Quality-improving and silicon-reducing recleaning process for low-grade iron ore concentrate

A technology of iron concentrate and process, which is applied in the field of quality improvement and silicon reduction re-election process of low-grade iron concentrate, which can solve problems such as unsatisfactory indicators, low sorting efficiency, and increased silicon content, so as to improve the comprehensive utilization rate of resources , increase pipeline concentrate output, and realize the effect of product structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

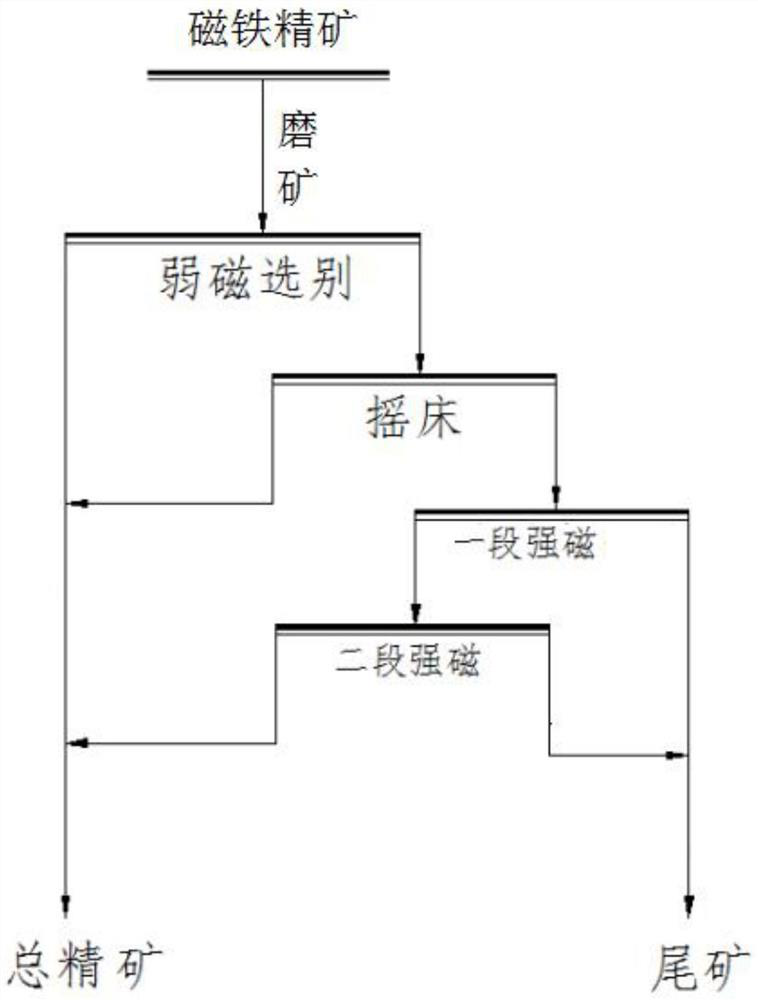

Embodiment 1

[0028] The concentrate with a grade of 32.74% in the No. 1 and No. 2 concentrators of Dahongshan is selected and re-selected after grinding. Firstly, the concentrate is ground to -325 mesh and accounts for 81.29% ore powder or slurry. Then, the ore powder or pulp is subjected to weak magnetic separation through an XCRS-type drum-shaped wet weak magnetic separator with a magnetic induction intensity of 100mT to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is separated by a shaking table with a stroke of 12mm and 350 strokes / min to obtain shaker concentrate and shaker tailings; the shaker tailings are passed through a SLon-500 vertical ring pulsating high-gradient magnetic separator with a magnetic induction intensity of 3000GS A section of strong magnetic concentrate (300A) is separated to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings. A section of strong mag...

Embodiment 2

[0030] The 36.59% ore concentrate of Dahongshan No. 1 concentrator is ground and re-selected. Firstly, the 36.59% ore concentrate is ground to -325 mesh, accounting for 82% ore powder or slurry. Then the ore powder or pulp is subjected to weak magnetic separation by XCTB-1224 magnetic separator with a magnetic induction intensity of 100mT to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is separated by a shaking table with a stroke of 10mm and 350 strokes / min to obtain shaking table concentrate and shaking table tailings; the shaking table tailings is passed through a section of strong magnetic ( 300A) to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings, and a section of strong magnetic concentrate is separated by the second section of strong magnetic (300A) of the SLON-2000 magnetic separator with a magnetic induction intensity of 3000GS to obtain a second sect...

Embodiment 3

[0032] The 34.72% grade concentrate of Dahongshan No. 1 Concentrator was selected and re-selected after grinding. Firstly, the concentrate was ground to -325 mesh and accounted for 80.95% ore powder or pulp. Then the ore powder or pulp is subjected to weak magnetic separation by XCTB-1224 magnetic separator with a magnetic induction intensity of 200mT to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is separated by shaking table with 14mm stroke and 450 strokes / min to obtain shaker concentrate and shaker tailings; shaker tailings are passed through a section of strong magnetic ( 400A) separation to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings, and a section of strong magnetic concentrate is separated by a SLON-2000 magnetic separator with a magnetic induction intensity of 3000GS in the second section of strong magnetic (400A) to obtain a second section of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com