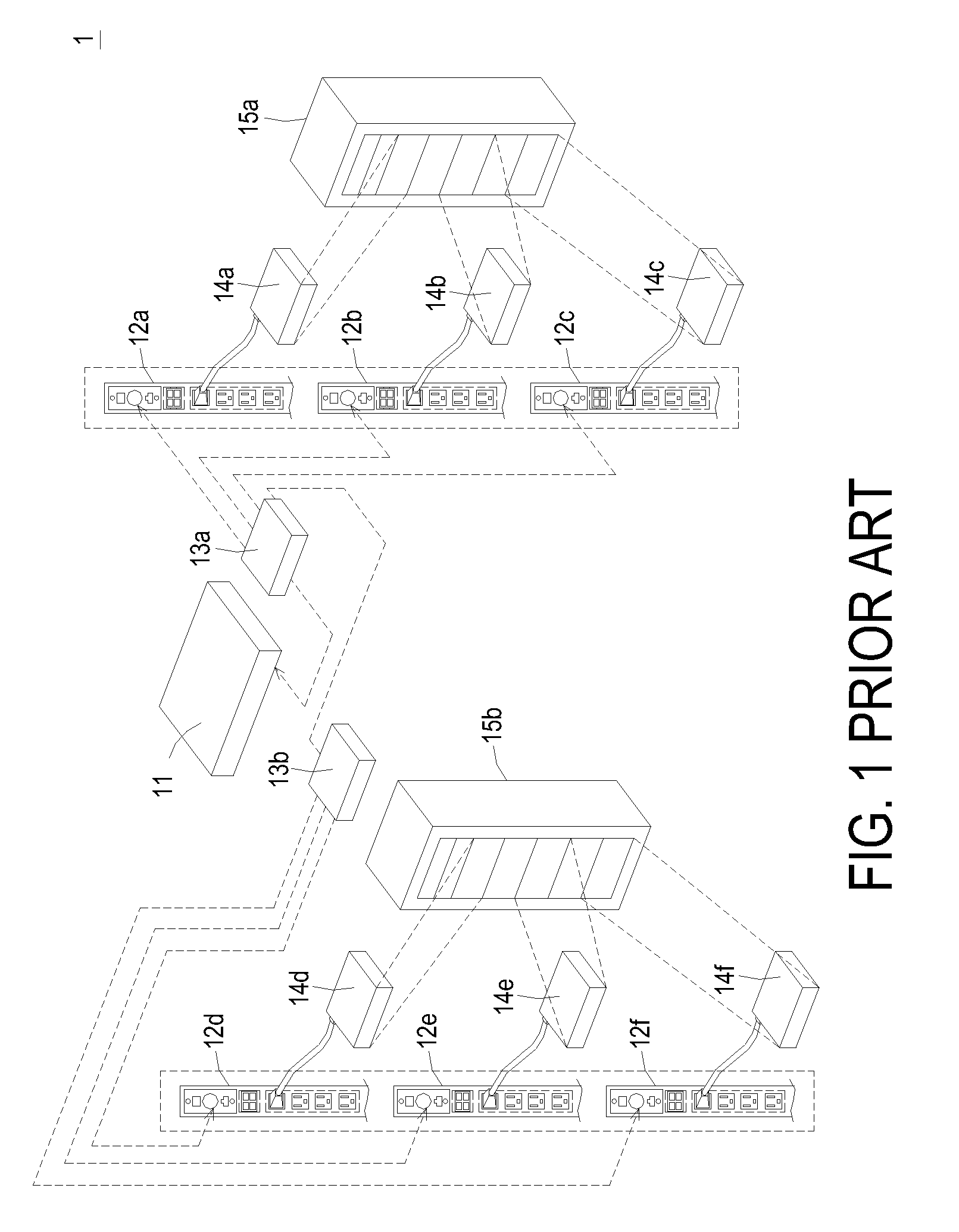

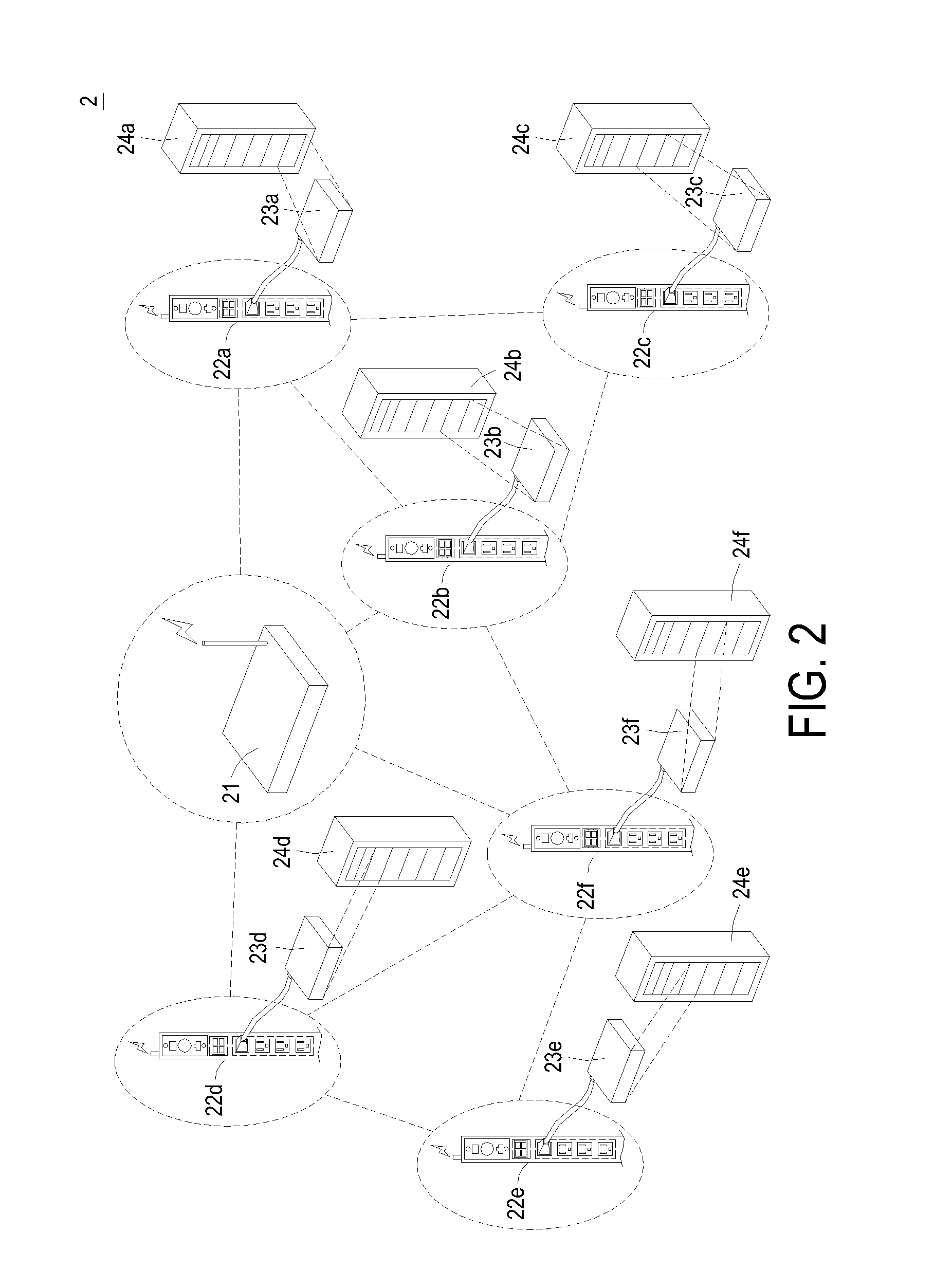

Power distribution unit and power management architecture employing the same

InactiveUS20110187193A1Without inflicting complexityIncrease costDc network circuit arrangementsPower network operation systems integrationCentral unitEngineering

Disclosed is a power distribution unit and power management architecture employing such power distribution unit. The power management architecture includes a remote power management system for managing a plurality of power appliances, and a plurality of power distribution units each of which is provided with wireless network connectivity. With the wireless network connectivity, the remote power management system and the power distribution units constitute a mesh link network for two-way data transmission. In operation, the remote power management system transmits a first profile to the power distribution units to allow the first control unit of the power distribution unit to real-timely control the operation of the power distribution units according to the management policy and / or the management principle recorded in the first profile.

Owner:DELTA ELECTRONICS INC

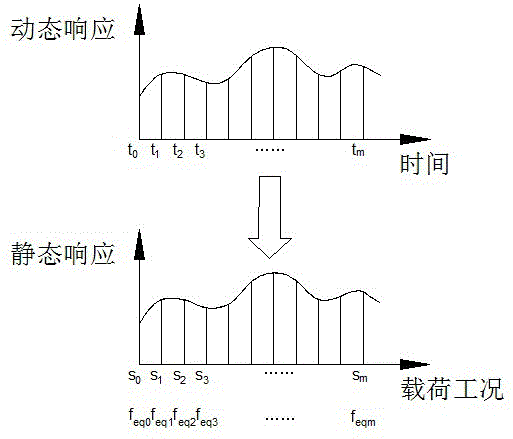

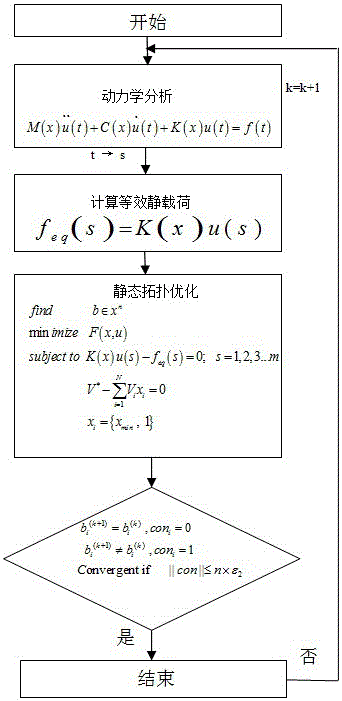

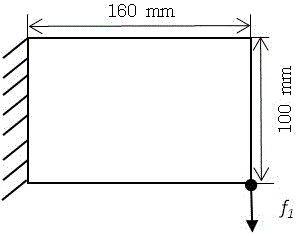

Dynamic response topological optimization method implemented by application of improved bi-directional evolutionary structural optimization (BESO) to equivalent static load method

InactiveCN106372347AReduce optimization timeCalculation speedDesign optimisation/simulationConstraint-based CADTopology optimizationPhases of clinical research

The invention relates to a dynamic response topological optimization method implemented by application of improved bi-directional evolutionary structural optimization (BESO) to an equivalent static load method. In the method, improved BESO is applied to the equivalent static load method to form an optimized iteration method for replacing an original variable density method, and establish a new convergence condition in order to improve a dynamic response topological optimization flow. By adopting the method, optimization time of a design circulation stage of which k is greater than 1 can be reduced effectively, and CPU (Central Processing Unit) total time needed by optimization in two examples is reduced by 21.8 percent and 25.3 percent compared with an original method; the method has the characteristics of high computation speed and simple optimization flow; along with the increase of external load acting points and the expansion of the optimization scale, design circulation times needed by optimization are increased, and the method has greater advantages.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

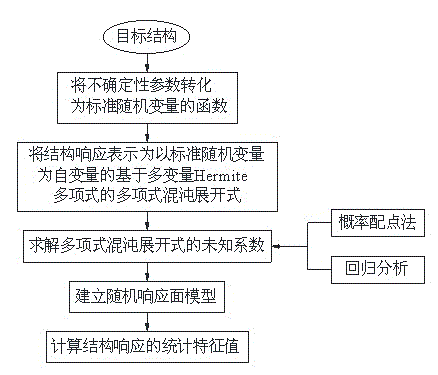

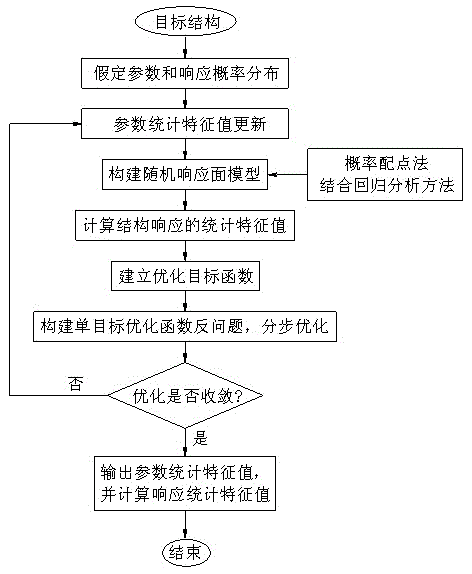

Stochastic model modification method based on uncertainty of stochastic response surface estimated parameter

ActiveCN102982250ASimplify the optimization processAvoiding the ill-conditioned sensitivity matrix problemSpecial data processing applicationsModel modificationError function

The invention relates to a stochastic model modification method based on uncertainty of a stochastic response surface estimated parameter, which comprises the following steps: 1, representing an uncertain parameter of a structure system as a function of a standard stochastic variable and representing a response of the structure system as a polynomial chaos expansion which uses the standard stochastic variable as an independent variable and is based on a Hermite polynomial, and solving an undetermined coefficient of the polynomial chaos expansion so as to establish a stochastic response surface model of the response of the structure system and calculate a statistical characteristic value of the response of the structure system; 2, utilizing an error function of a statistical characteristic value of the stochastic response surface model and the statistical characteristic value of the actually measured response to establish a target function required by stochastic model modification; 3, utilizing the target function to construct optimization inverse problems and modifying a parameter statistical characteristic value step by step; and 4, on the basis of the parameter statistical characteristic value obtained by stochastic modification, utilizing a stochastic response surface to calculate and obtain the statistical characteristic value of the response of the structure system. The method ensures modification accuracy when improving modification efficiency.

Owner:FUZHOU UNIV

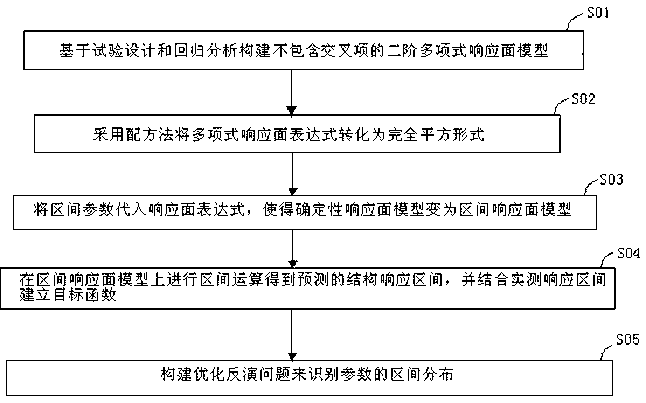

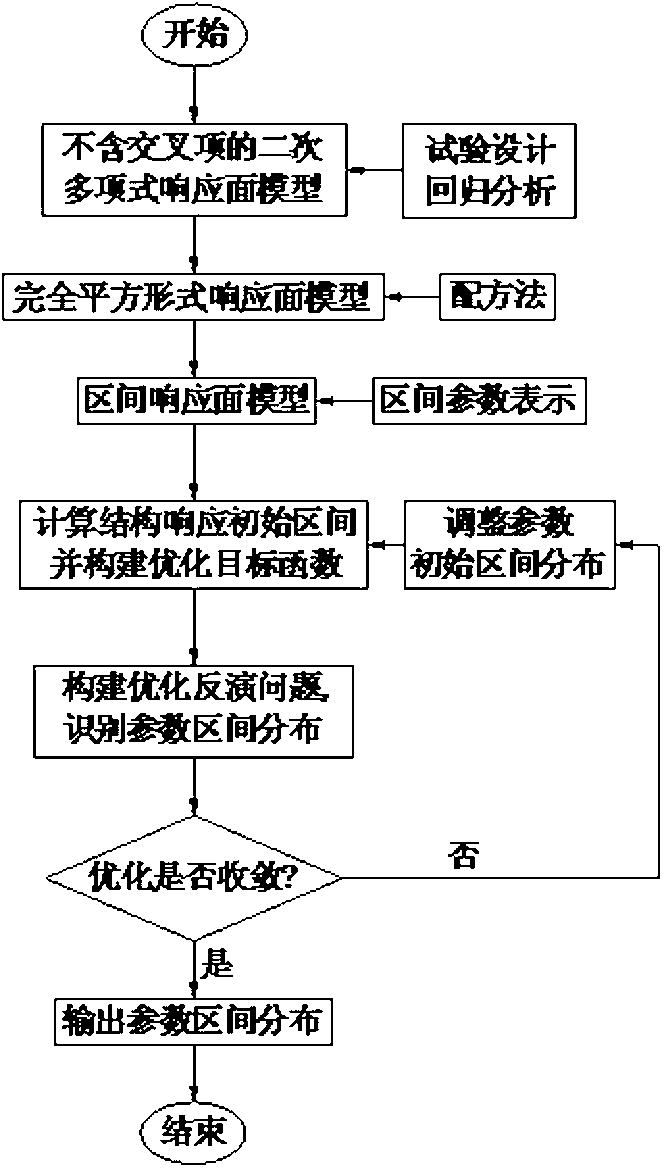

Random model updating method based on interval response surface model

ActiveCN103324798AImprove correction efficiencyGuaranteed calculation accuracySpecial data processing applicationsRegression analysisComputer science

The invention relates to random model updating method based on an interval response surface model. The method is characterized by including the steps of firstly, building a second-order polynomial response surface model without cross terms according to experiment design and regression analysis; secondly, using a square completing method to convert a polynomial response surface expression into perfect square; thirdly, substituting interval parameters into the response surface expression to allow the definite response surface model to be changed into the interval response surface model; fourthly, performing interval calculation on the interval response surface model to obtain predicted structural response intervals, and combining the predicted structural response intervals with actual response intervals to build a target function; fifthly, building a optimization inversion problem to identify interval distribution of parameters. By the method, the expansion problem of interval calculation is avoided, fast calculation of structural response intervals is considered, finite element analyzing calculation and sensitivity matrix building during (interval) random model updating are avoided, a large amount of calculation time and cost is saved, and ill-conditioned optimization is avoided as much as possible.

Owner:FUZHOU UNIV

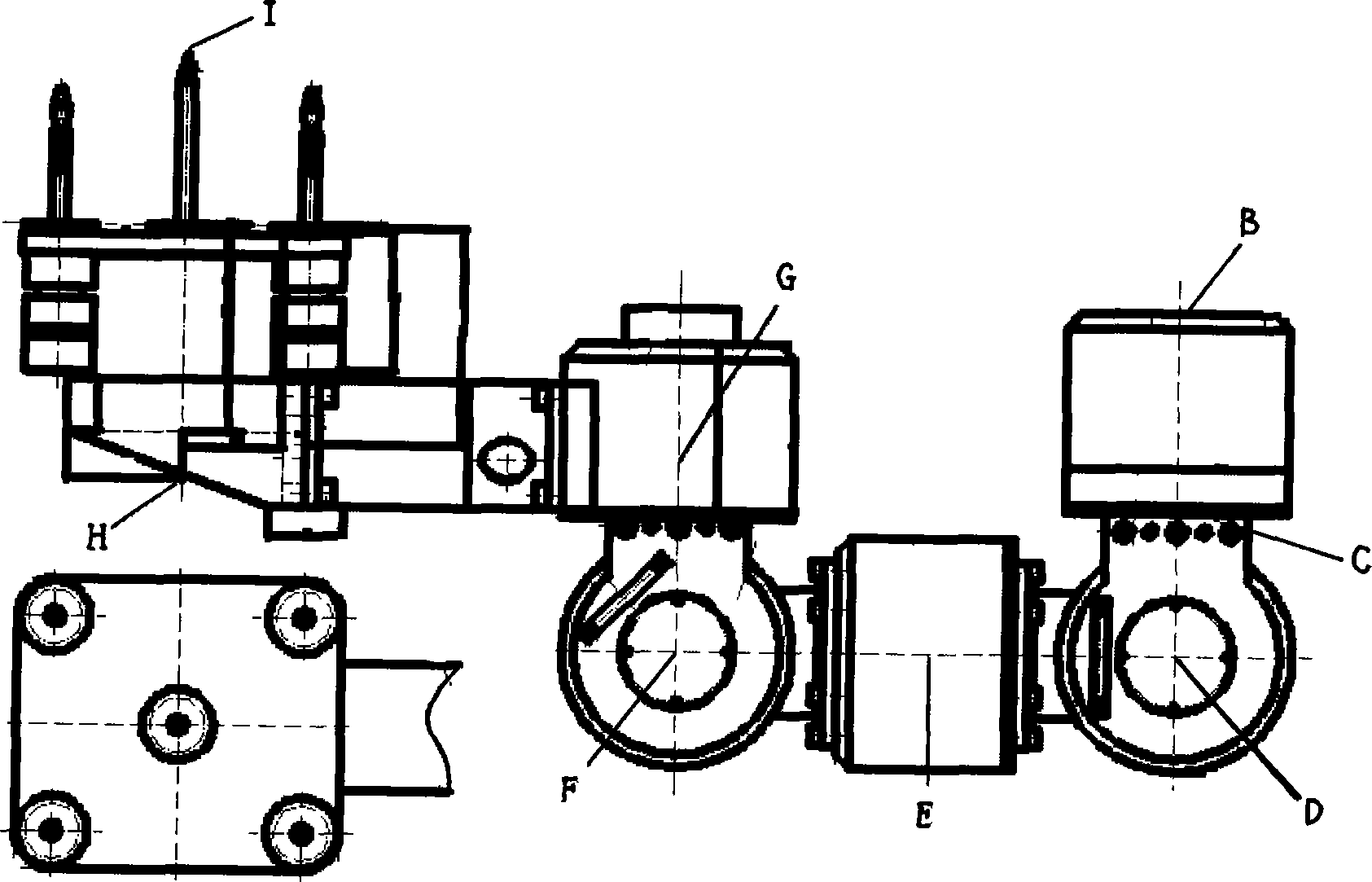

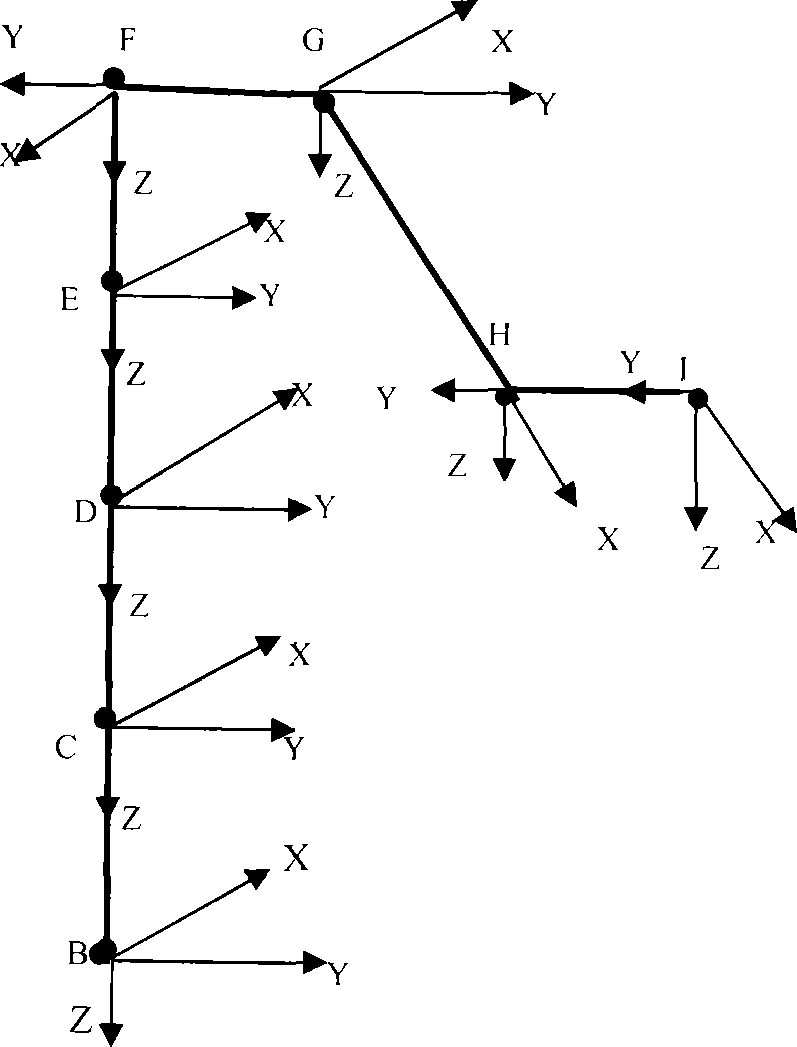

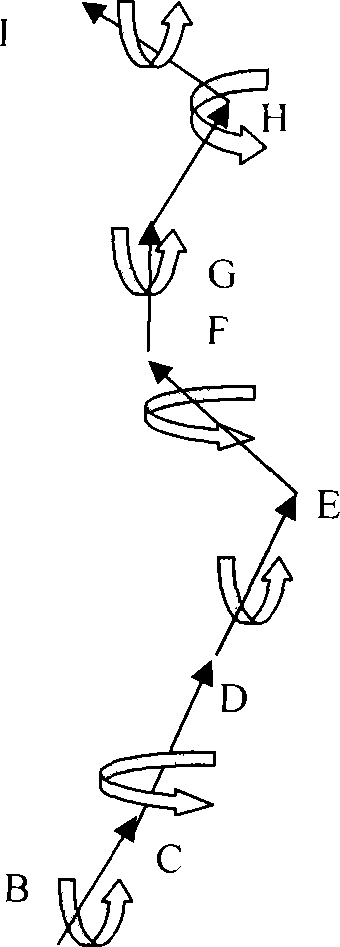

Kinematic inverse method for installation process of steam generator examining and repairing mechanical arm

InactiveCN101244561AAvoid kinematic equationsFast operationProgramme-controlled manipulatorComplex mathematical operationsBeta angleKinematics equations

The invention provides an inverse kinematical solution method during the installation process of an overhaul robot arm of a steam generator; wherein, the definitions of Alpha, Beta, and Gamma are as follows: at the initial stage, a base coordinate system is in the same attitude with a world coordinate system, then the base coordinate system revolves around the Y axis for the Alpha angle, next revolves around the X axis for the Beta angle, and finally revolves around the Y axis again for the Gamma angle, so as to obtain the ultimate attitude of the base coordinate system. The respective positions of the articulation points are: B point is the arithmetic endpoint of the robot arm, C, D, E, F, G, and H points are respectively the sixth to first articulation points, and I point is toe arithmetic endpoint; first, the coordinates of the articulation points of the robot arm are solved, and the coordinates of B, C and D points are resolved by means of the normal solutions during installation process; then, a vector HI is acquired based on the coordinate of I point and the attitude angles Alpha, Beta, and Gamma, so the coordinate of H point can be deduced; next, the coordinate of F point is solved; finally, the turn angles Theta (i) of the articulation points can be resolved (wherein, I=1, 2, 3, 4, 5, 6). The inverse kinematical solution method in the invention has the advantages of avoiding building up the kinematical equation of the robot arm, greatly reducing the amount of calculation, quickening the operational speed, and solving all the solutions.

