Patents

Literature

66 results about "Parametric analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

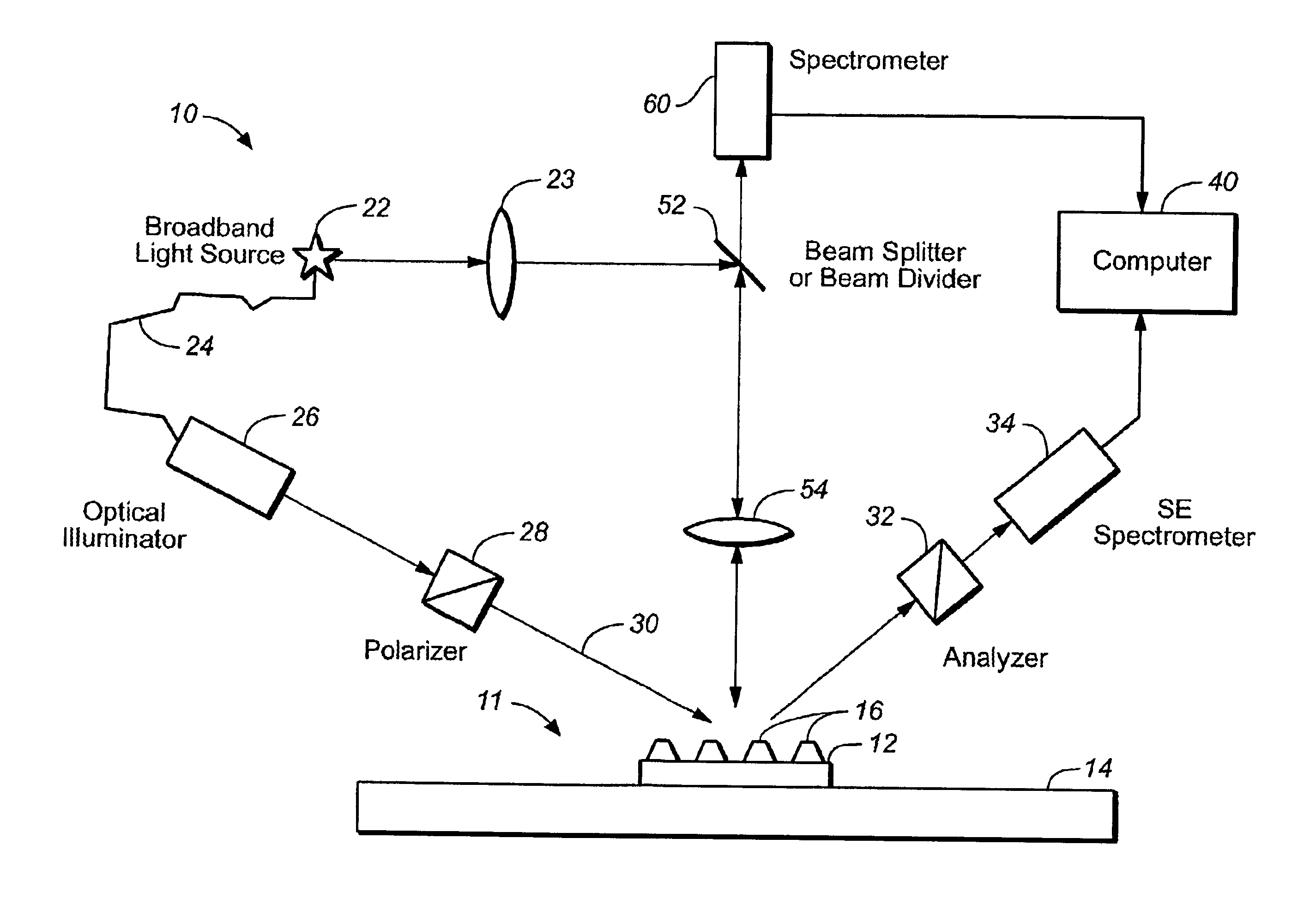

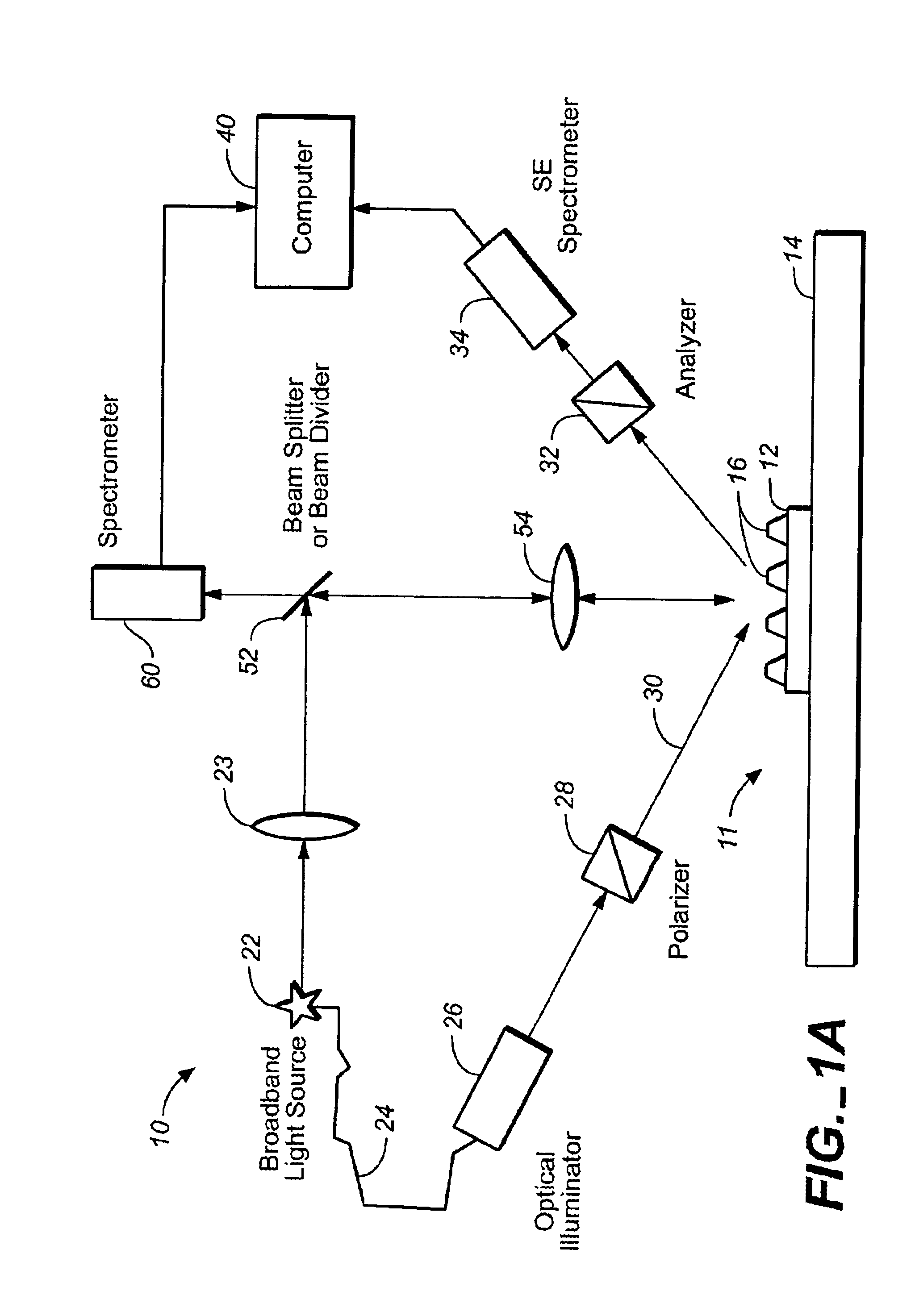

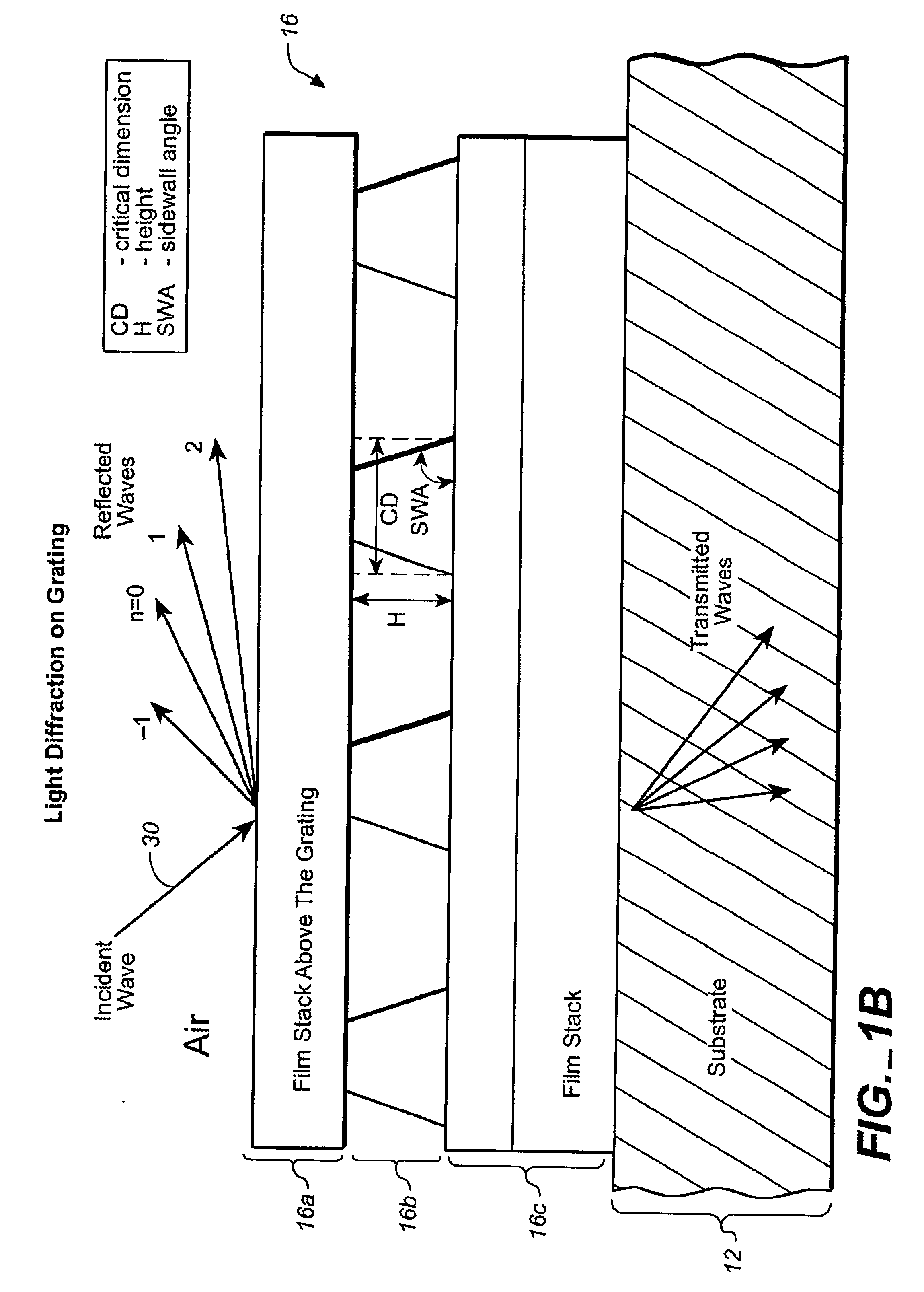

Parametric profiling using optical spectroscopic systems

InactiveUS7280230B2Simplify profile measurementRemove uncertaintyPolarisation-affecting propertiesScattering properties measurementsComputer scienceSemiconductor

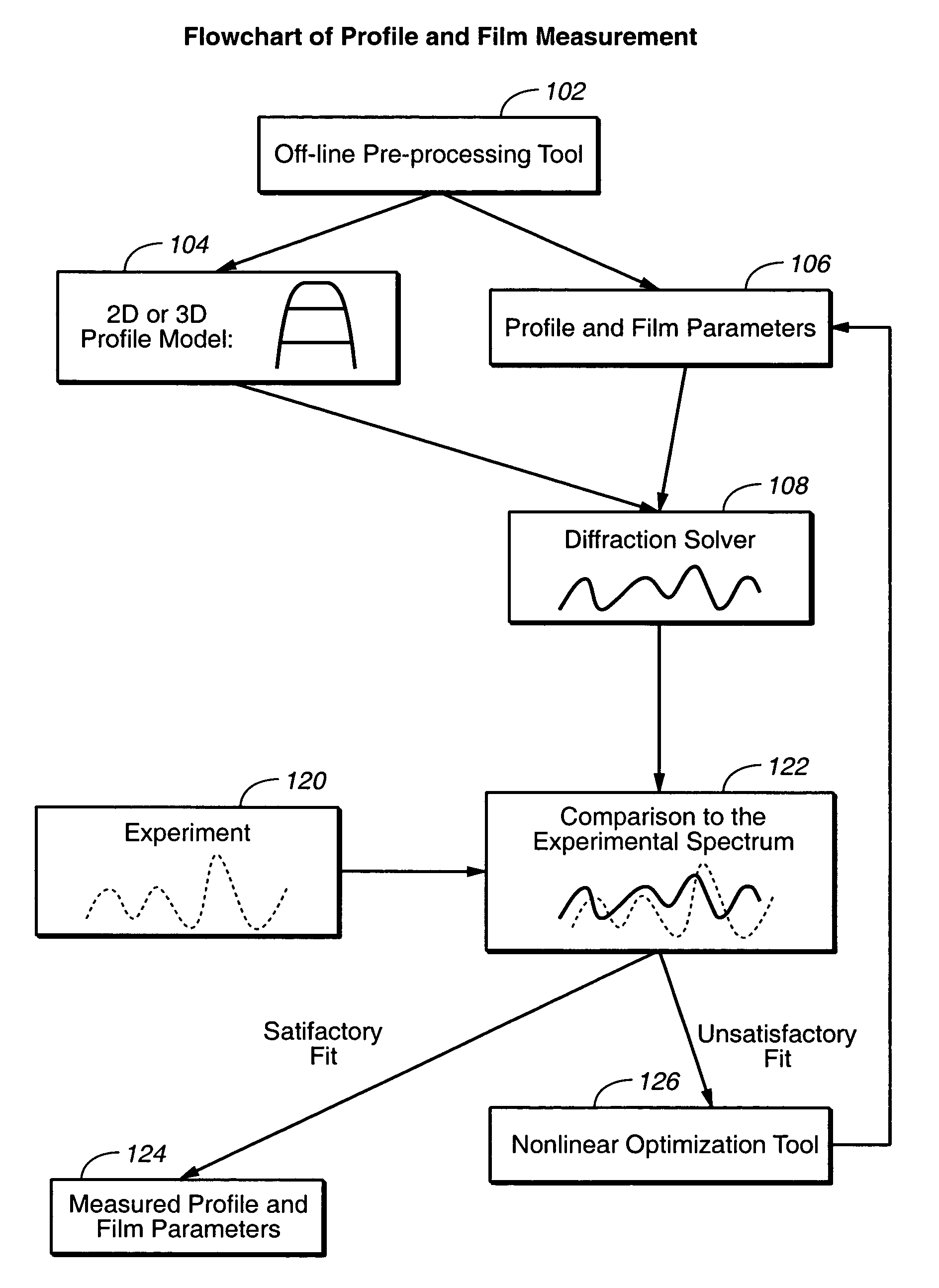

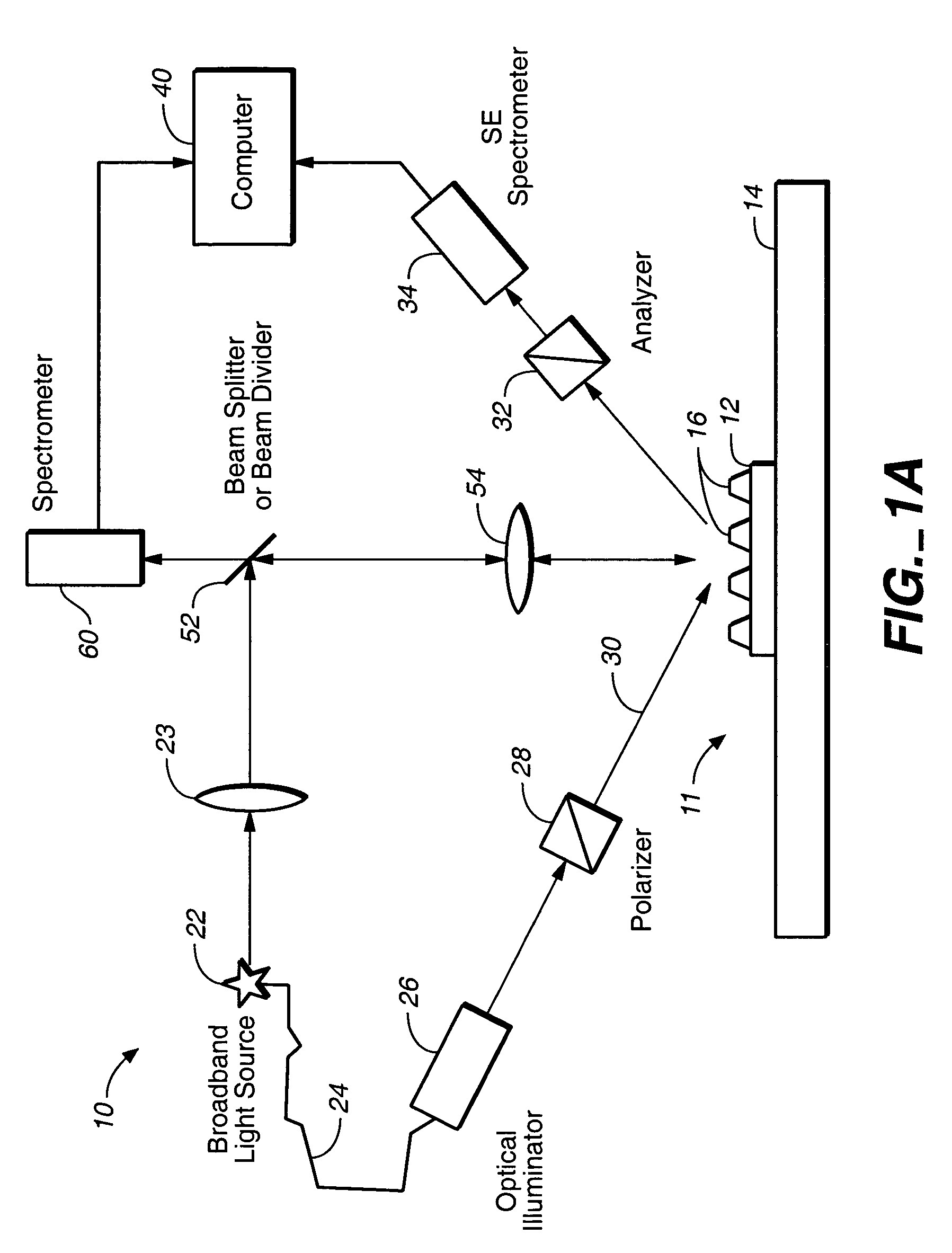

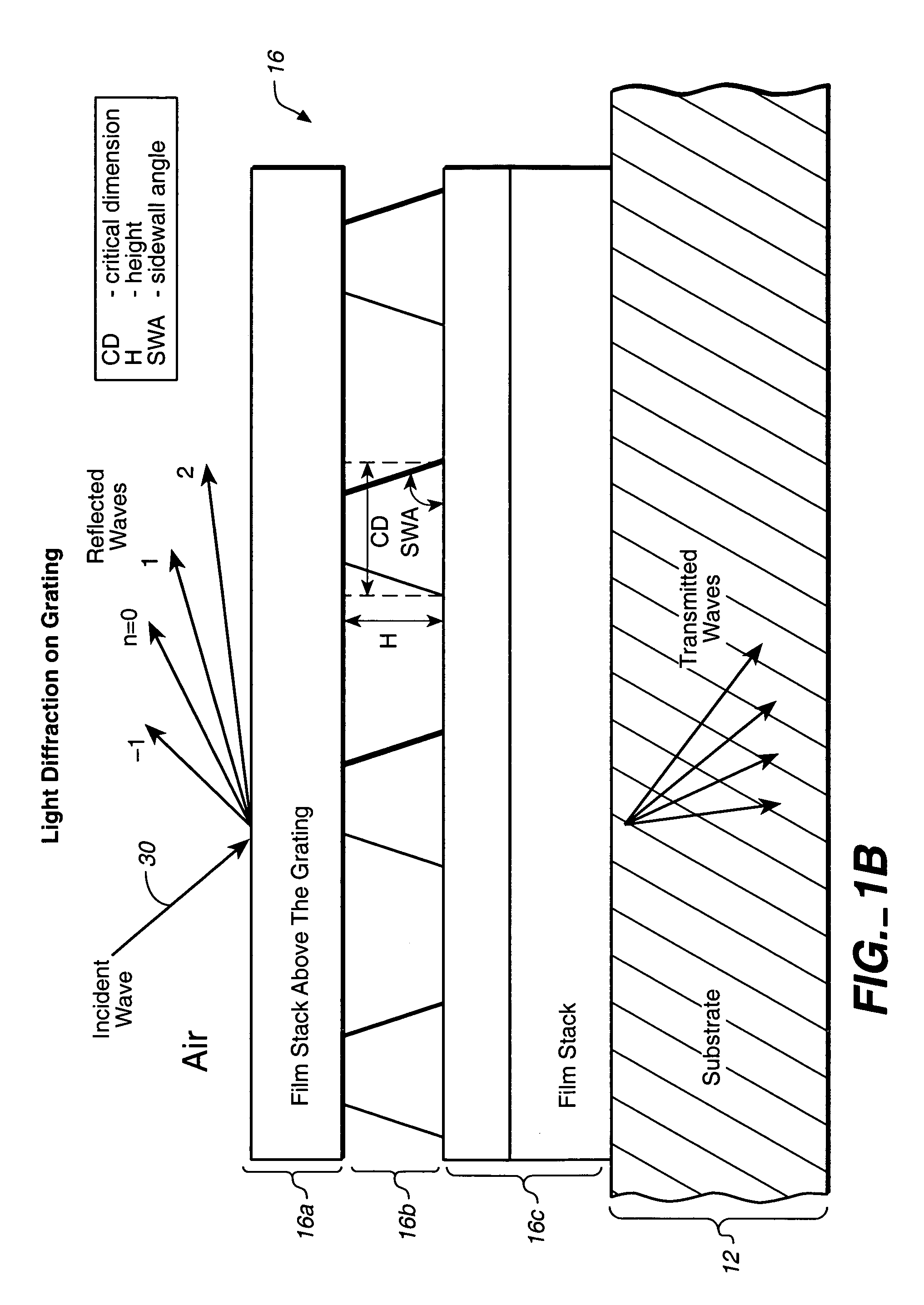

A gallery of seed profiles is constructed and the initial parameter values associated with the profiles are selected using manufacturing process knowledge of semiconductor devices. Manufacturing process knowledge may also be used to select the best seed profile and the best set of initial parameter values as the starting point of an optimization process whereby data associated with parameter values of the profile predicted by a model is compared to measured data in order to arrive at values of the parameters. Film layers over or under the periodic structure may also be taken into account. Different radiation parameters such as the reflectivities Rs, Rp and ellipsometric parameters may be used in measuring the diffracting structures and the associated films. Some of the radiation parameters may be more sensitive to a change in the parameter value of the profile or of the films then other radiation parameters. One or more radiation parameters that are more sensitive to such changes may be selected in the above-described optimization process to arrive at a more accurate measurement. The above-described techniques may be supplied to a track / stepper and etcher to control the lithographic and etching processes in order to compensate for any errors in the profile parameters.

Owner:KLA TENCOR TECH CORP

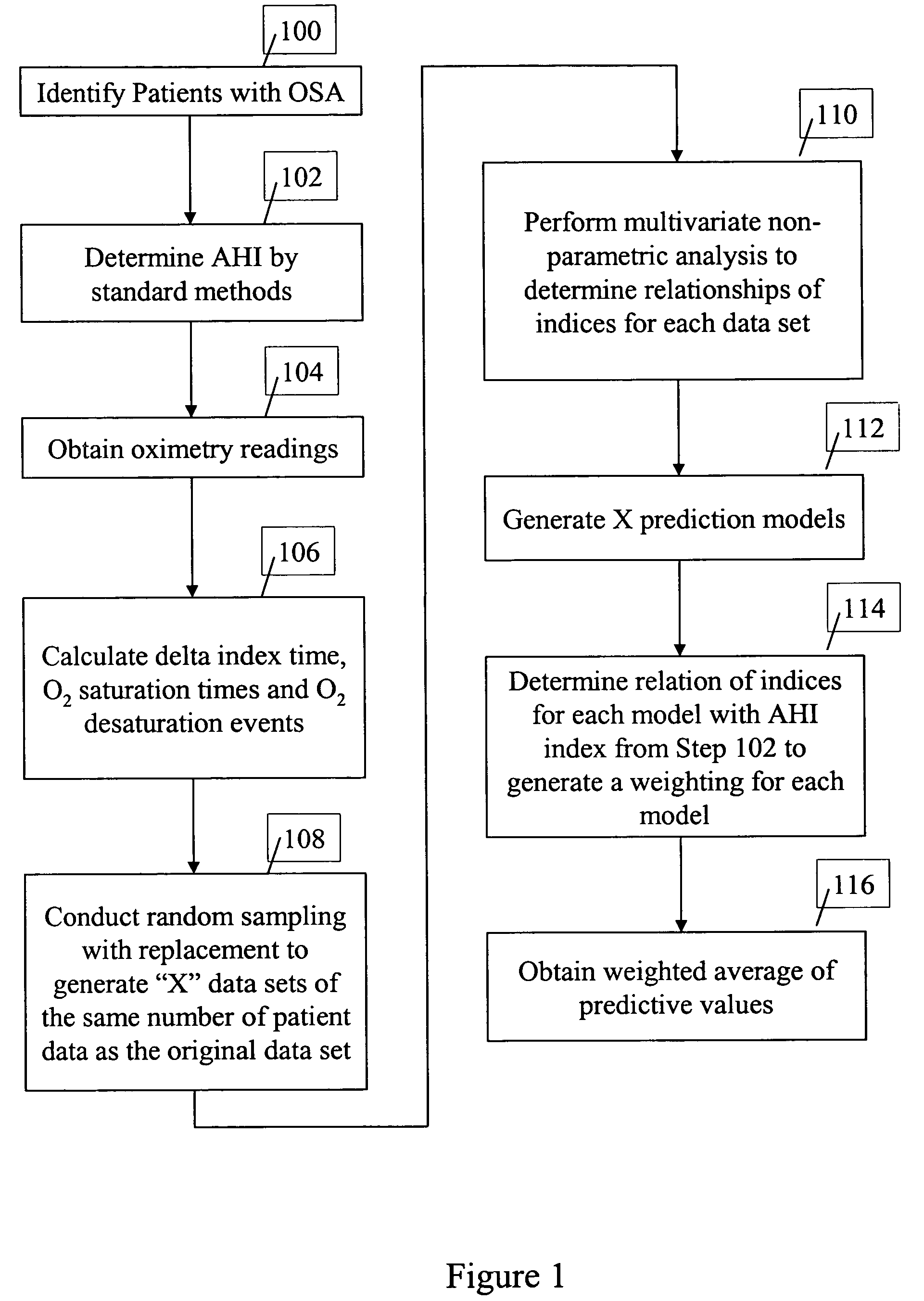

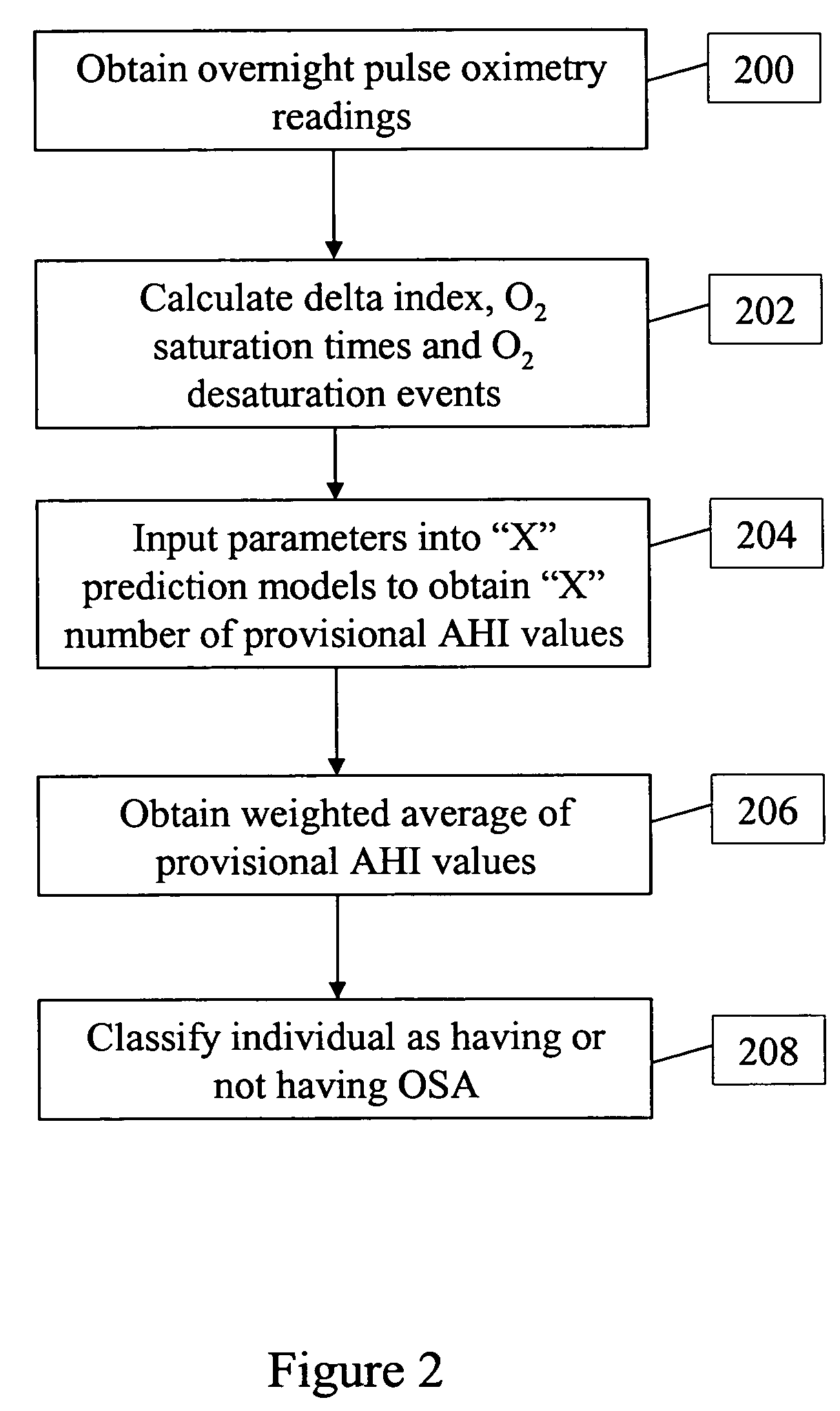

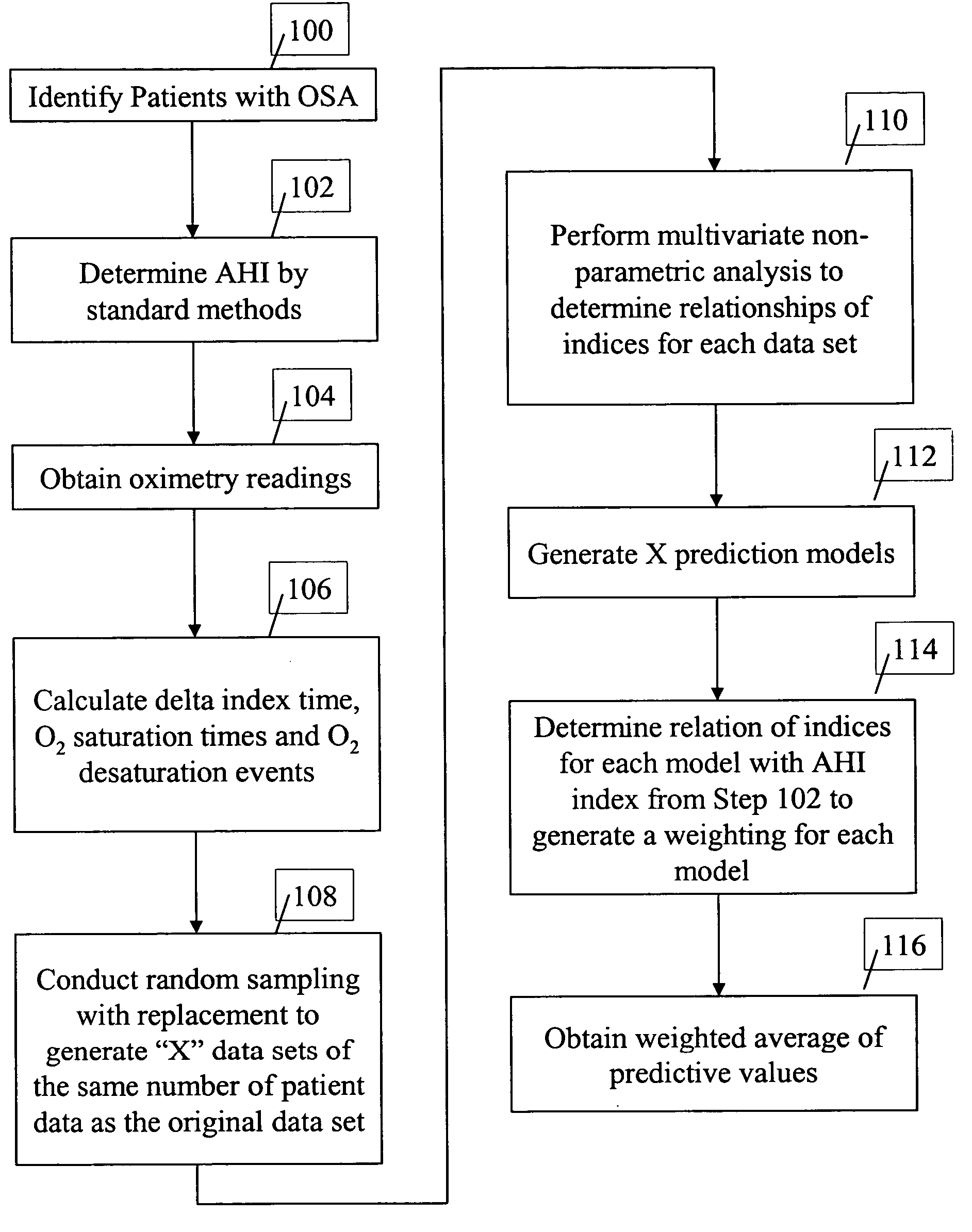

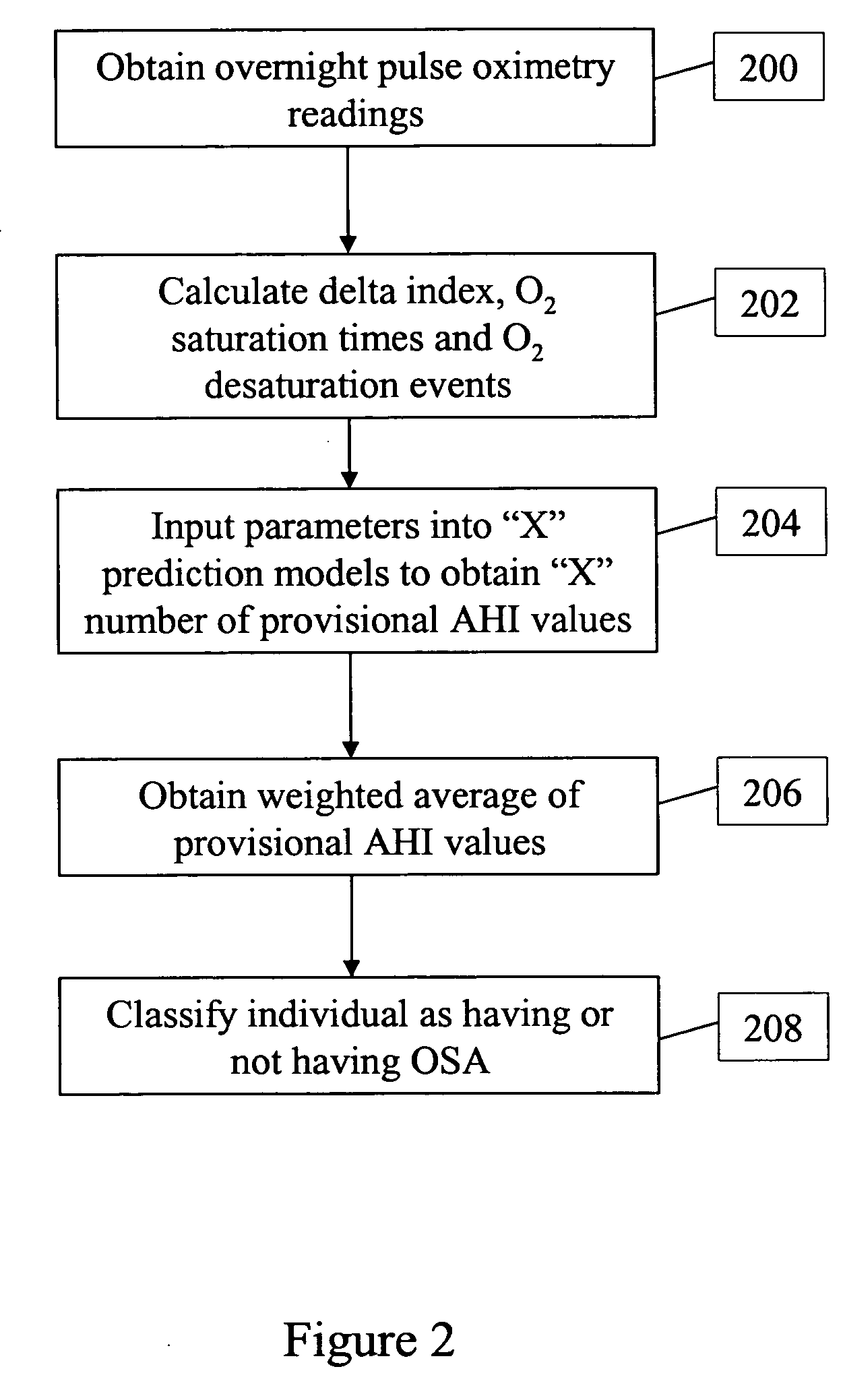

Method for predicting apnea-hypopnea index from overnight pulse oximetry readings

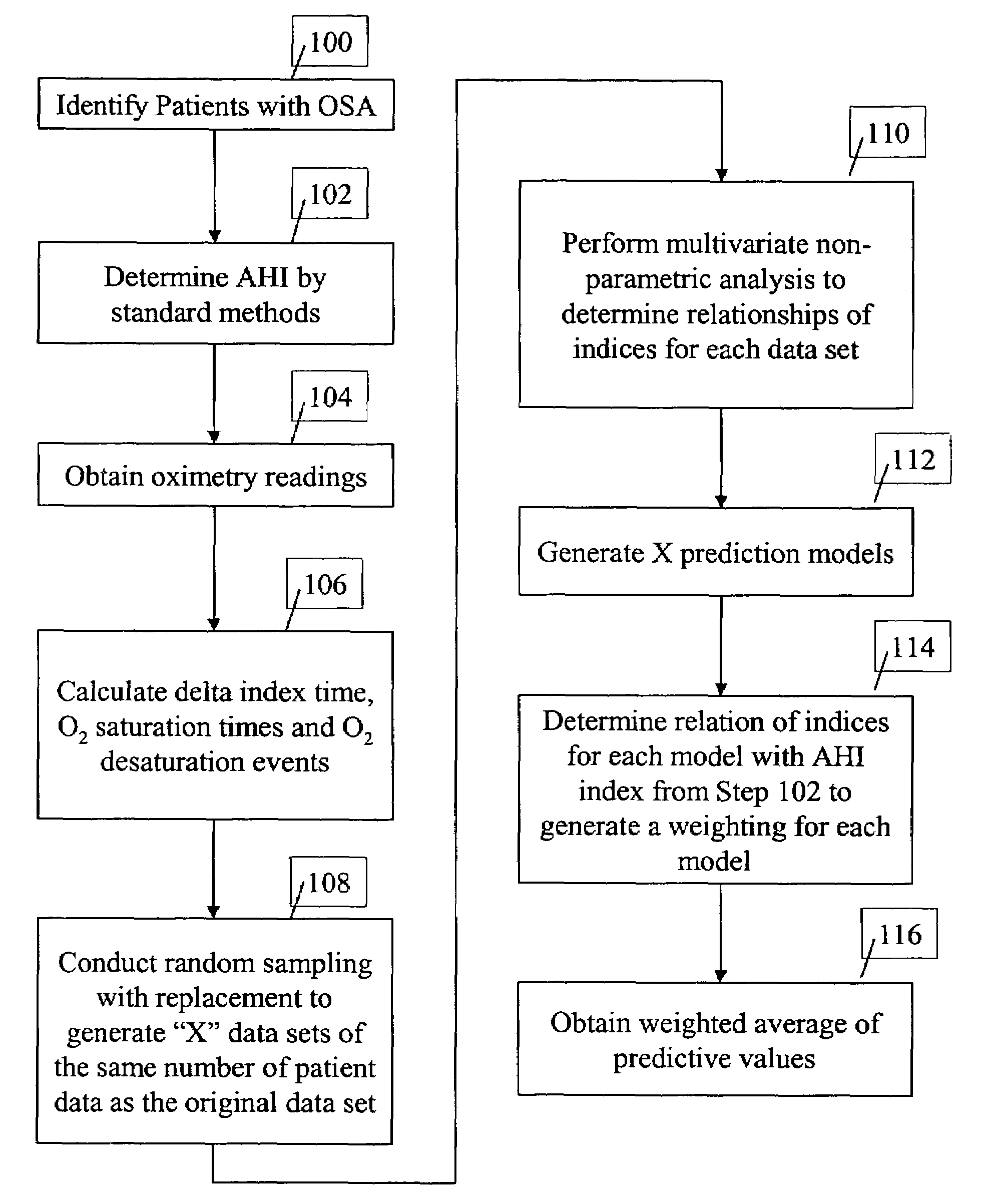

The present invention provides a predictive tool for predicting Apopnea Hypopnea Index (AHI) in the diagnosis of Obstructive sleep apnea (OSA). The predictive tool is developed by recording pulse oximetry readings, obtaining delta index, oxygen saturation times and oxygen desaturation events from the oximetry readings. A multivariate non-parametric analysis and bootstrap aggregation is performed to obtain predictive models which can be used to predictive AHI in an individual and to classify an individual as having or not having OSA.

