Patents

Literature

95results about How to "Applicable removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak acid cation exchange microballoon resin of magnetic acrylic acid series and synthesis method thereof

InactiveCN101948554AApplicable removalIncrease switching capacityCation exchanger materialsWater/sewage treatment by ion-exchangeSynthesis methodsMicrosphere

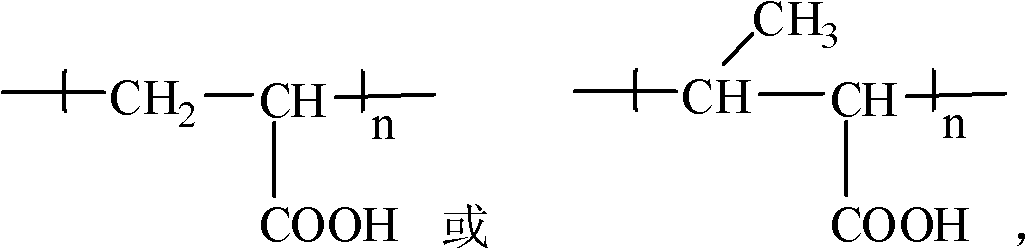

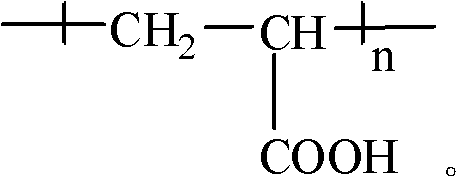

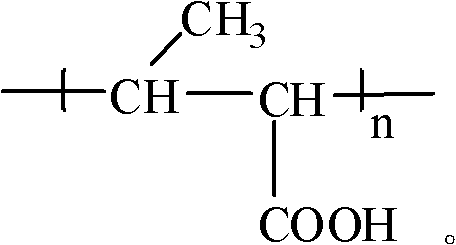

The invention discloses a weak acid cation exchange microballoon resin of magnetic acrylic acid series and a synthesis method thereof, belonging to the field of magnetic resin. The method comprises the following steps of: evenly mixing magnetic particles with the size of 0.01-10mu m with an oil phase, carrying out suspension polymerization under a certain temperature and conditions, and hydrolyzing to finally form the weak acid cation exchange resin. The microballoon resin consists of weak acid cation exchange microballoon resin frames and the magnetic particles packaged therein, wherein the weight ratio of the resin frames to the magnetic particles is 1:(0.05-1), a basic structure formula of the resin frames is shown following the specification of the invention: wherein n can be 1,2,3......; the weak acid volume exchange capacity of the resin is 1.0-5.0mol / L, the average particle diameter thereof is 20-500mum, the specific saturation magnetization intensity thereof is 5.1-33.4emu / g, and the weak acid exchange capacity is 1.0-5.0mol / L. The microballoon resin of the invention can be used in treatment of various water bodies and used for removing ammonia nitrogen and a plurality of metal ions, such as calcium, magnesium, copper, nickel, cadmium, and the like.

Owner:NANJING UNIV

Waste solution mercury removal adsorbent, preparation method and application method thereof

ActiveCN103623771ARealize recyclingTo achieve the purpose of mercury removalOther chemical processesWater/sewage treatment by sorptionLiquid wasteSorbent

Owner:SHANGHAI JIAO TONG UNIV

Nanofiber membrane and membrane adsorbing assembly for extracting uranium from seawater and brine water and application of nanofiber membrane and membrane adsorbing assembly

InactiveCN105080509AImprove adsorption efficiencyHigh mechanical strengthOther chemical processesProcess efficiency improvementIndustrial waste waterSpinning

The invention discloses a nanofiber membrane and a membrane adsorbing assembly for extracting uranium from seawater and brine water and application of the nanofiber membrane and the membrane adsorbing assembly. The nanofiber membrane is prepared by the steps: preparing polyacrylonitrile into a spinning solution; depositing polyacrylonitrile nanowires on a macromolecular non-woven fabric through an electrostatic spinning process to obtain a polyacrylonitrile nanofiber membrane; and then carrying out amidoximation on the polyacrylonitrile nanofiber membrane to obtain the nanofiber membrane. The membrane adsorbing assembly is prepared by the steps: preparing the nanofiber membrane into a rolled membrane assembly; and then carrying out amidoximation on the rolled membrane assembly to obtain the nanofiber membrane adsorbing assembly. The membrane adsorbing assembly disclosed by the invention is high in adsorption capacity, great in adsorption rate, stable in recycling performance and high in mechanical strength. The membrane adsorbing assembly not only is suitable for extracting uranium element from water bodies such as seawater or brine water and the like, but also is suitable for separating and recovering other noble metal or heavy metal ions from industrial wastewater, underground water and drinking water separately as well as removing metal ions from an organic phase.

Owner:和晶(上海)新能源科技有限公司

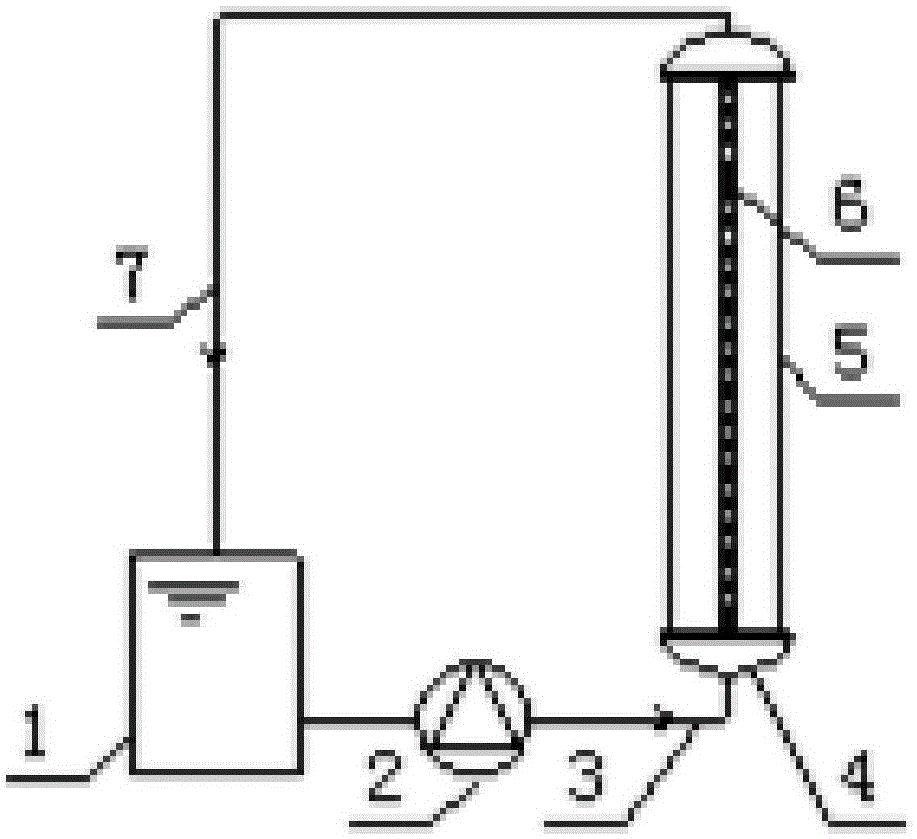

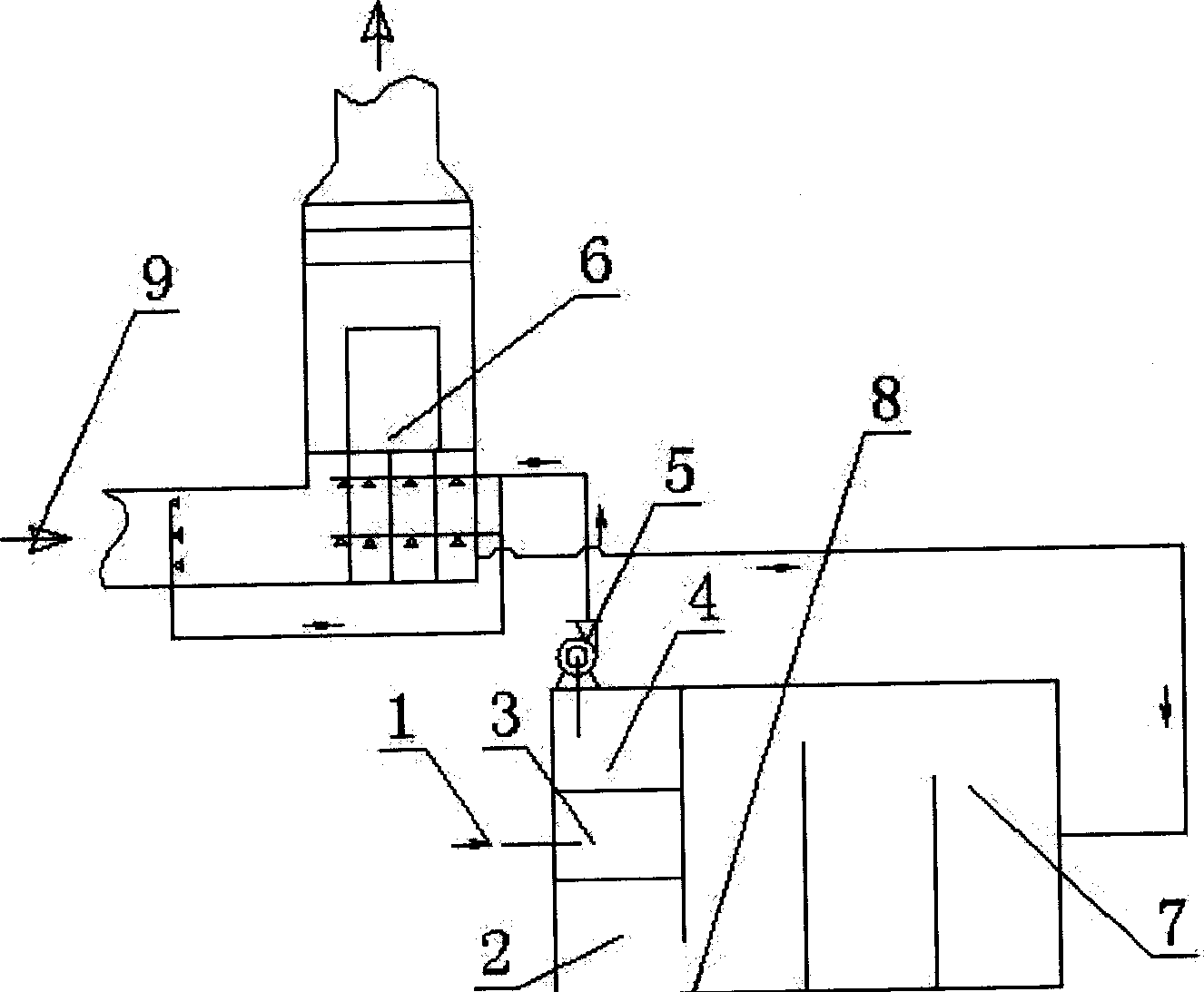

Process for removing sulfur dioxide for smoke using papermaking white mud

A craft that makes use of paper making white mud to eliminate sulfur dioxide in soot comprises the steps of: Add the circular water from pellucid pool and white mud to slurry pool; After mixing round, put them to serum pool, put them to desulfurization tower by add-pressure pump to contact with soot; Reacted liquor flow from the bottom of desulfurization tower and go to deposition pool; The circular water goes to pellucid pool to be used again. The present invention uses simple equipment, has high efficiency of desulfurization and low cost. It uses paper making white mud as desulfurization to change waster to treasure and has a large value to apply and extend.

Owner:吴金泉

Method for preparing polymerized ferrotitanium water purifying agent by adopting waste metatitanic acid

InactiveCN104140146AFulfil requirementsMeet the needs of useIron compoundsTitanium compoundsLiquid productPollution

The invention provides a method for preparing a polymerized ferrotitanium water purifying agent by adopting waste metatitanic acid and belonging to the technical field of water treatment, wherein waste metatitanic acid, sulphuric acid, sodium hydroxide and additives are taken as raw materials. The method for preparing the polymerized ferrotitanium water purifying agent by adopting waste metatitanic acid comprises the following steps: adding sulphuric acid into paste of waste metatitanic acid, controlling temperature to be 90-100 DEG C, filtering, adding sodium hydroxide into filtrate, adjusting pH to be 0.5-2.5 for obtaining an adjusting solution, carrying out polymerization for 0.1-0.5 hour at room temperature or under heating condition, adding the additives, standing and curing for 5-24 hours at room temperature to obtain a polymerized ferrotitanium water purifying agent liquid product, and solidifying for obtaining a polymerized ferrotitanium water purifying agent solid product. The method for preparing the polymerized ferrotitanium water purifying agent by adopting waste metatitanic acid has the advantages that waste metatitanic acid with high titanium content is utilized for preparing a high-efficiency water treatment reagent with good pollution cleaning and decolorizing performances, the polymerized ferrotitanium water purifying agent can be widely applied to the fields of municipal sewage and industrial wastewater and is especially applicable to removal of pollutants such as sewage chromaticity, organic matters and heavy metals, a preparation technology is simple, and preparation equipment is simple and low in cost.

Owner:UNIV OF JINAN

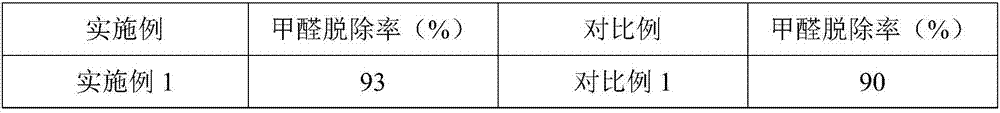

Preparation method of activated carbon adsorption material for removing medium and low-concentration formaldehyde

InactiveCN106179211AStable performanceRaw materials are simpleGas treatmentOther chemical processesActivated carbonCarbonization

The invention discloses a preparation method of an activated carbon adsorption material for removing medium and low-concentration formaldehyde, and belongs to the technical field of preparation of activated carbon adsorption materials. The key point of the technical scheme provided by the invention is that the preparation method comprises the following steps: by using walnut shells as a raw material, sequentially performing grinding, acid pickling, water washing and carbonization; sequentially performing washing, drying, modifying, ultrasonic combination, soaking, washing and drying on prepared activated carbon, thus obtaining the activated carbon adsorption material for removing the medium and low-concentration formaldehyde. The activated carbon adsorption material prepared by the preparation method disclosed by the invention is stable in performance, and is suitable for removing the low-concentration formaldehyde in a room; in addition, the raw material is simple and easy to obtain, and a treatment process is simple; the activated carbon adsorption material is suitable at home; when the concentration of formaldehyde gas is 0.8 to 1.0mg / m<3>, the adsorption rate of the prepared activated carbon adsorption material to the formaldehyde gas reaches 60 to 70 percent.

Owner:HENAN NORMAL UNIV

Method for preparing cationic cross-linked starch xanthate

InactiveCN102702367AApplicable removalFast binding reactionWater contaminantsWater/sewage treatment by flocculation/precipitationCross-linkFiltration

The invention discloses a method for preparing cationic cross-linked starch xanthate. The method comprises the following steps of: dissolving NaOH and 2,3-epoxypropyltrimethyl ammonium chloride in cold water, and stirring and mixing with starch; reacting for 9 minutes at the temperature of 60 DEG C in a fast microwave reactor; washing products by using an aqueous solution of ethanol, and finally, drying to obtain etherified starch; adding an alkaline solution prepared by water, sodium hydroxide and sodium chloride into etherified starch to be mixed to form slurry; dissolving epoxy chloropropane in the alkaline solution, dripping the mixture into the slurry, and reacting for 2 hours at the temperature of 50 DEG C; regulating the pH value of the solution to be at 7 by using hydrochloric acid; washing by using absolute ethyl alcohol after suction filtration, and drying to obtain the cross-linked etherified starch; dissolving the etherified starch into the water, adding a solution of sodium hydroxide and adding carbon disulfide, stirring to react for 2 hours at the temperature of 50 DEG C, adding a solution of magnesium sulfate, and continuously reacting for 10 minutes; and performing suction filtration, washing by using distilled water, acetone and diethyl ether in sequence, and drying to obtain the cationic cross-linked starch xanthate. When the cationic cross-linked starch xanthate is used for treating heavy metal wastewater, a cationic polymer is not required to be added.

