Kinematic inverse method for installation process of steam generator examining and repairing mechanical arm

A steam generator, kinematics inverse solution technology, applied in the direction of manipulators, program control manipulators, complex mathematical operations, etc., can solve problems such as algorithm difficulties

Inactive Publication Date: 2008-08-20

HARBIN ENG UNIV

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Solving the kinematics inverse solution of the robot is essentially solving the nonlinear equation of the transcendental function. Due to the complexity of the robot itself, it is very difficult to use a general algorithm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

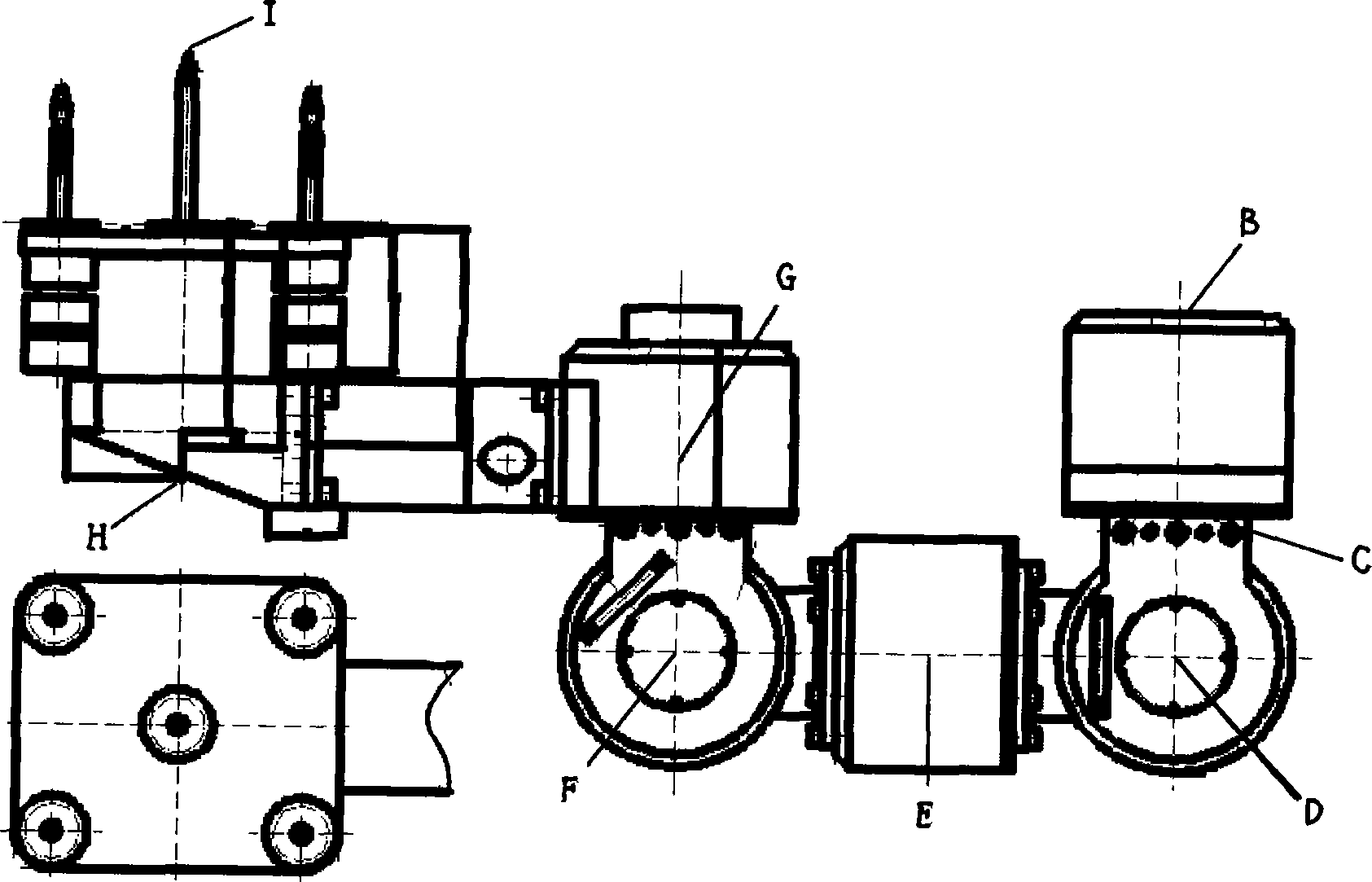

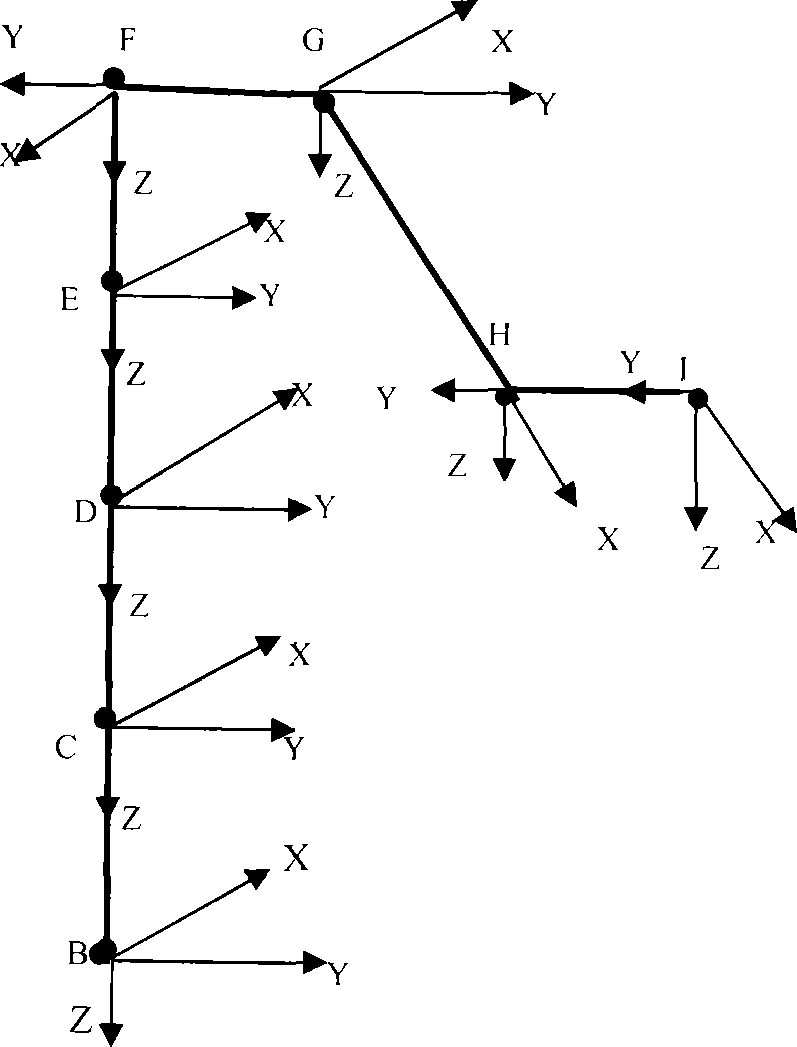

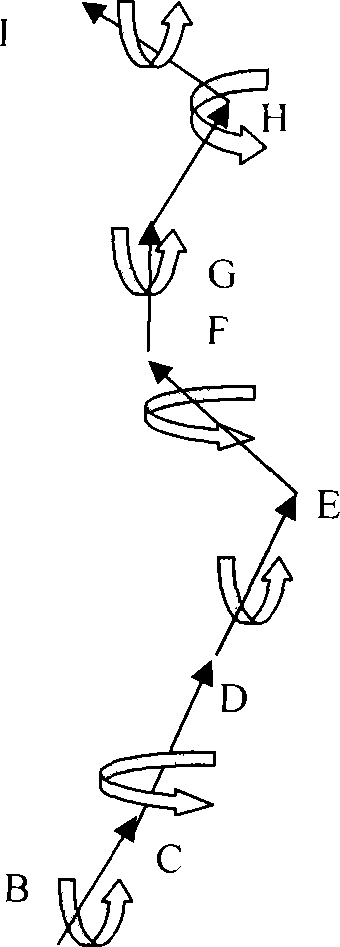

The invention provides an inverse kinematical solution method during the installation process of an overhaul robot arm of a steam generator; wherein, the definitions of Alpha, Beta, and Gamma are as follows: at the initial stage, a base coordinate system is in the same attitude with a world coordinate system, then the base coordinate system revolves around the Y axis for the Alpha angle, next revolves around the X axis for the Beta angle, and finally revolves around the Y axis again for the Gamma angle, so as to obtain the ultimate attitude of the base coordinate system. The respective positions of the articulation points are: B point is the arithmetic endpoint of the robot arm, C, D, E, F, G, and H points are respectively the sixth to first articulation points, and I point is toe arithmetic endpoint; first, the coordinates of the articulation points of the robot arm are solved, and the coordinates of B, C and D points are resolved by