Patents

Literature

77results about How to "Good sorting index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

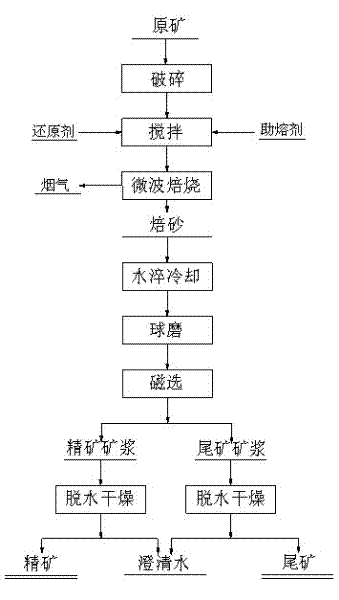

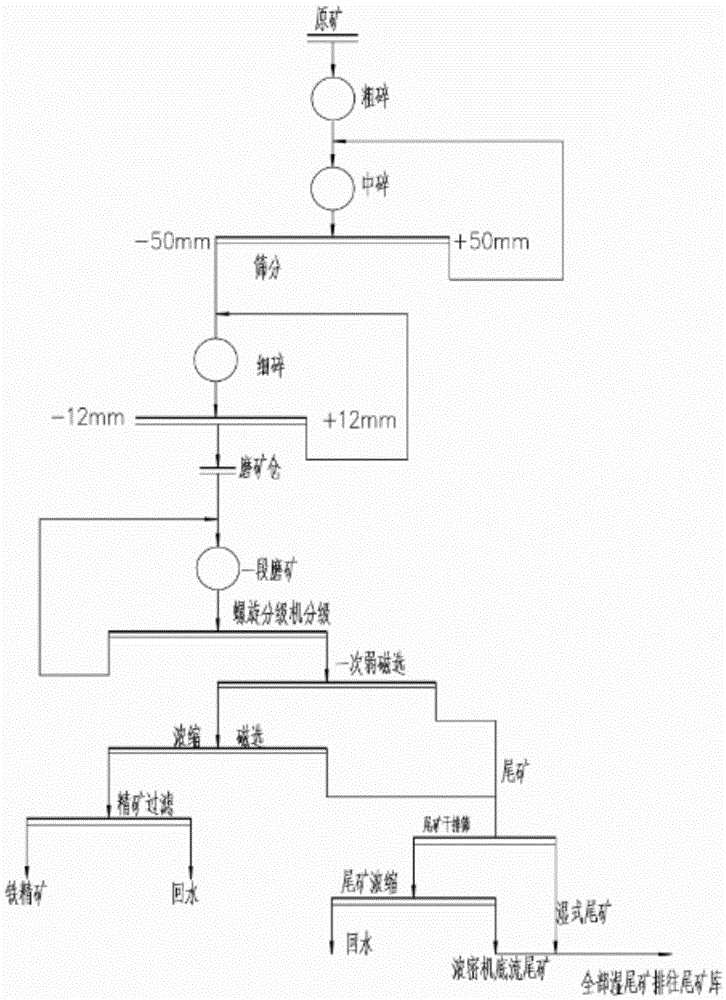

Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

InactiveCN102212677AReduce grinding energy consumptionShorten milling timeMagnetic separationMixed materialsQuenching

The invention relates to a method for refining iron and removing phosphorus from complex refractory high-phosphorus iron ore, in particular to a method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation, and belongs to the technical field of mineral processing, particularly iron ore beneficiation. The method comprises the following steps: crushing refractory high-phosphorus iron ore used as raw material into granules with granularity of less than 2mm; mixing the crushed raw ore with a fluxing agent and a reducing agent in a certain proportion; transferring the obtained mixed material into a microwave reaction furnace for reduction roasting; and carrying out water-quenching, cooling, ball-milling and wet-magnetic-separating on the obtained roasted ore to finally obtain iron ore concentrate. In the method, the ore is reduced by utilizing a microwave roasting technology, wherein microwave reduction roasting time is short, and the temperature of the ore is raised quickly; and meanwhile the fluxing agent is added so as to promote gangue softening and improve refractory ore structure together with microwave roasting reaction. By utilizing the method for sorting the high-phosphorus iron ore, the iron ore concentrate with grade of more than 58.39% can be obtained, and phosphorus removal rate reaches over 70.44%, thus a new technique is provided for sorting the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

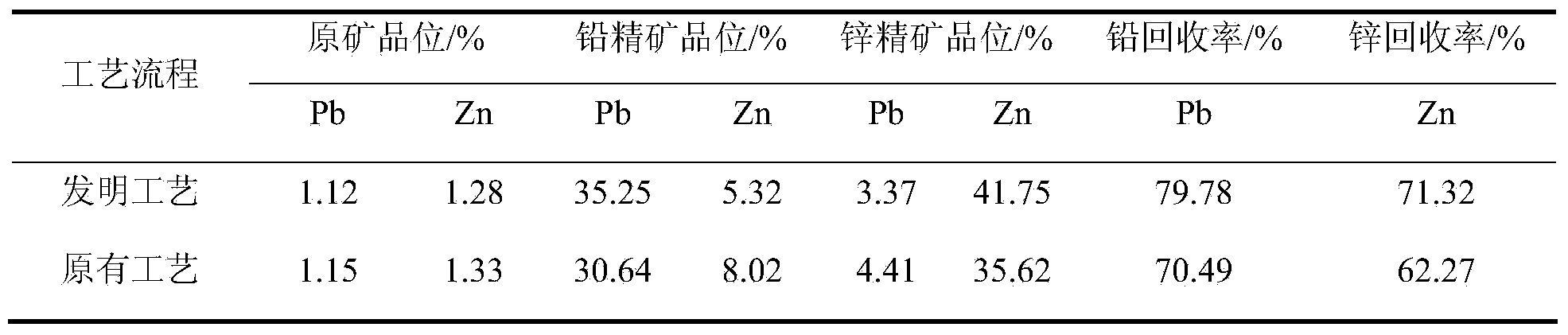

Flotation method for lead and zinc ore difficult to select

InactiveCN103639061AThe process is simple and reliableEasy to operateFlotationDibutyl dithiophosphateSulfite salt

The invention relates to a flotation method for lead and zinc ore difficult to select. The method includes the following steps of lead roughing, two-time lead scavenging, three-time lead fine selection, zinc roughing, two-time zinc scavenging and three-time fine selection. Lime serves as regulators, zinc sulfate and sodium sulfite serve as zinc inhibitor, diethyl dithiocarbamate and ethyl xanthogenate serve as lead collecting agents, copper sulfate serves as zinc activating agents, ammonium dibutyl dithiophosphate serves as zinc collecting agents, and terpenic oil serves as foaming agents. The lead and zinc ore difficult to select is processed by the adoption of lead differential flotation and zinc selection technological processes, and the practical problems that in original technological processes, zinc contains a high content of lead which contains a high content of the zinc, and the lead recovery rate and the zinc recover rate are low are solved. The technological processes are simple, reliable, easy to operate, and good in sorting index. Compared with the original technological processes, the method has the advantages that under the circumstance that raw ore contains the same lead and zinc, mutual containing of the lead and zinc is reduced, and the lead recovery rate and the zinc recovery rate are greatly increased and increased by 9.29% and 9.05% respectively.

Owner:GUANGXI UNIV

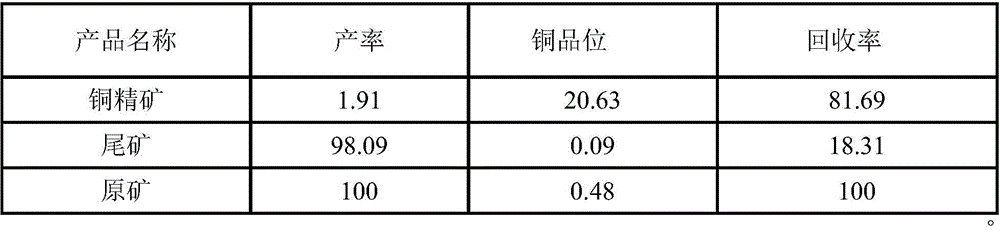

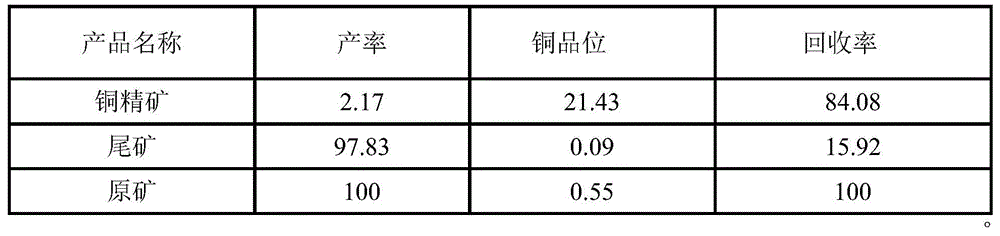

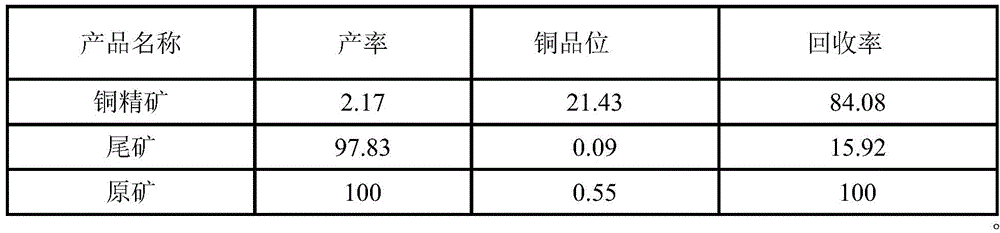

Beneficiation method for improving ore dressing recovery percentage of copper sulfide mineral hard to dispose

ActiveCN106269287AEfficient use ofNo pollution in the processFlotationSulfide mineralsCopper sulfide

The invention relates to a beneficiation method for improving the ore dressing recovery percentage of copper sulfide ore hard to dispose. By applying the method, flotation separation of copper sulfide mineral from hydrophobic silicate gangue talc and ferric sulfide mineral pyrite can be realized, and the preparing technical indexes of copper sulfide mineral can be improved. The method comprises the operations of ore grinding, size mixing, rougher flotation, scavenging and selection. According to the invention, a combined inhibitor TYZ01 has a selective inhibiting effect on talc and pyrite and cannot affect the flotation of copper pyrites, and a combined collecting agent TBS02 has strong collecting capability on copper pyrites; by using the two combined reagents, efficient utilization of copper sulfide mineral containing hydrophobic silicate gang and pyrite can be realized; proved by practices, by using the beneficiation method disclosed by the invention, good selection indexes can be obtained; and the adopted reagents, calcium lignosulfonate and Arabic gum, are organic macromolecule reagents, thus being easy to degrade and having no pollution to the environment.

Owner:苏尼特右旗朱日和铜业有限责任公司

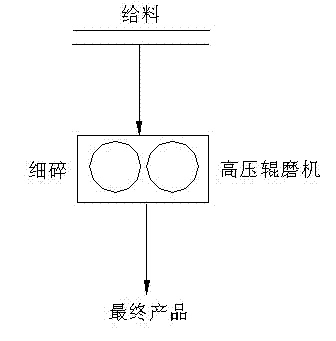

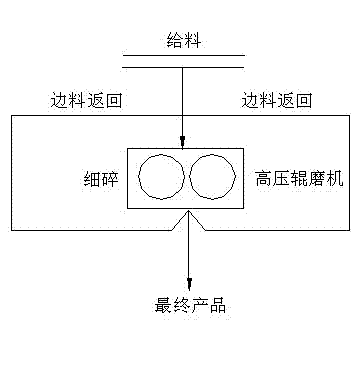

Method for crushing iron ore

ActiveCN102179284ASmall finenessReduce processing energy consumptionGrain treatmentsIronstoneClosed loop

The invention discloses a method for crushing an iron ore, comprising the following steps of primary crushing, ore washing and high pressure roller-milling, wherein the step of primary crushing uses a multi-level sieving cycling closed loop for crushing, and the step of high pressure roller-milling also uses a closed loop method; compared with the traditional crushing process flow, the process uses the production method of high pressure roller-milling scattering sieving closed loop process flow so that the range of the particle size of a final product is ensured to be narrow and the size thereof is uniform; the material in the final product of the ore is fully rolled and pressed by a high pressure roller miller so as to reduce the fineness of the material to the maximum degree, reduce the Bond index of the milling material, efficiently decrease the procedure energy consumption and steel ball consumption in milling operation and improve the selection index; moreover, the stable production process is ensured, the energy is saved and the consumption is reduced, much crushing and less milling are really realized, and the production capability of an ore factory is greatly improved.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING +1

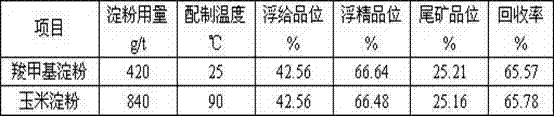

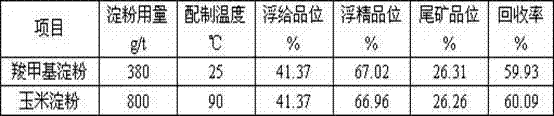

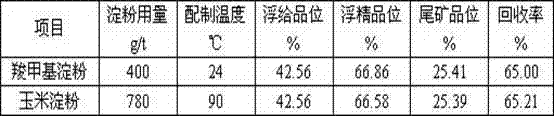

Carboxymethyl starch inhibitor for reverse flotation of hematite

InactiveCN103567078AReduce unit consumptionReduce consumptionFlotationCarboxymethyl starchProcess engineering

The invention provides a carboxymethyl starch inhibitor for reverse flotation of hematite. The carboxymethyl starch inhibitor is characterized in that water with the weight being 8 times to 10 times the weight of carboxymethyl starch and the carboxymethyl starch are sequentially added to a dispensing barrel at a room temperature, the water and the carboxymethyl starch are stirred for one hour, then, water is added for preparing a solution which is composed of, by weight, 1.5% to 3.0% of the carboxymethyl starch, and the carboxymethyl starch inhibitor is obtained. Compared with a frequently-used corn starch inhibitor, the carboxymethyl starch inhibitor has the advantages that the consumption of the carboxymethyl starch inhibitor is lowered by 44% to 50%, when the carboxymethyl starch inhibitor is prepared at the room temperature, the preparation process is simple, the energy consumption is reduced, the inhibiting effect is good, and the screening index is beneficially improved, and the carboxymethyl starch inhibitor is easy to store and not prone to deterioration when used at the room temperature.

Owner:ANSTEEL GRP MINING CO LTD

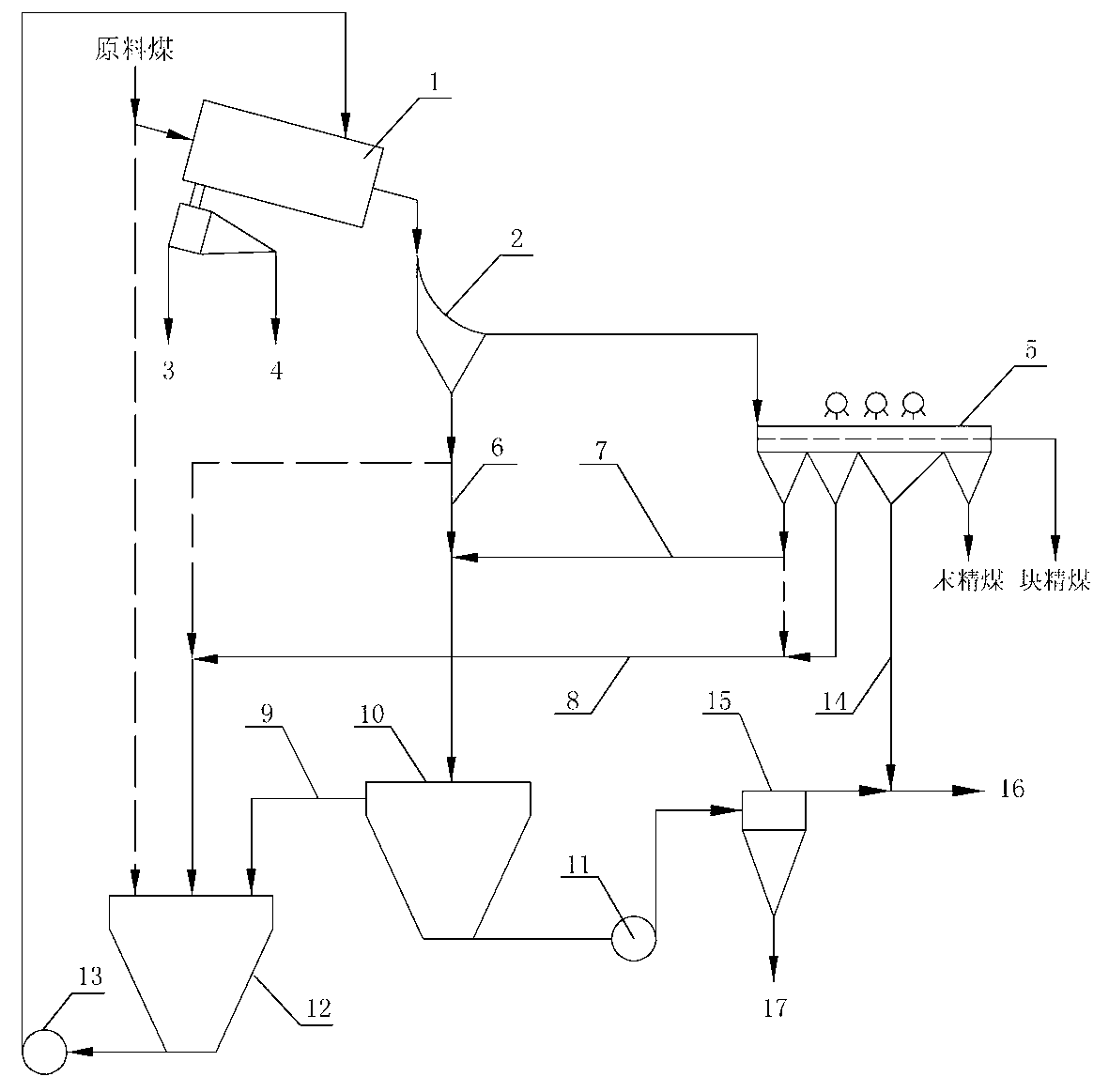

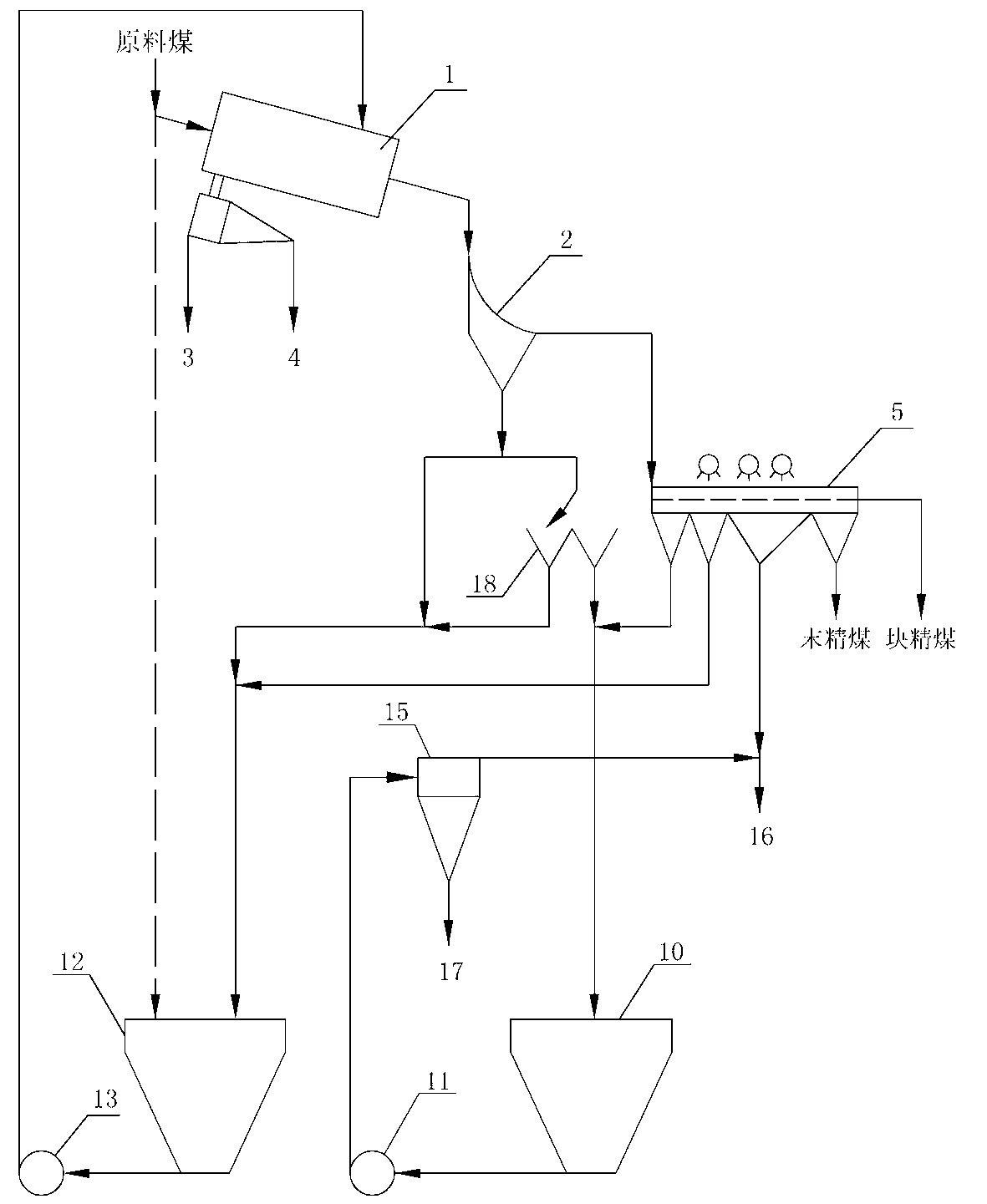

Method for guaranteeing high separation precision of coal slime heavy medium hydrocyclone

