Patents

Literature

98 results about "Lot number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lot number is an identification number assigned to a particular quantity or lot of material from a single manufacturer. Lot numbers can typically be found on the outside of packaging. For cars, a lot number is combined with a serial number to form the Vehicle Identification Number.

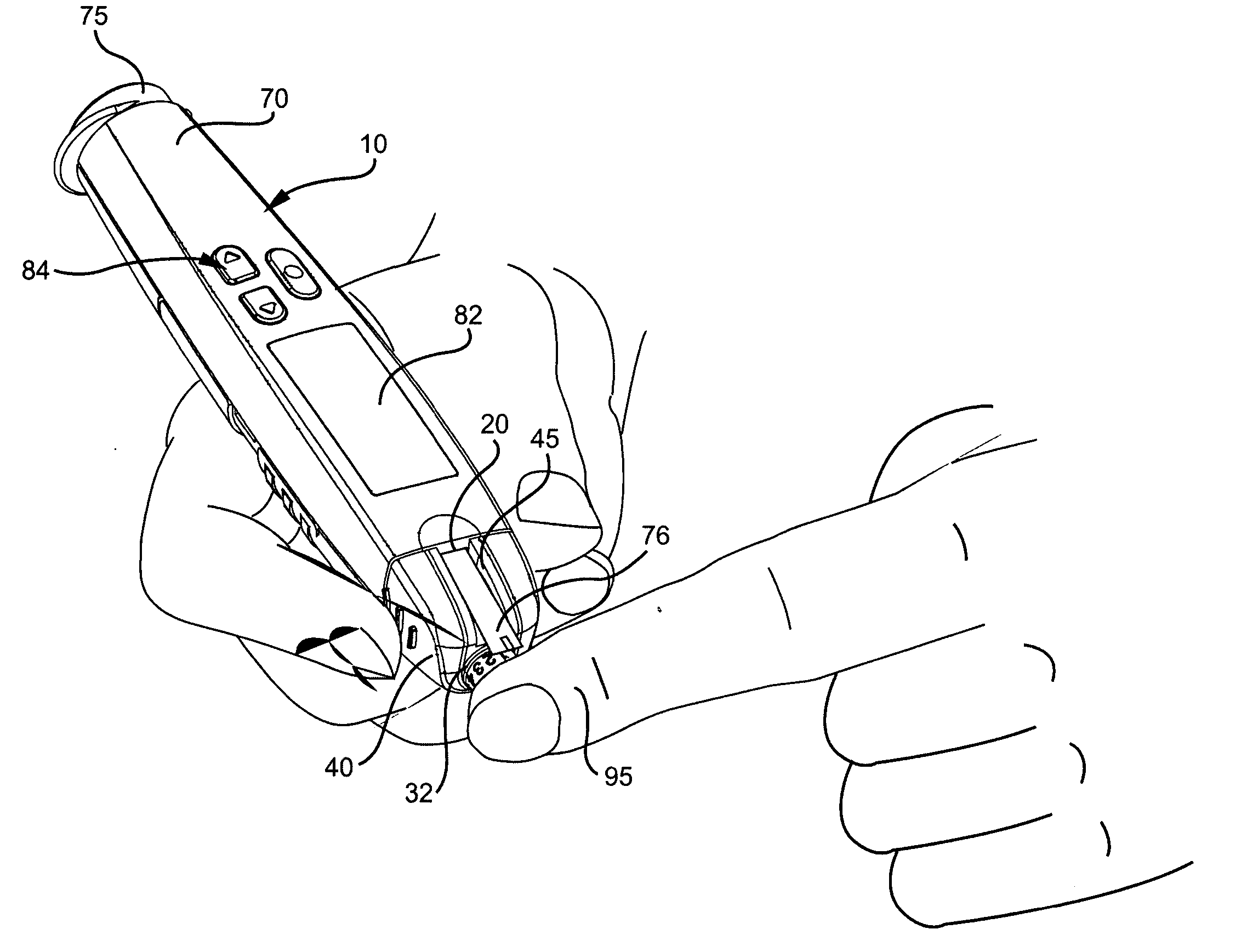

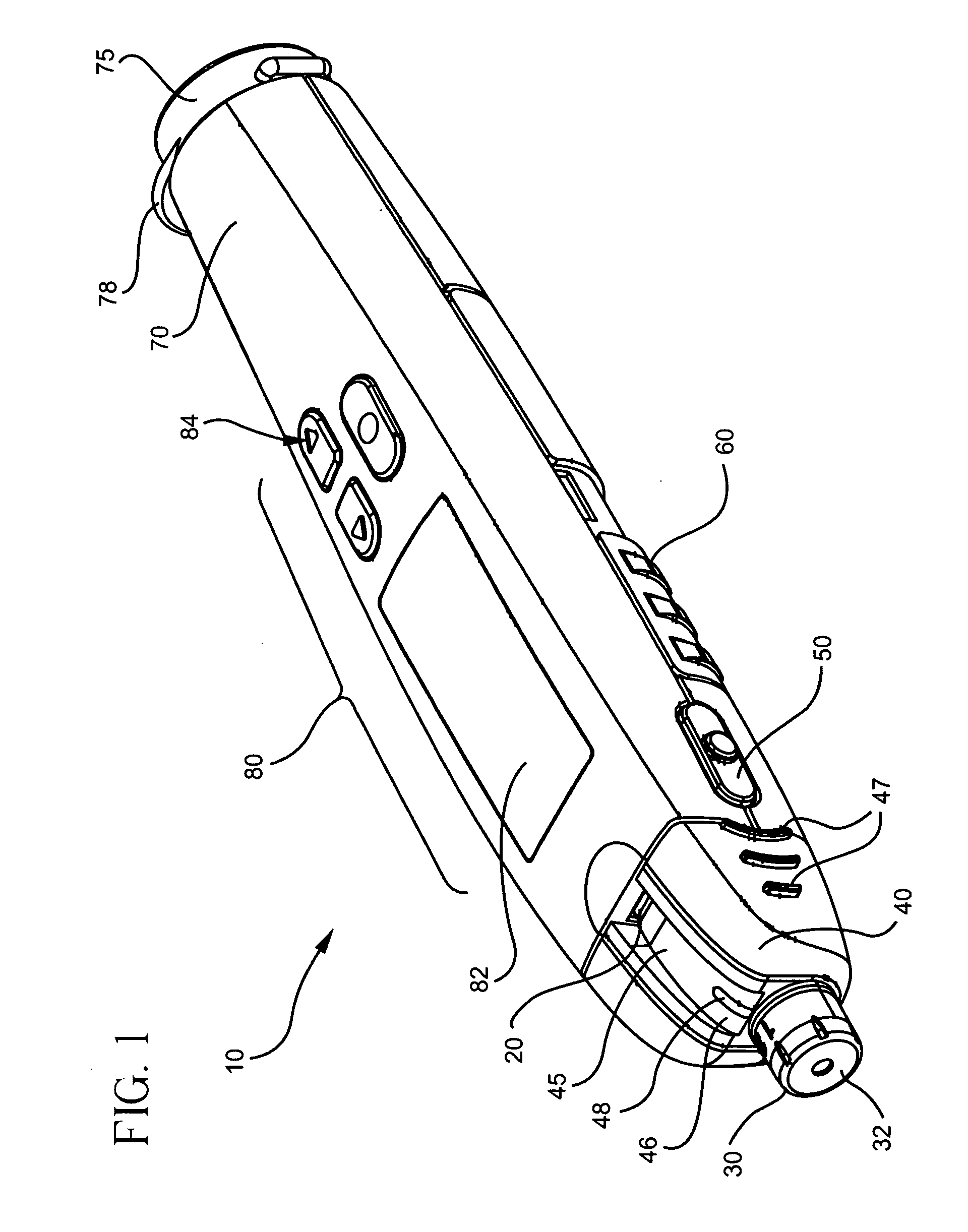

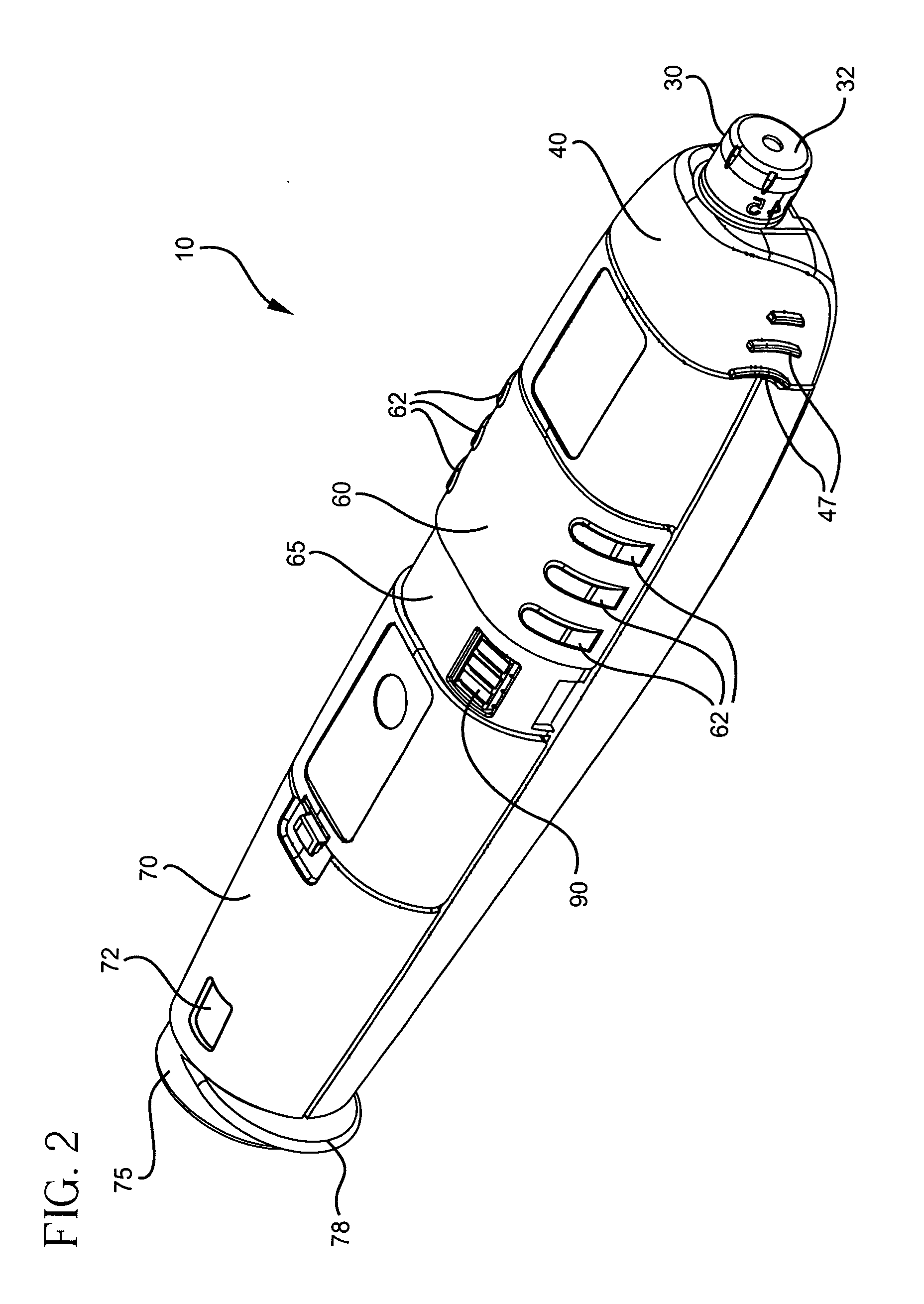

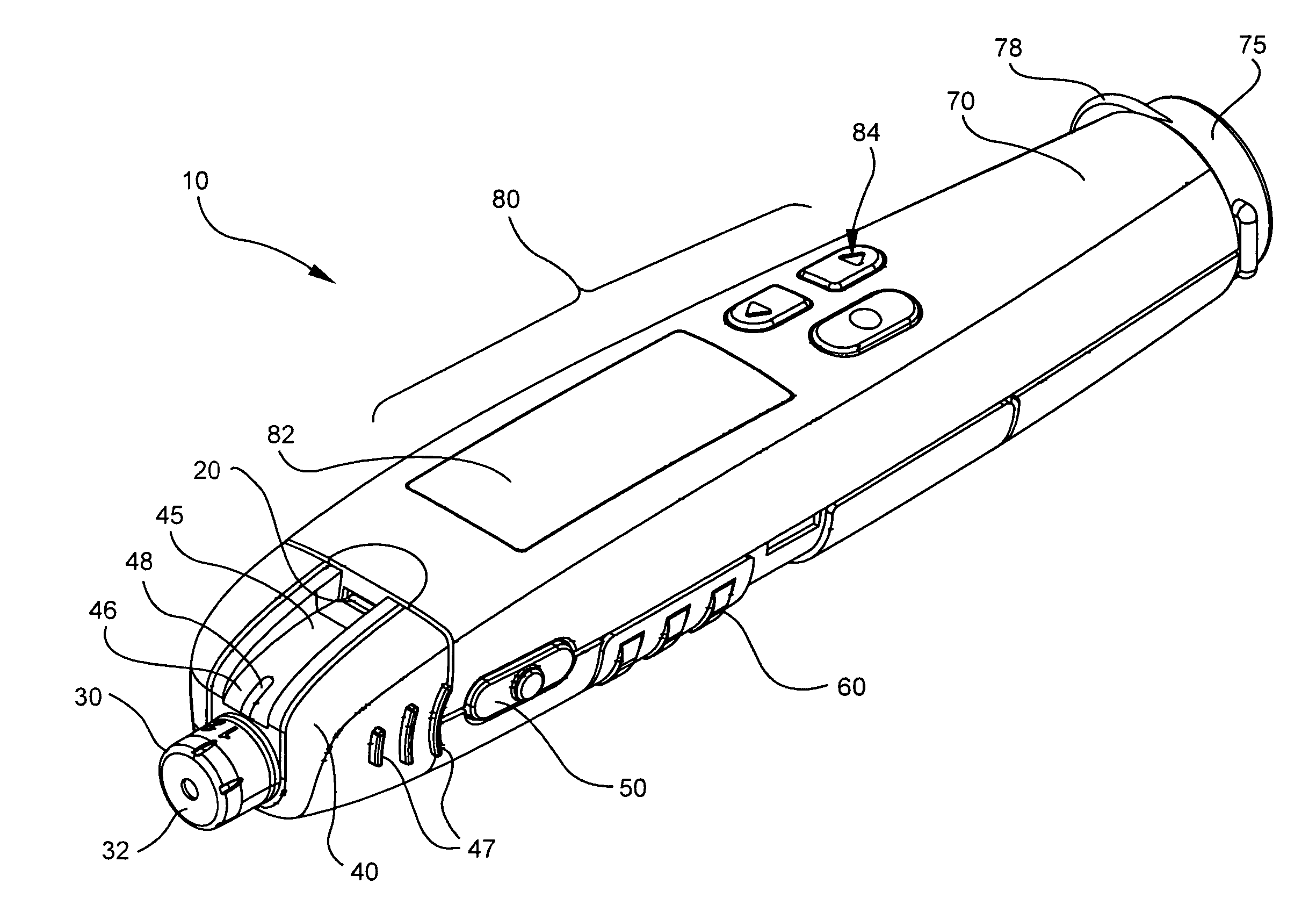

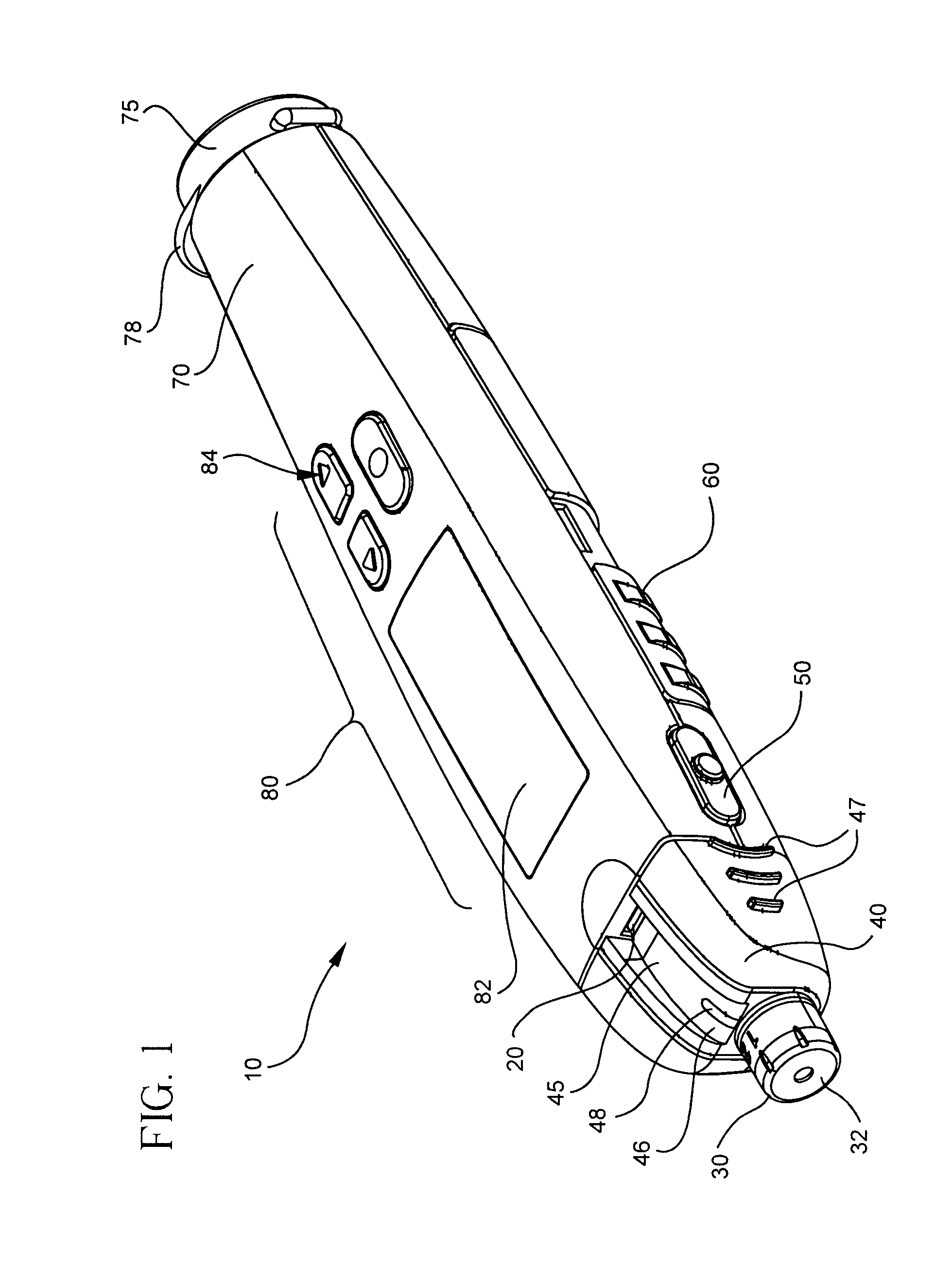

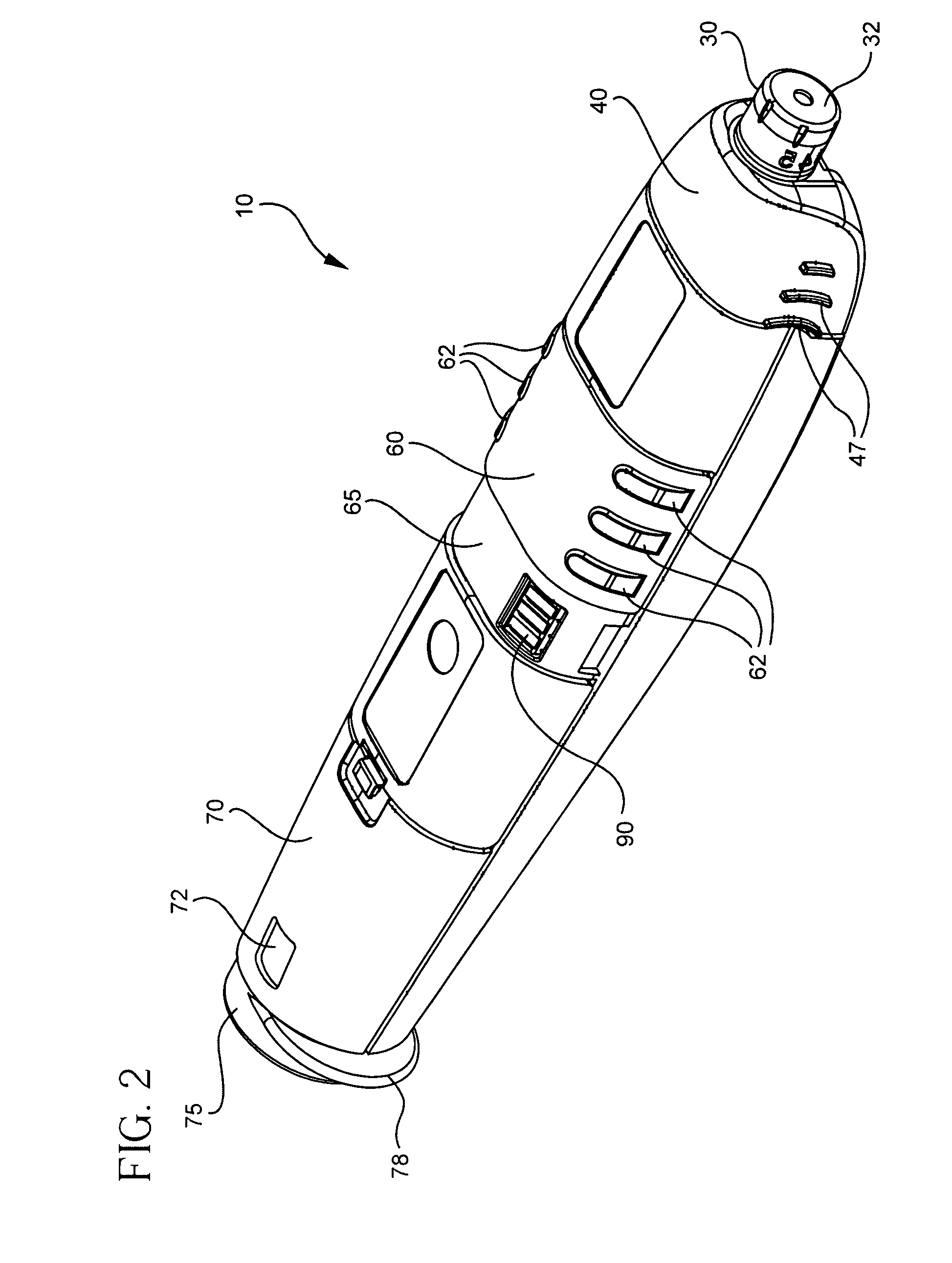

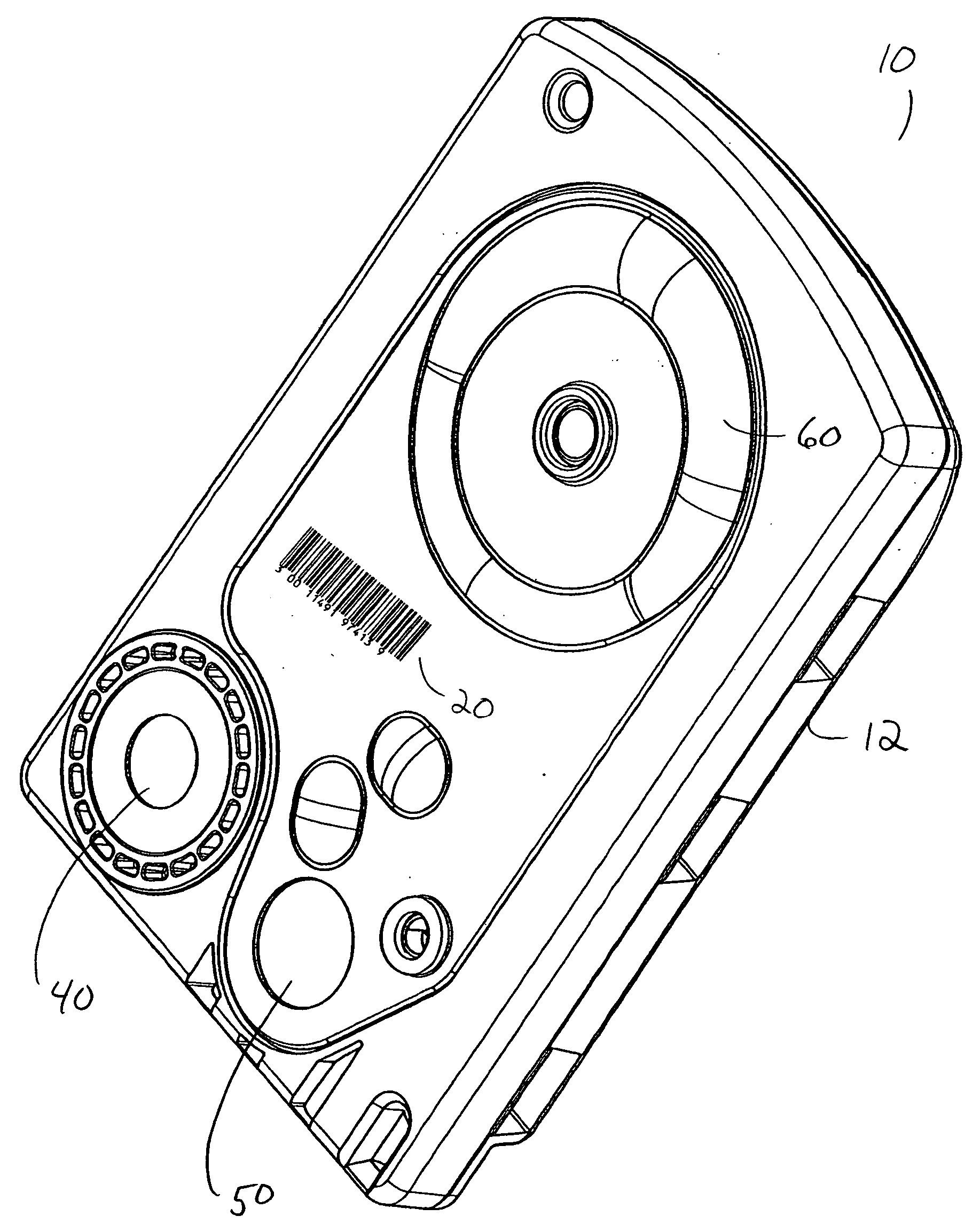

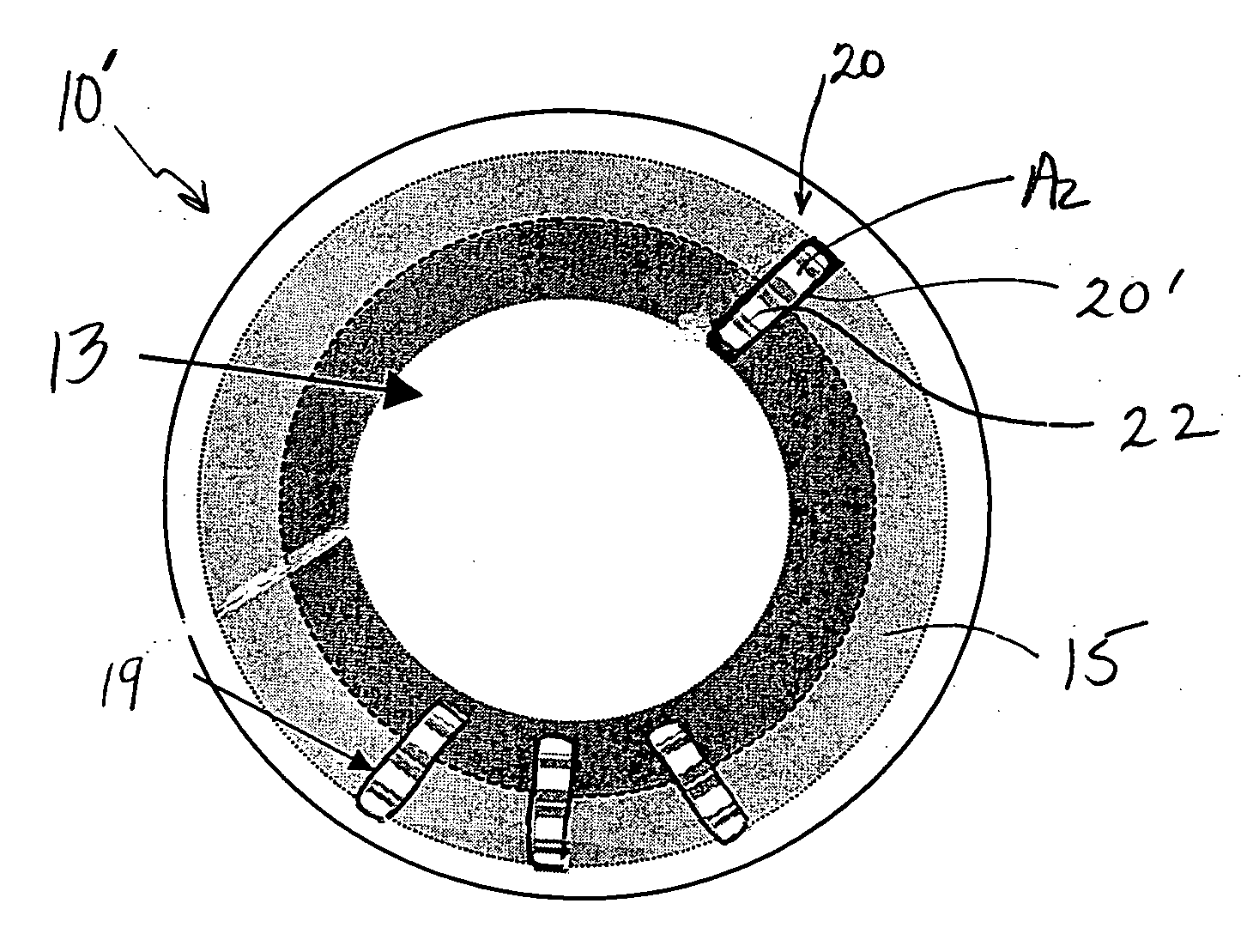

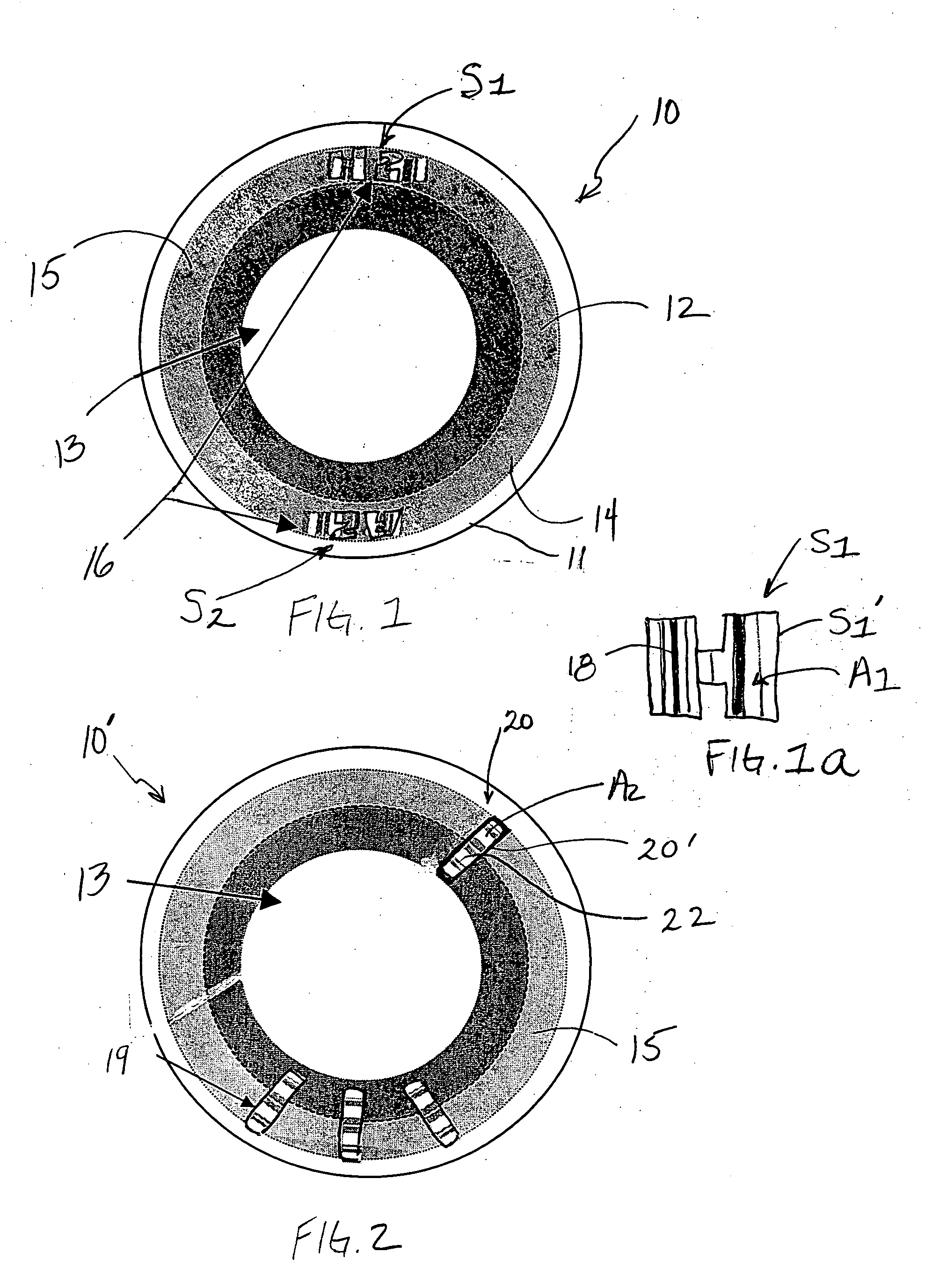

Blood glucose meter having integral lancet device and test strip storage vial for single handed use and methods for using same

InactiveUS20050240119A1Facilitates one-handed opening and closing of the vialEasy accessMicrobiological testing/measurementSensorsData connectionBlood glucose meters

A blood glucose meter having a test strip port and an adjustable lancet device disposed at the same end of the device body is disclosed. The device body further includes an enclosure at the proximal end of the device body which houses a test strip storage vial and which facilitates one-handed opening and closing of the vial to simplify access to test strips contained therein. The enclosure is further provided with a window which allows the reading of the lot numbers on the label of the test strip vial therein without necessitating removal of the vial. A data connector is also provided on the device body for communication access, such as to upload data from other devices or to download data to other devices. By combining these multiple components into a single device body, the blood glucose meter requires fewer steps for sampling and testing, and makes device use easier and more convenient.

