Patents

Literature

792 results about "Condensation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensation is the phase change of water vapor into a liquid. During the condensation process, water molecules lose the 600 cal/gm of latent heat that were added during the evaporation process. ... Condensation takes place in the presence of condensation nuclei and when the air is nearly saturated. Water vapor is darting around so fast in the air that the molecules tend to bounce off one another without bonding.

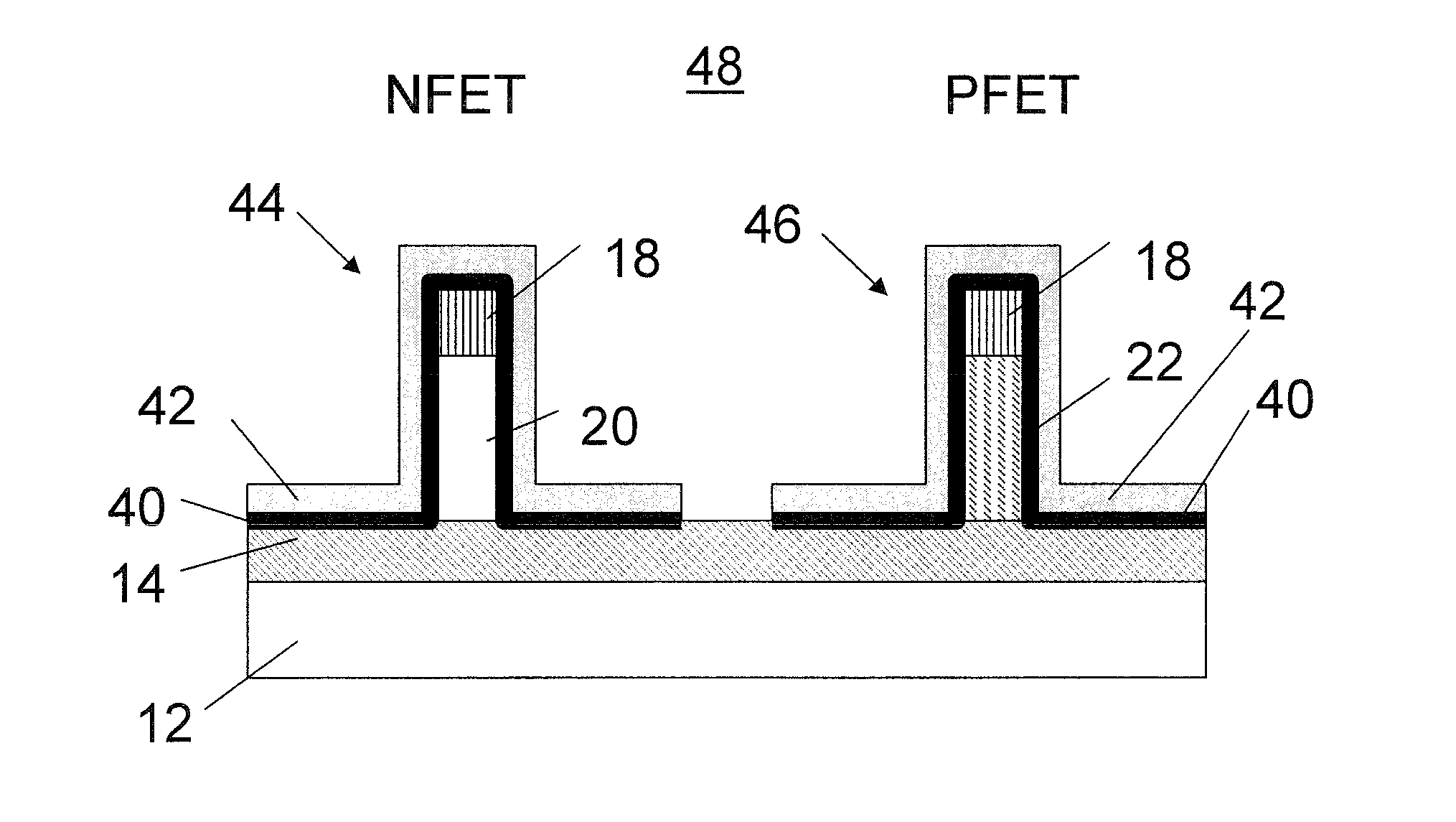

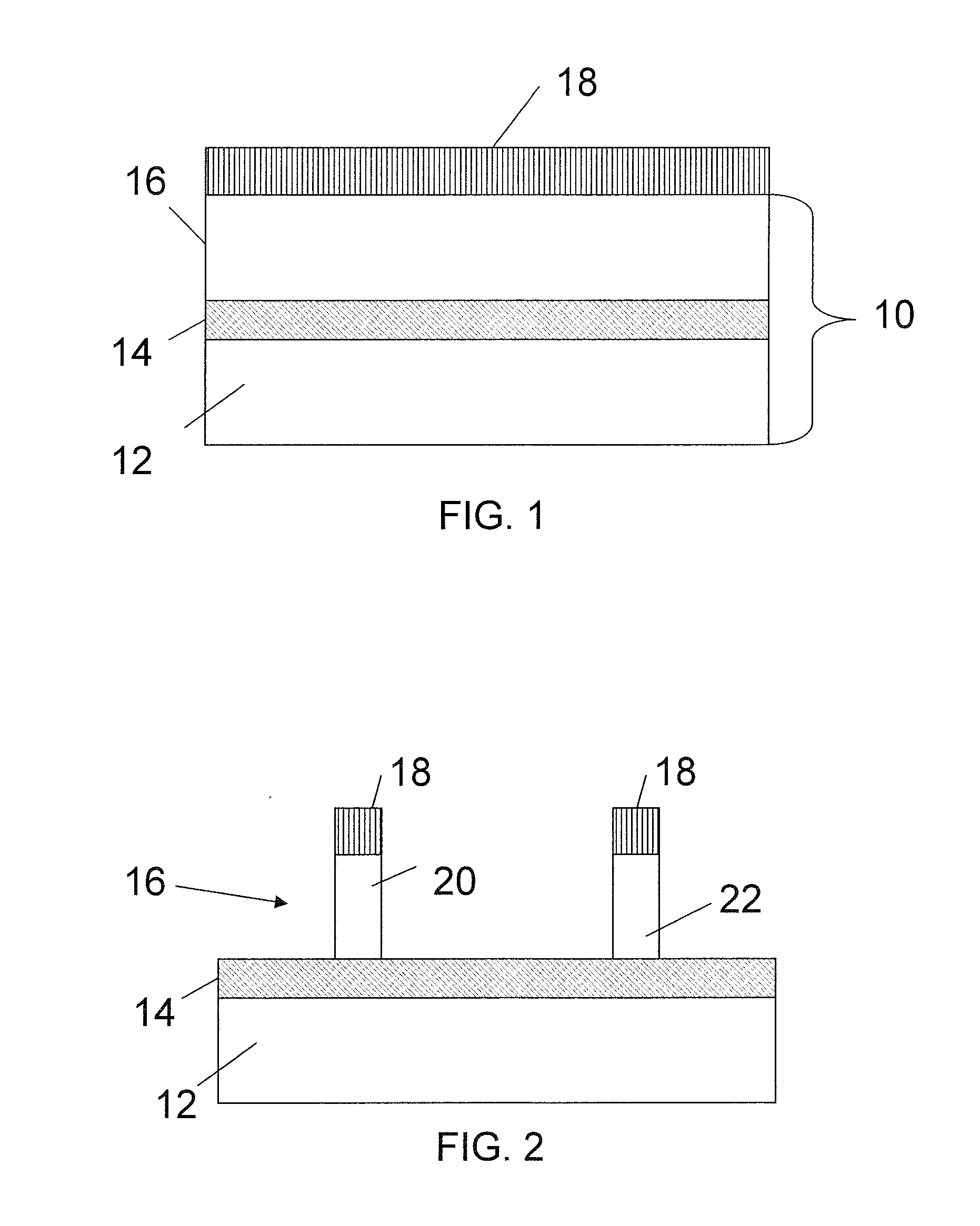

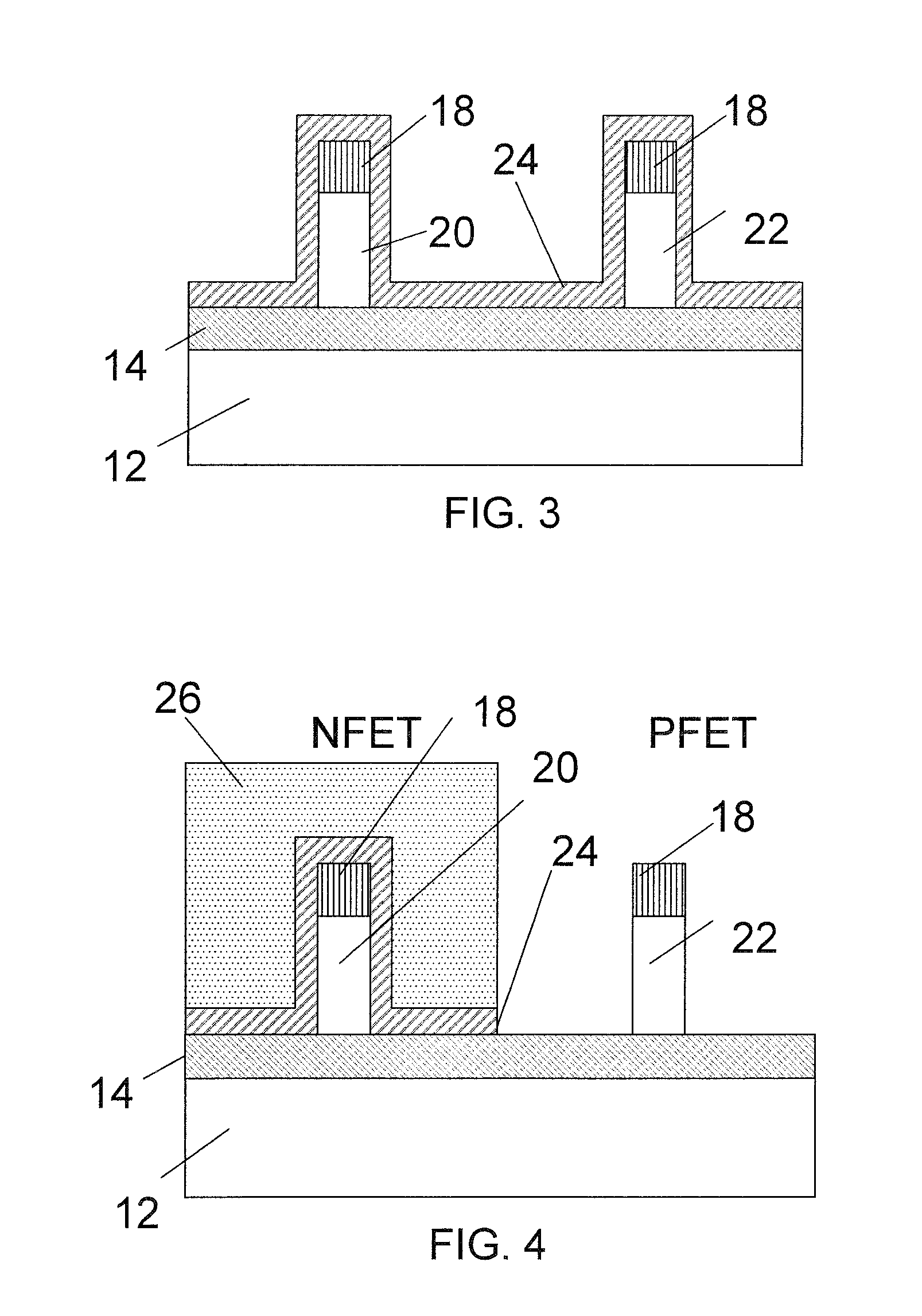

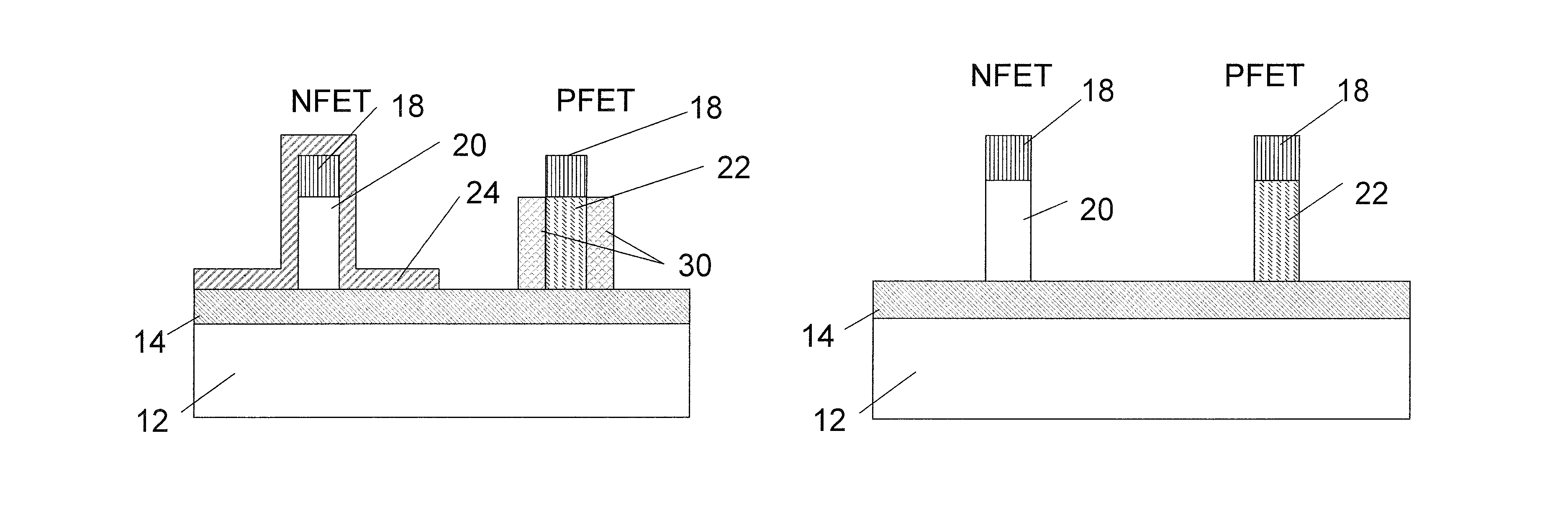

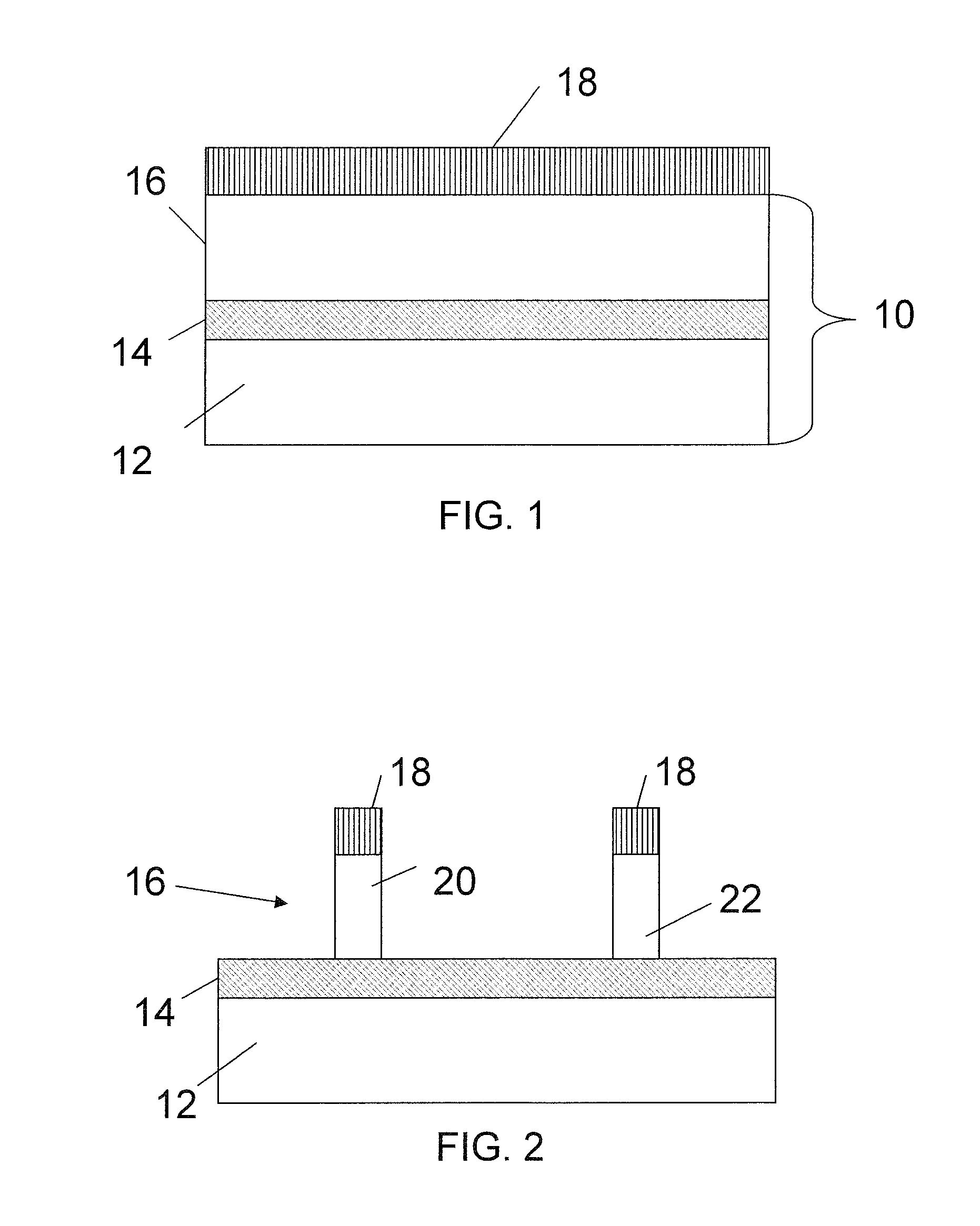

High-k/metal gate CMOS finfet with improved pfet threshold voltage

ActiveUS20110108920A1Solid-state devicesSemiconductor/solid-state device manufacturingCMOSCondensation process