Owner:VETERANS AFFAIRS U S DEPT OF +1

Parametric profiling using optical spectroscopic systems

InactiveUS6900892B2Semiconductor/solid-state device testing/measurementPolarisation spectroscopyParameter analysisProcess knowledge

A gallery of seed profiles is constructed and the initial parameter values associated with the profiles are selected using manufacturing process knowledge of semiconductor devices. Manufacturing process knowledge may also be used to select the best seed profile and the best set of initial parameter values as the starting point of an optimization process whereby data associated with parameter values of the profile predicted by a model is compared to measured data in order to arrive at values of the parameters. Film layers over or under the periodic structure may also be taken into account. Different radiation parameters such as the reflectivities RS, RP and ellipsometric parameters may be used in measuring the diffracting structures and the associated films. Some of the radiation parameters may be more sensitive to a change in the parameter value of the profile or of the films then other radiation parameters. One or more radiation parameters that are more sensitive to such changes may be selected in the above-described optimization process to arrive at a more accurate measurement. The above-described techniques may be supplied to a track / stepper and etcher to control the lithographic and etching processes in order to compensate for any errors in the profile parameters.

Owner:KLA TENCOR CORP

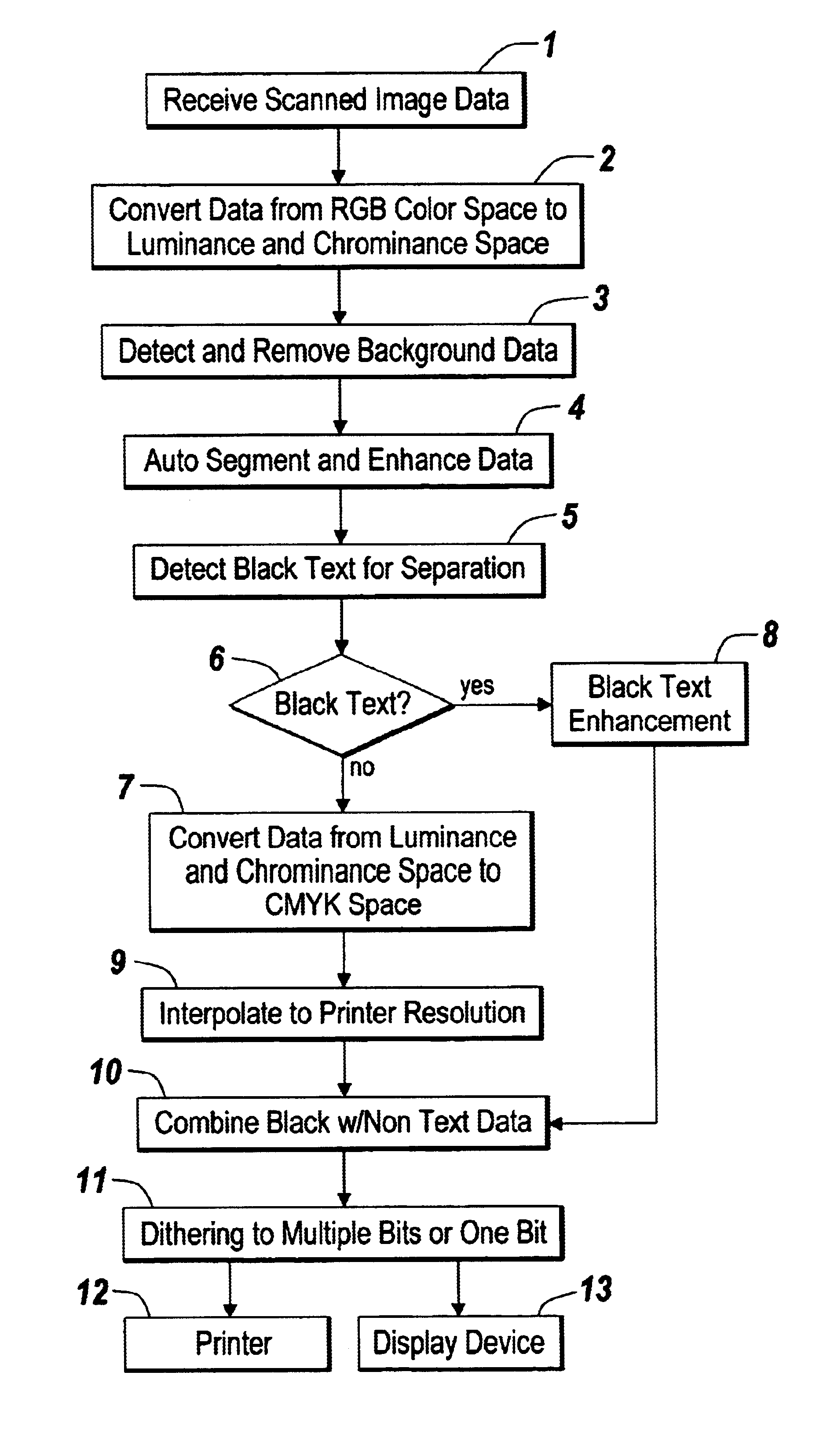

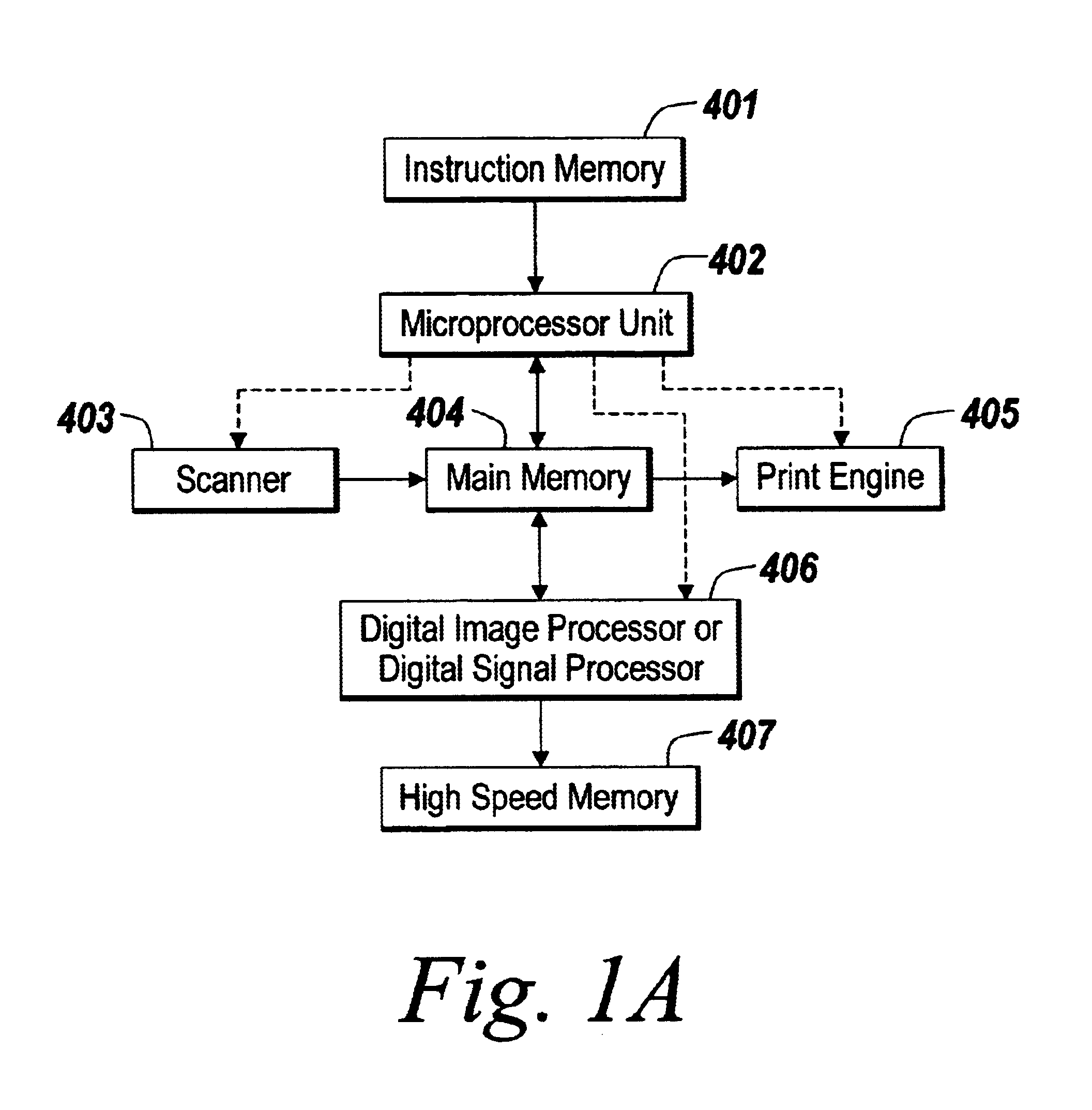

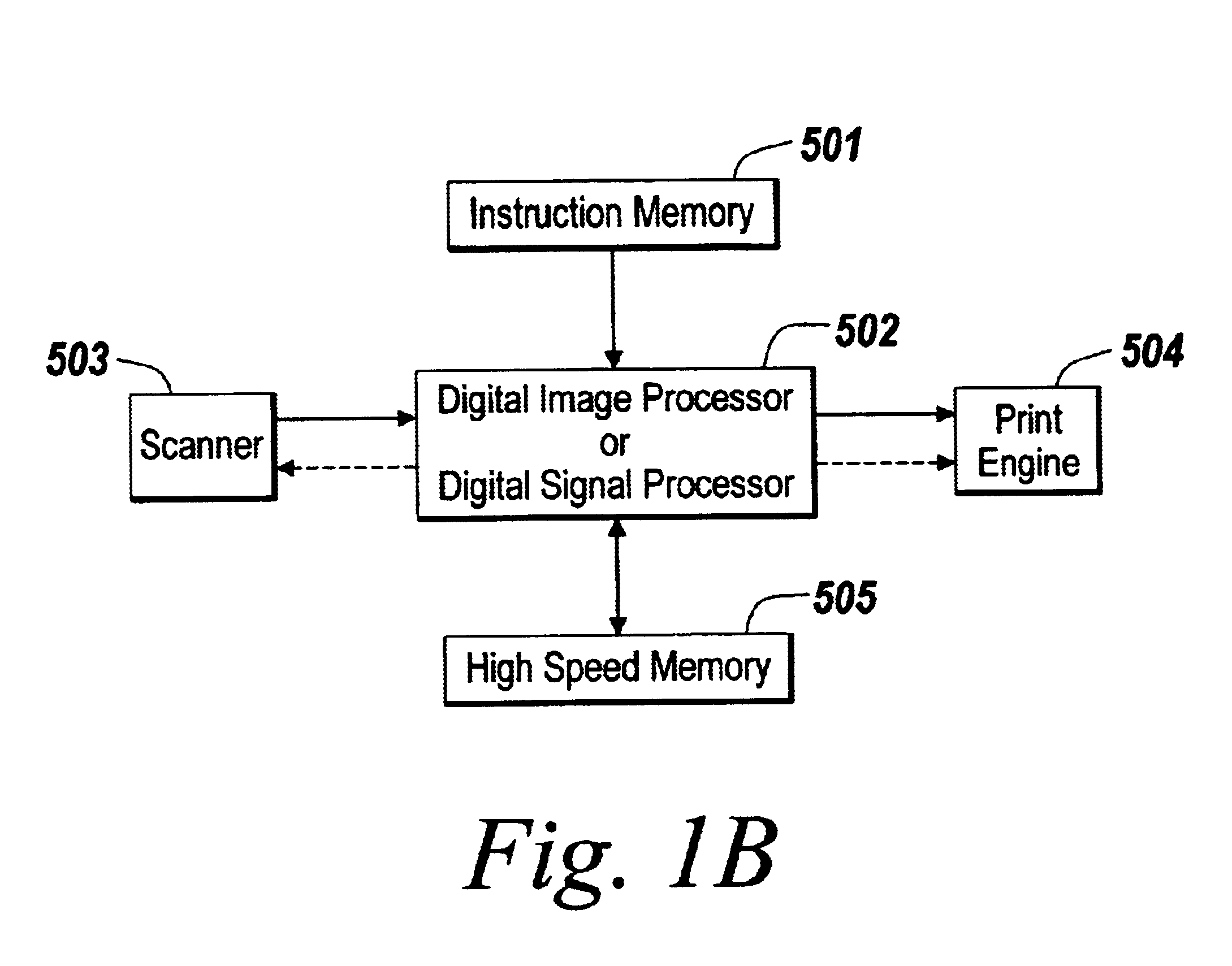

System and method for color copy image processing

InactiveUS6839151B1Reduce computing costLess errorDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

A system and method of processing an image including black text data and non-black text data are described. The system and method use a parametric analysis for discrimination of halftones, texts, and photographs. The parametric analysis provides results that track measurable image metrics without the inherent risk of errant decision making during classification. The creation of symbolic representations is intrinsically a classification process that is subject to error. It represents a fundamental departure from fuzzy logic image segmentation. In the parametric analysis, no pattern matching, no auto-correlation, no screening parameter calculation, and no conventional edge detector (such as a high pass filter) are used.

Owner:CSR IMAGING US

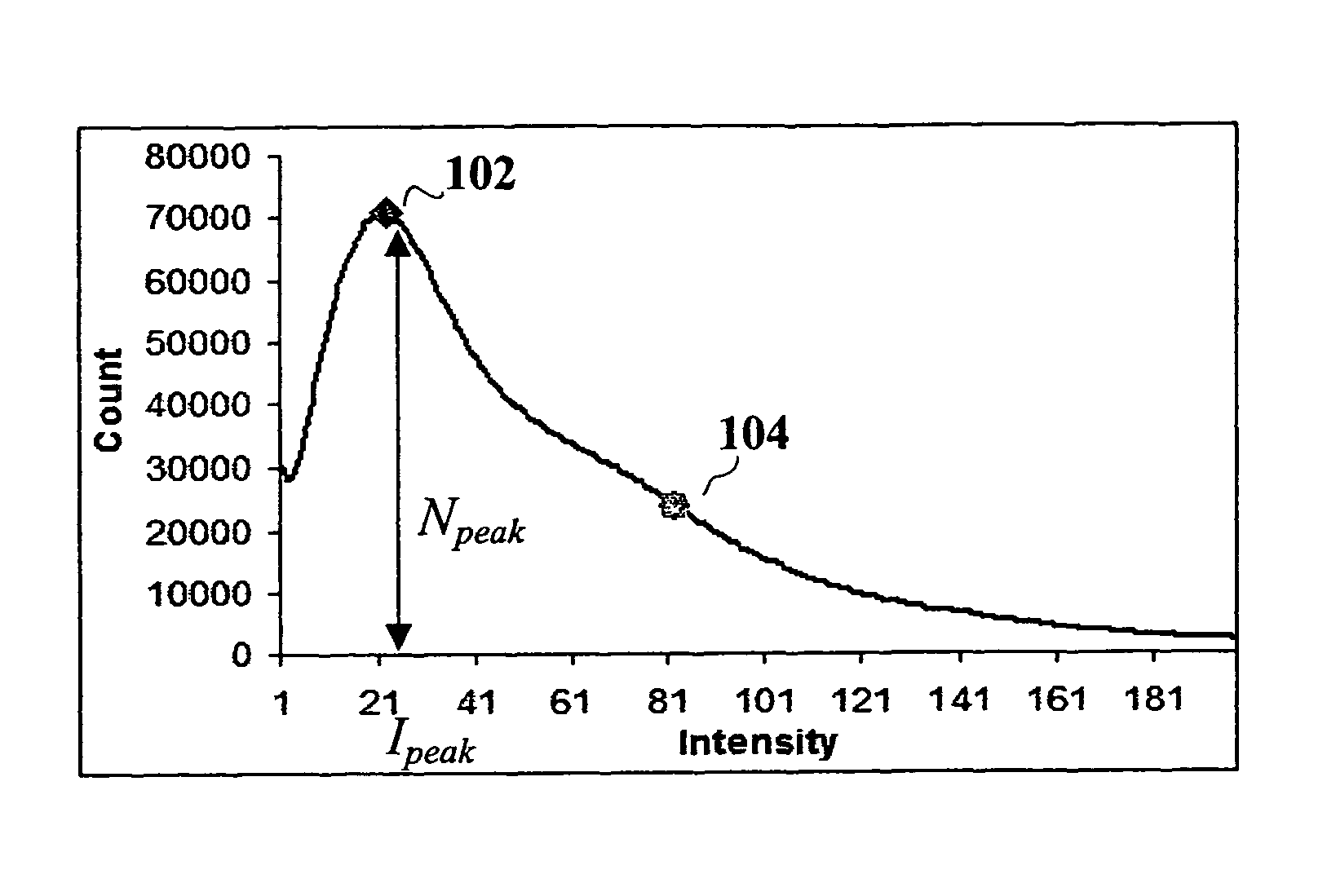

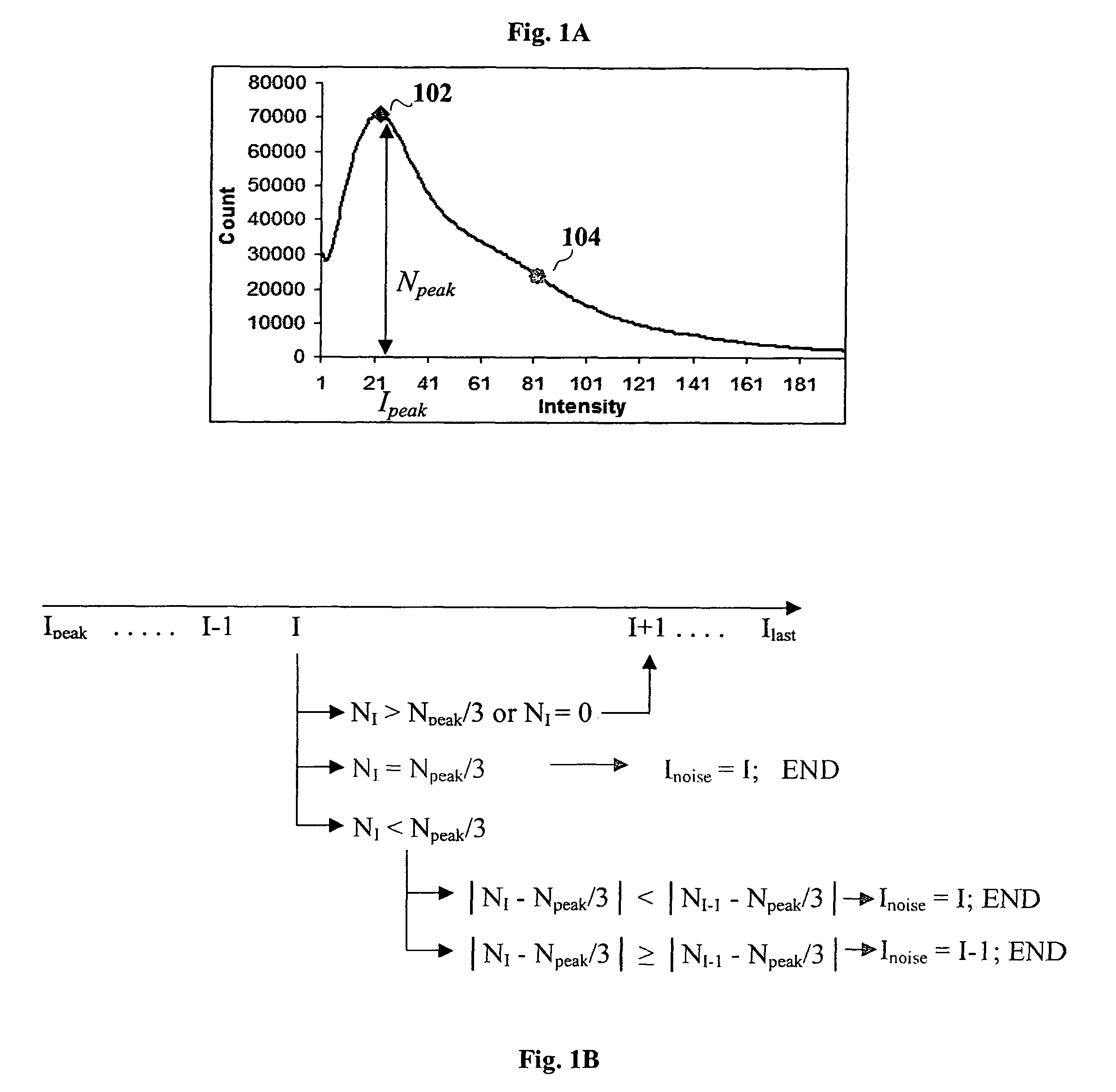

Automated methods for pre-selection of voxels and implementation of pharmacokinetic and parametric analysis for dynamic contrast enhanced MRI and CT

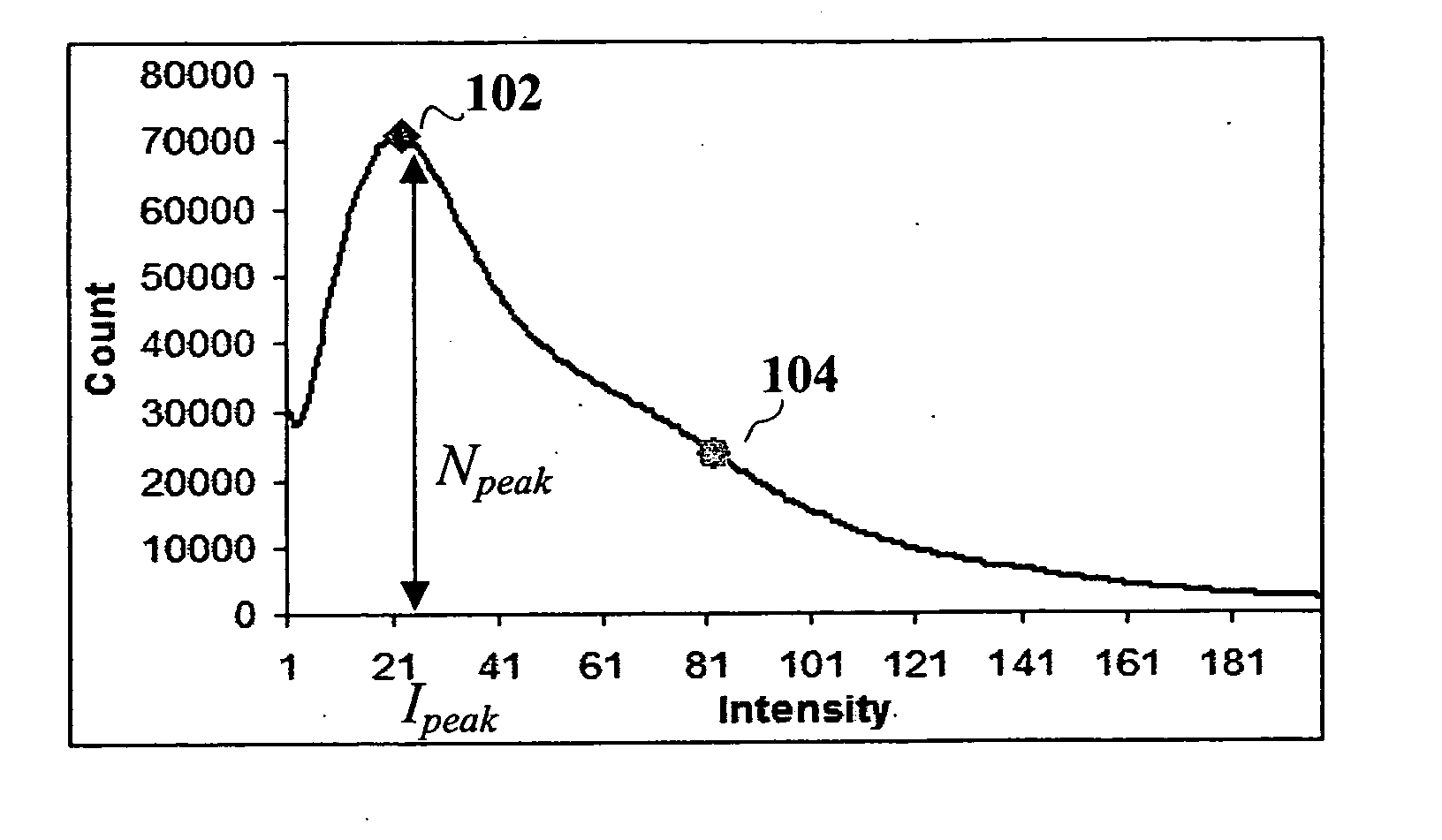

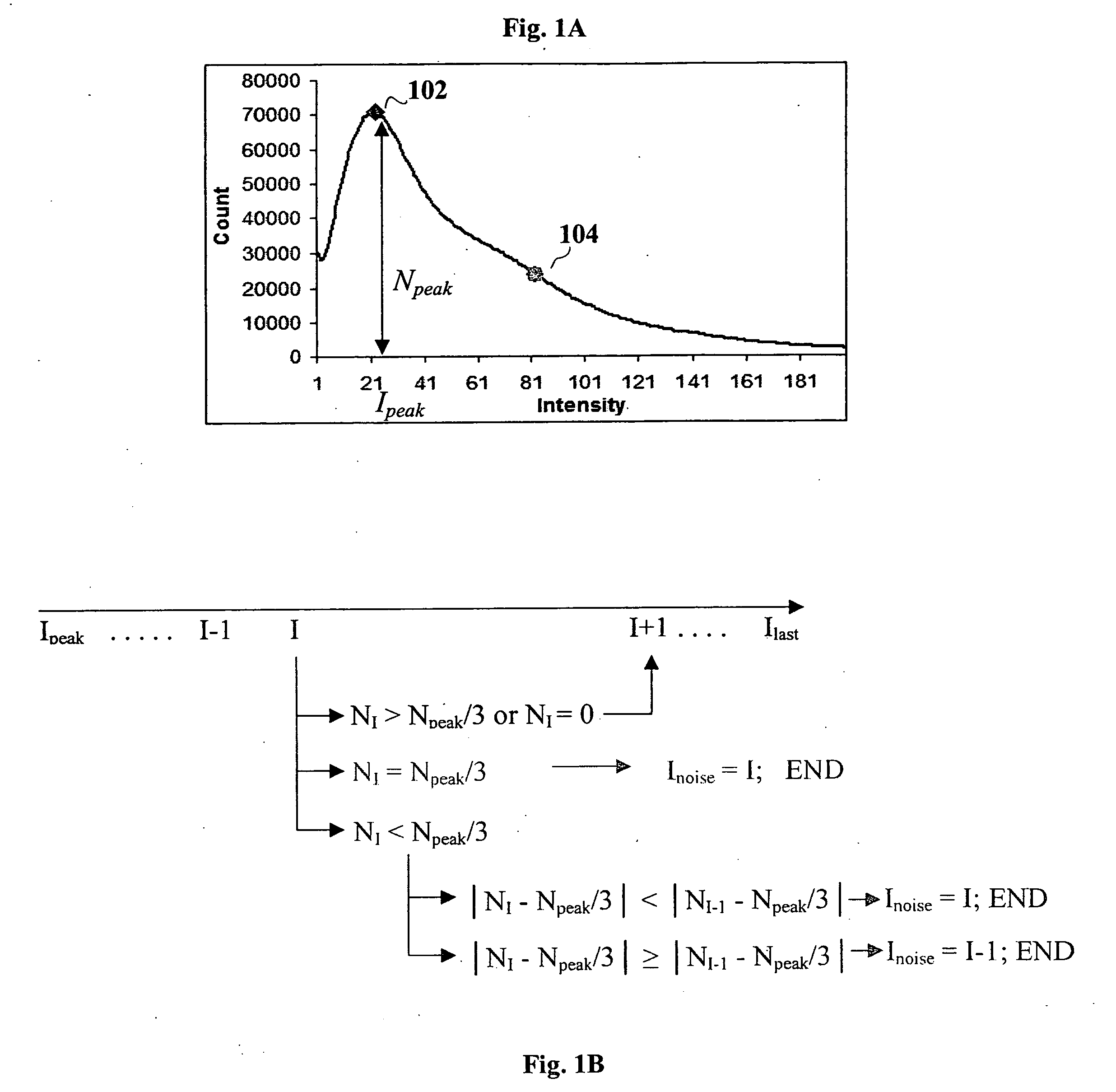

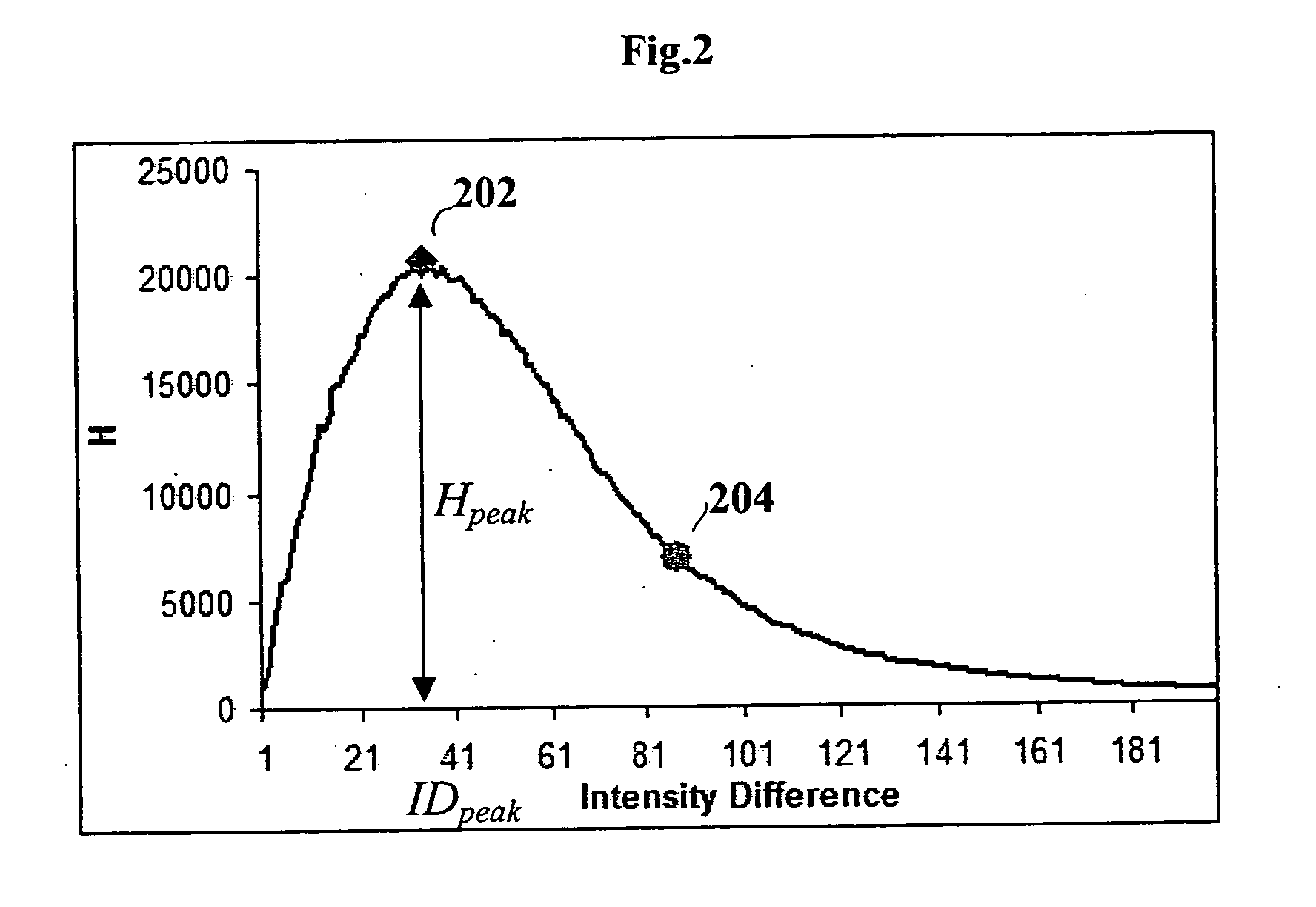

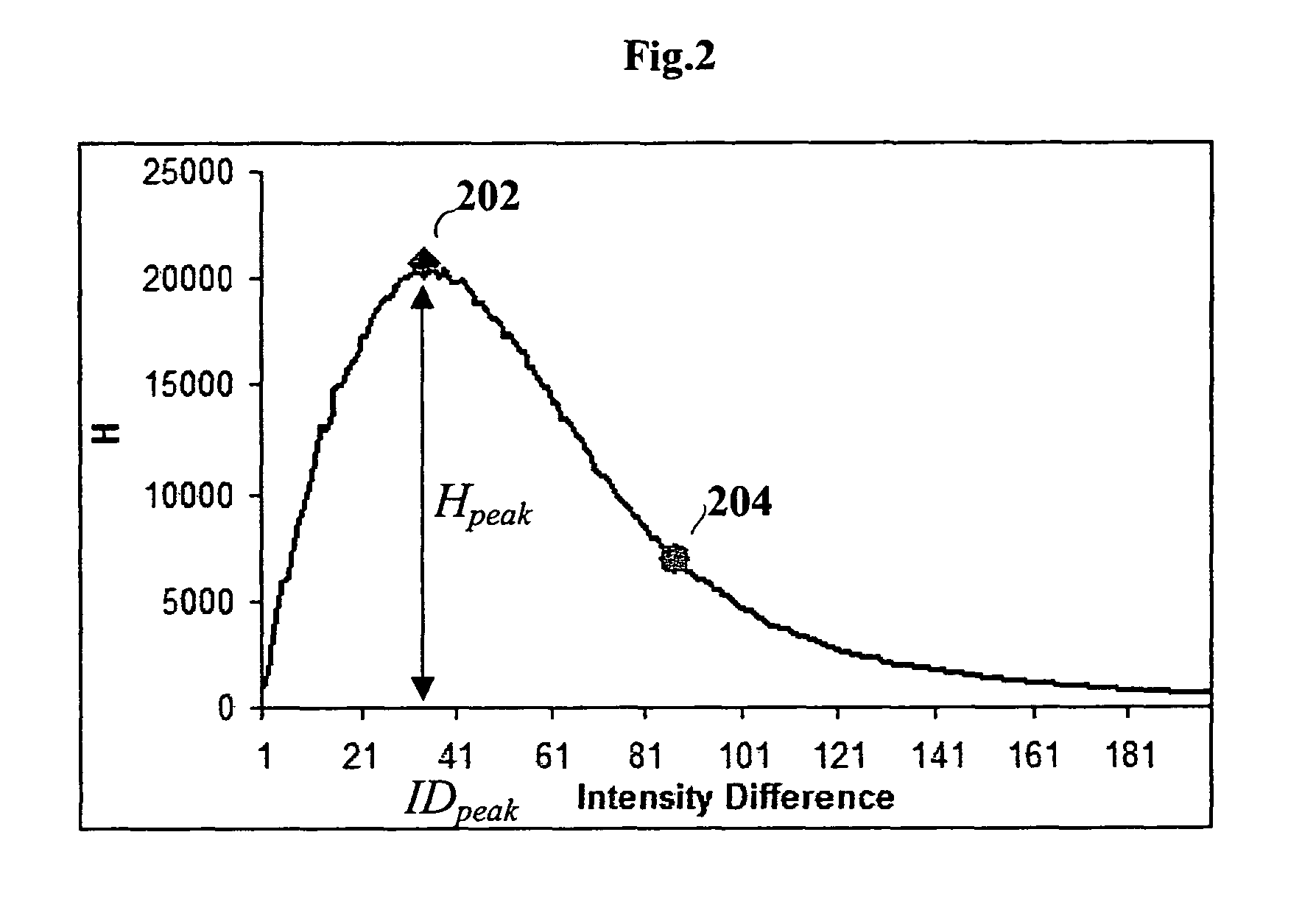

A method, system and computer-readable medium of filtering noise pixels and other extraneous data, including saturated fat tissue and air data in image data is provided. Examples of image data may include but are not limited to magnetic resonance imaging data and computed tomography data. The method includes receiving pixel count for each signal intensity value of the image data; determining a signal intensity value, Ipeak, corresponding to a pixel count of a greatest number of pixels, Npeak; setting a noise threshold at a signal intensity value, Inoise, corresponding to a pixel count, NI, such that NI, is determined based on Npeak; and filtering from the image data one or more pixels with signal intensity values below the noise threshold. NI, may be determined such that NI=Npeak / 3 or close to Npeak / 3.

