Patents

Literature

468results about How to "Remove uncertainty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

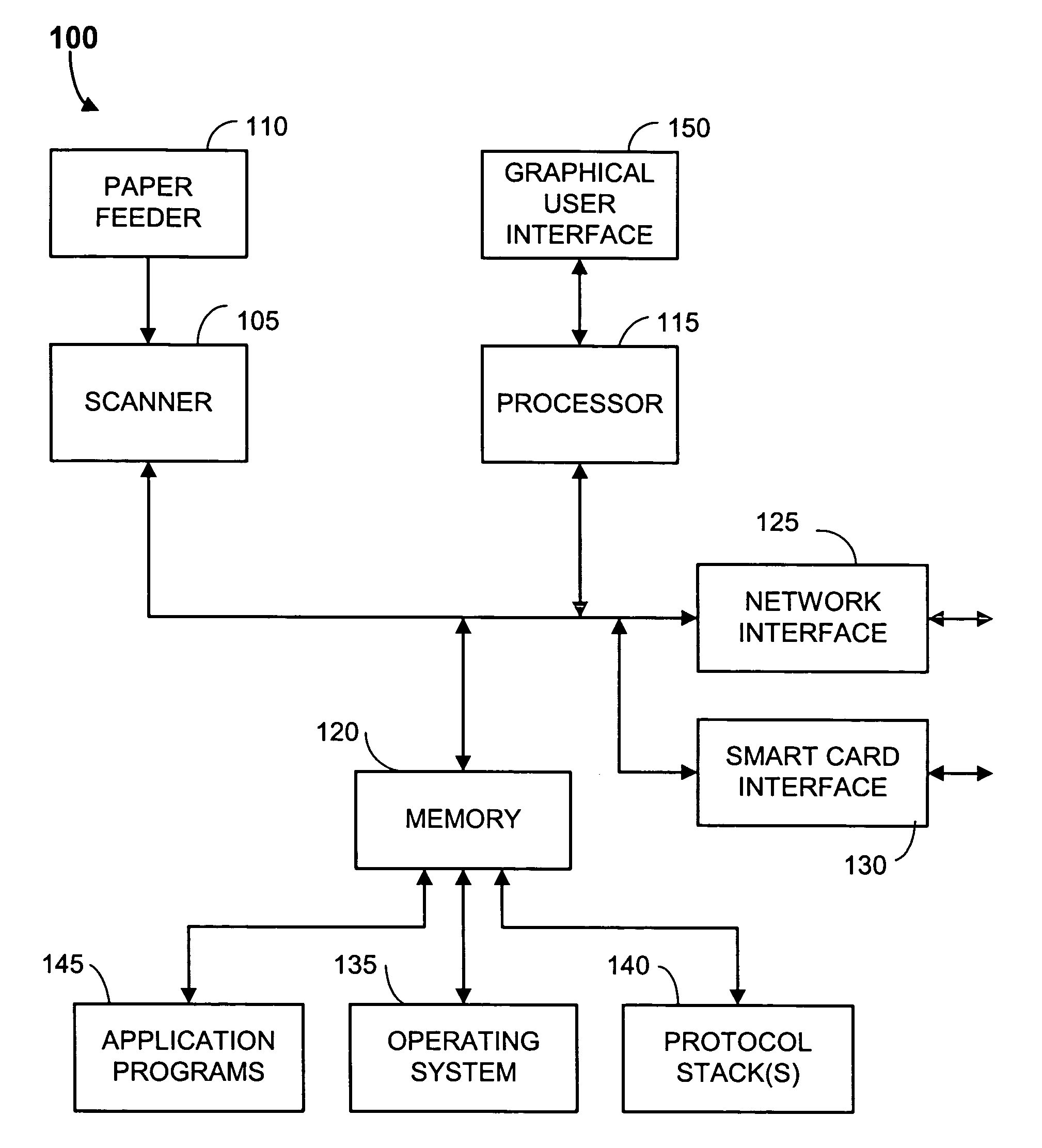

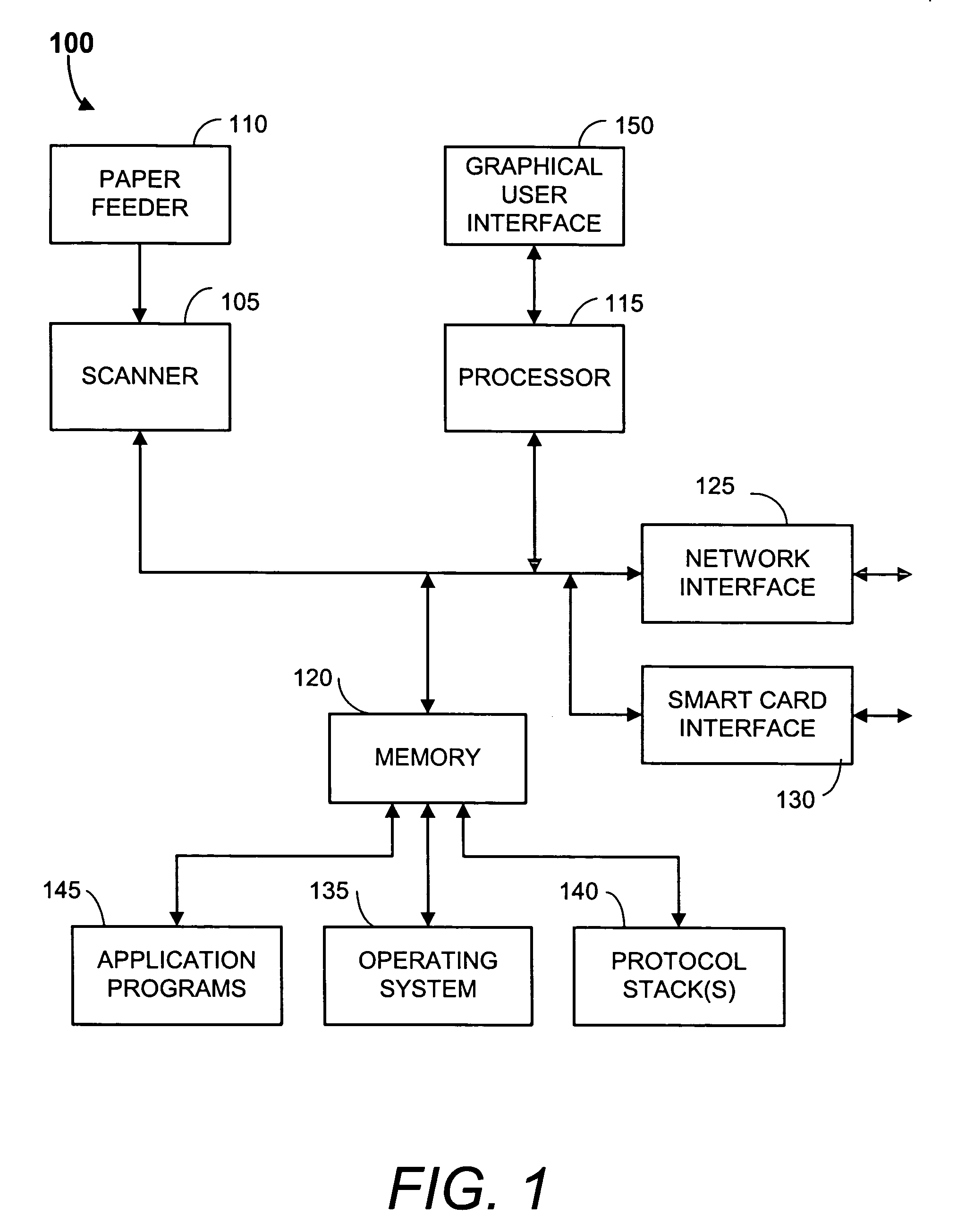

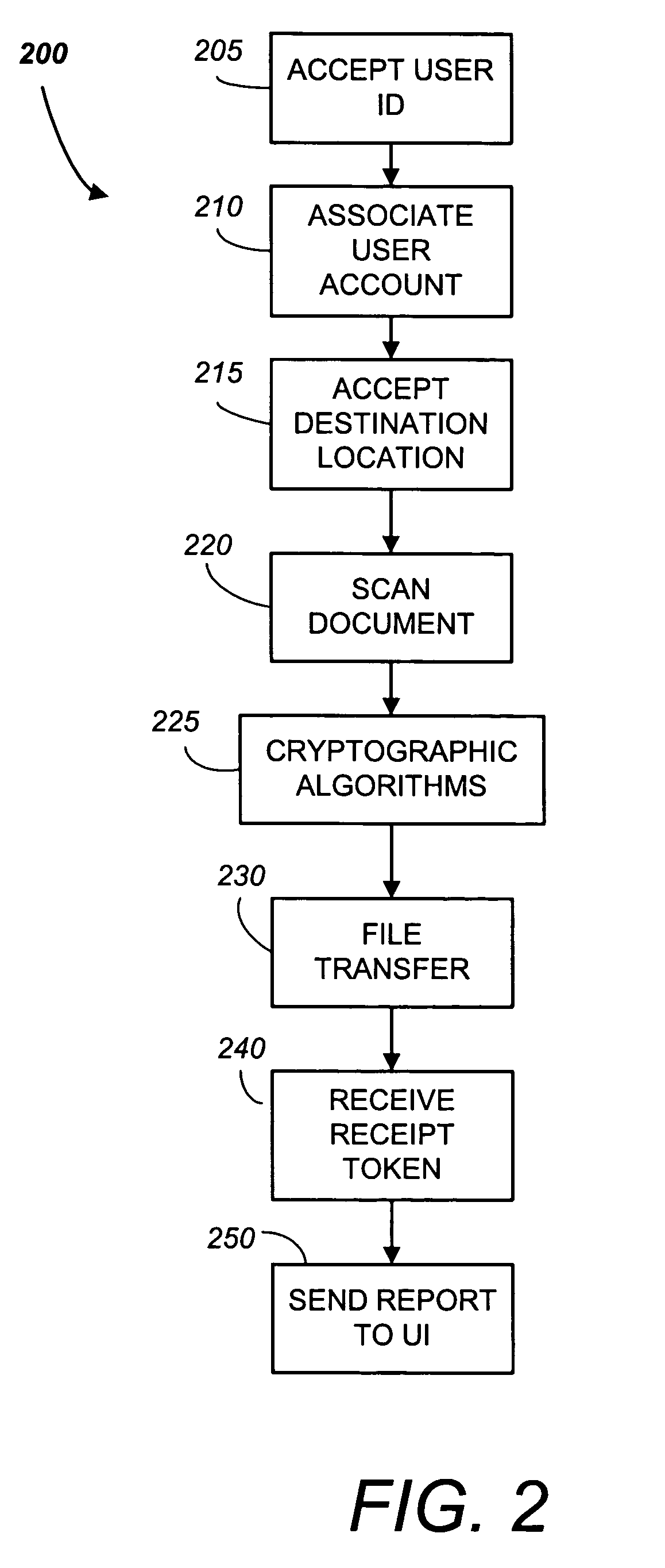

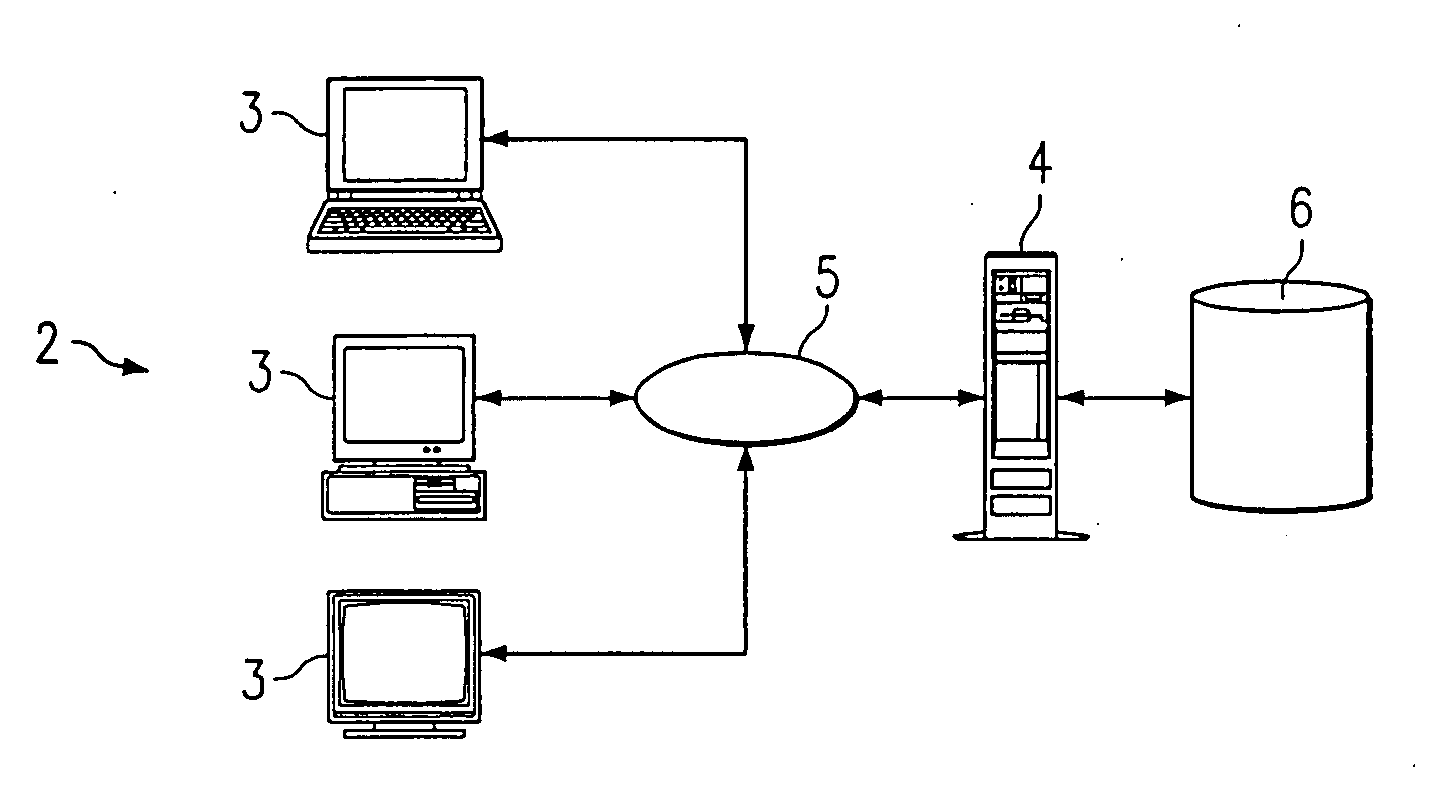

Network scanner for global document creation, transmission and management

InactiveUS20060072144A1Enhanced interactionStrong sender authentication securityTime-division multiplexComputer security arrangementsThe InternetNetwork communication

A network scanner, communication protocols, and client and server programs and are provided which provide an improved way to transmit legally binding documents, obviating the need for outmoded, legacy fax transmissions. Using the network scanner, a document may be scanned and transferred directly into any shared folder inbox residing on any computer attached to the Internet. Enhanced server systems and network communications and messaging protocols are provided that are more practical to use than email for sending documents such as executed legal documents or other documents requiring robust integrity and authenticatability. Similarly, the inventive network scanner, server systems and communication protocols provide improved ways to perform large file transfers and to manage bandwidth to minimize problems associated with uploading / downloading large files as attachments to / from email servers and for enabling user control over VoIP quality during file transmission sessions.

Owner:INTELLECTUAL PROPERTIES I KFT

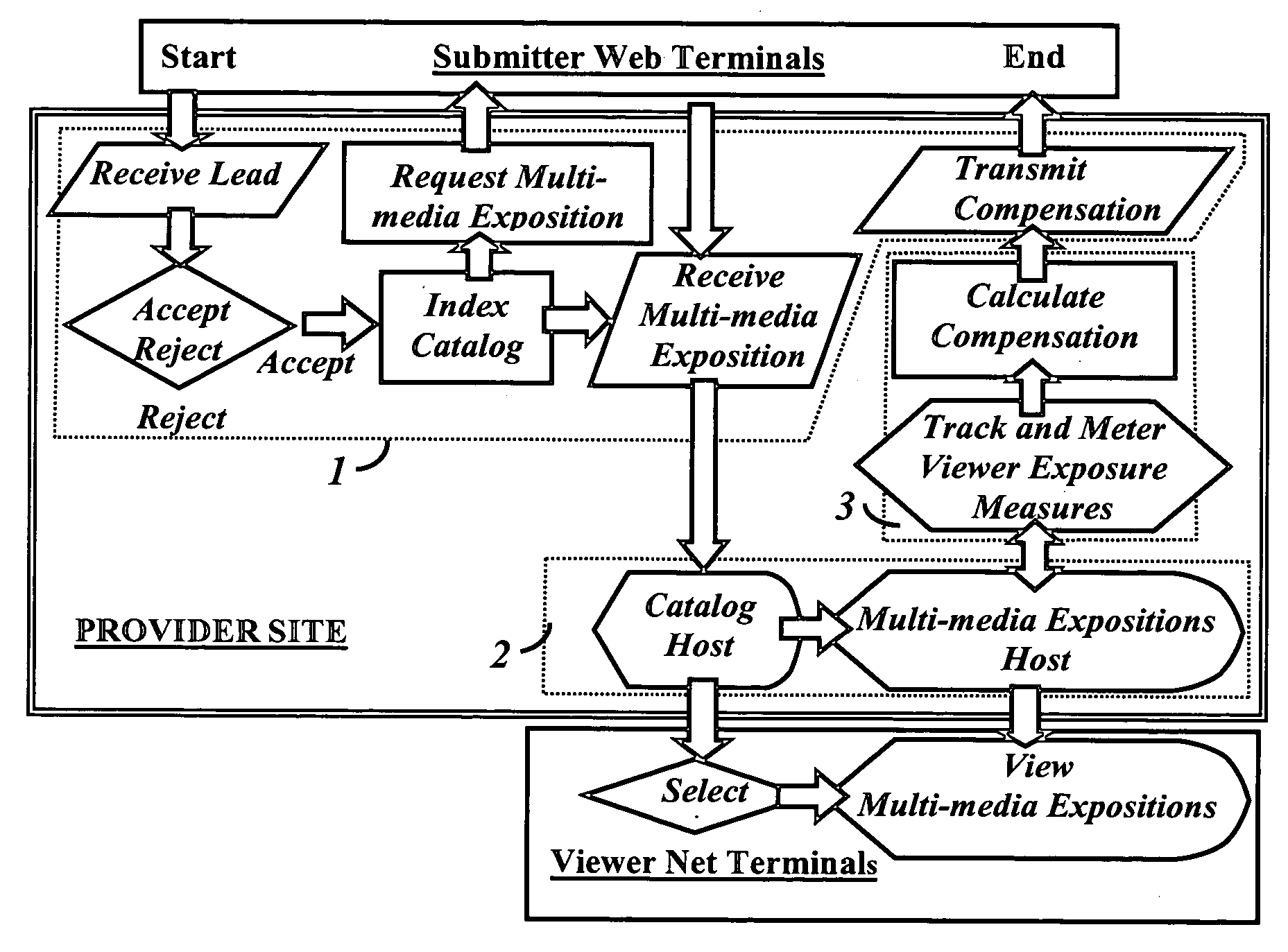

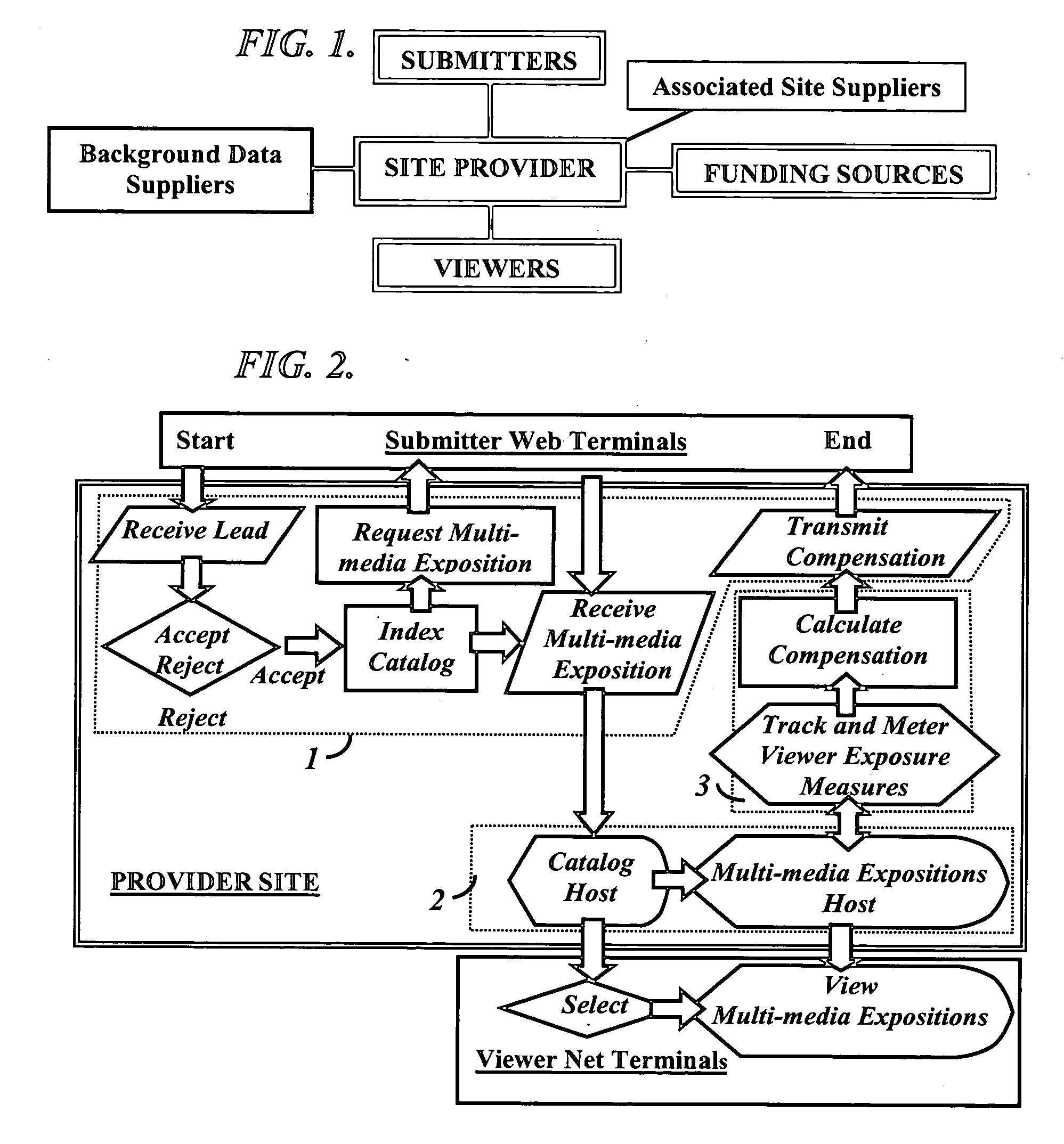

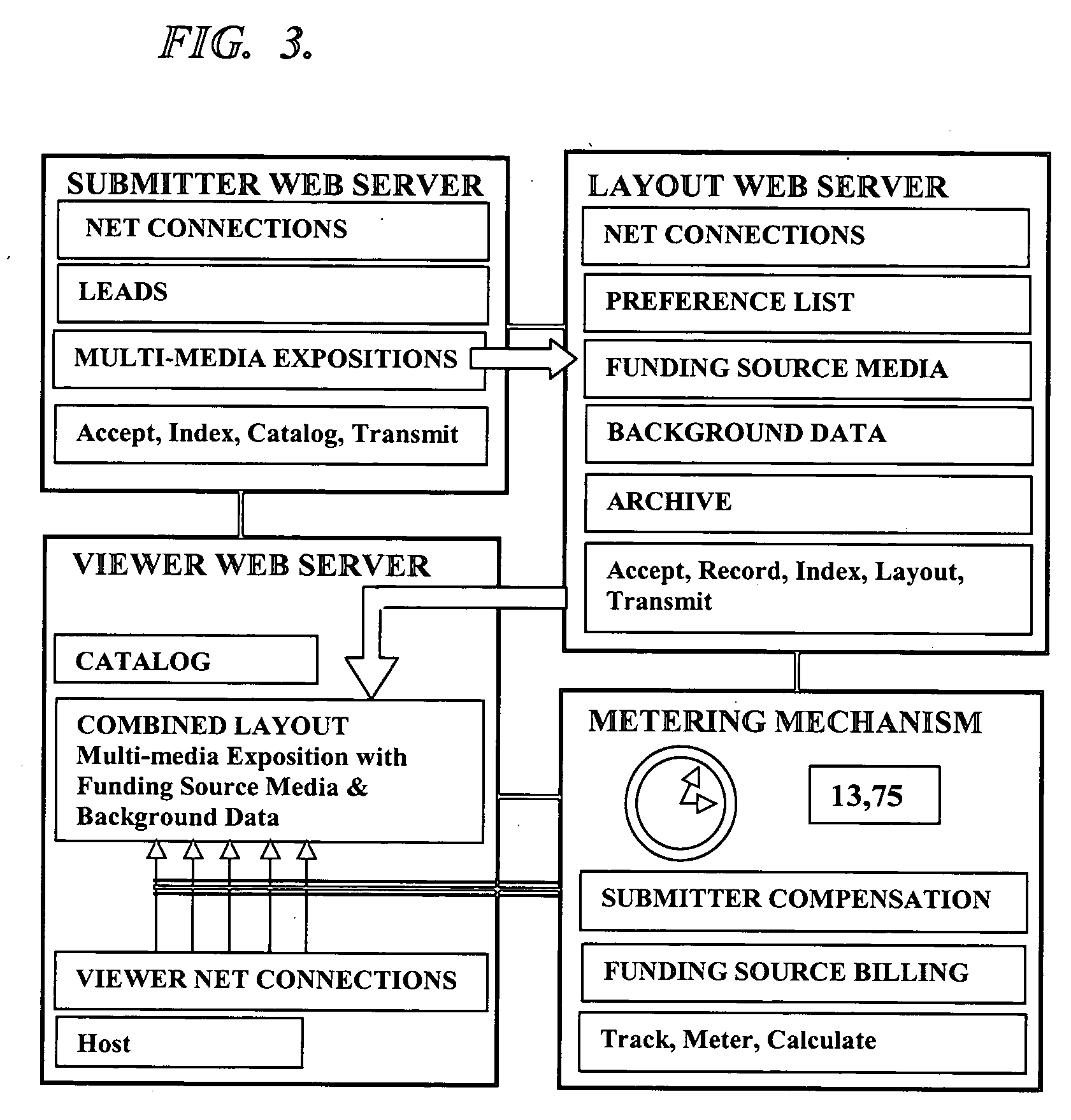

Internet news compensation system

InactiveUS20050049971A1High valueHigh chargeAdvertisementsComputer security arrangementsWeb siteCataloging

A computerized compensation system of disseminating a plurality of news and information items offered, contributed, and submitted by a plurality of independent submitters to an internet provider site. The provider site accepts, indexes, catalogs, tracks, meters, and calculates viewer exposure to each submitted news and information item chosen by a plurality of viewers. Compensation due individual submitters is transmitted in real time, as the submitter continues the submission to the provider web site. Billing of funding sources is provided.

