Patents

Literature

37results about How to "Achieve structural optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

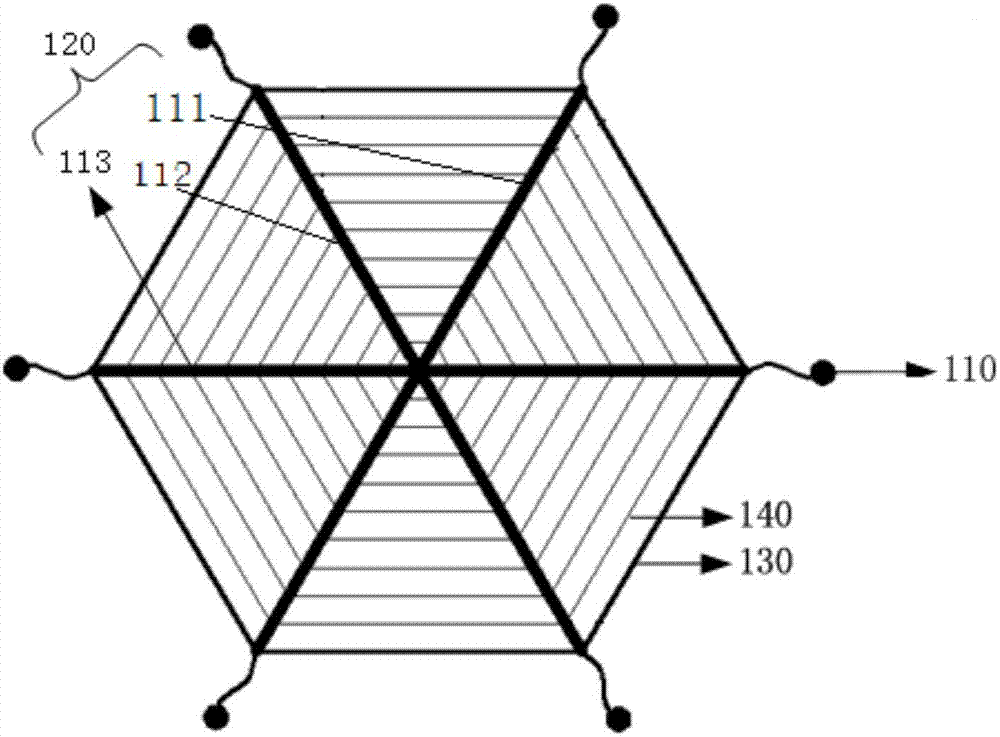

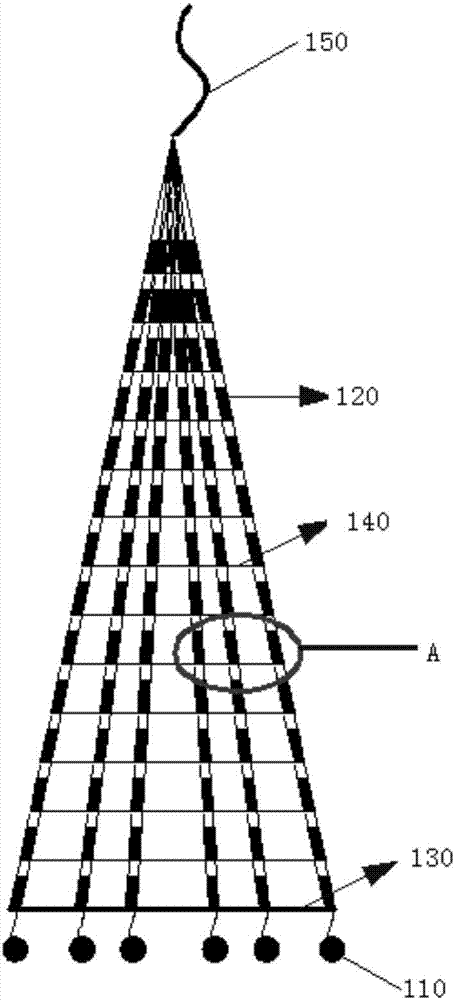

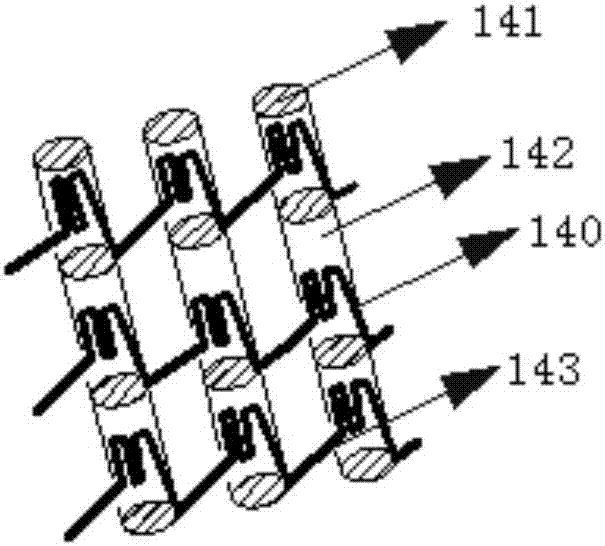

Bionic cobweb for capturing in orbit and its holding method

The invention provides a bionic cobweb for capturing in orbit and its holding method. The bionic cobweb for capturing in orbit takes a hollow rope as a radial line; multiple holding cabins for holding side contour lines or inner contour lines are arranged in the bionic cobweb. Thus the holding of the bionic cobweb can be realized under the condition of not increasing other structures.

Owner:NAT UNIV OF DEFENSE TECH

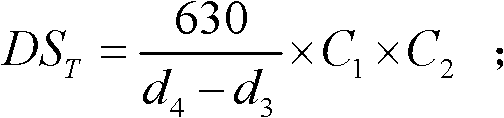

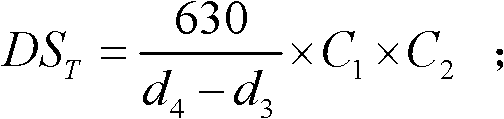

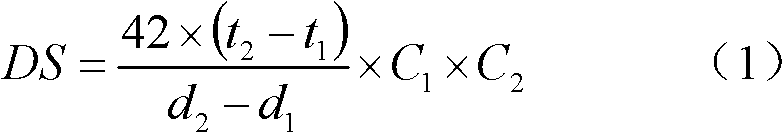

Method for evaluating rutting resistance of asphalt pavement structure

InactiveCN102494961AGuide structure combinationAchieve structural optimizationMaterial strength using repeated/pulsating forcesEngineeringRoad surface

The invention discloses a method for evaluating the rutting resistance of an asphalt pavement structure. The method is characterized by comprising the following steps of: firstly, setting a rutting test condition and carrying out full-depth rutting test on a test piece of an asphalt pavement combined structure; calculating according to the formula shown in the specification to obtain an overall dynamic stability DST of the asphalt pavement structure, wherein in the formula, d3 and d4 respectively represent displacement deformation corresponding to the 1890th milling and the 2520th milling; and finally, controlling the rutting resistance of each asphalt pavement combined structure according to a stability control standard [DS]T of the asphalt pavement structure, wherein if the DST is more than the [DS]T, the asphalt pavement structure meets the requirements of the rutting resistance. According to the method for evaluating the rutting resistance of the asphalt pavement structure, the rutting resistance of the asphalt pavement structure can be accurately reflected; and the method can be used as a beneficial guide to an asphalt pavement design.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

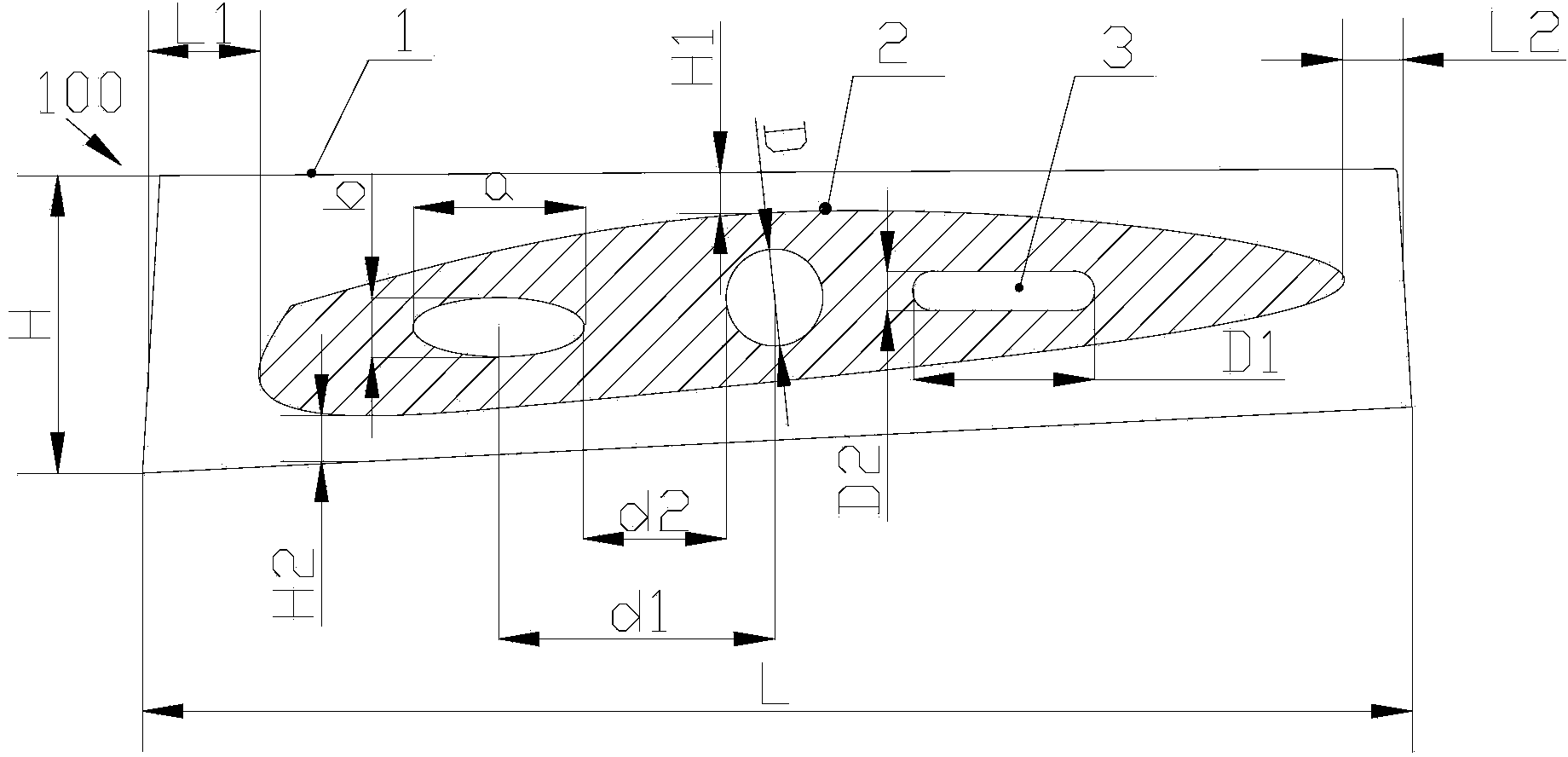

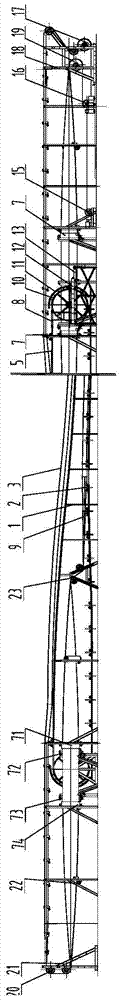

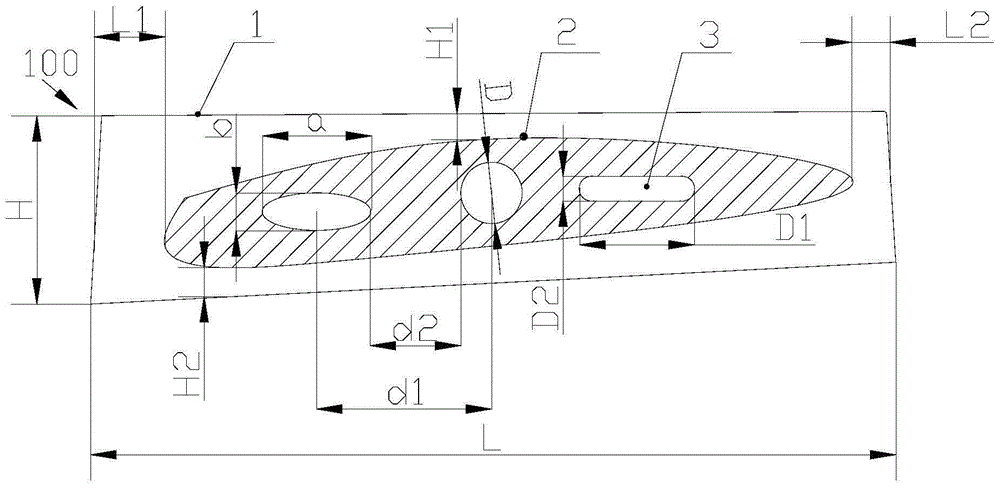

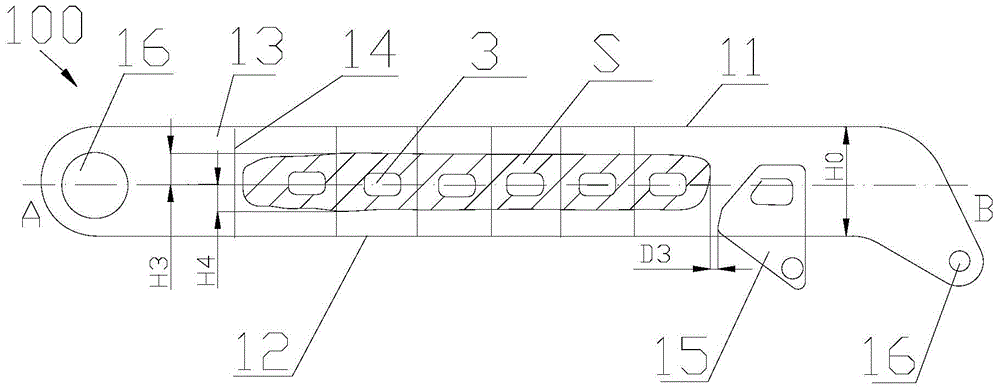

Crane and arm frame thereof

Owner:TAICANG LIBIAO INTELLIGENT TECH CO LTD

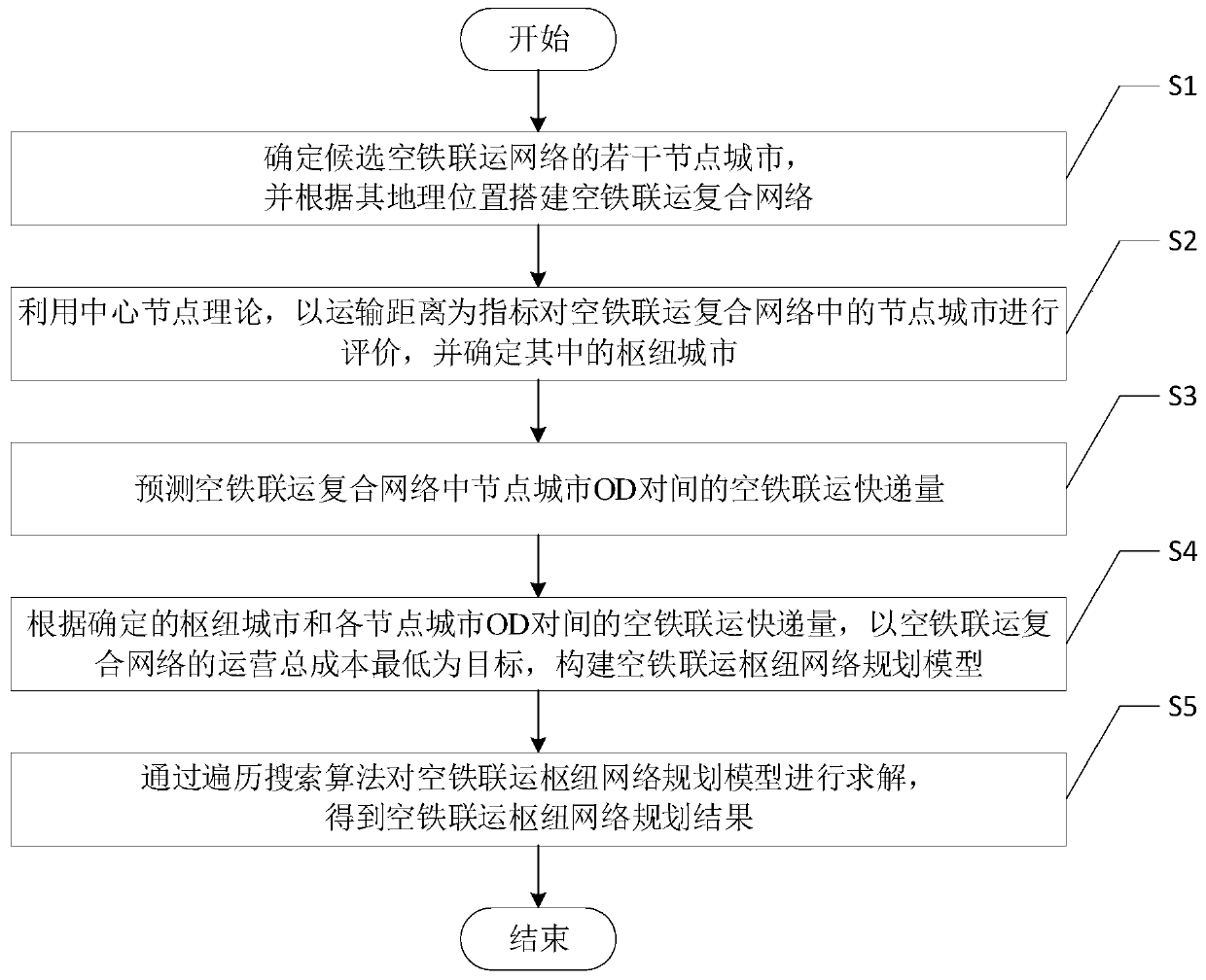

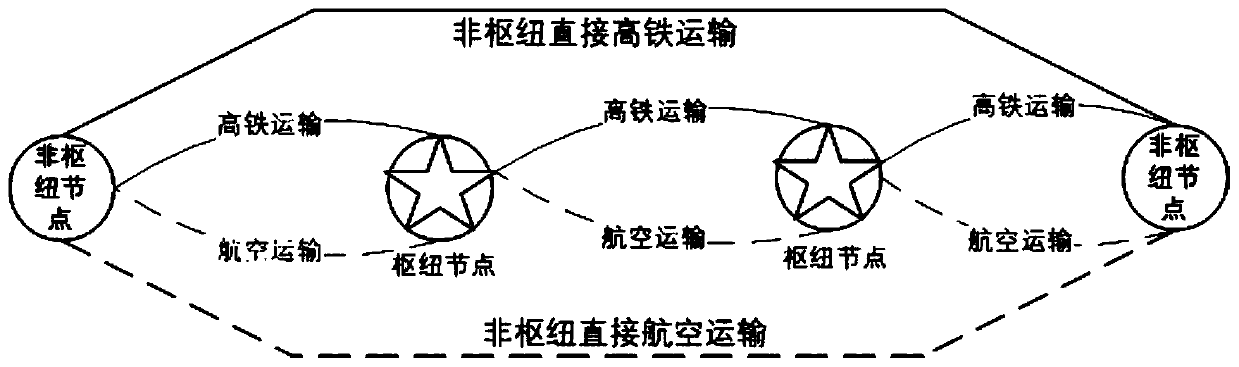

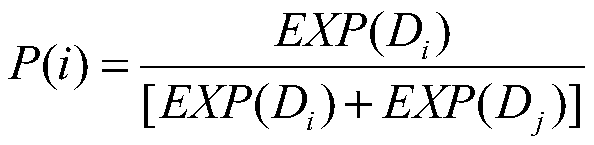

Air-railway combined transportation hub network planning method for field of freight transportation

ActiveCN110516869ARealize reasonable configurationAchieve structural optimizationForecastingResourcesAviationTransport network

The invention discloses an air-railway combined transportation hub network planning method for the field of freight transportation, and the method builds an air-railway combined transportation composite transportation network through the effective connection of a high-speed rail and an aviation line, integrates the technical advantages and market advantages of a high-speed rail and aviation transportation, and achieves the advantage complementation of the high-speed rail and aviation transportation. From the microcosmic perspective, the service level of the express industry is improved; in themacroscopic aspect, reasonable allocation of transportation resources, improvement of transportation efficiency and structural optimization of a comprehensive transportation system are achieved.