Owner:KONINKLJIJKE PHILIPS NV

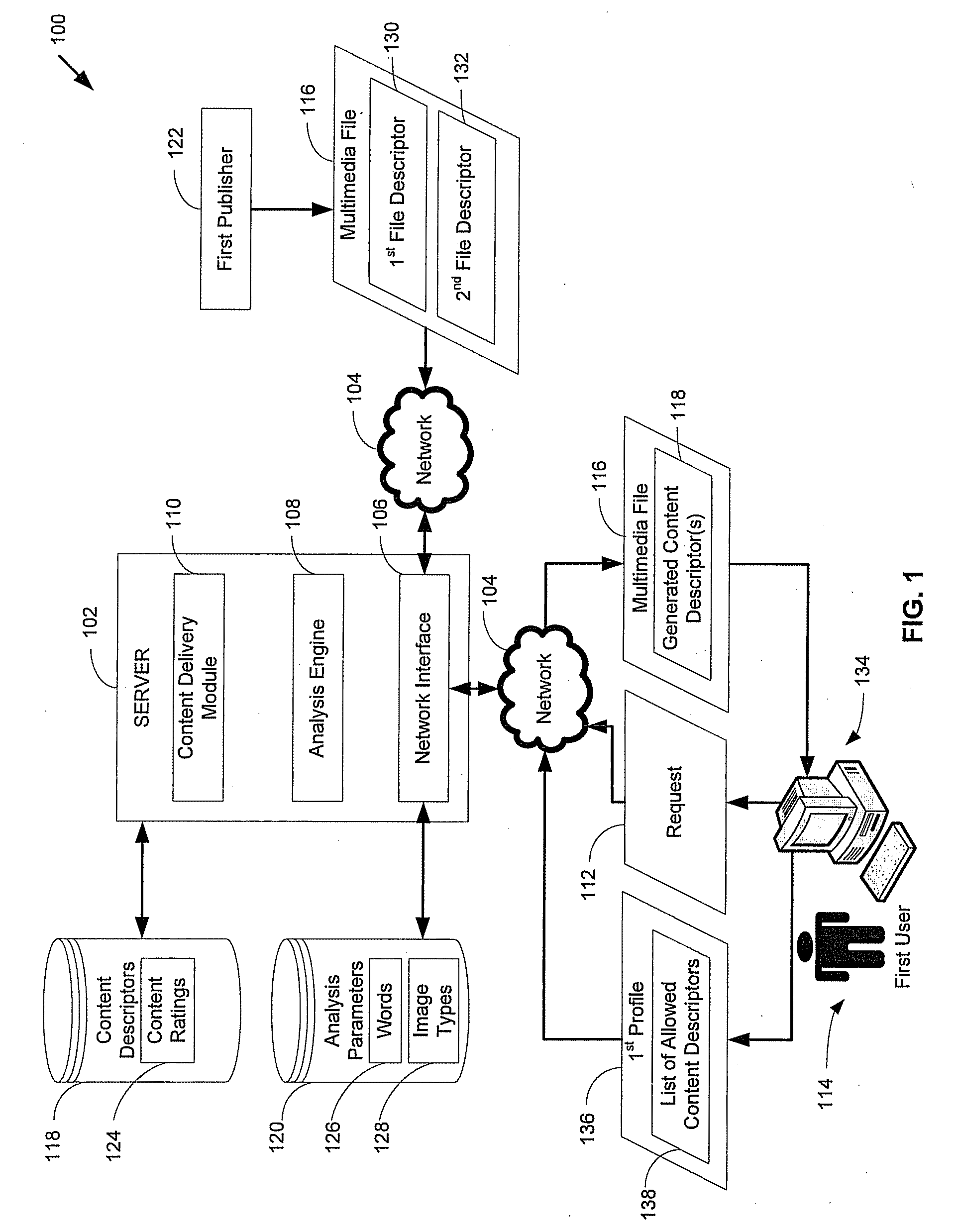

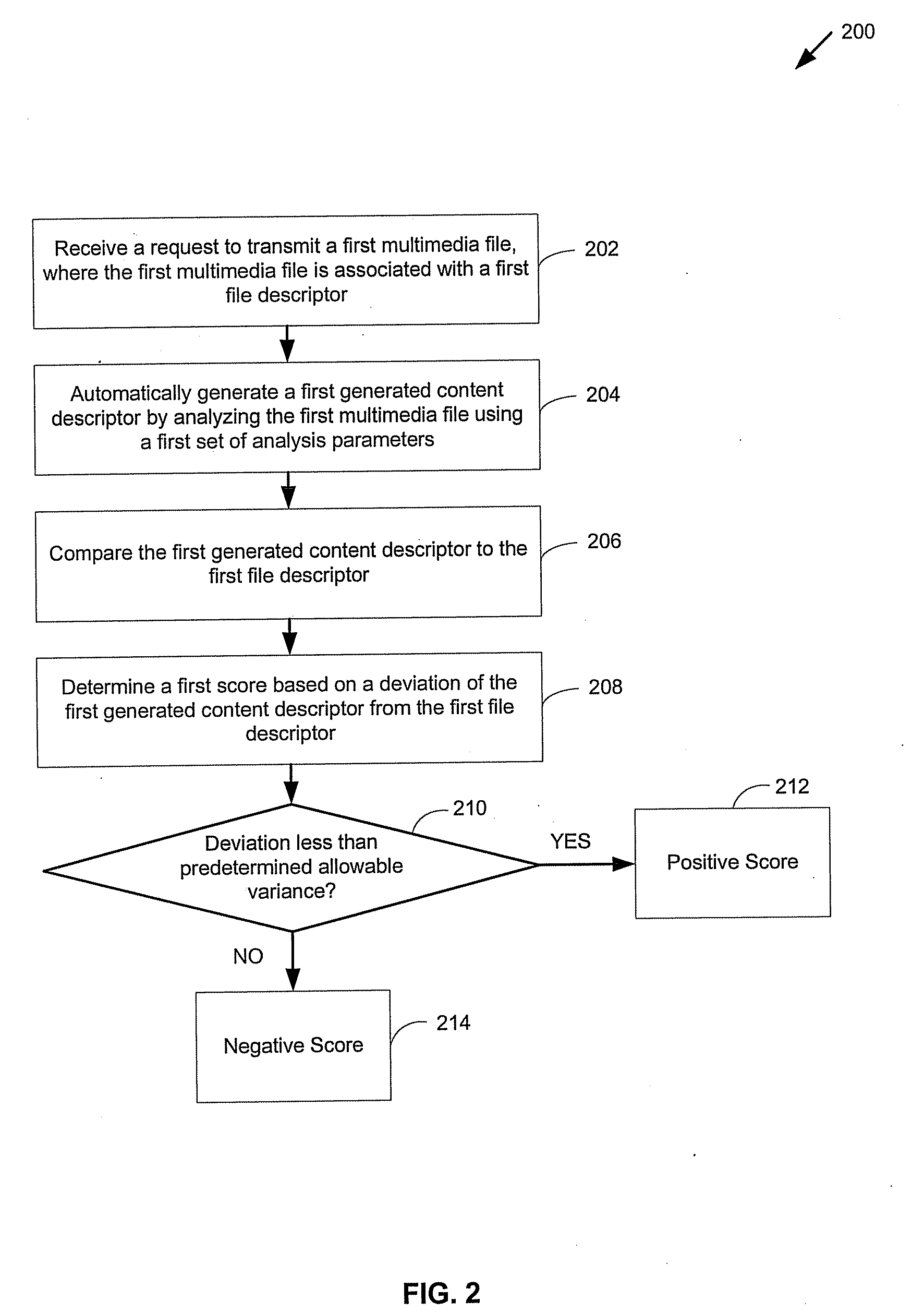

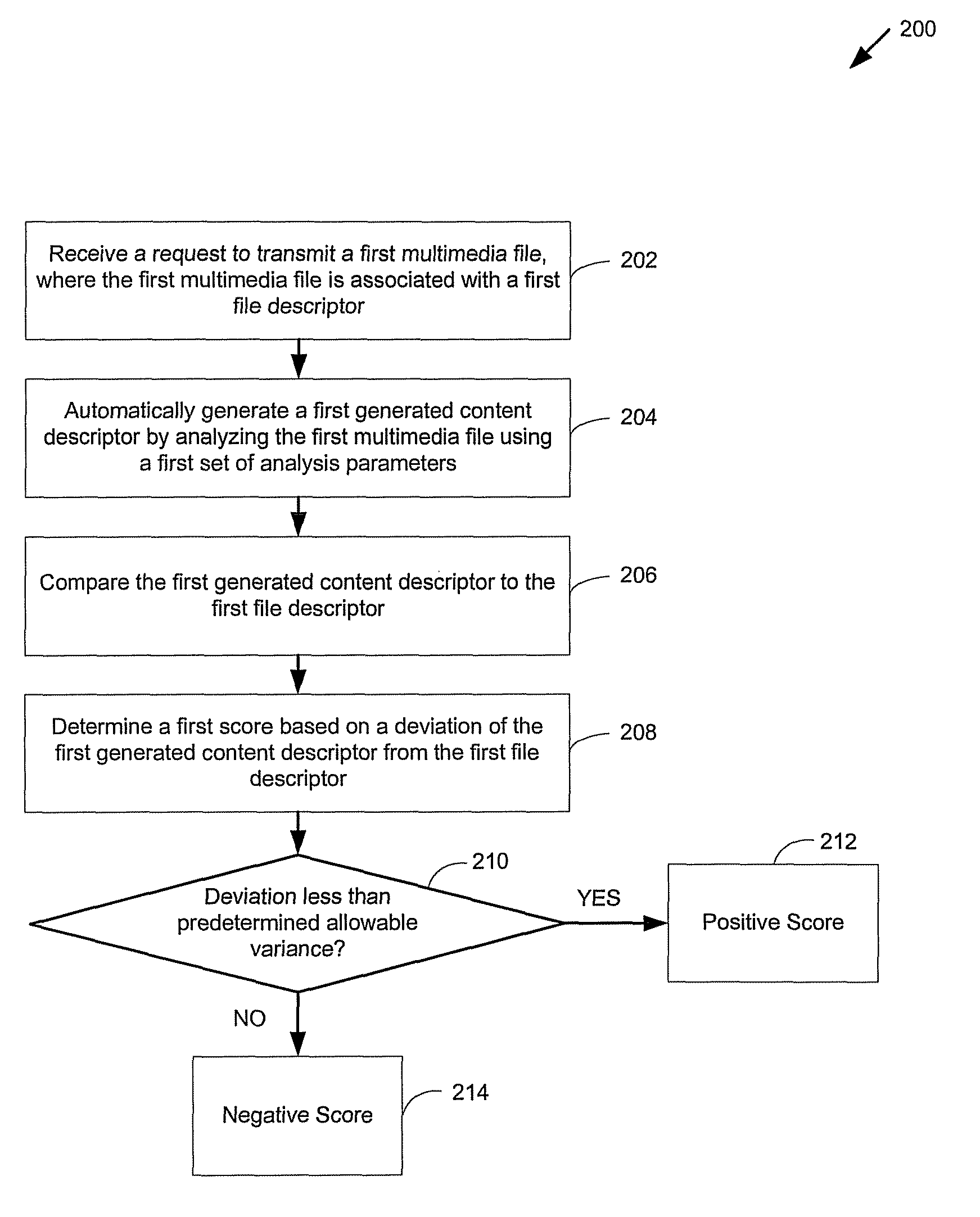

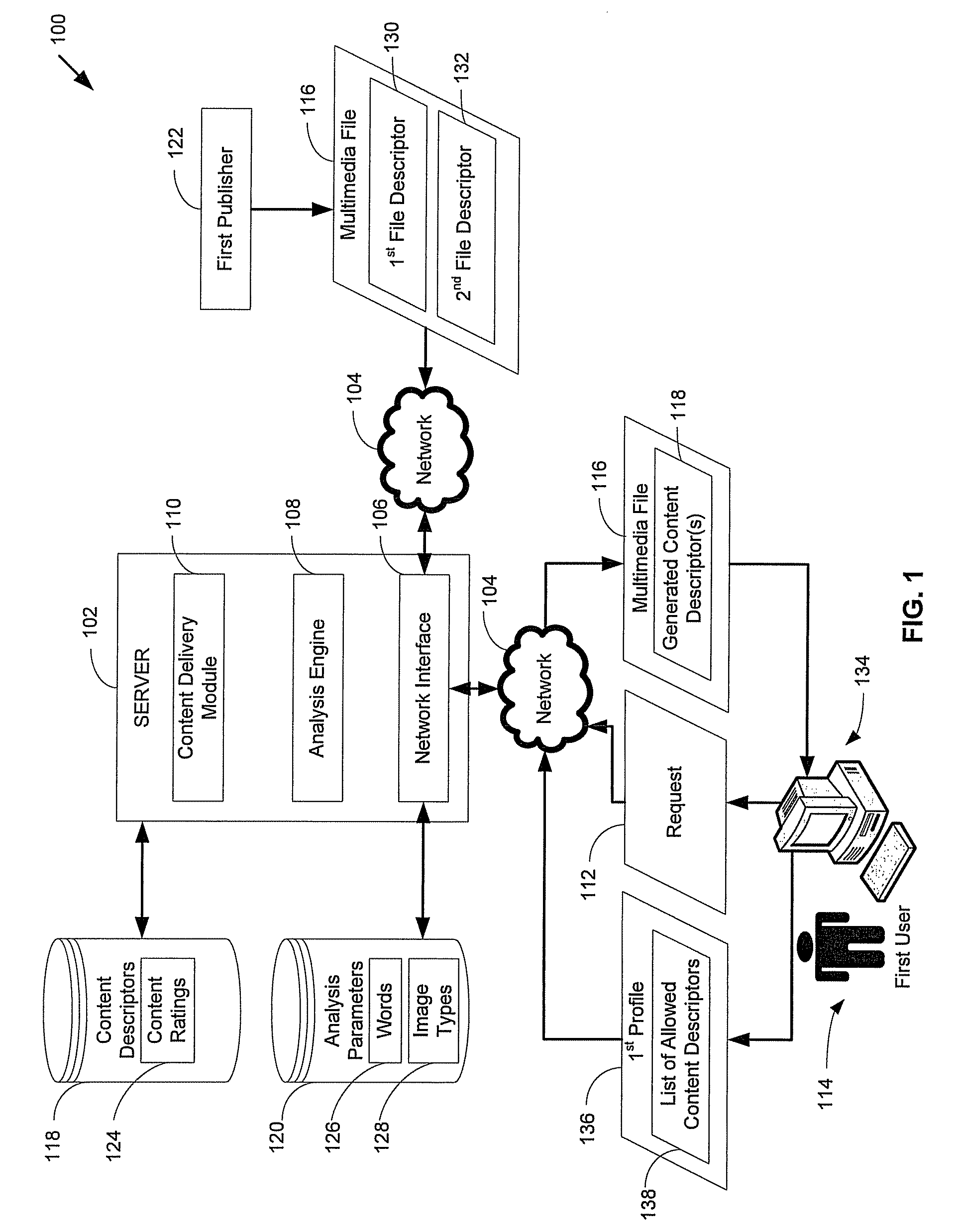

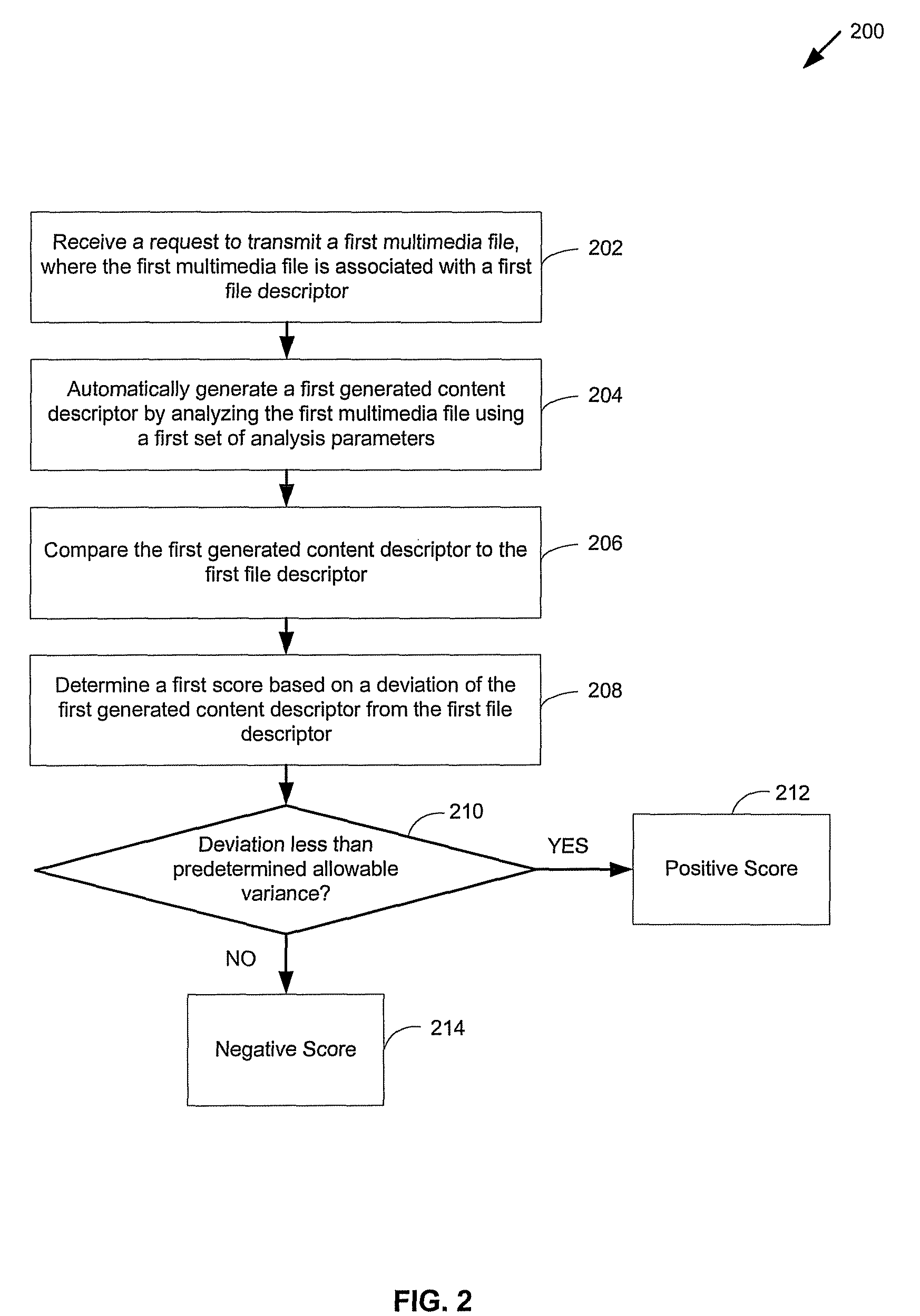

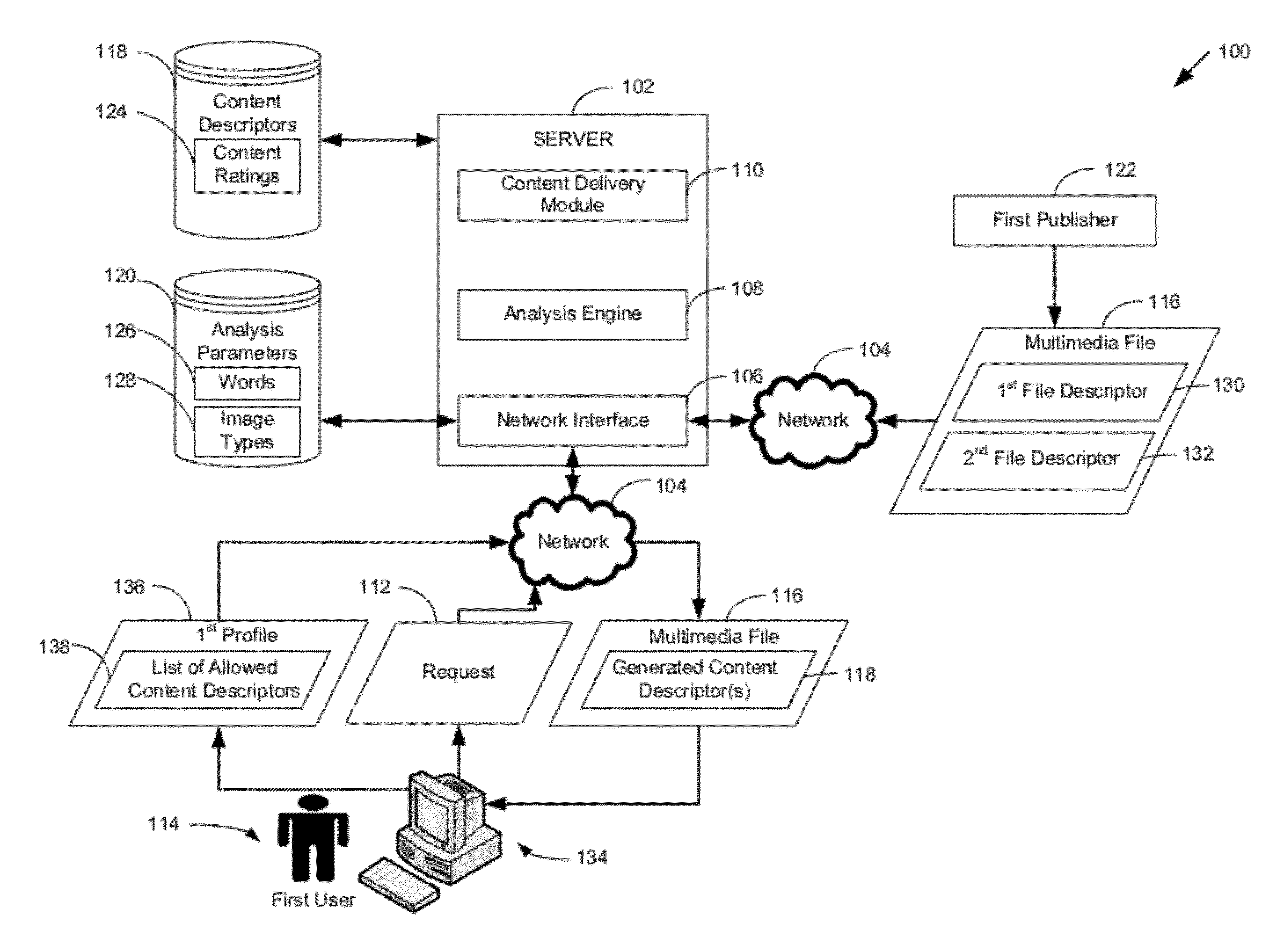

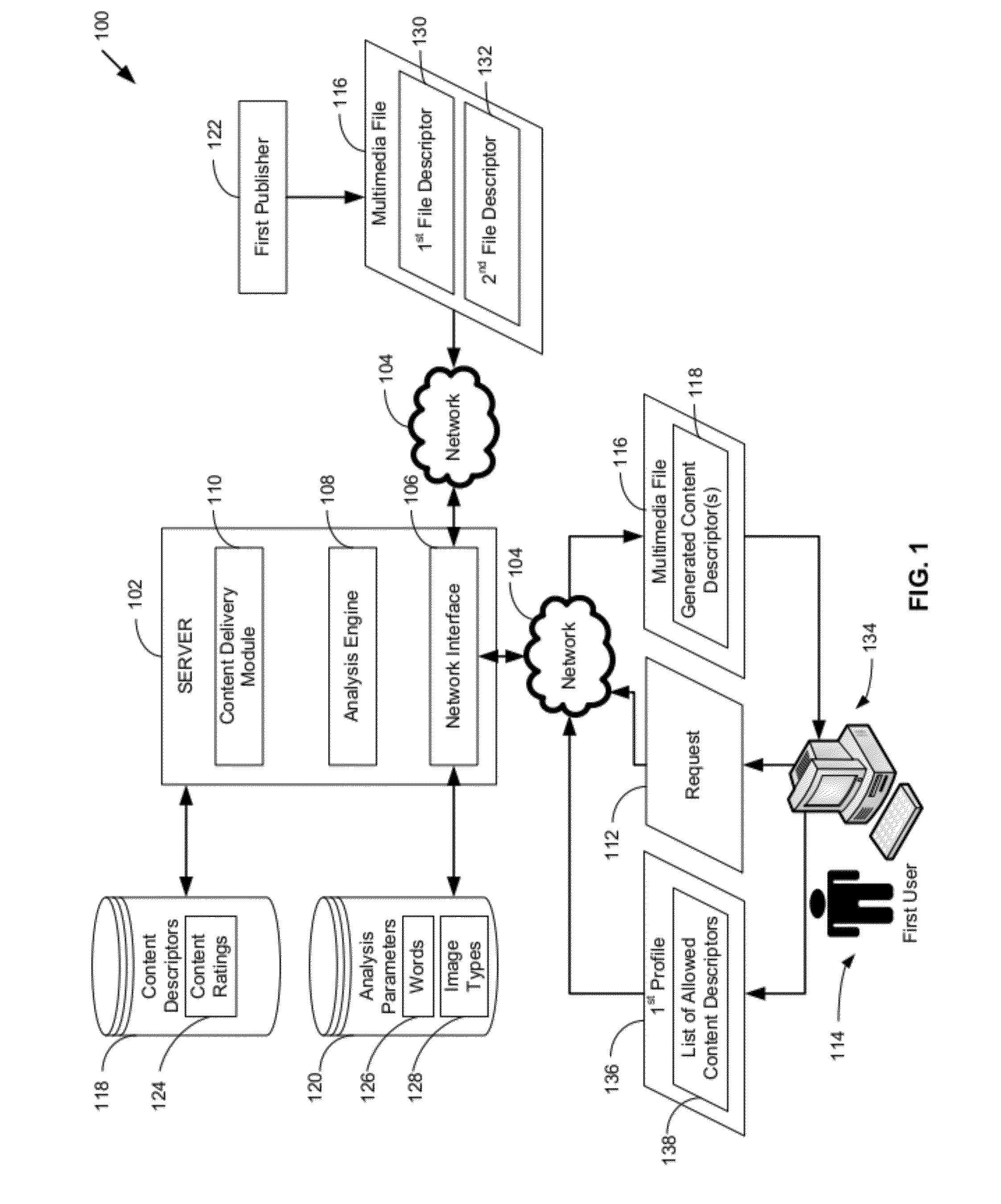

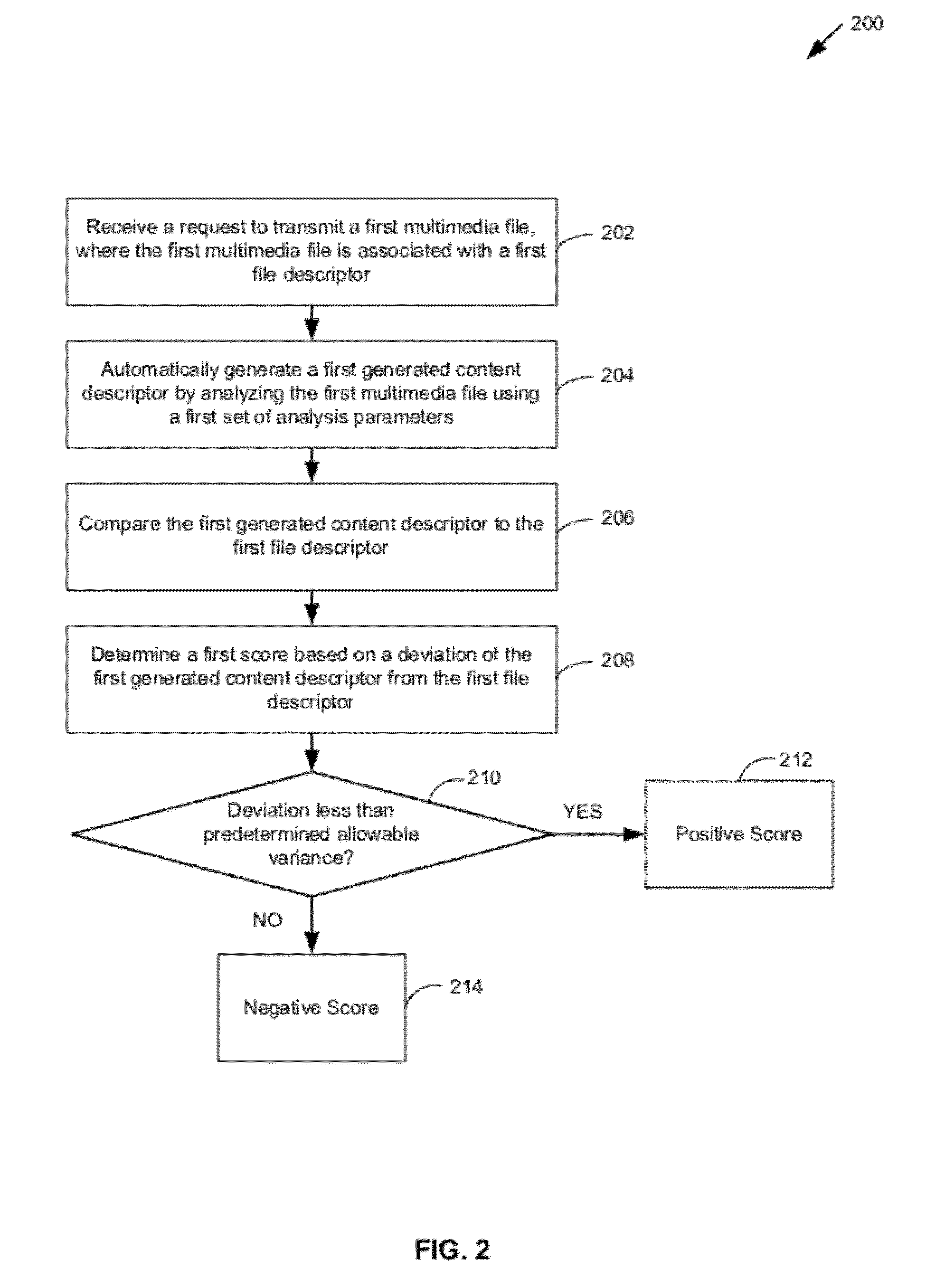

Parametric Analysis of Media Metadata

ActiveUS20100125586A1Data processing applicationsDigital data processing detailsFile descriptorMetadata

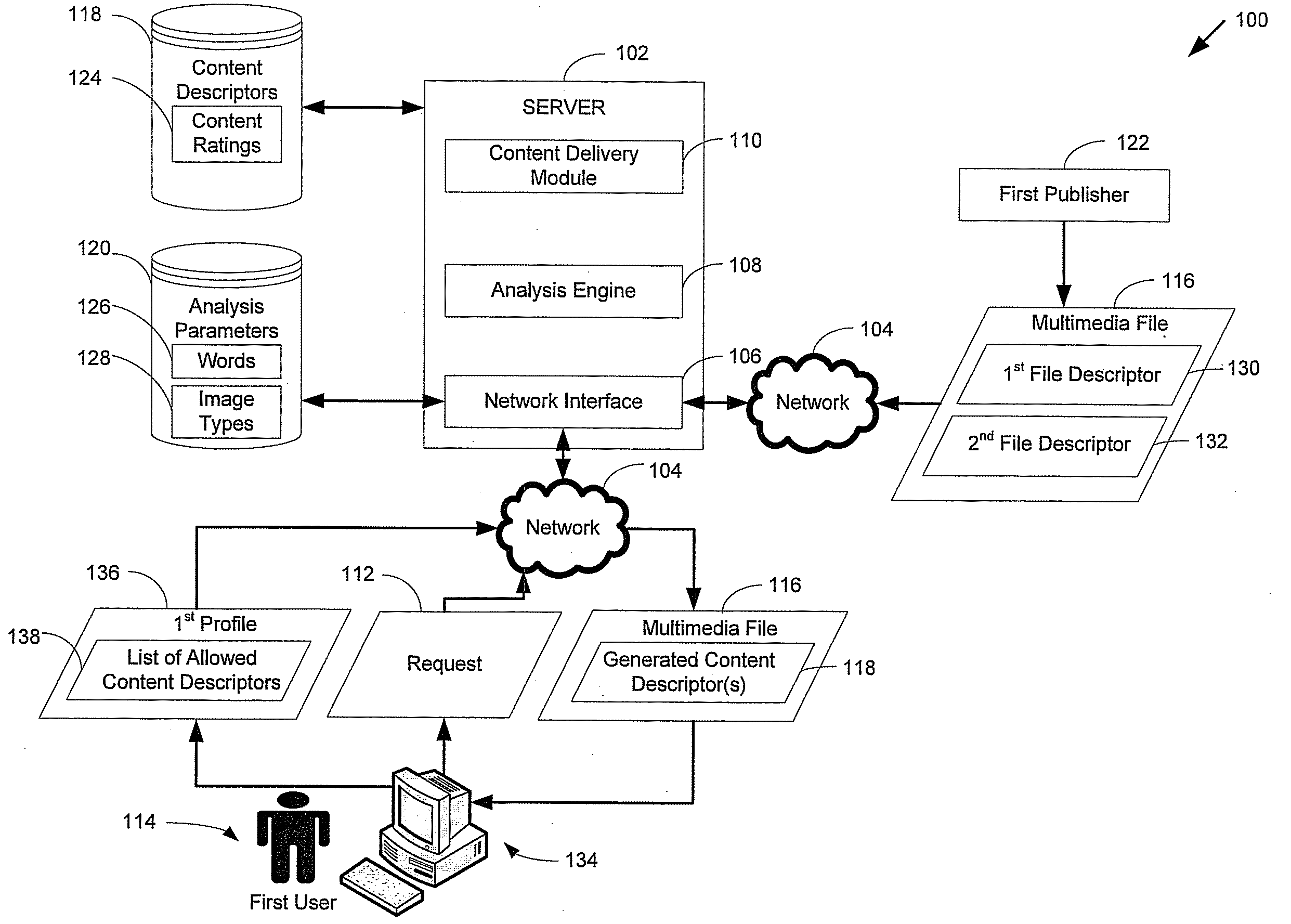

A method is disclosed that includes receiving a request to transmit a first multimedia file. The first multimedia file is associated with a first file descriptor. The method includes automatically generating a first generated content descriptor by analyzing the first multimedia file using a first set of analysis parameters. The method also includes comparing the first generated content descriptor to the first file descriptor and determining a first score based on a deviation of the first generated content descriptor from the first file descriptor.

Owner:AT&T INTPROP I L P

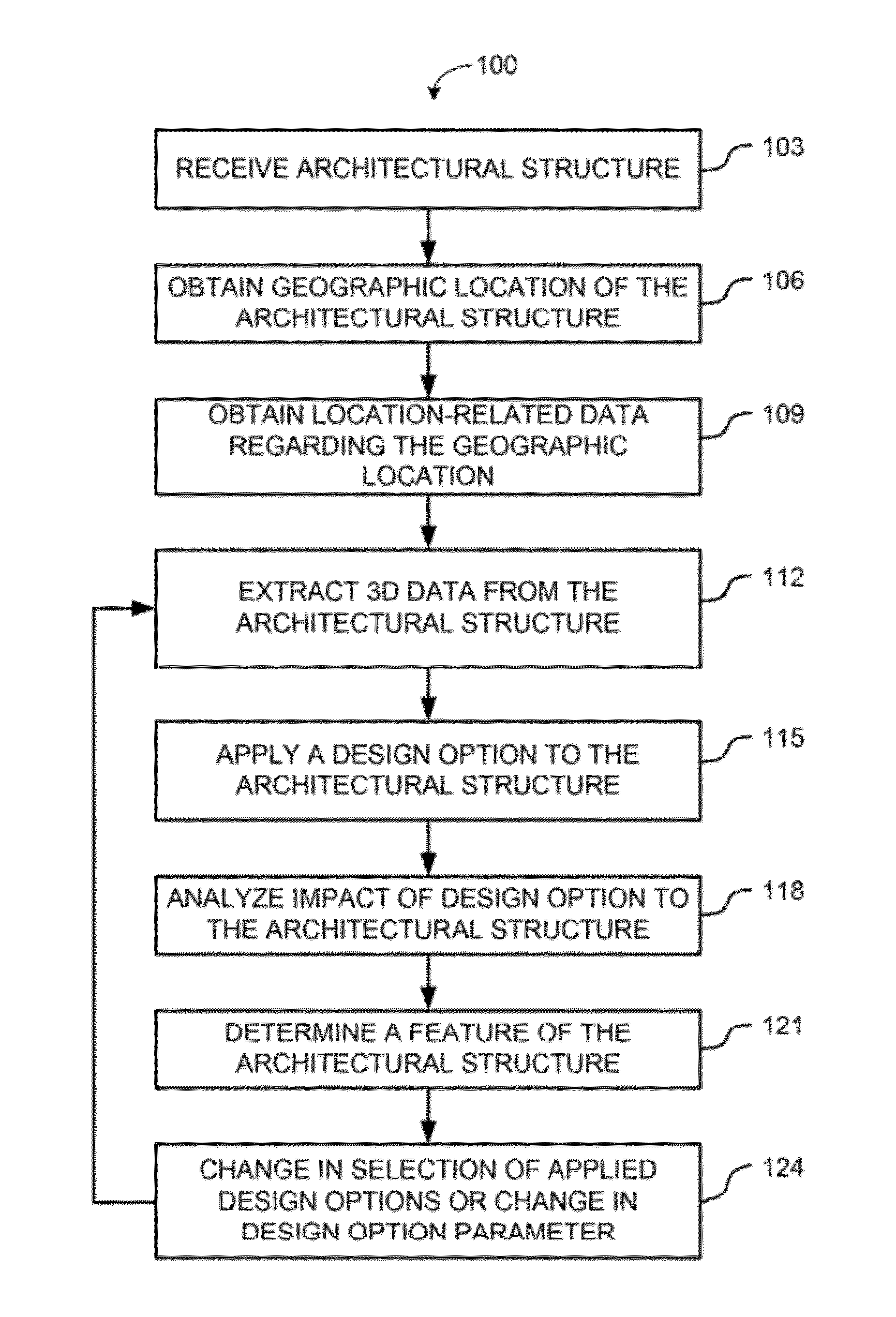

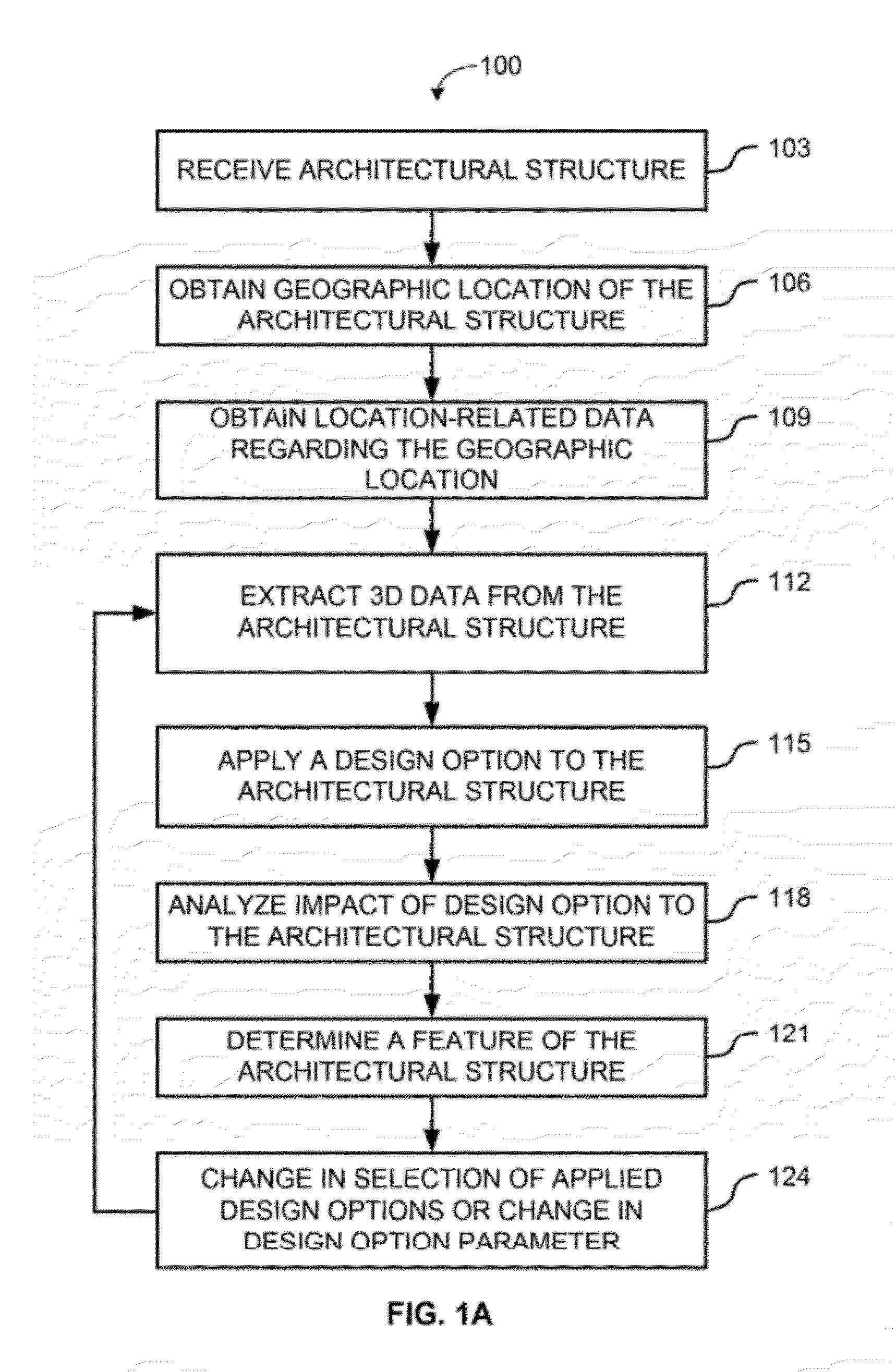

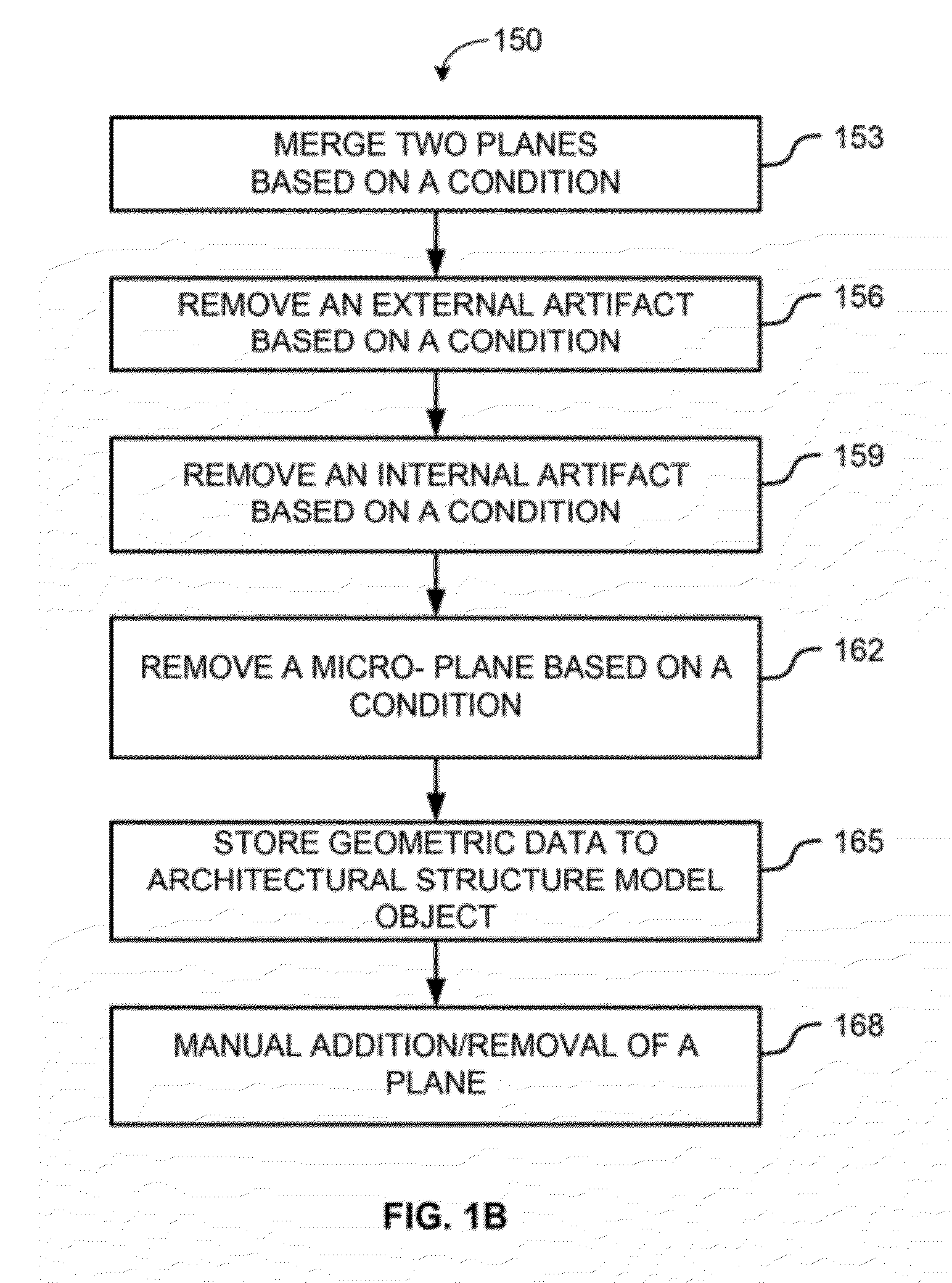

System and method for analyzing and designing an architectural structure using parametric analysis

InactiveUS20120173209A1Improve sustainabilityEasy accessGeometric CADSpecial data processing applicationsComputer Aided DesignDesign team

According to various embodiments of the invention, systems and methods are provided for parametrically analyzing architectural structures. Such embodiments may be utilized by architects and engineers as tools that assist in designing architectural structures that achieve specific design goals, such as those related to sustainability. For example, an embodiment may comprise a system that: (i) provides a sustainability on an architectural structure design created using a computer-assisted design (CAD) tool, and then (ii) applies a design option with a parametric value to that design to determine one or more improvements that provide a desired sustainability. Various embodiments may be accessed through a web-based platform, which provides a user with easier access and better collaboration between and among design team members.

