Computer aided design method and cad system for cutting head of cantilever roadheader

A cantilever roadheader and cutting head technology, applied in the field of cantilever roadheader cutting head computer aided design, CAD system, cantilever roadheader cutting head CAD system, can solve the problem of lack of theoretical support and low overall design level , The cutting head is difficult to adapt to the working conditions, etc., to achieve the effect of improving the level of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

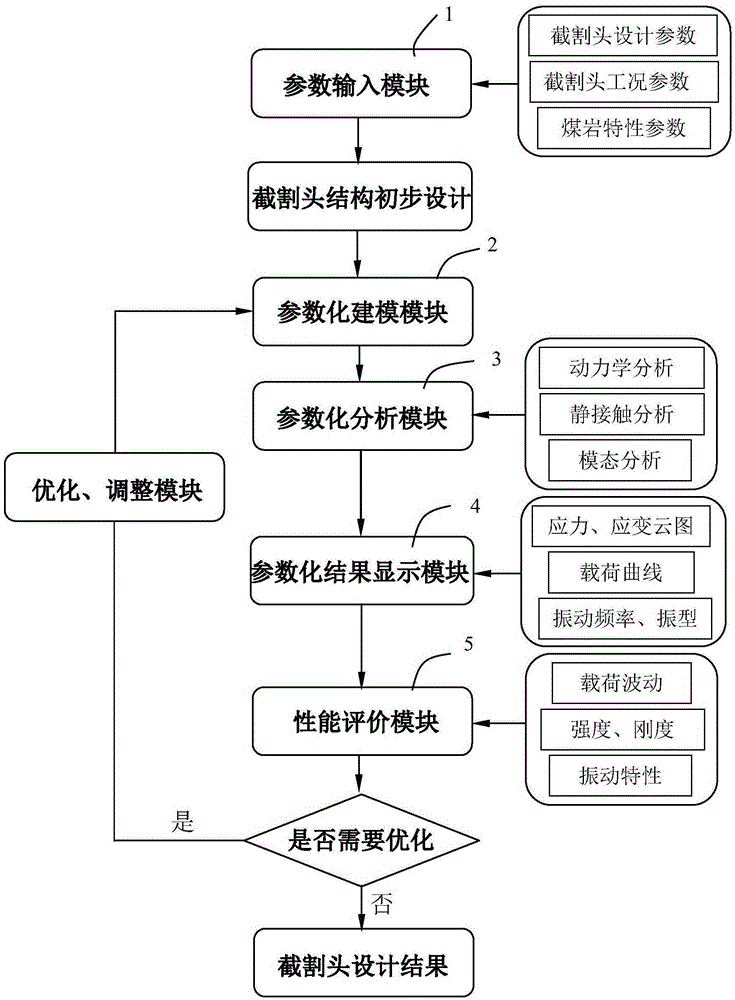

[0026] see figure 1 , a computer-aided design method for the cutting head of the cantilever roadheader, based on Visual C++ 2012 for secondary development of ANSYS14.5, including the following steps:

[0027] In the parameter input step, the designer inputs the design parameters of the cutting head, the working condition parameters of the cutting head and the characteristic parameters of the coal and rock according to the design requirements. Arrangement parameters of picks on the head body; cutting head working condition parameters include cutting speed and cross cutting speed of cutting head; coal rock characteristic parameters include coal rock density, Poisson's ratio, elastic modulus, friction angle , adhesion, expansion coefficient and fractal dimension;

[0028] In the parametric modeling step, the cutting head design parameters entered above are called, and the cutting head solid model is preliminarily established in combination with the pick arrangement theory; and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com