Dust suction system of woodworking engraving machine

A vacuum system and engraving machine technology, applied in wood processing equipment, dust removal, manufacturing tools, etc., can solve the problems of engraving machine vibration, dust suction pipes affecting the quality of dust collection, and unreasonable arrangement of dust suction and chip removal pipes, etc. , to achieve the effects of reducing machine tool vibration, optimizing structure and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

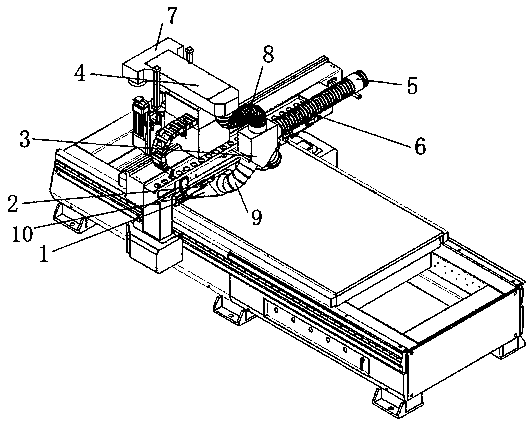

[0014] Such as figure 1 As shown, the dust suction system of the woodworking engraving machine of the present invention includes a top suction head 4 , a dust suction joint 3 , a dust suction pusher cover 1 and a dust suction pipe 6 . The dust suction joint 3 has four interfaces, the two interfaces on the bottom surface are connected to the vacuum pusher cover 1, the upper interface is connected to the top suction head 4, and the right side interface is connected to the dust outlet pipe 6 to discharge wood chips and dust.

[0015] The top suction head 4 is installed on the top of the woodworking engraving machine. The top suction head 4 has two front and rear ports. upper interface. Spindle suction cover 7 sucks dust and sawdust in processing and sends into top suction head 4, enters dust suction joint 3 by top suction head 4 again. The vacuum pusher cover 1 is connected to the beam of the woodworking engraving machine through two telescopic cylinders 2. The telescopic cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com