Method and equipment for deoxidizing low-concentration oxygen-containing coal bed gas

A low-concentration technology of coalbed methane, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problem that the production and reserves of natural gas cannot meet the needs of social and economic development, and achieve low operating costs, high system heat utilization, and process The effect of a compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

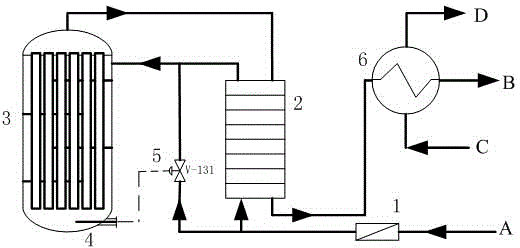

Method used

Image

Examples

Embodiment 1

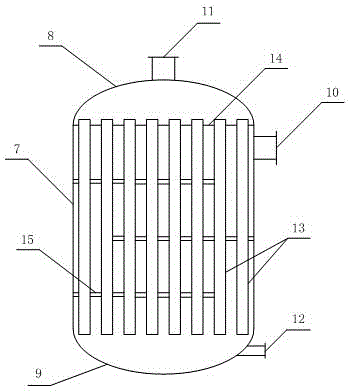

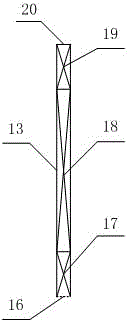

[0037] The fixed bed deoxidation reactor includes a shell (7), an upper head (8), a lower head (9), an oxygen-containing coalbed gas inlet (10), a deoxygenated coalbed gas outlet (11), a temperature measuring port (12), Tubes (13), tube sheets (14), vertical tubes (13) are arranged in the casing (7), the upper ends of the tubes are fixed on the tube sheet (14) connected to the casing (7), and the columns Three baffles (15) are installed between the tubes, the upper part of the shell (7) below the tube plate (14) has an oxygen-containing coalbed gas inlet (10), and the top of the upper head (8) has a deoxidation The coal bed gas outlet (11), the lower head (9) has a temperature measuring port (12).

[0038]The lower end of the tube array (13) is the tube gas inlet (16), the upper end is the tube gas outlet (20), the inner lower part of the tube tube (13) has a support packing (17), the middle part is a catalyst bed (18), and the upper part has filler (19).

[0039] The diamet...

Embodiment 2

[0045] The diameter of the fixed-bed deoxygenation reactor is 1000mm, and the height is 1200mm. There are 128 catalyst tubes installed in the reactor. The diameter of the tubes is 40mm, and the length is 650mm. The deflection baffle is a circular baffle, the area of the gap is 30% of the overall area of the circle, and the distance between the baffles is 500mm.

[0046] The deoxygenation process of oxygen-containing coalbed methane and the structure of the fixed-bed deoxygenation reactor are as described in Example 1. The deoxidation catalyst uses Cu as the catalytic active component, the active component content is 15wt%, the carrier alumina content is 85wt%, the catalyst particle size is 0.4-1.0mm, and the pore volume is 0.5cm 3 / g, bulk density 0.80g / cm 3 . Oxygen-containing coalbed methane treatment capacity is 350m 3 / h, the gas composition is (volume percentage): CH 4 Content 92.71%, O 2 Content 1.52%, N 2 Content 5.72%, other gas content 0.05%. The operating ...

Embodiment 3

[0050] The diameter of the fixed bed deoxygenation reactor is 1000mm, and the height is 1200mm. There are 108 catalyst tubes installed in the reactor. The diameter of the tubes is 38mm, and the length is 700mm. The deflection baffle is a circular baffle, the area of the gap is 20% of the overall area of the circle, and the distance between the baffles is 400mm.

[0051] The deoxygenation process of oxygen-containing coalbed methane and the structure of the fixed-bed deoxygenation reactor are as described in Example 1. The deoxidation catalyst is spherical, with Cu as the catalytic active component, the active component content is 20wt%, the carrier alumina content is 80wt%, the catalyst particle size is 0.6-1.2mm, and the pore volume is 0.4cm 3 / g, bulk density 0.68g / cm 3 . Oxygen-containing coalbed methane treatment capacity is 300m 3 / h, the gas composition is (volume percentage): CH 4 Content 85.69%, O 2 Content 3.01%, N 2 The content is 11.13%, and the content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com