Multi-tower combined reactor

A reactor and controller technology, applied in the field of reactors, can solve the problems of complete reaction of unfavorable reactants, high acidity, inability to switch, etc., and achieve the effect of avoiding process complexity and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

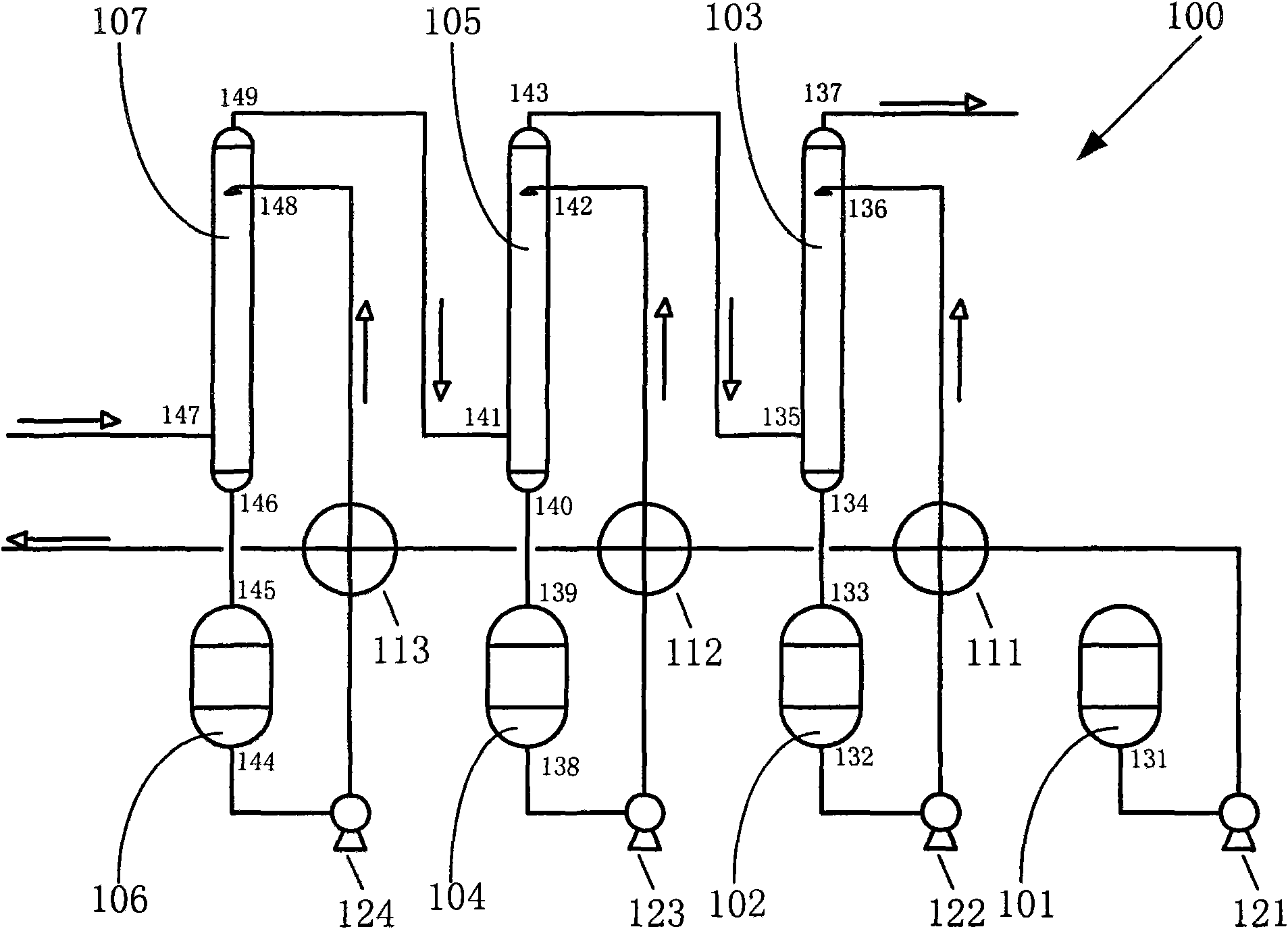

[0021] Such as figure 1 As shown, the present invention provides a multi-tower combined reactor 100 in a specific embodiment. The multi-tower combined reactor 100 includes a crotonaldehyde feed tank 101, three reactor groups (not marked), a ketene gas input pipeline (not marked), a gas output pipeline (not marked) and one Root liquid output pipeline (not marked).