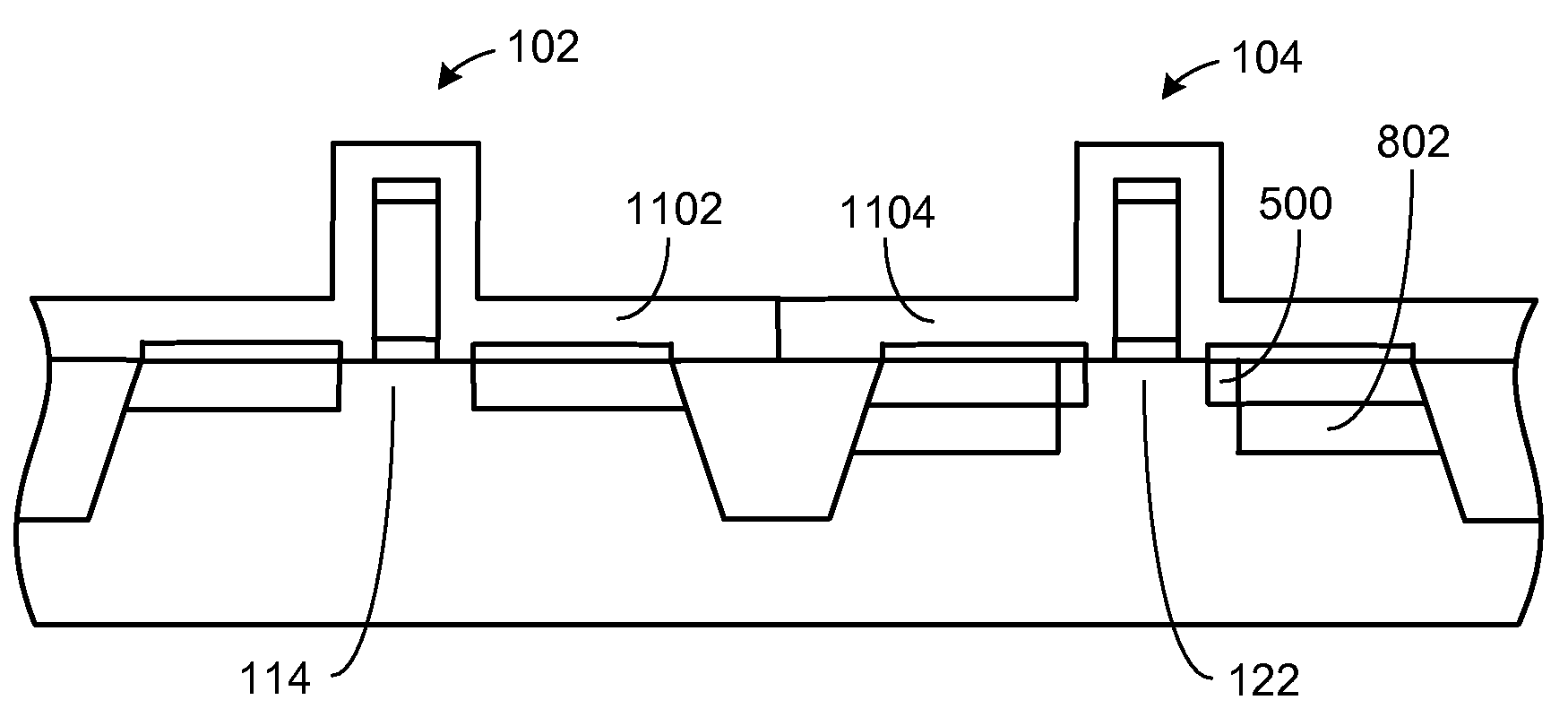

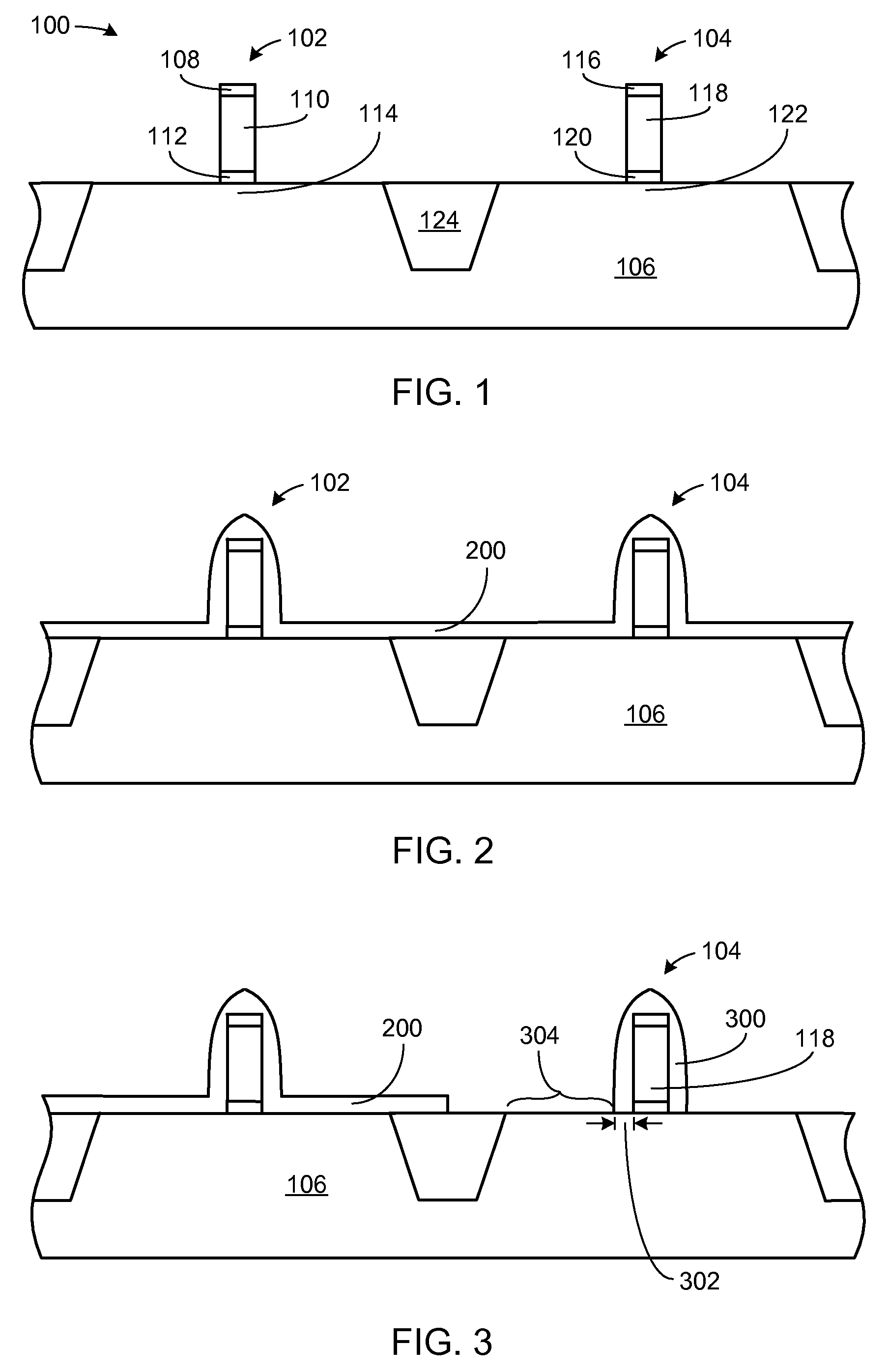

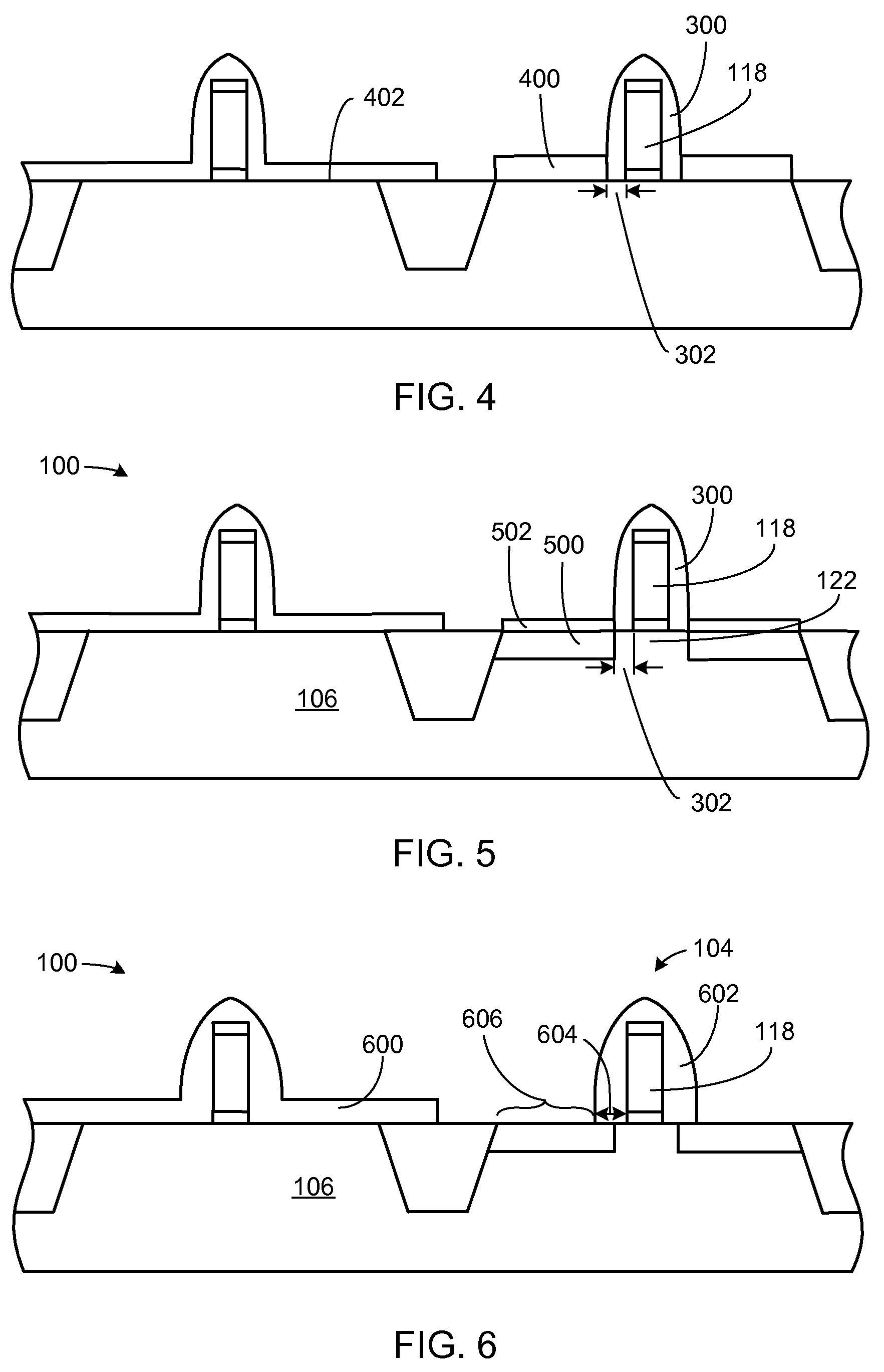

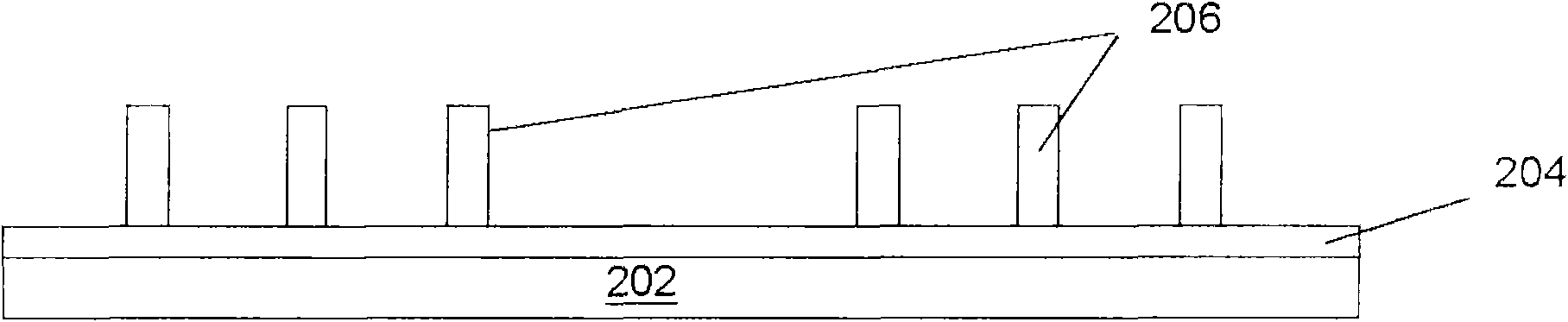

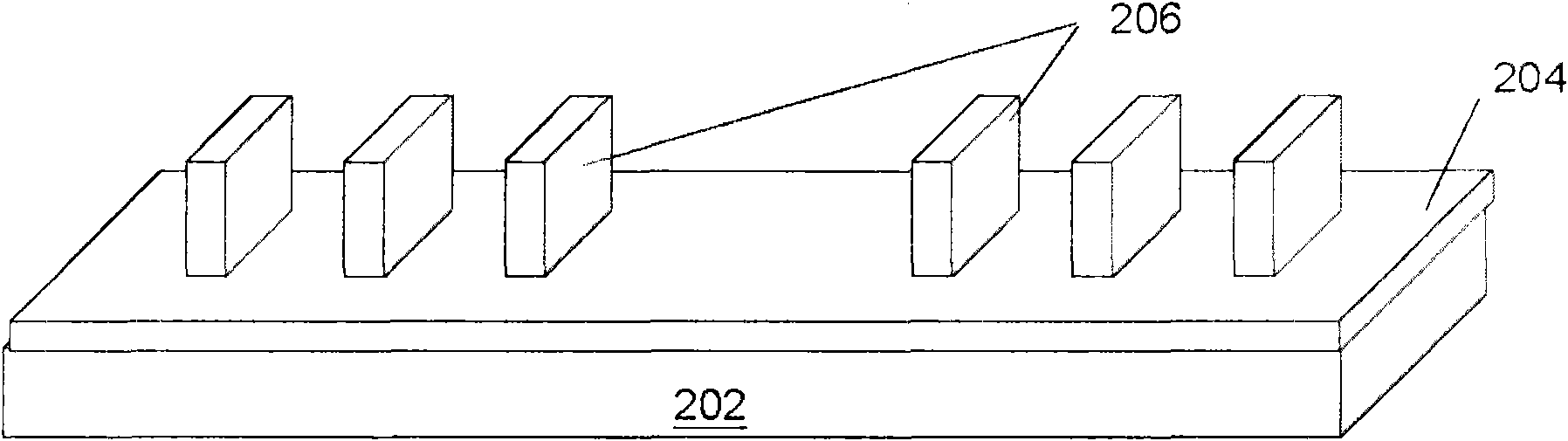

A device and method for fabrication of fin devices for an integrated circuit includes forming fin structures in a semiconductor material of a semiconductor device wherein the semiconductor material is exposed on sidewalls of the fin structures. A donor material is epitaxially deposited on the exposed sidewalls of the fin structures. A condensation process is applied to move the donor material through the sidewalls into the semiconductor material such that accommodation of the donor material causes a strain in the semiconductor material of the fin structures. The donor material is removed, and a field effect transistor is formed from the fin structure.

Owner:GLOBALFOUNDRIES US INC

High-K/metal gate CMOS finFET with improved pFET threshold voltage

