Over-temperature protection circuit, semiconductor device and fabrication method of semiconductor device

An over-temperature protection circuit and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, and electric solid-state devices, can solve the problems of poor temperature sensitivity of over-temperature protection circuits, and avoid process complexity and high cost. The effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

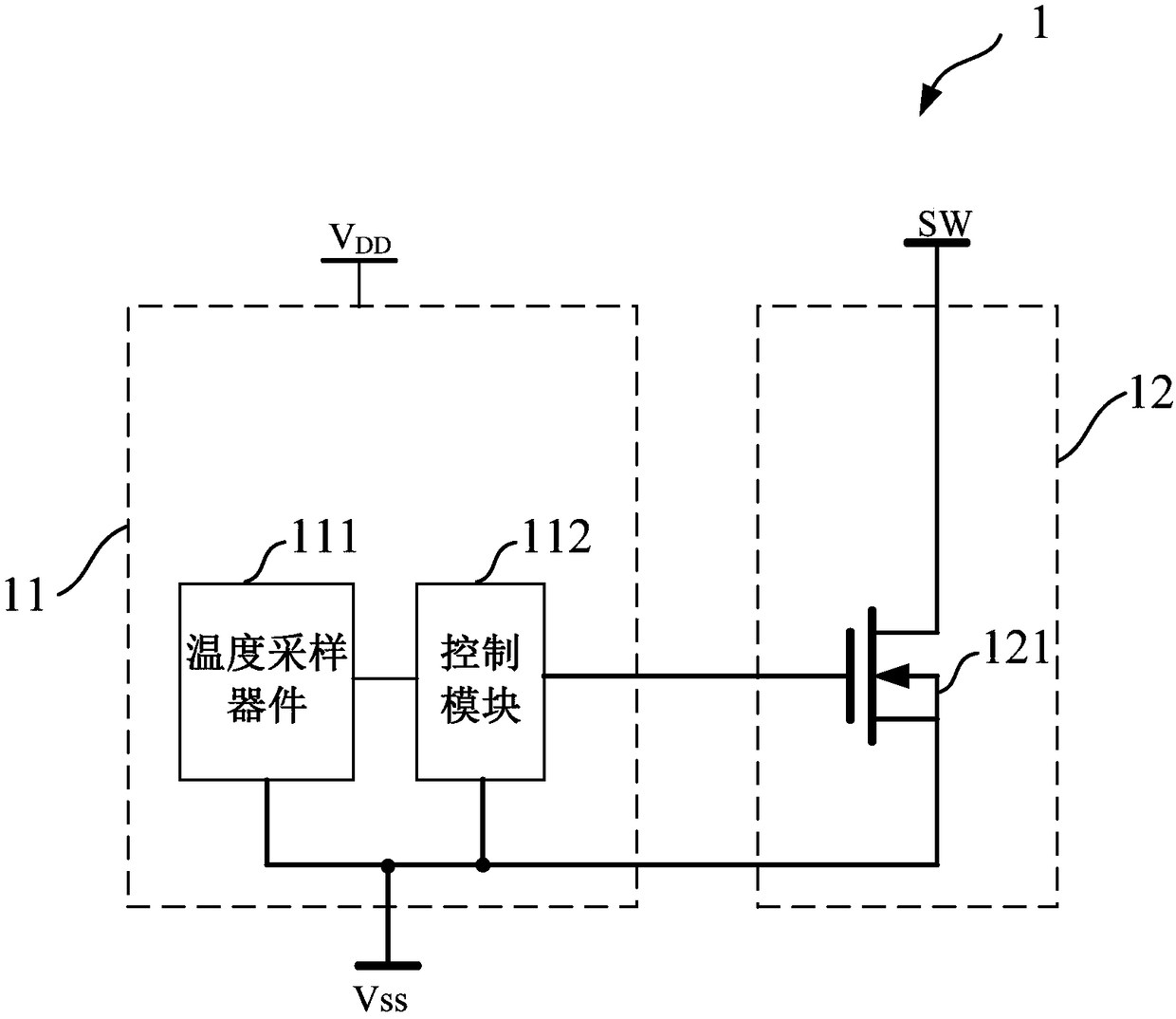

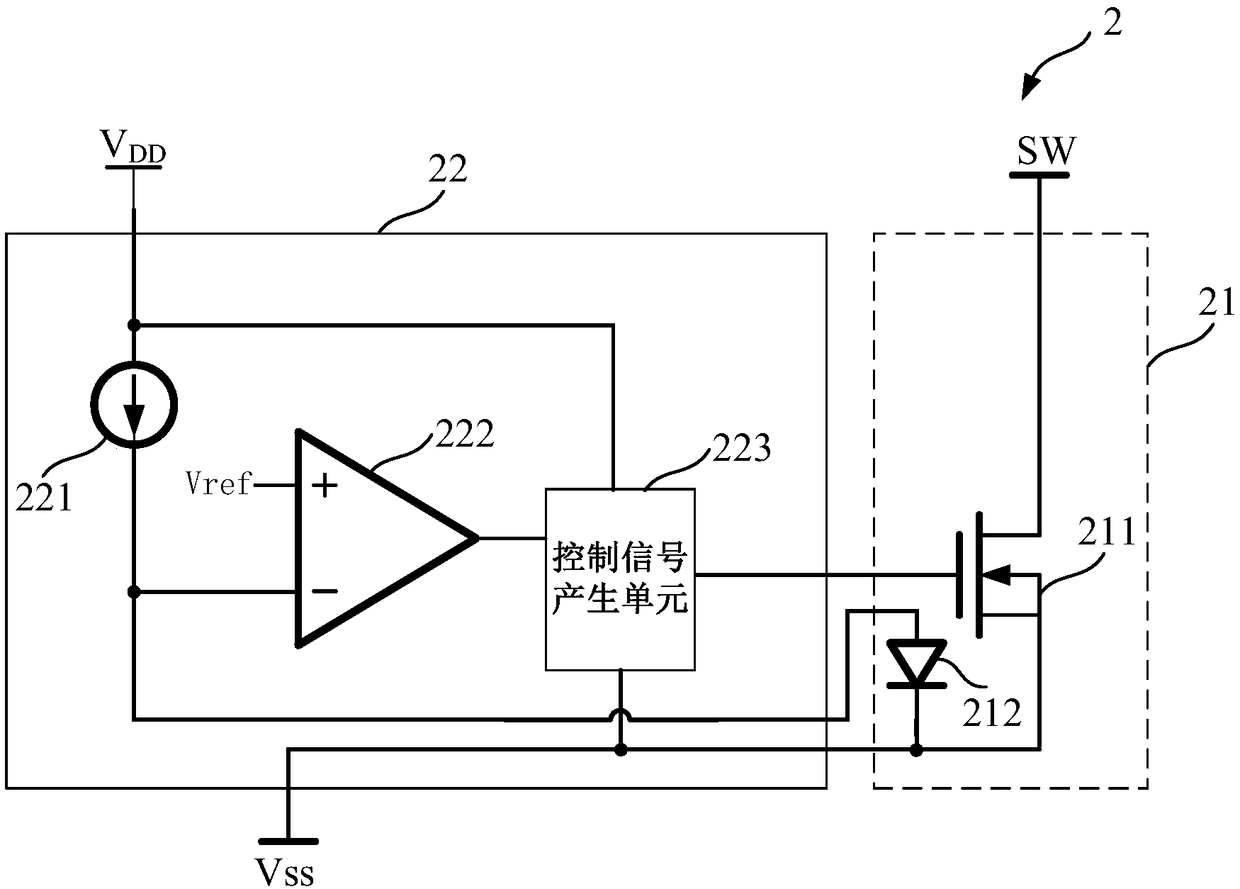

[0068] Such as figure 2 As shown, the present invention provides an over-temperature protection circuit 2, and the over-temperature protection circuit 2 includes:

[0069]A semiconductor device 21 and a control module 22 ; the semiconductor device 21 includes a MOS field effect transistor 211 and a temperature sampling tube 212 ; the control module 22 includes a current source 221 , a comparator 222 and a control signal generating unit 223 .

[0070] Such as figure 2 As shown, one end of the current source 221 is connected to the power supply voltage VDD, and the other end is grounded after passing through the temperature sampling tube 212 to provide a constant current source.

[0071] Specifically, in this embodiment, the temperature sampling tube 212 is a diode, the anode of the diode is connected to the input terminal of the comparator 222 (inverting input terminal in this embodiment), and the cathode is grounded to VSS. In practical applications, the temperature sampli...

