Defect detecting parametric analysis method

A defect detection and parameter analysis technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as limited ability of engineers, increased production cost, frequent replacement, etc., to improve online production Situation, reduce production cost, improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

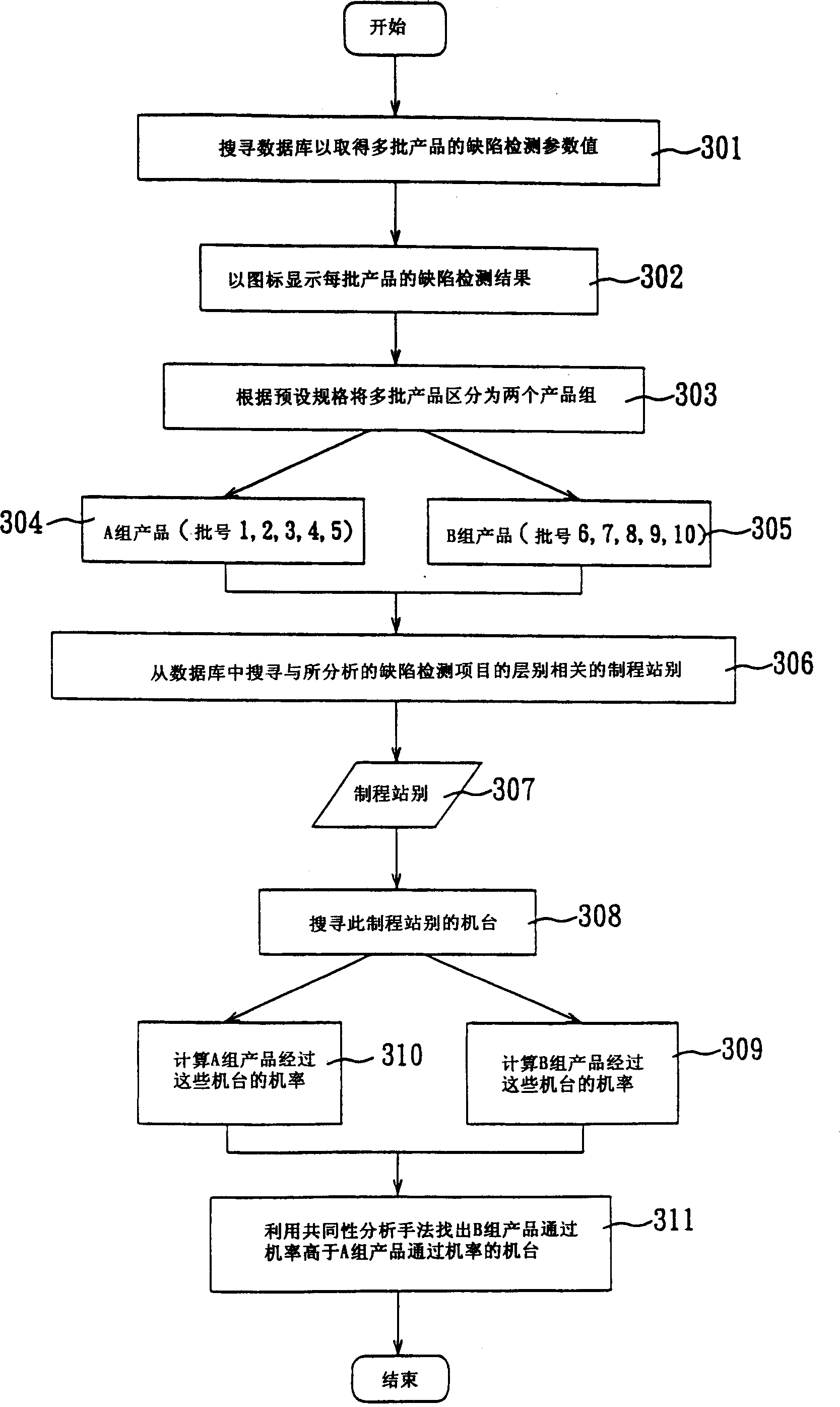

[0030] The defect detection parameter analysis method according to the preferred embodiment of the present invention will be described below with reference to the accompanying drawings, wherein the same components are represented by the same symbols.

[0031] Such as image 3 As shown, the figure shows the flow chart of the defect detection parameter analysis method of the preferred embodiment of the present invention, which is used to quickly and correctly determine which machine has a problem when the defect detection data of a semiconductor product is abnormal.