means of the normal solutions during installation process; then, a vector HI is acquired based on the coordinate of I point and the attitude angles Alpha, Beta, and Gamma, so the coordinate of H point can be deduced; next, the coordinate of F point is solved; finally, the turn angles Theta (i) of the articulation points can be resolved (wherein, I=1, 2, 3, 4, 5, 6). The inverse kinematical solution method in the invention has the advantages of avoiding building up the kinematical equation of the robot arm, greatly reducing the amount of calculation, quickening the operational speed, and solving all the solutions.

Description

(1) Technical field The invention relates to a steam generator maintenance system, in particular to a six-degree-of-freedom mechanical arm for steam generator primary side maintenance. (2) Background technology The nuclear reactor cooling system of a nuclear power plant is called the primary circuit system. Its main function is to transfer the heat generated during normal operation of the reactor to the steam generator (SG for short), and heat the water on the secondary circuit side and convert it into saturation for driving the turbogenerator set. steam. The steam generator is the connection hub between the primary and secondary loops in the nuclear power plant, and it is also one of the equipment with the most faults in the operation of the nuclear power plant. The working performance, safety and reliability of the steam generator are crucial to the safe and stable operation of the whole system. Because there are radioactive substances in the steam generator, people can...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B25J9/16G06F17/10

Inventor 朱齐丹张智夏桂华陆军蔡成涛王立辉原新栗蓬刘其端包卫卫

Owner HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com