Owner:SOUTHWEST JIAOTONG UNIV

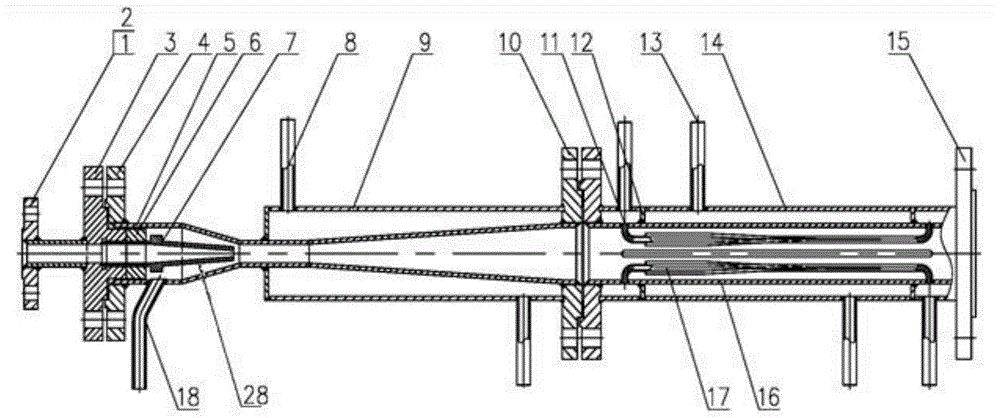

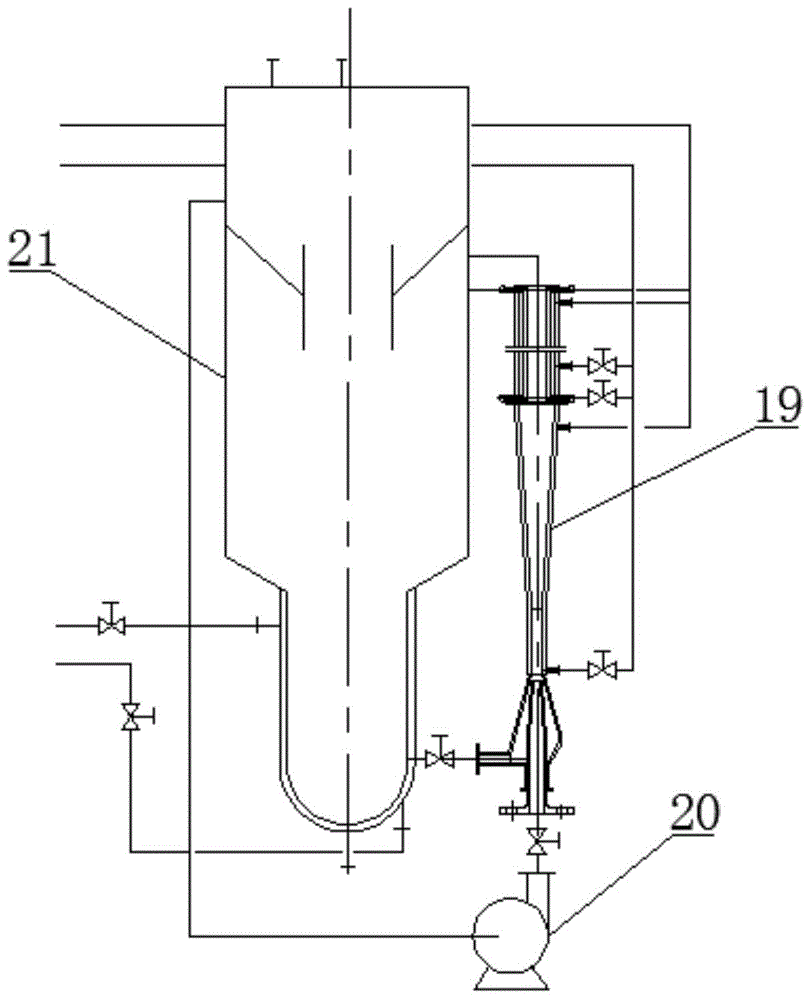

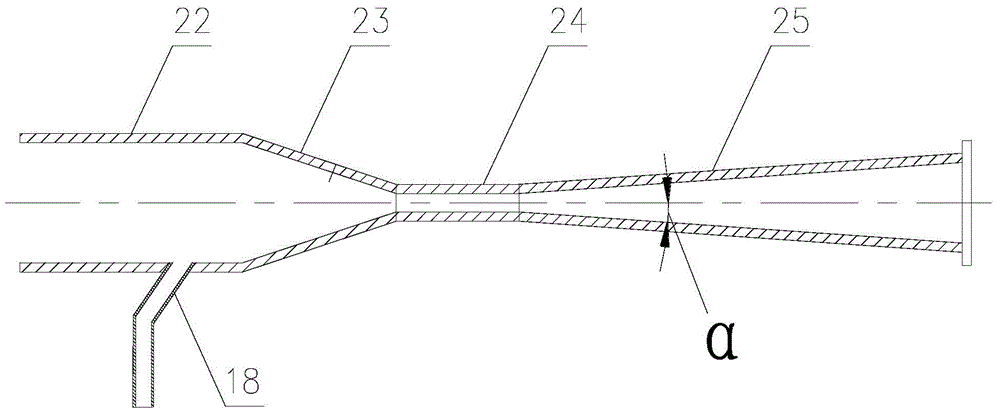

Efficient dispersed venturi ejection reactor

InactiveCN104549056AAchieve structural optimizationSimple structureChemical/physical/physico-chemical nozzle-type rreactorsPhosphorus compoundsWorking temperatureEngineering

The invention relates to an efficient dispersed venturi ejection reactor, which comprises a high-speed jet nozzle, venturi equipment and a heat insulation jacket, wherein the connecting end of the high-speed jet nozzle and the venturi equipment is connected and sealed by a non-standard flange and a venturi flange, and a venturi section hot steam inlet and outlet pipe is arranged on a venturi heat insulation jacket; a drainage tube section hot steam inlet and outlet pipe is arranged on a drainage tube heat insulation jacket, and a finned tube is arranged in the drainage tube heat insulation jacket. Hydrogen peroxide is ejected out by the nozzle at high speed, and a negative pressure area is formed in a suction chamber, so that a yellow phosphorus liquid containing an arsenic impurity flows through a suction tube into the suction chamber, the yellow phosphorus is efficiently dispersed under the action of jet turbulence, and then the yellow phosphorus and the hydrogen peroxide are subjected to a sufficient contact and mixing reaction in a throat tube and are drained along a diffusion tube and a drainage tube; an outer-layer heat insulation jacket allows the reactor to be at appropriate work temperature. Through the driving of a circulating pump, the uninterrupted contact and mixing reaction of the hydrogen peroxide and the yellow phosphorus is realized, and the ultimate purpose of arsenic removal of the yellow phosphorus is achieved.

Owner:TIANJIN UNIV

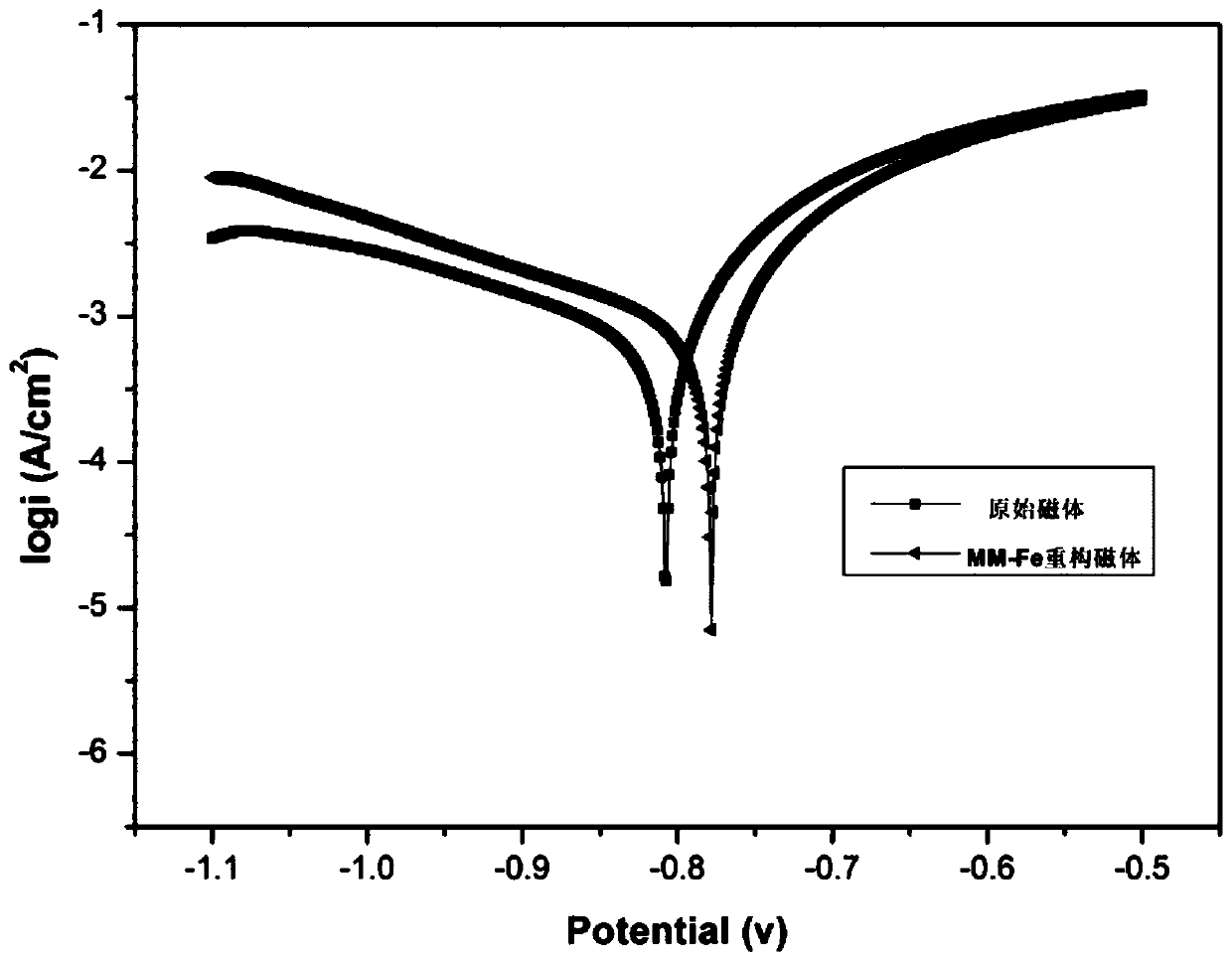

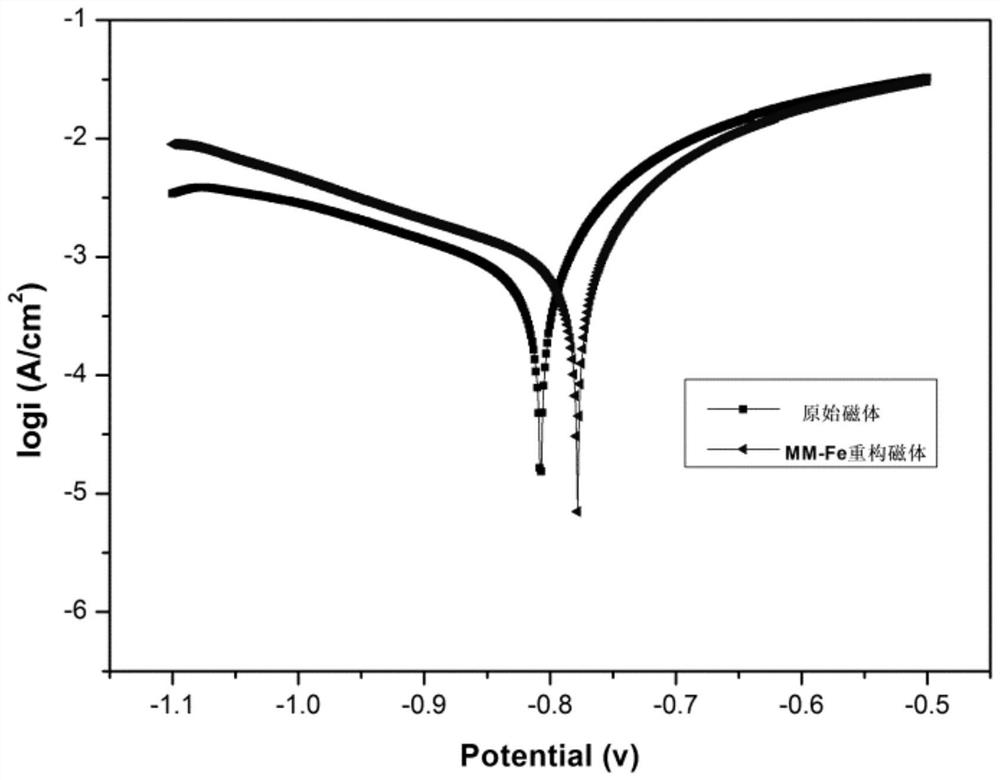

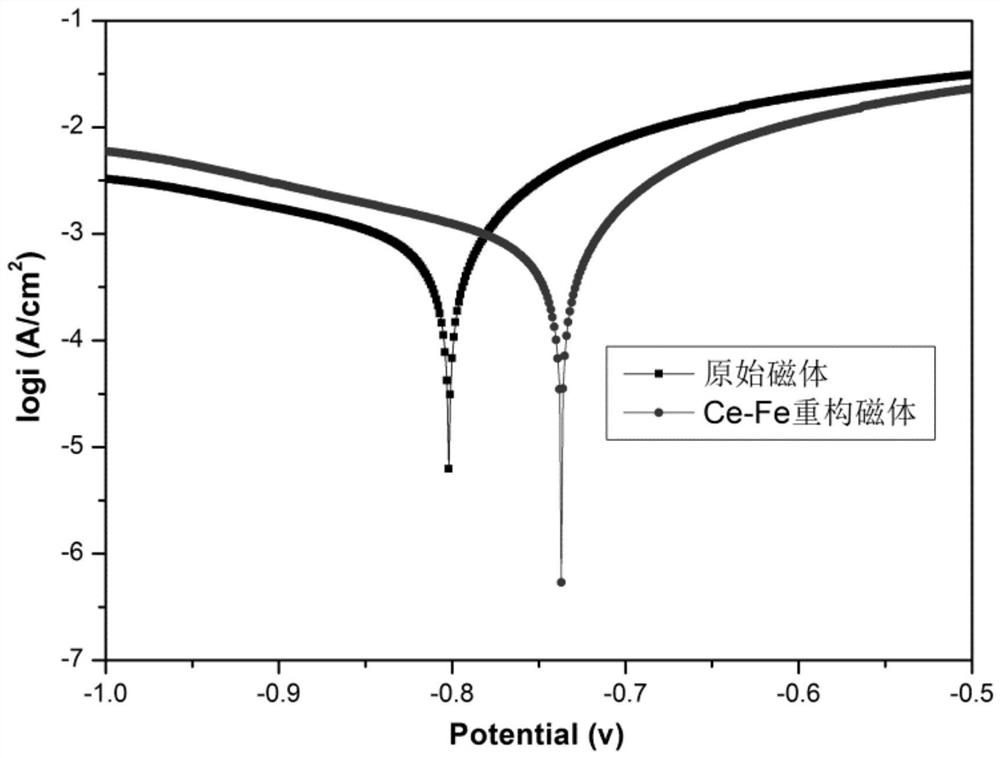

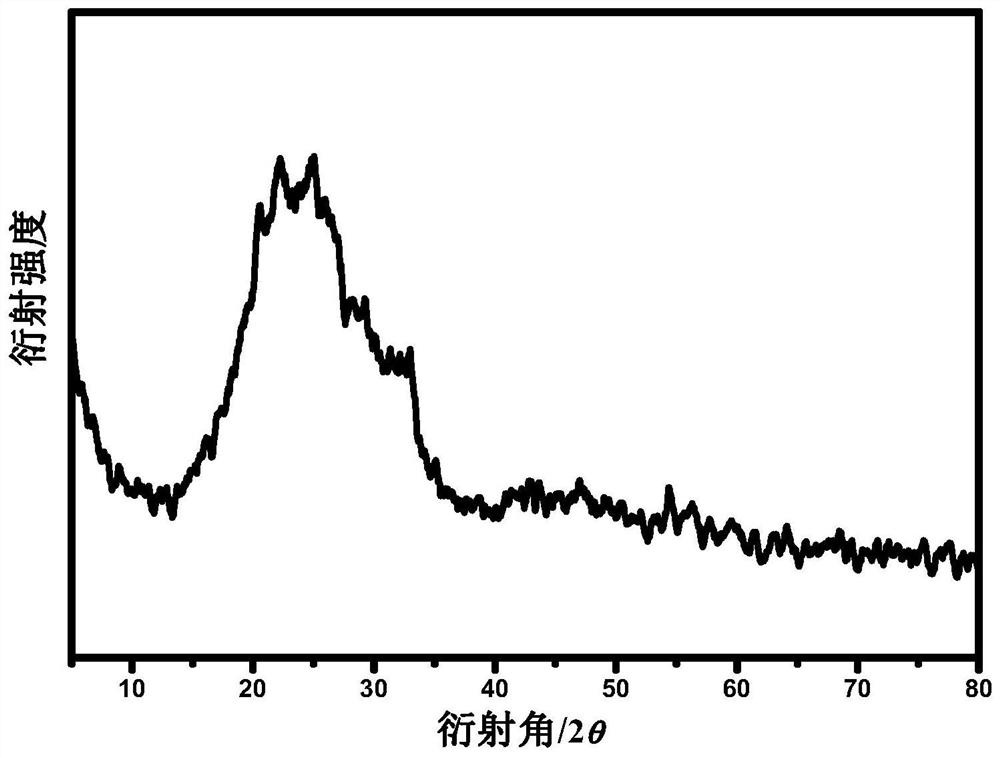

High-corrosion-resistance permanent magnet rich in high-abundance rare earth and preparation method of high-corrosion-resistance permanent magnet rich in high-abundance rare earth

ActiveCN109859920AIncrease the proportionIncrease useInductances/transformers/magnets manufactureMagnetic materialsMagnetic phaseSintered magnets

The invention belongs to the technical field of permanent magnet materials, and particularly relates to a high-corrosion-resistance permanent magnet rich in high-abundance rare earth and a preparationmethod of the high-corrosion-resistance permanent magnet rich in the high-abundance rare earth. The high-corrosion-resistance permanent magnet rich in the high-abundance rare earth comprises a strongmagnetic phase and a crystal boundary rare-earth-rich phase, wherein the strong magnetic phase e is an MM-Fe-B phase, and the crystal boundary rare-earth-rich phase is an MM-Fe phase. According to the method for preparing the permanent magnet, through a double-alloy process, an MM-Fe-B main phase alloy and an MM-Fe auxiliary alloy are prepared, smelted and crushed to prepare powder; the preparedMM-Fe auxiliary alloy powder is added into the main alloy to be evenly mixed according to the mass percent of 1% to 5%; and orientation pressing, sintering and heat treatment are conducted, and the finally sintered magnet is obtained. MM-Fe is introduced in a crystal boundary, thus distribution of the crystal boundary rare-earth-rich phase can be optimized, the crystal boundary rare-earth-rich phase partially replaces an original crystal boundary phase prone to corrosion, the intrinsic corrosion resistance of the MM-Fe-B magnet is improved, through the method, the proportion of low-cost rare earth La / Ce in the magnet is further increased, the material cost is lowered, the technological process is simple, and the high-corrosion-resistance permanent magnet rich in high-abundance rare earth is suitable for scale production.

