All-ceramic knuckle bearing for high temperature, easy corrosion and easy oxidation working environment

A joint bearing, easy to corrode technology, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of difficult to guarantee the working life, metal material corrosion resistance, weak anti-oxidation ability, restricting the application of metal joint bearings, etc., to achieve Improve performance and application range, avoid ditching lubrication structure, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

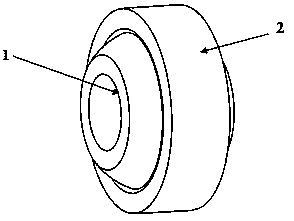

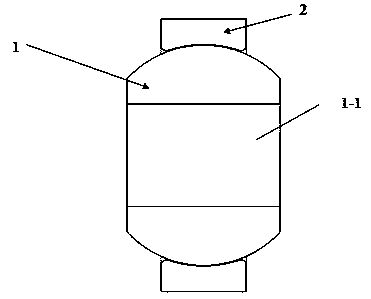

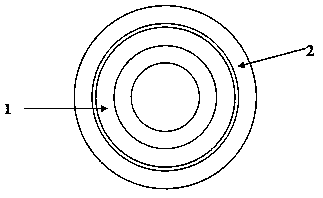

[0019] Such as Figure 1-Figure 6 An all-ceramic joint bearing used in high temperature, easy to corrode, and easy to oxidize environments, including an inner ring 1 and an outer ring 2, the inner side of the outer ring 2 is an inner arc surface, and the outer side is a cylindrical outer surface; the inner ring 1 The outer side is an outer arc surface, and the inner side is a hollow cylinder 1-1; the bearing width of the inner ring 1 is 3-5mm larger than that of the outer ring 2, and the inner ring 1 can swing around in the outer ring 2, and the inner ring 1 swings The angle is 0-21°; the inner wall of the outer ring 2 is closely attached to the outer wall of the inner ring 1; both the inner ring 1 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com