Owner:SEFAIRA

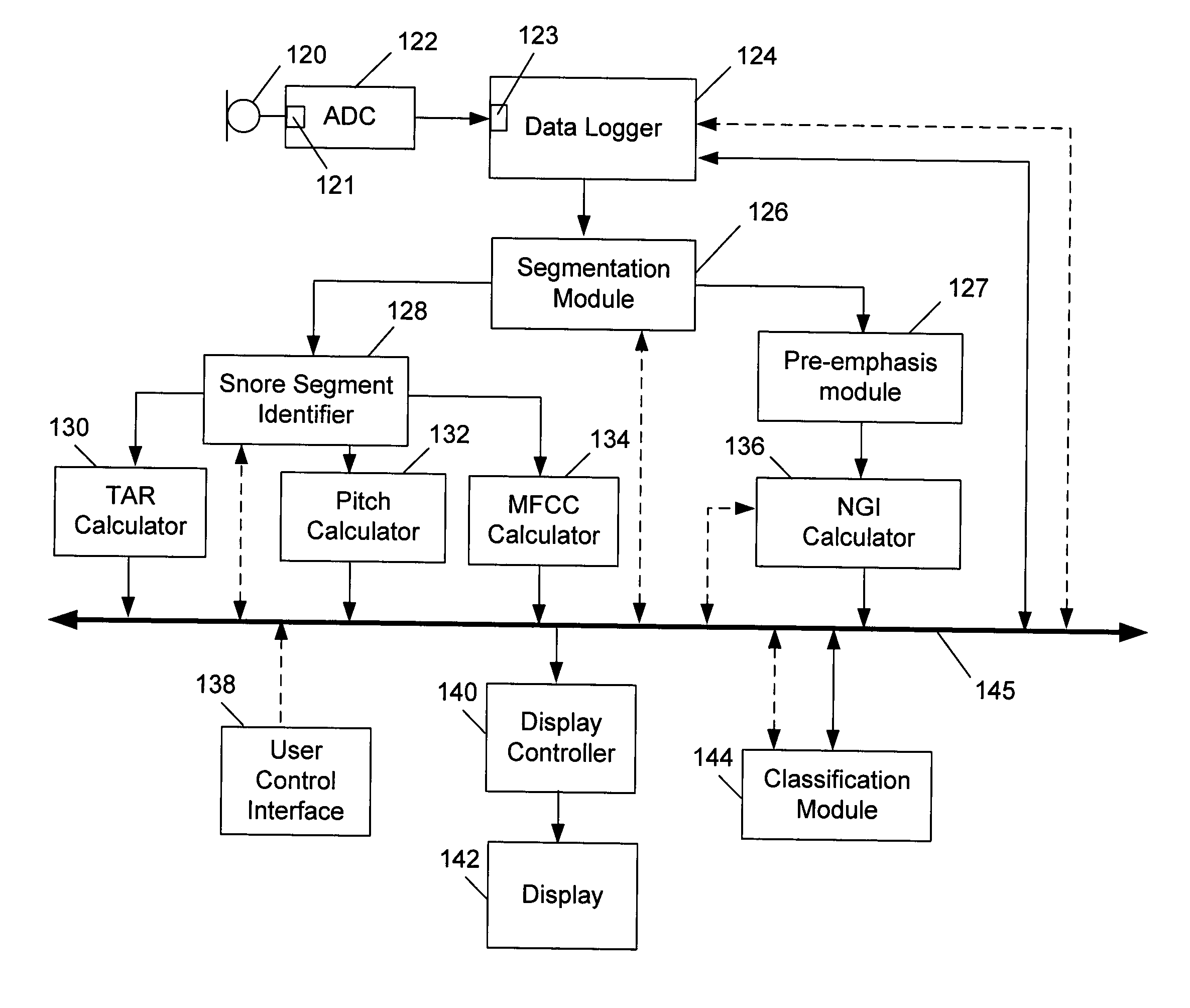

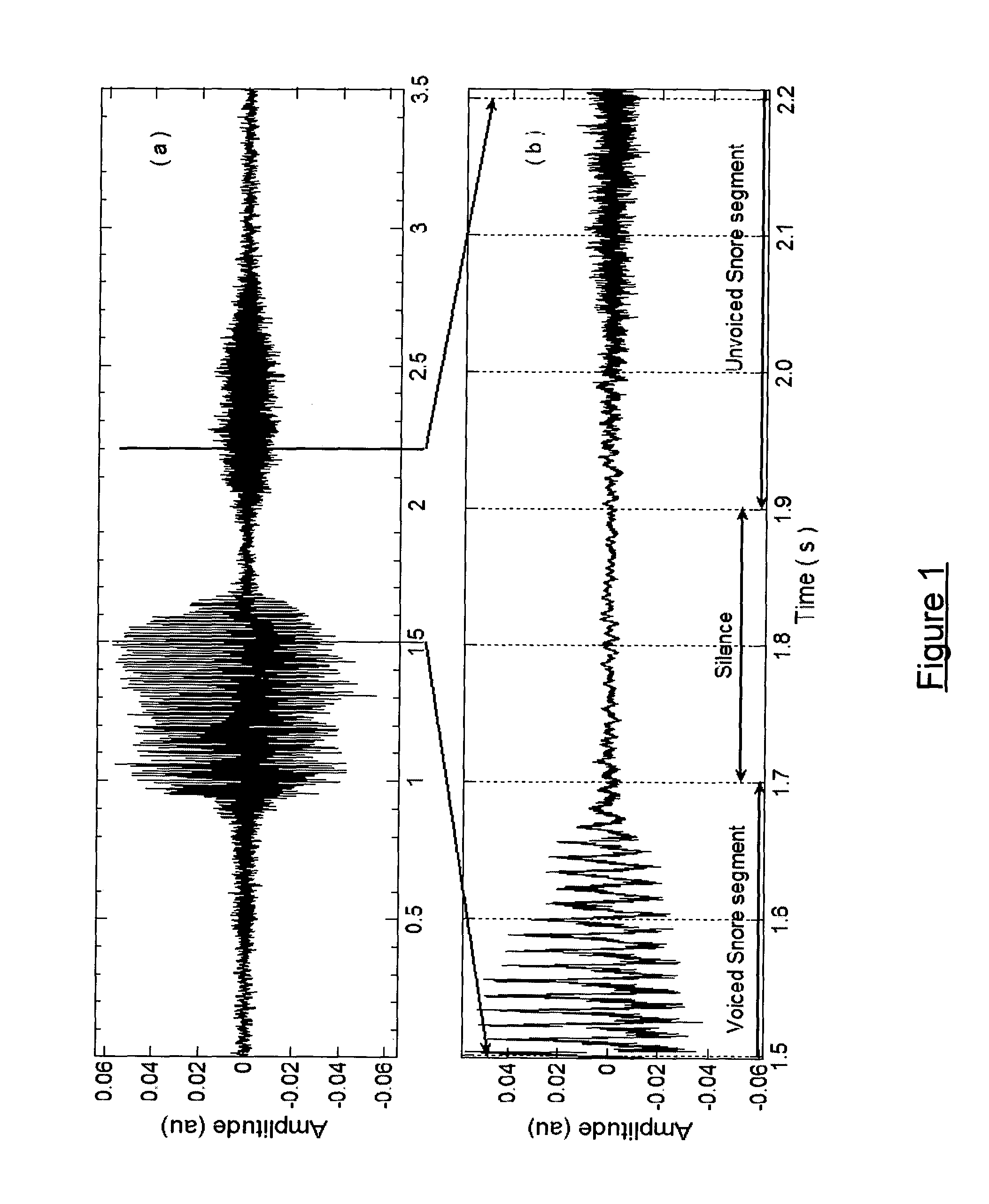

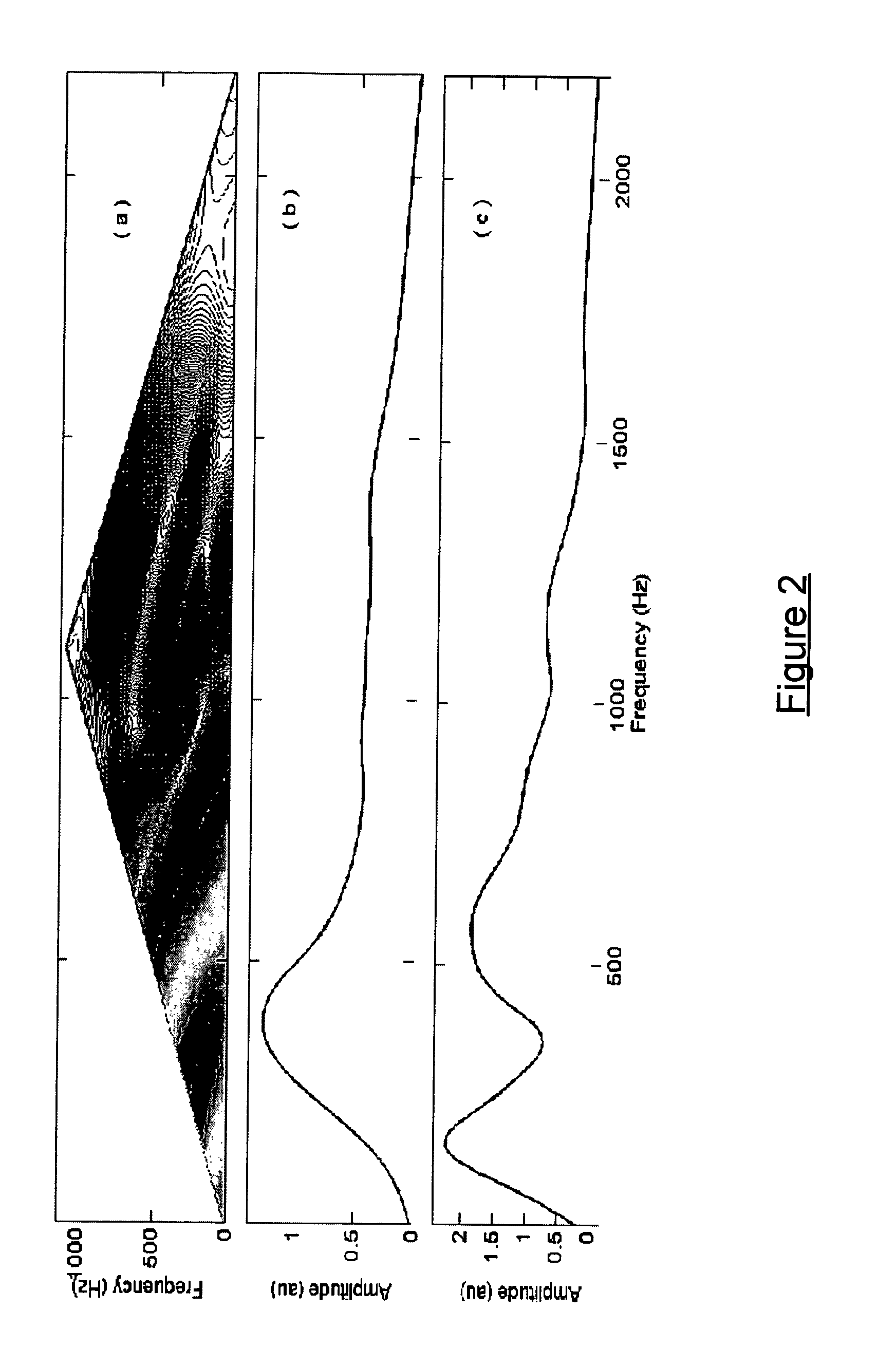

Multi-parametric analysis of snore sounds for the community screening of sleep apnea with non-gaussianity index

An apparatus for diagnosing sleep disorders such as OASHS from snore sounds includes a segmentation module (126) coupled to a data logger (124) to provide segments of the digitized audio signal to a Snore Segment Identifier (128). A total airways response (TAR) module (130), pitch calculator (132), and MFCC calculator (134) are each coupled to an output side of the snore segment identifier module (128). Each of these modules is respectively arranged to calculate pitch, bispectrum, diagonal slice, and MFCC parameters for the snore segments received from the snore segment identifier (128). Similarly, the NGI calculator (136) produces a non-Gaussianity index for the digitized audio signal. A classification module (144) is arranged to process the calculated parameters and compare a resulting diagnosis probability to a predetermined threshold value. The results of this comparison are then indicated on video display (142), which communicates with the classification module (133) via display controller (140) and bus (145). For example, if the results of the comparison are over threshold then display (142) is driven to indicate “OS AHS is present.”

Owner:THE UNIV OF QUEENSLAND

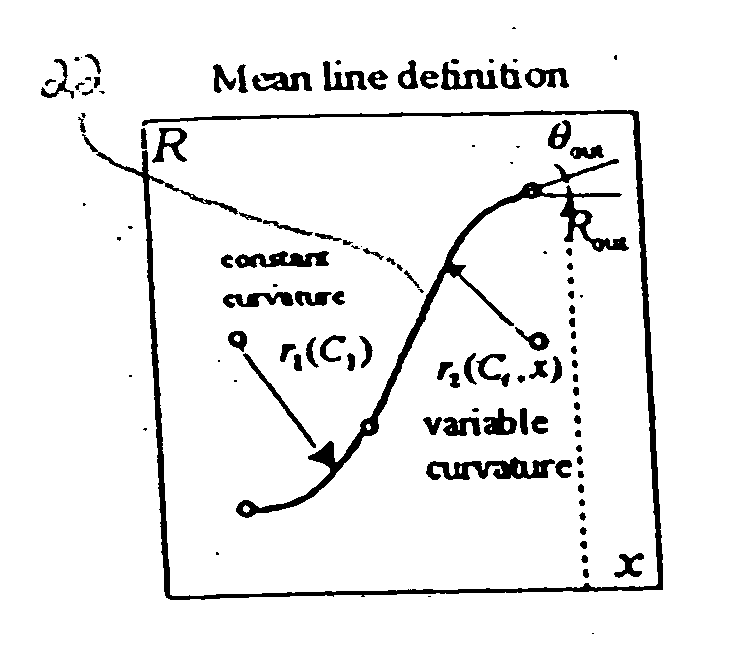

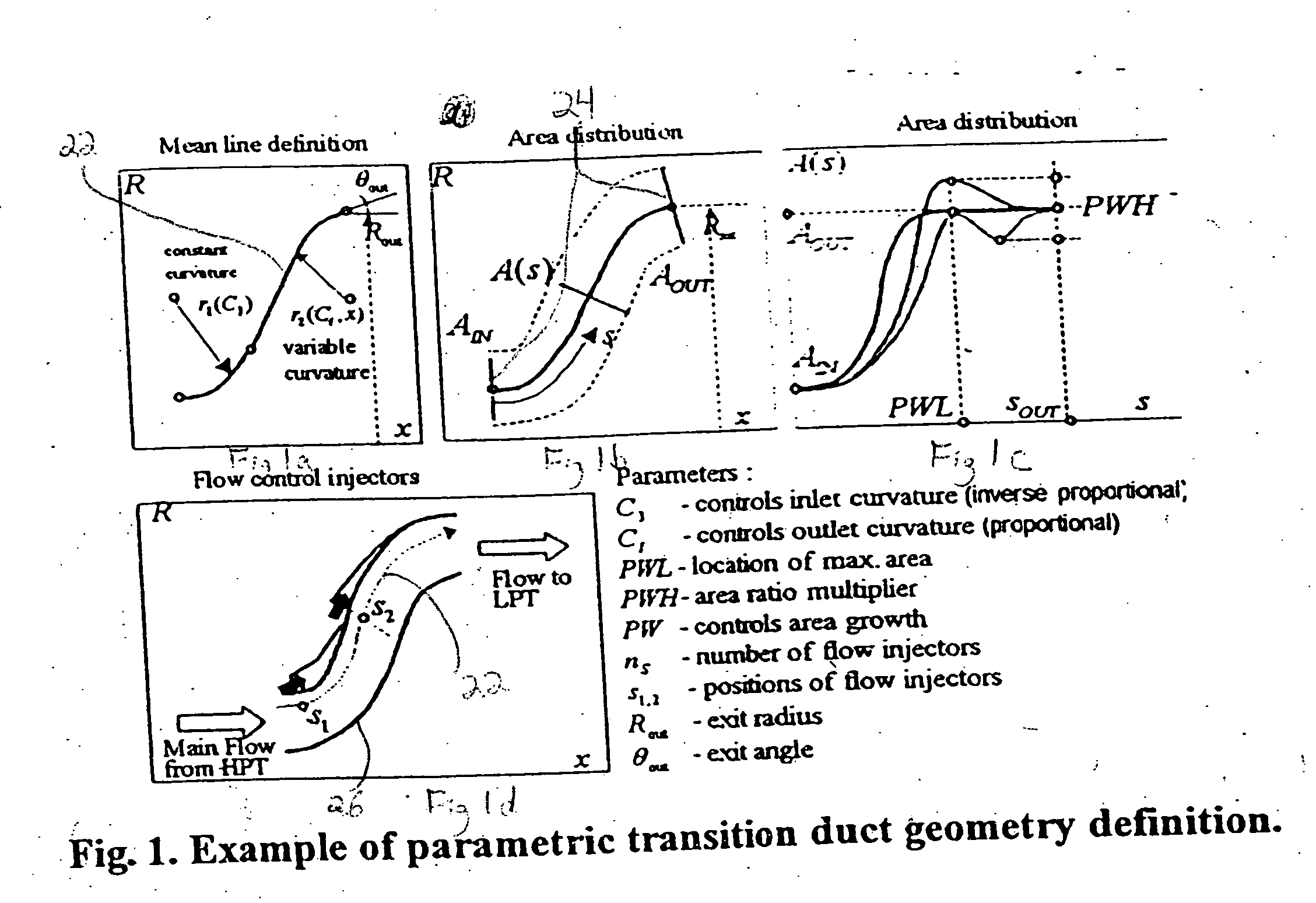

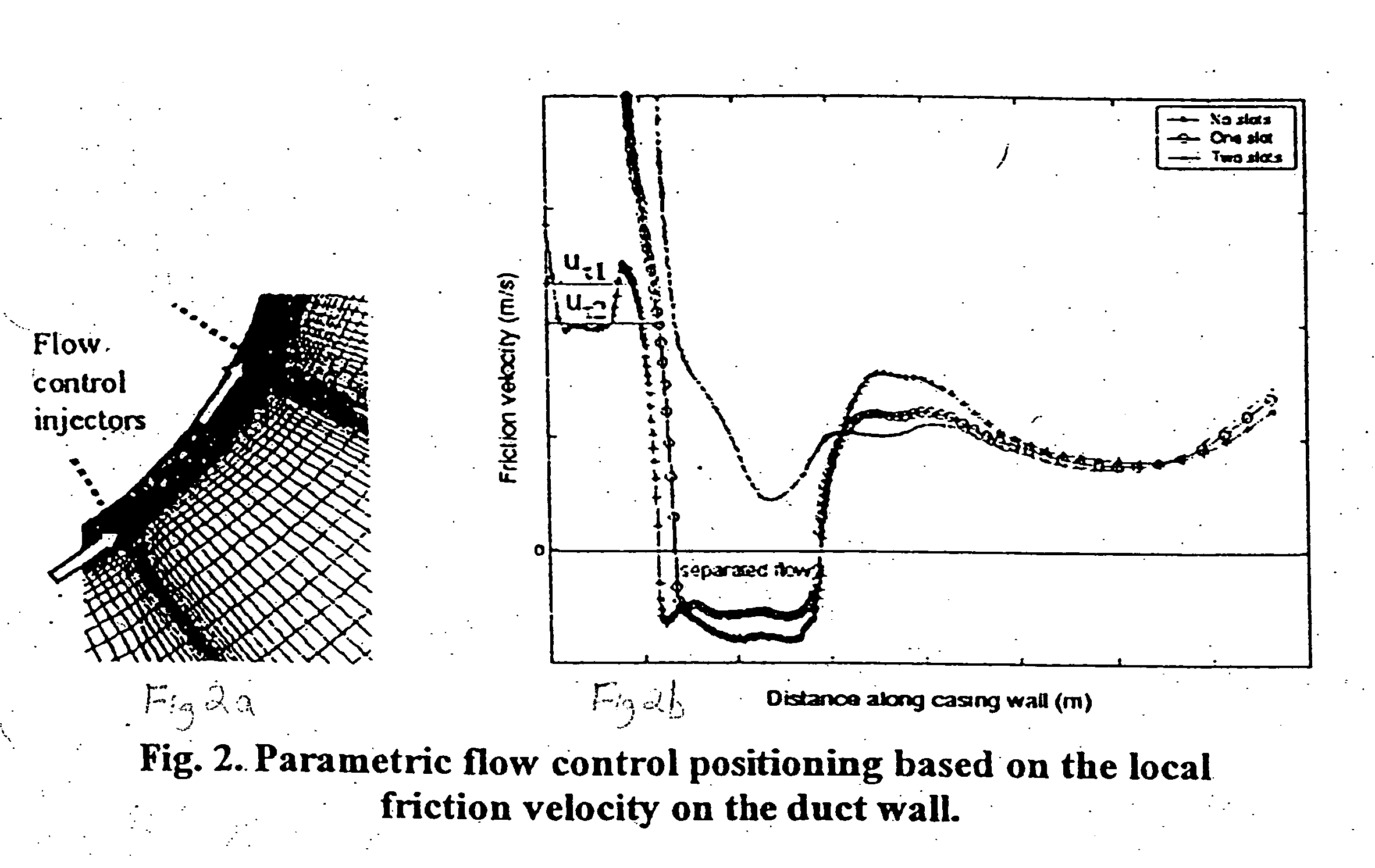

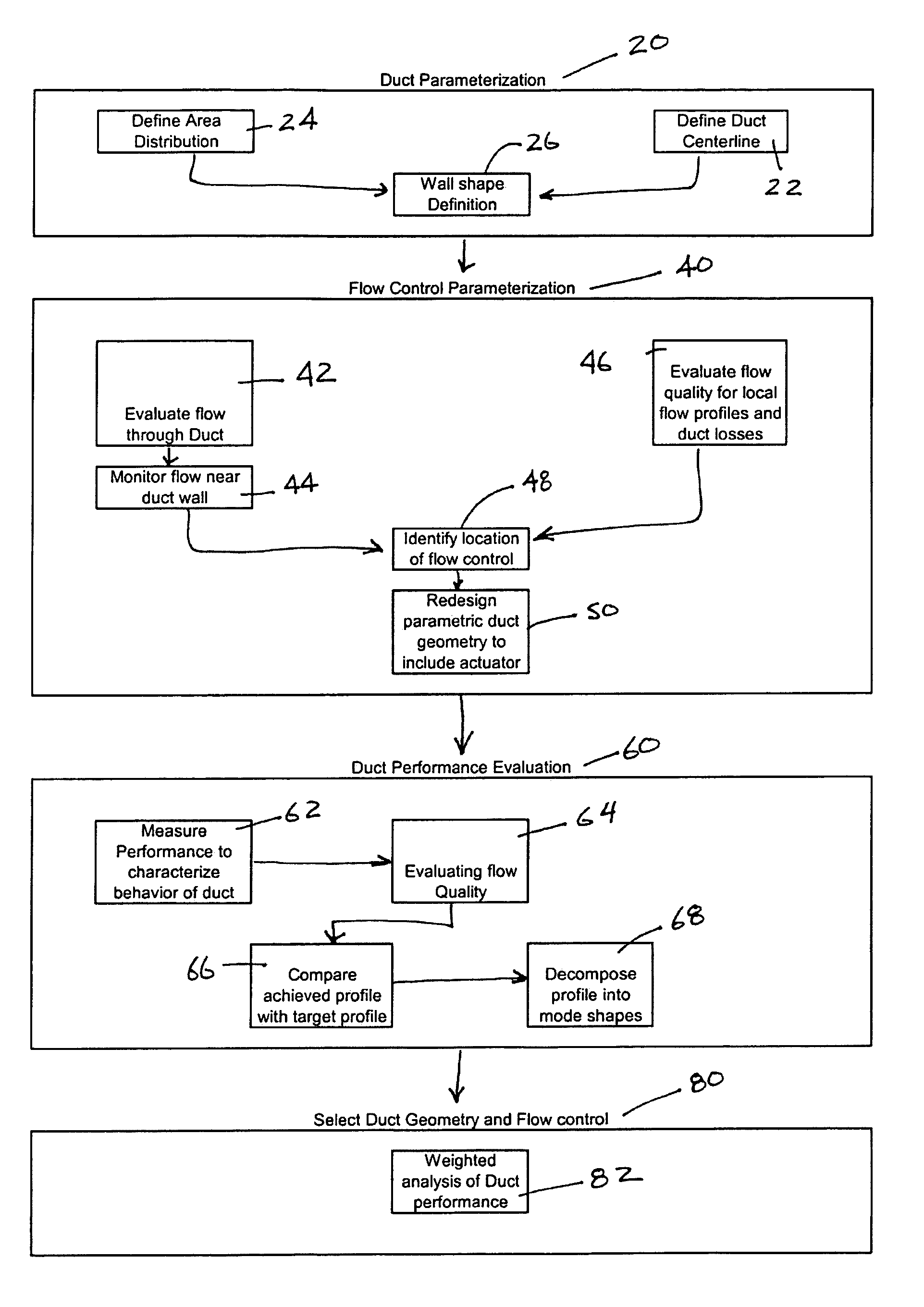

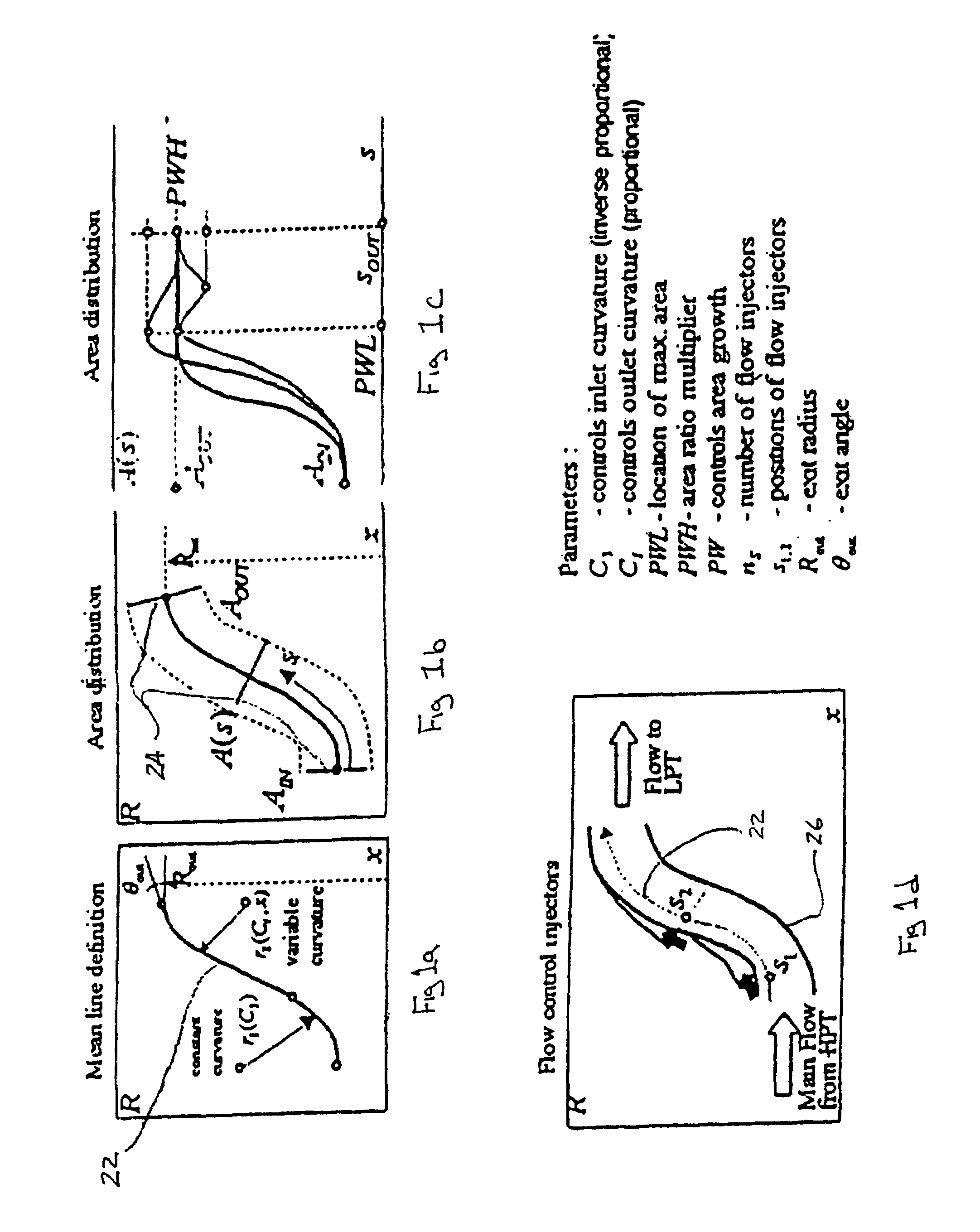

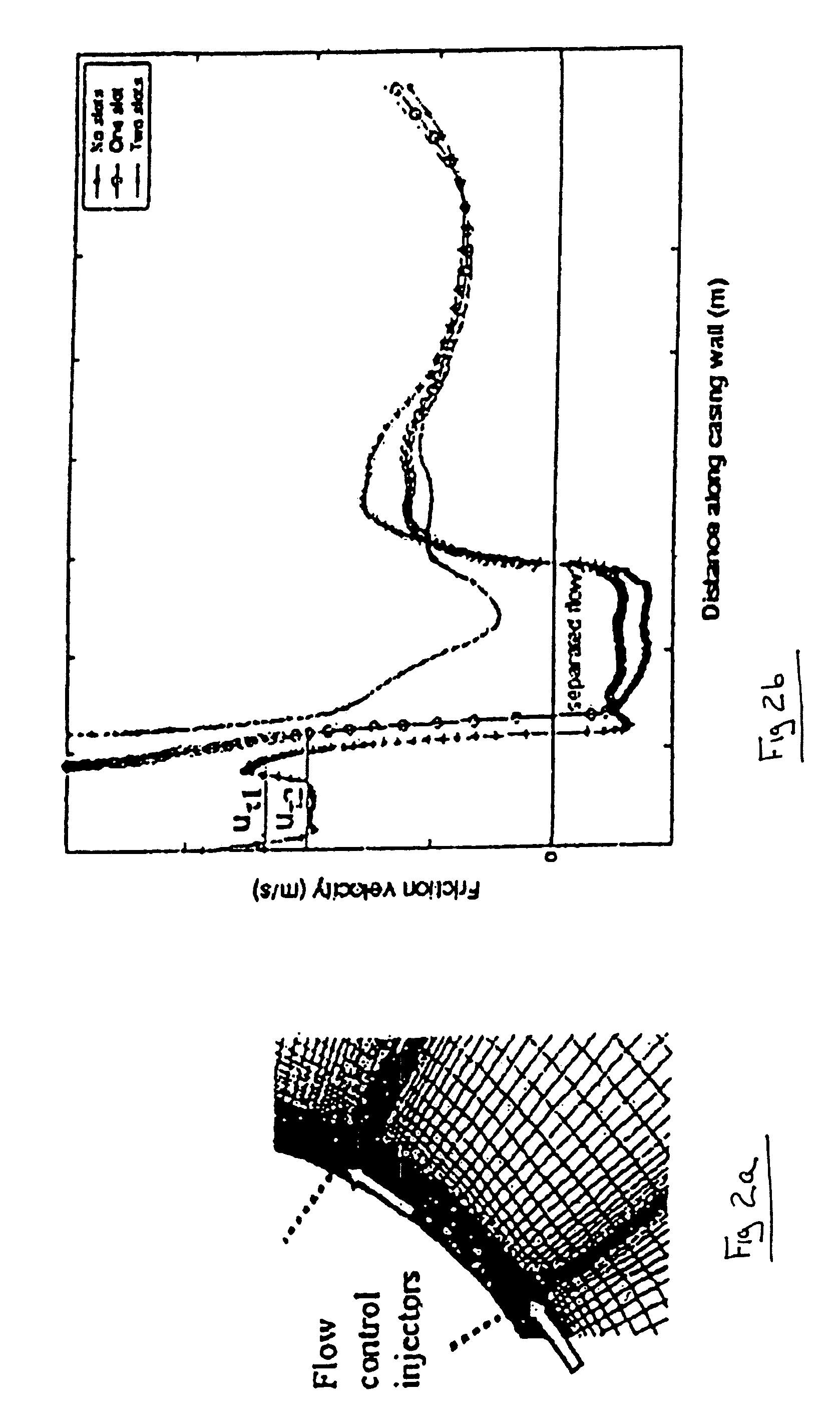

Coupled parametric design of flow control and duct shape

InactiveUS20060069533A1Shorten the lengthLarge offsetBlade accessoriesEfficient propulsion technologiesEngineeringActuator

A method for designing gas turbine engine components using a coupled parametric analysis of part geometry and flow control is disclosed. Included are the steps of parametrically defining the geometry of the duct wall shape, parametrically defining one or more flow control actuators in the duct wall, measuring a plurality of performance parameters or metrics (e.g., flow characteristics) of the duct and comparing the results of the measurement with desired or target parameters, and selecting the optimal duct geometry and flow control for at least a portion of the duct, the selection process including evaluating the plurality of performance metrics in a pareto analysis. The use of this method in the design of inter-turbine transition ducts, serpentine ducts, inlets, diffusers, and similar components provides a design which reduces pressure losses and flow profile distortions.