ActiveCN103230829AAvoid the phenomenon that the liquid level is unstable or even emptiedGuaranteed uptimeWet separationThermodynamicsProcess engineering

Disclosed is a method for guaranteeing high separation precision of a coal slime heavy medium hydrocyclone. A shunt is cancelled in a device which is utilized in the method; a minus sieve chute of a clean coal medium discharge curved screen and a first section of a minus sieve chute of a clean coal medium drainage screen are respectively connected with a pipeline; one ends of the pipelines are inserted into a slime qualified medium barrel which is provided with an overflow pipe; all or partial minus sieve qualified heavy suspension liquid of the clean coal medium discharge curved screen and the first section of the minus sieve chute of the clean coal medium drainage screen enters into the slime qualified medium barrel; and heavy suspension liquid inside the slime qualified medium barrel flows into a raw coal qualified medium barrel after a liquid level of the slime qualified medium barrel is increased to a certain height. The method for guaranteeing the high separation precision of the coal slime heavy medium hydrocyclone has the advantages of enabling the shunt to be cancelled, saving equipment investment, simplifying the operation process, avoiding unstable liquid level even emptying of the slime qualified medium barrel due to improper manual operation, being capable of providing stable working conditions for the coal slime heavy medium hydrocyclone and guaranteeing the high separation precision of the coal slime heavy medium hydrocyclone.

Owner:唐山国华科技国际工程有限公司

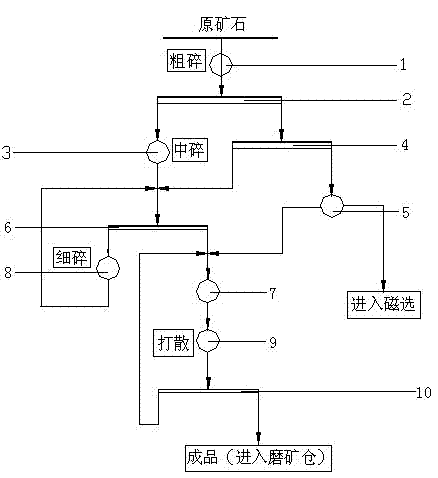

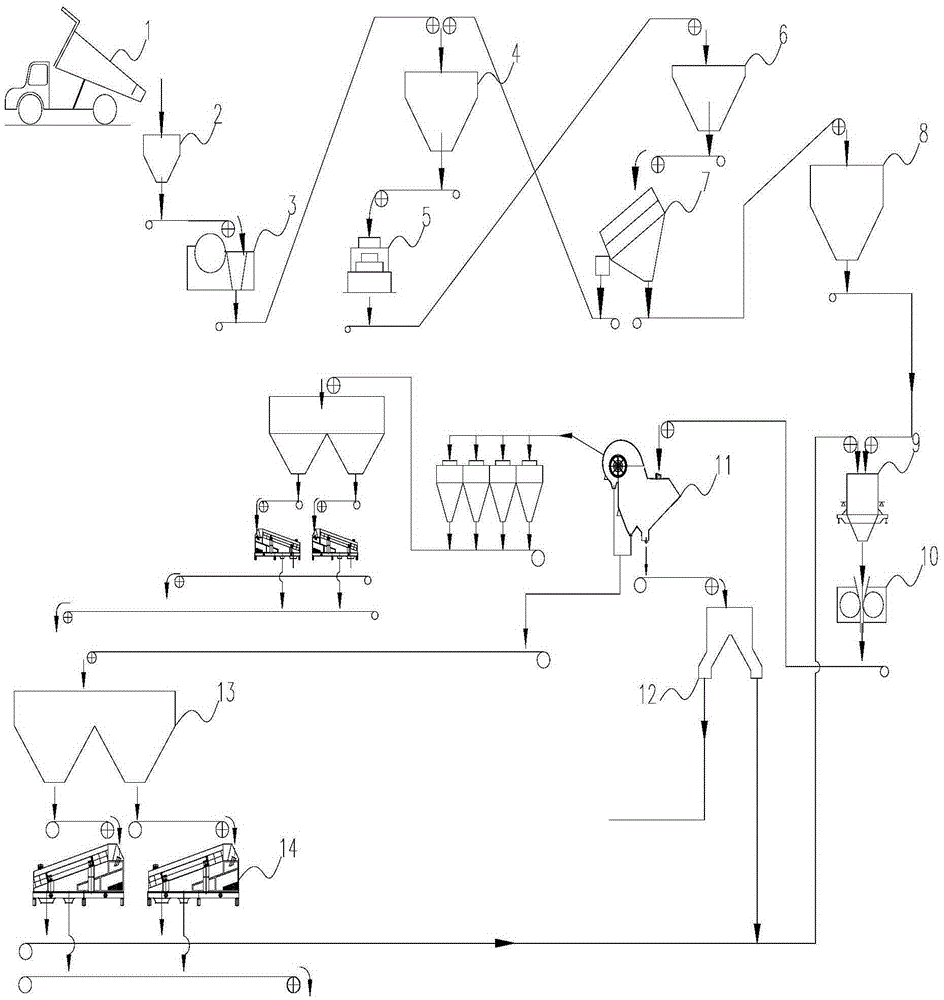

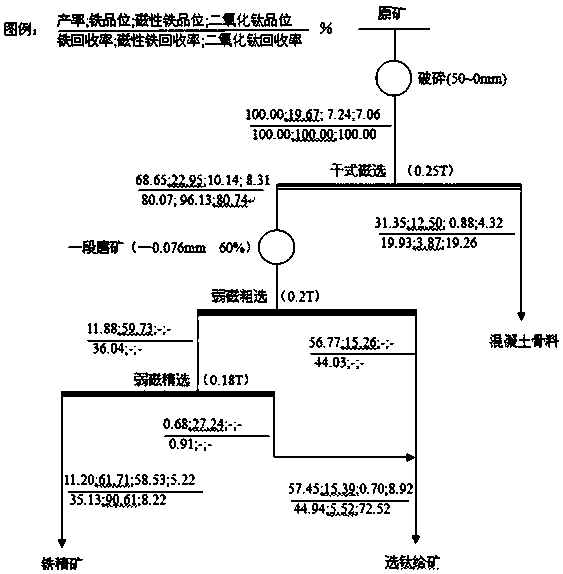

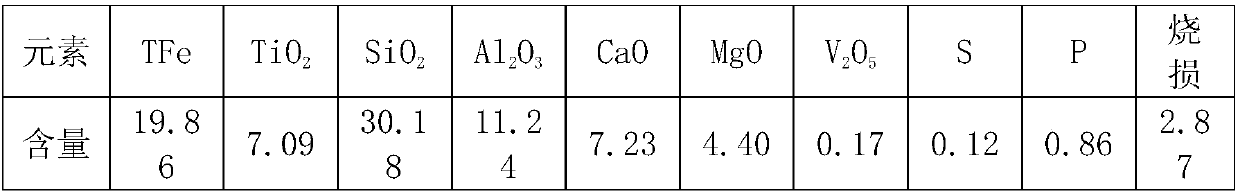

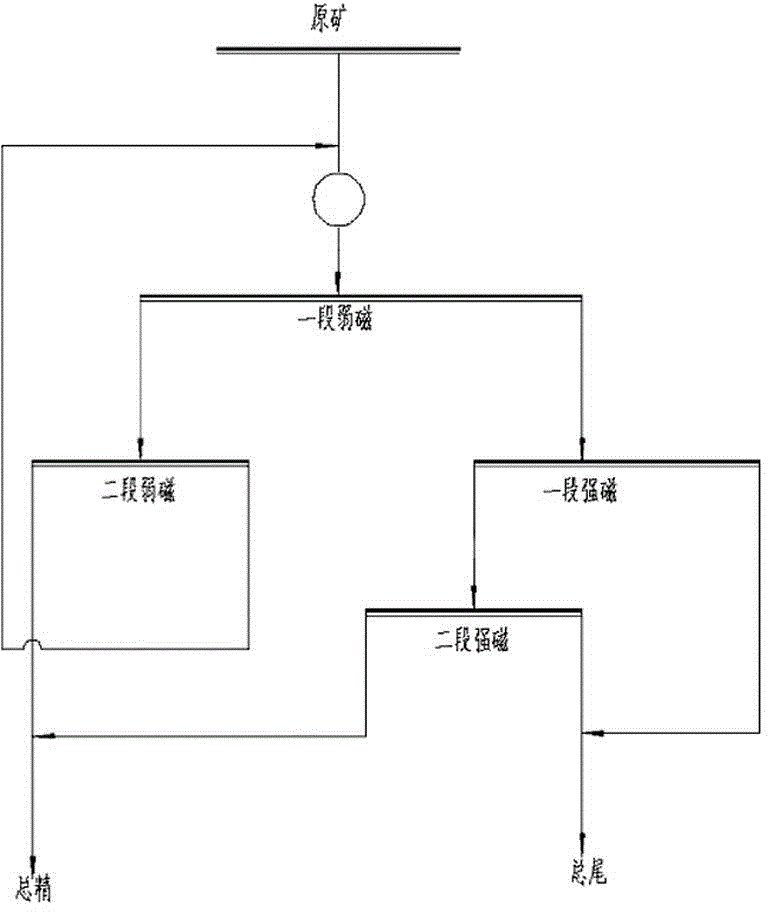

Mineral separation process and system for ultra-lean magnetite ore

ActiveCN105413842AReduce the cost of beneficiationReduce total beneficiation costMagnetic separationGrain treatmentsMagnetiteWet grinding

The invention provides a mineral separation process and system for an ultra-lean magnetite ore. The mineral separation process for the ultra-lean magnetite ore comprises the following steps of sequentially carrying out coarse crushing, intermediate crushing and fine crushing on a raw magnetite ore to obtain a fine-particle ore; carrying out dry magnetic separation on the fine-particle ore, and throwing tailings to obtain a dry concentrate; and carrying out wet grinding and separation on the dry concentrate. The dry pre-separation step is additionally arranged in the mineral separation process, so that the technical problems of high ore grinding and magnetic separation energy consumption, high cost, high mineral separation water consumption, tailing pond construction and the like are solved.

Owner:中冶沈勘工程技术有限公司

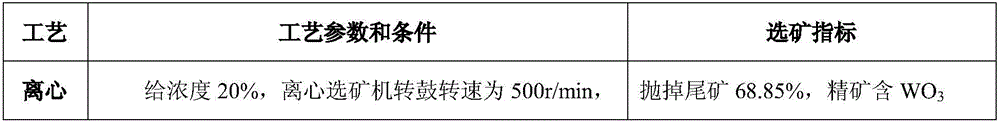

Mineral separation method for recycling wolframite from tailing

ActiveCN106669964AImprove the quality of selectionReduce the amount of oreSolid separationMechanical material recoveryGravity separationMagnetic separation

The invention discloses a mineral separation method for recycling wolframite from a tailing. The mineral separation method comprises the following steps that (1) gravity separation of a centrifugal machine is conducted for tailing discarding and preenrichment; (2) sulphide ore flotation is conducted; (3) magnetic separation is conducted and magnetic impurities are removed; (4) high-gradient magnetic separation is conducted for wolframite enrichment; (5) tabling gravity separation is conducted to obtain coarse grained wolframite; and (6) flotation is conducted to obtain fine grained wolframite. By means of centrifugation gravity separation preenrichment, the separation grade of the wolframite is improved, the ore feeding quantity and the mud content of wolframite separation are reduced, and flotation reagent dosage is saved. By means of the sulphide ore flotation and magnetic separation iron removal, the disturbance of sulphide minerals and magnetic minerals on wolframite separation is reduced. According to the mineral separation characteristics of the wolframite, the separation index of the wolframite is improved by adopting the high-gradient magnetic separation and the coarse grained and fine grained wolframite grading and separation process. Efficient recycling of the wolframite in low-grade wolframite tailing resources is achieved, and the mineral separation method is environmentally friendly, efficient and energy saving, and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

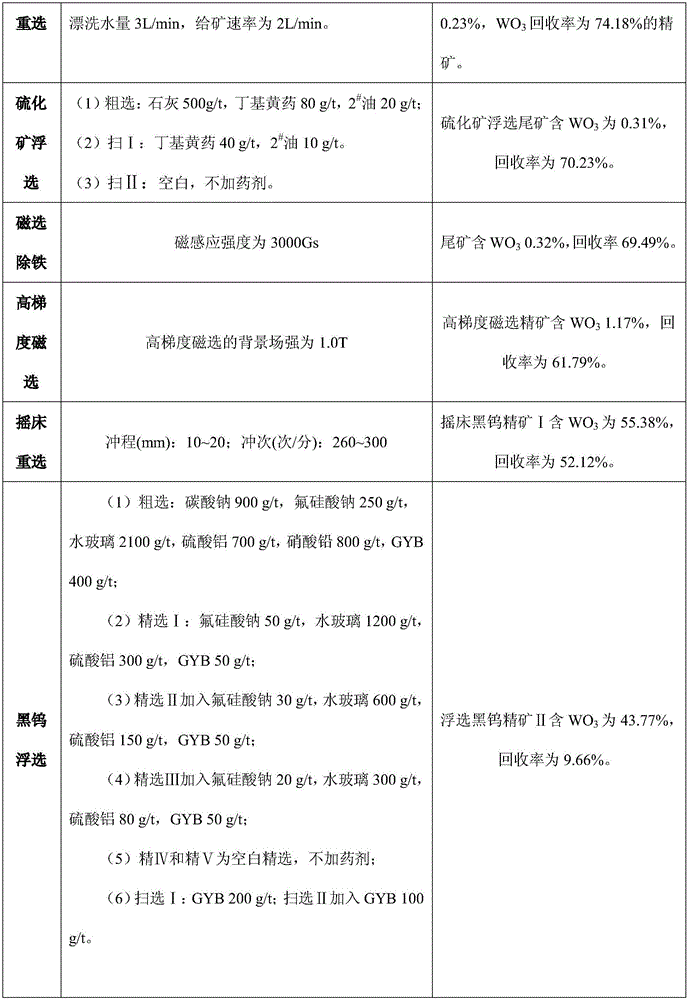

Column type short-stage tungseten crude grading process and equipment

The invention relates to a post-type tungsten selecting method, wherein it uses two cyclone-static foam float selecting posts as selecting devices, with three slurry barrels, liquid level controller and mine circulator. It first feeds the mine into slurry barrel, adds float select agent to mix the slurry; feeds the slurry via feeding pump to the rough float selecting post to be separated and selected; then the rough selected and fine selected mines flow into the fine selecting float selecting post, and the rough selected mine is discharge at the bottom of rough selecting float selecting post, to be selected in the fine selecting post; and the fine selected mine is discharged at the upper fine mine outlet, and the tail mine is discharge at the bottom outlet into mine buffer pool, to be fed back to the slurry barrel. The invention has low cost and high efficiency.

Owner:CHINA UNIV OF MINING & TECH

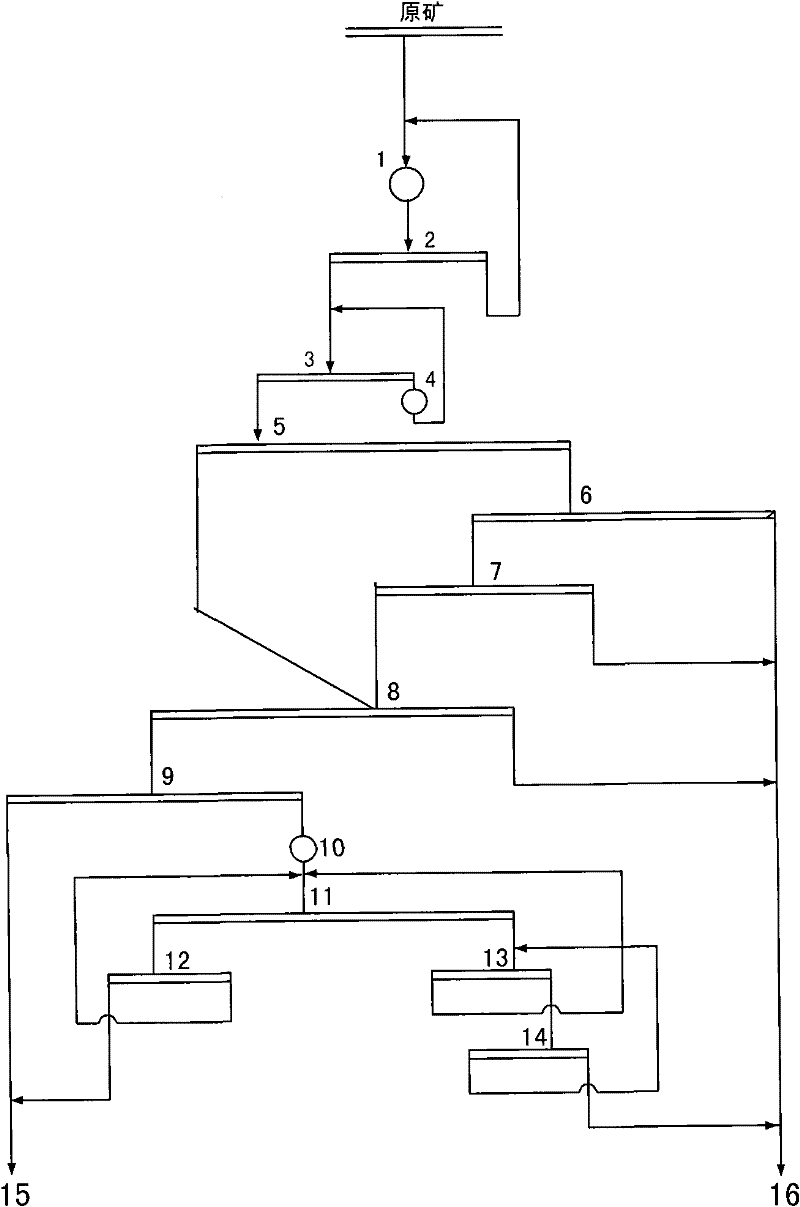

Novel separation process of multi-metal lean hematite

ActiveCN102228863AEfficient separationImprove concentrate gradeFlotationWet separationMetalMetallurgical industry

The invention belongs to the technical field of mineral separation in the metallurgical industry, and in particular relates to a novel separation process of multi-metal lean hematite, which is characterized in that a separation method of two sections of continuous ore grinding, magnetic separation, reverse floatation, regrinding and centrifuging through a centrifugal machine is adopted so that iron minerals and other metal minerals are separated. The novel separation process comprises the following steps of: subjecting primary ball grinding, primary grading, secondary grading, secondary ball grinding, one-section weak magnetic separation, one-section strong magnetic separation, one-section strong magnetic fine separation, reverse floatation operation separation, two-section magnetic separation and regrinding to multi-metal symbiotic lean hematite ores; carrying out one-section rough separation, one-section fine separation, one-section scavenging and two-section scavenging; merging weak magnetic concentrate and secondary reverse floatation concentrate to form final concentrate; and merging two-section strong magnetic tailings and reverse floatation tailings to form final tailings. After the novel separation process is adopted for separation, raw ore grade is 30.505 percent, the concentrate obtained after the separation has better selection indexes such as a grade of 64.14 percent, a yield of 28.59 percent, a metal recovering rate of 60.13 percent, and a tailing grade of 17.03 percent. The grade of the concentrate can be improved from about 58 percent to 64.14 percent.