ActiveUS7993999B2Solid-state devicesSemiconductor/solid-state device manufacturingCondensation processCMOS

A device and method for fabrication of fin devices for an integrated circuit includes forming fin structures in a semiconductor material of a semiconductor device wherein the semiconductor material is exposed on sidewalls of the fin structures. A donor material is epitaxially deposited on the exposed sidewalls of the fin structures. A condensation process is applied to move the donor material through the sidewalls into the semiconductor material such that accommodation of the donor material causes a strain in the semiconductor material of the fin structures. The donor material is removed, and a field effect transistor is formed from the fin structure.

Owner:GLOBALFOUNDRIES U S INC

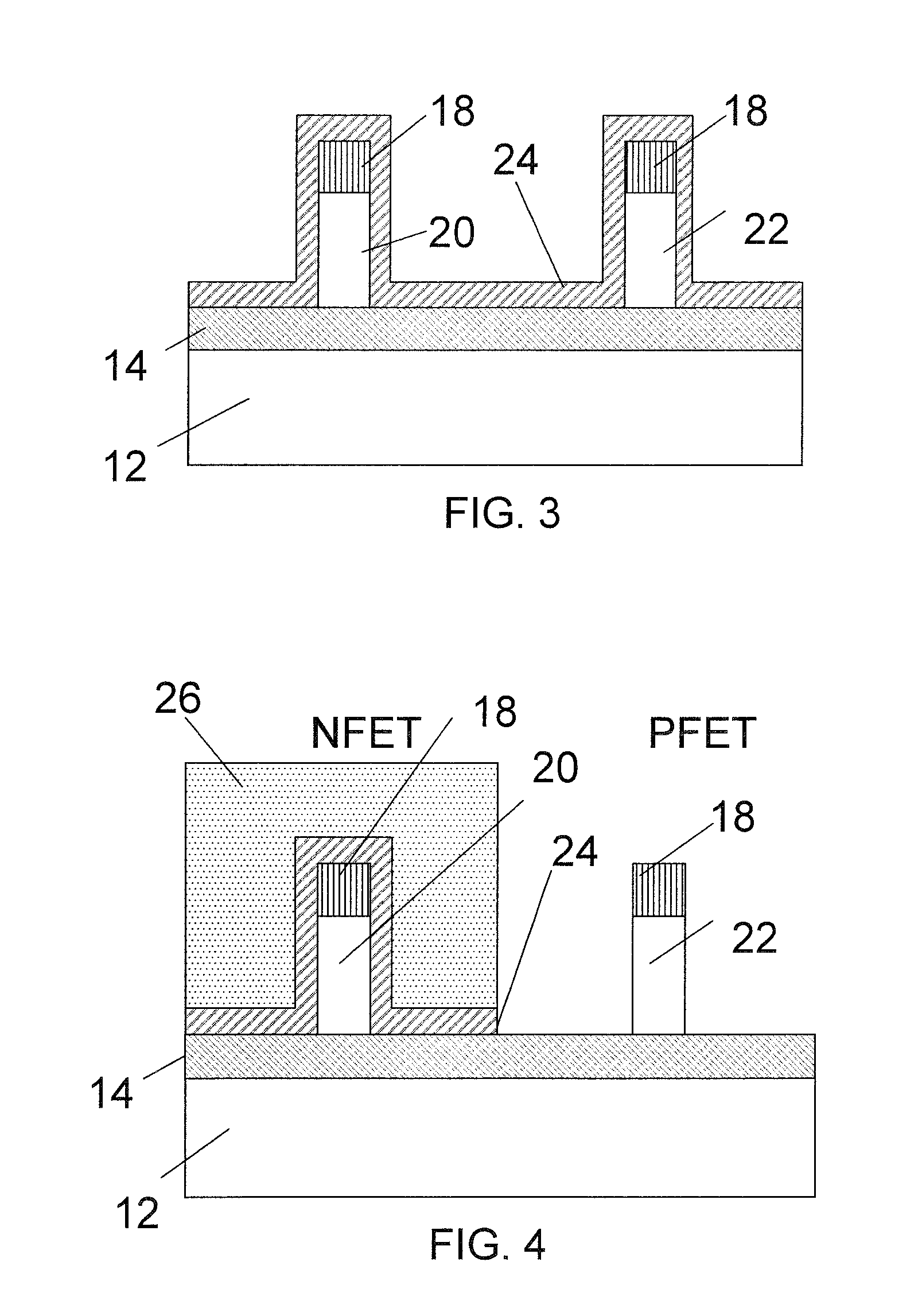

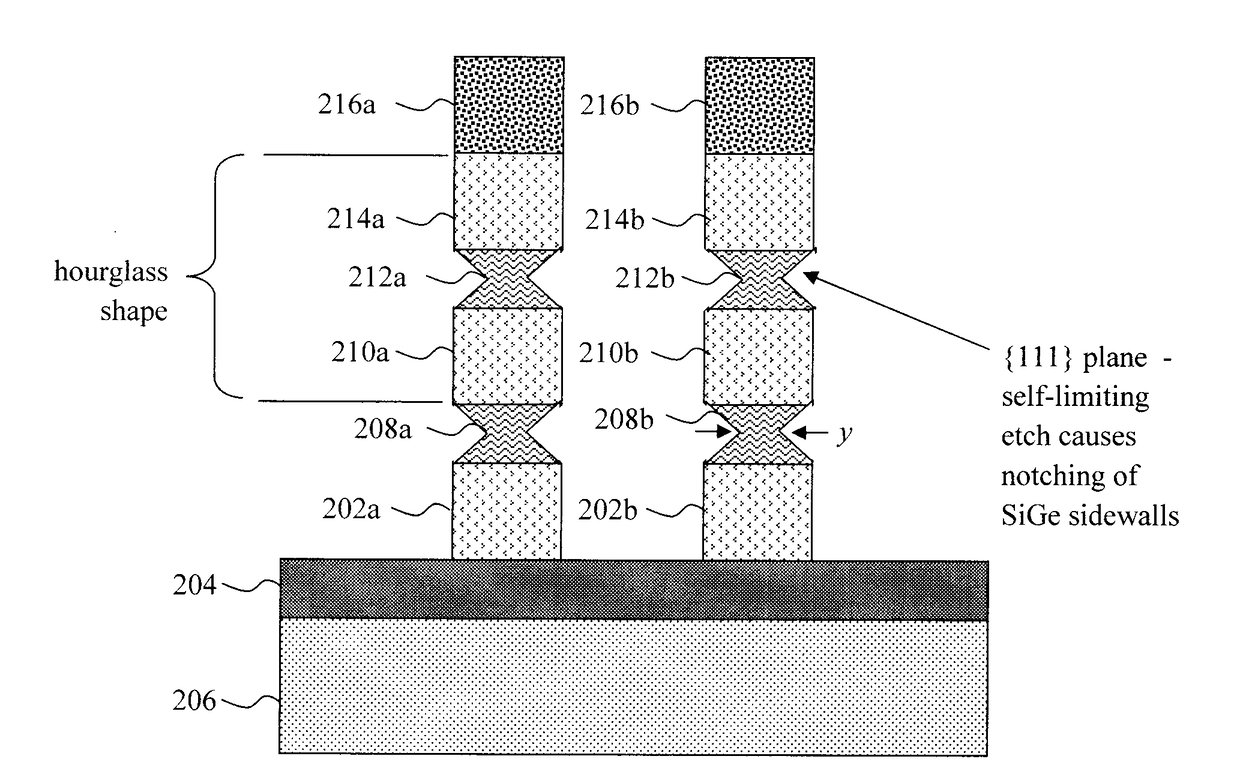

Stacked Nanowires

ActiveUS20170104062A1Semiconductor/solid-state device manufacturingSemiconductor devicesCondensation processNanowire