Owner:HARBIN ENG UNIV

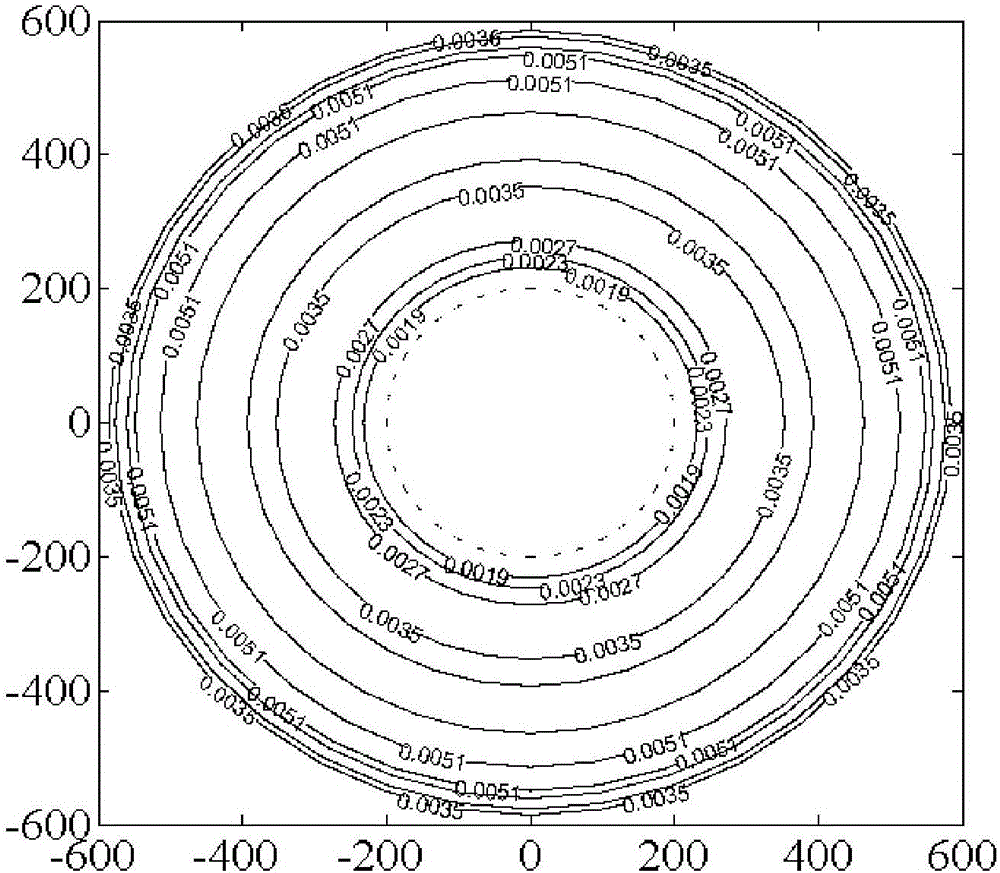

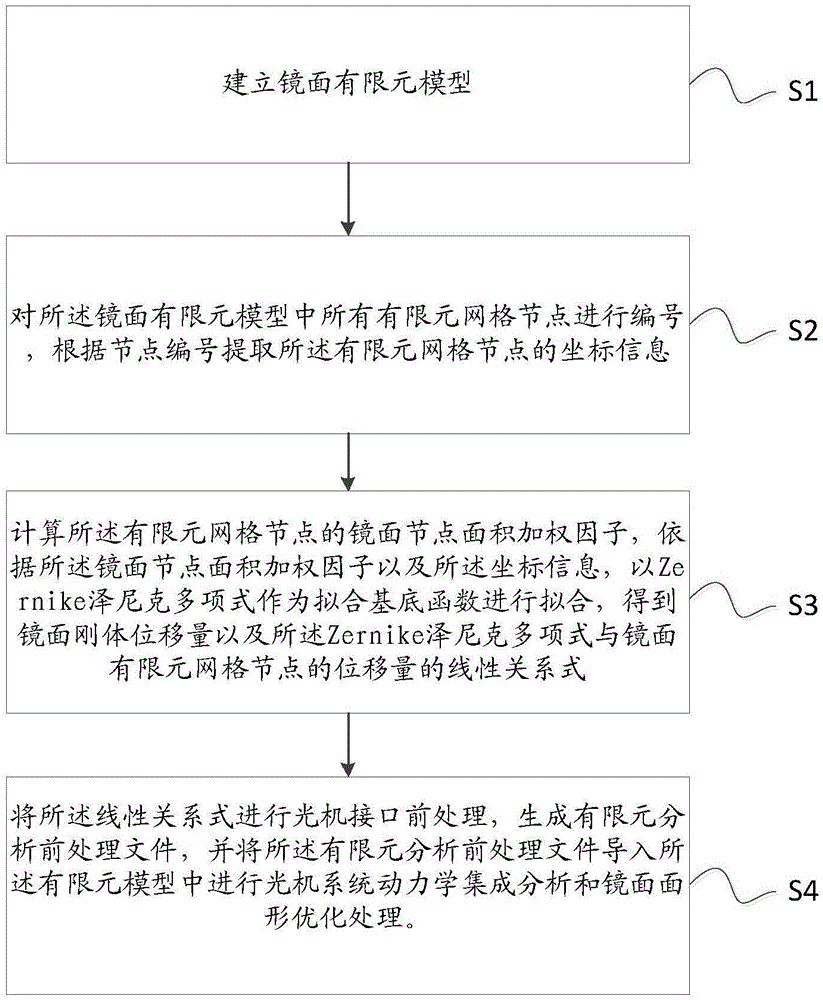

Optomechanical integrated analysis method for pre-processing interface program and mirror surface shape optimization method

ActiveCN106649922ASimplify the optimization processSolve the problem of decreased fitting accuracyDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

The invention discloses an optomechanical integrated analysis method for pre-processing interface program and mirror surface shape optimization method. The method comprises the steps of establishing a mirror finite element model, numbering all finite element mesh nodes in the mirror finite element model, based on the node number extracting coordinate information of finite element mesh nodes, calculating the weighted factor of the mirror node area of the finite element mesh node, based on the weighted factor and coordinate information of the mirror node area, using the Zernike Zernike polynomials as the basis functions for fitting, acquiring the relationship between the displacement of the mirror rigid body and the displacement of the Zernike Zernike polynomial and the mirror mesh node, conducting optomechanical interface pre-processing of the linear relation to generate the finite element analysis pre-processing file, introducing the finite element analysis pre-processing file into the finite element model for the optomechanical system dynamics integration analysis and mirror surface shape optimization. The optomechanical integrated analysis method for pre-processing interface program and mirror surface shape optimization method solves the problem that a large amount of fitting data leads to a large amount of calculation and a failure of fitting in an optomechanical program post-processing.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

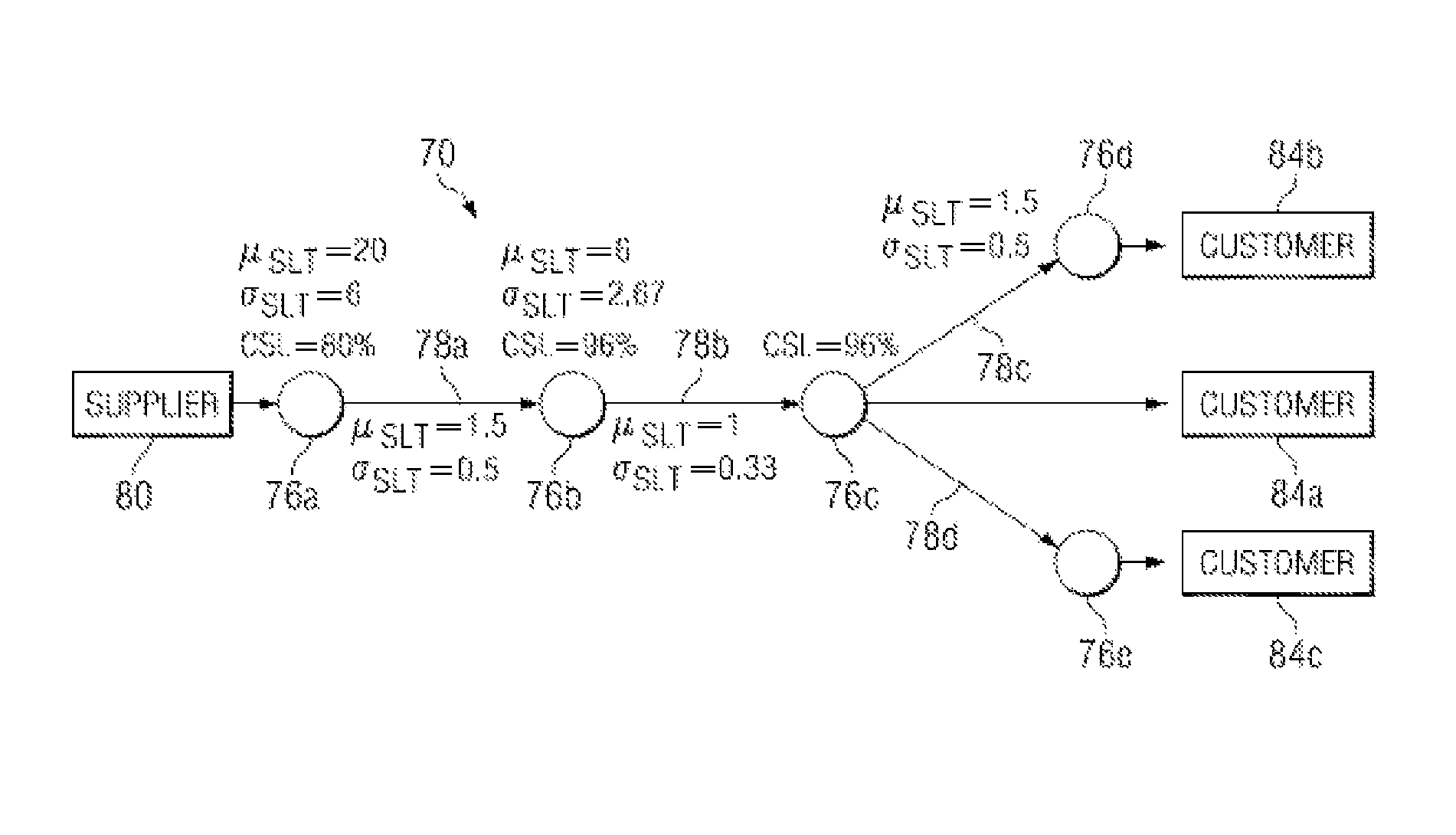

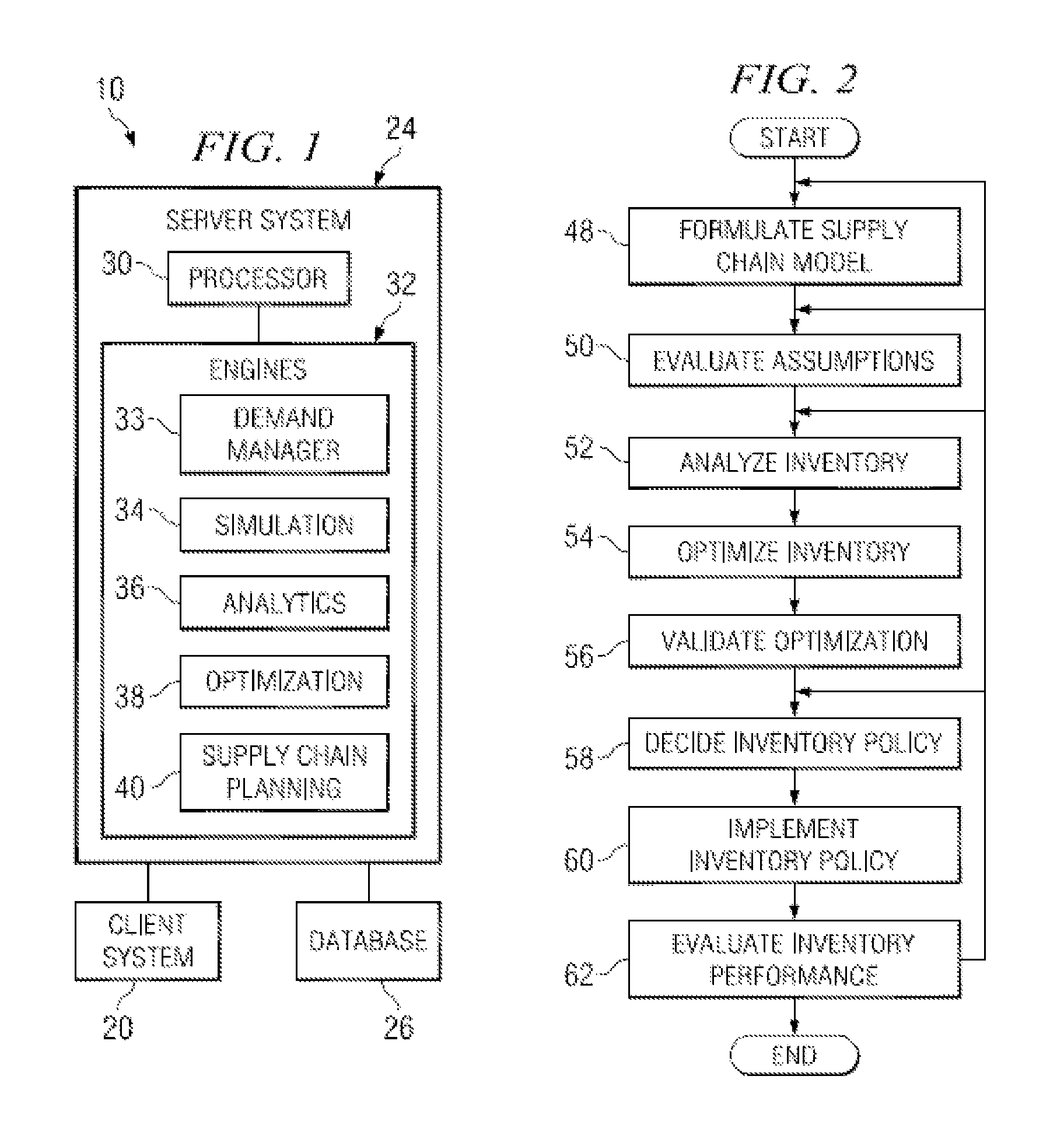

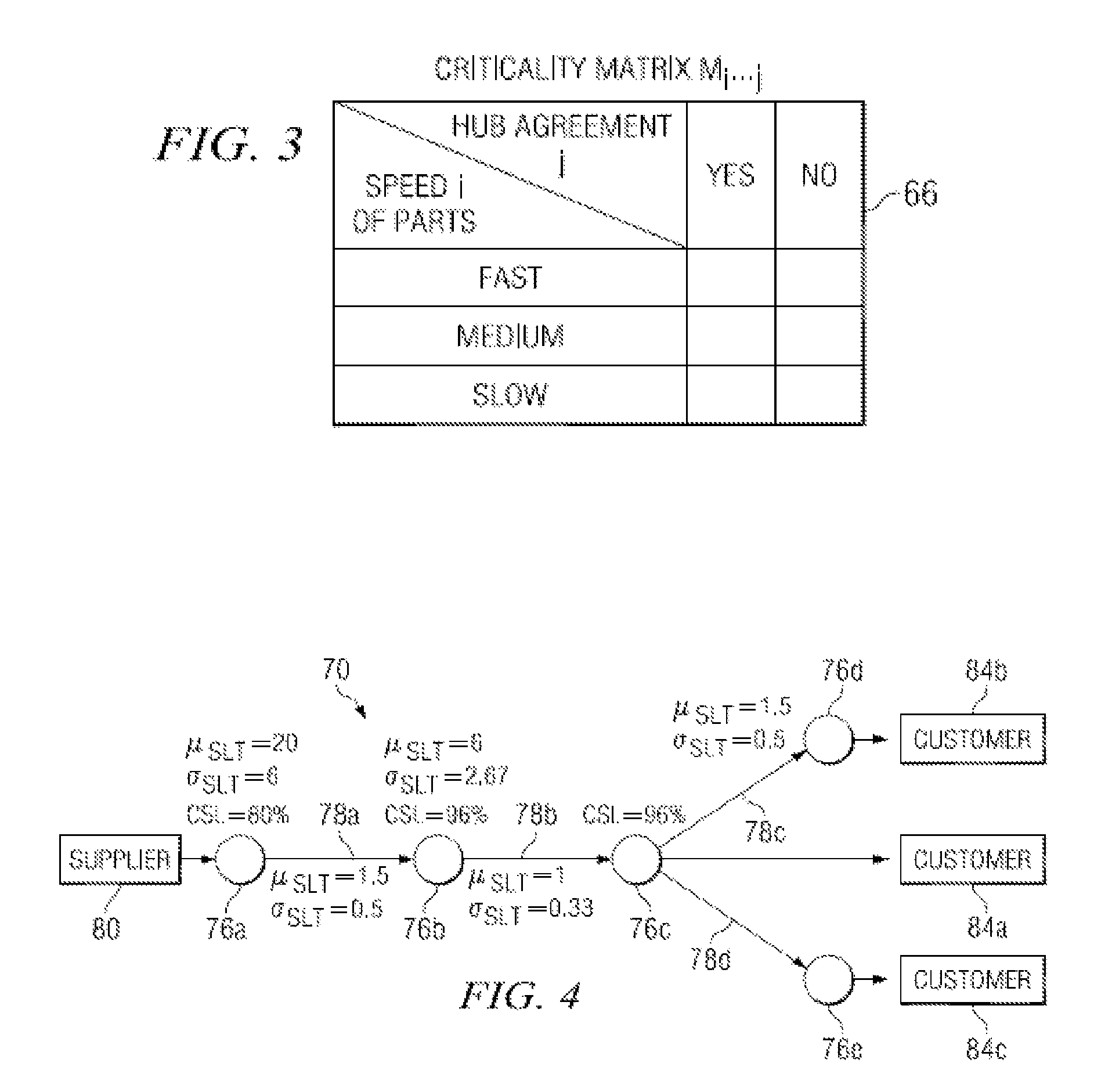

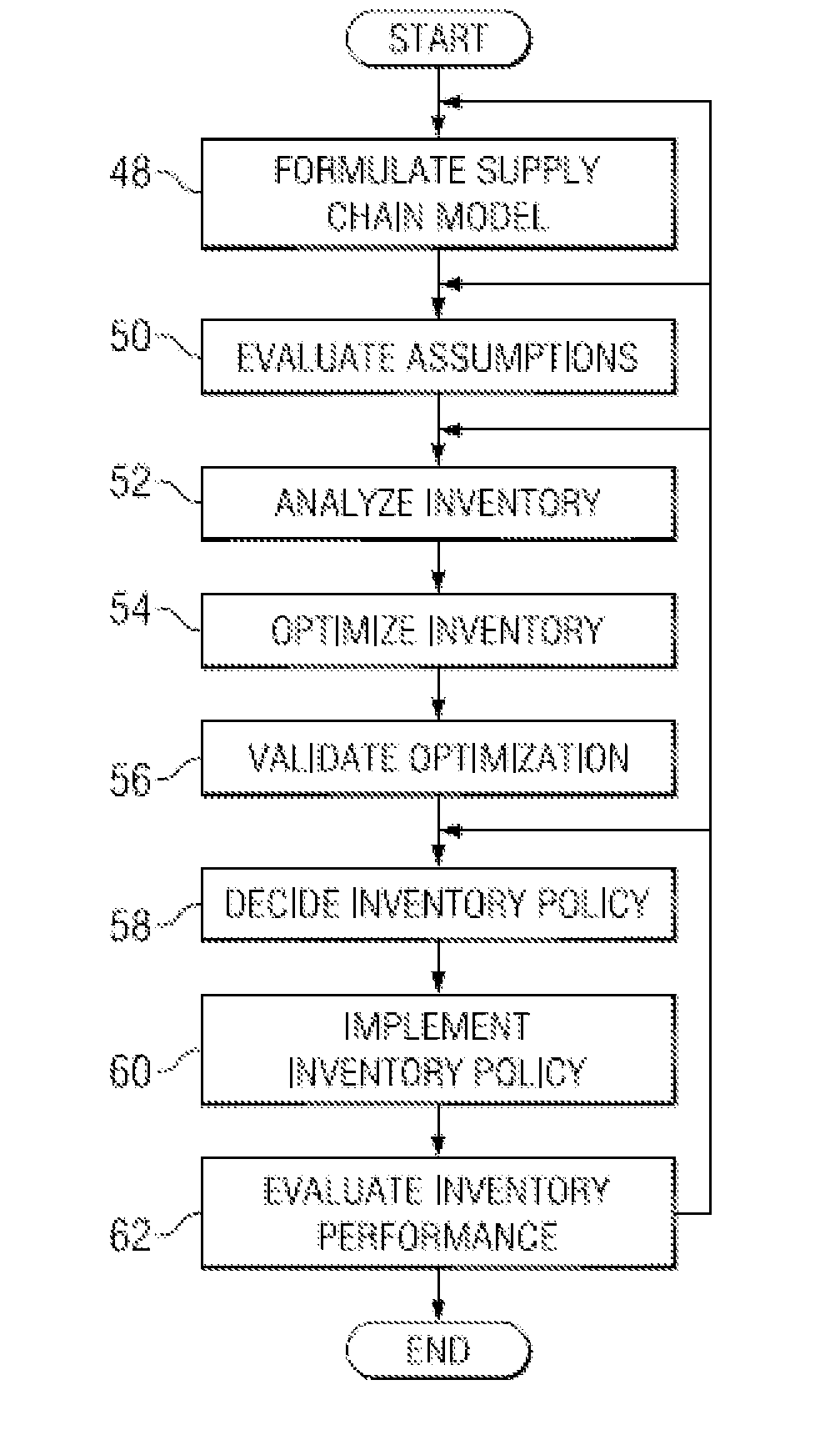

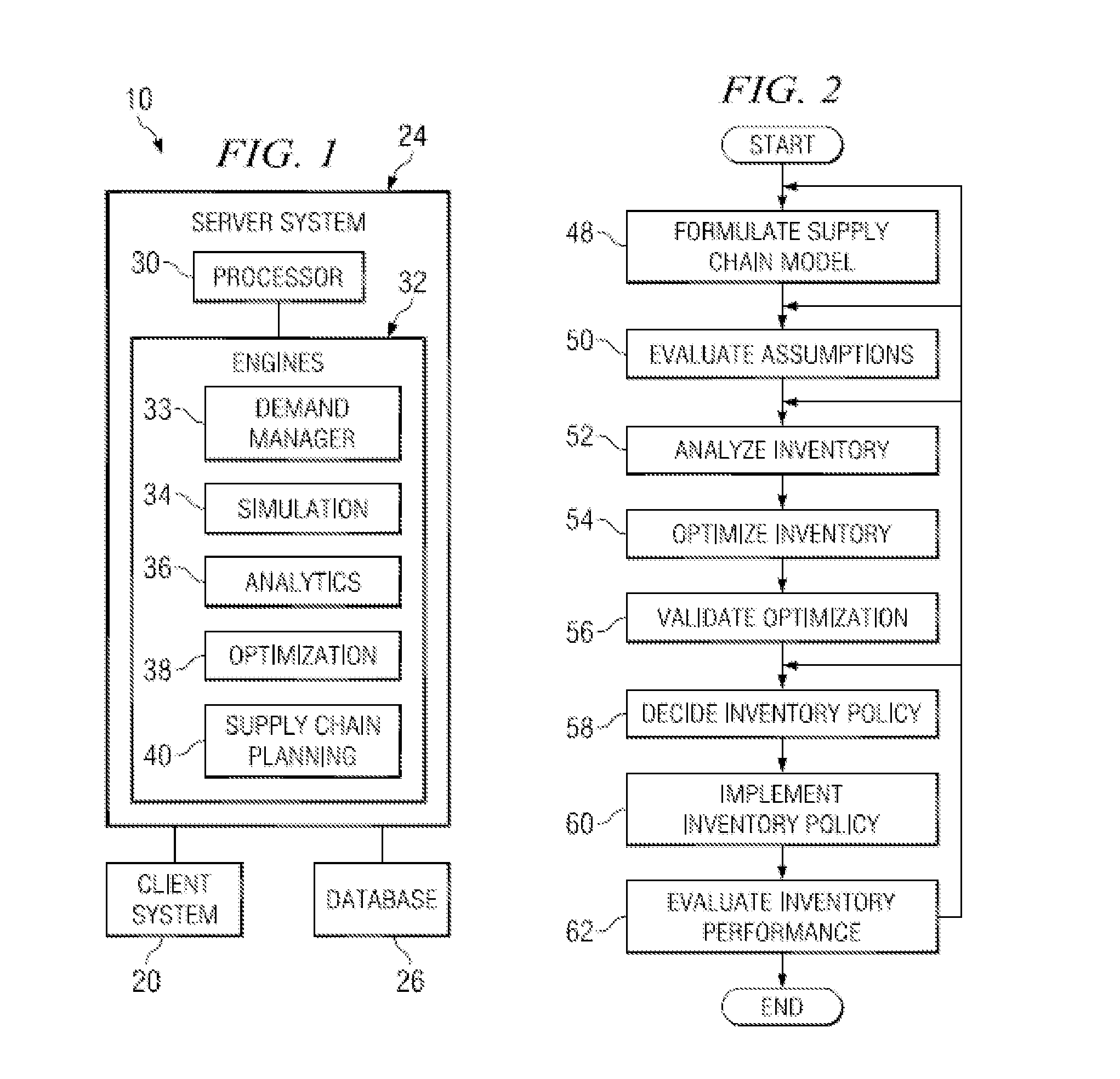

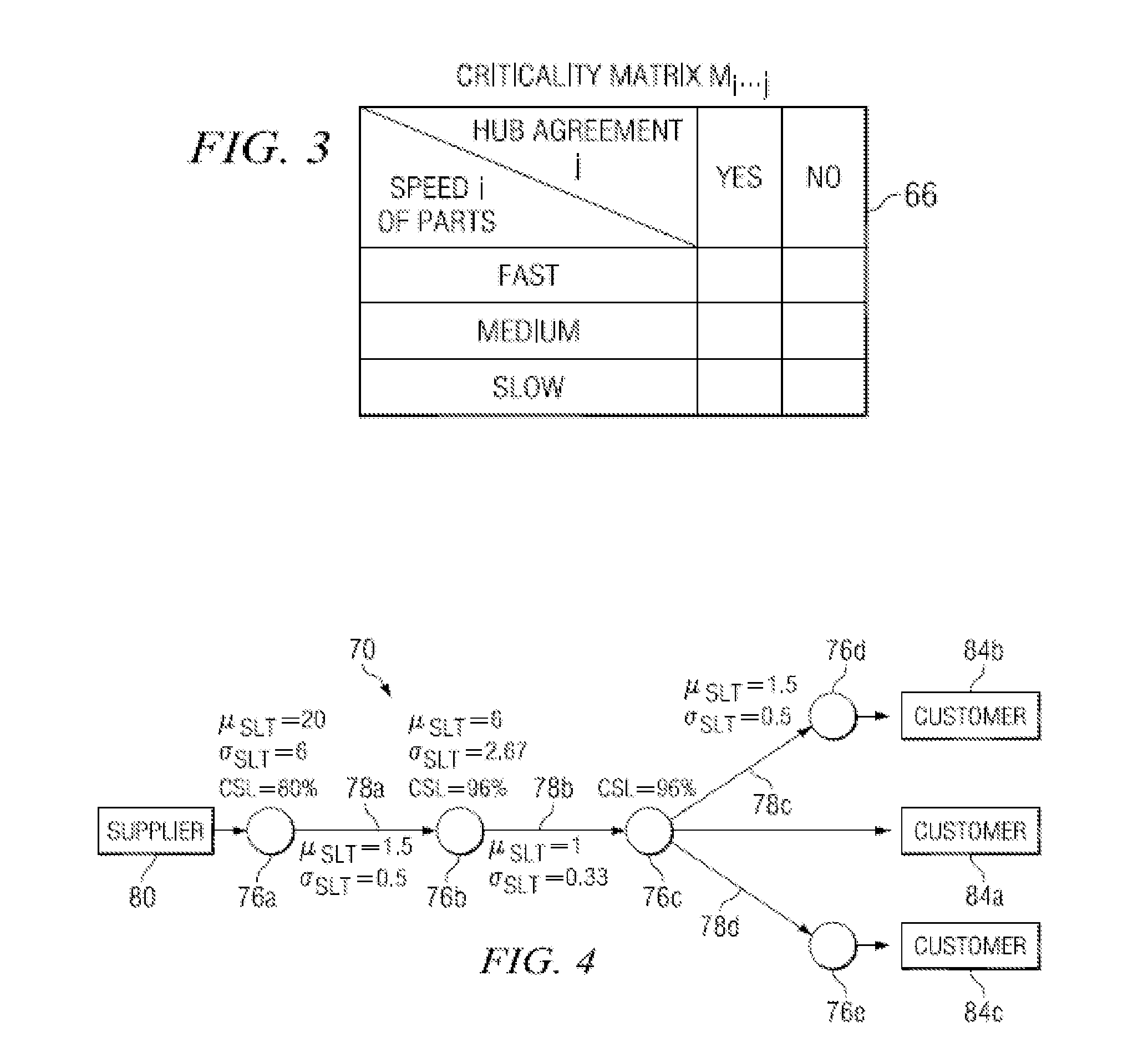

Determining order lead time for a supply chain using a probability distribution of order lead time

ActiveUS8428987B2Disadvantages can be reduced eliminatedSimplify the optimization processResourcesLogisticsTime rangeLead time

A system and method is disclosed for estimating demand of a supply chain including accessing a probability distribution of order lead time of the supply chain. The supply chain has nodes including a starting node and an ending node and a path from the starting node to the ending node. The probability distribution of order lead time describes ending node demand of the ending node versus order lead time. The path is divided into order lead time segments which are associated with the probability distribution of order lead time by associating each order lead time segment with an order lead time range of the probability distribution of order lead time. A demand percentage is estimated for each order lead time segment in accordance with the probability distribution of order lead time, such that each demand percentage describes a percentage of a total ending node demand of an order lead time segment.