Owner:ANSTEEL GRP MINING CO LTD

Chemical metallurgy method for extracting beryllium oxide from chrysoberyl

InactiveCN103088206AFully consider the protectionFully consider the comprehensive utilizationProcess efficiency improvementWater vaporDump leaching

The invention discloses a chemical metallurgy method for extracting beryllium oxide from chrysoberyl. The chemical metallurgy method is a comprehensive treatment technology for carrying out chemical metallurgy on refractory chrysoberyl with not more than 0.5% of Be. The chemical metallurgy method is characterized by comprising the following steps of: carrying out structural transformation roasting on the minerals by using ammonium fluosilicate as a structural transforming agent in the presence of activator limestone; cooling the roasted minerals and using water to spray dump leaching beryllium; precipitating beryllium for the ammonium fluoroberyllate solution by using ammonium bicarbonate to obtain basic beryllium carbonate; calcining the basic beryllium carbonate to release carbon dioxide and water vapor to obtain the product beryllium oxide; and concentrating and crystallizing a beryllium-precipitated solution which is the beryllium fluoride solution under reduced pressure, and drying the concentrated and crystallized solution in air flow to obtain the product ammonium fluoride. The chemical metallurgy method disclosed by the invention is simple in process, low in price, free of pollution, high in metal recovery rate, low in production cost and capable of effectively separating and extracting beryllium in the chrysoberyl.

Owner:戴元宁

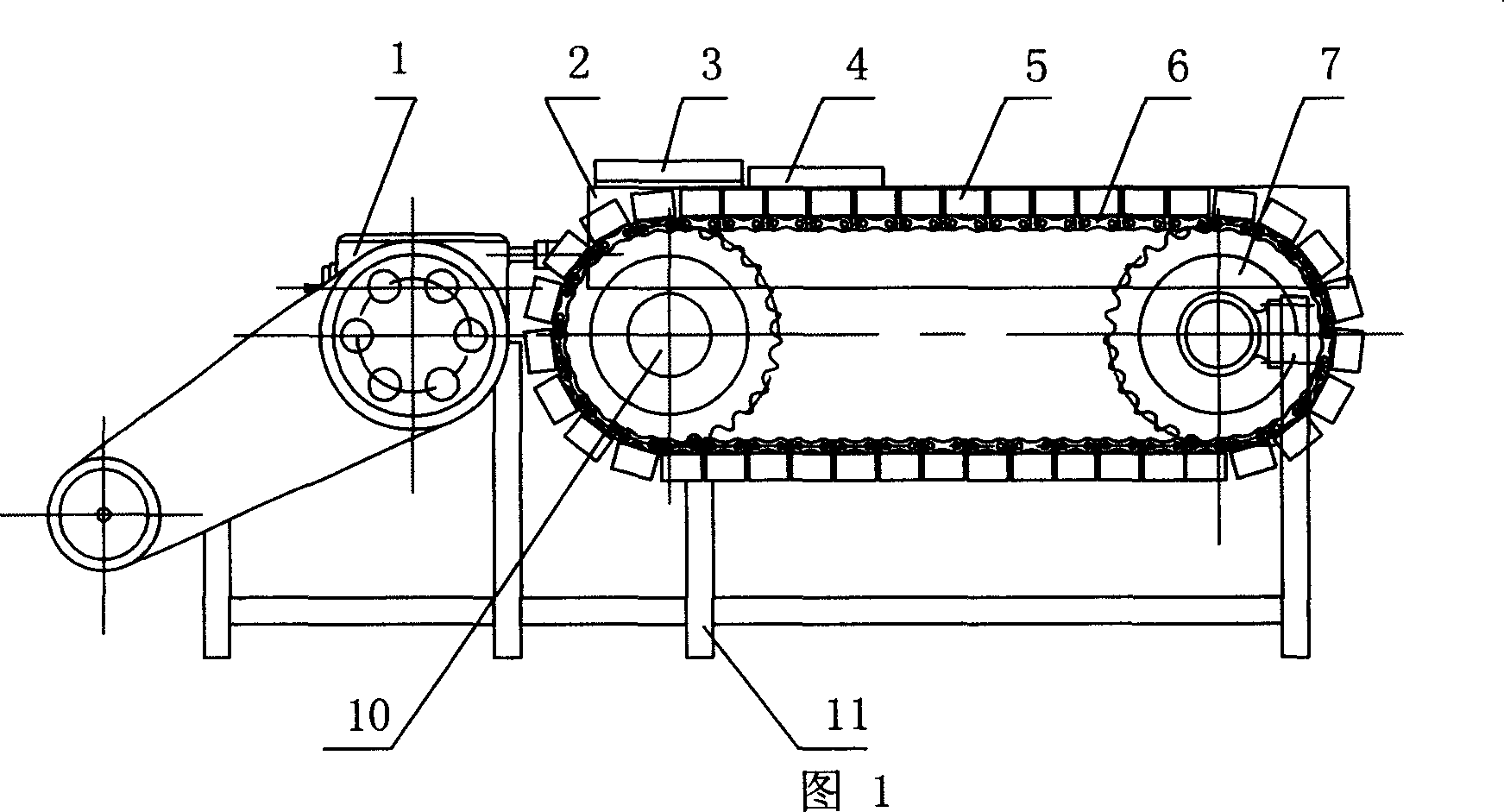

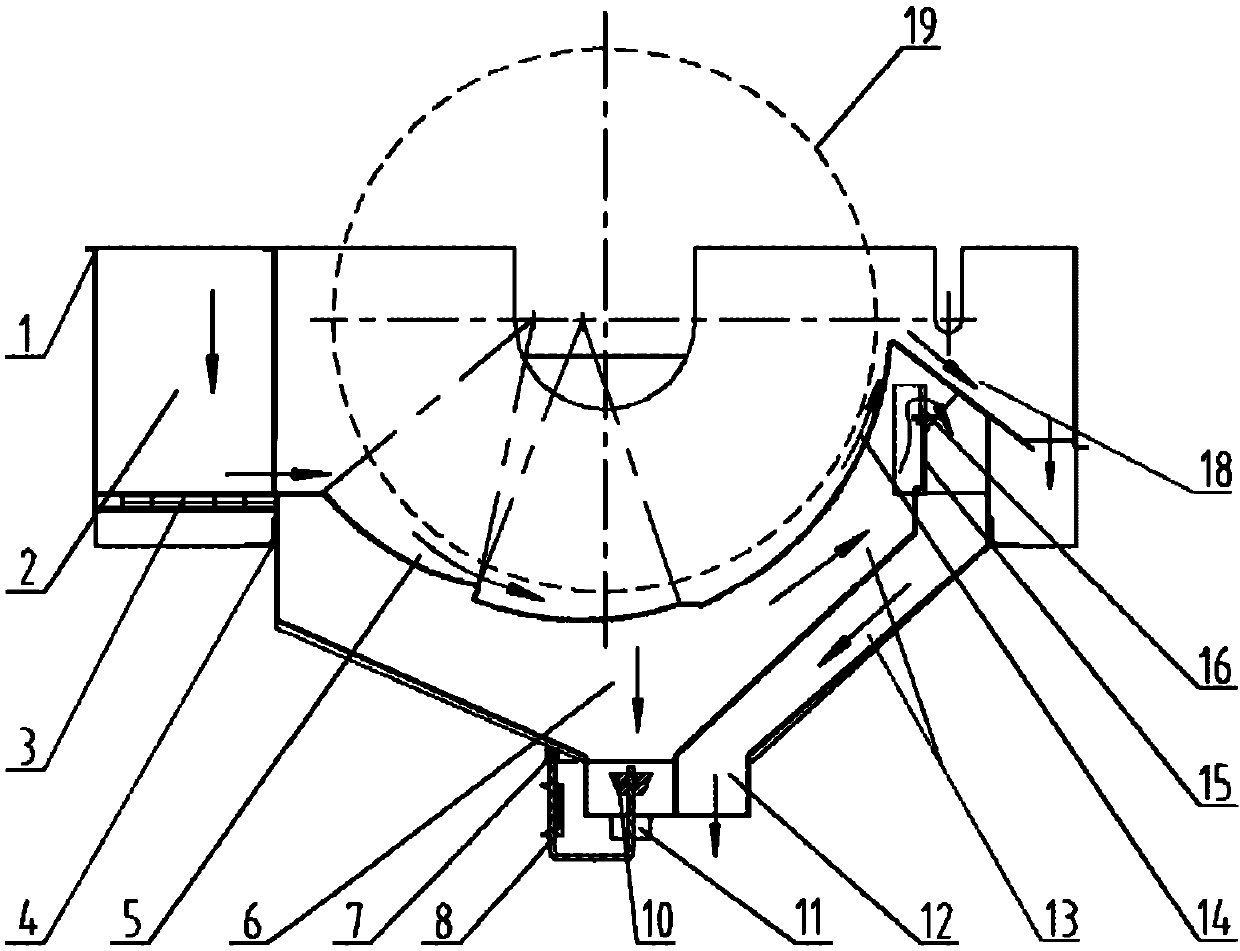

Magnetic shaker

InactiveCN101062487AStrong magnetic forceImprove sorting efficiencyMagnetic separationWet separationMagnetic bearingEngineering

The magnetic rocker comprises the bracket with bed head and surface which sets mineral and water supply grooves, magnetic bearing mechanism along the direction of the bed with magnetic system set on the magnetic bearing mechanism. The introduction of compound force field solves the serious issue of mixture, increasing selection efficiency, improving selection index. It meets special requirement for magnetic mineral and non-magnetic mineral separation and nonmetal equipment requirement except iron ones.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Flotation method of zinc oxide ore

InactiveCN106111350AImprove stabilityReduce sheddingDifferential sedimentationFlotationFlocculationFoaming agent

The invention provides a flotation method of zinc oxide ore. The method comprises the steps that in the pretreatment process of flotation, the zinc oxide ore is crushed and levigated firstly, and the slurry concentration is adjusted to range from 15wt% to 20wt%; a scattering agent and a gangue mineral inhibitor are added in sequence, and then a flocculating agent is added for selective flocculation; then pregelatinized starch is added, the mixture is evenly stirred, and then sulfuric acid is added to adjust the pH value of slurry to 1-5; and a collecting agent and a foaming agent are added after stirring is carried out at a low speed for 2-5 minutes, and zinc concentrate is obtained through flotation according to a conventional process. Through addition of the pregelatinized starch, stability of selective floccules is enhanced, then the sulfuric acid is added so that tight absorption between smithsonite and carbon dioxide microbubbles generated through a reaction can be achieved, and then zinc minerals-floccules are recovered through conventional flotation, so that the beneficiation index of the ore is increased, and consumption of the collecting agent and the foaming agent can be effectively reduced.