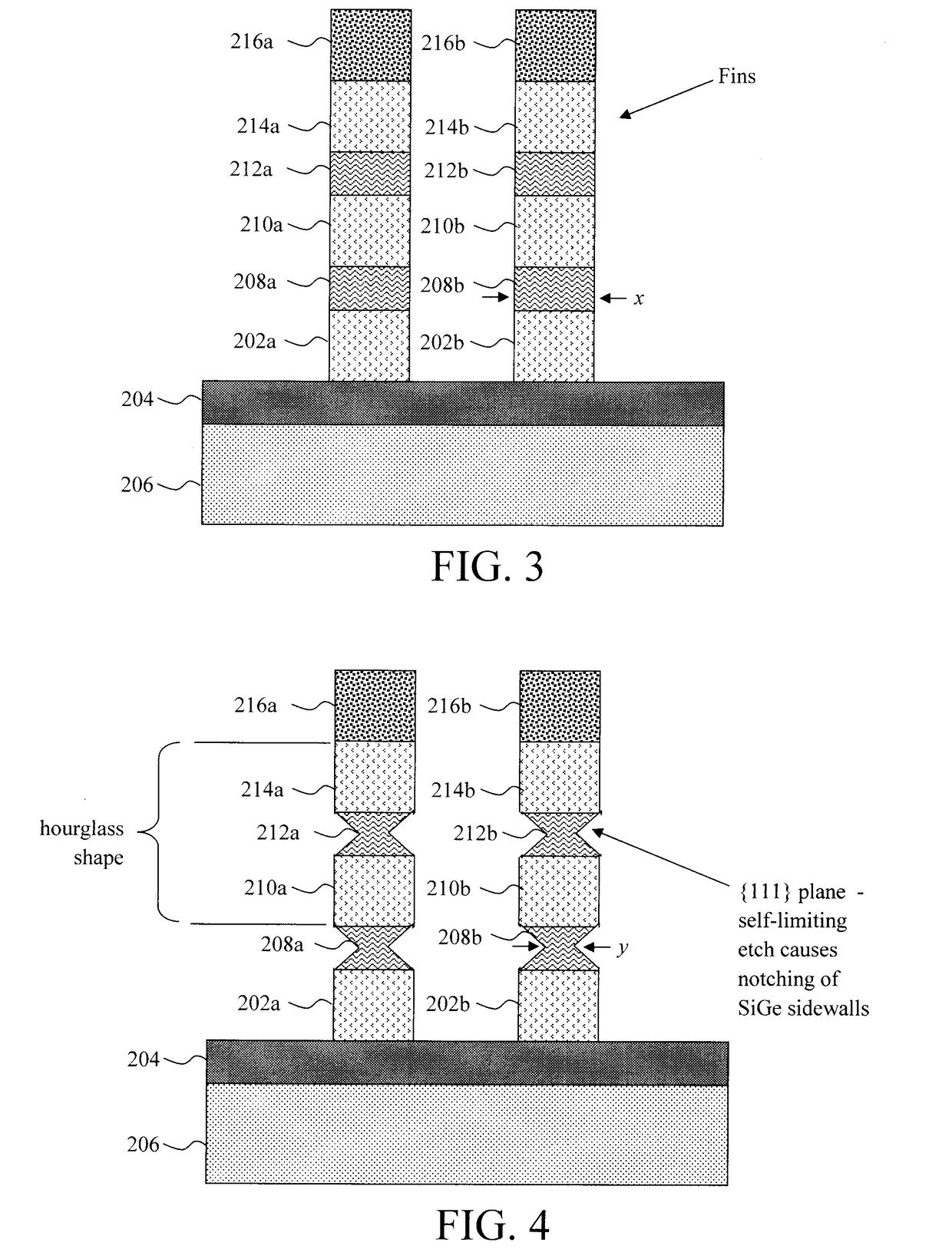

Techniques for producing stacked SiGe nanowires using a condensation process without parasitic Ge nanowires as an undesired by-product. In one aspect, a method of forming SiGe nanowires includes the steps of: forming a stack of alternating Si and SiGe layers on a wafer; patterning fins in the stack; selectively thinning the SiGe layers in the fins such that the Si and SiGe layers give the fins an hourglass shape; burying the fins in an oxide material; and annealing the fins under conditions sufficient to diffuse Ge from the SiGe layers in the fins to the Si layers in the fins to form the SiGe nanowires. A FET device and method for formation thereof are also provided.

Owner:IBM CORP

Integrated circuit system employing a condensation process

ActiveUS20090039388A1Semiconductor/solid-state device manufacturingSemiconductor devicesCondensation processGate dielectric

An integrated circuit system that includes: providing a PFET device including a PFET gate and a PFET gate dielectric; forming a source / drain extension from a first epitaxial layer aligned to a first PFET gate sidewall spacer; and forming a source / drain from a second epitaxial layer aligned to a second PFET gate sidewall spacer.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

