After-package test parametric analysis method

A technology of testing parameters and analysis methods, which is applied in the field of process parameter analysis, can solve problems such as increasing production costs, increasing pass rates, and frequent personnel changes, and achieves the effects of reducing production costs, increasing pass rates, and improving online production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

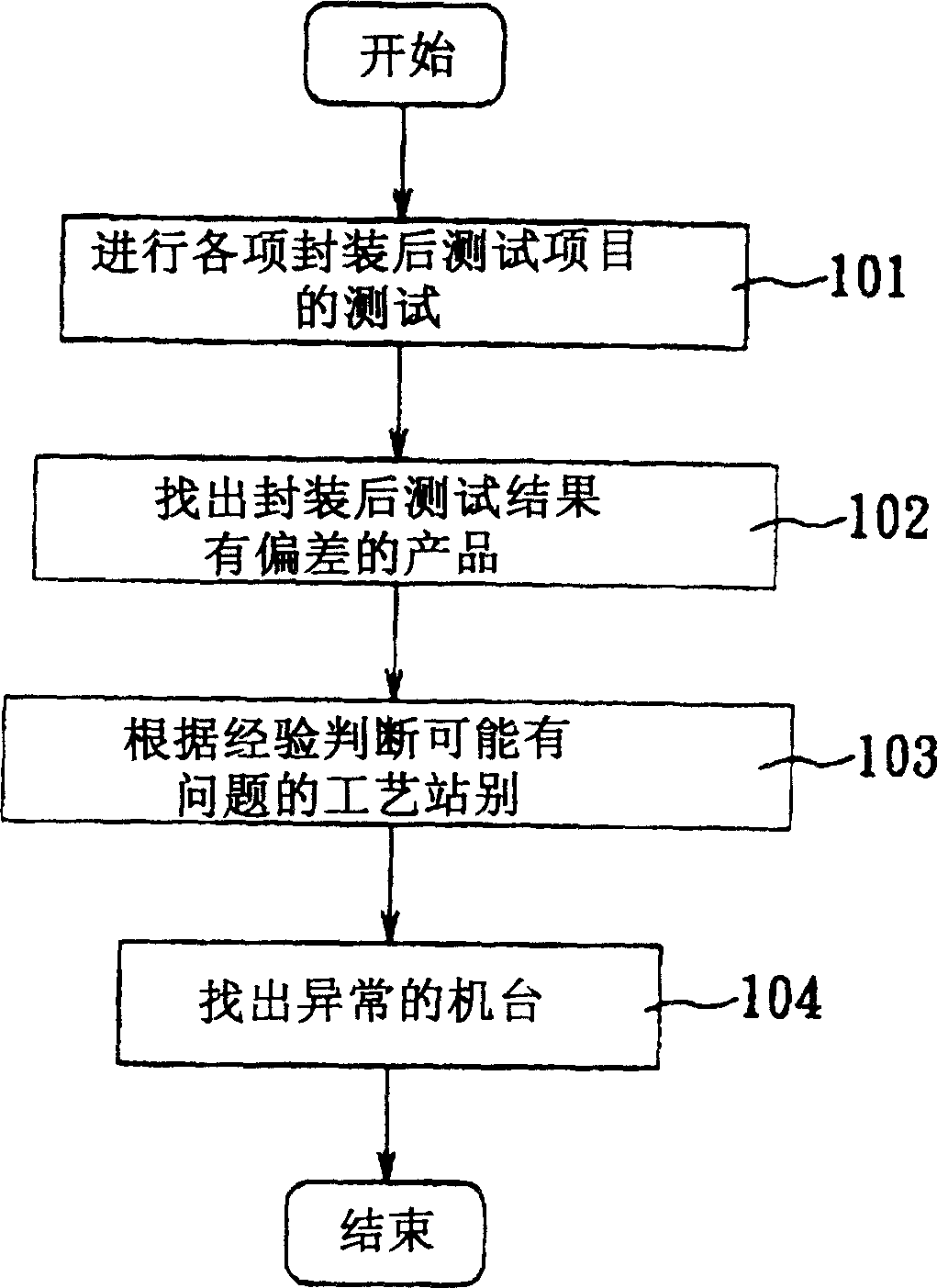