Owner:BETTINGER DAVID S

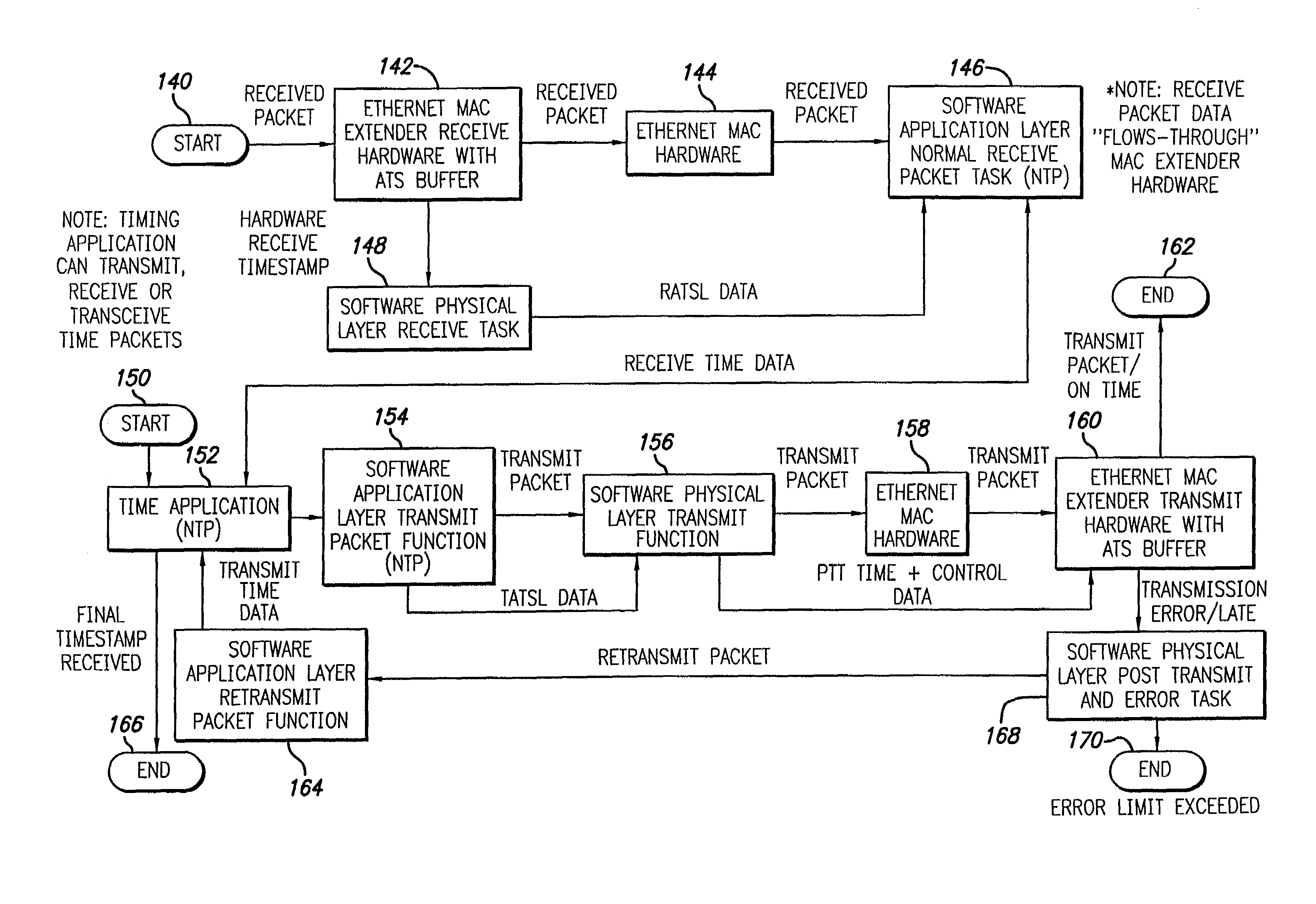

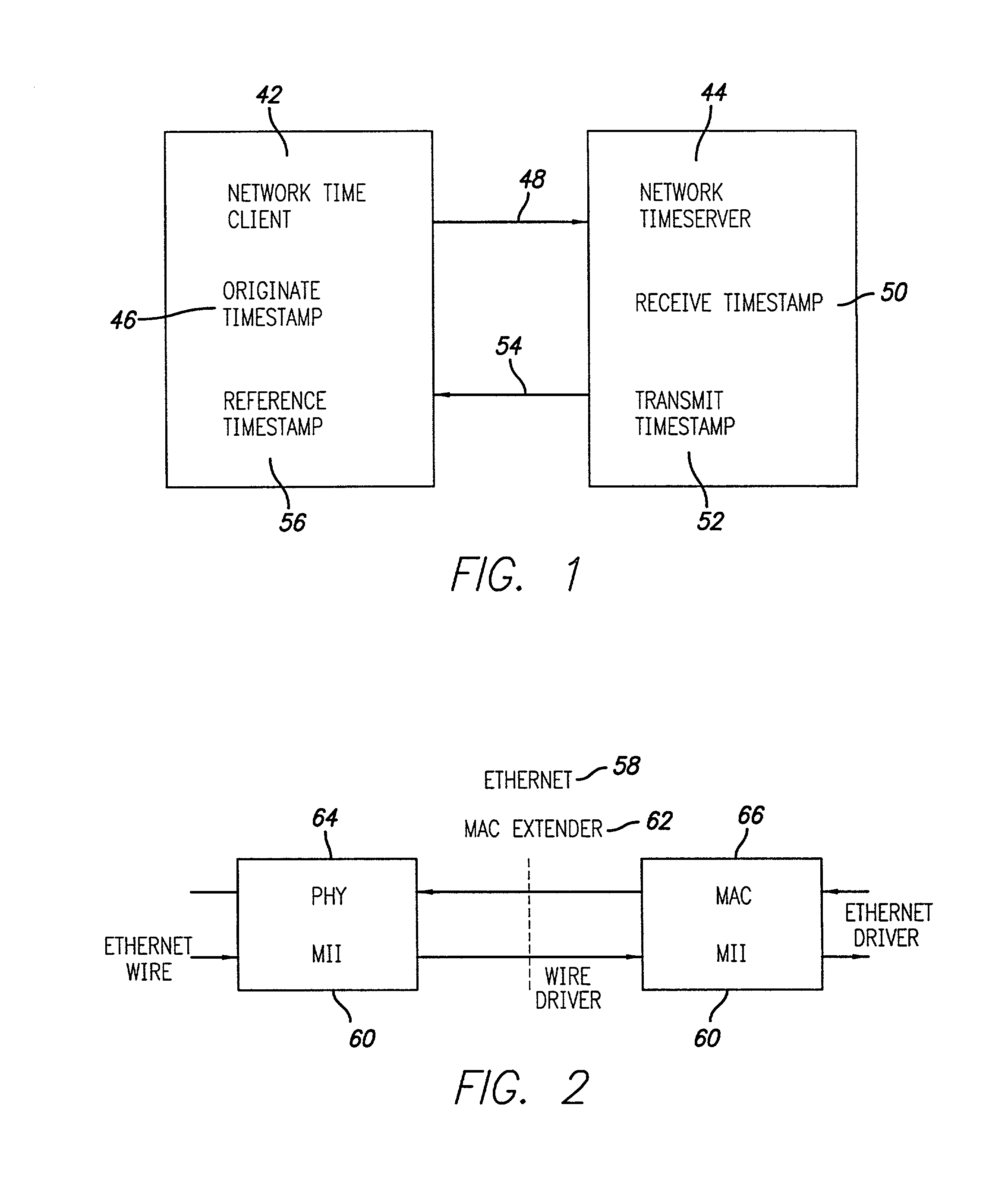

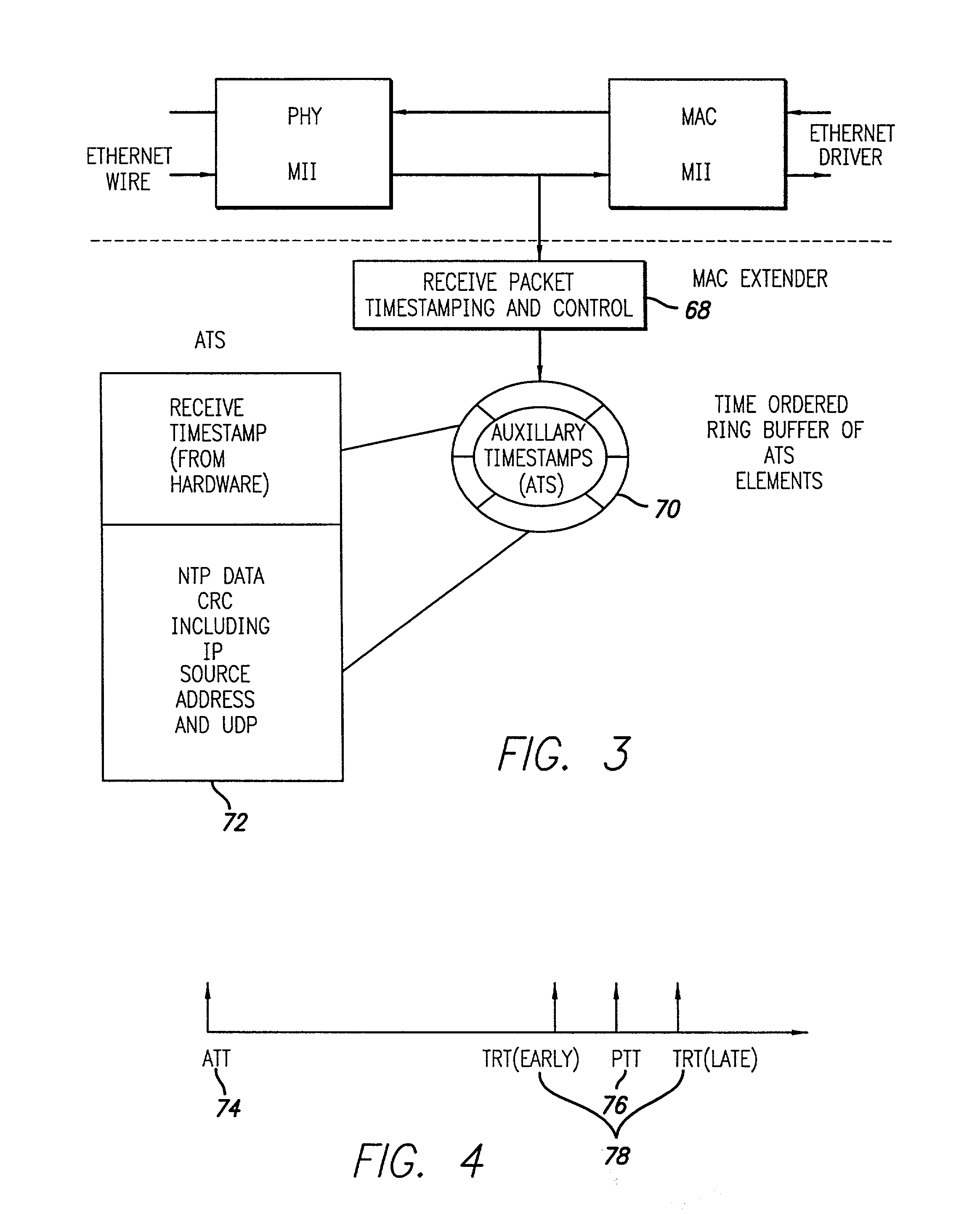

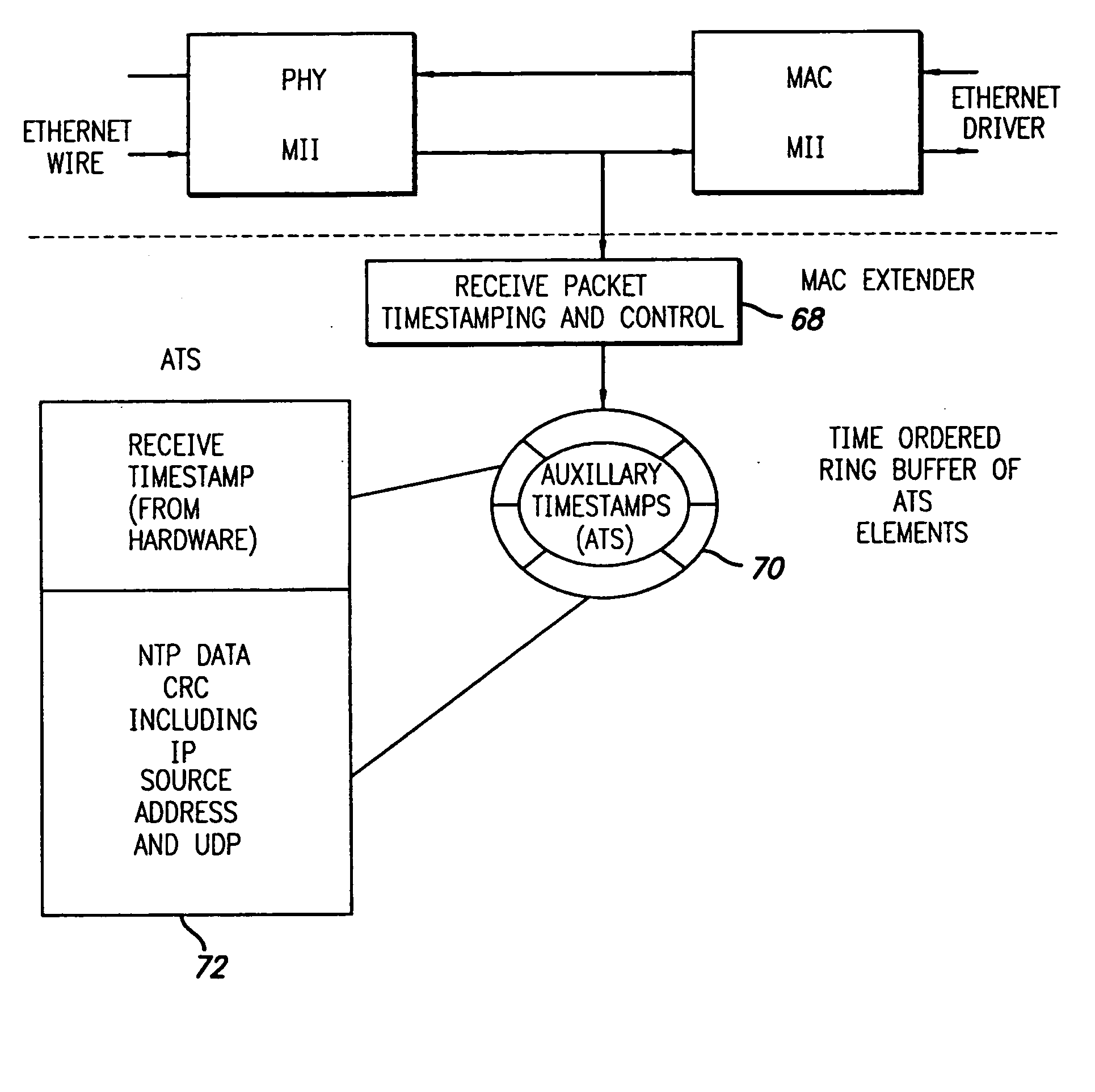

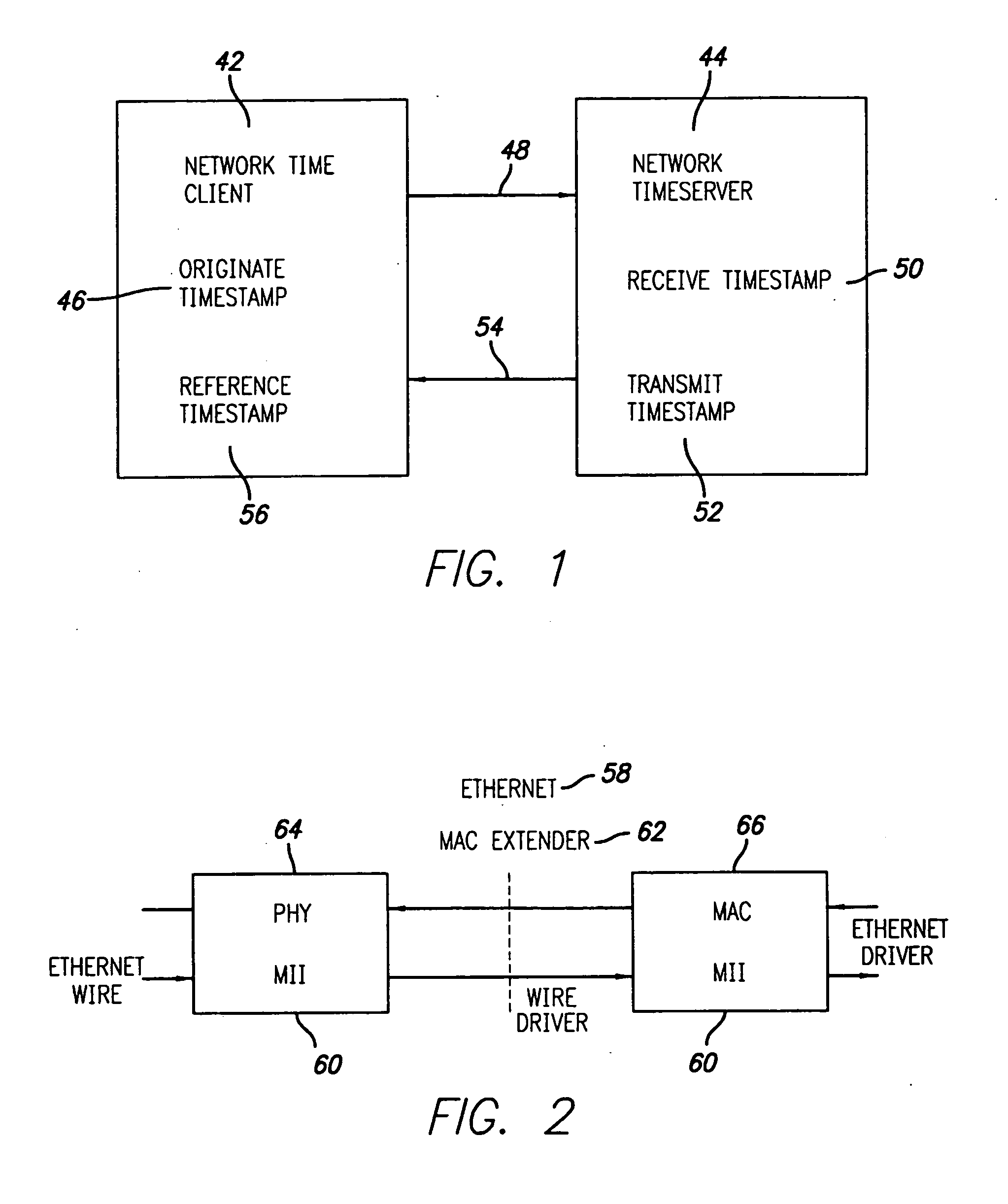

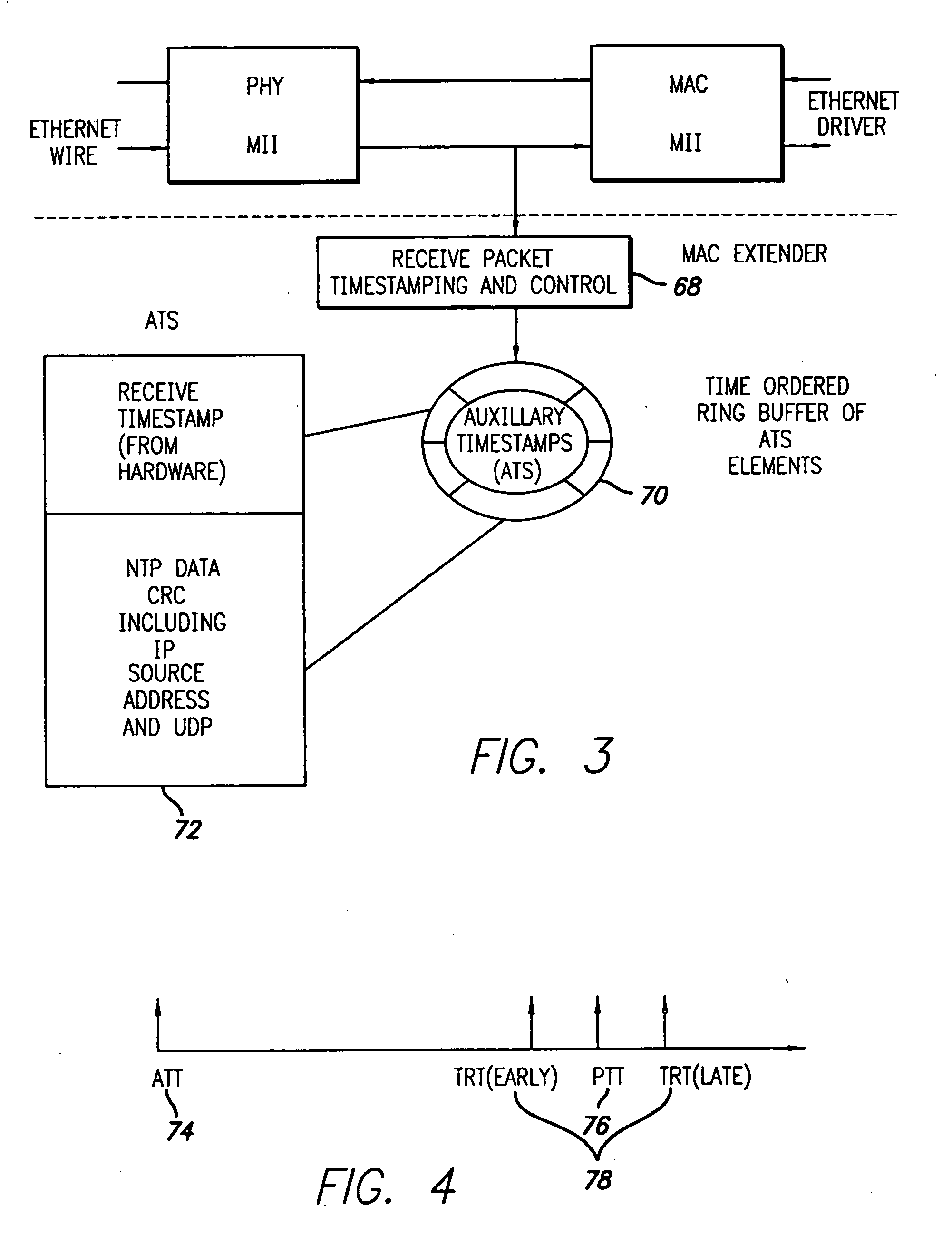

Precise network time transfer

InactiveUS6985499B2Reduce uncertaintyUncertainty in receive buffers is removedTime-division multiplexStore-and-forward switching systemsNetwork packetRelease time

The invention comprises a method and apparatus for reducing uncertainty in timing on the network. The uncertainty in receive buffers is removed by time stamping the arriving packets before sending the packets to the receive buffer. The uncertainty in the transmission buffer is removed by giving the packets a timestamp in the future, and holding the packets until precisely that time. Time precision is ensured by only releasing time packets at the host physical layer to network boundary at the time specified within the packet.

Owner:MICROSEMI FREQUENCY & TIME

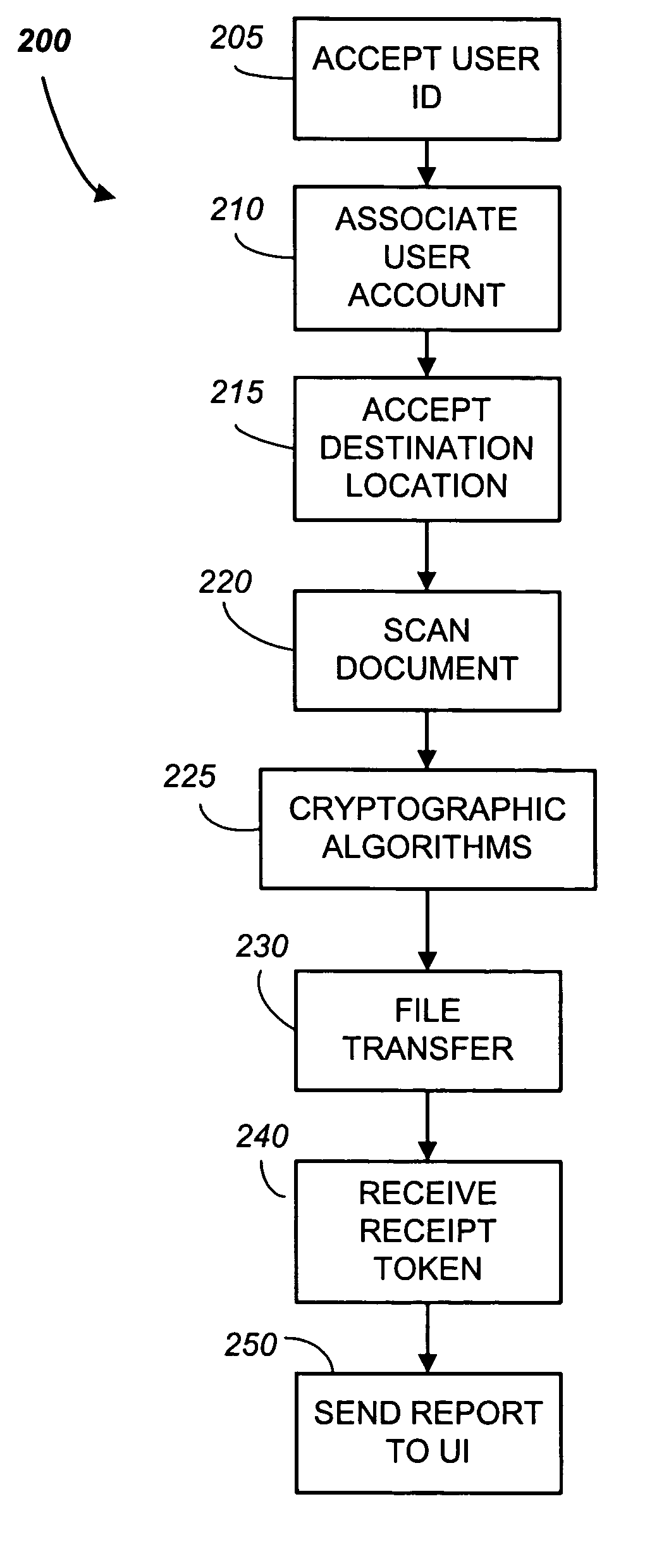

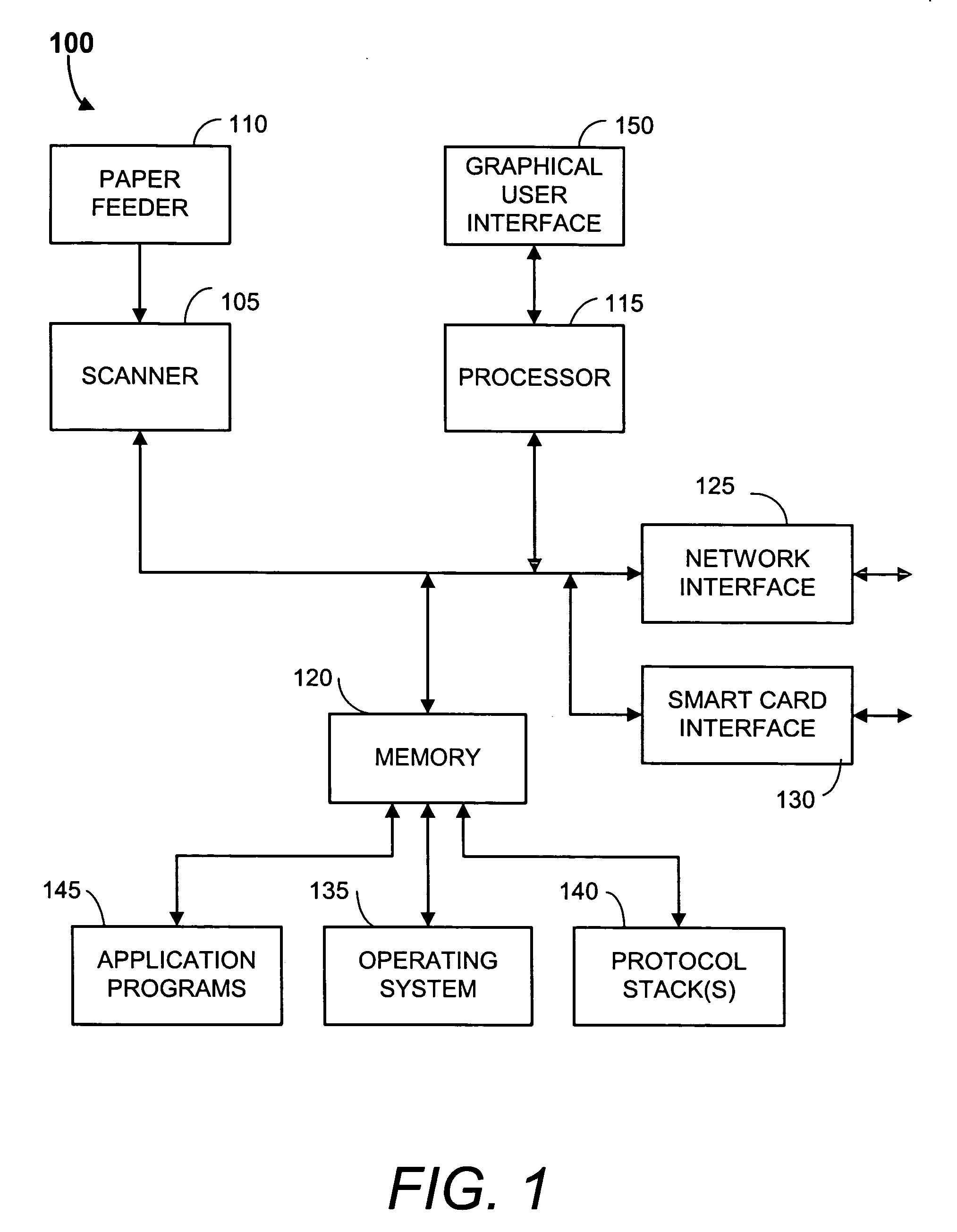

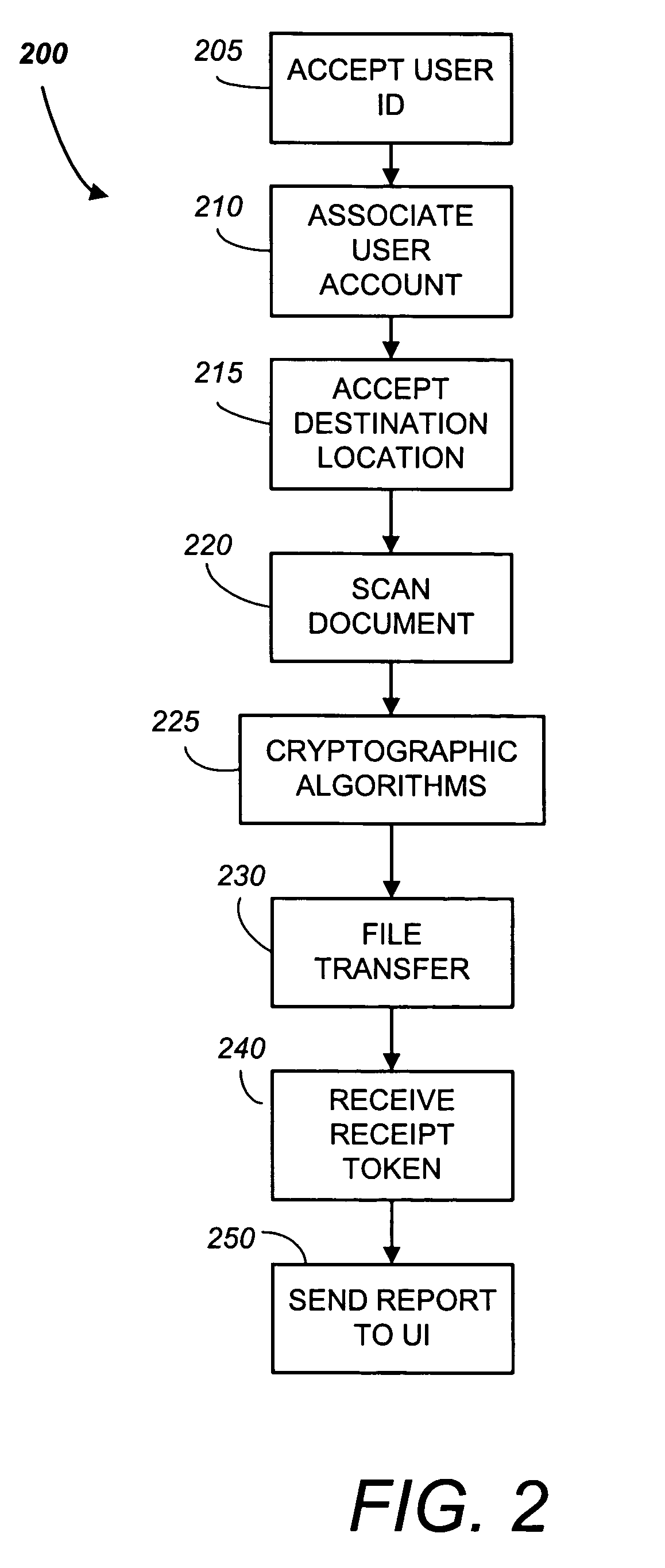

Network scanner for global document creation, transmission and management

InactiveUS7672003B2Enhanced interactionRemove uncertaintySpecial service for subscribersTime-division multiplexFile transmissionNetwork Communication Protocols

A network scanner, communication protocols, and client and server programs and are provided which provide an improved way to transmit legally binding documents, obviating the need for outmoded, legacy fax transmissions. Using the network scanner, a document may be scanned and transferred directly into any shared folder inbox residing on any computer attached to the Internet. Enhanced server systems and network communications and messaging protocols are provided that are more practical to use than email for sending documents such as executed legal documents or other documents requiring robust integrity and authenticatability. Similarly, the inventive network scanner, server systems and communication protocols provide improved ways to perform large file transfers and to manage bandwidth to minimize problems associated with uploading / downloading large files as attachments to / from email servers and for enabling user control over VoIP quality during file transmission sessions.

Owner:INTELLECTUAL PROPERTIES I KFT

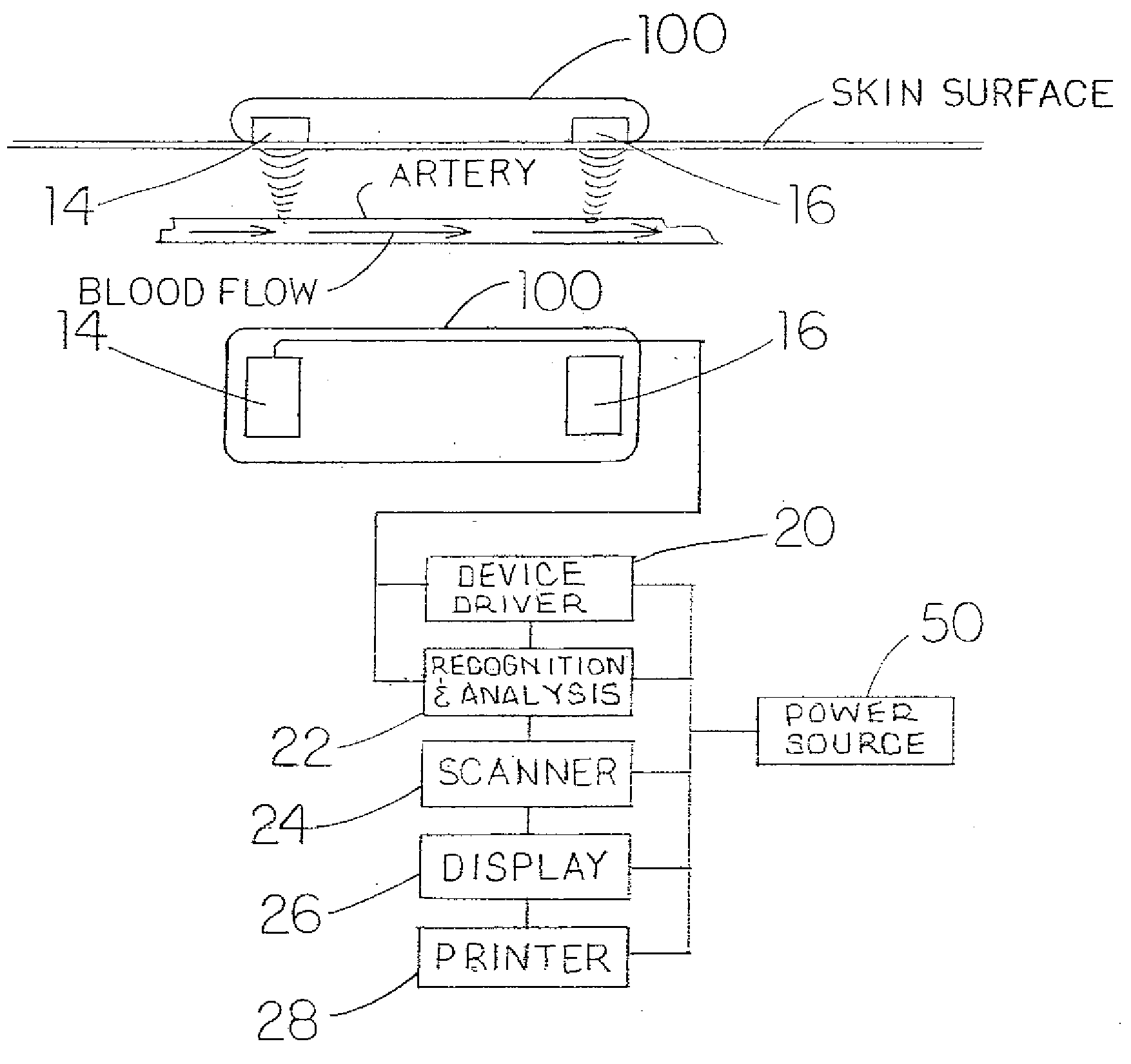

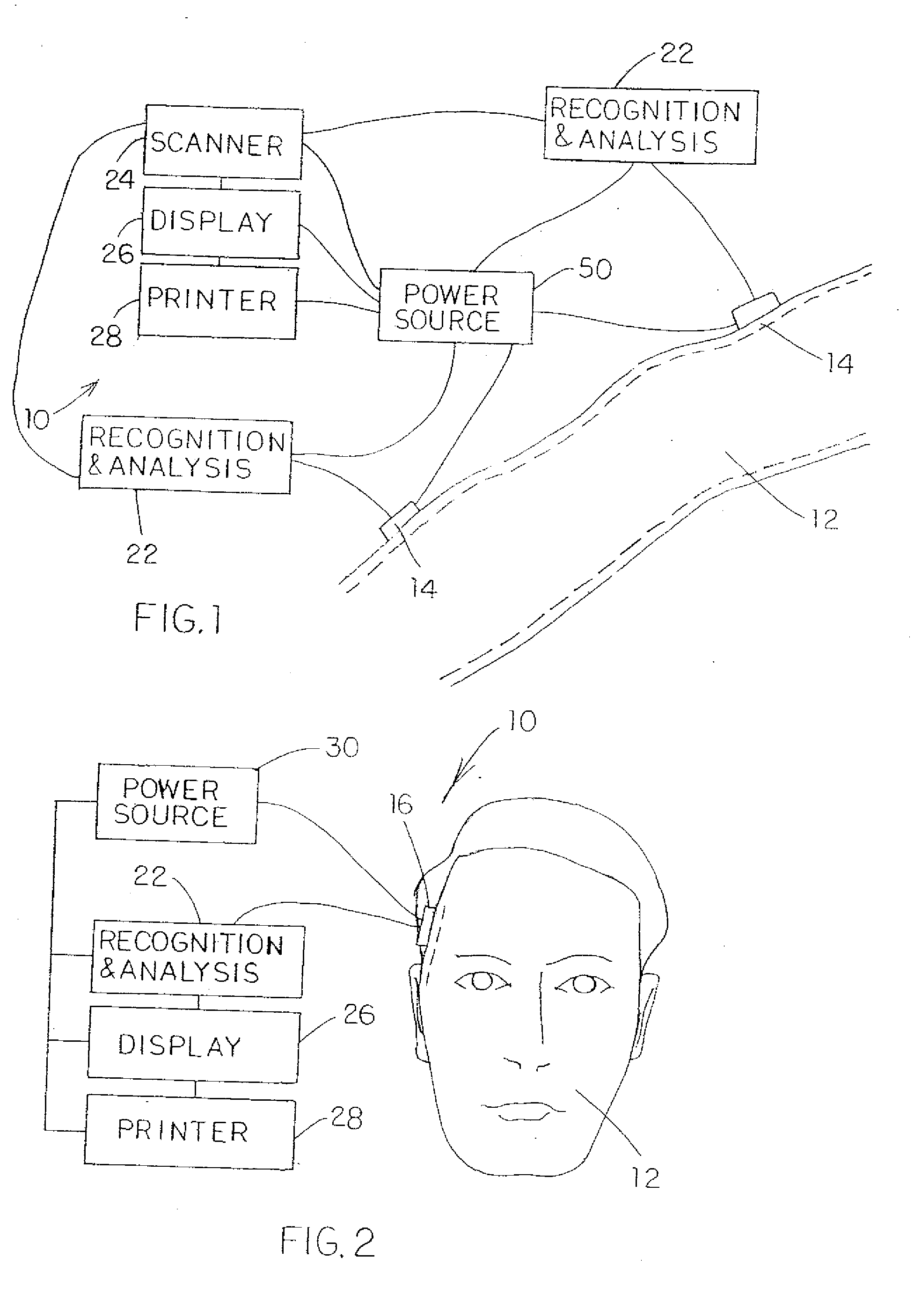

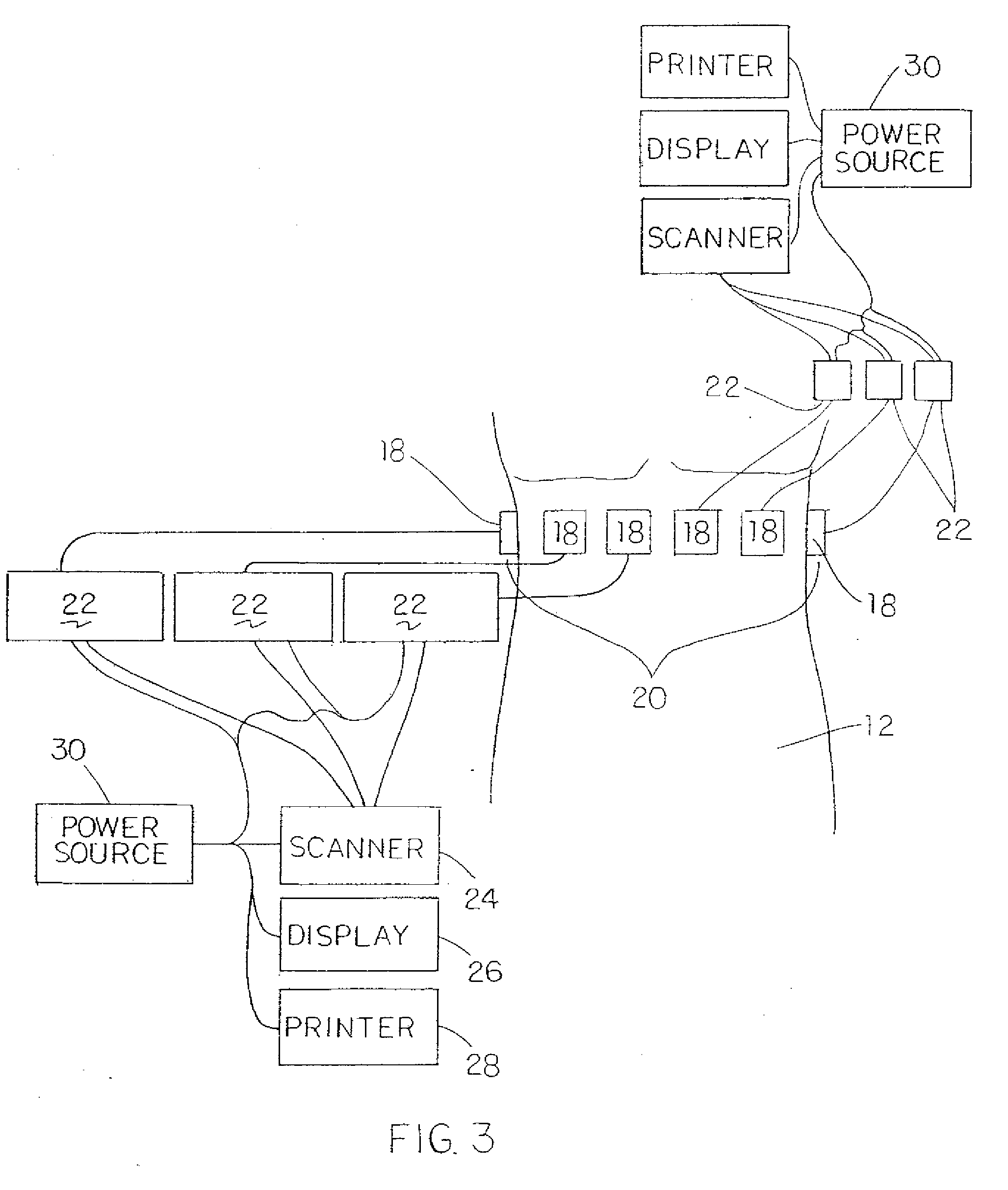

Multiparameter whole blood monitor and method

InactiveUS20090270695A1Increase turnaround timeRemove uncertaintyBlood flow measurement devicesEvaluation of blood vesselsPulse pressureIntravascular catheter