Owner:RAYTHEON TECH CORP +1

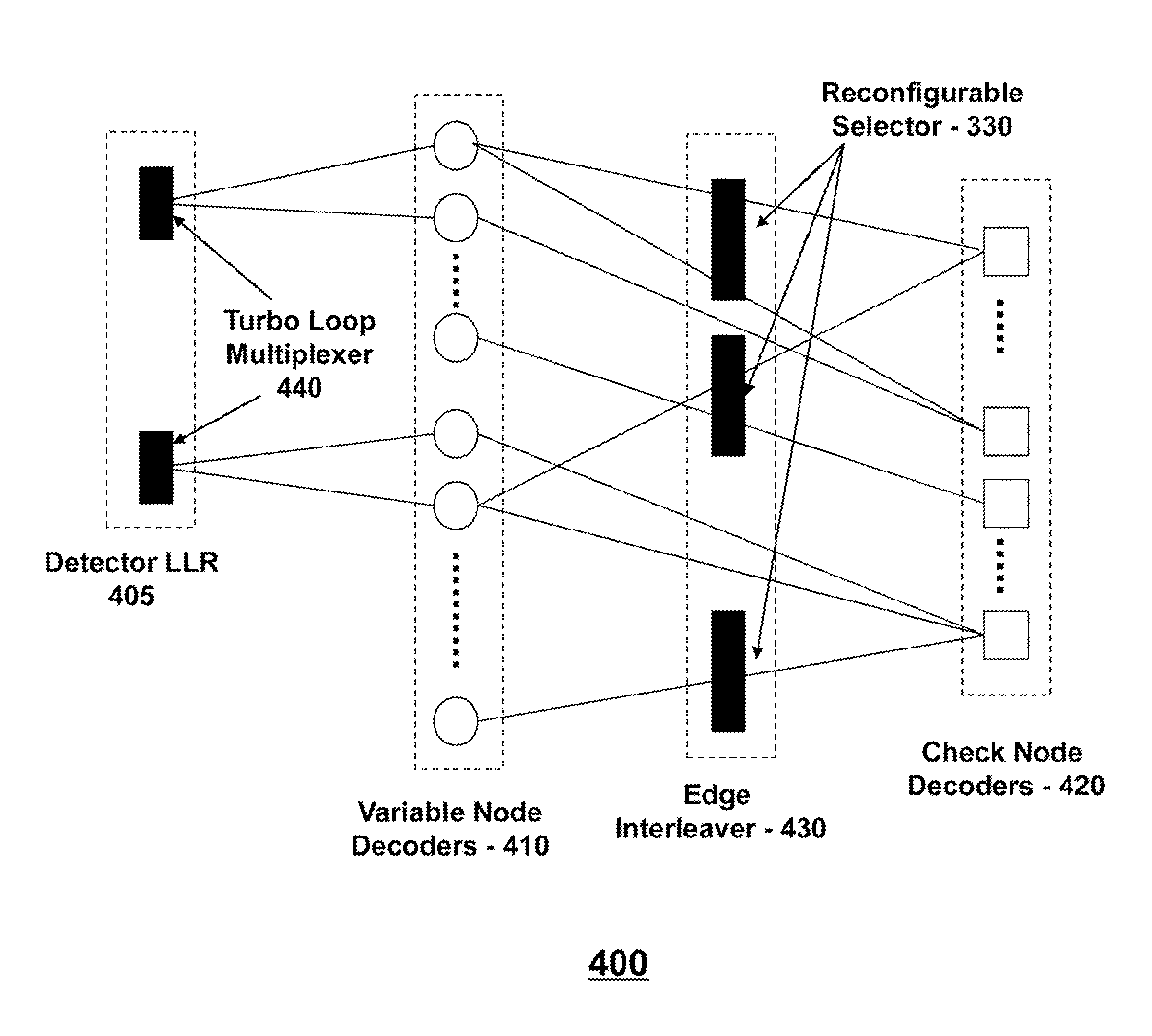

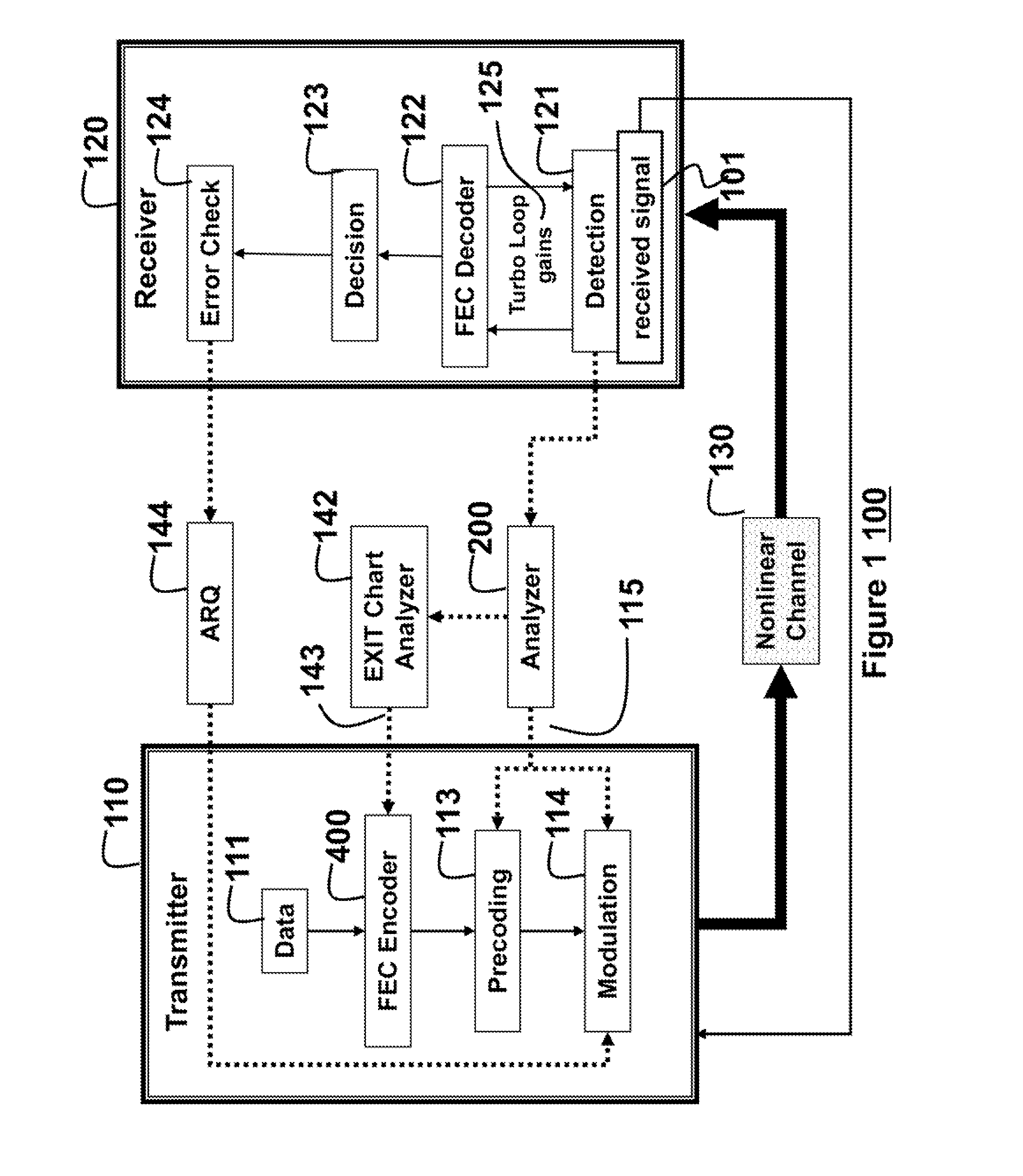

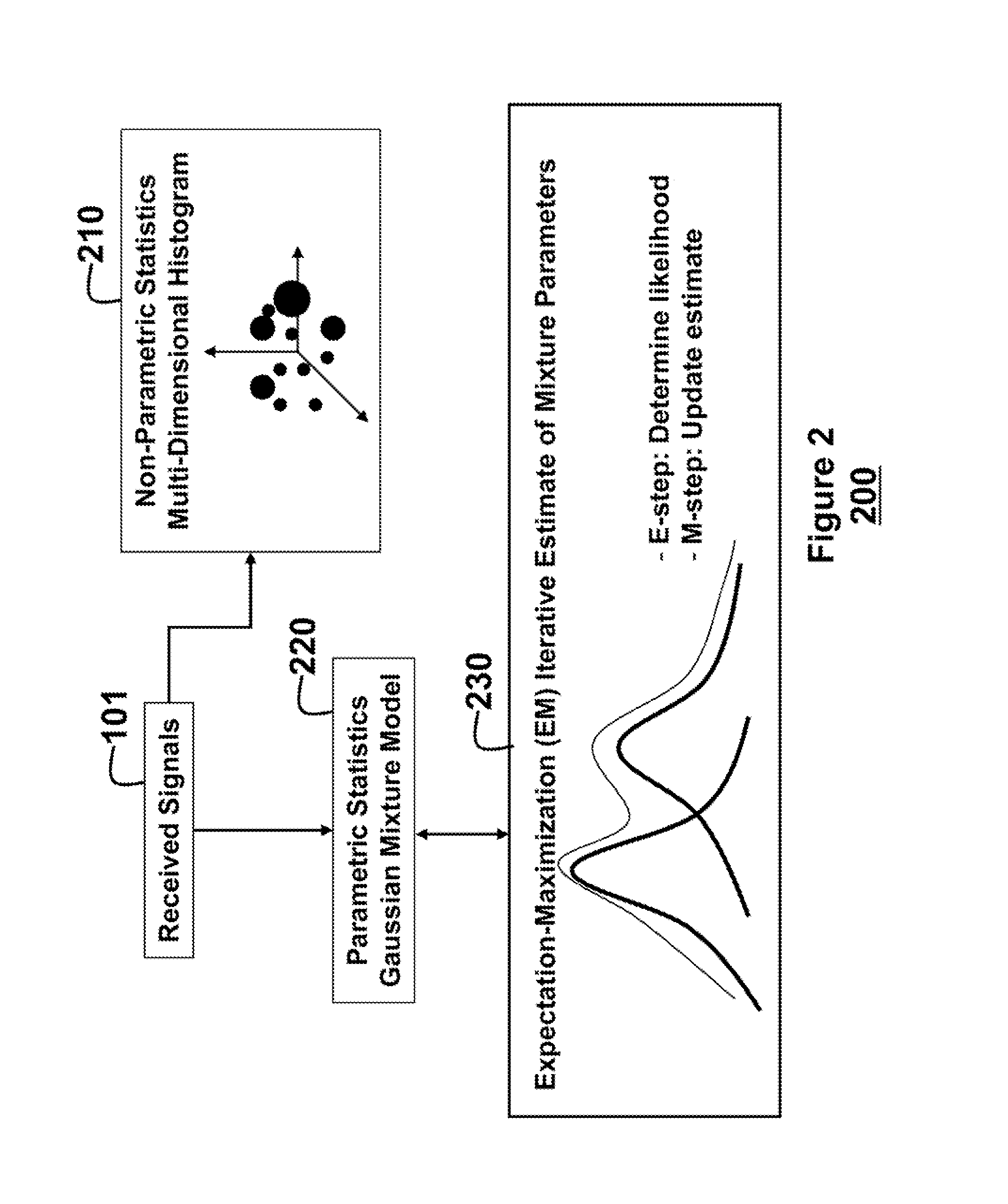

Adaptively Coding and Modulating Signals Transmitted Via Nonlinear Channels

ActiveUS20140133848A1Improve reliability and efficiencyReduce nonlinear distortionError detection/prevention using signal quality detectorChecking code calculationsNonlinear distortionChannel statistics

An adaptive coding scheme for nonlinear channels improves reliability and an efficiency in digital communication networks. The method monitors channel statistics to analyze an extrinsic information transfer chart of the channels. The channel statistics are fed back to the transmitter to adapt forward error correction coding. A parametric analysis method uses a Gaussian mixture model. The statistical information feedback can adapt an ARQ sheme by adding a weighted received signal to the original coded signals to reduce nonlinear distortion. Trellis shaping, can make the transmitting signal preferable for nonlinear channels.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Method for predicting apnea-hypopnea index from overnight pulse oximetry readings

The present invention provides a predictive tool for predicting Apopnea Hypopnea Index (AHI) in the diagnosis of Obstructive sleep apnea (OSA). The predictive tool is developed by recording pulse oximetry readings, obtaining delta index, oxygen saturation times and oxygen desaturation events from the oximetry readings. A multivariate non-parametric analysis and bootstrap aggregation is performed to obtain predictive models which can be used to predictive AHI in an individual and to classify an individual as having or not having OSA.

Owner:VETERANS AFFAIRS U S DEPT OF +1

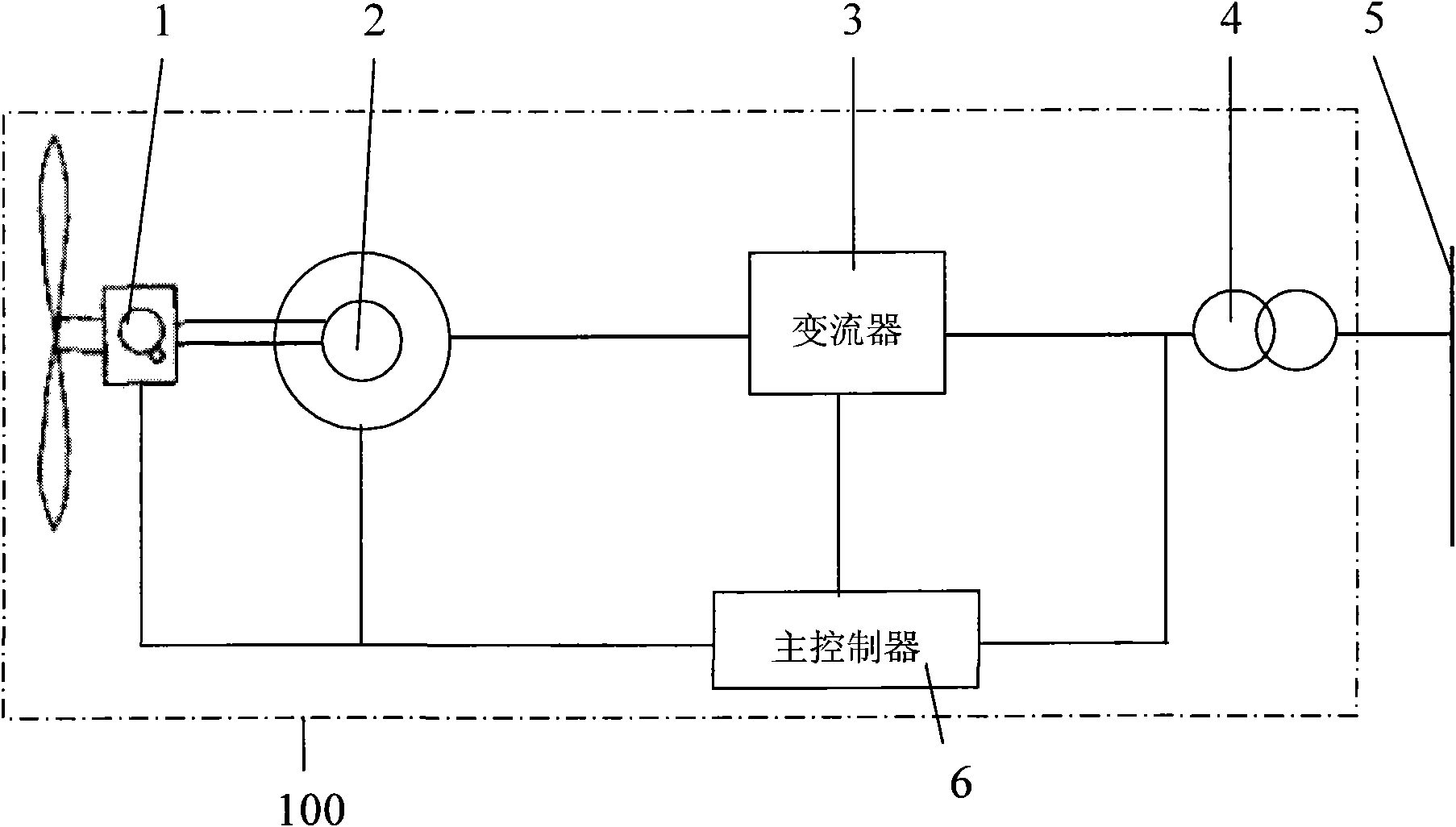

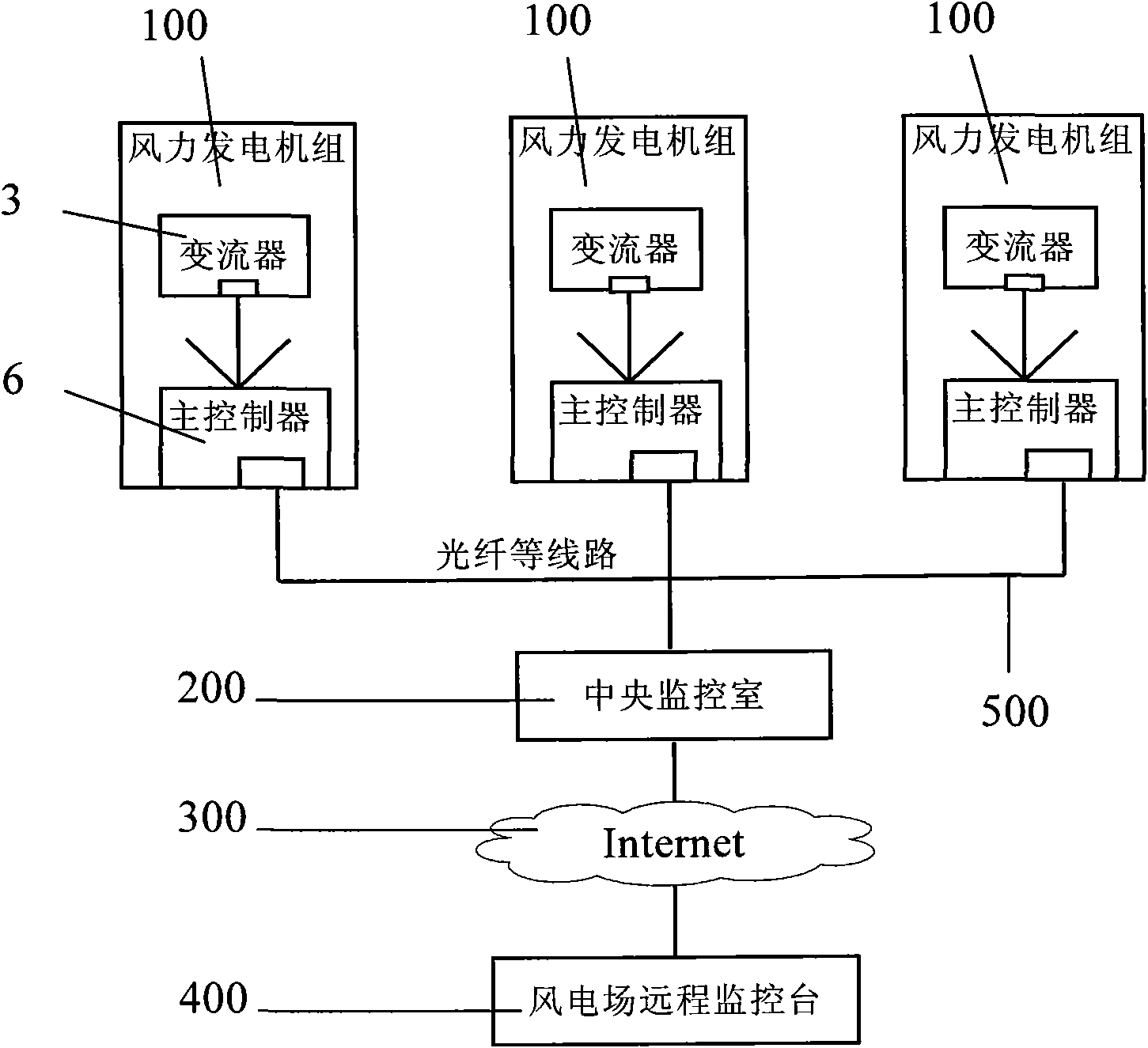

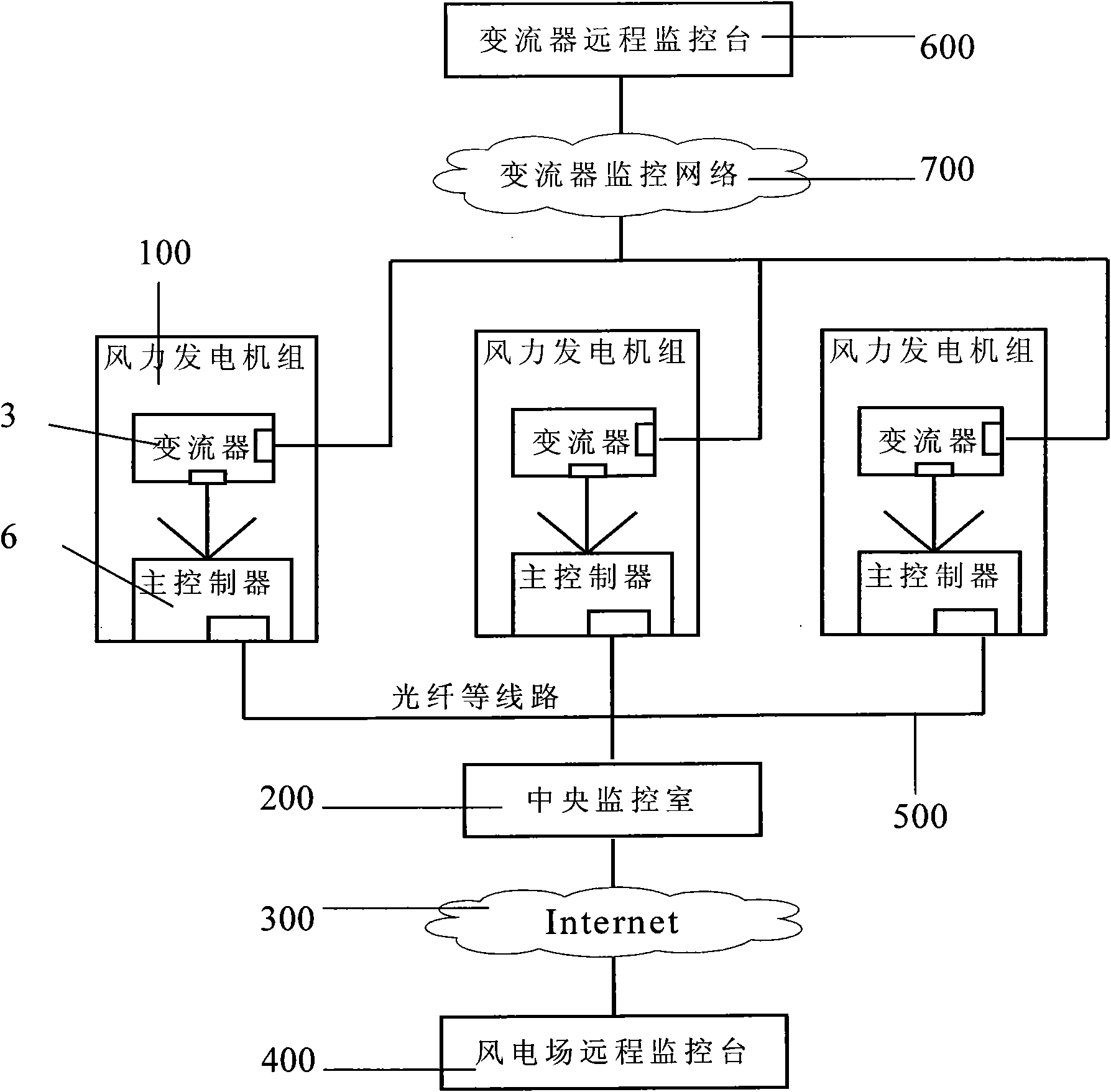

Converter remote monitoring system used for wind power generation

ActiveCN101576056ATimely monitoringTimely maintenanceWind motor controlMachines/enginesDaily operationCommunication link

The invention relates to a converter remote monitoring system used for wind power generation, comprising a plurality of wind power generating sets. Each wind power generating set comprises a converter and a converter remote monitoring console which is provided with built-in converter monitoring software; and a converter monitoring network is formed by networking the converters, wherein the converter remote monitoring console and the converter monitoring network are in communication link. The system communicates with the converter remote monitoring console at the far end by the independent converter monitoring network, and the maintenance personnel directly monitor and maintain the converters and correlative systems so as to sufficiently utilize the data resources acquired and recorded by the converter; the selection of converter monitoring parameters is not restricted by the communication mode, the capacity and the communication protocol of a main controller, but depends on the communication mode, the capacity and the communication protocol of the converter monitoring network, thereby greatly improving the maintenance efficiency and quality of the wind power generating sets, shortening fault treatment time, realizing parametric analysis and fault prevention in daily operation, and obviously saving the maintenance cost.

Owner:SHENZHEN HOPEWIND ELECTRIC CO LTD

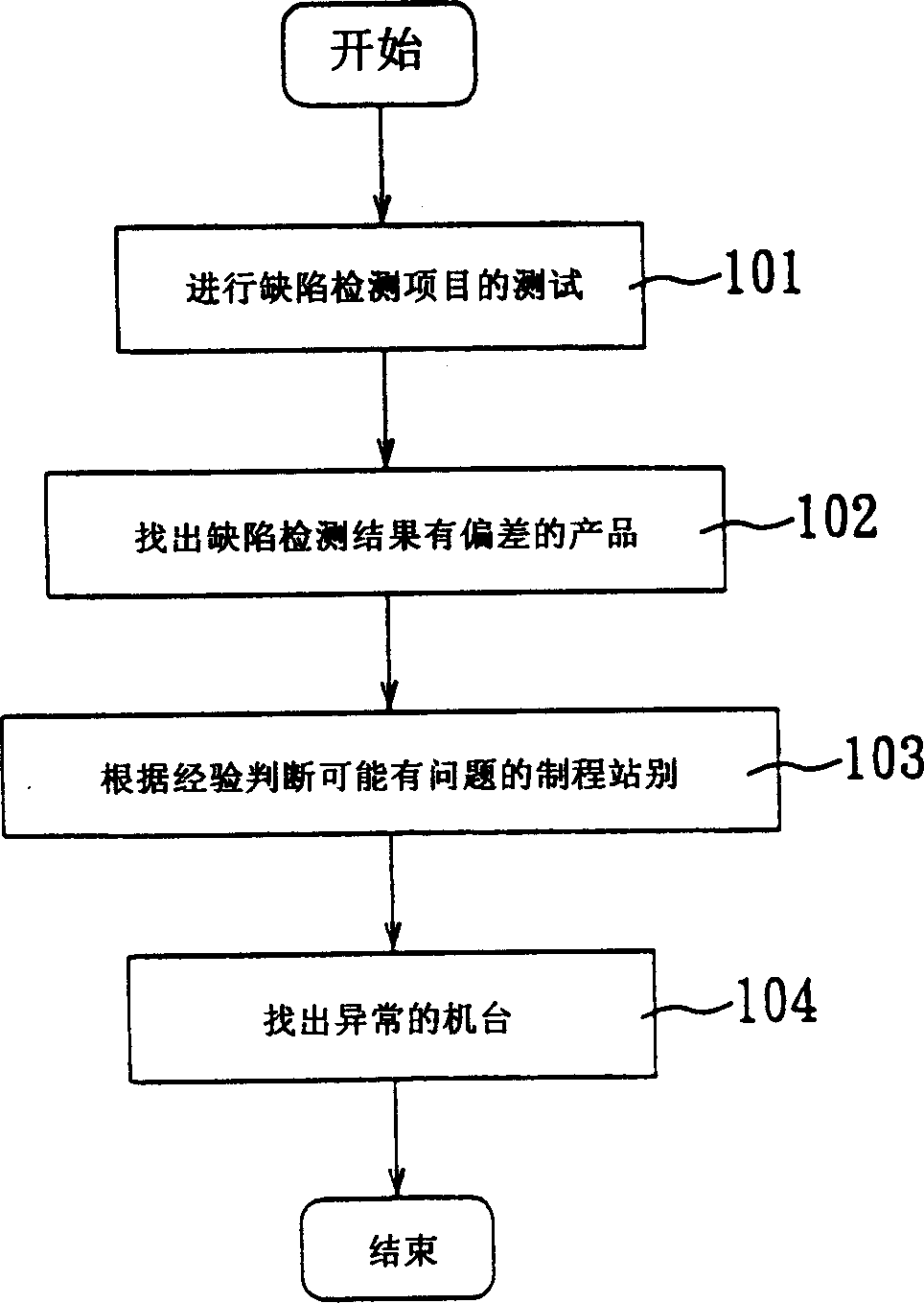

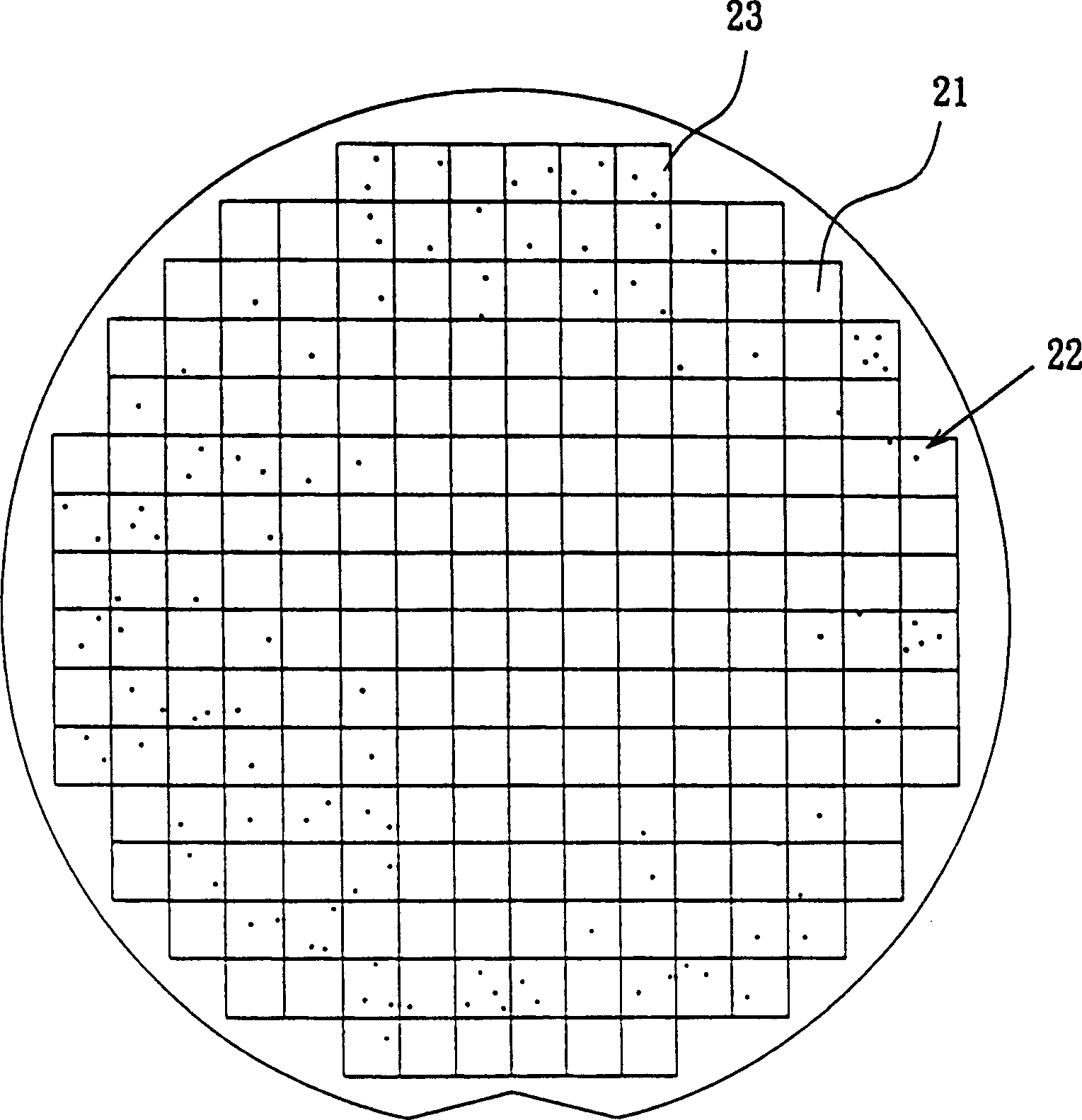

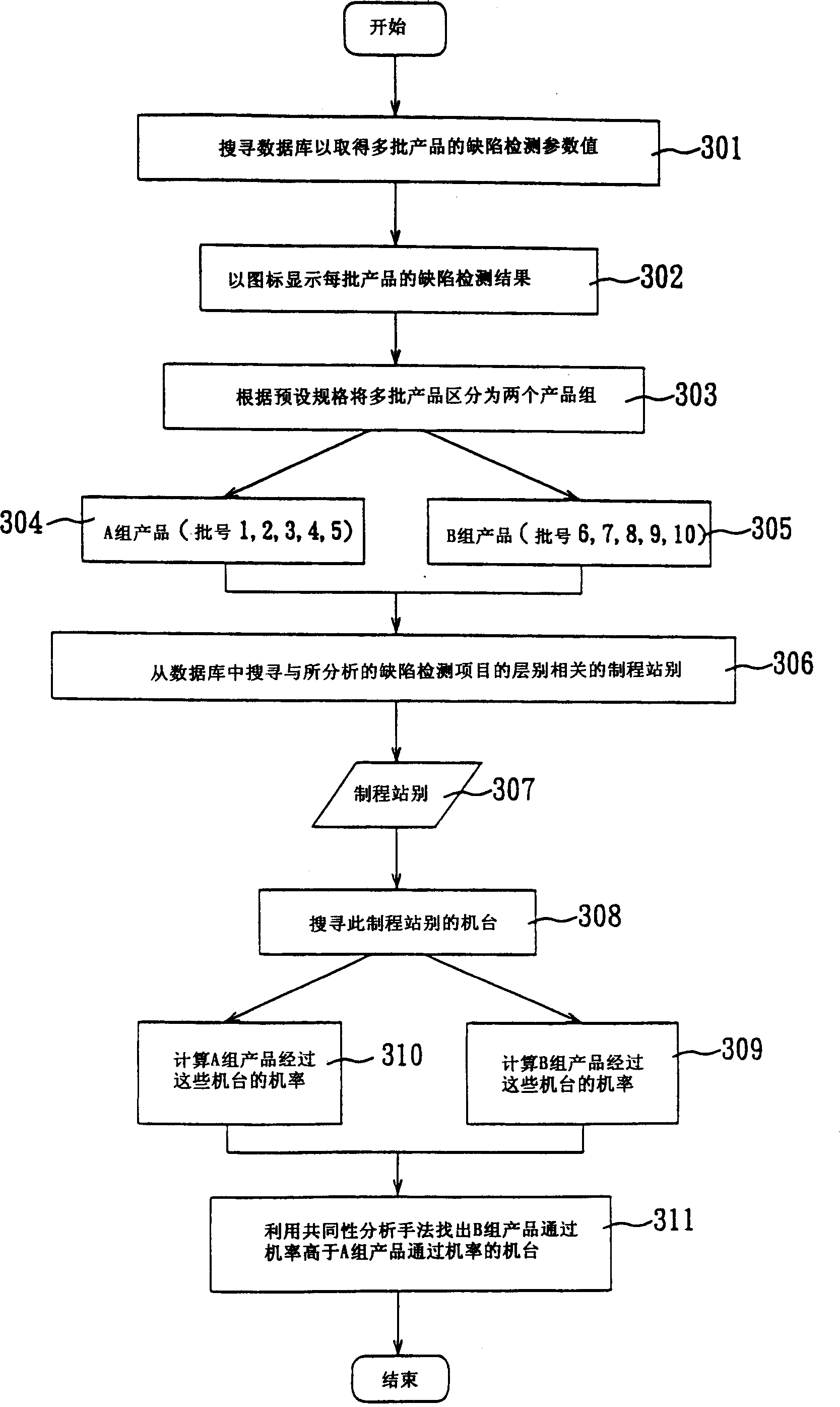

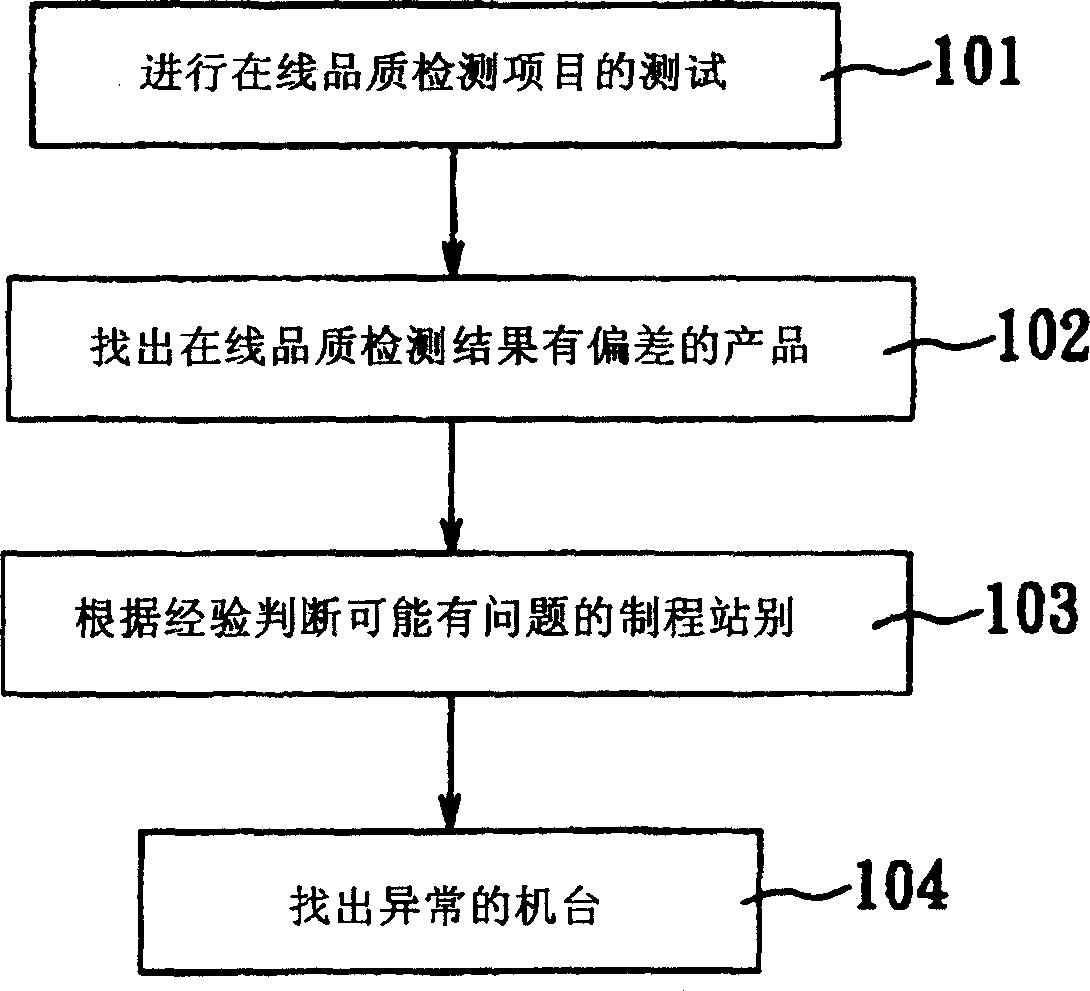

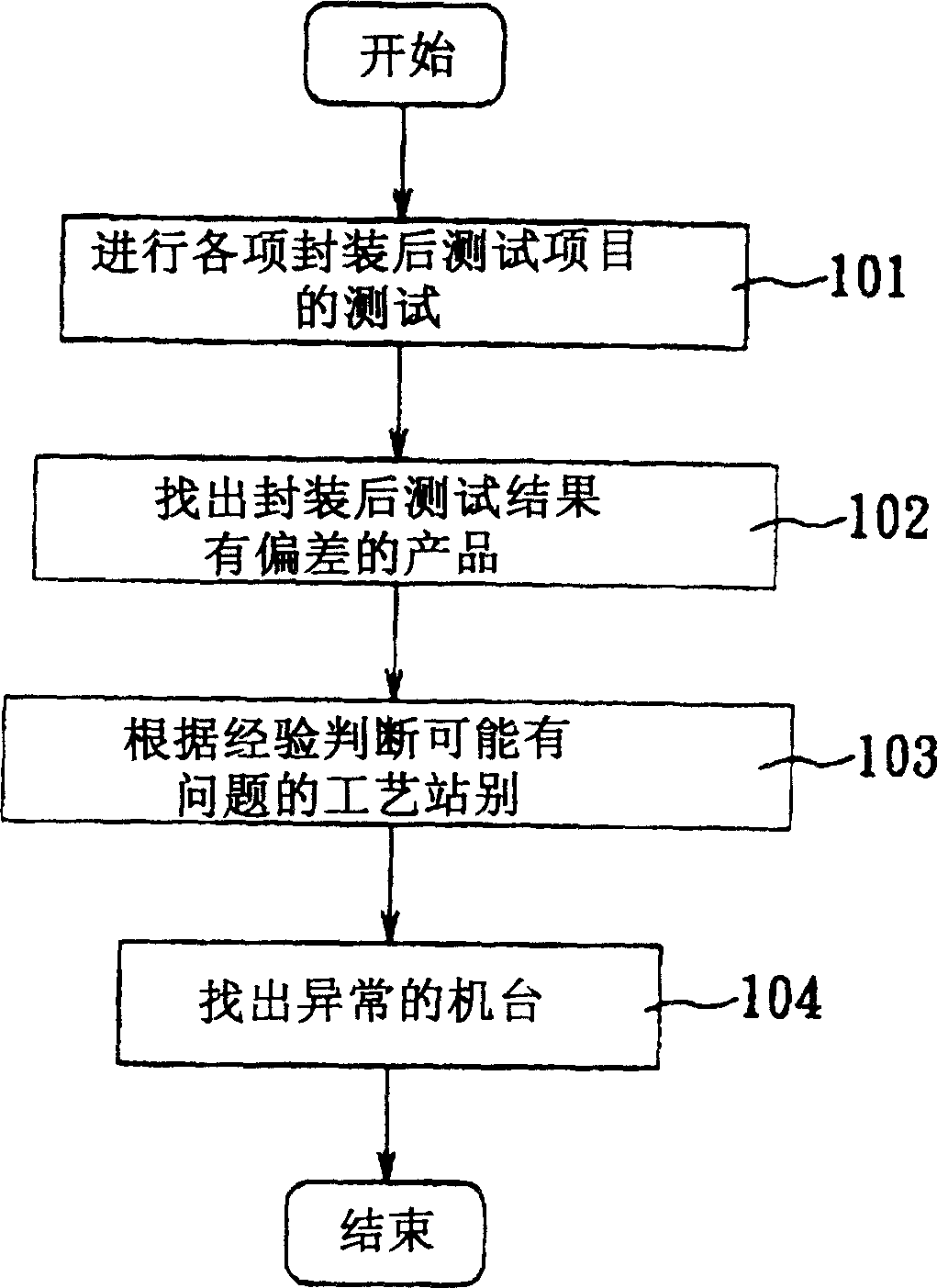

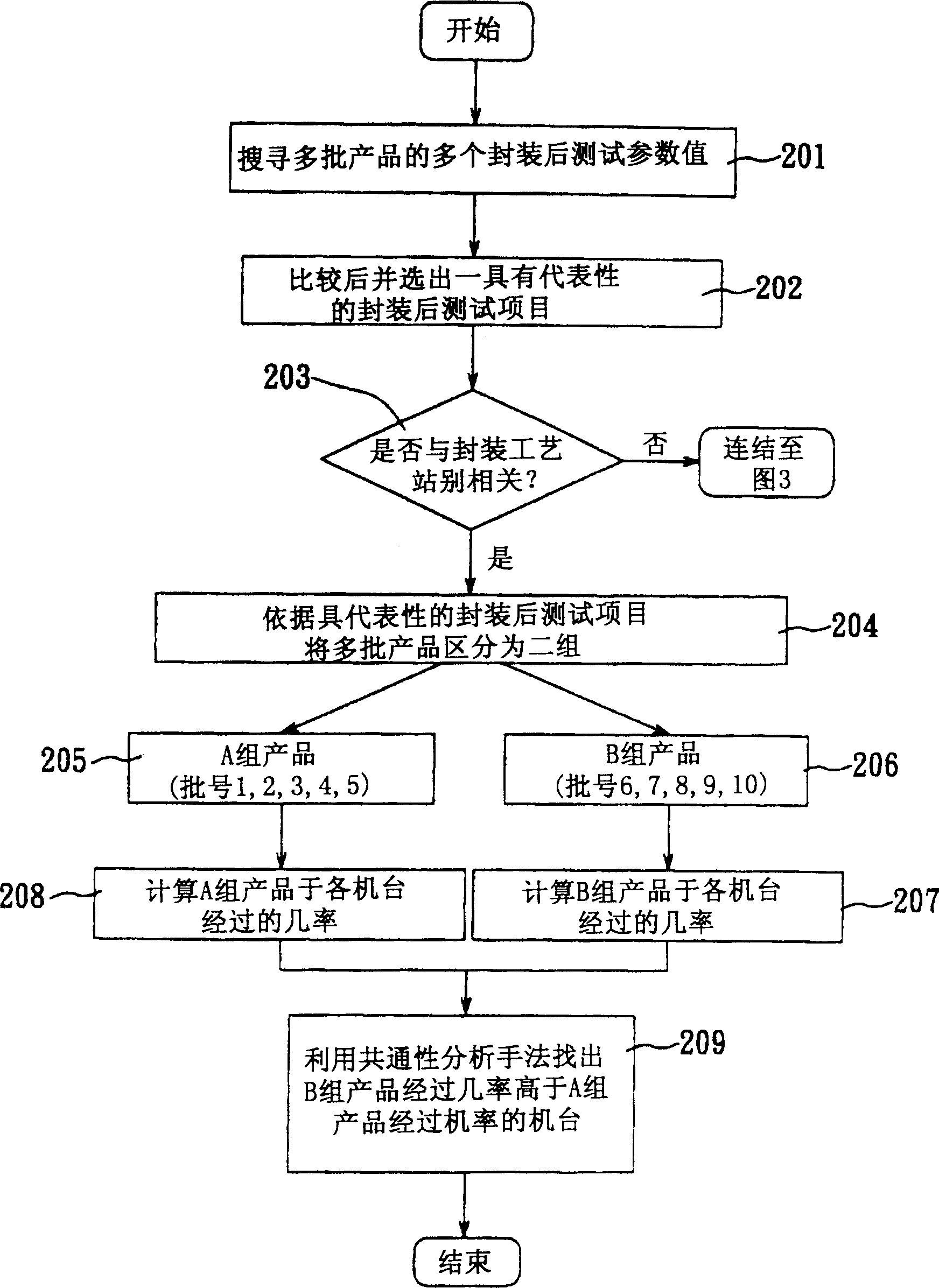

Defect detecting parametric analysis method

InactiveCN1521822AImprove efficiencyReduce errorsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSoftware engineeringProduct group