Owner:SHAANXI UNIV OF TECH

Preparation and application of environmental-protective aqueous paint remover

InactiveCN104513519AEnvironmentally friendlyEasy constructionChemical paints/ink removersPotassium hydroxideBENZYL ALCOHOL/WATER

A preparation and an application of an environmental-protective aqueous paint remover are disclosed. The environmental-protective aqueous paint remover is prepared from following raw materials, by weight, 22-25% of benzyl alcohol, 15-18% of sodium p-toluene sulfonate, 3.0-4.0% of potassium hydroxide, 0.8-1.4% of sodium gluconate, 4-8% of a cosolvent and 45-55% of tap water. The paint remover is prepared by following steps: (1) adding the sodium p-toluene sulfonate, the sodium gluconate, the potassium hydroxide to the tap water to obtain a mixture and stirring the mixture to enable the sodium p-toluene sulfonate, the sodium gluconate and the potassium hydroxide to be completely dissolved; and (2) adding the benzyl alcohol, triethanolamine and ethanol to obtain a mixture and stirring the mixture for dissolving the benzyl alcohol, the triethanolamine and the ethanol to obtain a transparent liquid product with a color from white to yellow. The paint remover is alkaline and is subjected to a paint removing experiment during a use process with a heating temperature being 50-70 DEG C. The environmental-protective aqueous paint remover is advantaged in that: (1) the paint remover is water-soluble and is environmental-protective when being used for replacing a volatile solvent paint remover; (2) the paint remover is free of toxic chemical products; (3) the paint remover is suitable for removing various paints; (4) the paint remover is alkaline and is free of damaging a base material; and (5) the paint remover is not liable to volatilize, can be used repeatedly and is low in comprehensive cost.

Owner:SHANGHAI LICHANG ENVIRONMENTAL ENG

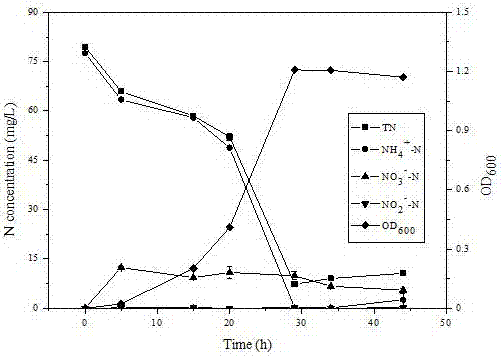

Acinetobacter baumannii AL-6 and application thereof

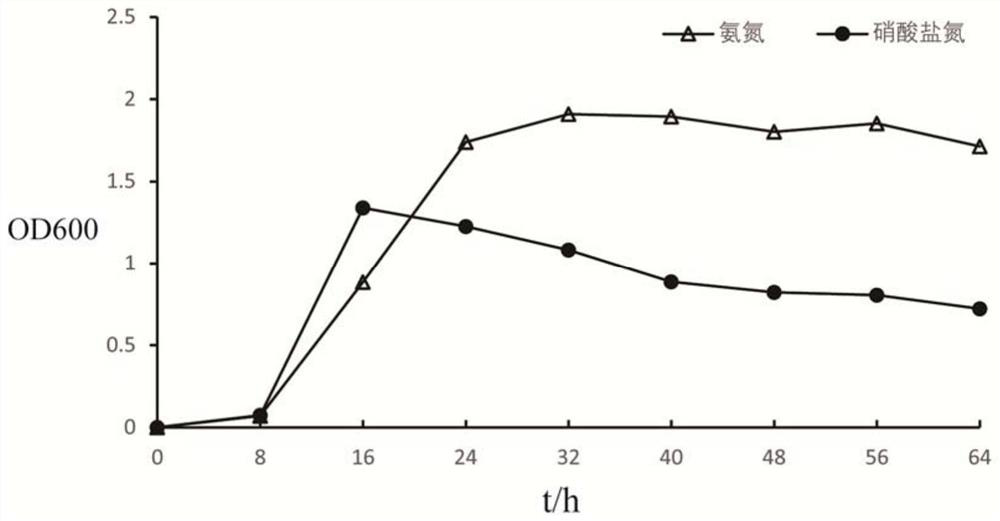

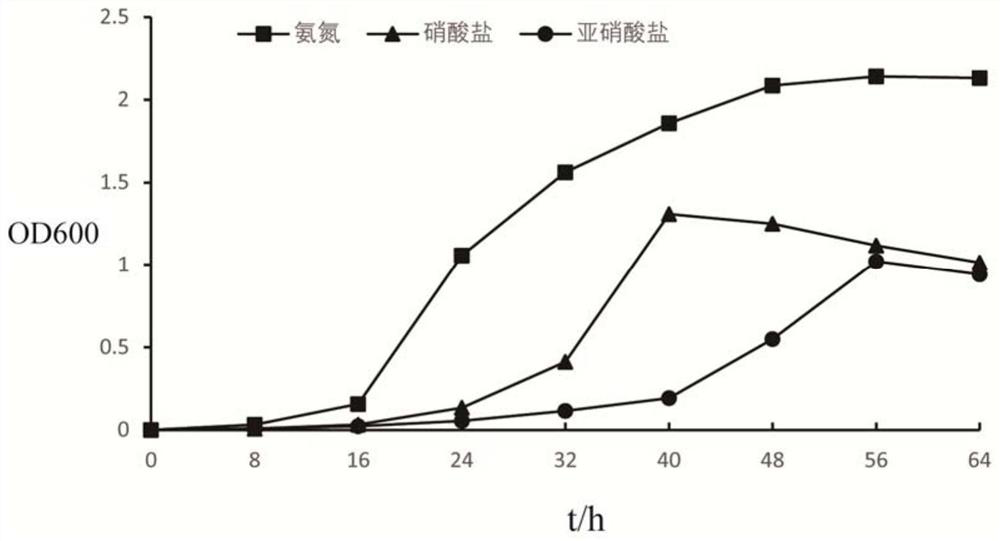

InactiveCN106987547AApplicable removalSimple processBacteriaWater contaminantsBiotechnologyNitration

The invention discloses Acinetobacter baumannii AL-6 and an application thereof. The strain is preserved in the China General Microbiological Culture Collection Center (CGMCC) in November 8th, 2016, and the preservation number is CGMCC No. 13248. The strain can conduct denitrification through heterotrophic nitrification-aerobic denitrification. Under the aerobic condition, with CH3COONa as a carbon source and NH4+-N as a nitrogen source, removal of 81.9-99.9% of NH4+-N and 59.7-90.8% of TN can be achieved; with NO3--N as a nitrogen source, the removal rate of NO3--N is 50.2%, and the removal rate of TN is 48.2%; with NO2--N as a nitrogen source, the removal rate of NO2--N is 50.3%, and the removal rate of TN is 48.8%. The strain AL-6 has good application prospects in the field of treatment of wastewater containing highly concentrated ammonia-nitrogen or nitrate nitrogen or nitrite nitrogen.

Owner:CHONGQING UNIV

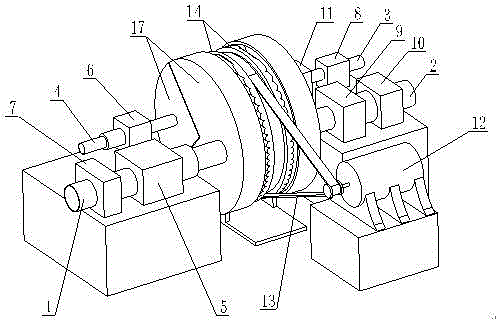

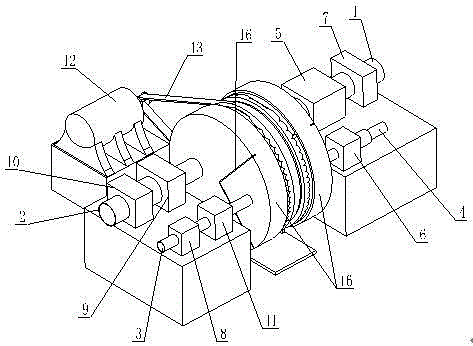

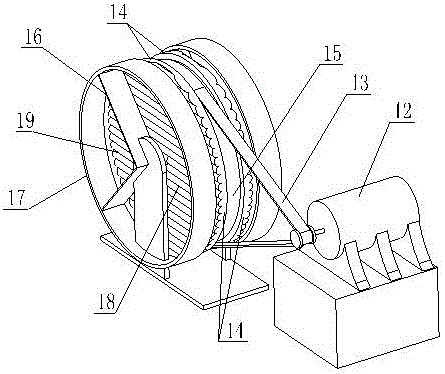

Using method for rotary device for removing indoor harmful gas

InactiveCN106247449AEasy to useReasonable designMechanical apparatusAir treatment detailsMolecular sieveEnvironmental engineering

The invention relates to the technical field of purifying equipment, in particular to a using method for a rotary device for removing indoor harmful gas. The rotary device comprises a motor, a driving belt, an adsorption rotary, a baffle and an adsorption cover. The rotary device is used for removing indoor harmful gas by adopting an adsorption catalytic technology, and is specially used for removing indoor harmful gas to purify environment. The rotary device adopts an adsorption rotary structure, and a calcium type molecular sieve is taken as an adsorbent to be arranged on the adsorption rotary. The rotary device is low in energy consumption, doses not generate secondary pollution, is relatively high in stability, can be suitable for removing indoor harmful gas, is compact and simple in structure, and has a wide application prospect. Besides, the using method is reasonable in design, is convenient and quick to use, and is suitable for popularization and application.

Owner:苏州云白环境设备股份有限公司

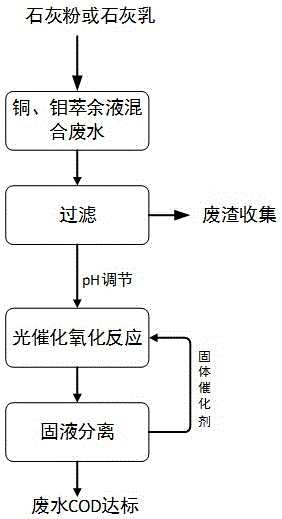

Method for removing COD (chemical oxygen demand) from copper/molybdenum extraction raffinate mixed wastewater

InactiveCN105152433AApplicable removalNo subsequent regeneration is requiredMultistage water/sewage treatmentSulfateSorbent

The invention discloses a method for removing COD (chemical oxygen demand) from copper / molybdenum extraction raffinate mixed wastewater, which mainly comprises the following steps: adding lime powder or lime milk into wastewater so as to be combined with sulfate in the wastewater to generate a calcium sulfate precipitate, adsorbing and removing disperse oil by using the calcium sulfate as an adsorbent, filtering, deeply degrading COD in the filtrate in the photocatalytic oxidation reaction process, and carrying out solid-liquid separation to obtain the solid catalyst and the wastewater with the COD of less than 100 mg / L, wherein the solid catalyst can be returned to the photocatalytic oxidation reaction for cyclic utilization. The method has the advantages of simple technique, low operating cost and no need of subsequent adsorbent regeneration, and has favorable market prospects.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