Owner:NANJING UNIV OF SCI & TECH

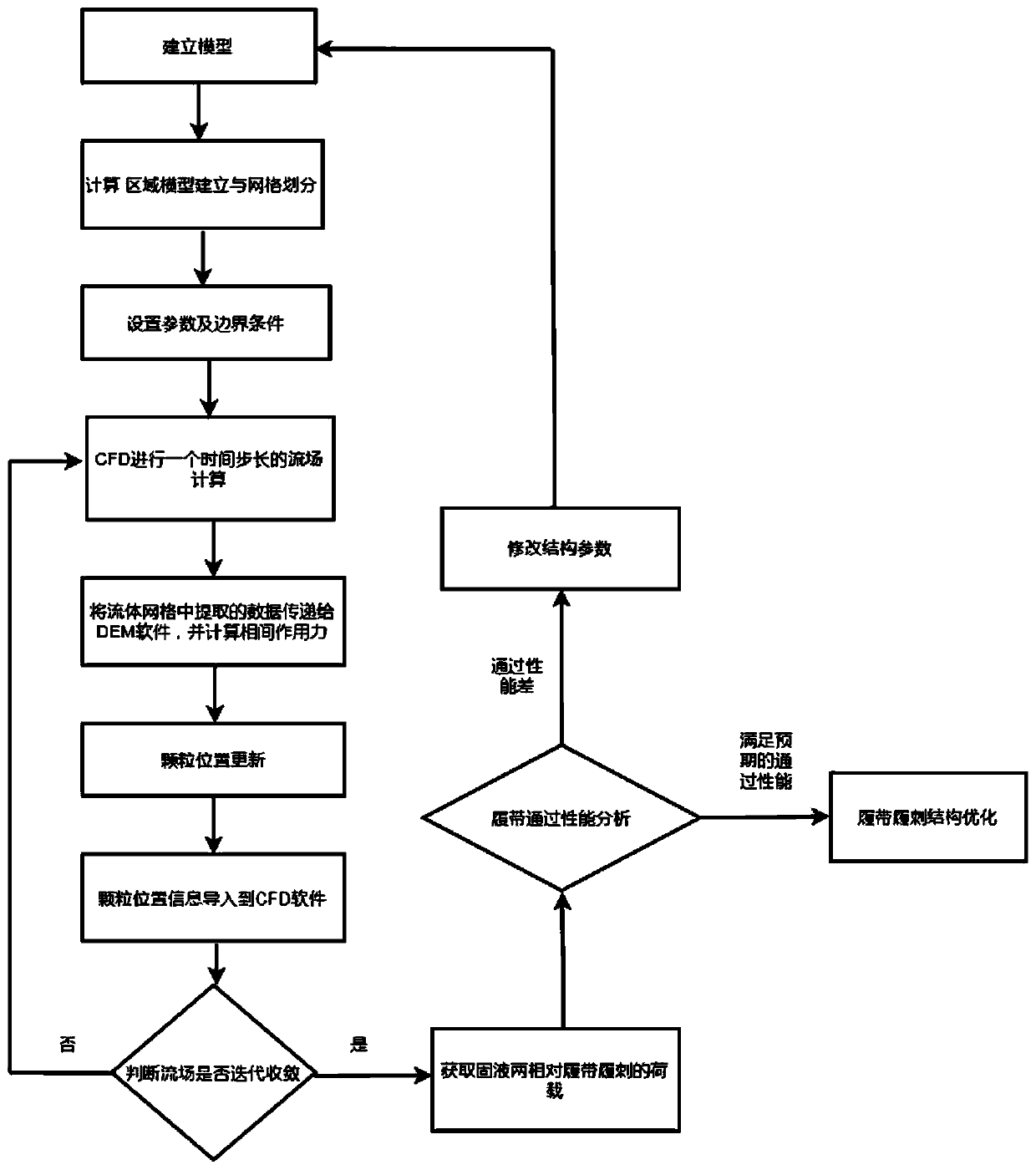

A track shoe thorn structure optimization calculation method based on CFD-DEM coupling simulation

ActiveCN109948275AChange structure parametersAchieve structural optimizationSpecial data processing applicationsCouplingPhysical model

The invention discloses a track shoe thorn structure optimization calculation method based on CFD-DEM coupling simulation. The method comprises the following specific steps: (1) establishing a physical model; (2) calculation area setting and grid division; (3) setting parameters and boundary conditions in CFD-DEM coupling; (4) performing coupling simulation, and acquiring acting forces of solid and liquid relative to crawler belt thorns; And (5) analyzing crawler belt track thorn structure optimization. Through post-processing analysis on a simulation calculation result, crawler belt track thorn structure parameters (crawler belt thorn height, crawler belt thorn thickness, crawler belt thorn mold drawing angle and crawler belt thorn form) are changed, and structure optimization is performed on crawler belt thorns, so that the hook traction force (namely the difference between soil thrust and driving resistance) of the crawler belt vehicle is improved, and the trafficability of the crawler belt vehicle is improved.