Owner:FUZHOU UNIV

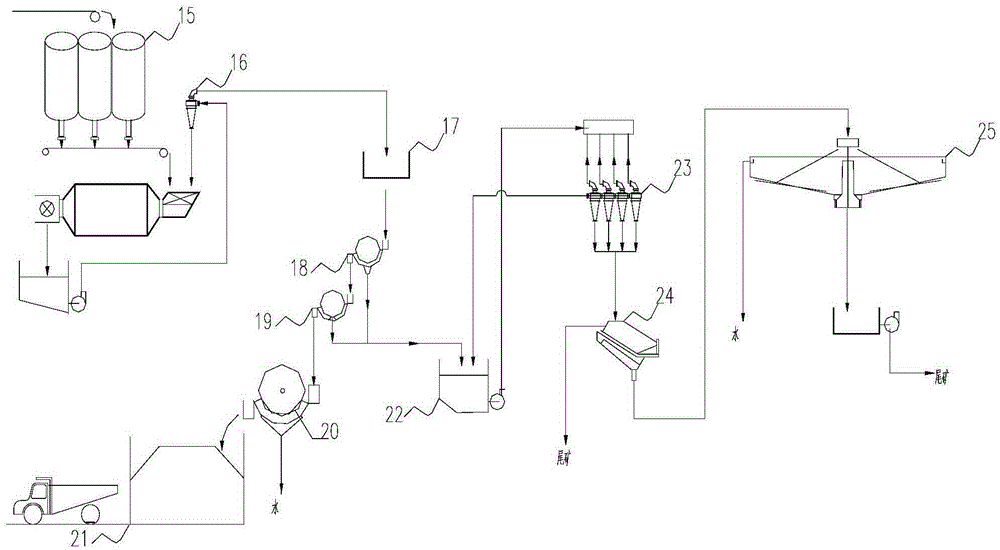

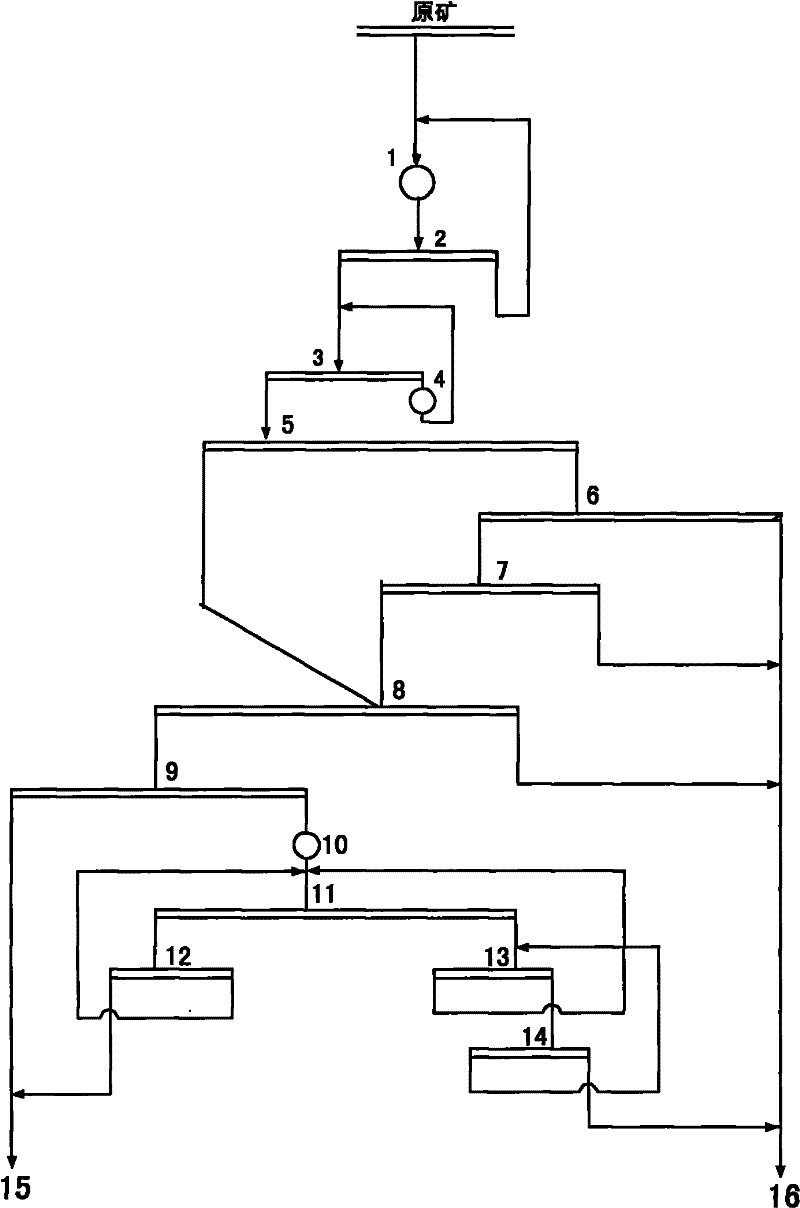

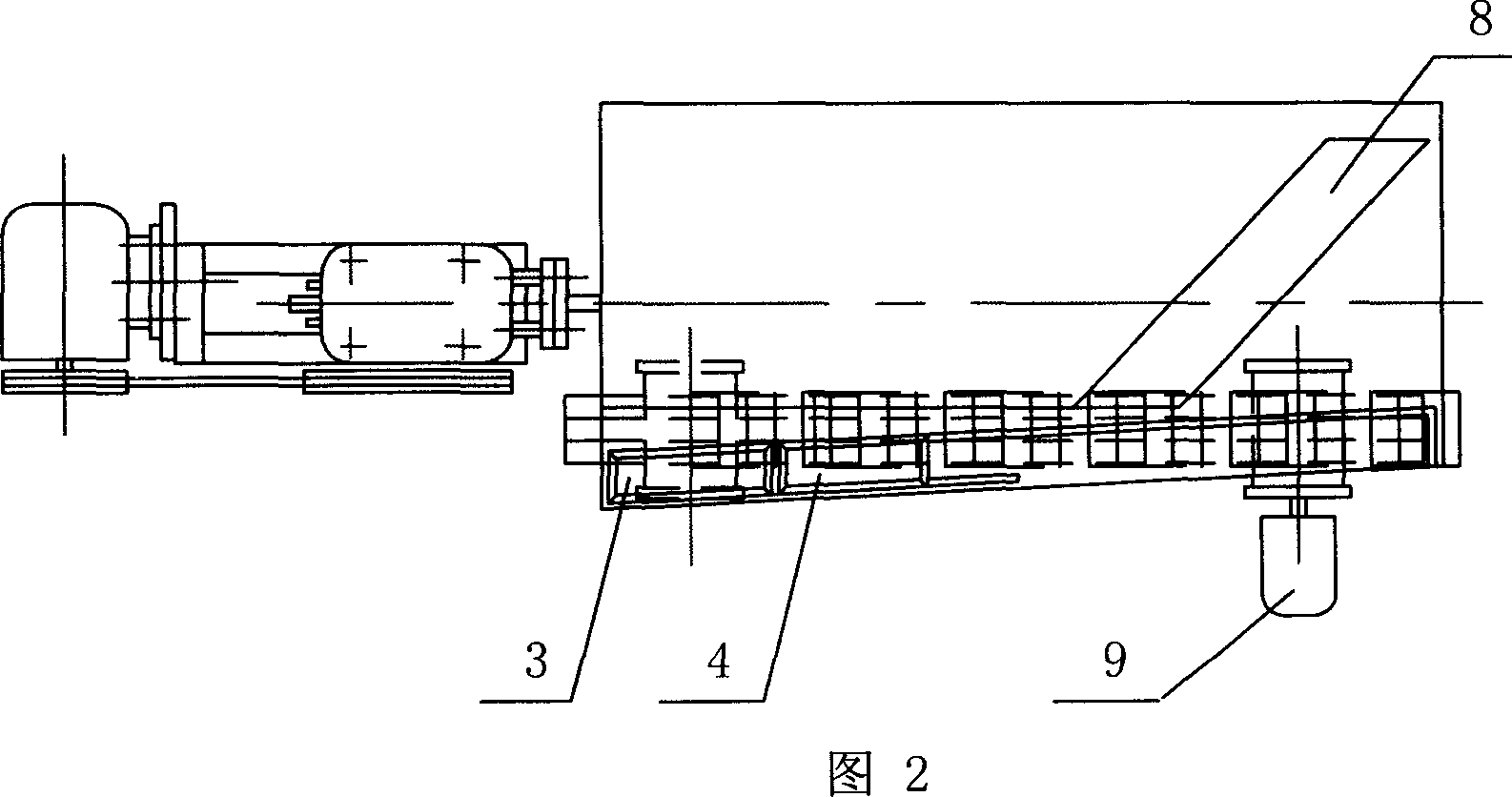

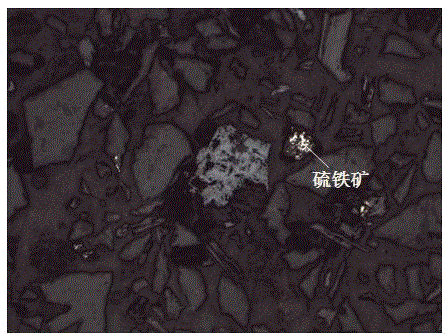

Beneficiation method for recovering pyrites from coal gangue

The invention discloses a beneficiation method for recovering pyrites from coal gangue. The method adopts the following processes: (1) the coal gangue is classified by a double-layer vibrating sieve after crushing; classified coarse products are separated by a heavy-medium vibrating chute to obtain concrete products and tailing; and after mediums are removed from the concentrate products, coarse pyrites are obtained; (2) classified intermediate products are separated by an ore sand shaker to obtain intermediate pyrites and tailing; and (3) classified fine products perform the ore grinding classification, the sludge removal, the flotation and the separation to obtain coal and pyrite products and tailing. The method crushes the coal gangue to divide into different coarse and fine particle grades; the coarse particle grade adopts the heavy-medium vibrating chute with relatively lower production cost to separate out coarse gangue minerals so as to reduce the direct ore grinding cost; and in particular, the method is suitable for the coal gangue with nonuniform embedding particle size, can greatly improve the recovery rate of the pyrites, and synchronously extracts other valuable elements in the separation process to increase the additional value.

Owner:唐山联众选煤科技有限公司

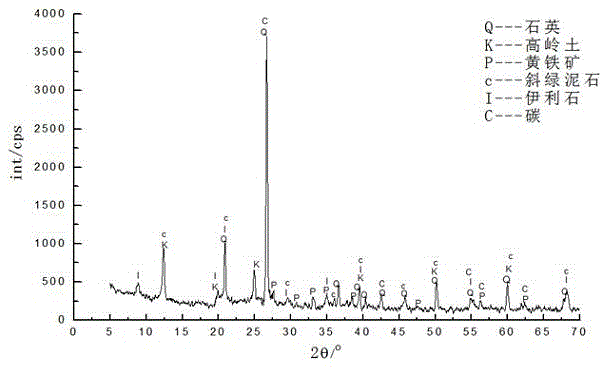

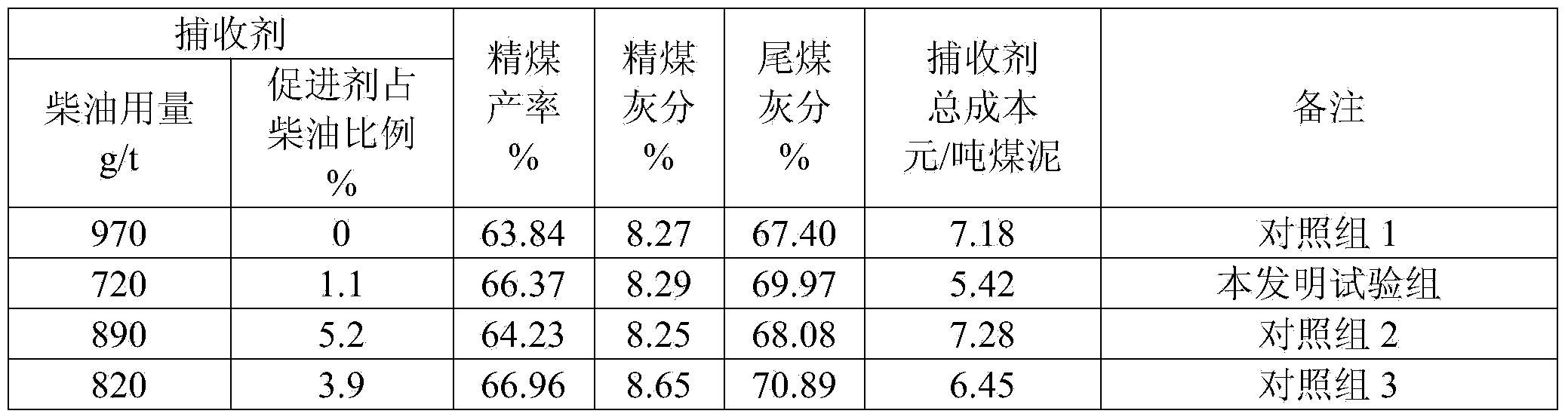

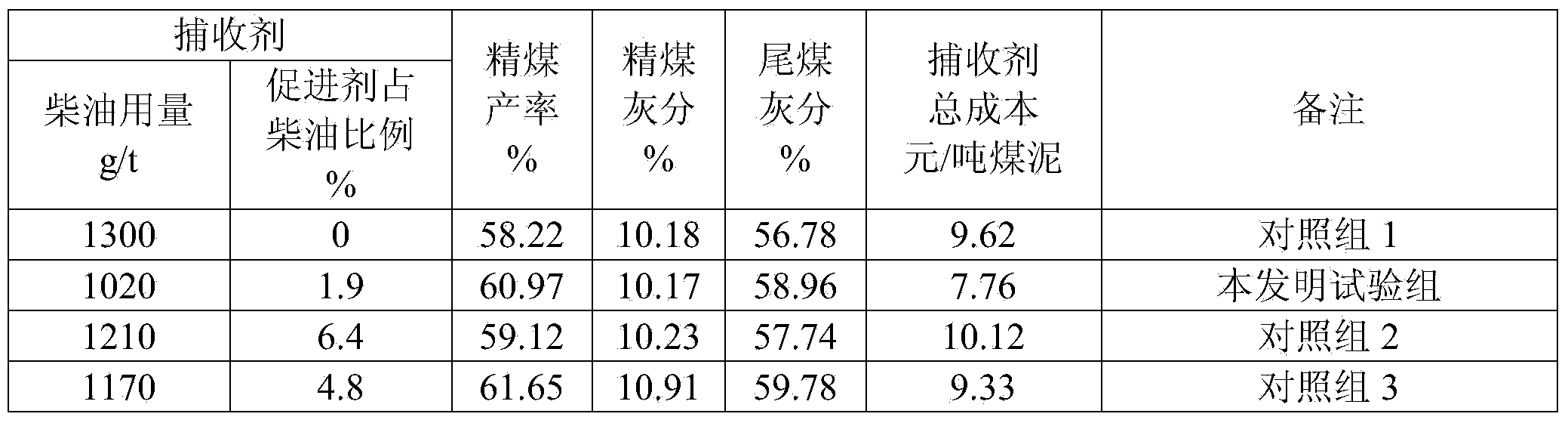

Preparation method of coal slime flotation accelerant and coal slime flotation method

ActiveCN104028385AImprove conversion rateGood harvesting effectFlotationReaction temperatureAlkylphenol

The invention discloses a preparation method of coal slime flotation accelerant and a coal slime flotation method. The accelerant uses alkylphenol polyoxyethylene ether and sulfamic acid with the polymerization degree n=4-12 as raw materials, the mole ratio of the alkylphenol polyoxyethylene ether to the sulfamic acid is 1:0.5-1:0.6, reaction temperature is controlled at 70-90 DEG C, stirring is performed constantly during synchronization, reaction time is 30-40 minutes, and products are cooled to normal temperature after reaction to obtain the accelerant. When the accelerant is used for coal slime flotation, the amount of the accelerant accounts for 0.5-2wt% of that of collecting agent. Compared with methods independently using the hydrocarbon oil collecting agent, the coal slime flotation method using the accelerant has the advantages that under the situation of equivalent cleans ash, clean coal yield can be increased by 2-3wt%, oil saving rate can reach 20-30wt%, use amount of the hydrocarbon oil collecting agent is reduced favorably, separation index can be optimized, and overall economical benefits can be increased.

Owner:SHANDONG UNIV OF SCI & TECH

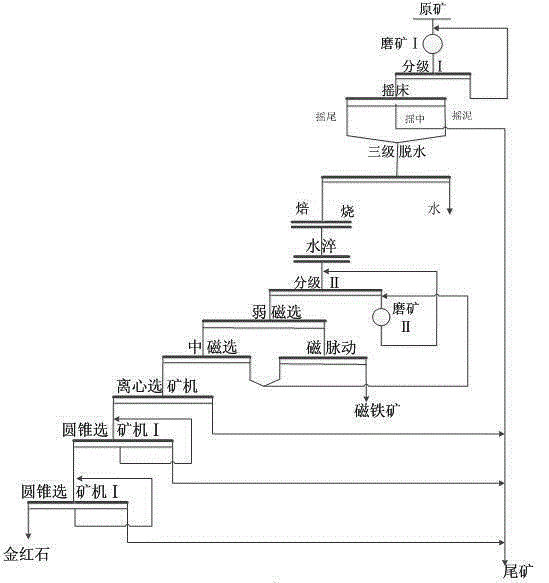

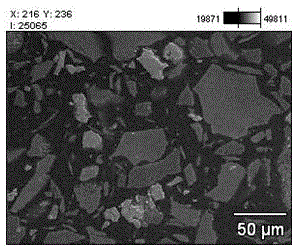

Processing method for fine-grained disseminated rutile ore difficult to separate

ActiveCN105057086AIncrease added valueReduce follow-up costsMagnetic separationWet separationFluidized bedMagnetite

The invention relates to a processing method for fine-grained disseminated rutile ore difficult to separate, and belongs to the technical field of mineral processing. The method is characterized in that under the operating conditions of primary grinding, a shaking table is adopted for primary separation so as to remove coarse-grained disseminated gangue, so that subsequent operating cost is reduced. Fluidized bed tube type calcination is adopted for reducing hematite into magnetite, so that nature difference between the hematite and the rutile is enhanced, separation between the hematite and the rutile is promoted, and influences on the rutile recovery effect from iron are reduced. The magnetite is recovered after calcination, so that the additional value of rutile ore utilization and processing is increased; ideal separation indexes of the fine-grained rutile obtained by monomer separation are achieved through level flow separation devices, namely, suspension vibration cone separators.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

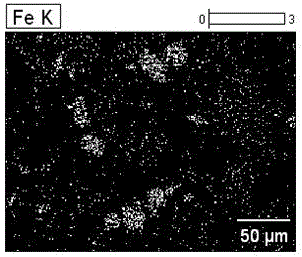

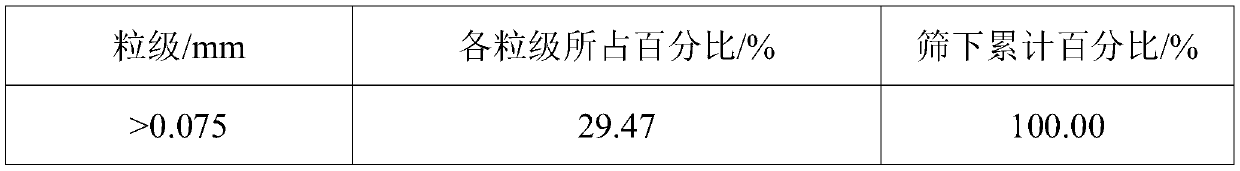

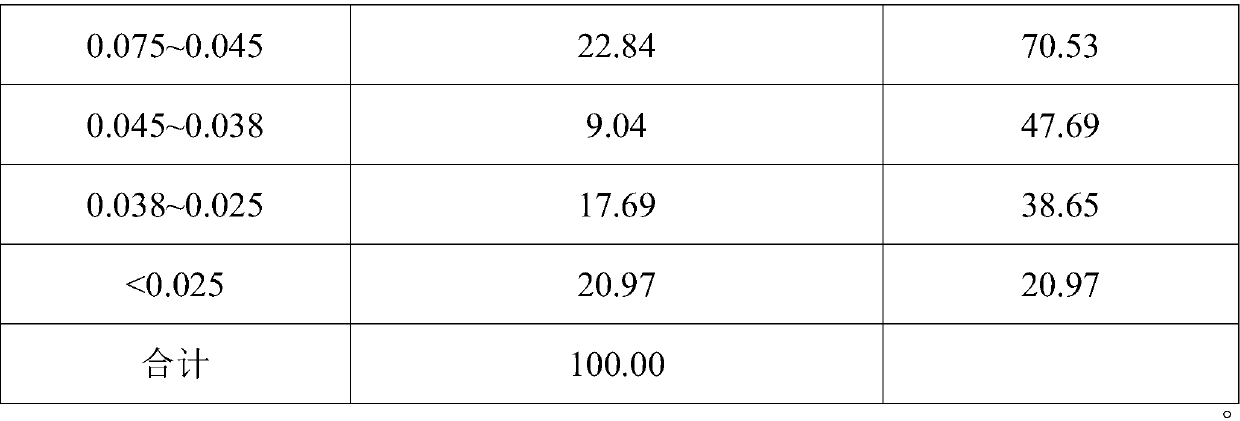

Flotation process for recovering micro-fine particle mica from micro-fine particle iron separation tailings

InactiveCN110586330AFully dispersedEliminate the effects of flotationFlotationLower limitGranularity

The invention relates to a valuable mineral recovery process of tailings, in particular to a flotation process for recovering micro-fine particle mica from micro-fine particle iron separation tailings. According to the process, fine particles are removed by one-time grading operation; the flotation process is formed by one-time roughing, five-time concentration and one-time scavenging; middlings are selected, merged and subjected to dehydration, concentration and reagent removal treatment respectively; in the regime of agent, a combined regulator, a mixed inhibitor and a mixed collecting agentare used; the state of an obtained ore pulp is fully adjusted, the lower limit of the floatable granularity of mica minerals reaches 0.025 mm, high-quality mica concentrates are obtained, the yield of the mica concentrates is larger than or equal to 11.86%, the content of mica in the mica concentrates is larger than or equal to 97.21%, and the recovery rate of the mica is larger than or equal to48.25%. The mica recovery rate is high, the valuable mineral resource recovery efficiency is improved, and economic benefits are brought to enterprises.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

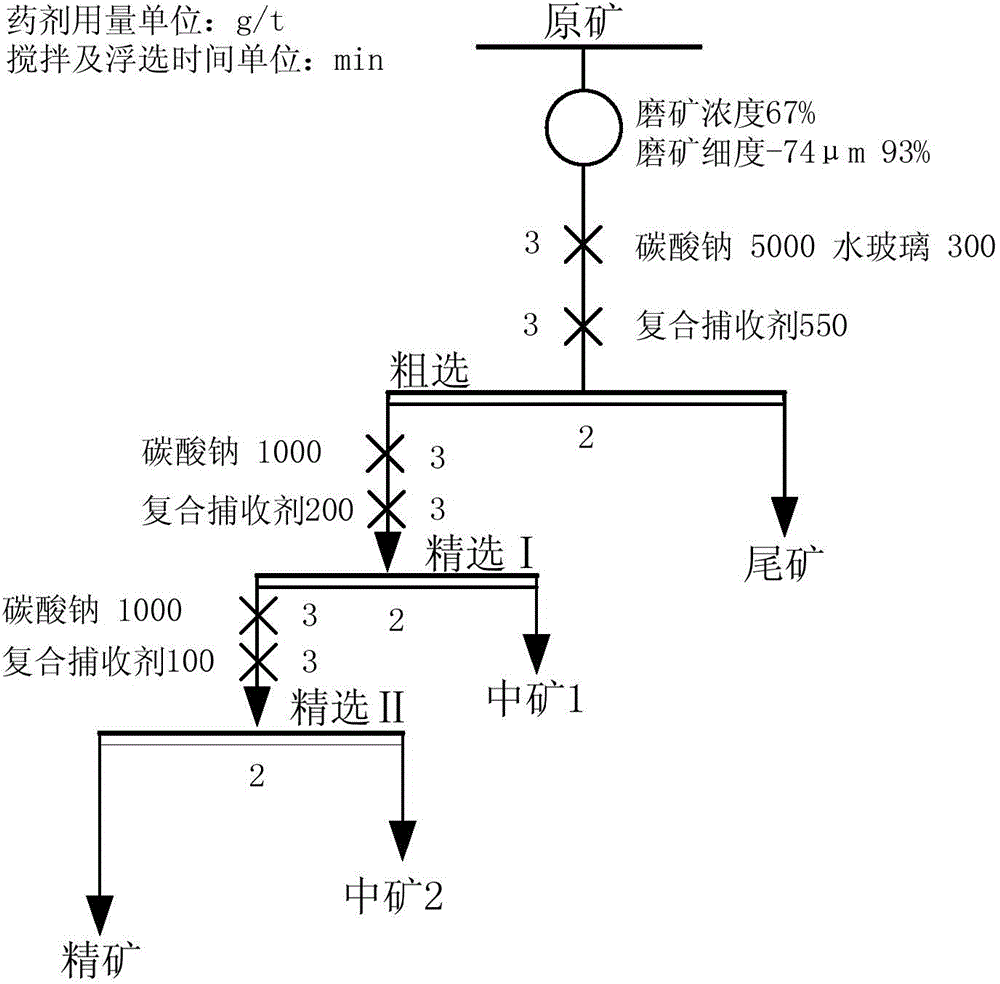

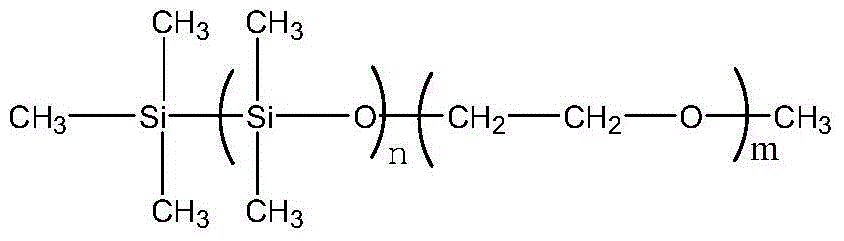

Bauxite direct flotation composite collector and application method thereof

InactiveCN104148191AImprove surface activityImprove performanceFlotationFoaming agentChemical composition

The invention discloses a collector for bauxite direct flotation desilicification and an application method of the collector. The collector is characterized by comprising the chemical component of a mixture of monocarboxyl fatty acid, an organosilicon surfactant, a polyoxyethylene ether surfactant and a mining foaming agent, wherein the compounding mass percents of the monocarboxyl fatty acid, the organosilicon surfactant, the polyoxyethylene ether surfactant and the mining foaming agent are 70-80%, 5-10%, 5-10% and 10-20% respectively. The collector has the obvious advantages that by adding the surfactants without collecting ability, the dispersing performance of the fatty acid collector is improved, the collecting performance of the fatty acid collector is improved, recovery of aluminum oxide is improved, and the use quantity of medicaments is reduced; on the condition of not conducting desliming, the flotation effect of diaspore bauxite with a medium and low alumina-silica ratio (2.5-5) is prominent.