Owner:NEW PARADIGM CONCEPTS

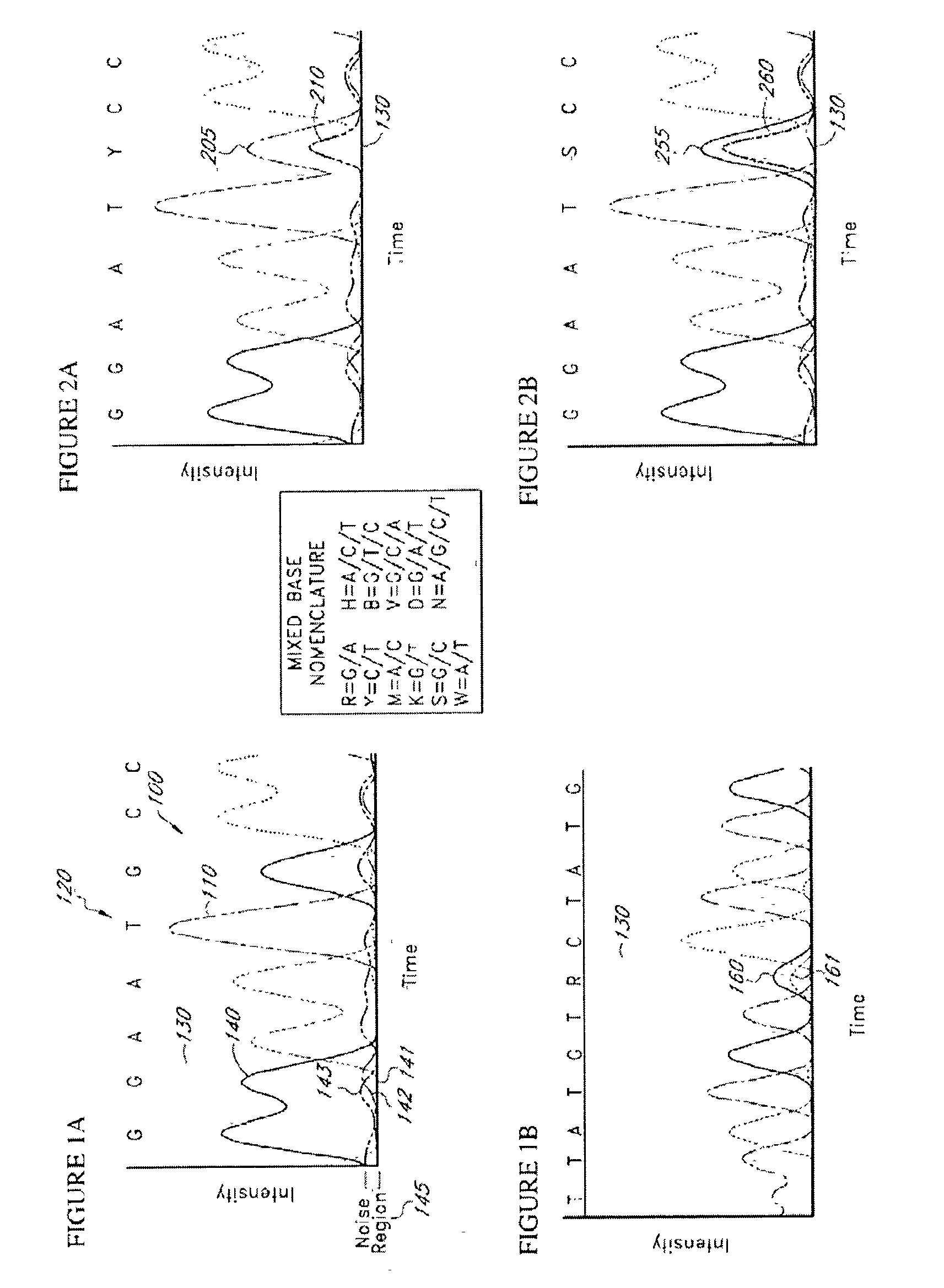

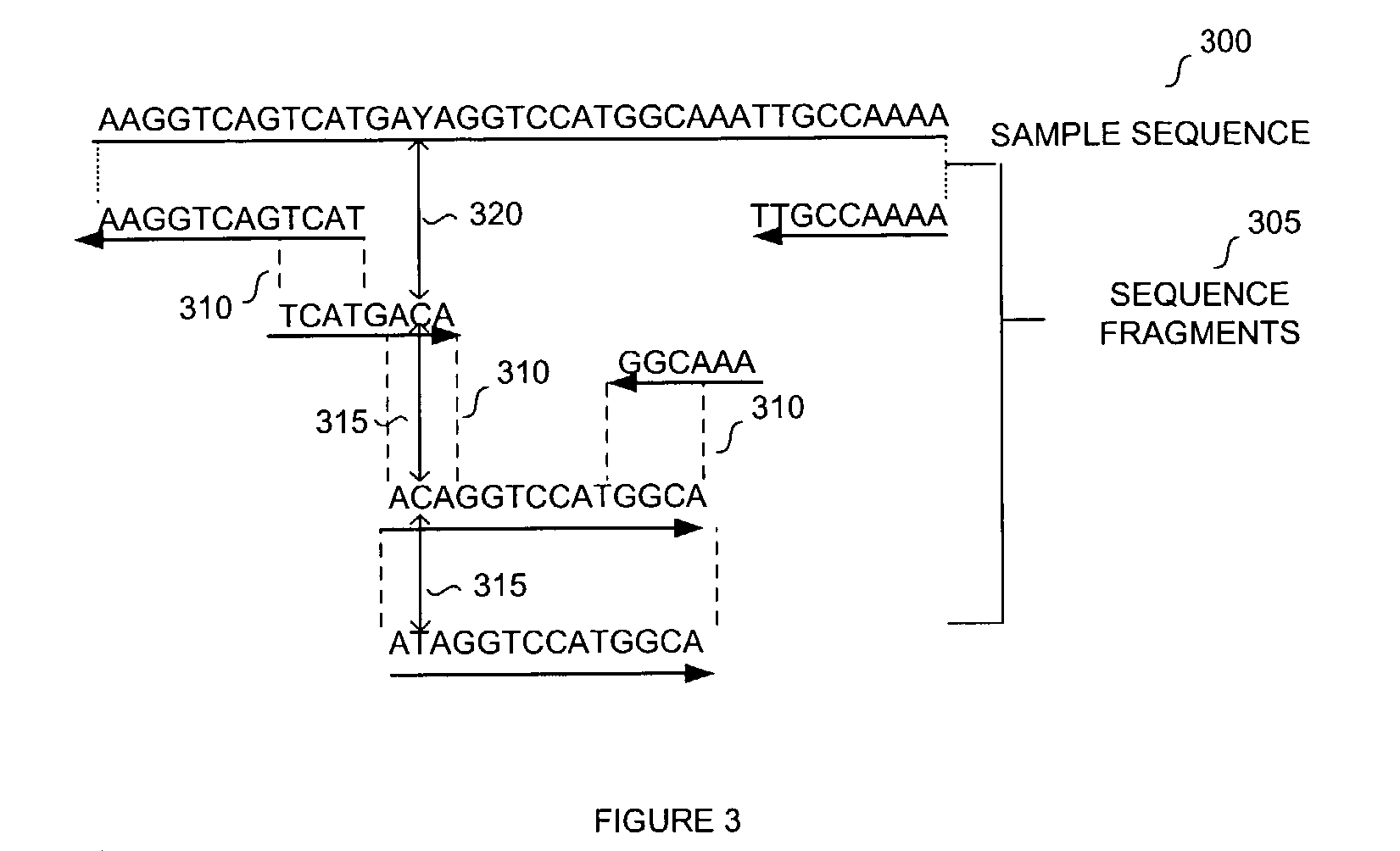

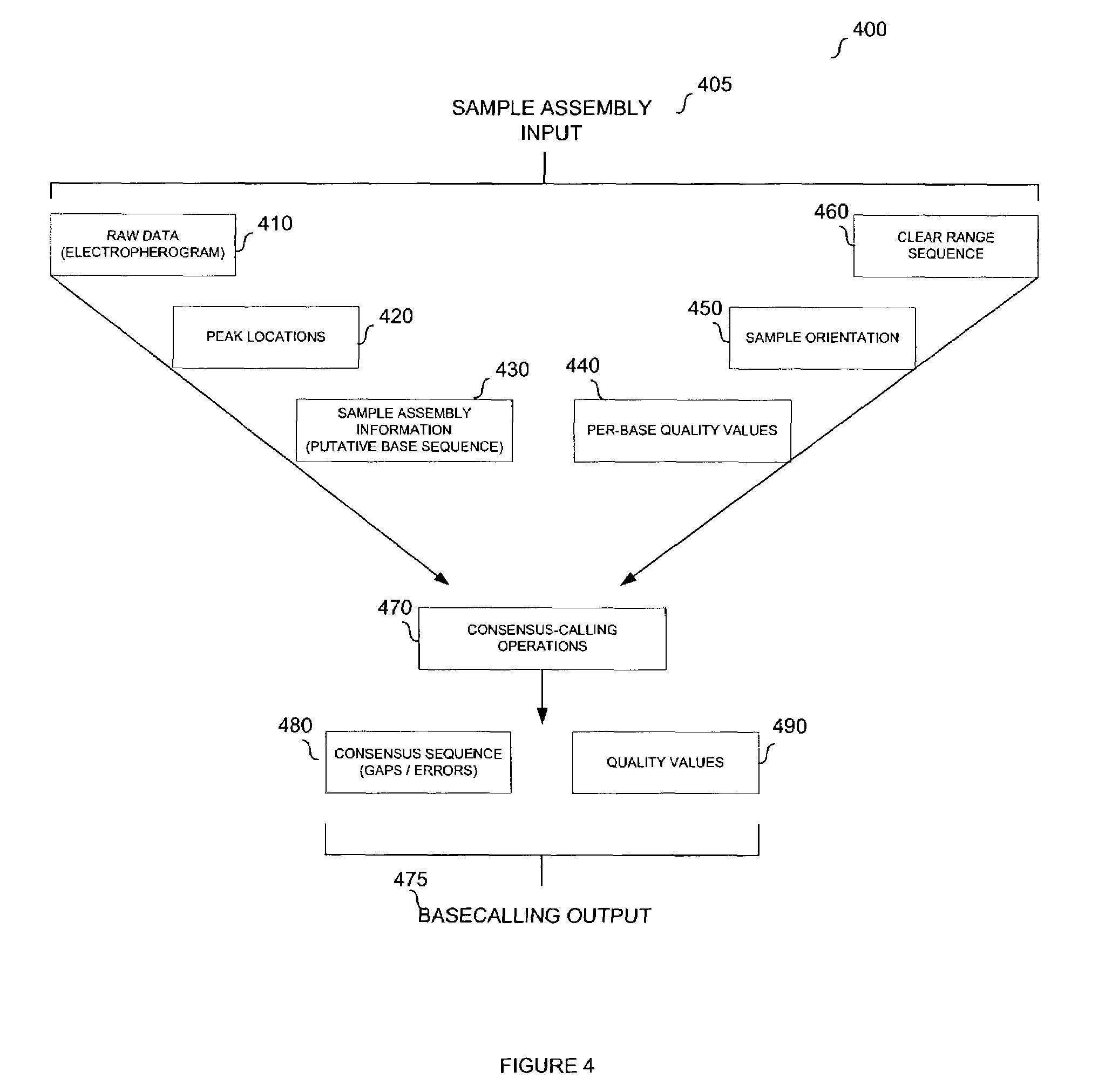

System and method for consensus-calling with per-base quality values for sample assemblies

InactiveUS7406385B2Quality improvementRemove uncertaintyMicrobiological testing/measurementBiological testingSequence analysisNucleotide

The present teachings disclose a method for evaluation of a polynucleotide sequence using a consensus-based analysis approach. The sequence analysis method utilizes quality values for a plurality of aligned sequence fragments to identify consensus basecalls and calculate associated consensus quality values. The disclosed method is applicable to resolution of single nucleotide polymorphisms, mixed-based sequences, heterozygous allelic variants, and heterogeneous polynucleotide samples.

Owner:APPL BIOSYSTEMS INC

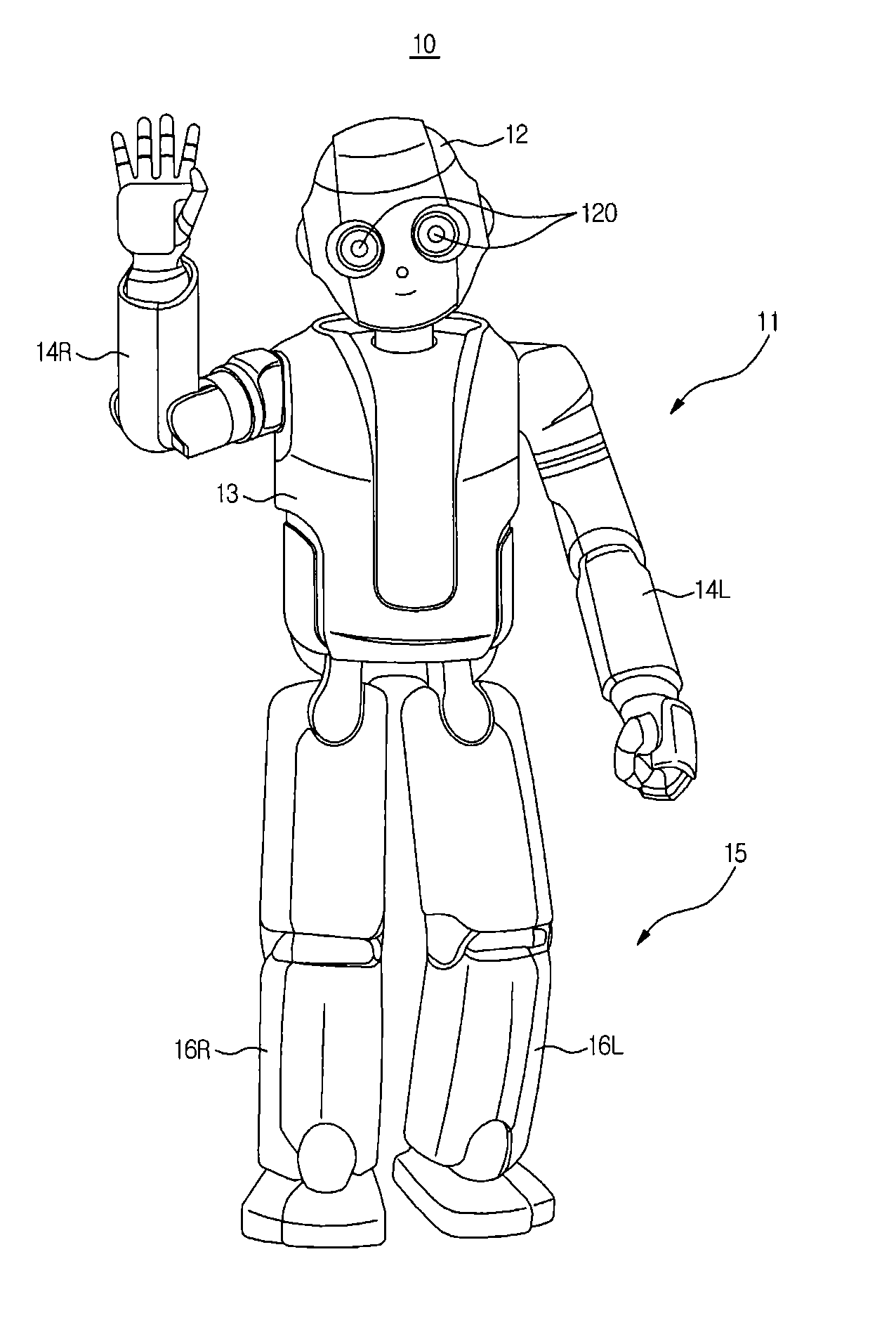

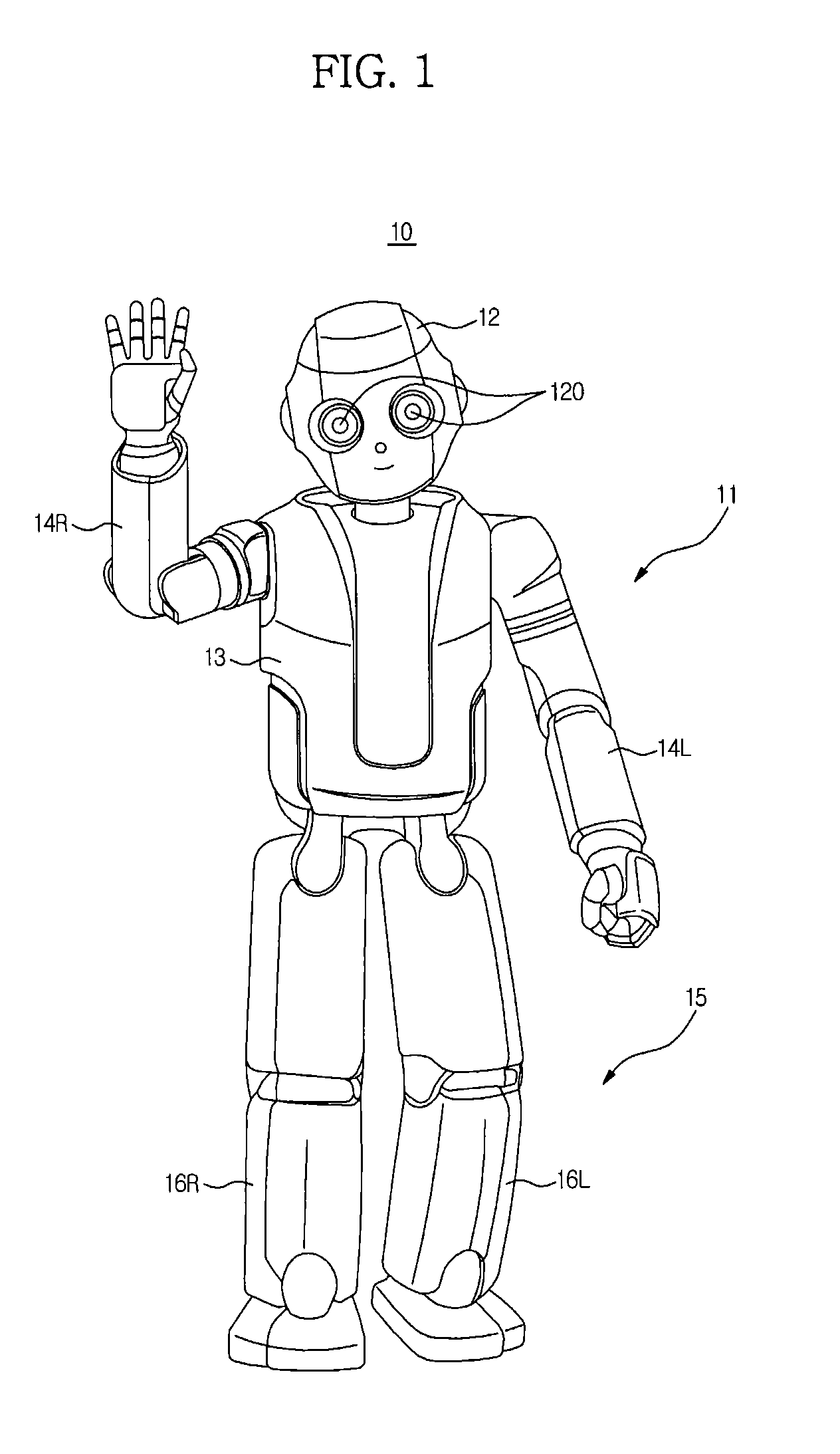

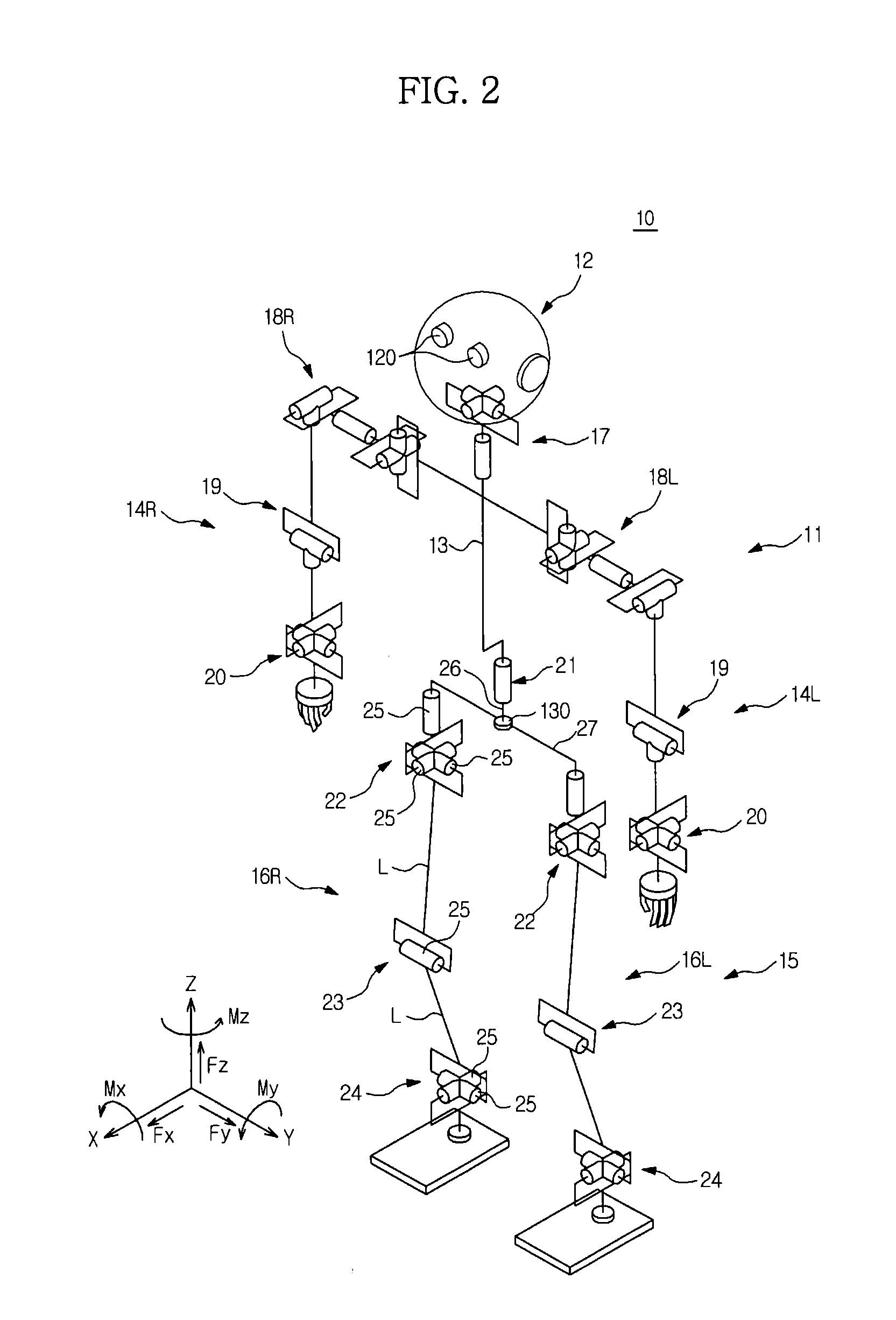

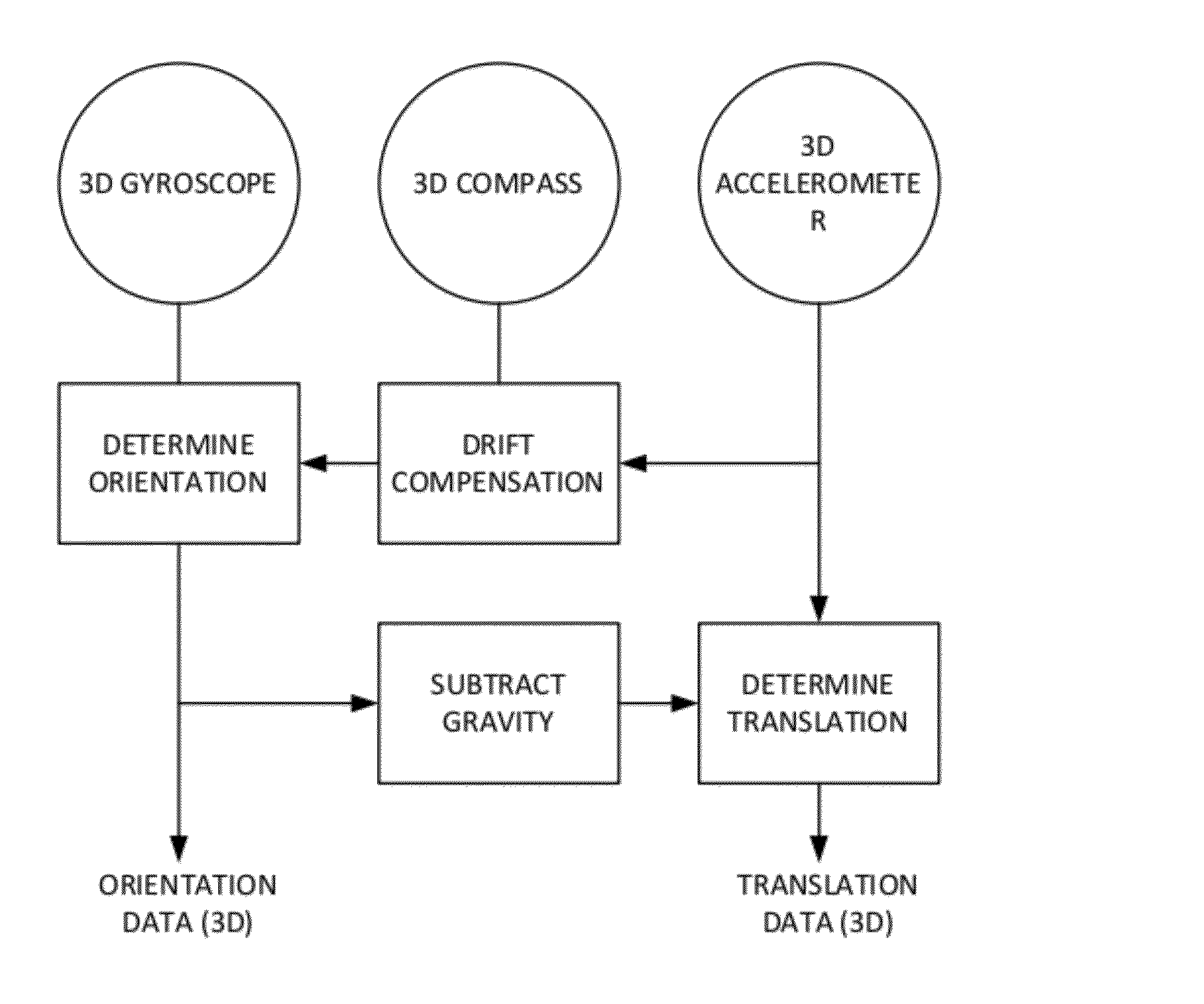

Mobile apparatus and localization method thereof

ActiveUS20130166137A1Improve performanceRemove uncertaintyVehicle testingRegistering/indicating working of vehiclesFilter systemMobile device

A mobile apparatus and a localization method thereof which perform localization of the mobile apparatus using a distributed filter system including a plurality of local filters independently operated and one fusion filter integrating results of localization performed through the respective local filters, and additionally apply accurate topological absolute position information to the distributed filter system to improve localization performance (accuracy, convergence and speed in localization, etc.) of the mobile apparatus on a wide space. The mobile apparatus includes at least one sensor, at least one first distribution filter generating current relative position information using a value detected by the at least one sensor, at least one second distribution filter generating current absolute position information using the value detected by the at least one sensor, and a fusion filter integrating the relative position information and the absolute position information to perform localization.

Owner:SAMSUNG ELECTRONICS CO LTD

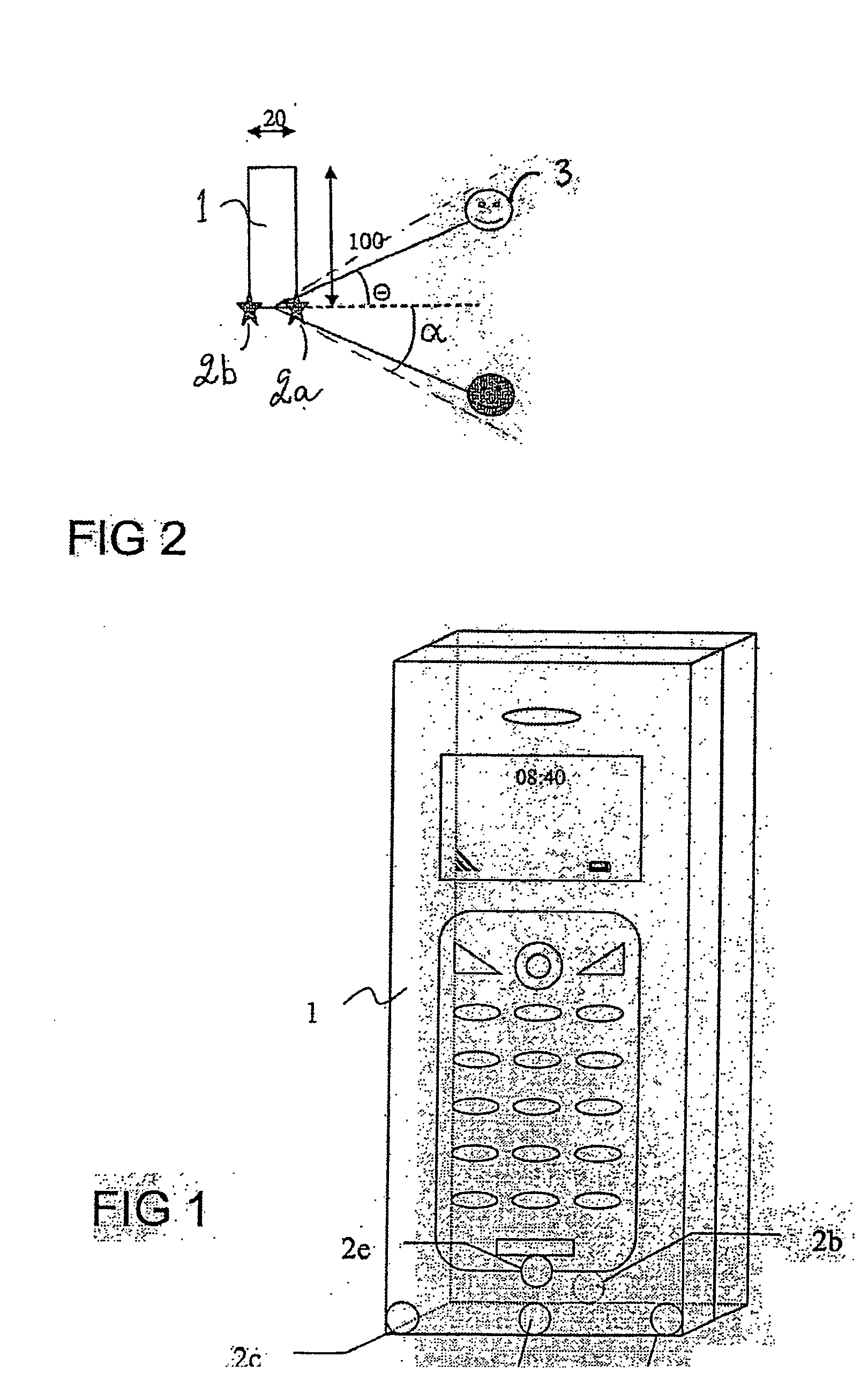

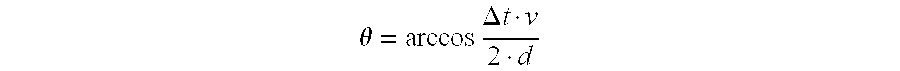

Device And Method For Voice Activity Detection

A device includes a sound signal analyser configured to determine whether a sound signal comprises speech. The device further includes a microphone system configured to discriminate sounds emanating from sources located in different directions from the microphone system so that sounds only emanating from a range of directions are included as signals possibly containing speech.

Owner:SONY CORP

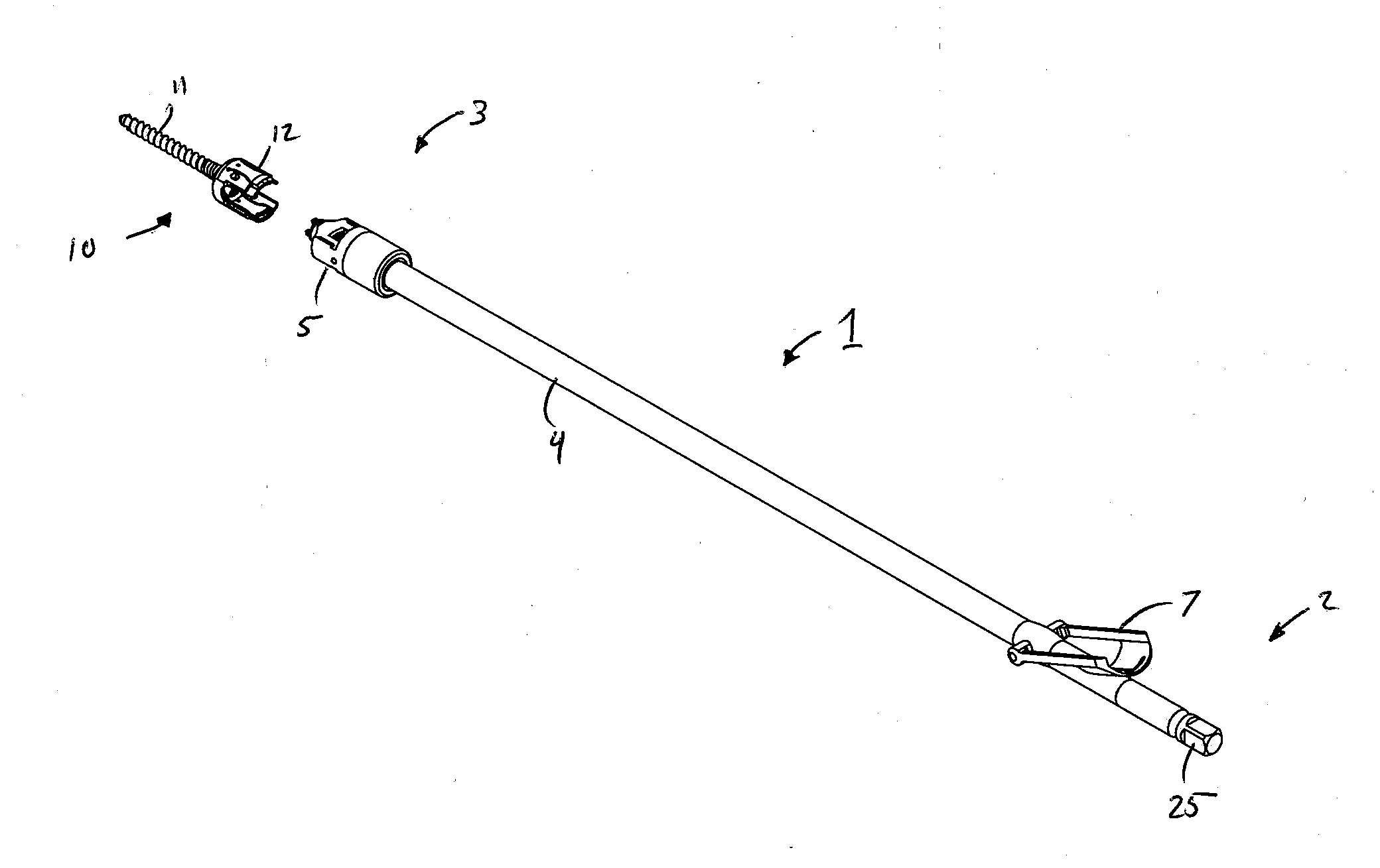

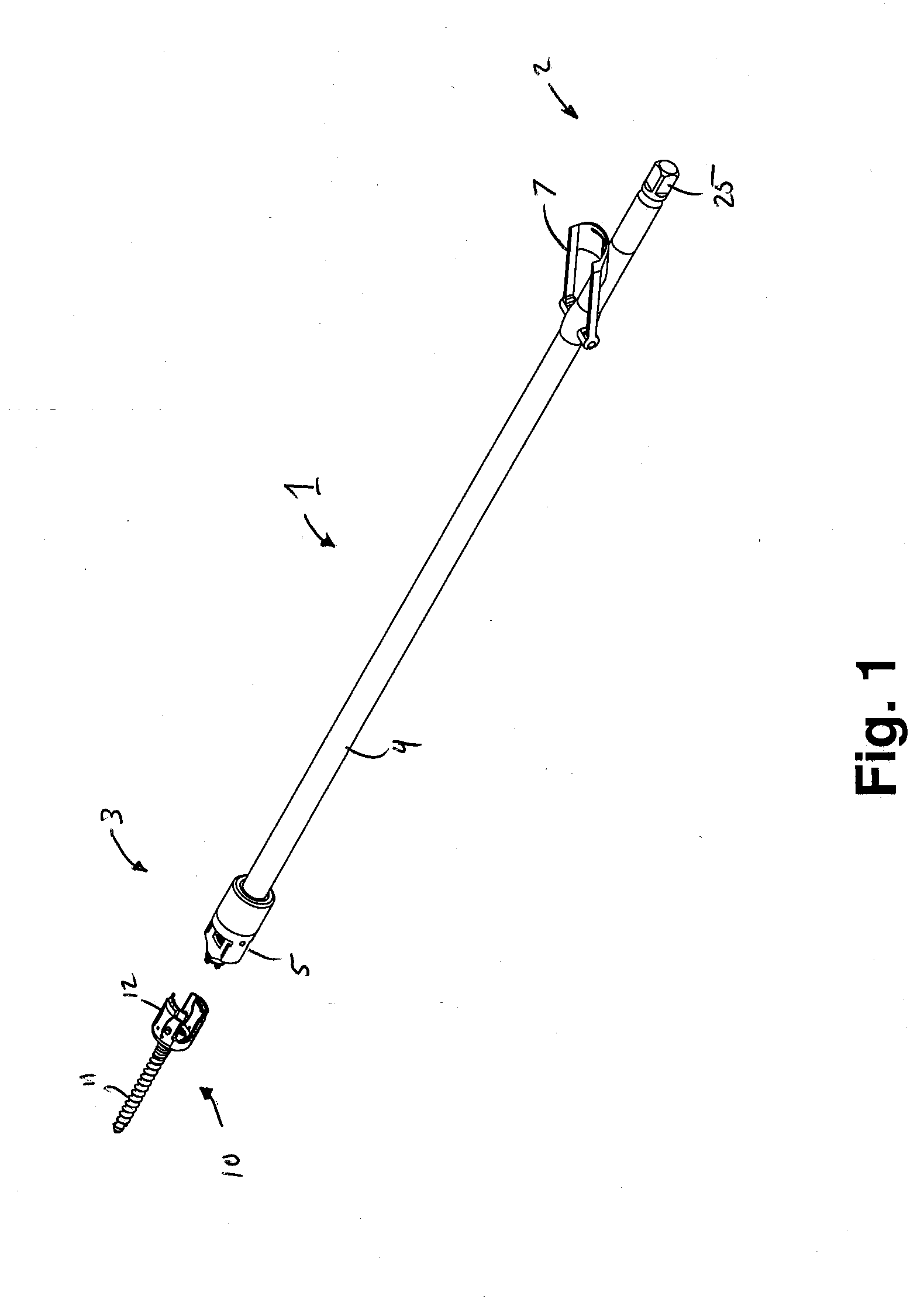

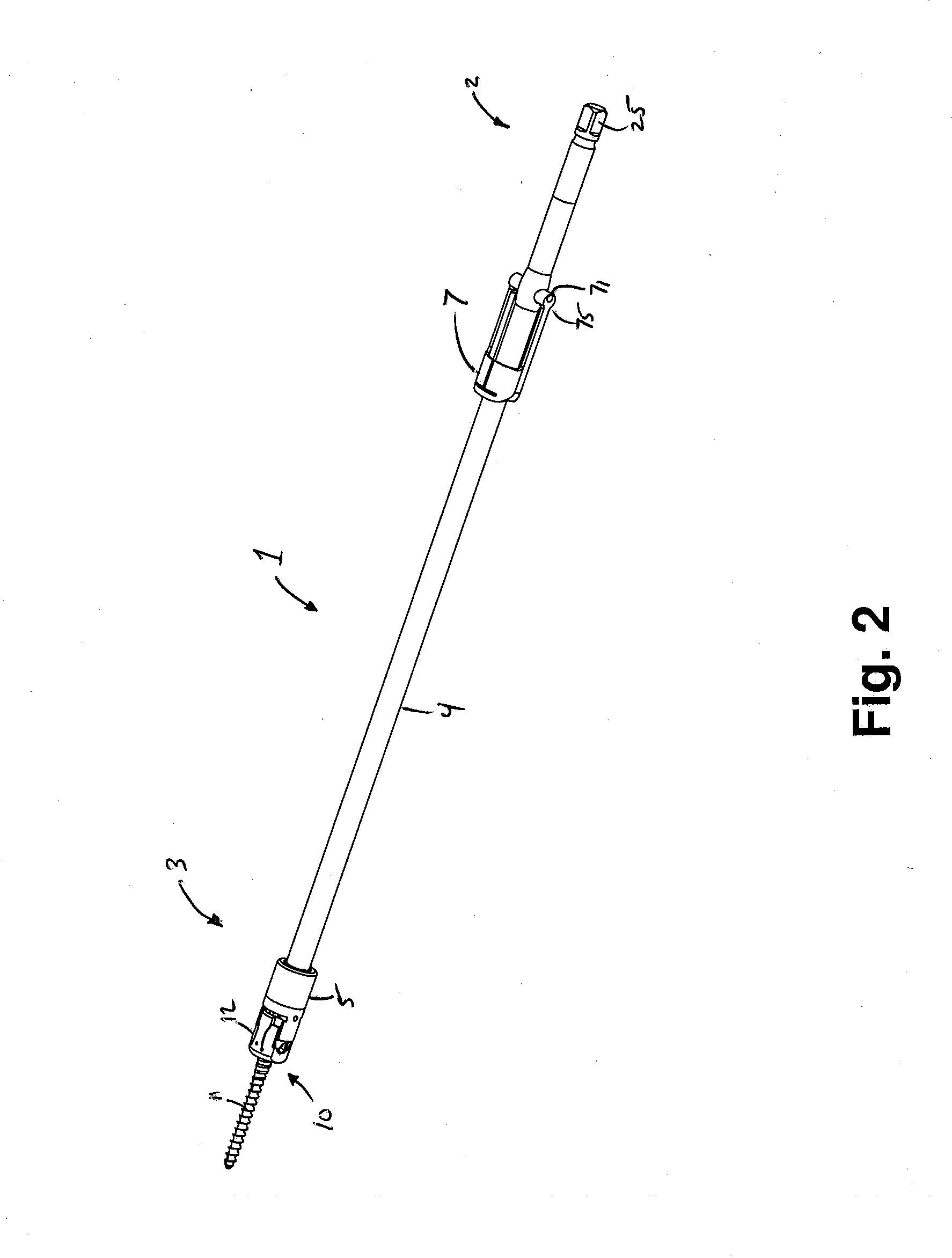

Insertion Instrument for a Spinal Fixation System

InactiveUS20090234395A1Easy to operate mechanicallyGuaranteed uptimeInternal osteosythesisNon-surgical orthopedic devicesSpinal columnEngineering