Owner:BECTON DICKINSON & CO

Blood glucose meter having integral lancet device and test strip storage vial for single handed use and methods for using same

ActiveUS20080058631A1Facilitates one-handed opening and closing of the vialEasy accessMicrobiological testing/measurementSensorsData connectionBlood glucose meters

Owner:EMBECTA CORP

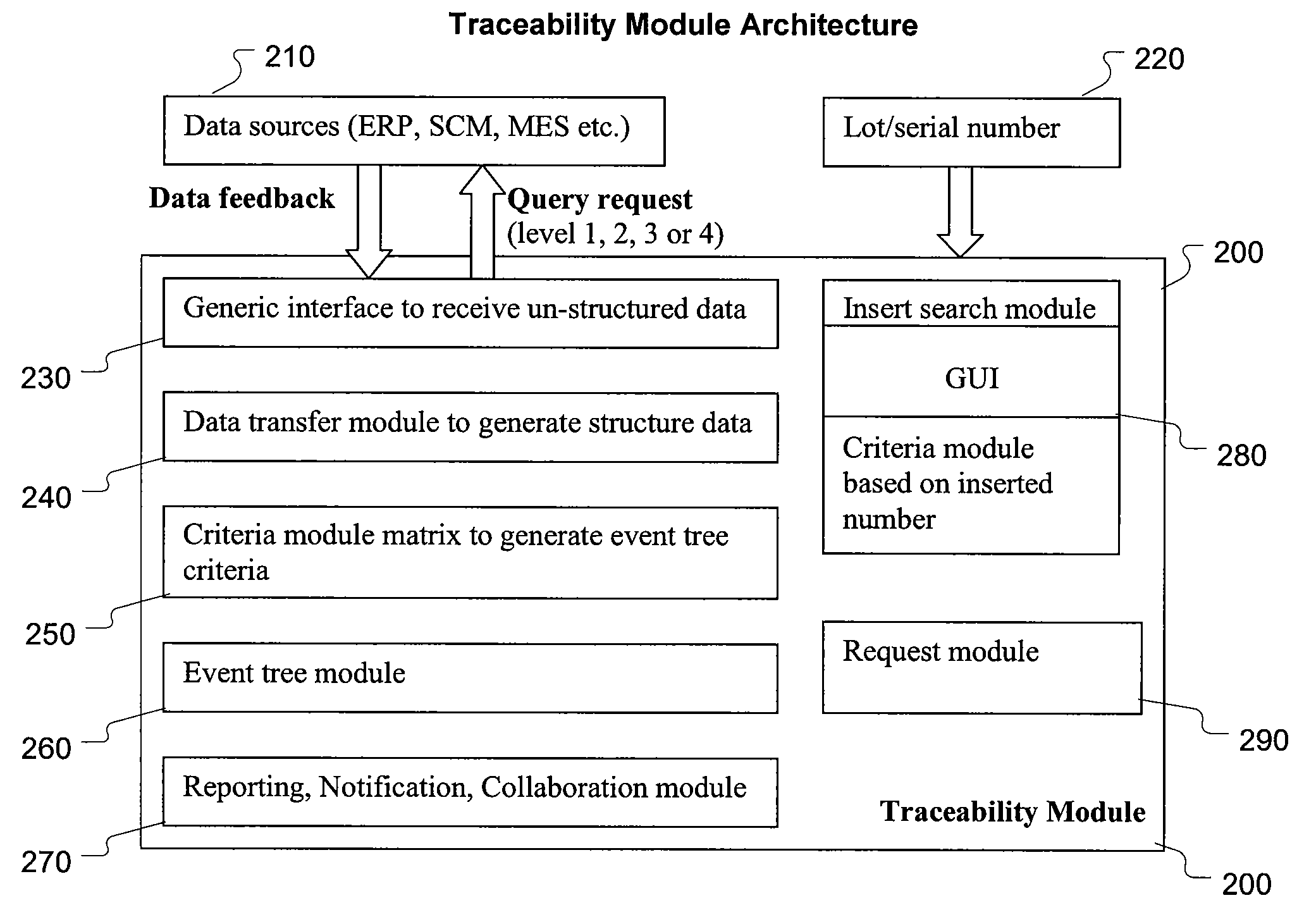

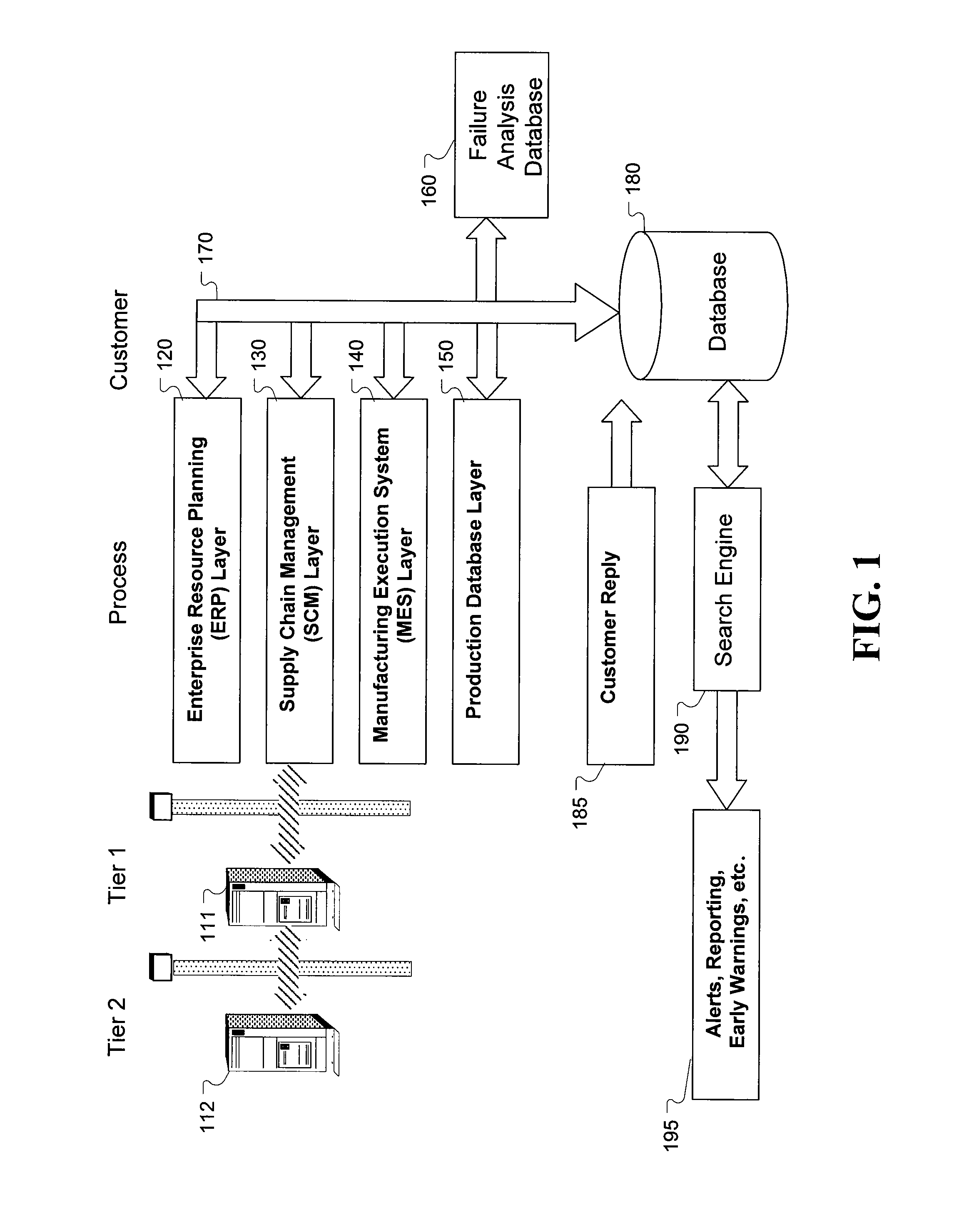

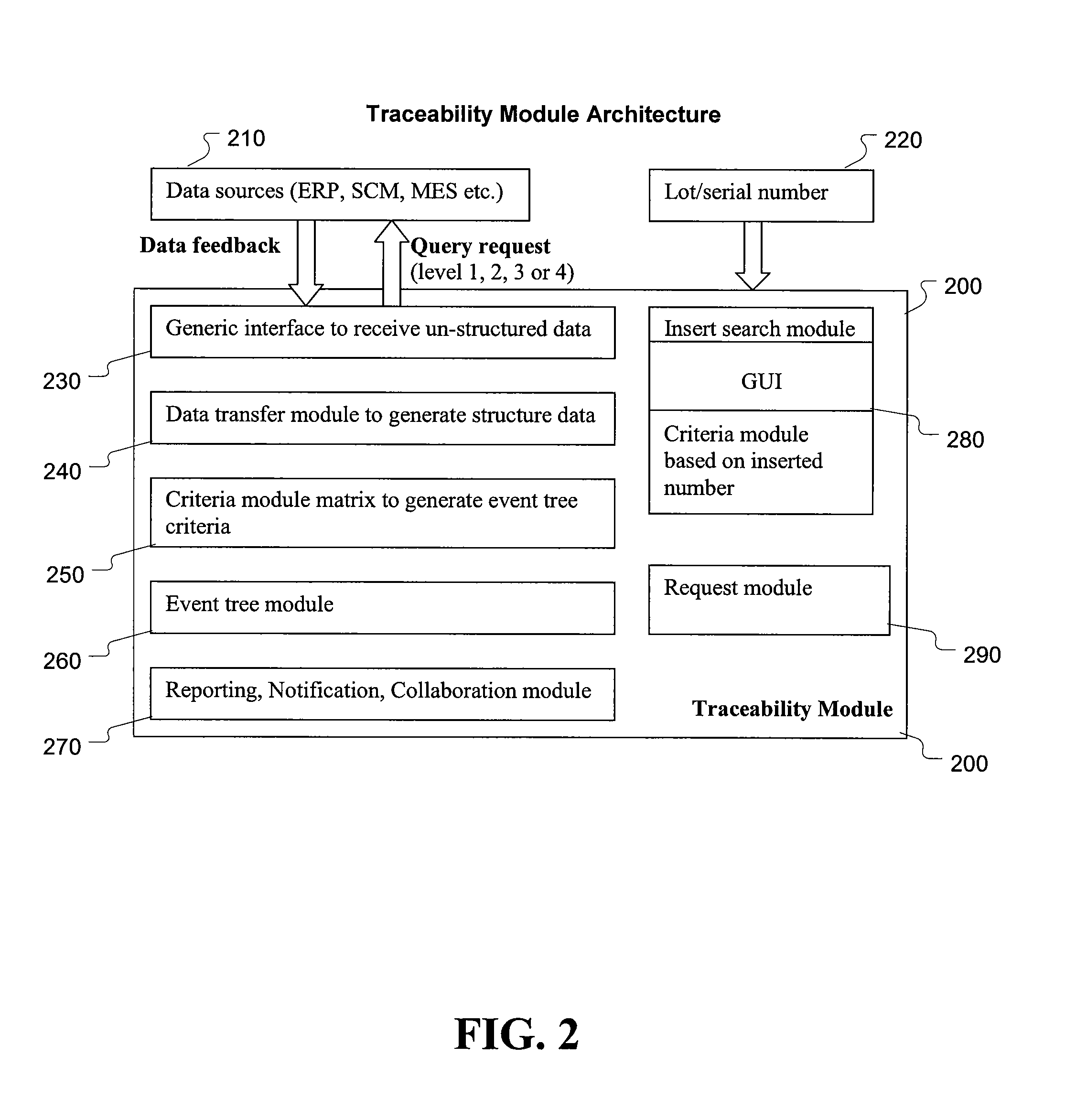

Search engine to improve product recall traceability activities

InactiveUS20090254535A1Avoid damageIncrease costWeb data indexingDigital data processing detailsTime rangeHuman search engine

The present invention provides an improved method of handling product recall activities through traceability. One embodiment of the present invention involves gathering data in a multi-layered database architecture containing supply, process, test, and customer layers. The data is supplied to a traceability module which contains a search engine to link and access the data. The search engine enables a search by part number, lot number, serial number, time stamp, and date / time frame. A traceability analysis is generated from the search, allowing failure analysis of the data. This analysis is performed through an event list over the entire supply, manufacturing, and customer data, facilitating backward and forward traceability of parts and components of the parts. This failure analysis further facilitates automatic response such as automatic warning and automatic recall to manufacturers and customers.

Owner:IBM CORP

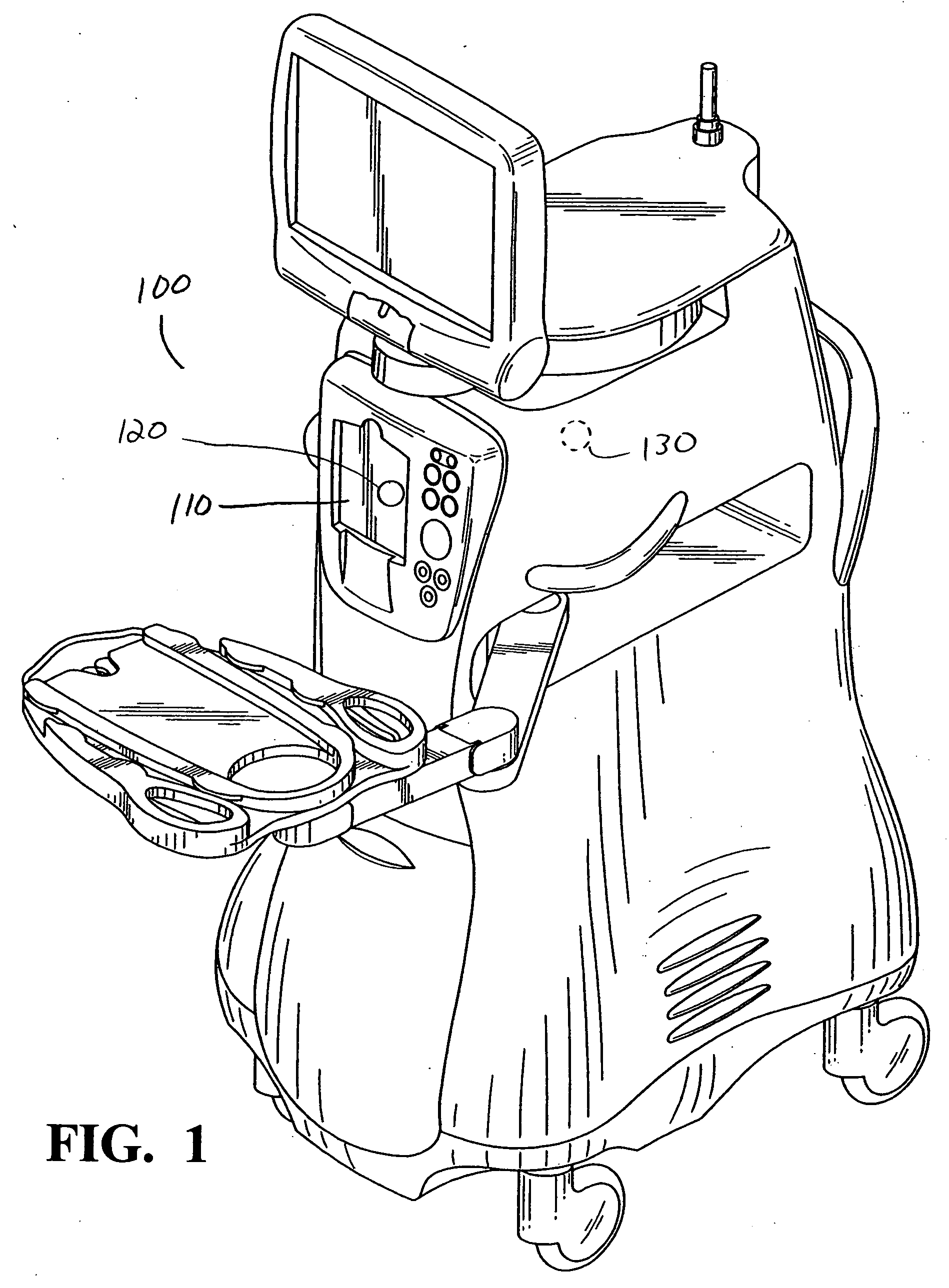

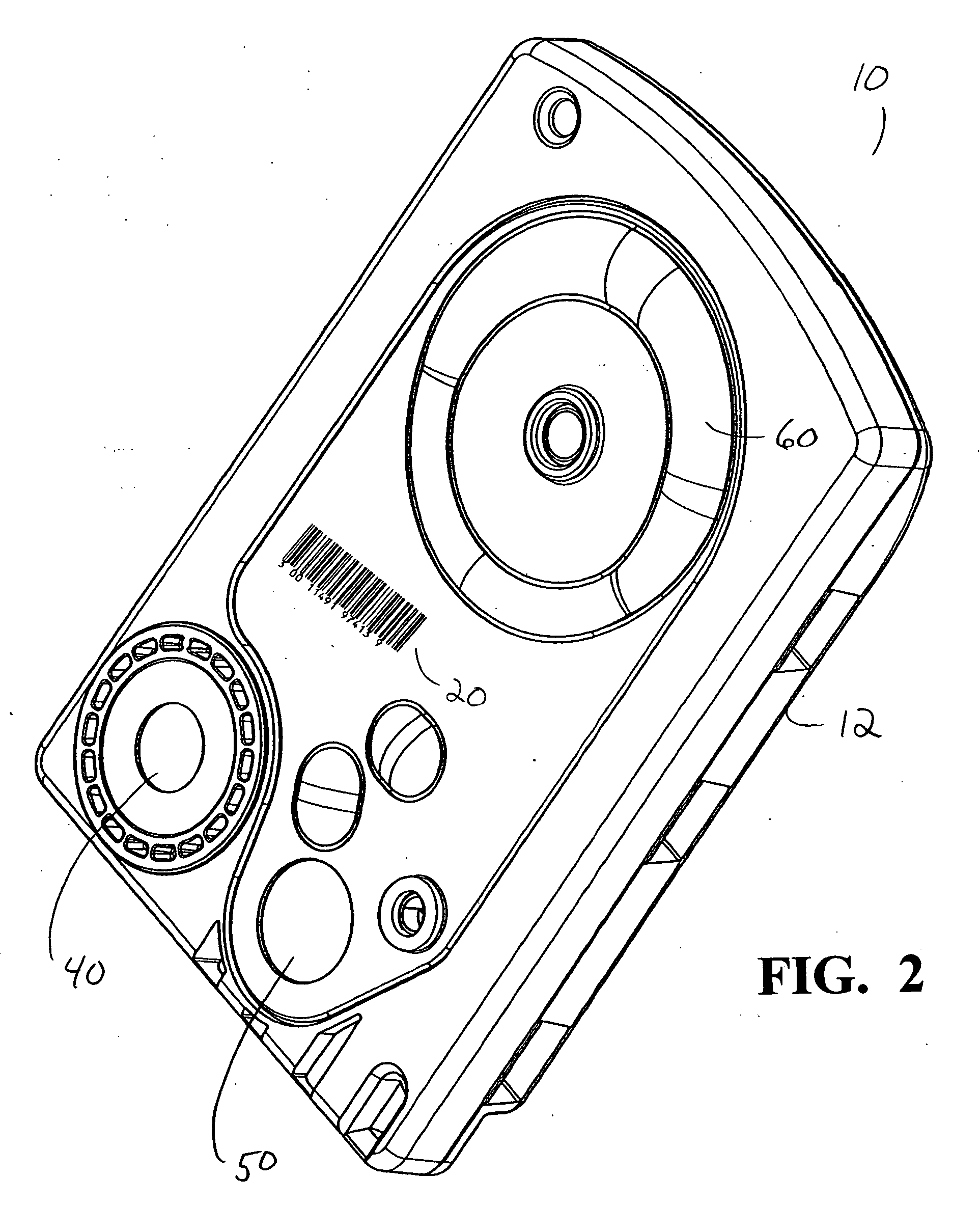

Surgical cassette

ActiveUS20070107490A1Easy to identifyTesting/calibration apparatusEye surgeryMagnetic tapeEngineering

A surgical system and cassette, the cassette having an identification method that is specific to the cassette. Suitable methods include bar coding or Radio Frequency Identification (“RFID”). Cassette information that may be encoded include features such as lot number and performance characteristics, such as pressure sensor calibration data, flow and pressure data and any other performance characteristics of the cassette captured during testing of the cassette at manufacture.

Owner:ALCON INC

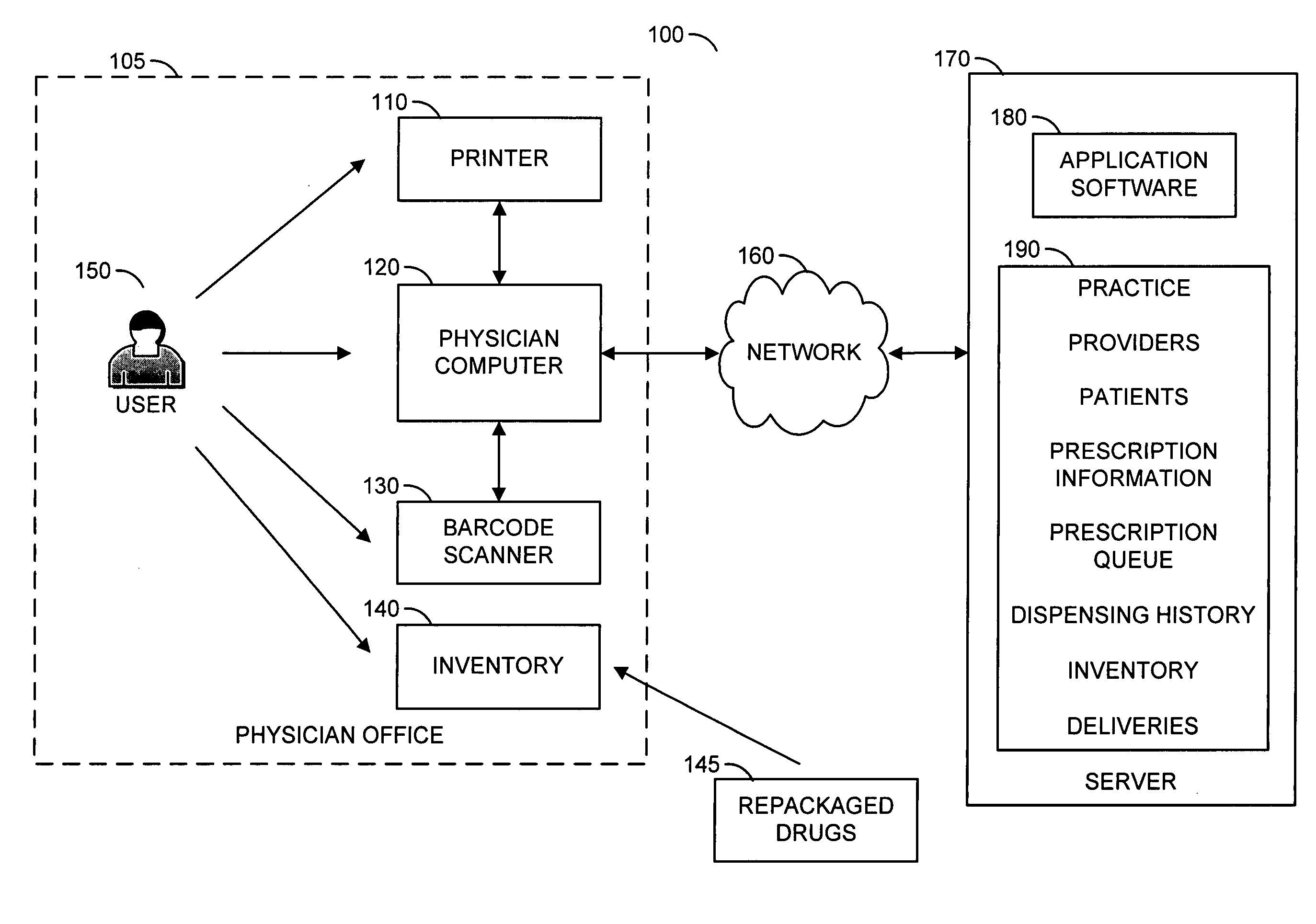

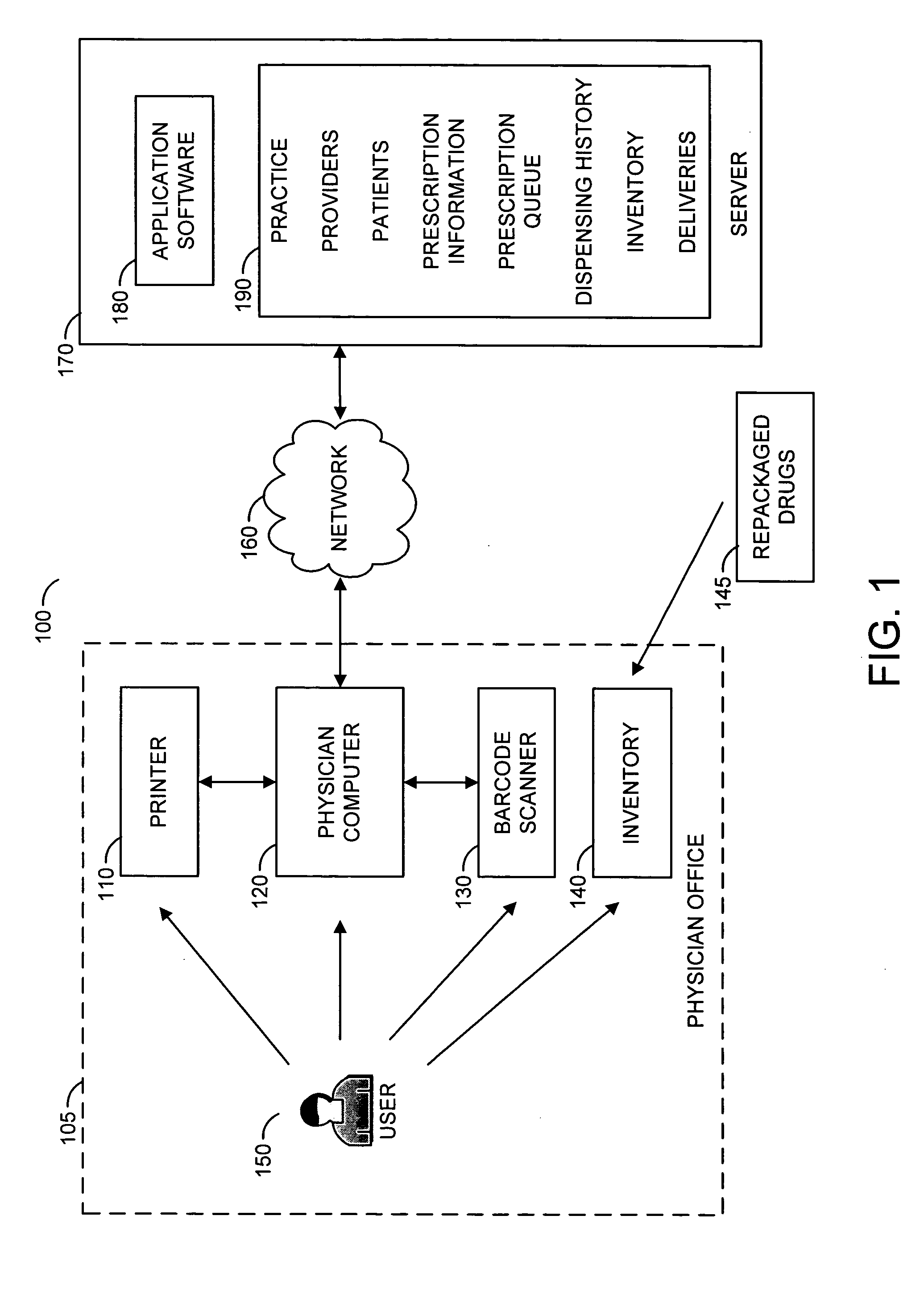

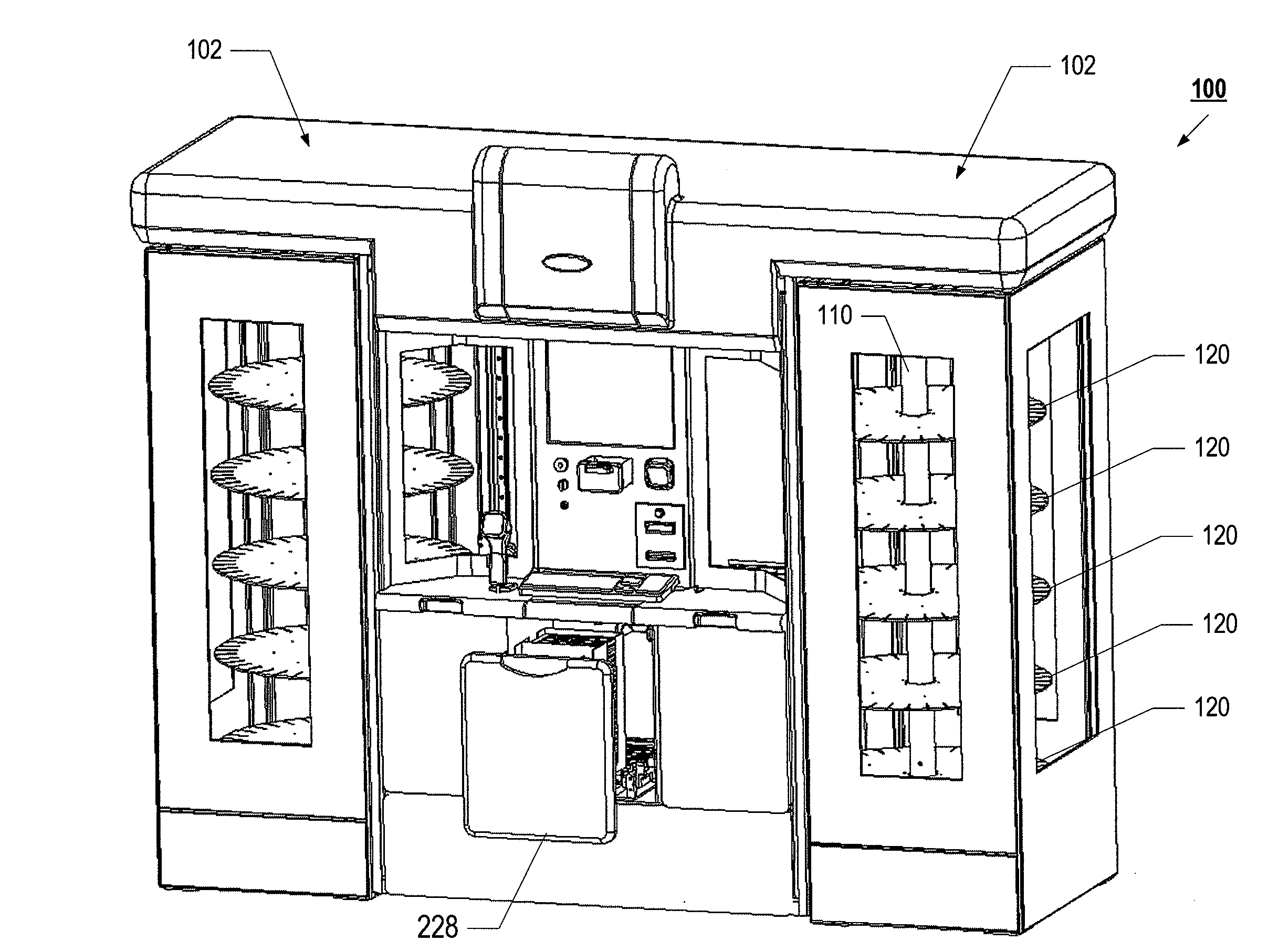

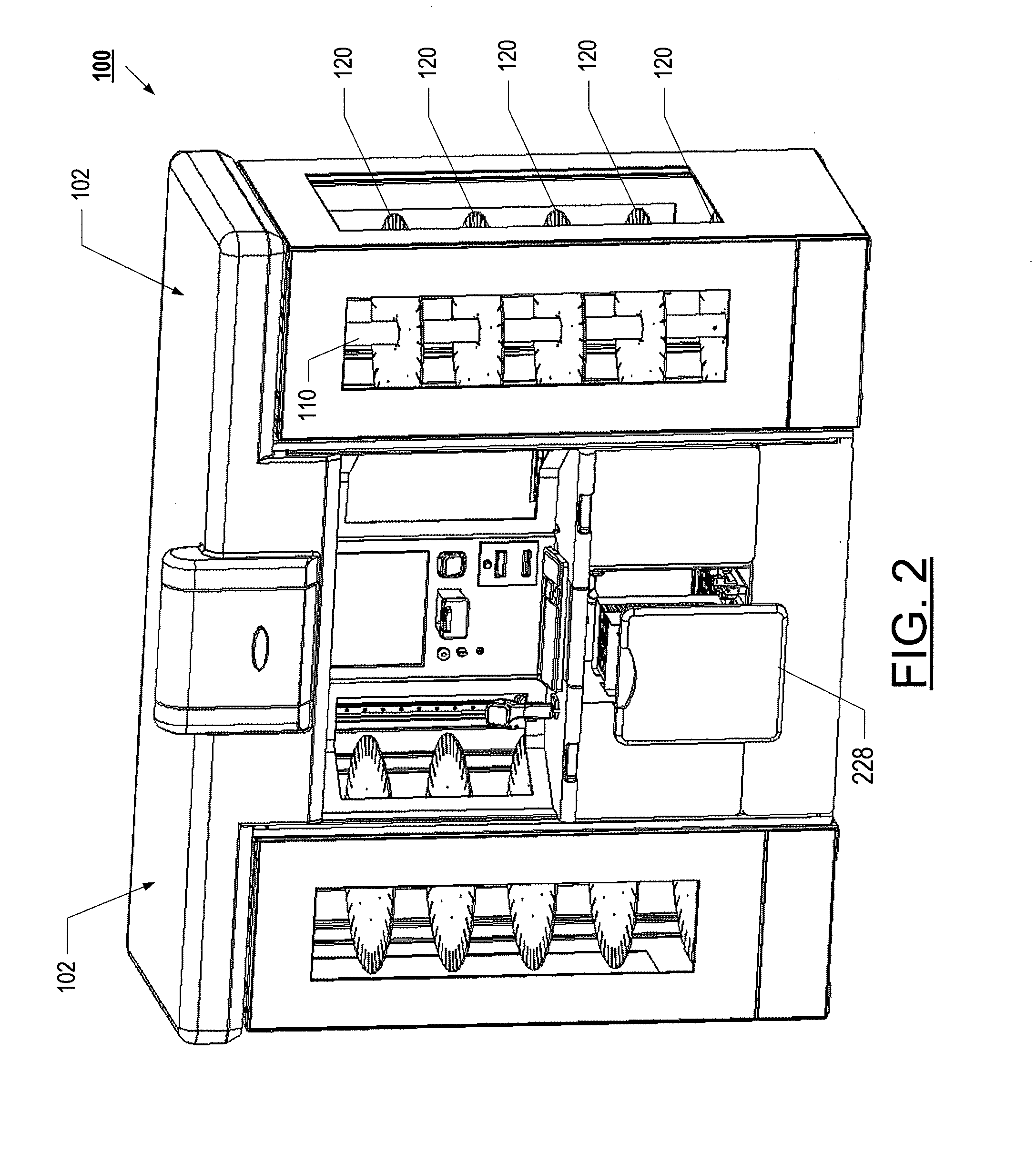

Dispensing system with real time inventory management

InactiveUS20050283259A1Reducing dispensing errorReduce problemsElectric controllersIgnition automatic controlSystem maintenanceInventory management

An integrated dispensing and inventory tracking system is provided for use in conjunction with a medical practice. Data records of inventoried items, such as repackaged drugs or other medical supplies, can be maintained by the system and accessed by a user through a graphical user interface displayed by a browser. The data records can include information pertaining to user-defined inventory categories, minimum and maximum quantities associated with tracked inventory items, quantities on hand associated with tracked inventory items, lot numbers associated with tracked inventory items, and / or related information. Inventory data records can be updated in real time in response to dispensing transactions and / or deliveries of additional inventory items. Various alert status conditions can also be detected by the system, allowing users of the system to be notified of circumstances requiring immediate attention.

Owner:DISPENSING SOLUTIONS

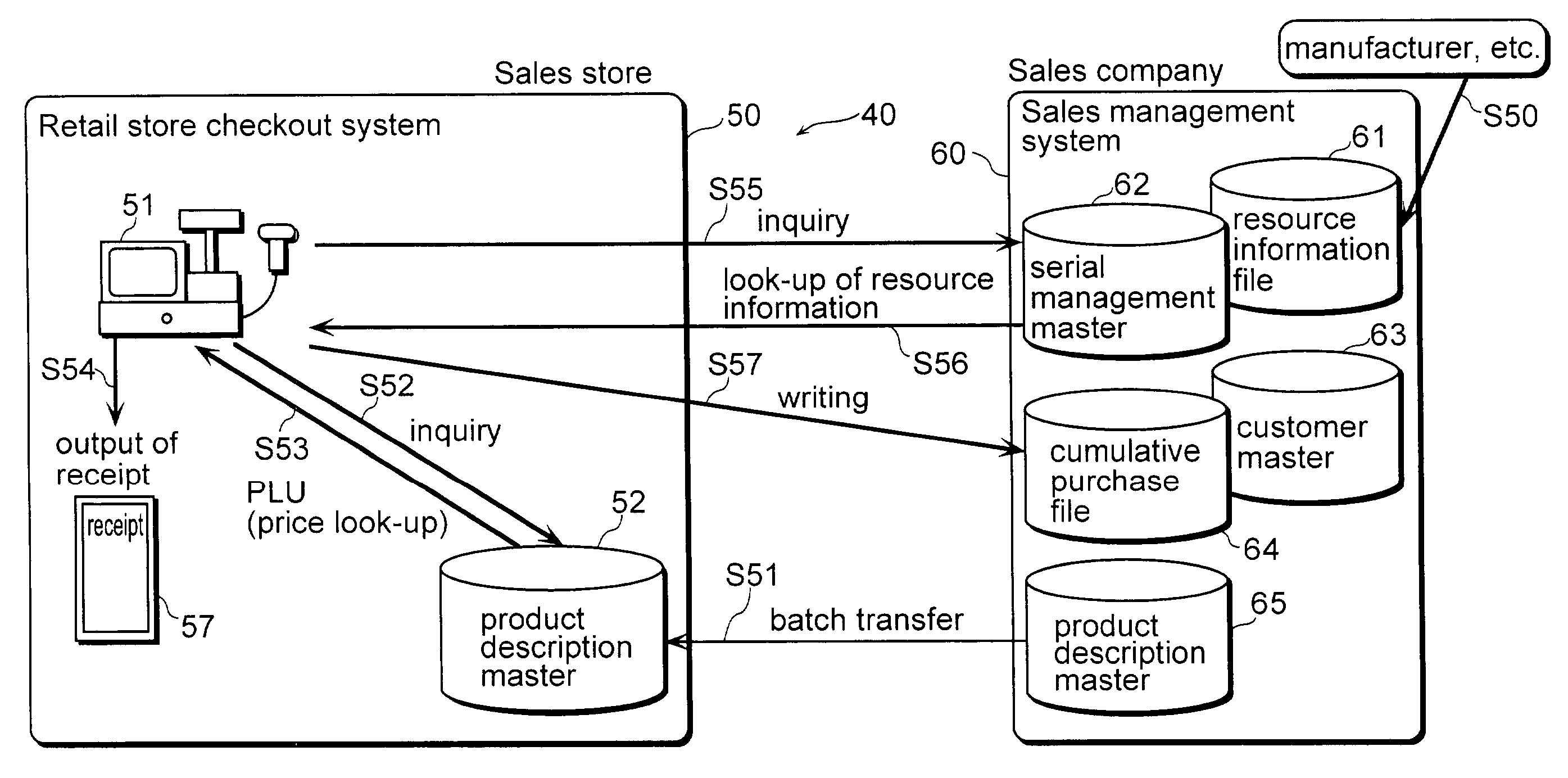

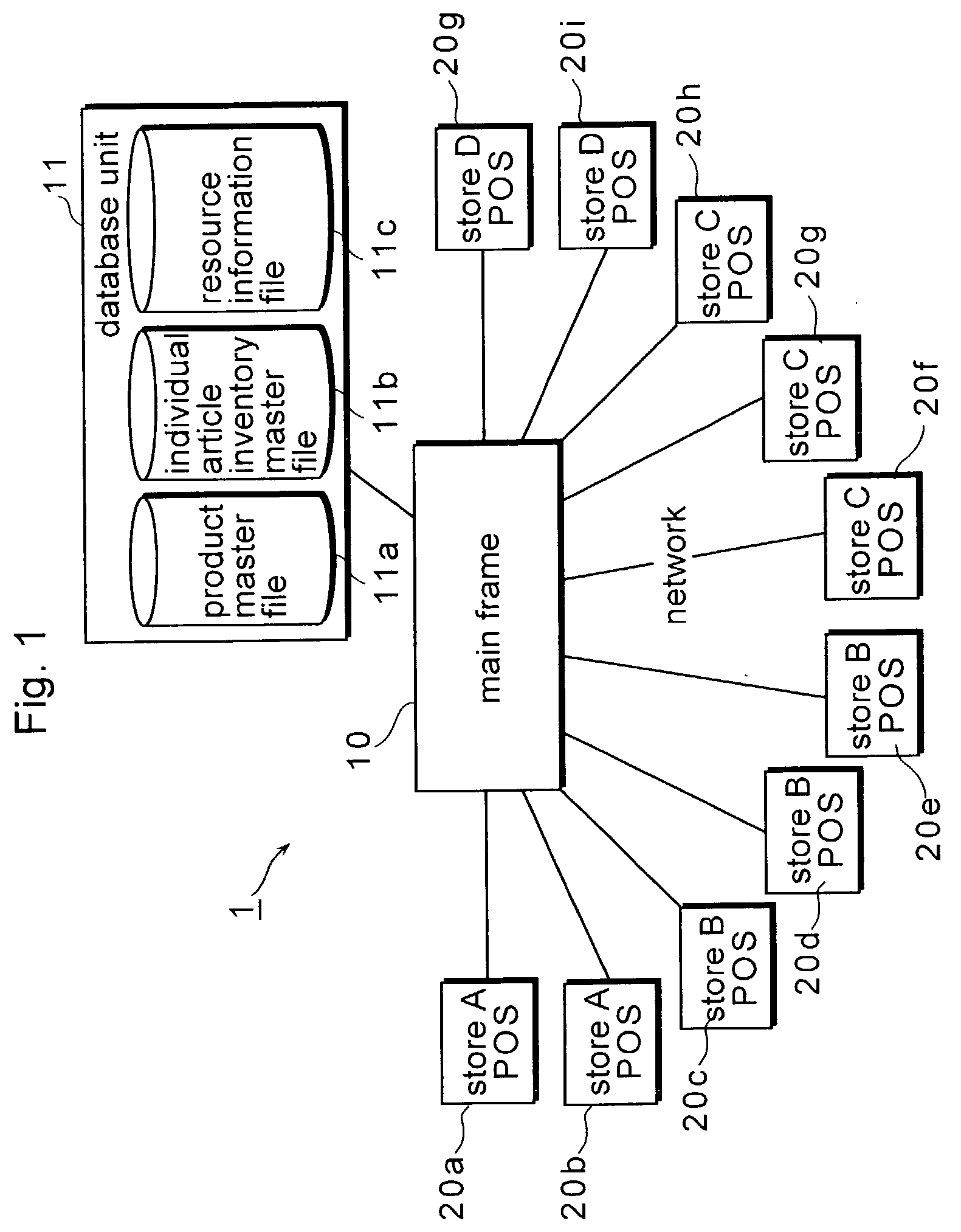

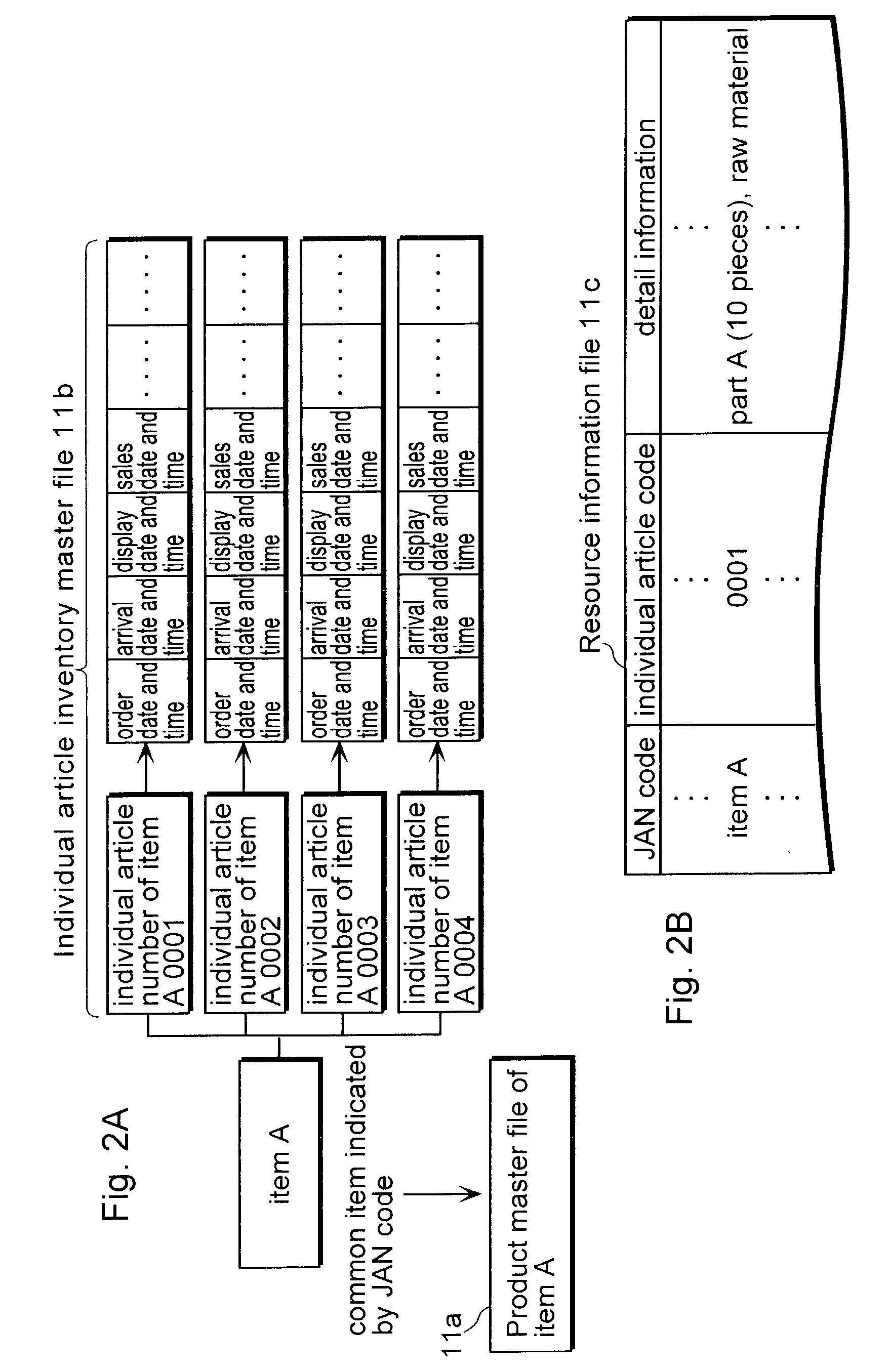

Product marked with product code, product information inquiry system, product information inquiry device and POS system

InactiveUS20030213844A1Extend product lifeEasy maintenanceCo-operative working arrangementsCash registersAdditive ingredientWorld Wide Web

A product code includes an item code 30a, an individual article code 30b and a detail code 30c. The item code 30a is a code specifying an item to which the product belongs, such as a JAN code. The individual article code 30b is a code identifying the product uniquely, such as a bar code indicating a lot number or a serial number marked on the product at the time of manufacturing. The detail code 30c is a code indicating detail information of the product including information about the sources of the product, and component parts, raw materials or ingredients of the product. The detail code 30c is, for example, a two-dimensional code describing parts and raw materials, a production place and feed and chemicals used in the raising process if the product is livestock meat or cultivated fish, etc., and chemical fertilizers and pesticides used for the ingredients if the product is food, as the detail information of the product according to MRP.