Owner:CENT SOUTH UNIV

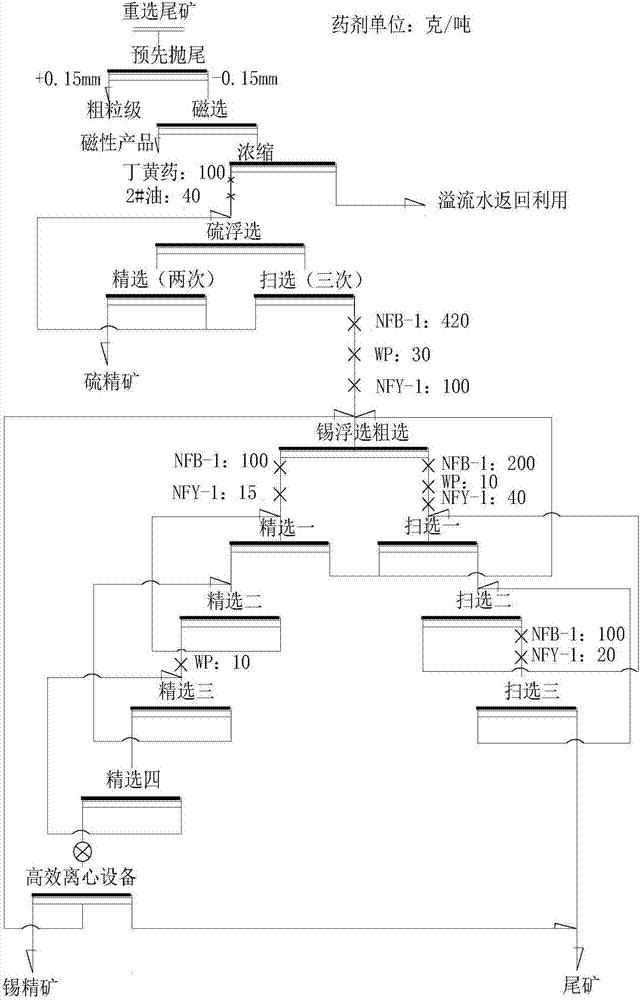

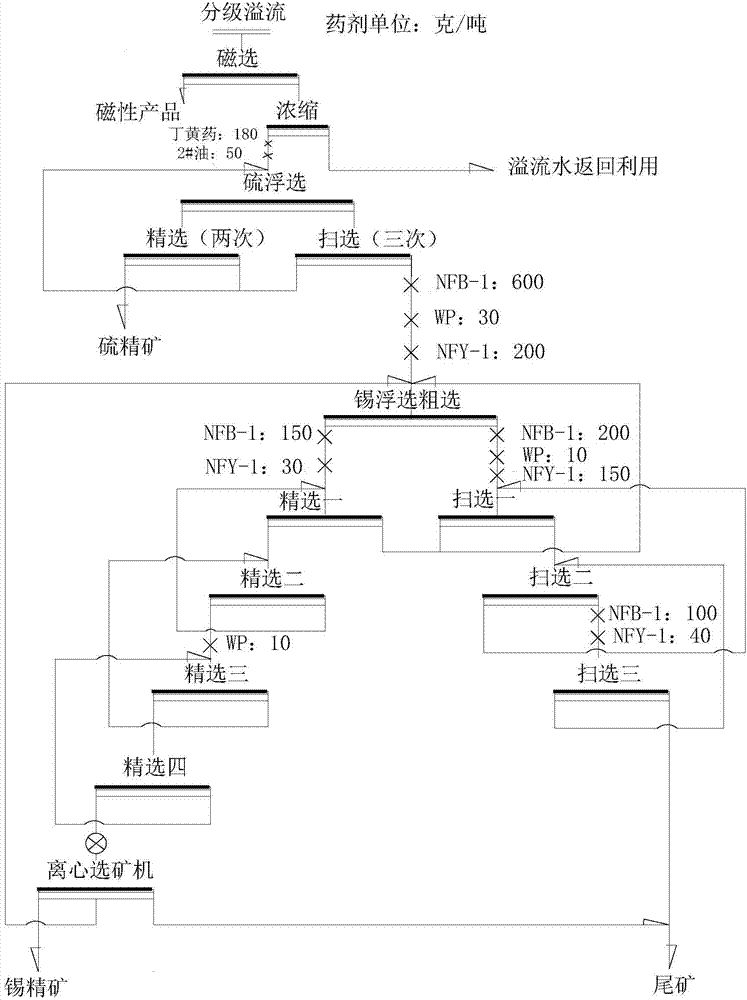

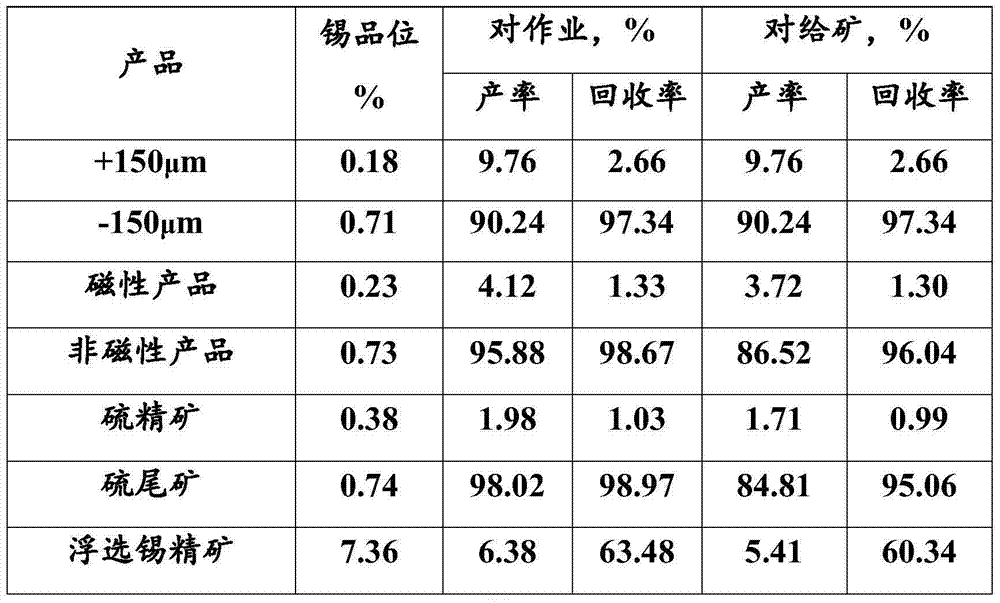

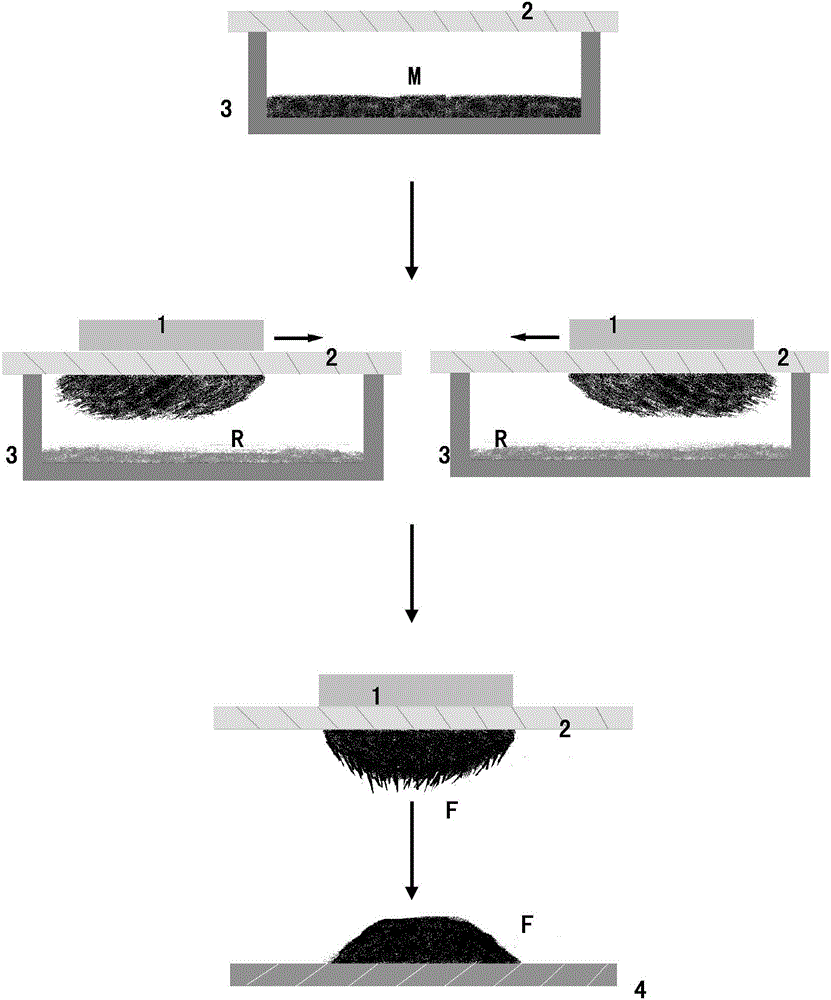

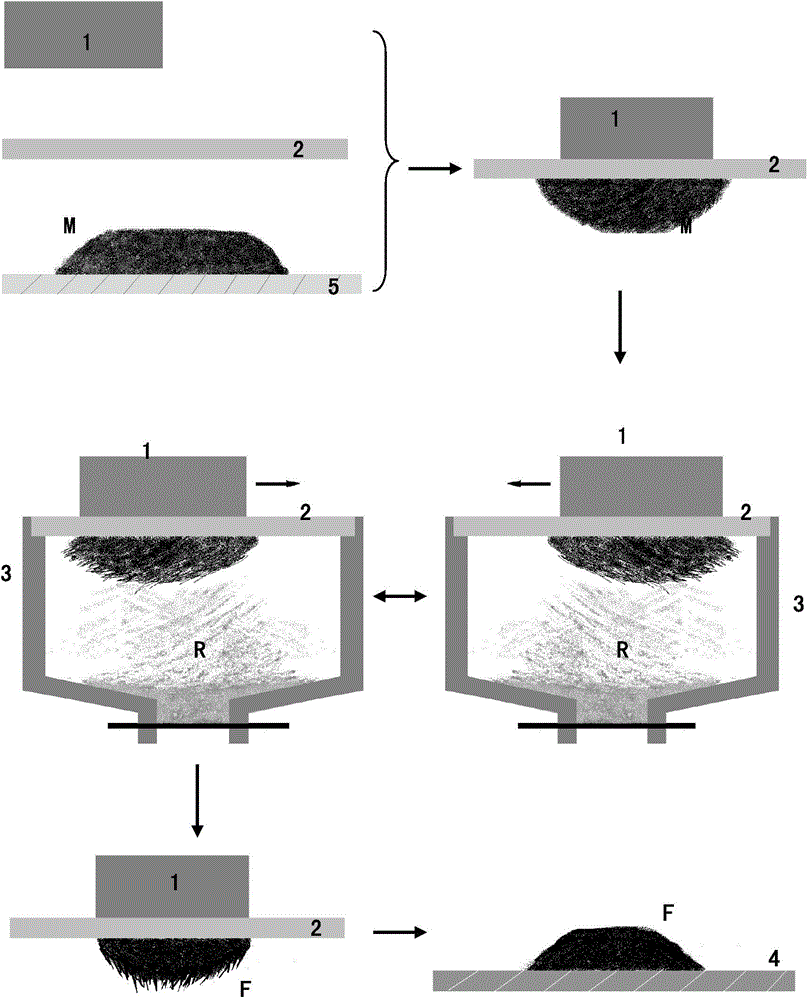

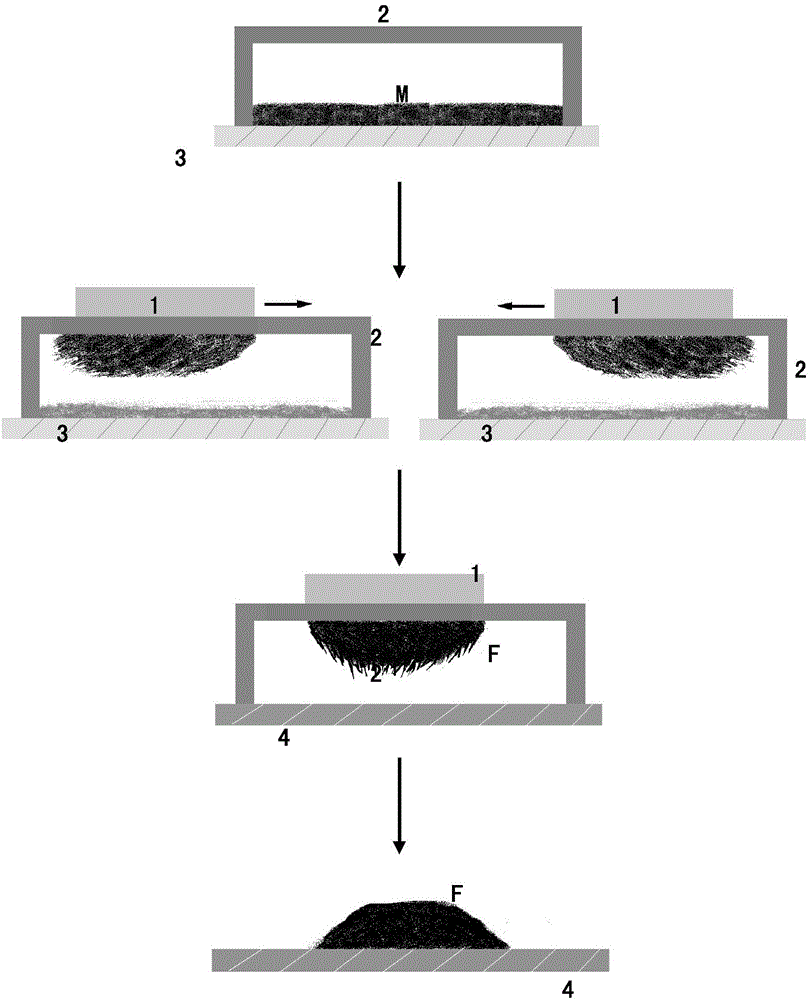

Reprocessing method of tin flotation rough concentrate and industrial application thereof

The invention provides a reprocessing method of tin flotation rough concentrate. The reprocessing method is characterized by comprising the steps of reselecting and reprocessing to recover the tin flotation rough concentrate through efficient centrifugal equipment, and returning the acquired reselected ores into a tin flotation system. According to the reprocessing method provided by the invention, the tin flotation rough concentrate can be recycled to meet the indexes that the final concentrate grade is 40%, the operation recovery is above 70%, and the raw ore of a concentrating plant is above 11% by the efficient centrifugal equipment; furthermore, after the efficient centrifugal equipment and the flotation system are closed, middlings can be directly returned to the tin flotation system, so as to prevent the loss of intermediate products.

Owner:临武县南方矿业有限责任公司

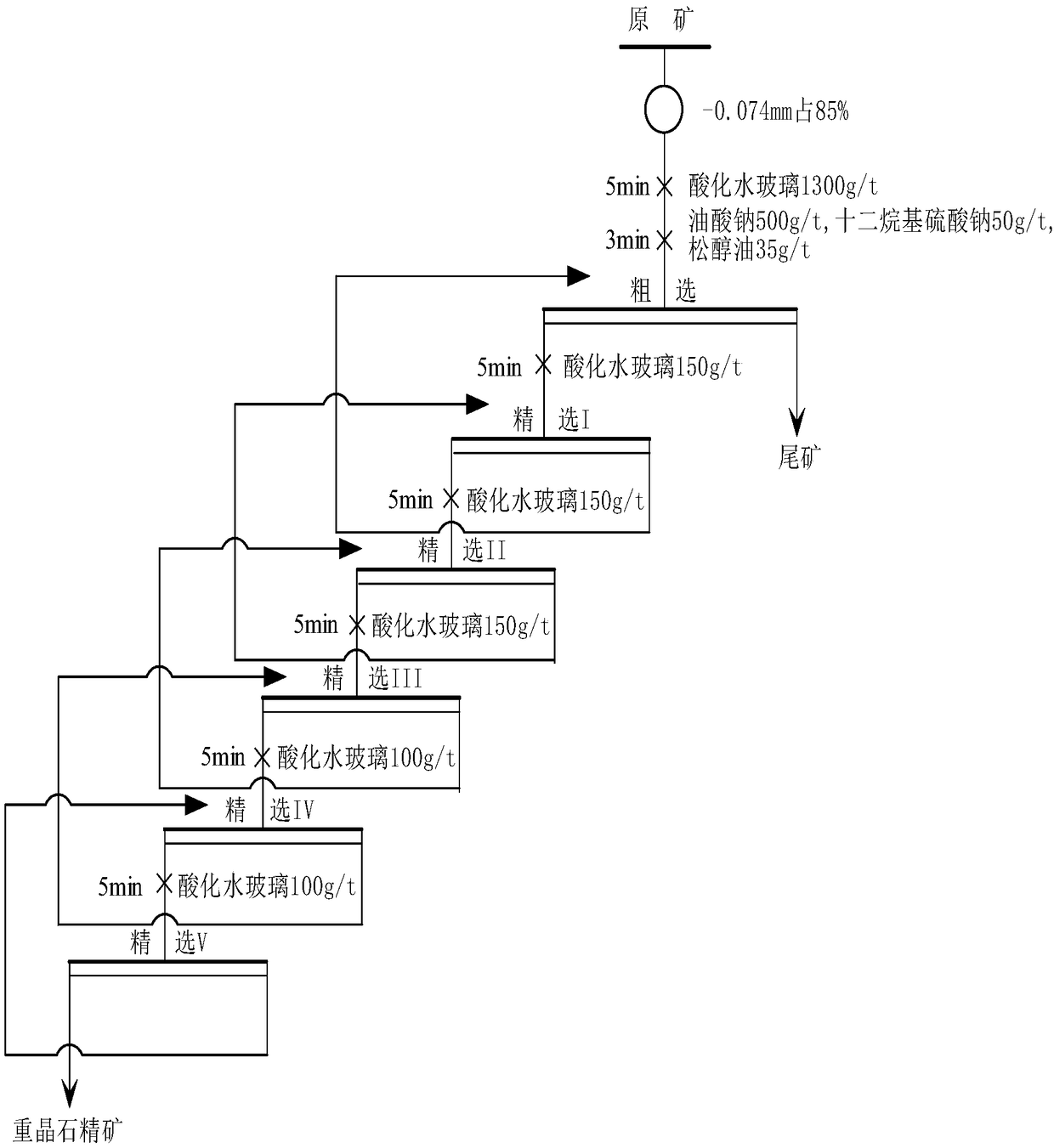

Beneficiation method for barite rich in calcite and witherite

The invention provides a beneficiation method for barite rich in calcite and witherite. According to the beneficiation method, the problem that the quality of flotation concentrate is poor due to thefact that the floatability of gangue minerals such as the calcite and fluorite is similar to that of the barite is solved. The beneficiation method is characterized in that acidified sodium silicate is adopted for inhibition and dispersion so that separation of the barite from the gangue minerals can be well realized; and a combined collecting agent composed of sodium oleate and sodium dodecyl sulfate is selected, so that relatively strong collecting capacity and good selectivity on the barite and the witherite are realized. According to the beneficiation method, barite concentrate with the relatively high recovery rate can be obtained, the quality of the concentrate meets the requirements of national standard first-grade products of drilling grade barite powder, and the barite ores rich in the calcite and the witherite can be developed and utilized.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