A medical instrument apparatus and method is provided to insert and release medical implants. This invention pertains generally to medical instruments and more specifically to spinal implant insertion instruments for spinal fixation systems. The insertion instrument may provide a positive locking and unlocking actuator, preferably in the form of a lever, which ensures that the pedicle screw and yoke assembly is either mechanically locked to the insertion instrument or unlocked to the insertion instrument. The positive locking and unlocking actuator of the insertion instrument eliminates guesswork for the surgeon because the surgeon can readily know if the pedicle screw and yoke assembly is attached to the insertion instrument or not. Superelastic components may also be included to shift components in a first direction and pull components under superelastic tension in a second direction for increased holding force.

Owner:PIONEER SURGICAL TECH INC

Methods and systems for dealing with perspective distortion in connection with smartphone cameras

ActiveUS20120218444A1Reduce Perspective DistortionReduce distortion problemsTelevision system detailsColor television detailsComputer graphics (images)Radiology

Arrangements are detailed to aid a user in positioning a camera-equipped device (e.g., a smartphone) at a particular viewing position relative to an object being imaged. Other embodiments discern the device's viewing position, and then undertake image or other processing that is dependent on such viewpoint. A great number of other features and arrangements are also detailed.

Owner:DIGIMARC CORP

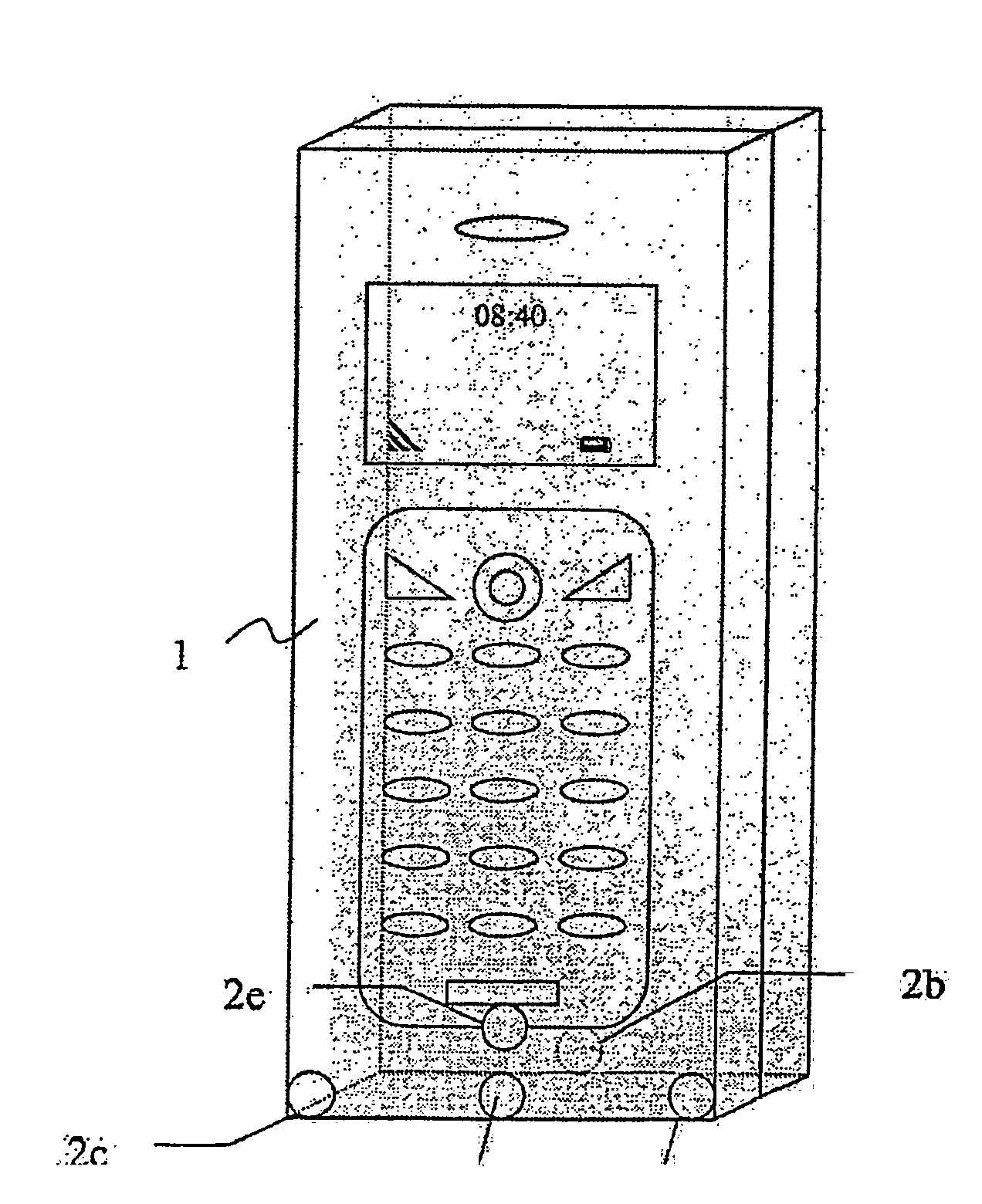

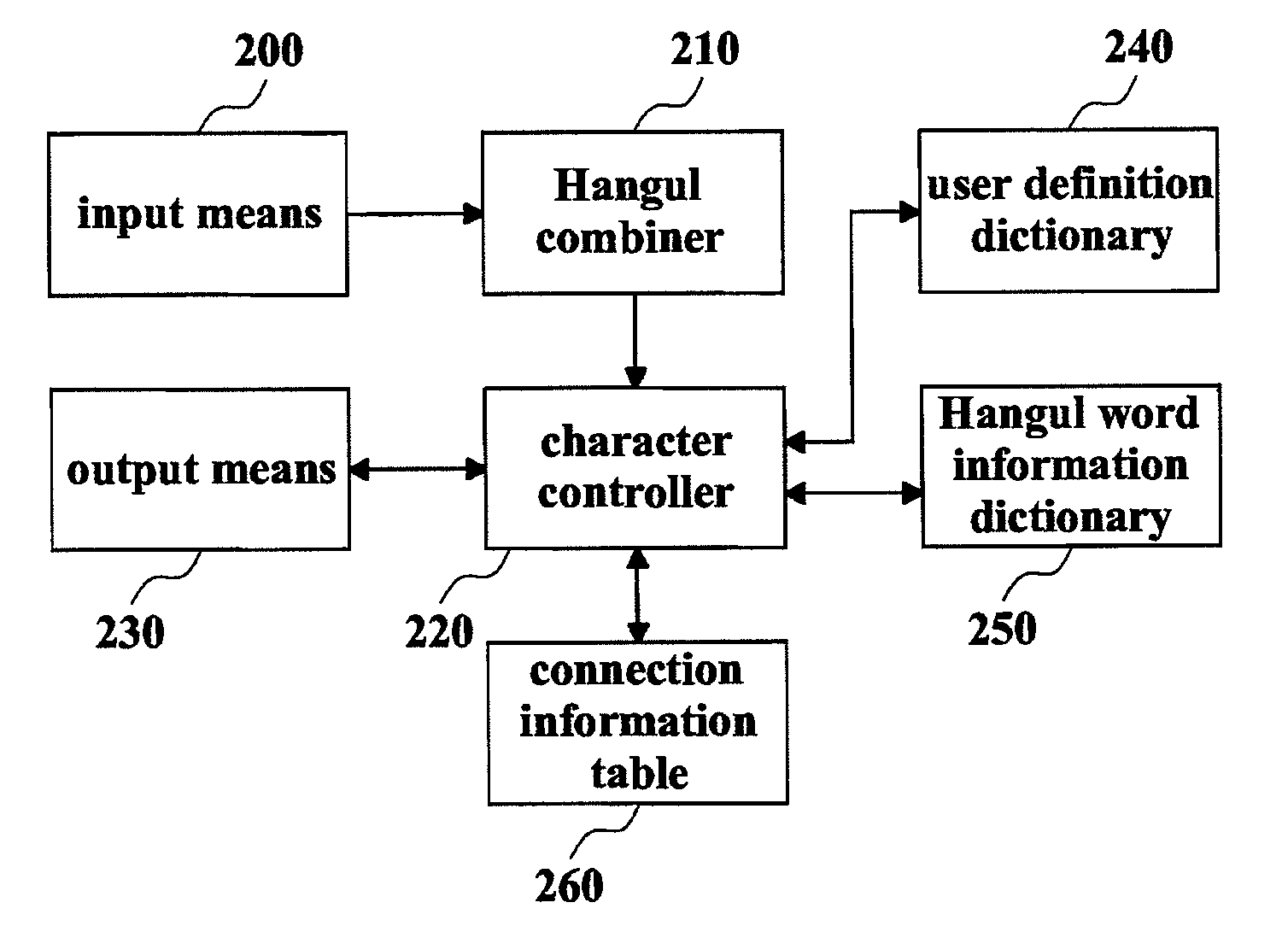

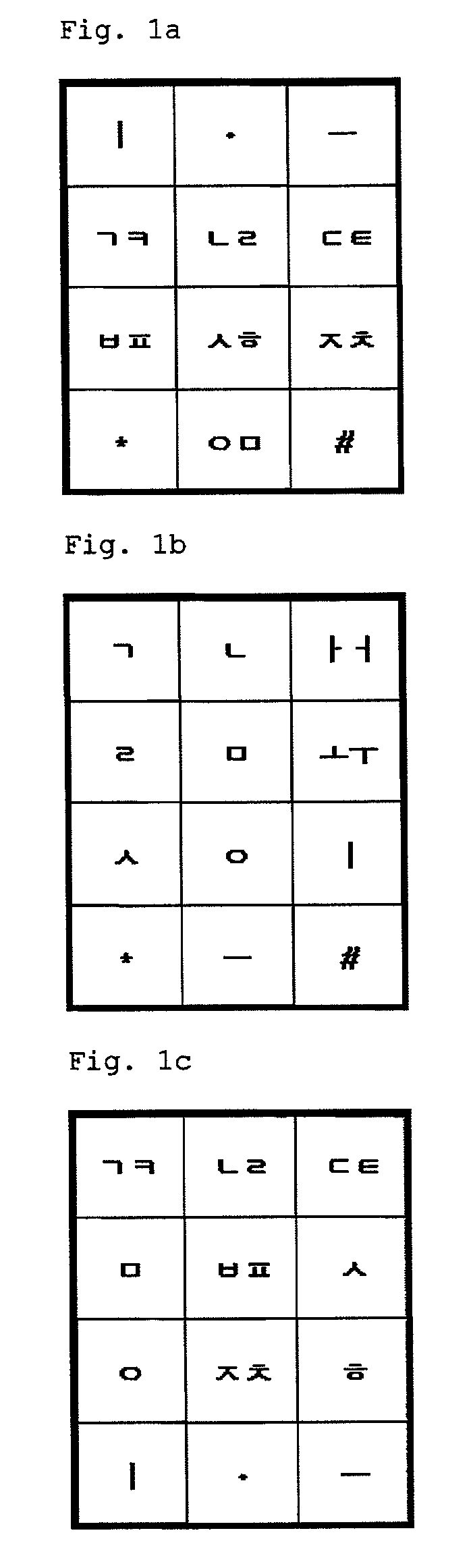

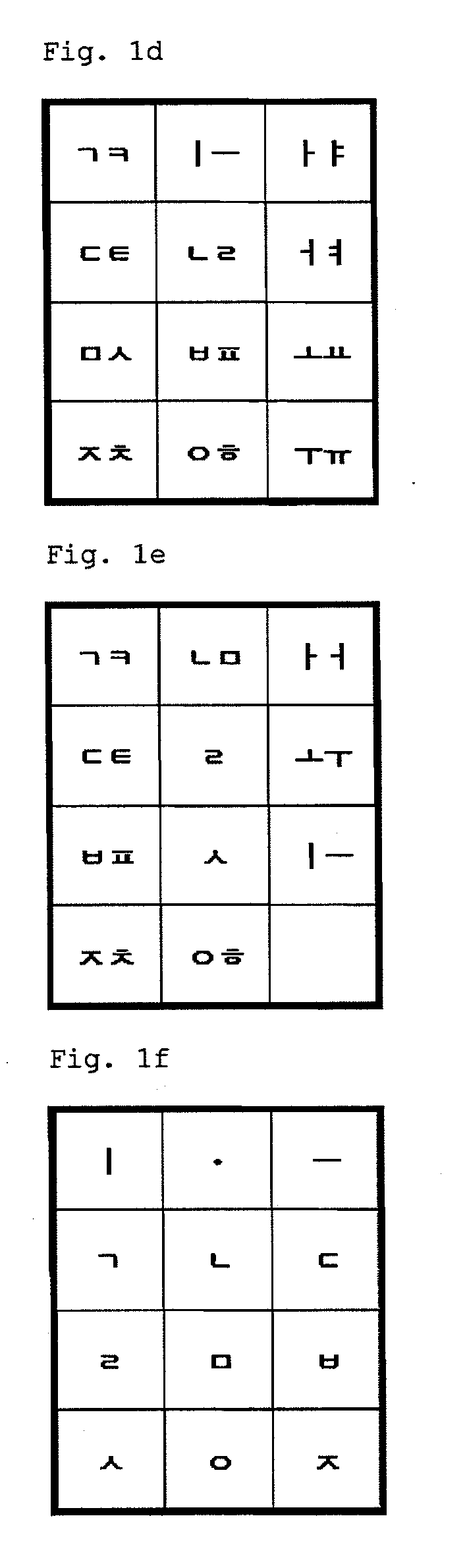

Apparatus and Method for Expressing Hangul

InactiveUS20080158023A1Remove uncertaintyElectronic switchingTelephone set constructionsAudiologyConsonant

The present invention relates to an apparatus and a method for expressing Hangul. More specifically, the present invention relates to an apparatus and a method for expressing Hangul by which Hangul can be inputted, without using a separate function key, to an information appliance with an input means which comprises a multi key to which a plurality of jamos (consonants and vowels of Hangul) are assigned.

Owner:NEOPAD

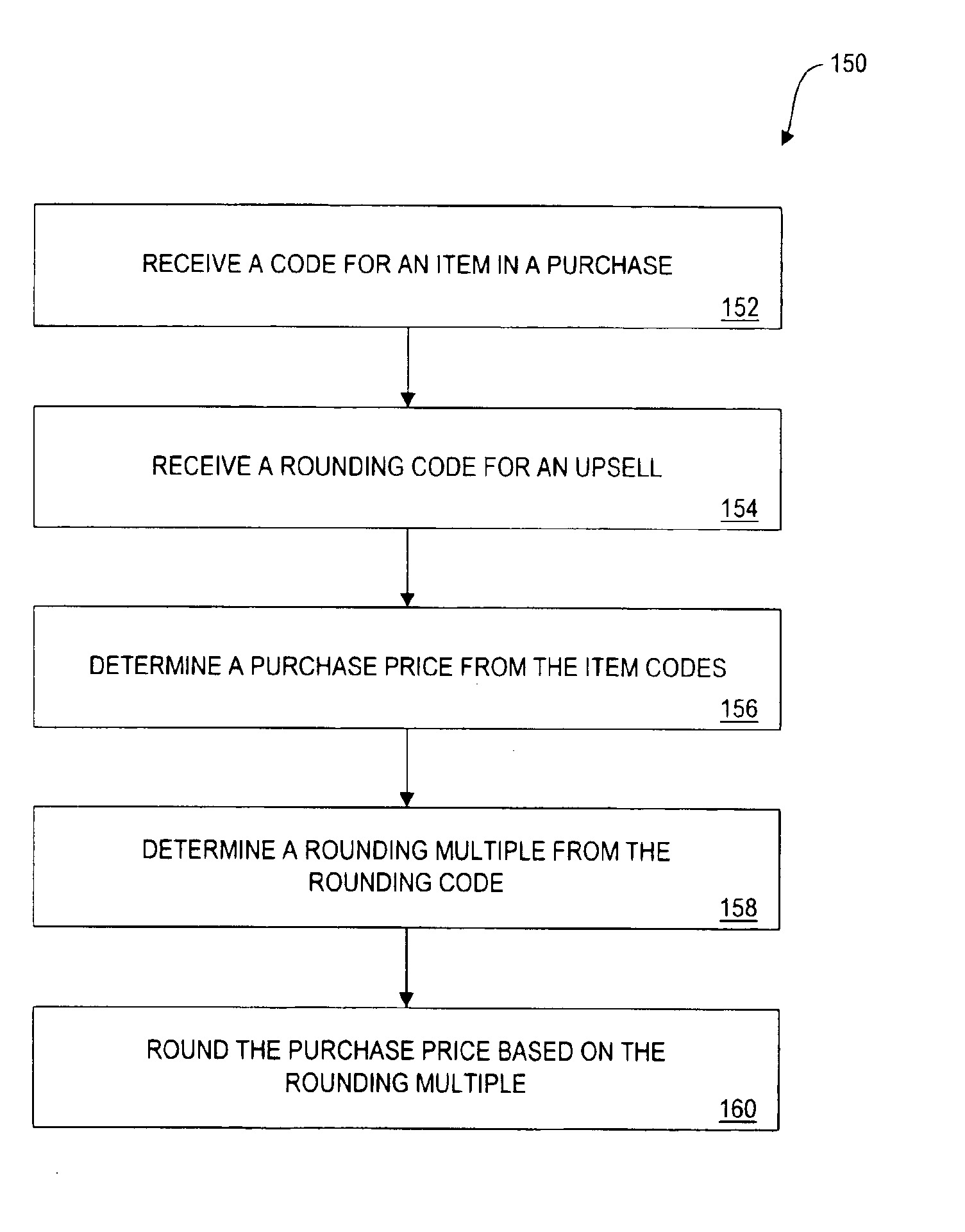

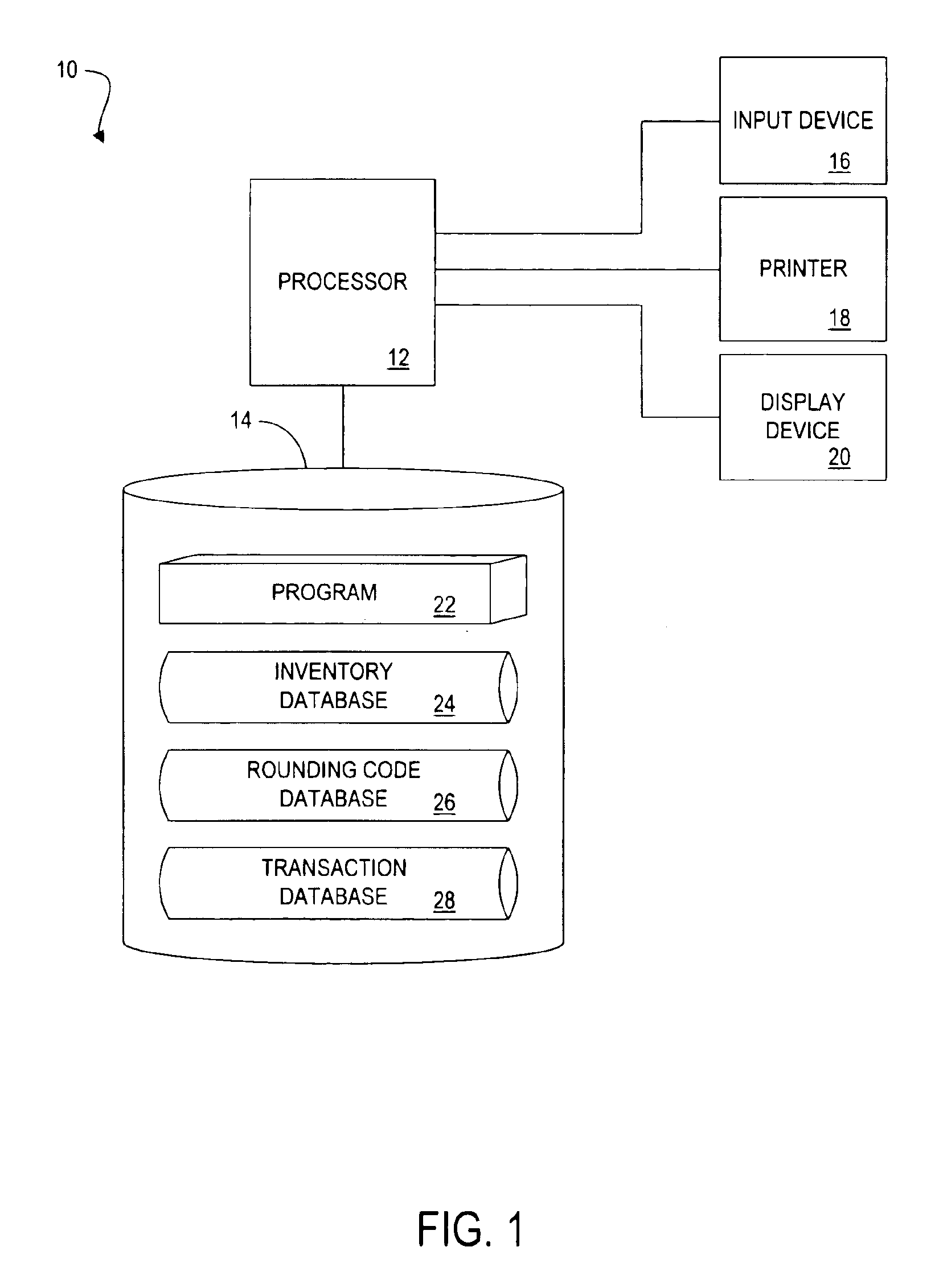

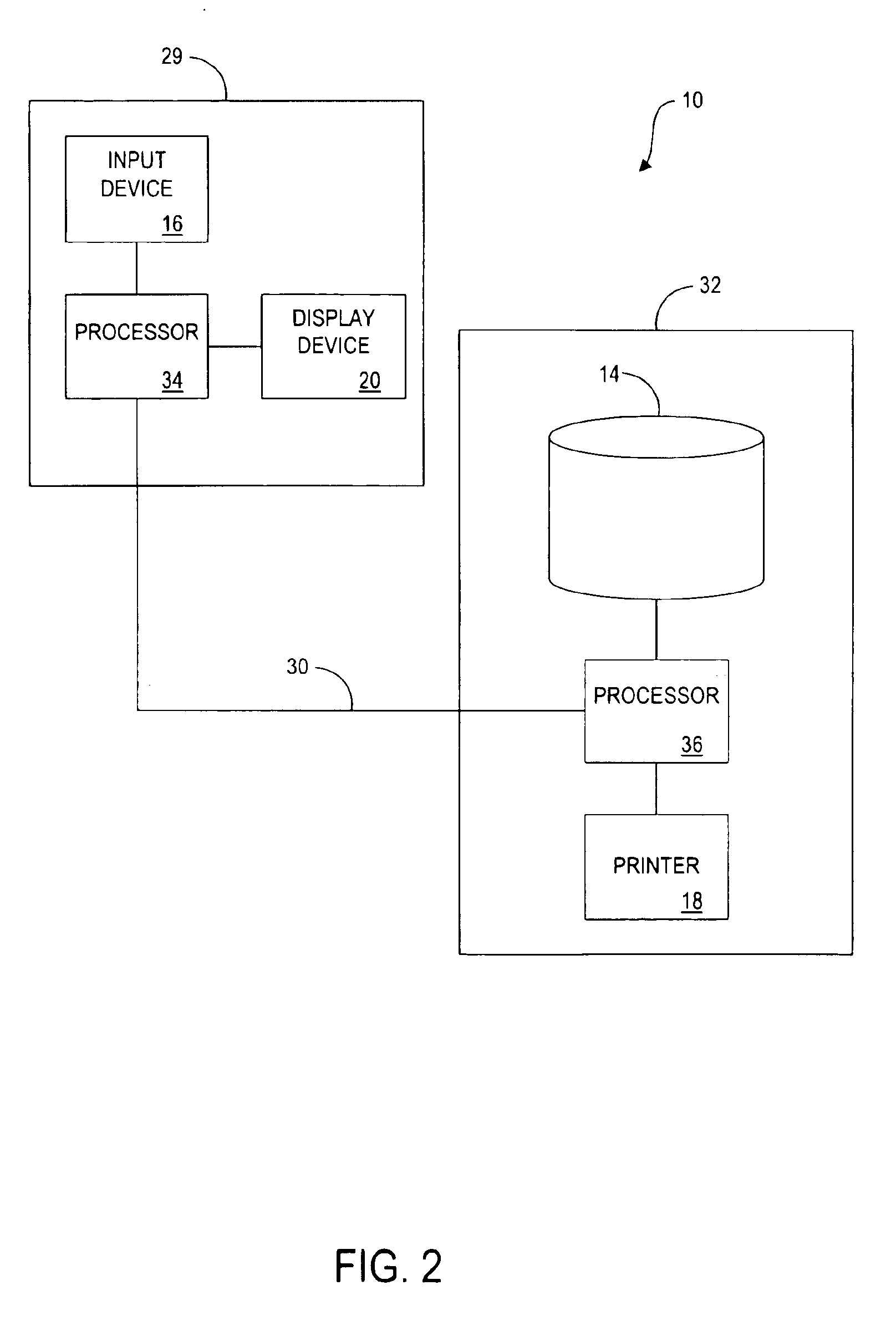

Method and apparatus for processing a supplementary product sale at a point-of-sale terminal

InactiveUS7072850B1Remove uncertaintyHand manipulated computer devicesDiscounts/incentivesBarcodeComputer terminal

Upsells are made accessible to customers so customers may select upsells as they select items in their purchase. Each upsell has an associated rounding code. For example, the rounding code may be determinable from a bar code printed on an adhesive label that is affixed to the upsell. A POS terminal receives the rounding code, by scanning the label or other means. Typically, the rounding code is read in a manner similar to the manner in which items in the purchase are read by the POS terminal. The purchase price (sum of all item prices and any tax) is rounded, based on the rounding code. For example, given a purchase price of $8.26, and a rounding code that indicates a multiple of $5, the purchase price would be rounded up to the next-higher multiple of $5 ($10.00). The customer would pay the rounded price in exchange for the items and the upsell. Thus, the difference between the rounded price and the purchase price ($10.00−$8.26 =$1.74) is effectively the price the customer pays for the upsell.

Owner:RETAILDNA +2

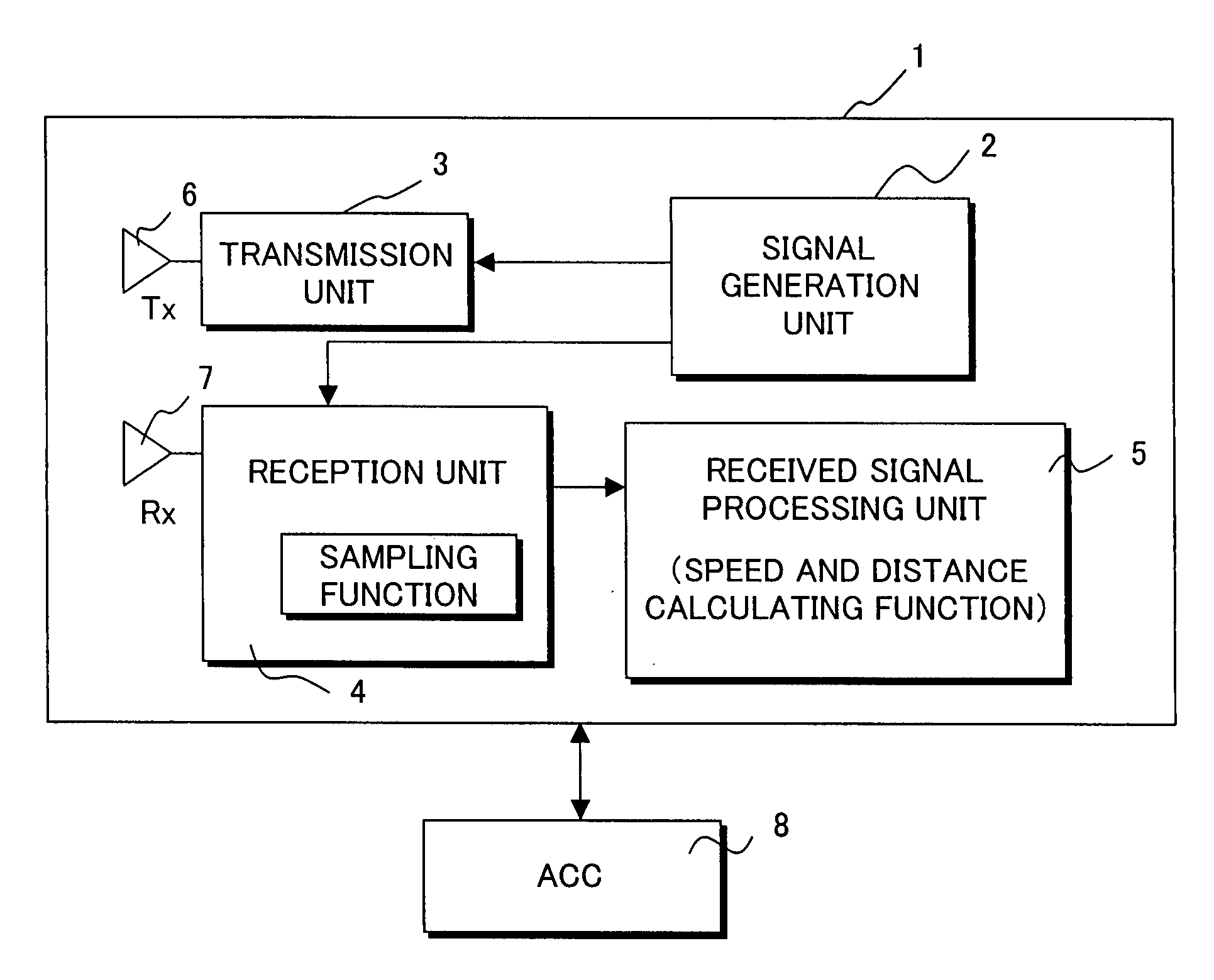

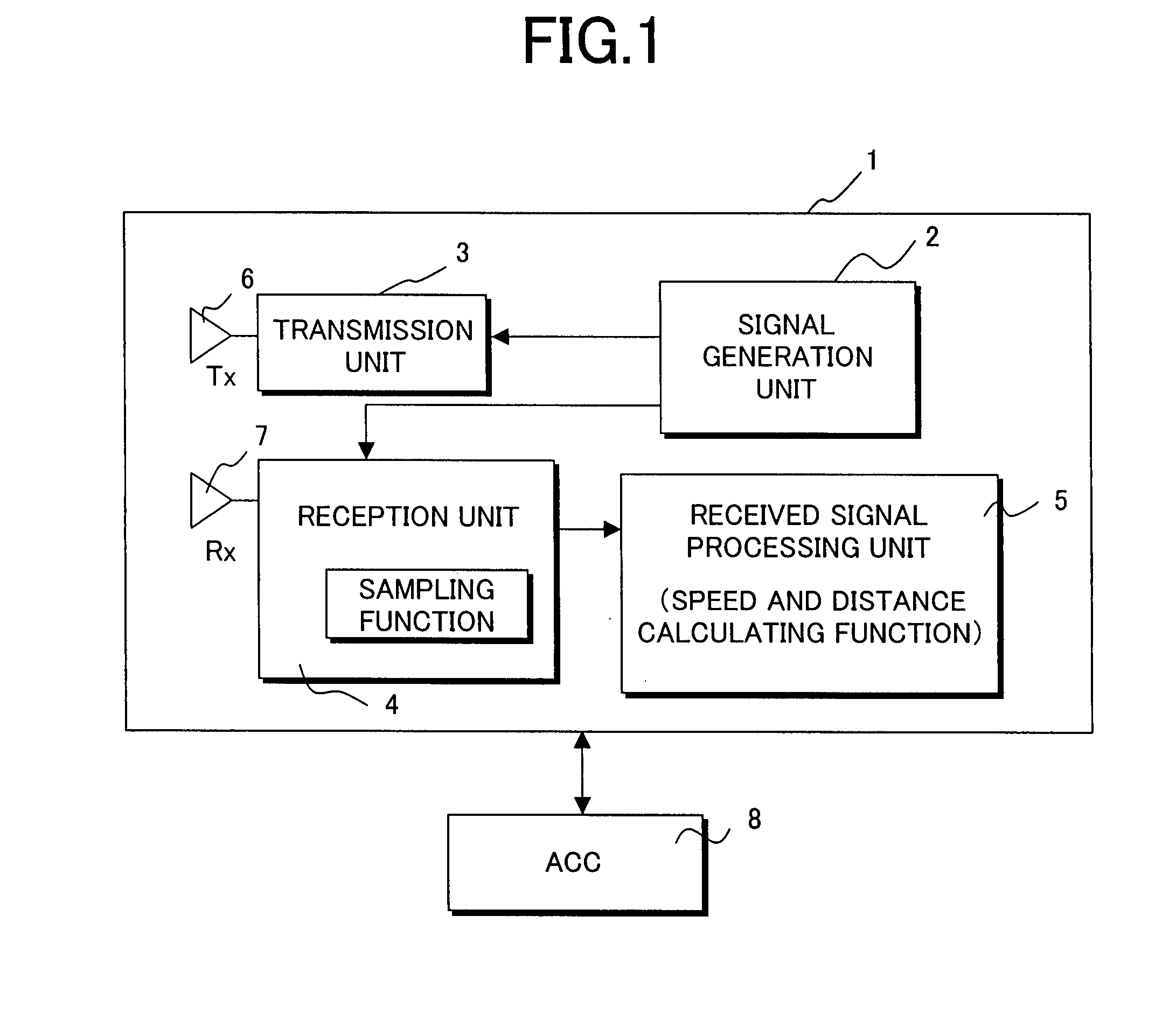

Radar, radio frequency sensor, and radar detection method

InactiveUS20080100500A1Reduce uncertaintyImprove accuracyRadio wave reradiation/reflectionEngineeringRadar detection

In a sensor and a radar for measuring the distance and the moving speed of a target by radiating a radio frequency, particularly a millimeter wave, compatibility between cost reduction and high detection performance has been conventionally a significant problem. In the present invention, the frequency of a transmitted signal changes during a fixed time while performing digitally-frequency-modulation on frequency sweeping straight lines extending, with different slopes relative to the time axis, from plural slightly different initial values serving as starting points, the signal is transmitted after being modulated so as to periodically repeat the sweep time serving as a unit, signal components corresponding to the respective sweeping slopes are digitally sampled, in synchronization with the transmitted modulation signal, from a received signal which is reflected and returned from a target, and the received signal is analyzed.

