Reprocessing method of tin flotation rough concentrate and industrial application thereof

A tin flotation and reprocessing technology, applied in the field of tin flotation coarse concentrate reprocessing, can solve the problems of over-crushing of cassiterite, difficulty in effective recovery of fine-grained grades, etc., achieving low energy consumption, good sorting indicators, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

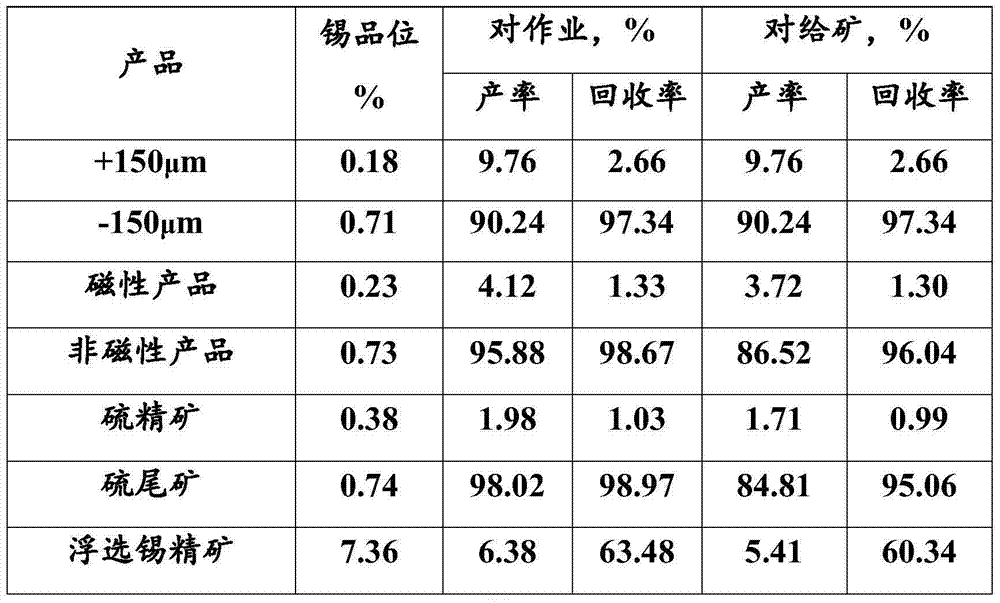

[0086] See Table 1 for the technical indicators of re-recovering the tin flotation concentrate of the gravity separation tailings through high-efficiency centrifugal equipment.

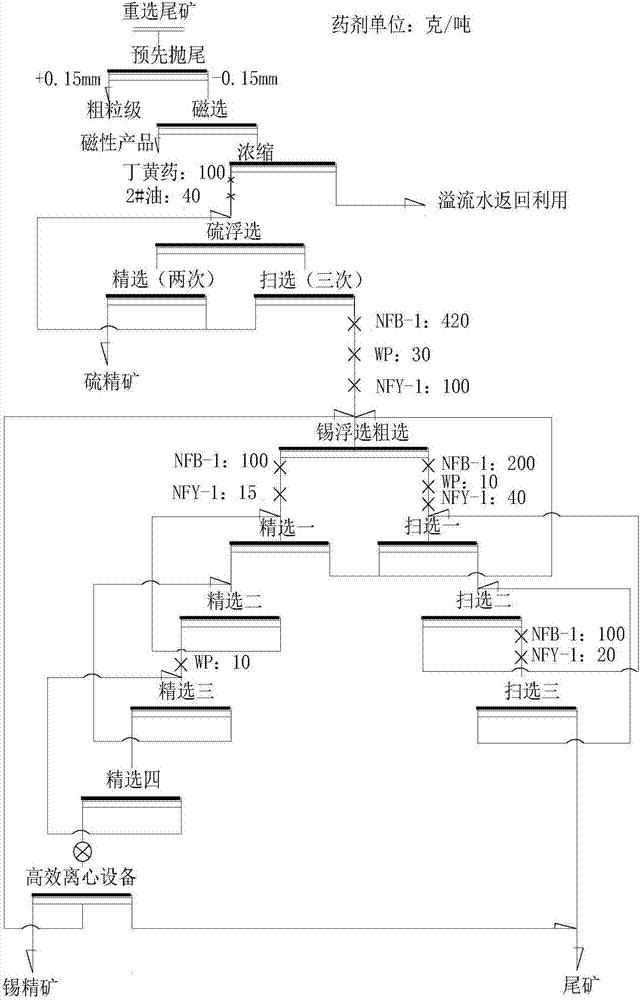

[0087] The specific process is as follows:

[0088] (1) Carry out shaking table gravity separation according to conventional methods to the gravity separation raw ore of Yuling polymetallic mine of Linwu County South Mining Co., Ltd.;

[0089] (2) carry out flotation to gravity separation tailings, comprise the following steps:

[0090] (2.1) Carry out magnetic separation at first, obtain magnetic product and nonmagnetic product; Wherein the tin grade of magnetic product is 0.23%, the tin grade of nonmagnetic product is 0.73%;

[0091] (2.2) Concentrating the non-magnetic product after magnetic separation;

[0092] (2.3) carry out sulfur flotation to the product after concentration; Described sulfur flotation comprises two times of beneficiation and three times of scavenging; The tin grade of the su...