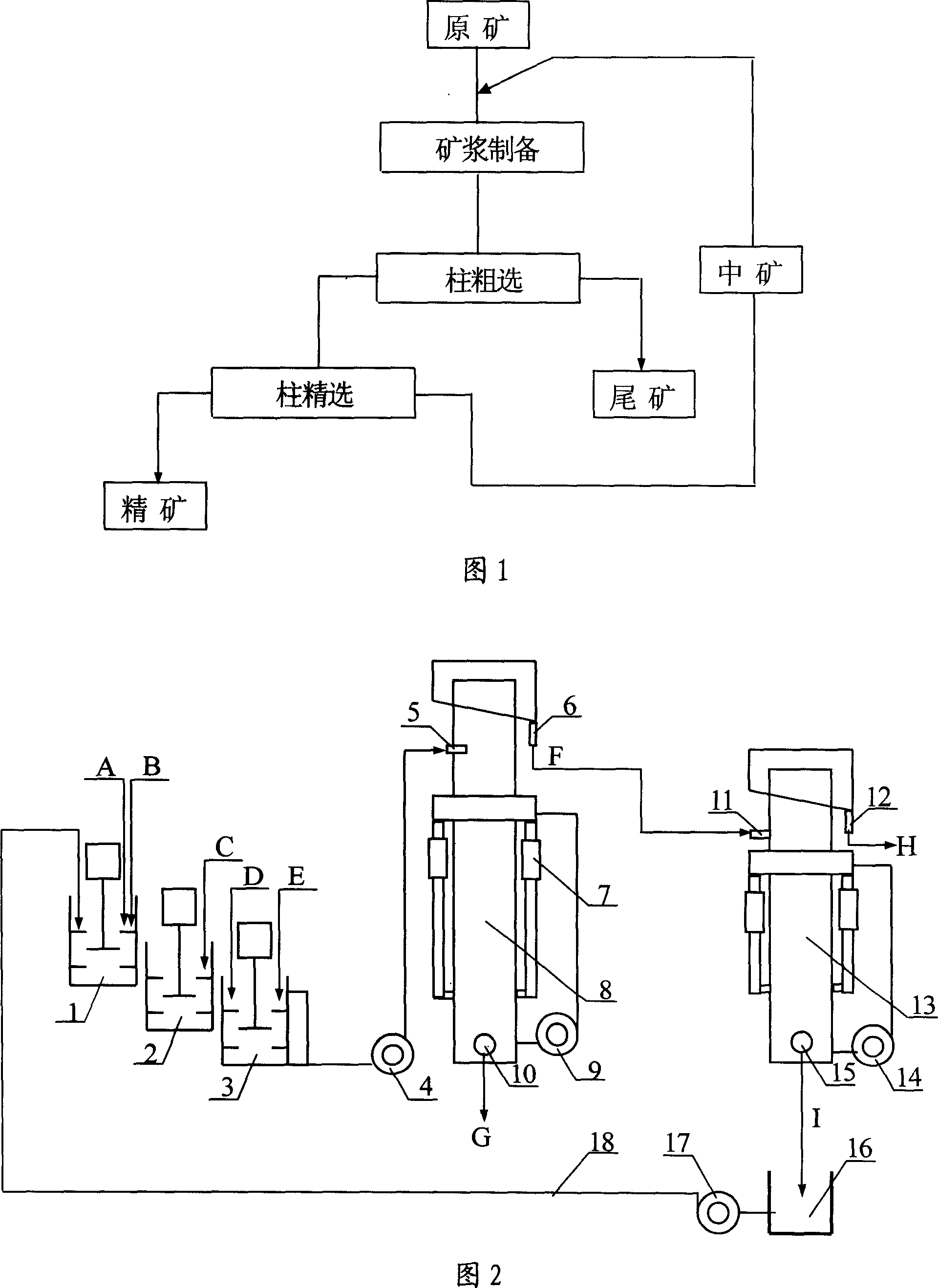

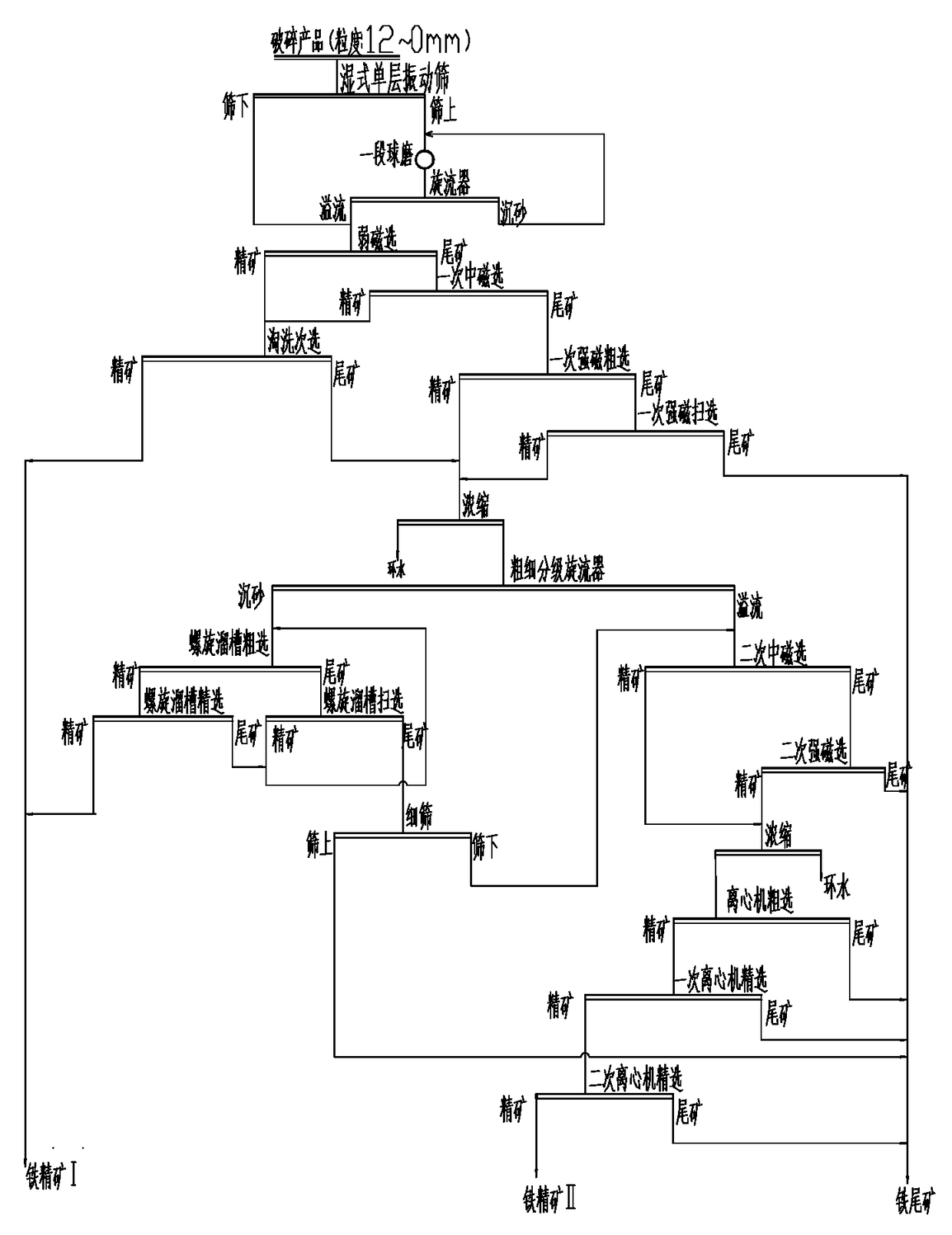

High-yield two-product mixed maghemite beneficiation process

The invention relates to a high-yield two-product mixed maghemite beneficiation process. The high-yield two-product mixed maghemite beneficiation process comprises three-section breakage including coarse breaking, medium breaking and fine breaking on mixed maghemite, and is characterized by further comprising the following steps: sieving operation, a one-section closed circuit grinding operation implemented by a one-section ball-milling-cyclone, primary beneficiation operation, coarse and fine classification operation, reselection operation, secondary magnetic separation operation and centrifuging operation; a primary magnetic separation operation sieve treats overflow products of one-section closed circuit grinding operation, sieving operation and undersizes, the coarse and fine classification operation treats bulk concentrate obtained by primary beneficiation, the reselection operation treats coarse grain products of the coarse and fine classification operation, the secondary beneficiation operation treats coarse particle products of the coarse and fine classification operation, and the centrifuging operation treats bulk concentrates of secondary weak magnetic separation. The high-yield two-product mixed maghemite beneficiation process has the advantages that iron ore concentrates I with grade being 62% for pelletizing raw materials and iron ore concentrates II with grade being 58% for sintered raw materials can be selected out.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

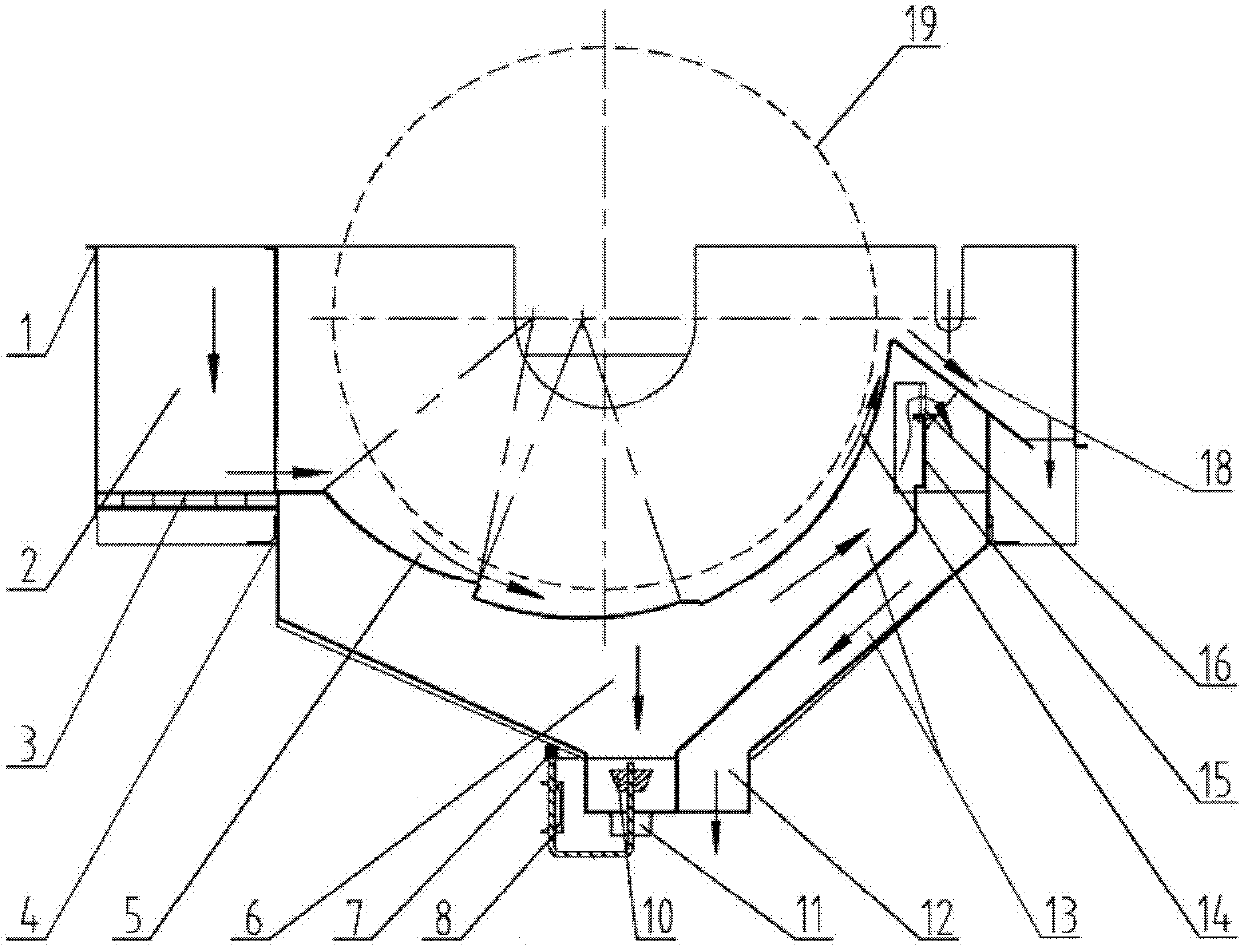

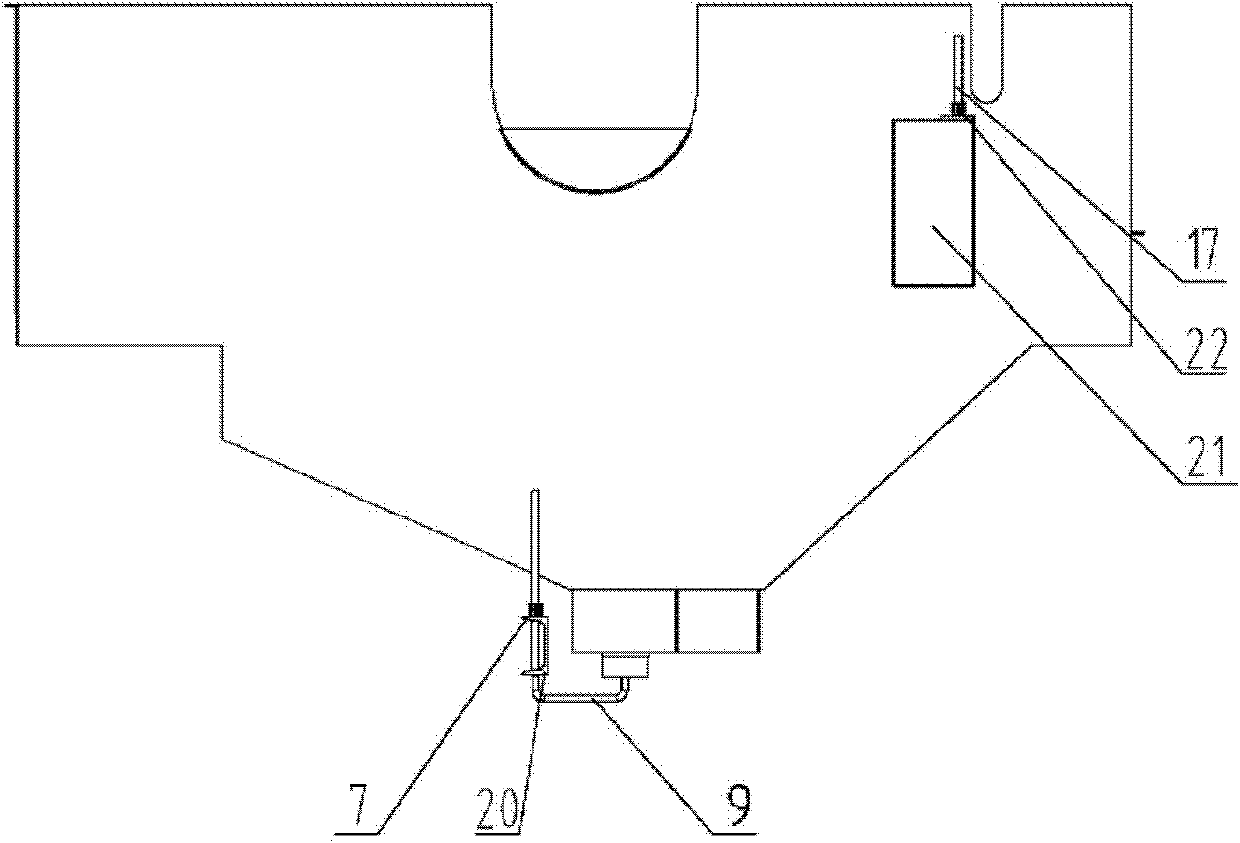

Wet magnetic separator groove body

InactiveCN102166544AIncrease catch ratePrevent precipitationMagnetic separationMagnetic separatorEngineering

The invention relates to the technical field of magnetic separators, in particular to a wet magnetic separator groove body (1). The wet magnetic separator groove body comprises an ore feeding space (2), a separation space (5), a tailing discharging space, a concentrate conveying space (14) and a liquid level adjusting mechanism (16), wherein the liquid level adjusting mechanism (16) is used for adjusting the ore pulp liquid level height in the groove body (1). The wet magnetic separator groove body (1) with the liquid level adjusting mechanism (16) has the characteristics of adaptability to higher fluctuation of an ore feeding amount and adjustable ore pulp liquid level height in the groove body; the matching relation between the height of the separation liquid level and the ore feeding amount is the best. At the same time, the invention also provides the ore feeding space (2) with a pre-magnet (3) and the separation space (5) with a step groove body structure. The magnetic ore catching probability can be effectively improved; ore pulp is prevented from precipitating; and crude ores do not sink into the groove to block the groove at the same time, so that the best working condition is achieved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Simple and efficient dry magnetic separation method

ActiveCN104549725AHigh recovery rateRaise the gradeMagnetic separationGranularityReciprocating motion

The invention discloses a simple and efficient dry magnetic separation method. A magnetic separation component adopted by the method comprises a magnetic body, a partition plate and a tailings receiver, wherein a selection space is constructed by the partition plate and the tailings receiver; and a selection medium is air. According to the method, firstly, to-be-selected ore powder acts on the other side of the partition plate under the action of the magnetic body to generate magnetic aggregates and a magnetic chain; the magnetic body moves on the fixed partition plate in a reciprocating manner, so that the separation time is prolonged; the ore powder generates 'exclusion action' and 'throwing-off action'; the magnetic selection grading capacity is obviously improved. When the simple and efficient dry magnetic separation method is applied to treatment of 70%-86% of iron ore of which the iron grade is 27.36%-49.58% and the granularity is less than 75 microns, iron concentrate of which the iron grade is greater than or equal to 59.85% and the iron recovery rate is greater than or equal to 73.52% is obtained; and the selection indexes of existing dry magnetic iron ore are greatly improved.