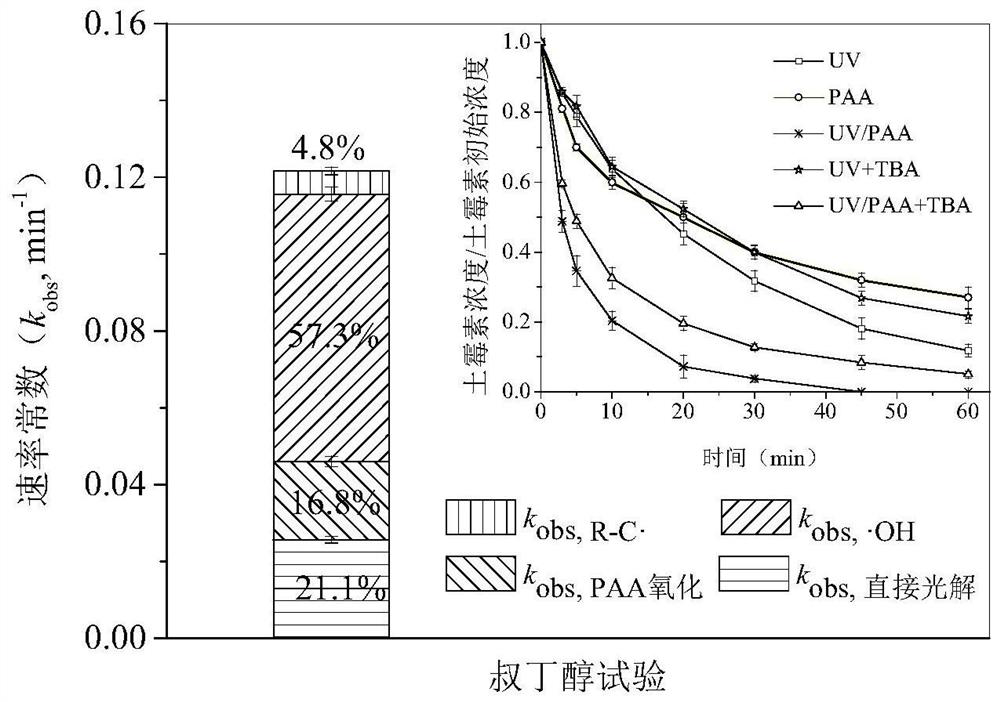

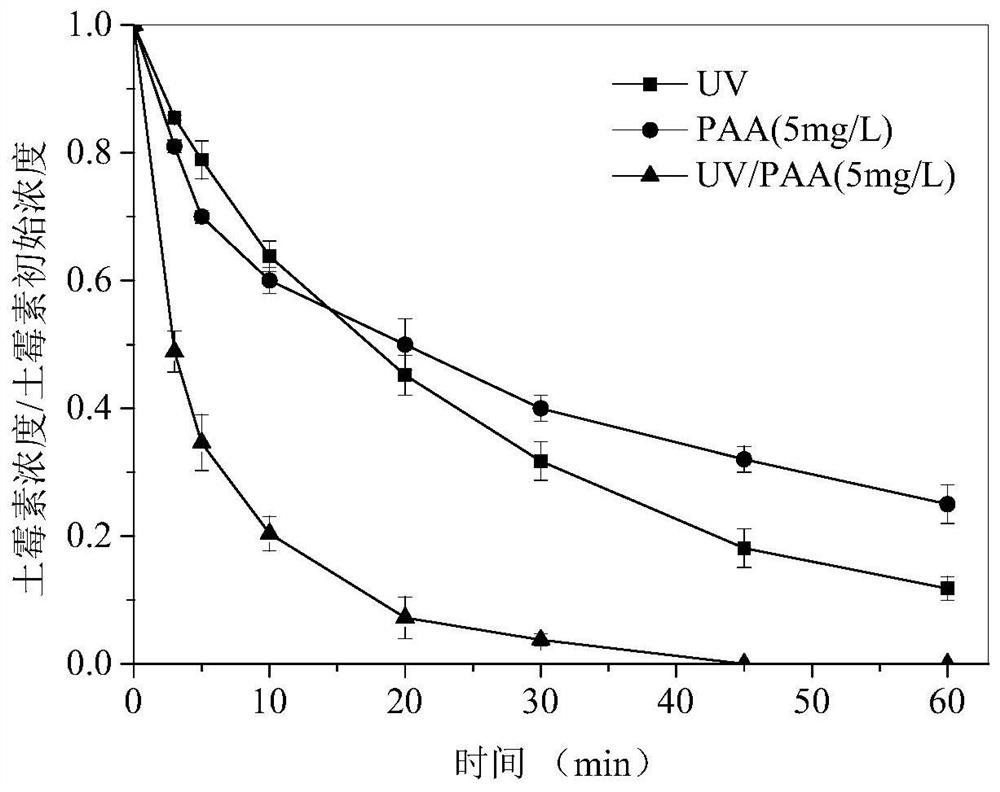

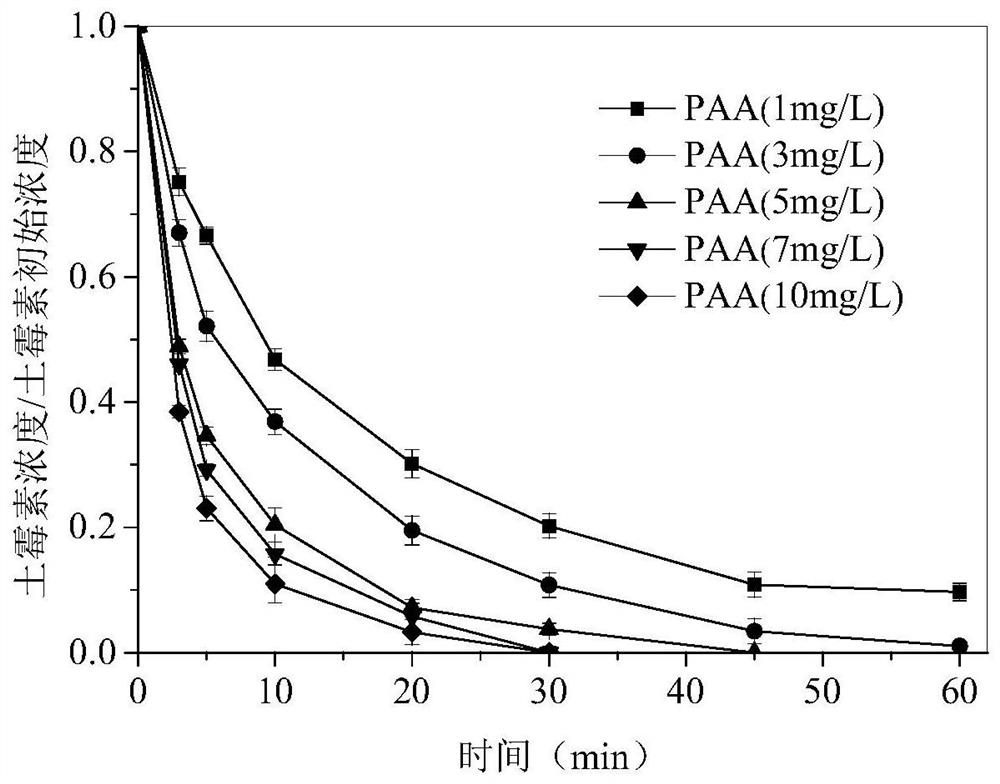

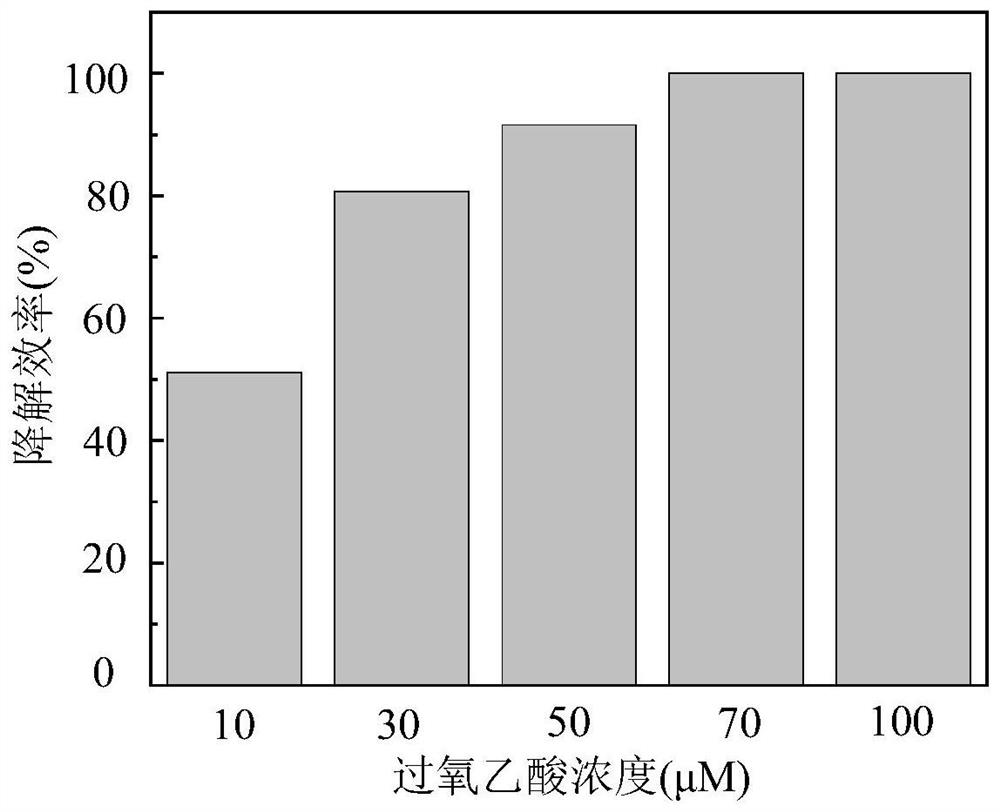

Application of ultraviolet/peroxyacetic acid in removal of degradation-resistant antibiotics in village and town sewage

PendingCN112142182AEfficient processing technologyApplicable removalWater/sewage treatment by irradiationWater treatment compoundsPhoto catalyticUltraviolet lights

The invention discloses a method for removing degradation-resistant antibiotics in village and town sewage by using ultraviolet / peroxyacetic acid (UV / PAA), which comprises the following steps: addingan oxidant peroxyacetic acid into antibiotic-containing water, irradiating the mixed solution by using ultraviolet light, activating peroxyacetic acid by using ultraviolet light to generate strong oxidizing free radicals, and in combination with the action of ultraviolet direct photolysis and peroxyacetic acid oxidation, synergistically degrading the degradation-resistant antibiotics in the sewage. According to the photocatalytic advanced oxidation technology based on UV irradiation, strong oxidizing free radicals are generated through ultraviolet light activation to oxidize and remove antibiotics, and the method has the advantages of being high in treatment efficiency, little in secondary pollution, easy and convenient to operate, low in cost and the like.

Owner:TONGJI UNIV

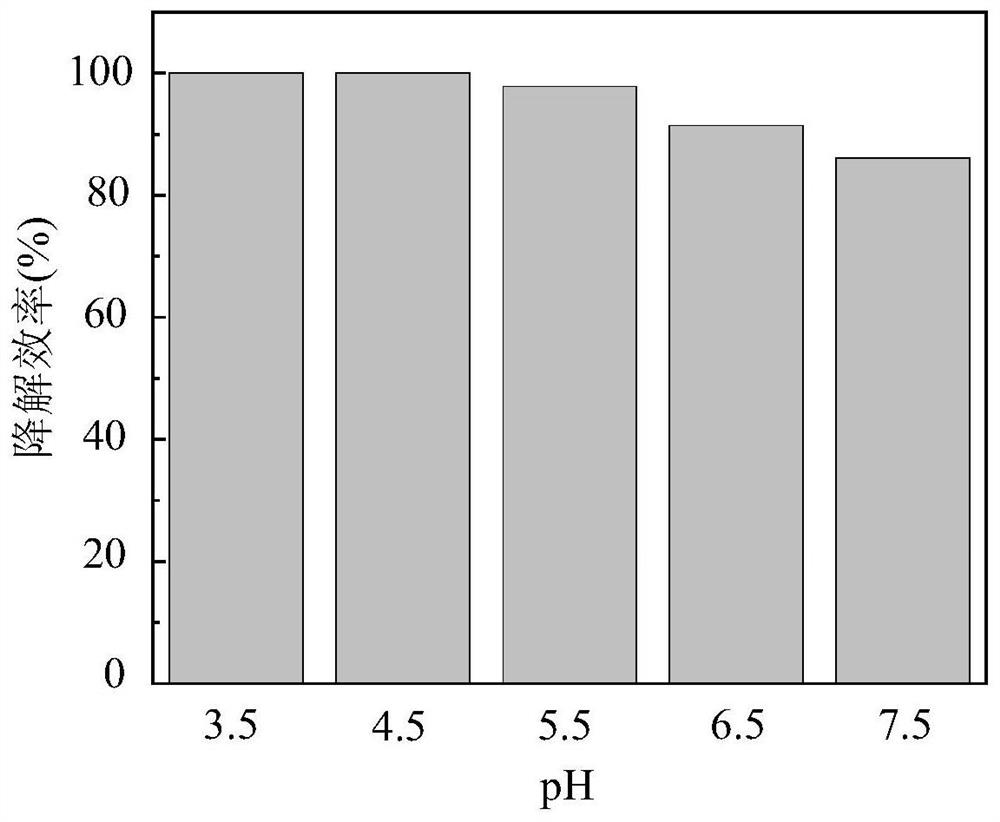

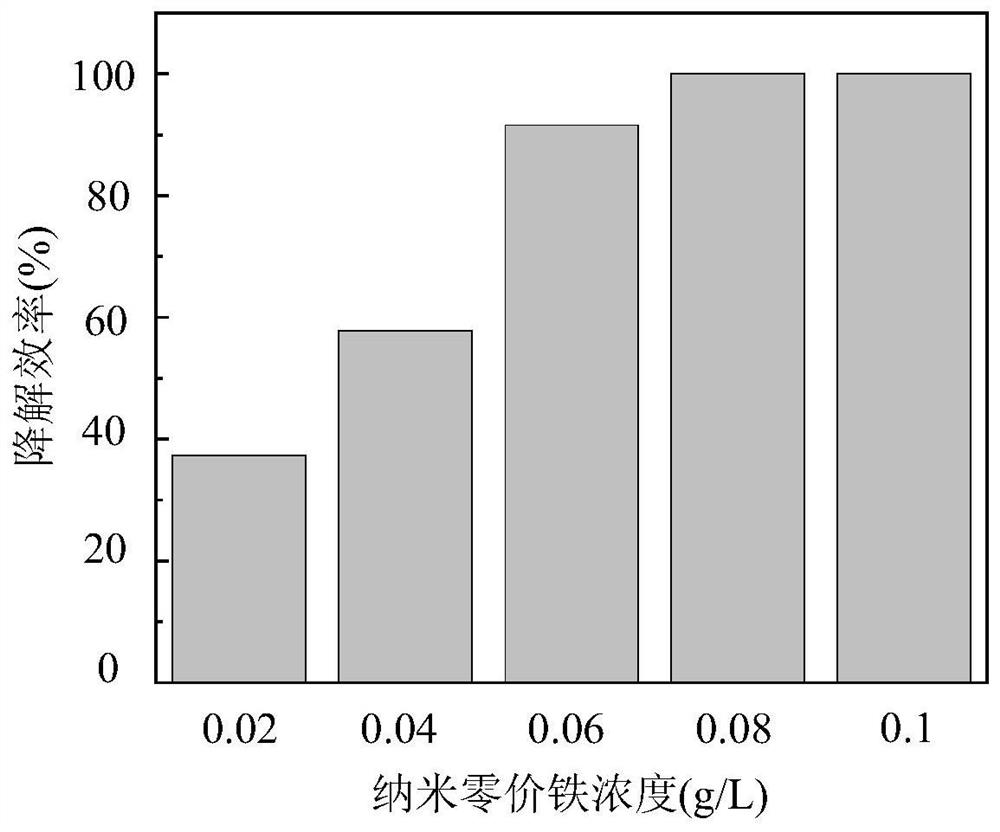

Method for degrading antibiotics in water by activating peracetic acid through zero-valent metal

ActiveCN112723518AImprove activation efficiencyReduce utilization costWater contaminantsEnergy based wastewater treatmentMicrobiologyHydroxyl radical

The invention discloses a method for degrading antibiotics in water by activating peracetic acid through zero-valent metal. According to the method, peracetic acid which is high in oxidation-reduction potential, widely applied to the disinfection field and few in by-products is selected as a precursor for generating hydroxyl radicals, and the peracetic acid is activated by the zero-valent metal to generate strong oxidizing free radicals so as to degrade antibiotics in the water body. The method comprises the following specific steps: adding a proper amount of a strong oxidant, namely the peroxyacetic acid into a to-be-treated water body containing antibiotics, then adding the zero-valent metal with a concentration of 0.02 g / L-0.1 g / L as an activating agent, adjusting the pH value of a reaction solution to 3-9, and carrying out uniform stirring and reacting at room temperature for 30 minutes so as to oxidize and degrade the antibiotics. The zero-valent metal used in the method has the advantages of being low in cost, high in activation efficiency, easy to recycle and the like, the peracetic acid can be completely activated within 30 min, and high antibiotic degradation efficiency is achieved, so the method is a novel antibiotic degradation technology which is rapid, efficient and environmentally friendly.

Owner:HUAQIAO UNIVERSITY

Catalyst for removing low-concentration formaldehyde in gases and application thereof

InactiveCN102000603AReduce energy consumptionIncrease storage capacityMolecular sieve catalystsDispersed particle separationMolecular sieveCarbon dioxide

The invention belongs to the technical field of gas purification treatment, relating to a catalyst for removing low-concentration formaldehyde in gases and the application thereof. The catalyst is characterized by using at least two of Ag, Co, Fe and Cu as main active components which are loaded on an HZSM-5 type molecular sieve carrier and are 1-20 percent by weight of the catalyst. The catalyst is filled in a reactor and applied to two alternately operating stages, i.e. a storage stage and a regeneration stage, wherein the reactor can be inflated with ozone, can be used for heating at a controlled temperature and can carry out DBD (Dielectric Barrier Discharges). At the storage stage, low-concentration formaldehyde in the gases is firstly stored on the catalyst; and at the regeneration stage, ozone or oxygen-contained gas is introduced for heating or carrying out the DBD so that the formaldehyde stored on the catalyst is fully oxidized into carbon dioxide and water, wherein the oxygen content in the introduced oxygen-contained gas at the regeneration stage is 20-100 percent, and air can be directly used as the oxygen-contained gas at the regeneration stage. In the invention, the provided catalyst with the function of selective storing and catalytic oxidation on the formaldehyde has the advantages of low energy consumption and no secondary pollution, is extremely suitable for removing low-concentration formaldehyde in gases and is particularly suitable for removing formaldehyde pollutants in indoor air.