Owner:BLUE YONDER GRP INC

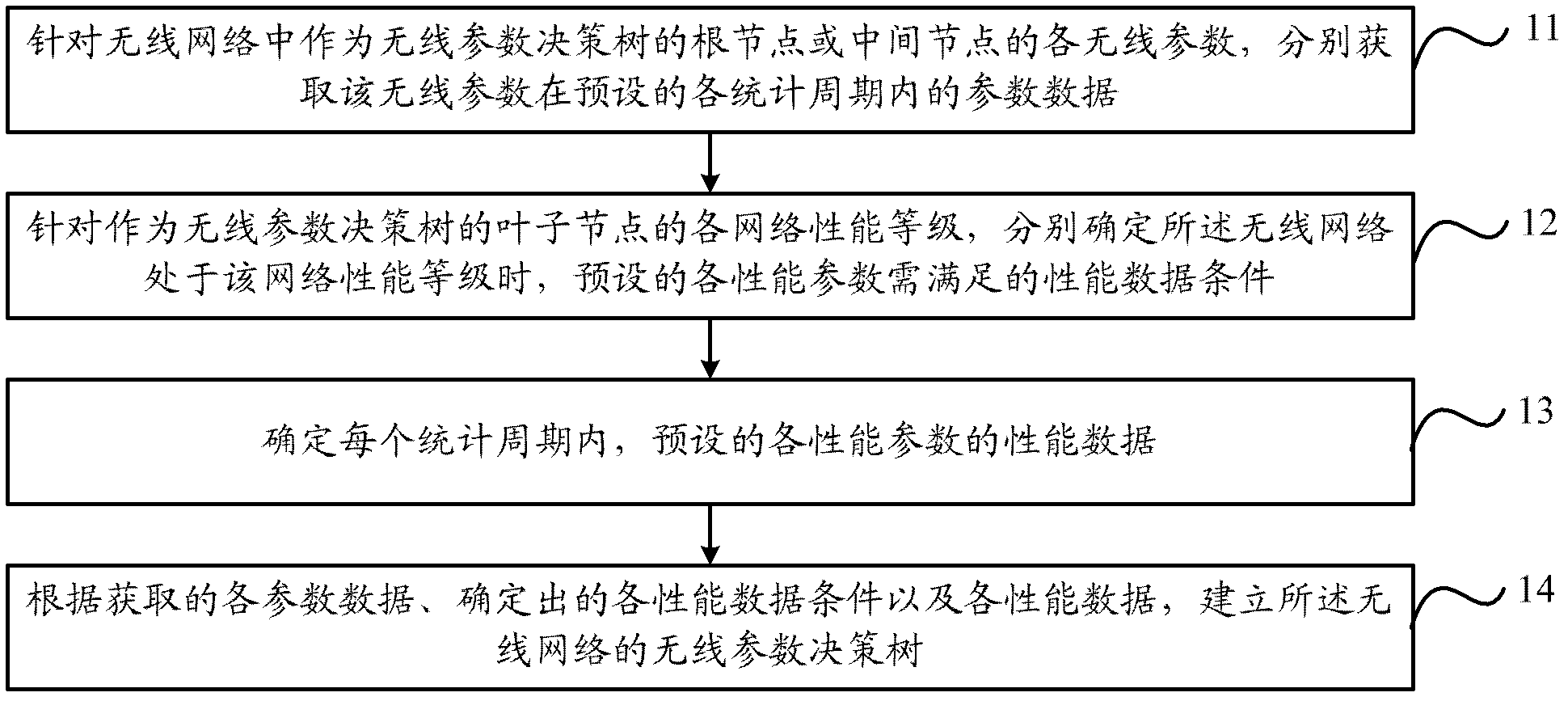

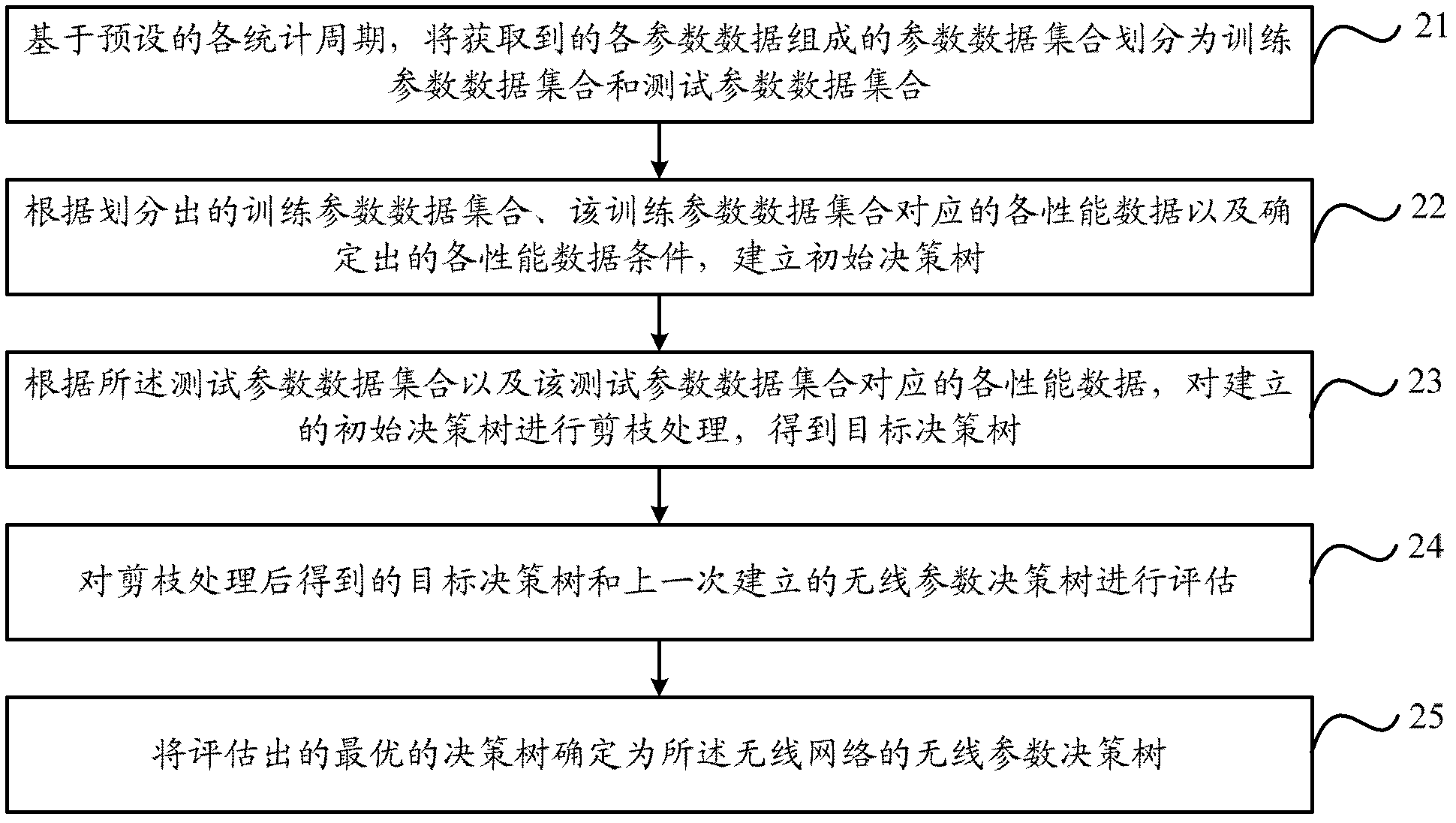

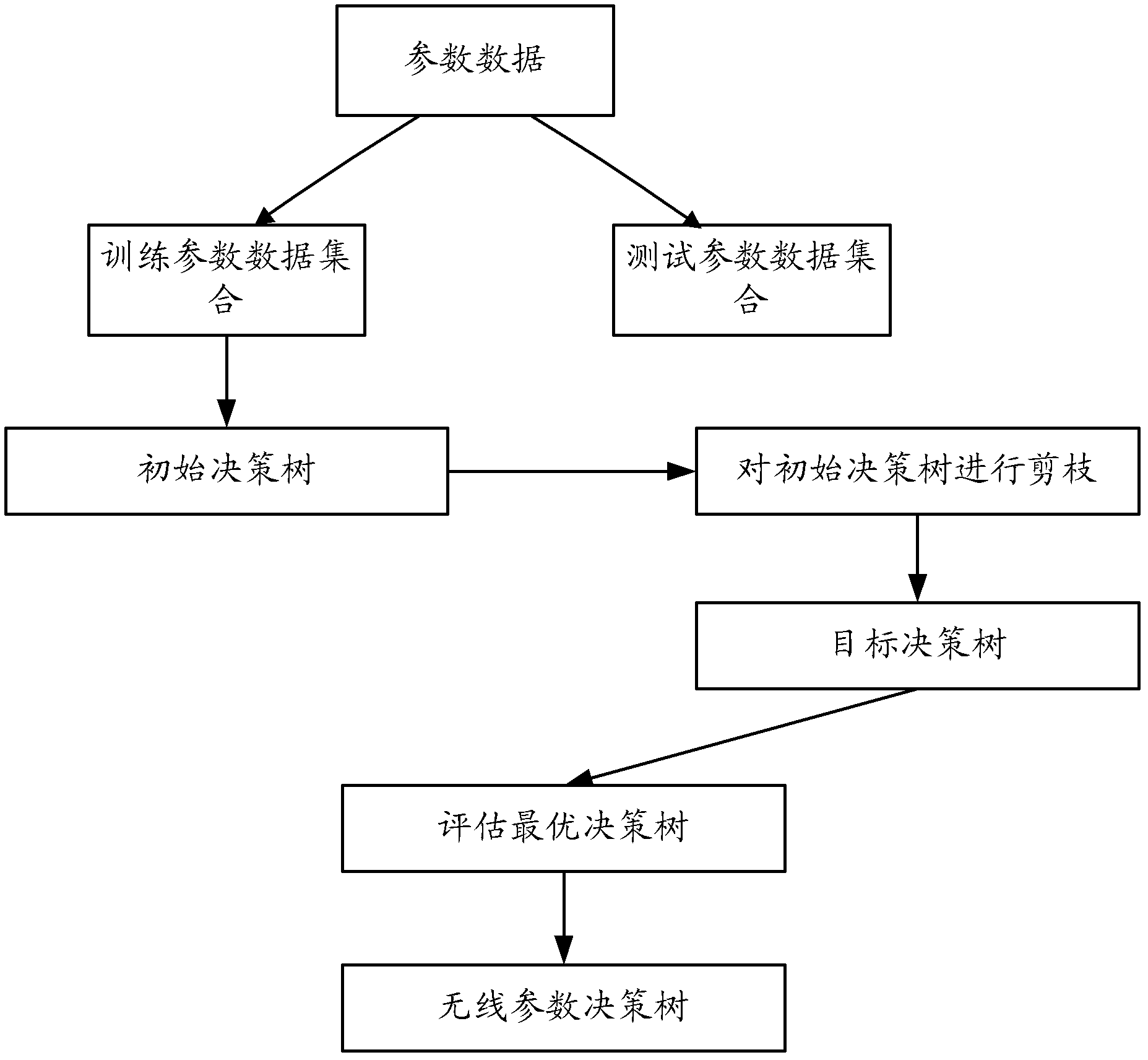

Method and device of building decision-making tree and method and device of network performance optimization

ActiveCN103108343AIncrease flexibilitySimplify the optimization processWireless communicationDecision-makingReal-time computing

The invention discloses a method and device of building a decision-making tree and a method and device of network performance optimization. The method of the network performance optimization comprises the steps of obtaining preset current parameter data of wireless parameters in a wireless network to be optimized; forecasting a network performance level of the wireless network according to a wireless parameter decision-making tree of the wireless network and the obtained parameter data; judging whether the wireless network needs performance optimizing or not according to the forecast network performance level; and if a judging result is yes, the parameter data of the wireless parameters conduct adjusting so as to optimize network performance of the wireless network. By the adoption of the technical scheme, the problems that in the prior art, flexibility of network performance optimization is low, and a process is complex and lags are solved.

Owner:CHINA MOBILE GROUP DESIGN INST

Determining Order Lead Time for a Supply Chain Using a Probability Distribution of Order Lead Time

ActiveUS20110208560A1Disadvantages can be reduced eliminatedSimplify the optimization processResourcesLogisticsTime rangeTime segment

A system and method is disclosed for estimating demand of a supply chain including accessing a probability distribution of order lead time of the supply chain. The supply chain has nodes including a starting node and an ending node and a path from the starting node to the ending node. The probability distribution of order lead time describes ending node demand of the ending node versus order lead time. The path is divided into order lead time segments which are associated with the probability distribution of order lead time by associating each order lead time segment with an order lead time range of the probability distribution of order lead time. A demand percentage is estimated for each order lead time segment in accordance with the probability distribution of order lead time, such that each demand percentage describes a percentage of a total ending node demand of an order lead time segment.

Owner:BLUE YONDER GRP INC

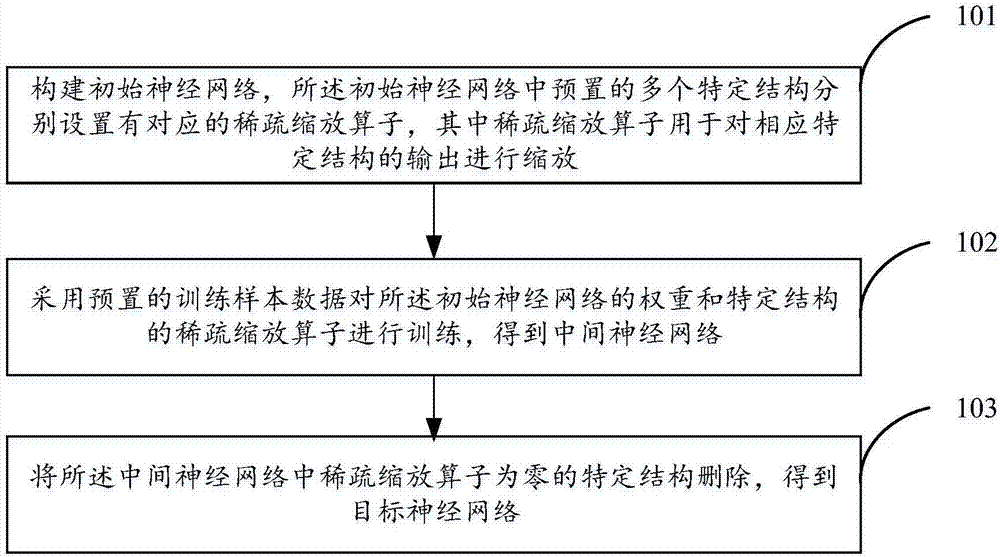

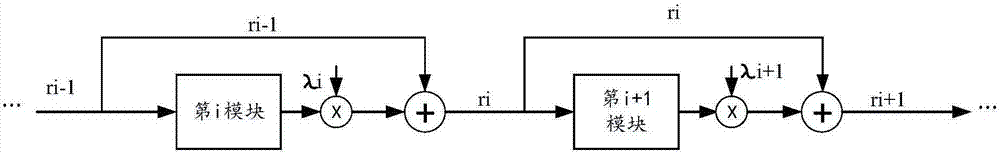

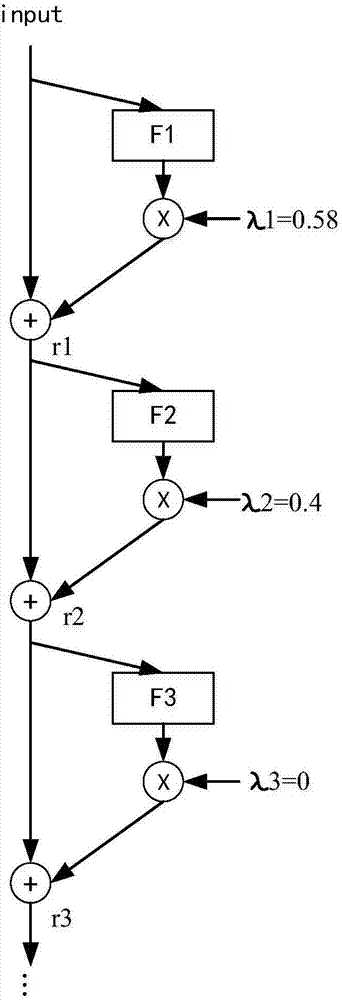

Method and device for building neural network

InactiveCN107247991AAccuracy is not affectedRun fastPhysical realisationNeural learning methodsHybrid neural networkMachine learning

Owner:BEIJING TUSEN WEILAI TECH CO LTD

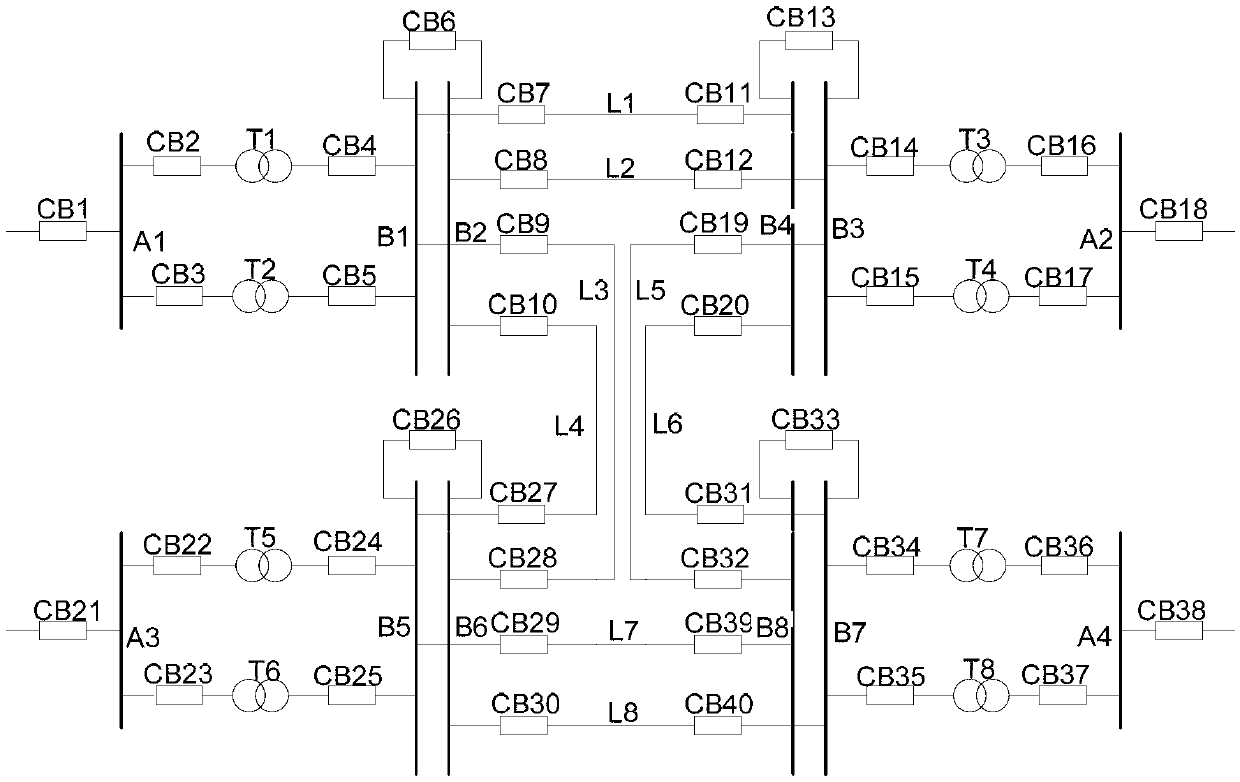

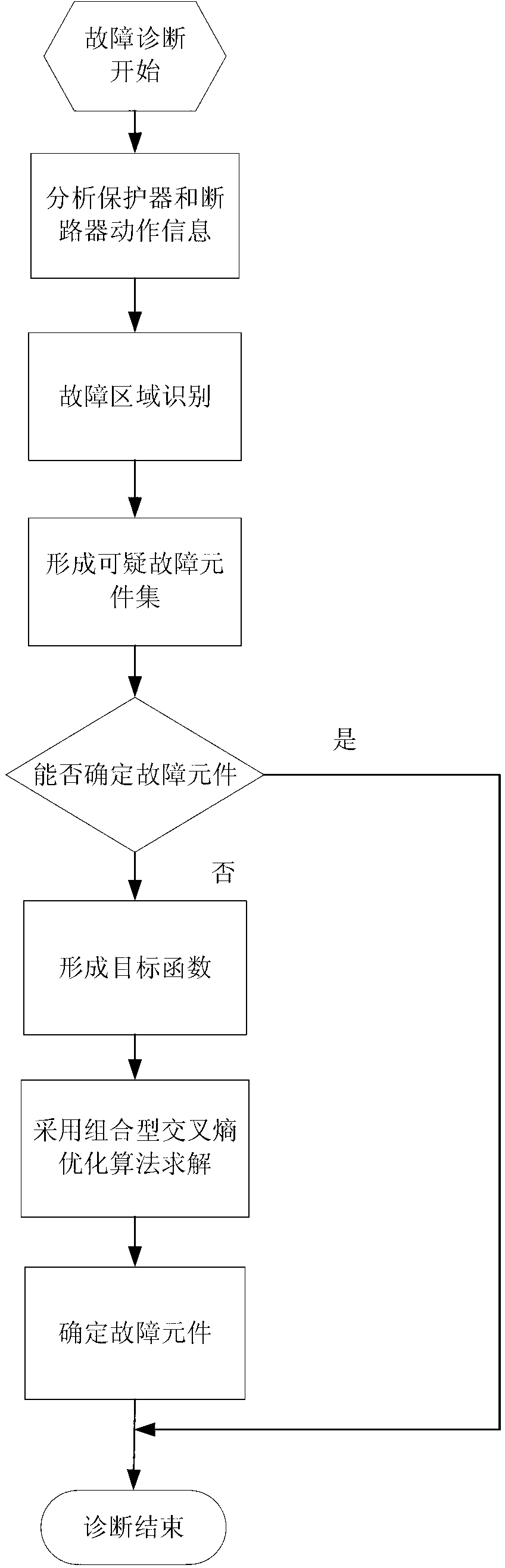

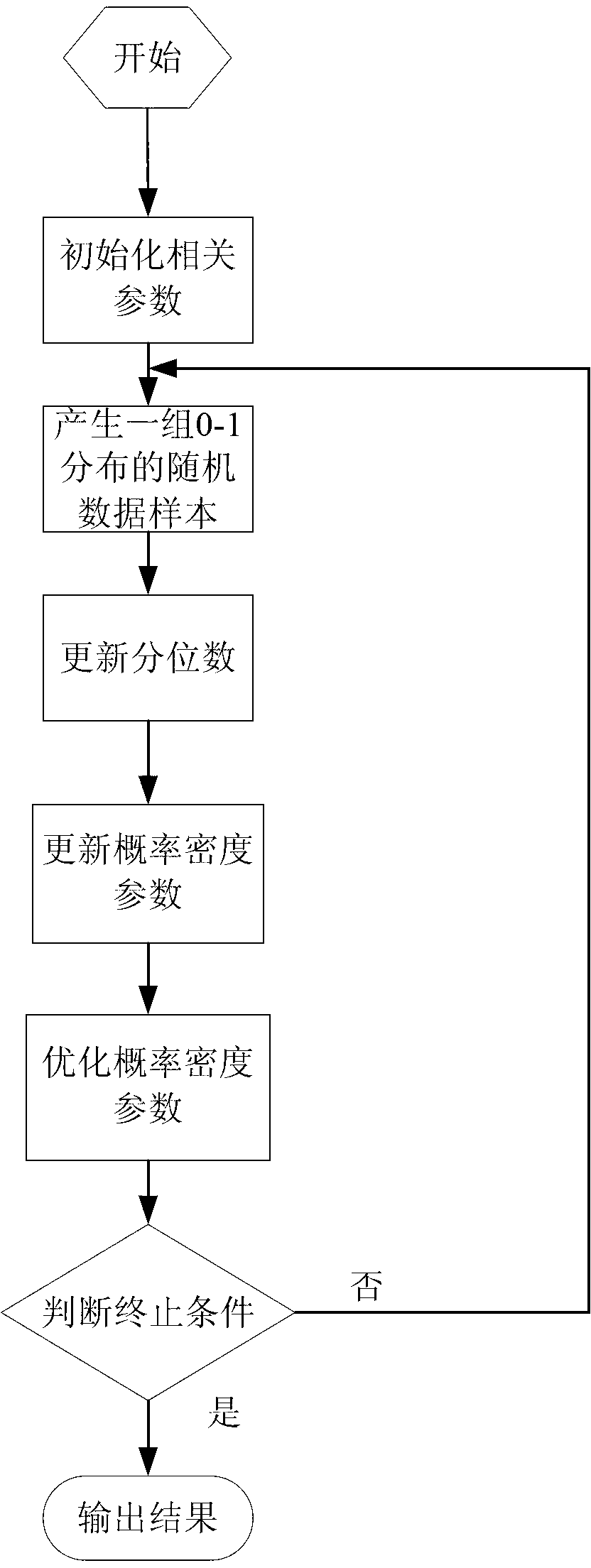

Grid fault diagnosing method based on combined type cross entropy algorithm

InactiveCN103344881ASolve for stabilityThe population mean has a small range of variationFault locationInformation technology support systemGrid faultControl system