Owner:SYST RES +2

Inorganic optical taggant and method of making

InactiveUS6899827B2Overcomes shortcomingDesired performanceCell electrodesMachines/enginesExplosive AgentsTitanium oxide

Owner:UT BATTELLE LLC

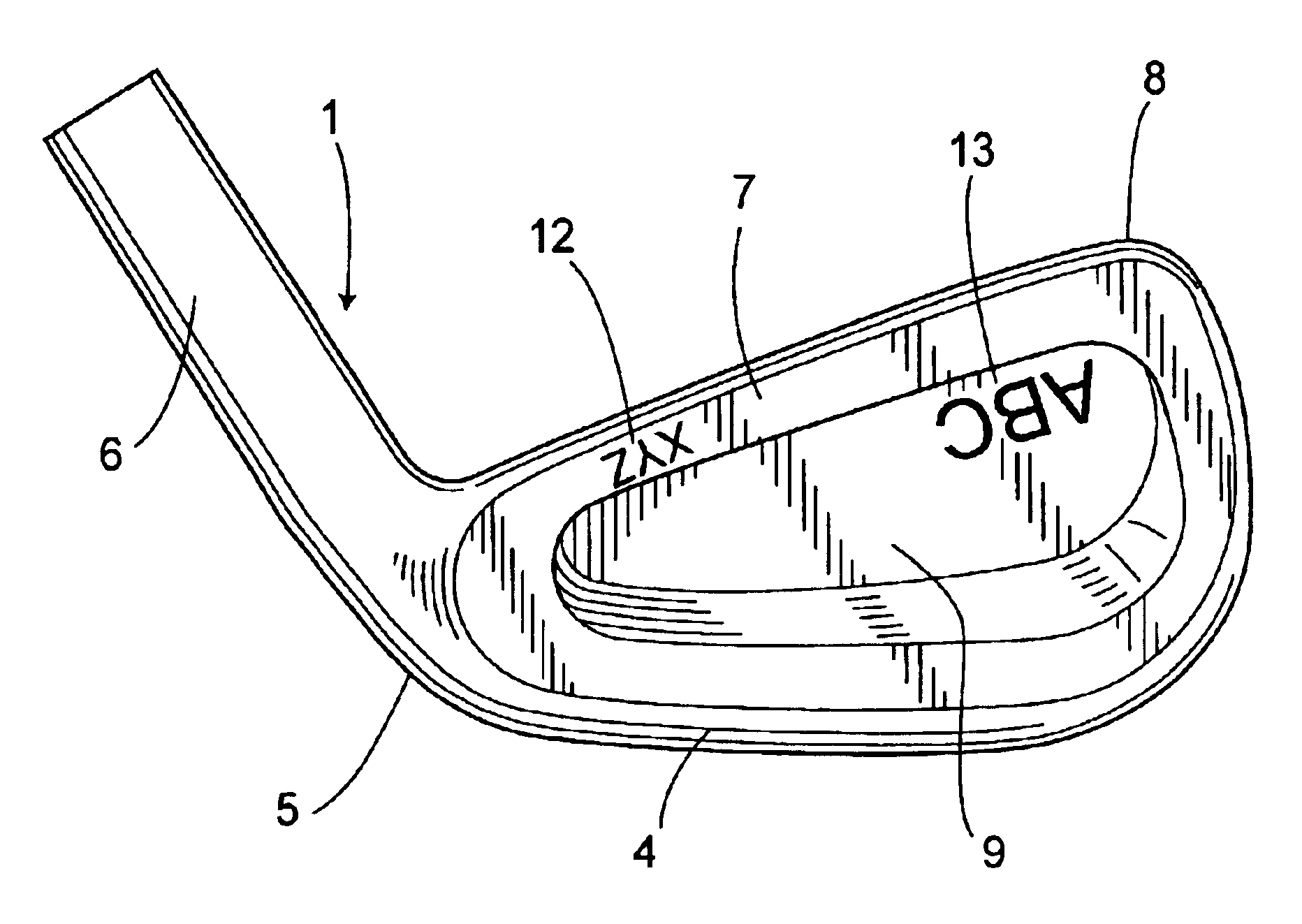

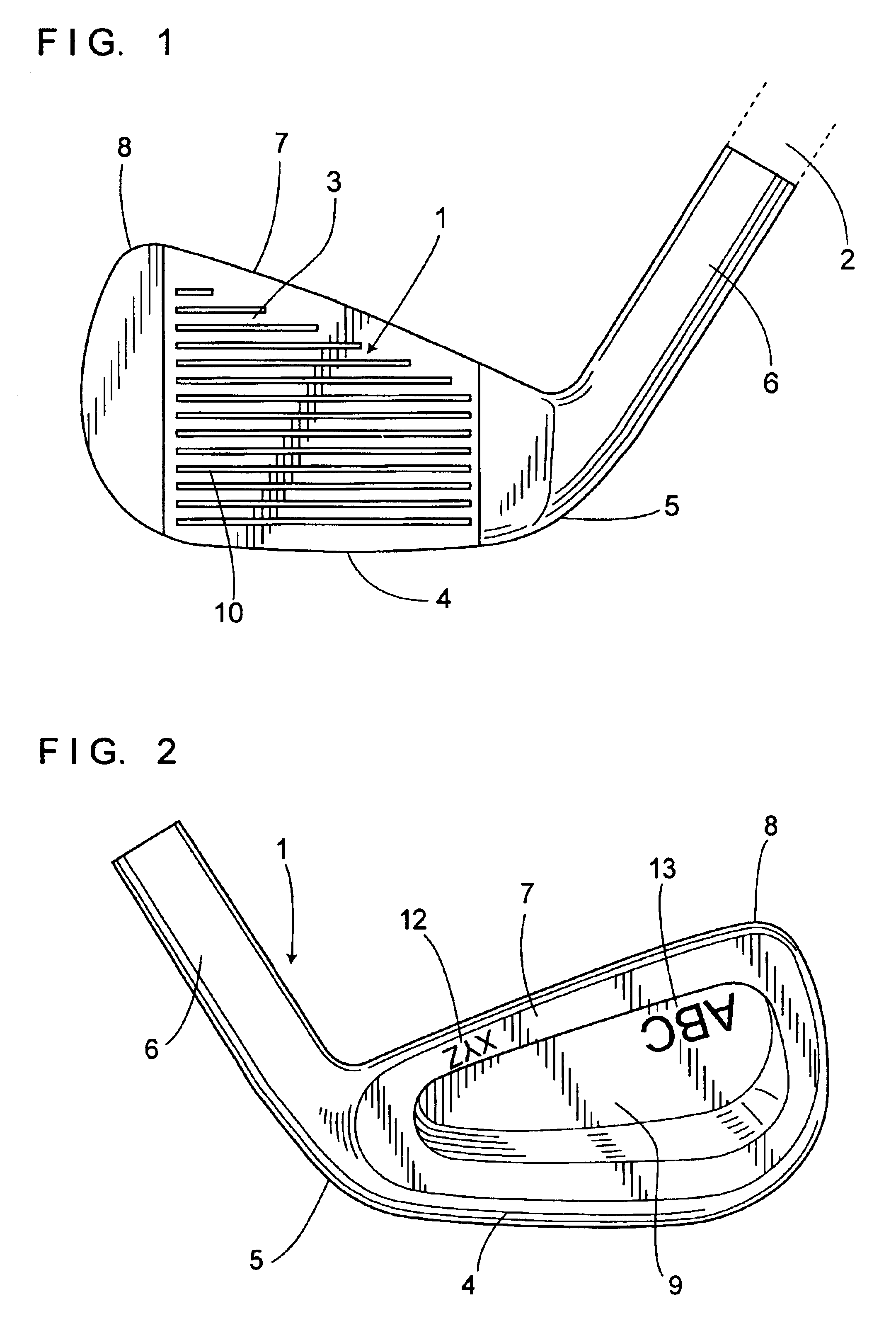

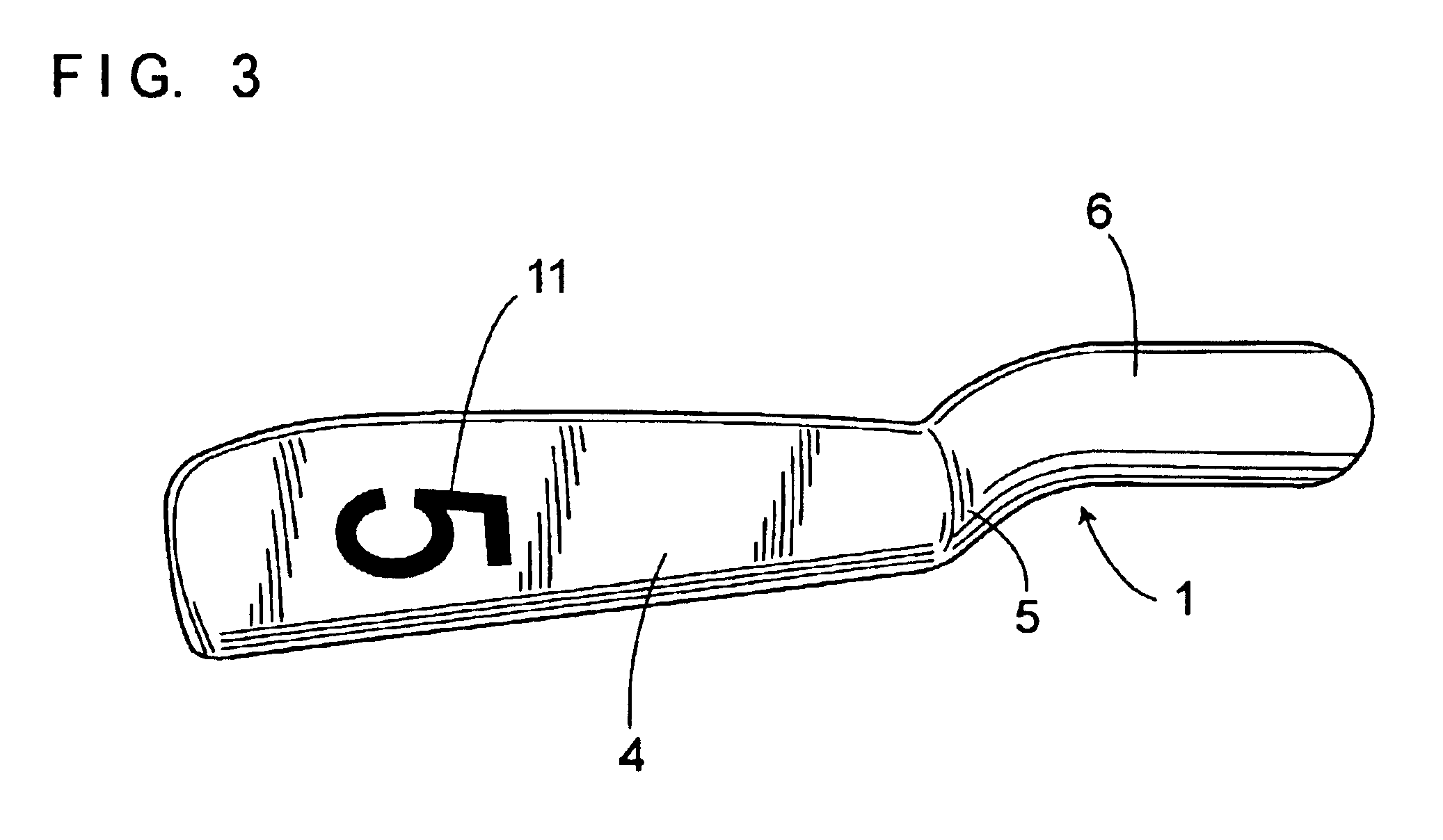

Method of manufacturing a golf club head

InactiveUS6713717B2Welding/soldering/cutting articlesMetal working apparatusDisplay deviceLaser beam machining

A method of manufacturing a golf club head by which face lines, a club number display and logo marks can be formed without being affected by the configuration and material of the club head. Face lines 10, a club number display 11 and logo marks 12 and 13 are formed on the surface of a golf club head 1, using a laser beam processing machine. Stamps and receiving dies are no longer required for a respective production lot number or a respective club number, so that costs and time required for fabricating impressing stamp dies and receiving dies can be saved. Further, face lines 10, club number display 11 and logo marks 12 and 13 are able to be formed without being affected by the configuration and material of the golf club head 1.

Owner:ENDO MFG COMPANY

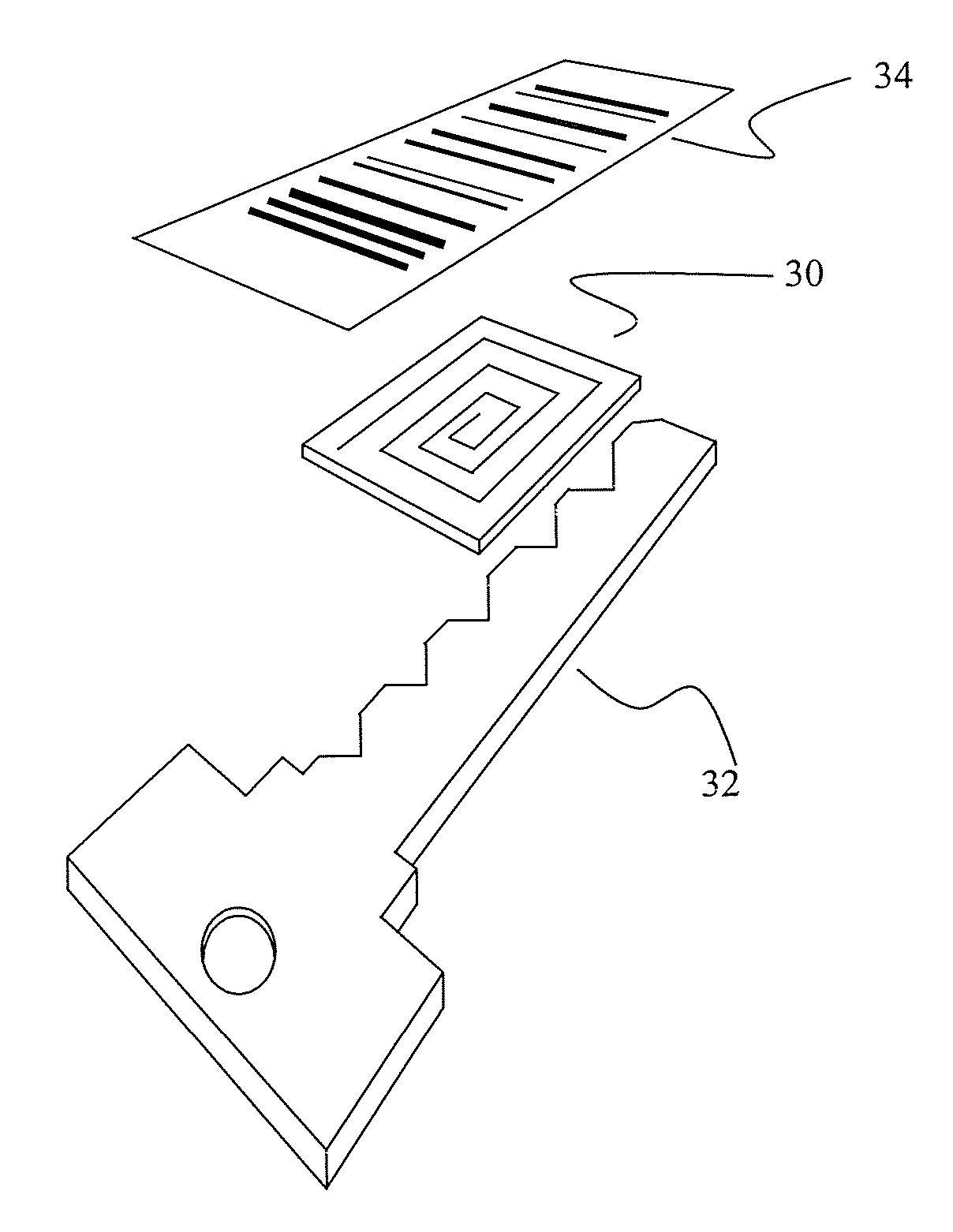

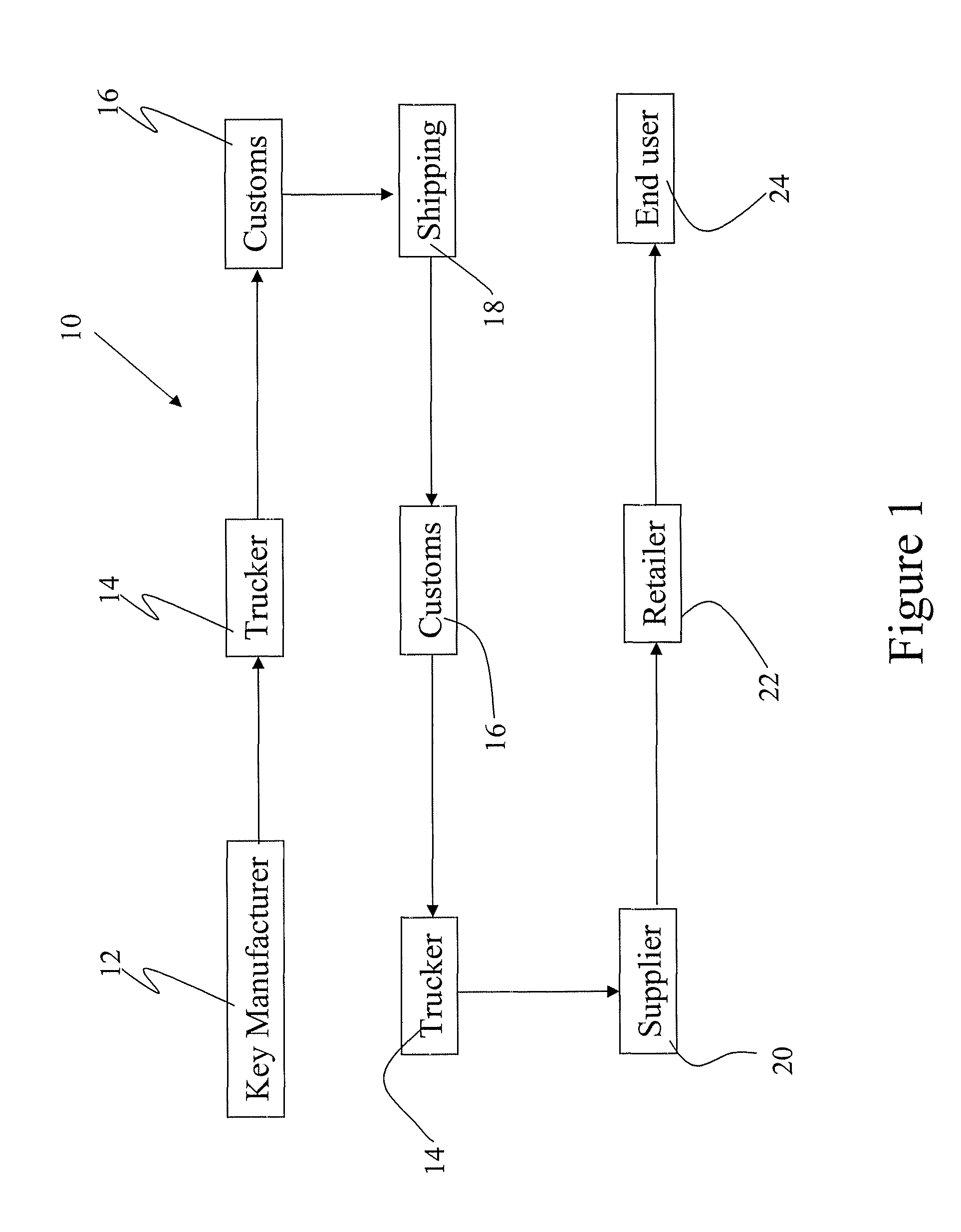

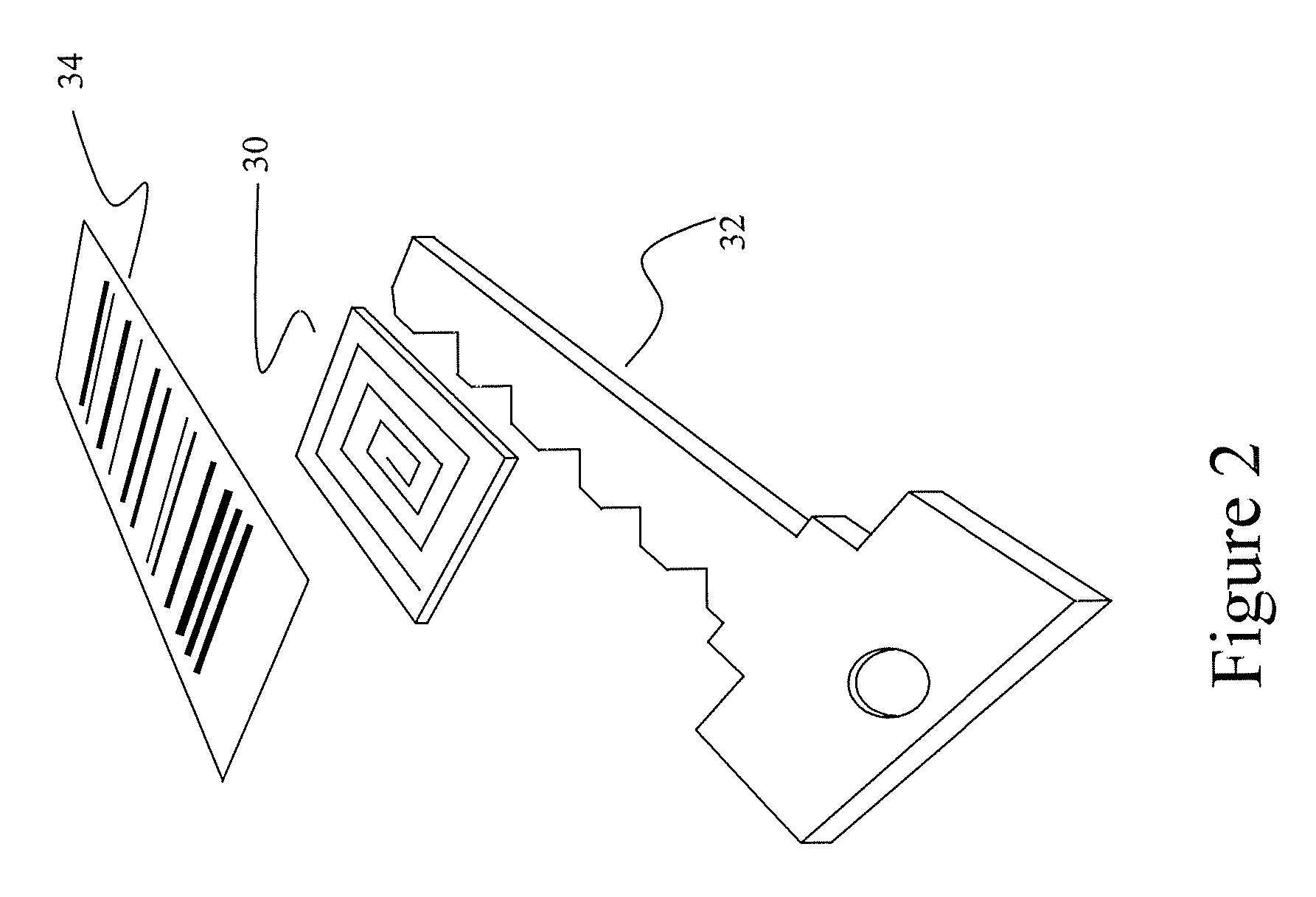

Radio frequency identification (RFID) system for manufacturing, distribution and retailing of keys

ActiveUS8074481B2Electric signal transmission systemsDigital data processing detailsEngineeringLot number

A key assembly having an identification member secured to the key. In one embodiment, the identification member includes a programmable device that contains information indicative of one or more characteristics of the key that can be used to identify at least one of a) the type of key, b) the type of key blank, c) an origination address, d) a destination address, e) a manufacturer, f) a manufacturing date, and g) a lot number. Another embodiment may include a key, and an identification member secured to the key, wherein the identification member includes a programmable device that contains information indicative of a) the key type, b) the type of key blank, and c) cutting instructions for a key cutter to determine cut characteristics. Additional embodiments may include an automobile key and an identification member secured to the automobile key, where in the identification member includes memory for use as mobile data storage.

Owner:HY KO PRODS

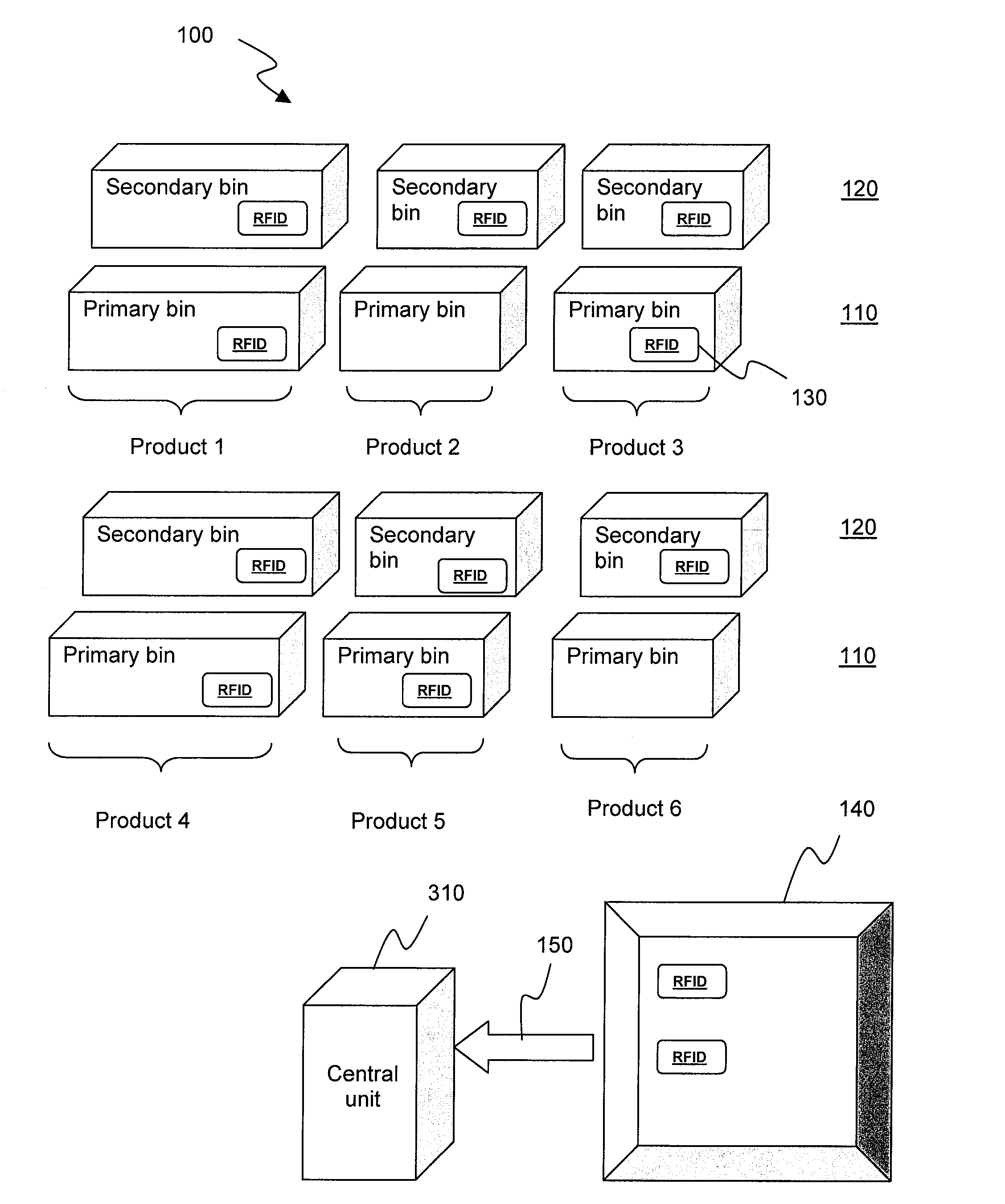

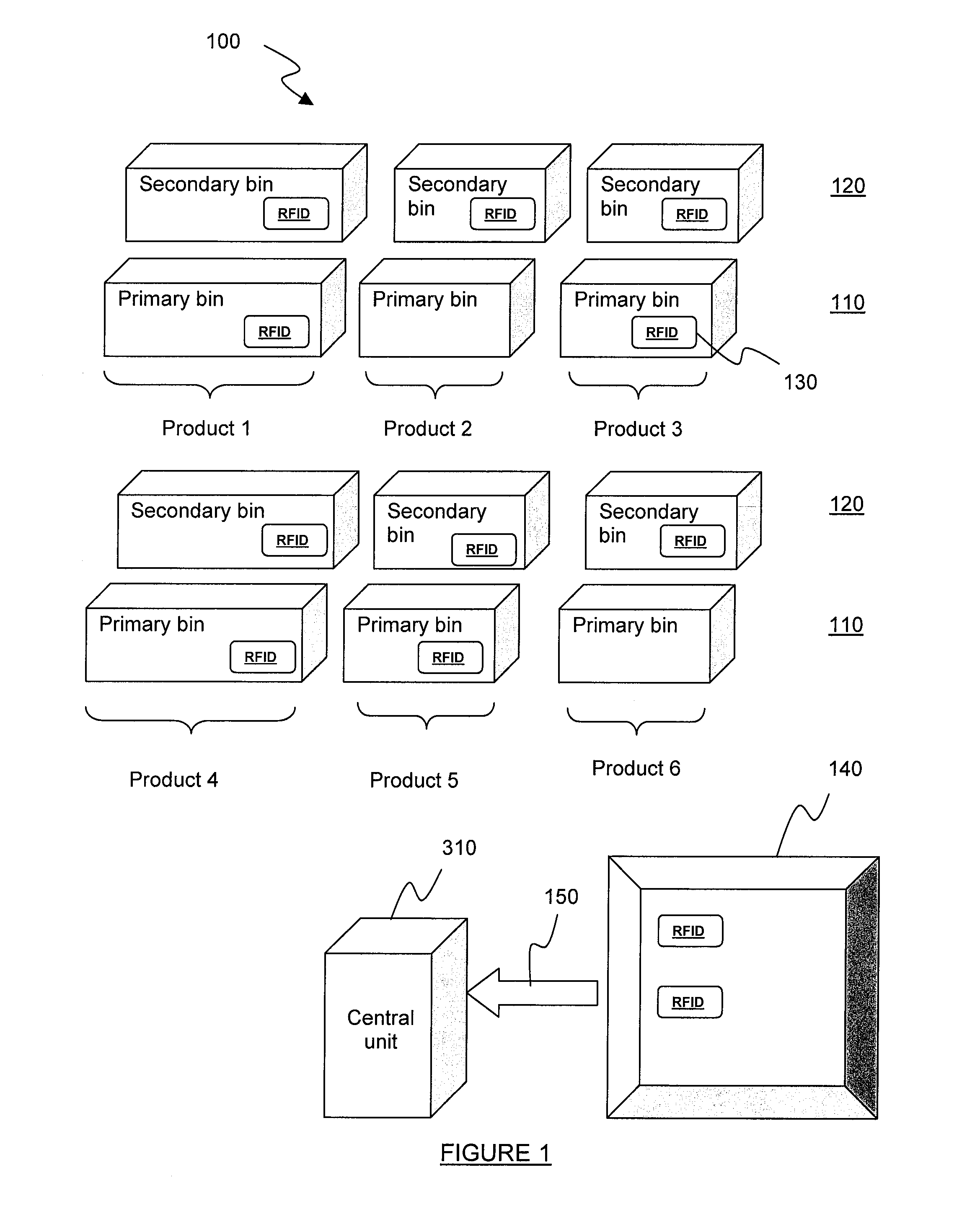

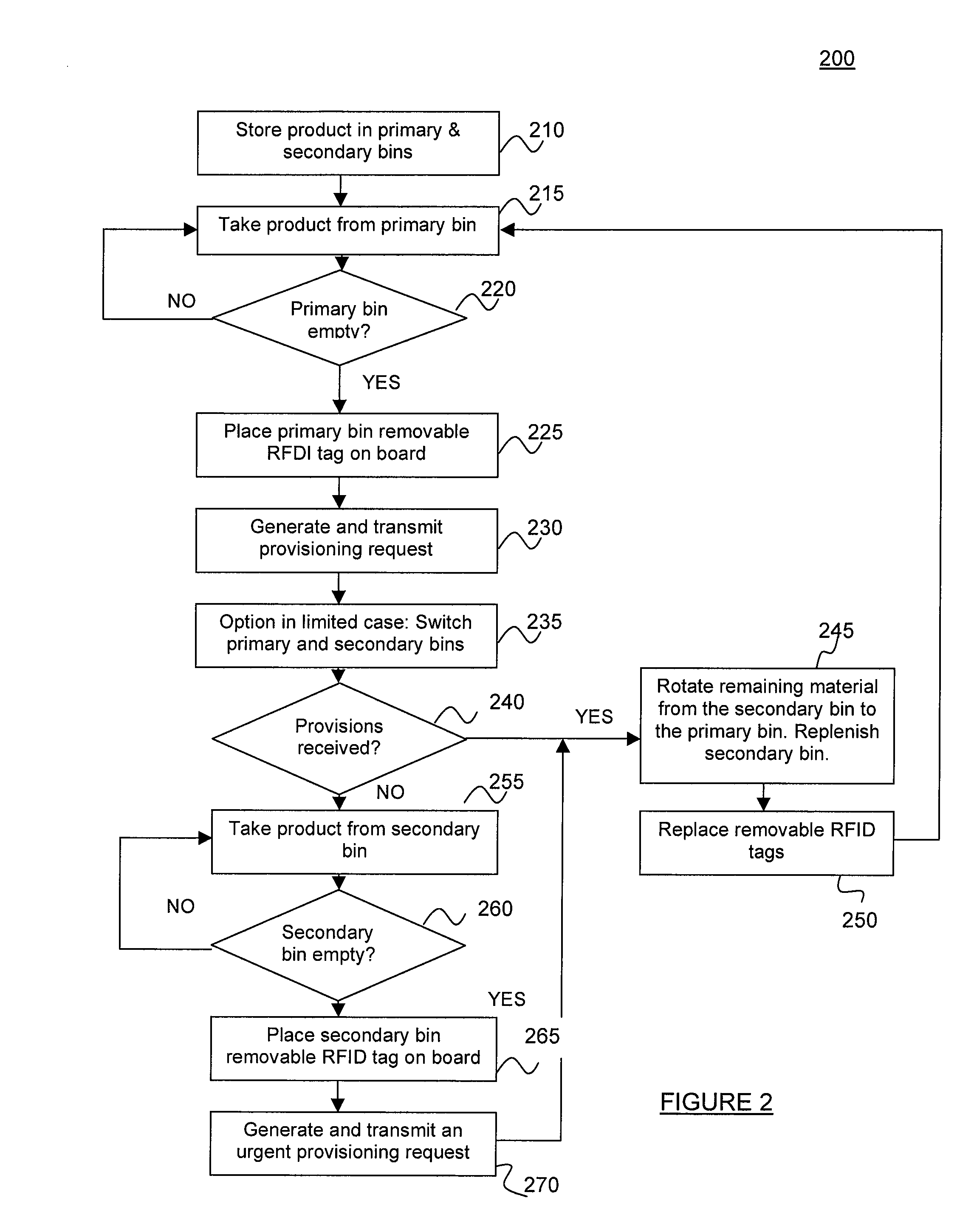

System and method for tracking medical products in a two bin per medical product replenishment system

ActiveUS8113424B2Electric signal transmission systemsHand manipulated computer devicesMedical productEngineering

The present relates to a system and method for tracking medical products in a two bin per medical product replenishment system. The system and method comprising storing medical product information including lot number and date of receipt, and recording replenishment requests and generated date. The system and method further correlate the date of receipt of the medical product having the particular medical product information with the generated date of recorded replenishment requests to identify probable corresponding replenishment requests. Also, the system and method correlate identified probable corresponding replenishment requests with location information of corresponding RFID tags to determine corresponding probable locations.