A defect detecting parametric analysis method comprises the steps of, searching the data base to obtain the defect detecting parameter value for a plurality of products, dividing the products into at least one acceptable product group and one disqualified product group, searching the process stations relating to the defect detecting items from the data base, searching for machine benches where the acceptable product set passes during the process, searching for machine benches where the disqualified product set passes during the process, determining the machine bench in which the passing probability of the disqualified product set is higher than that of the acceptable product set.

Owner:POWERCHIP SEMICON CORP

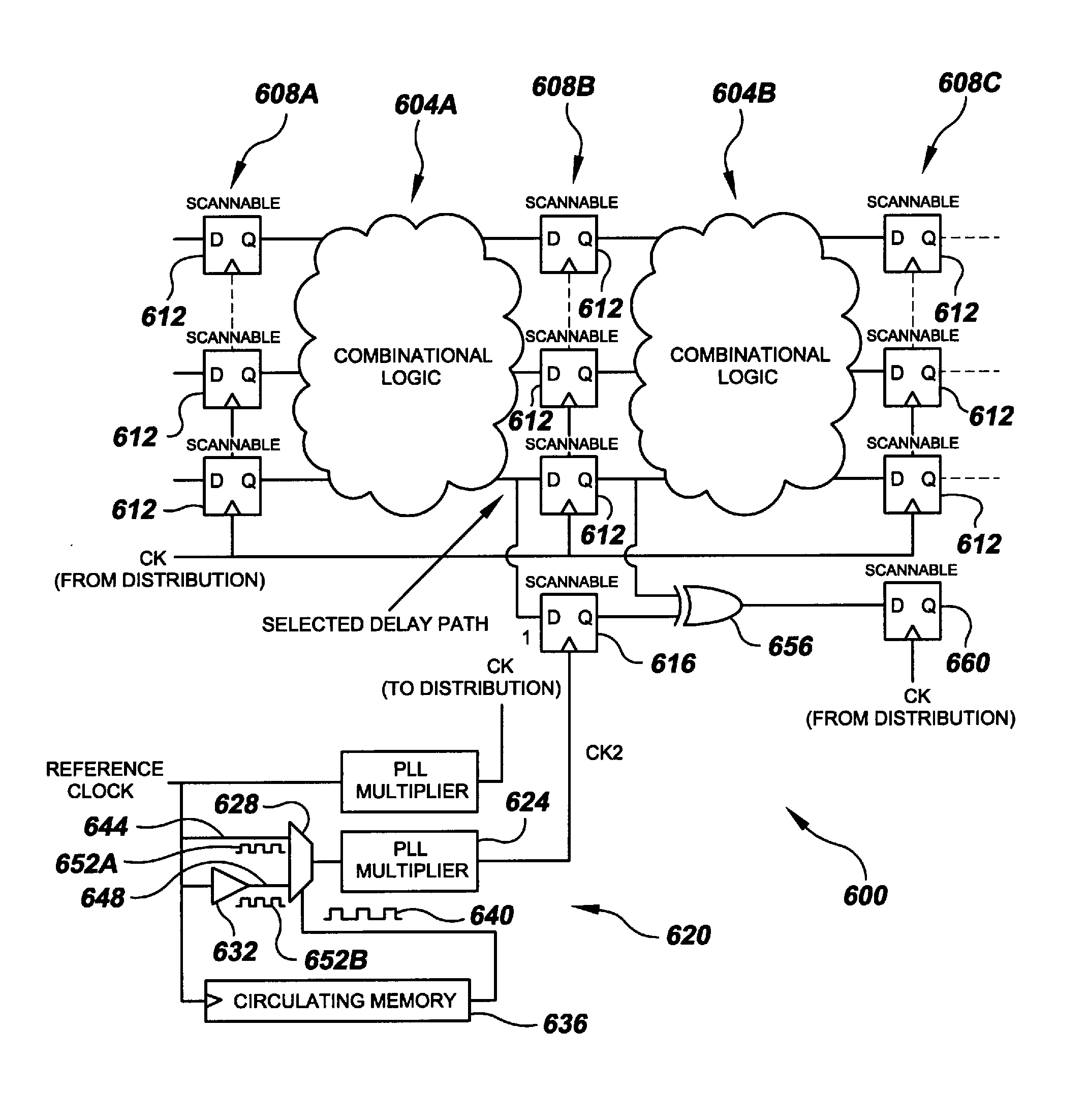

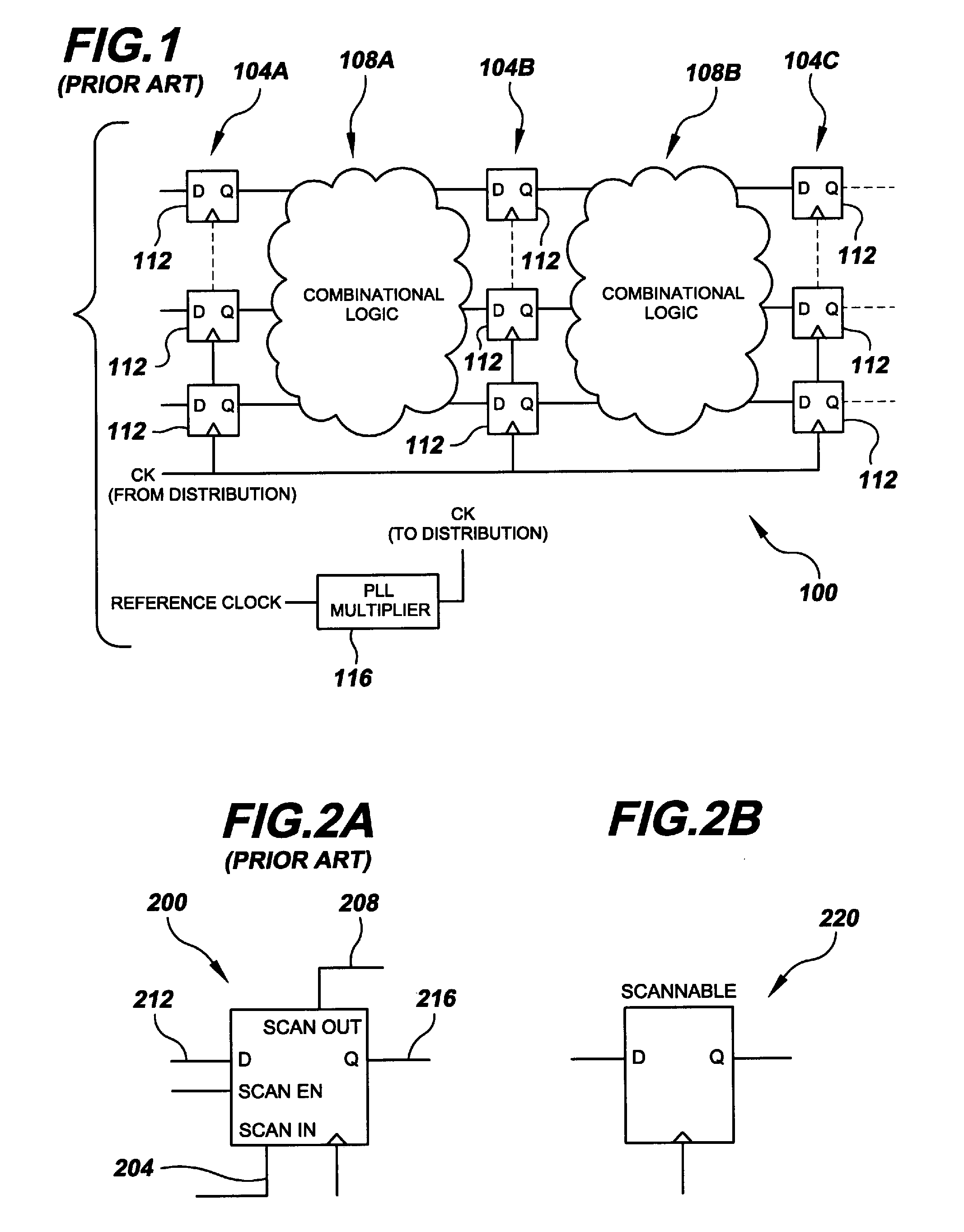

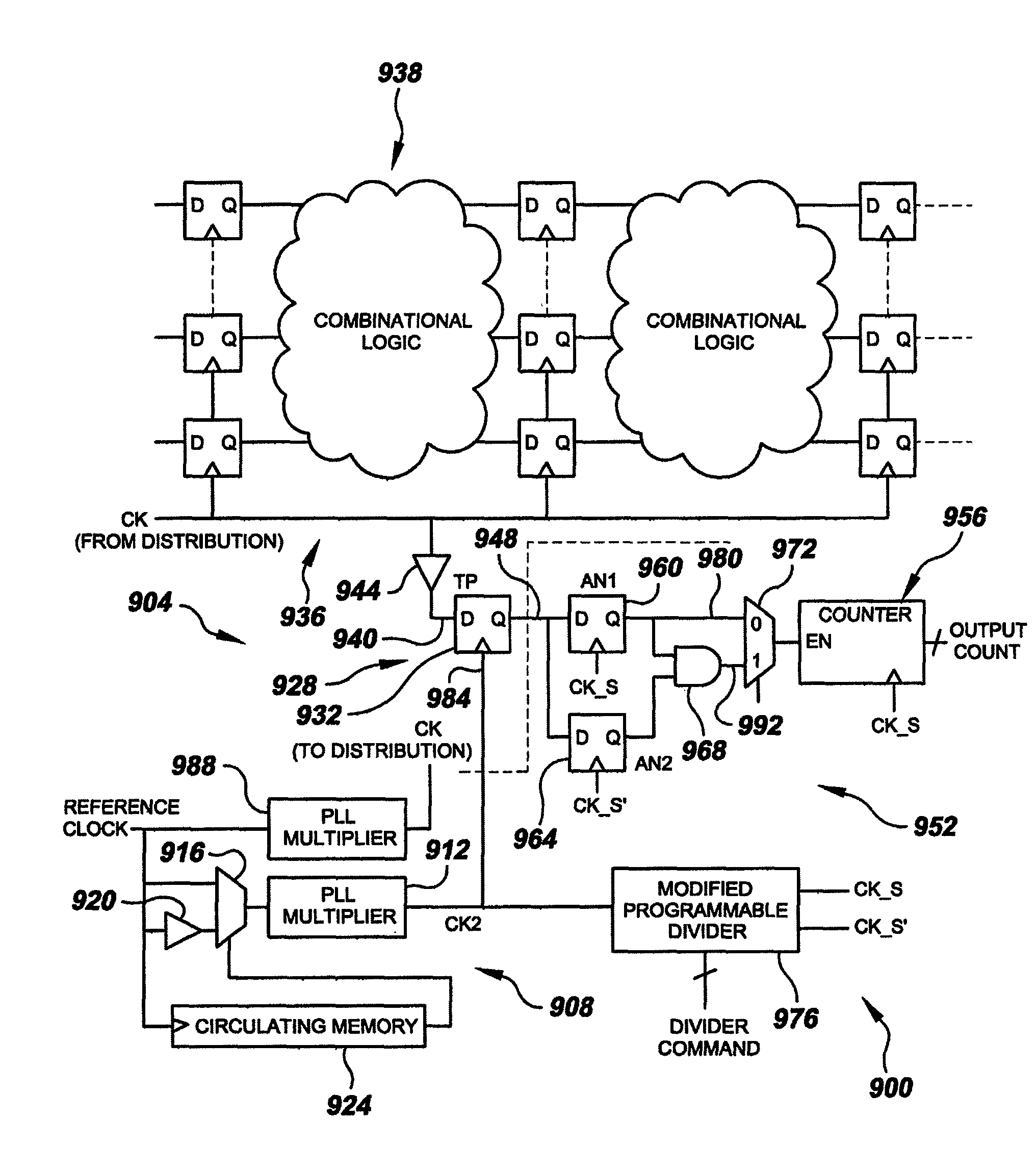

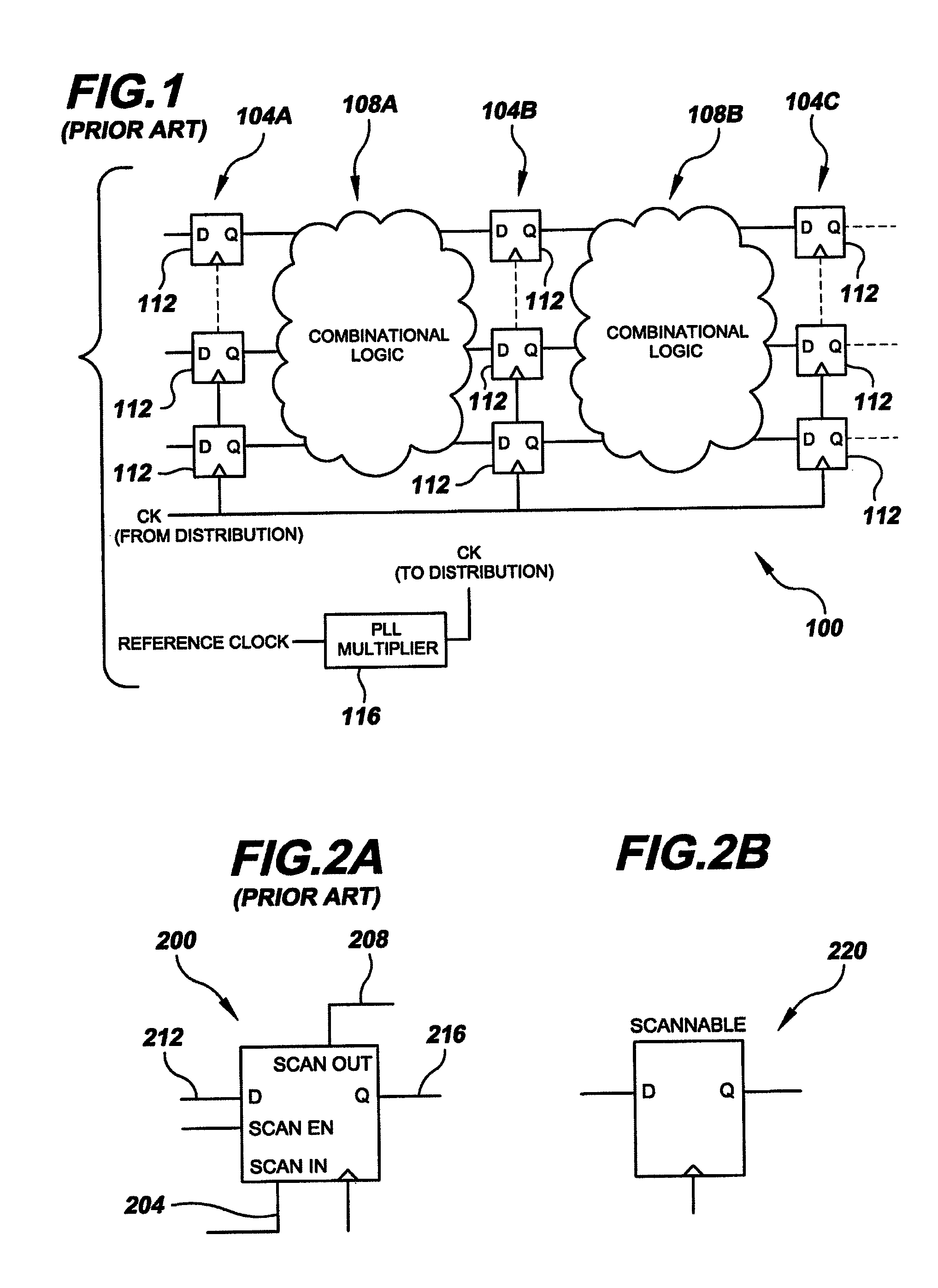

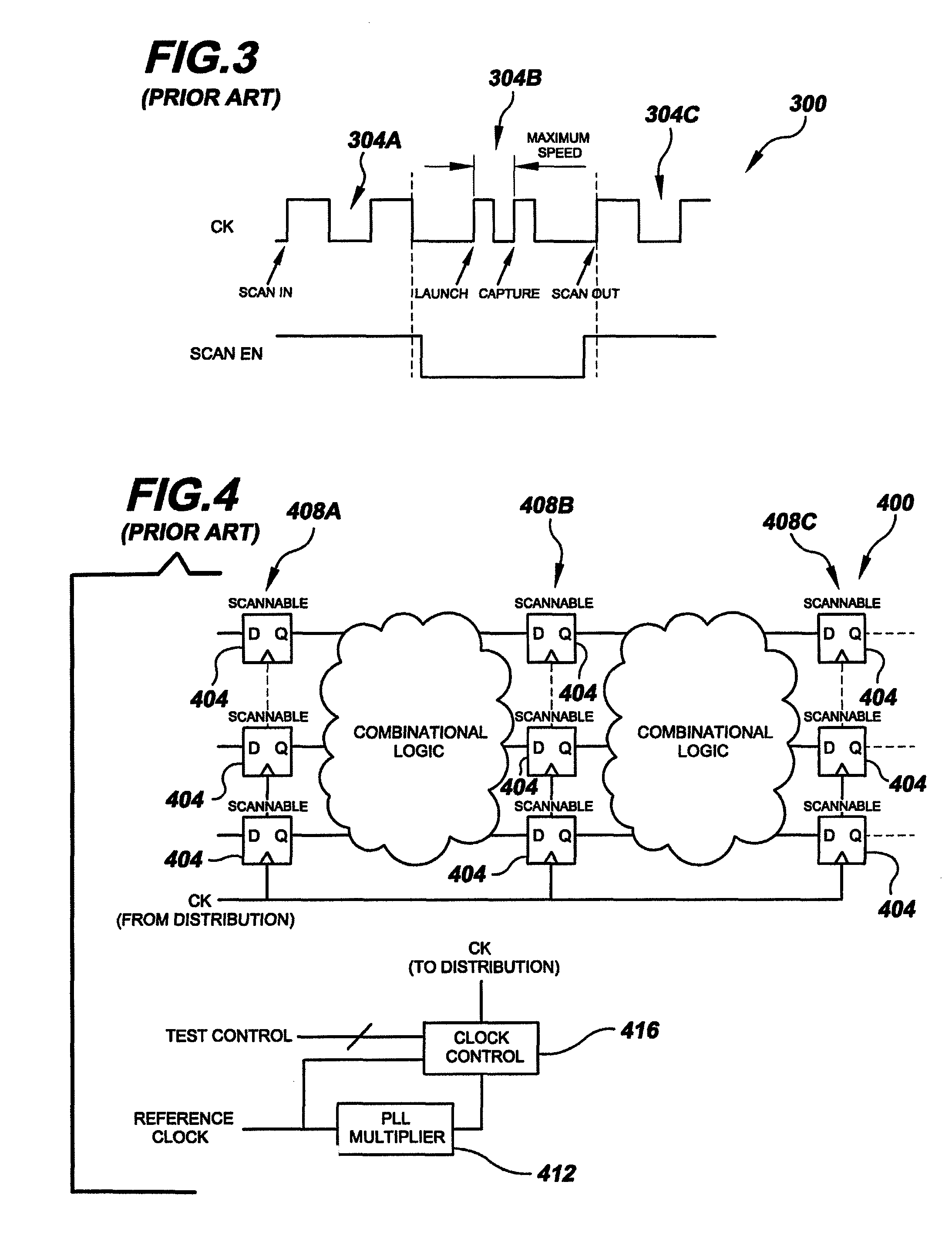

Systems and Methods for Testing and Diagnosing Delay Faults and For Parametric Testing in Digital Circuits

InactiveUS20090198461A1Good delayNoise figure or signal-to-noise ratio measurementResistance/reactance/impedenceDelayed timeCircuit delay

Delay-fault testing and parametric analysis systems and methods utilizing one or more variable delay time-base generators. In embodiments of the delay-fault testing systems, short-delay logic paths are provided with additional scan-chain memory elements and logic that, in conjunction with the one or more variable-delay time-base generators, provides the effect of over-clocking without the need to over-clock. Related methods provide such effective over-clocking. In embodiments of parametric analysis systems, test point sampling elements and analysis circuitry are clocked as a function of the output of the one or more variable-delay time-base generators to provide various parametric analysis functionality. Related methods address this functionality.

Owner:DFT MICROSYST

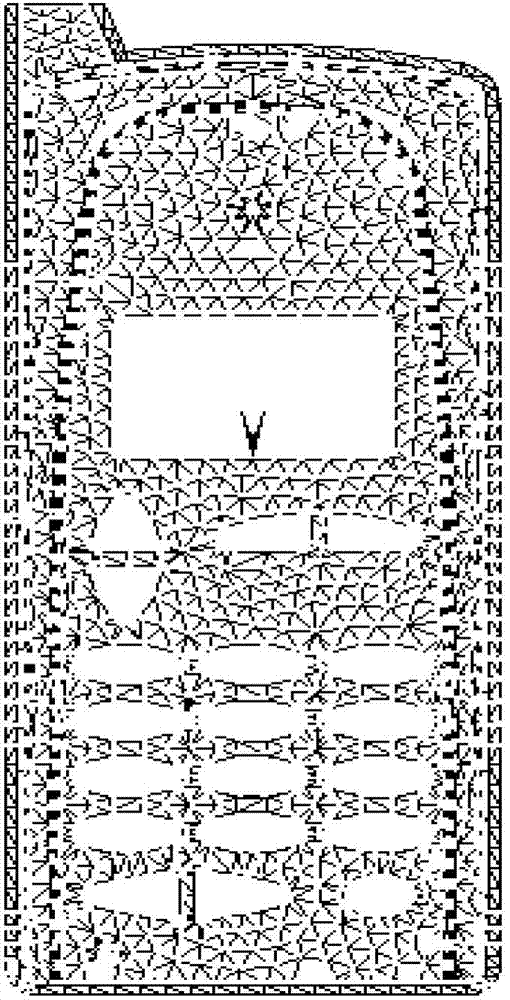

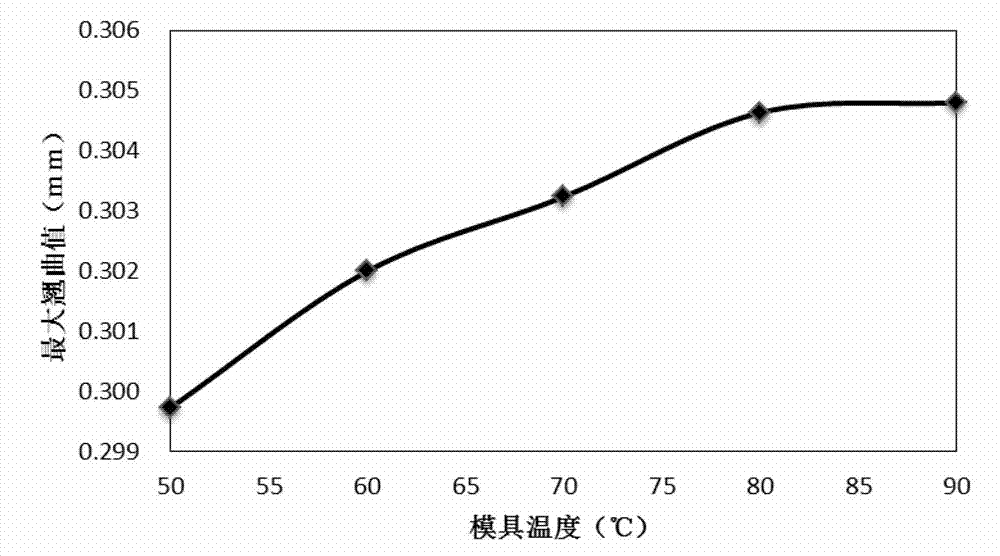

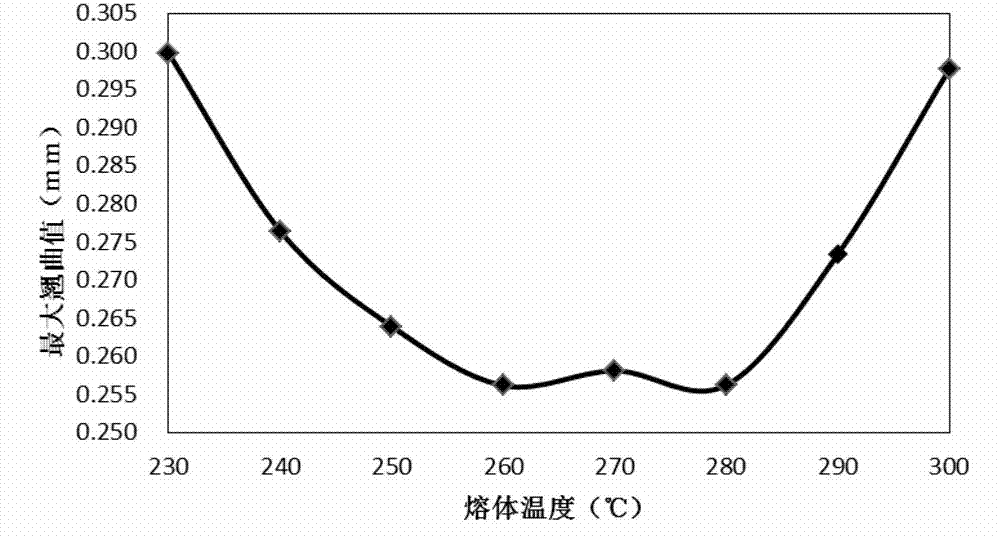

Parametric analysis method of effect of injection molding process to plastic part buckling deformation

InactiveCN103093062AQuick analysisEfficient analysisSpecial data processing applicationsSimulationInjection molding process

The invention discloses a parametric analysis method of effect of an injection molding process to plastic part buckling deformation and aims to solve the technical problem that the prior parametric analysis method of plastic part buckling deformation is low in efficiency. The technical scheme is that the parametric analysis method of effect of the injection molding process to plastic part buckling deformation comprises of first, conducting secondary development to a commercialize mold flow analysis software MoldFlow to achieve parametric calculation and background execution of injection molding numerical modeling; then embedding MoldFlow secondary development procedures into an open-type multidisciplinary parametric analysis and optimization design platform BOSS Quattro, and automatically modifying process parameters according to a BOSS Quattro parametric analysis module and invoking the MoldFlow secondary development procedures to calculate plastic part buckling deformation; and last, acquiring plastic part buckling deformation under conditions of different process parameter values after automatically modifying and calculating the plastic part buckling deformation for several times. Analysis results of the parametric analysis method of effect of the injection molding process to plastic part buckling deformation provides variation tendencies of buckling deformation within each parameter value range, and provides the basis for arrangement of process parameters in the practical production. The whole analysis process is automatically finished, human input is reduced and analysis efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

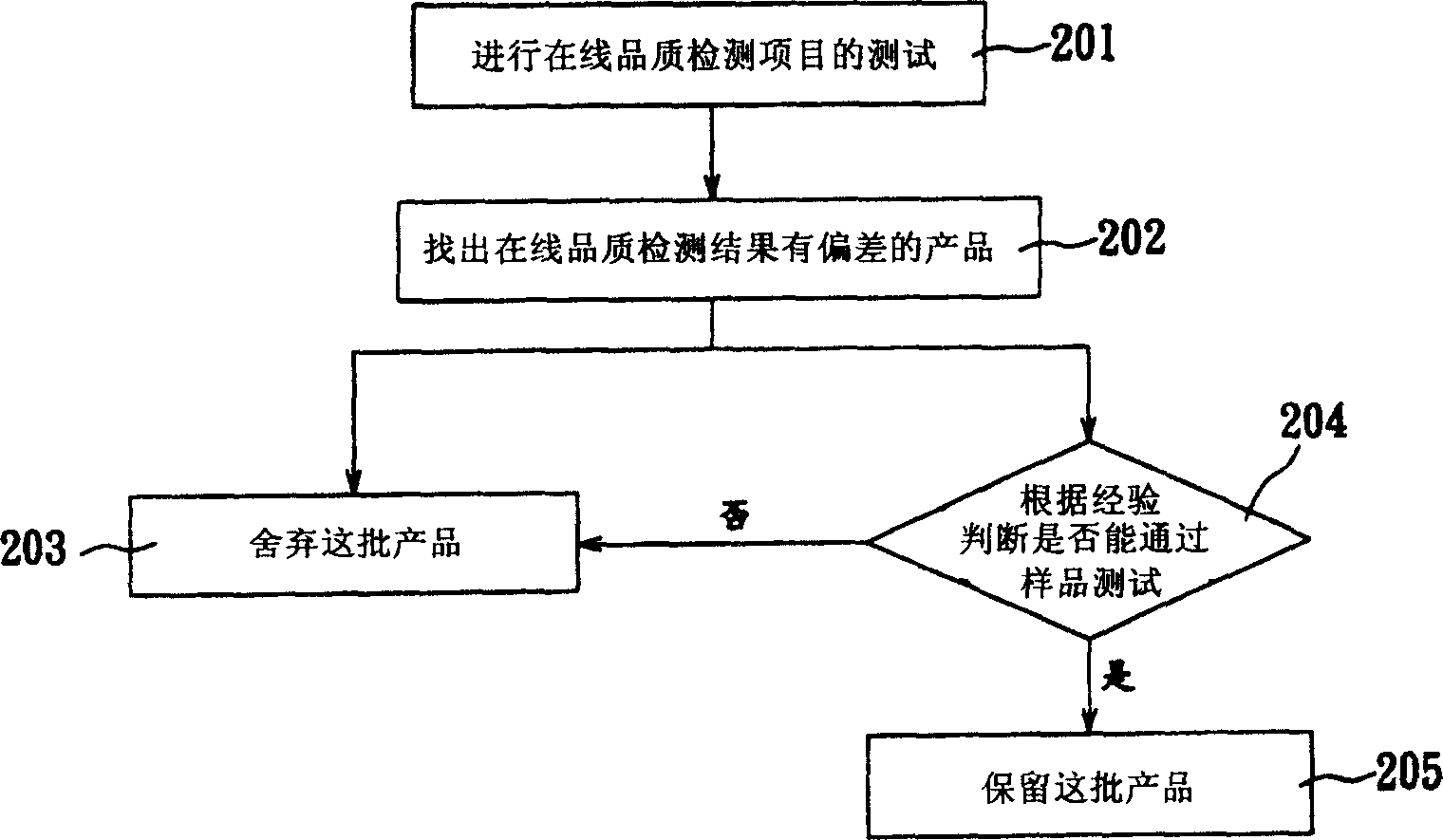

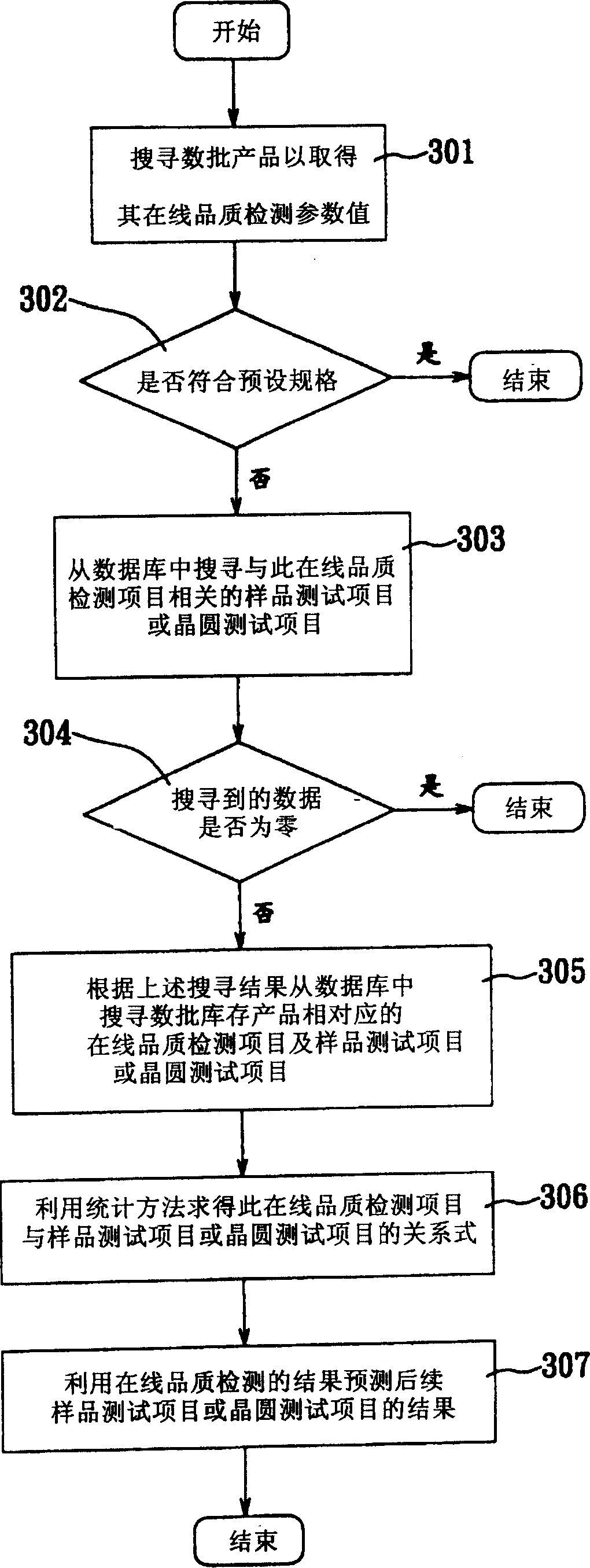

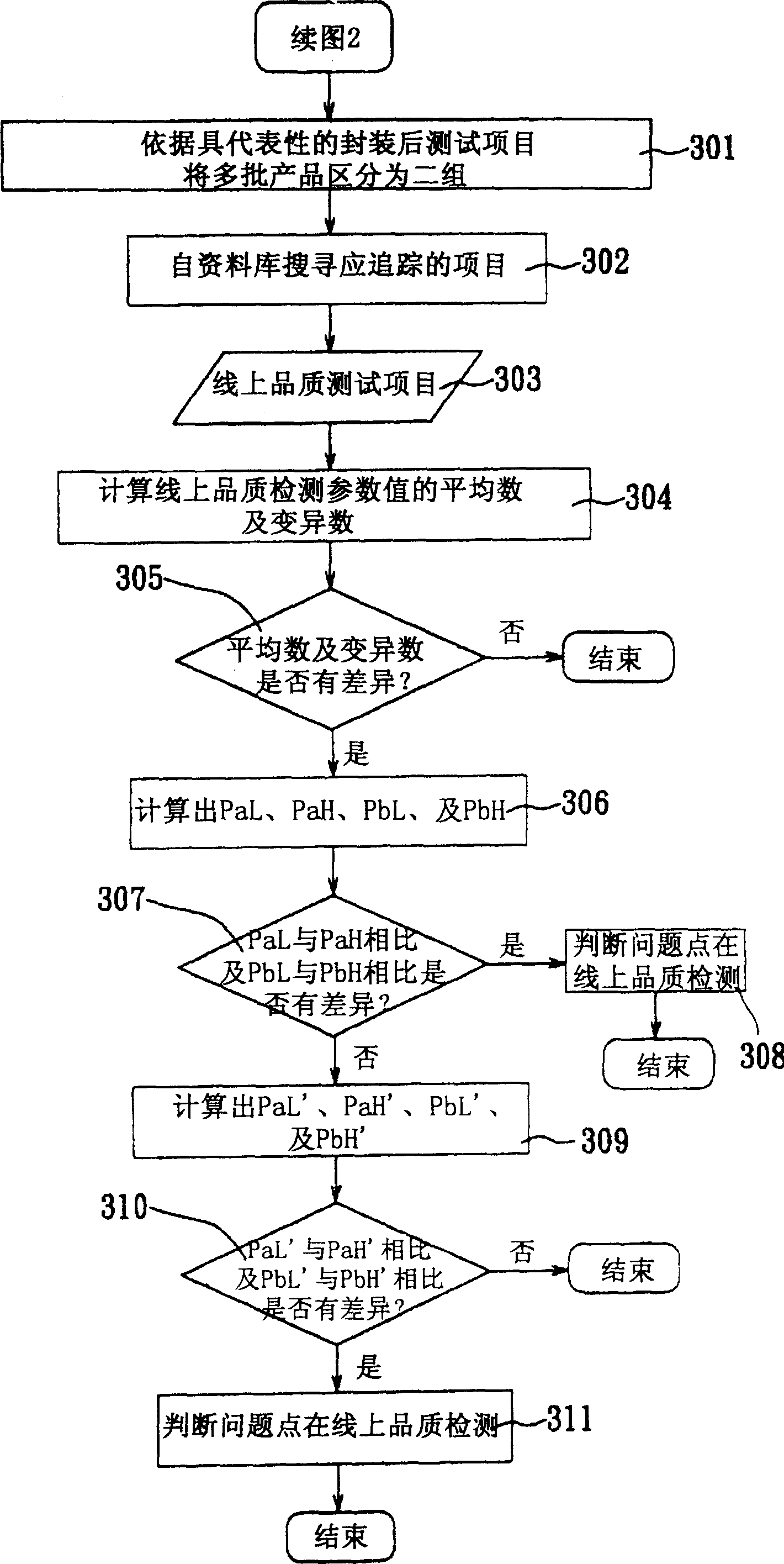

Online quality detecting parametric analysis method

InactiveCN1521824AImprove efficiencyYield ForecastSemiconductor/solid-state device testing/measurementEngineeringData mining

An online quality detection parametric analysis method comprises the steps of, analyzing the online quality detecting parameter value meets the predetermined specifications, searching the sample testing items or chip testing items relating to online quality detecting items from the data base, searching the testing parameter values items corresponding to each batch of inventory products from the data base, generating the relational expression between the online quality detecting items and the sample testing items, or the relational expression between the online quality detecting items and the chip testing items.