Owner:DALIAN UNIV OF TECH

Poly ferro-silicon-titanium coagulant used for treating low-sludge amount water and preparation technology thereof

InactiveCN104817148AEfficient decontamination performanceEfficient water treatment with high decontamination performanceWater/sewage treatment by flocculation/precipitationIndustrial effluentSludge

The invention relates to a method for preparing a high-molecular ferro-silicon-titanium coagulant used for water treatment; wherein the high-molecular ferro-silicon-titanium coagulant is formed by production of nontoxic titanium mud solid refuse during a titanium white production process. The preparation method comprises the following steps: performing an acid leaching reaction at a first phase on titanium mud by a hydrochloric acid solution to obtain a leaching liquid I and a filter residue I; performing the acid leaching reaction at a second phase on the filter residue I by a concentrated sulfuric acid solution to obtain a leaching liquid II and a filter residue II; then performing an alkali leaching reaction on the filter residue II by highly basic; and finally performing an oxidation slaking reaction on a mixed leaching liquid of the leaching liquid I, the leaching liquid II and a leaching liquid III by an oxidizing agent. The coagulant used for water treatment has high efficiency for removing organic matter and chroma, and can be used for pretreatment and deep treatment for city sewage or industrial wastewater.

Owner:UNIV OF JINAN

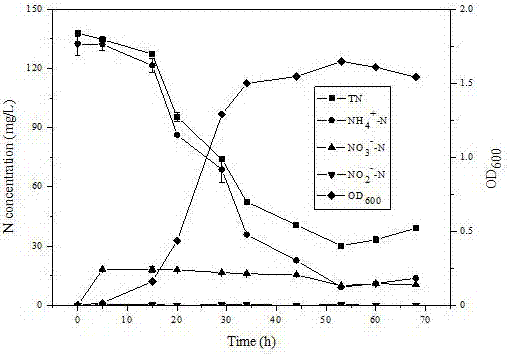

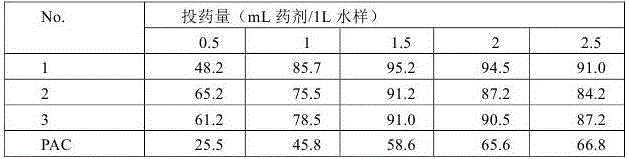

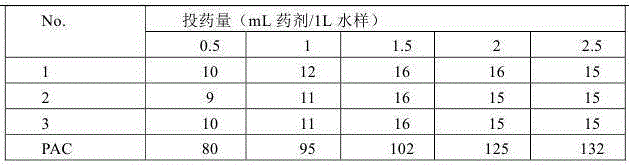

Pseudomonas nitroreducens. strain and application thereof

InactiveCN113249254AApplicable removalSimple processBacteriaWater contaminantsBiotechnologyAmmoniacal nitrogen

The invention provides a Pseudomonas nitroreducens. strain and application thereof. The strain is Pseudomonas nitroreducens. Pf2, and is preserved in China Center for Type Culture Collection, and the preservation number is CCTCC NO: M2021274. The strain can synchronously perform nitrification and denitrification by taking organic carbon as a carbon source under an aerobic condition, and is suitable for removing organic wastewater containing ammonia nitrogen or nitrate, the NH4 < + > -N removal rate can reach 92.7 percent, and the NO3 < - > -N removal rate can reach 100 percent; and the treatment process can be greatly simplified, the treatment efficiency is improved, and the operation and maintenance cost is reduced.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

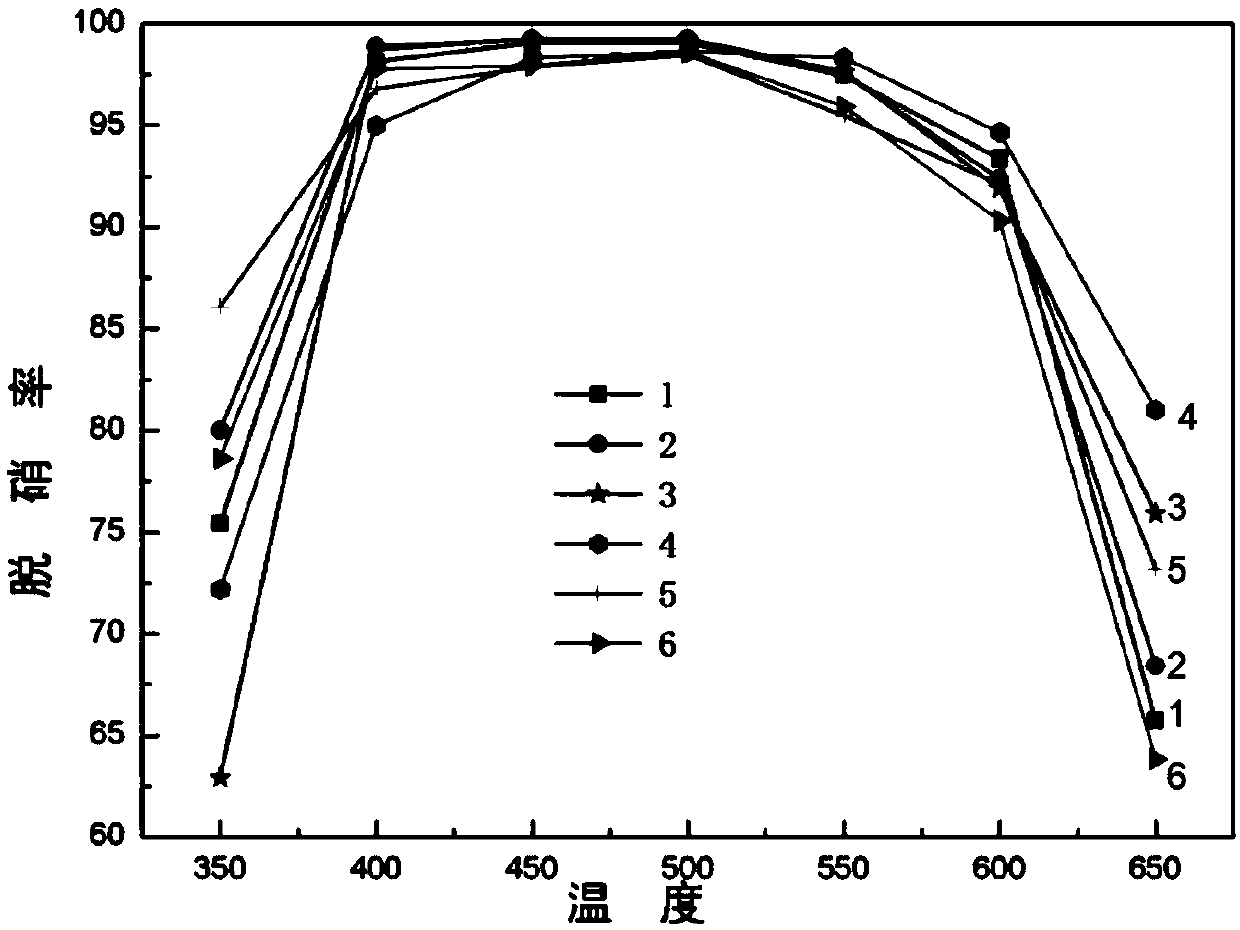

Environment-friendly type high-temperature denitrification catalyst and preparation method thereof

ActiveCN109513438ASimple preparation processHarm reductionGas treatmentInternal combustion piston enginesIonChemistry

The invention relates to an environment-friendly type high-temperature denitrification catalyst and a preparation method thereof. The preparation method comprises the following steps: taking tungstenzirconium composite oxide as a main catalyst component, one or more of barium, erbium, tin, iron, molybdenum, cobalt, copper, manganese or lanthanum as a co-catalyst, titanium white powder as a carrier component and aluminum oxide as an auxiliary molding agent; preparing co-catalyst ion salt into a saturated solution; immersing the titanium white powder carrier into the co-catalyst solution according to the equal volume; after drying and pulverizing, uniformly mixing with the auxiliary molding agent aluminum oxide; uniformly stirring a tungsten zirconium ion saturated solution of the main catalyst component, an organic molding agent and a powder material, mixing, ageing and extruding and molding; and drying and roasting to obtain an integral honeycomb catalyst. The catalyst provided by theinvention has the advantages of relatively good high-temperature denitrification effect and thermal stability, toxin-free components, environment friendliness, simple preparation technology and the like; and the environment-friendly type high-temperature denitrification catalyst is especially applicable to removal of high-temperature NOx in tail gas of high-speed diesel engines and denitrification of fixed-source high-temperature tail gas of a petrochemical industry and the like.

Owner:NANJING UNIV OF TECH

Load type honeycomb ceramic catalytic material and preparation method thereof

InactiveCN106890649ALow costEfficient removalGas treatmentDispersed particle separationHigh humidityCerium

The invention provides a load type honeycomb ceramic catalytic material which is prepared from, by weight parts, 100-200 parts of honeycomb ceramics, 0.6-1.4 parts of manganese salt, 0.1-12 parts of ferric salt, copper salt, cerium salt or zinc salt, 4-18 parts of catalyst carrier, 0.5-14 parts of nanoscale anion powder, 0.45-3 parts of inorganic binder, 0.05-1.2 parts of organic binder, 0.2-1 part of surfactant and 60-90 parts of water. The load type honeycomb ceramic catalytic material is low in cost and can efficiently remove formaldehyde and purify air under conditions of indoor temperature, high humidity and large blast capacity. The invention further provides a method for preparing the load type honeycomb ceramic catalytic material. The method is simple, convenient to use, low in production cost and favorable for achieving industrial production and large-scale popularization.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

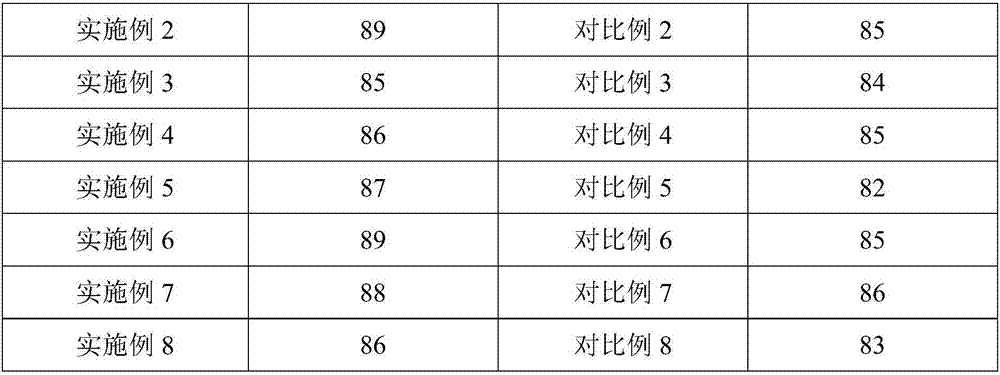

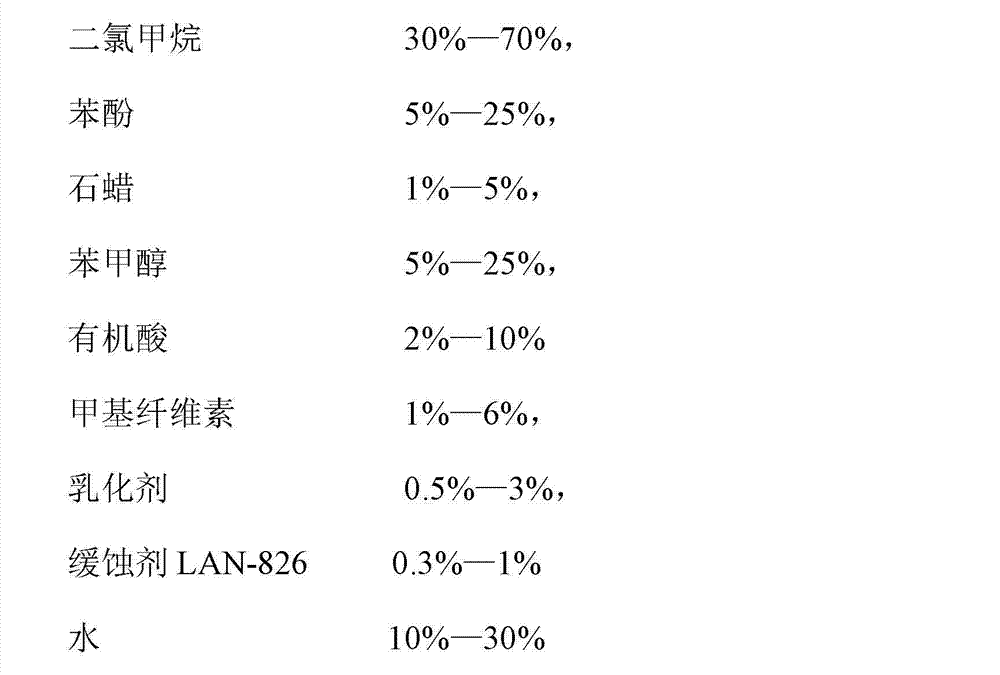

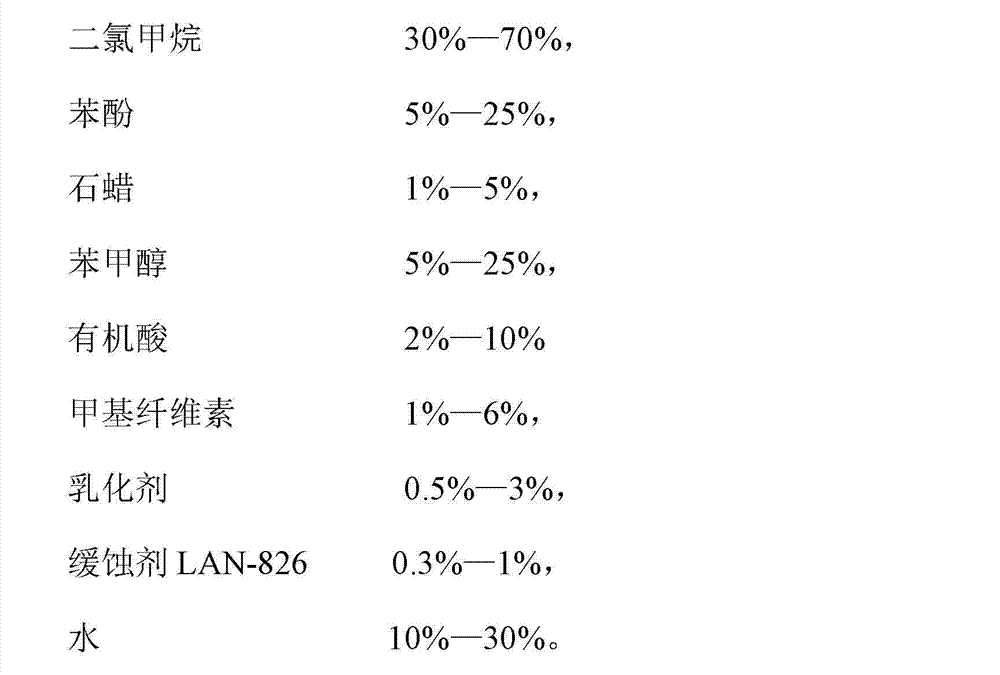

Efficient metal paint remover and preparation method thereof

InactiveCN102816473AGood paint removal effectHigh speedChemical paints/ink removersParaffin waxBENZYL ALCOHOL/WATER

The present invention discloses a paint remover for a metal surface. The paint remover is characterized by comprising the following components, by weight, 30-70% of dichloromethane, 5-25% of phenol, 1-5% of paraffin, 5-25% of benzyl alcohol, 2-10% of an organic acid, 1-6% of methyl cellulose, 0.5-3% of an emulsifier, 0.3-1% of a corrosion inhibitor LAN-826, and 10-30% of water. The metal paint remover of the present invention has characteristics of low solvent evaporation, good paint removing effect, rapidness, low use cost, and no corrosion on metal substrates, and can be widely applicable for paint layer removing of surfaces of carbon steel, stainless steel, copper, aluminum and other metal substrates.