Owner:XIANGTAN UNIV

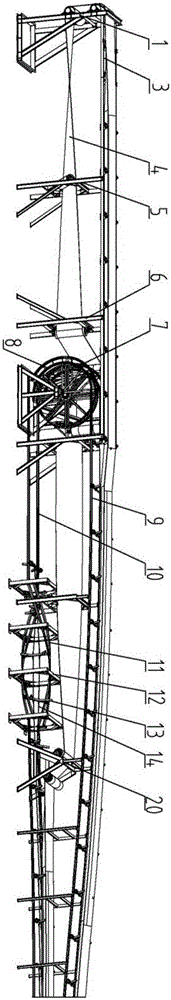

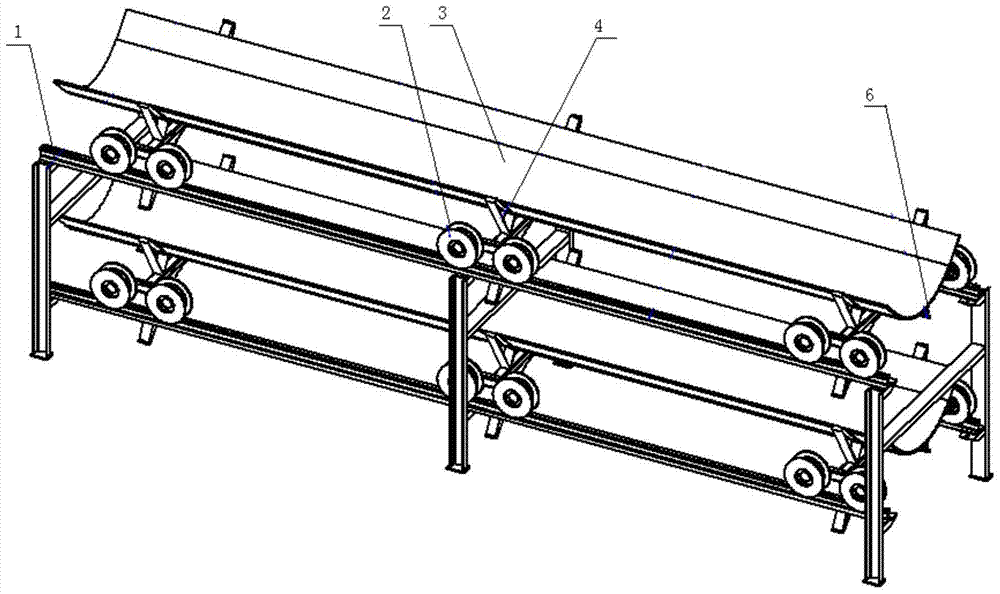

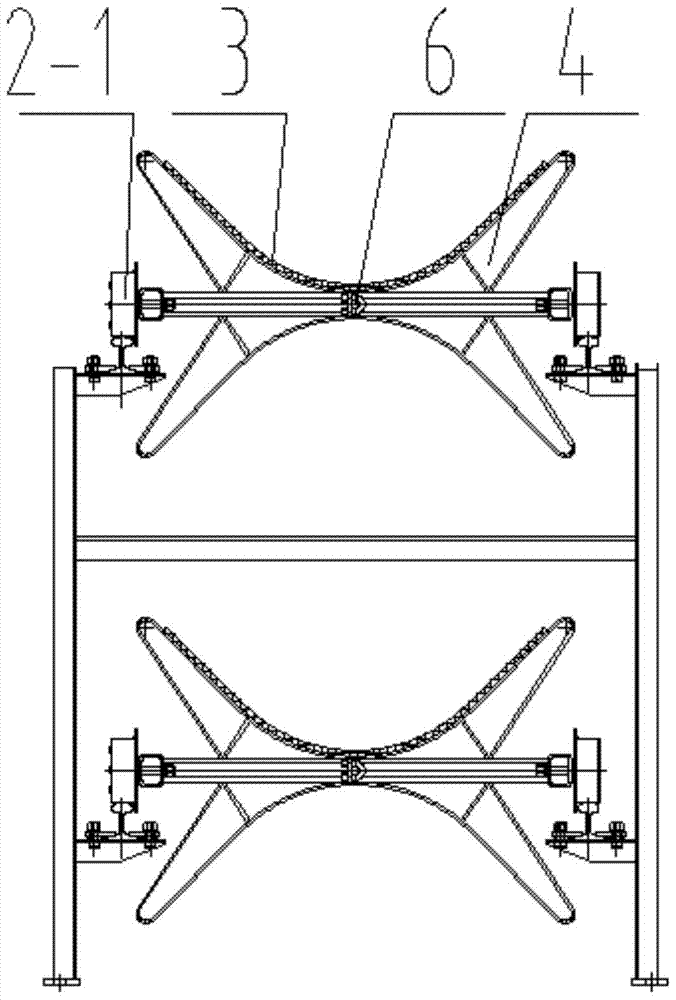

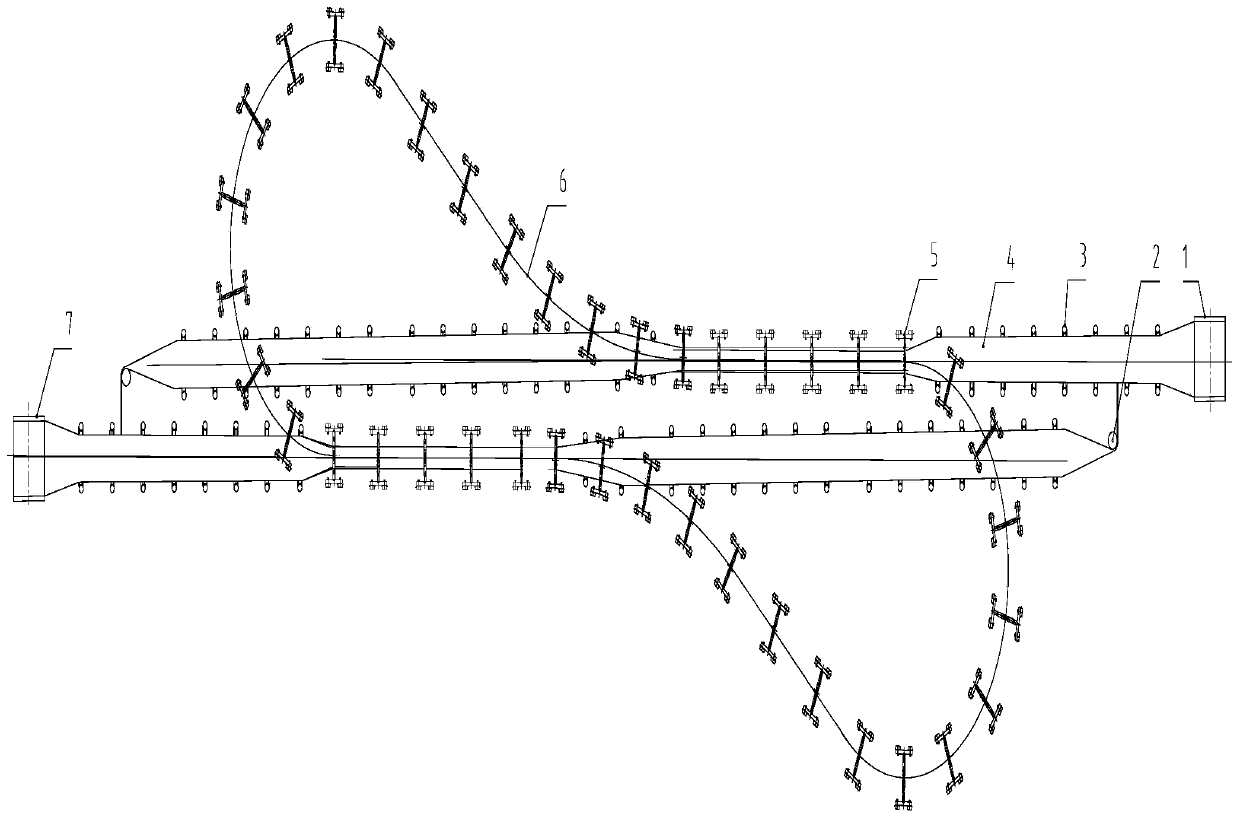

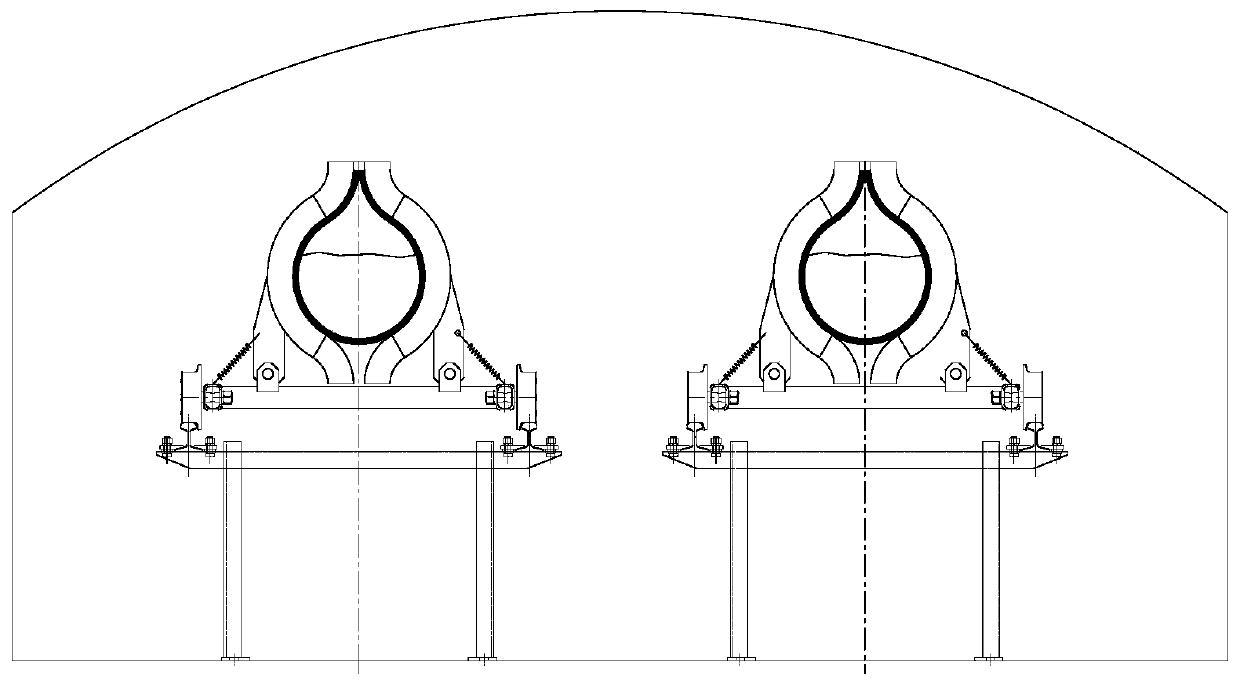

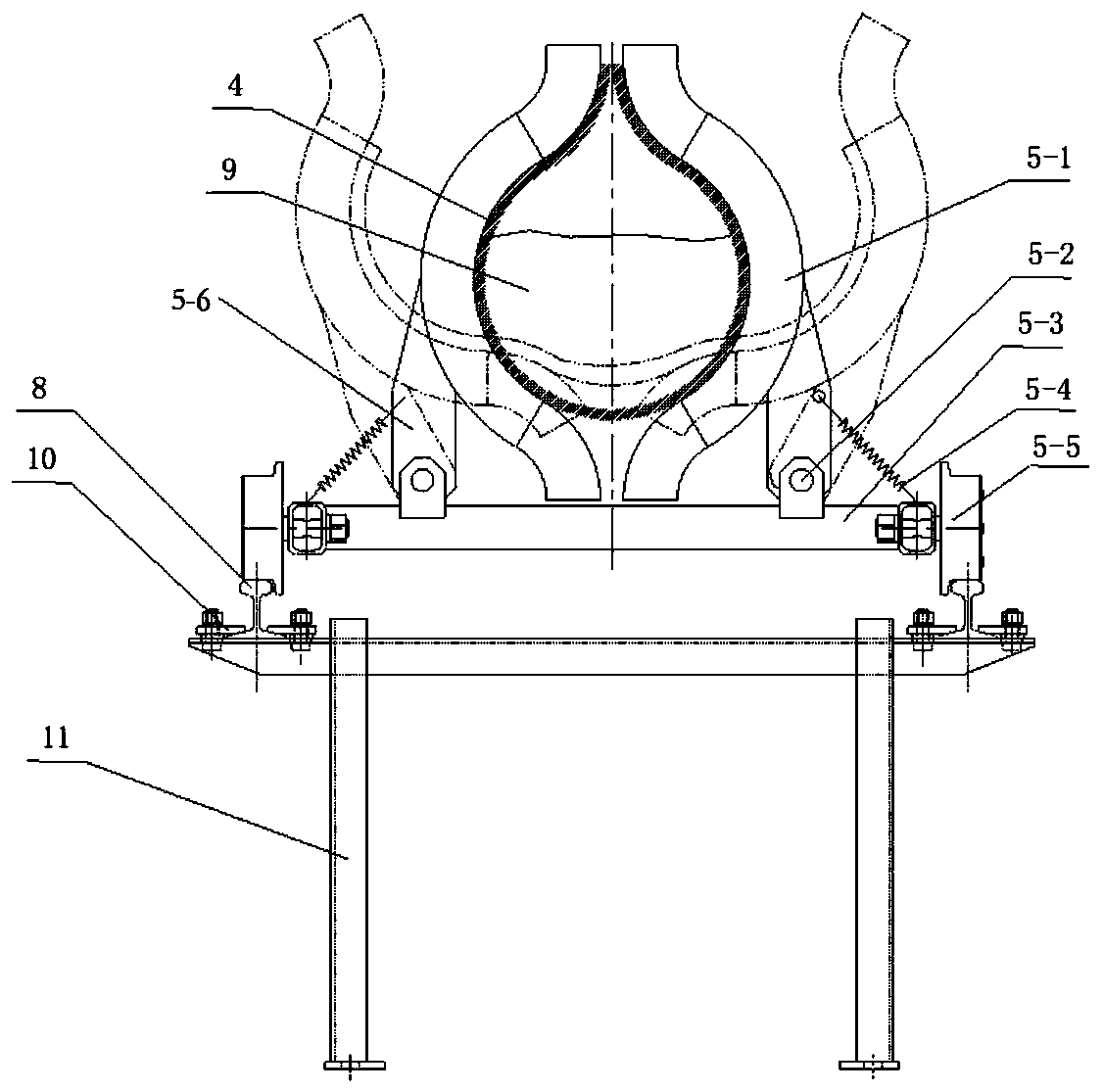

Rail belt-type conveyor with rotary wheel structures

InactiveCN105692068AAchieve structural optimizationStrong complementarityConveyorsHeadframeEngineering

The invention relates to a rail belt-type conveyor with rotary wheel structures. The rail belt-type conveyor comprises a support, a headstock, a tailstock, an upper guide rail, a lower guide rail, the rotary wheel structures, spiral steering mechanisms, towing trolleys, a tape, a steel wire rope, a driving roller, steering racks and vertical racks, wherein the tape is arranged on support roll groups on two ends of the support for rotation in a surrounding manner; the towing trolleys are separated from the tape or are in contact with the tape on the middle part of the support through the rotary wheel structures and the spiral steering mechanisms; the upper guide rail and the lower guide rail are both arranged on the support through pressing plates; the headstock is arranged on the head part of the support; the tailstock is arranged on the tail part of the support; and the steering racks and the vertical racks are arranged between the tailstock and the headstock. The rail belt-type conveyor has the advantages that the structure of the conveyor is optimized, and the use cost is lowered, so that complementary advantages are realized; the operation cost is greatly lowered; a part of ordinary support rolls are replaced by the towing trolleys, so that the cost and assembly cost are lowered; and revolutionary innovation is brought to bulk material transportation.

Owner:LIBO HEAVY MACHINE TECH

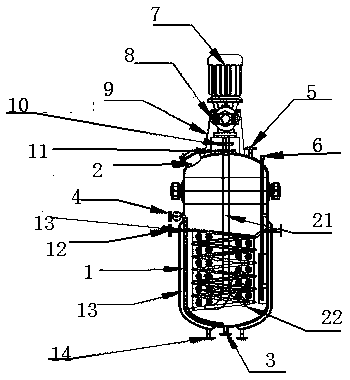

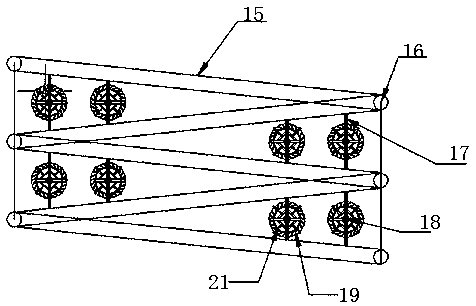

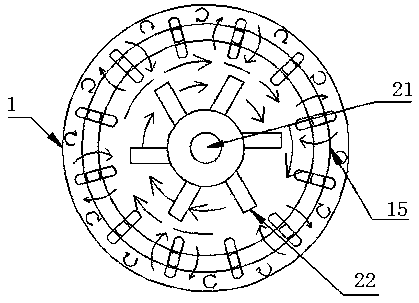

Efficient spiral coil reaction device

InactiveCN107638859AThe overall structure is ingeniously designedLow costChemical/physical/physico-chemical stationary reactorsSpiral coilPower component

The invention relates to an efficient spiral coil reaction device. The efficient spiral coil reaction device is characterized in that the efficient spiral coil reaction device comprises a tank component, a power component, a heat exchanger assembly and a stirring component, wherein the power component is installed above the tank component; part of the heat exchange assembly is installed on the outer wall of the tank component, and the other part of the heat exchange assembly is installed in a tank; the stirring component is installed in the tank component, and the top of the stirring componentis connected with the power component; the heat exchange assembly comprises a steam inlet, a clamp sleeve, a heating coil pipe and a condensate outlet; the steam outlet is formed in the upper end ofthe clamp sleeve; the clamp sleeve is installed at the two sides of the outer wall of the tank; the condensate outlet is formed in the bottom of the clamp sleeve; the heating coil pipe is installed inthe tank, the upper end of the heating coil pipe is connected with the steam inlet, and the lower end of the heating coil pipe is connected with the clamp sleeve.

Owner:盐城市大丰匀力机械制造厂

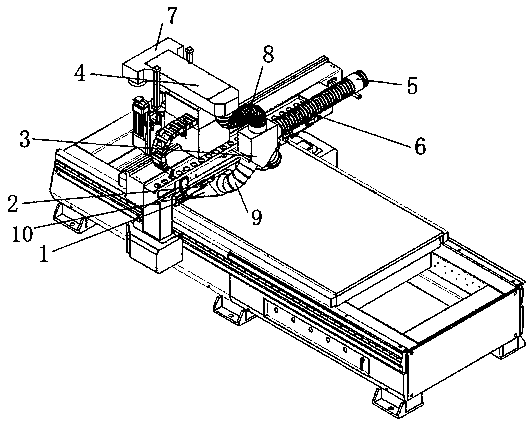

Dust suction system of woodworking engraving machine

PendingCN110154176AAchieve structural optimizationShorten the lengthDirt cleaningBark-zones/chip/dust/waste removalEngineeringWoodworking

The invention provides dust suction system of a woodworking engraving machine. The system involves a main shaft dust suction cover, a top suction head, a dust suction connector, a dust suction and material pushing cover and a dust suction pipeline; one end hole of the top suction head is connected with the main shaft dust suction cover, and the other end hole of the top suction head is connected with the dust suction connector; and the outlet of the dust suction and material pushing cover is connected with the dust suction connector, and the dust suction connector is connected with the dust suction pipeline. The top suction head is firstly arranged at the top of the woodworking engraving machine, the dust suction connector and the dust suction and material pushing cover are arranged on a cross beam of the woodworking engraving machine, dust and saw dust are sucked into the main shaft dust suction cover to be sent to the top suction head, then enters from the top suction head to the dust suction connector, the dust suction and material push cover moves along with the cross beam of the woodworking engraving machine, and wood can be pushed to advance while the dust is sucked. The dustsuction pipeline is connected with a dust collector to discharge the dust and the saw dust. According to the system, the functions of all parts are fully utilized, and the structure optimization of the dust suction system of the woodworking engraving machine is realized. In the working process, the saw dust and the dust enter from the main shaft dust suction cover and the dust suction and material pushing cover, are conveyed out by the dust suction pipeline, a dust suction hole is increased, and the length of the dust suction pipeline is shortened.

Owner:JINAN ZHONGKE CNC EQUIP CO LTD

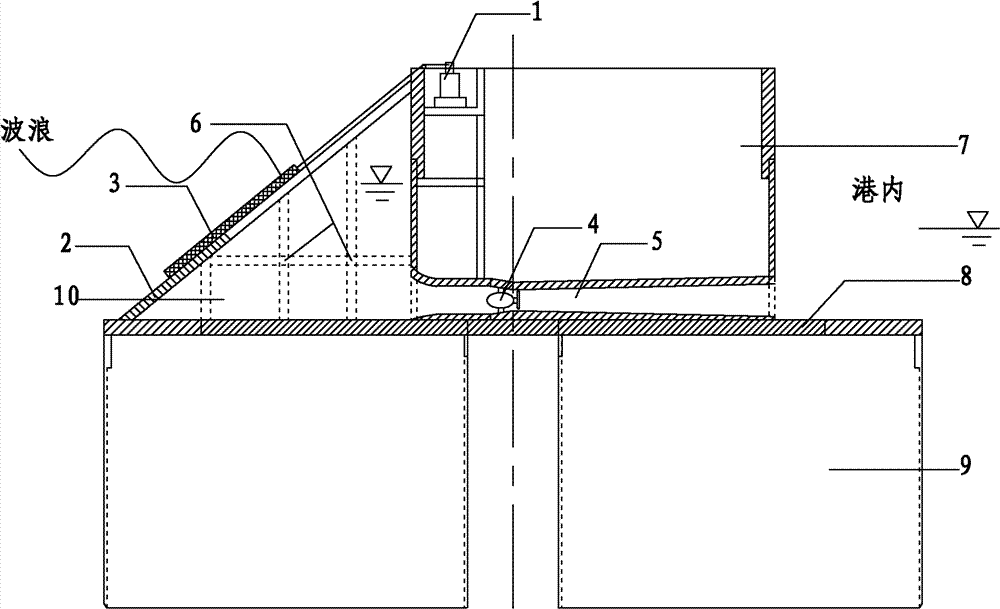

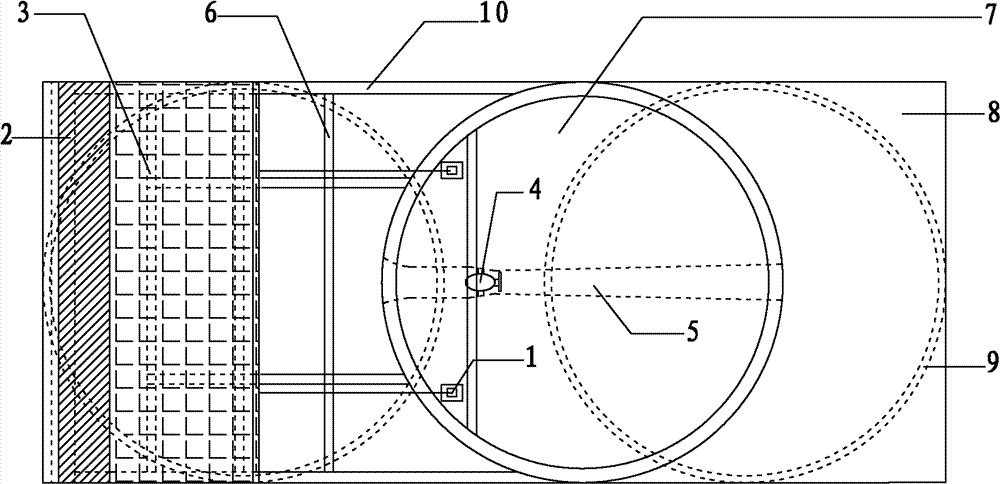

Breakwater capable of generating electricity by using waves

ActiveCN102155000BMeet stability requirementsAchieve structural optimizationBreakwatersQuaysElectricityWave power generation

The invention discloses a breakwater capable of generating electricity by using waves. The upstream side of the cylindrical breakwater is provided with a water accumulating structure; the water accumulating structure comprises two side walls fixedly connected with the cylindrical breakwater; the bottoms of the two side walls are fixedly connected with a reinforced concrete cover plate; the two side walls are provided with inclined upstream fixed front baffle plates; the bottoms of the fixed front baffle plates are fixedly connected with the reinforced concrete cover plate; the reinforced concrete cover plate, the two side walls, the cylindrical breakwater and the fixed front baffle plates form a water accumulating pond with a water accumulating structure; a support frame of the water accumulating structure is arranged in the water accumulating pond; the bottom of the cylindrical breakwater is provided with a drainage flow channel communicated with the water accumulating pond; the drainage flow channel is communicated with the cylindrical breakwater; and a hydraulic power generation unit is arranged in the drainage flow channel. The breakwater capable of generating electricity by using waves has a wave-preventing function, is provided with a wave power generation device, has structural stability and high energy conversion efficiency, and realizes structural optimization.

Owner:TIANJIN UNIV

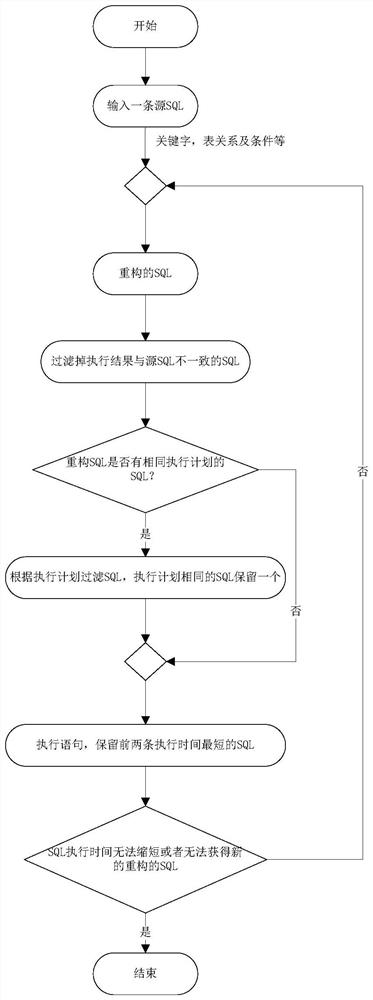

Automatic method and system for realizing database SQL optimization execution based on artificial intelligence

PendingCN113505141ASolve wasteSolve the problem that the expected optimization efficiency cannot be achievedNeural architecturesSpecial data processing applicationsTable (database)Industrial engineering

The invention discloses an automatic method and system for realizing database SQL optimization execution based on artificial intelligence, belongs to the technical field of operation and maintenance monitoring, and aims to solve the technical problems that an existing technical method in the prior art cannot achieve expected optimization efficiency and the SQL execution efficiency after optimization of the existing technical method does not achieve a better effect, meanwhile, causes a waste of resources is caused. The method comprises the steps of optimizing a database table structure and an executed SQL statement according to different database types and rules through artificial intelligence; the method specifically comprises the following steps: S1, completing SQL statement optimization training through an artificial intelligence machine learning algorithm to obtain SQL statements with perfect performance; S2, recording the optimized SQL statements, feeding back a report regularly, comparing a source SQL statement and a final optimized SQL statement, and giving an optimization analysis result at the same time.

Owner:上海沄熹科技有限公司

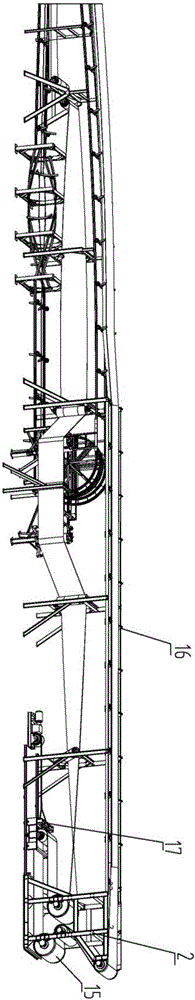

Track Belt Conveyor

ActiveCN105416993BAchieve structural optimizationStrong complementarityConveyorsHeadframeClosed loop

The invention relates to a rail type belt conveyor. The rail type belt conveyor comprises a support, a machine head frame, a machine tail frame, an upper guide rail, a lower guide rail, a towing trolley, a rubber belt, a steel wire rope, closed-loop systems, a driving roller, an elevating supporting roller set, a redirection frame and a triangular frame. The elevating supporting roller set is mounted at the position, close to the machine head frame, of the support, the redirection frame is mounted on the machine tail frame, a redirection drum is arranged on the machine head frame, and a tensioning vehicle is arranged at the position, close to one side of the redirection drum, of the support; and the triangular frame is arranged at the position, between the two closed-loop systems, of the support, and the rubber belt is wound around the elevating supporting roller set, the redirection drum, the tensioning vehicle, a supporting roller on the redirection frame and a supporting roller on the triangular frame. The rail type belt conveyor has the beneficial effects that a traditional rubber belt machine structure is removed, a supporting belt trolley is used for replacing a part of a common supporting roller, the cost and the mounting cost are reduced, and revolutionary innovation is brought to bulk conveying.

Owner:LIBO HEAVY MACHINE TECH

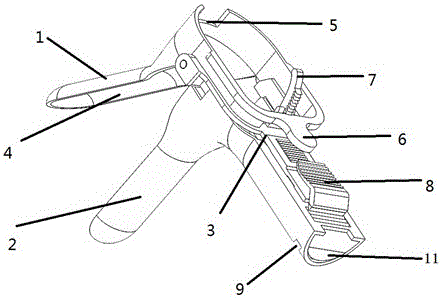

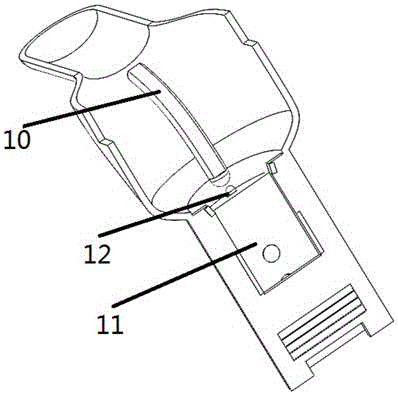

Disposable aseptic vagina illuminating system

InactiveCN105796045AAchieve structural optimizationIncrease illuminationSurgeryEndoscopesButton batteryEngineering

The invention relates to a disposable aseptic vagina illuminating system. The disposable aseptic vagina illuminating system comprises an upper support member, a lower support member, a connecting piece and a light source part, wherein the upper support member comprises a discharge flue, a clamping groove and an expansion key; the lower support member comprises a light guide column and a shifting switch groove; the connecting piece comprises a positioning groove and an anti-sliding part; the light source part comprises a dual-color LED (Light-Emitting Diode) cold light source, a PCB (Printed Circuit Board), a button cell and a shifting switch; the light source part is arranged on an operation part; during use, the light source is positioned outside the body of a patient, light emitted from the light source is introduced into a cavity through the arc-shaped light guide column, and the trapezoidal light emitting end of the arc-shaped light guide column can gather light, so that high illuminance and a good illumination effect are achieved. The disposable aseptic vagina illuminating system has the beneficial effects that a dual-color LED is adopted to realize optimization of a light source structure, and a white and blue dual-color light field illuminates an examination area intensively, so that the high illuminance and the good illumination effect are achieved, a clear visual field is provided for a doctor during diagnosis, and an examination result is more accurate.