The invention provides a grid fault diagnosing method based on the combined type cross entropy algorithm. The method comprises the steps of collecting the action messages of a protector and a breaker by means of a data acquiring and monitoring control system and a relaying information system, marking off faulty sections and determining a suspended fault element set, establishing an objective function based on suspended fault elements and solving the function by means of the cross entropy algorithm, identifying a fault element through the obtained optimal solution, and outputting a diagnosing result. According to the grid fault diagnosing method based on the combined type cross entropy algorithm, a fault diagnosing model is established according to the action messages of the protector and the breaker, the optimal solution of the model is obtained by means of the cross entropy algorithm, and then the fault element is identified. The grid fault diagnosing method based on the combined type cross entropy algorithm can be used for on-line grid fault diagnosis.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Selectively translating specified document portions

InactiveUS20130232406A1Avoid loadEasy to separateSoftware engineeringDigital computer detailsTerm memoryDocument preparation

Owner:MICROSOFT TECH LICENSING LLC

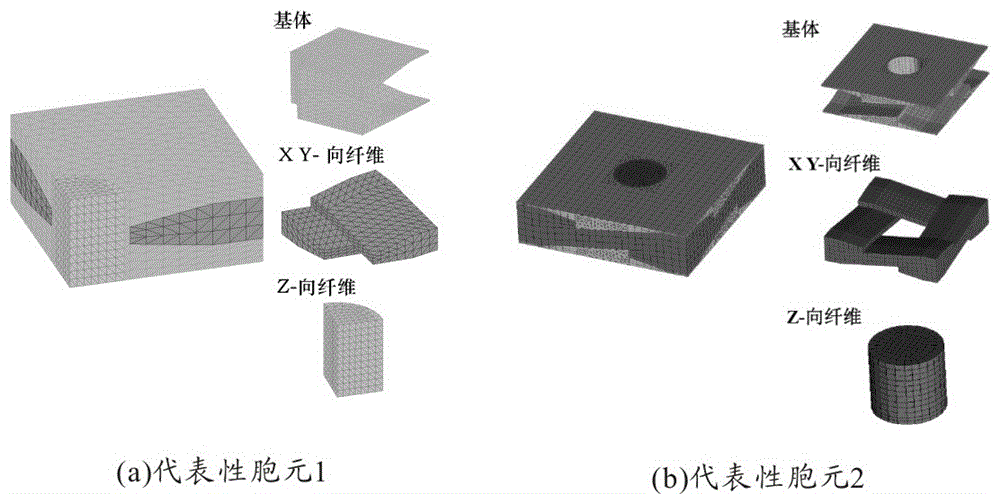

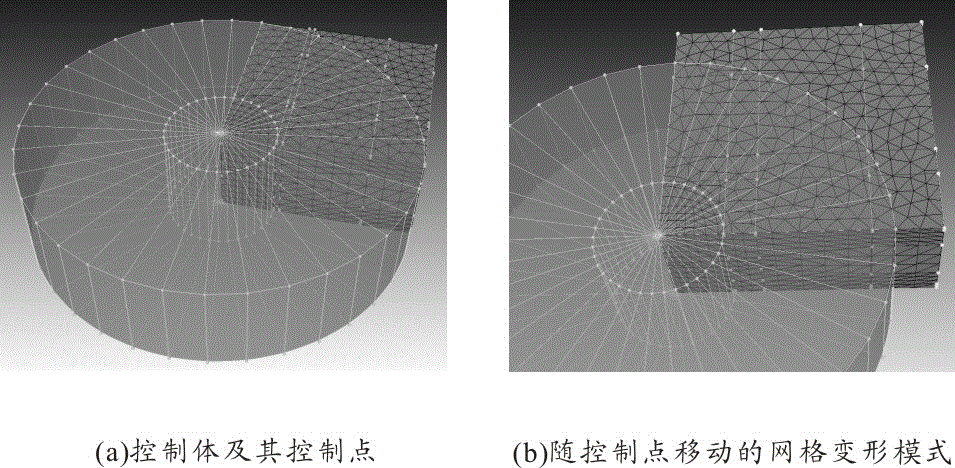

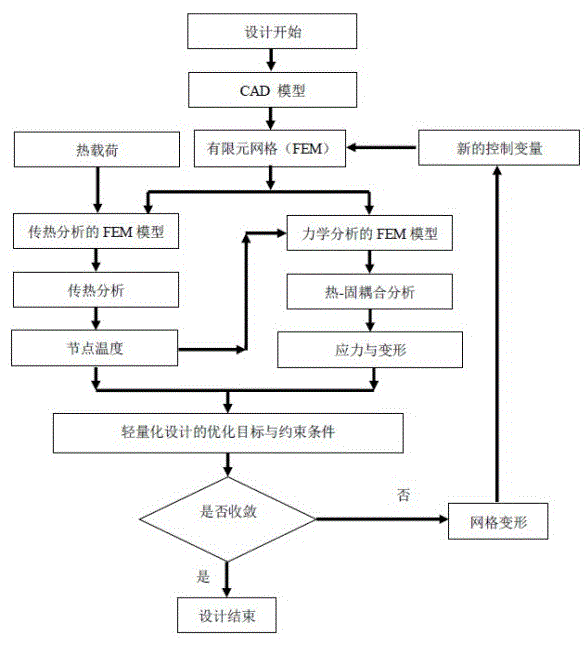

Design method of woven fabric composite material properties based on controllable microstructure

InactiveCN106649984ASimplify the optimization processReduce design costGeometric CADDesign optimisation/simulationAutomotive engineeringMicrostructure

The invention provides a design method of woven fabric composite material properties based on controllable microstructure. The design method utilizes universal single-cell thought and establishes mesoscopic / macroscopic heat transfer / mechanical an analysis model; based on mesh deformation method, through the meso-scale of typical periodic cell elements and the change in the form of the cell, and combined with multiscale analysis and multi-objective optimization, the design method is capable of quickly effectively meeting the requirements of targeted design and the 'lightweight' pursuit. The technology has the advantages of being low in cost and short in design period to gain physical property parameter which suits the need of 2D, 2.5D, 5D, and 3D woven fabric composite material.

Owner:魏东

Method and structure for variable pitch microwave probe assembly

InactiveUS7161344B2Simplify the optimization processReduce inventory costsElectrical measurement instrument detailsElectrical testingCoplanar waveguideEngineering

A coplanar waveguide (CPW) probe includes at least one center probe element, each having a respective center probe contact point and at least one peripheral probe element, each having a respective peripheral contact point. The pitch between the at least one center contact point and the at least one peripheral contact point is adjustable.

Owner:GLOBALFOUNDRIES INC

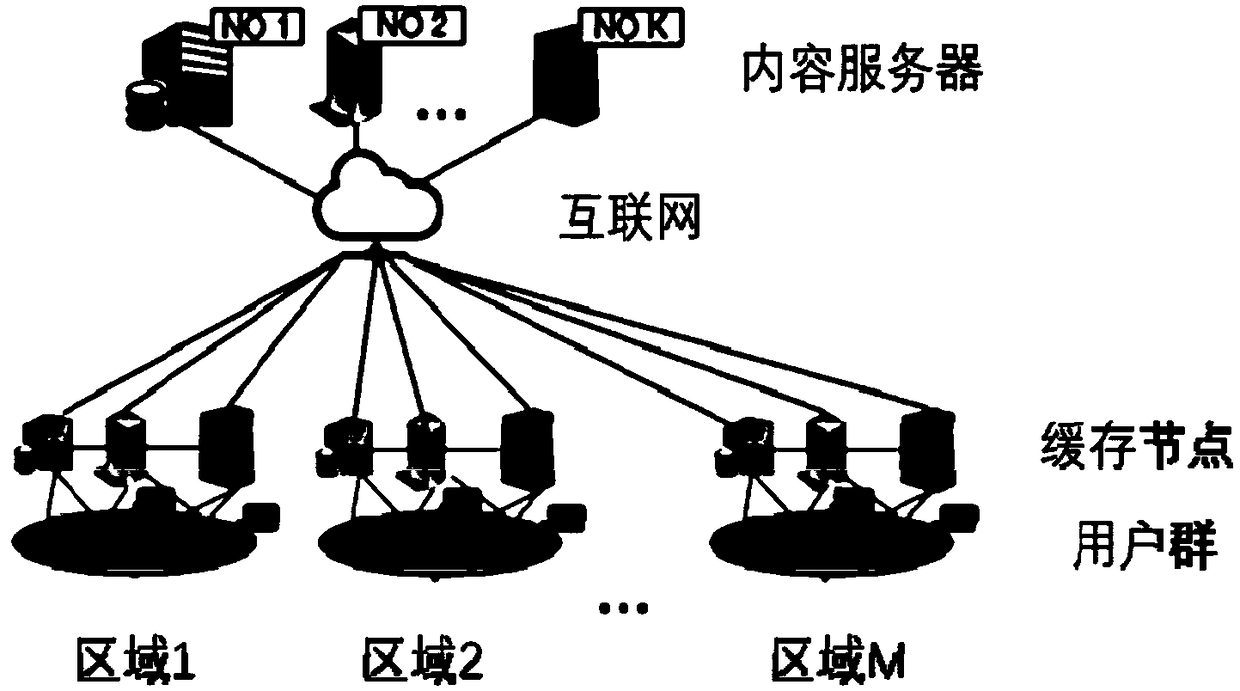

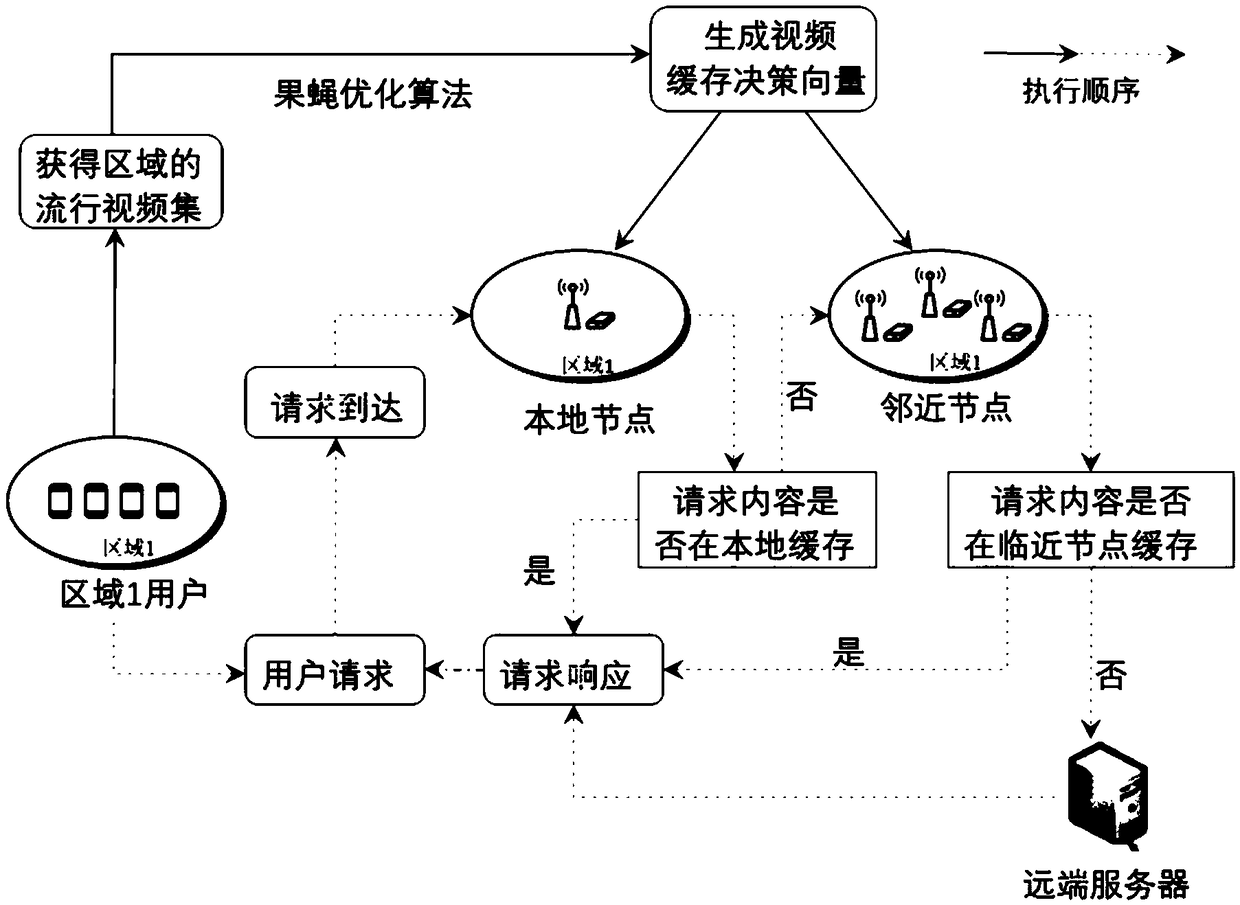

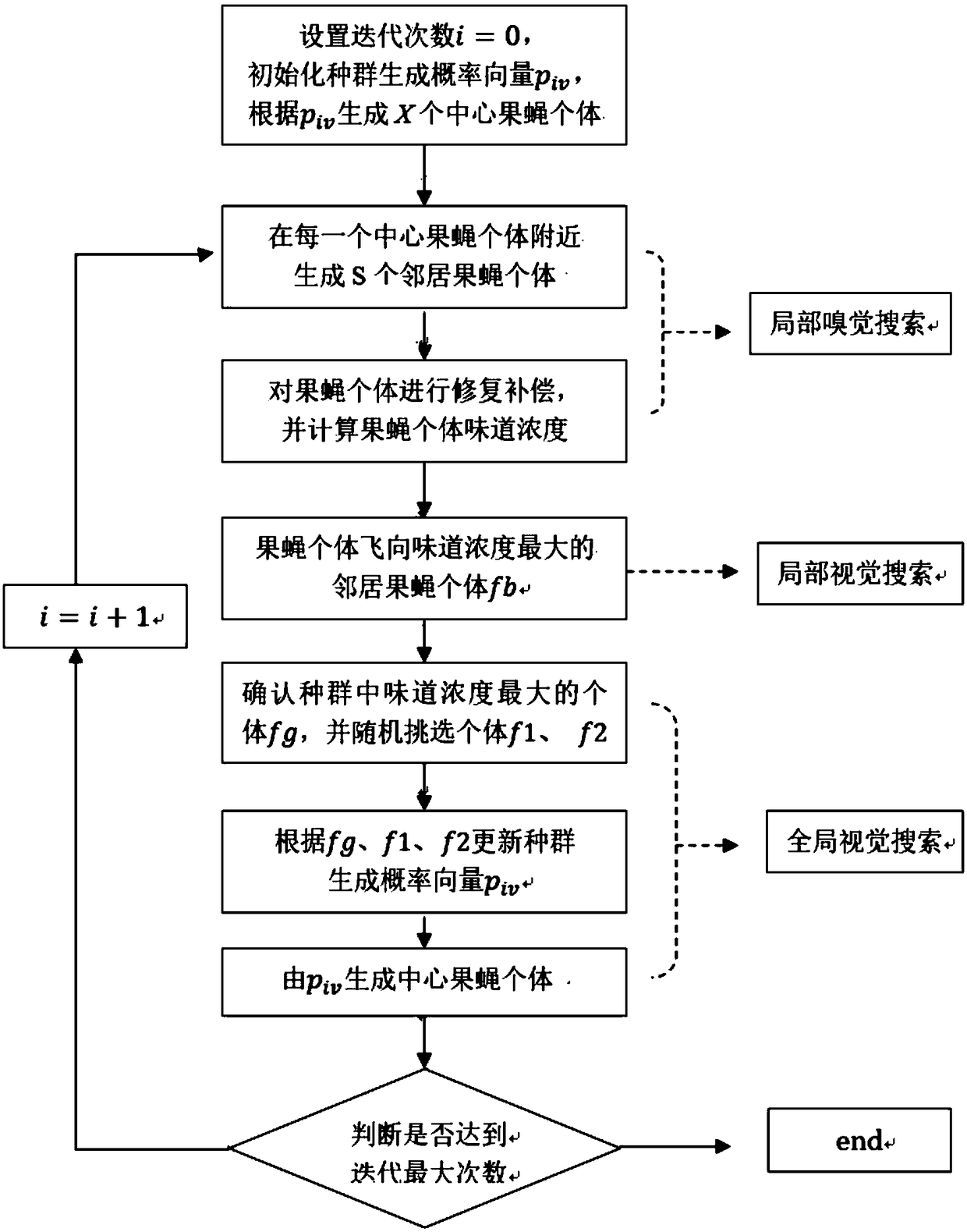

Edge collaboration cache arrangement method based on drosophila optimization algorithm

ActiveCN108848395AEasy to implementOptimal caching strategyArtificial lifeSelective content distributionVideo transmissionParallel computing

The invention discloses an edge collaboration cache arrangement method based on a drosophila optimization algorithm. The method comprises the following steps: (1) obtaining a popular video set and a user demand vector of an area according to the historical request information of users in the area; (2) according to the popular video set and the user demand vector, establishing a target optimizationproblem with the maximization of a total video transmission delay reduction amount in the area as the target, and solving the target optimization problem based on the drosophila optimization algorithm to generate a cache arrangement decision; (3) allocating a video cache task for each cache node according to the cache arrangement decision; and (4) when a user request arrives on the cache node, ifthe cache node does not cache corresponding contents, downloading the contents from a neighbor cache node that caches the contents and has the minimal delay, and if all cache nodes in the area have no cache response contents, downloading the cache response contents from a remote server. By adoption of the edge collaboration cache arrangement method disclosed by the invention, the cache hit rate can be improved, the average video transmission delay is reduced, and the user experience quality is improved.

Owner:SOUTHEAST UNIV

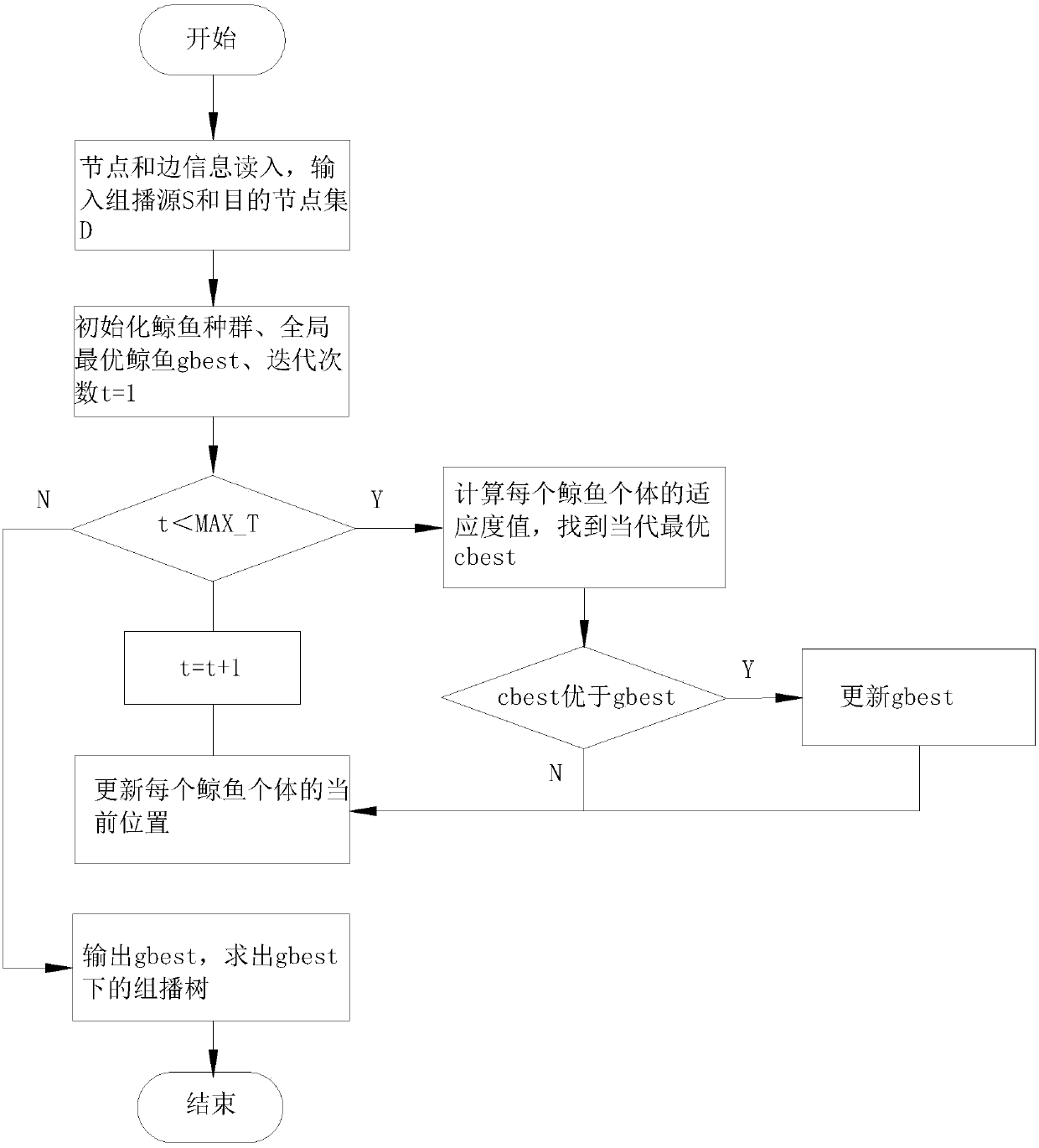

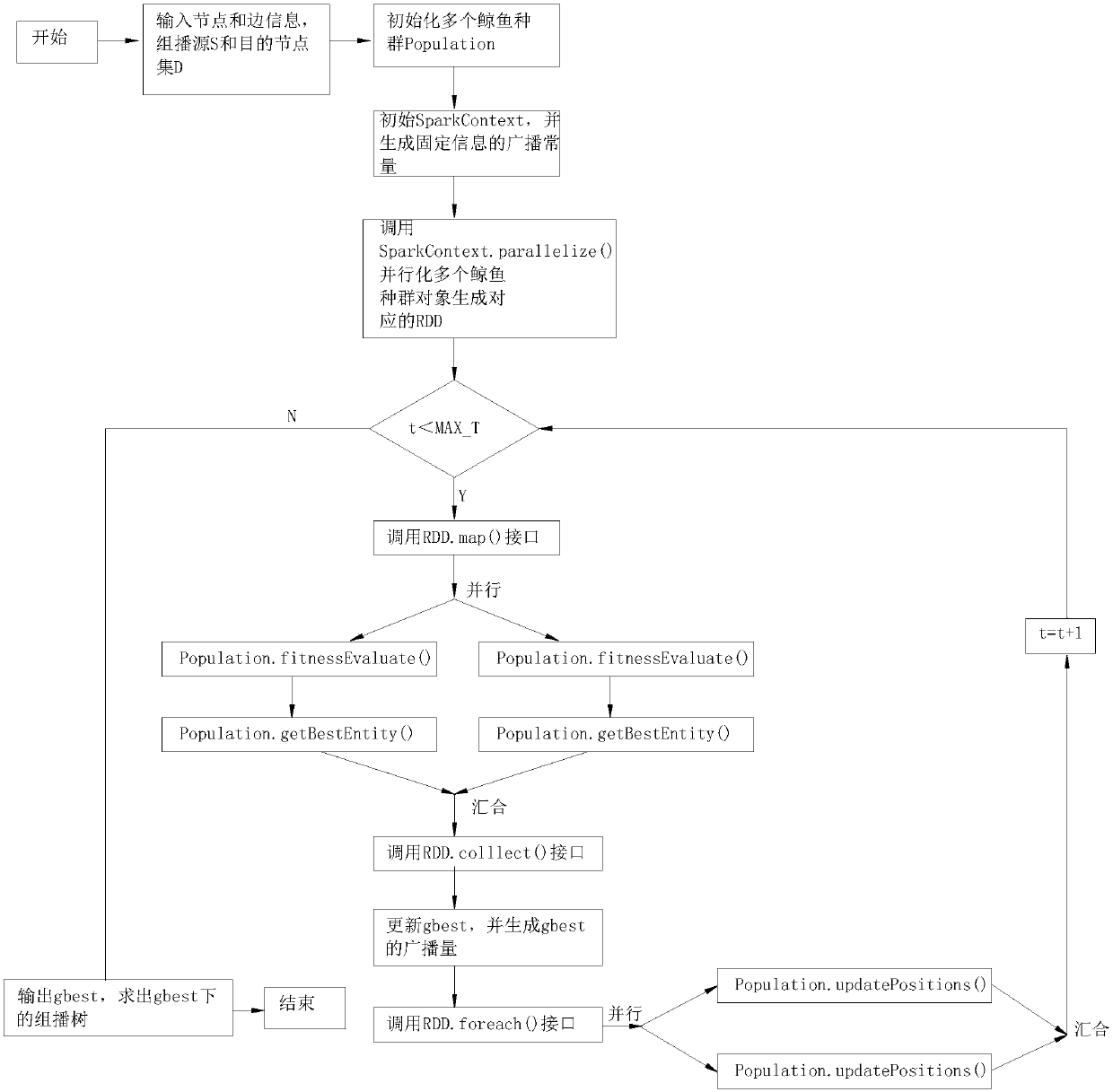

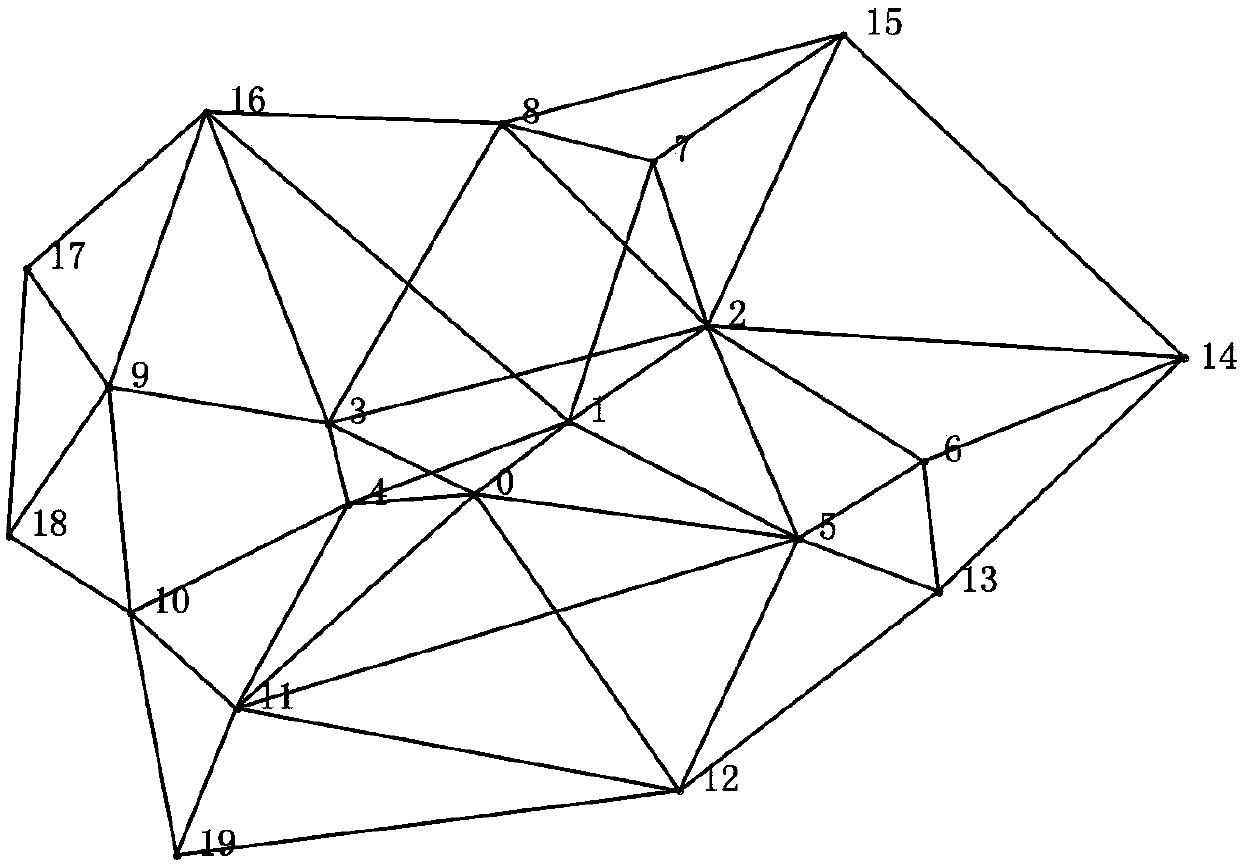

Whale optimization algorithm-based multicast routing optimization method and application of whale optimization algorithm-based multicast routing optimization method to Spark platform