Owner:自贡鸿鹤化工股份有限公司

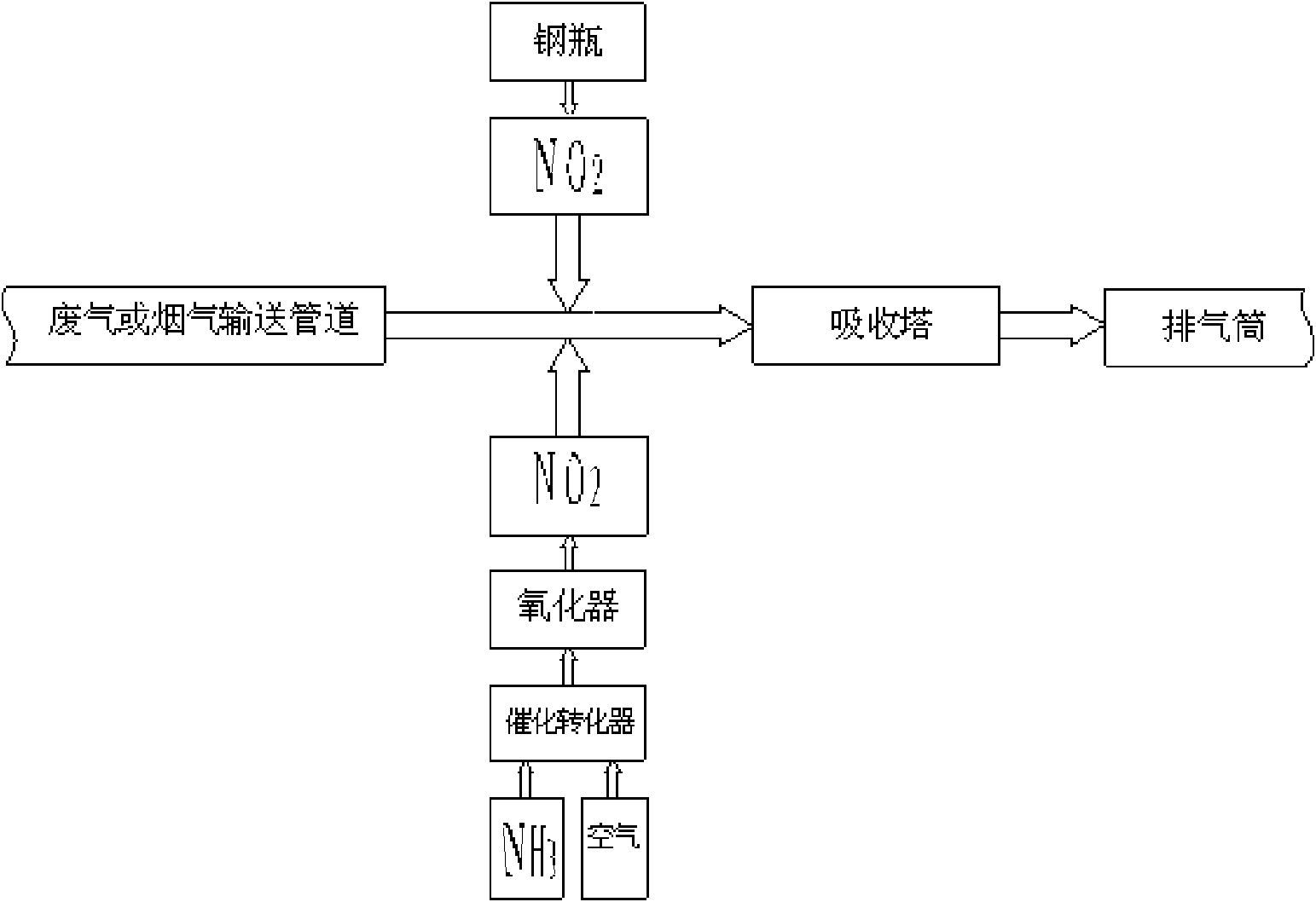

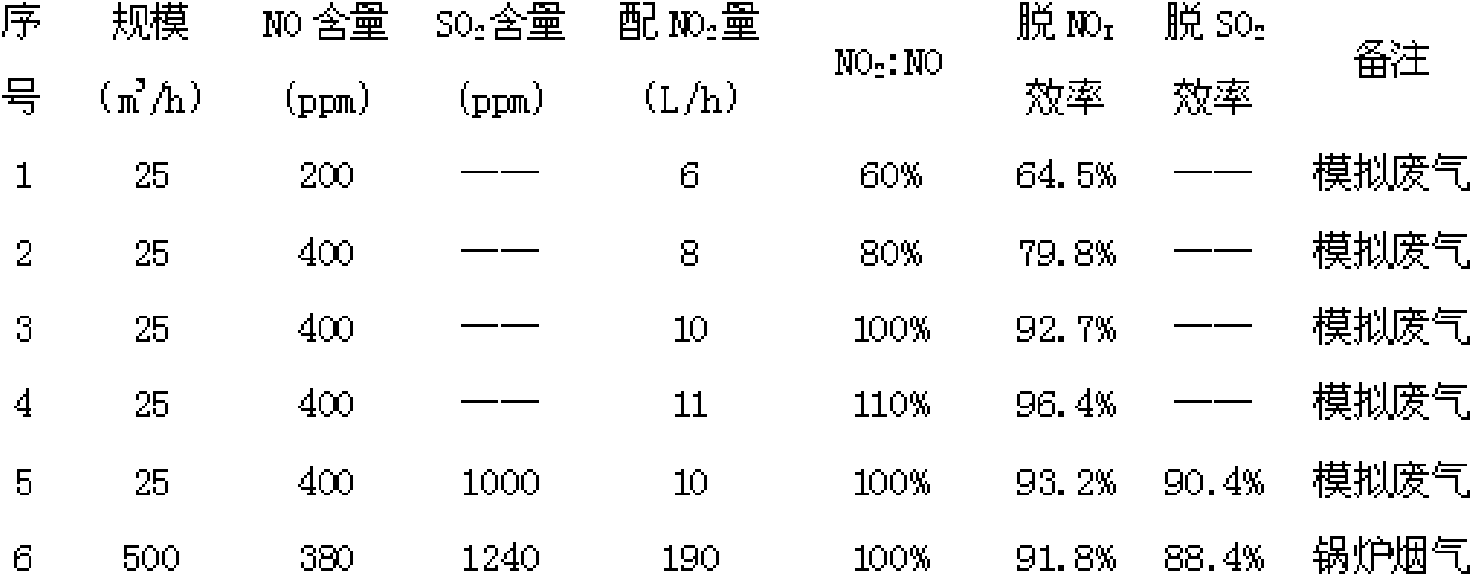

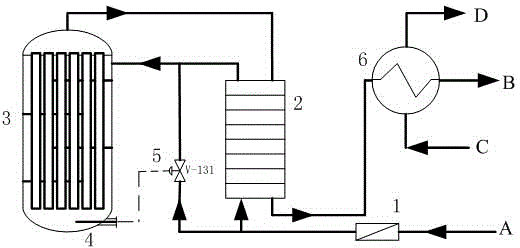

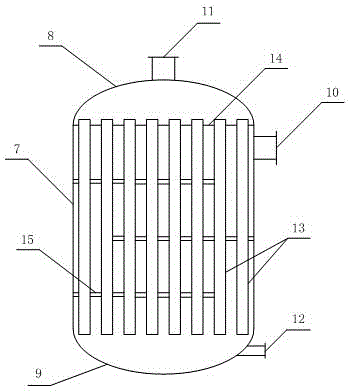

Method for removing nitrogen oxides in waste gas or flue gas

InactiveCN101664633AShort processEasy to operateDispersed particle separationNitric oxideExhaust pipe

The invention relates to a method for removing nitrogen oxides in waste gas or flue gas, comprising the following steps of: connecting an absorbing tower in series on a waste gas or flue gas conveyingpipeline at the front of an exhaust pipe, adding NO2 at the front of the absorbing tower and introducing the NO2 into flue gas or waste gas flow for mixing after being metered, then using a removingagent to treat the mixed gas by absorbing and removing of the absorbing tower with the removing agent and then discharging the mixed gas from the exhaust pipe; and adopting the following technical scheme: connecting the absorbing tower in series on the waste gas or flue gas conveying pipeline, connecting a nitrogen dioxide cylinder laterally at the front of the tower to directly add NO2 into the waste gas or flue gas conveying pipeline or connect a catalytic converter and an oxidizer laterally at the front of the absorbing tower, oxidizing NH3 released by a liquid ammonia cylinder into NO2 which is then mixed in the flue gas or waste gas conveying pipeline, and then carrying out absorbing and removing treatments by the absorbing tower. The method overcomes the defects that the existing method for denitrifying and denitrating waste gas or flue gas has complex treating technique, high cost, large waste and higher condition and requirements on treated flue gas and waste gas and the like,is applicable to denitration of flue gas and waste gas of nitrogen oxides containing nitric oxide as main material, and is especially applicable to removing nitrogen oxides of flue gas of a boiler.

Owner:XIANGTAN UNIV

Method and equipment for deoxidizing low-concentration oxygen-containing coal bed gas

The invention discloses a method for deoxidizing a low-concentration oxygen-containing coal bed gas. The method comprises the following steps: preheating a fixed bed deoxidization reactor; feeding the oxygen-containing coal bed gas into the reactor after penetrating through a flame arrester, a preheater and a preheater bypass; carrying out deoxidization reaction when the reaction temperature is 350-650 DEG C, the operation pressure is 0-0.4MPa and the gaseous hourly space velocity is 2,000-20,000h<-1>; feeding a hot deoxidized coal bed gas into the preheater and exchanging heat with a cold oxygen-containing coal bed gas; and feeding the cooled oxygen-containing coal bed gas into a cooler, cooling and dewatering, and feeding to a coal bed gas delivery pipeline. The method has the advantages of being good in safety, good in deoxidization effect, low in investment, convenient to operate and low in operation cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

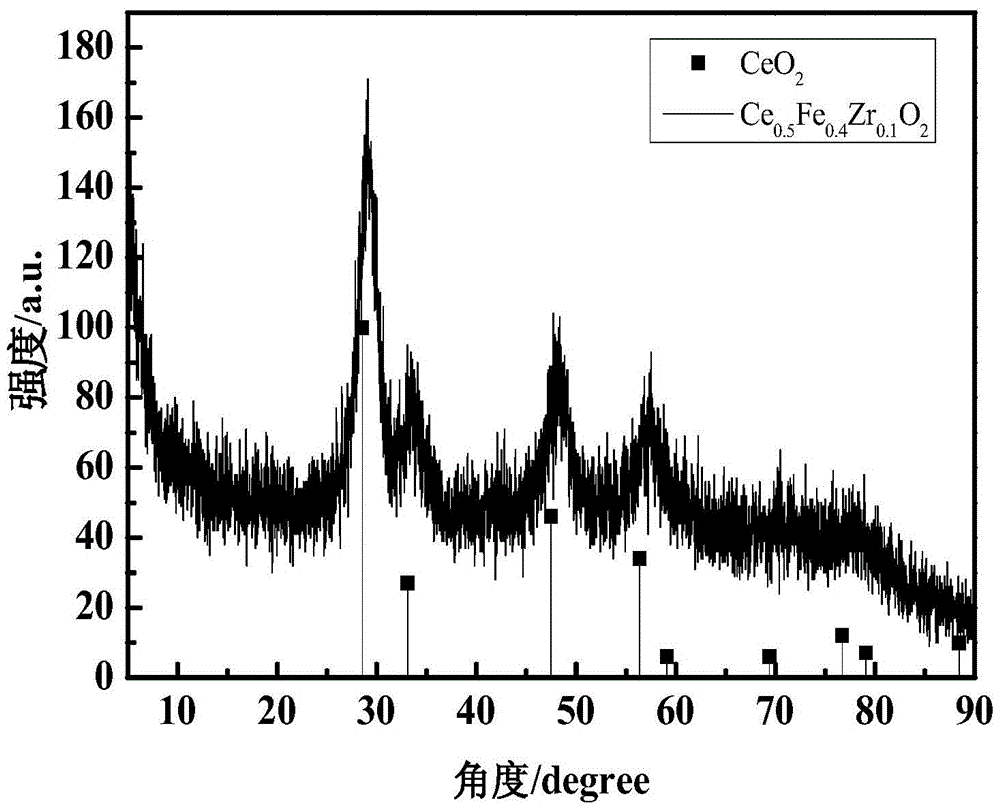

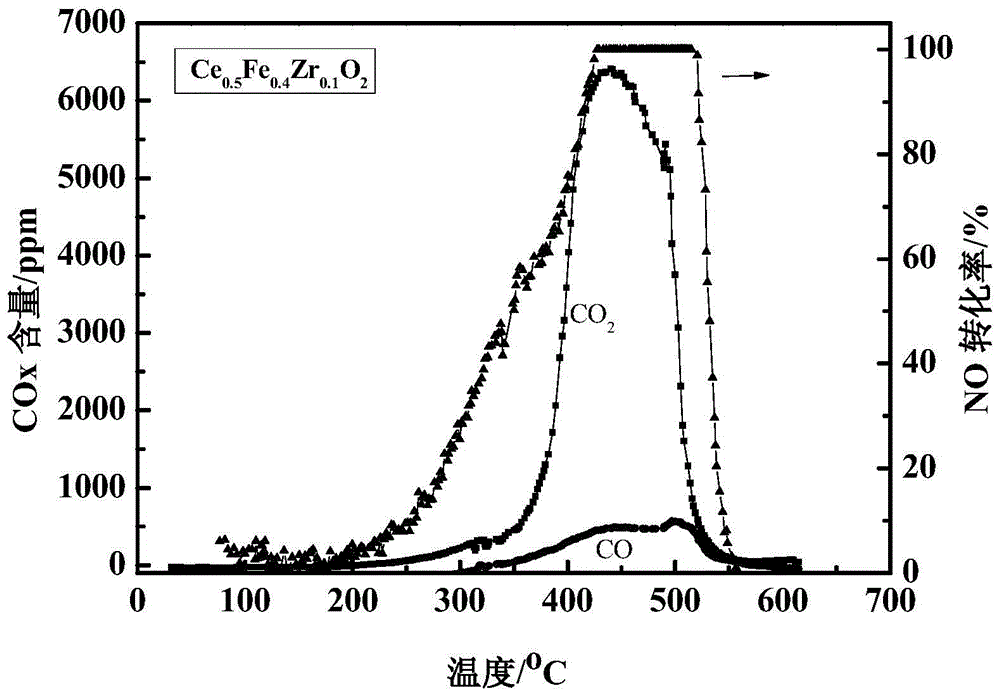

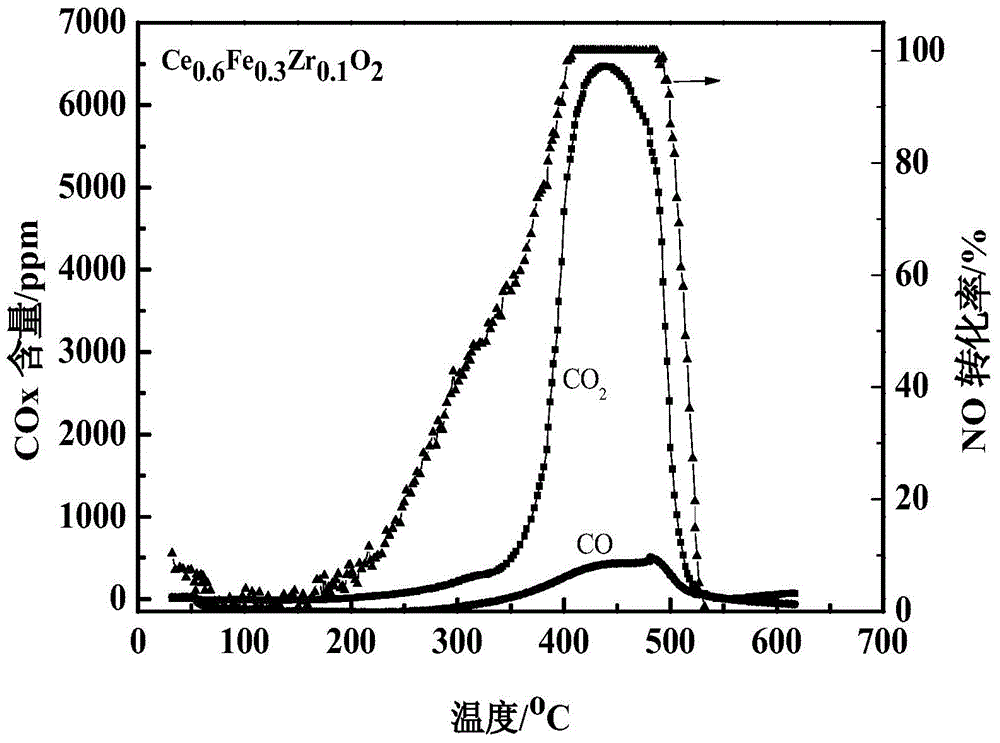

Three-dimensional composite oxide catalyst for removing NO and coal smoke particles simultaneously and preparation method and application thereof