Owner:LOGI D

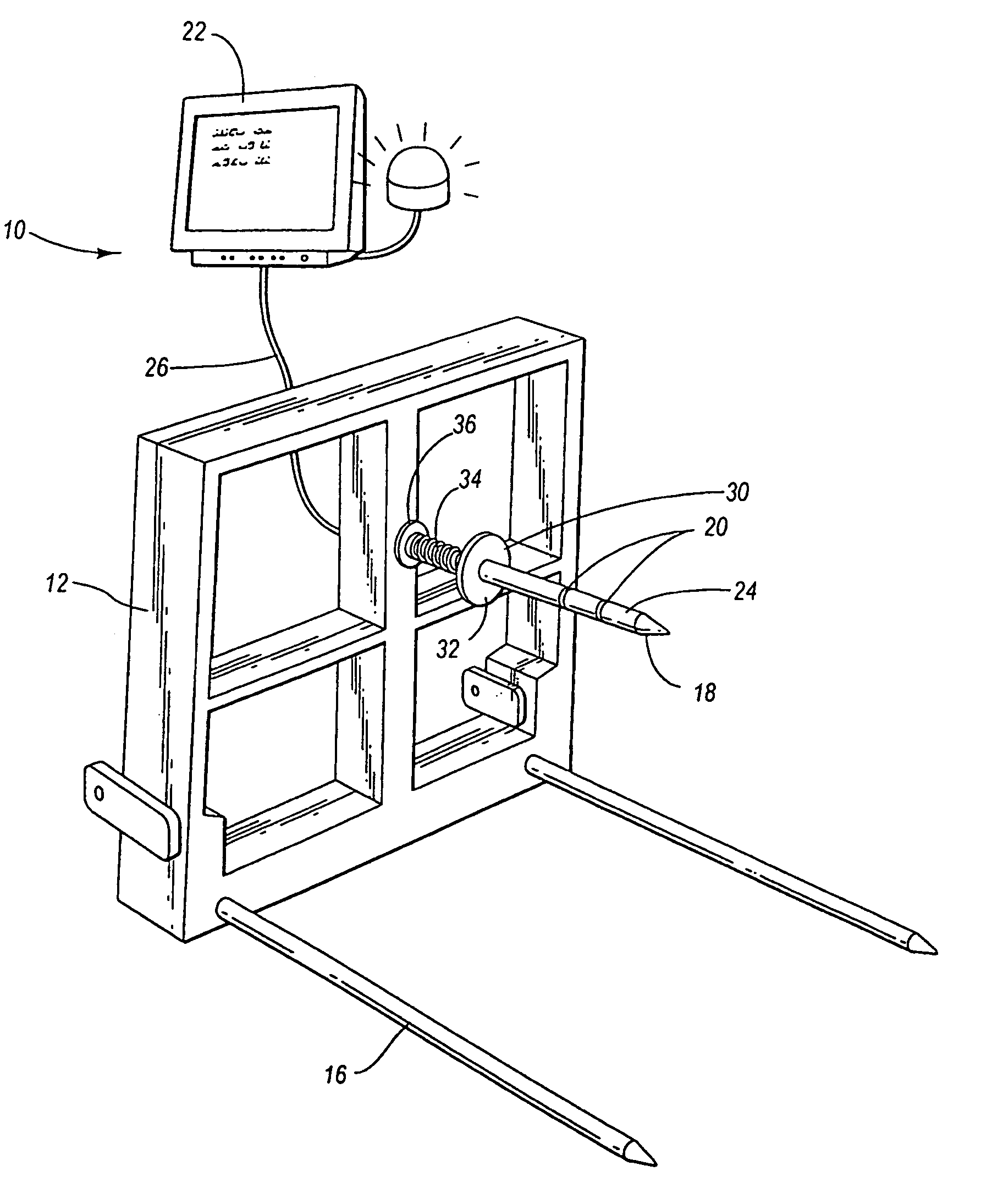

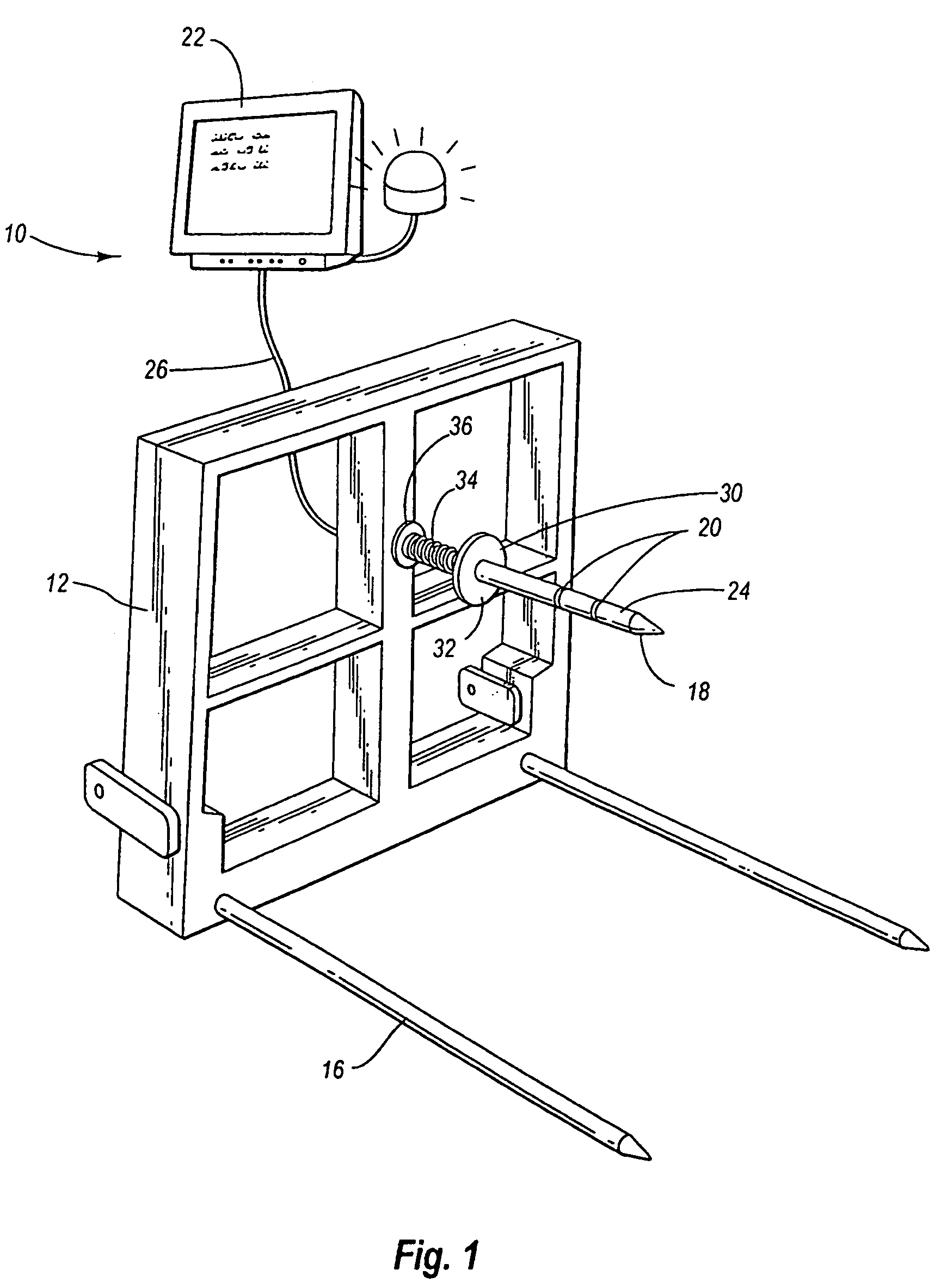

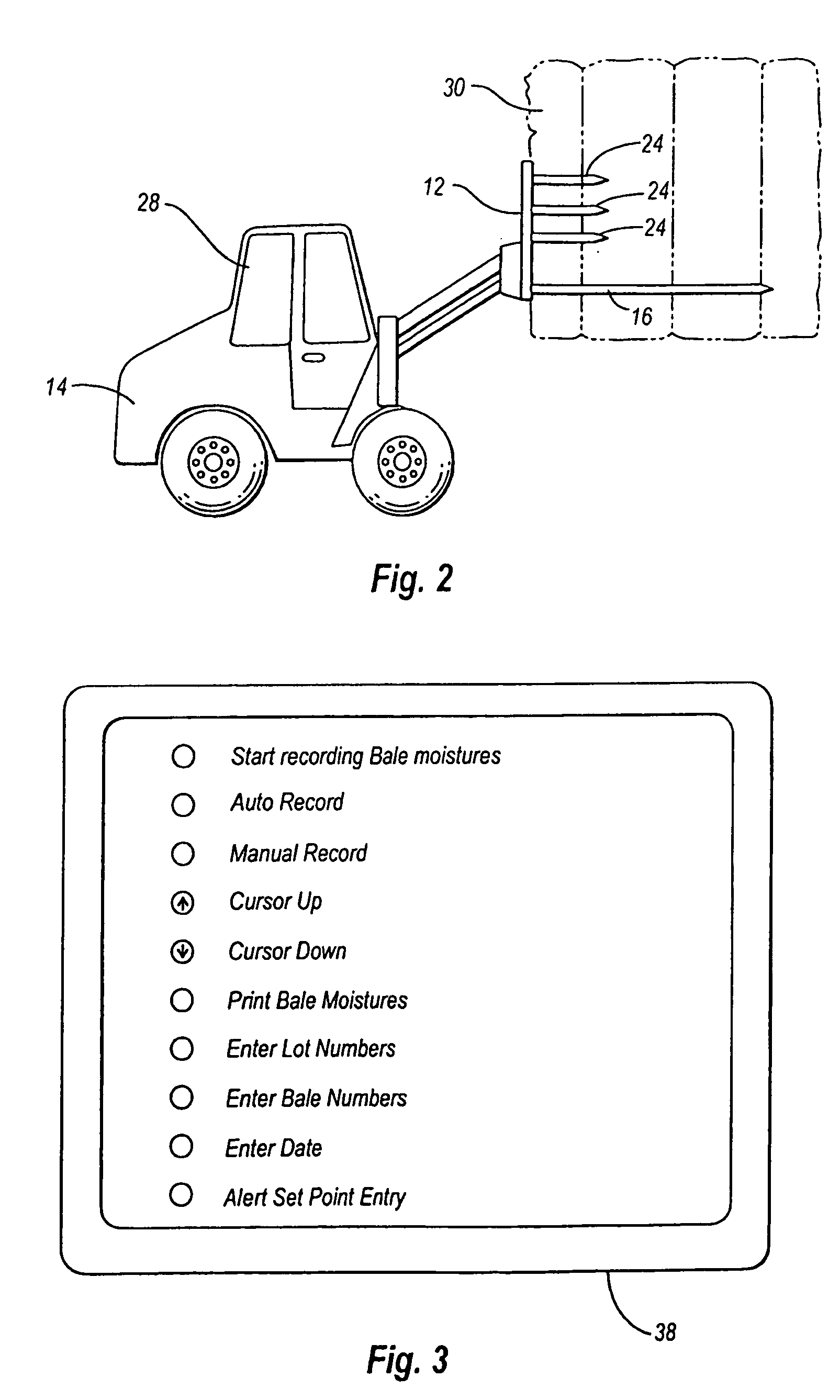

Bale loader moisture sensing system

A moisture sensing system for use with a bale loading vehicle. The moisture sensing system includes one or more probes that are inserted into the center of a hay bale or other agricultural product that obtain moisture readings of the product. The moisture readings are stored in memory, and may be printed in a report of moistures over a certain period of time, in a certain location, in a certain lot number, in a certain truckload, or other grouping of bales.

Owner:LOUCKS LEVI L +1

Automatic identification symbology suitable for contact lens manufacturing verification

InactiveUS20060001828A1Quantity minimizationOptical surface grinding machinesEye diagnosticsSymbolic SystemsEngineering

A method of identifying one or more characteristics of an ophthalmic lens by embedding a second marking inside the perimeter of a first marking formed on the lens. In one embodiment, the first marking may be a toric marking indicative of the ballast and / or cylindrical axis and the second marking, placed inside the first marking, may indicate one or more other lens characteristic such as power, SKU or lot number, for example. The invention includes a lens made according to the method.

Owner:BAUSCH & LOMB INC

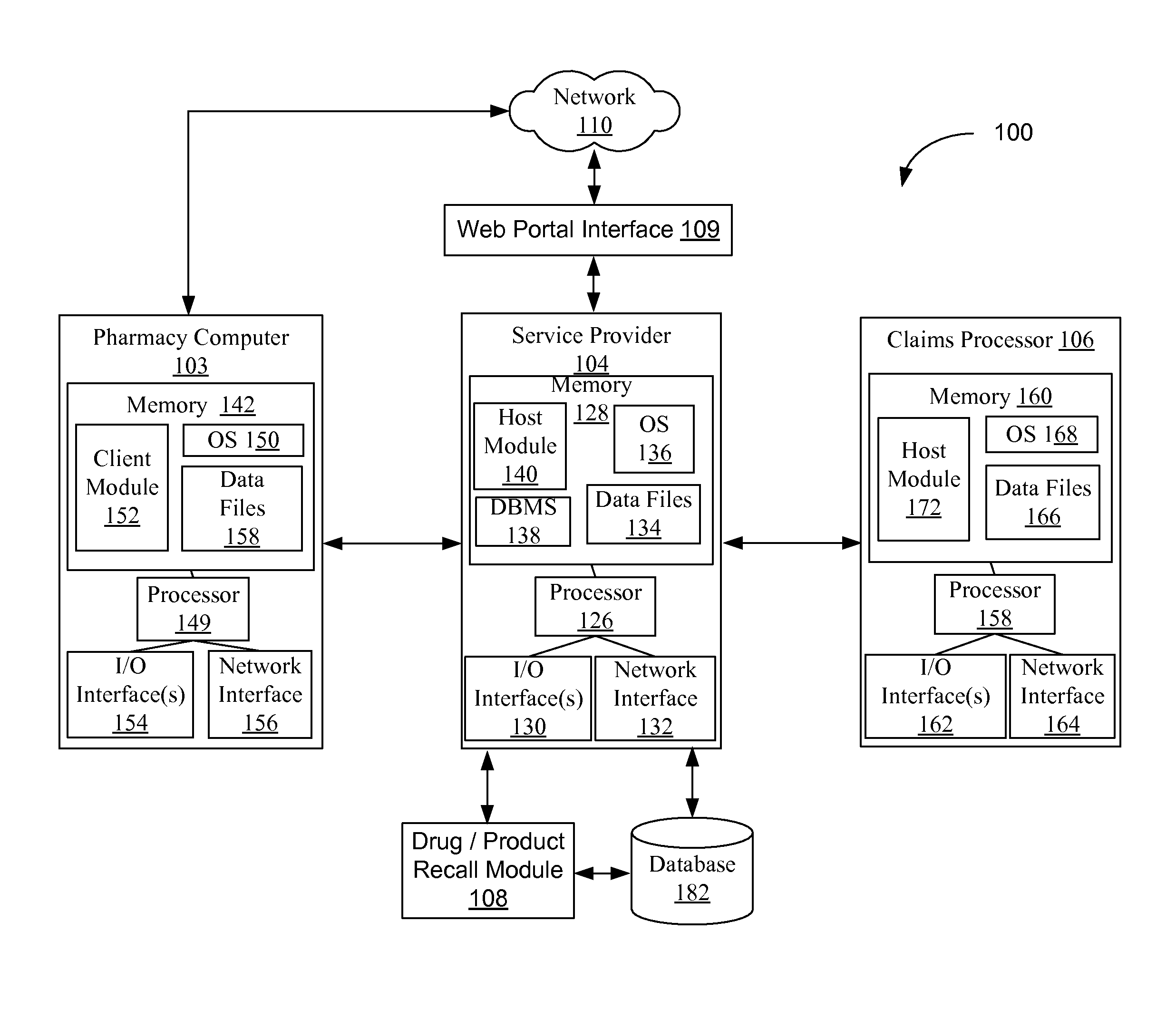

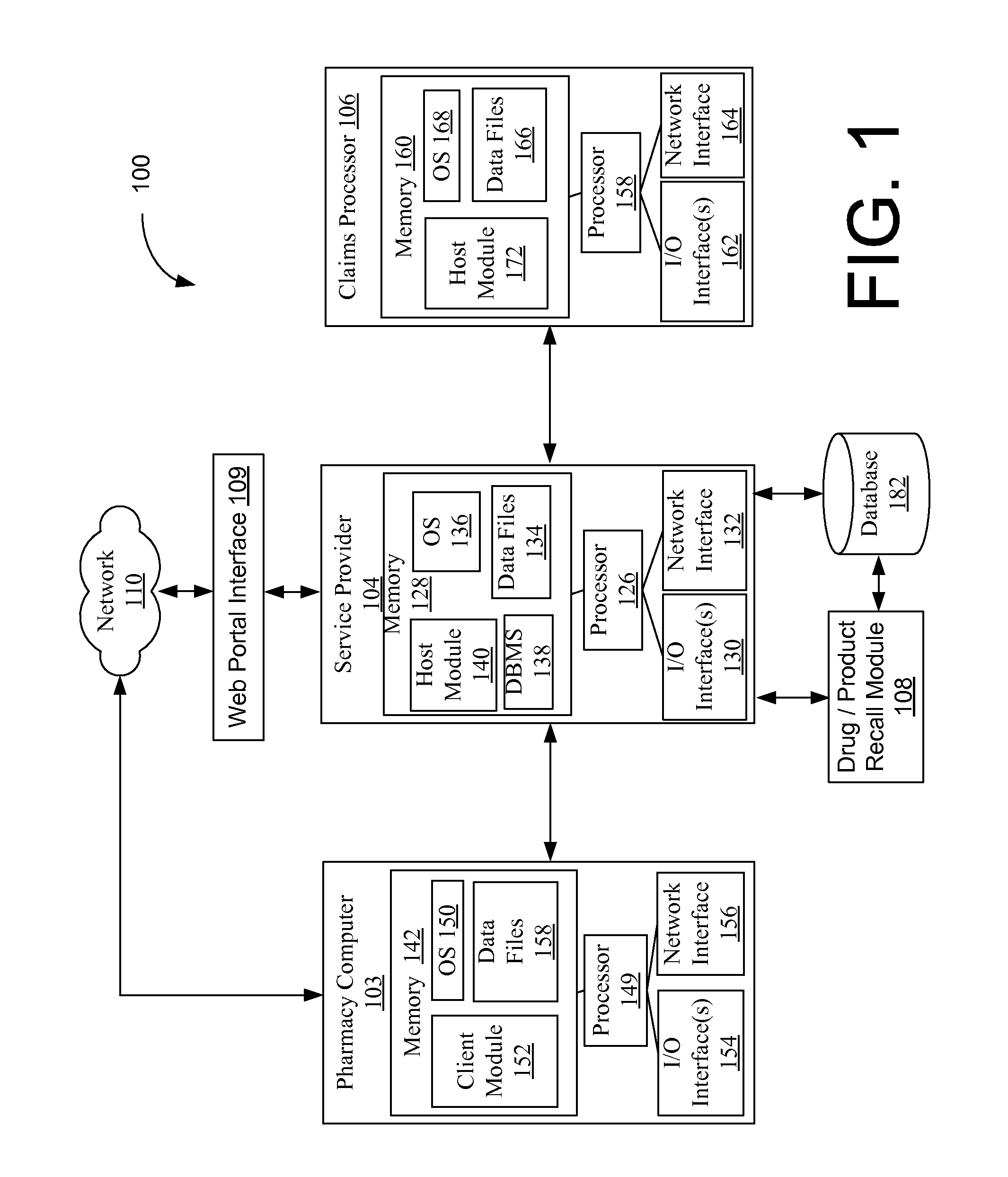

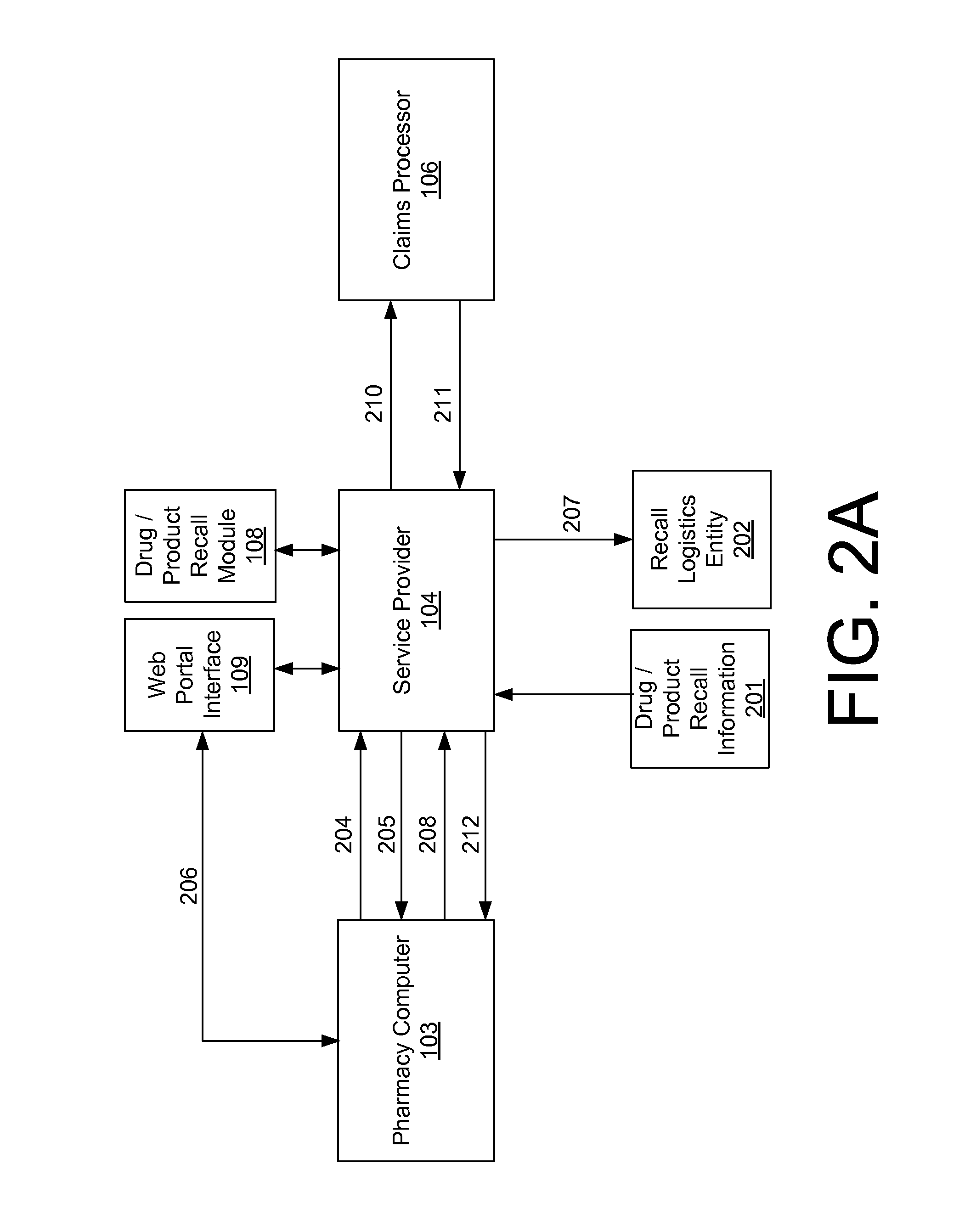

Systems and methods for supporting drug or product recalls

Systems and methods may be provided for supporting drug or product recalls. The systems and methods may include receiving a healthcare transaction request from a pharmacy computer associated with a pharmacy, wherein the healthcare transaction request includes an identification of a prescribed drug or product; determining, based upon the identification of the prescribed drug or product, that the prescribed drug or product is associated with a recall; providing, in response to the determination that the prescribed drug or product is associated with the recall, a response that includes information for accessing a web portal interface; receiving, over the web portal interface, lot numbers associated with pharmacy inventory of the prescribed drug or product; determining that one or more of the received lot numbers are affected by the recall; and generating a notification identifying the received lot numbers that are associated with the pharmacy inventory.

Owner:MCKESSON CORPORATION

Gamma and temperature hardened pharmaceutical devices

ActiveUS20100017159A1Overcomes shortcomingThermometerLavatory sanitoryRelevant informationExtreme temperature

A system and method for implementing embedded electronics in environments where radiation or extreme temperatures are used is disclosed. Embedded electronics are affixed to various components of a pharmaceutical system, thereby enabling the customer to download pertinent information about the component, such as lot number, date of manufacturer, test parameters, etc. Additionally, these electronics allow an array of functions and features to be implemented, such as integrity tests and diagnostics. The electronics in the pharmaceutical components utilize a technology that is not as susceptible to radiation and extreme temperatures as traditional electronics.

Owner:MILLIPORE CORP

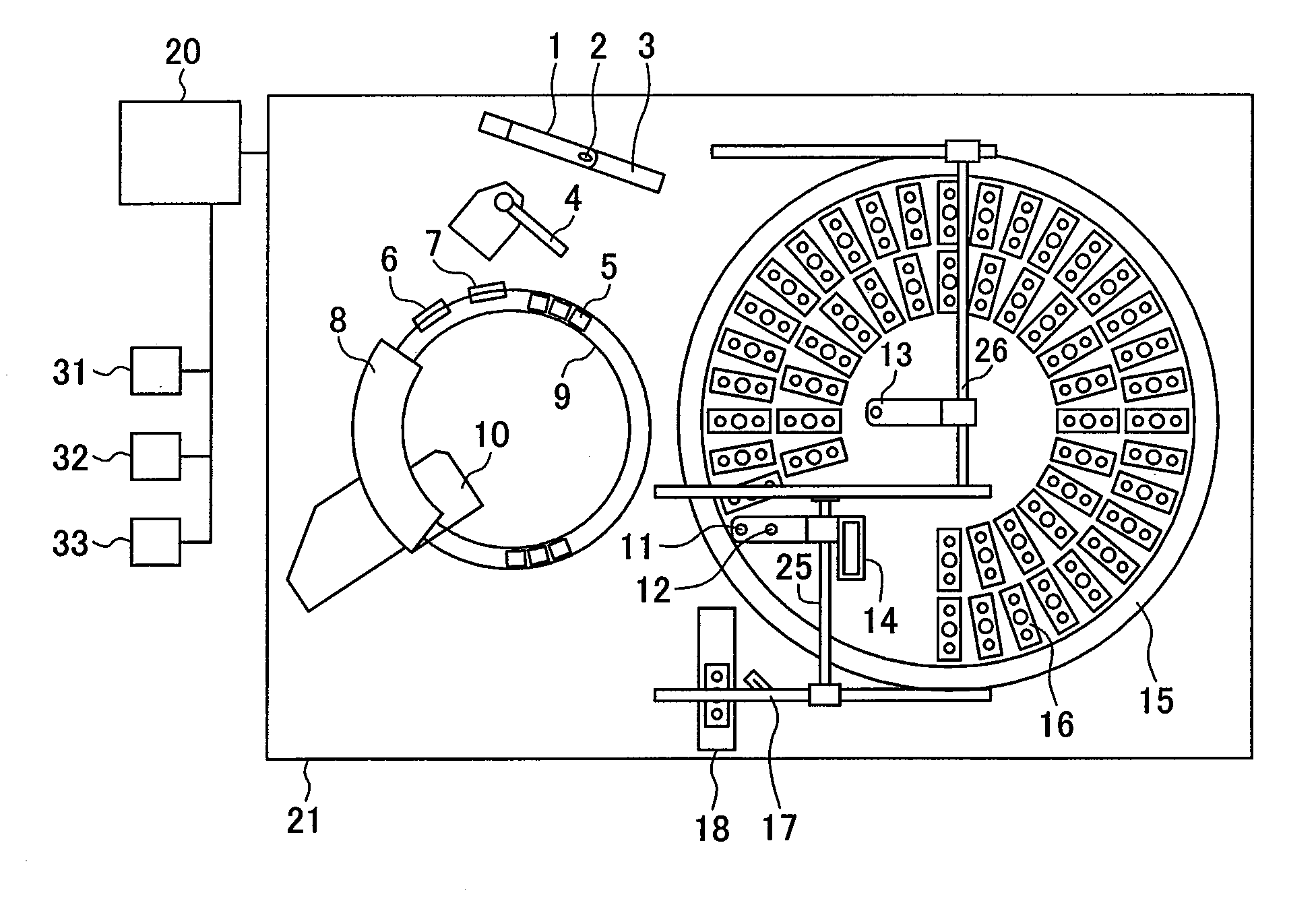

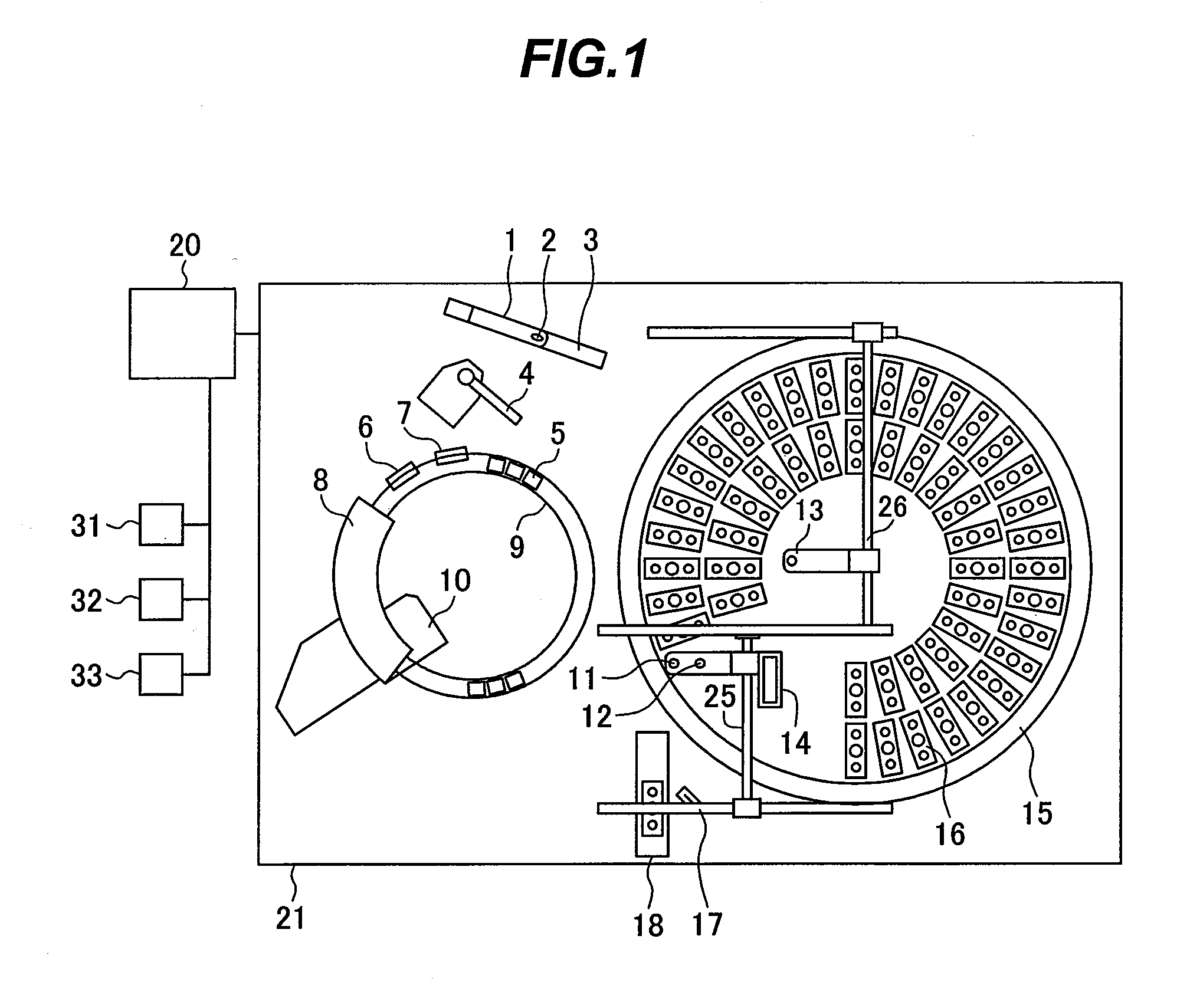

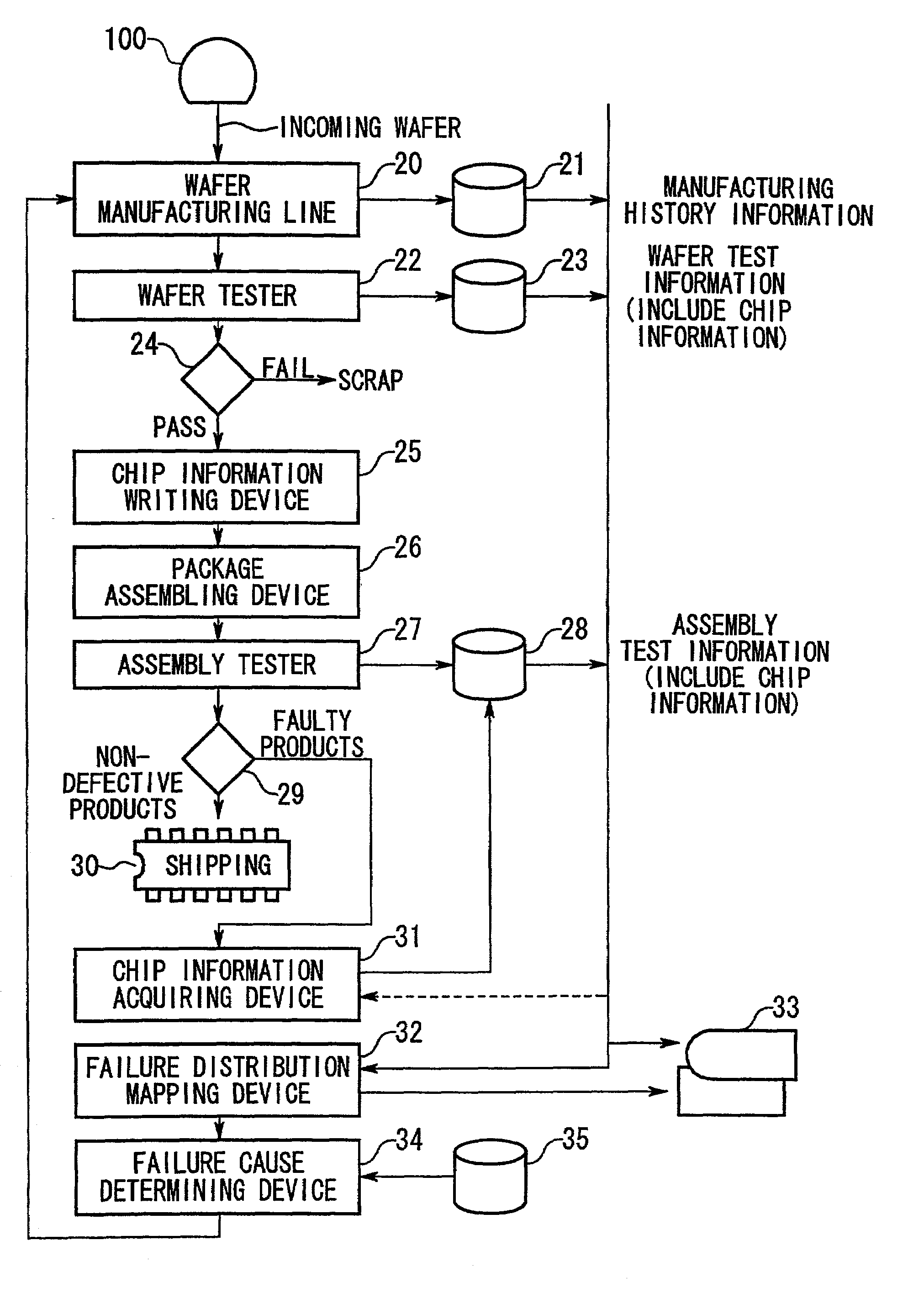

Automatic analyzer

ActiveUS20090142231A1Reliable resultsLow reliabilityBiological testingChemical/physical/physico-chemical processesTime segmentCalibration curve

The automatic analyzer stores: a predetermined period from the opening of a reagent vessel to the deterioration of the reagent; a reagent production lot number, reagent vessel unsealing time, and reagent expiration date as reagent information kept on a reagent-set-by-set basis; and relevant calibration curve factor information. The automatic analyzer judges whether a calibration curve factor for a reagent set is applicable or not to another reagent set of the analyzer with the same production number based on the predetermined period from the reagent vessel unsealing time and on the reagent expiration date.