ActiveCN107911300ASimplify the optimization processTroubleshoot multicast routing issuesData switching networksParallel computingRate of convergence

The invention discloses a whale optimization algorithm-based multicast routing optimization method and application of the whale optimization algorithm-based multicast routing optimization method to aSpark platform. According to the method, as for a specific multicast routing optimization problem, improvements are made on a whale optimization algorithm, so that the whale optimization algorithm canbe applied to solving the multicast routing optimization problem; the whale optimization algorithm that optimizes continuous problems is mapped to a discrete search space through the binary codes ofposition information, and the ideas of algorithms such as individual crossover, mutation, and taste concentration are introduced into a position update strategy, so that the method can be more suitable for solving the multicast routing problem; and therefore, the optimization process of multicast routing can be simplified, convergence speed can be increased. The invention also discloses the application of the whale optimization algorithm-based multicast routing optimization method to the Spark platform, and therefore, the parallelization of the whale optimization algorithm-based multicast routing optimization method can be realized on the Spark platform, and the execution speed of the algorithm is greatly accelerated.

Owner:SOUTHWEST JIAOTONG UNIV

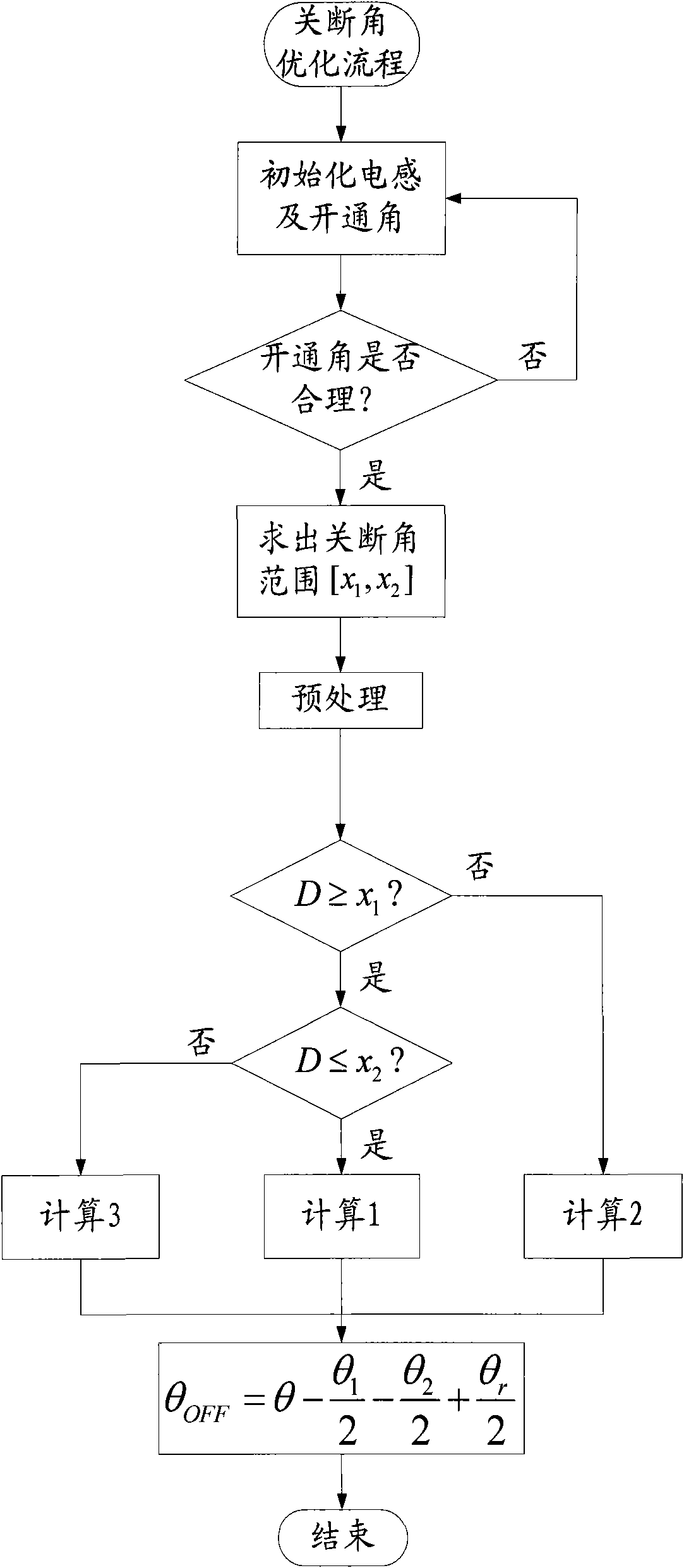

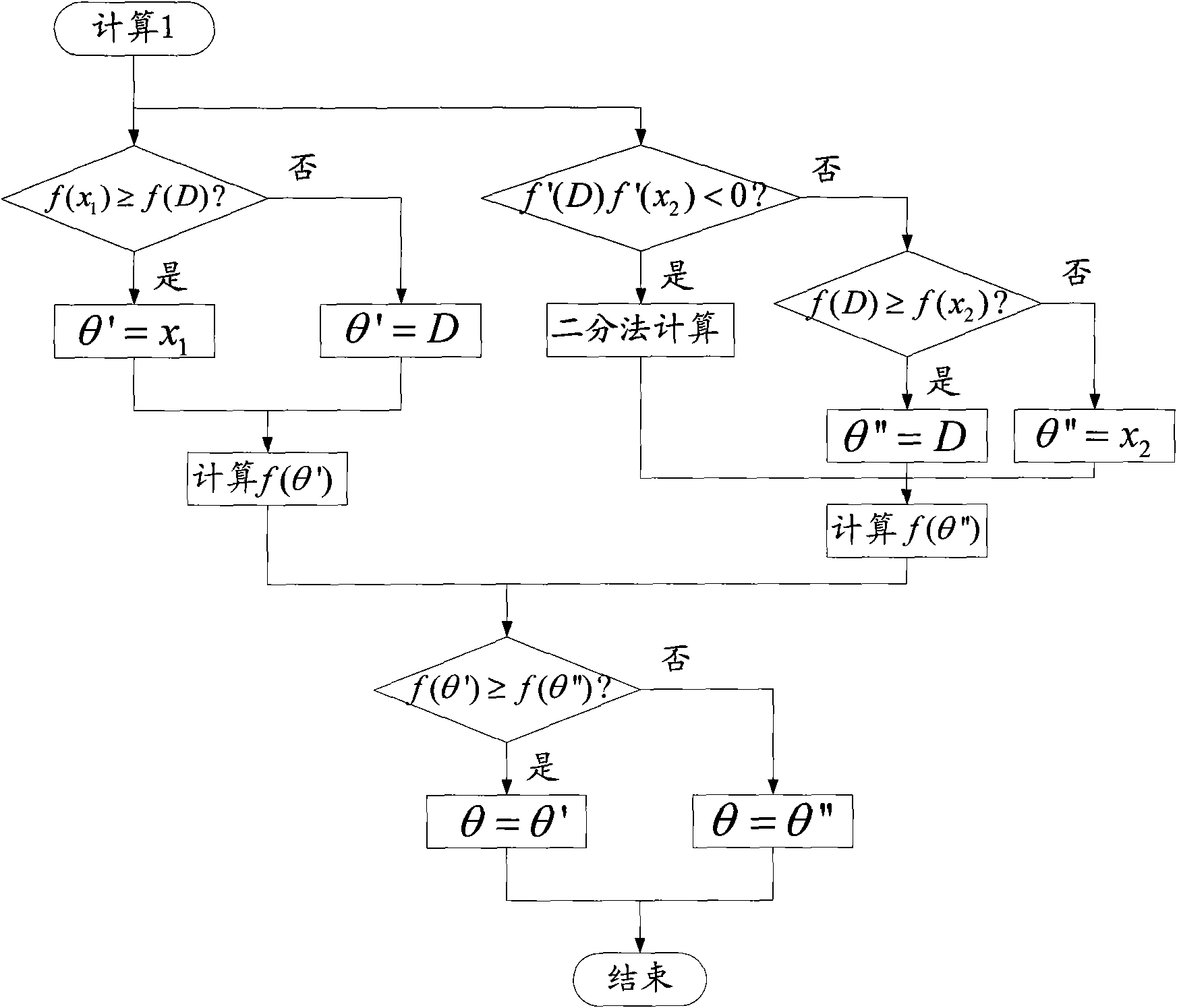

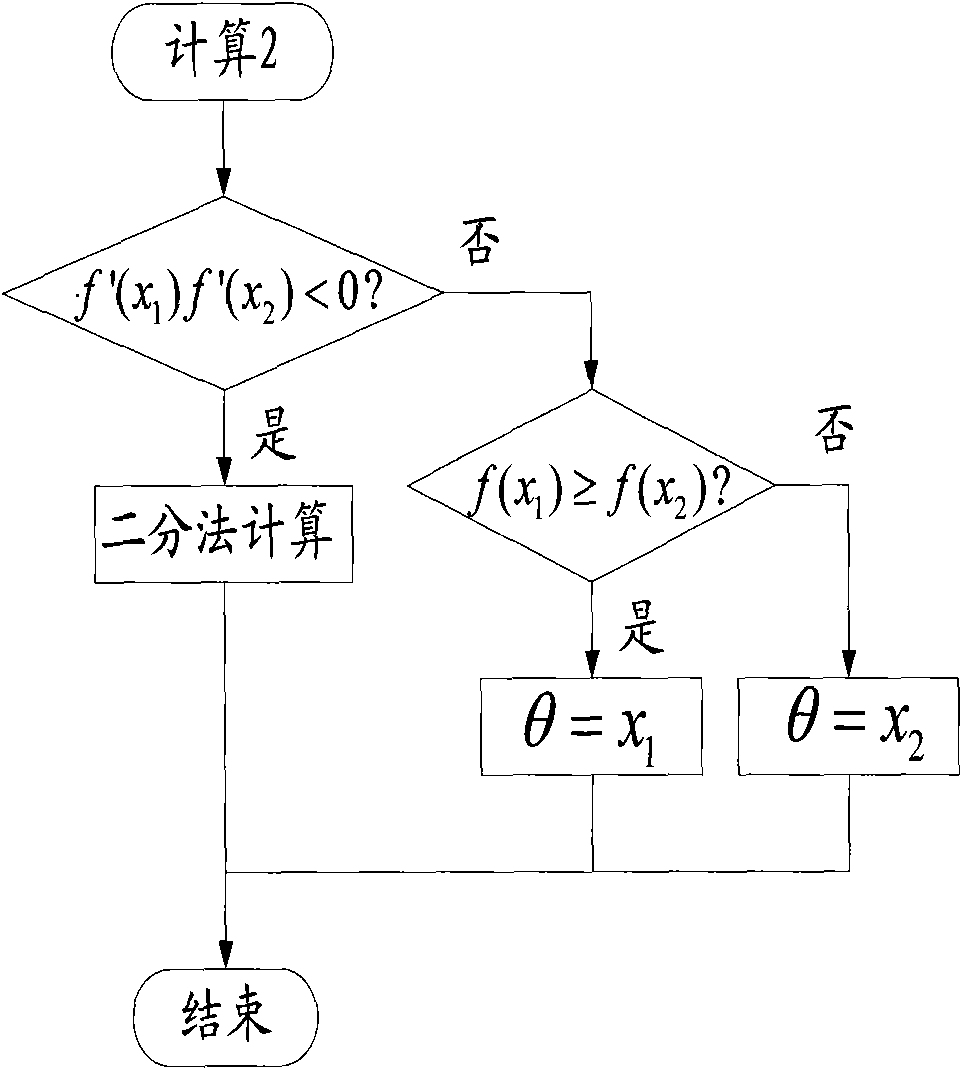

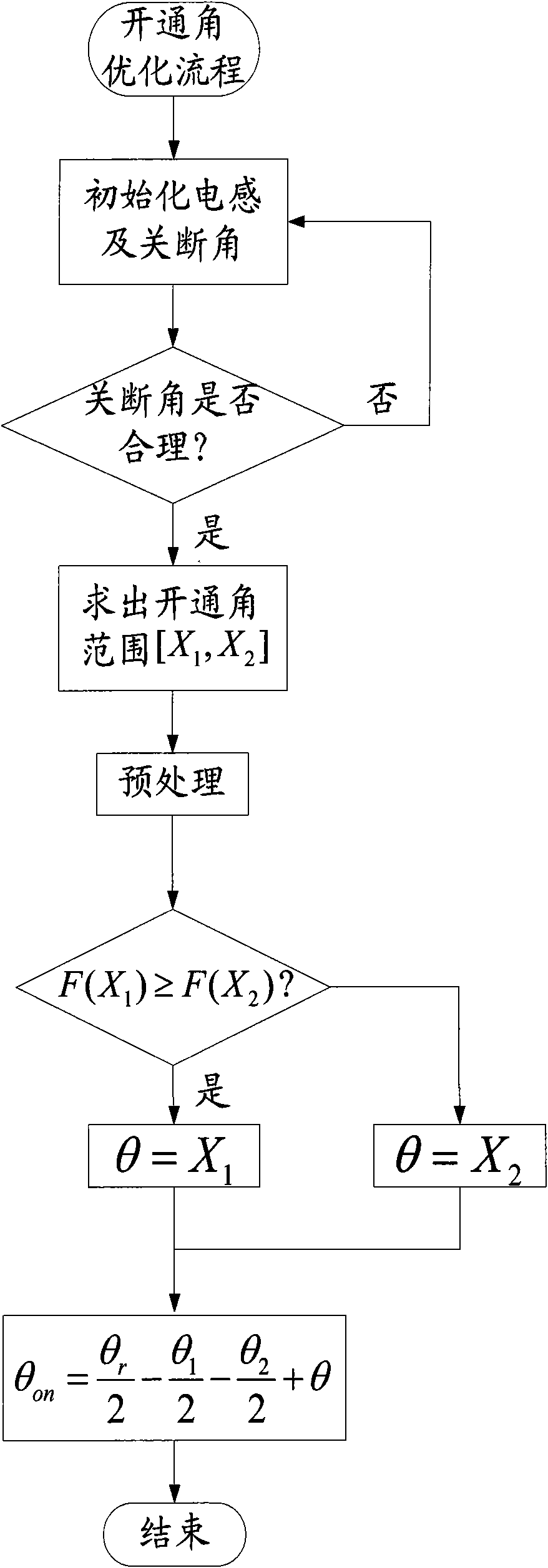

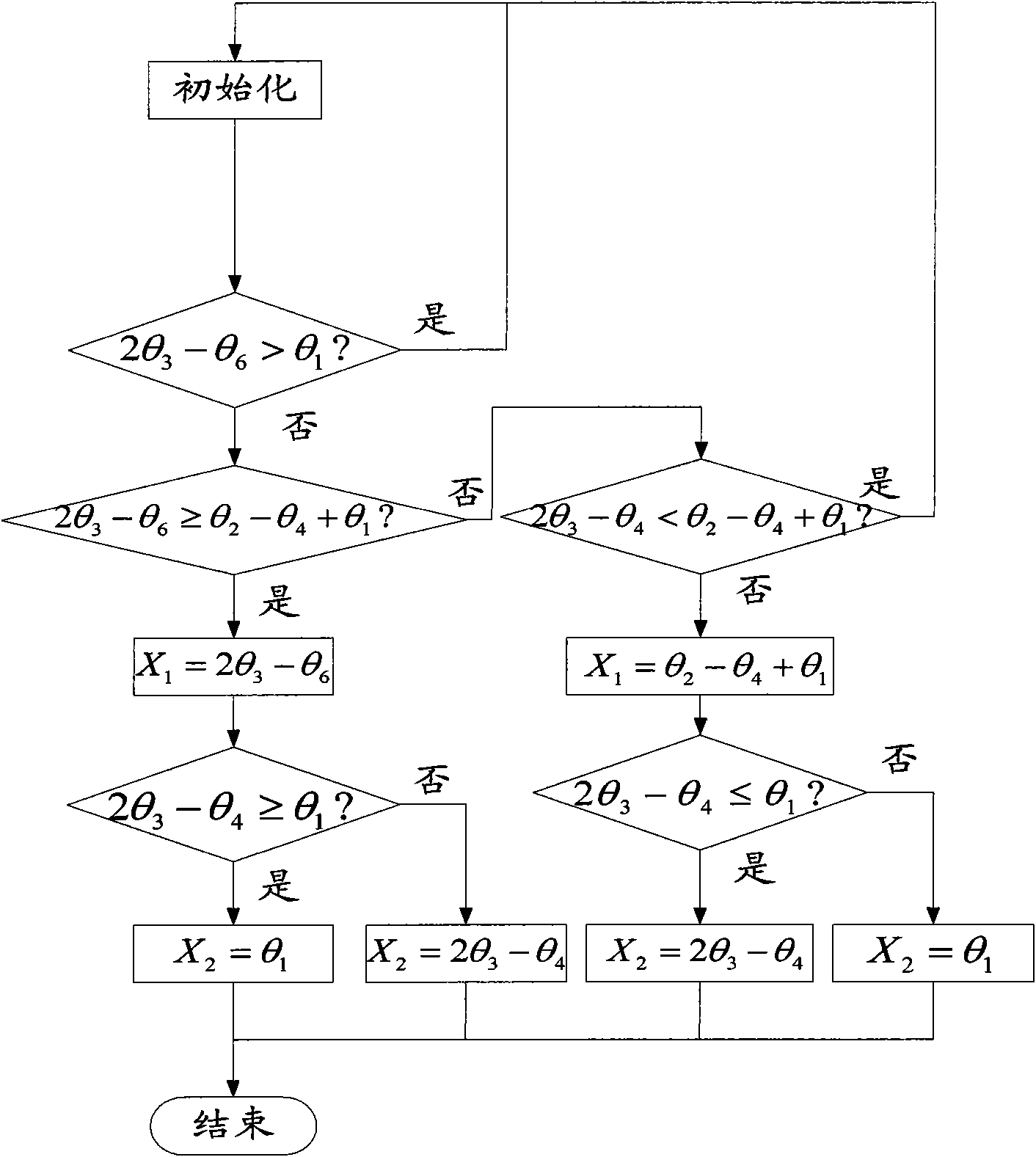

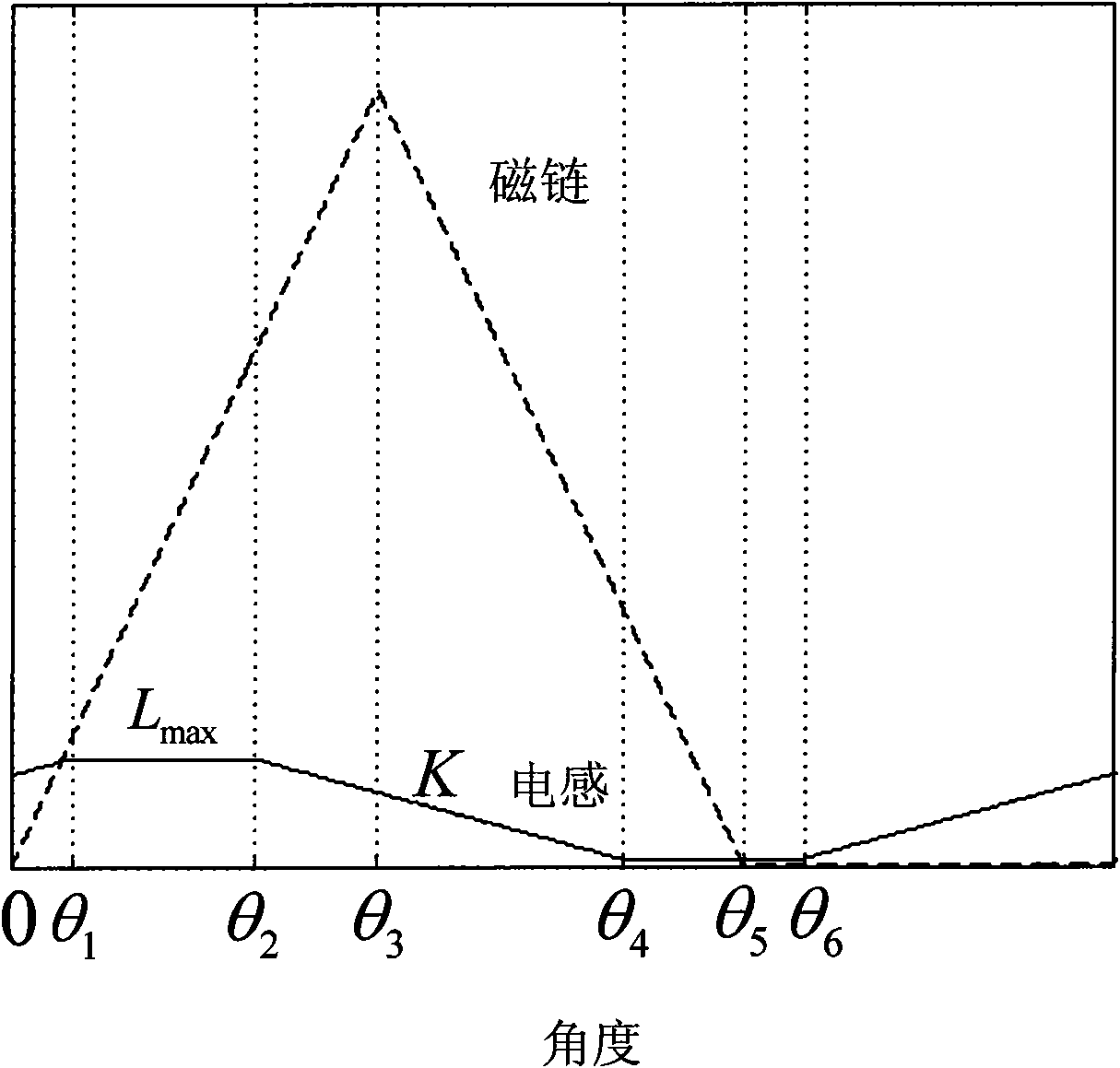

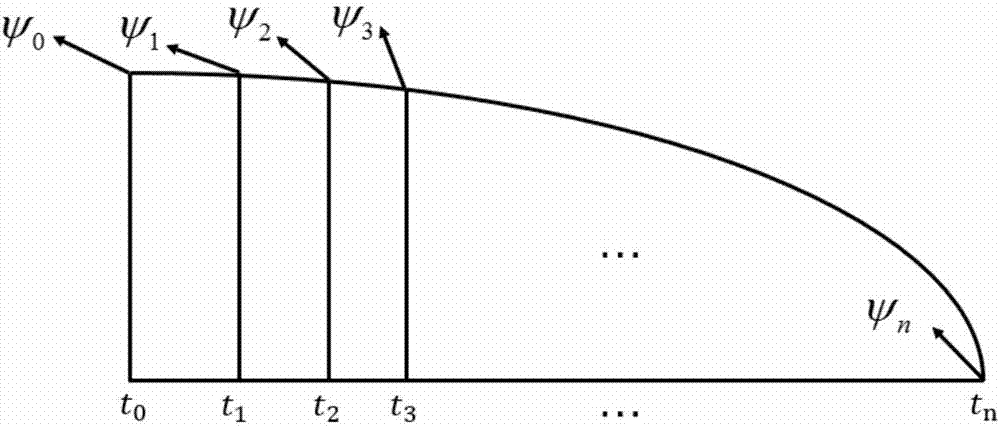

Method for fixing turn-on angle and optimizing turn-off angle of switched reluctance generator