Owner:HITACHI LTD

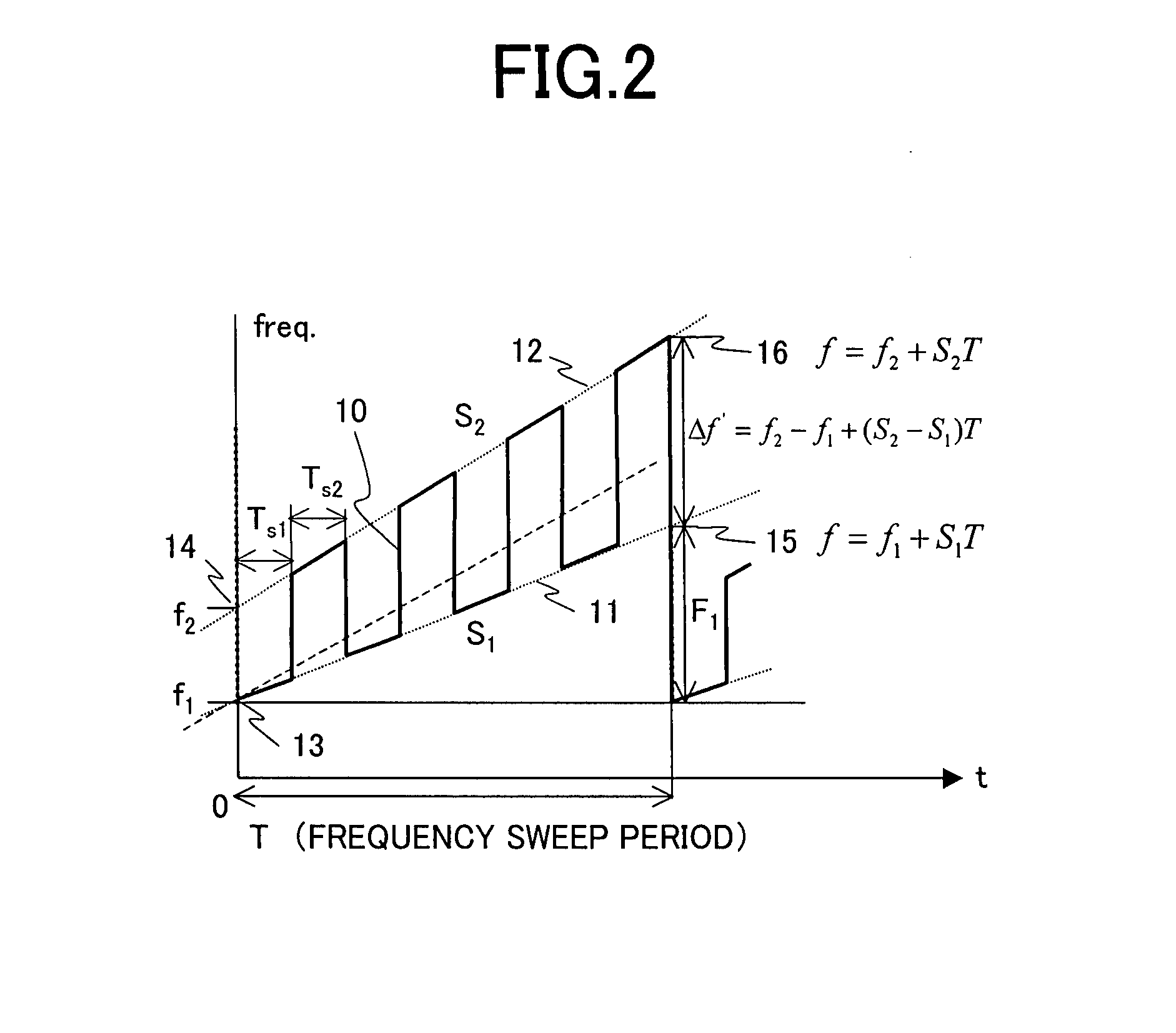

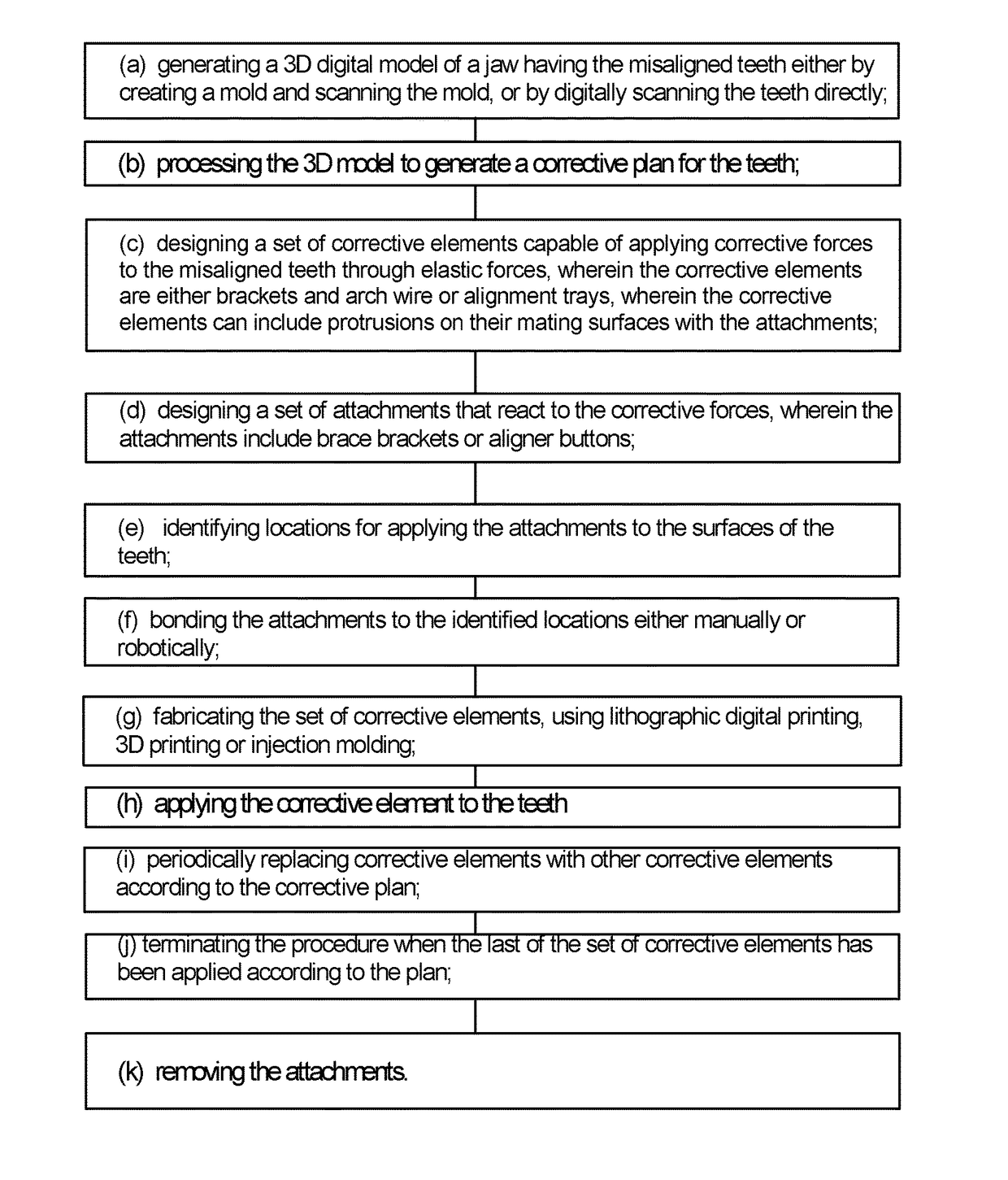

Automated Placement of Dental Orthodontic Attachments

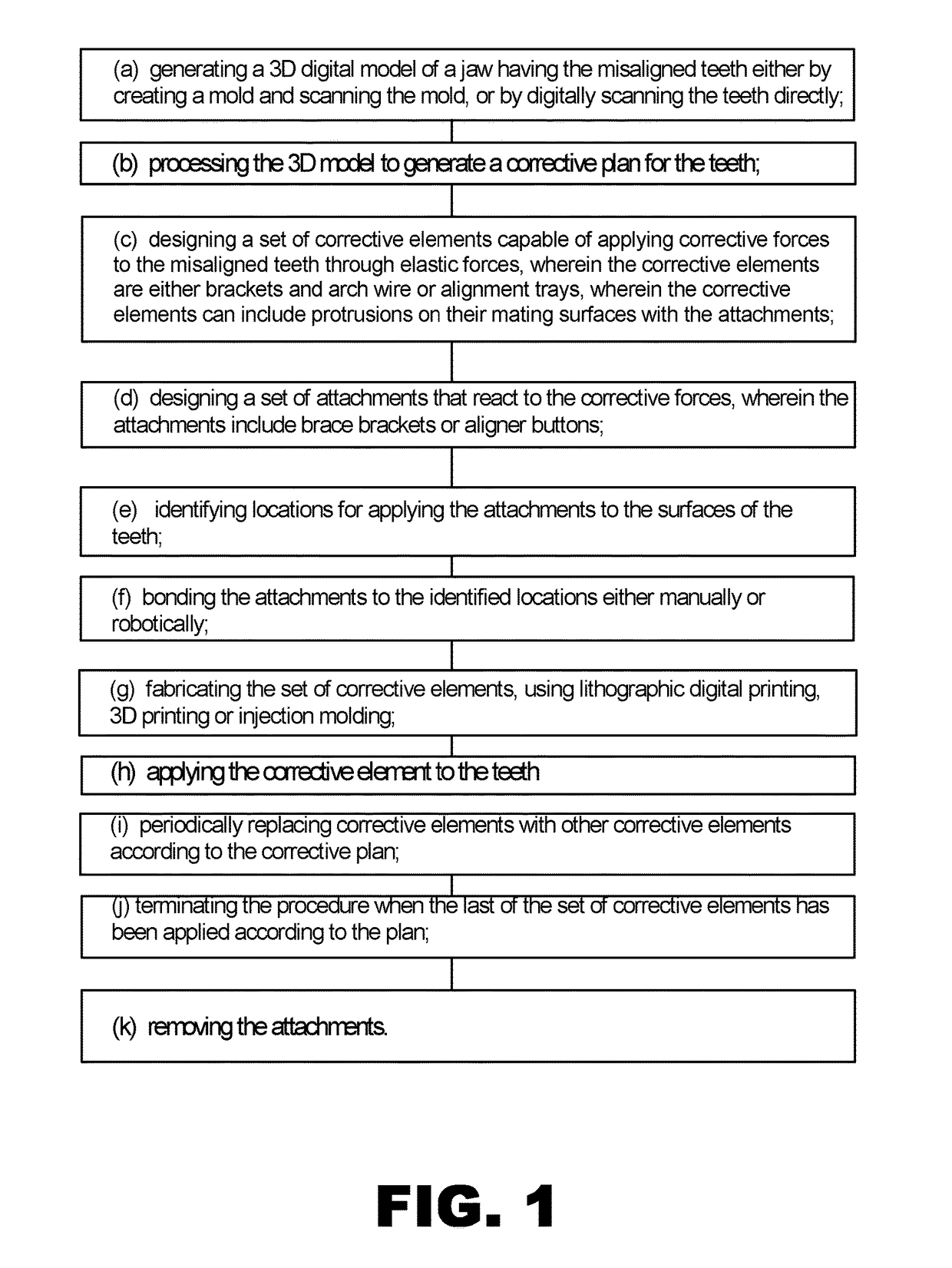

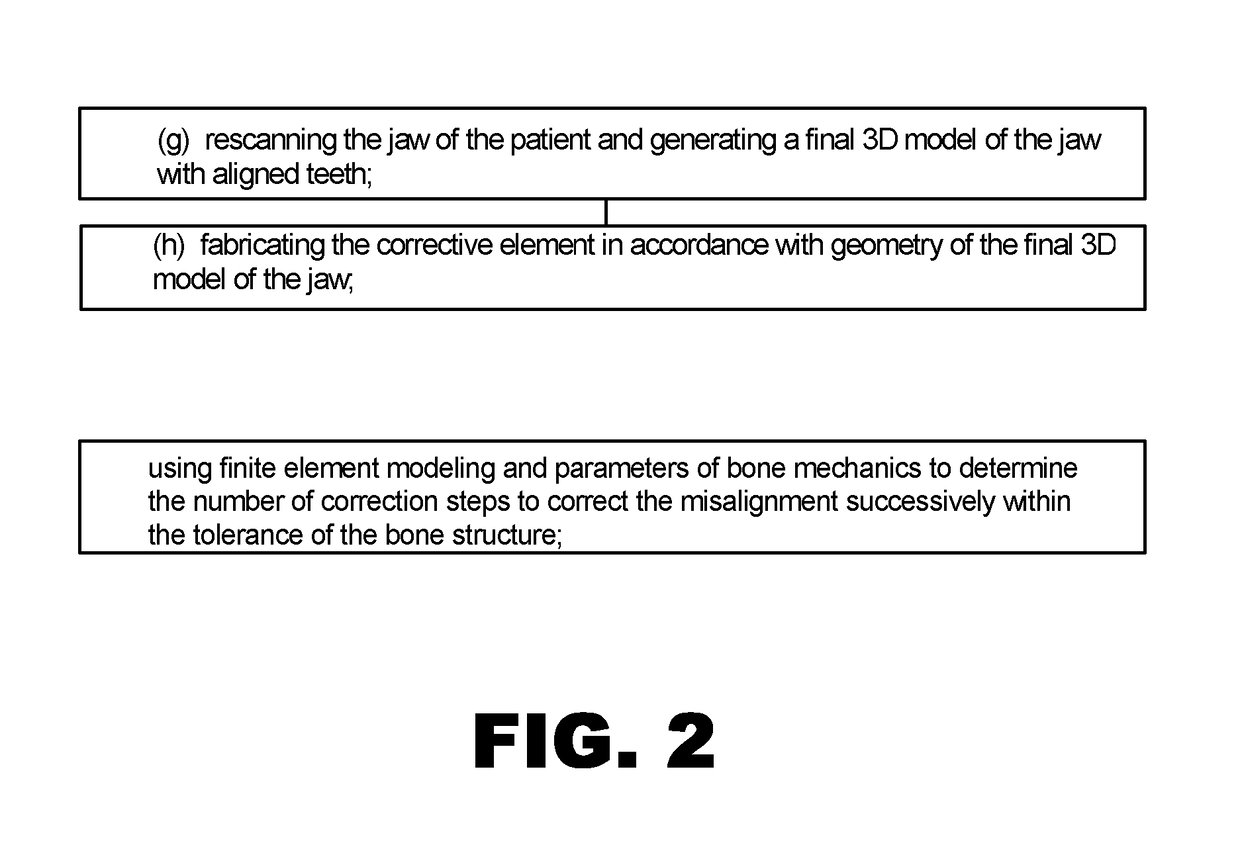

InactiveUS20170231721A1Accurate placementCorrect attachment errorArch wiresBracketsElement analysisEngineering

An automated procedure for correcting teeth misalignment in orthodontics using the steps of Generating a 3D digital model of a jaw having the misaligned teeth. Processing the 3D model to generate a corrective plan. Designing a set of corrective elements capable of applying corrective forces to the misaligned teeth through elastic forces. Designing a set of attachments that react to the corrective forces. identifying locations for applying the attachments to the surfaces of the teeth; Bonding the attachments to the identified locations. Rescanning the jaw of the patient and generating a final 3D model of the jaw with aligned teeth. Fabricating the corrective element in accordance with geometry of the final 3D model of the jaw. Applying the corrective element to the teeth wherein. Removing the attachments. A second 3D scan can be made to determine errors, and finite element analysis may be used to determine force vectors.

Owner:BRACHIUM

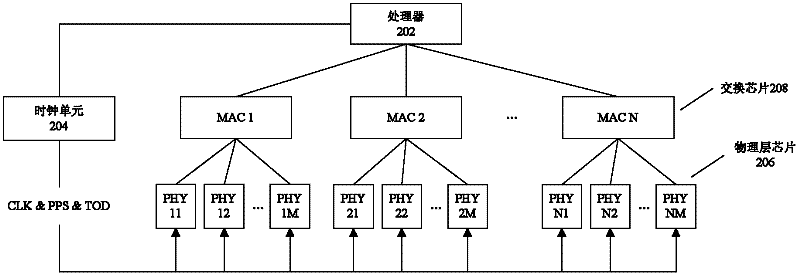

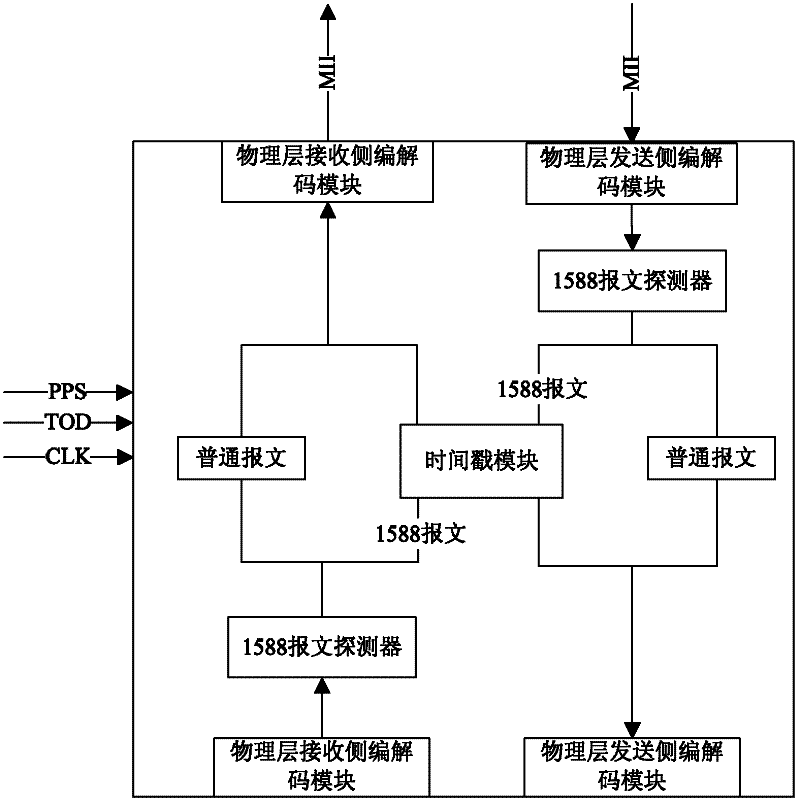

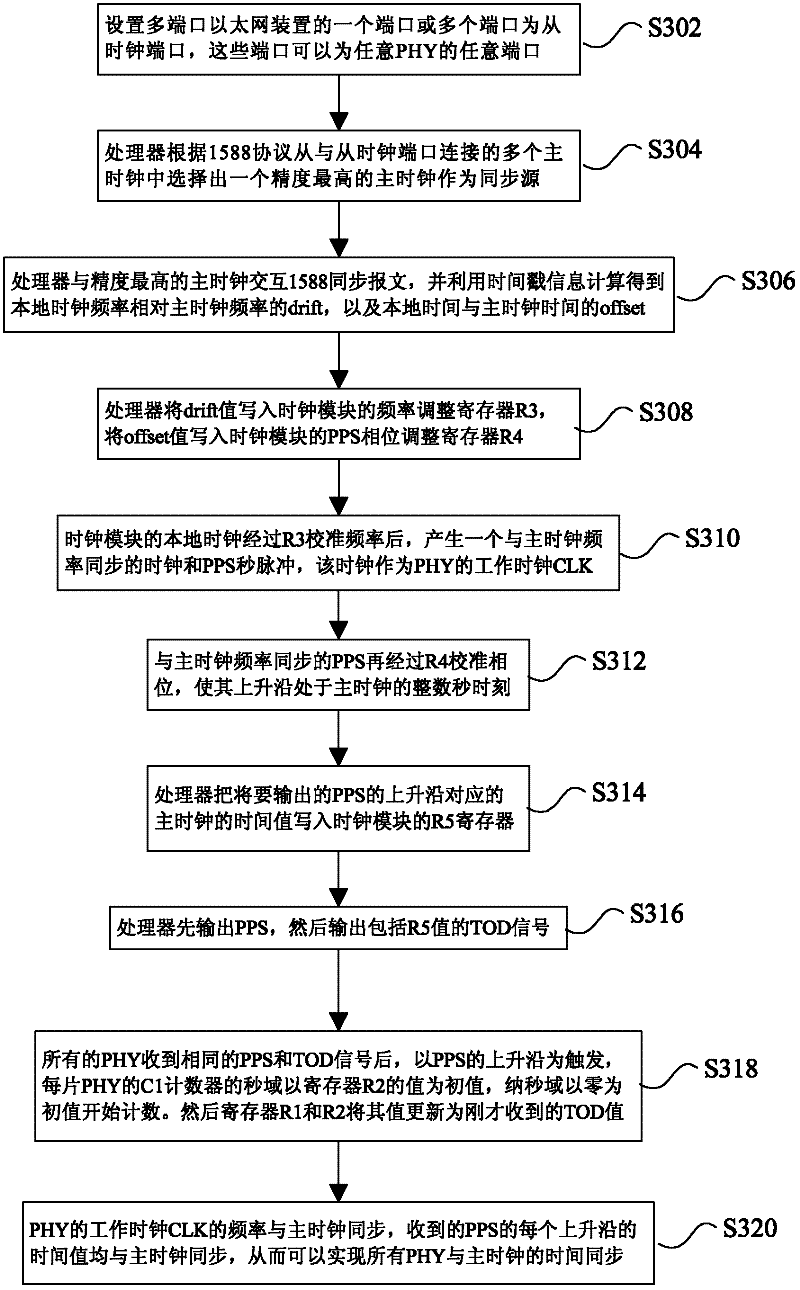

Method and device for synchronizing clocks

InactiveCN102394715ATime synchronizationRemove uncertaintyTime-division multiplexNetwork linkPhysical layer

The invention discloses a method and a device for synchronizing clocks. The method comprises the following steps of: calculating frequency drift and time migration between a local clock and a master clock; calibrating the local clock by using the frequency drift, and calibrating second pulse signals by using the time migration; and synchronizing the time of work clocks and time stamp modules in physical layer chips by using TOD (time of date) of the calibrated local clock, the calibrated second pulse signals and the rising edge of the calibrated second pulse signals. According to the method and the device, the problem of low synchronization accuracy caused by nondeterminacy of network link delay introduced by the physical layer chips and asymmetry of duplex paths in the prior art is solved, and the time of a plurality of physical layer chips and the master clock is synchronized.

Owner:山东海润数聚科技有限公司

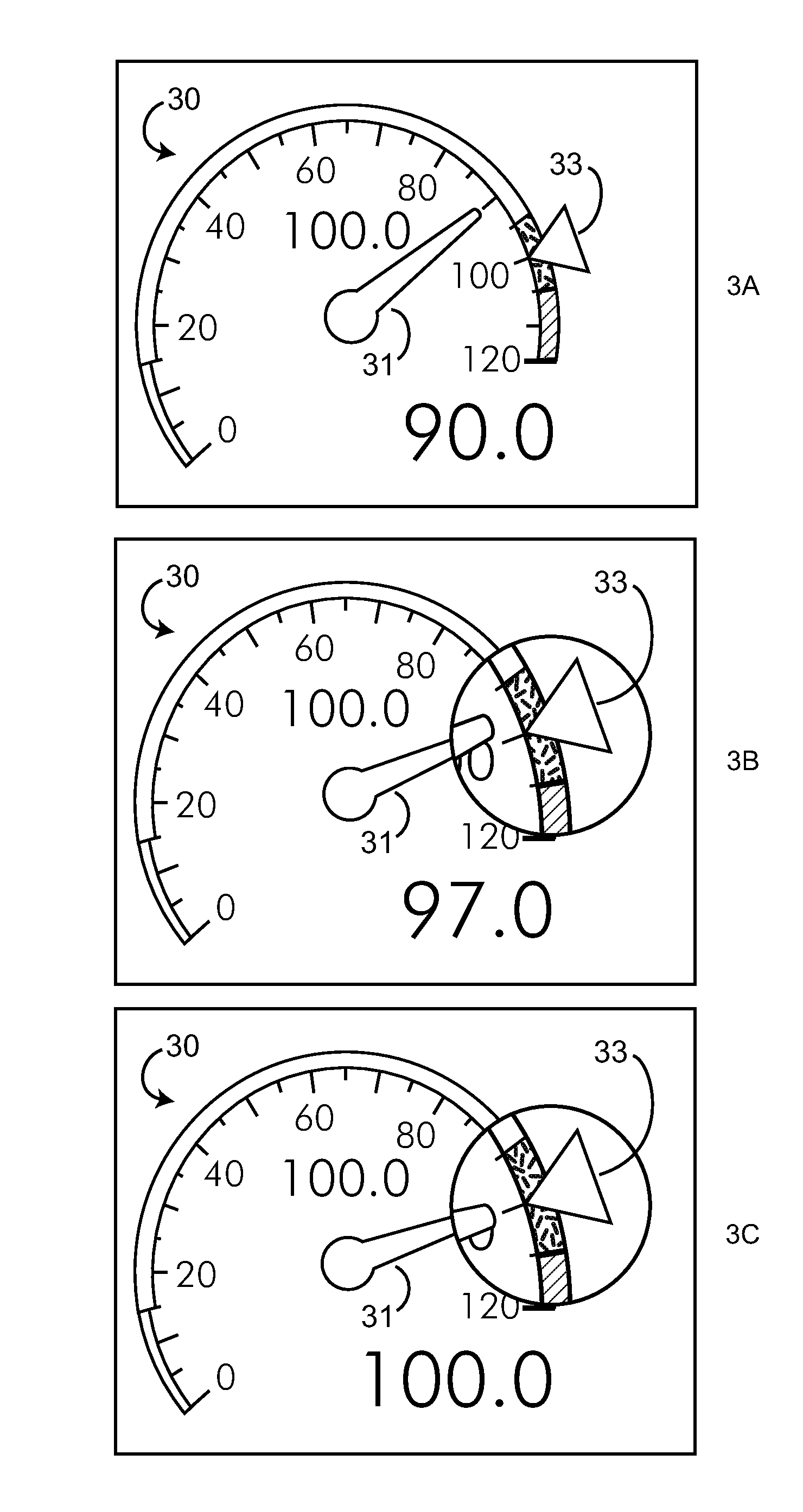

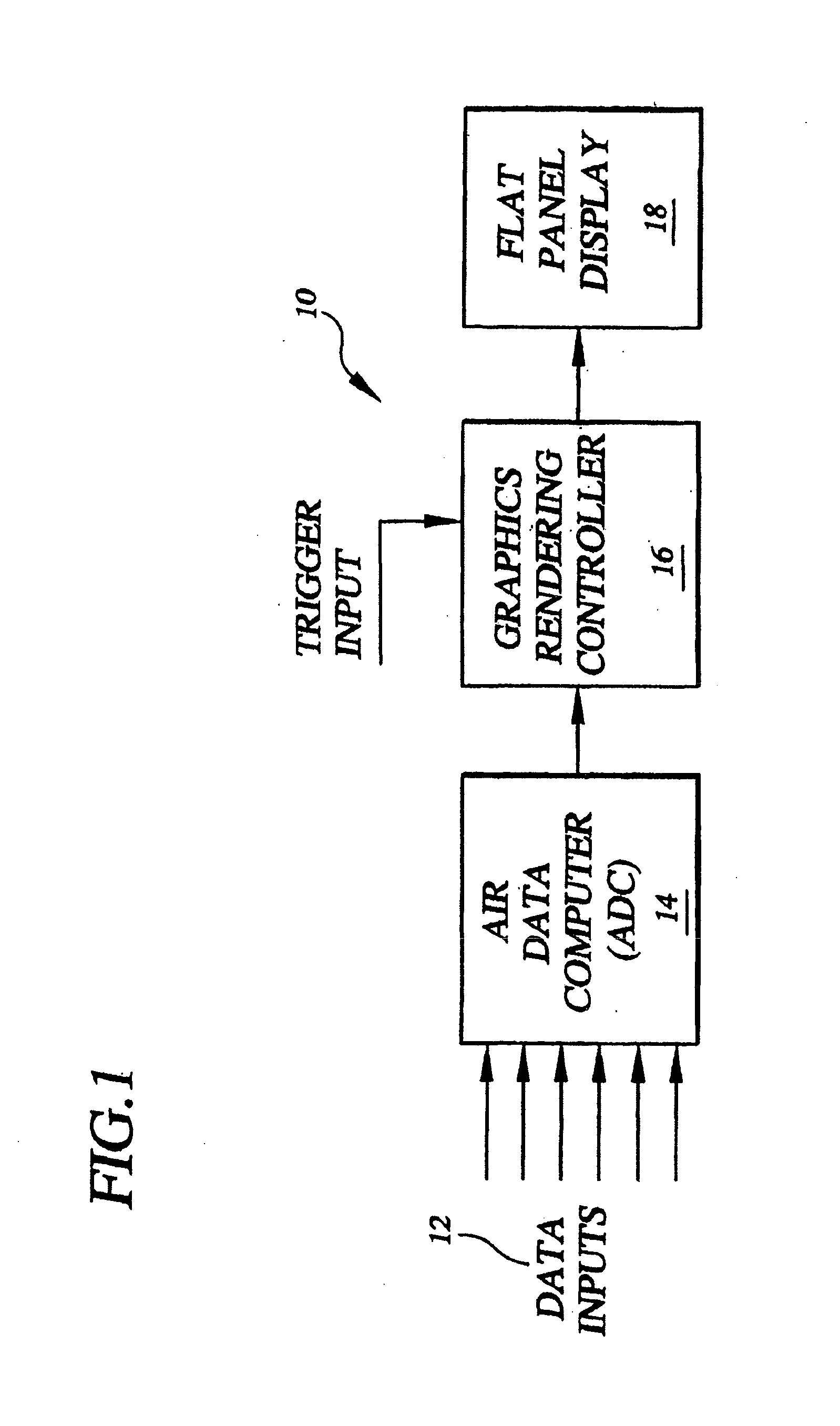

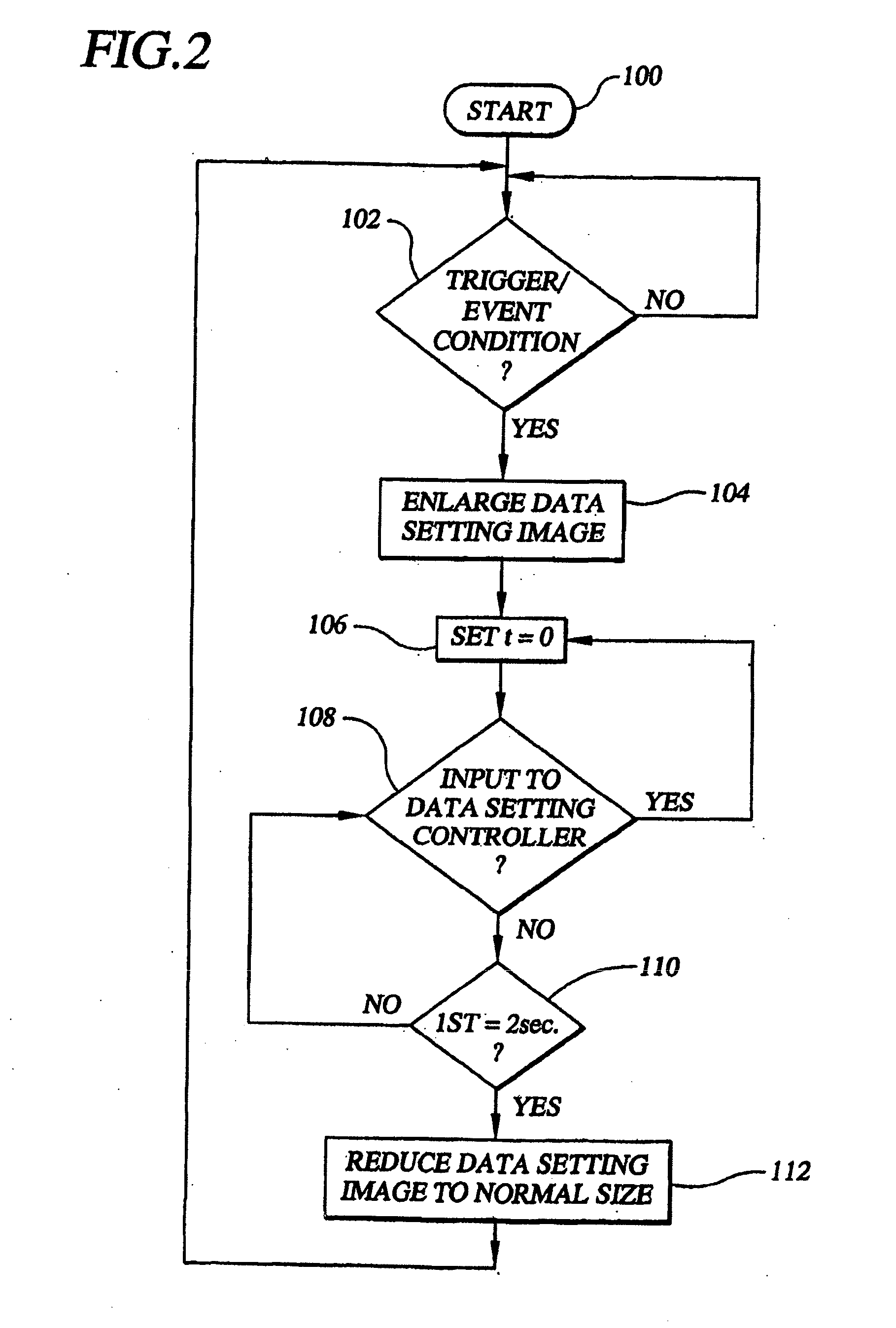

Method and System for Highlighting an Image Representative of a Flight Parameter of an Aircraft

ActiveUS20110001636A1Easily view and enterIncrease in sizeAnalog and numerical indicationAnalogue computers for trafficFlat panel displayAerospace engineering

A method and system for highlighting a parameter image representative of a flight parameter of an aircraft to a user in a multi-parameter aircraft instrument display, such as a flat panel display. An electronic instrument display is configured to present parameter images, at least one of which includes a first indicator configured to indicate a specific value (e.g., a target value) for a flight parameter and a second indicator configured to indicate an actual flight parameter value that changes according to variations in the flight parameter. A graphics rendering controller is configured to generate the parameter images and to enlarge a portion of the parameter image when the actual flight parameter value is within a predetermined range from the target value.