Owner:HITACHI HIGH-TECH CORP

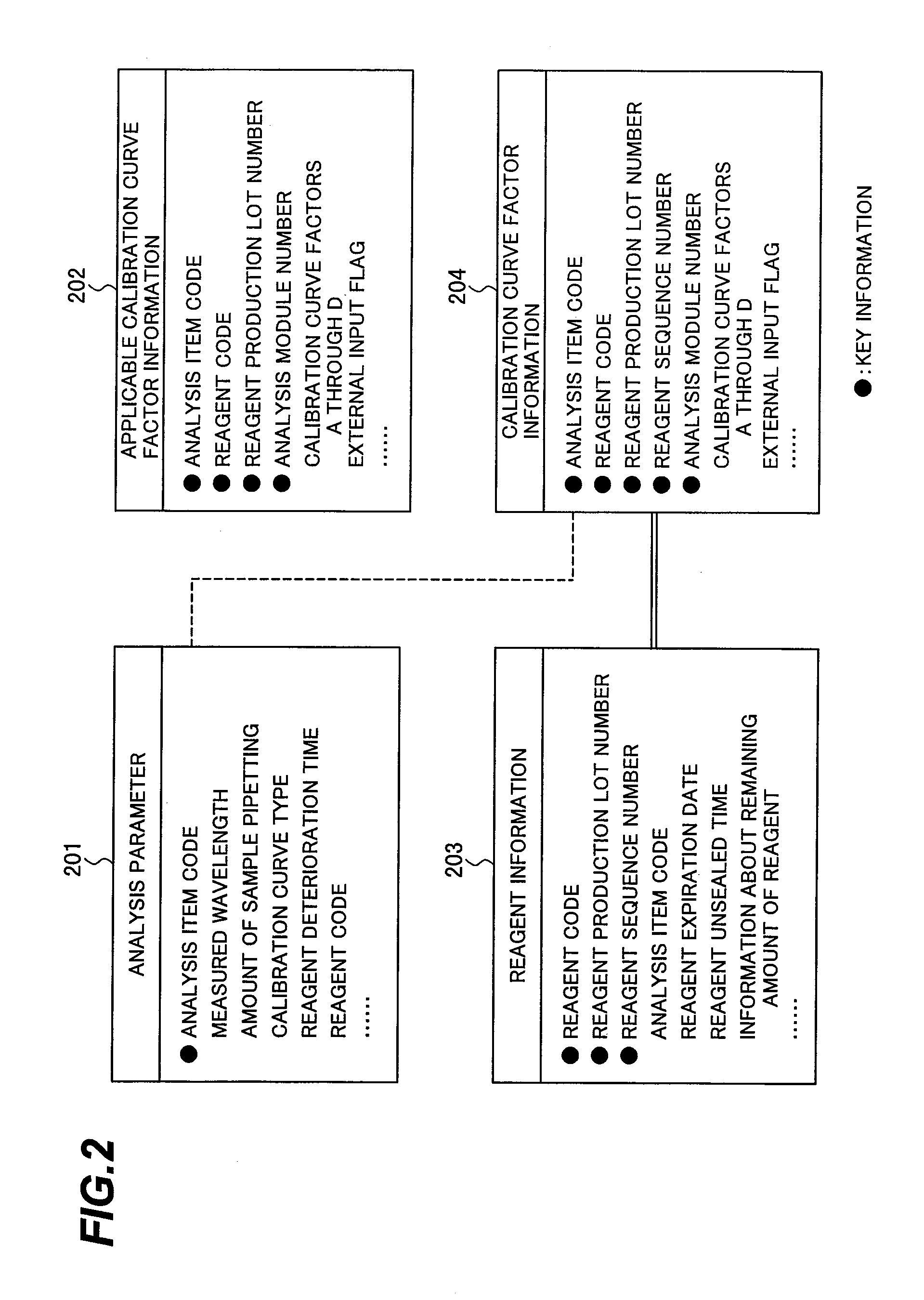

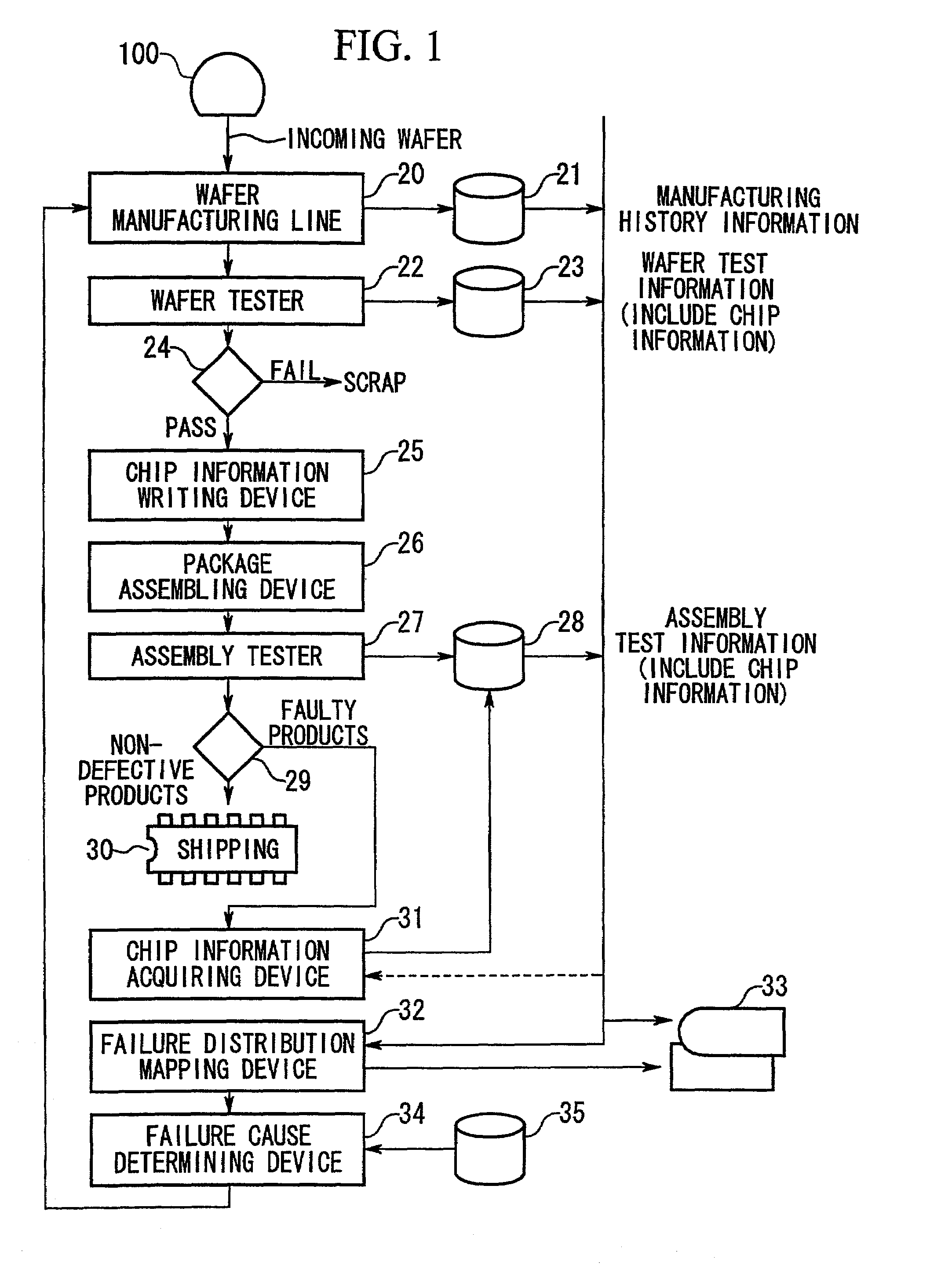

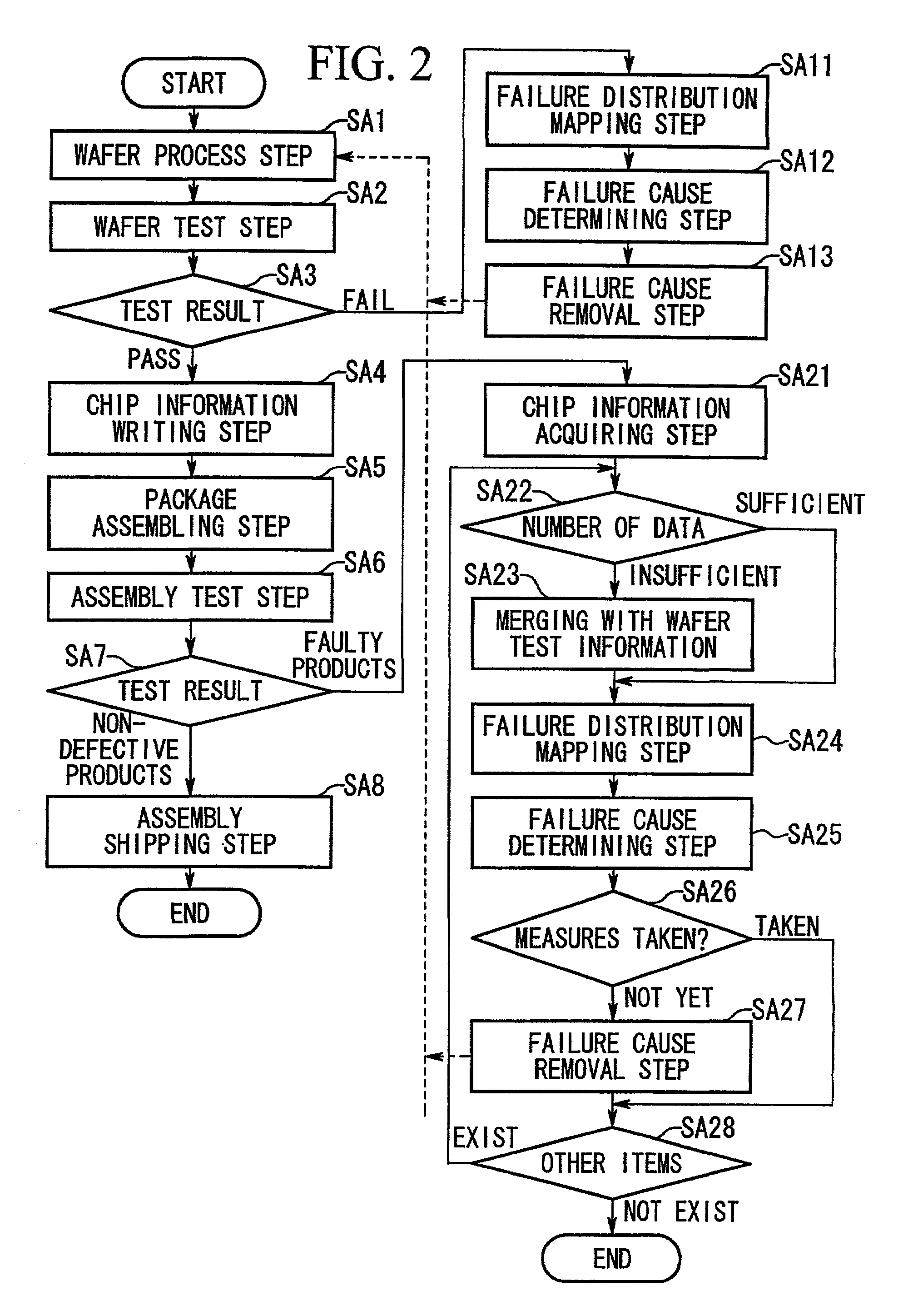

Method of manufacturing semiconductor devices

InactiveUS7054705B2Improve chip yieldStable productionSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringFailure causes

A semiconductor device manufacturing system is provided in which chip position information is read without removing resin from a package so that the cause of a failure can be quickly identified and removed and the yield of chips can be rapidly improved. A replacement address reading device reads redundancy addresses from a semiconductor device which is determined as faulty in a test performed after the semiconductor device has been sealed into a package. A chip position analyzing device estimates, from the combination of these redundancy addresses, a lot number, a wafer number and a chip number of the faulty semiconductor device. A failure distribution mapping device maps the distribution of faulty chips in each wafer in the lot based on these numbers thus obtained. A failure cause determining device identifies which manufacturing device or processing step has caused the failures in the wafer process based on the above distribution.

Owner:LONGITUDE SEMICON S A R L

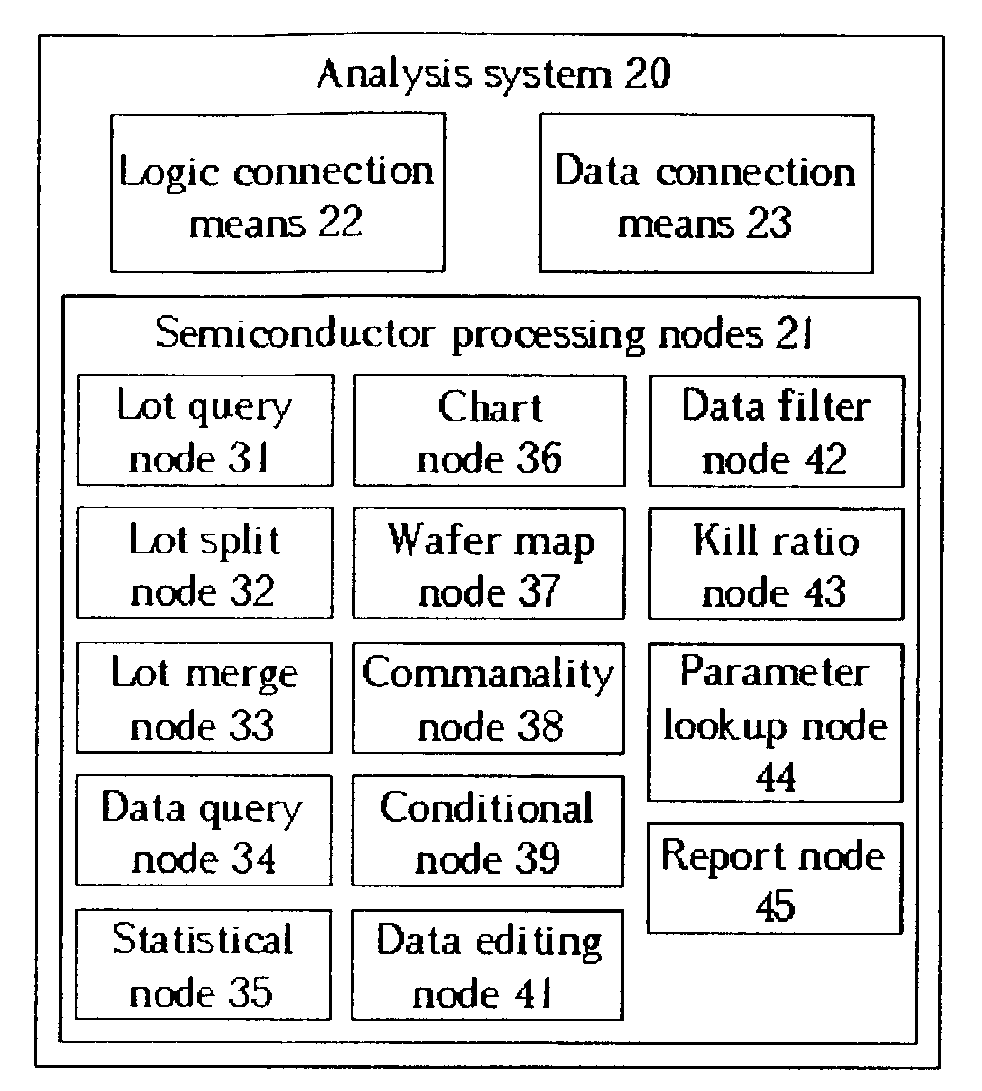

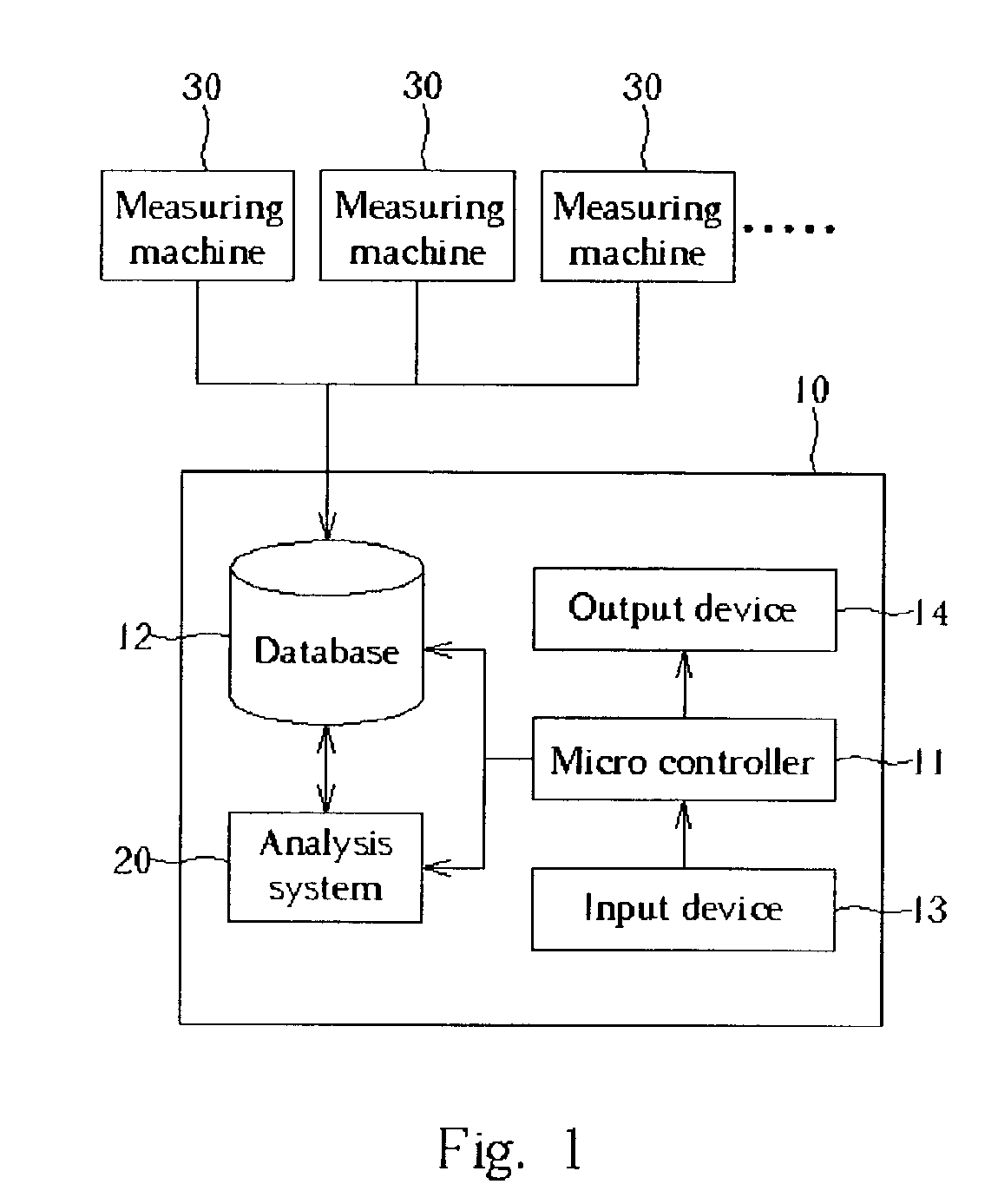

Automatic intelligent yield improving and process parameter multivariate system and the analysis method thereof

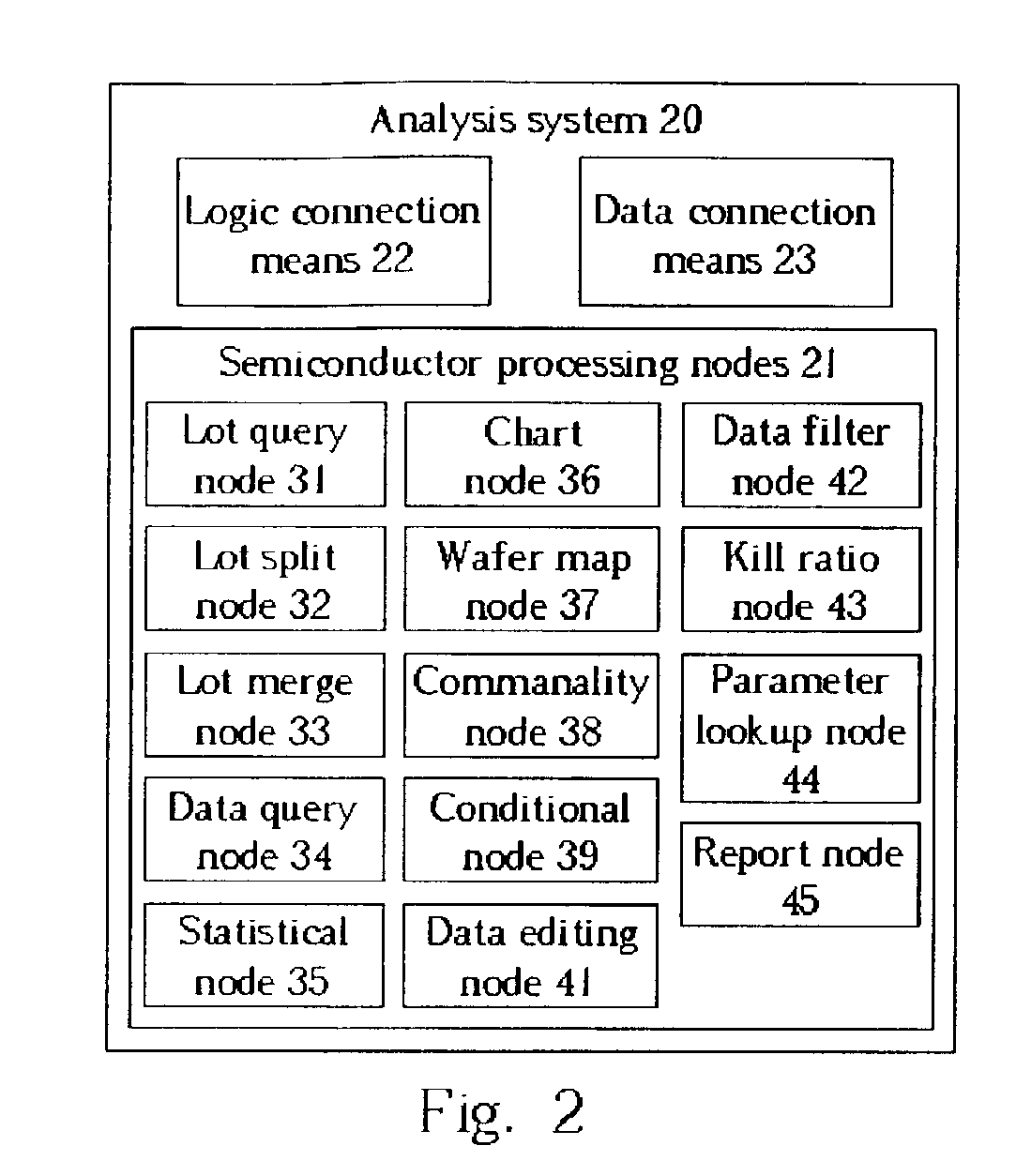

ActiveUS7079677B2Increase flexibilityAccuracyProgramme controlSemiconductor/solid-state device manufacturingData connectionMultivariate analysis

An automatic intelligent yield improving and process parameter multivariate analysis system and the analysis method thereof. The system is applied to a computer to set up analysis procedures for analyzing process parameters obtained from each measuring machine in semiconductor testing process by utilizing data mining technology. The system includes a plurality of semiconductor processing nodes having different functions. The system links each of the semiconductor processing node to another semiconductor processing node by a logic means so that the computer can process the semiconductor processing nodes sequentially. The system also links the semiconductor processing nodes by a data connection means to allow microprocessors to load necessary parameter data or wafer lot numbers from corresponding semiconductor processing nodes by a data connection means.

Owner:POWERCHIP SEMICON MFG CORP

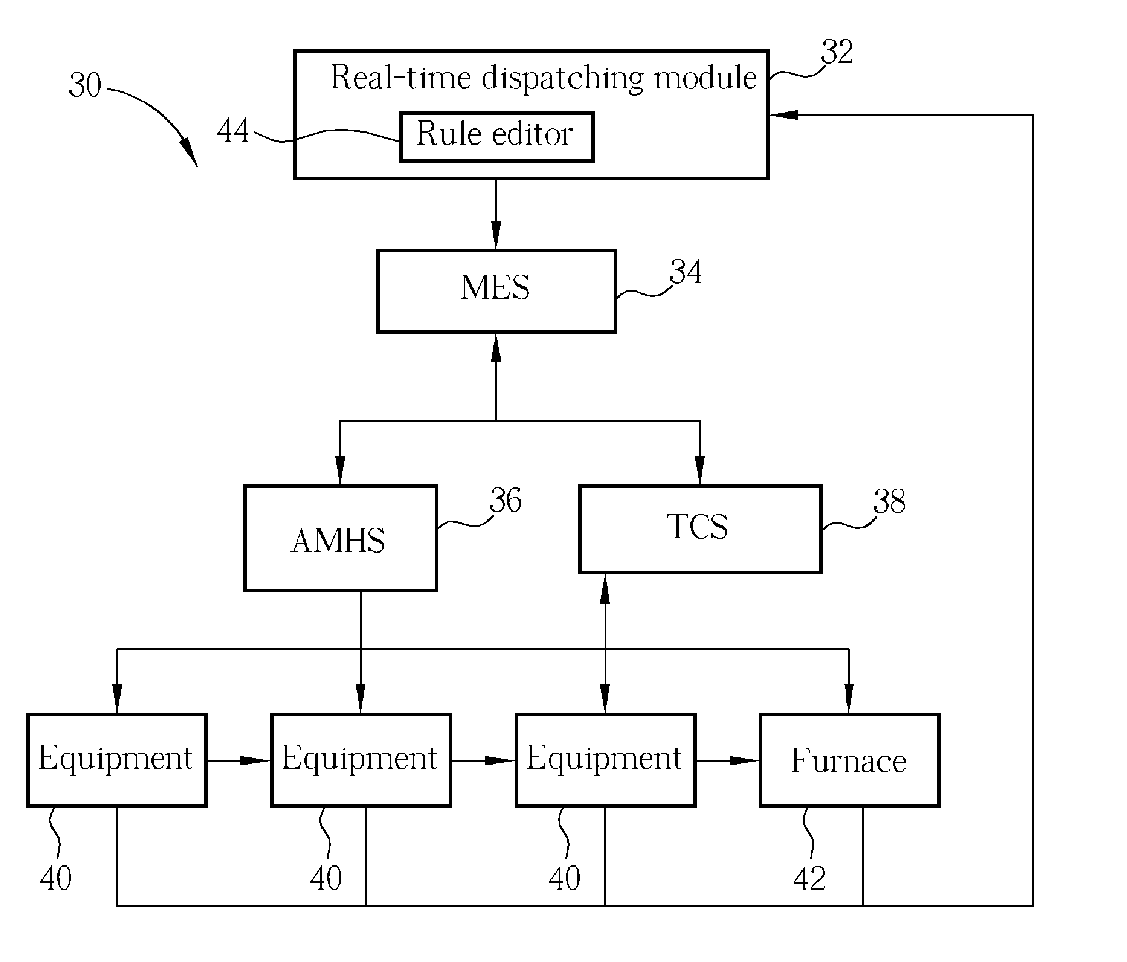

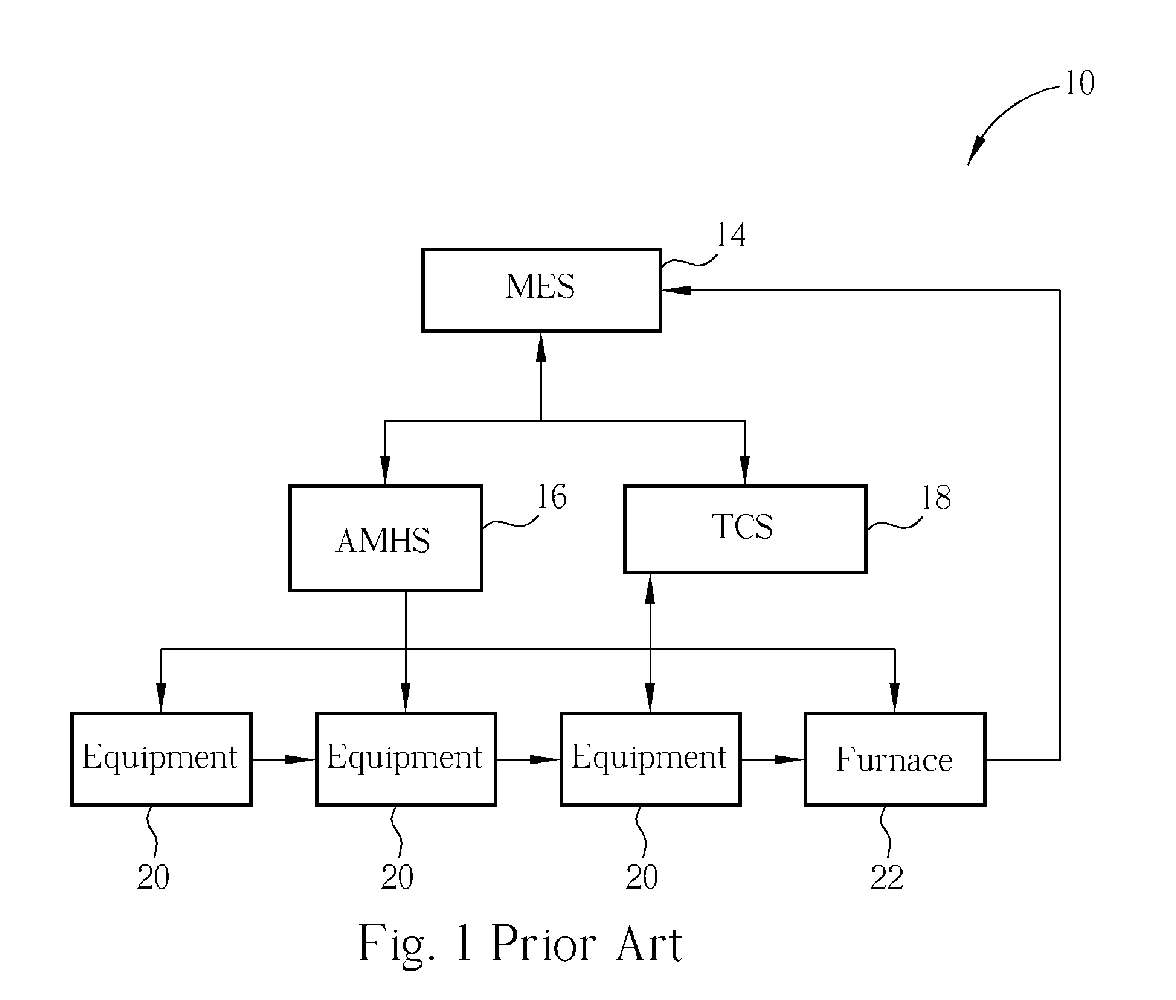

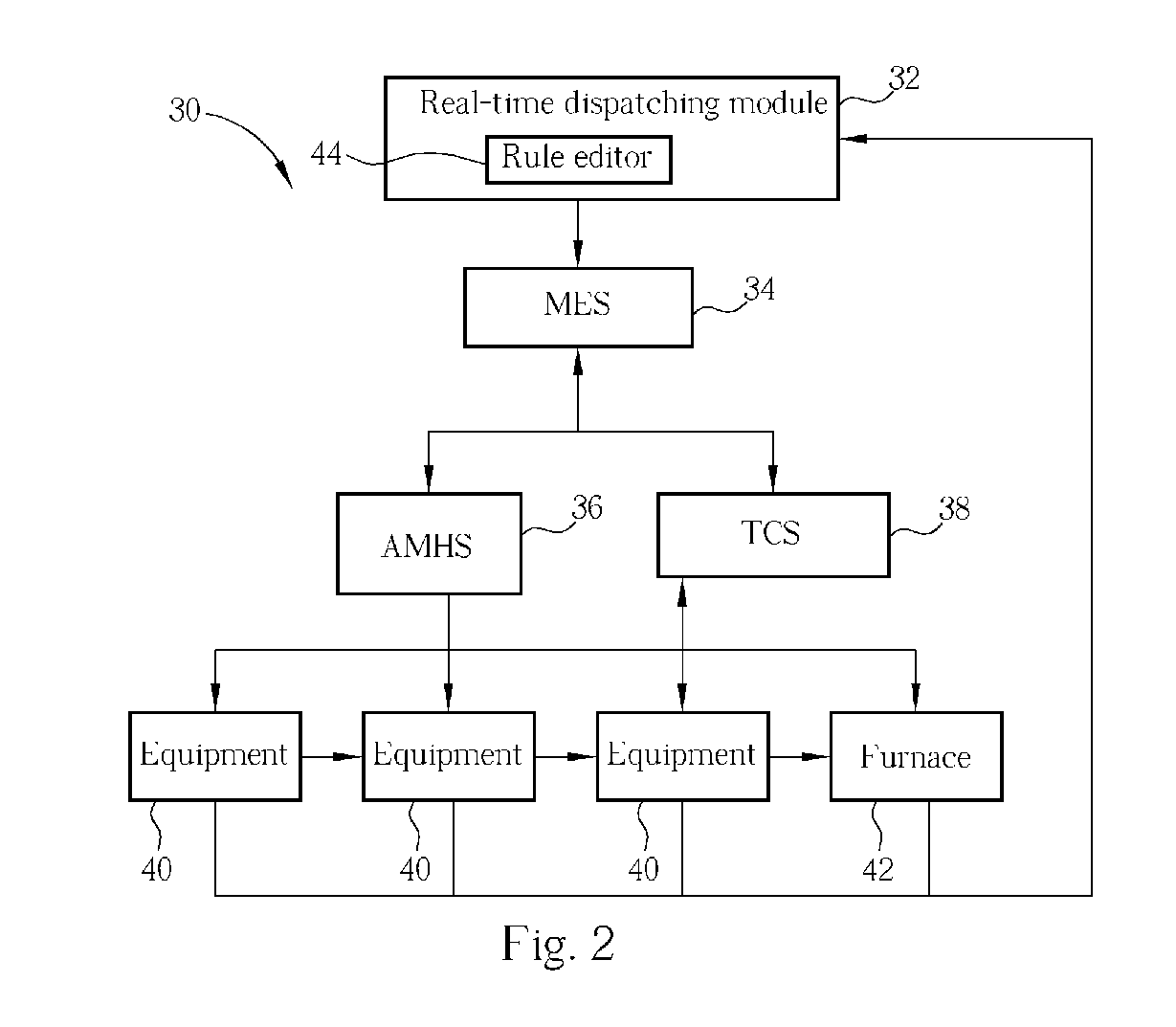

System and method thereof for real-time batch dispatching manufacturing process

InactiveUS20050256599A1Reduce standby timeIncrease profitSemiconductor/solid-state device manufacturingResourcesComputer moduleManufacturing execution system

The present invention provides a system and method for real-time batch dispatching in a manufacturing process. The system includes a bottleneck equipment, a real-time dispatching module for calculating a time point of forming a batch and deciding the lot numbers of a plurality of products which are included in the batch at the time point, and a manufacturing execution system electronically connected to the bottleneck equipment and the real-time dispatching module for receiving the batch transmitted from the real-time dispatching module so as to choose the plurality of products according to the lot numbers and controlling the plurality of products to be simultaneously processed by the bottleneck equipment at the same time point.

Owner:POWERCHIP SEMICON CORP

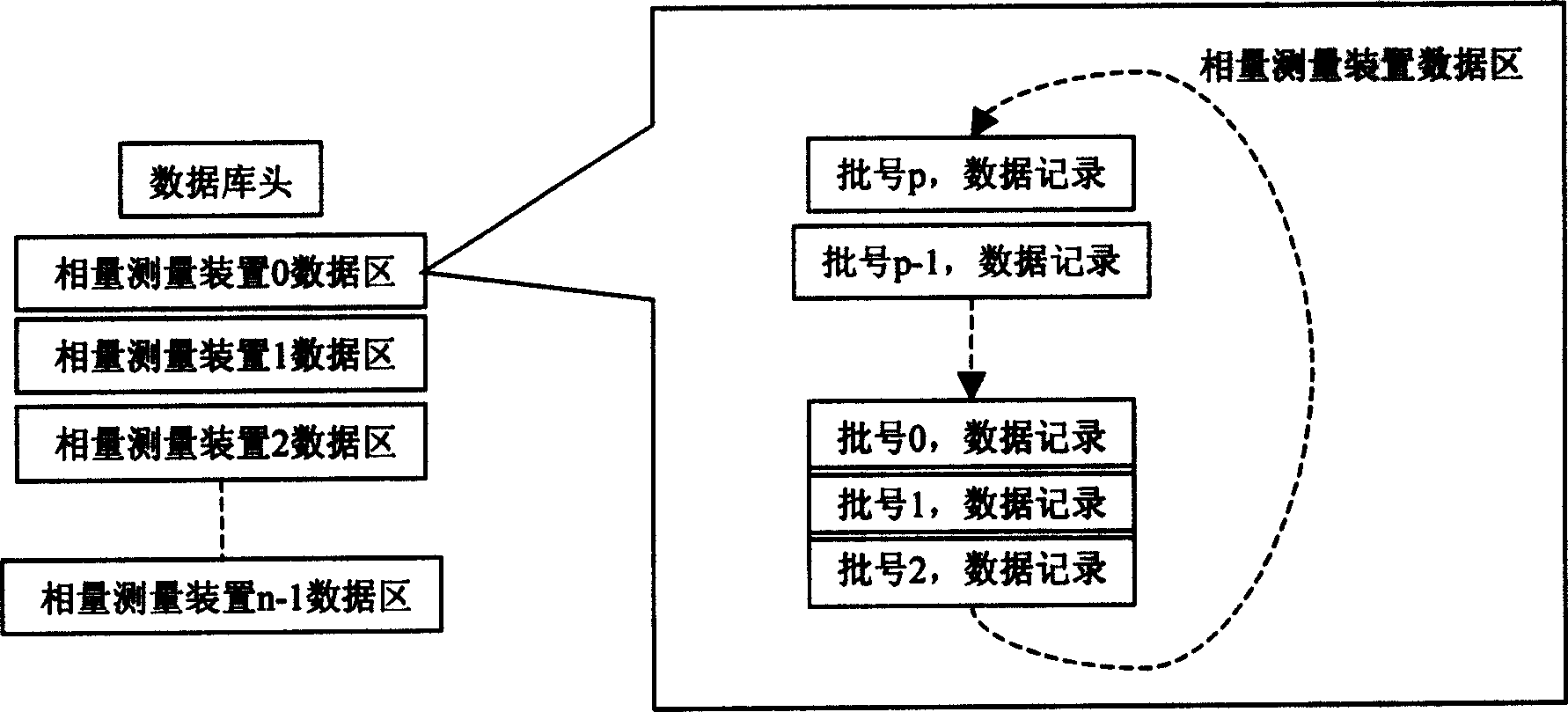

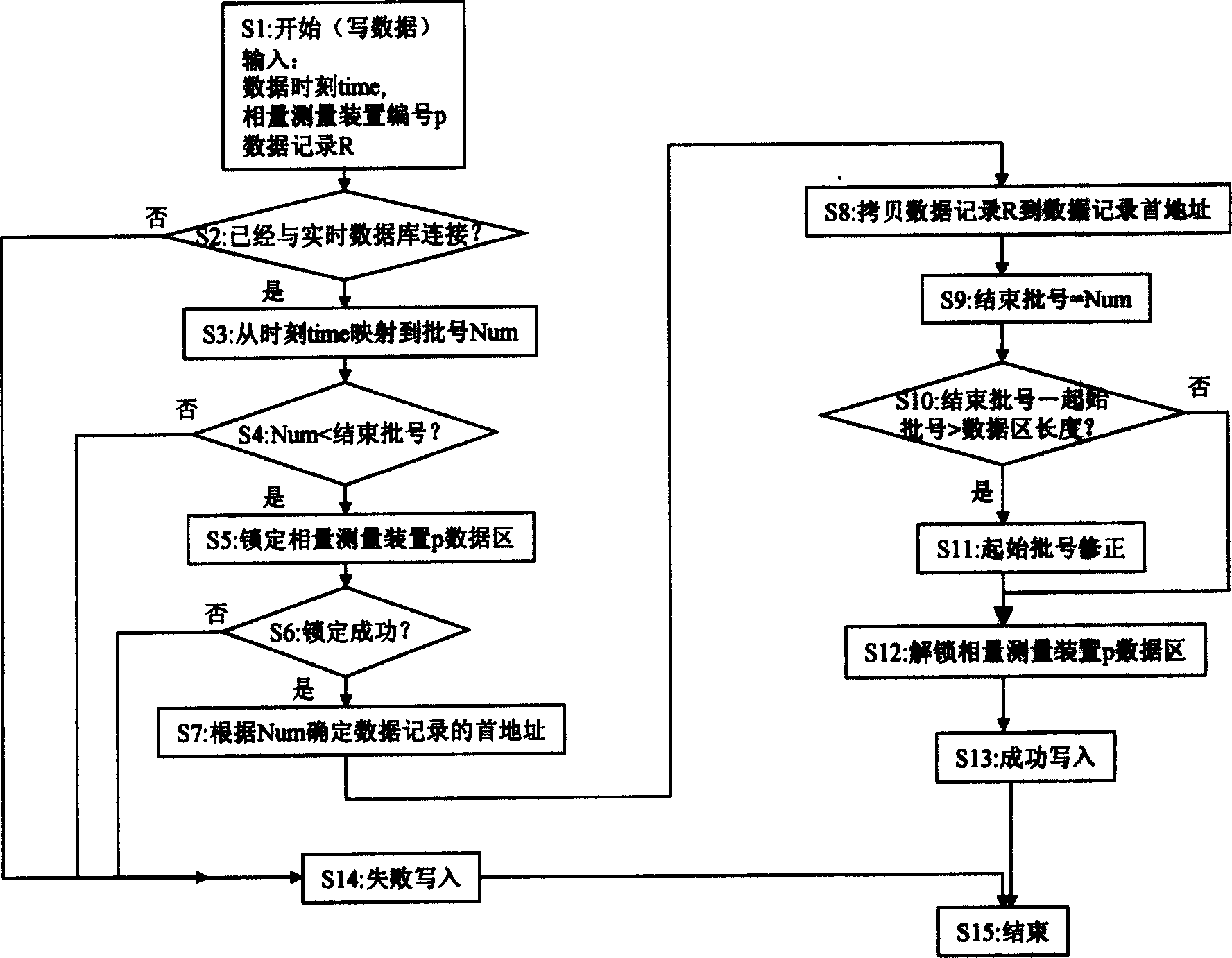

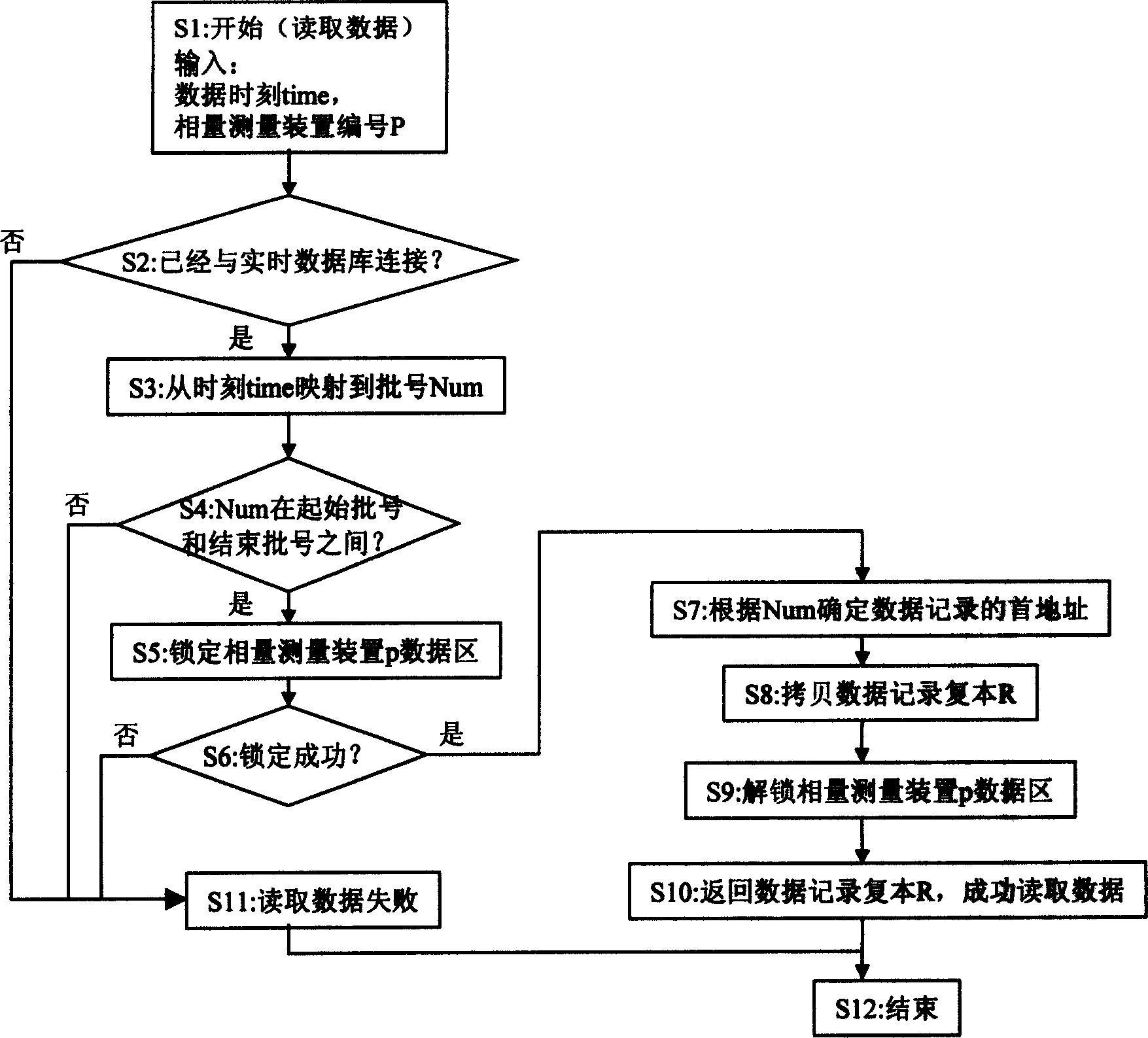

Data monitoring method in electric network safe dynamic monitoring system

InactiveCN1472688AGuaranteed time consistencyEnsure consistencyMemory adressing/allocation/relocationSpecial data processing applicationsInternal memoryReal-time data