InactiveCN101557189AImprove versatilityNot limited by precisionElectric generator controlPhase currentsSingle variable

The invention discloses a method for fixing a turn-on angle and optimizing a turn-off angle of a switched reluctance generator, belonging to the technical field of control of the switched reluctance generators. The method is as follows: 1. a phase current expression is firstly derived according to a voltage equation of the switched reluctance generator, an average electromagnetic power expression in a cycle is calculated by integration based thereon, and a factor which is only related to the turn-on angle and the turn-off angle is separated therefrom. 2. The turn-on angle is then fixed, the turn-off angle changes in a reasonable range, the factor is taken as a single-variable function of the turn-off angle, and the turn-off angle which is corresponding to the maximum value is solved by three situations according to the features of a high order derivative thereof. The method is based on the theory, simple and easy to operate and good in universality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

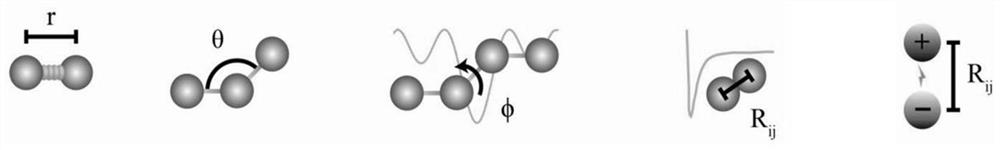

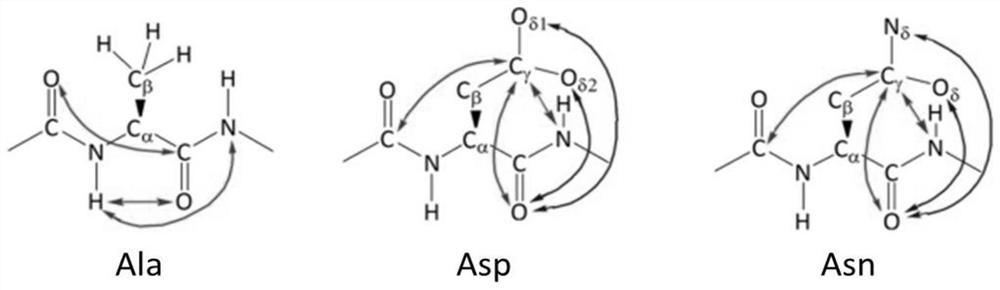

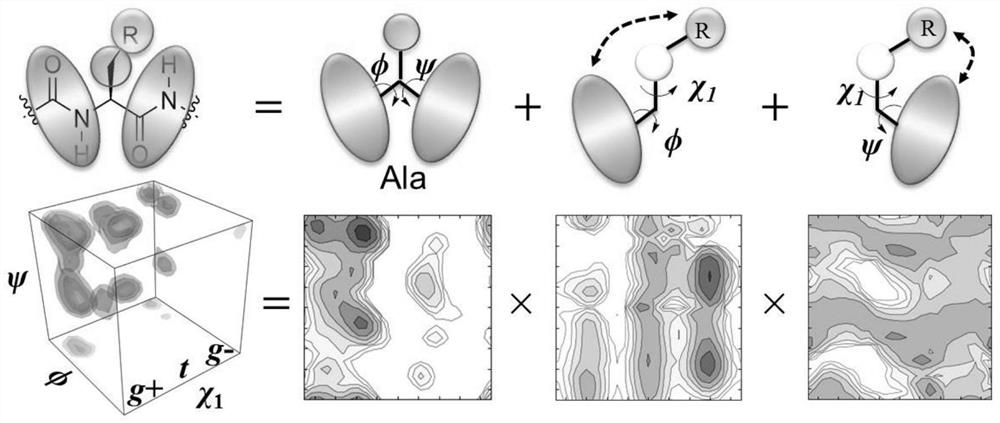

Coupling dihedral angle parameter optimization method based on CMAP potential function and protein force field

PendingCN111755064ASimplify the optimization processEasy and convenientSystems biologyInstrumentsSAA proteinProtein molecules

The invention relates to the technical field of molecular dynamics simulation, in particular to a protein force field, and more particularly relates to a coupling dihedral angle parameter optimizationmethod based on a CMAP potential function. According to the optimization method, an existing protein force field is taken as a parent force field, local intrinsic conformation preference in a crimp library is taken as a fitting target, and dihedral angle parameters of amino acid residues in the parent force field are optimized, so that local conformation distribution obtained through molecular dynamics simulation and distribution in the crimp library reach preset similarity. The invention also relates to a protein force field obtained by the optimization method. According to the method, coupled dihedral angles in protein molecules can be simply and efficiently optimized at the same time, the dihedral angle parameter optimization process is simple, efficient and automatic, the residue specific force field RSFF2C with high compatibility is obtained, and the method can be widely applied to various kinds of MD software.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

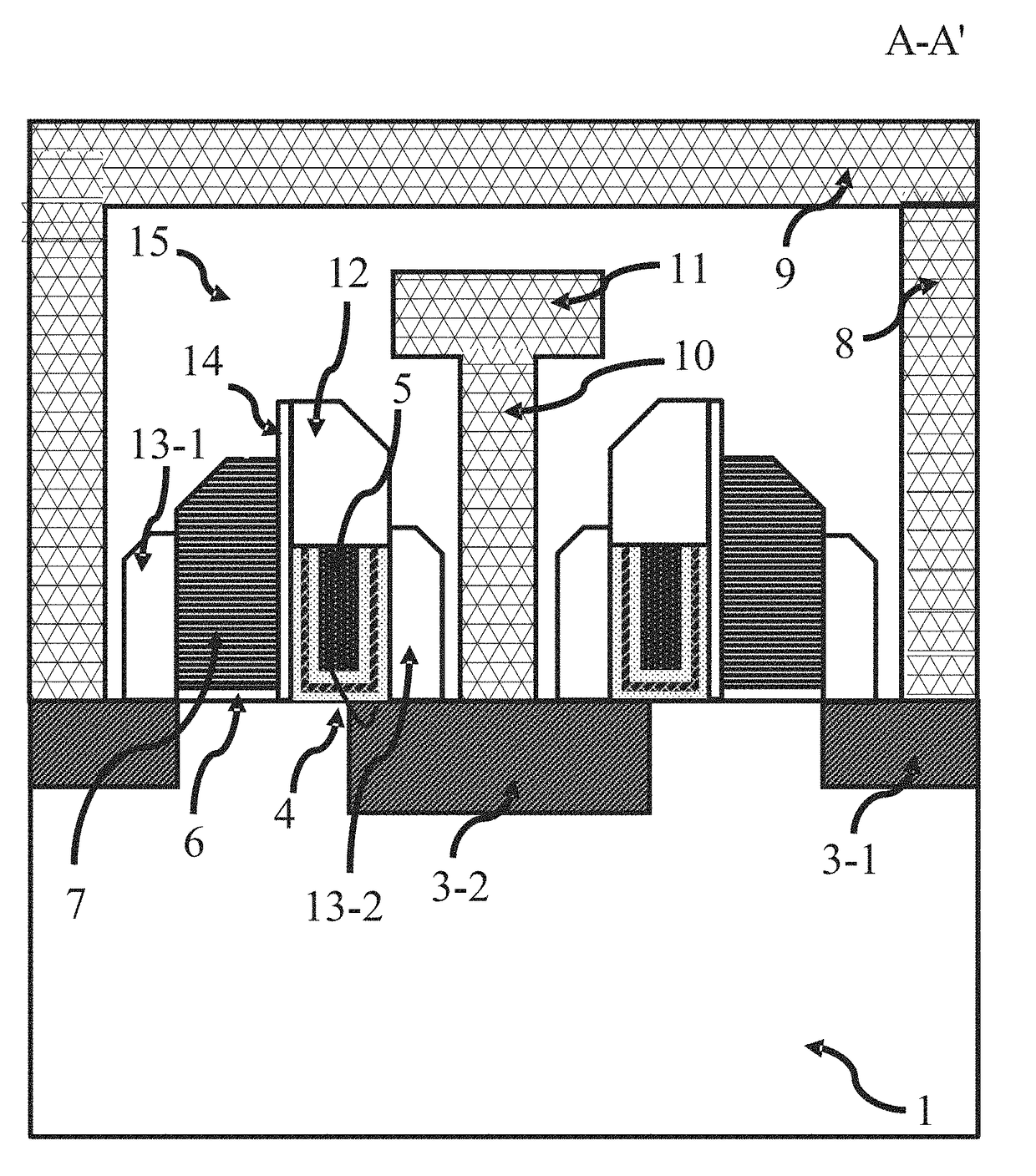

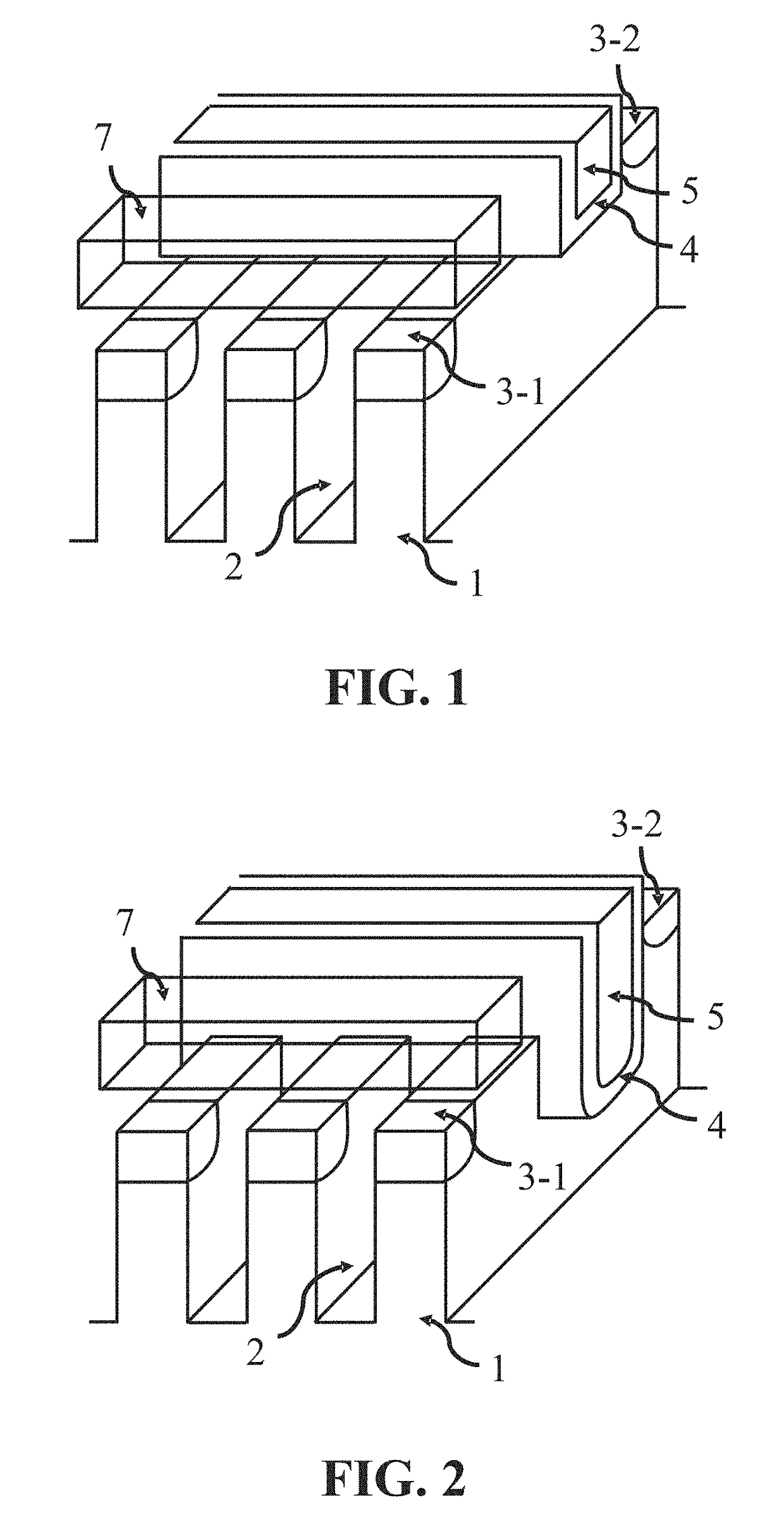

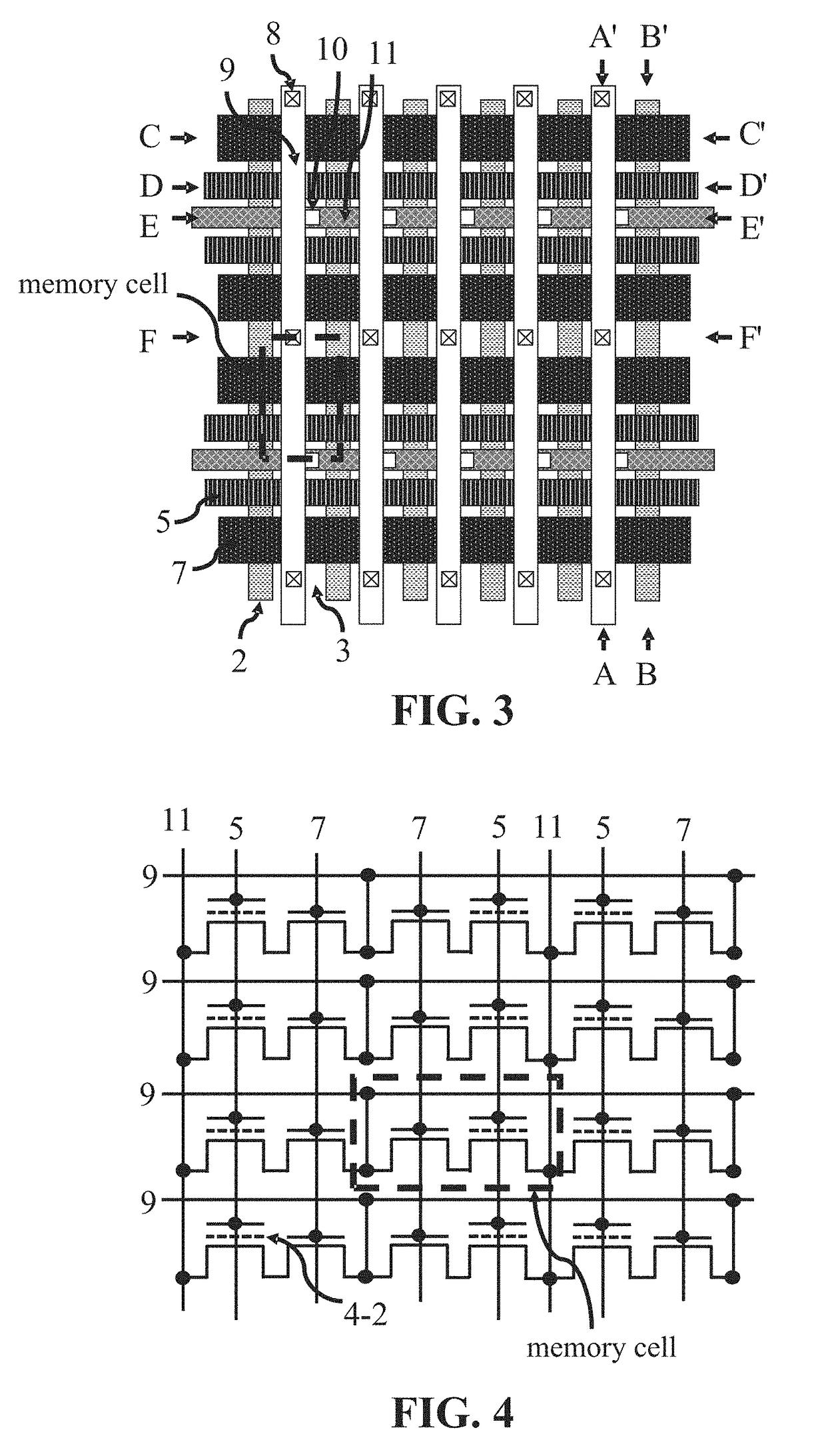

Flash Memory

ActiveUS20170221916A1Simplify optimizationDecrease memory cell areaSolid-state devicesRead-only memoriesEngineeringSemiconductor

A cheap and high performance 1.5 transistor-type flash memory highly compatible to external of memory region is provided. The flash memory has sacrifice film formed on substrate. U-shaped groove is formed on sacrifice film, where multiple insulating film is laminated. Multiple insulating film includes silicon nitride film as charge storage layer. Low resistive material is disposed on multiple insulating film to form control gate. Select gate is formed on insulating film on side of control gate in self-aligned manner. Semiconductor regions opposite in conductivity to substrate on both sides of adjoining control gate and select gate to form source and drain, respectively. Thus, a 1.5 transistor-type flash memory is formed with adjoining control gate and select gate between source and drain. In MOS-type transistor with control gate, threshold voltage is changeable according to injection / emission of charge to silicon nitride as charge storage layer, and thus work as non-volatile memory.

Owner:ROBUSTFLASH TECH

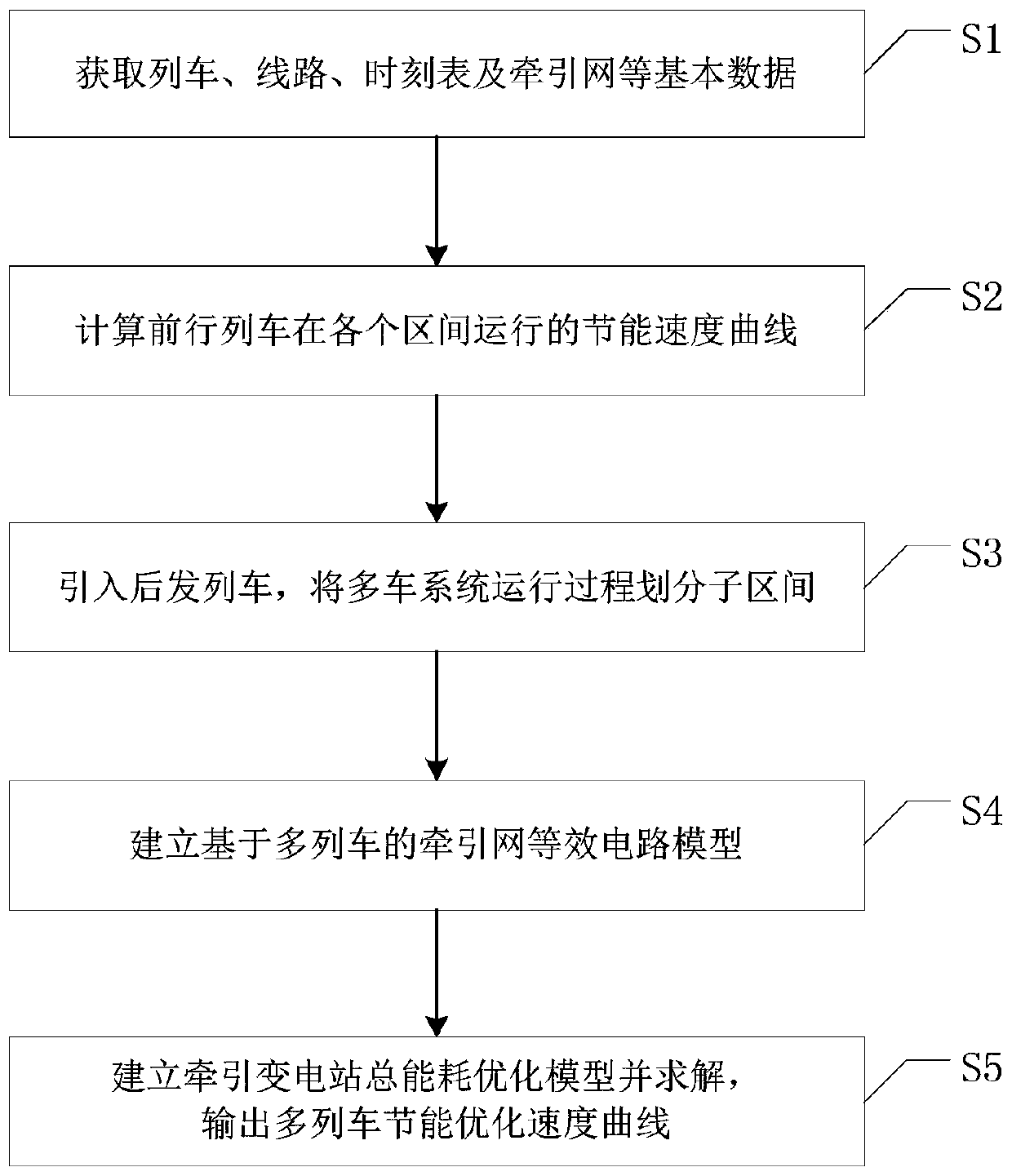

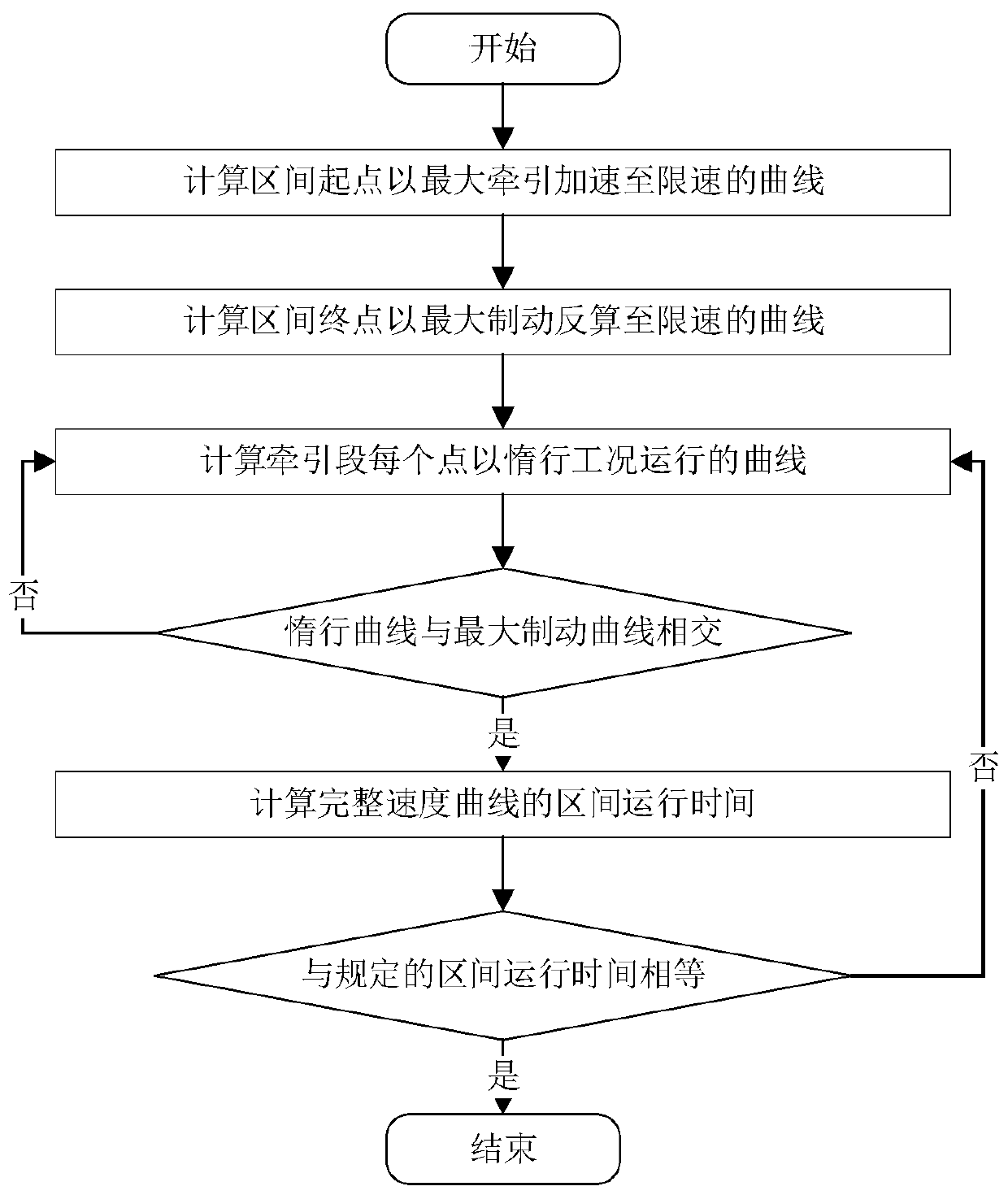

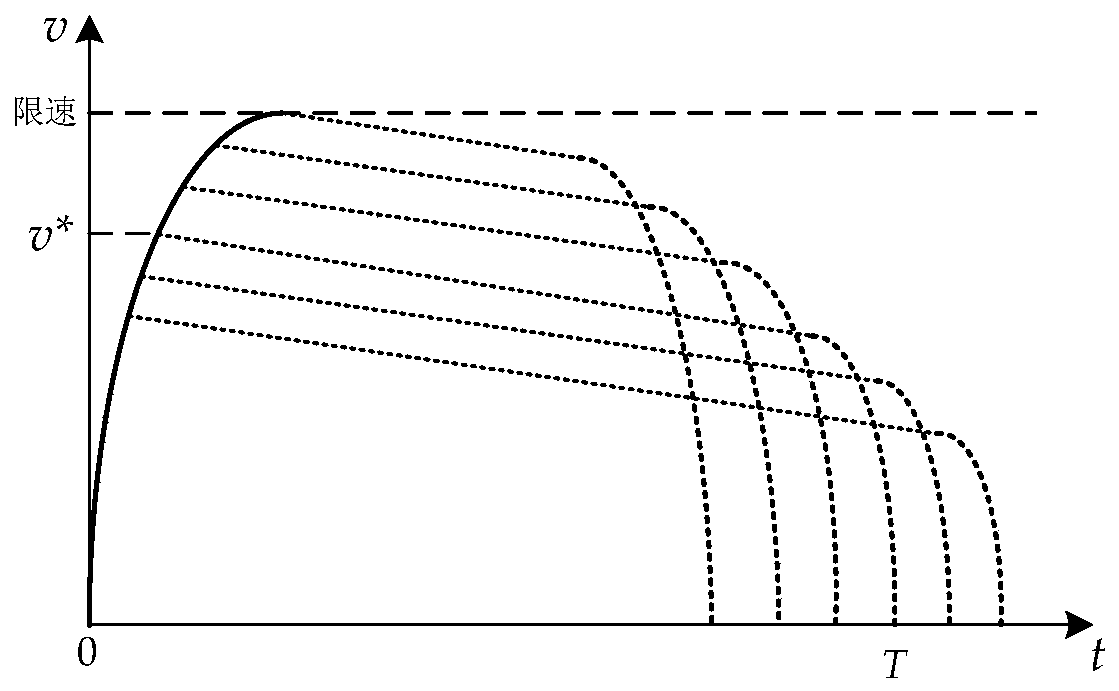

Multi-train speed curve collaborative optimization method considering network loss