[0022] The crotonaldehyde feed tank 101 is a crotonaldehyde raw material storage tank of the multi-tower combined reactor 100, and is used to continuously or intermittently input the crotonaldehyde raw material into the multi-tower combined reactor 100. The crotonaldehyde feed tank 131 includes at least one crotonaldehyde outlet 131.

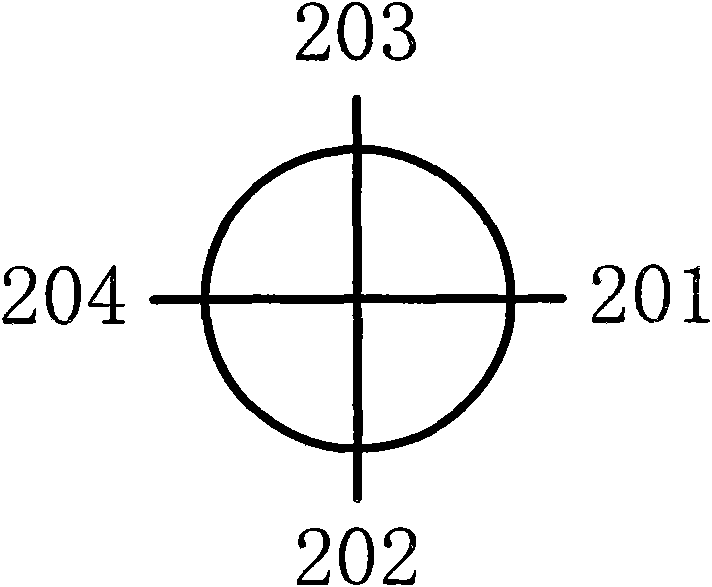

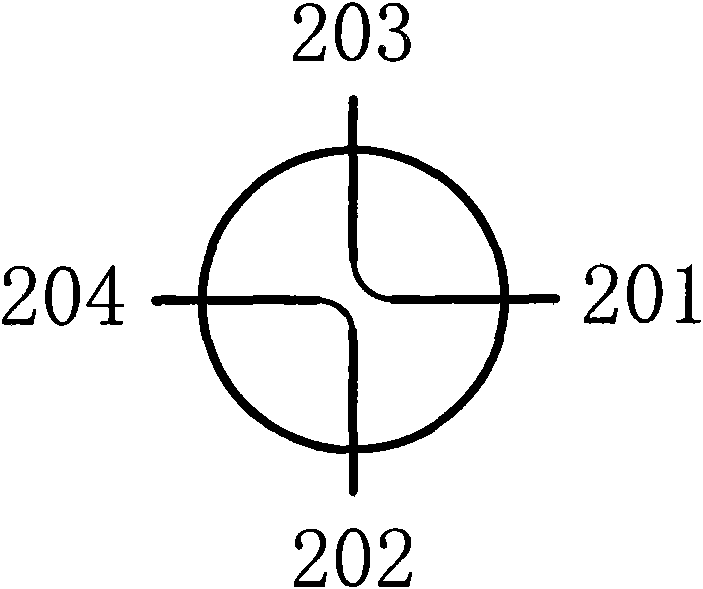

[0023] Each reactor group includes a polymerization tower, a polymerization kettle and a four-way controller. The polymerization tower is a reactor for preliminary polymerization of crotonaldehyde and ketene, and the polymerization vessel is a reactor for further reaction of crotonaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com