Embodiment 2

[0087] Such as Figure 6 As shown, the present invention provides a method for preparing the semiconductor device 21, the specific steps are as follows:

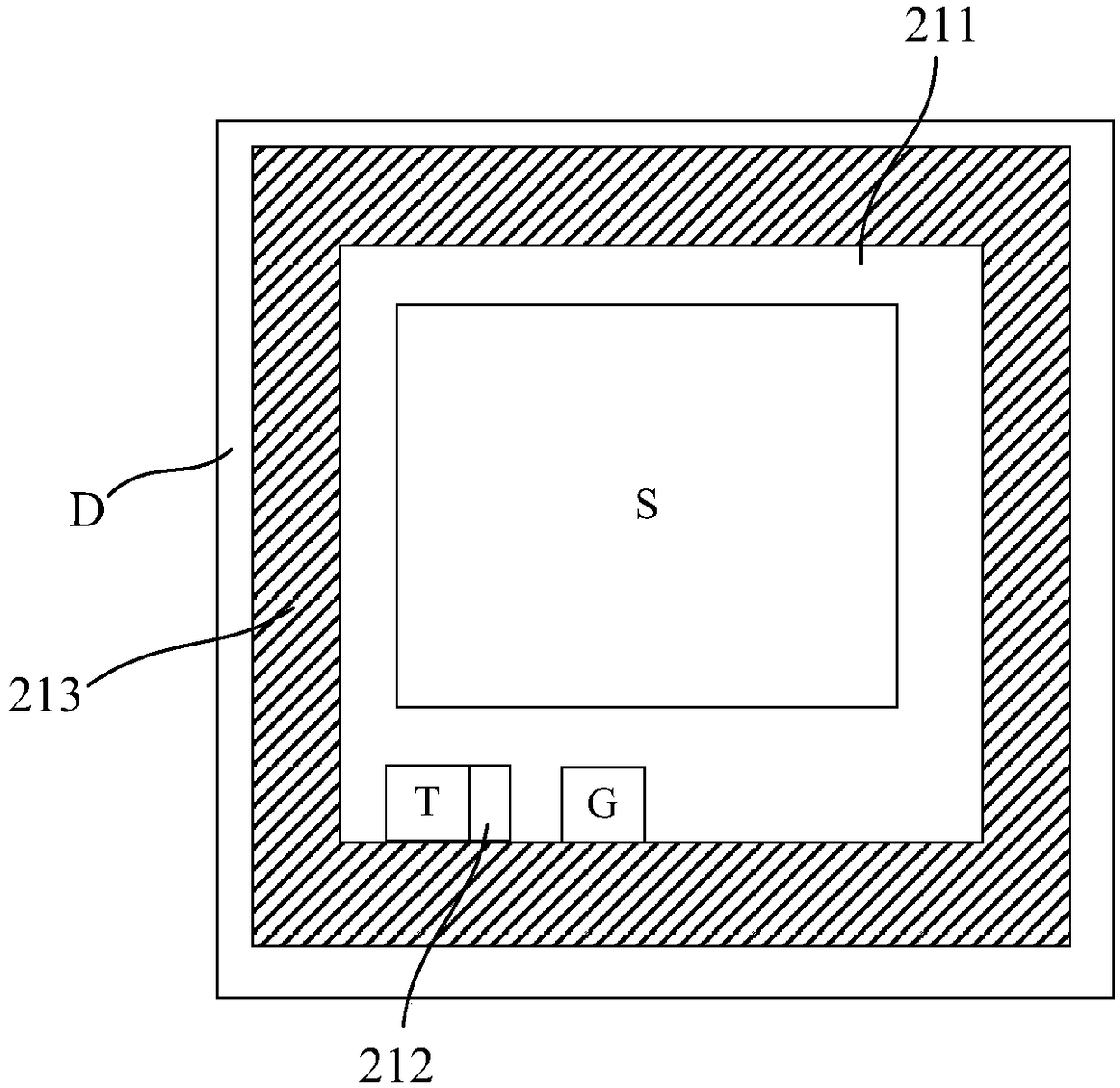

[0088] Step S1 : providing a substrate 214 , and performing termination implantation on the substrate 214 to form a termination region 213 .

[0089] Specifically, such as Figure 6 As shown, in this embodiment, the conductivity type of the substrate 214 is N-type doping, an epitaxial layer 214a is formed on the substrate 214, and the conductivity type of the epitaxial layer 214a is N-type doping, and The doping concentration is smaller than the doping concentration of the substrate 214 . Perform oxidation treatment on the surface of the epitaxial layer 214a, then perform terminal photolithography, and form the terminal region 213 by ion implantation, as image 3 and Figure 6 As shown, the terminal area 213 is a ring structure.

[0090] Step S2: Form a field oxygen layer 215 on the surface of the epitaxial layer 214a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com