Embodiment 2

[0102] See Table 2 for the technical indicators of reclaiming the flotation tin concentrate that overflows through the high-efficiency centrifugal equipment for gravity separation raw ore pre-sizing and classification overflow.

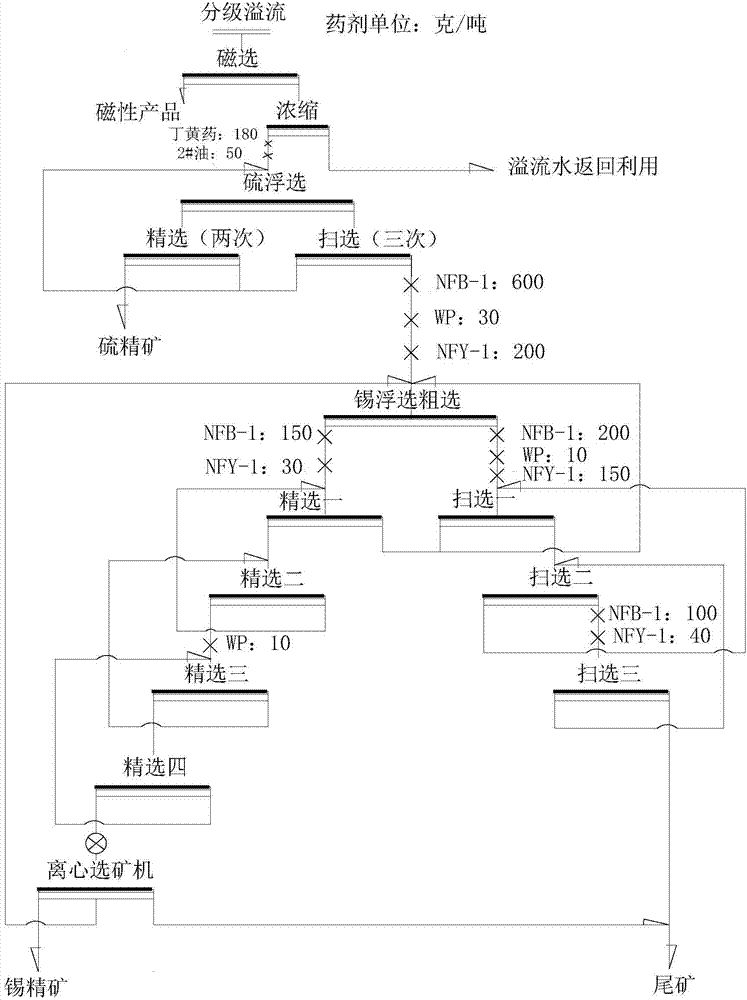

[0103] The specific process is as follows:

[0104] (1) Slurry grading is carried out on the gravity separation raw ore of Yuling Polymetallic Mine of Linwu County Nanfang Mining Co., Ltd. in advance, and -19μm fine-grained slurry, +38μm shaker can choose particle size and +150μm, so that The fine-grained sludge enters the flotation as an overflow, and the optional particle size of the shaker enters the re-election as an underflow; the metal distribution rate of the +150μm particle size is only 2.15%, but the yield accounts for 9.82%, and most For conjoined organisms. After this grade enters the flotation system, it will interfere with the recovery of effective target minerals and affect the selection index. Therefore, the pre-throwing method is ado...

Embodiment 3

[0117] Embodiment 3, different equipment compares the rate of recovery of tin flotation concentrate

[0118] The flotation tin concentrate is reprocessed through different recovery equipment, and the specific technical indicators are shown in Table 3.

[0119] Table 3. Comparison of recovery rates of tin flotation concentrates by different equipment

[0120]

[0121] It can be seen from the table that using high-efficiency centrifugal equipment to recover tin flotation concentrate can obtain the indicators of final tin concentrate grade of 40%, operational recovery rate of more than 70%, and recovery rate of more than 11% of the raw ore of the dressing plant. The technical and economic indicators of industrial application have obvious advantages compared with the research indicators of cassiterite flotation test in similar mines.

[0122] The present invention forms a closed-circuit system through the high-efficiency centrifugal equipment and tin flotation, which avoids th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com