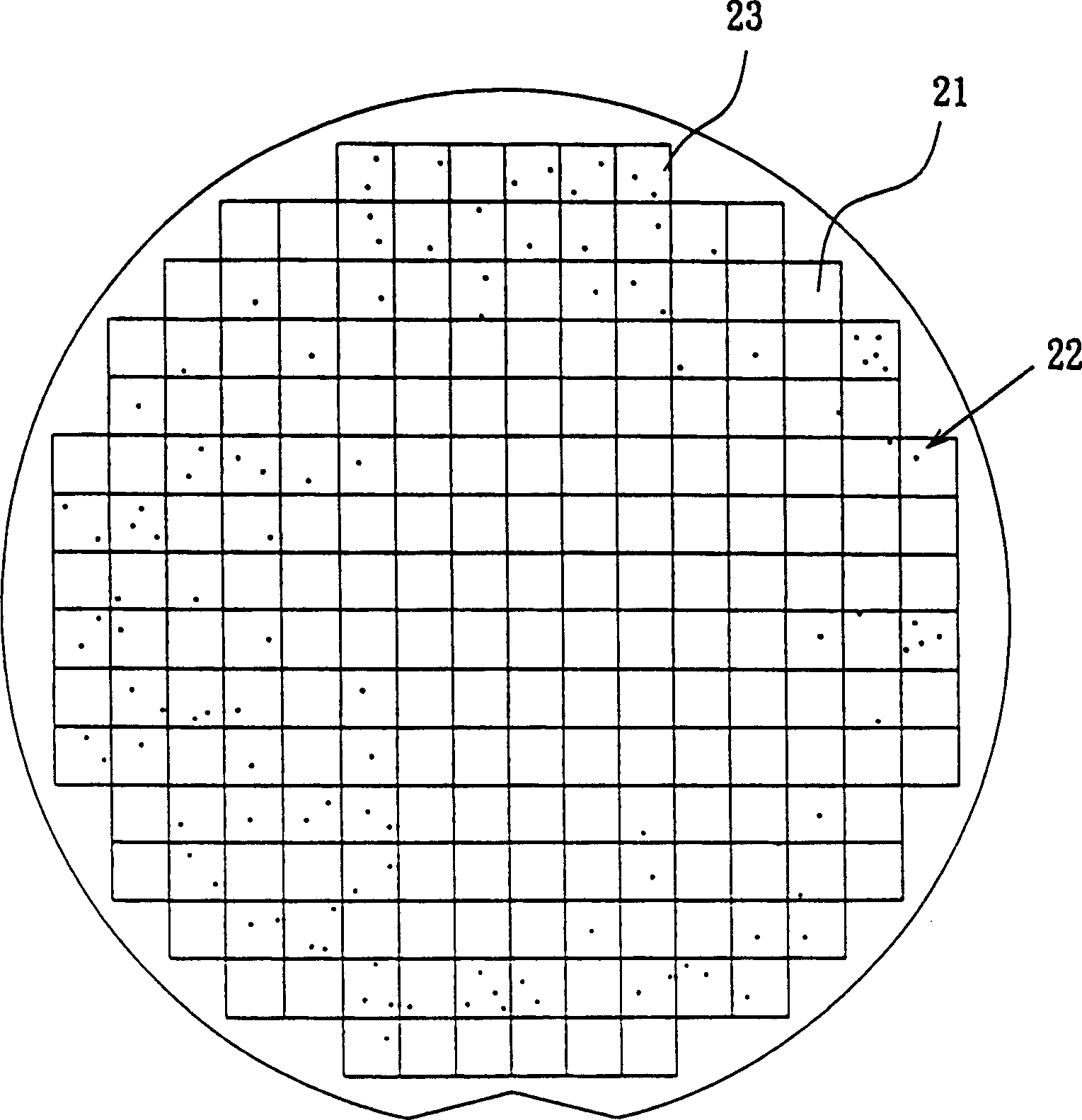

[0032] First, step 301 searches a database to obtain defect detection parameter values of multiple batches of products. Among them, each batch (lot) of products has a lot number (lot number), and each batch of products includes 25 wafers, and each batch of products passes through multiple machines with multiple processes, and one or more wafers in each batch of products of the wafers are inspected by at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com