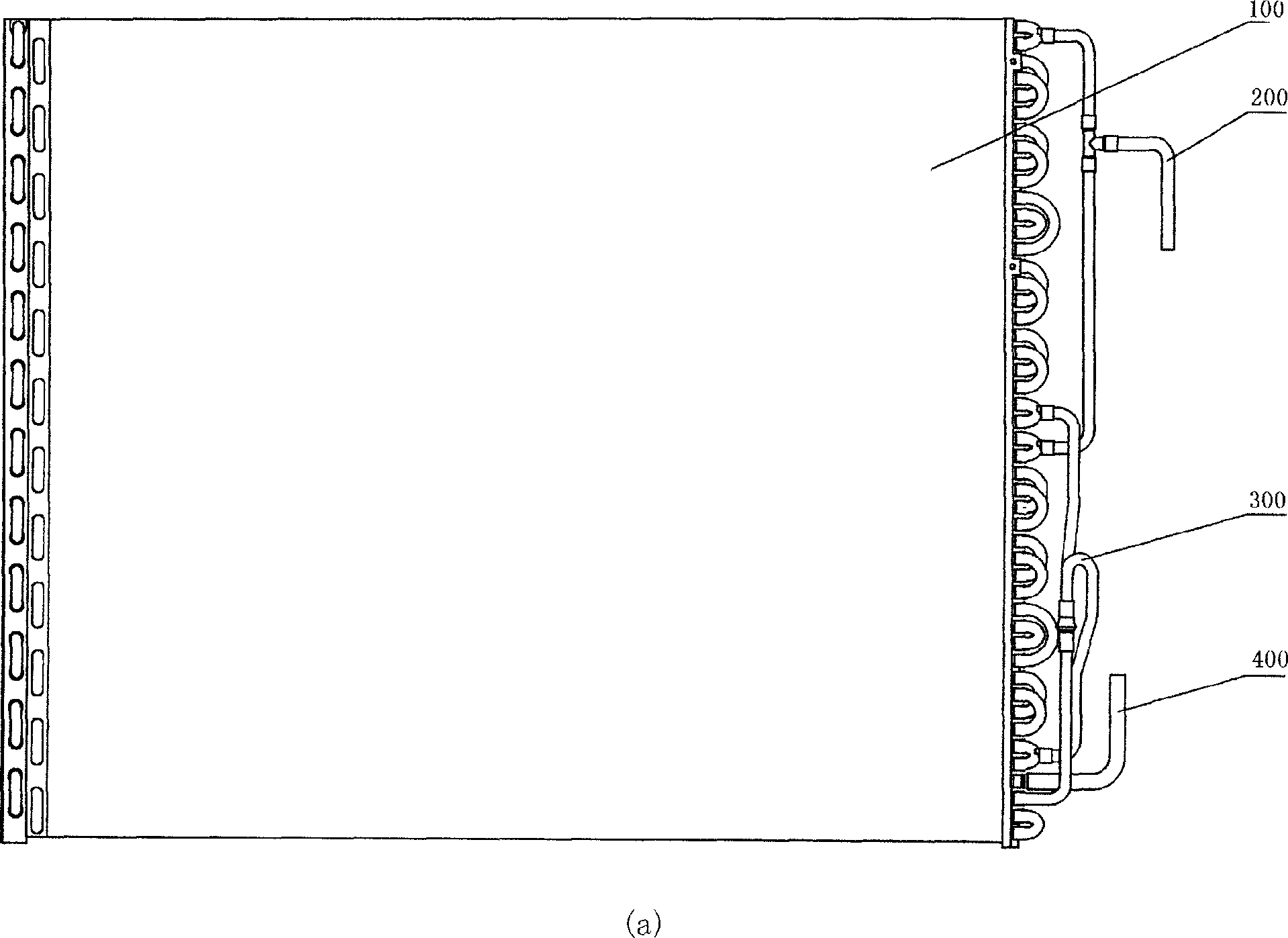

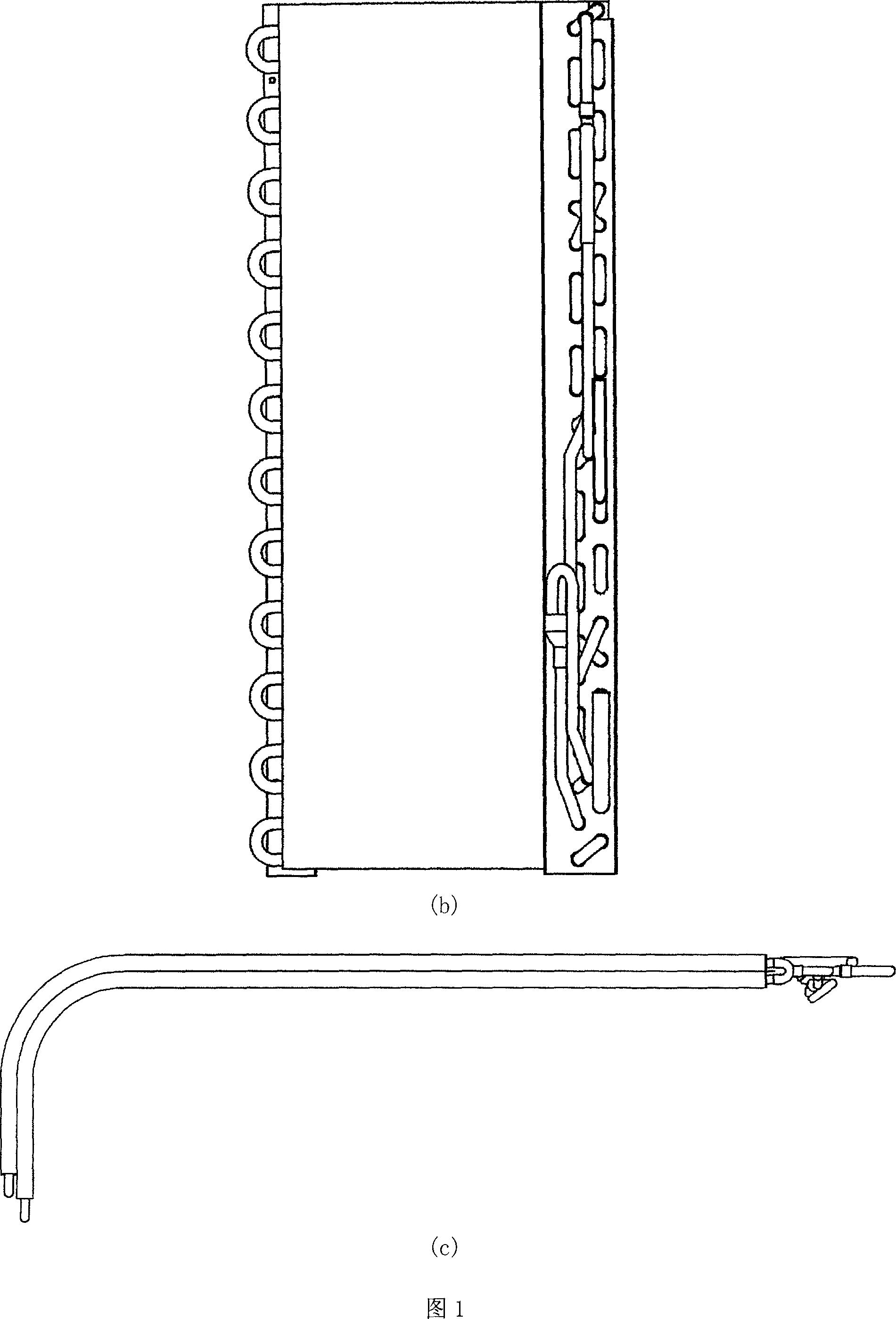

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

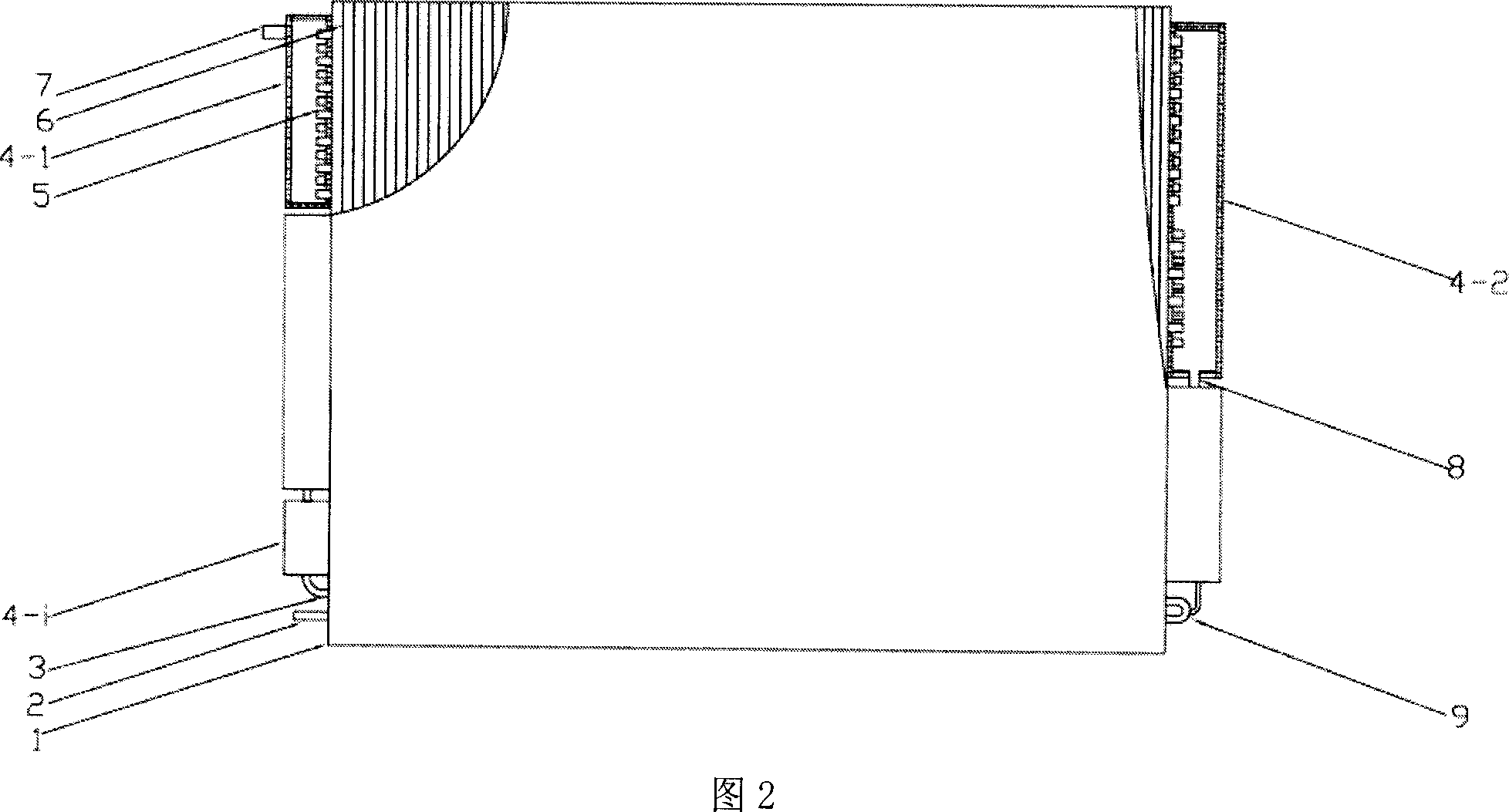

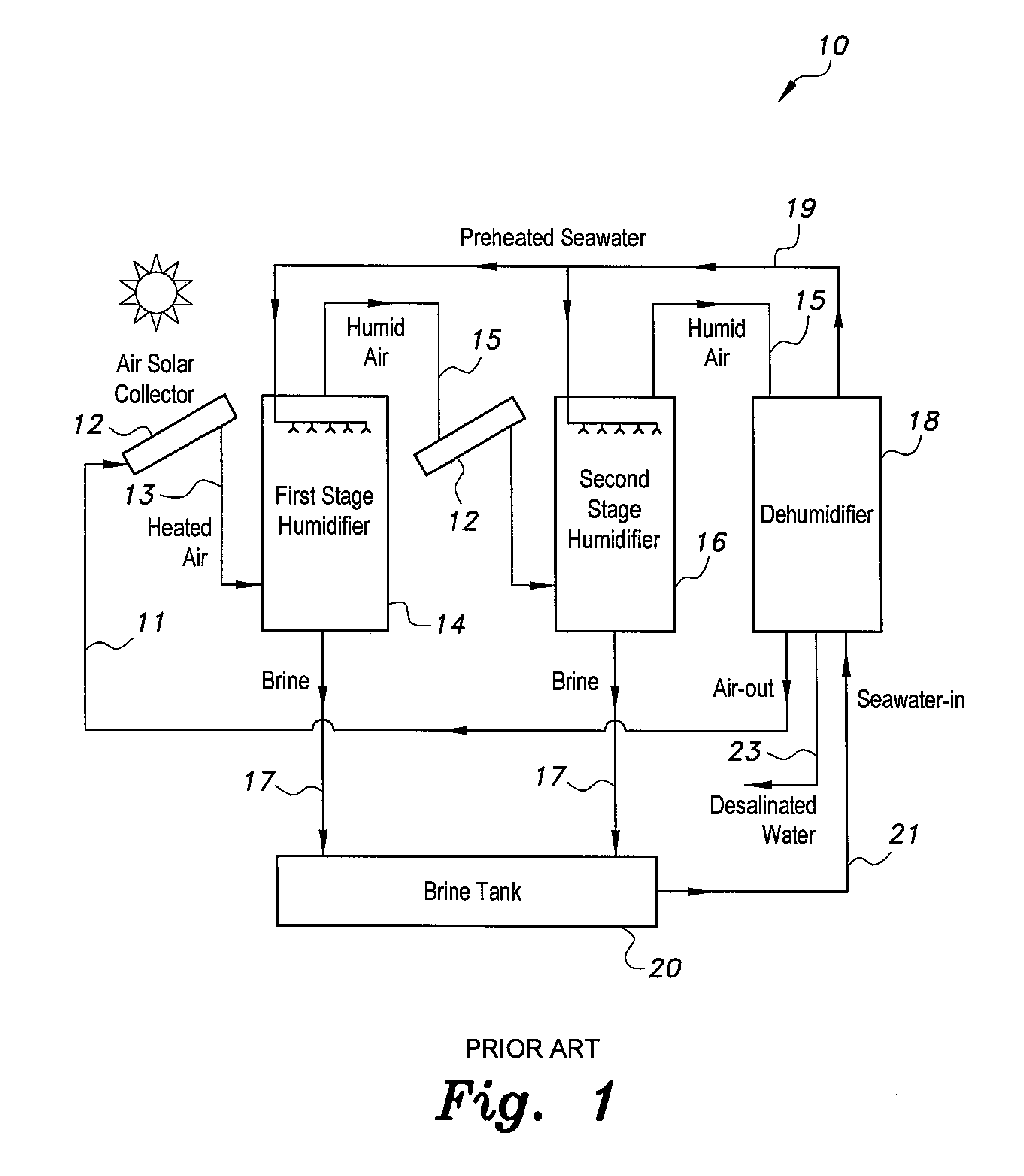

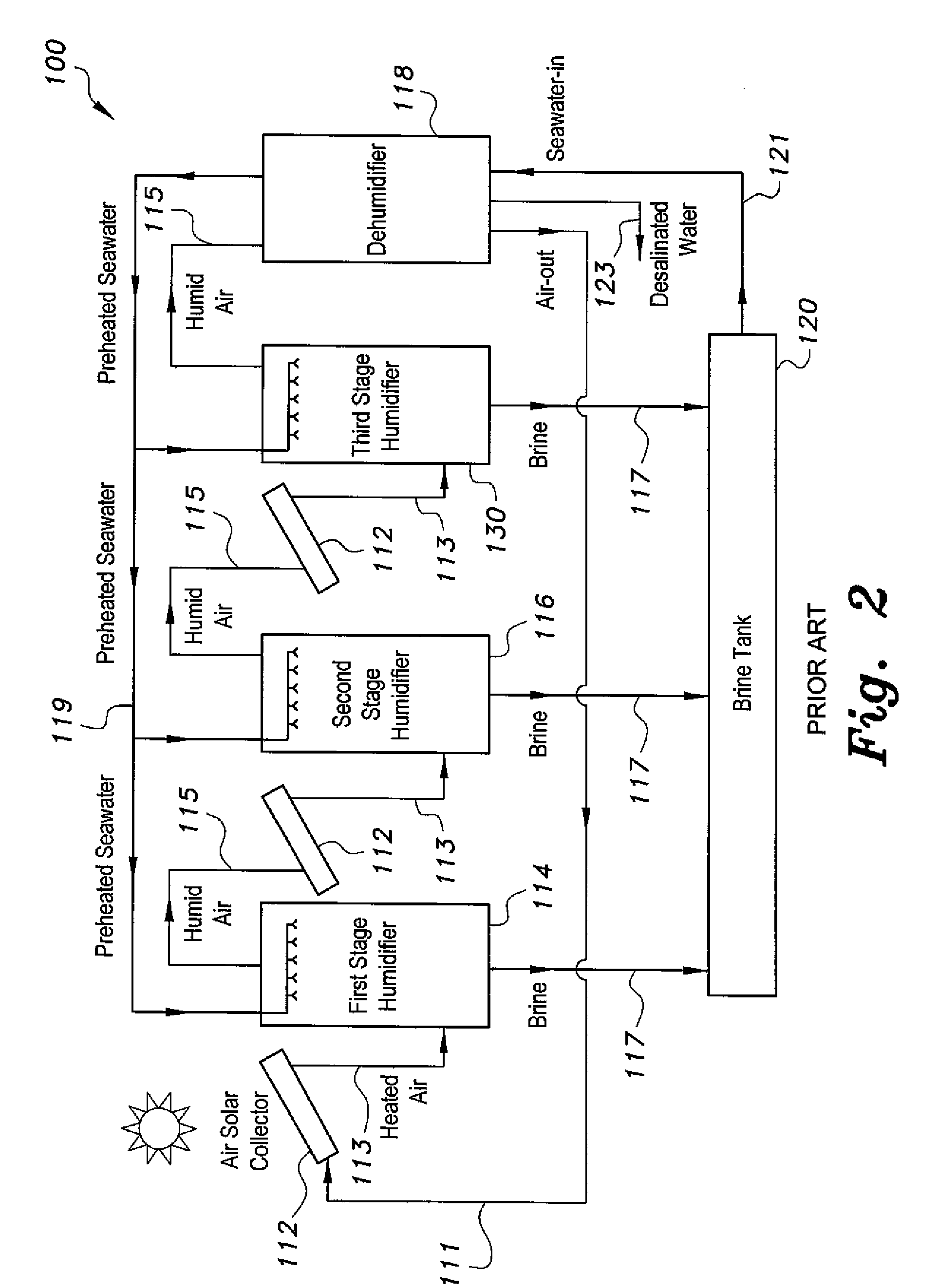

Solar-powered humidification-dehumidification desalination system

InactiveUS20140197022A1Efficient evaporationLess energy consumptionGeneral water supply conservationSeawater treatmentCondensation processSaline water

The solar-powered humidification-dehumidification desalination system includes a supply of saline / brackish water passing through a dehumidifier / condenser. The saline / brackish water is preheated in the dehumidifier / condenser due to the condensation process. A plurality of humidifying stages includes respective humidifiers and respective solar collectors. The solar collectors heat air, and the heated air passes through respective humidifiers to evaporate the preheated saline / brackish water, separating pure water from the brine. The humid air is reheated and recirculated through the humidifying stages and the dehumidifier, and the desalinated water from the dehumidifier via condensation is collected to and processed. The system recirculates the brine successively from each humidifier to the next for more efficient evaporation and less energy consumption.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

