Mineral processing process for improving quality and reducing silicon of iron ore concentrate

A technology of iron concentrate and process, which is applied in the field of beneficiation process of improving the quality of iron concentrate and reducing silicon, can solve the problems of failing to meet the requirements of pipeline transportation, high silicon grade, resource loss, etc., and meet the requirements of process management. Good sorting index and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

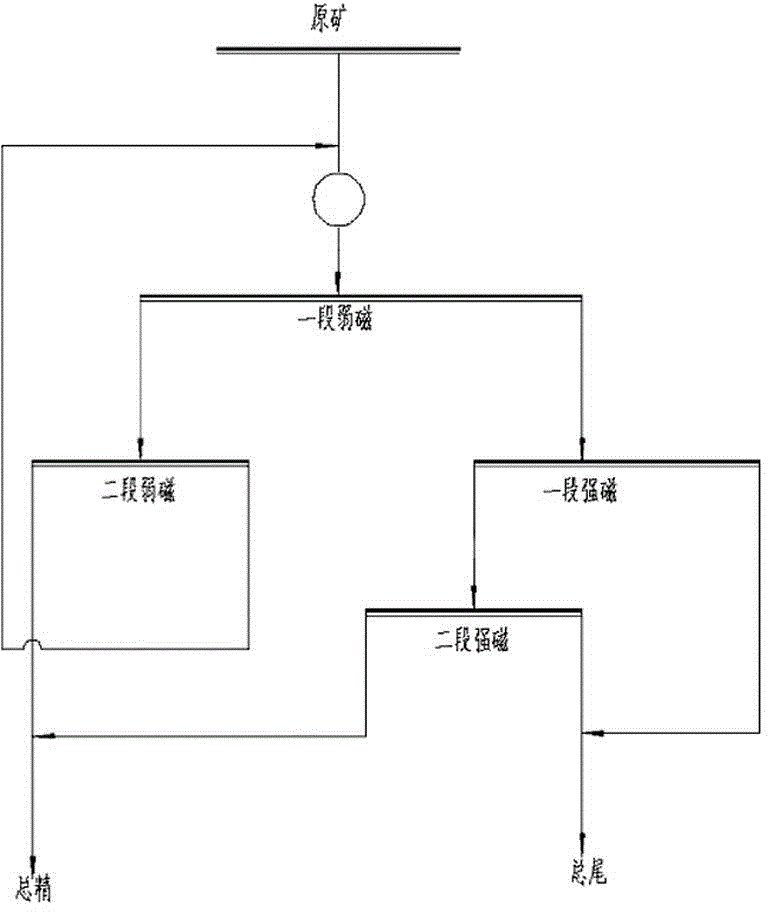

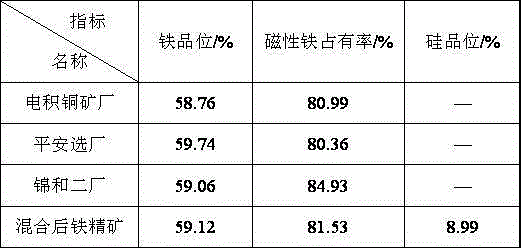

Embodiment 1

[0041] The iron grade is 58%, the silicon grade is 10%, and the iron concentrate with a particle size of -200 mesh accounts for 72% is finely ground to the ore powder with a particle size of -325 mesh accounting for 80%. The ore powder after grinding is magnetically separated by a CTB / N / S-1230 magnetic separator with a magnetic induction intensity of 800T to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is magnetically separated by a SLon-2000 magnetic separator with a magnetic induction intensity of 12000T to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings. The first stage of weak magnetic concentrate is magnetically separated by CTB / N / S-1230 magnetic separator with a magnetic induction intensity of 1000T to obtain the second stage of weak magnetic concentrate and the second stage of weak magnetic tailings, and the second stage of weak magnetic tailings is ret...

Embodiment 2

[0043] The iron grade is 60%, the silicon grade is 9%, and the iron concentrate with a particle size of -200 mesh accounts for 75% is finely ground to a particle size of -325 mesh and accounts for 80% of the ore powder. The ore powder after grinding is magnetically separated by a CTB / N / S-1024 magnetic separator with a magnetic induction intensity of 1000T to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is magnetically separated by a SLon-1500 magnetic separator with a magnetic induction intensity of 14000T to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings. The first stage of weak magnetic concentrate is magnetically separated by a CTB / N / S-1024 magnetic separator with a magnetic induction intensity of 1200T to obtain the second stage of weak magnetic concentrate and the second stage of weak magnetic tailings, and the second stage of weak magnetic tailings is r...

Embodiment 3

[0045] The iron grade is 59%, the silicon grade is 8%, and the iron concentrate with a particle size of -200 mesh accounts for 70% is finely ground to the ore powder with a particle size of -325 mesh accounting for 80%. The ore powder after grinding is magnetically separated by a CTB / N / S-924 magnetic separator with a magnetic induction intensity of 900T to obtain a section of weak magnetic concentrate and a section of weak magnetic tailings. A section of weak magnetic tailings is magnetically separated by a SLon-1000 magnetic separator with a magnetic induction intensity of 10000T to obtain a section of strong magnetic concentrate and a section of strong magnetic tailings. The first stage of weak magnetic concentrate is magnetically separated by a CTB / N / S-924 magnetic separator with a magnetic induction intensity of 800T to obtain the second stage of weak magnetic concentrate and the second stage of weak magnetic tailings, and the second stage of weak magnetic tailings is retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com