The method incldues the following steps: writing in and fetching real-time data, using shared internal memory mode as internal memory of real-time databank and ensuring data uniformity by write / read lock; picking up real-time data locus and to directly pick up fetching data from databank for those high-level application which wants to obtain locus within front 1s, synchronizing the real-time data, picking up the real-time data from each phasor measuring storage zone in sequence as per lot number corresponding to this moment by the databank, using long integer as indexing to quickly locate stored position of the rea-time data.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

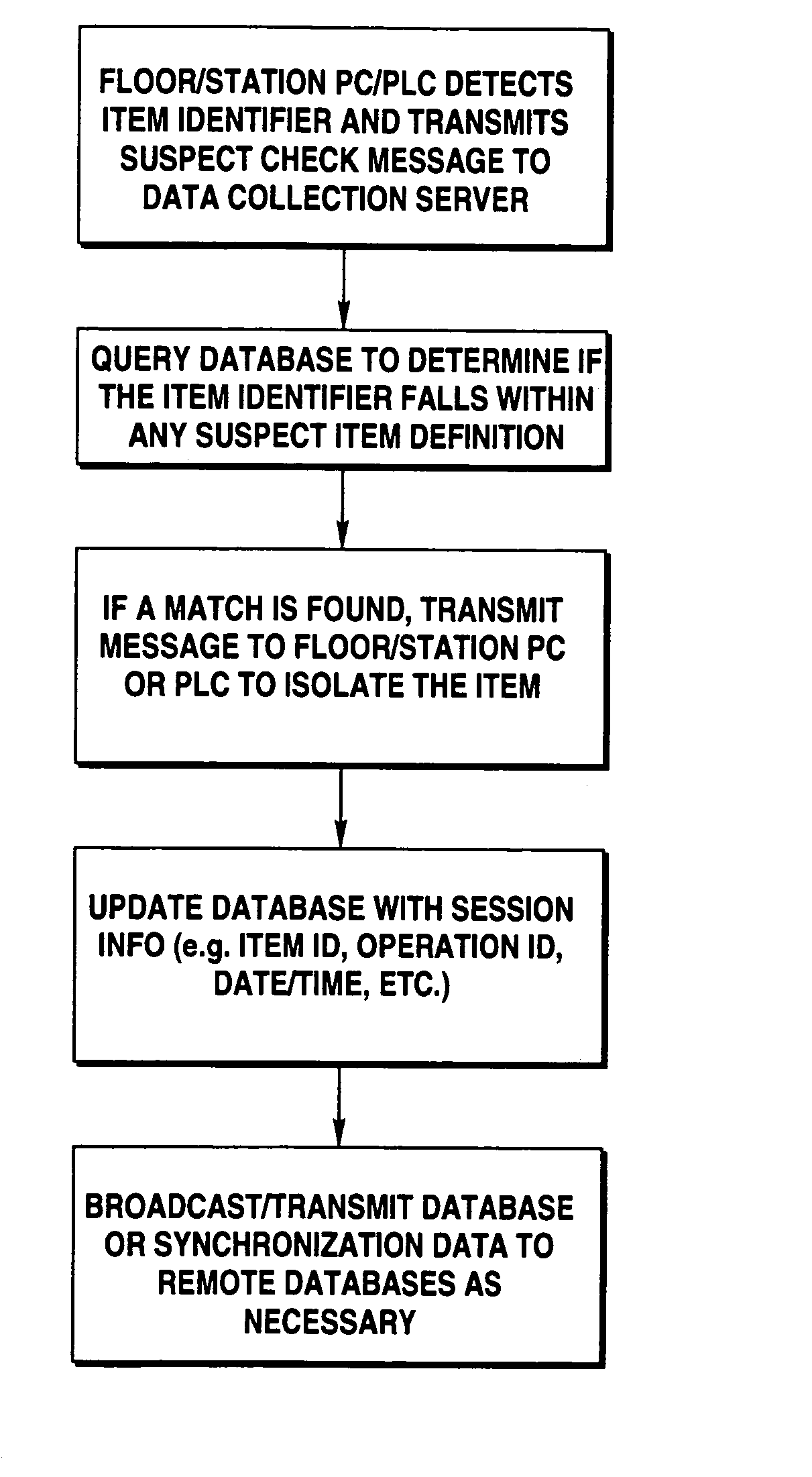

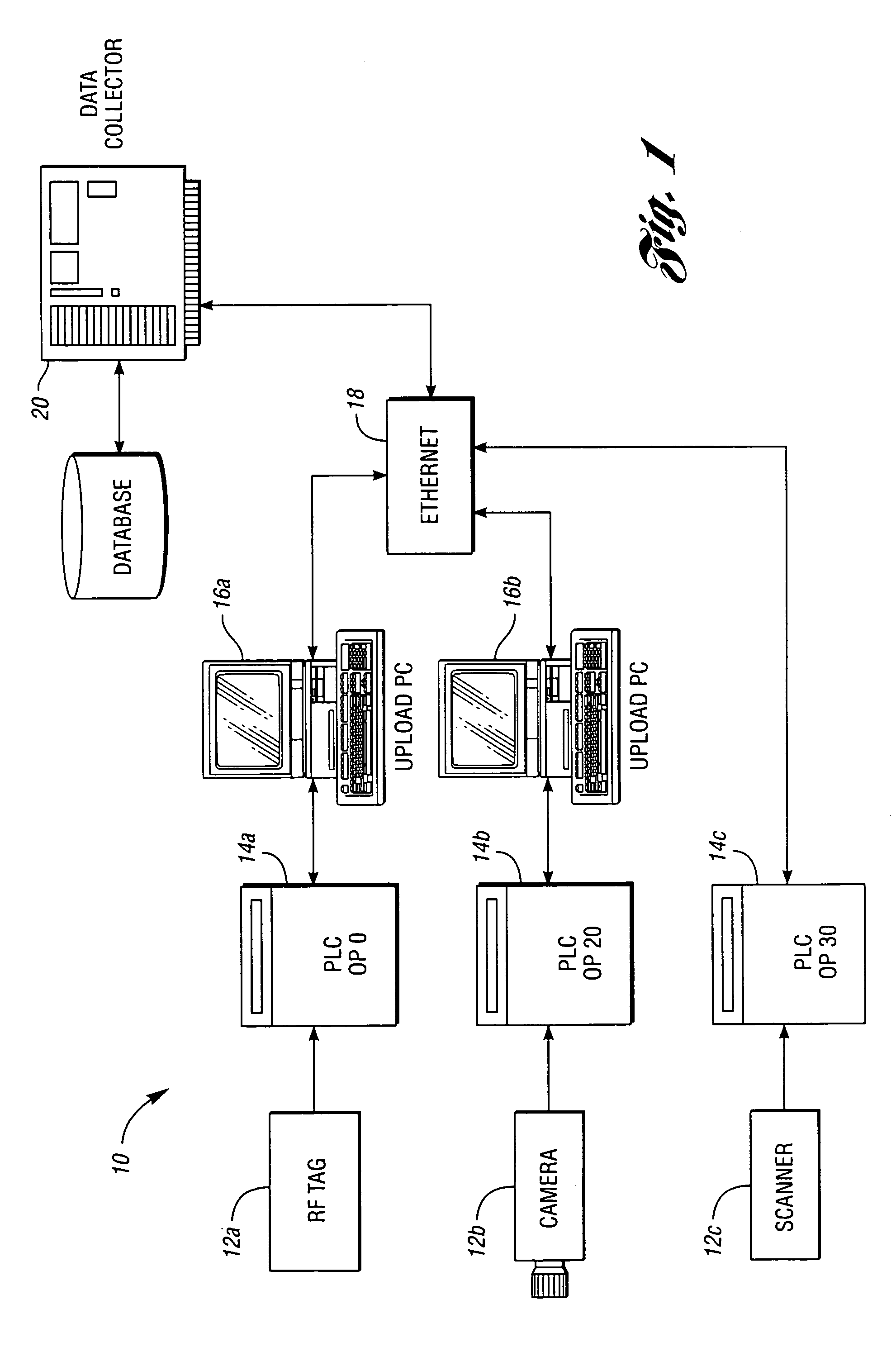

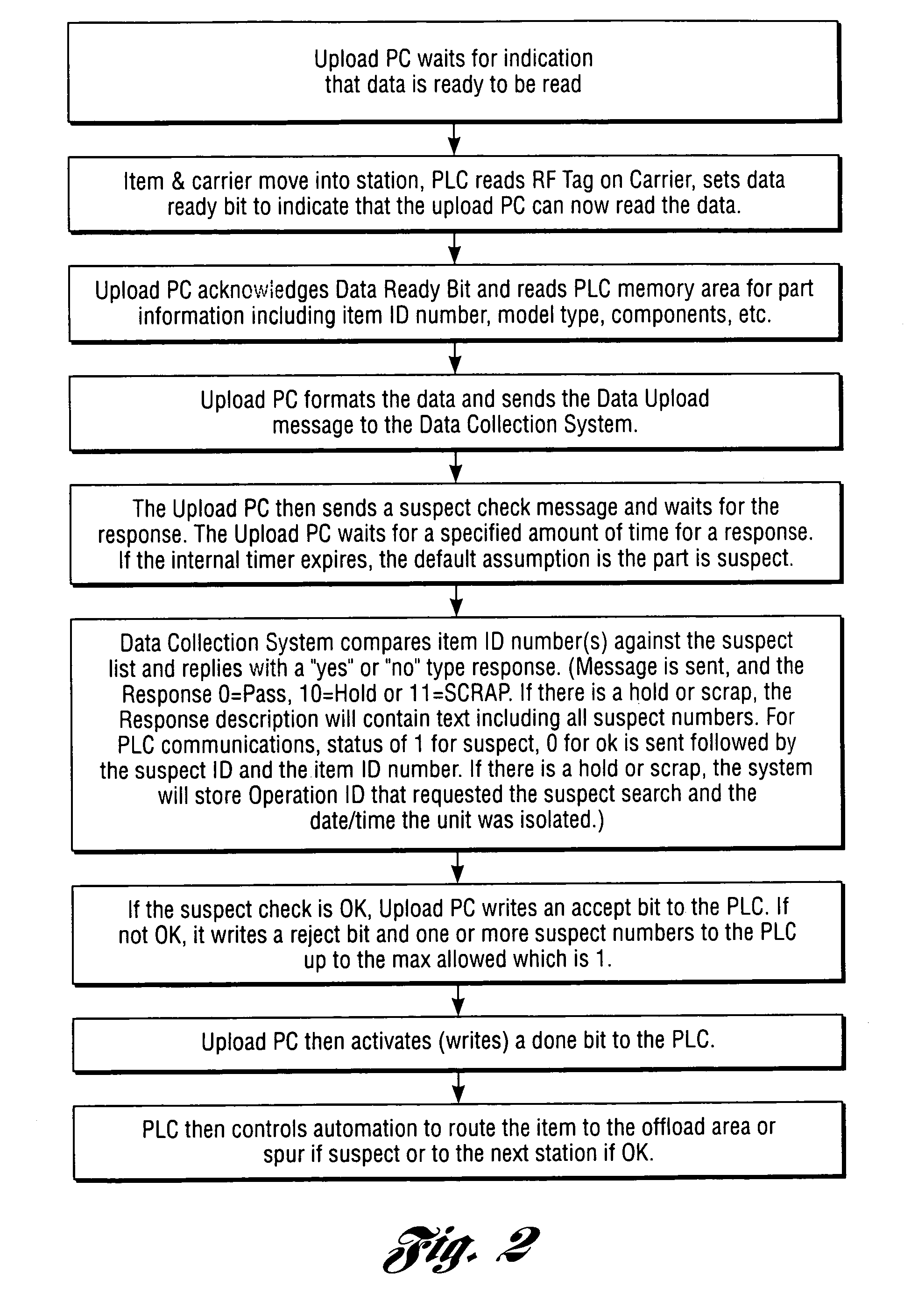

Method and system for automatically isolating suspect items in a manufacturing or assembly environment

A computer-implemented method and system includes capabilities for receiving suspect item definitions (e.g. item serial numbers, lot numbers, operation identifiers, date ranges, etc.) into a computer database, detecting item identifiers in a manufacturing or assembly process, and comparing the item identifiers with the suspect item definitions. If the detected item identifier falls within one of the suspect item definitions, the item is automatically isolated or otherwise rejected from manufacturing or assembly process. Other aspects of the invention include functionality for determining the location of suspect items. Locations may be inferred and off-site. Another aspect includes automatically modifying the manufacturing or assembly process to bypass one or more suspect manufacturing or assembly operations. A plurality of user interfaces are provided for defining, locating and managing suspect items. Suspect item definitions and location information may by broadcast or otherwise communicated to distributed locations (e.g. holding areas, warehouses, etc.).

Owner:FORD MOTOR CO

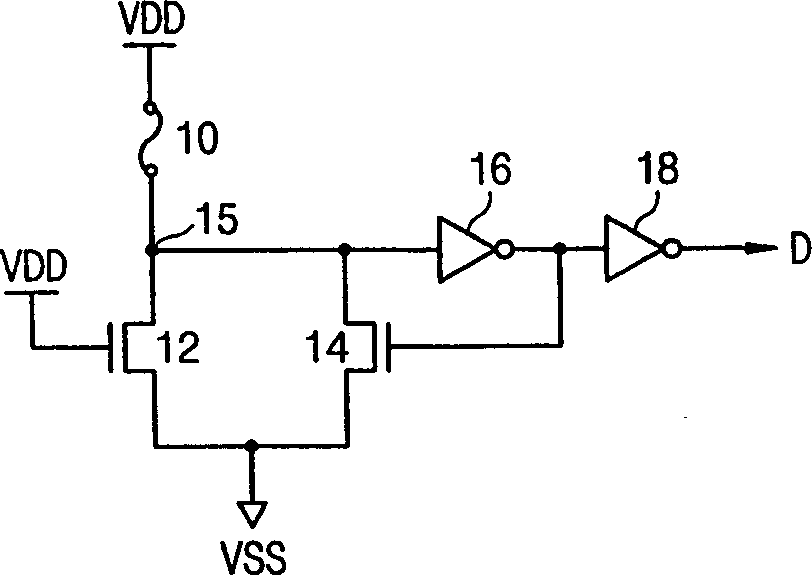

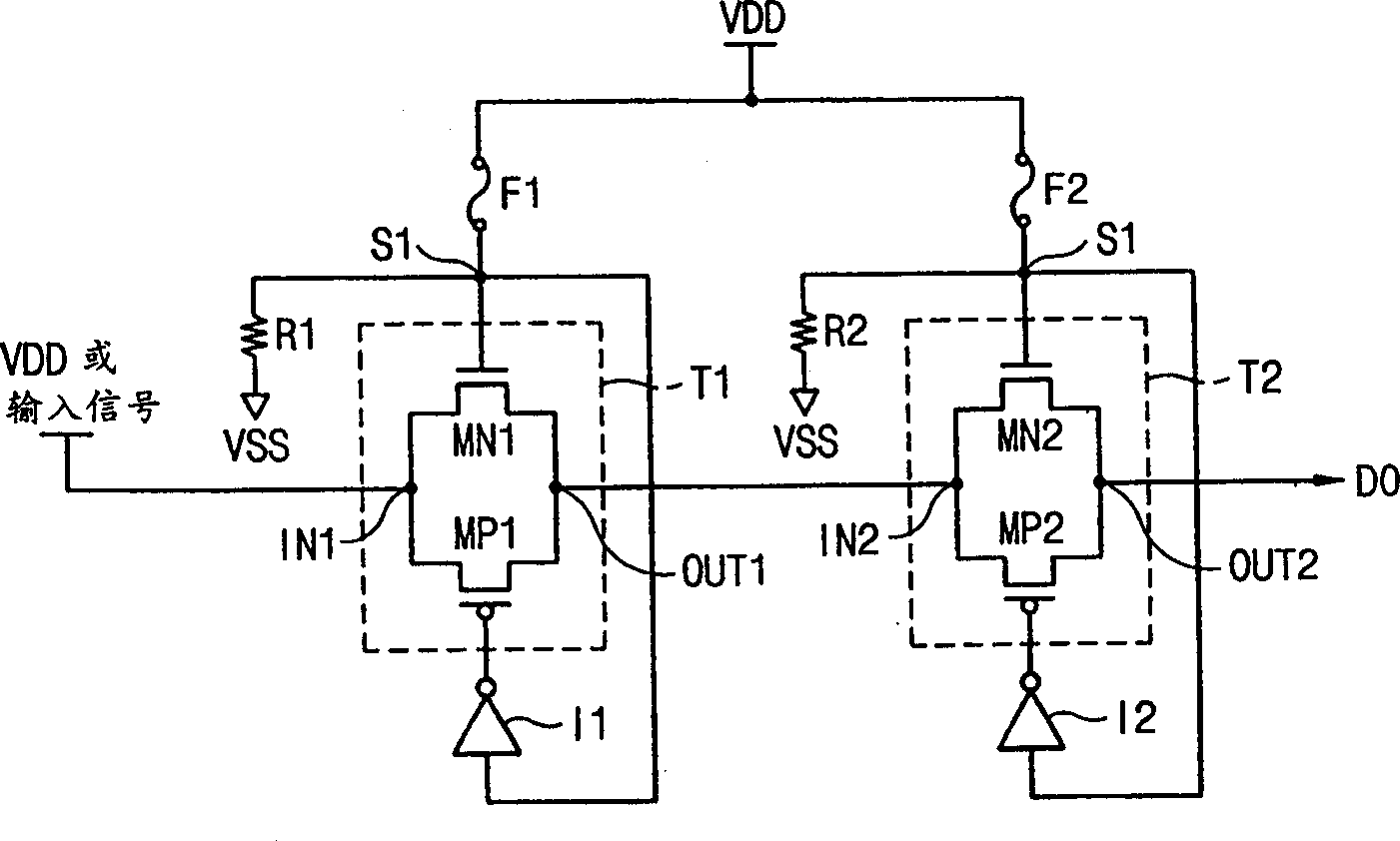

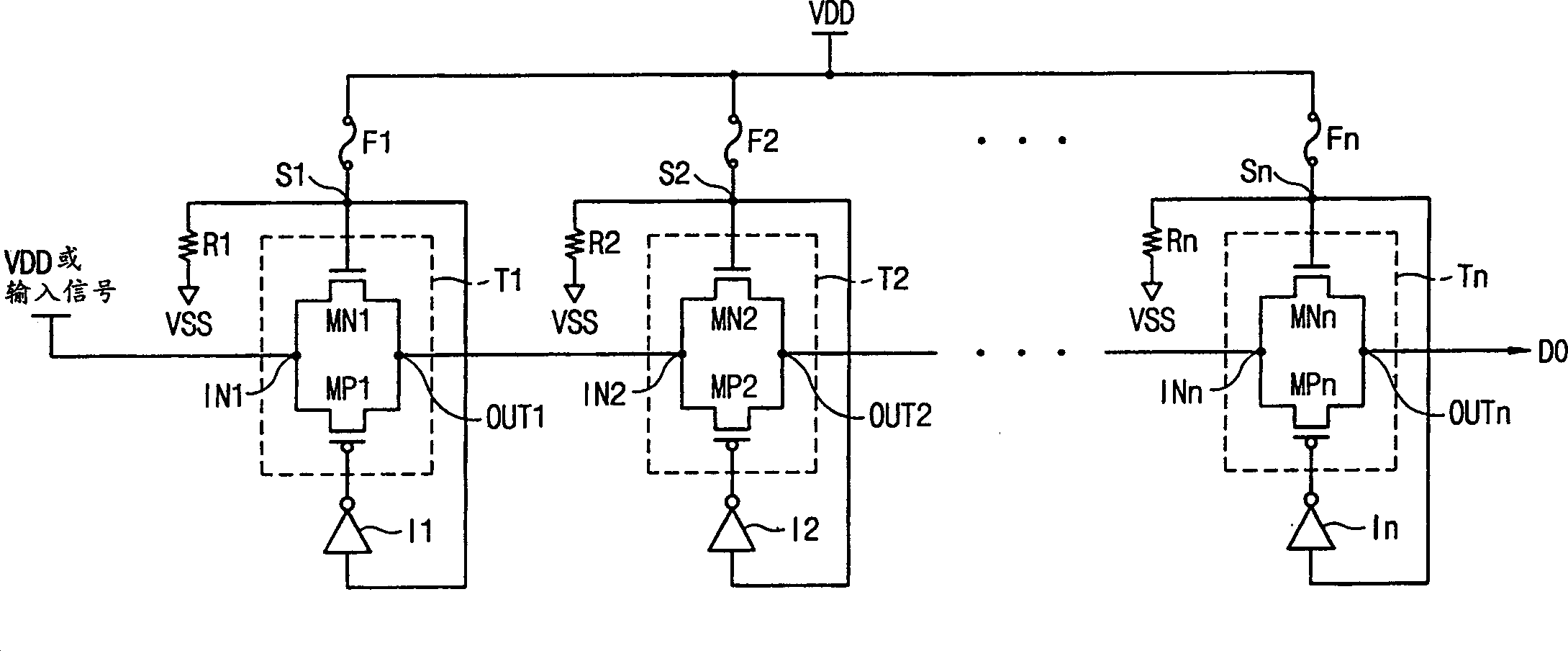

Fuse circuit used for semiconductor integrated circuit

InactiveCN1349259AReduce programming defectsDefect Generation Rate ReductionSemiconductor/solid-state device detailsSolid-state devicesGeneration rateSemiconductor

In a fuse circuit including programmable fuses in a semiconductor integrated circuit, the fuses store specific information related to the semiconductor integrated circuit, such as redundancy information, wafer lot number, die lot number, and die position on the wafer, etc. While a conventional semiconductor integrated circuit utilizes a single fuse for storing one bit of specific information, the fuse circuit in the present invention utilizes a plurality of fuses for storing identical bit information. Consequently, in the case where a fuse has not been cut out correctly, the fuse circuit of the present invention can reduce programming defects, whereby defect generation rates are remarkably decreased.

Owner:SAMSUNG ELECTRONICS CO LTD

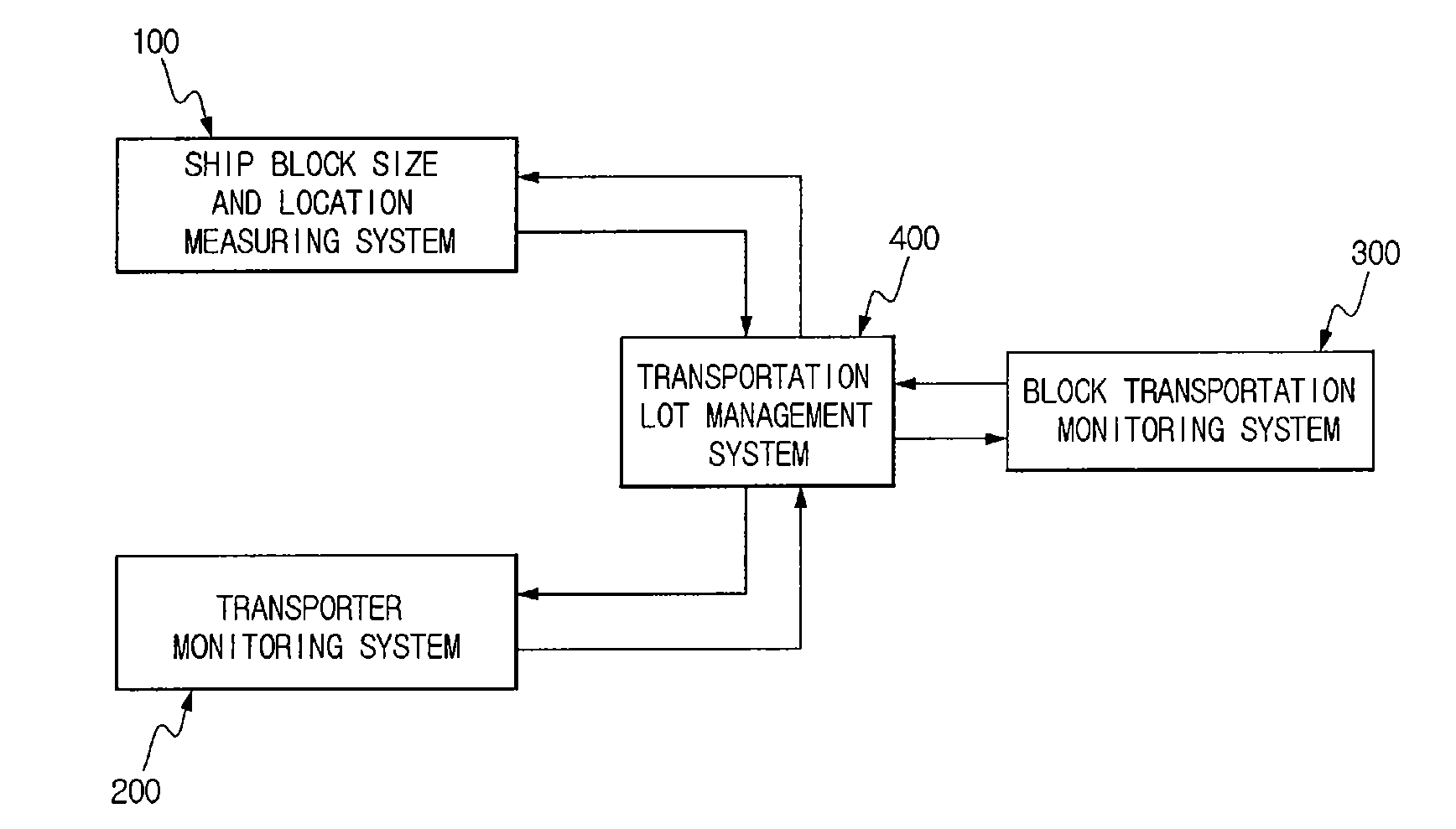

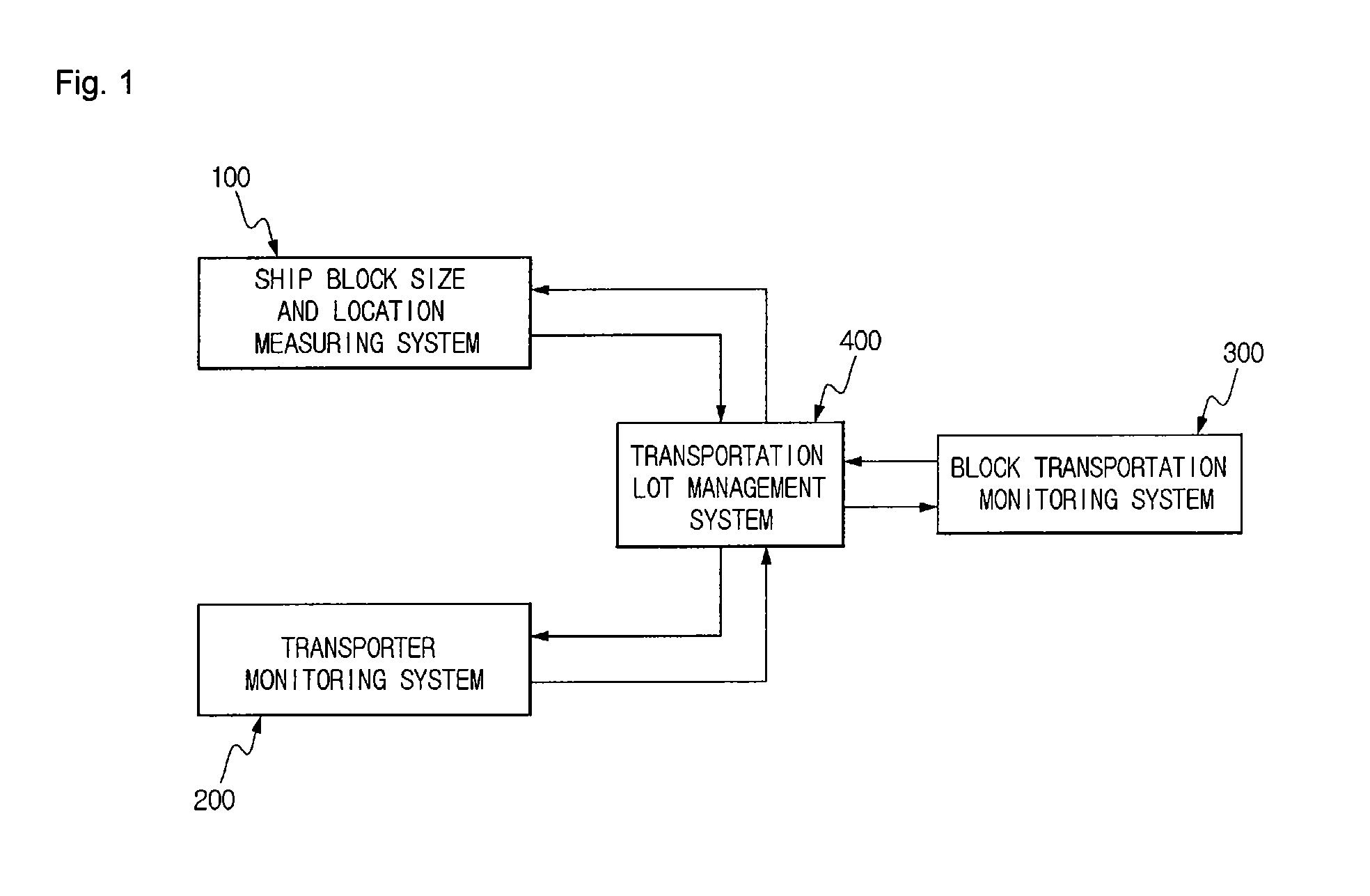

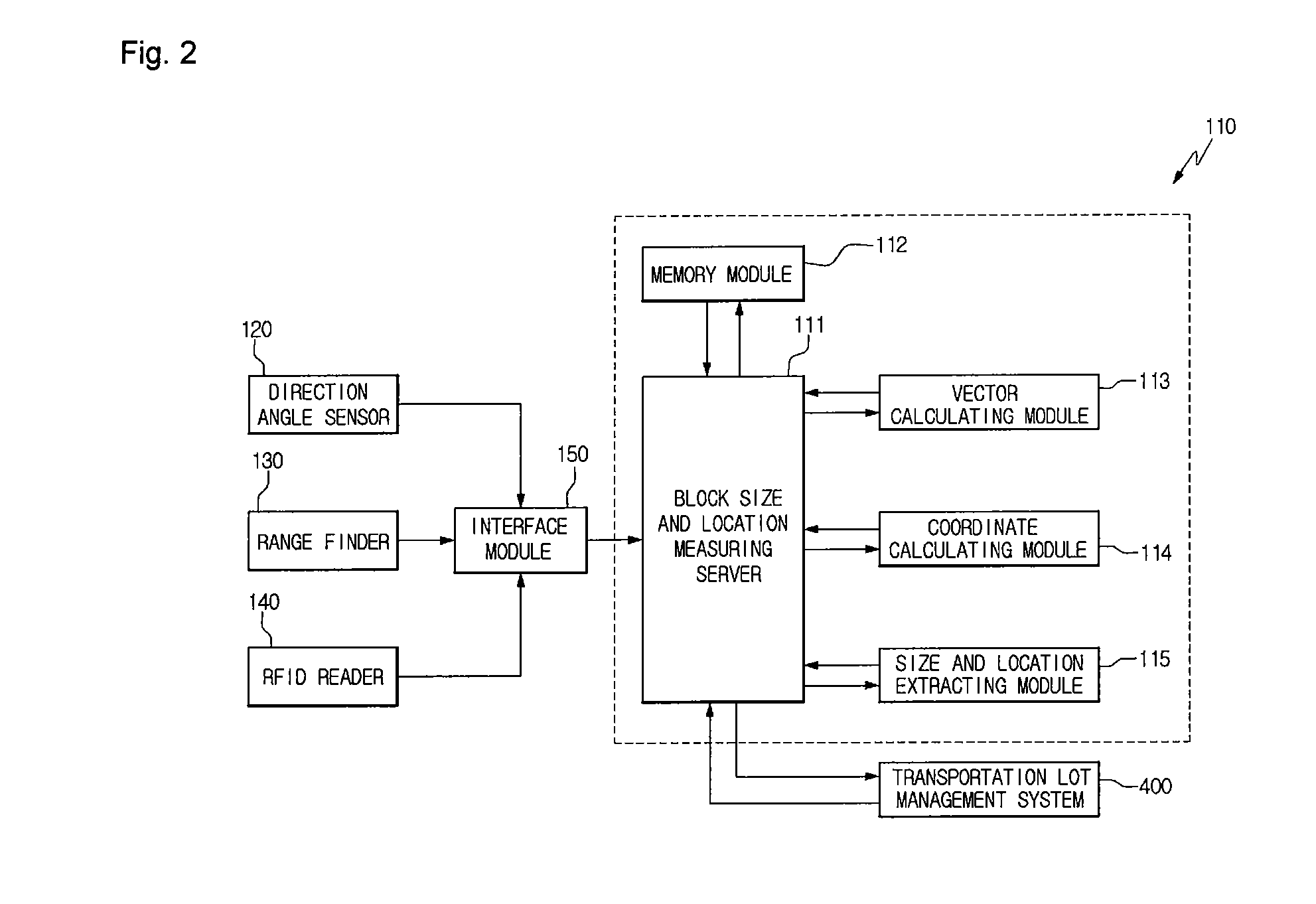

Apparatus for managing the operation of a ship block

ActiveUS8653945B2Efficient use ofEasy to transportResourcesSubscribers indirect connectionControl systemMonitoring system

Provided is an apparatus for managing the operation of a ship block, including a ship block size and location measuring system, a transporter monitoring system, a block transportation monitoring system and a transportation lot number management system. The ship block size and location measuring system includes a direction angle sensor, a range finder, a radio frequency identification (RFID) reader and a control system, and the control system includes a block size and location measuring server, a vector calculating module, a coordinate calculating module, a size and location extracting module, and a memory module.

Owner:HYUNDAI HEAVY IND CO LTD

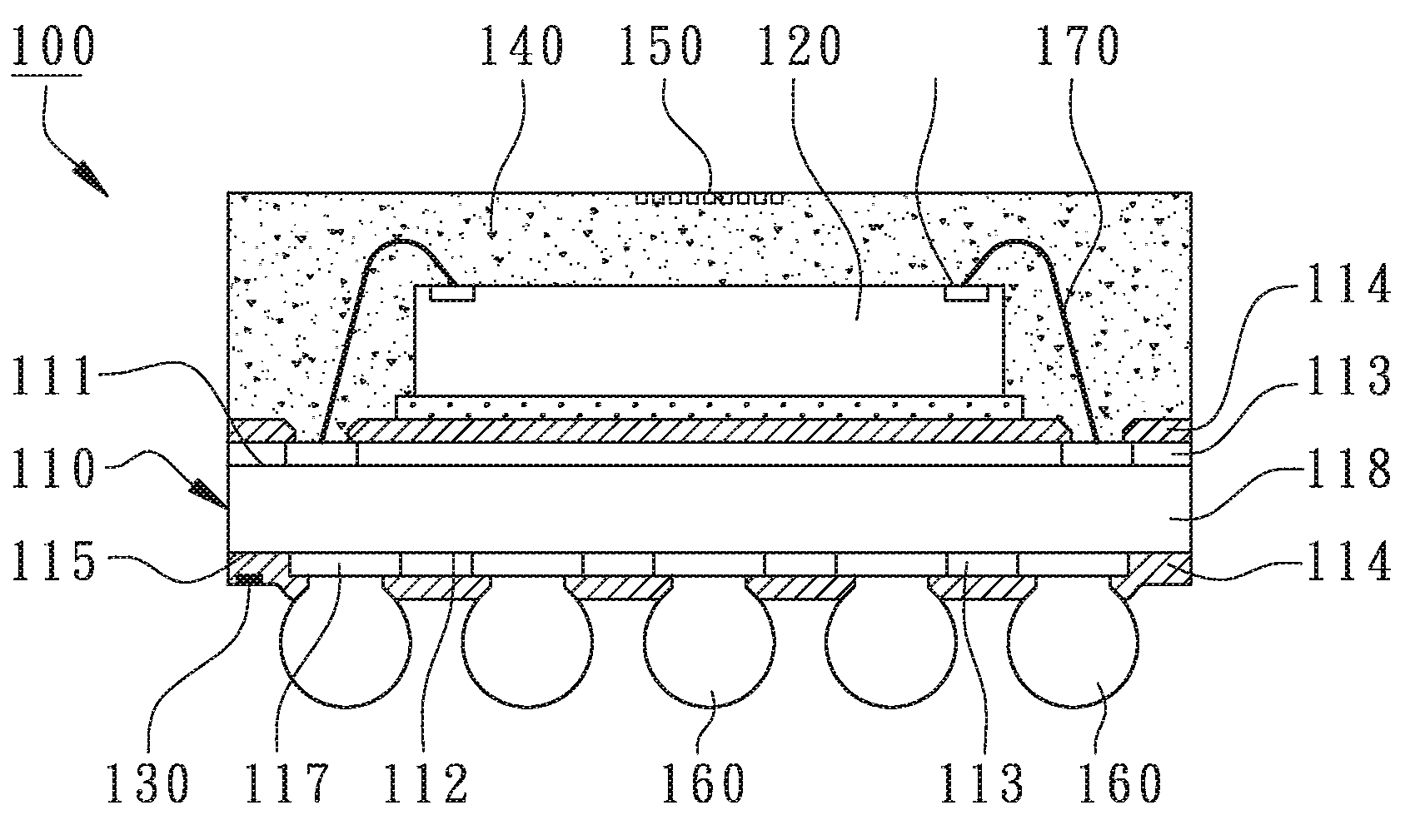

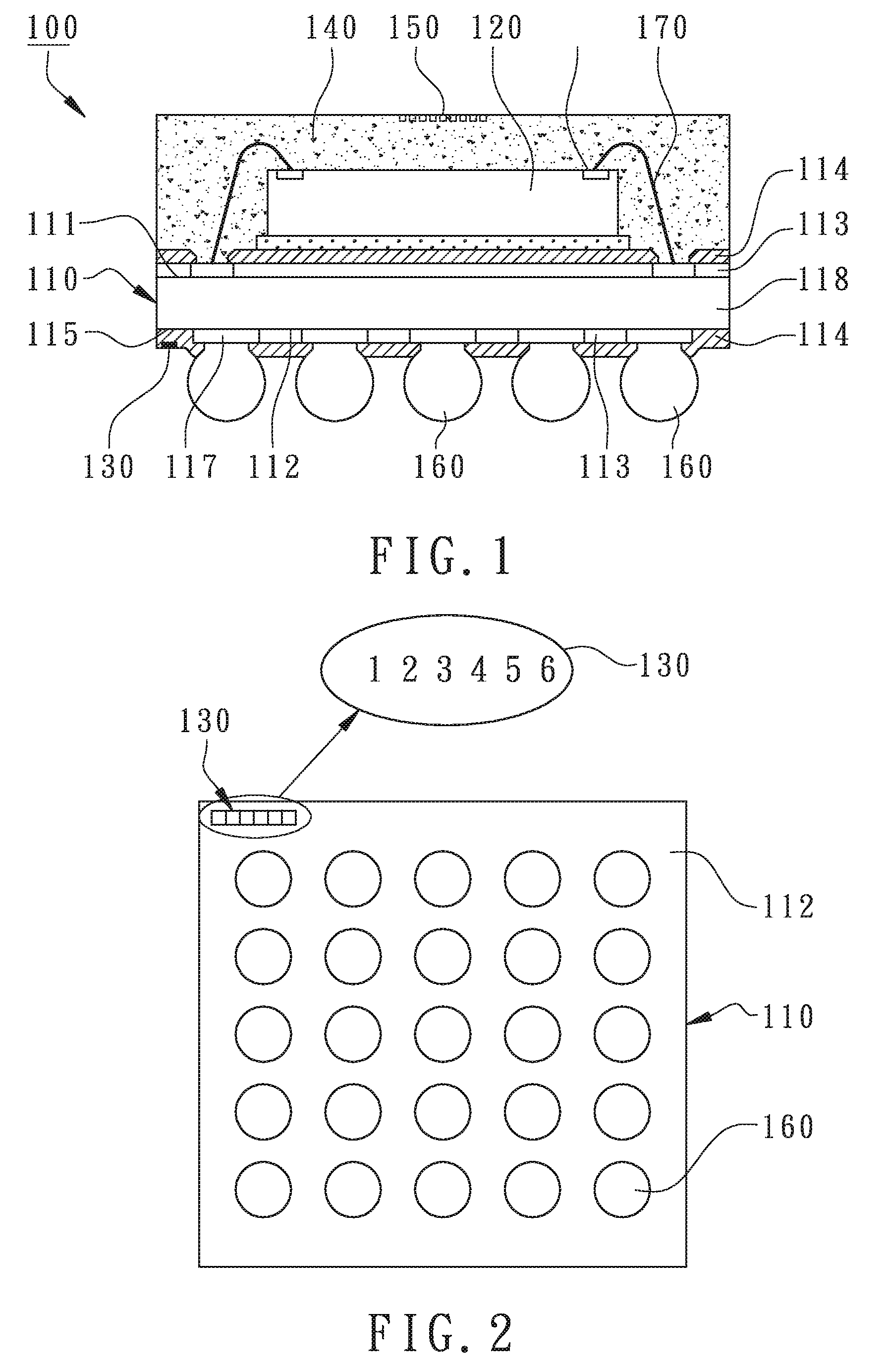

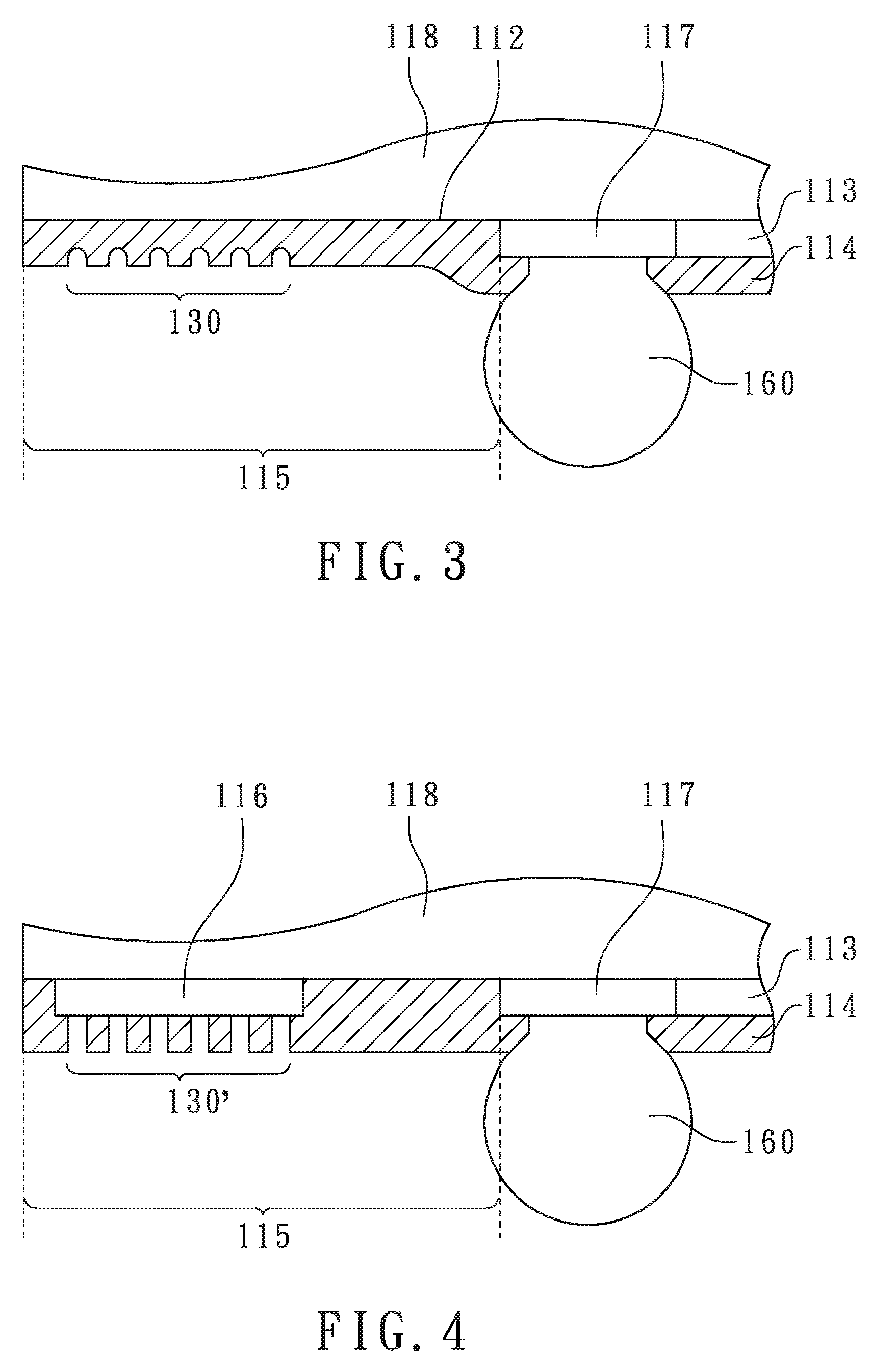

Semiconductor package having substrate ID code and its fabricating method

InactiveUS7884472B2Reduce complexitySemiconductor/solid-state device detailsSolid-state devicesSolder maskQuality control