Owner:INNOVATIVE SOLUTIONS & SUPPORT

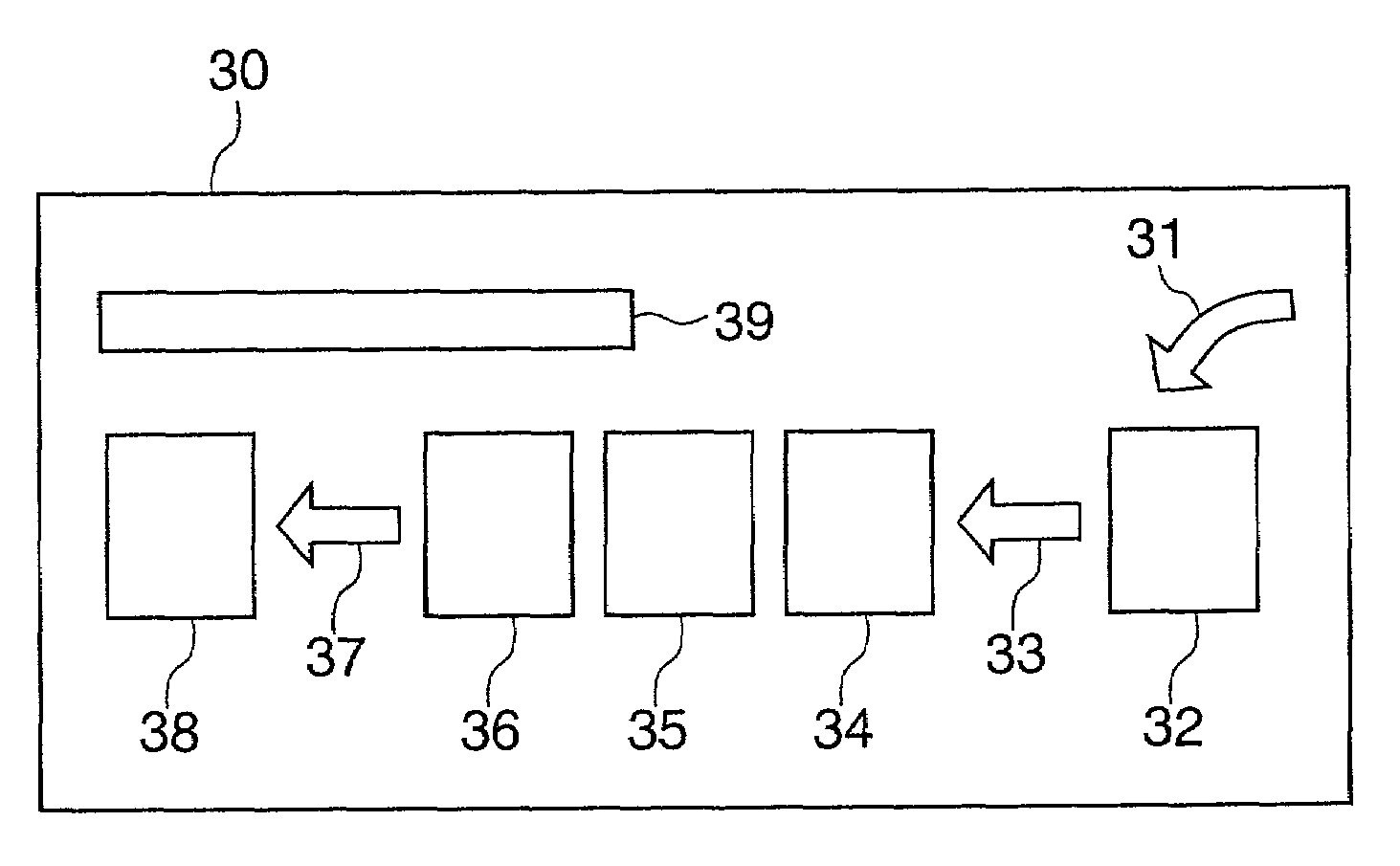

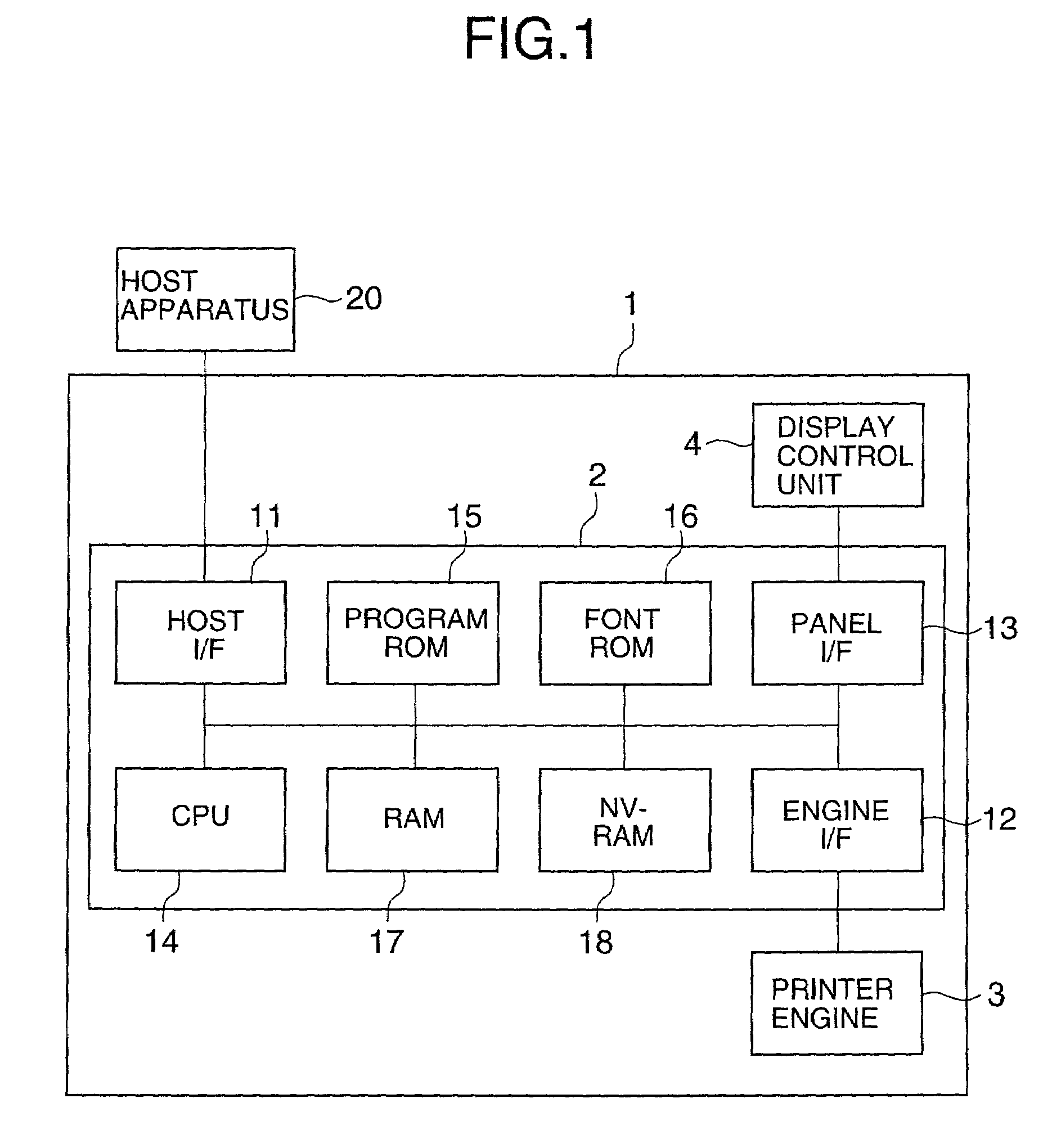

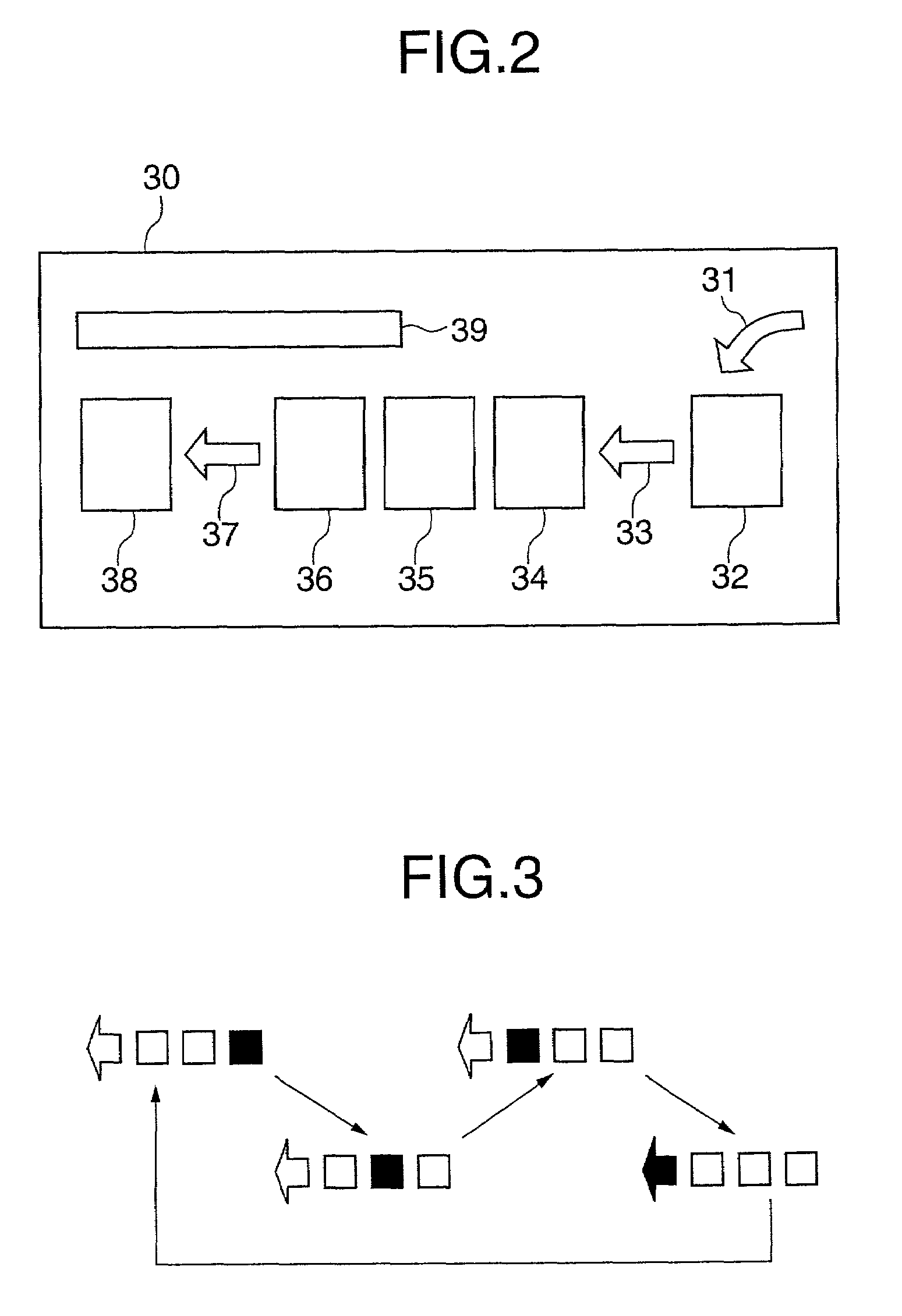

Printing apparatus

InactiveUS7362464B2Easy for users to understandEasy to understandVisual presentation using printersDigital computer detailsComputer graphics (images)Imaging data

A printing apparatus includes an image data input means for receiving input data, image data processing means for processing the image data and drawing the image data in an image memory unit, printing means for forming an image on a transfer sheet using the image data drawn in the image memory unit, and display means for displaying, either dynamically or successively, which process the image data is undergoing at any given moment, beginning with image data reception and ending with image data printing.

Owner:RICOH KK

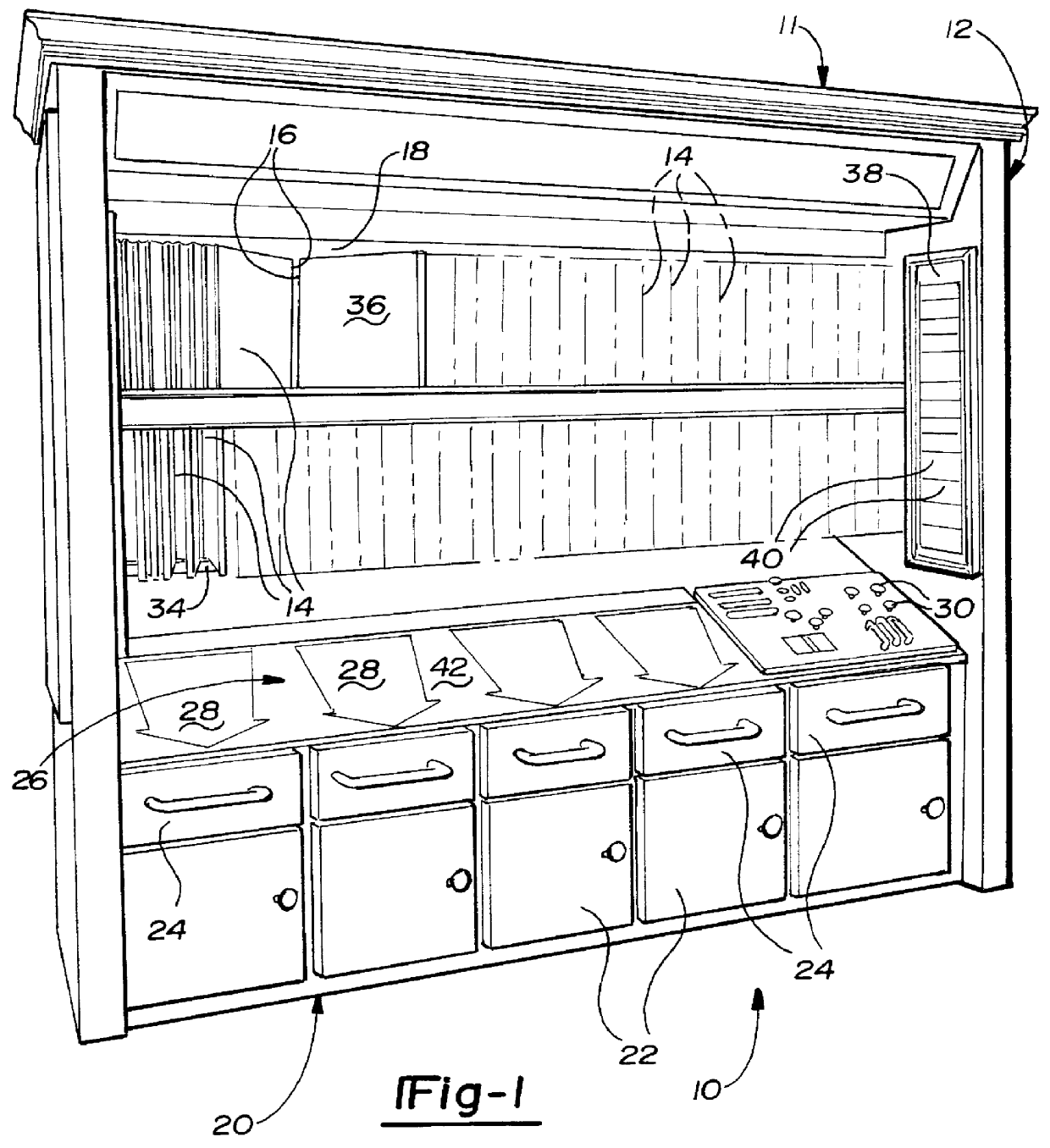

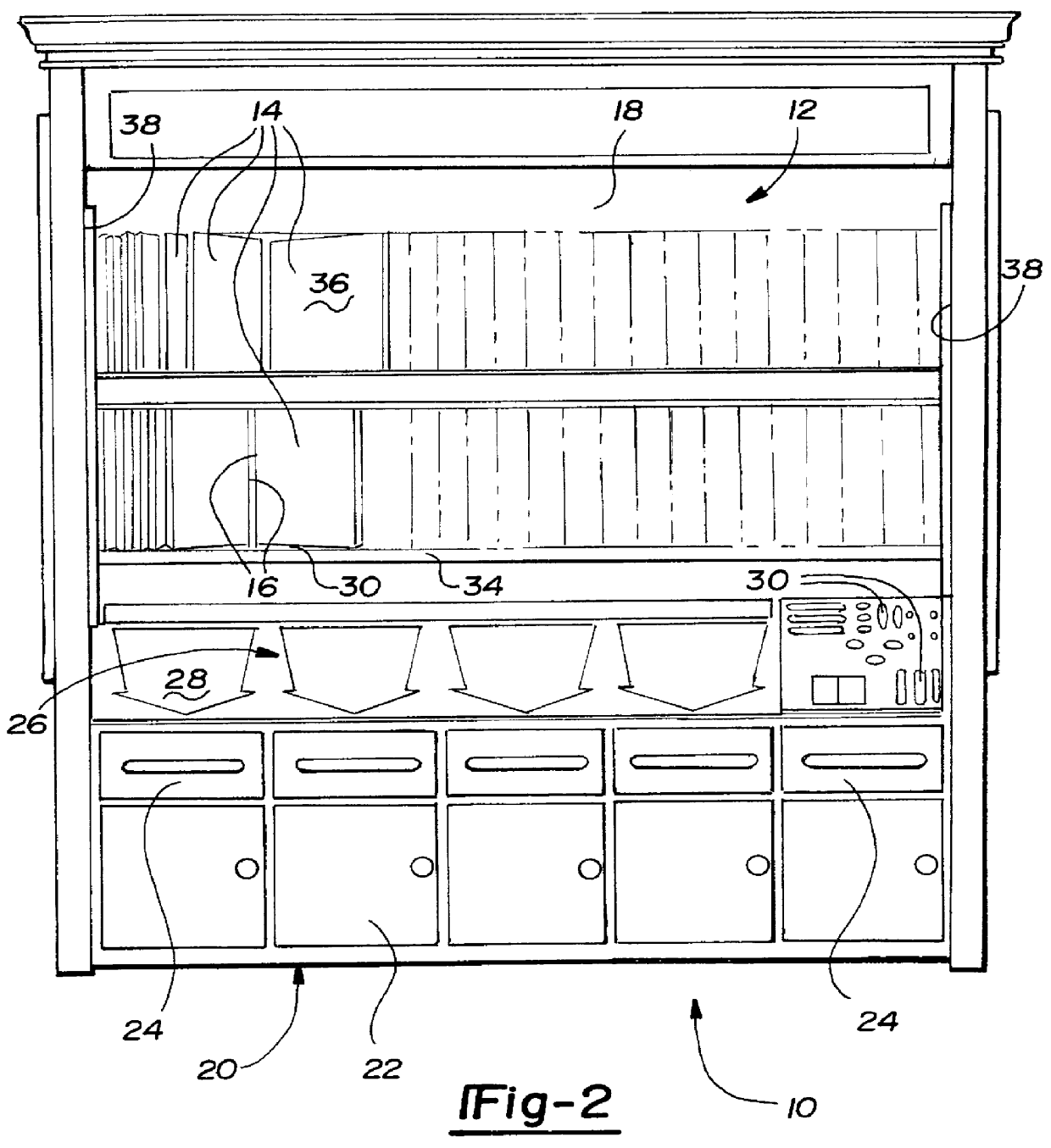

Merchandising unit with door display

InactiveUS6102502AEliminate uncertaintyFacilitates immediate substitutionShow cabinetsFiling appliancesEngineeringMechanical engineering

A merchandising unit for the display of consumer products particularly cabinetry components. The unit includes a plurality of cabinet door samples allowing the consumer to examine the individual doors. The doors are pivotably mounted within the unit along parallel axes facilitating full examination. The merchandising unit also includes a section for displaying the various hardware offerings and a lower section displaying base cabinetry and drawers. All of these features allow the consumer to directly examiner the cabinetry components for making an informed purchase.

Owner:KRAFTMAID CABINETRY

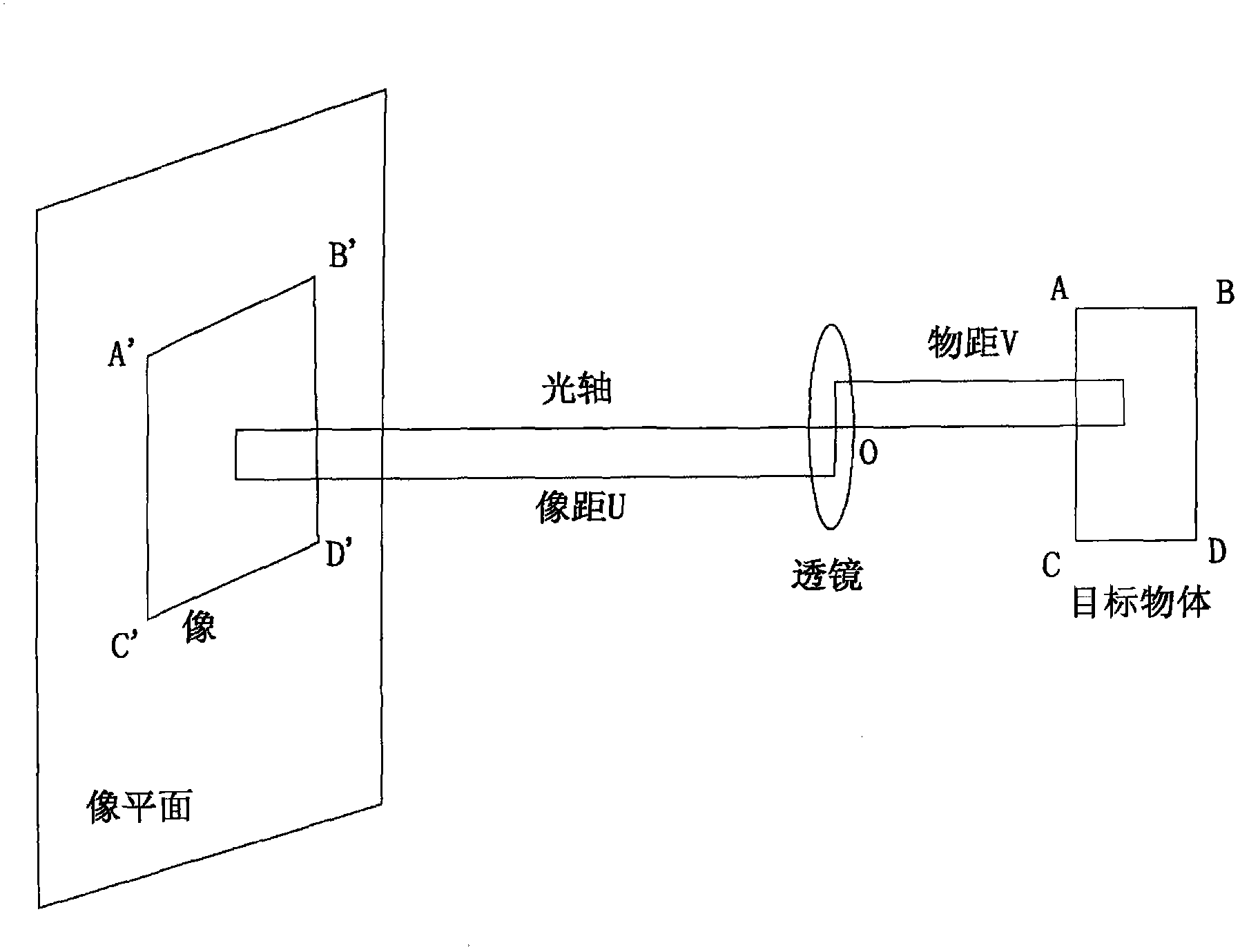

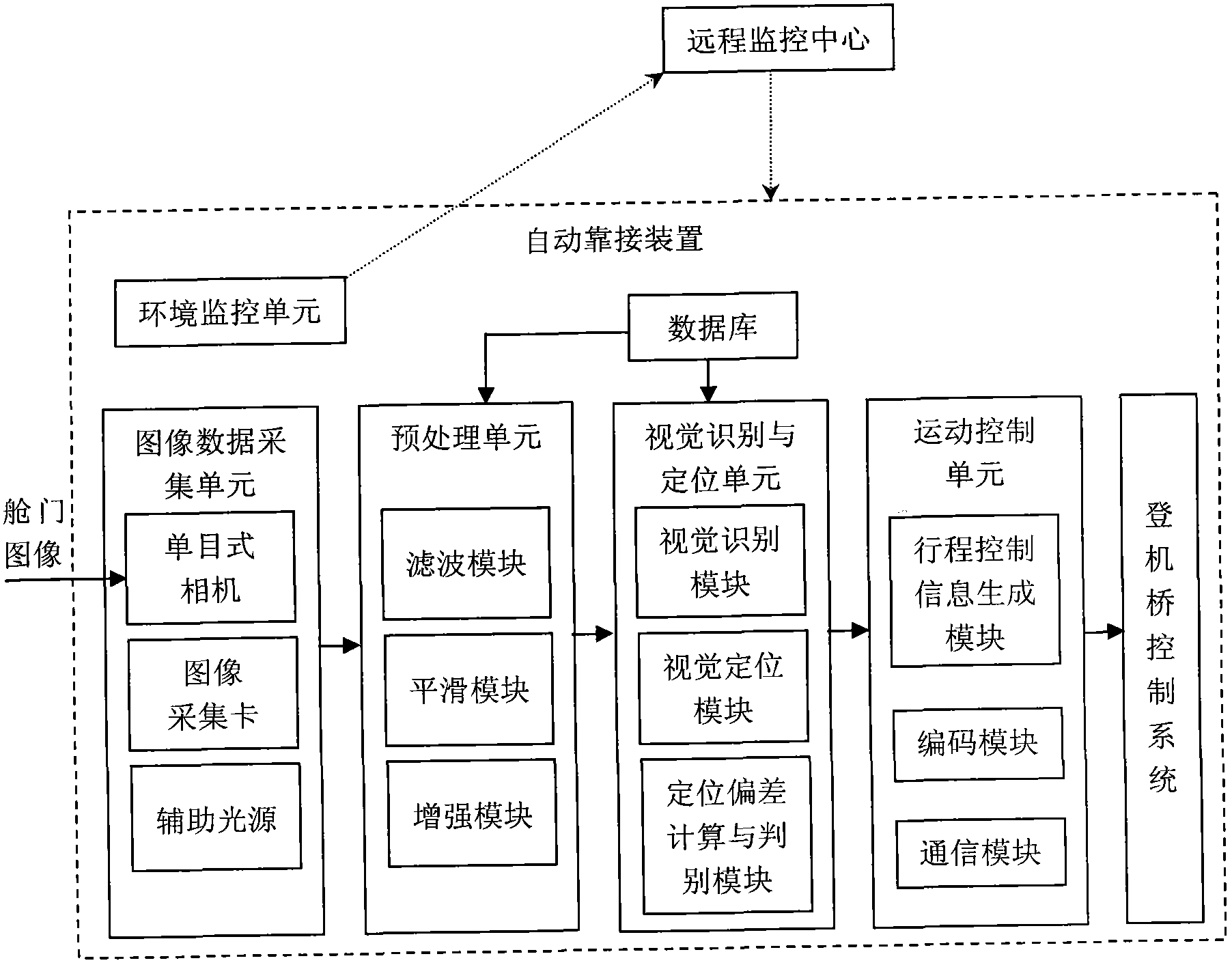

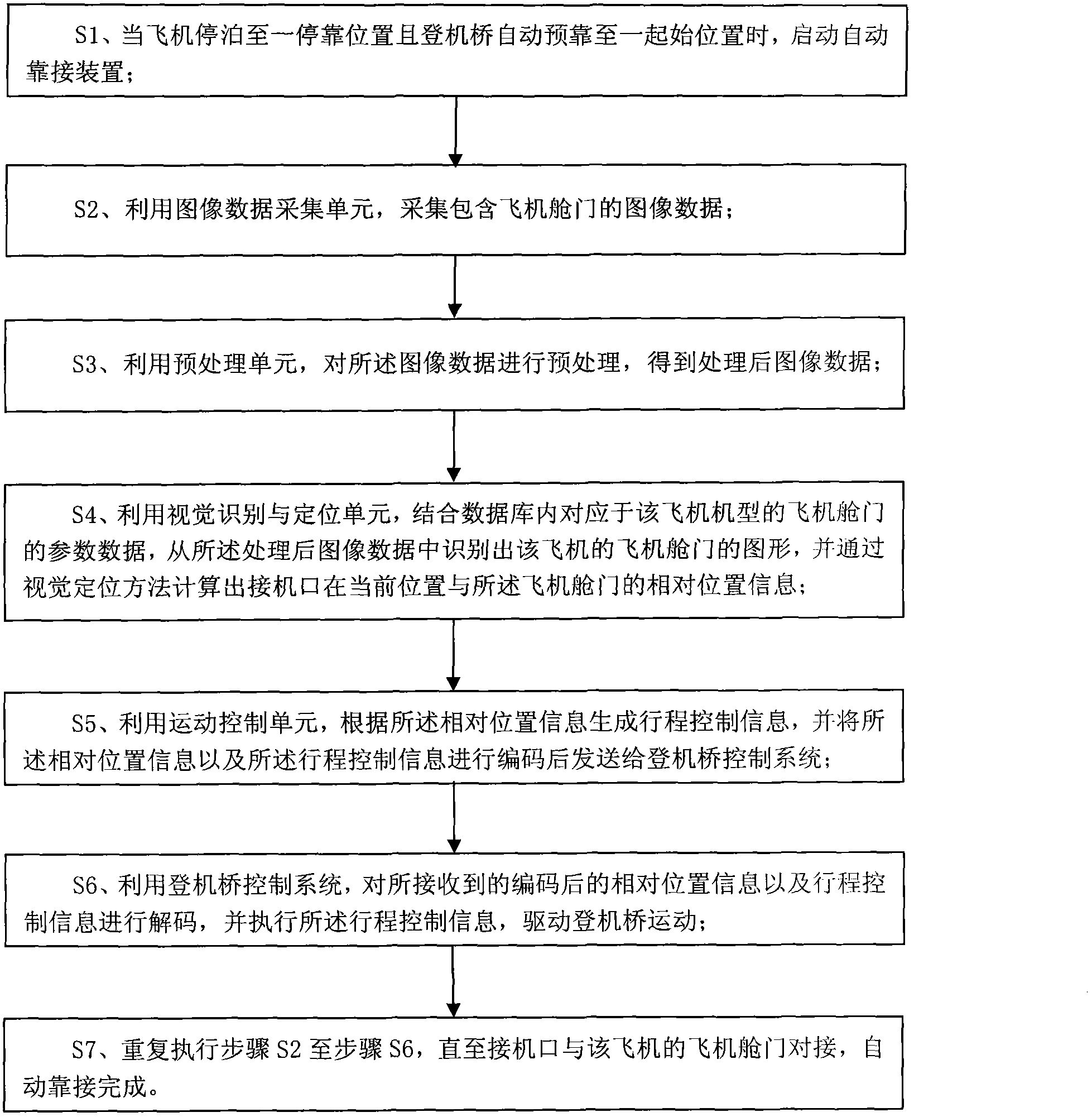

Air bridge and automatic abutting method therefor

ActiveCN103419944ASimple maintenance monitoringAvoid interferenceGround installationsAirplaneData acquisition unit

The invention relates to an air bridge and an automatic abutting method therefor. The air bridge comprises an airplane connector, a lifting mechanism, a travelling mechanism and an automatic abutting device. The automatic abutting device comprises an image data acquisition unit, a preprocessing unit, a database, a visual identification and positioning unit, a motion control unit and a bridge control system. When an airplane parks at a parking position and the air bridge automatically abuts at an initial position, the automatic abutting device is started; image data of a hatch door of the airplane, included in the image data acquisition unit, is preprocessed; an image meeting the features of the hatch door of the airplane is recognized from the processed image data; information about the position of the airplane connector relative to the hatch door is calculated; travel control information is generated according to the information about the relative position; the relative position information and the travel control information are encoded and transmitted to the bridge control system; finally, the received information is decoded, the travel control information is executed, and the air bridge is driven to move until automatically abutting to the hatch door.

Owner:SHENZHEN CIMC TIANDA AIRPORT SUPPORT

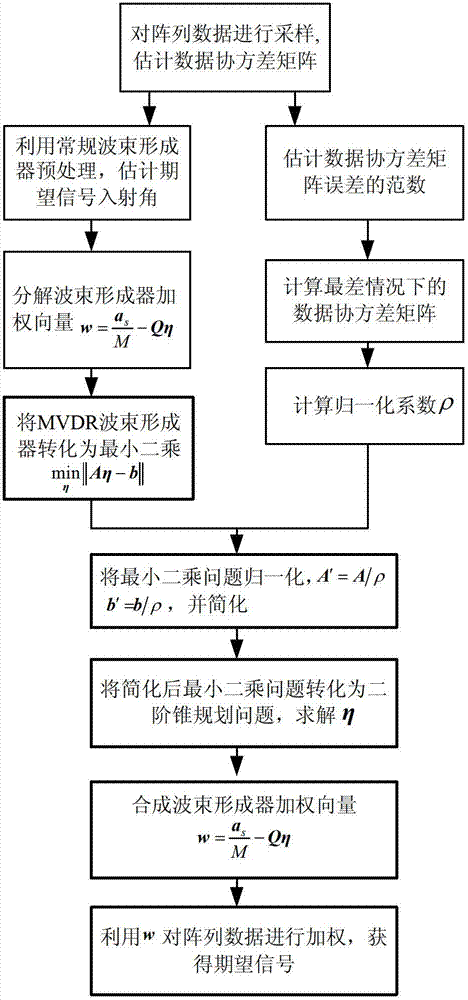

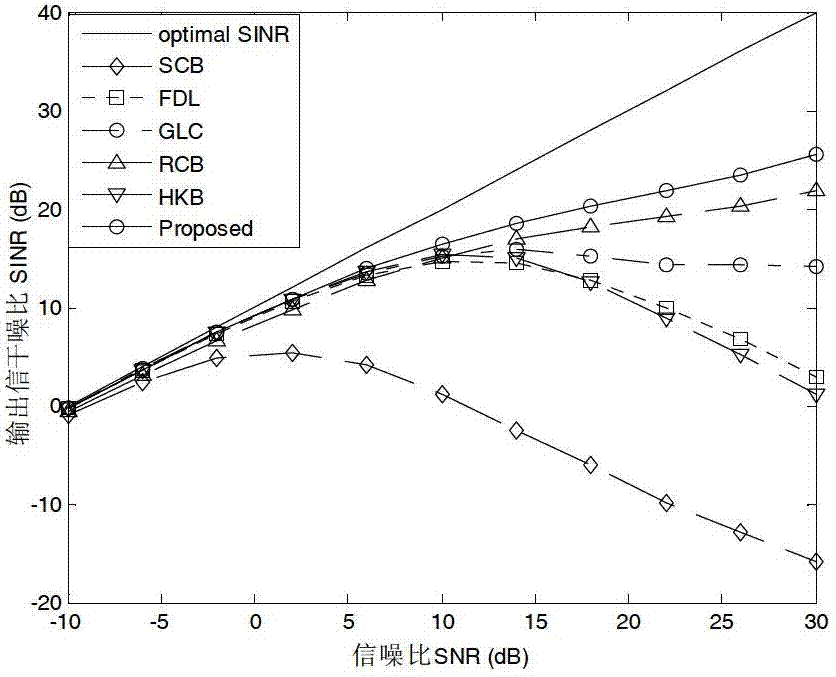

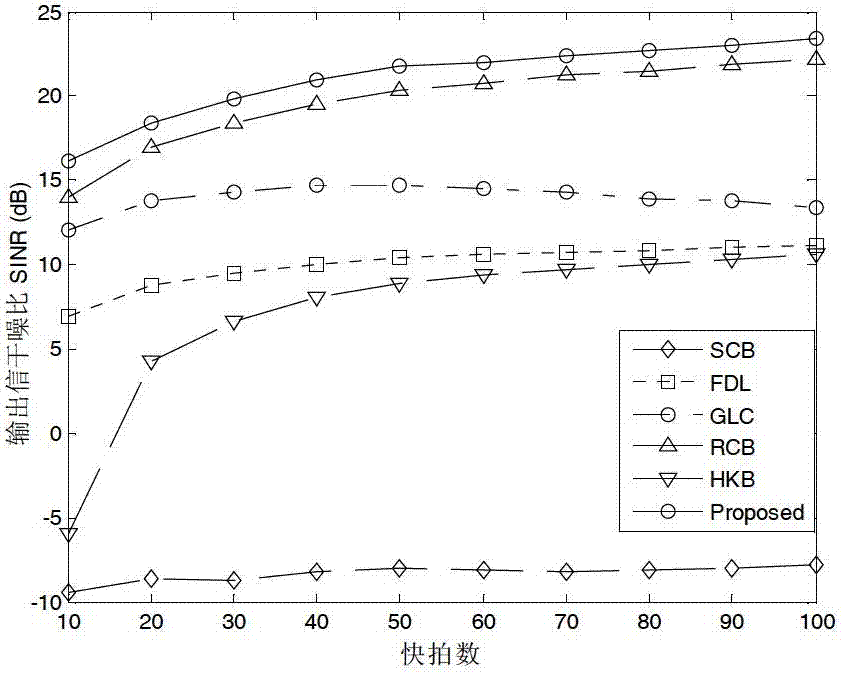

Robust beam forming method based on robust least-square

InactiveCN103245941AHigh output SINRImprove robustnessWave based measurement systemsSpatial transmit diversitySelf adaptiveSecond-order cone programming

The invention provides a robust beam forming method based on a robust least-square. The method has the following steps: decomposing the weight of a beam forming device into two parts of static stage weight and self-adaptive weight by utilizing a generalized sidelobe cancellation device, transforming the standard MVDR (Minimum Variance Distortionless Response) beam forming device expression into a least-square form, acquiring data covariance matrix in the worst condition under the norm restrict of real data covariance matrix and estimated data covariance matrix error, utilizing the data covariance matrix to modify the least-square problem and to transform the problem into a robust least-square problem, further transforming the problem into a second order cone planning problem, and acquiring an optimal solution by utilizing an efficient interior point method. The method has better performances in the following aspects: (1) the output signal interference noise ratio and the power estimated accuracy when the existence conditions are mismatched, (2) the nulling depth of the interference direction in the beam pattern, (3) low mismatching sensibility to the parameter needed to be estimated in advance in the arithmetic. The method has certain the oretical meaning and utility value.