InactiveCN105727964AHigh activityUniform pore sizeHeterogenous catalyst chemical elementsDispersed particle separationComposite oxideOxide

The invention provides a three-dimensional composite oxide catalyst for removing NO and coal smoke particles simultaneously and a preparation method and application thereof.The preparation method comprises the steps that under the stirring condition, a cerium source, an iron source and a zirconium source are dissolved in an organic solvent, the mixture is stirred to be uniform at the temperature of 20 DEG C to 45 DEG C, and a precursor solution is formed; a template agent is weighed and added to the precursor solution to be dipped, and then suction filtration and drying are carried out; solids obtained through drying are heated in a heating furnace for the first time and heat preservation is carried out, and then the solids obtained through drying are heated for the second time and heat preservation is carried out, and the three-dimensional composite oxide catalyst is obtained.The three-dimensional composite oxide catalyst is a cerium, iron and zirconium composite oxide, and the composition of the catalyst is Ce0.9-xFexZr0.1O2, wherein x ranges from 0.1 to 0.4.According to the catalyst, the temperature at which the coal smoke particles are combusted to be converted into CO2 and the temperature for NO conversion can be reduced to the same range, meanwhile, the NO conversion rate is increased, and the activity of catalytic coal smoke combustion is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Environment-friendly aqueous paint remover and preparation method thereof

InactiveCN105255248AEnvironmentally friendlyEasy constructionChemical paints/ink removersPotassium hydroxideEnvironmental engineering

The invention provides an environment-friendly aqueous paint remover. The environment-friendly aqueous paint remover is characterized by being prepared from, by weight, 15-20% of phenylcarbinol, 20-28% of paratoluenesulfonic acid sodium salt, 6.0-8.0% of potassium hydroxide, 3.0-4.0% of sodium gluconate, 2-5% of a cosolvent and 30-40% of tap water. The environment-friendly aqueous paint remover has the advantages of being environmentally friendly, free of toxicity, free of damage to base materials, capable of being repeatedly applied and low in integrated cost.

Owner:关勇河

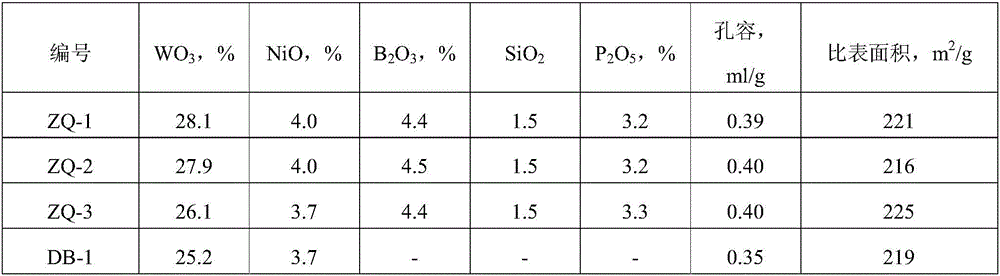

High-activity hydrofining catalyst and preparation method thereof

ActiveCN106622314AGuaranteed uniform contactIncrease loadPhysical/chemical process catalystsDispersitySlurry

The invention discloses a high-activity hydrofining catalyst and a preparation method thereof. The preparation method includes the steps: (1) taking water as solvents, and preparing slurry of silicon-phosphorus-containing alumina; (2) adding a boron-containing compound, a VIB metal compound and a VIII metal compound into the slurry, and filtering mixture to obtain filter cakes and filter liquor; (3) mixing the filter liquor, SB powder and adhesive solvents to obtain binding agents, and sequentially rolling, forming, drying and roasting the binding agents and the filter cakes to obtain the hydrofining catalyst. The silicon-phosphorus-containing alumina is a compound of SiO2, P2O5 and Al2O3. According to the preparation method, metal salt easily dissolved in water is added into the slurry, aluminum oxide, additives and the metal salt in the slurry uniformly contact with each other, the filter cakes are dried and formed, loading capacity and dispersity of metal components are improved, and synergistic effects of the additives and metal active components are furthest achieved. The catalyst is particularly applicable to removal of polycyclic aromatic hydrocarbon in naphthenic base distillate oil.

Owner:CHINA NAT OFFSHORE OIL CORP +3

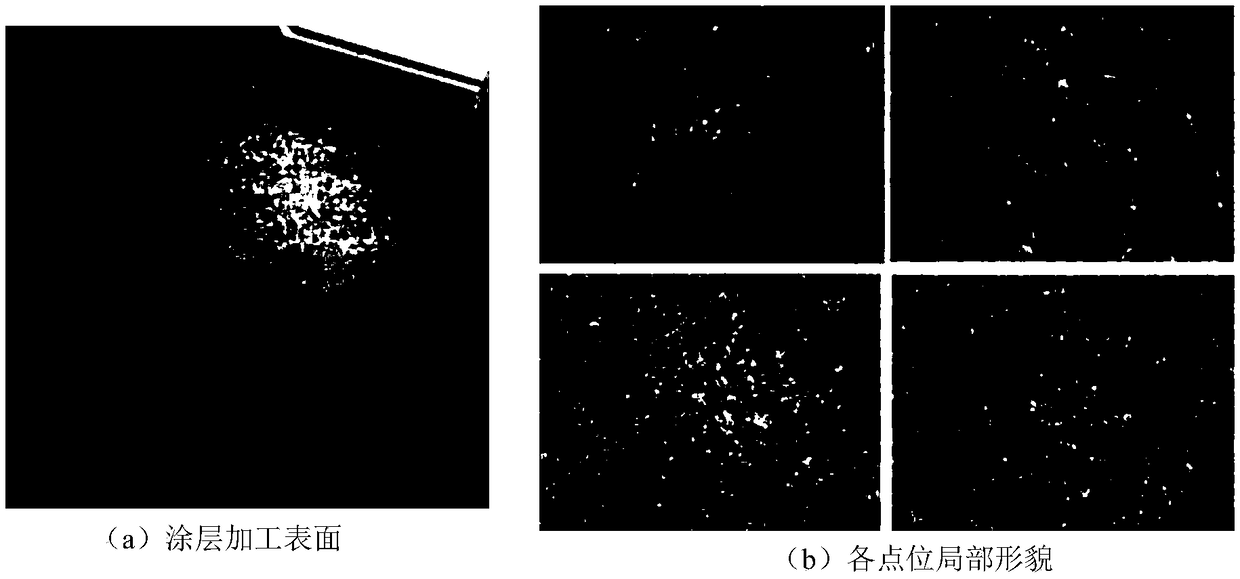

Preparation and application method of amino mold plastic abrasives for aircraft coating layer removal

InactiveCN109048699ACost-effectiveSimple processGrinding devicesGrain treatmentsMachiningMaterials science

The invention discloses a preparation and application method of amino mold plastic abrasives for aircraft coating layer removal, and belongs to the technical field of material surface polishing. The preparation method of the amino mold plastic abrasives is characterized in that amino mold plastic is firstly crushed; then, crushed amino mold plastic particles are crushed and screened; the particleswith different particle size grades and obtained by screening are mixed according to a certain ratio to prepare abrasives; and the air jet machining is performed on the abrasives to remove aircraft coating layers. The aircraft coating layers are aircraft cover surface coating layers. After the air jet machining is performed on the amino mold plastic abrasives, prepared through the method, to remove the aircraft coating machines, obvious damage is not discovered on the surfaces of basal bodies, so that the removing effect of the coating layers is excellent, and the efficient, green and nondestructive removal of the aircraft coating layers can be realized. The used amino mold plastic abrasives can be recycled.

Owner:CHANGZHOU JOEL PLASTIC +1

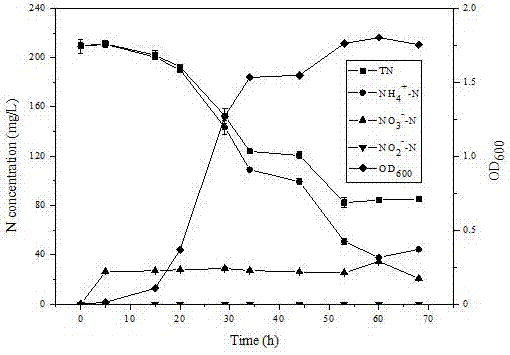

Bacterial strain with heterotrophic nitrification and aerobic denitrification function and application thereof

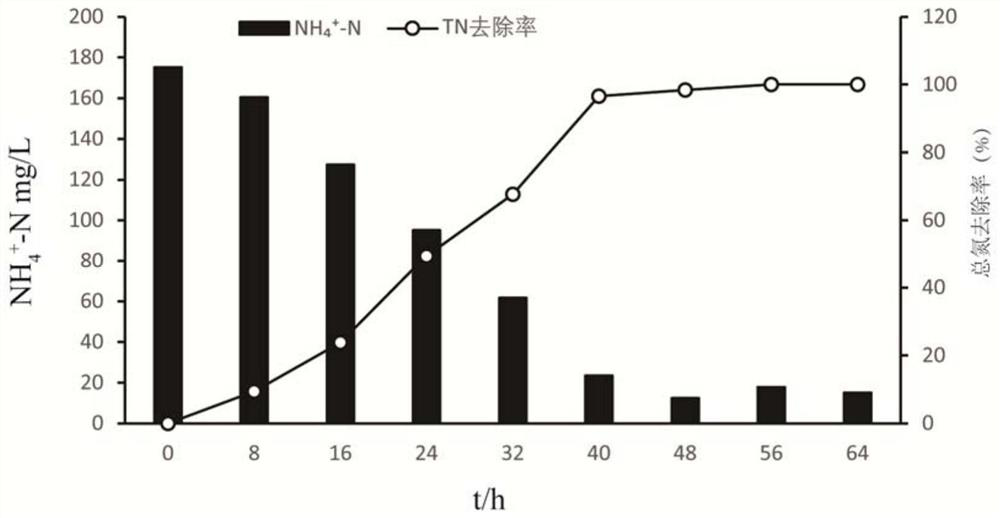

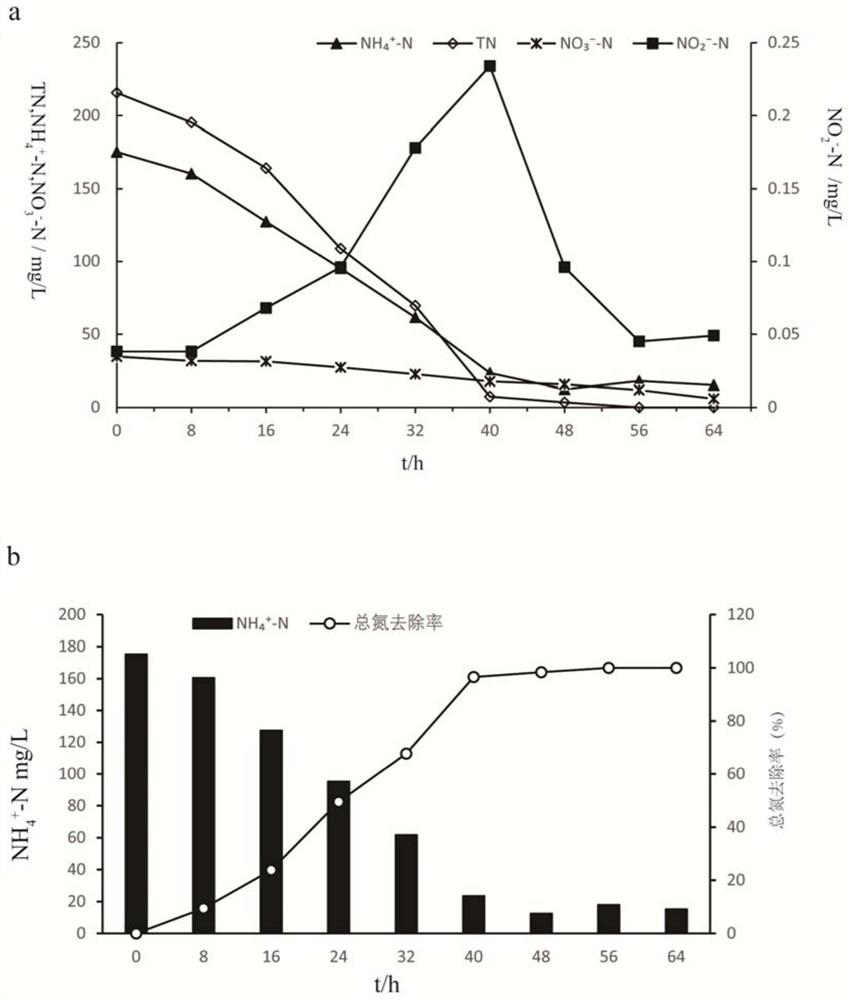

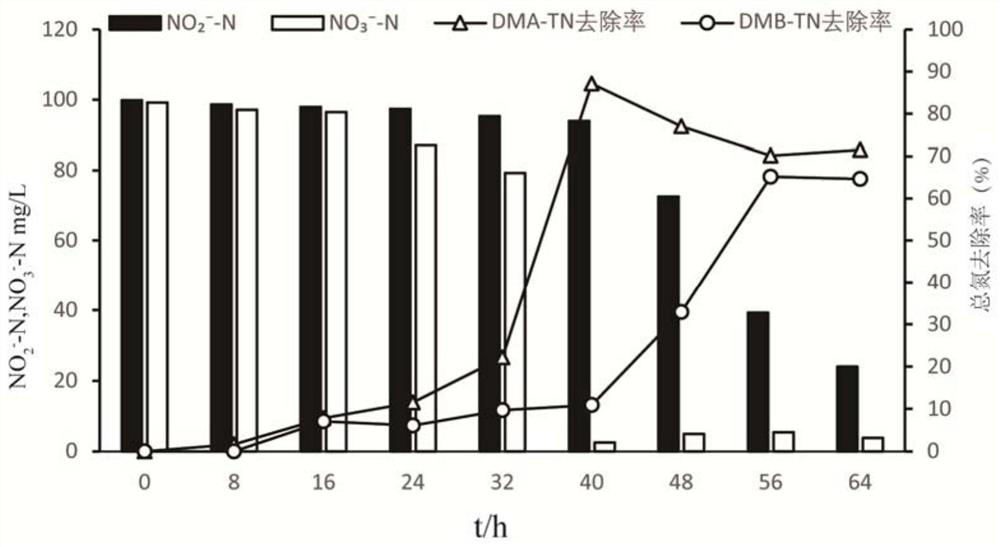

InactiveCN113234626AAmmonia nitrogen removal effect is goodAerobic denitrification ability is obviousBacteriaWater contaminantsEcologyEnvironmental chemistry