Owner:JIANGXI HUAQINGBOEN BIOTECH CO LTD

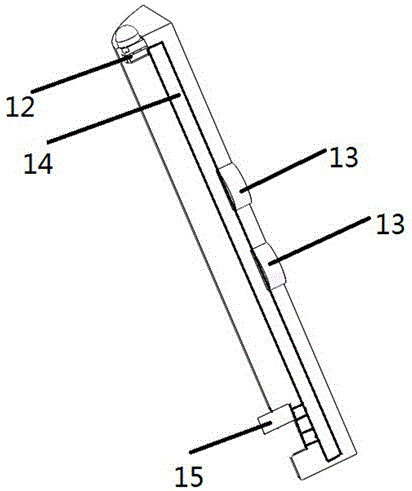

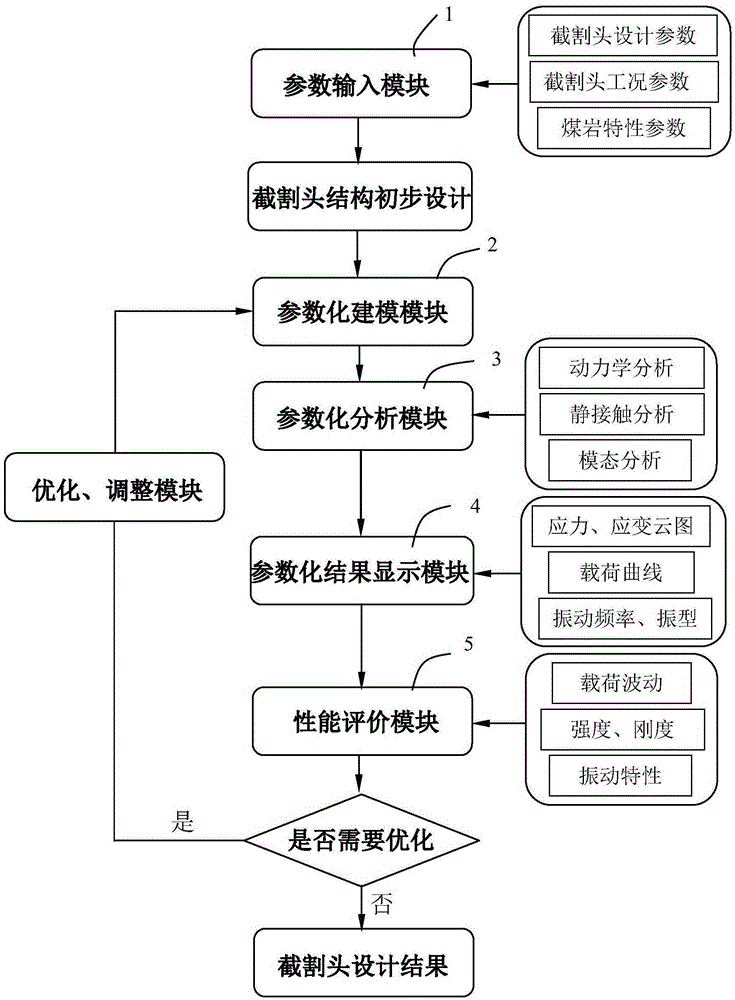

Computer aided design method and cad system for cutting head of cantilever roadheader

InactiveCN103324800BAchieve structural optimizationImprove the level ofSpecial data processing applicationsComputer Aided DesignElement analysis

The invention discloses a computer-aided design method for a cantilever-type heading machine cutting head and a CAD (computer-aided design) system of the cantilever-type heading machine. Based on Visual C++ 2012, ANSYS14.5 is subjected to secondary development by the computer-aided design method which comprises following modules: a parameter input module, a parametric modeling module, a parametric analysis module, a parametric result displaying module, a performance evaluation module and an optimization and adjustment module; the computer-aided design method includes that a designer enters cutting head design parameters, cutting head condition parameters and coal and rock characteristic parameters, a system can automatically complete modeling and finite element analysis processes, and feedback analysis result files for the designer to perform optimization and adjustment of design parameters. Design of the cantilever-type cutting head under different coal and rock geological conditions and cutting conditions can be realized; performance of the cutting head can be predicted by simulating a cutting process by the aid of the finite element analysis, so that structure optimization of the cutting head can be realized according to analysis results, and level of cutting head design is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

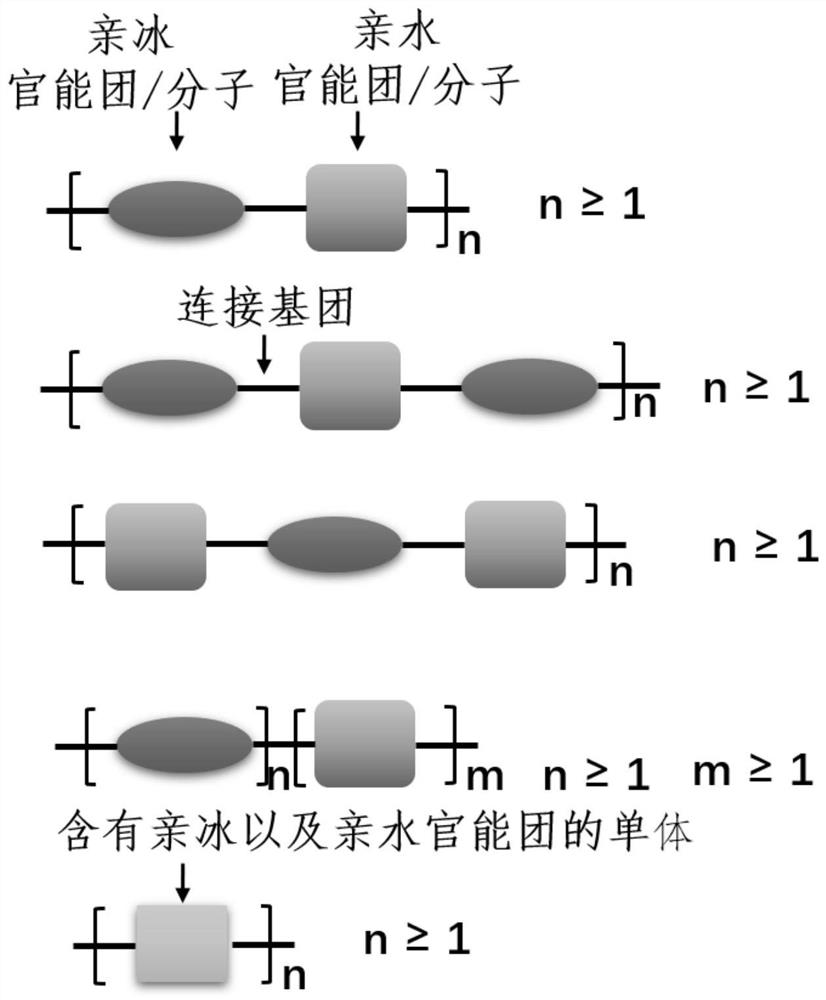

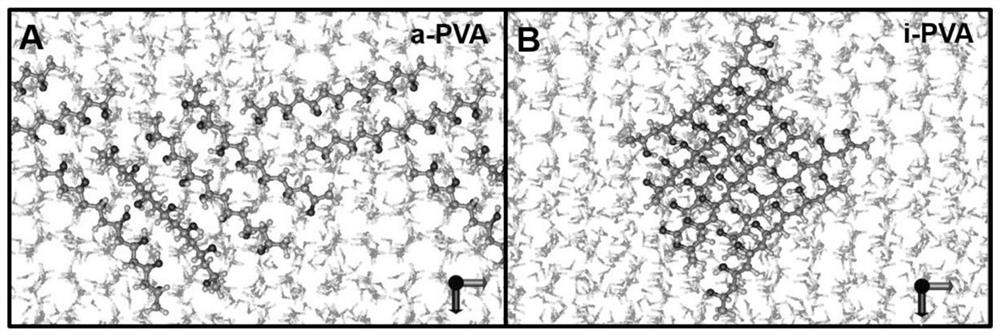

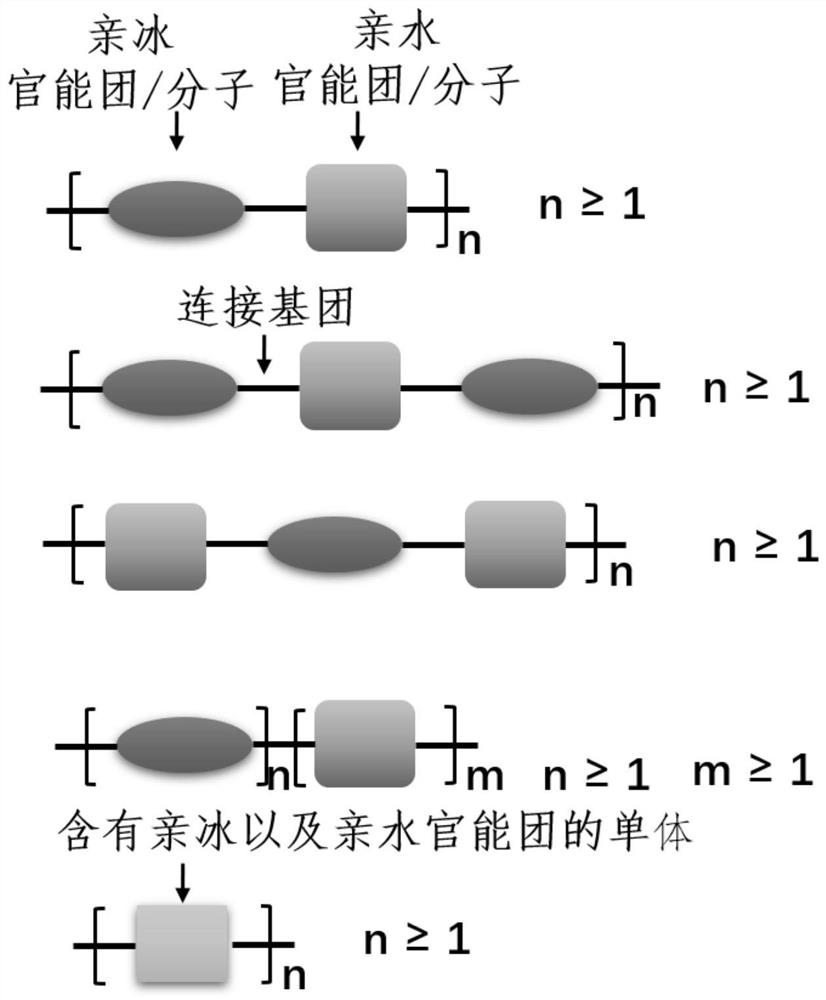

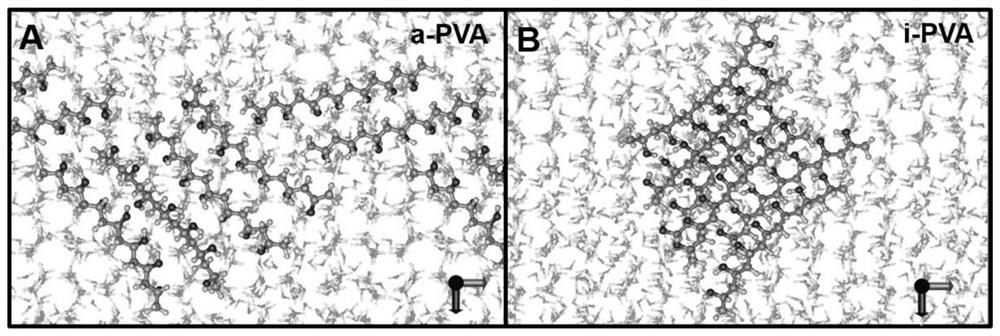

Molecular design method of ice control material

ActiveCN111790327AHigh affinityImprove adsorption capacityChemical/physical/physico-chemical processesPhysicsEngineering

The invention relates to a molecular design method of an ice control material. The method comprises the following steps: constructing a compound molecular structure library, wherein the compound molecules containing a hydrophilic group and an ice-affinity group; evaluating the spreading performance of each compound molecule on an ice-water interface by adopting molecular dynamics simulation (MD simulation); and screening out compound molecules with required ice affinity and water affinity. A mechanisms of the ice affinity and water affinity of an ice control material is proposed for the firsttime; MD simulation is introduced into molecular structure design of an ice control material; ice affinity and water affinity of the designed ice control material are simulated and evaluated by molecular dynamics, the ice control performance of the ice control material can be predicted, and structural optimization can be realized. An ice control mechanism and an MD simulation mode are combined, sothat the limitation that an existing ice control material can only be subjected to performance analysis and material screening through an experimental trial-and-error method in the research and development process of the existing ice control material is well solved, and a new thought of molecular structure design is provided.

Owner:北京玳衲芈珂生物科技有限公司

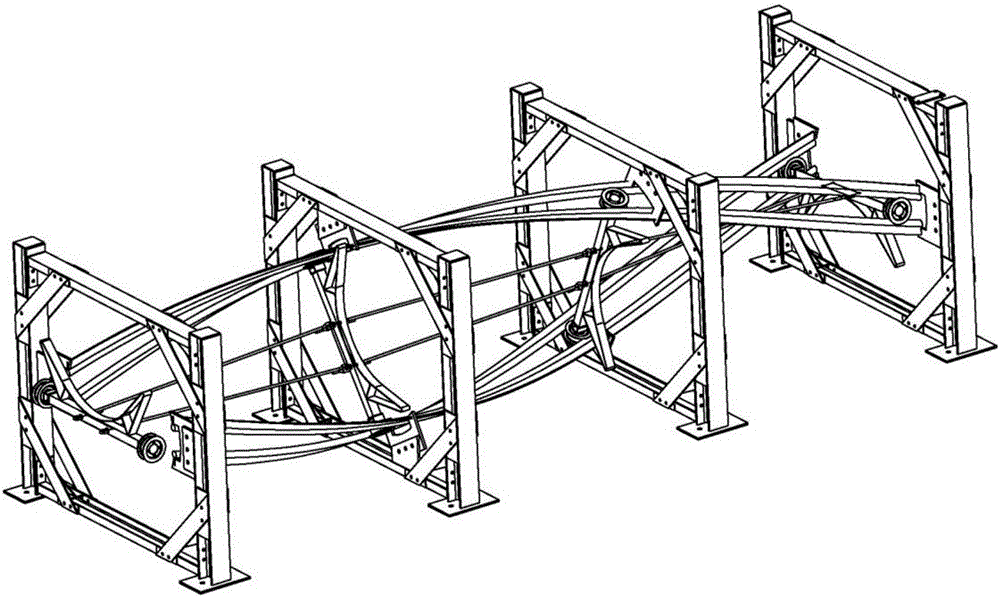

Novel low-resistance circular tube belt conveyor

ActiveCN109941689AImprove reliabilityExtended service lifeMechanical conveyorsClosed loopEngineering

The invention relates to a novel low-resistance circular tube belt conveyor which comprises a machine frame, a driving roller, redirecting roller groups, a carrier roller group, a conveying belt, a plurality of moving trolleys, a steel wire rope and a tail roller, wherein the driving roller, the redirecting roller groups, the carrier roller group, the conveying belt, the moving trolleys, the steelwire rope and the tail roller are installed on the machine frame; the driving roller and the tail roller are respectively positioned at two ends of the machine frame; the two redirecting roller groups are arranged at the end, close to the driving roller, of the machine frame and the end, close to the tail roller, of the machine frame respectively; the conveying belt surrounds the driving roller,the redirecting roller groups and the tail roller to be connected end to end to form a closed loop, and the conveying belt is further supported by the carrier roller group; and the plurality of movingtrolleys are arranged on the steel wire rope at equal distances. The novel low-resistance circular tube belt conveyor has the advantages that the reliability of the conveyor is improved, and the service life of the conveyor is prolonged. The moving trolleys and the conveying belt are combined to operate, so that the structural optimization of the conveyor is achieved, the using cost is reduced, and the complementation of advantages is achieved.

Owner:LIBO HEAVY MACHINE TECH

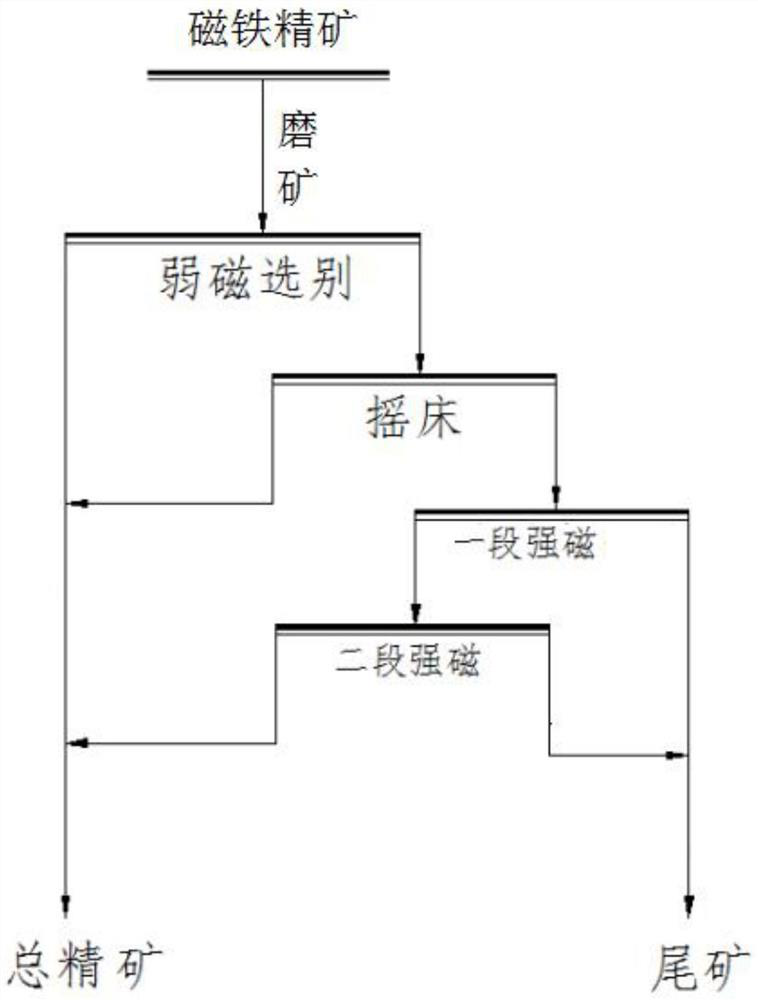

Quality-improving and silicon-reducing recleaning process for low-grade iron ore concentrate

PendingCN114289175AGood sorting indexIncrease productivityMagnetic separationWet separationOre concentrateMineralogy

The invention discloses a quality-improving and silicon-reducing recleaning process for low-grade iron ore concentrate. The process comprises the following specific steps that the iron ore concentrate is ground into ore powder or ore pulp with-325 meshes accounting for 80-82%; performing low-intensity magnetic separation on the mineral powder or the ore pulp to obtain first-section low-intensity magnetic concentrate and first-section low-intensity magnetic tailings; the first-section weak magnetic tailings are subjected to bed grading to obtain table concentrate and table tailings; the table tailings are subjected to first-stage strong magnetic separation to obtain first-stage strong magnetic concentrate and first-stage strong magnetic tailings, and the first-stage strong magnetic concentrate is subjected to second-stage strong magnetic separation to obtain second-stage strong magnetic concentrate and second-stage strong magnetic tailings. By the adoption of the process, low-grade concentrate of a concentration plant has selectability, the yield of pipeline concentrate can be further greatly increased, product structure optimization is achieved, the resource comprehensive utilization rate of complex refractory ore is further increased, and economic benefits are increased.