ActiveCN111114596AOptimize and update speed curveReduce energy consumptionRailway traffic control systemsRegenerative brakeSimulation

The invention discloses a multi-train speed curve collaborative optimization method considering network loss. The method comprises the following steps: acquiring basic data of trains, lines, timetables, traction networks and the like; calculating an energy-saving speed curve of a preceding train running in each section, introducing a posterior train, dividing the running process of the multi-trainsystem into sub-sections, establishing a traction network equivalent circuit model based on multiple trains, establishing and solving a traction substation total energy consumption optimization model, and outputting a multi-train energy-saving optimization speed curve. According to the invention, the running speed curve of a single train in each section is optimized such that train traction energy consumption is reduced, the utilization rate of regenerative braking energy is increased by cooperatively optimizing speed curves of multiple trains, single-train optimization and multi-train optimization are combined, meanwhile, train traction energy consumption is reduced, the utilization rate of regenerative braking energy is increased, and finally the total energy consumption of a traction substation is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

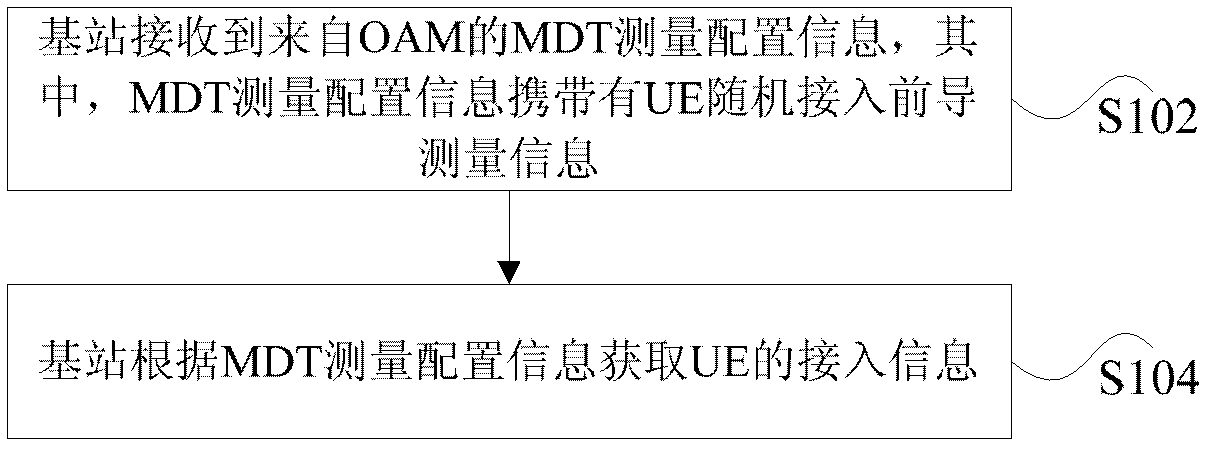

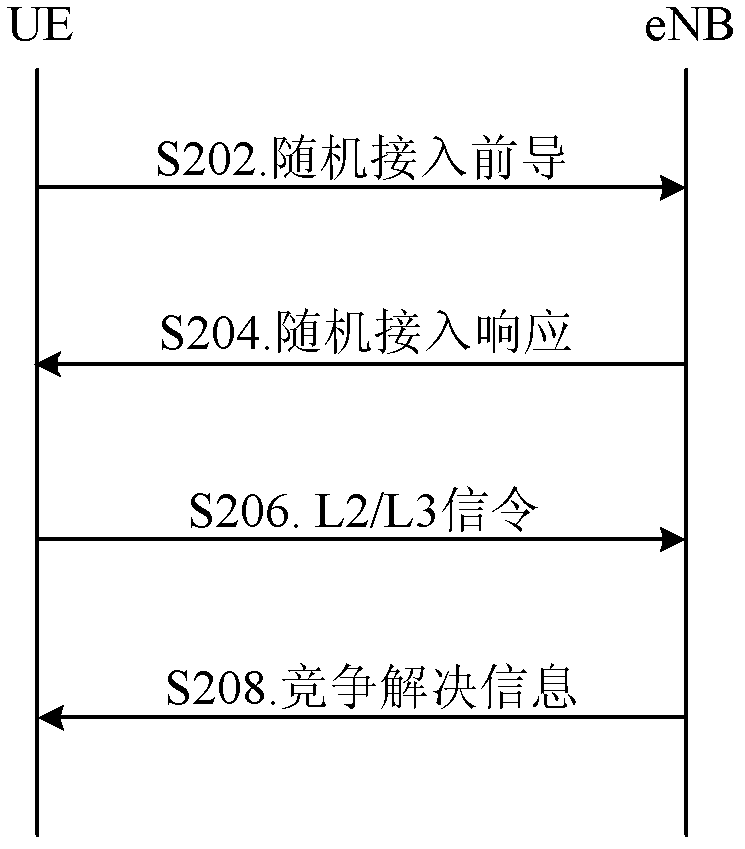

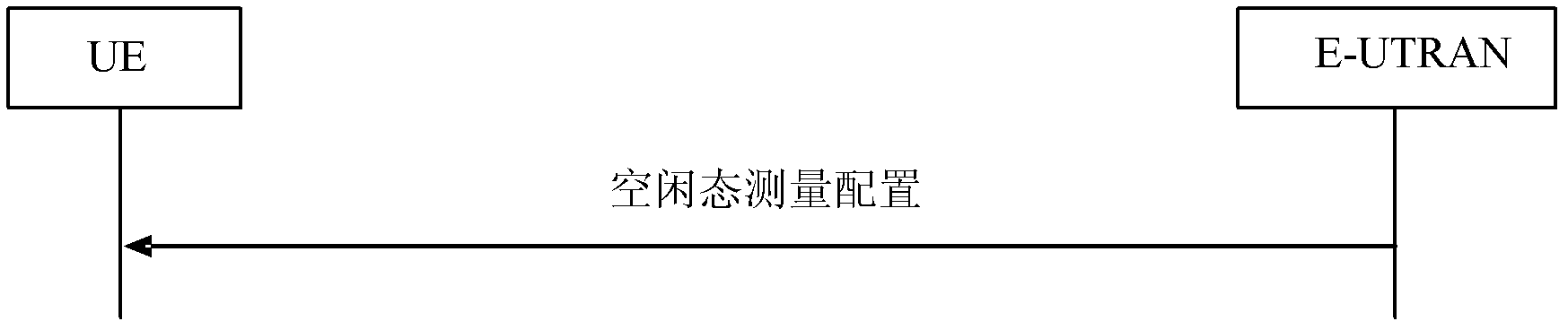

User equipment (UE) access information acquisition method and device

InactiveCN102595482ASimplify the optimization processReduce operation and maintenance costsWireless communicationRandom-access channelInformation acquisition

The invention discloses a user equipment (UE) access information acquisition method and device. The UE access information acquisition method comprises the following steps: a base station receives MDT (Minimization of Drive Tests) measurement configuration information from OAM (Operation Administration and maintenance), wherein the MDT measurement configuration information carries UE random access preamble measurement configuration information; and the base station acquires the access information of UE according to the MDT measurement configuration information. According to the UE access information acquisition method and device, the base station automatically acquires the access information of the UE by using an MDT technology according to the MDT measurement configuration information issued by the OAM, and further evaluates the random access property of a cell at certain time slot according to the access information without the need of simulating such complex operations by using a test instrument, thus the optimization flow of a random access channel is simplified, the manual intervention degree is reduced, and the user network operation and maintenance cost is saved.

Owner:ZTE CORP

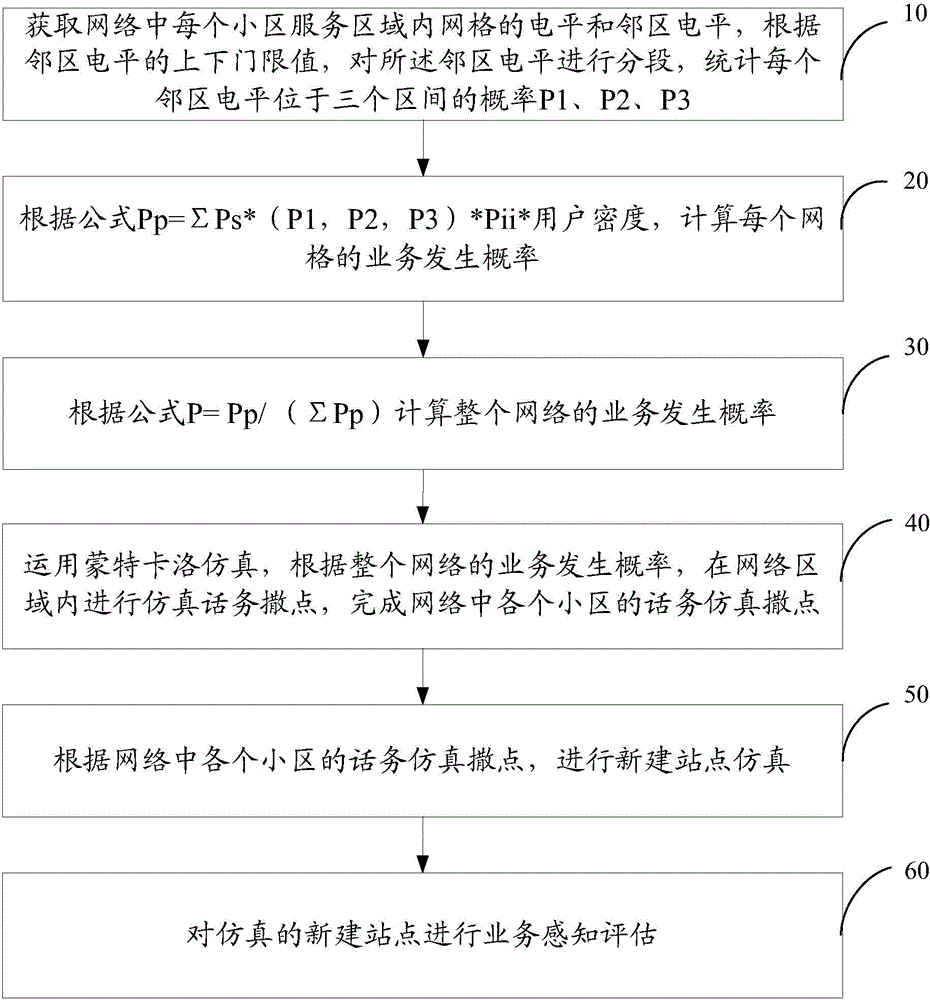

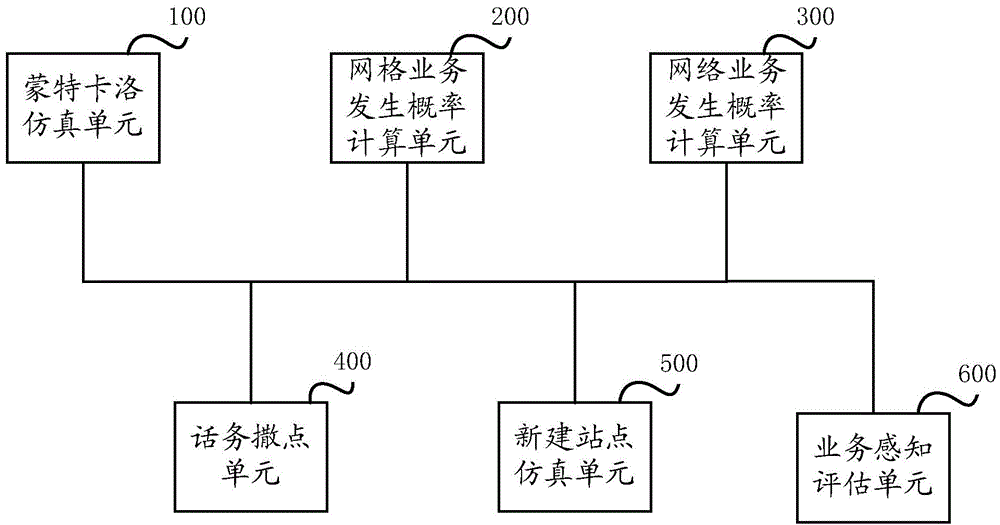

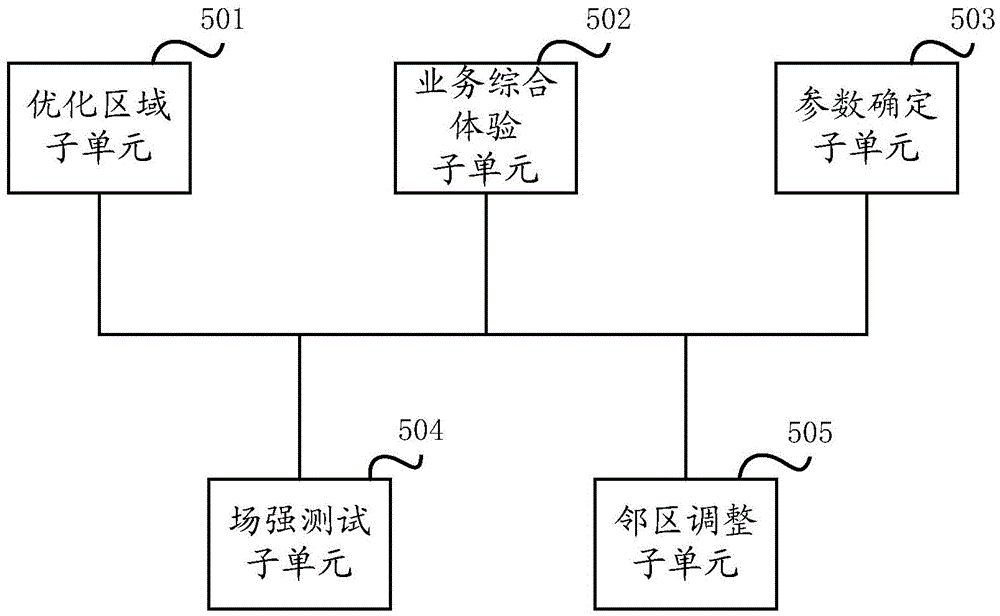

Service simulation-perception-evaluation method and system

ActiveCN104469834ASimplify the determination processSimplified assessmentNetwork planningDevice simulationMaterial resources

The invention provides a service simulation-perception-evaluation method and system. The method comprises the following steps: acquiring the levels of grids in each cell service area and the levels of adjacent cells in a network, segmenting the levels of the adjacent cells according to the upper threshold values and lower threshold values of the levels of the adjacent cells, and counting probabilities P1, P2 and P3 that the level of each adjacent cell is positioned in three intervals; calculating the service occurrence probability of each grid; calculating the service occurrence probability of the entire network; simulating telephone traffic scattering in a network area according to the service occurrence probability of the entire network by using Monte Carlo simulation; simulating a new site according to the telephone traffic simulation scattering of each cell in the network; and performing service perception and evaluation on the simulated new site. Compared with the prior art, the service simulation-perception-evaluation method and system have the advantages that comprehensive optimization of service perception can be performed by making full use of MR (Measurement Result) data; service scattering, the determination and evaluation of the new site and network optimizing flow can be greatly simplified; and manpower and material resources are greatly saved.

Owner:CHINA MOBILE GRP FUJIAN CO LTD

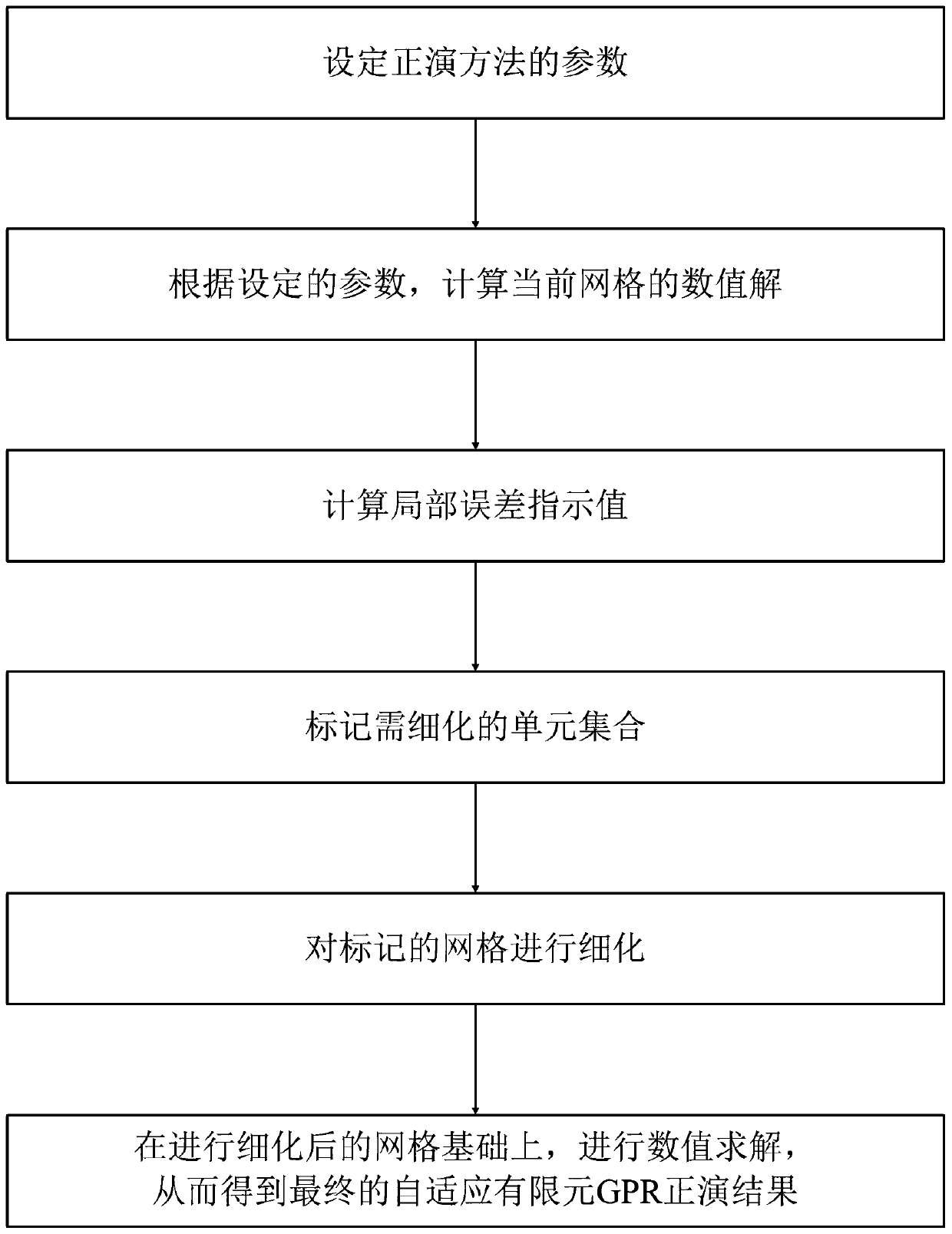

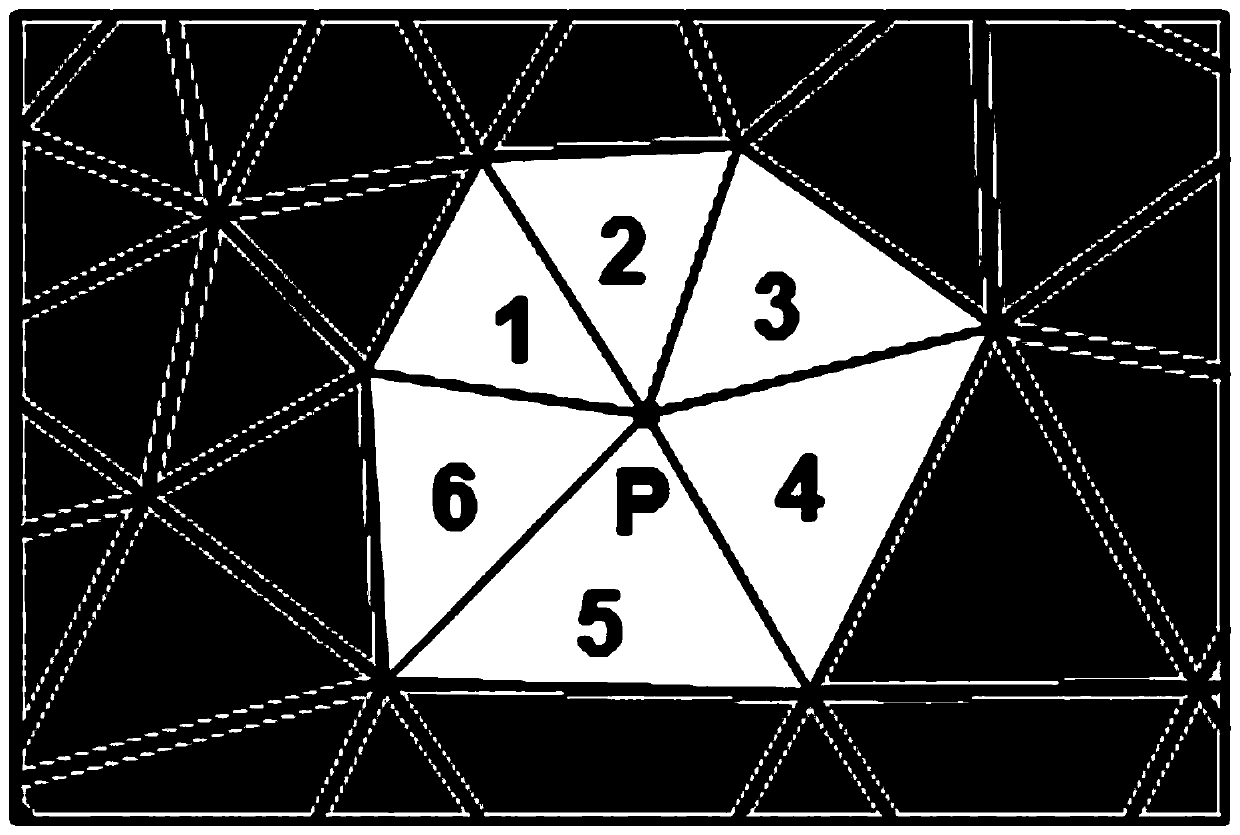

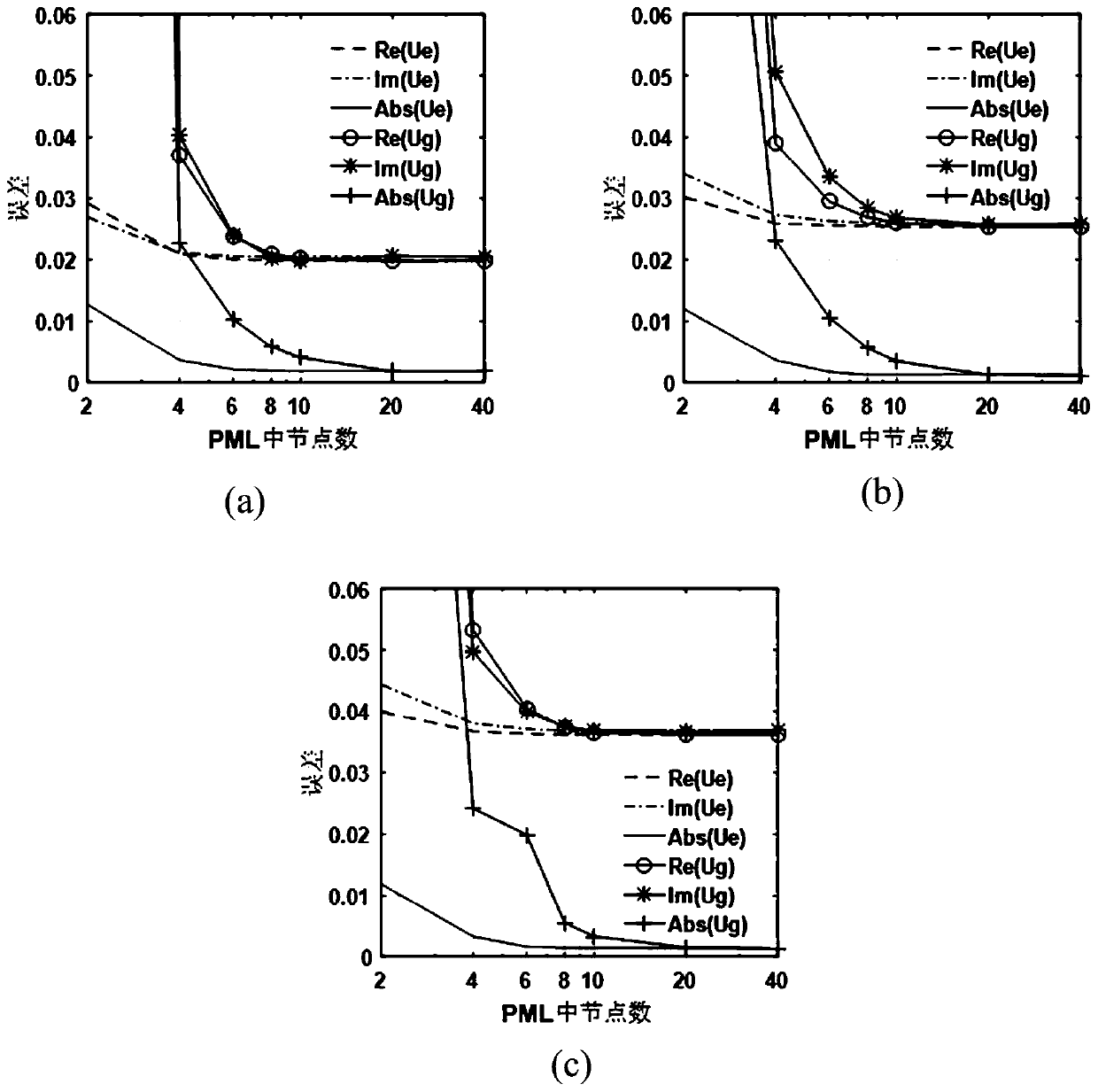

Adaptive finite element GPR frequency domain forward modeling method

ActiveCN110210129ASimplify the parameter optimization processGood absorptionDesign optimisation/simulationComplex mathematical operationsSelf adaptiveNumeric Value

The invention discloses an adaptive finite element GPR frequency domain forward modeling method. The method comprises the steps of setting parameters of a forward modeling method; calculating a numerical solution and a local error indication value of the current grid; marking a unit set needing to be refined; refining the marked grid; and carrying out numerical solution to obtain a final self-adaptive finite element GPR forward modeling result. The invention provides a self-adaptive finite element GPR forward modeling method. Based on a posteriori error estimation strategy, a posteriori errorestimation strategy is acquired. A self-adaptive finite element method is adopted to carry out GPR frequency domain forward modeling, EPML boundary conditions are introduced into frequency domain forward modeling calculation, the parameter optimization process is simplified, a good absorption effect can be achieved under the condition that the thickness of an absorption layer is small, the degreeof freedom of nodes can be reduced, and the calculation cost is saved to a great extent.