The invention provides a bacterial strain with heterotrophic nitrification and aerobic denitrification functions and application. The bacterial strain is (Achromobacter xylosoxidans) pf1, the bacterial strain is preserved in the China Center for Type Culture Collection, and the preservation number is CCTCC NO: M2021273. The bacterial strain can synchronously perform nitrification and denitrification for nitrogen removal by taking organic carbon as a carbon source under an aerobic condition, and is suitable for removal of organic wastewater containing ammonia nitrogen, nitrate and nitrite. In the ammonia nitrogen wastewater with the initial concentration of 175 mg / L, the total nitrogen removal rate can reach 100%, the accumulation of intermediate products is less, and secondary pollution is avoided; in nitrate or nitrite wastewater with the initial concentration of 100 mg / L, the total nitrogen removal rate can reach 87.1% or 65.1%. After the industrial turtle breeding wastewater is treated, nitrogen and phosphorus in the industrial turtle breeding wastewater can be remarkably removed.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

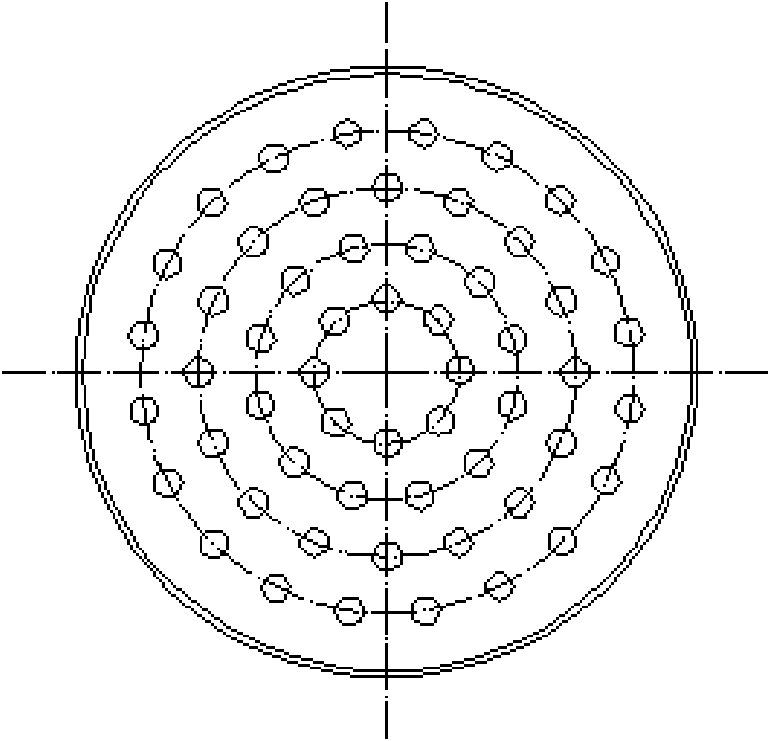

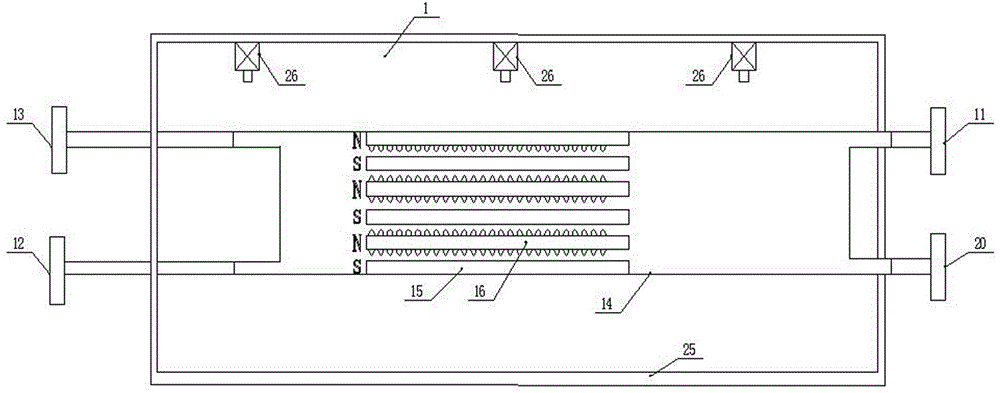

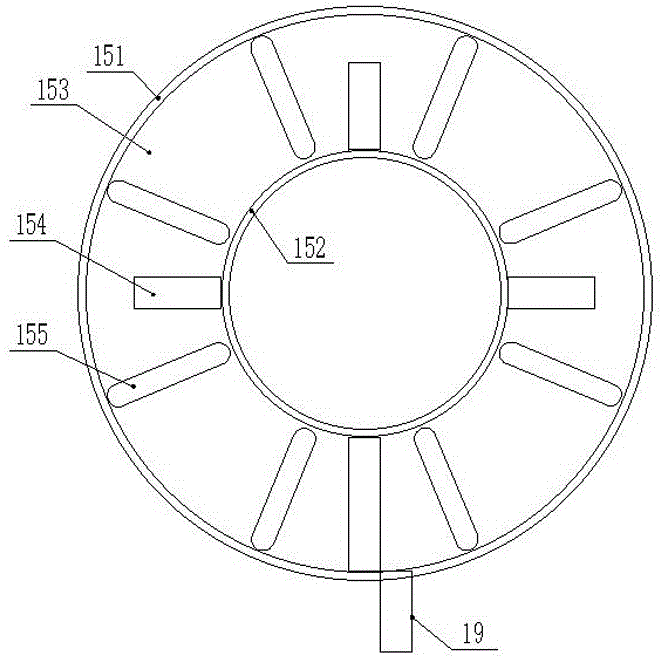

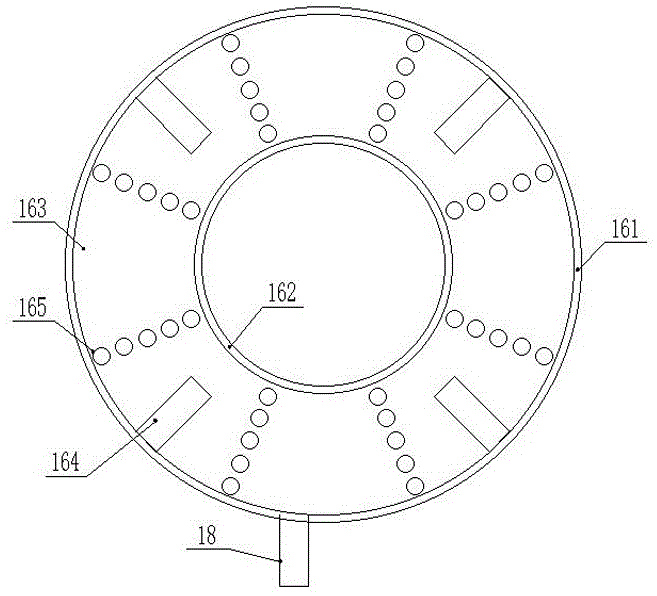

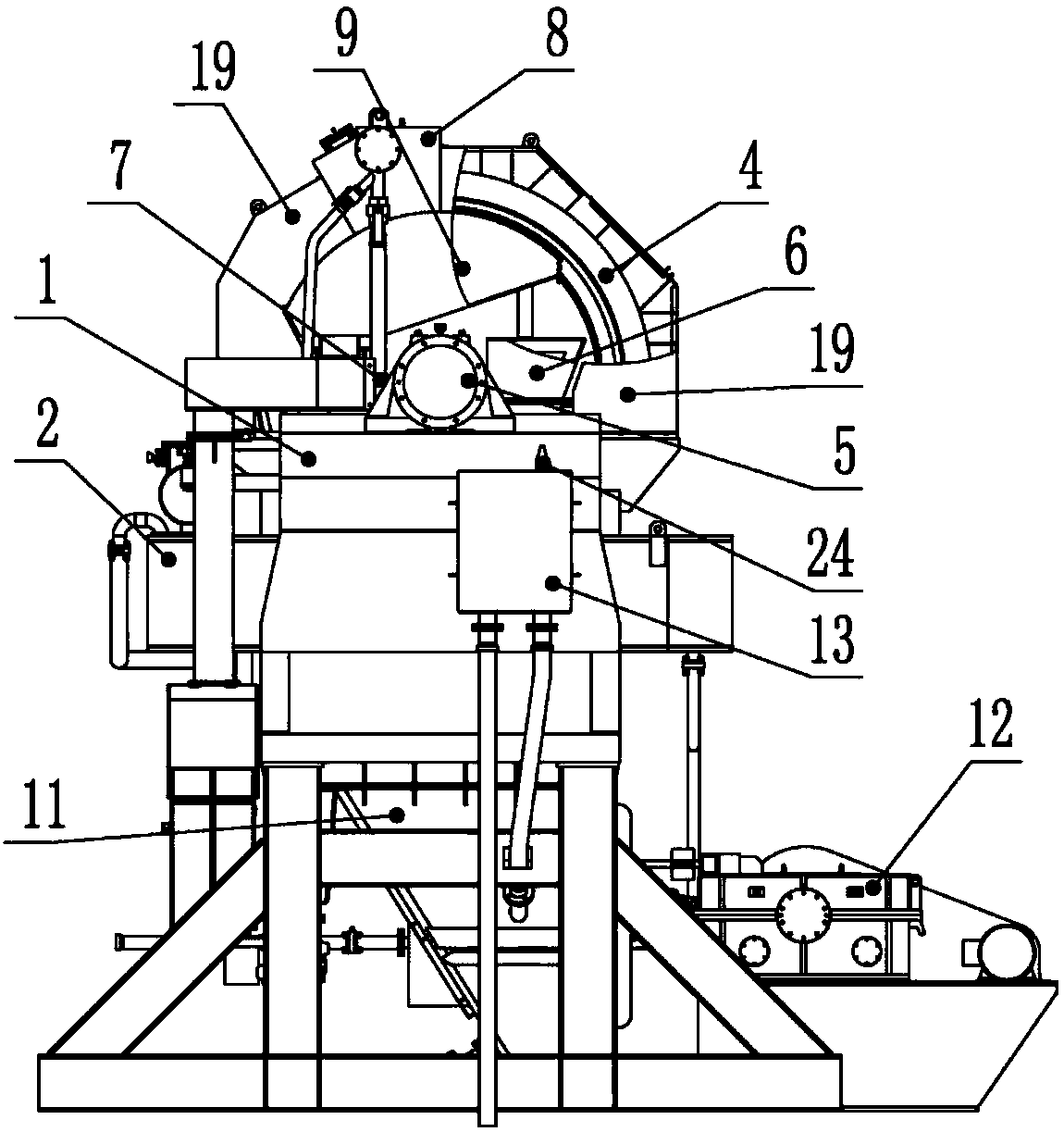

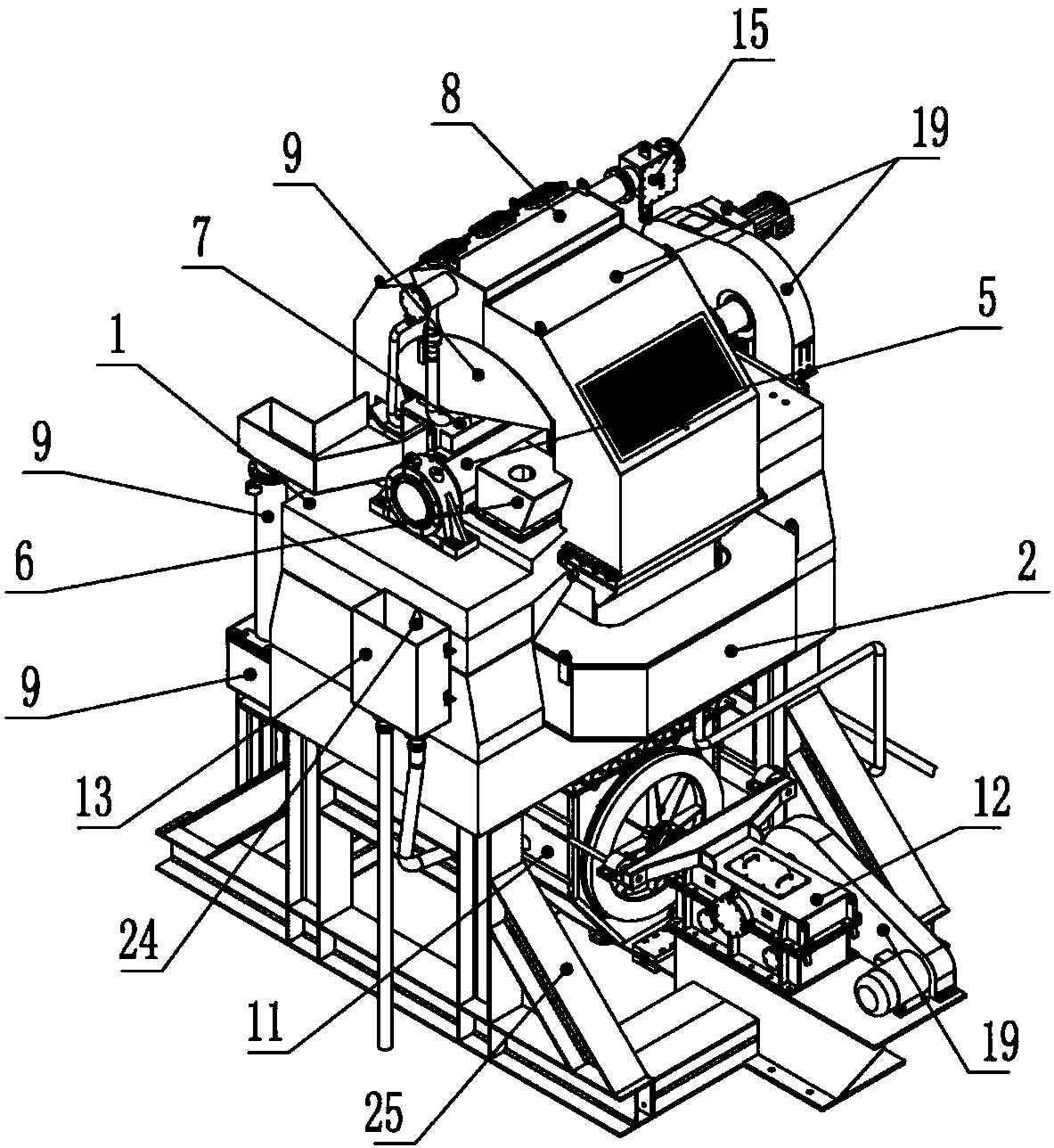

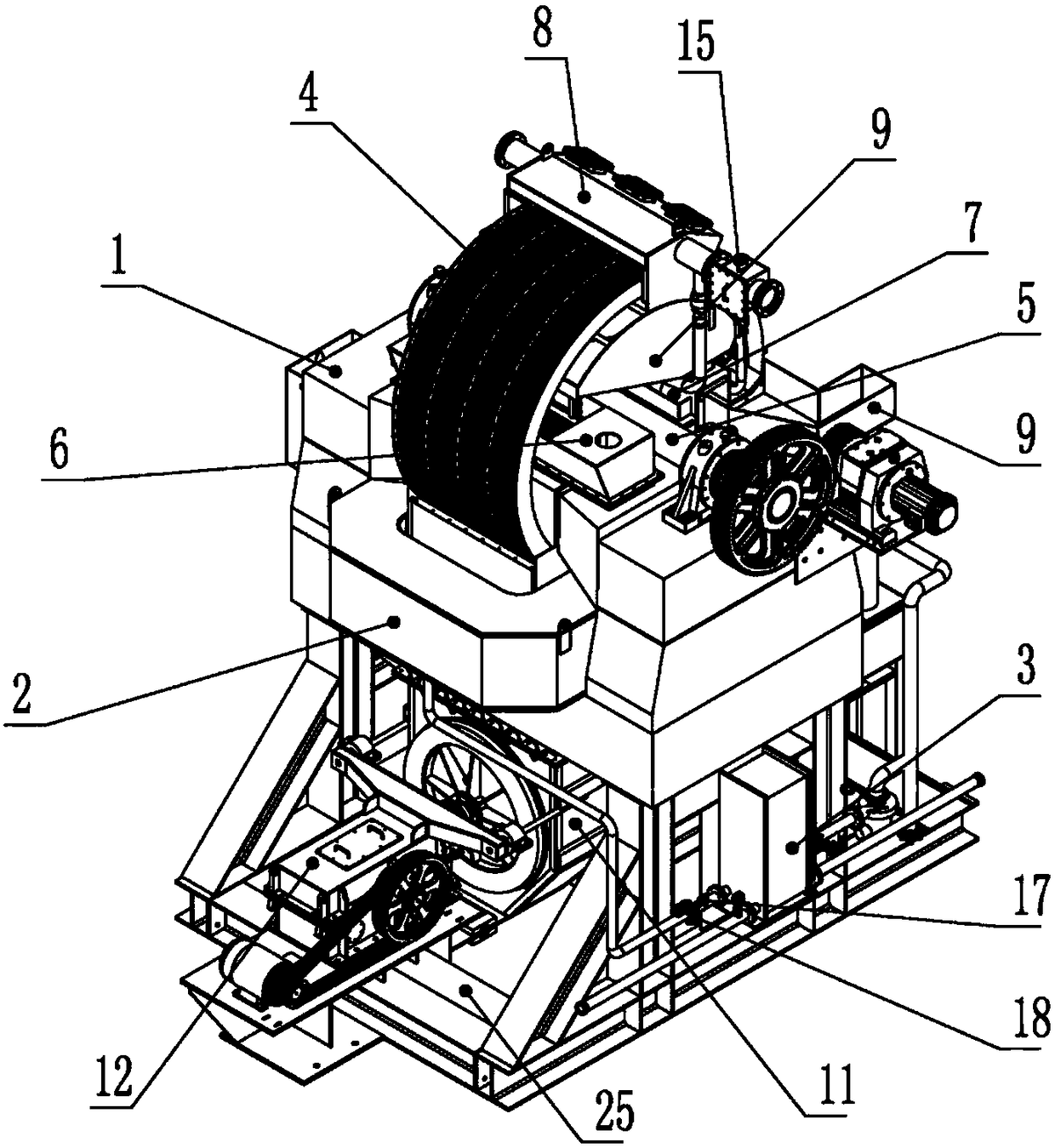

Full-automatic wet process high-gradient magnetic field magnetic separation device

ActiveCN106513168AImprove feasibility and reliabilityHigh control precisionHigh gradient magnetic separatorsAutomatic controlEngineering

The invention relates to removing equipment for trace metal magnetic impurities in ceramic powder, belongs to the technical field of high-purity ceramic powder preparing, and particularly relates to a full-automatic wet process high-gradient magnetic field magnetic separation device. The device comprises a ladder, a hopper, a stirring tank, a magnetic separation machine, a diaphragm pump, a concentrate collecting tank, a tailing tank, an automatic control box, other control valves and the like. The full-automatic wet process high-gradient magnetic field magnetic separation device is a magnetic separation device capable of achieving automatic control, has high feasibility and reliability and is high in control precision. The background magnetic field and the gradient magnetic field of the magnetic separation device are large and adjustable, the maximum magnetic field gradient is higher than 1,000 T, and the magnetic separation device is suitable for removing high-content metal impurities and can also be suitable for removing trace metal impurities. Water or absolute ethyl alcohol can be adopted in the magnetic separation device to serve as media, and the application range is wider.

Owner:ZHONGBEI UNIV

Method for removing surface coating of titanium pipe and titanium alloy pipe

InactiveCN102206829AWon't happenReduce pollutionPhotography auxillary processesChemical reactionElectrolysis

The invention discloses a method for removing the surface coating of a titanium pipe and a titanium alloy pipe. The method comprises the following steps of: firstly, mixing FeCl3, HCL and water into a solution; then soaking the titanium pipe or the titanium alloy pipe in the solution; removing the coating on the surface of the titanium pipe and the titanium alloy pipe through chemical reaction of FeCl3 in the solution and the coating on the surface of the titanium pipe or the titanium alloy pipe; meanwhile, charging compressed air into the solution to convert Fe<2+> in the