Owner:HARBIN ENG UNIV

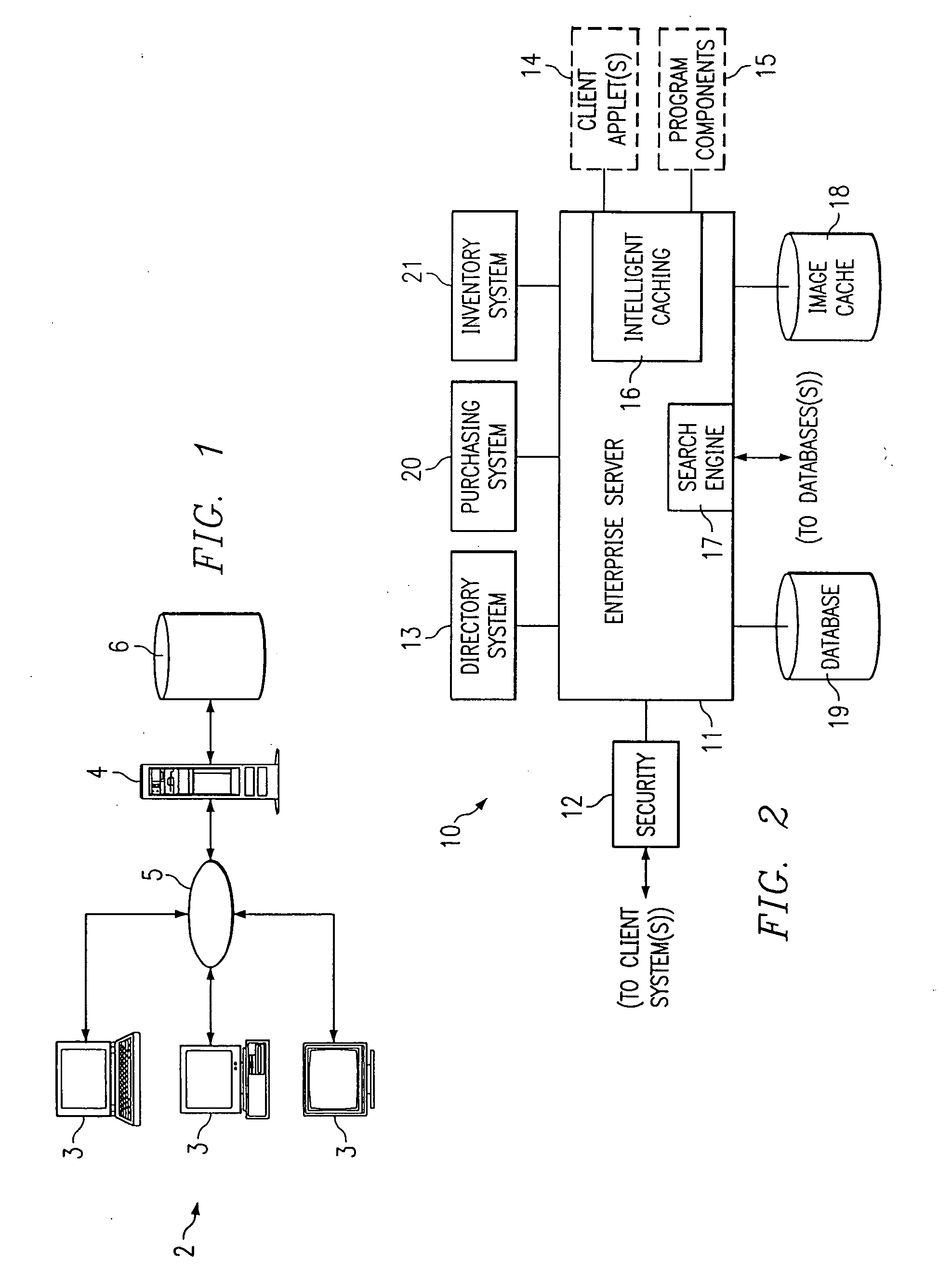

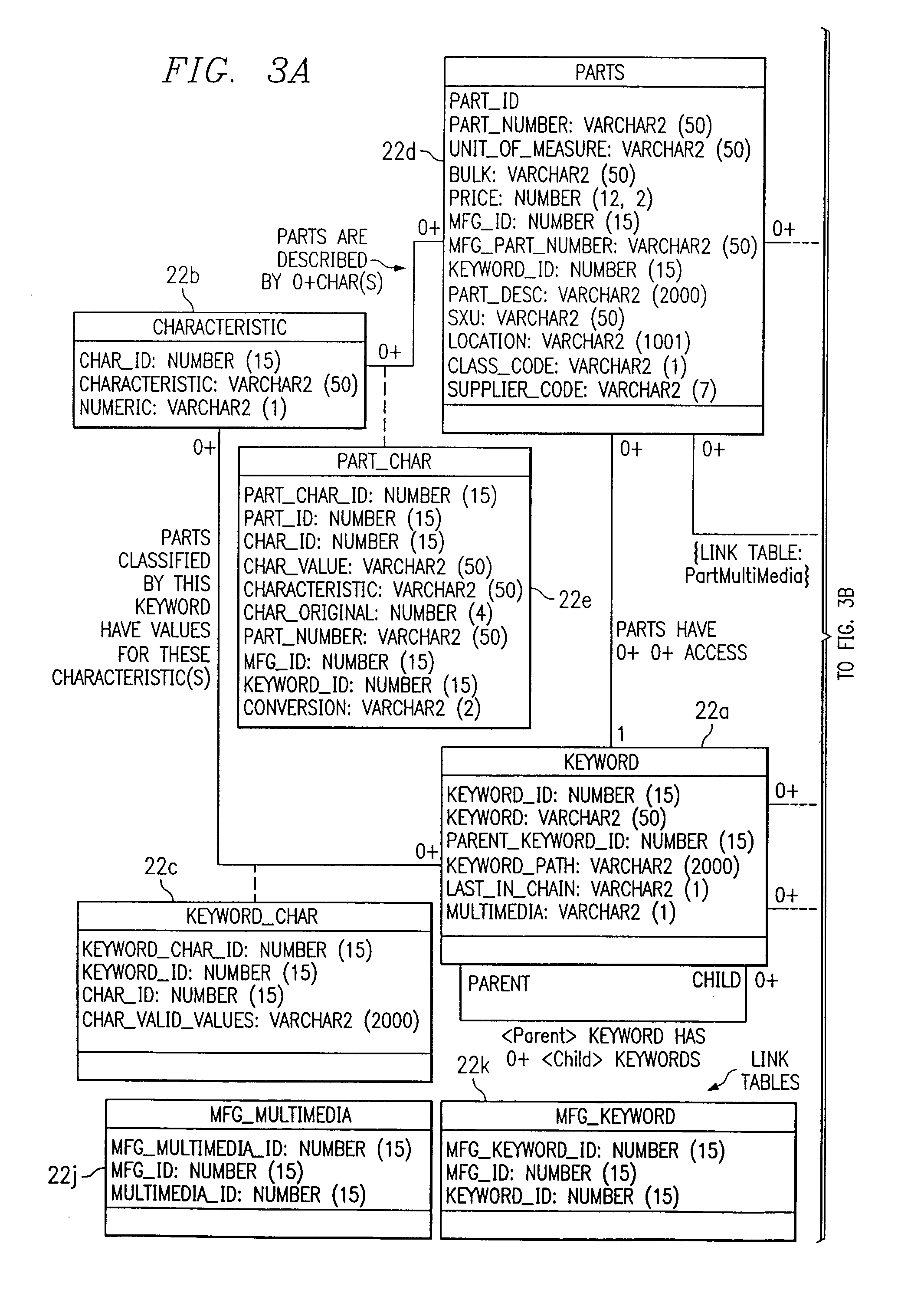

Database system facilitating textual searching

InactiveUS20050234888A1Disadvantages can be reduced eliminatedProblems can be reduced eliminatedDigital data processing detailsRelational databasesUser inputData mining

A computer-implemented method for searching for a desired item includes, in response to user input specifying an alphanumeric string associated with a desired item, searching a database that comprises information associated with items for an alphanumeric string that matches the user-specified alphanumeric string to determine item names and item descriptions for all matching items corresponding to the matching alphanumeric string. The determined item names and item descriptions for the matching items are provided for display to the user. In response to user input indicating a desire to view attribute values for attributes of the particular matching item, attribute names and attribute values for attributes of the particular matching item are determined and provided for display to the user.

Owner:CATERPILLAR INC

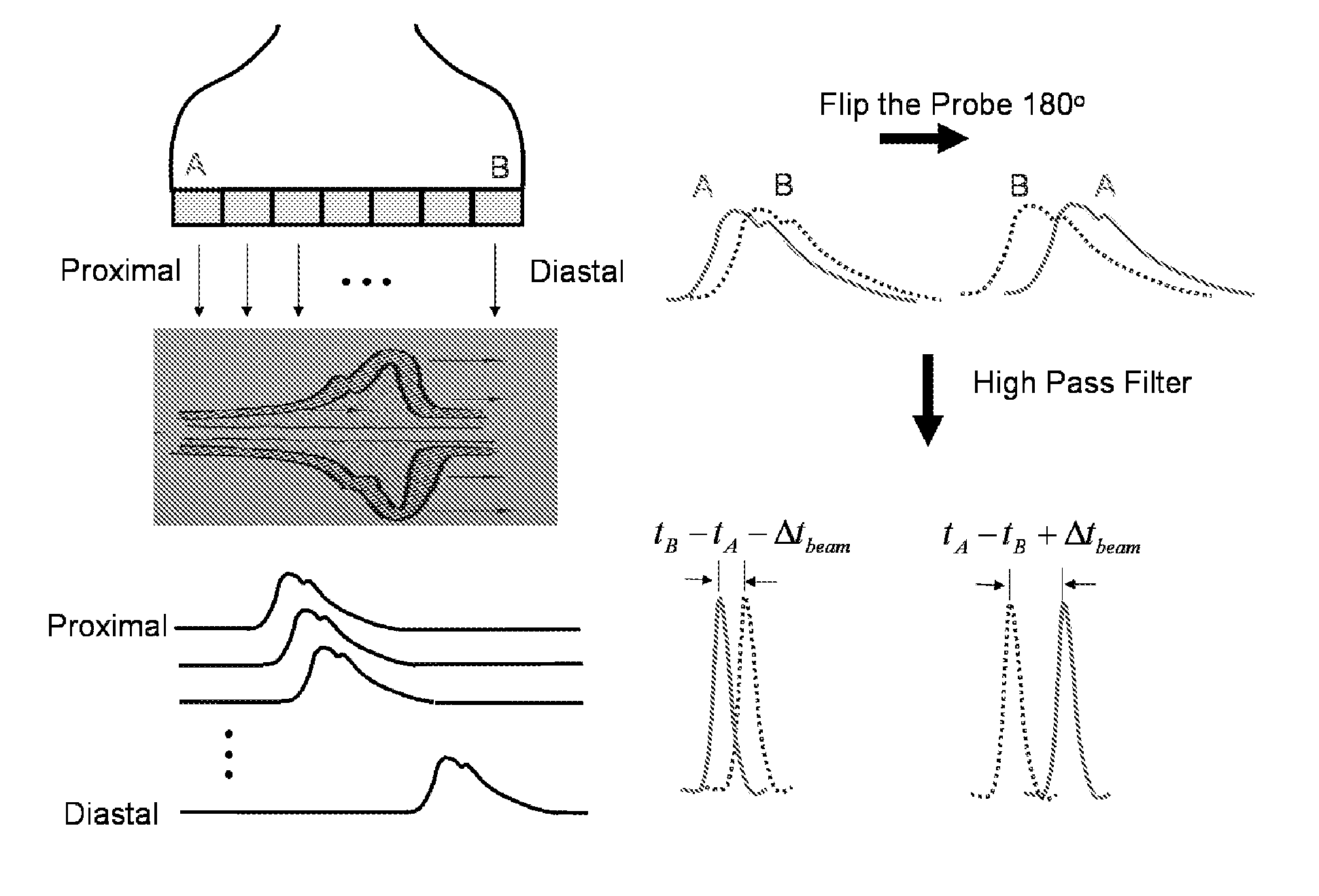

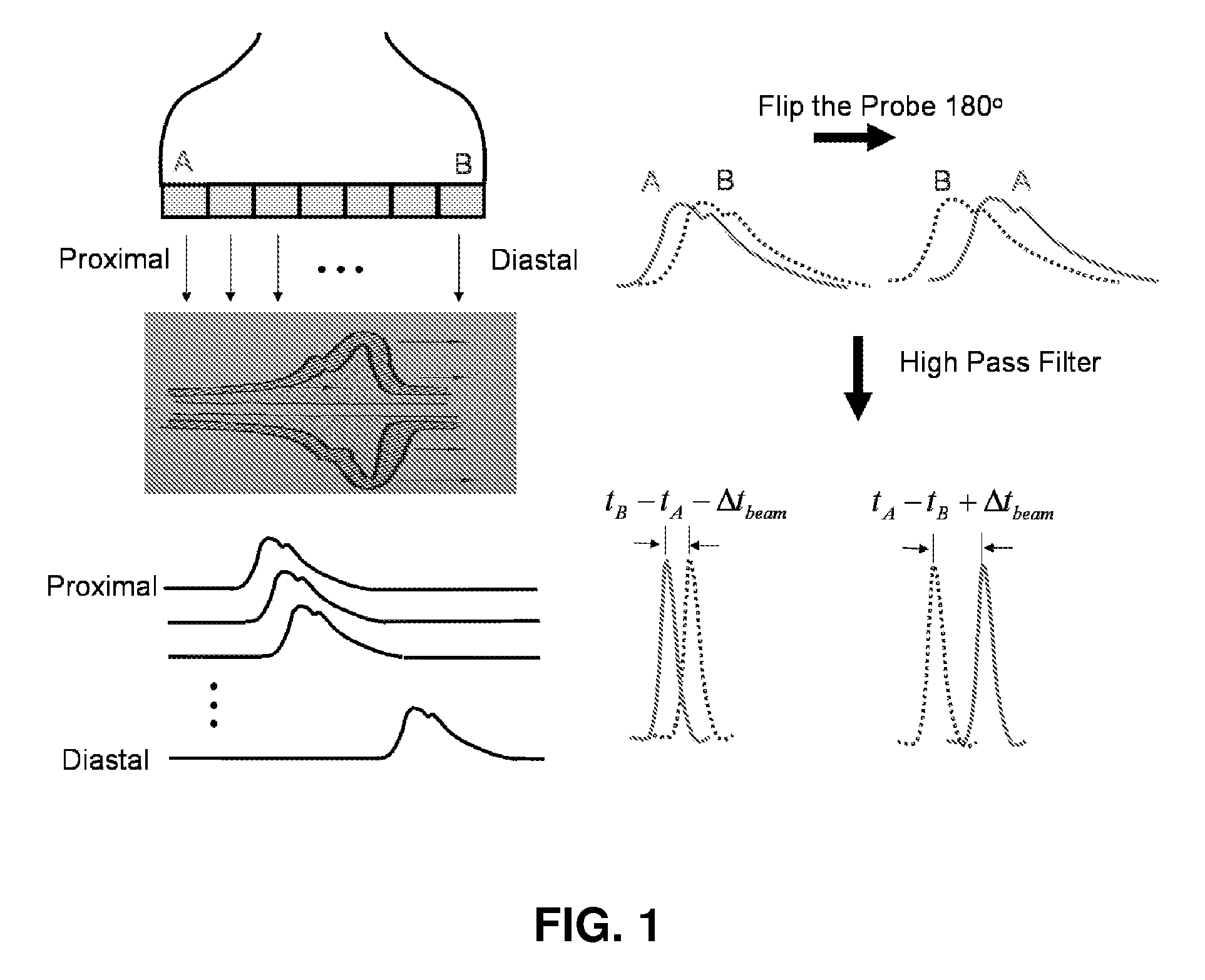

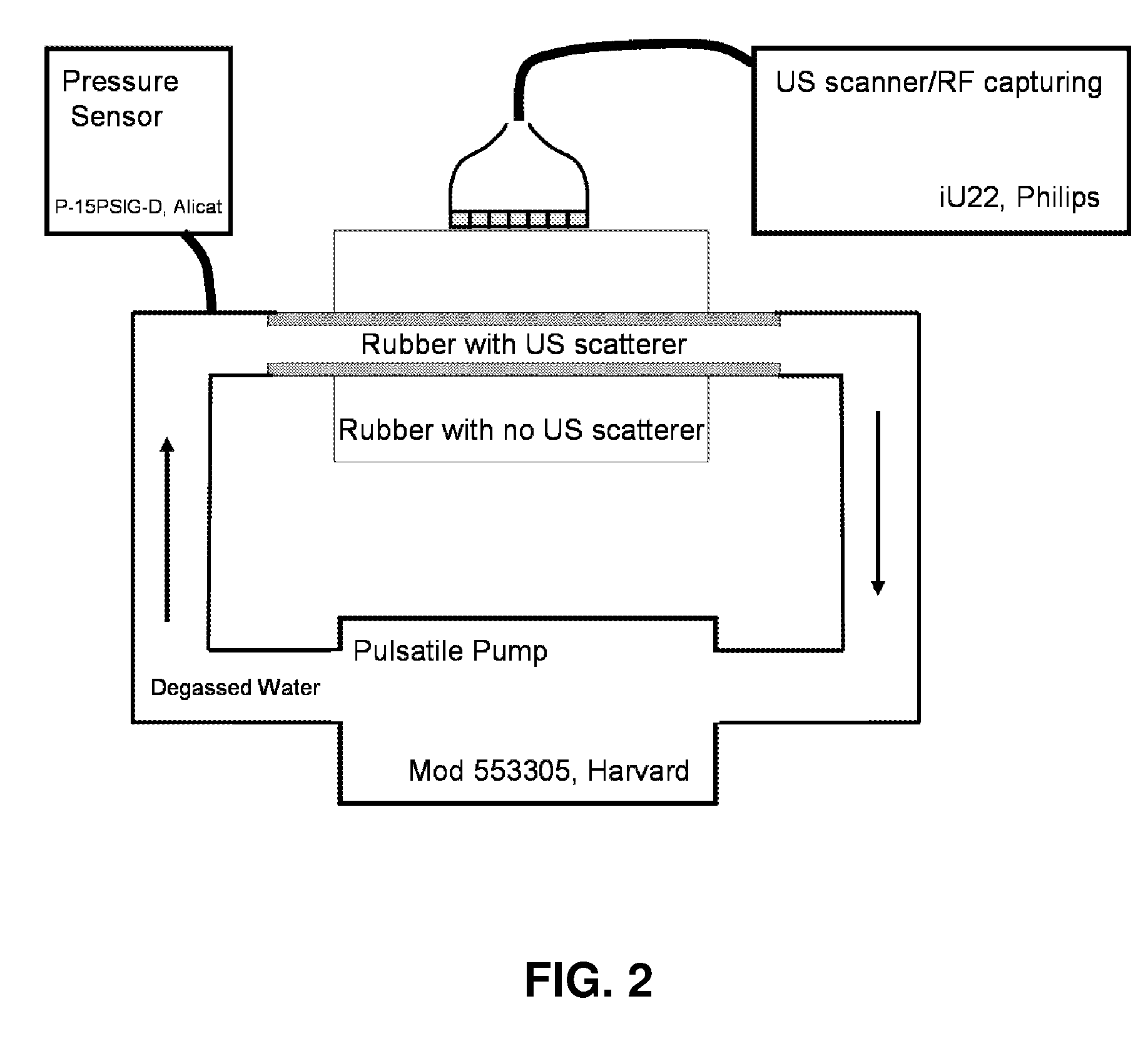

Measurement of tissue elastic modulus

ActiveUS20080081994A1Easy to measureEasy to quantifyWave based measurement systemsBlood flow measurement devicesArterial velocityMedicine

An optimized elastic modulus reconstruction procedure can estimate the nonlinear elastic properties of vascular wall from intramural strain and pulse wave velocity (PWV) measurements. A noninvasive free-hand ultrasound scanning procedure is used to apply external force, comparable to the force in measuring a subject's blood pressure, to achieve higher strains by equalizing the internal arterial baseline pressure. PWV is estimated at the same location where intramural strain is measured. The reconstructed elastic modulus is optimized and the arterial elastic modulus can be determined and monitored using a simple dual elastic modulus reconstruction procedure.

Owner:RGT UNIV OF MICHIGAN

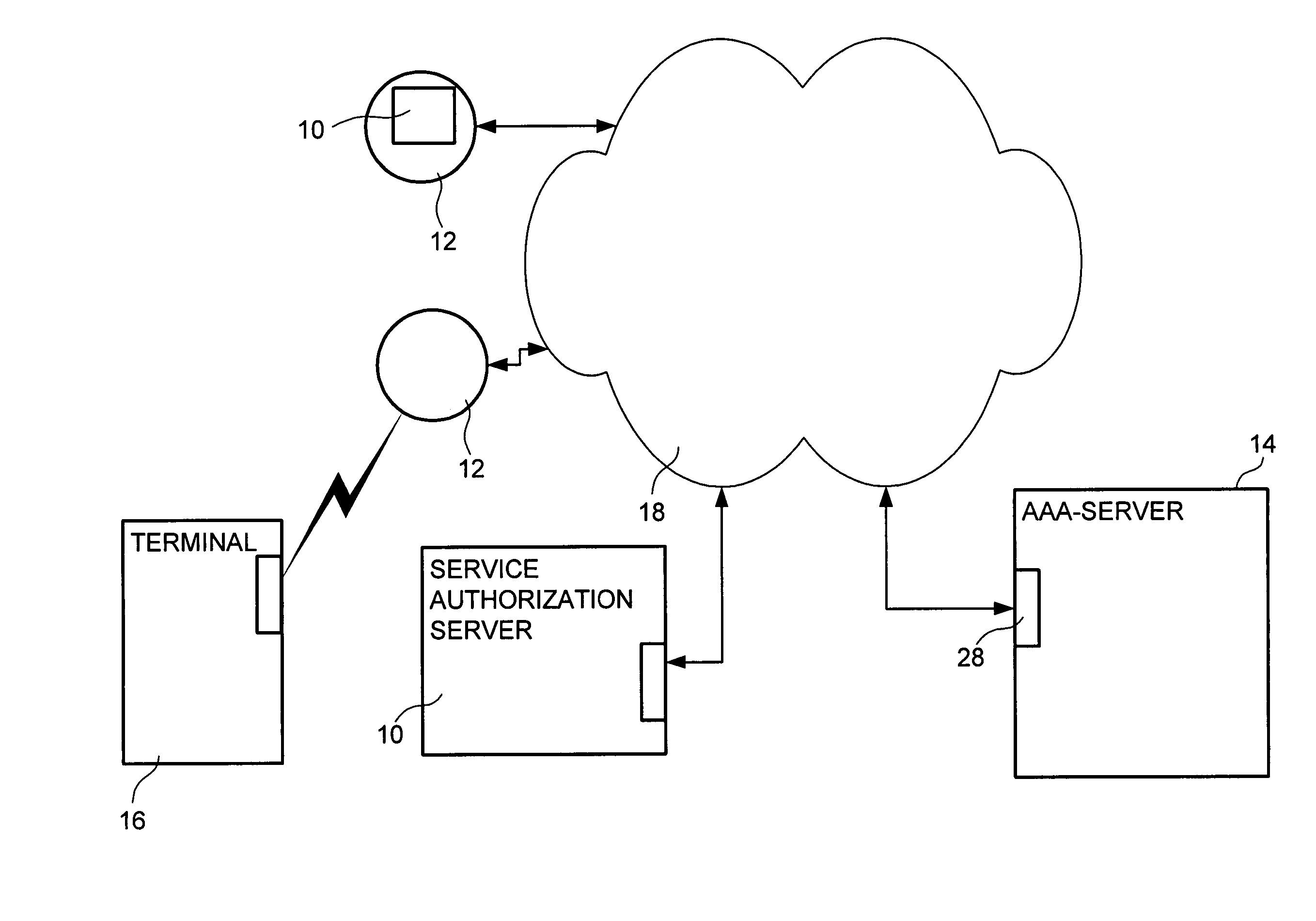

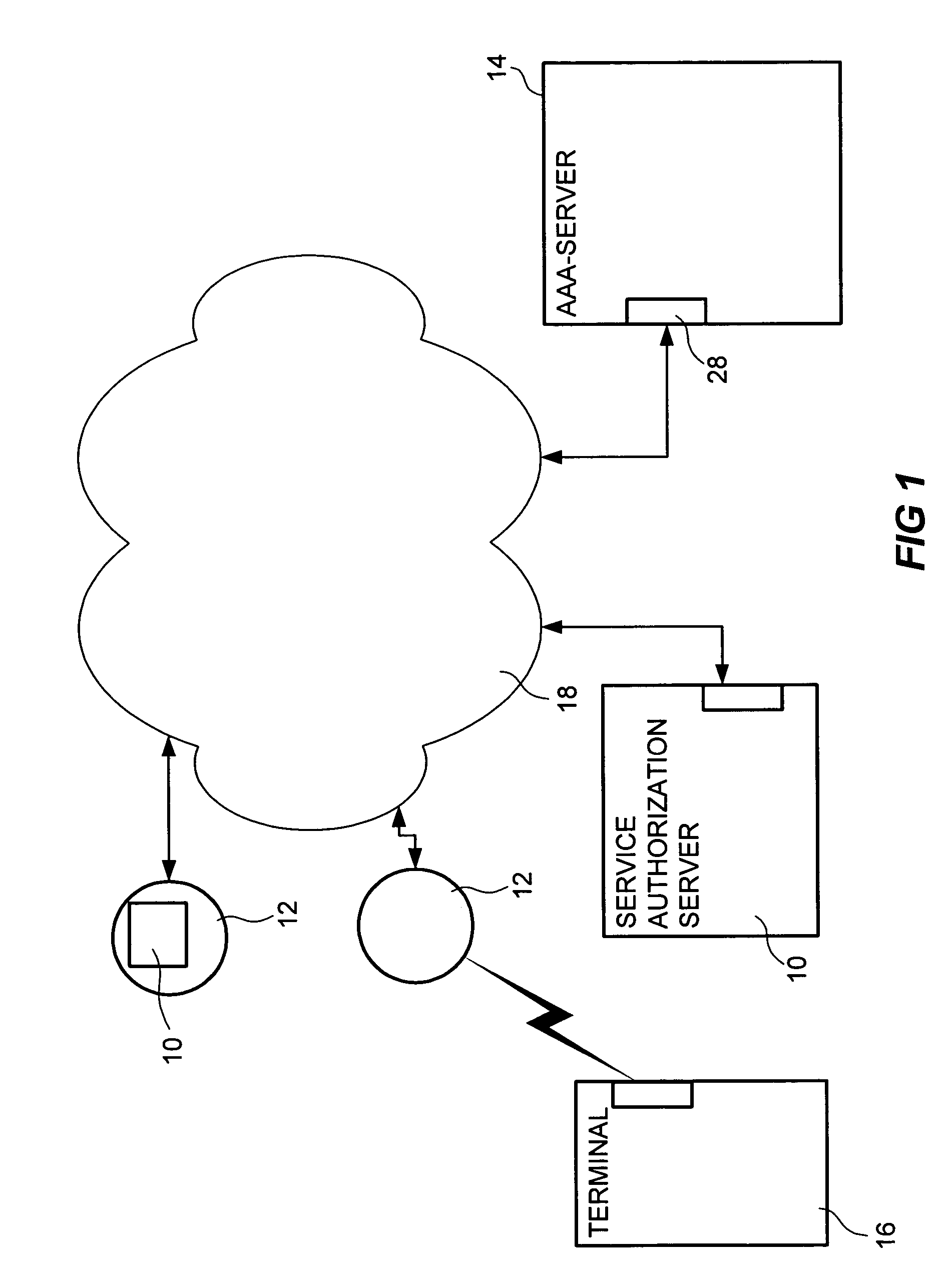

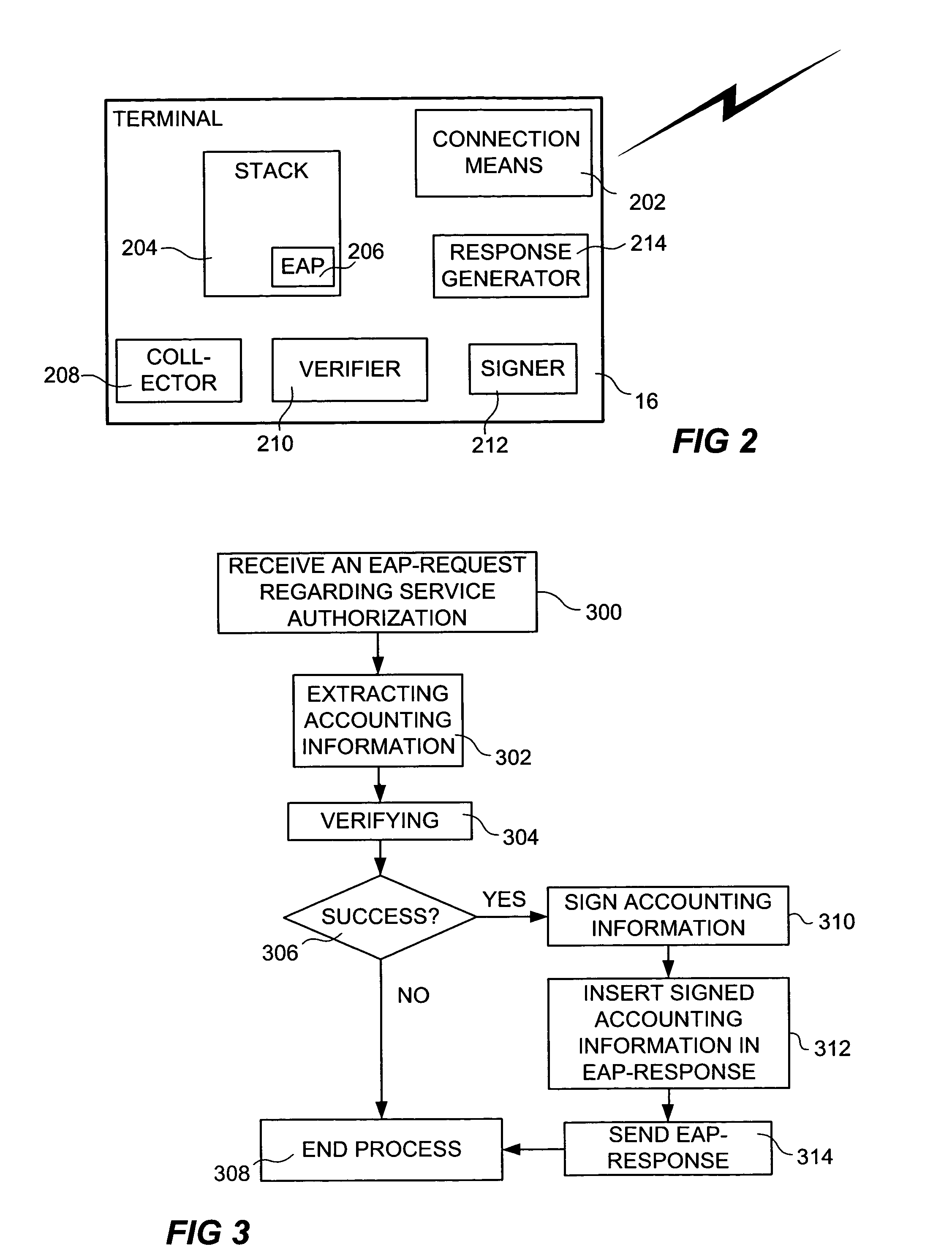

Method, system and devices for transferring accounting information

ActiveUS7251733B2Reduce deliverySufficient effortUser identity/authority verificationData resettingDigital signatureComputer terminal

A method in a system for transferring accounting information, a system for transferring accounting information, a method in a terminal, a terminal, a method in an Extensible Authentication Protocol (EAP) service authorization server, an EAP service authorization server, a computer program, an Extensible Authentication Protocol response (EAP-response) packet, wherein the method:meters data related to a service used by at least one terminal,provides the metered data as accounting information to at least one Extensible Authentication Protocol (EAP) service authorization server,sends, by means of an Extensible Authentication Protocol request (EAP-request), a service authorization request from the at least one EAP service authorization server to the at least one terminal,digitally signs accounting information, in the at least one terminal,includes, at the at least one terminal, the digitally signed accounting information in an Extensible Authentication Protocol response (EAP-response), andsends the digitally signed accounting information to an AAA-server.

Owner:CONVERSANT WIRELESS LICENSING LTD

Method and apparatus for parallel multi-view point video capturing and compression

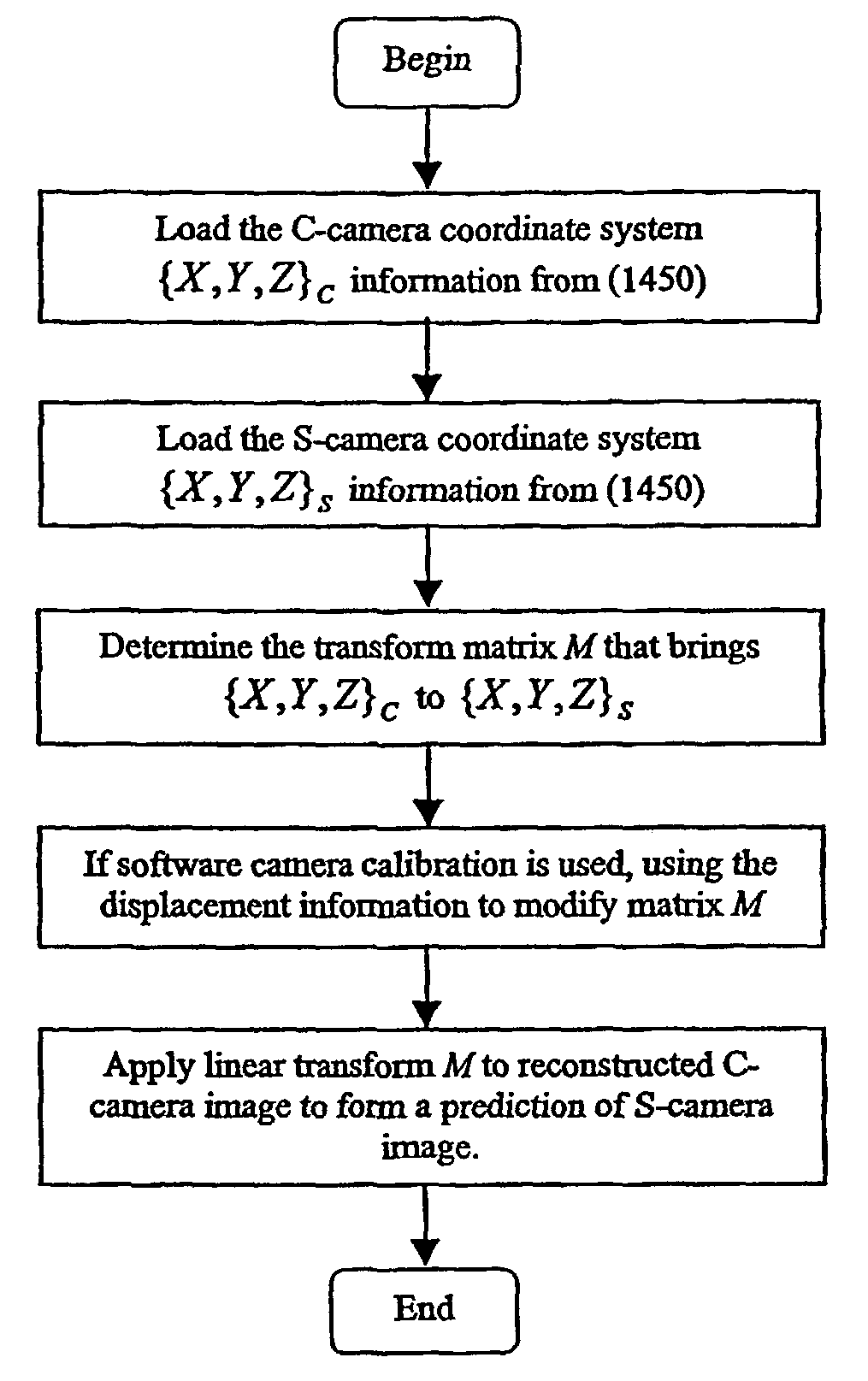

InactiveUS7035453B2Remove uncertaintyTelevision system detailsPicture reproducers using cathode ray tubesDigital videoInstructions per second

A method and apparatus for digital video capturing and compression supports multi-viewpoint interactive video applications. Multiple (typically hundreds of) video cameras centripetally placed in a three dimensional space acquire real-time visual pictures of the same 3D scene from multiple viewpoints at the rate of 20˜30 frames per second (fps). Parallel Multi-Viewpoint Video Capturing and Compression (PMVCC) supports the operation of the apparatus. In an exemplary realization, a Multi-DSP Array (MDA) architecture uses hundreds of high-performance digital signal processors (DSPs) working in parallel to obtain a sustained computation power of hundreds of GIPS (Giga Instructions Per Second).