Owner:POWERTECH TECHNOLOGY INC

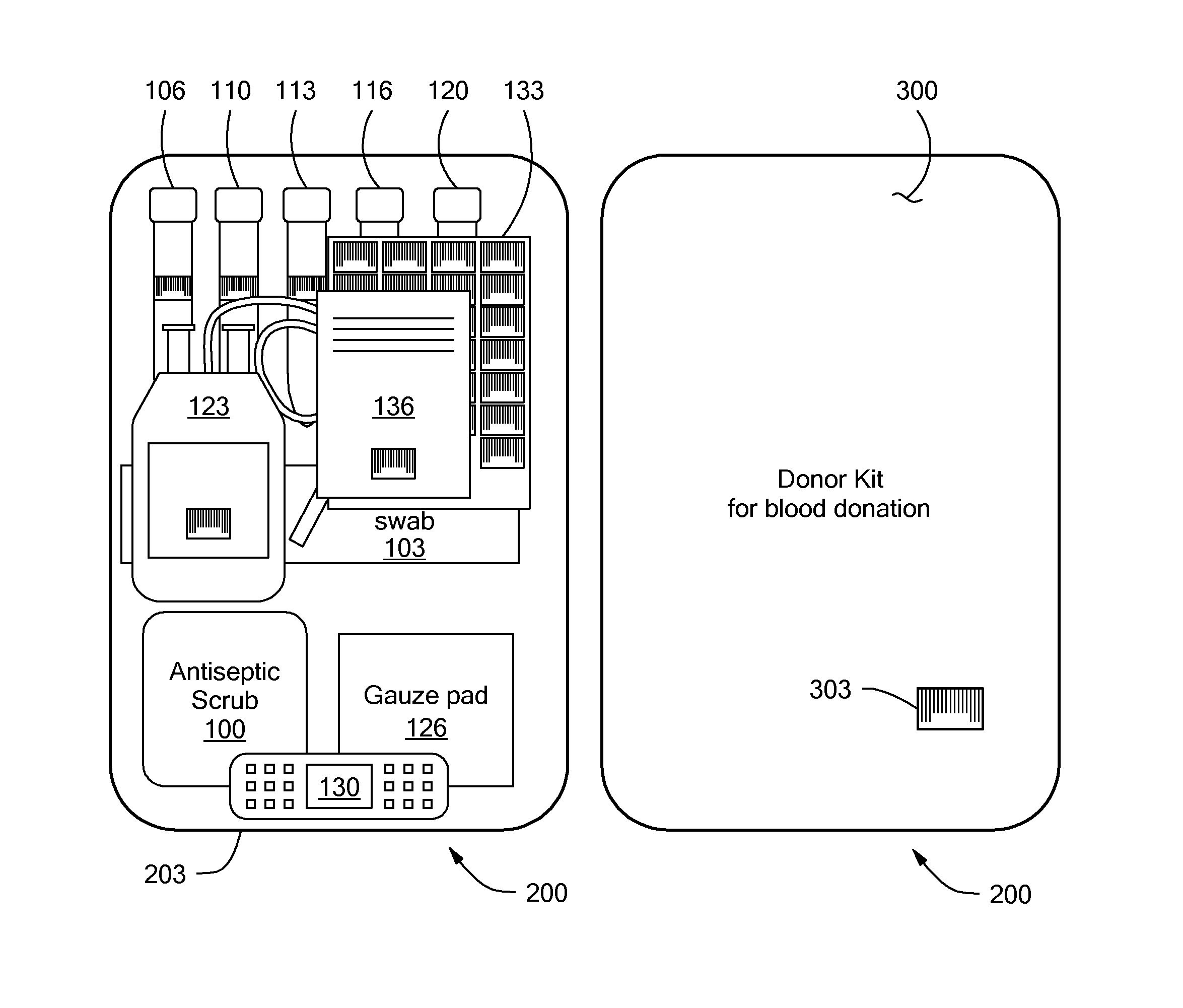

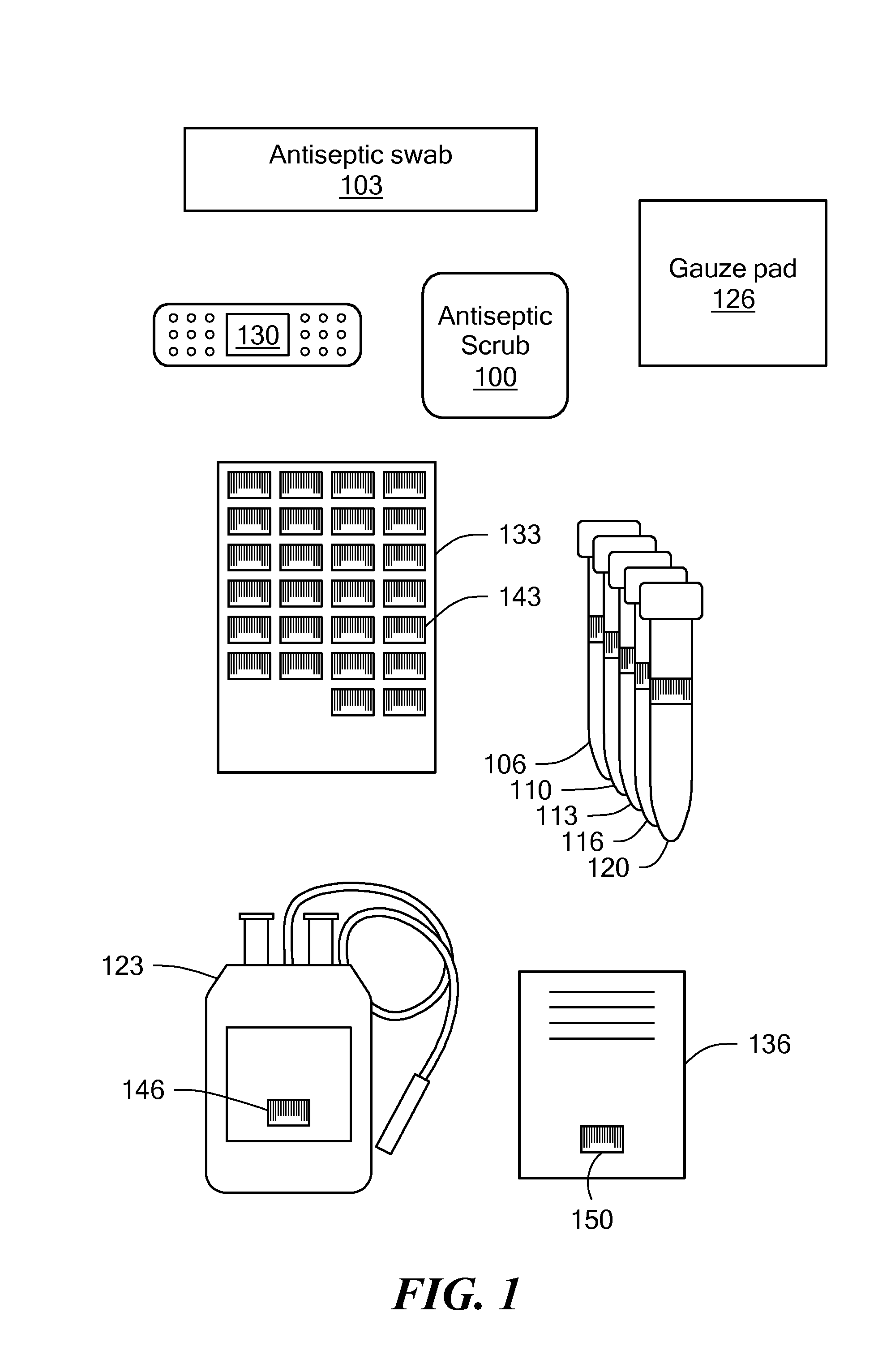

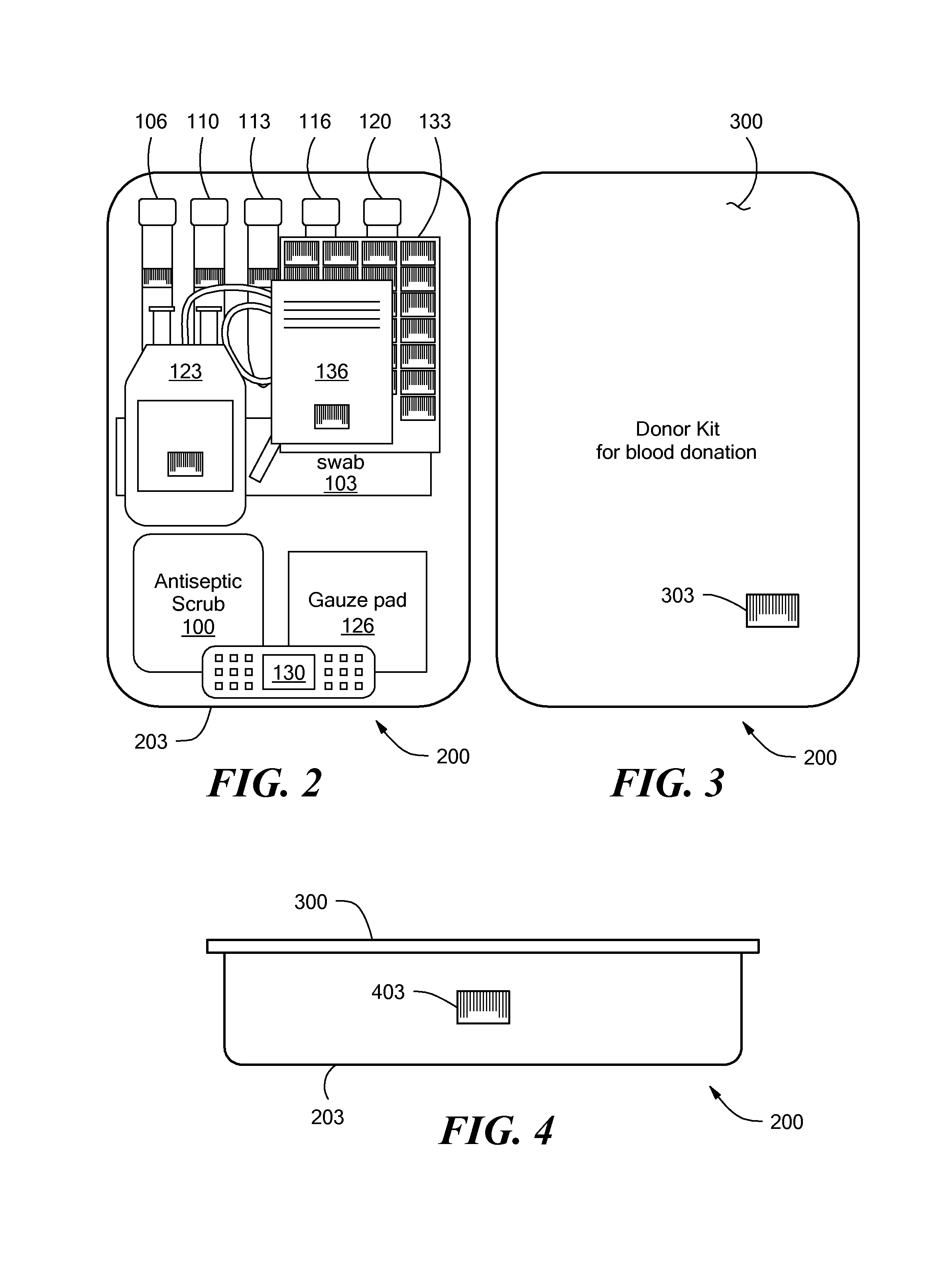

Donated blood collection kit

InactiveUS9539374B2Bioreactor/fermenter combinationsBiological substance pretreatmentsBlood collectionMedicine

A donated blood collection kit includes an easy-to-open closed container. Stored within the container are items necessary or useful for collecting donated blood, such as an antiseptic scrub, an antiseptic swab, test tubes, a blood collection container, a gauze pad and a sheet of pre-printed adhesive barcode labels. Each kit is assigned a unique identification when the kit is manufactured. The identification may eventually be used as the unique donor identification for a unit of donated blood that is collected using the items in the kit. The container is pre-labeled with the unique identification, such as by a barcode or an RF-ID tag. The test tubes and, if included, the blood collection container are pre-labeled with the same unique donor identification. The adhesive barcode labels in the container are pre-printed with the same unique donor identification and may be affixed to items that are not provided in the kit but, nonetheless, should be associated with the unit of blood that may be collected using the kit. Information about lot numbers and expiration dates for the items in the kit may be encoded in the kit's unique identification and / or stored in a database in association with the kit's identification.

Owner:HAEMONETICS

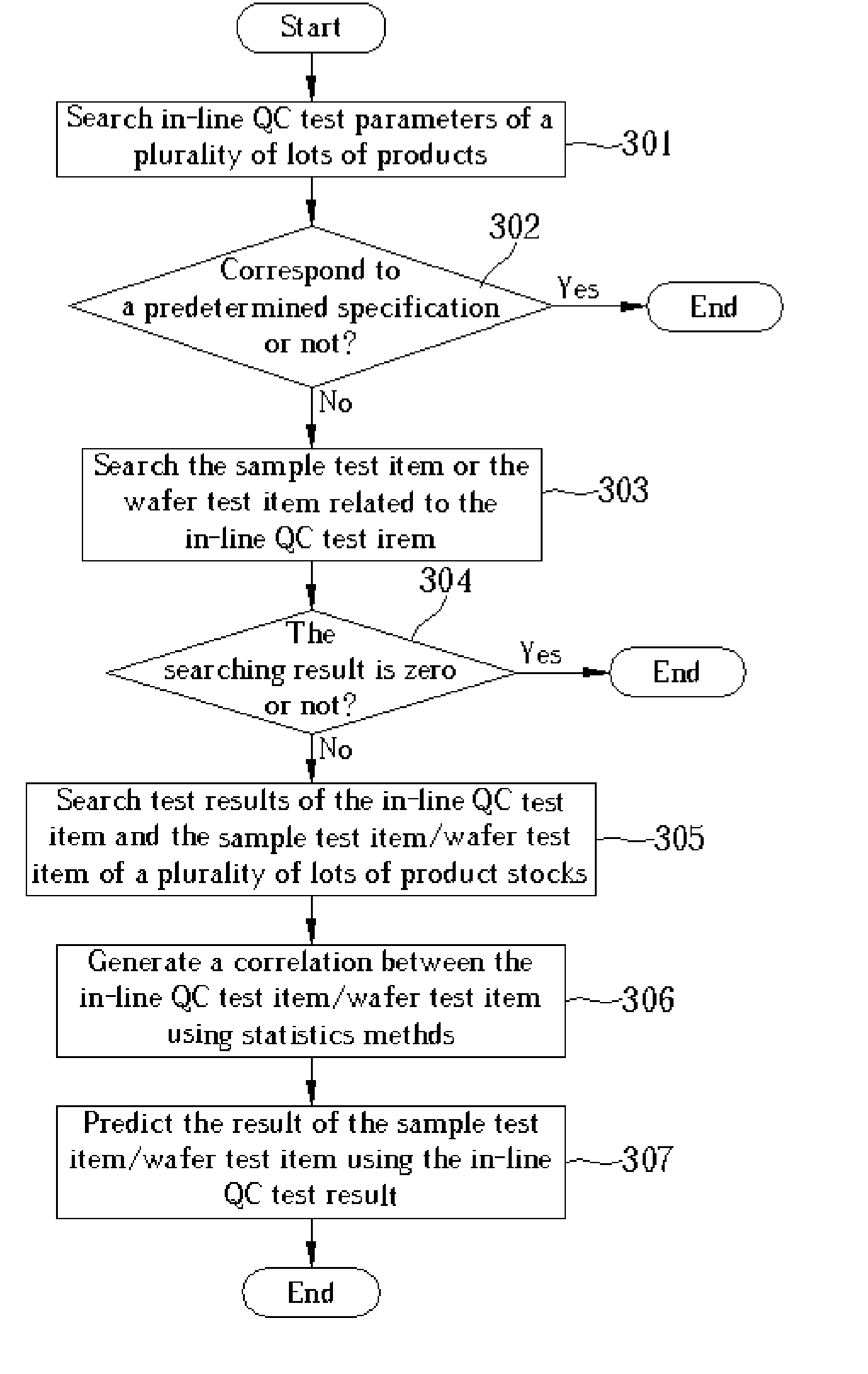

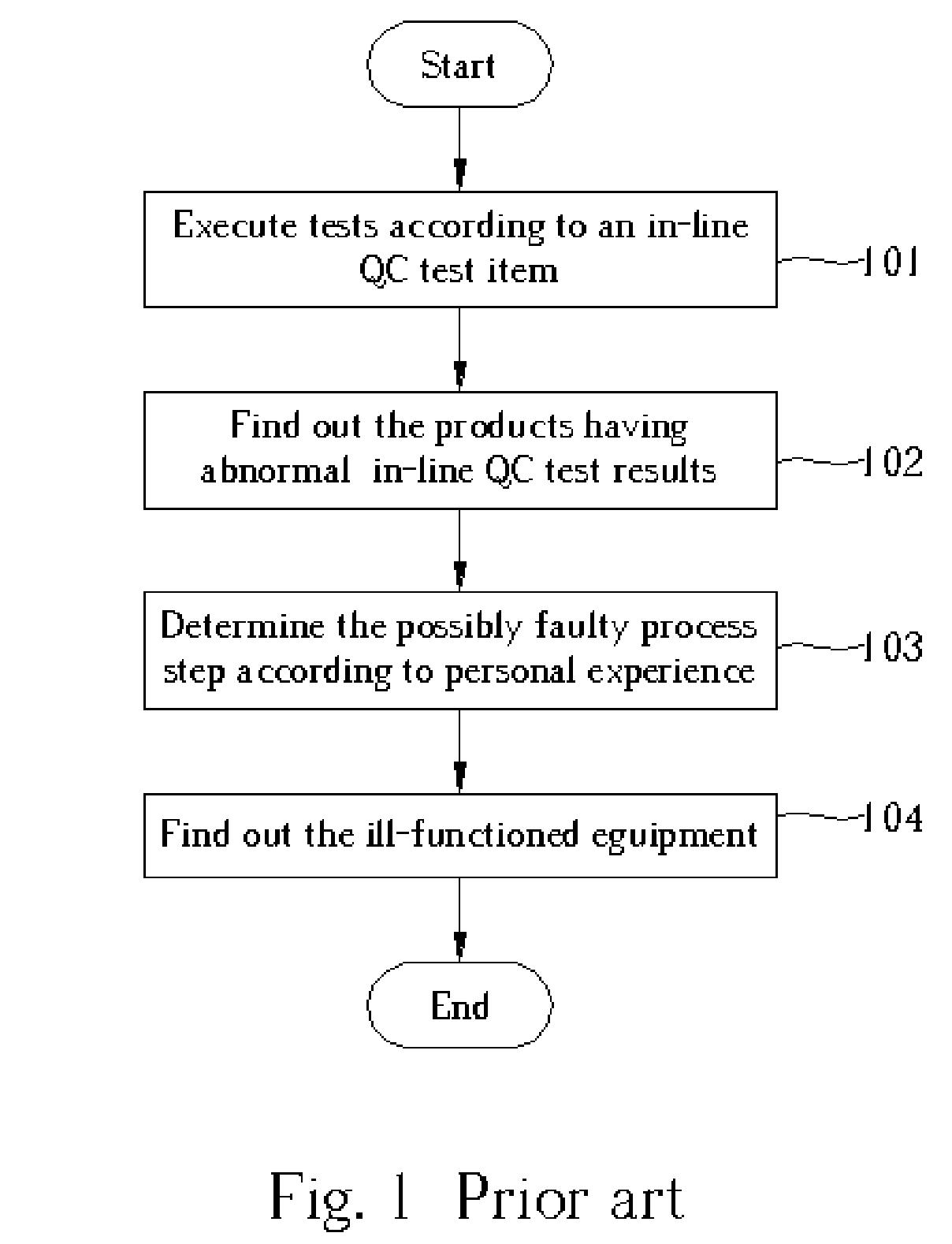

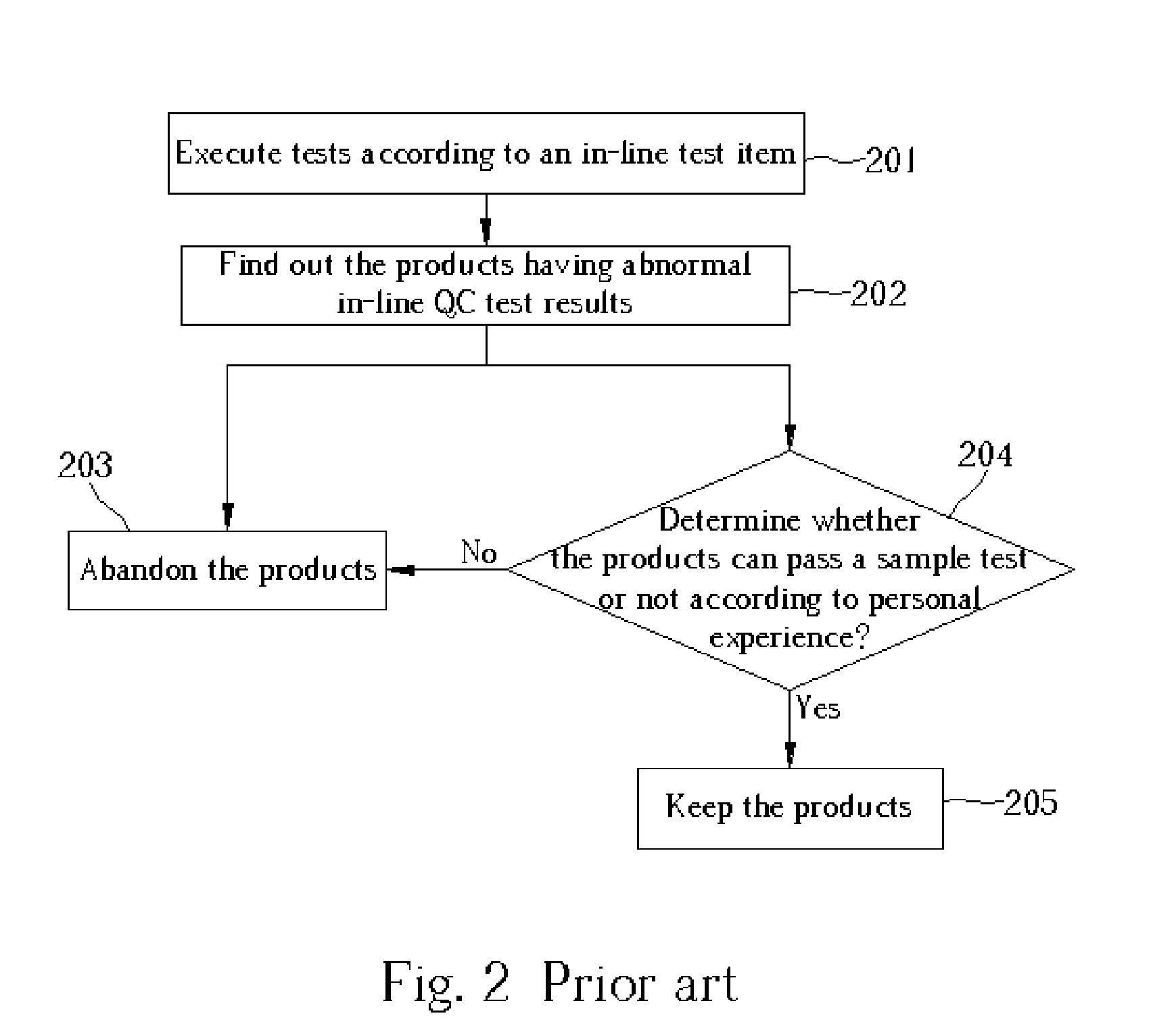

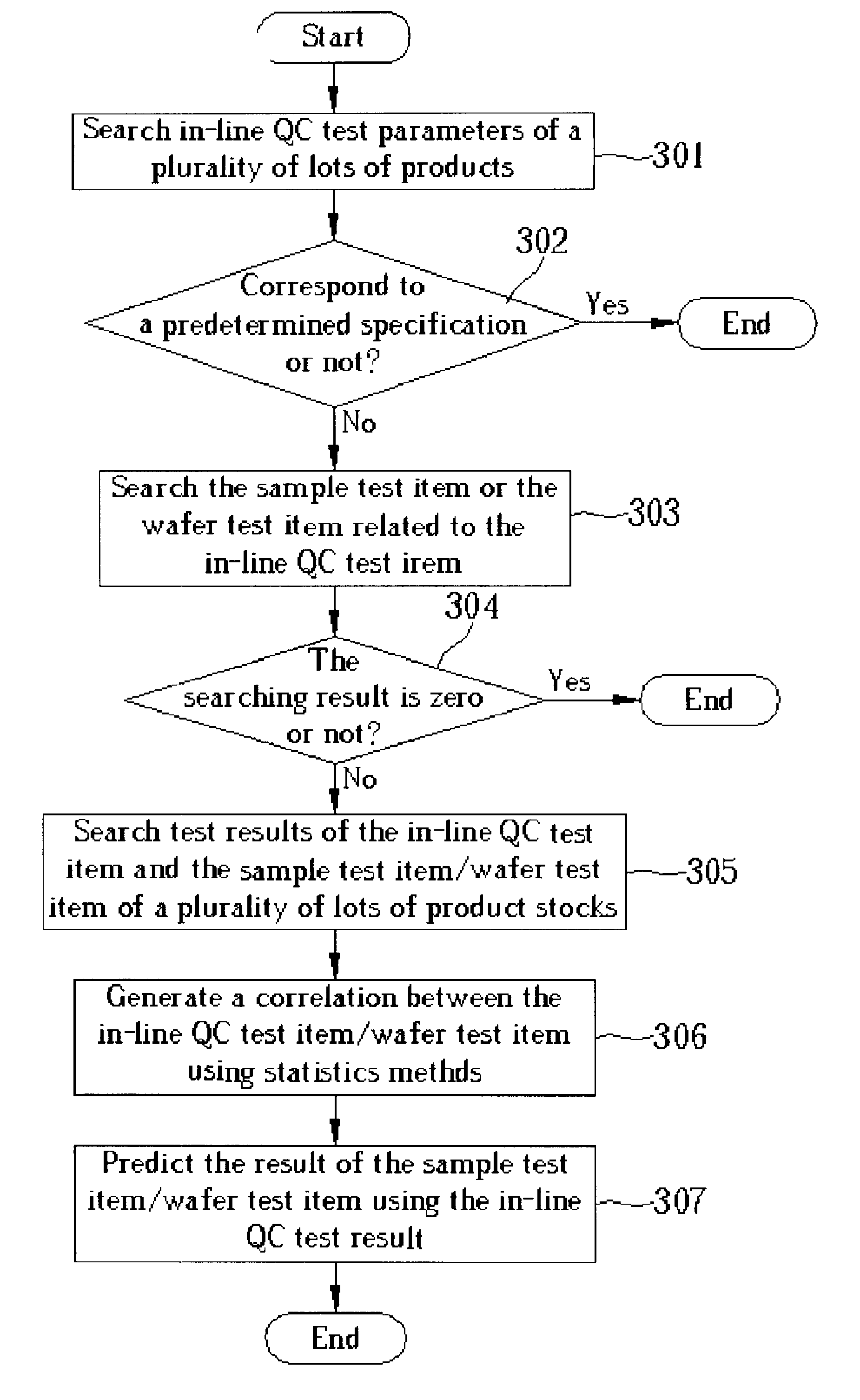

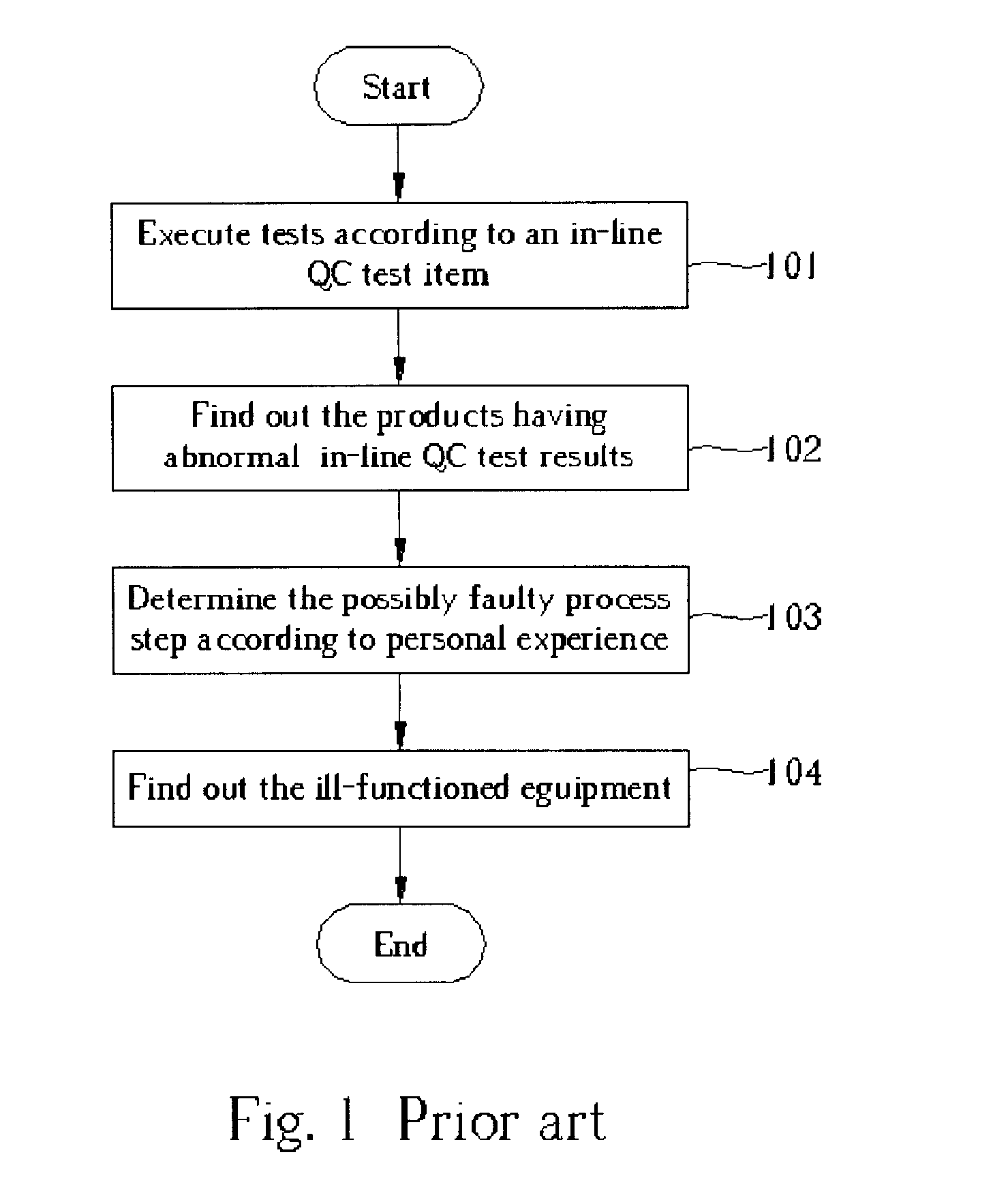

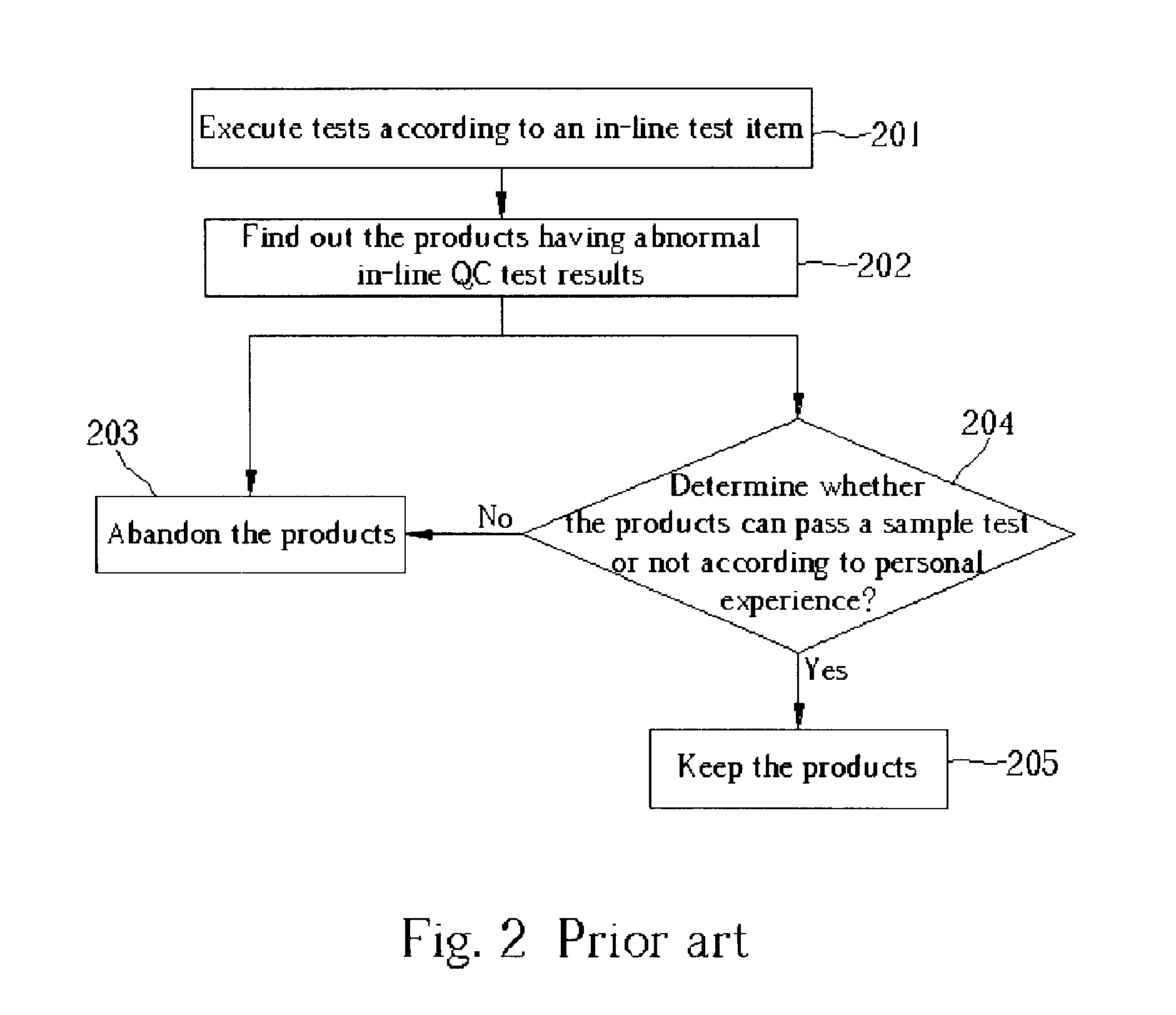

Method for analyzing in-line qc test parameters

InactiveUS20050004773A1High yieldAvoid mistakesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringAnalysis method

A method for analyzing in-line QCtest parameters is used to analyze a plurality of lots of products, each lot of products having a lot number and being formed using a plurality of equipments. At least one wafer of each lot of products is tested by at least one in-line QC test item to generate an in-line QC test parameter. The in-line QC test item, a sample test item and a wafer test item related to the in-line QC test item are stored in a database. The database further stores the in-line QC test parameter and data of a plurality of lots of high-yield product stocks, such as various test items and test parameters. The method includes the following steps: analyzing the in-line QC test parameter to determine whether the in-line QC test parameter corresponds to a predetermined spec or not; searching the database to find out the sample test item or the wafer test item related to the in-line QC test item when the in-line QC test parameter does not correspond to the predetermined spec; searching the database to find out the corresponding test parameters of the high-yield product stocks according to the in-line QC test item and the searched sample test item or the wafer test item; and generating a correlation to illustrate the relationship between the in-line QC test item and the sample test item, or the relationship between the in-line QC test item and the wafer test item according to the searched high-yield product stocks.

