Design method of woven fabric composite material properties based on controllable microstructure

A composite material and physical parameter technology, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as increasing design and processing costs, changing manufacturing and processing technology, shortening the design cycle, increasing production costs, The effect of simplifying the optimization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

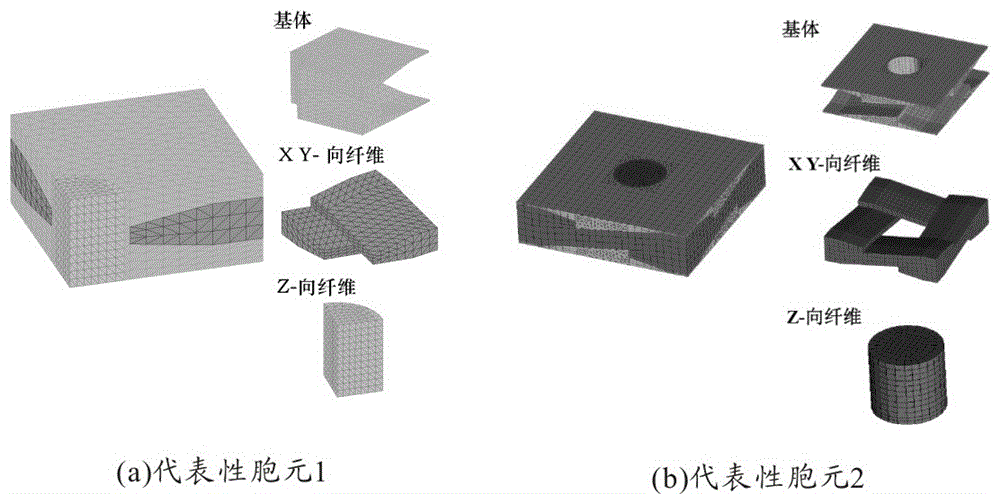

[0031] The invention is a controllable microstructure-based method for designing physical property parameters of braided composite materials. Firstly, a finite element (FEM) model for analyzing the mesoscopic heat transfer characteristics of braided composite materials is established. The reasonable selection of representative cells has an important impact on the prediction of material physical parameters. built as attached figure 1 a Finite element model of a representative cell of a woven composite. In the calculation, the fiber filament is T300, the matrix material is epoxy resin, the fiber filament diameter is 7 μm, and the axial length is 300 μm. The detailed parameters are shown in Table 1. A rotationally symmetric boundary is applied on the two faces in the x and y directions that meet the fiber in the z direction, and a symmetric boundary is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com