Owner:YUXI DAHONGSHAN MINING

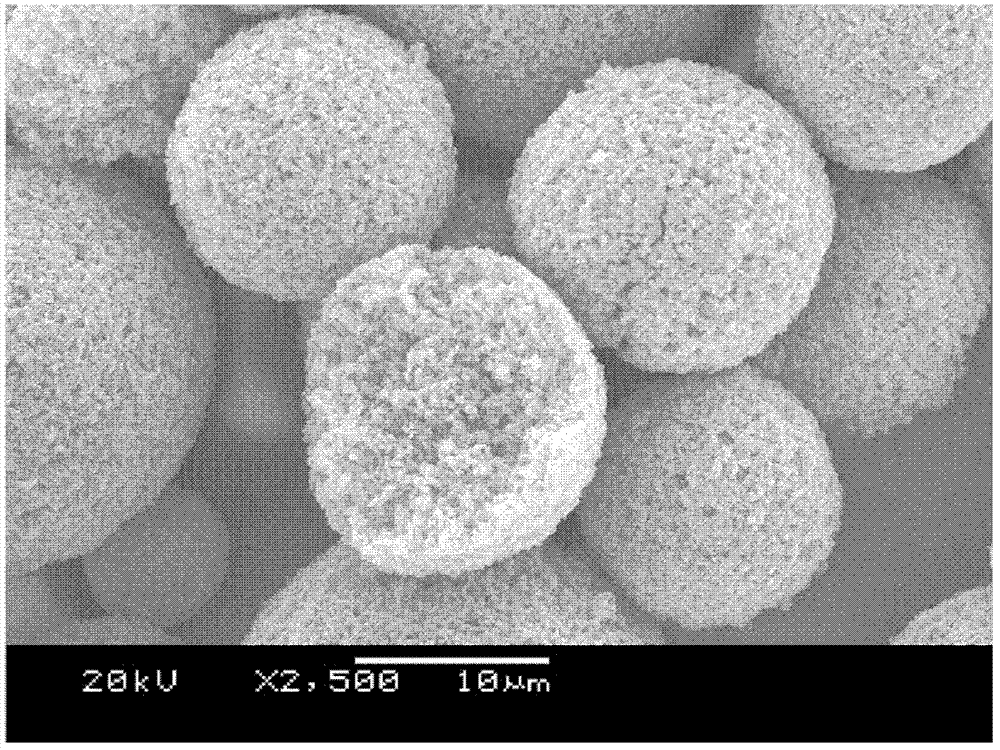

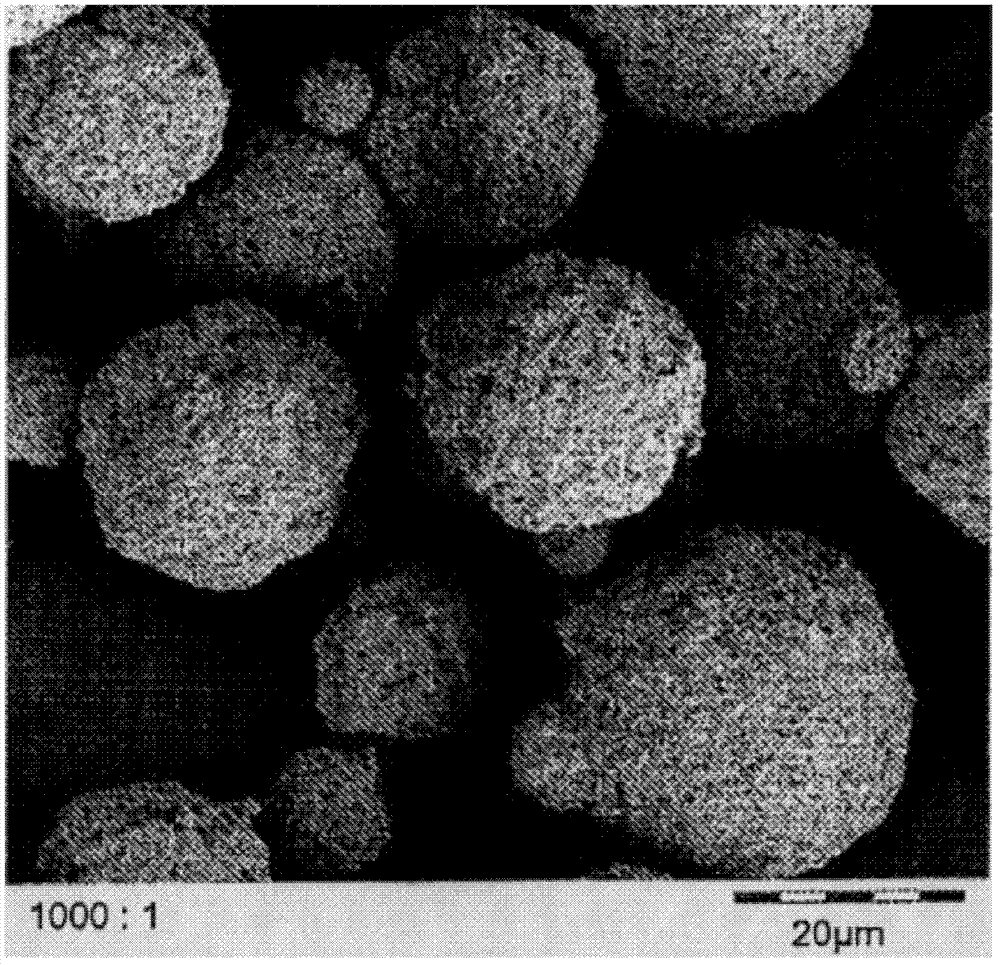

LiFePO4 (lithium iron phosphate) positive electrode material with specific morphology and structure and lithium secondary battery

ActiveCN102509790BEasy to makeImprove high current charge and discharge performanceMaterial nanotechnologyCell electrodesCarbon layerLithium iron phosphate

The present invention relates to a lithium iron phosphate anode material with specific morphology and structure and a secondary battery using the same. The carbon-coated lithium iron phosphate anode material with specific morphology and structure of the present invention is characterized in that: the material contains spherical or spherical-like secondary particles prepared from sheet-shaped primary particles through conglomeration. A space exists among the primary particles; the average particle size of the secondary particles is 12 microns to 28 microns; the primary particles are sheet-shaped carbon-coated lithium iron phosphate particles; and the average particle size and average thickness of the primary particles in the two-dimensional plane are respectively 0.2 microns to 1 micron and 60 nanometers to 90 nanometers. The carbon layer evenly coated on the surface of the primary particles of the lithium iron phosphate anode material with specific morphology and structure of the present invention can ensure the conductive capability of the active material, maximally utilize the capacity of the active material, and improve large-current charge-discharge property of the material. In addition, the form of secondary particles performs excellently in aspects such as the active substance utilization rate, the large-current charge-discharge capability, and the capacity retention ratio of the electrode material with circulation.

Owner:天齐锂业(江苏)有限公司 +2

All-ceramic knuckle bearing for high temperature, easy corrosion and easy oxidation working environment

InactiveCN110173506AAvoid ditching lubricated structuresHigh strengthShaftsBearing componentsWorking environmentAll ceramic

The invention provides an all-ceramic knuckle bearing for a high temperature, easy corrosion and easy oxidation environment. The all-ceramic knuckle bearing mainly comprises an inner ring and an outerring, the inner ring and the outer ring are made of zirconia, alumina or silicon carbide ceramic materials, and are assembled into a whole through a corresponding assembly technology; the inner sideof the outer ring is provided with an inner arc surface, the inner ring is provided with an outer arc surface, the width dimension of the inner ring is larger than 3-5 mm of the width dimension of theouter ring, and the movable swing angle of the inner ring is 0-21 degrees. According to the all-ceramic knuckle bearing, the knuckle bearing is manufactured by adopting the ceramic material, the ceramic material has the characteristics of high temperature resistance, corrosion resistance, high hardness, no magnetism permeability, wear resistance and self-lubricating property, the structure of theknuckle bearing can be optimized, a lubricating groove is not need to form, the strength and the application range of the knuckle bearing are improved, and a foundation is laid for application of complex environments such as high temperature and easy corrosion of the knuckle bearing.

Owner:SHENYANG JIANZHU UNIVERSITY

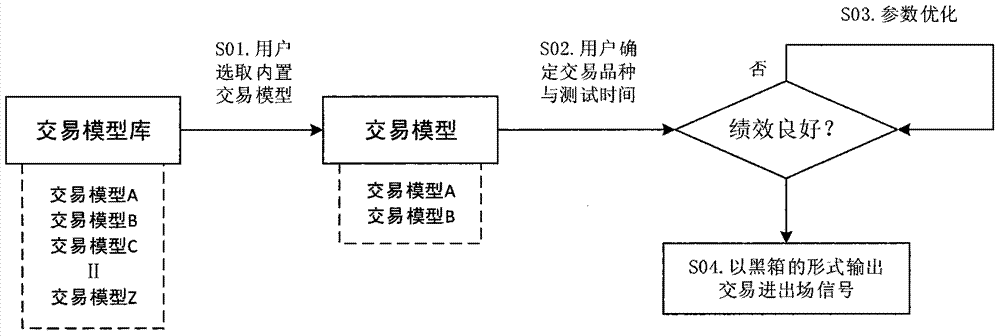

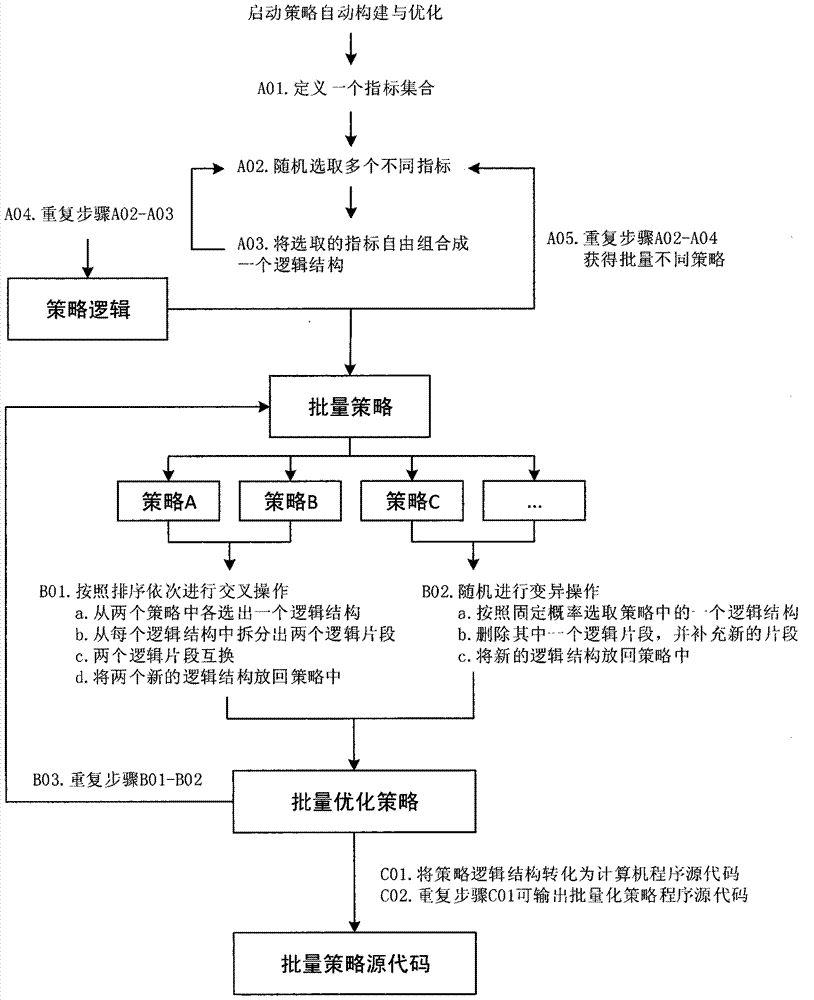

An automatic construction and optimization method for programmed trading strategies

ActiveCN104346171BEasy to filterAchieve structural optimizationFinanceSpecific program execution arrangementsAnalysis dataOpen source

The invention discloses a method for automatically constructing and optimizing a programmed trading strategy, which includes the following steps: A. automatically constructing the logic structure of the strategy in batches; B. automatically optimizing the logic structure of the strategy, and the logic structure of the strategy is in the optimization process Change; C. Output the logical structure of the policy as a policy instance. Using the present invention, users can quickly obtain a specified number of strategy source codes without analyzing data and writing codes, and the transaction logic of each strategy is different; on the one hand, the present invention reduces the difficulty and cost of programmatic transaction strategy development, At the same time, the source code of the strategy can be opened to maintain the flexibility of strategy development and avoid the unreliability of black-box signals.

Owner:石玉峰

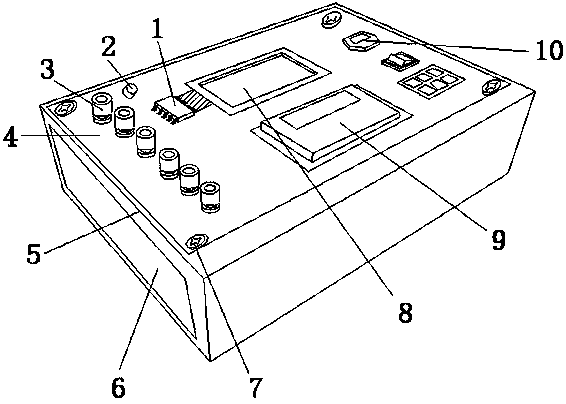

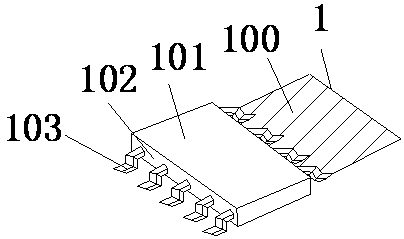

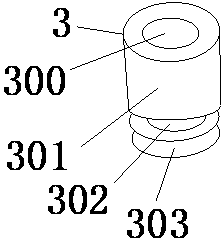

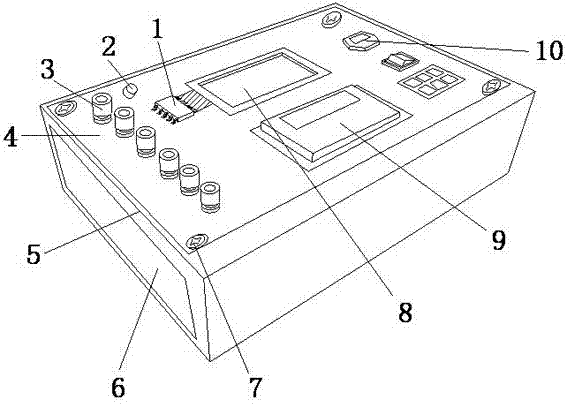

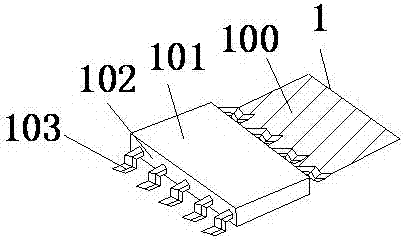

A fully automatic assembly and testing machine for electronic transformers

InactiveCN107068378BAchieve structural optimizationAnalytics integration is fastElectrical testingInductances/transformers/magnets manufactureData displayMicrocontroller

The invention discloses a full-automatic assembly tester for an electronic transformer. The full-automatic assembly tester comprises an intelligent single chip microcomputer, an adjustment knob, more than two binding post pipes, an integrated circuit board, an aluminum alloy frame, an anti-collision side plate, a fixed bolt, a data display panel, a program memory board and a power supply plug-connection slot, the more than two binding post pipes are arranged side by side in a straight line and vertically fixed on he integrated circuit board, the binding post pipes are electrically connected with the integrated circuit board, the adjustment knob is arranged on the integrated circuit board, the adjustment knob is in clearance fit with the integrated circuit board, the data display panel is embedded into the integrated circuit board, and the program memory board is embedded into the integrated circuit board. The intelligent single chip microcomputer is provided with a transmission silicon crystal plate, a single chip microcomputer mainboard, a welding side plate and a conveying pin; therefore, structure optimization of the full-automatic assembly tester of the electronic transformer is achieved, the tester is intelligently matched with operation of the integrated single chip microcomputer program, the tester is automatic and efficient, and test data is rapidly analyzed and integrated and extremely high in accuracy.