Owner:POWERCHIP SEMICON CORP

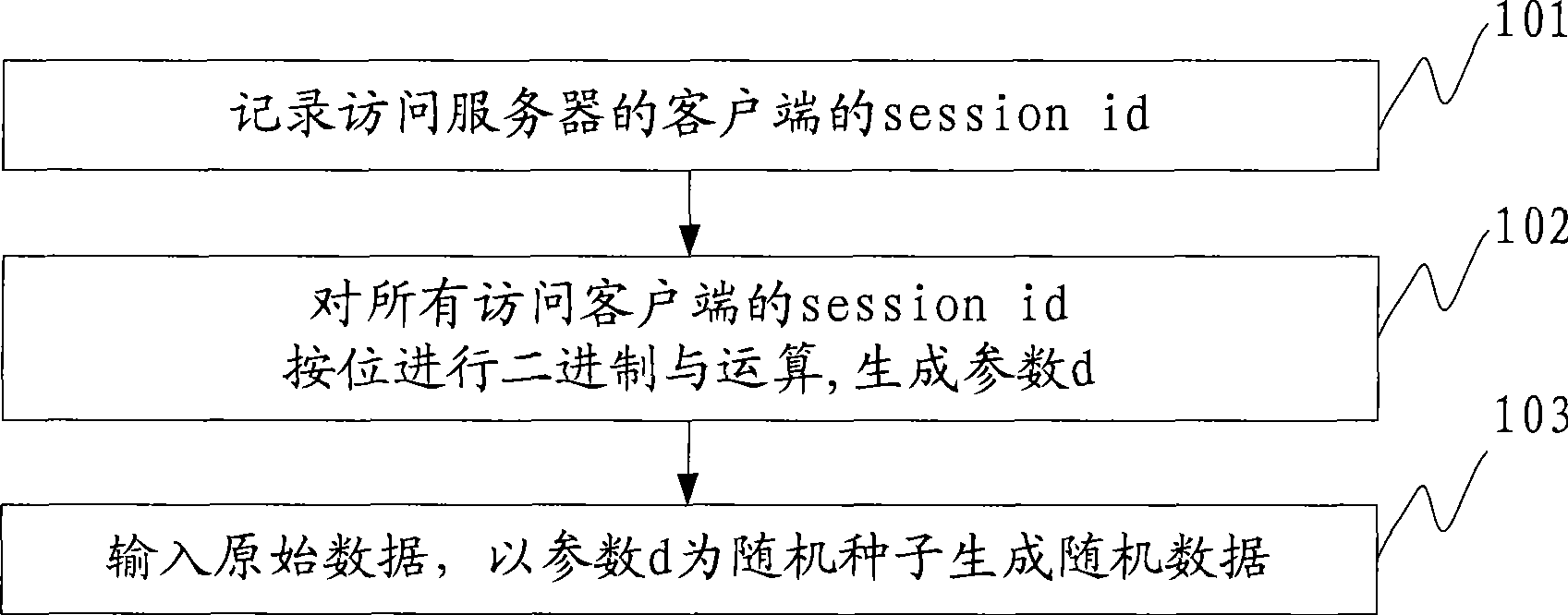

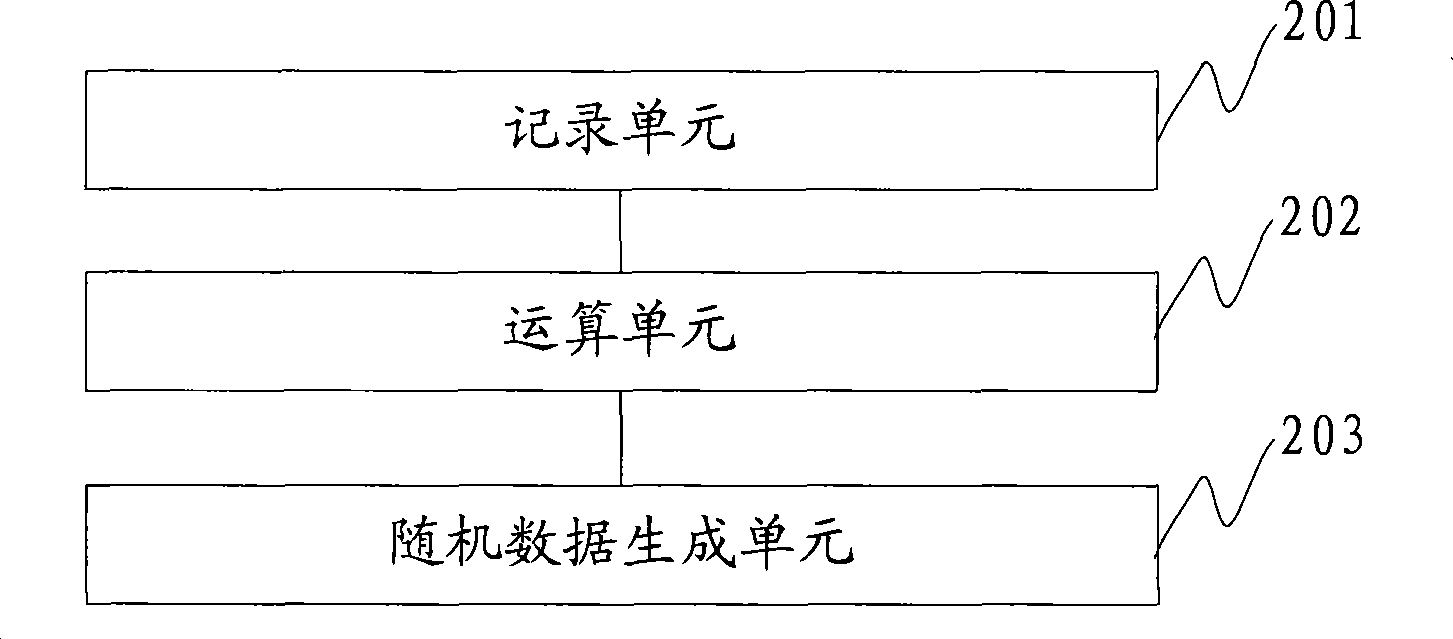

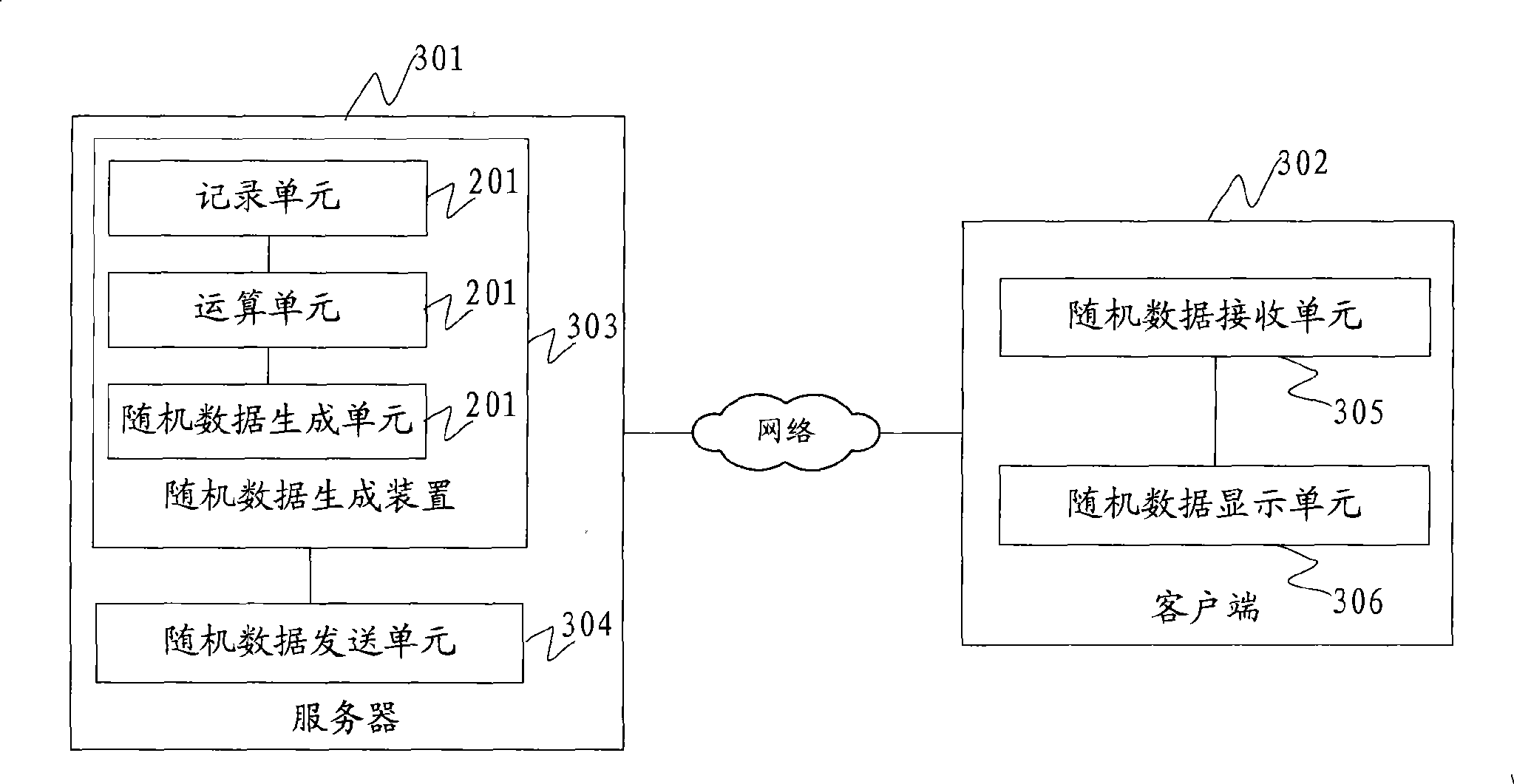

Method, apparatus and system for on-line generating random data

InactiveCN101414918AImprove fairnessImprove satisfactionSpecial service provision for substationRandom number generatorsOriginal dataRandom seed

The invention provides a method for generating random data on line. The method comprises the steps as follows: a client-side session id accessing a server is recorded; bitwise binary operation is carried out on all client-side session ids to generate a parameter d; original data is input; and the parameter d is used as a random seed to generate the random data. The random data is generated by recording the client-side session id accessing the server on line, generating the parameter d on line and using the parameter d as the random seed, thereby improving the efficiency and increasing the fairness and the satisfaction degree of the user. The invention also discloses a random data online generator and a random data online generating system. In the actual application, the random data online generating system can be a building opening quotation lot number remote live broadcasting system.

Owner:BEIJING SOHU NEW MEDIA INFORMATION TECH

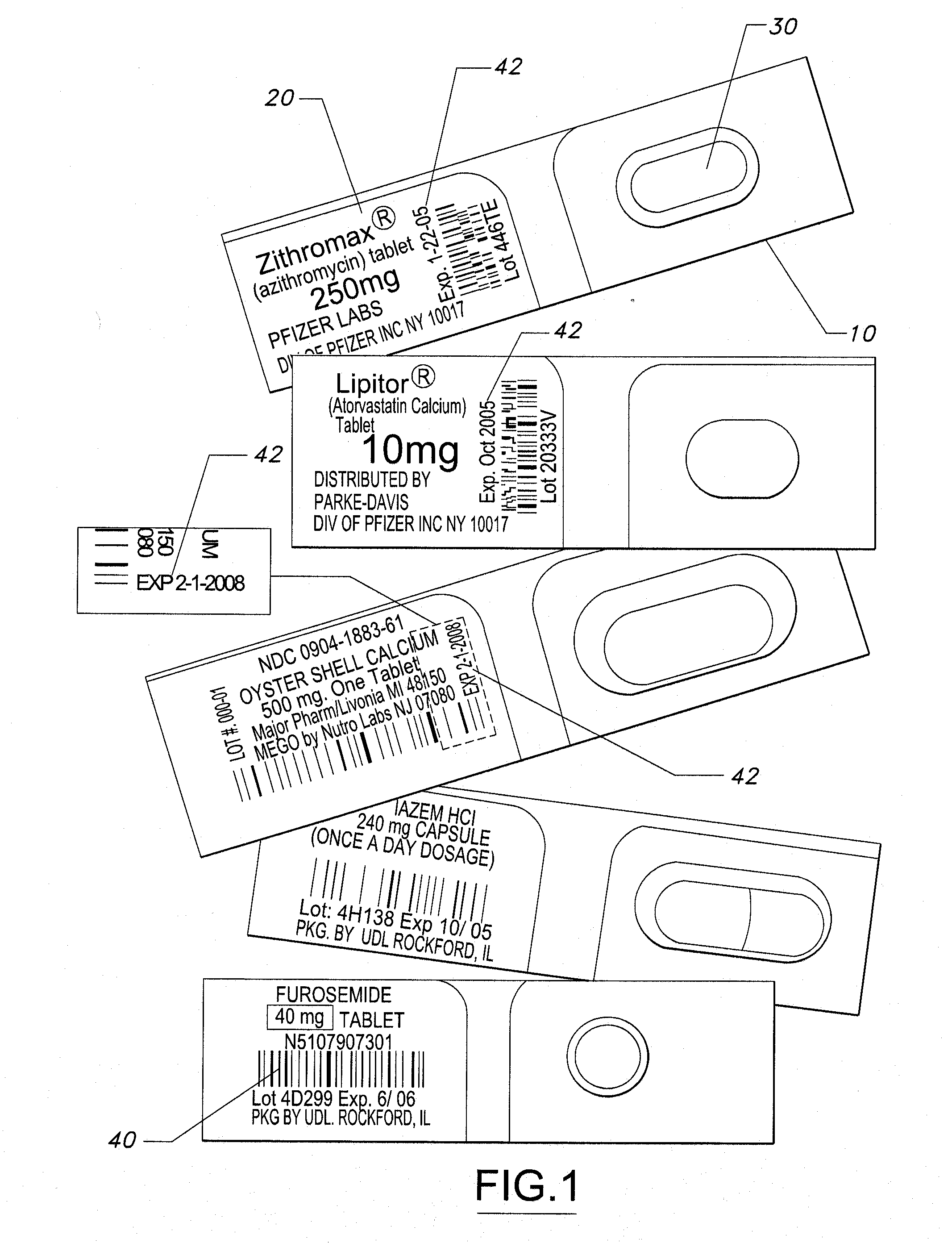

System, method, apparatus and computer program product for capturing human-readable text displayed on a unit dose package

ActiveUS20080300794A1Character and pattern recognitionDiagnostic recording/measuringText displayComputer science

A system, method, apparatus and computer program product are provided for capturing human-readable text displayed on a unit dose package. In particular, identification information associated with a unit dose package may be used to determine a location and / or a format in which human-readable text, such as an expiration date or lot number associated with the corresponding unit dose medication, is displayed on the unit dose package. Once the location and / or format of the human-readable text has been determined, this information can be used in order to scan the unit dose medication and translate the human-readable text into machine-readable text using, for example, optical character recognition.

Owner:OMNICELL

Method for analyzing in-line QC test parameters

InactiveUS6959252B2High yieldAvoid mistakesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringTest item

A method for analyzing in-line QCtest parameters is used to analyze a plurality of lots of products, each lot of products having a lot number and being formed using a plurality of equipments. At least one wafer of each lot of products is tested by at least one in-line QC test item to generate an in-line QC test parameter. The in-line QC test item, a sample test item and a wafer test item related to the in-line QC test item are stored in a database. The database further stores the in-line QC test parameter and data of a plurality of lots of high-yield product stocks, such as various test items and test parameters. The method includes the following steps: analyzing the in-line QC test parameter to determine whether the in-line QC test parameter corresponds to a predetermined spec or not; searching the database to find out the sample test item or the wafer test item related to the in-line QC test item when the in-line QC test parameter does not correspond to the predetermined spec; searching the database to find out the corresponding test parameters of the high-yield product stocks according to the in-line QC test item and the searched sample test item or the wafer test item; and generating a correlation to illustrate the relationship between the in-line QC test item and the sample test item, or the relationship between the in-line QC test item and the wafer test item according to the searched high-yield product stocks.

Owner:POWERCHIP SEMICON CORP

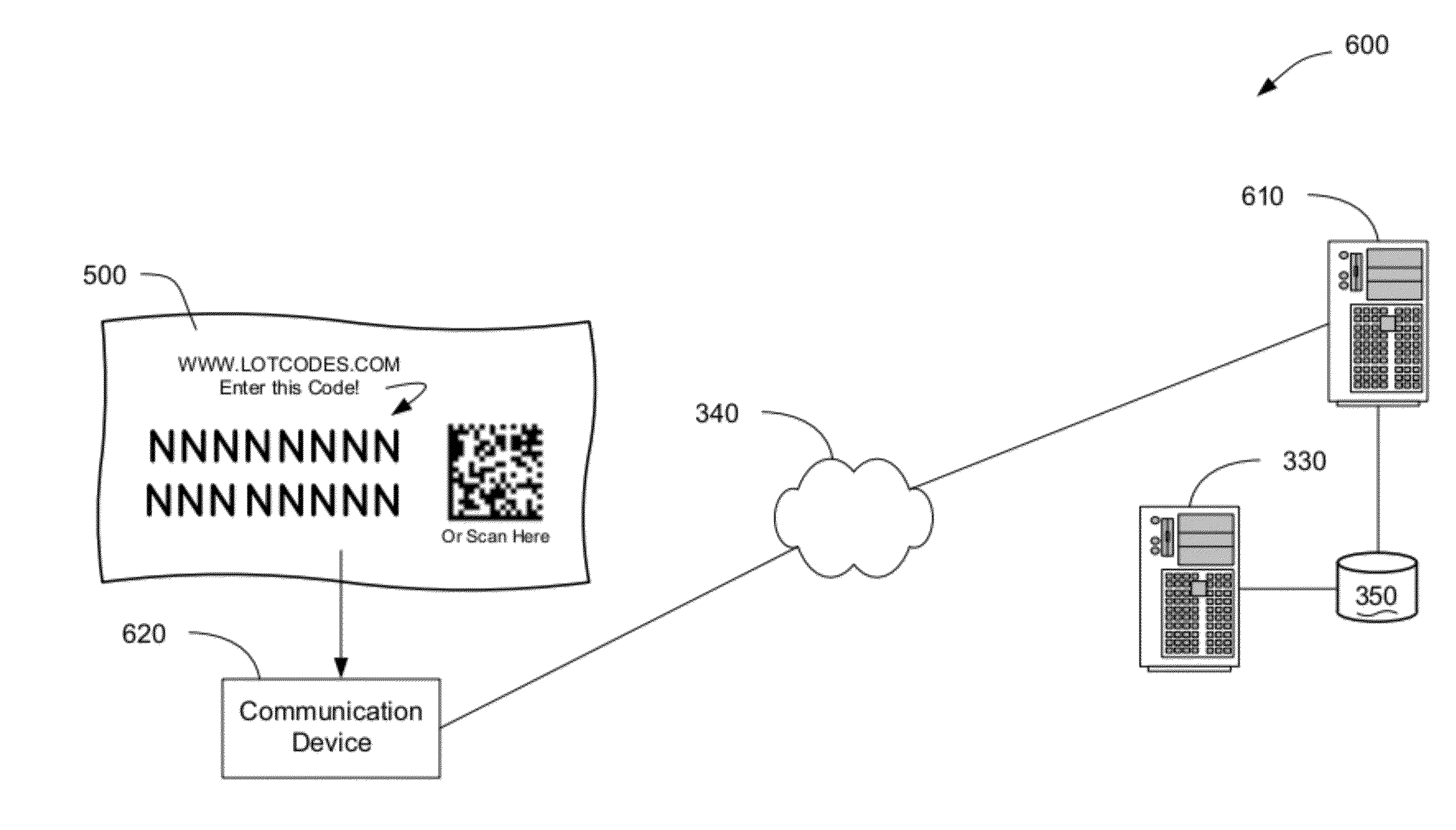

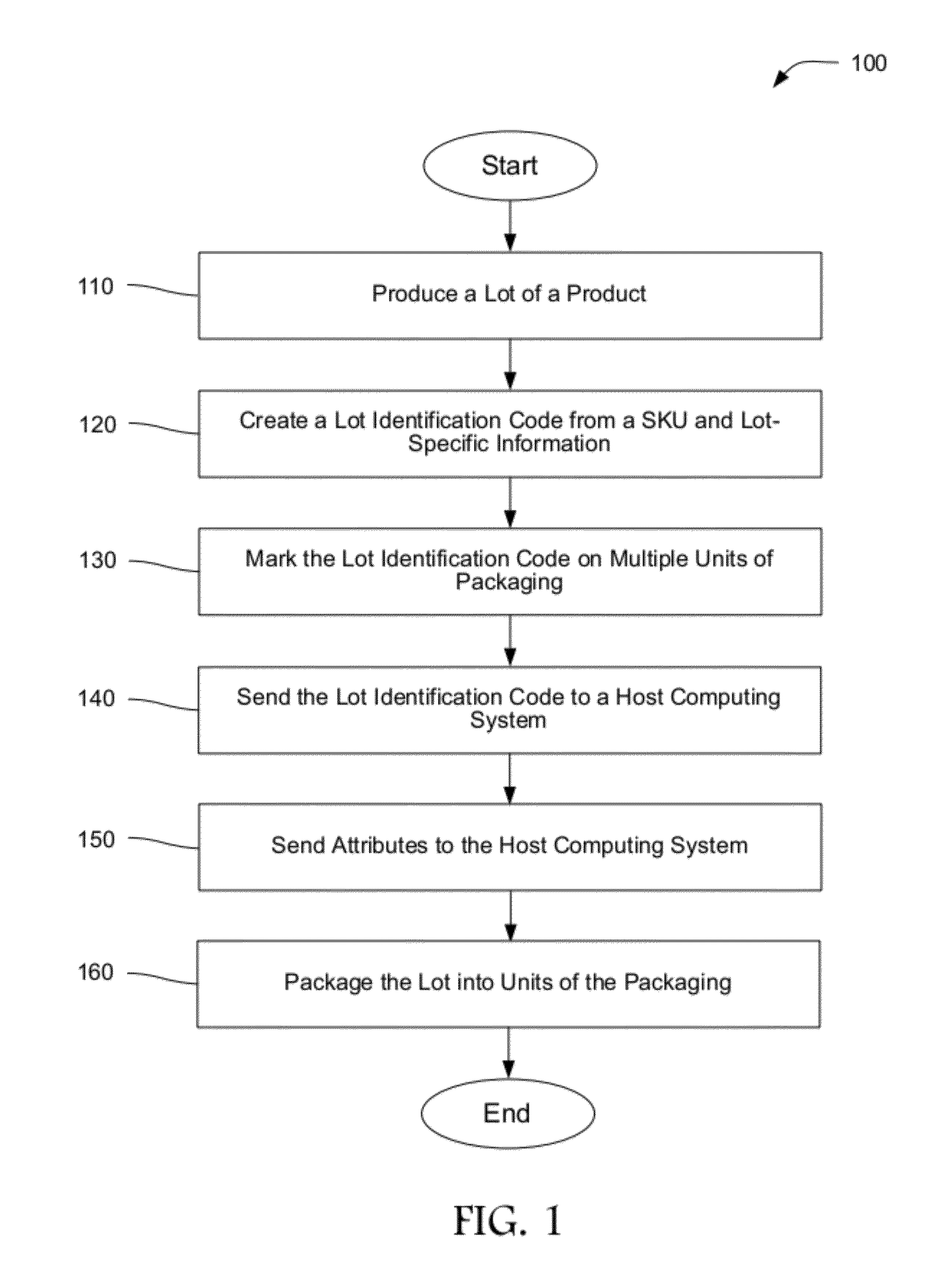

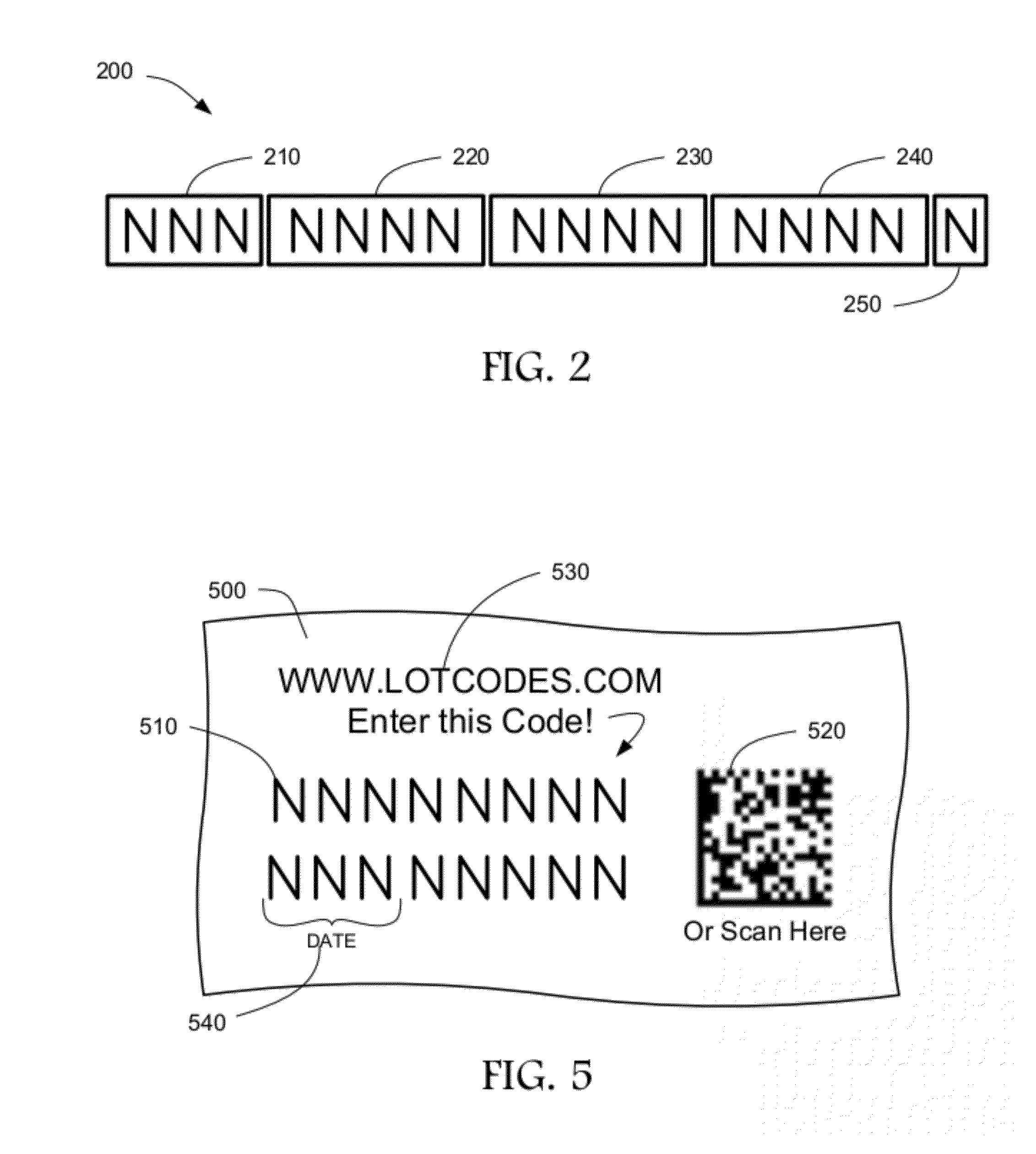

Lot Identification Codes for Packaging

InactiveUS20120059660A1Data processing applicationsDigital data processing detailsChecksumComputer science

Lot identification codes marked on packaging comprise a fixed number of digits with substrings representing each of a date, a SKU, a lot number, and optionally a line and a checksum. The same fixed number of digits is used for the lot identification codes employed by multiple producers across an industry, or across multiple industries. The lot identification codes are therefore readily recognizable by search engines and otherwise reduce the number of steps required for consumers and others along the supply chain to obtain lot-specific information about packaged goods. Additionally, whenever an individual submits a lot identification code, it provides an opportunity to collect information about the product at that point along the supply chain. The information can link the quality of the product at the time and place of the request to the time and place of the packaging.

Owner:YOTTAMARK

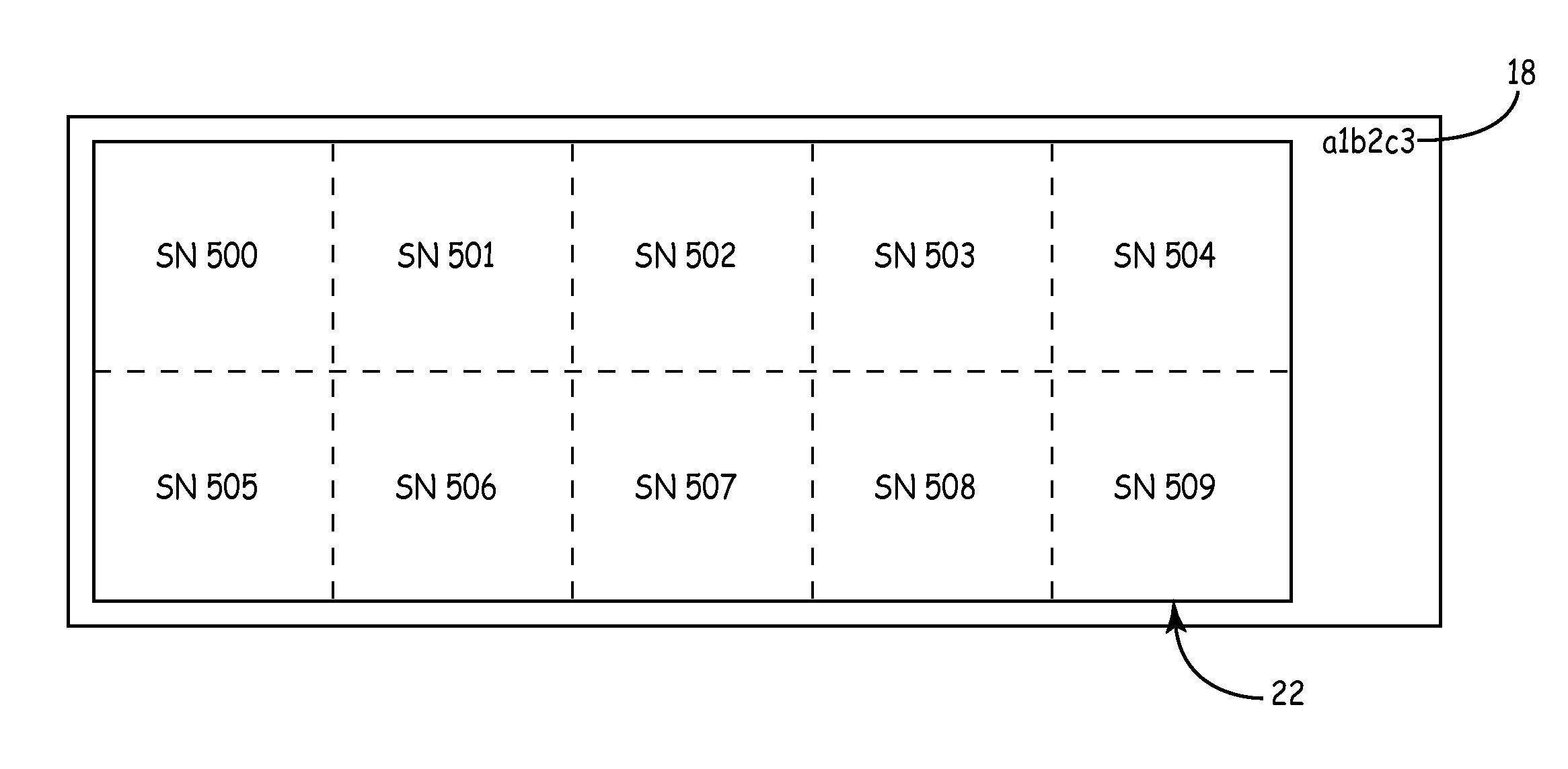

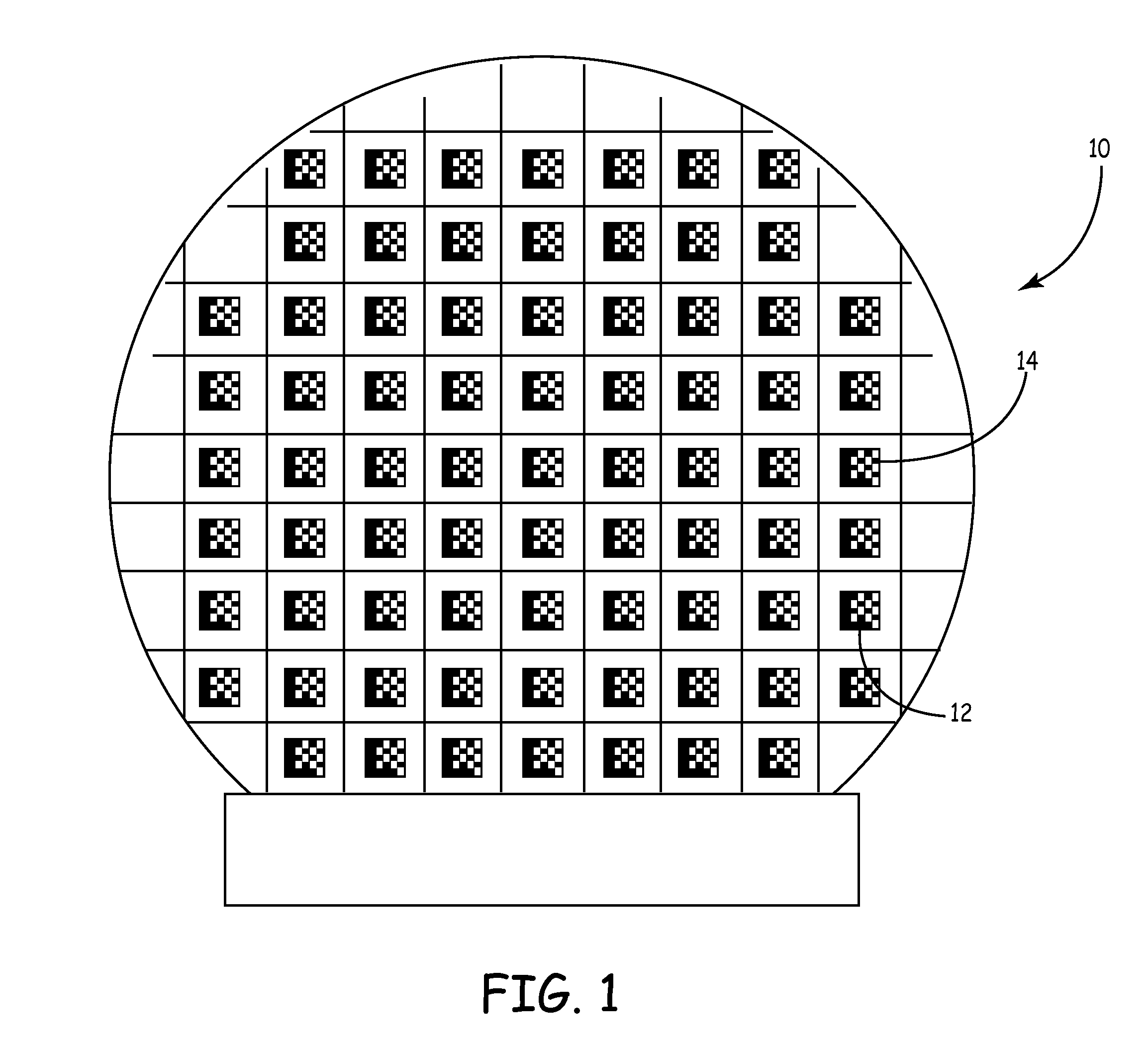

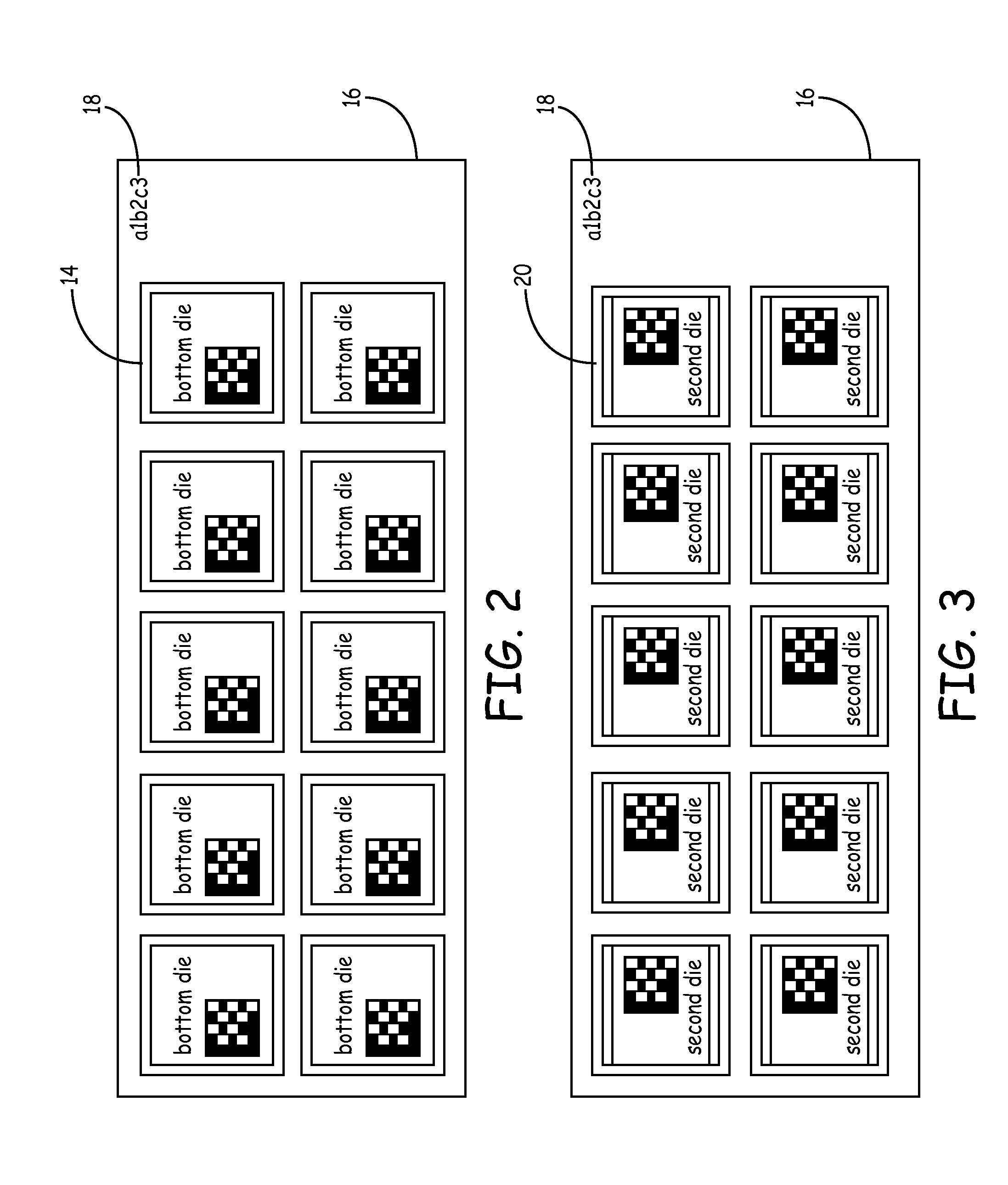

Method for Tracing Individual Dies

InactiveUS20110259951A1Semiconductor/solid-state device detailsSolid-state devicesUnique identifierDie bonding

A method for tracing individual dies within stacked chip scale packages includes the steps of recording unique die identifiers from layers of marked dies and associating the unique identifiers with a die bonding substrate and the resulting die or stacked chip scale packages. The unique die identifiers are also associated with wafer numbers, x-y positions on a wafer, wafer lot numbers or any combination thereof.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com