Owner:REALITY COMMERCE CORP

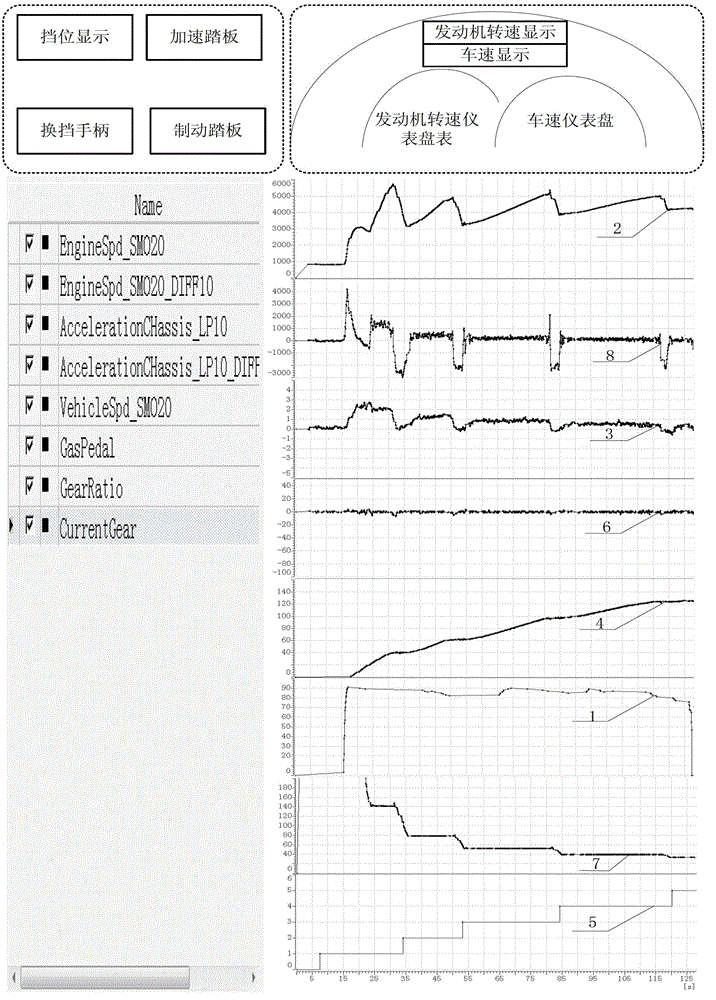

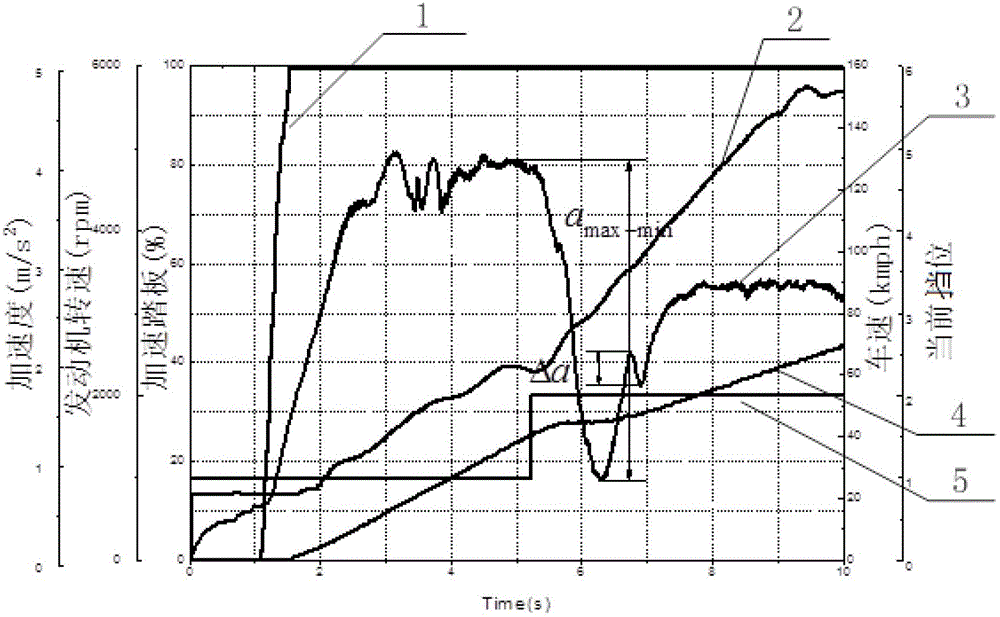

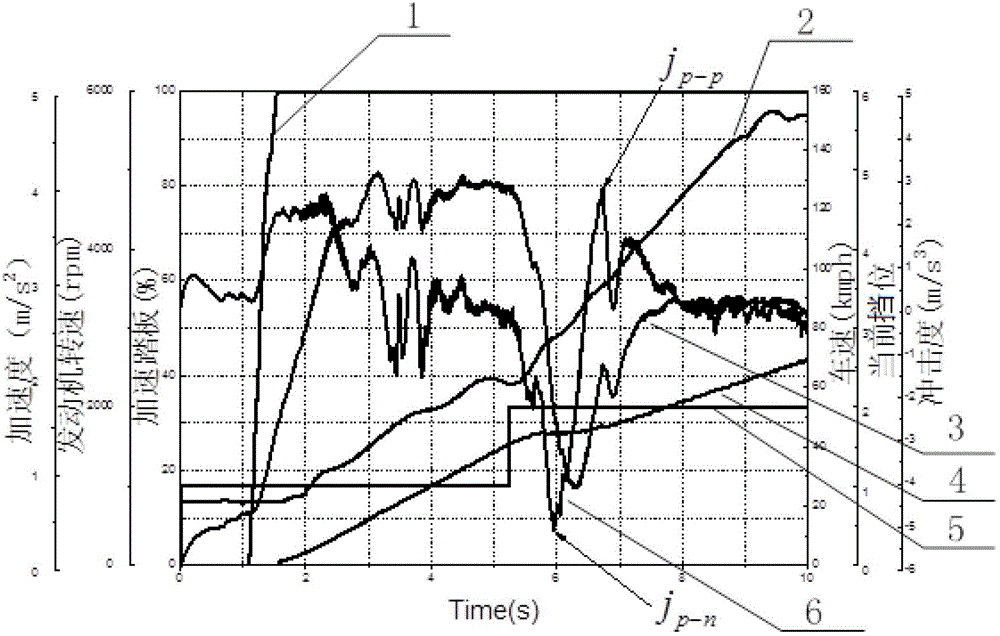

Vehicle gear-shifting quality evaluation testing method and system

The invention discloses a vehicle gear-shifting quality evaluation testing method, which comprises the steps of: 1) at a vehicle gear-shifting quality evaluation testing preparation stage: establishing a vehicle database by adopting an SQL (structured query language) server; establishing a vehicle gear-shifting quality evaluation module by adopting MATLAB / Simulink and determining the core algorithm of the vehicle gear-shifting quality evaluation module; and selecting the type of a vehicle to be tested and a testing system to be used; 2) at a vehicle gear-shifting quality testing stage: conducting gear-shifting rule testing, Tip in testing, Tip out testing, Fast Off testing, brake control logic testing, operability testing, start testing, acceleration testing and driving during a traffic jam; and 3) at a vehicle gear-shifting quality evaluation stage: calling data of the vehicle database as data input of the vehicle gear-shifting quality evaluation model and obtaining an evaluation result through data processing and the like; and outputting the evaluation result a graphical user and result display interface. The invention additionally provides a vehicle gear-shifting quality evaluation testing system.

Owner:JILIN UNIV

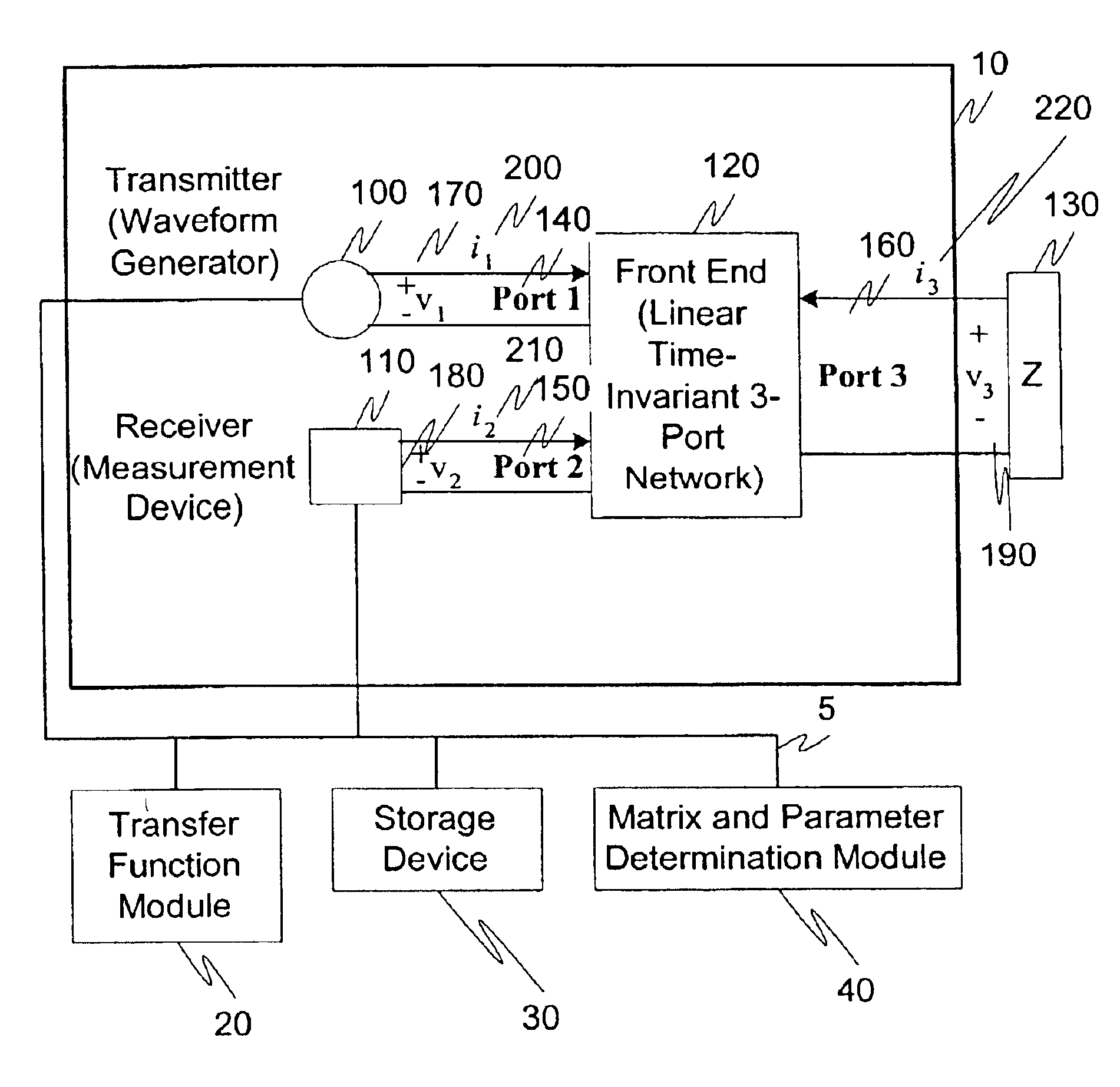

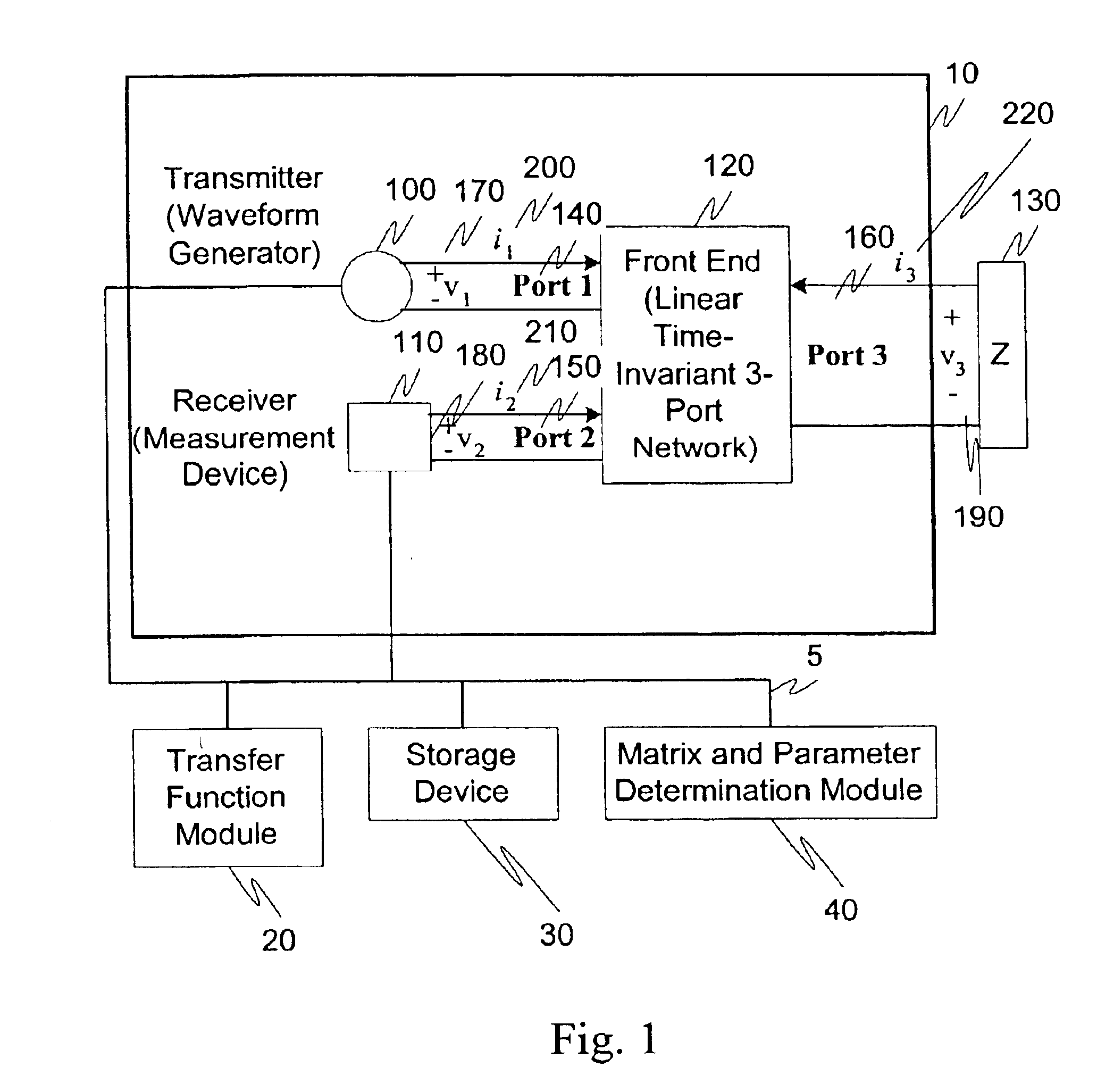

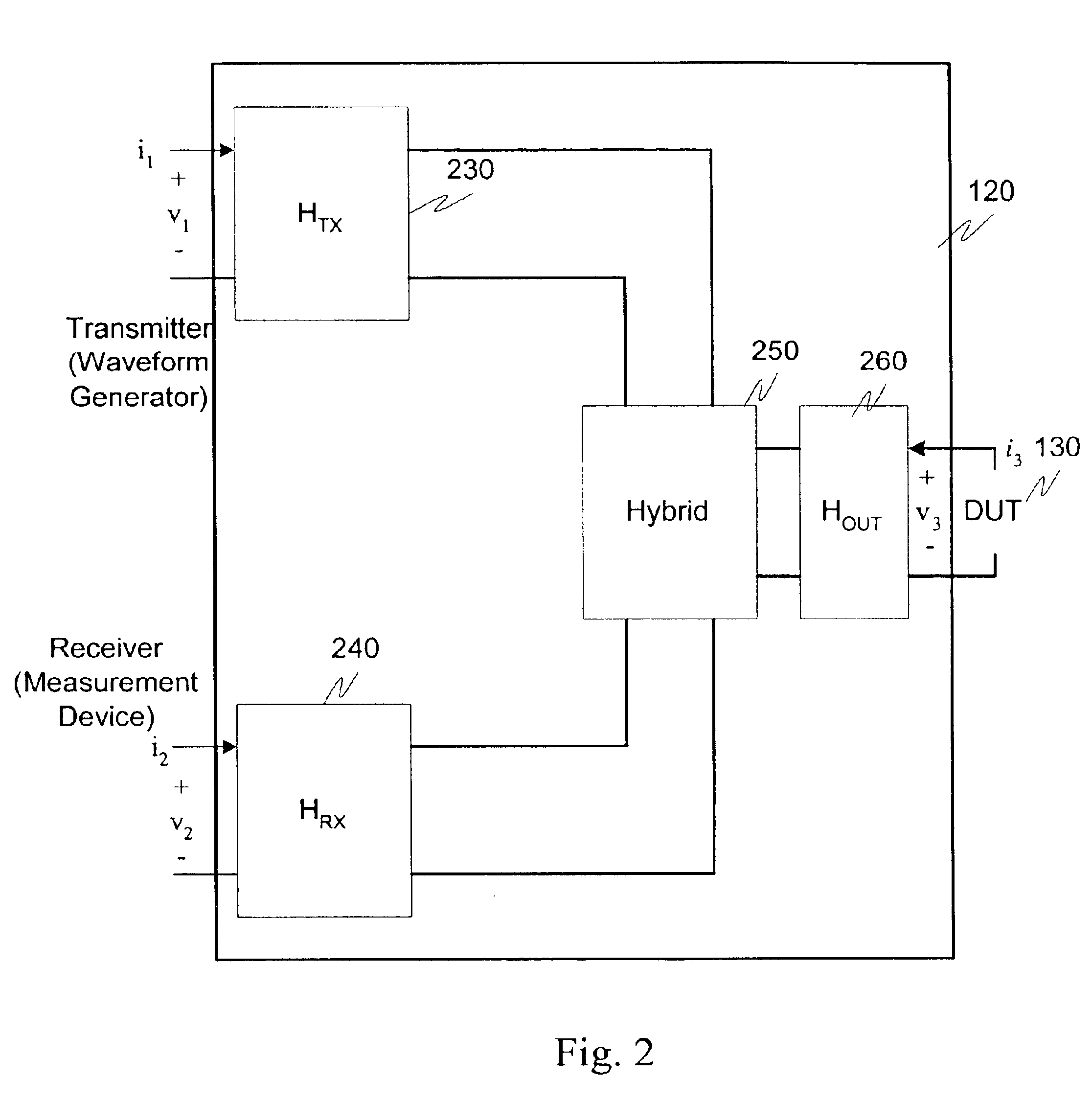

Modeling and calibrating a three-port time-domain reflectometry system

InactiveUS6842012B2Valid conversionRemove uncertaintyResistance/reactance/impedenceLine-transmission monitoring/testingTime domainDSL modem

A three-port TDR front end comprises numerous components. An exemplary three-port TDR front end is a DSL modem. Information-bearing TDR signals are distorted as they pass through these components. With a perfect model of the response of its front-end, a TDR system usually can compensate for the effects of its front-end. In reality, however, the electrical characteristics of each component vary from design-to-design, board-to-board, and slowly over time. The result is imperfect knowledge about the true response of the front-end, errors in the model of the front-end, and degraded TDR performance. At least for this reason it is important to precisely calibrate the response of the TDR front-end through the use of a TDR modeling system.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

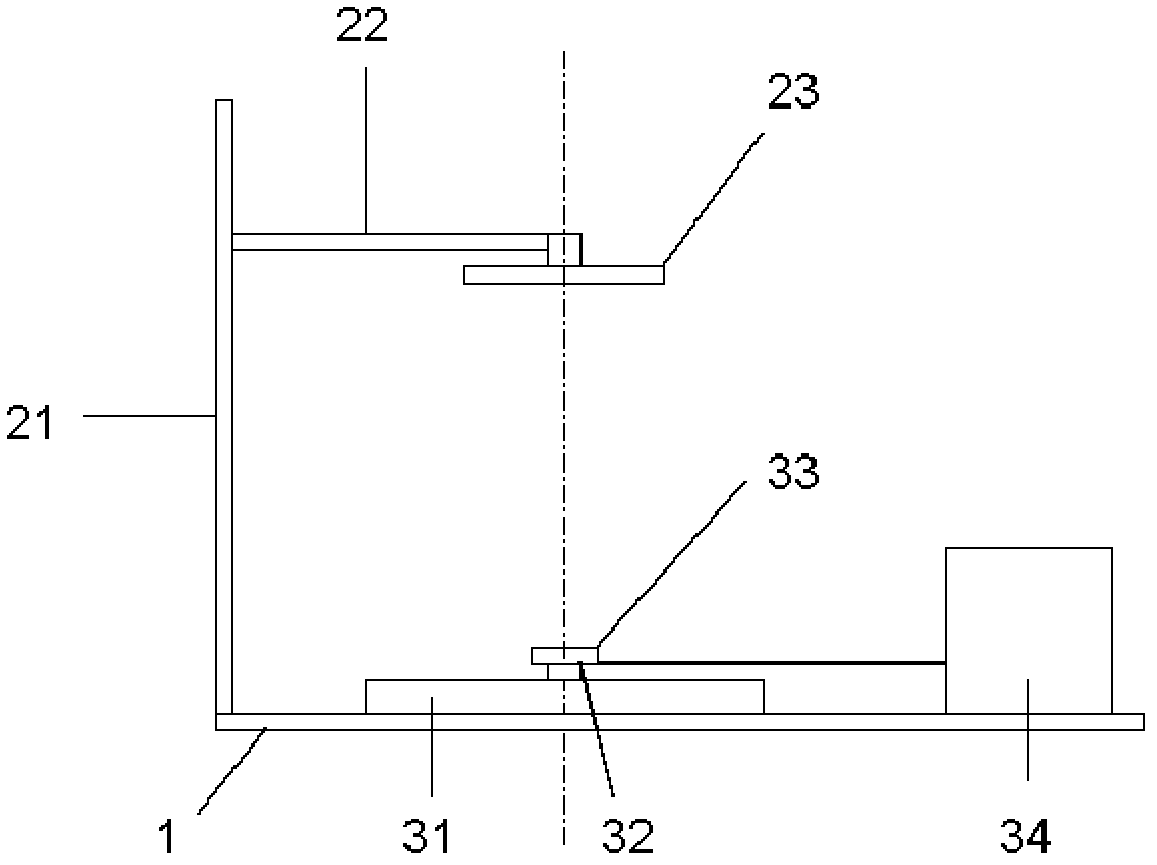

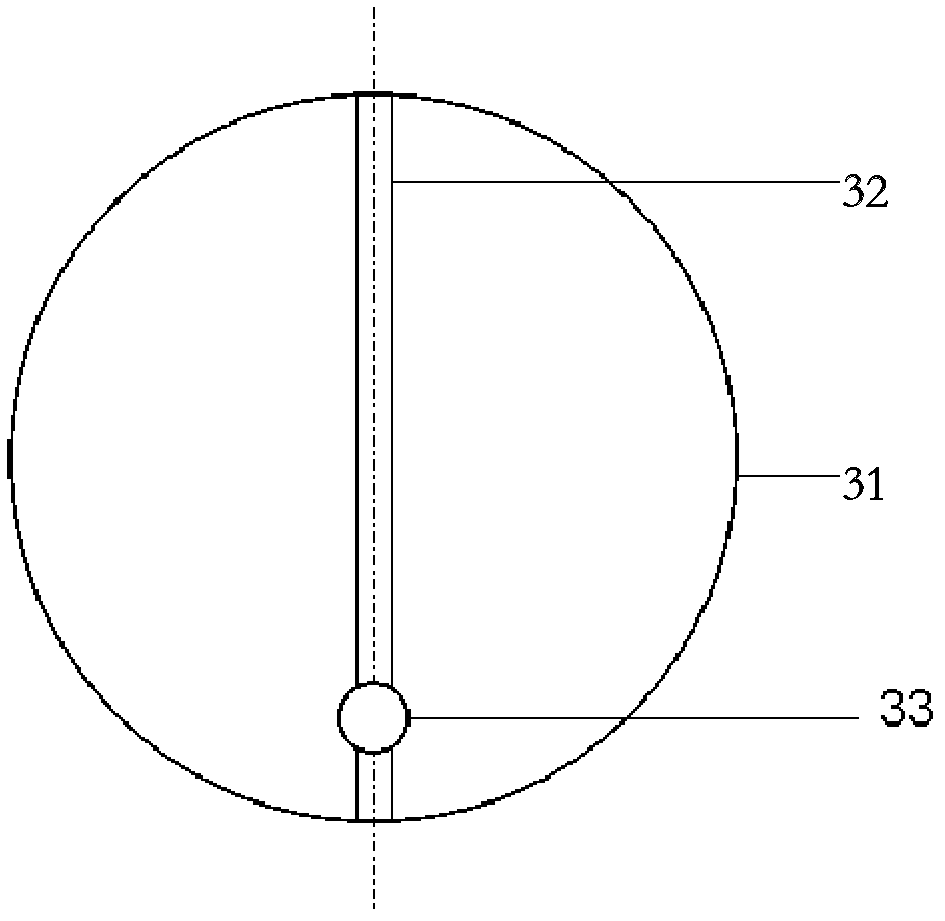

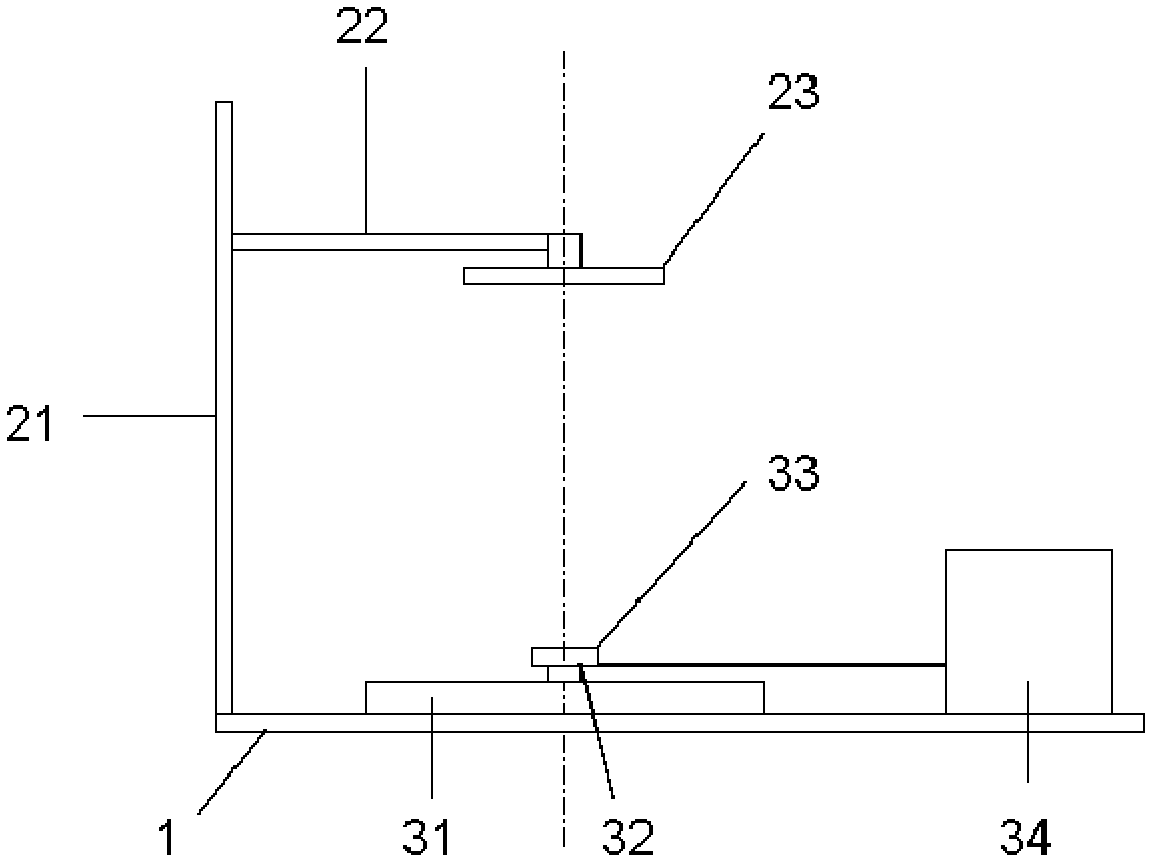

Performance measuring device of surface light source lamp

InactiveCN102620918ASolving the lack of measurement devices for the performance of surface light luminairesSimple structureLamps testingTesting optical propertiesColor rendering indexEngineering

A performance measuring device of a surface light source lamp comprises a horizontal baseboard, a support and a testing table. The support comprises a vertical support and a horizontal support, the vertical support is vertically fixed on the horizontal baseboard, the horizontal support is horizontally arranged on the vertical support and is capable of being in parallel translation vertically, and the horizontal support is provided with a lamp fixing device. The testing table comprises a horizontal disc, a probe and a detector, the horizontal disc is arranged on the horizontal baseboard and capable of rotating for 360 degrees, the horizontal disc is provided with a linear guiderail, the probe is installed on the linear guiderail and capable of moving along the linear guiderail, and the detector is arranged on the horizontal baseboard and connected with the probe. The performance measuring device is simple in structure, eliminates uncertainty in measuring, leads measuring to be standard, and can be used in measuring of parameters including light intensity, spectrum, color temperature, surface temperature and color rendering index of various surface light source lamps including light-emitting diode surface light source lamps, organic light-emitting diode surface light source lamps and electroluminescence surface light source lamps.

Owner:SHANGHAI JIAO TONG UNIV

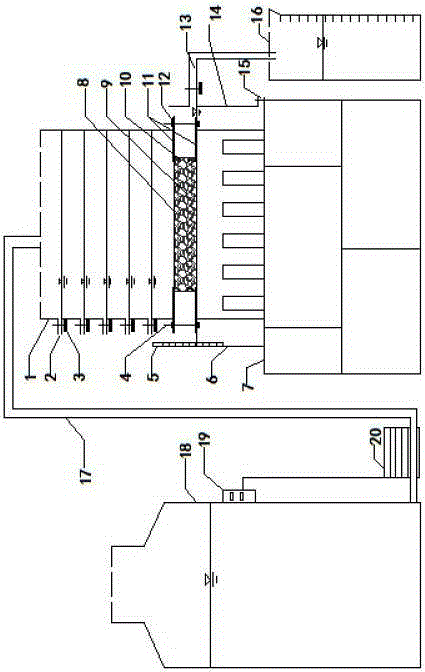

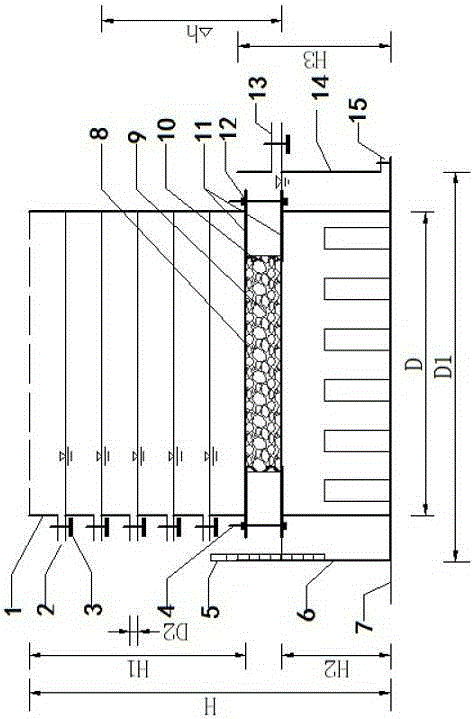

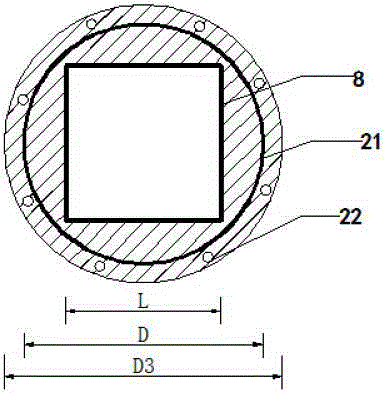

Penetration coefficient determination apparatus for permeable asphalt concrete track board test piece, and test method thereof

ActiveCN105203443AReasonable structureSimple and fast operationPermeability/surface area analysisWater storageGraduated cylinder

The invention provides a penetration coefficient determination apparatus for a permeable asphalt concrete track board test piece, and a test method thereof. The determination apparatus comprises a test device and a water supply device, and the test device comprises a workbench, an overflow water tank, an upper sleeve, a lower sleeve, two flanges, an electronic thermometer and a measuring cylinder; the outer sidewall of the upper sleeve is provided with water overflow ports connected with the inside of the upper sleeve, the two same flanges are provided with a ring of a slot, and the two flanges and the sleeve are cemented to form an integral body; the lower sleeve is connected through the overflow water tank, and the overflow water tank is provided with an overflow port and a water drainage port; the test piece is placed between the two flanges, a rubber sealing pad is arranged between each of the flanges and the test piece, the flanges are provided with screw holes, and the test piece is fixed through allowing long bolts to traverse through the screw holes and through using nuts; and the water supply device comprises a water storage barrel, a water pump and a power switch. The apparatus has the advantages of reasonable structure, simple operation, satisfactory solving of the seepage problem of the side wall, realization of flexible control of hydraulic gradient, and reasonable and reliable determination result.

Owner:YANGZHOU UNIV

Network time transfer

InactiveUS20050190797A1Reduce uncertaintyRemove uncertaintyTime-division multiplexNetwork connectionsPhysical layerTime transfer

The invention comprises a method and apparatus for reducing uncertainty in timing on the network. The uncertainty in receive buffers is removed by time stamping the arriving packets before sending the packets to the receive buffer. The uncertainty in the transmission buffer is removed by giving the packets a timestamp in the future, and holding the packets until precisely that time. Time precision is ensured by only releasing time packets at the host physical layer to network boundary at the time specified within the packet.

Owner:MICROSEMI FREQUENCY & TIME

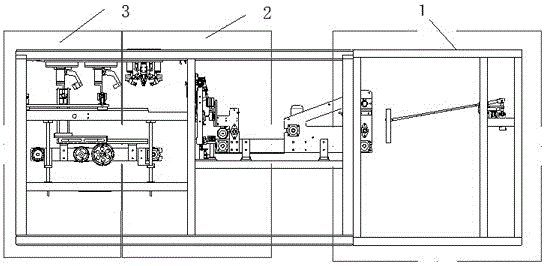

Automatic packaging machine and operating method thereof

ActiveCN106829059ASimple structureStable and efficient workWrapper twisting/gatheringEngineeringMachine tool

The invention relates to an automatic packaging machine and an operating method thereof. The machine comprises a bag feeding device, a bag sheathing device, and a sealing bag-delivery device. The bag feeding device comprises a bag crossing catch rod for catching on a bag-carrying opening of a packaging bag. The bag crossing catch rod is driven by a first driving mechanism to swing up and down. A first sucking disc is arranged above a first belt conveyor mechanism. The first sucking disc is driven by a second driving mechanism to move laterally and vertically and driven by a third driving mechanism to swing up to place the sucked packaging bag on the first belt conveyor mechanism. The bag feeding device is provided with two bag hanging mechanisms operating alternatively. The bag sheathing device comprises a bag opening mechanism, a bag distracting and conveying mechanism and a bag fixing and arranging mechanism which are arranged on a frame. The sealing bag-delivery device comprises a bag fixing and arranging mechanism, a heat-sealing mechanism and a cold pressing mechanism which are arranged above a second belt conveyor mechanism in order in an output direction. Finger cylinder groups for clamping a packaging bag are arranged on the upper portions of both sides of the second belt conveyor mechanism, and each finger cylinder group comprises a first finger cylinder, a second finger cylinder, and a third finger cylinder, and is fixed to a second slider. The automatic packaging machine is capable of achieving automatic packaging, and also can ensure the quality of sealing.

Owner:ZHANGZHOU JIALONG TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com