Owner:张天昊 +1

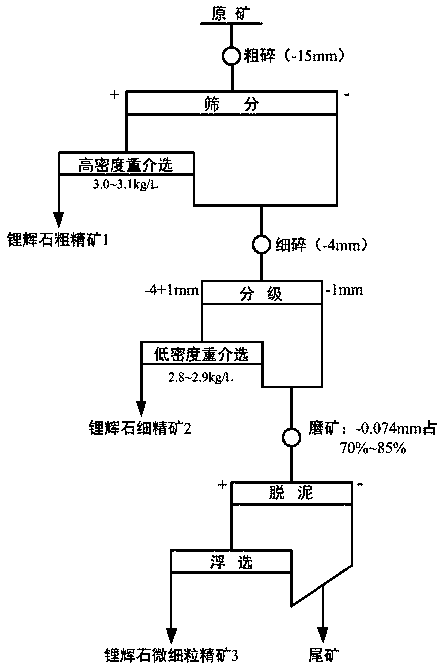

Spodumene particle-size double-dense-medium-flotation benefication method

The invention discloses a spodumene particle-size double-dense-medium-flotation benefication method, and belongs to the technical field of mineral machining. The method adopts two sections of crushingflow; through screening (or classification) treatment, high-density dense medium separation and low-density dense medium separation, thick-particle spodumene concentrate products and fine-particle spodumene concentrate products are obtained; cyclone overflowing products are concentrated for ore grinding; a cyclone is used for mud removal; and sunk sand enters the flotation operation to obtain fine-particle spodumene concentrate products. The method has the advantages of high adaptability, low production cost, capability of obtaining the concentrate products with different particle sizes and reduction of the crushing and ore grinding energy consumption and the medicament use level.

Owner:KUNMING UNIV OF SCI & TECH

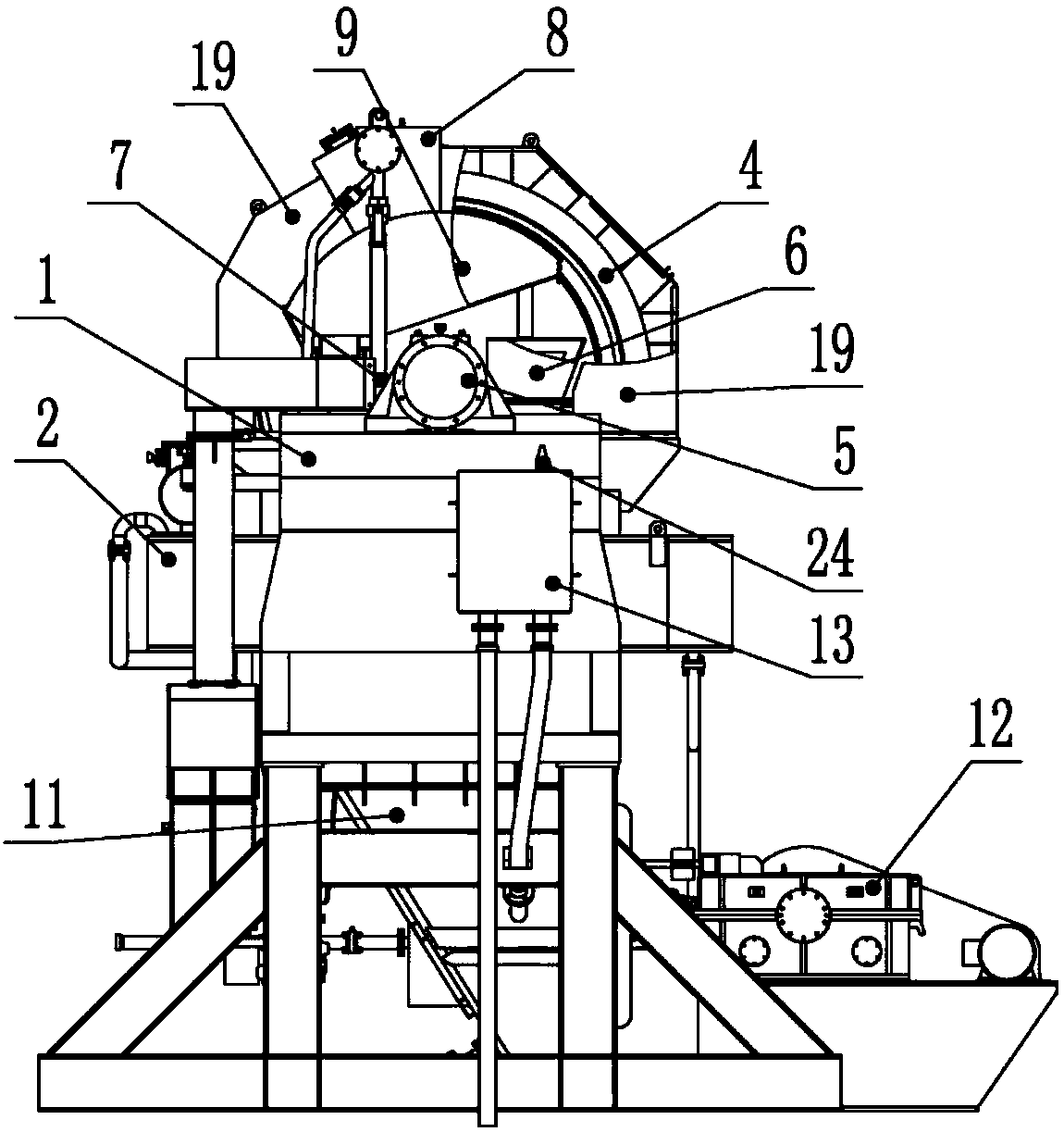

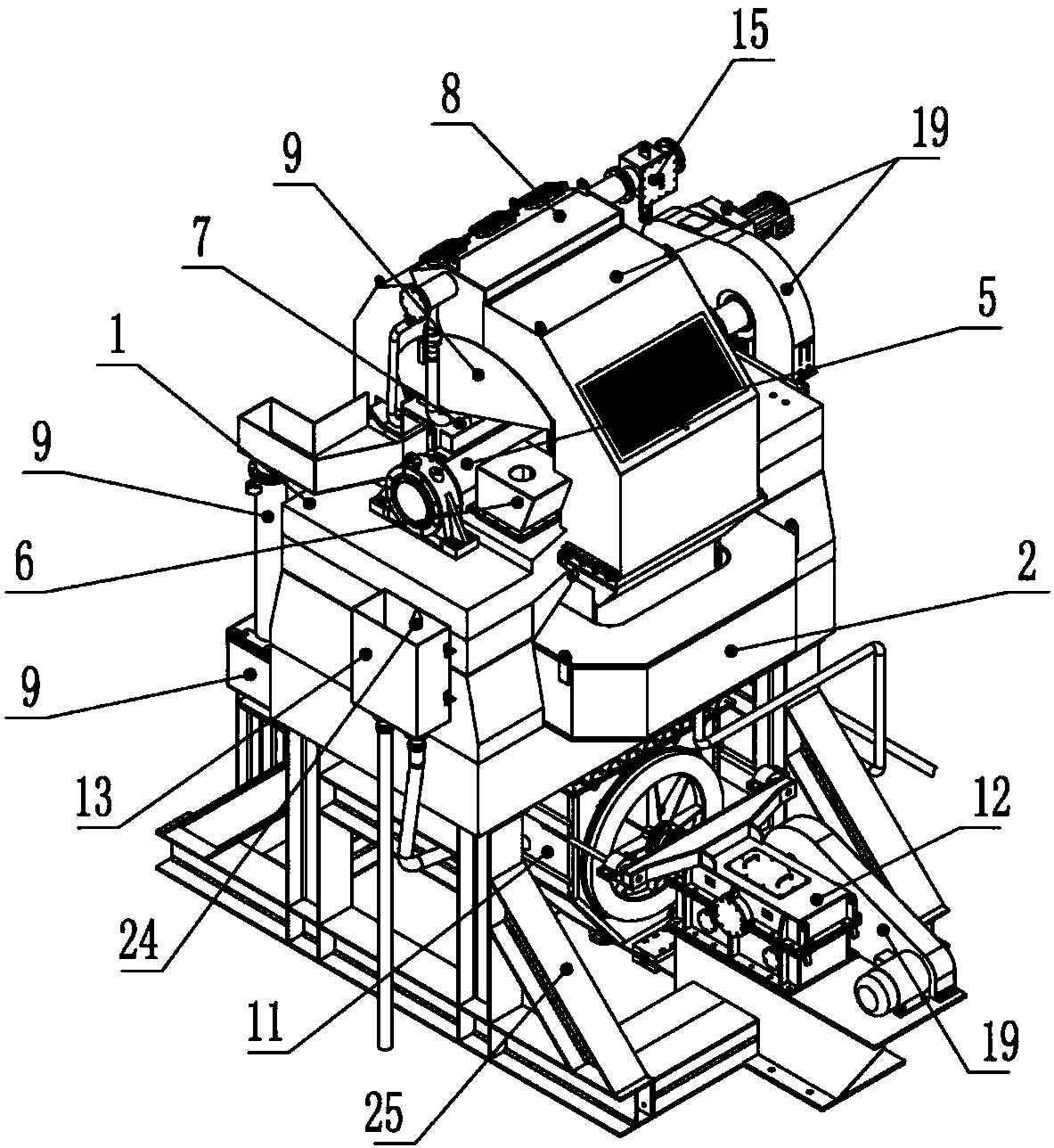

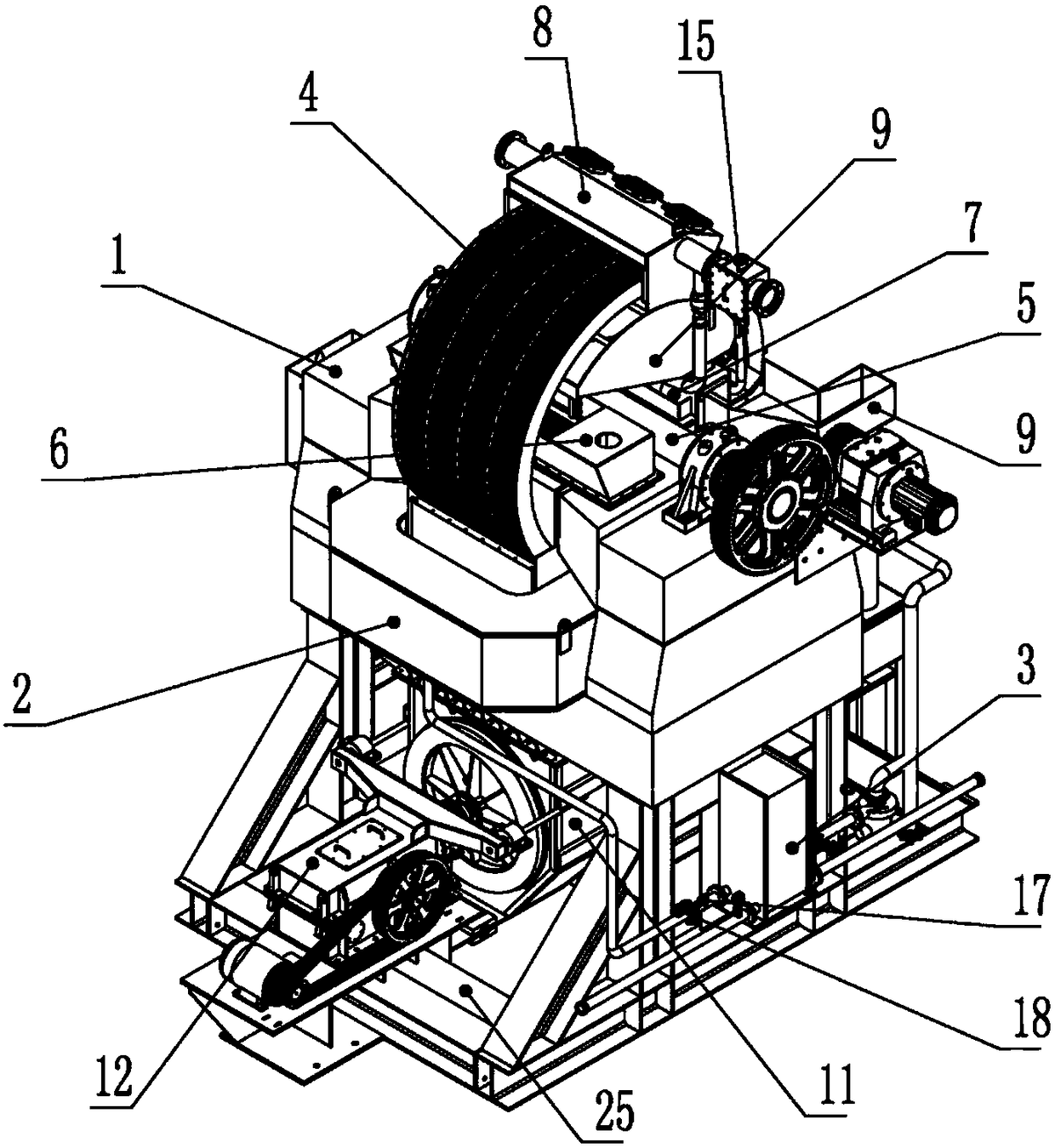

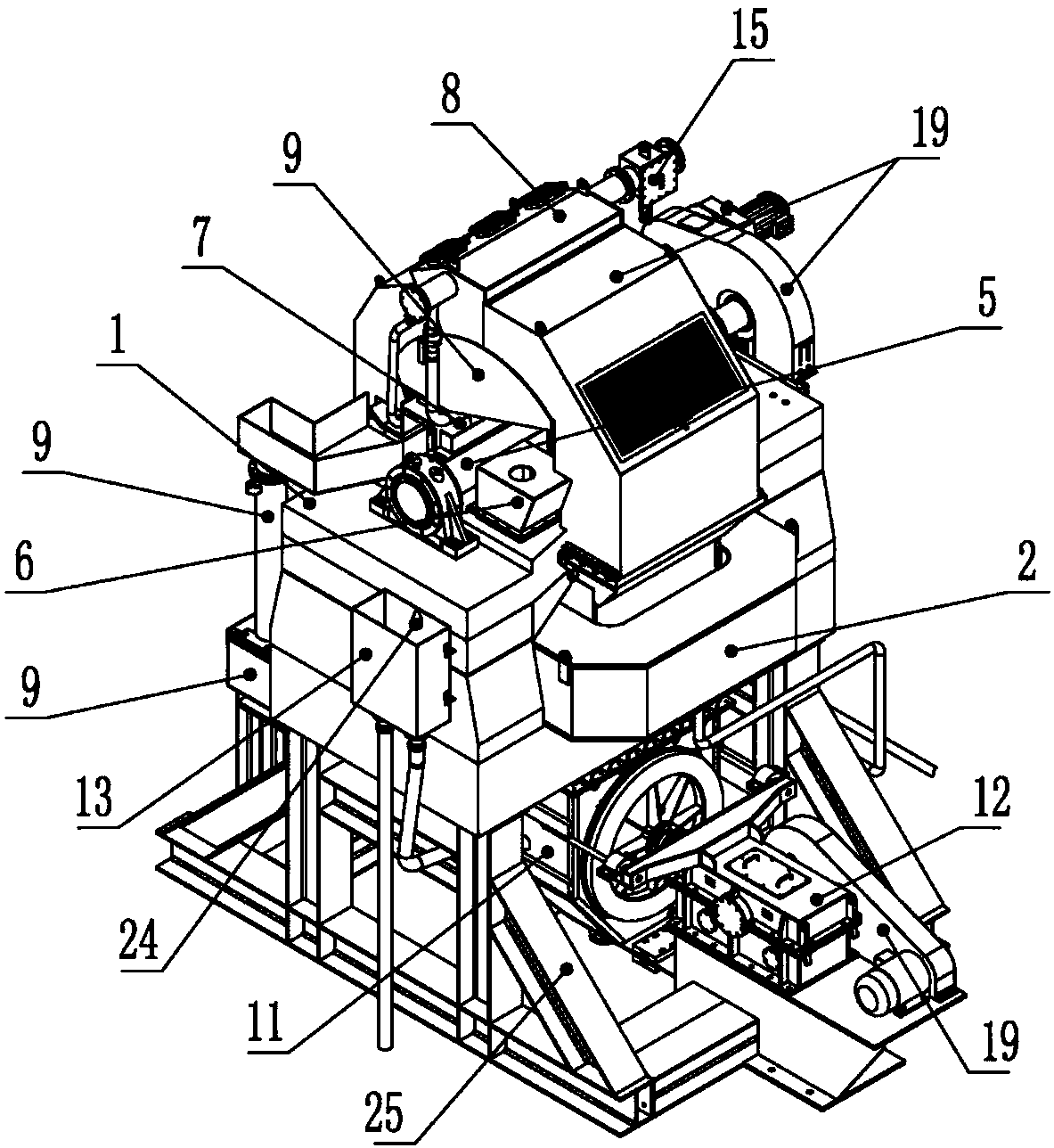

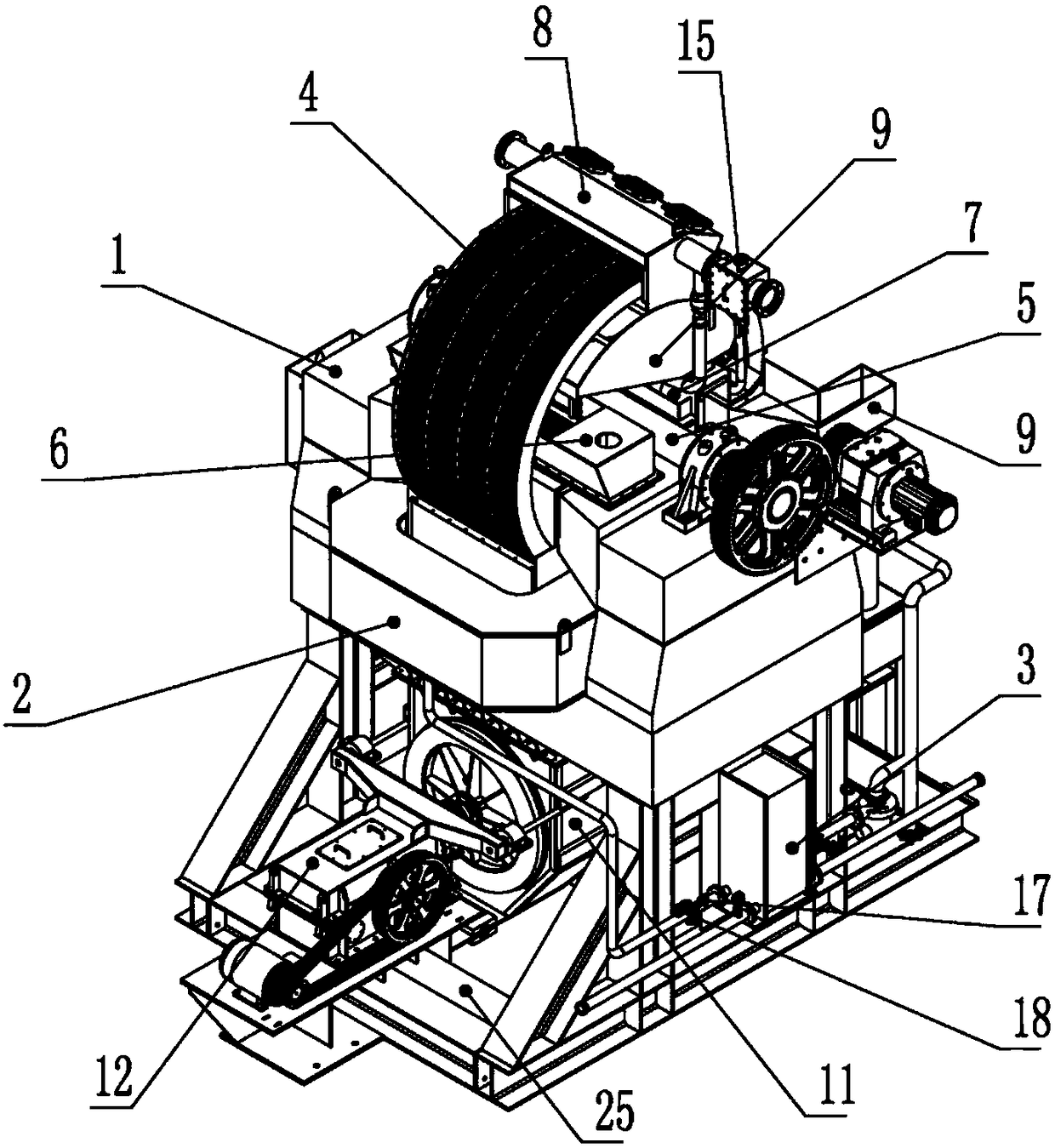

Wet high gradient strong magnetic separator

PendingCN108262159AApplicable removalGood sorting indexHigh gradient magnetic separatorsCollection systemSlurry

The invention provides a wet high gradient strong magnetic separator. The wet high gradient strong magnetic separator comprises an excitation system, a sorting collection system, a safety and isolation system and an adjustment system. The excitation system provides a background magnetic field for sorting. The sorting collection system is used for separating a magnetic material and a non-magnetic material in ore slurry containing magnetic ores through magnetic separation. The safety and isolation system is used for granularity isolation of a fed material, isolation of impurities in water, pollution isolation of an insulation coolant, magnetic field isolation of a magnetic-fearing part, safety protection of a motor, a coil and a media box module, and personal safety protection for operators.The adjustment system is used for adjusting background magnetic field strength, a rotation ring rotation rate, pulsation amplitude and frequency, liquid level height and rinsing water and ore unloading water amount / angle. The multiple parts or modules realize division and cooperation between systems so that the reliable and stable strong magnetic sorting of the weak magnetic minerals is realized.