Owner:CENT SOUTH UNIV

Method for fixing turn-off angle and optimizing turn-on angle of switched reluctance generator

InactiveCN101582670AImprove versatilityNot limited by precisionElectric generator controlPhase currentsComputer science

The invention discloses a method for fixing a turn-off angle and optimizing a turn-on angle of a switched reluctance generator, and belongs to the technical field of switched reluctance generator control. The method comprises the following steps of: 1, firstly deducing a phase current expression according to a voltage equation of the switched reluctance generator, integrating based on the expression to evaluate an average electromagnetic power expression in a cycle, and isolating a factor only related to the turn-on angle and the turn-off angle from the expression; and 2, then fixing the turn-off angle, making the turn-on angle change in a reasonable range, taking the factor as a one-variable function of the turn-on angle, and solving the turn-on angle corresponding to the maximum value of the one-variable function according to the characteristic of higher derivative of the one-variable function. The method has the advantages of theoretical basis, simpleness and good commonality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

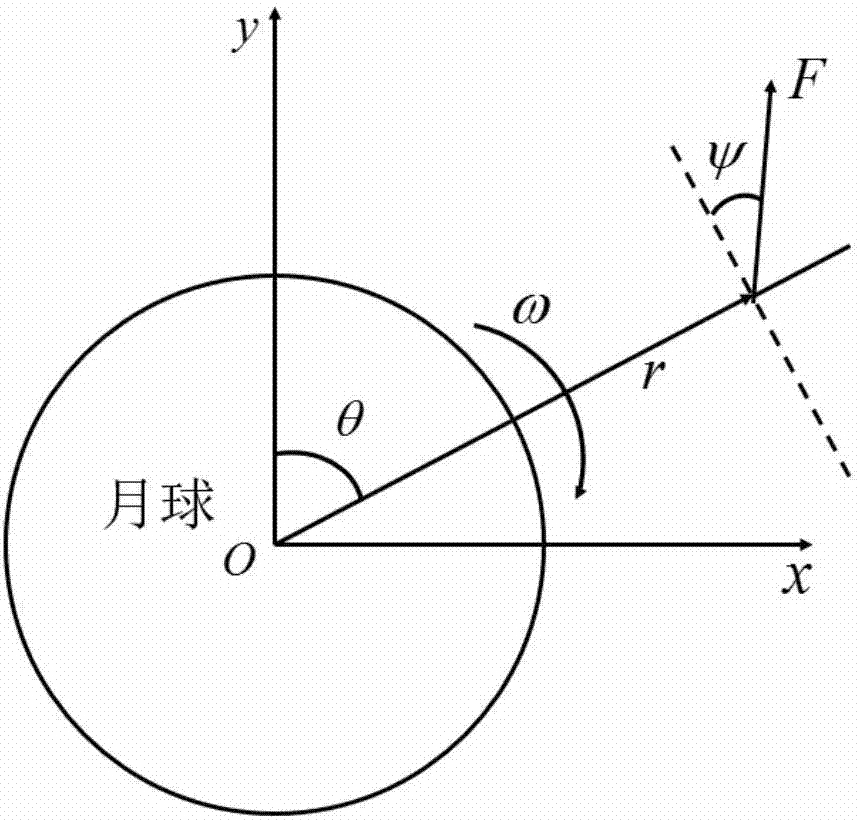

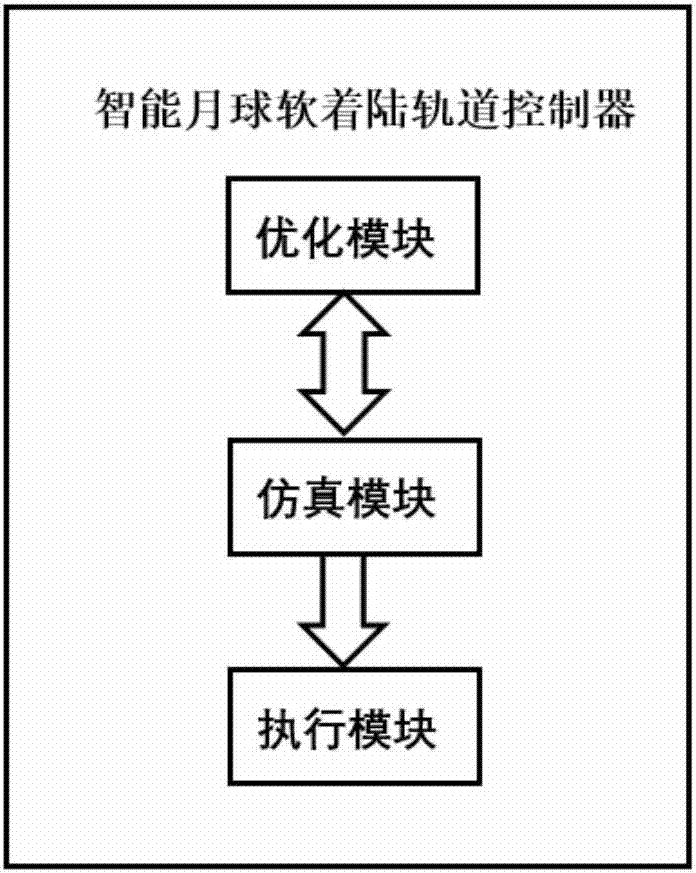

Intelligent lunar soft landing orbit controller

InactiveCN107203133AReduce sizeImprove search abilitySimulator controlDesign optimisation/simulationDynamic modelsComputer module

The invention discloses an intelligent lunar soft landing orbit controller. The orbit controller comprises a simulation module, an optimizing module and an execution module, wherein in the simulation module, the lunar soft landing orbit is divided into a plurality of segments, a thrust direction angle changing curve of the orbit is fitted by aid of thrust direction angles of nodes at segmentation and corresponding moments, and then the whole soft landing orbit is obtained through simulation of a soft landing dynamic model. The optimal thrust direction angles of the nodes and the optimal soft landing terminal moment are obtained through optimizing of the optimizing module. The optimizing module adopts an improved intelligent algorithm, the improved intelligent optimizing method controls the size of subgroups, disturbance factors are added, searching variety is improved, and the optimizing module has very high searching capacity and can search a lunar soft landing orbit requiring the least fuel consumption through optimizing. An optimal soft landing command signal is transmitted to the execution module, and the optimal lunar soft landing control requiring the least fuel consumption is realized finally.

Owner:ZHEJIANG UNIV

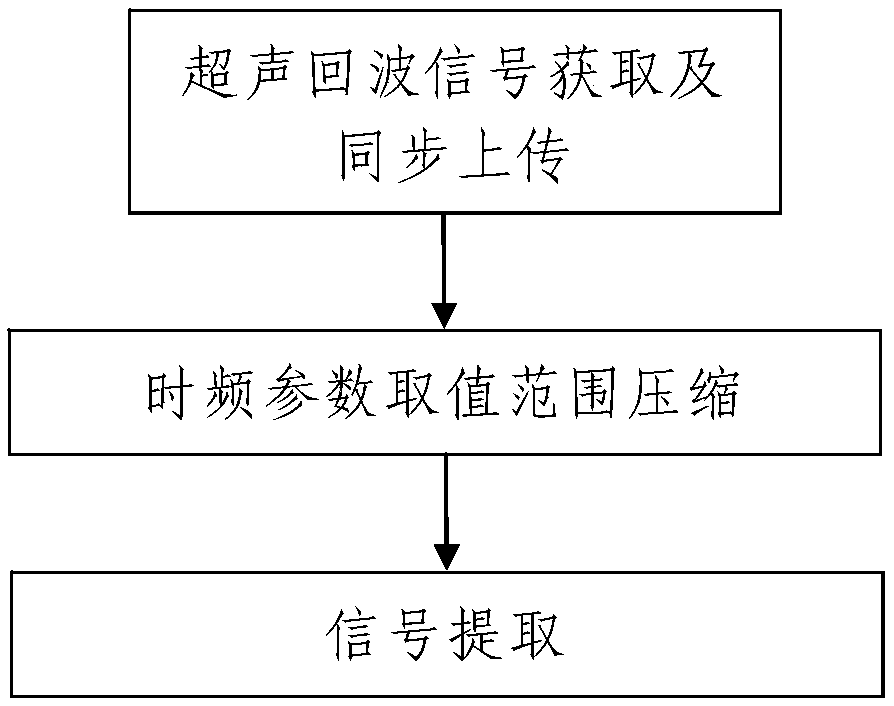

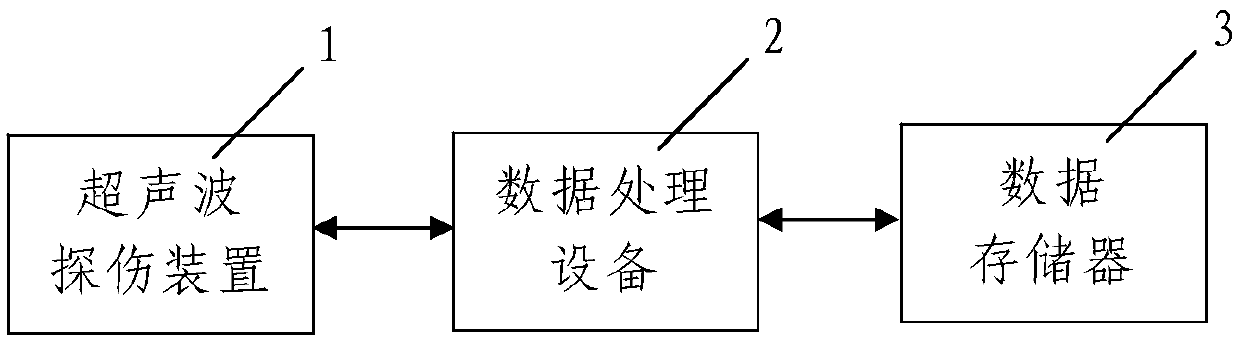

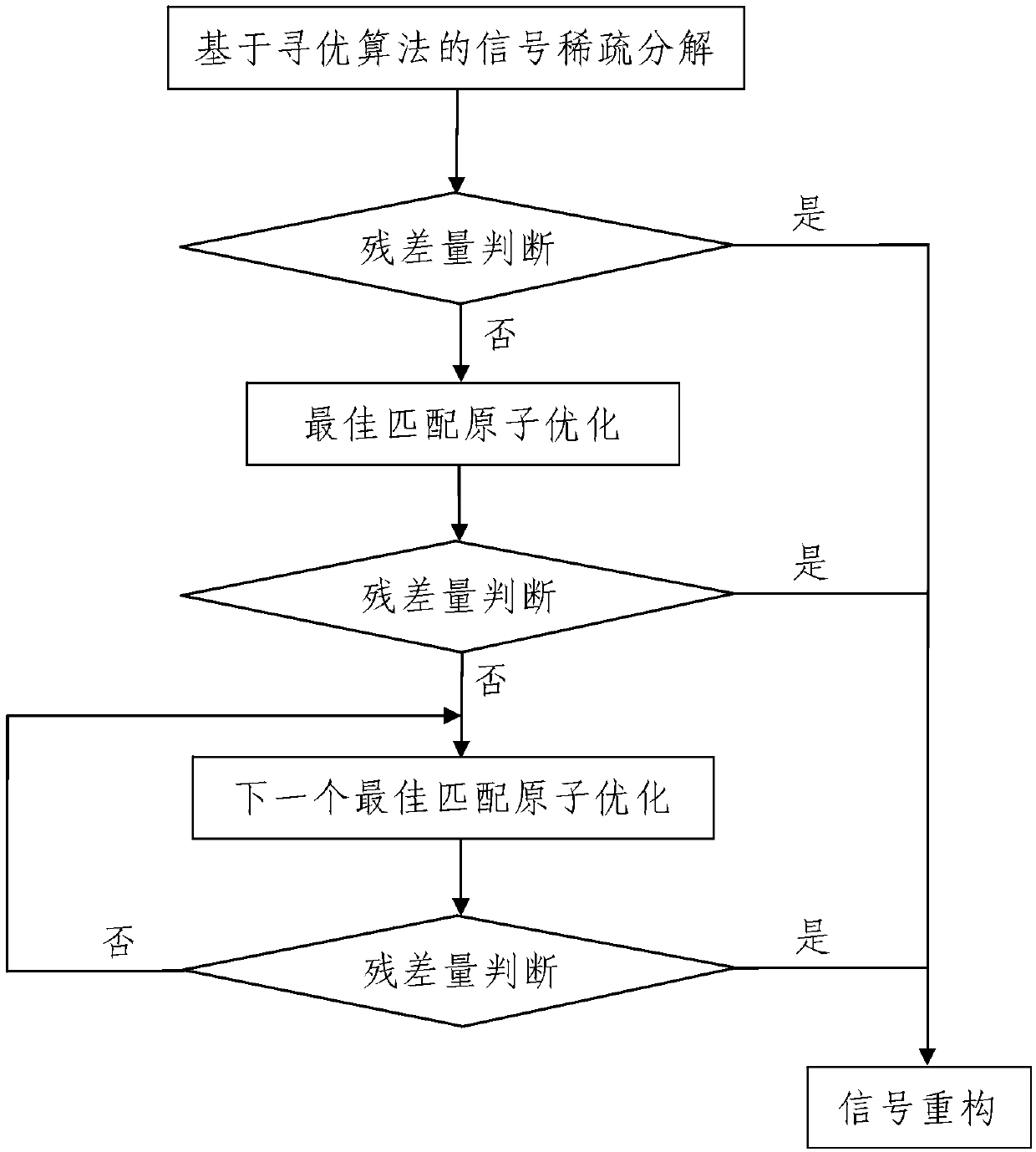

Ultrasonic echo signal extraction method based on multi-scale matching tracking

ActiveCN109632973AThe method steps are simpleReasonable designProcessing detected response signalGabor atomSonification

The invention discloses an ultrasonic echo signal extraction method based on multi-scale matching tracking. The method comprises the following steps: step one, ultrasonic echo signal acquisition and synchronous uploading; step two, time frequency parameter value range compression: compressing value ranges of time frequency parameters of a Garbo atom used for performing sparse decomposition on a to-be-processed signal f(t) by adopting the data processing equipment, wherein the time frequency parameters comprise a scale parameter, a displacement parameter, a frequency parameter and a phase parameter; step three, signal extraction as follows: step 301, signal sparse decomposition based on optimization algorithm; and step 302, signal reconstruction. The method disclosed by the invention is simple in step, reasonable in design, convenient for realization, and good in use effect; the value range of each parameter in the time frequency parameters is compressed, and then the optimal matching atom is searched by adopting the signal sparse decomposition method based on the optimization algorithm, the signal extraction speed can be greatly accelerated, and the signal extraction precision canbe effectively improved.

Owner:XIAN UNIV OF SCI & TECH

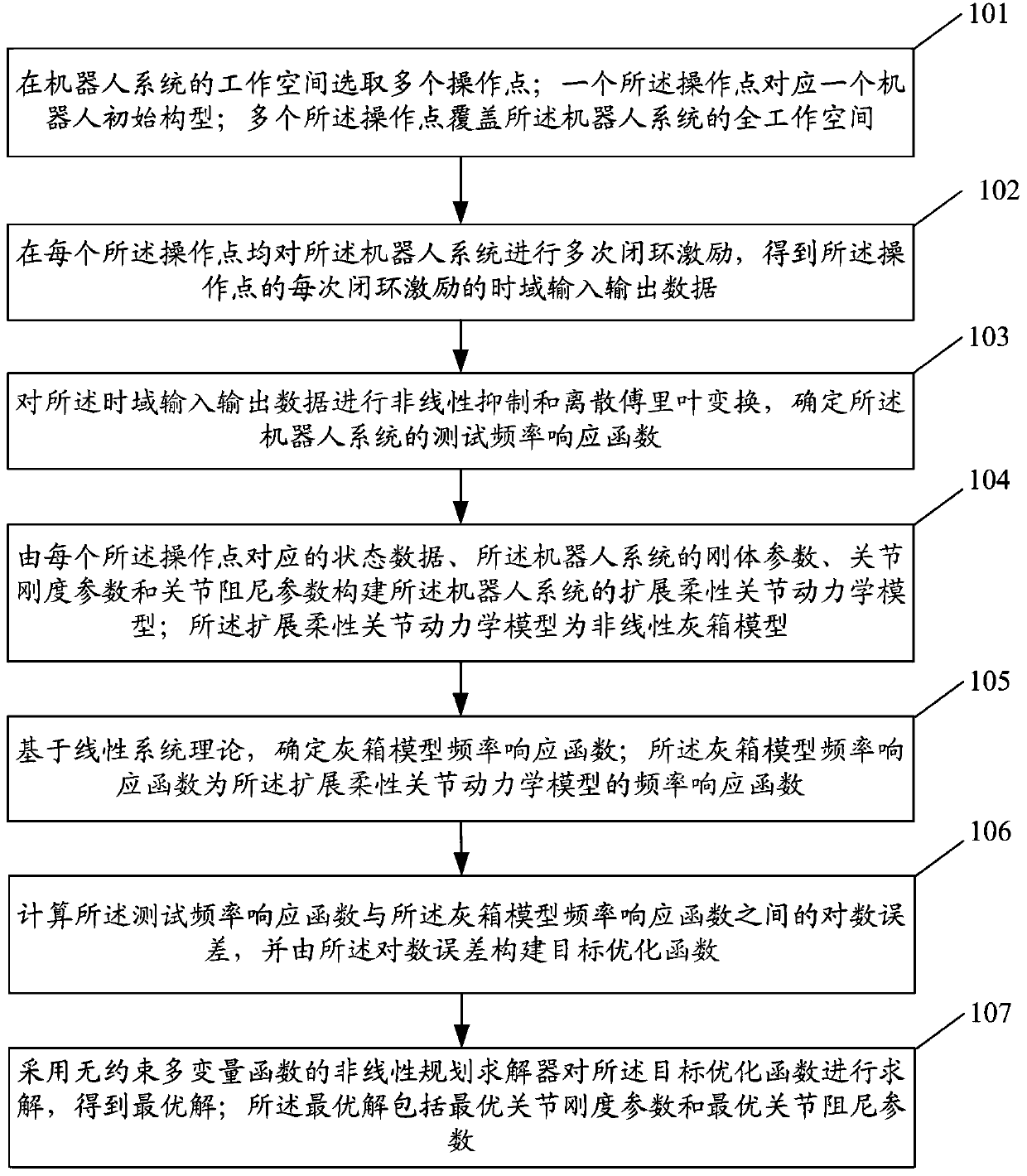

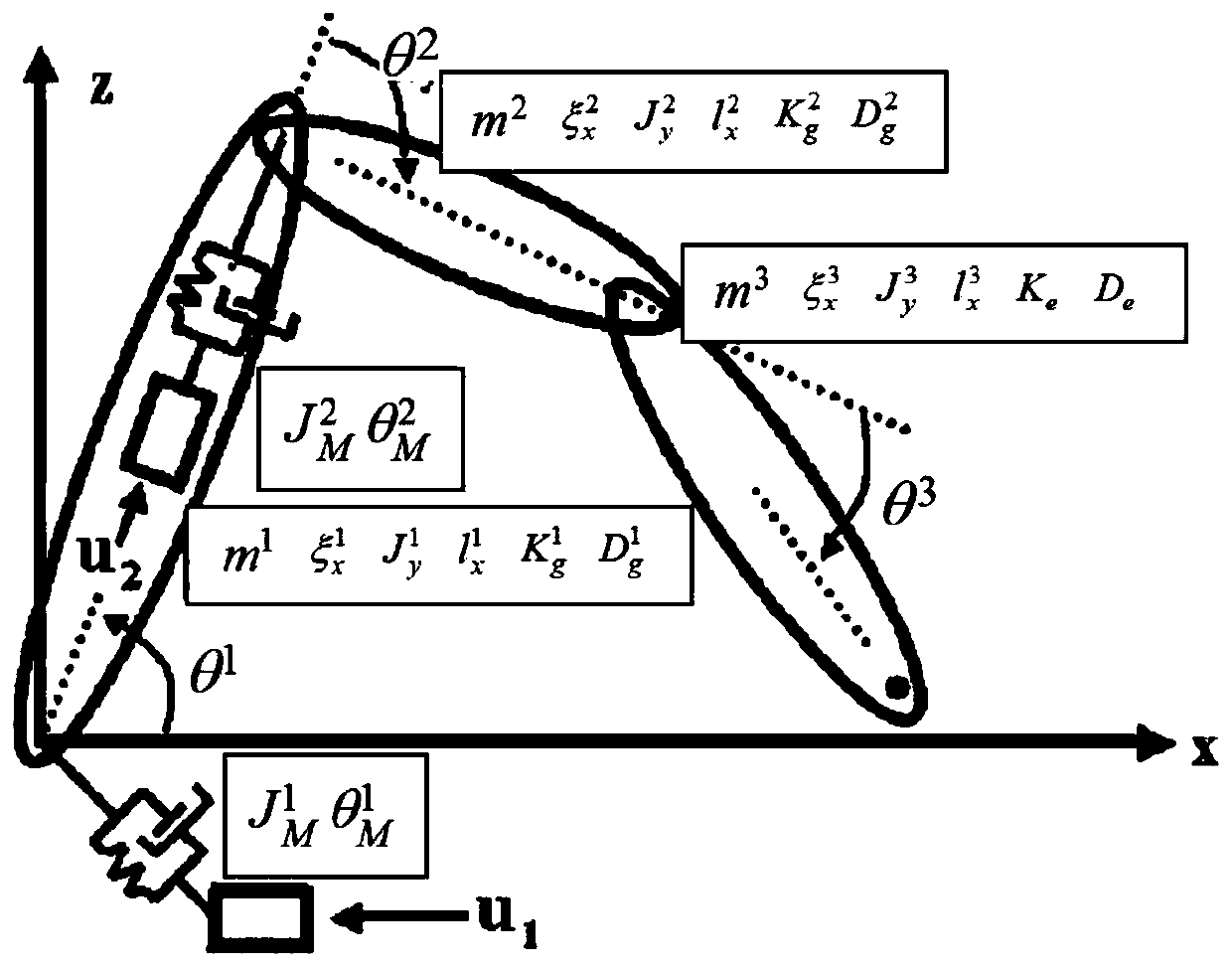

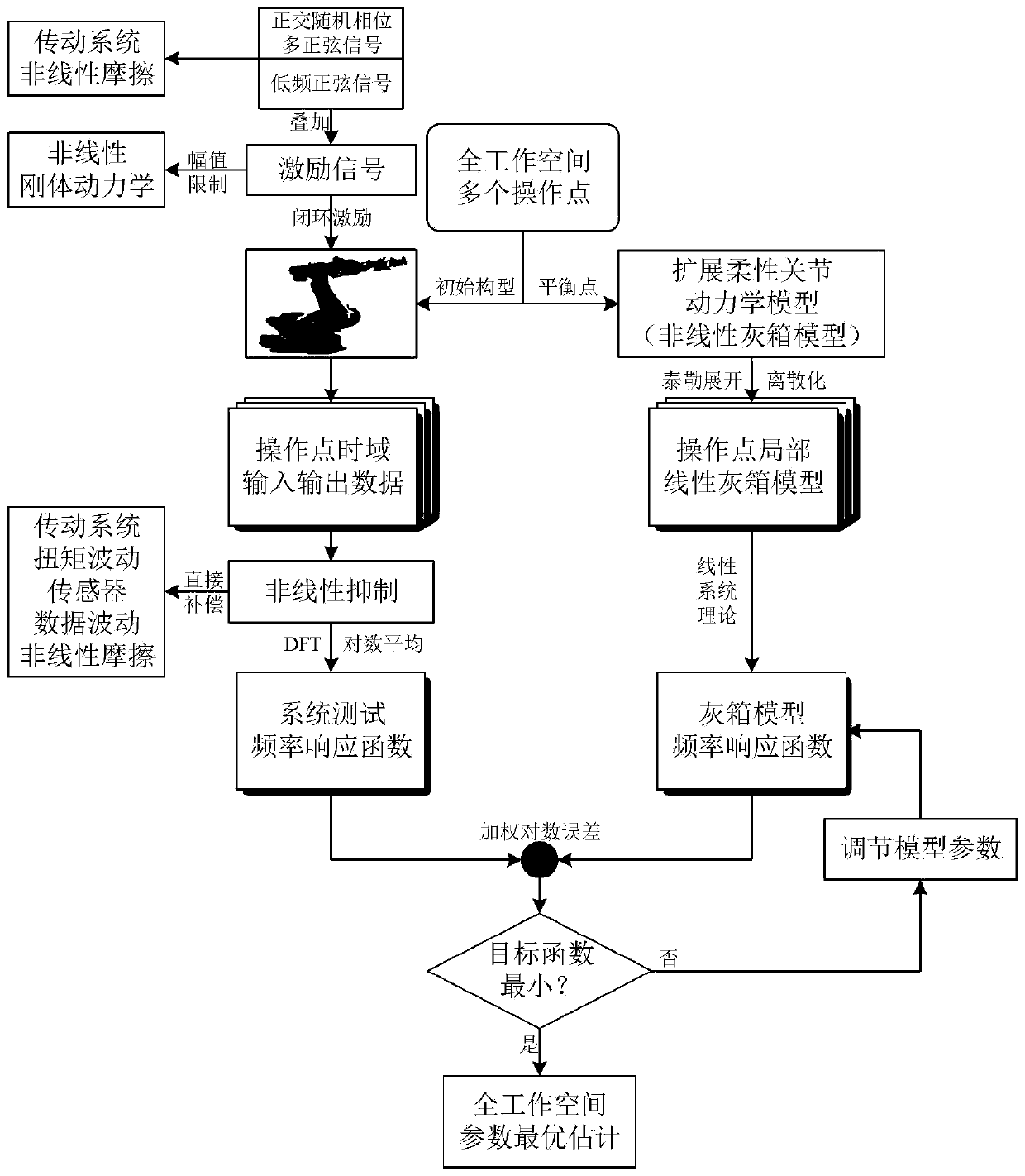

Grey box model parameter identification method and system for robot system

ActiveCN111546336AAccurate identificationOvercoming the issue of being limited to certain statesProgramme-controlled manipulatorRobotic systemsTime domain

The invention discloses a grey box model parameter identification method and system for a robot system. The method comprises the steps that multiple times of closed-loop excitation are carried out onthe robot system at each operation point selected in a working space to obtain time domain input and output data of each time of closed-loop excitation of the operation points; nonlinear suppression and discrete Fourier transform are carried out on the time domain input and output data to determine a test frequency response function; according to state data corresponding to the operation points, and rigid body parameters, joint rigidity parameters and joint damping parameters of the robot system, an extended flexible joint dynamical model of the robot system is constructed, and a grey box model frequency response function is determined; a target optimization function is constructed according to a logarithmic error between the test frequency response function and the grey box model frequency response function; and the target optimization function is solved to obtain an optimal joint rigidity parameter and an optimal joint damping parameter. According to the method, the accurate identification of unknown joint elastic parameters in the dynamical model of the robot system can be realized.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com