Owner:POWERCHIP SEMICON CORP

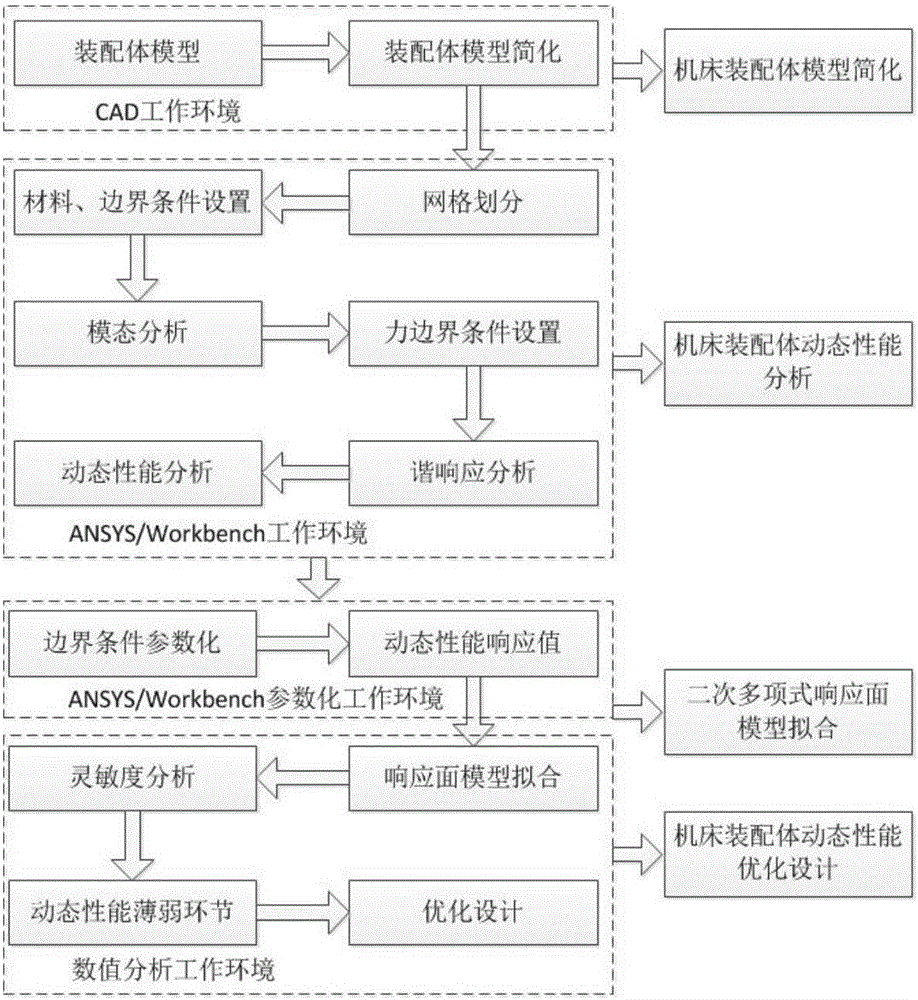

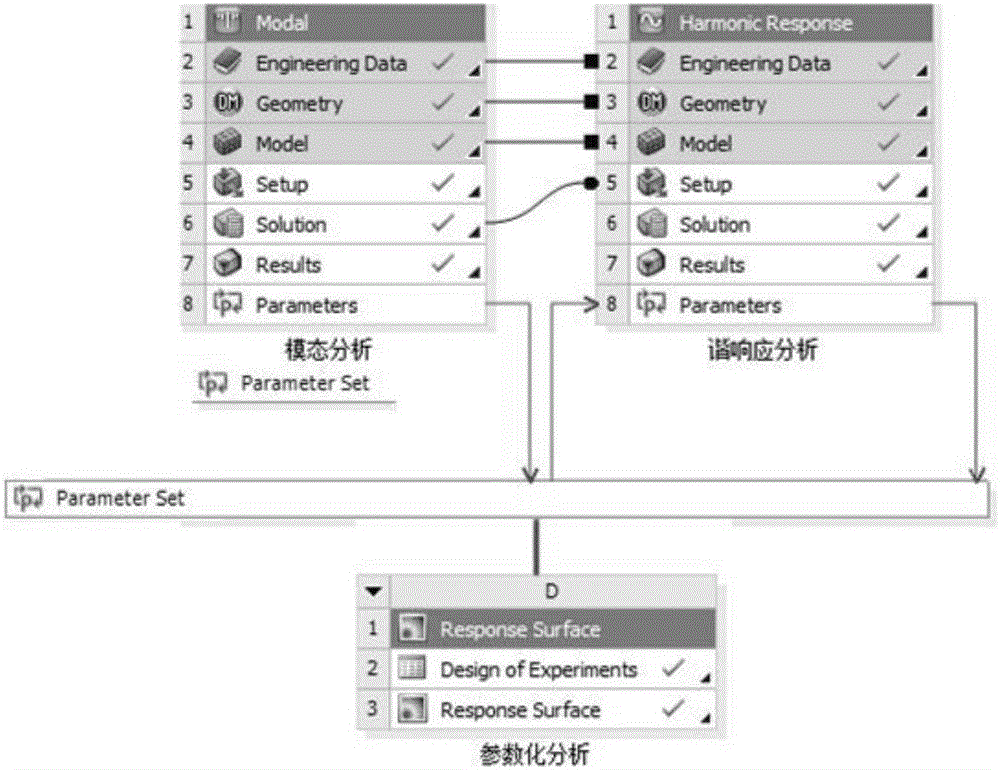

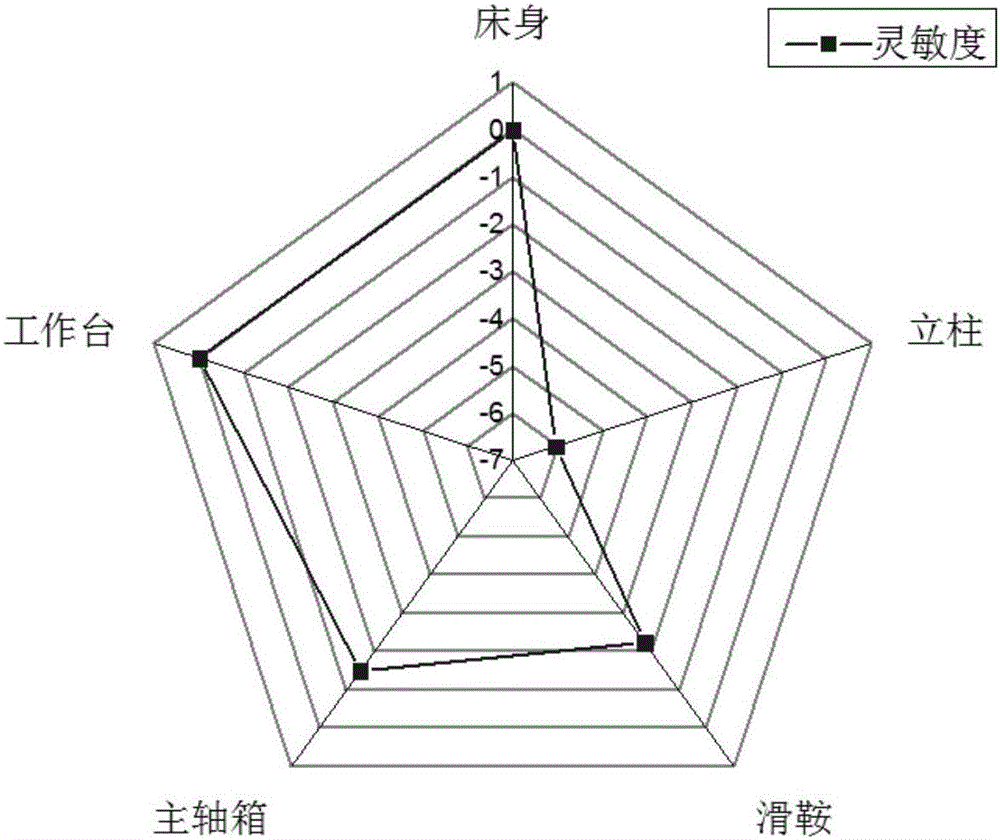

Dynamic property optimization design method for foundation major parts of machine tool

InactiveCN106777820AHigh precisionAvoid duplicationDesign optimisation/simulationSpecial data processing applicationsEngineeringQuality characteristics

The invention discloses a dynamic property optimization design method for foundation major parts of a machine tool. The method includes the steps that a machine tool assembly is simplified according to the dynamics simulation analysis requirement, and the simplified assembly is imported into ANSYS / Workbench for mesh generation, material setting and boundary condition setting to complete modal analysis of the machine tool assembly; in harmonic response analysis, the maximum amplitude response values of the end of a spindle box of the machine tool assembly under the action of simple harmonic force in the X direction, the Y direction and the Z direction are obtained by simulating the actual working state of a tool; finally, experiment design of quality characteristic parameters of the foundation major parts is carried out with the parametric analysis technology, and a response surface model between the dynamic property response values of the machine tool and the quality characteristics of the foundation major parts is obtained through fitting. By analyzing the response surface model, the weak link of the foundation major parts in the dynamic property of the machine tool can be qualitatively found out, the tendency of influences of changes of the foundation major parts on the dynamic property of the machine tool can be quantitatively predicted, and the precision of machine tool design can be improved.

Owner:XI AN JIAOTONG UNIV

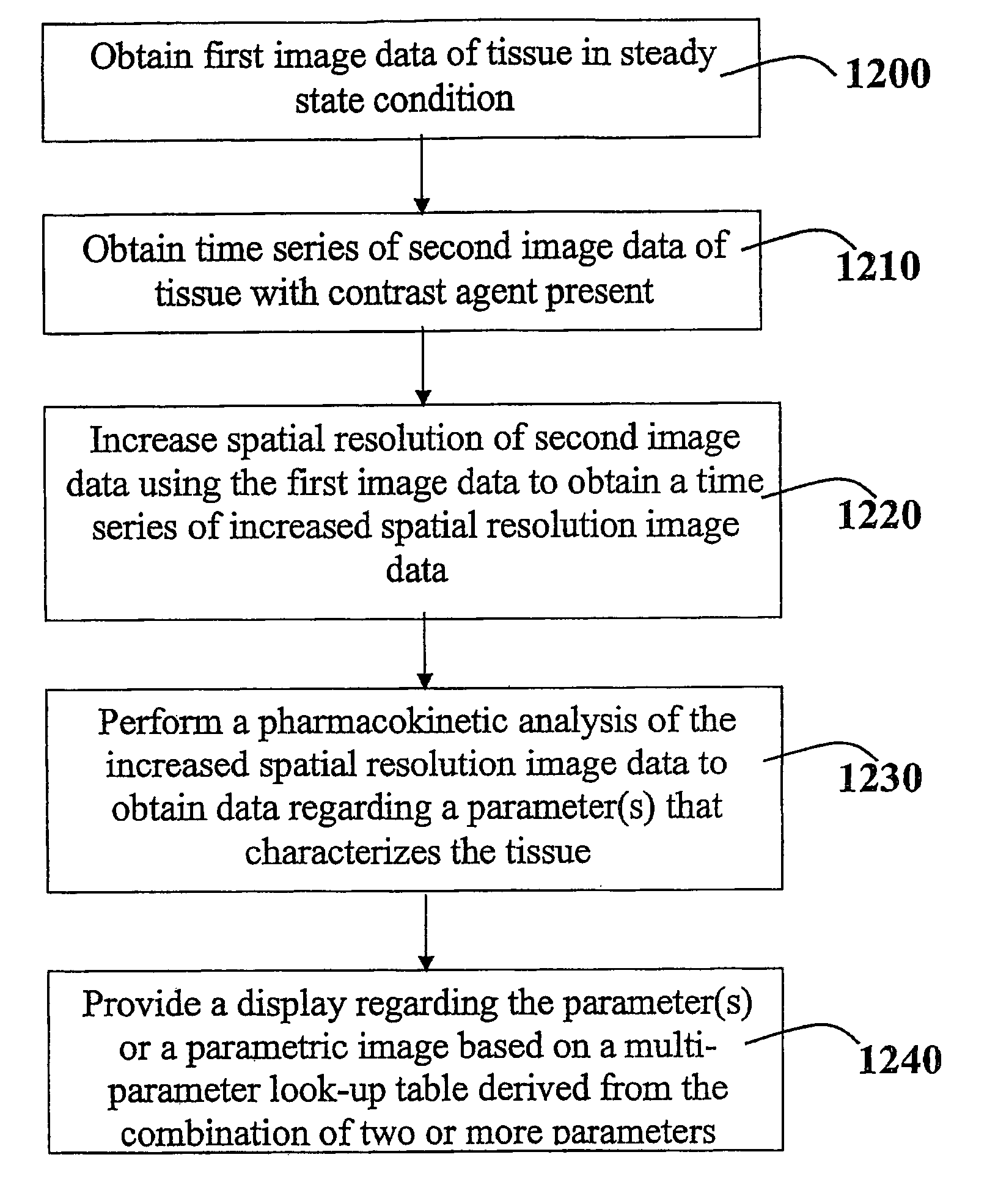

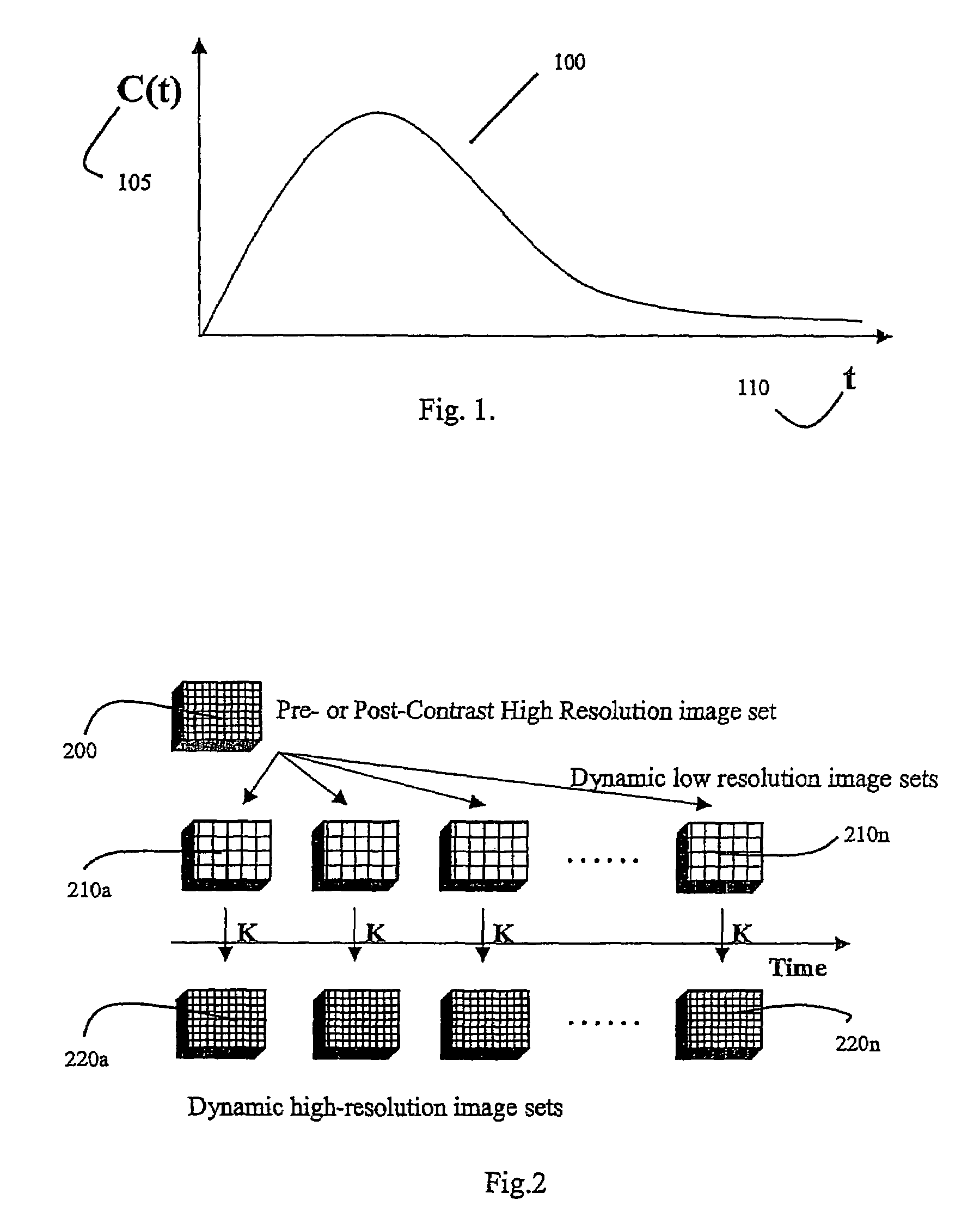

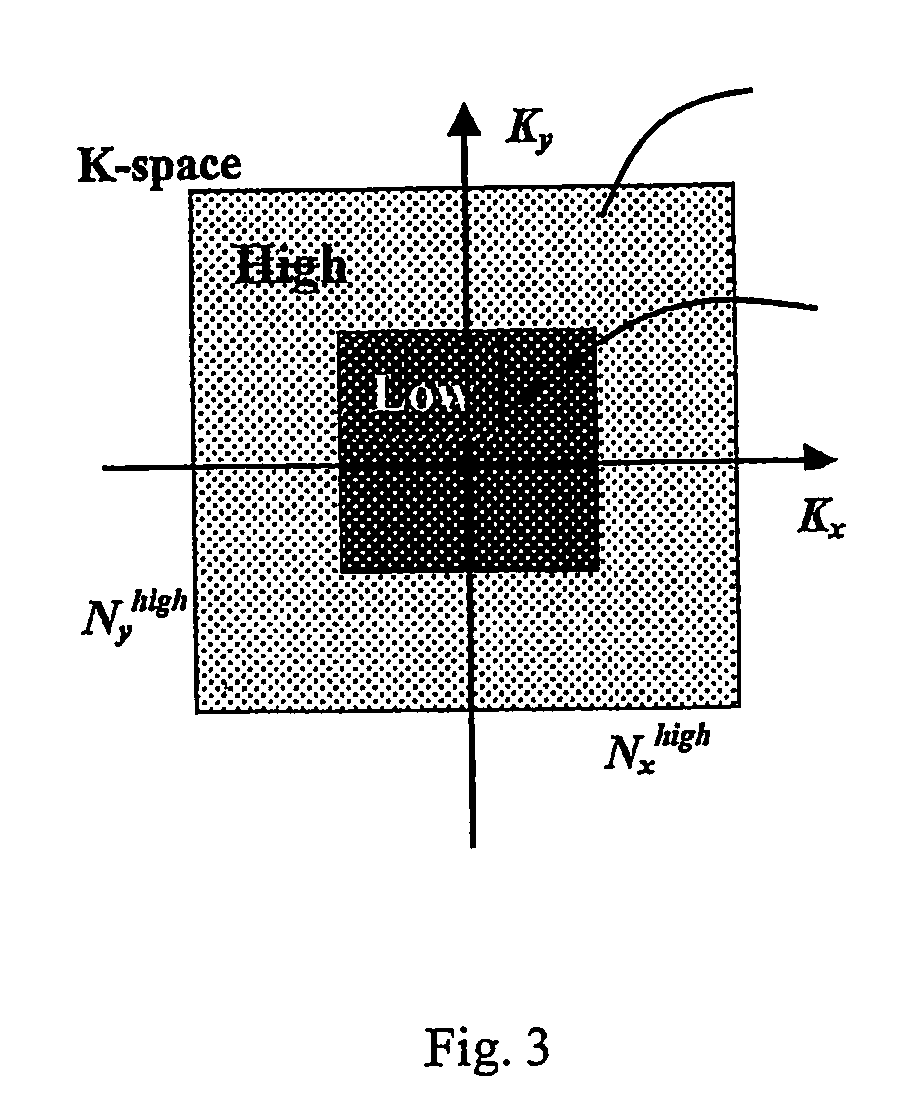

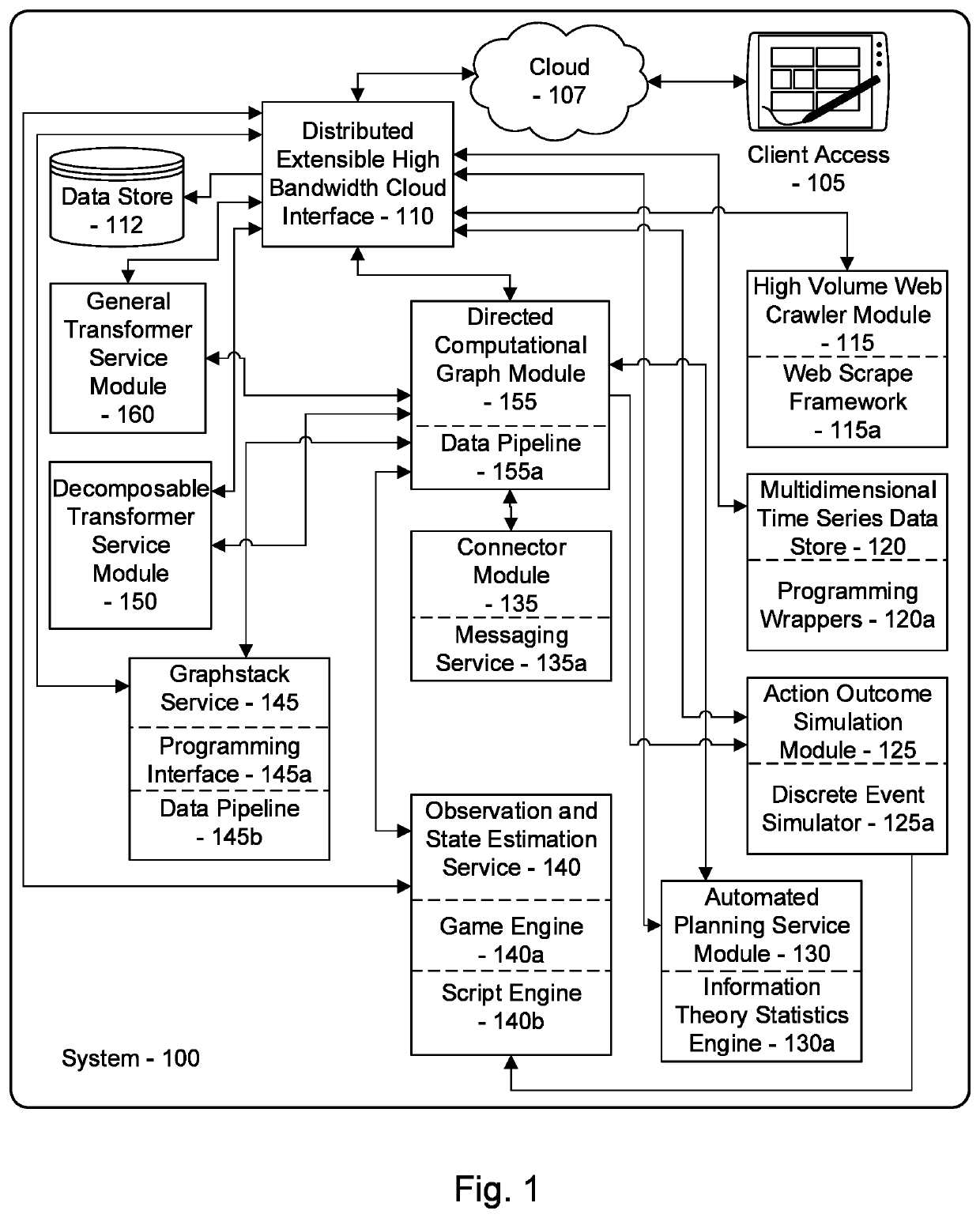

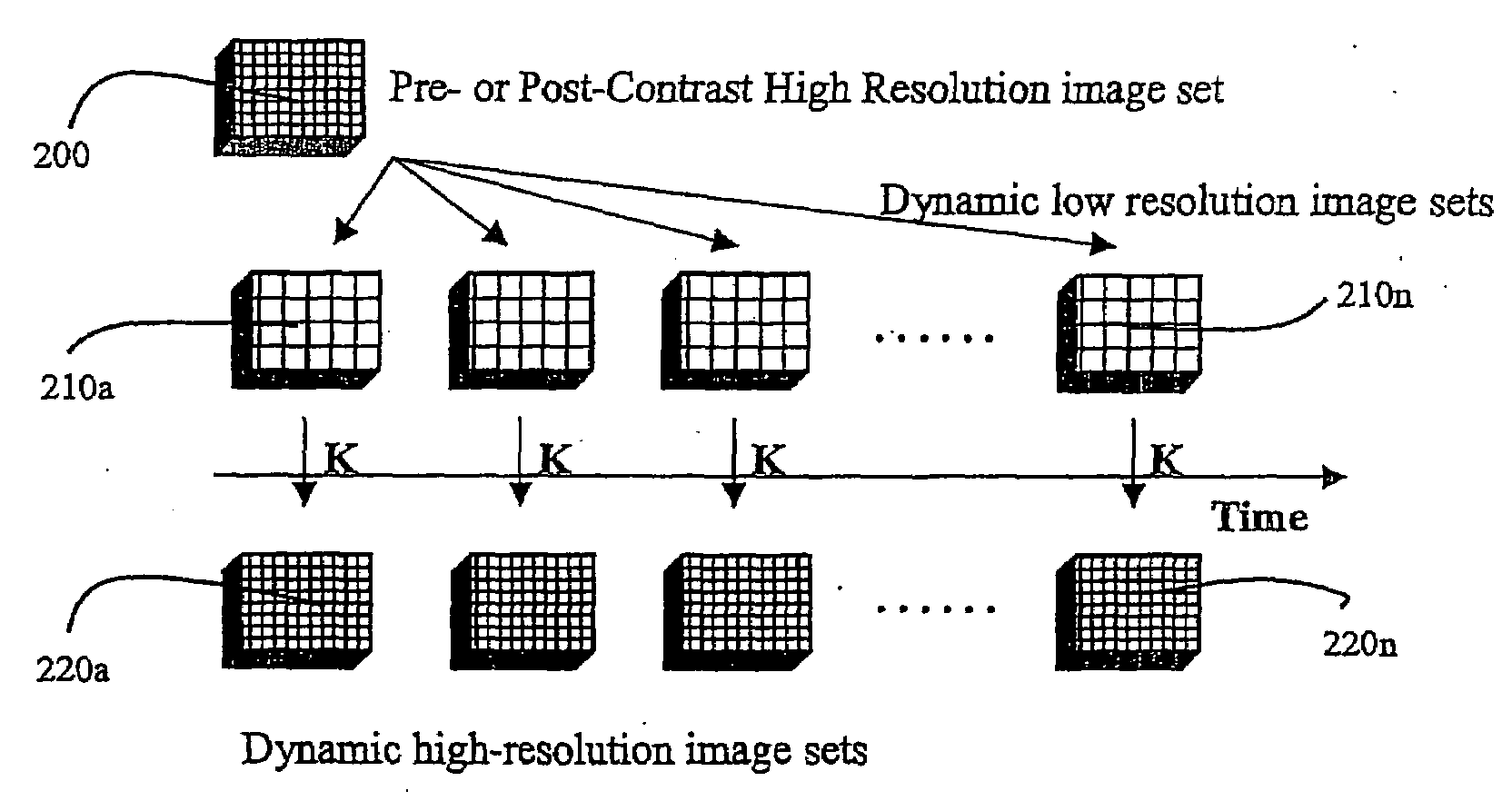

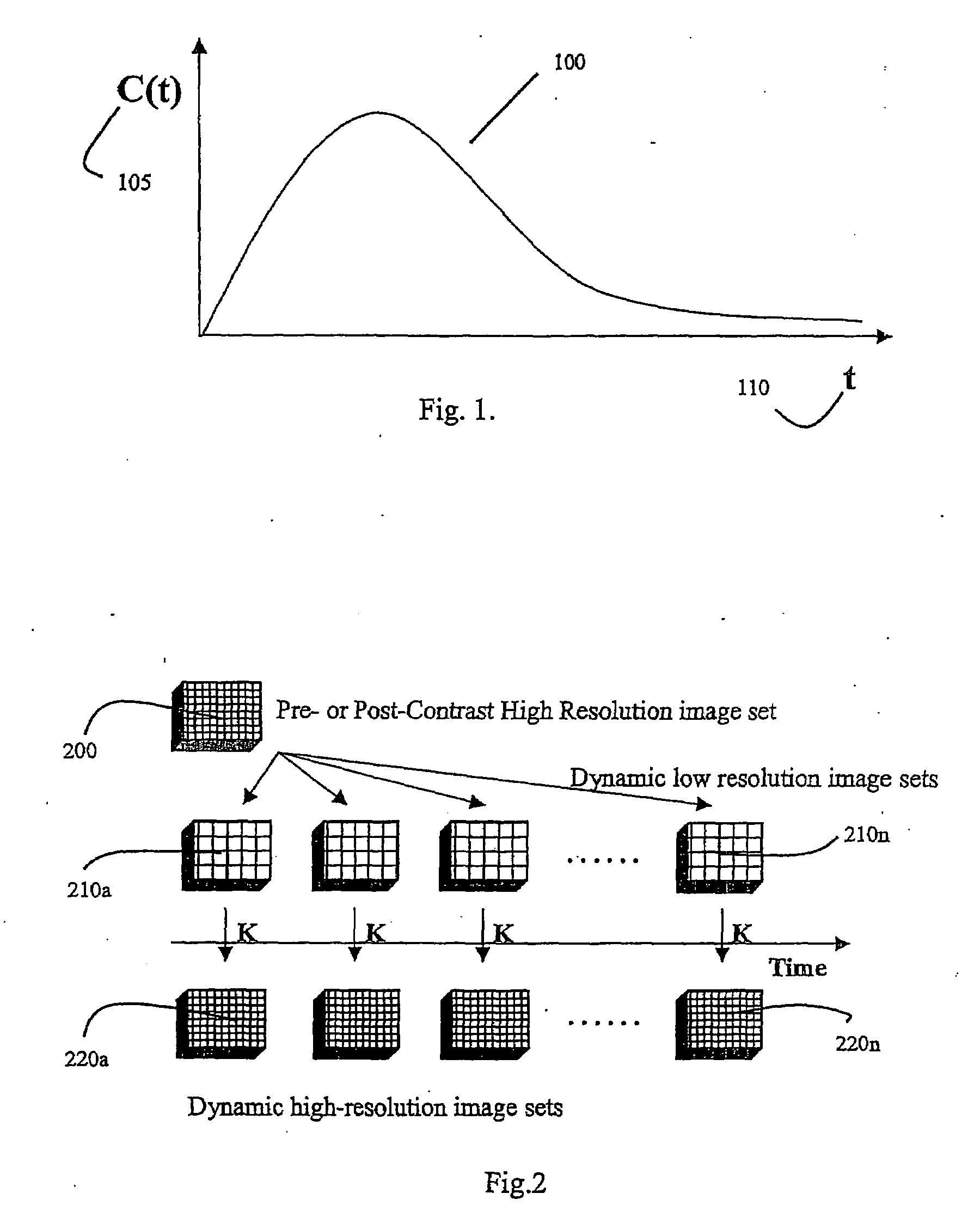

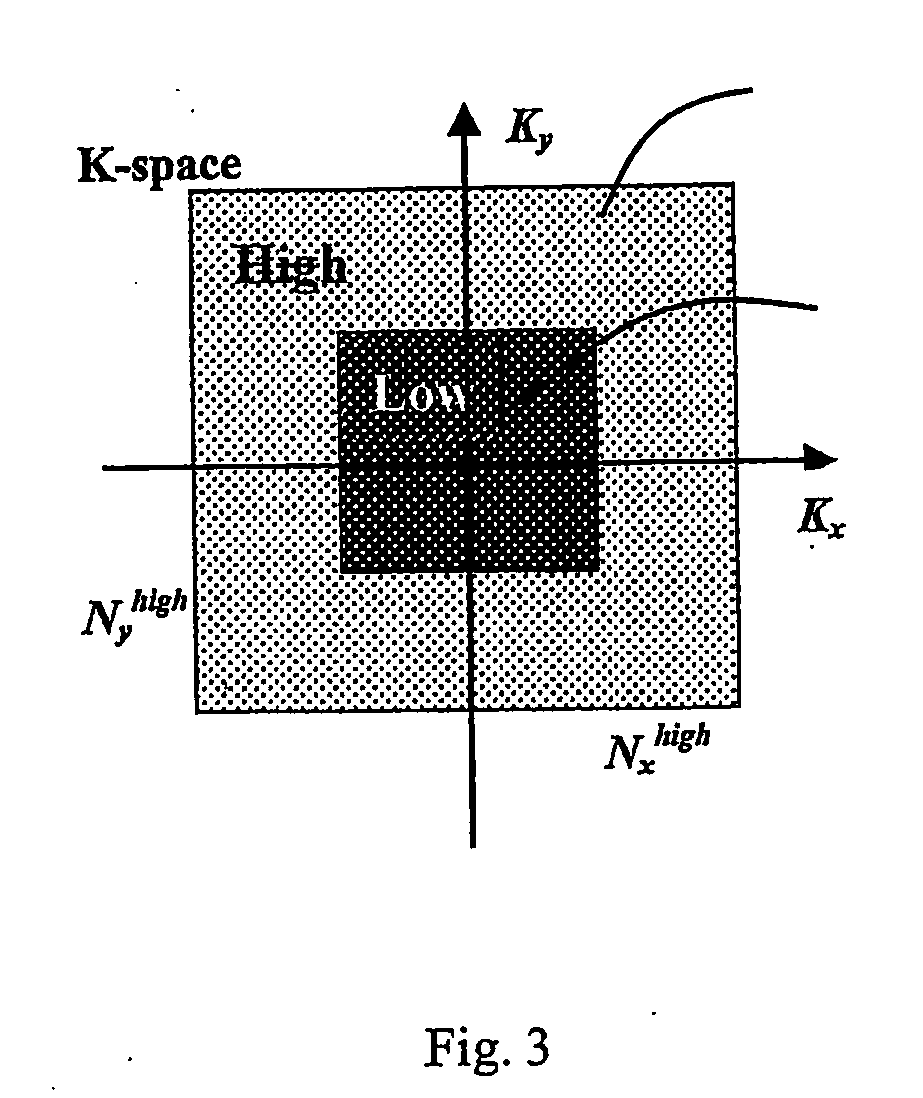

Method for tracking of contrast enhancement pattern for pharmacokinetic and parametric analysis in fast-enhancing tissues using high-resolution MRI

A method for performing a high-resolution pharmacokinetic analysis for calculation of tissue parameters for a fast-enhancing tissue enables medical personnel to accurately determine pharmacokinetic parameters in fast-enhancing tissues. The method includes obtaining mask image data of the tissue when it is in a steady state condition, obtaining a time series of image data of the tissue when the contrast agent is flowing in the tissue, and increasing a spatial resolution of the time series of image data using the mask image data to obtain a time series of increased spatial resolution image data. The method further includes performing a pharmacokinetic analysis to obtain data including at least one parameter that characterizes the tissue, providing a multi-parameter look-up table derived from a combination of two or more parameters, and providing a display including one parameter or a parametric image, where the parametric image is derived from the look-up table.