Owner:LONGI MAGNET CO LTD

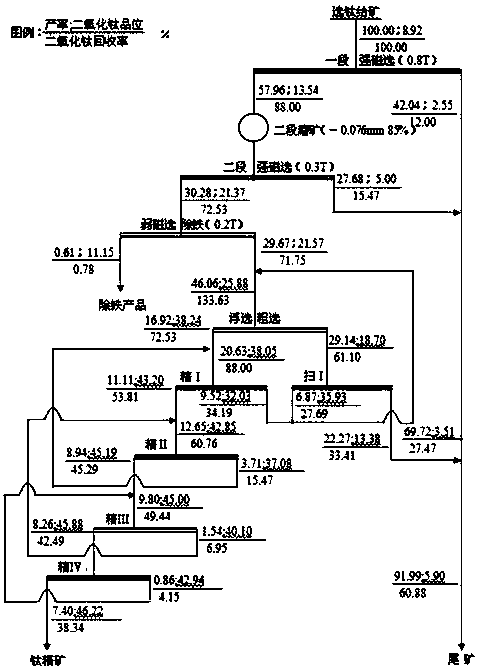

Method for sorting low-grade titaniferous magnetite

ActiveCN107649278AReduce follow-up job processingImprove the quality of selectionHigh gradient magnetic separatorsFlotationBeneficiationLow graded

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Mineral processing process for improving quality and reducing silicon of iron ore concentrate

ActiveCN104689905AFully dissociatedGood sorting indexMagnetic separationMagnetic separatorMineral processing

The invention discloses a mineral processing process for improving the quality and reducing silicon of iron ore concentrate. The process comprises the following steps: finely grinding raw ores to obtain ore powder or ore pulp of which the ore powder or ore pulp with the granularity of 325 meshes accounts for 80%, performing magnetic separation by using a 800-1000T magnetic separator to obtain a section of inferior fine magnetite concentrate and a section of inferior magnetic tailing, performing magnetic separation on the section of inferior magnetic tailing by using a 10000-14000T magnetic separator to obtain a section of high fine magnetic concentrate and a section of high magnetic tailing, performing magnetic separation on the section of inferior fine magnetite concentrate by using a 800-1200T magnetic separator to obtain two sections of inferior fine magnetite concentrate and two sections of inferior magnetic tailing, feeding back the two sections of inferior magnetic tailing to an ore grinding procedure for fine grinding, and performing magnetic separation on the section of high fine magnetic concentrate by using a 6000-10000T magnetic separator to obtain two sections of high fine magnetite concentrate and two sections of high magnetic tailing; and combing the two sections of inferior fine magnetite concentrate and the two sections of high fine magnetite concentrate to obtain total fine concentrate, and combining the section of high magnetic tailing and the two sections of high magnetic tailing to obtain total tailing. By adoption of the process, the grade of the iron ore concentrate can be increased by about 8.5%, the grade of a silicon product can be reduced by about 6.5%, the fineness of the iron ore concentrate can be improved, the abrasion of a conveying pipeline can be reduced, and the process is short in process procedure, low in operation cost and applicable to industrial popularization and application.

Owner:YUXI DAHONGSHAN MINING

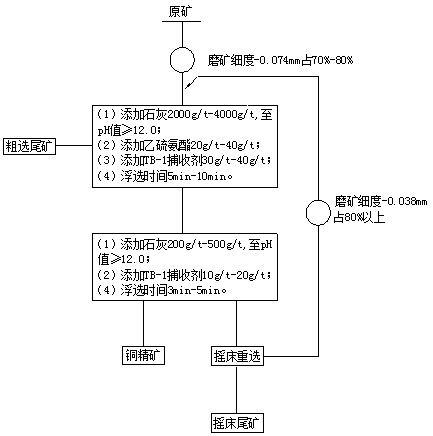

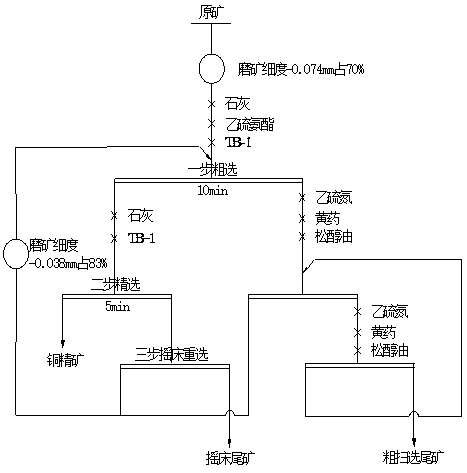

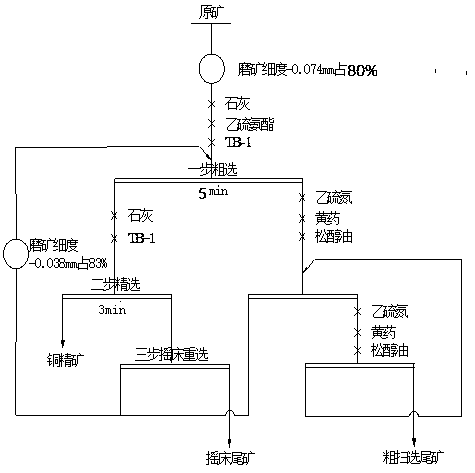

Process method for separating talc and chalcopyrite through three-step method and collecting agent used in process method

ActiveCN111570077AAvoid inclusionsEfficient separationFlotationWet separationThiocarbamateChalcopyrite

The invention provides a process method for separating talc and chalcopyrite through a three-step method and a collecting agent used in the process method. The method comprises the steps of carrying out ore grinding, carrying out first-step roughing, carrying out second-step concentration, and carrying out third-step table reselection and regrinding operation. The process method aims at separationof the talc and the chalcopyrite, the preferential copper separation technological process is adopted for the first time under the condition that a special-effect talc inhibitor is not added, and effective separation of the talc and the chalcopyrite is achieved. According to the process method, the collecting agent TB-1 formed by mixing isobutyl xanthate propionitrile ester, N-allyl-O-alkyl thiocarbamate and Spans type sorbitan ester is adopted to strengthen flotation of the chalcopyrite, the thickness of a foam layer is adjusted through the defoaming performance of the collecting agent TB-1,and the relative floating speed of the talc and the chalcopyrite is changed; and the flotation and reselection combined technological process is adopted, and effective separation of talc and chalcopyrite is achieved through three steps. The flotation reagent adopted in the process method has the characteristics of low toxicity or no toxicity, environment friendliness, good effect and the like, and an environment-friendly and high-efficiency process method for separating the talc and the chalcopyrite is provided.

Owner:安徽铜冠产业技术研究院有限责任公司

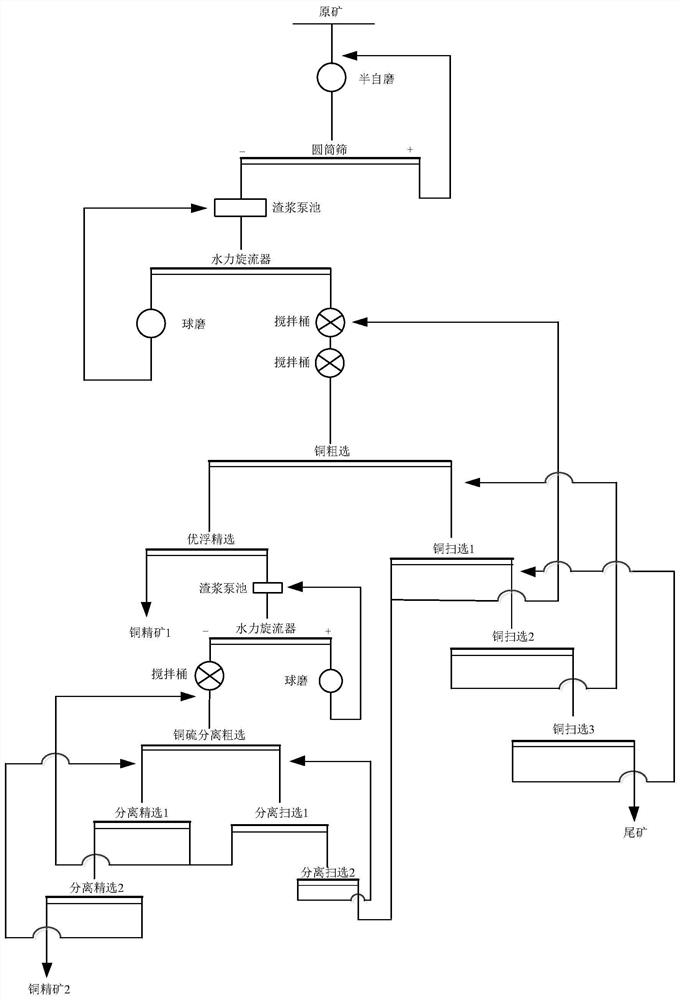

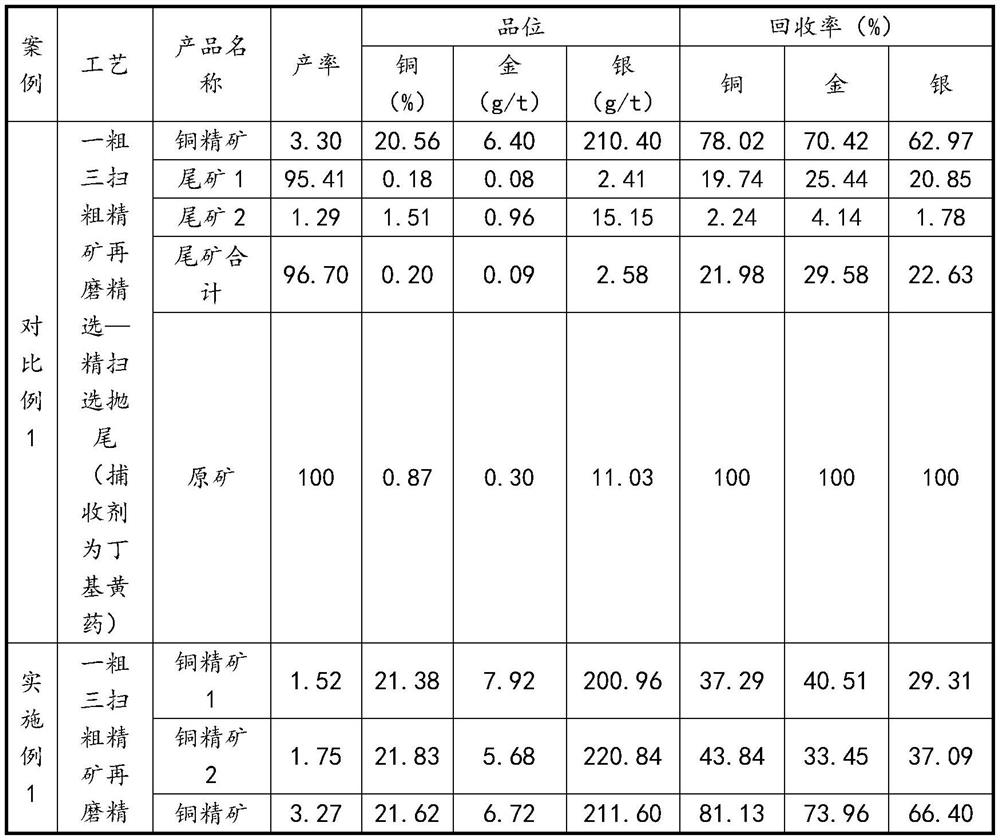

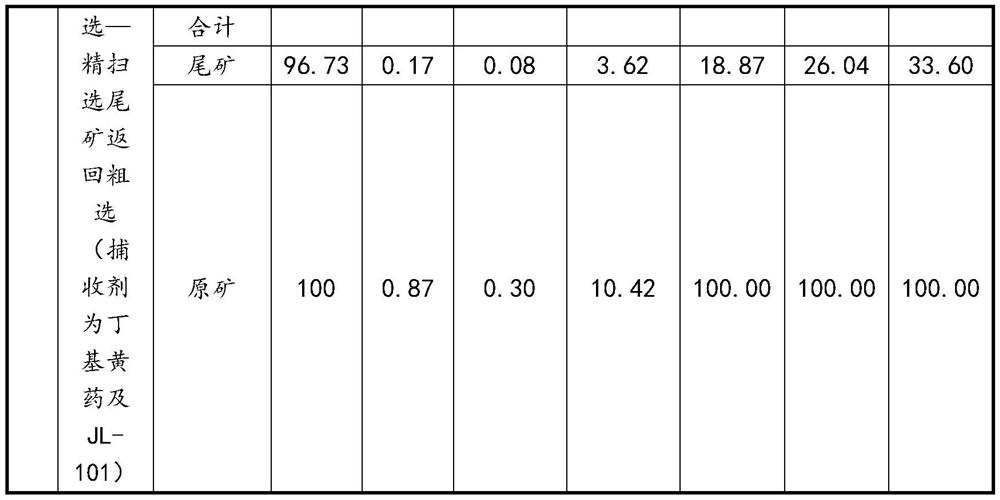

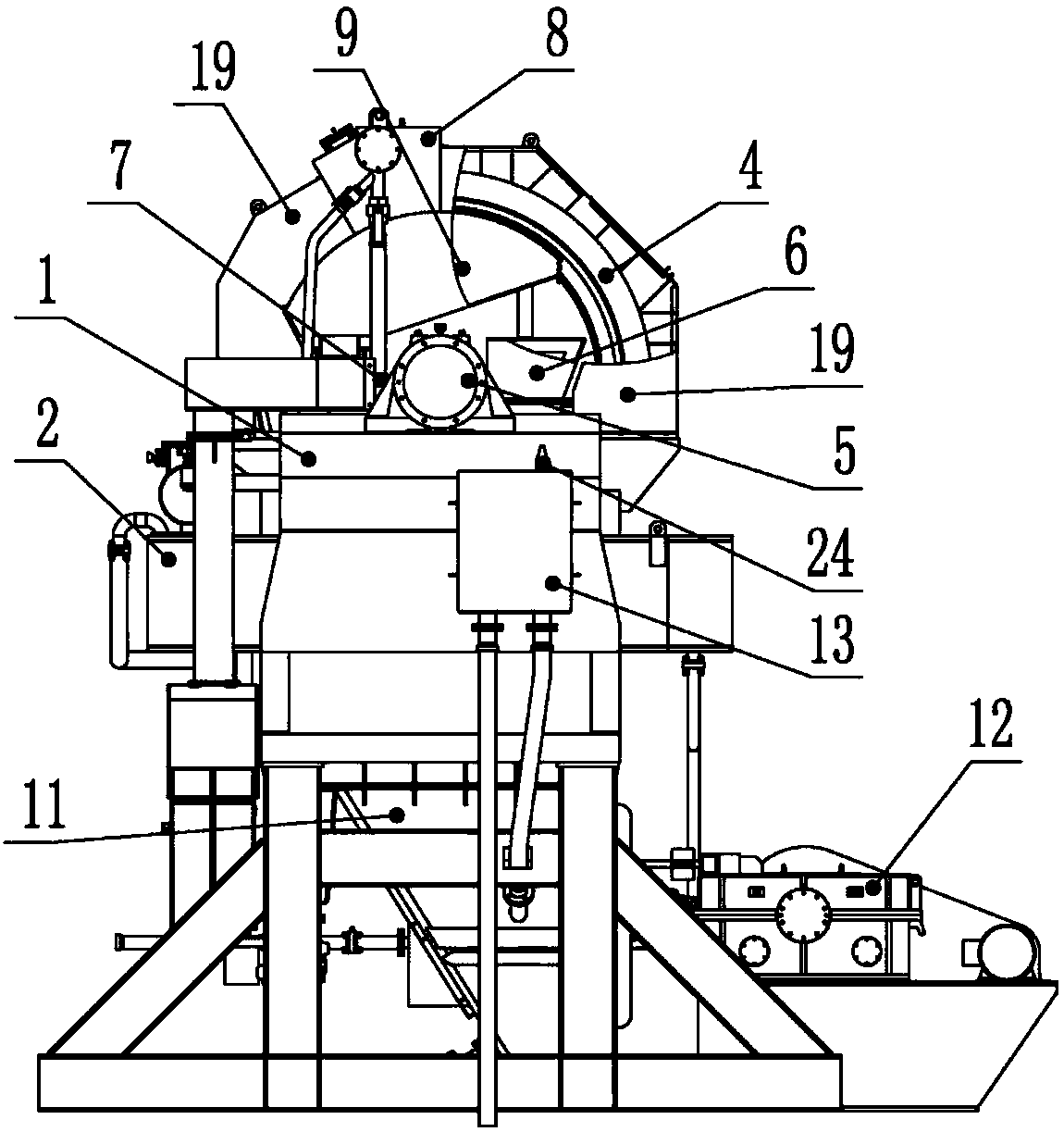

Beneficiation method for fine-grained disseminated copper ore in plateau area

ActiveCN113333153AWiden the difference in hydrophobicityEasy to recycleMechanical material recoveryWet separationEngineeringMetal recycling

The invention relates to a beneficiation method for fine-grained disseminated copper ore in a plateau area. The method comprises the following steps: performing semi-autogenous grinding chemical adding and ore grinding, chemical adding and pulp mixing in a slurry pump pool, ore pulp grading and an ore grinding grading system for grinding ore in a ball mill, and obtaining copper concentrate I through one-time roughing, three-time scavenging and one-time optimal flotation concentration, and enabling optimal flotation tailings to be subjected to regrinding grading, copper-sulfur separation and separation and concentration to obtain second copper concentrate, conducting separation and scavenging, and returning separation and scavenging tailings for roughing. According to the method, a flotation reagent adding point is optimized, a novel copper mineral collecting agent is developed, the flotation technological process is optimized, operability is good, the grade of the copper concentrate can be improved, the metal recovery rate of copper and associated element gold and silver in the copper concentrate is increased, the copper concentration operation capacity is greatly released, the mine production and operation benefits are increased, reference is provided for development of mines of the same type, and the beneficiation method is particularly suitable for processing skarn type copper ore with embedded fine particles in the plateau area.

Owner:ZIJIN MINING GROUP +1

Wet high gradient strong magnetic separator

PendingCN108262161AApplicable removalGood sorting indexHigh gradient magnetic separatorsCollection systemMagnetic separator

Owner:LONGI MAGNET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com