Owner:CHINA THREE GORGES UNIV

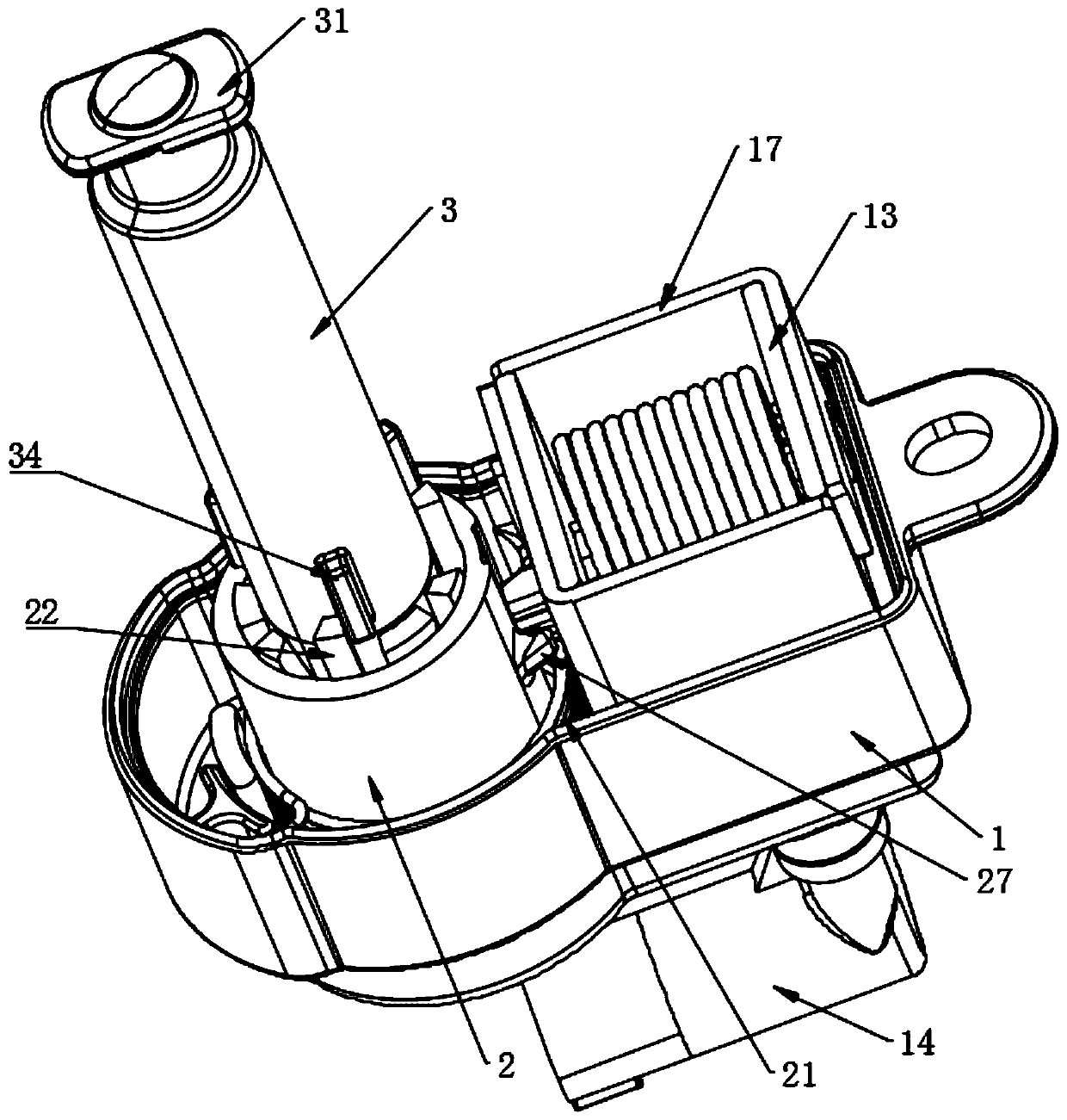

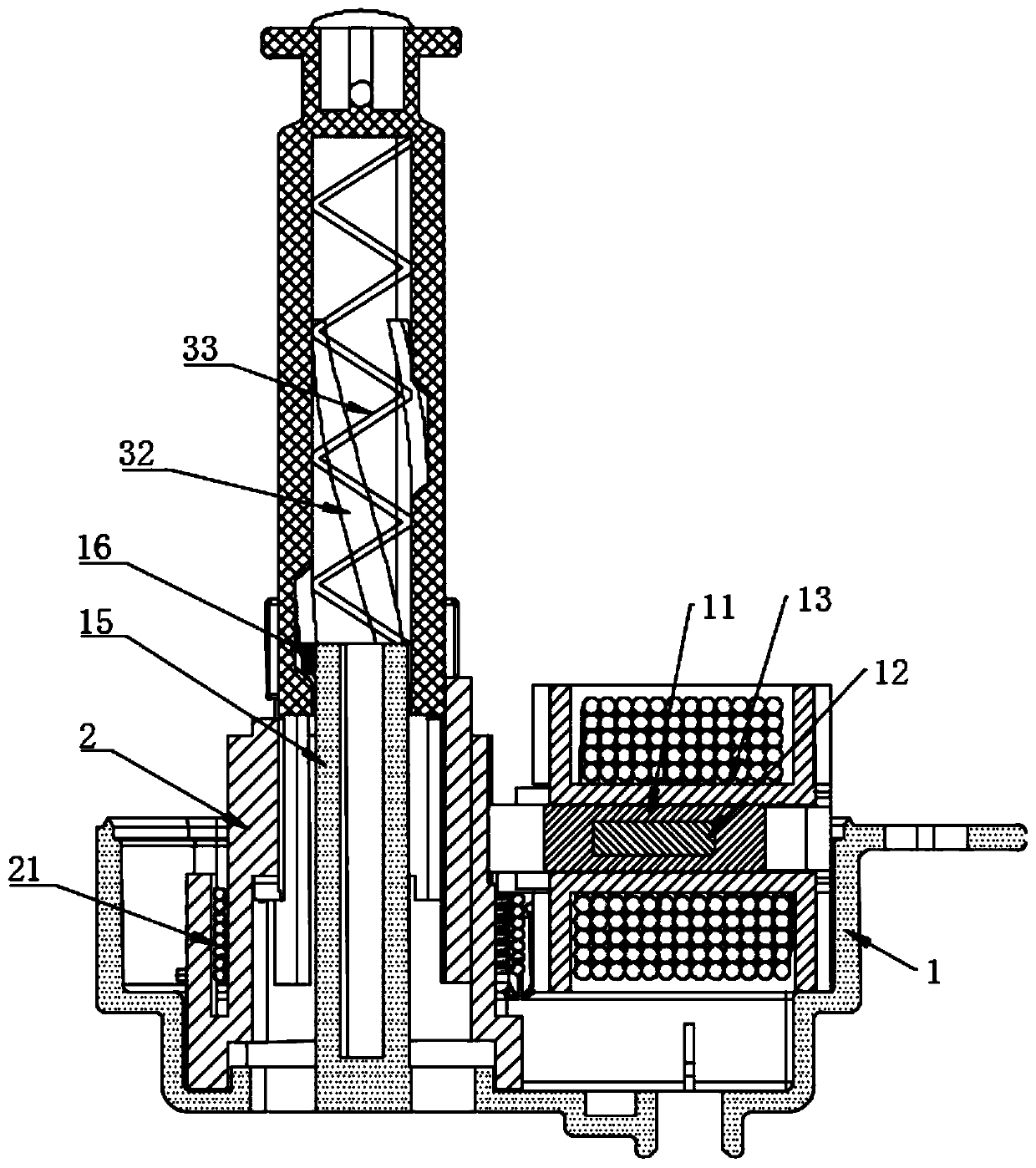

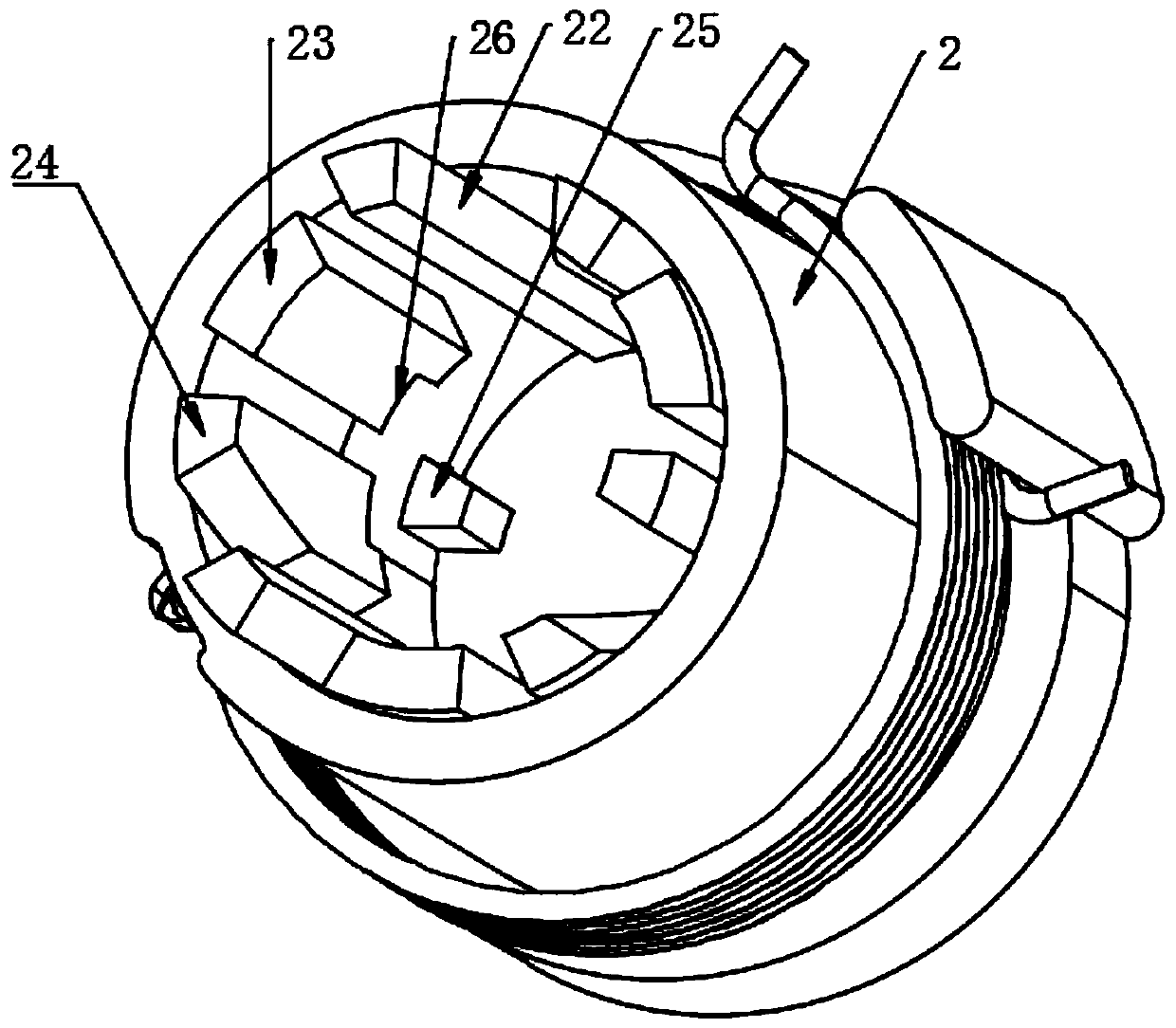

Novel locking device

PendingCN111021851AReduce manufacturing costAchieve structural optimizationElectrical locking actuatorsStructural engineeringMechanical engineering