Owner:KONINKLJIJKE PHILIPS NV

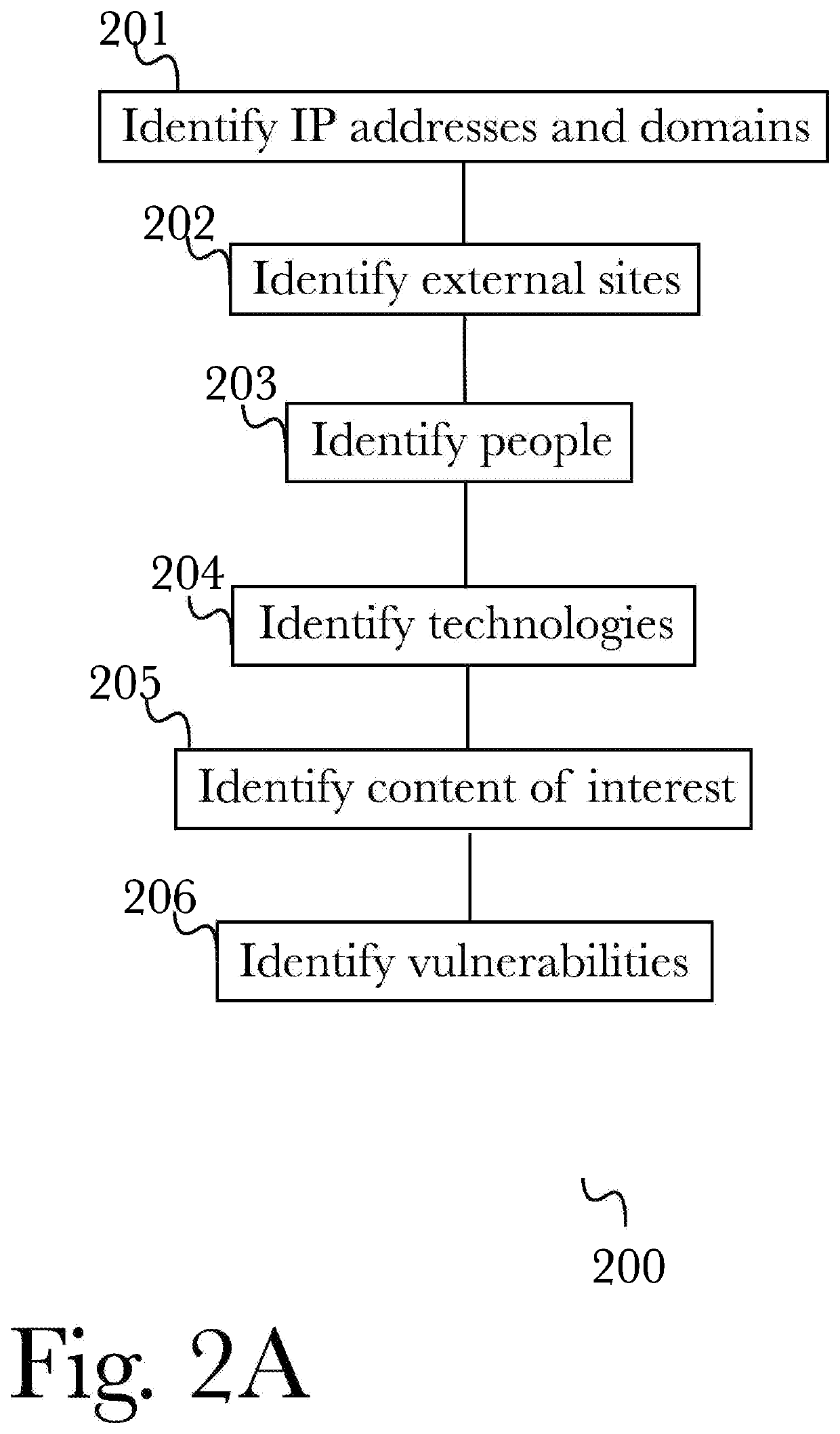

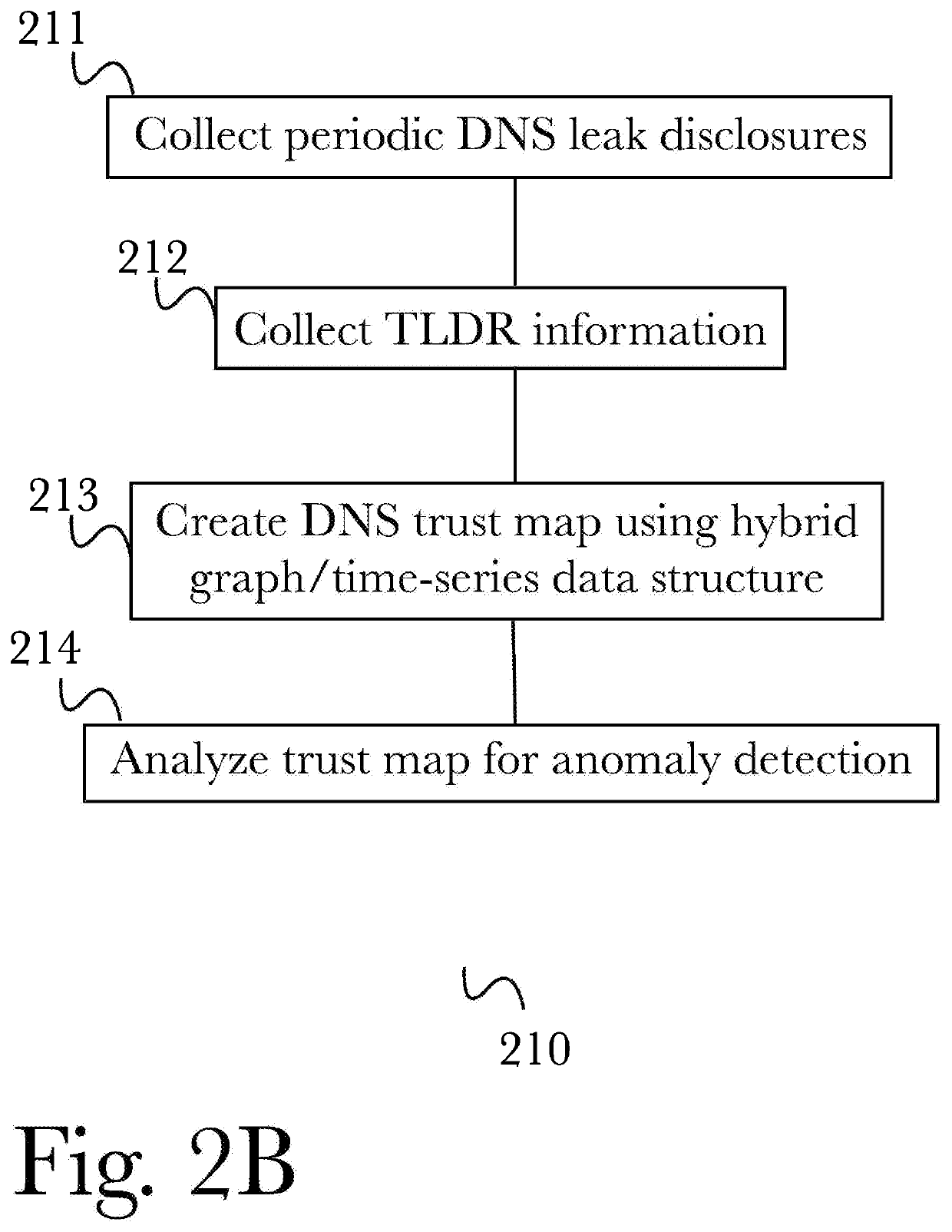

Parametric analysis of integrated operational technology systems and information technology systems

A system and method for analyzing integrated operational technology and information technology systems with sufficient granularity to predict their behavior with a high degree of accuracy. The system and method involve creating high-fidelity models of the operational technology and information technology systems using one or more cyber-physical graphs, performing parametric analyses of the models to identify key components, scaling the parametric analyses of the models to analyze the key components at a greater level of granularity, and iteratively improving the models testing them against in-situ data from the real-world systems represented by the high-fidelity models.

Owner:QOMPLX INC

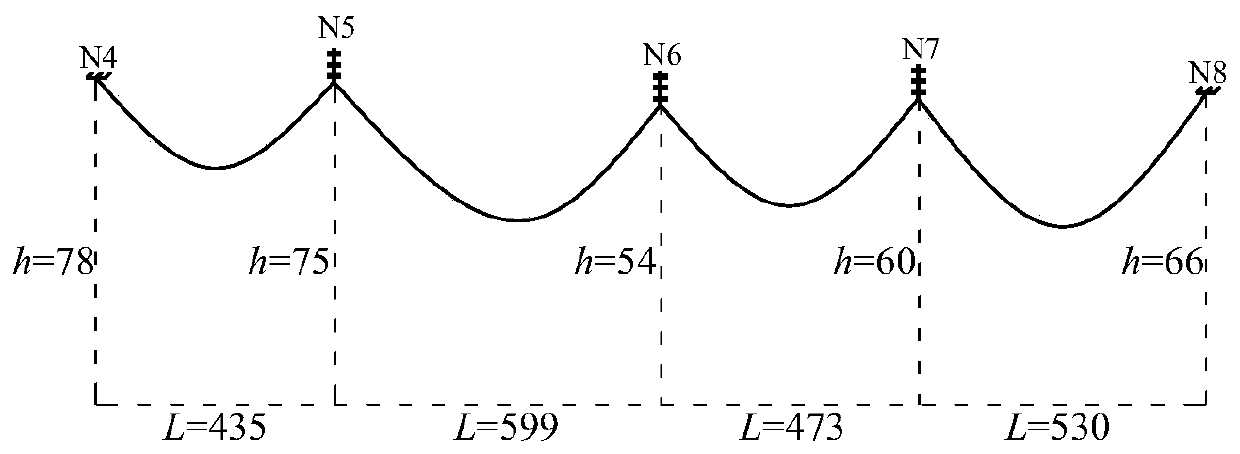

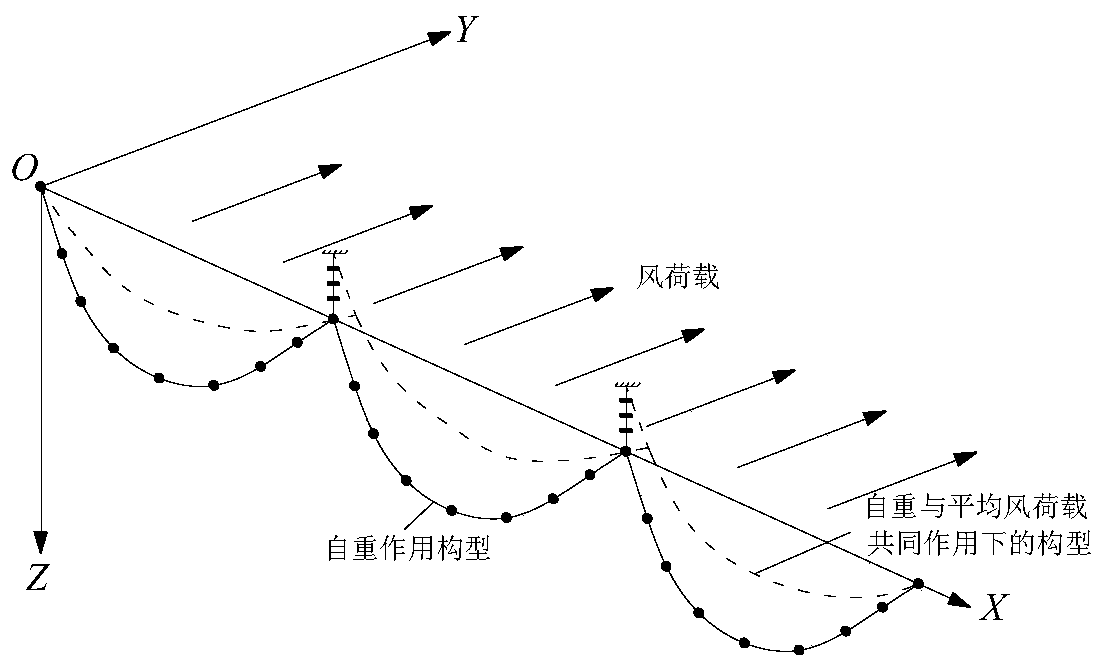

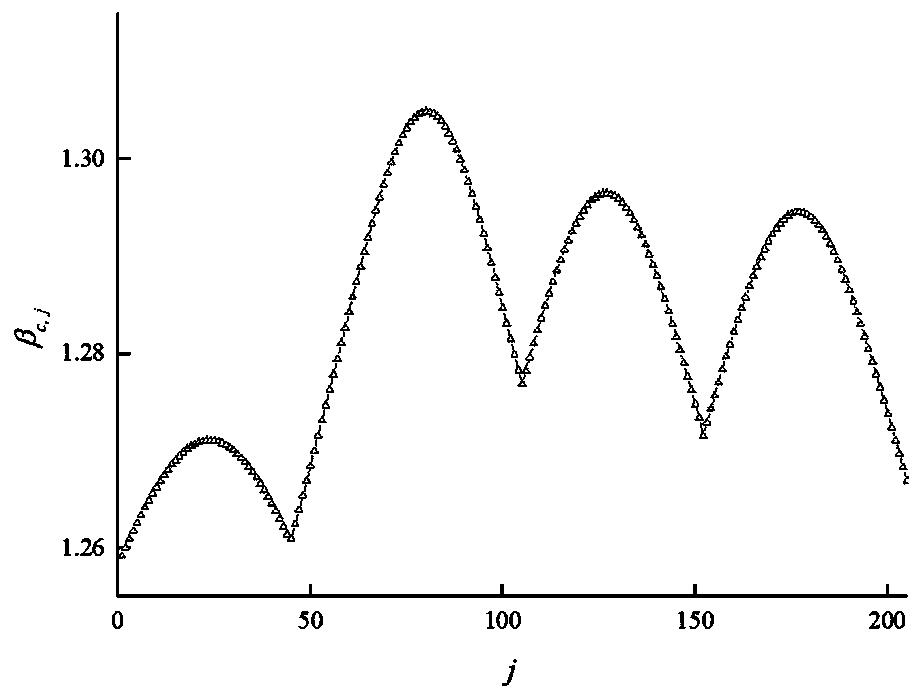

A simplified calculation method for dynamic windage yaw of an iced conductor

InactiveCN109902351AAccurately account for pulsation effectsDoes not increase the amount of calculationSpecial data processing applicationsTime domainCalculation error

The invention discloses a simplified calculation method for dynamic windage yaw of an iced conductor. The simplified calculation method comprises the following steps: solving an equivalent static windload of the iced conductor based on a gust load envelope line method (GLE); instroducing A height difference correction coefficient, so that the problem that a rigid straight rod method is inaccuratein gravity load estimation when the height difference of a line hanging point is large is solved; Taking the circular-section ice-coated wire as an example, carrying out verification and parametric analysis on the effectiveness of the simplified calculation method by adopting a time domain method to obtain a change rule of the windage yaw angle of the ice-coated wire along with wind speed, ice coating density and ice coating thickness. According to the calculation method, the pulsation effect of the wind load can be accurately considered, excessive calculated amount cannot be increased, calculation errors of the gravity load of the wire caused by large height difference of line hanging points are avoided, and the calculation method is suitable for batch analysis of multiple parameters such as the icing shape, density, thickness and aerodynamic coefficient of the wire.

Owner:ZHEJIANG UNIV

Method for tracking of contrast enhacement pattern for pharmacokinetic and parametric analysis in fast-enhancing tissues using high -resolution mri

A method for performing a high-resolution pharmacokinetic analysis for calculation of tissue parameters for a fast-enhancing tissue enables medical personnel to accurately determine pharmacokinetic parameters in fast-enhancing tissues. The method includes obtaining mask image data of the tissue when it is in a steady state condition, obtaining a time series of image data of the tissue when the contrast agent is flowing in the tissue, and increasing a spatial resolution of the time series of image data using the mask image data to obtain a time series of increased spatial resolution image data. The method further includes performing a pharmacokinetic analysis to obtain data including at least one parameter that characterizes the tissue, providing a multi-parameter look-up table derived from a combination of two or more parameters, and providing a display including one parameter or a parametric image, where the parametric image is derived from the look-up table.

Owner:KONINKLJIJKE PHILIPS NV

Parametric analysis of media metadata

Owner:AT&T INTPROP I LP

Systems and methods for testing and diagnosing delay faults and for parametric testing in digital circuits

InactiveUS7917319B2Noise figure or signal-to-noise ratio measurementElectronic circuit testingCircuit delayDigital electronics

Delay-fault testing and parametric analysis systems and methods utilizing one or more variable delay time-base generators. In embodiments of the delay-fault testing systems, short-delay logic paths are provided with additional scan-chain memory elements and logic that, in conjunction with the one or more variable-delay time-base generators, provides the effect of over-clocking without the need to over-clock. Related methods provide such effective over-clocking. In embodiments of parametric analysis systems, test point sampling elements and analysis circuitry are clocked as a function of the output of the one or more variable-delay time-base generators to provide various parametric analysis functionality. Related methods address this functionality.

Owner:DFT MICROSYST

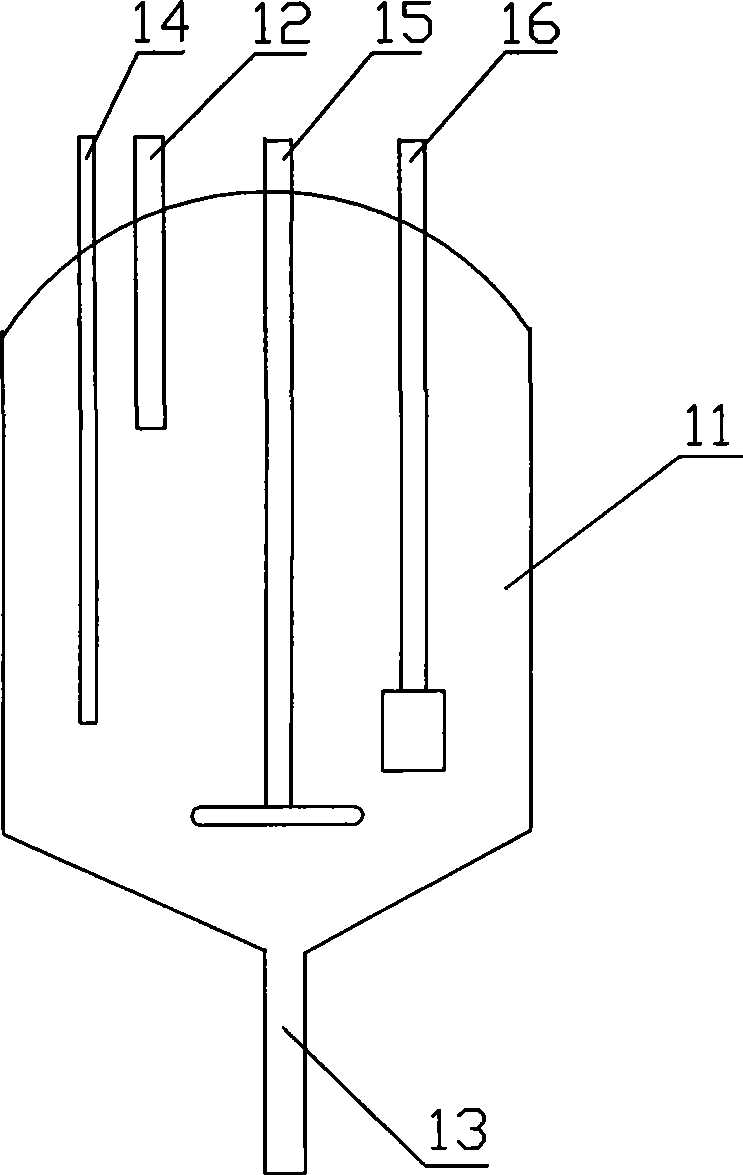

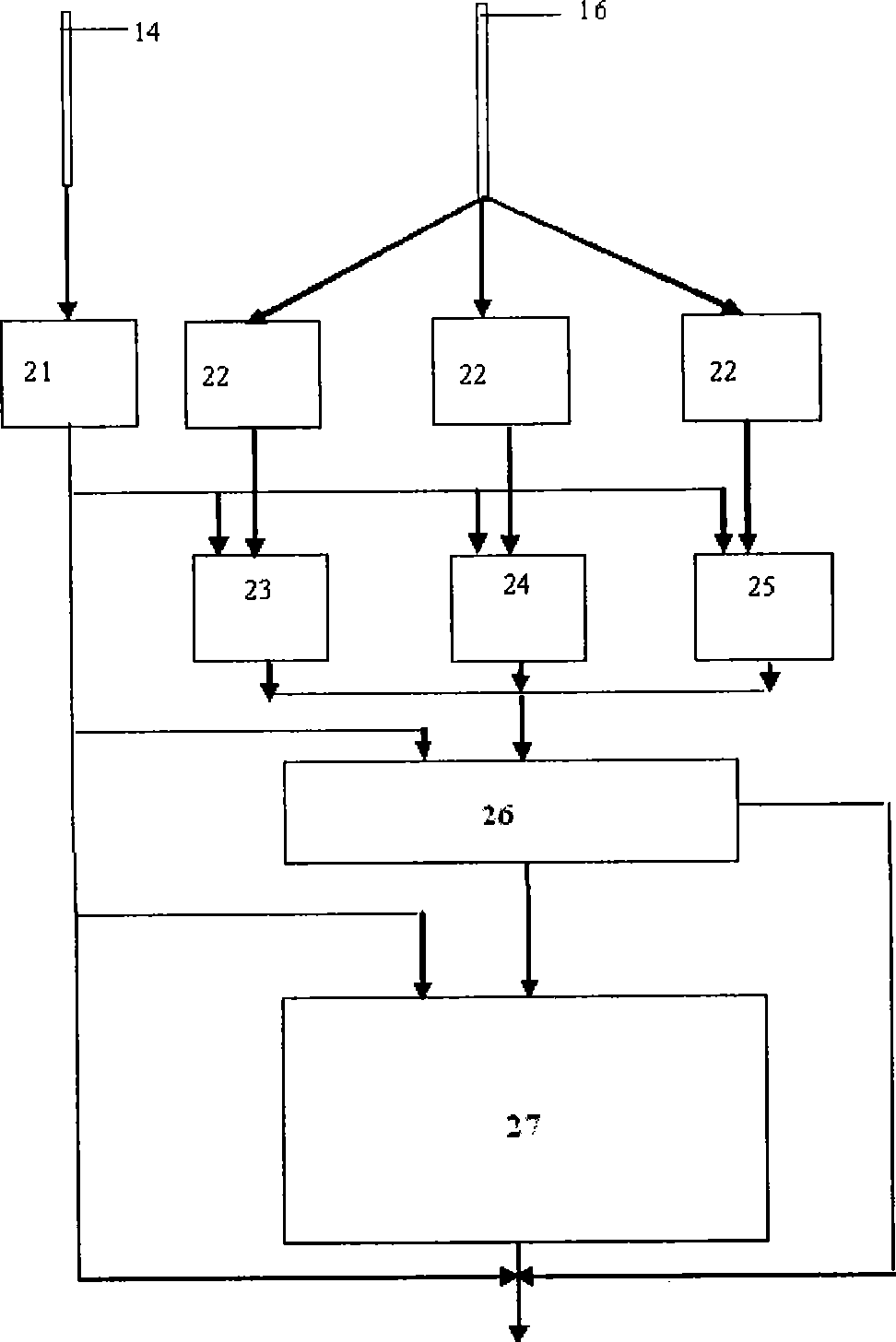

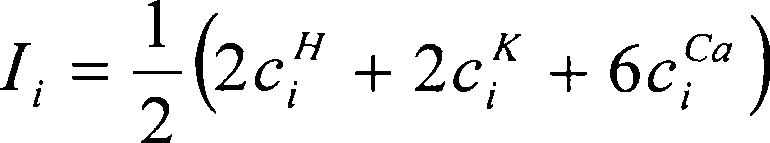

Substance surface property parametric analysis system

The invention discloses a system for analyzing material surface property parameters. The system can determine surface electric potential of materials accurately. A determining system comprises a sample processing device and a detection system, wherein the sample processing device comprises a sample accommodation device which is used for accommodating the determined materials and liquid, is also provided with a liquid inlet pipe and a liquid outlet pipe which are communicated with the sample accommodation device, wherein the liquid outlet pipe is connected with a constant flow pump, and the sample accommodation device is also provided with a stirring device; the detection system comprises an ionic activity detecting device, an ionic activity operating module and a surface parameter operating module, and the surface parameter operating module is used for receiving the ionic activity operated by the ionic activity operating module so as to work out the surface potential of the determined materials; and in a further technical proposal, total surface charge quantity, surface charge density, surface electric field intensity and specific surface area of the determined materials can be analyzed sequentially so as to realize the combined analysis of the material surface property parameter.

Owner:重庆为讯科学仪器有限责任公司

Coupled parametric design of flow control and duct shape

InactiveUS7610179B2Shorten the lengthLarge offsetBlade accessoriesGas turbine plantsEngineeringActuator

A method for designing gas turbine engine components using a coupled parametric analysis of part geometry and flow control is disclosed. Included are the steps of parametrically defining the geometry of the duct wall shape, parametrically defining one or more flow control actuators in the duct wall, measuring a plurality of performance parameters or metrics (e.g., flow characteristics) of the duct and comparing the results of the measurement with desired or target parameters, and selecting the optimal duct geometry and flow control for at least a portion of the duct, the selection process including evaluating the plurality of performance metrics in a pareto analysis. The use of this method in the design of inter-turbine transition ducts, serpentine ducts, inlets, diffusers, and similar components provides a design which reduces pressure losses and flow profile distortions.

Owner:RTX CORP +1

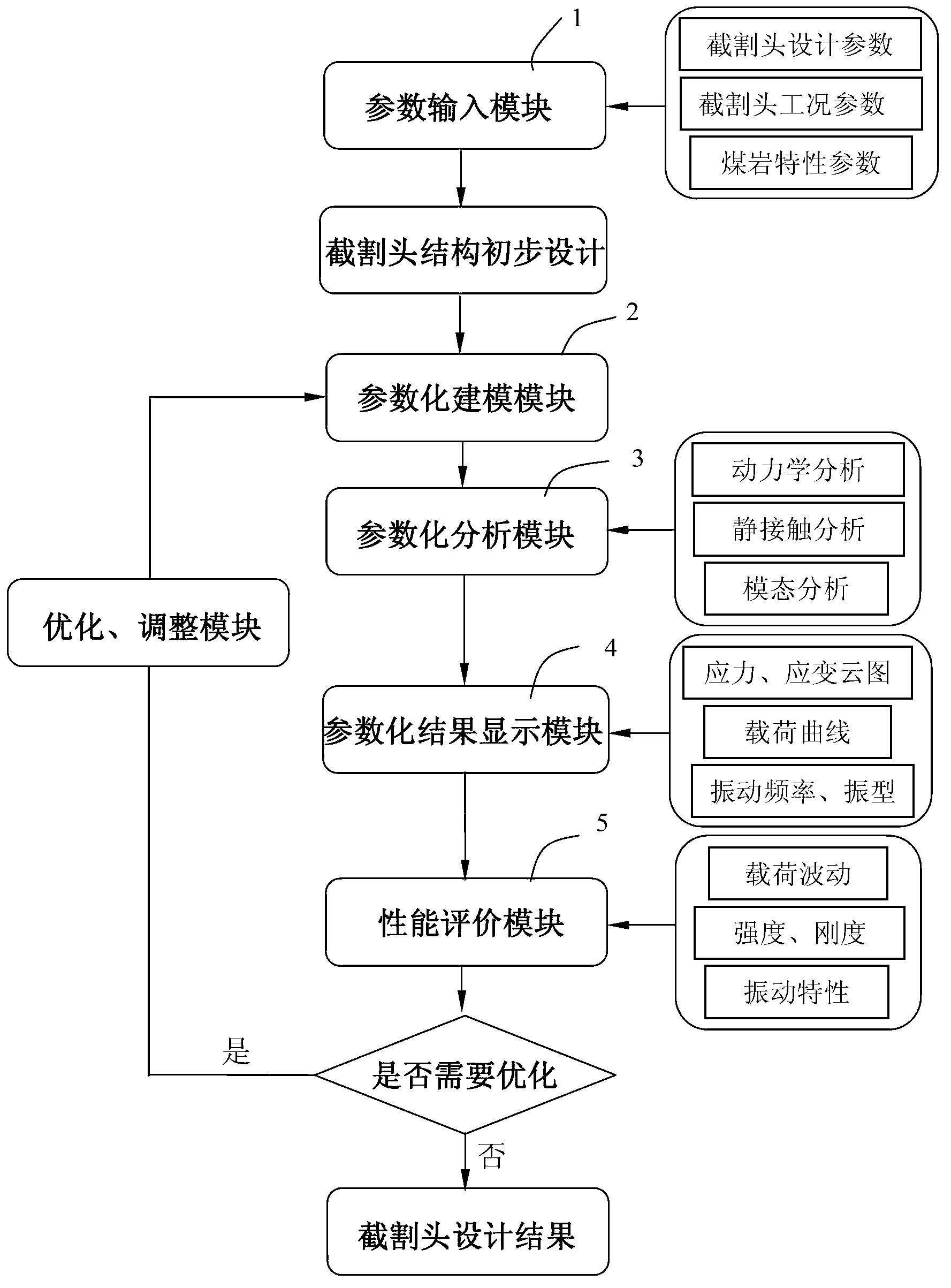

Computer-aided design method for cantilever-type heading machine cutting head and CAD (computer-aided design) system of cantilever-type heading machine cutting head

InactiveCN103324800AAchieve structural optimizationImprove the level ofSpecial data processing applicationsComputer Aided DesignElement analysis

The invention discloses a computer-aided design method for a cantilever-type heading machine cutting head and a CAD (computer-aided design) system of the cantilever-type heading machine. Based on Visual C++ 2012, ANSYS14.5 is subjected to secondary development by the computer-aided design method which comprises following modules: a parameter input module, a parametric modeling module, a parametric analysis module, a parametric result displaying module, a performance evaluation module and an optimization and adjustment module; the computer-aided design method includes that a designer enters cutting head design parameters, cutting head condition parameters and coal and rock characteristic parameters, a system can automatically complete modeling and finite element analysis processes, and feedback analysis result files for the designer to perform optimization and adjustment of design parameters. Design of the cantilever-type cutting head under different coal and rock geological conditions and cutting conditions can be realized; performance of the cutting head can be predicted by simulating a cutting process by the aid of the finite element analysis, so that structure optimization of the cutting head can be realized according to analysis results, and level of cutting head design is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

Parametric Analysis of Media Metadata

A method is disclosed that includes receiving, from a device of a user, a request to transmit a multimedia file. The method also includes automatically generating a generated content descriptor based on an analysis of the multimedia file using at least one analysis parameter. The method includes determining whether the generated content descriptor satisfies filter criteria of a profile associated with the user. The method further includes rejecting the request to transmit the multimedia file when the generated content descriptor does not satisfy the filter criteria of the profile. The method includes transmitting the multimedia file along with the generated content descriptor when the generated content descriptor satisfies the filter criteria of the profile.

Owner:AT&T INTPROP I LP

After-package test parametric analysis method

InactiveCN1521823AReduce manufacturing costImprove processing efficiencySemiconductor/solid-state device testing/measurementElectronic circuit testingSoftware engineeringAnalysis method

A parametric analysis method after package comprises the steps of, searching the data base to obtain the test parameter value after package for each batch of the products, comparing these parameter values, choosing representative parameter value and items, determining whether the test items relates to the packing station, if the result is relevant, dividing the products into at least a first acceptable product group and a first disqualified product group, searching for machine benches where the first acceptable product group passes during the process, searching for machine benches where the first disqualified product group passes during the process, determining the machine bench in which the passing probability of the first disqualified product set is higher than that of the first accepted product set.

Owner:POWERCHIP SEMICON CORP

Automated methods for pre-selection of voxels and implementation of pharmacokinetic and parametric analysis for dynamic contrast enhanced MRI and CT

A method, system and computer-readable medium of filtering noise pixels and other extraneous data, including saturated fat tissue and air data in image data is provided. Examples of image data may include but are not limited to magnetic resonance imaging data and computed tomography data. The method includes receiving pixel count for each signal intensity value of the image data; determining a signal intensity value, Ipeak, corresponding to a pixel count of a greatest number of pixels, Npeak; setting a noise threshold at a signal intensity value, Inoise, corresponding to a pixel count, NI, such that NI is determined based on Npeak; and filtering from the image data one or more pixels with signal intensity values below the noise threshold. NI may be determined such that NI=Npeak / 3 or close to Npeak / 3.

Owner:KONINKLJIJKE PHILIPS NV

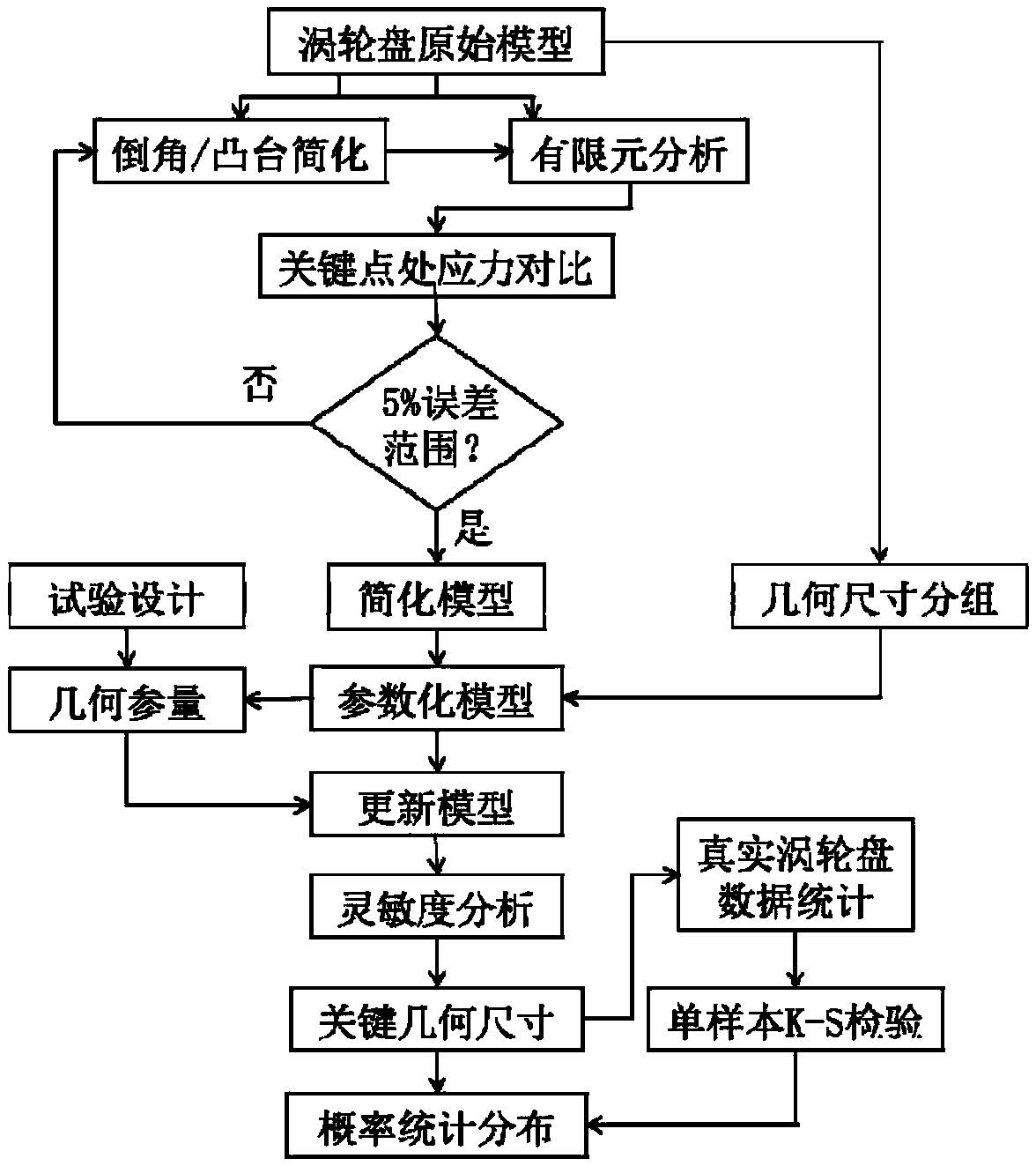

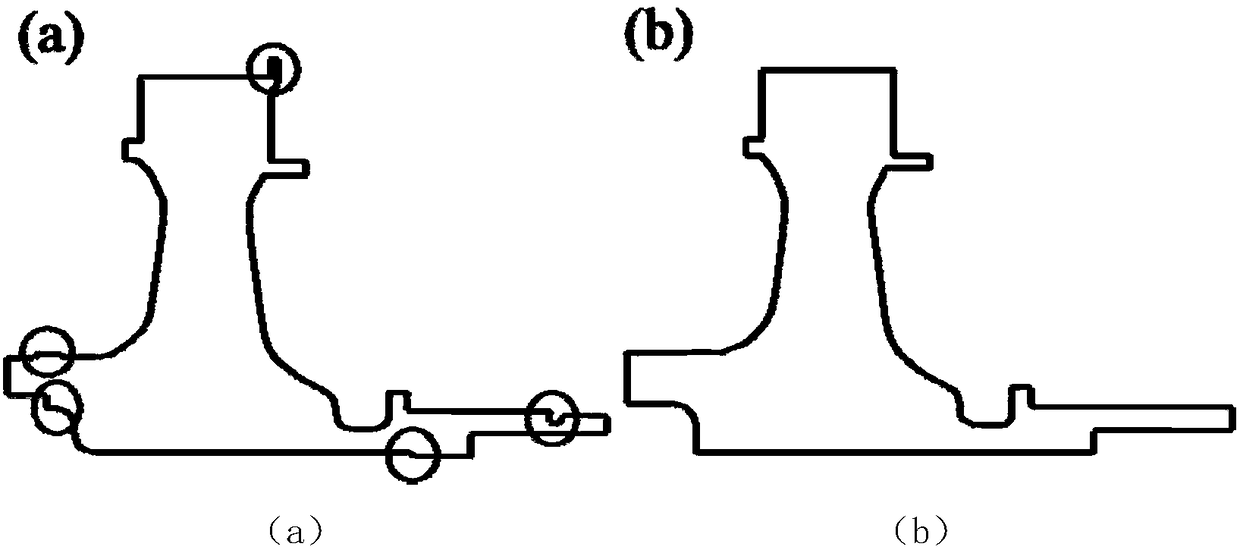

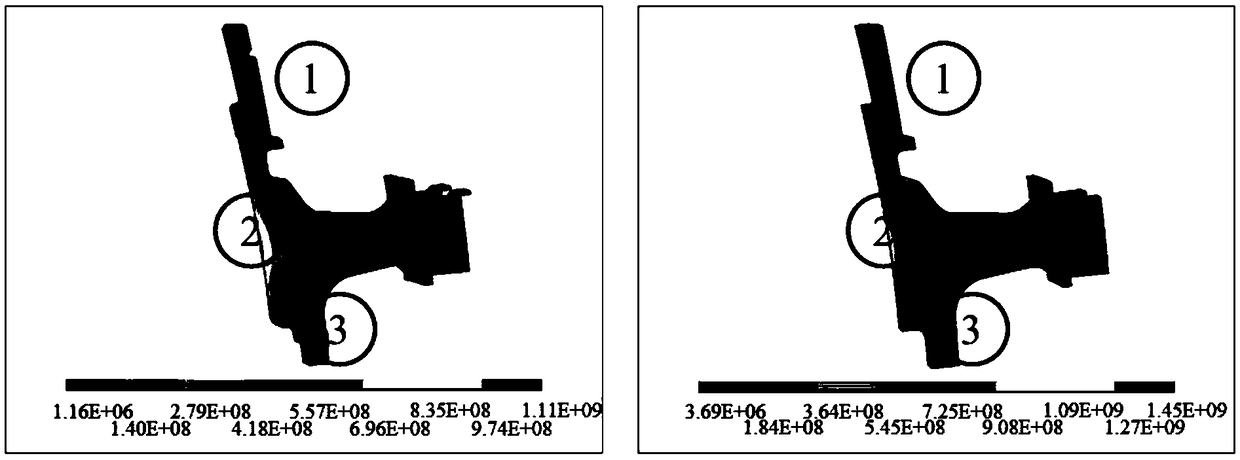

Geometric size probability statistics characteristic analysis method used in turbine disc probability reliability analysis

ActiveCN108920836AImprove computing efficiencyGuaranteed Stress ErrorGeometric CADDesign optimisation/simulationComputation processModel parameters

The invention relates to a geometric size probability statistics characteristic analysis method used in turbine disc probability reliability analysis. The geometric size probability statistics characteristic analysis method comprises the steps that a geometric model of a turbine disc is simplified, wherein a periodic sector is taken, and finite element calculation is performed according to periodic symmetric boundary conditions, and model simplification is performed in the calculation process; 2, parametric modeling of the model is performed, wherein geometrical fully-constrained parametric analysis is conducted on the simplified model to form a full-parametric model; 3, geometric dimensions are grouped, wherein parameters are divided into N groups during sensitivity calculation, and eachgroup includes about 10 parameters; 4, sensitivity analysis is performed, wherein an experiment design (DOE) method is adopted to conduct hypercube sampling on random geometric parameters, sensitivityanalysis is performed, and factors having the maximum counter stress influence are screened out; 5, dimension statistics and hypothesis testing are performed, wherein real turbine disc data is counted according to the screened key geometric dimensions, a single sample K-S checking method is utilized to check the distribution type of the key dimensions, and geometric size probability statistics distribution is obtained.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com