solution into Fe<3+> so as to recycle the solution; and finally, recovering non-ferrous metal ions in the solution in which the titanium pipe or the titanium alloy pipe is soaked through electrolysis. The method disclosed by the invention has the advantages of simple operation process, simple field requirement, less investment and less pollution to the environment; and in a processing process, no corrosion is generated on a titanium pipe or titanium alloy pipe matrix through the solution, no waste gas and no nitric oxide smoke are generated and no damages are caused to the environment and operators.

Owner:WESTERN TITANIUM TECH

Wet high gradient strong magnetic separator

PendingCN108262159AApplicable removalGood sorting indexHigh gradient magnetic separatorsCollection systemSlurry

The invention provides a wet high gradient strong magnetic separator. The wet high gradient strong magnetic separator comprises an excitation system, a sorting collection system, a safety and isolation system and an adjustment system. The excitation system provides a background magnetic field for sorting. The sorting collection system is used for separating a magnetic material and a non-magnetic material in ore slurry containing magnetic ores through magnetic separation. The safety and isolation system is used for granularity isolation of a fed material, isolation of impurities in water, pollution isolation of an insulation coolant, magnetic field isolation of a magnetic-fearing part, safety protection of a motor, a coil and a media box module, and personal safety protection for operators.The adjustment system is used for adjusting background magnetic field strength, a rotation ring rotation rate, pulsation amplitude and frequency, liquid level height and rinsing water and ore unloading water amount / angle. The multiple parts or modules realize division and cooperation between systems so that the reliable and stable strong magnetic sorting of the weak magnetic minerals is realized.

Owner:LONGI MAGNET CO LTD

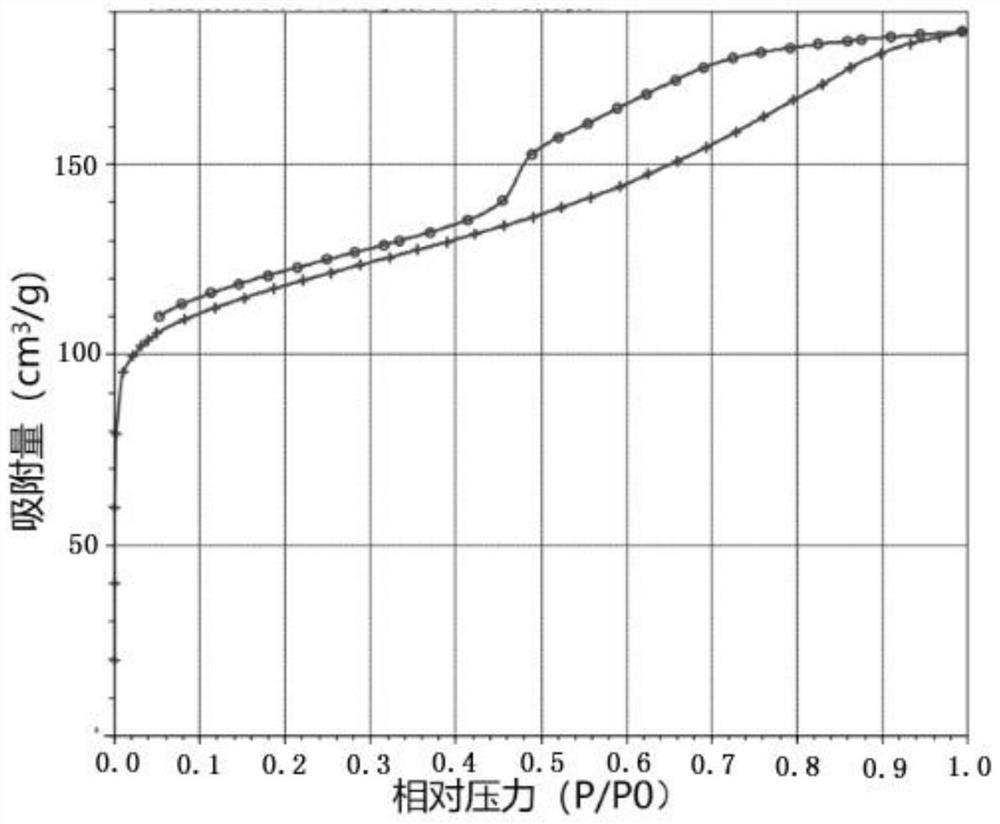

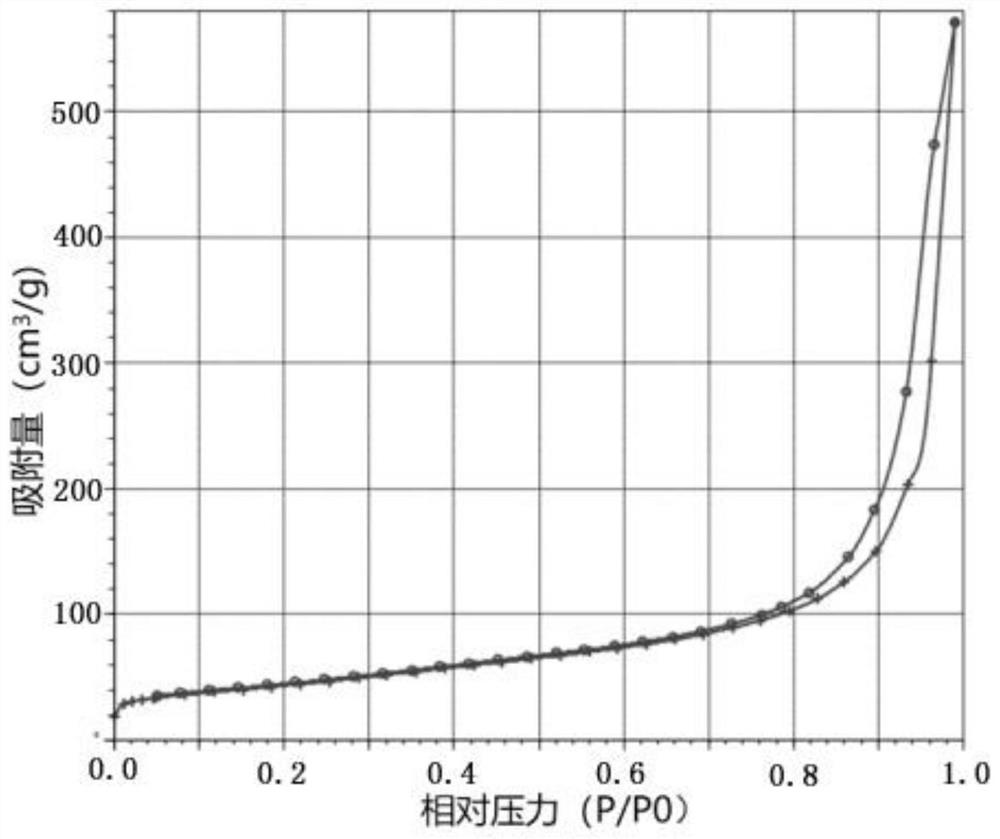

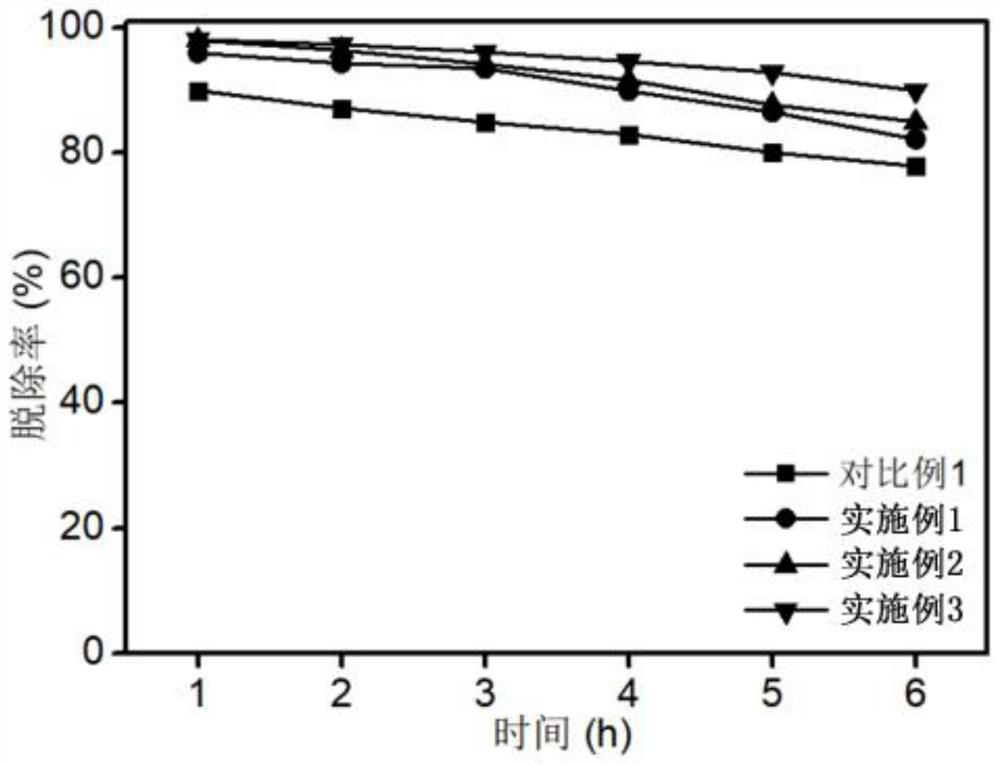

Adsorbing material for removing carbonyl sulfide by carbon material loaded ionic liquid and application of adsorbing material

ActiveCN113070040AImprove removal effectImprove adsorption capacityOther chemical processesGas purification with selectively adsorptive solidsTetrafluoroborateCarbon nanotube

The invention discloses an adsorbing material for removing carbonyl sulfide by carbon material loaded ionic liquid and application of adsorbing material. A preparation method of the adsorbing material comprises the following steps: adding ionic liquid into a diluting solvent, carrying out ultrasonic mixing for 4-8 minutes, then adding a carbon material at room temperature, carrying out stirring impregnation for 8-12 hours, finally putting the obtained mixture into a vacuum drying oven, conducting drying at 60-80 DEG C for 4-8 hours, and storing the obtained adsorbing material product in an N2 atmosphere dryer, wherein the ionic liquid is 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, the carbon material is activated carbon or multi-walled carbon nanotubes, and the activated carbon is semi-coke. When the adsorbing material is used for adsorption treatment of carbonyl sulfide in mixed gas, the adsorbing material has the advantages of being high in carbonyl sulfide removal rate, good in cyclicity and the like, the preparation method of the adsorbing material is simple, and the adsorbing material has potential industrial application value.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com