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

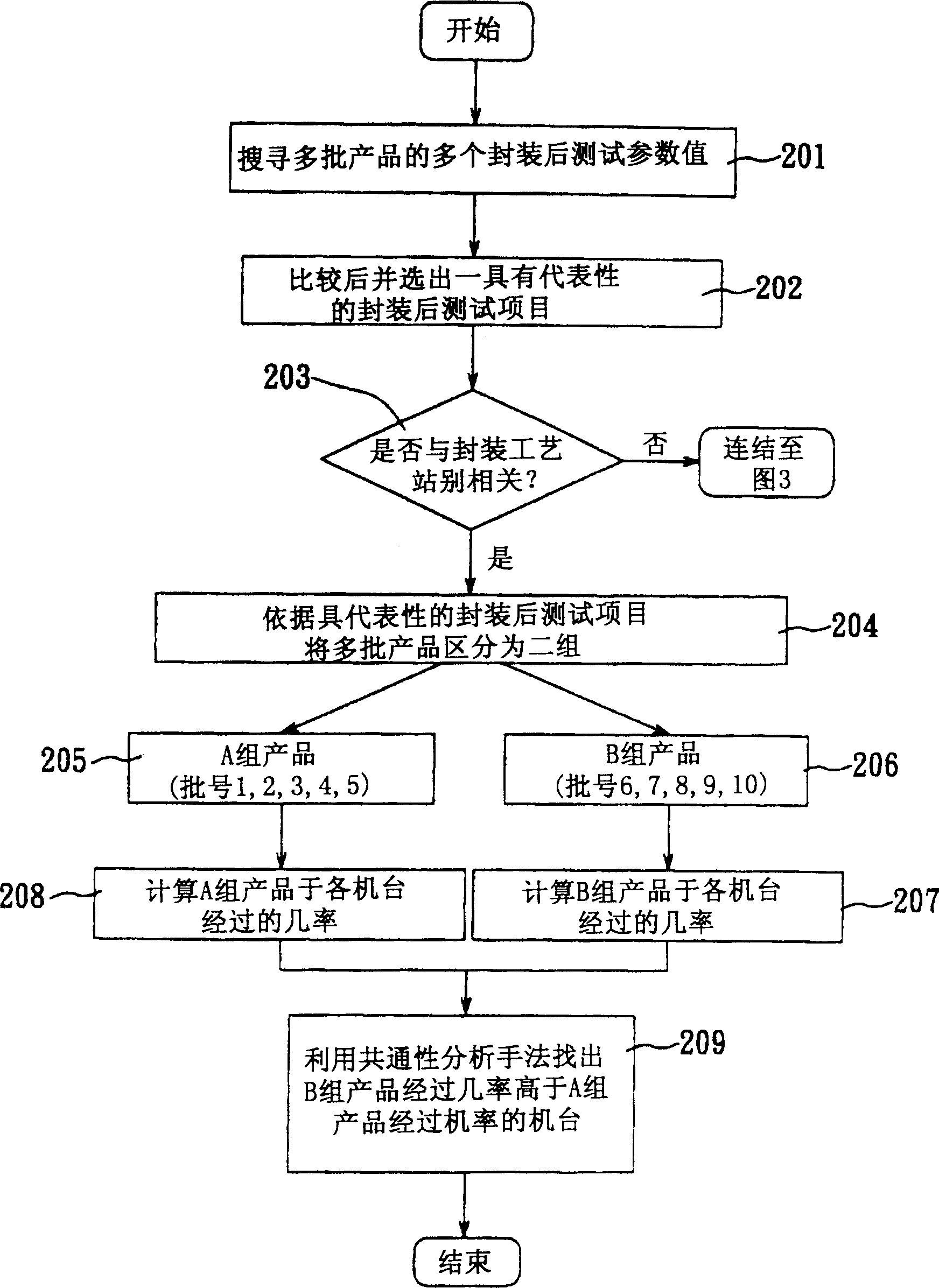

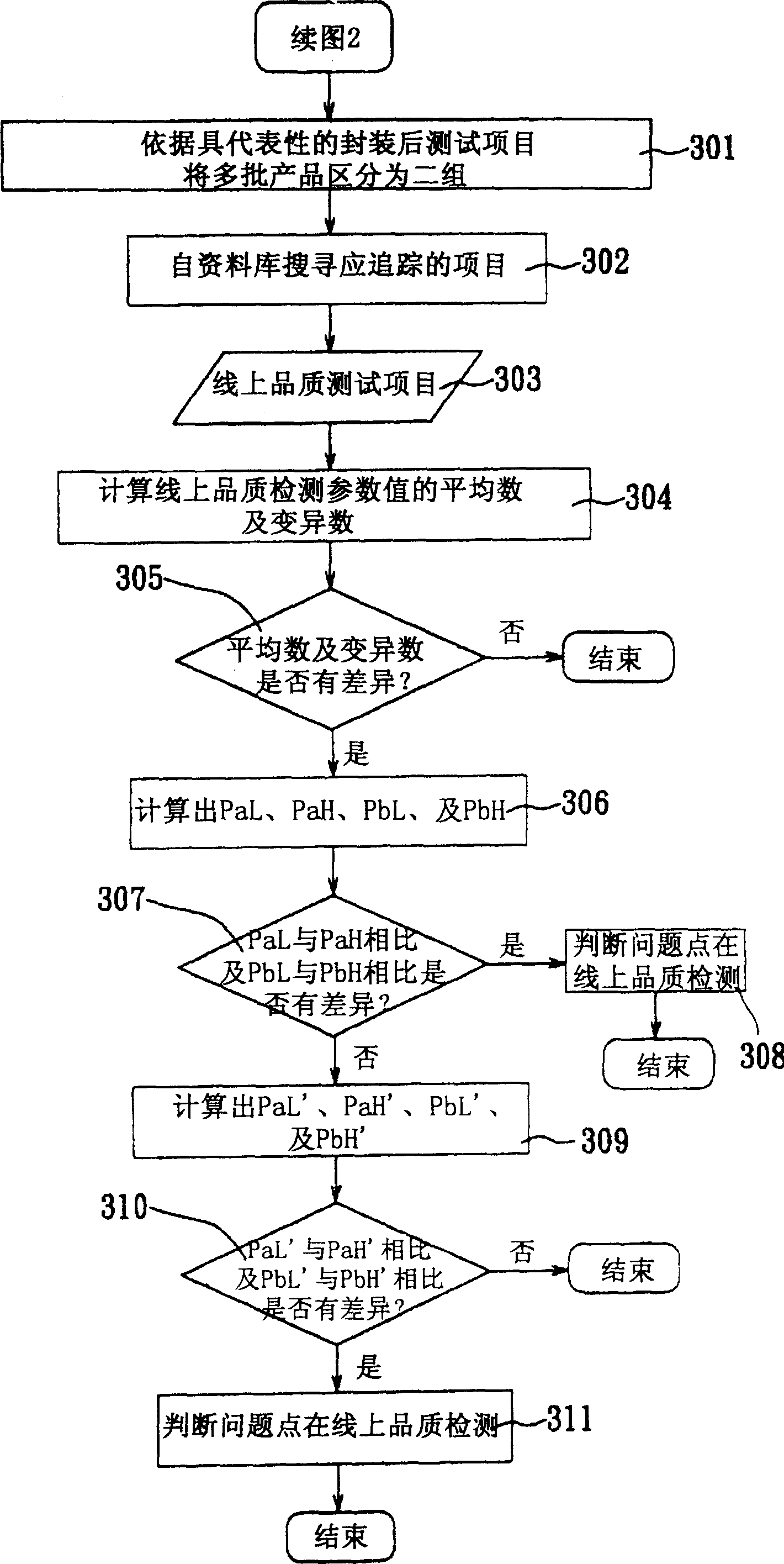

[0019] The post-package test parameter analysis method according to a preferred embodiment of the present invention will be described below with reference to related figures, wherein the same components will be described with the same reference symbols.

[0020] Such as figure 2 As shown, it shows the flow chart of the post-package test parameter analysis method of the preferred embodiment of the present invention. This embodiment can analyze and find out the problem packaging machine.

[0021] batch number

Project A

Project B

C project

Lot 1

20%

5%

6%

Lot 2

19%

7%

9%

Lot 3

23%

5%

7%

…

…

…

…

Lot n

22%

6%

8%

average

22%

6%

7%

[0022] The percentages shown here are the unqualified rates of each post-package test item for each batch number; in this step, the repr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com