Owner:宁波岚骐智能科技有限公司

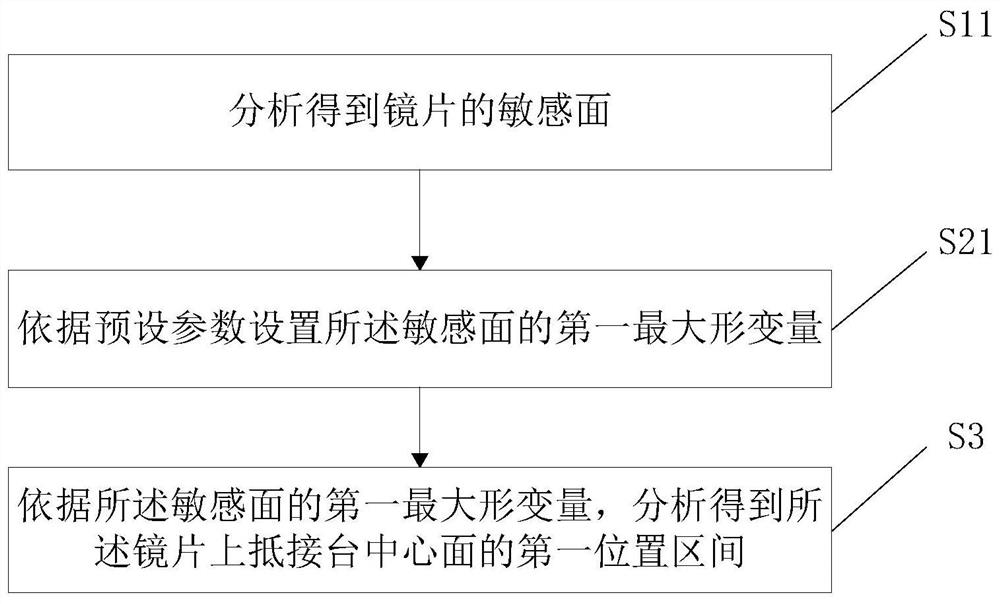

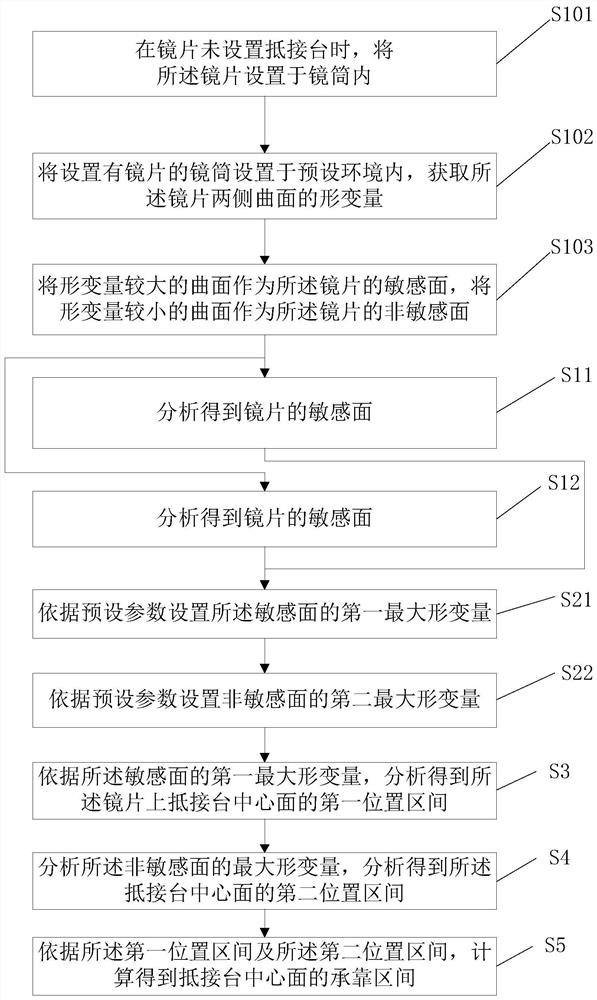

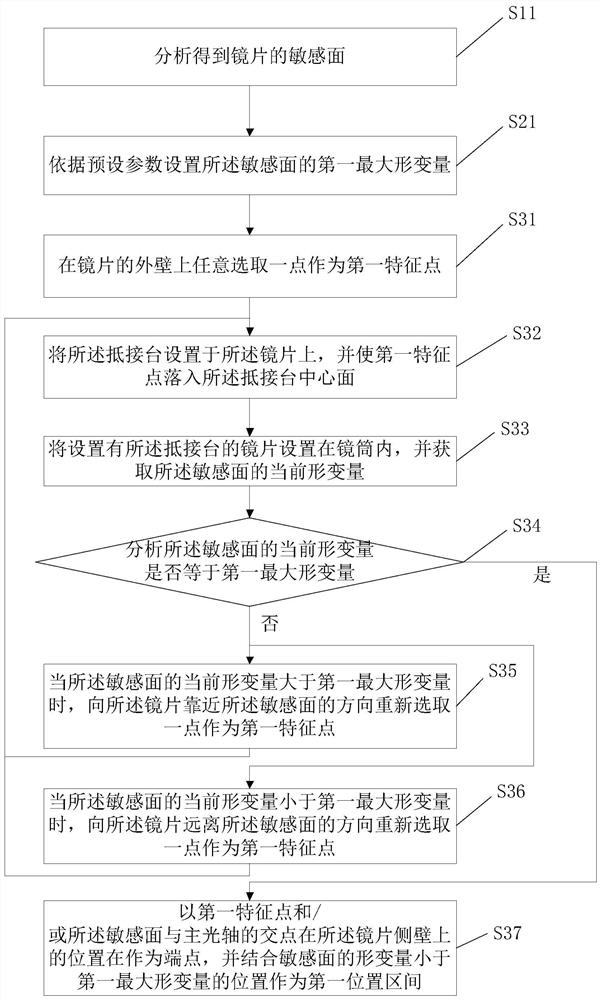

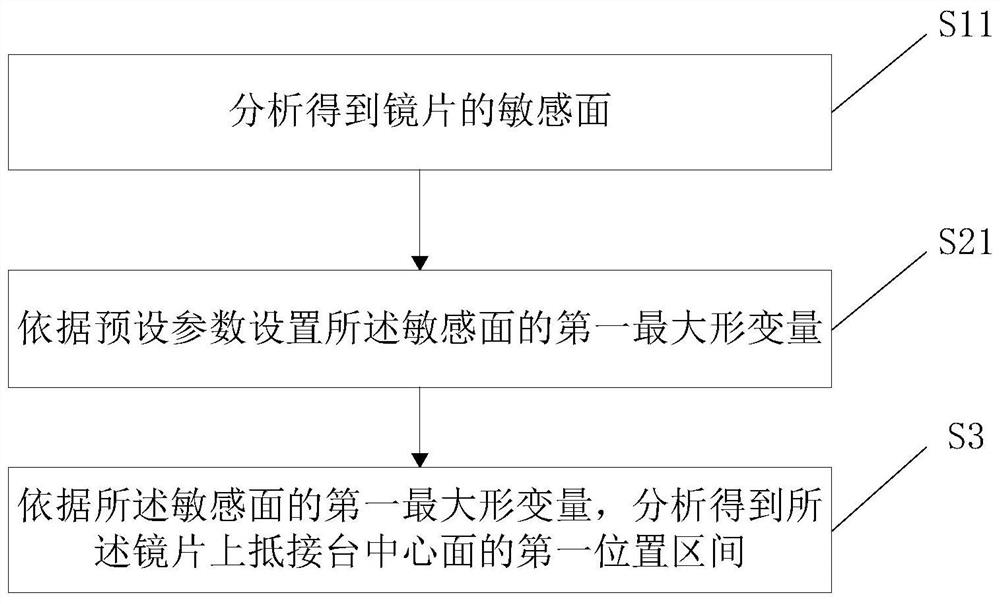

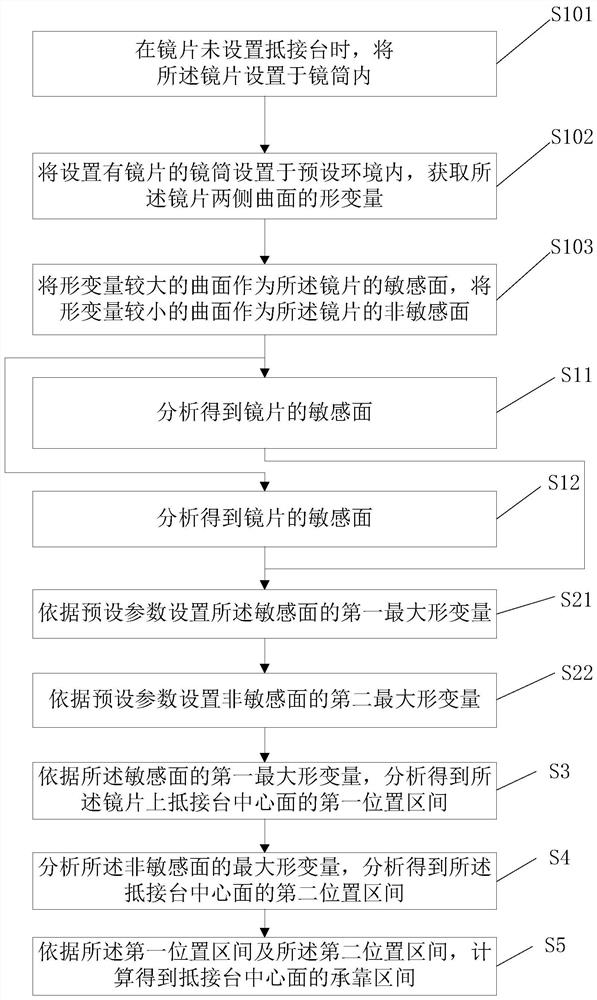

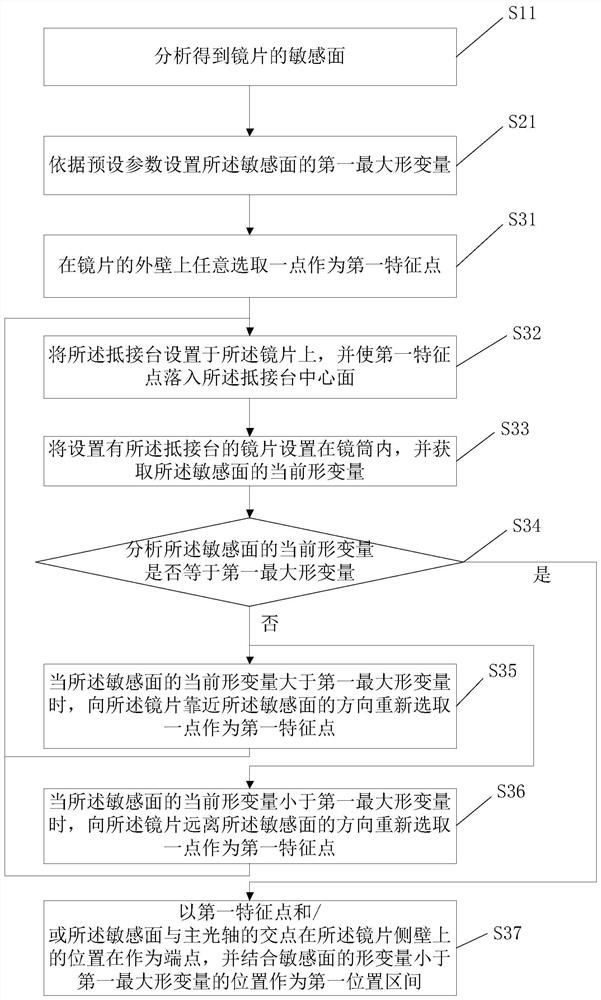

Lens design method

The invention relates to the field of optical devices, in particular to a lens design method which comprises the following steps: S11, analyzing to obtain a sensitive surface of a lens; s21, setting a first maximum deformation quantity of the sensitive surface according to a preset parameter; and S3, analyzing to obtain a first position interval of the central surface of the abutting table on the lens according to the first maximum deformation quantity of the sensitive surface. Through the setting of the steps, the pressure in the radial direction of the lens is reduced, then the possibility of deformation is reduced, the possibility that the lens is difficult to image is reduced, and the imaging quality of the lens is improved.

Owner:JIAXING ZHONGRUN OPTICAL TECH

A Molecular Design Method for Ice Control Materials

ActiveCN111790327BHigh affinityImprove adsorption capacityDesign optimisation/simulationChemical/physical/physico-chemical processesThermodynamicsIce water

The invention relates to a molecular design method for ice-controlling materials, comprising: constructing a molecular structure library of compounds, the compound molecules containing hydrophilic groups and ice-loving groups; using molecular dynamics simulation (MD simulation) to evaluate the stability of each compound molecule on ice Spreading performance of water two-phase interface; screening out compound molecules with desired ice affinity and water affinity. The present invention proposes the mechanism of the ice affinity and hydrophilicity of the ice control material for the first time, introduces MD simulation into the molecular structure design of the ice control material, and evaluates the ice affinity and water affinity of the designed ice control material through molecular dynamics simulation. Affinity, to predict the ice control performance of ice control materials, and to achieve structural optimization. By combining the ice control mechanism with MD simulation, the present invention solves the limitation that the current research and development of ice control materials can only use the "trial and error method" to analyze the performance of existing materials and screen materials, and provides A new idea of molecular structure design.

Owner:北京玳衲芈珂生物科技有限公司

Full-automatic assembly tester for electronic transformer

InactiveCN107068378AAchieve structural optimizationAnalytics integration is fastElectrical testingInductances/transformers/magnets manufactureData displayMicrocontroller

The invention discloses a full-automatic assembly tester for an electronic transformer. The full-automatic assembly tester comprises an intelligent single chip microcomputer, an adjustment knob, more than two binding post pipes, an integrated circuit board, an aluminum alloy frame, an anti-collision side plate, a fixed bolt, a data display panel, a program memory board and a power supply plug-connection slot, the more than two binding post pipes are arranged side by side in a straight line and vertically fixed on he integrated circuit board, the binding post pipes are electrically connected with the integrated circuit board, the adjustment knob is arranged on the integrated circuit board, the adjustment knob is in clearance fit with the integrated circuit board, the data display panel is embedded into the integrated circuit board, and the program memory board is embedded into the integrated circuit board. The intelligent single chip microcomputer is provided with a transmission silicon crystal plate, a single chip microcomputer mainboard, a welding side plate and a conveying pin; therefore, structure optimization of the full-automatic assembly tester of the electronic transformer is achieved, the tester is intelligently matched with operation of the integrated single chip microcomputer program, the tester is automatic and efficient, and test data is rapidly analyzed and integrated and extremely high in accuracy.

Owner:CHINA THREE GORGES UNIV

Cranes and their jibs

Owner:TAICANG LIBIAO INTELLIGENT TECH CO LTD

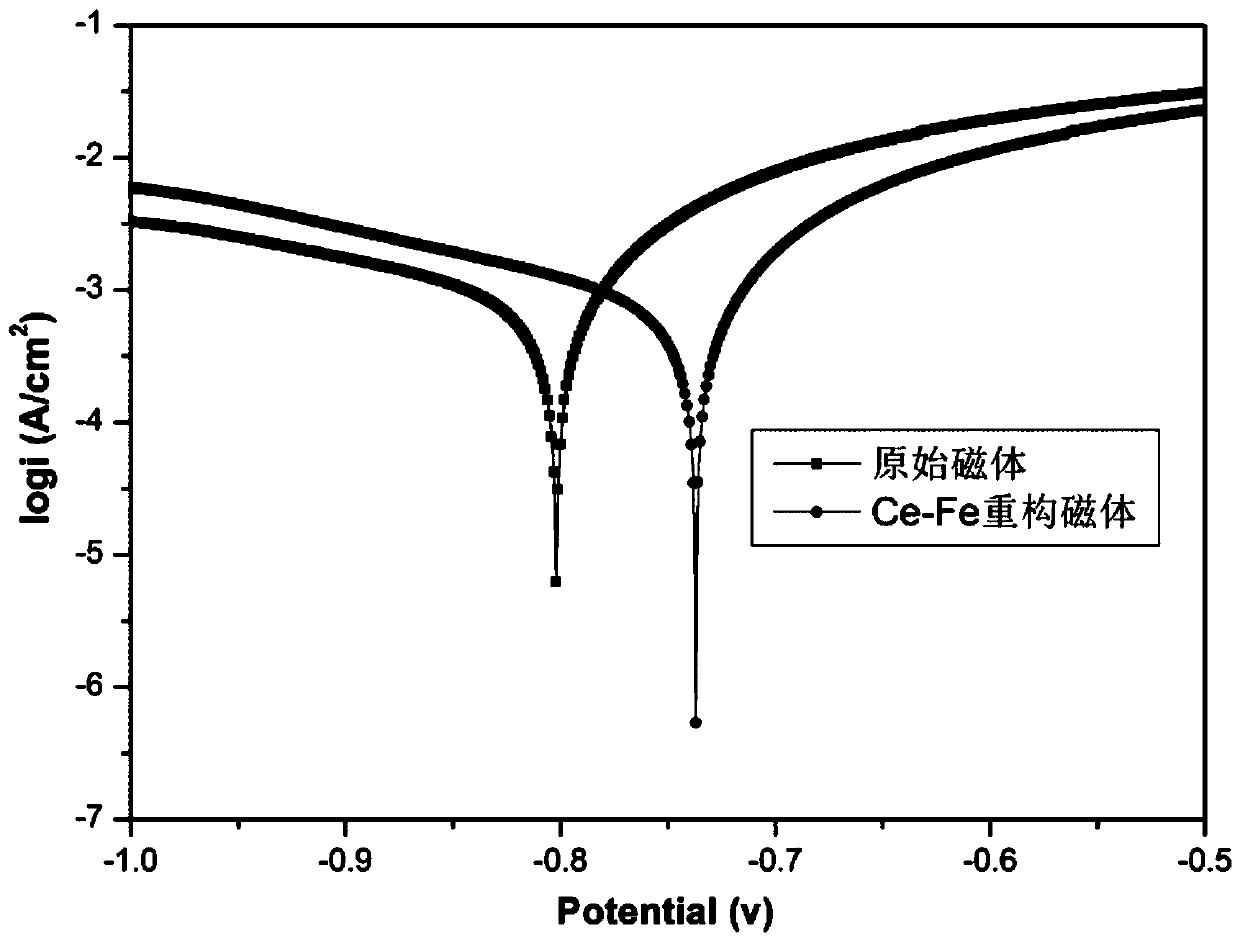

A high-corrosion-rich high-abundance rare earth permanent magnet and its preparation method

ActiveCN109859920BIncrease the proportionIncrease useInductances/transformers/magnets manufactureMagnetic materialsSintered magnetsAlloy

The invention belongs to the technical field of permanent magnet materials, in particular to a high-corrosion-rich and high-abundance rare earth permanent magnet and a preparation method thereof. A high-corrosion-rich and high-abundance rare-earth permanent magnet includes a ferromagnetic phase and a grain boundary-rich rare-earth phase, wherein the ferromagnetic phase is an MM-Fe-B phase, and the grain-boundary rare-earth-rich phase is an MM-Fe phase. A kind of method for preparing above-mentioned permanent magnet, described method prepares MM-Fe-B main phase alloy and MM-Fe auxiliary alloy respectively by double-alloy process, respectively smelting, pulverizing by crushing; The prepared MM-Fe auxiliary alloy The alloy powder is added to the main alloy in a proportion of 1%-5% by mass and mixed evenly; orientation pressing, sintering, and heat treatment are performed to obtain a final sintered magnet. The introduction of MM-Fe at the grain boundary can not only optimize the distribution of the rare earth-rich phase at the grain boundary, partially replace the original erodible grain boundary phase, and improve the intrinsic corrosion resistance of the MM-Fe-B magnet, but also this method further improves the low-cost The proportion of rare earth La / Ce in the magnet reduces the cost of materials, and the process is simple, which is suitable for large-scale production.

Owner:NANJING UNIV OF SCI & TECH

A method of designing a lens

The invention relates to the field of optical devices, in particular to a method for designing a lens, comprising the following steps: S11, analyzing and obtaining a sensitive surface of the lens; S21, setting a first maximum deformation variable of the sensitive surface according to preset parameters; S3, according to The first maximum deformation amount of the sensitive surface is analyzed to obtain the first position interval of the lens abutting on the central surface of the stage. Through the arrangement of the above steps, the pressure in the radial direction of the lens is reduced, thereby reducing the possibility of deformation, reducing the possibility that the lens is difficult to image, and increasing the imaging quality of the lens.

Owner:JIAXING ZHONGRUN OPTICAL TECH

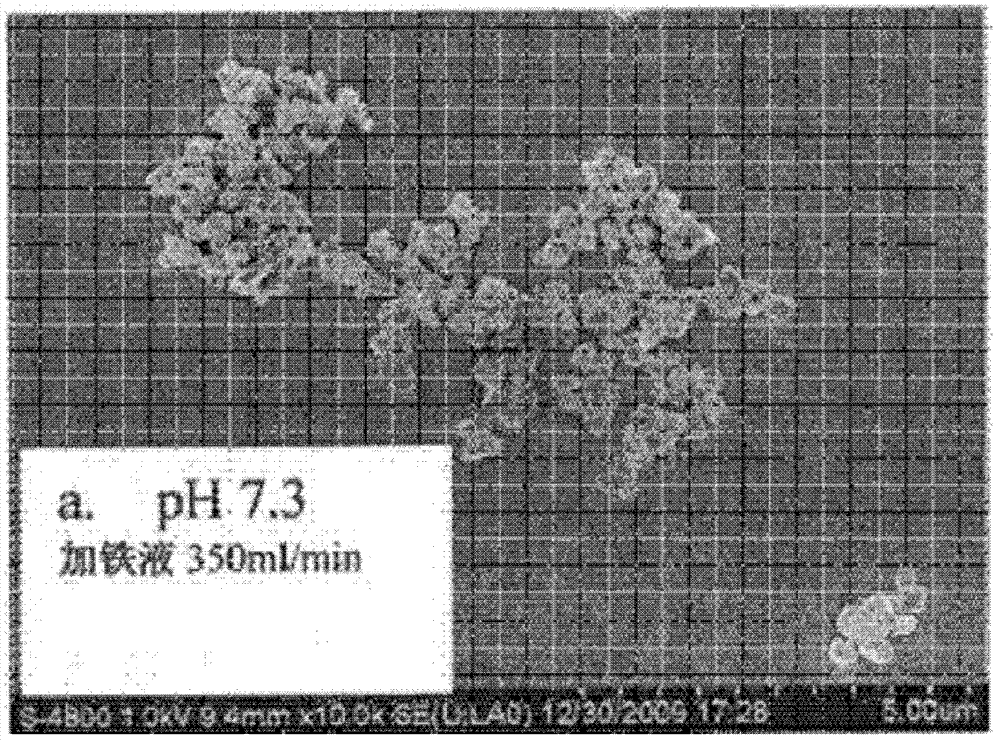

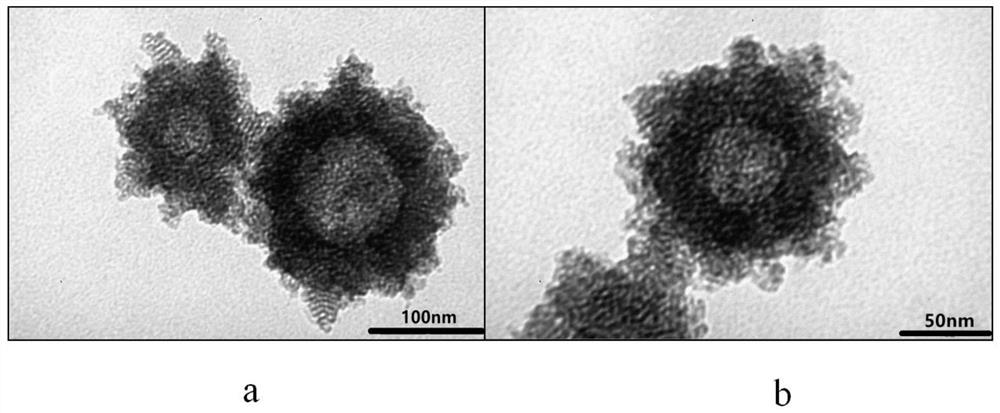

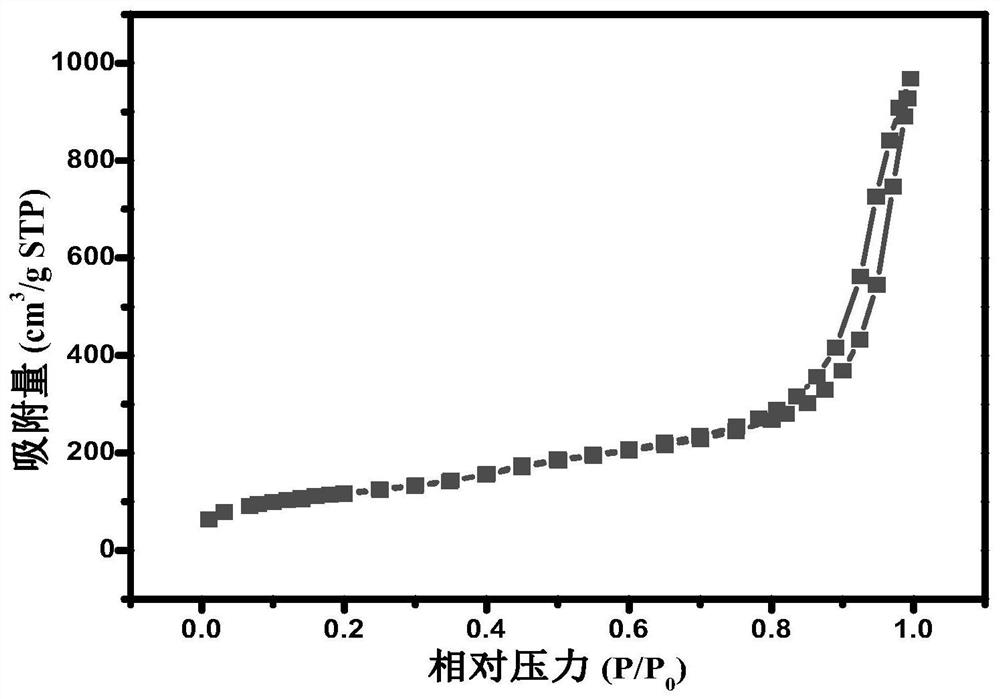

One-step synthesis of spherical hollow mesoporous bismuth sulfide/silica nanomaterials

ActiveCN110217819BHigh purityAchieve structural optimizationMaterial nanotechnologySilicaBismuth sulfideMicrosphere

The invention relates to the technical field of preparation of hollow nano-biological materials, and more specifically relates to a one-step synthesis method of spherical hollow mesoporous bismuth sulfide / silicon dioxide nano-materials. Using orthosilicate, surfactant, albumin, inorganic bismuth source, dilute nitric acid, sodium hydroxide, ammonium nitrate, and absolute ethanol as raw materials, through constant temperature crystallization, template removal, and centrifugation, hollow mesoporous Bi 2 S 3 / SiO 2 nanomaterials to greatly increase the Bi 2 S 3 / SiO 2 The purity of nanomaterials, the expansion of Bi 2 S 3 / SiO 2 Applications of nanomaterials. This process is a rapid and controllable synthesis of hollow mesoporous Bi 2 S 3 / SiO 2 The process of nanomaterials can realize the synthesis of hollow mesoporous Bi by changing the addition amount of surfactant, tetraethyl silicate and albumin 2 S 3 / SiO 2 The controllable adjustment of the particle size of the microsphere and the thickness of the hollow layer of the nanomaterial. Hollow mesoporous Bi prepared by the inventive method 2 S 3 / SiO 2 The properties of the nanometer material are as follows: the particle diameter is 80-150nm, the thickness of the hollow outer layer is 10-20nm, and the product purity reaches 99.9%.

Owner:SHANXI MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com