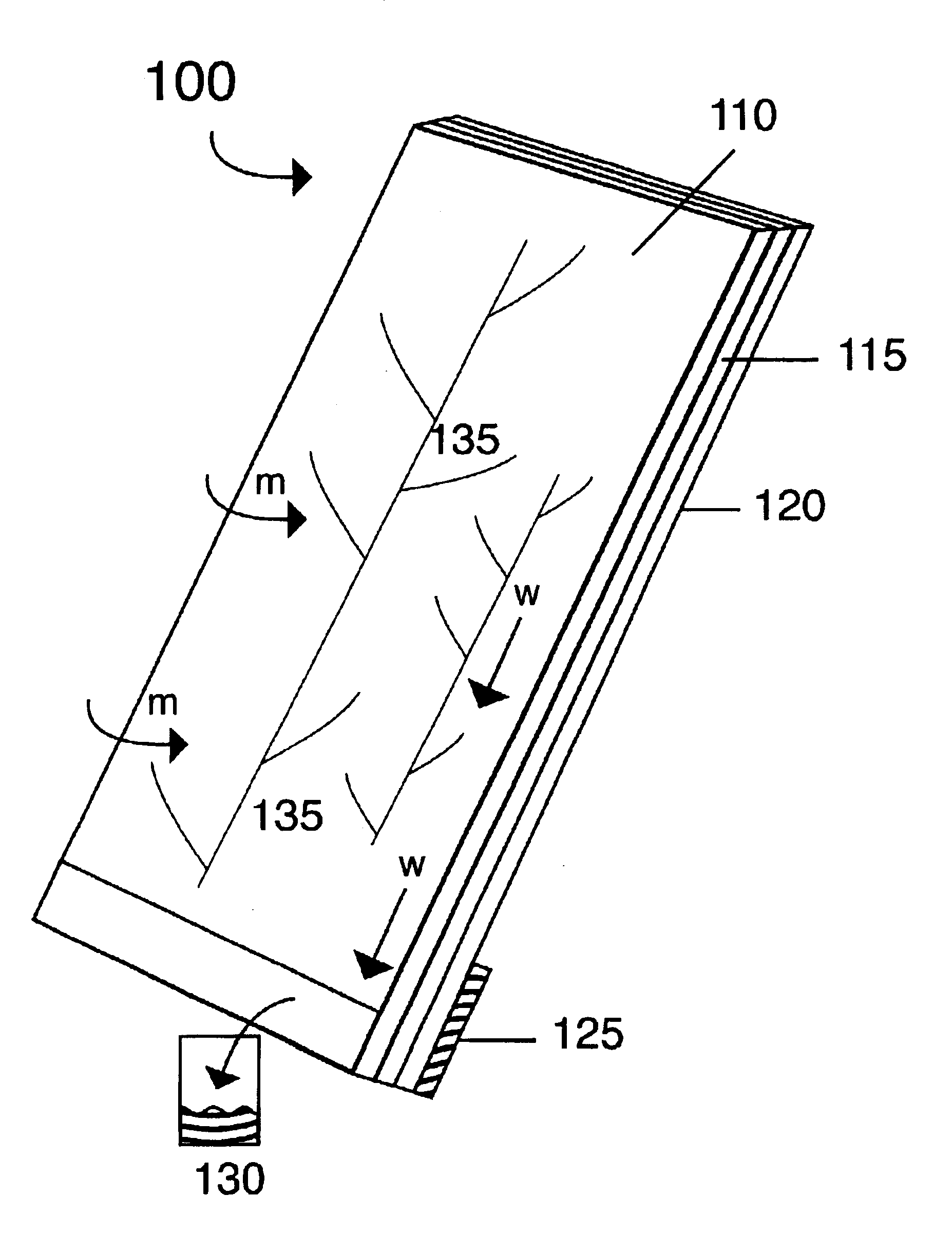

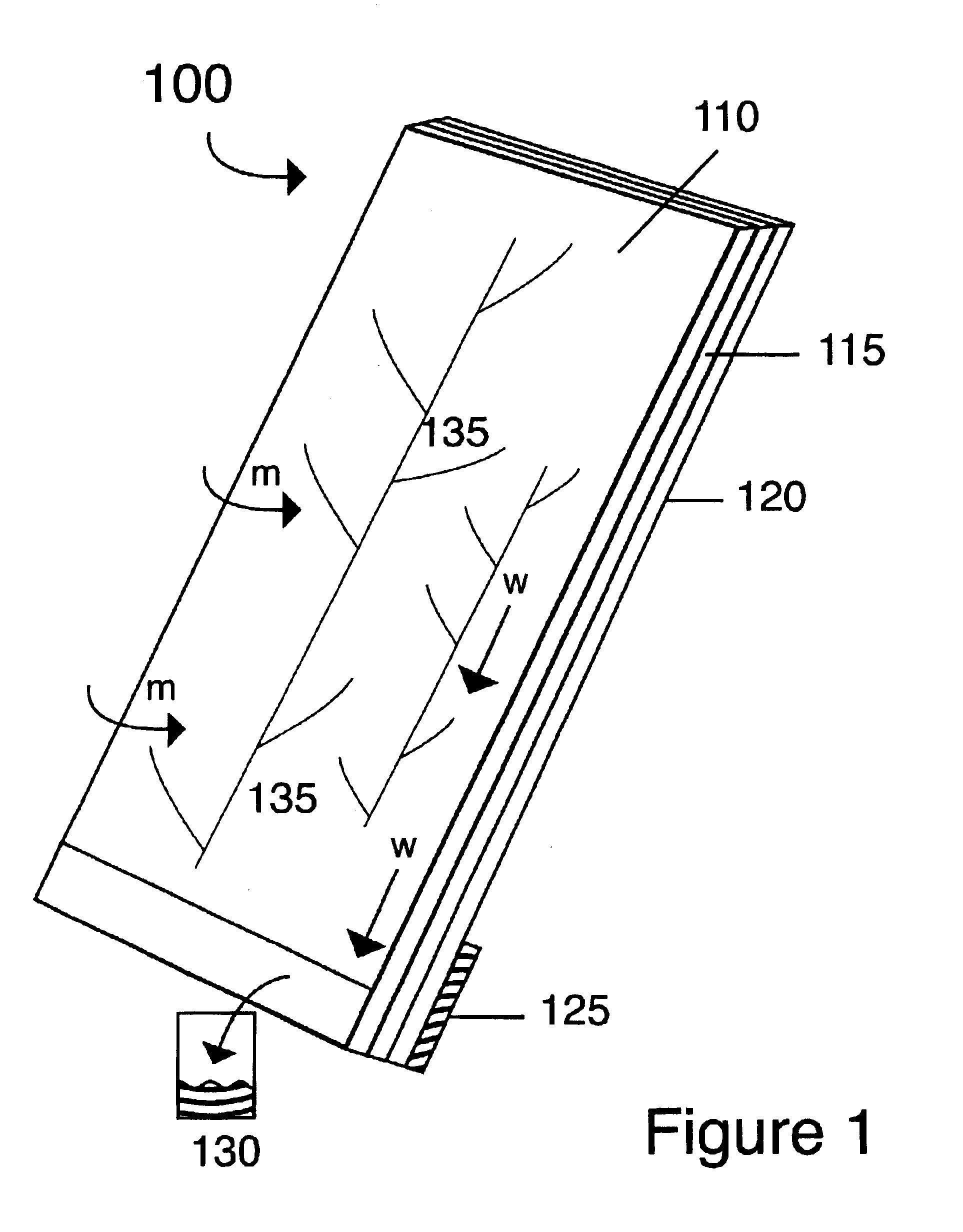

Apparatus and method for harvesting atmospheric moisture

InactiveUS6828499B2Easy to collectLow costThermo-electric condensationLiquid degasificationCondensation processEngineering

A condensation panel to be used for harvesting water from atmospheric moisture during those times of the diurnal cycle when relative humidity is at or near 100% utilizes very localized cooling to optimize condensation on a surface whose materials promote the condensation and collection of the water. The panel is passive in the sense that it can be deployed and left in an unmaintained condition for considerable periods of time. At least one time each day, almost certainly in the morning, water harvested by the process of assisted condensation can be collected for use.

Owner:WATER REGENERATION SYST +1

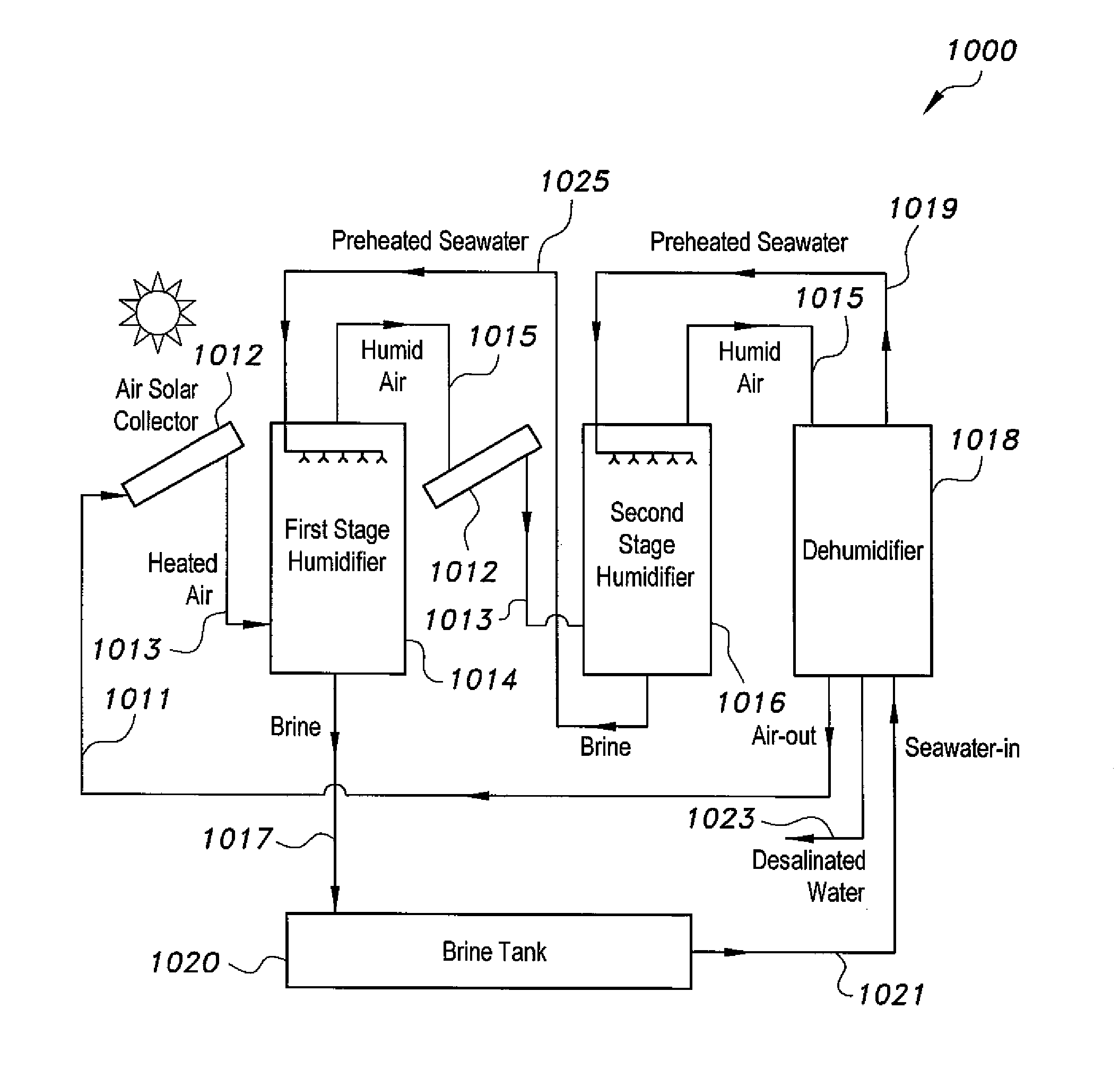

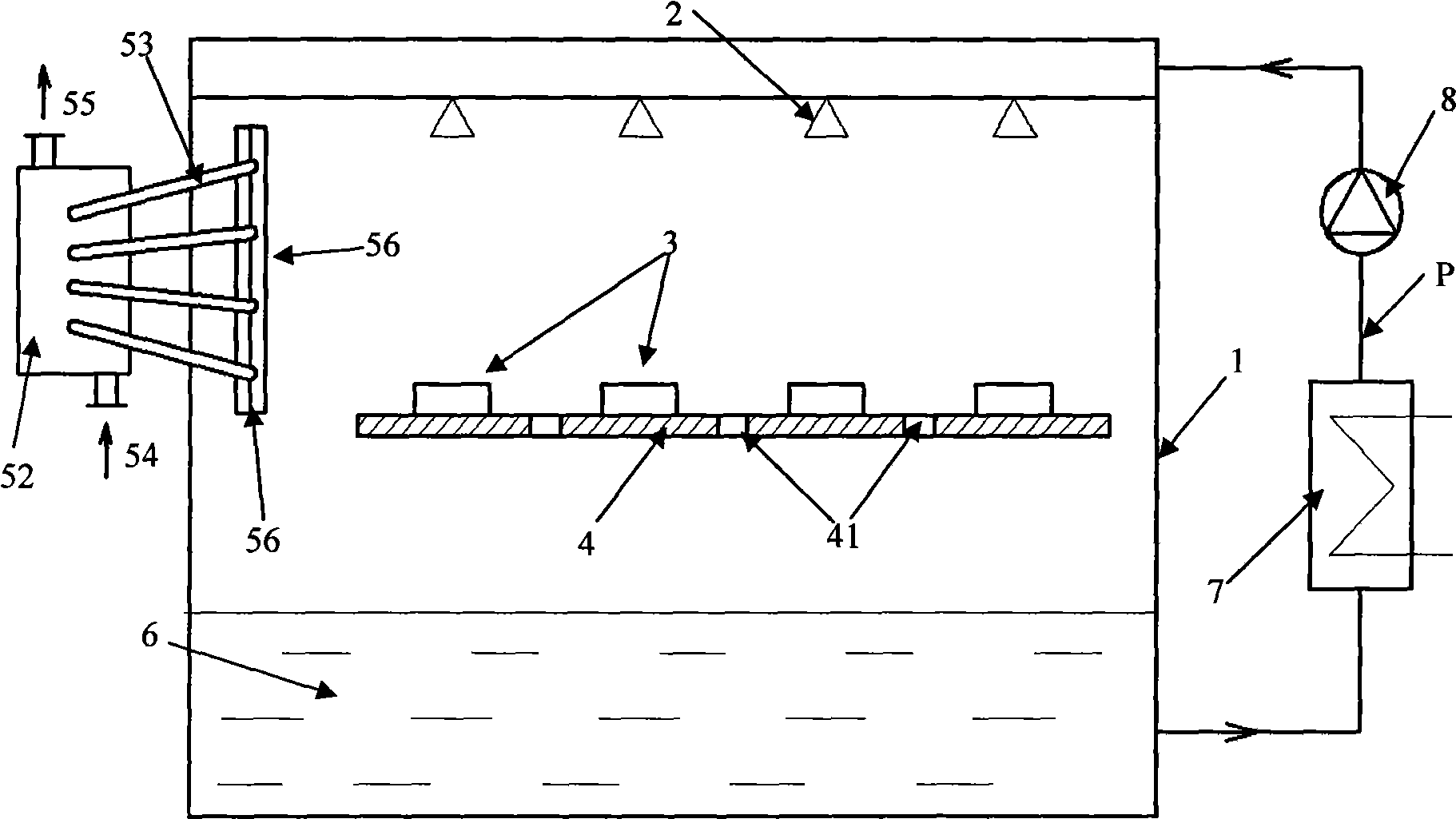

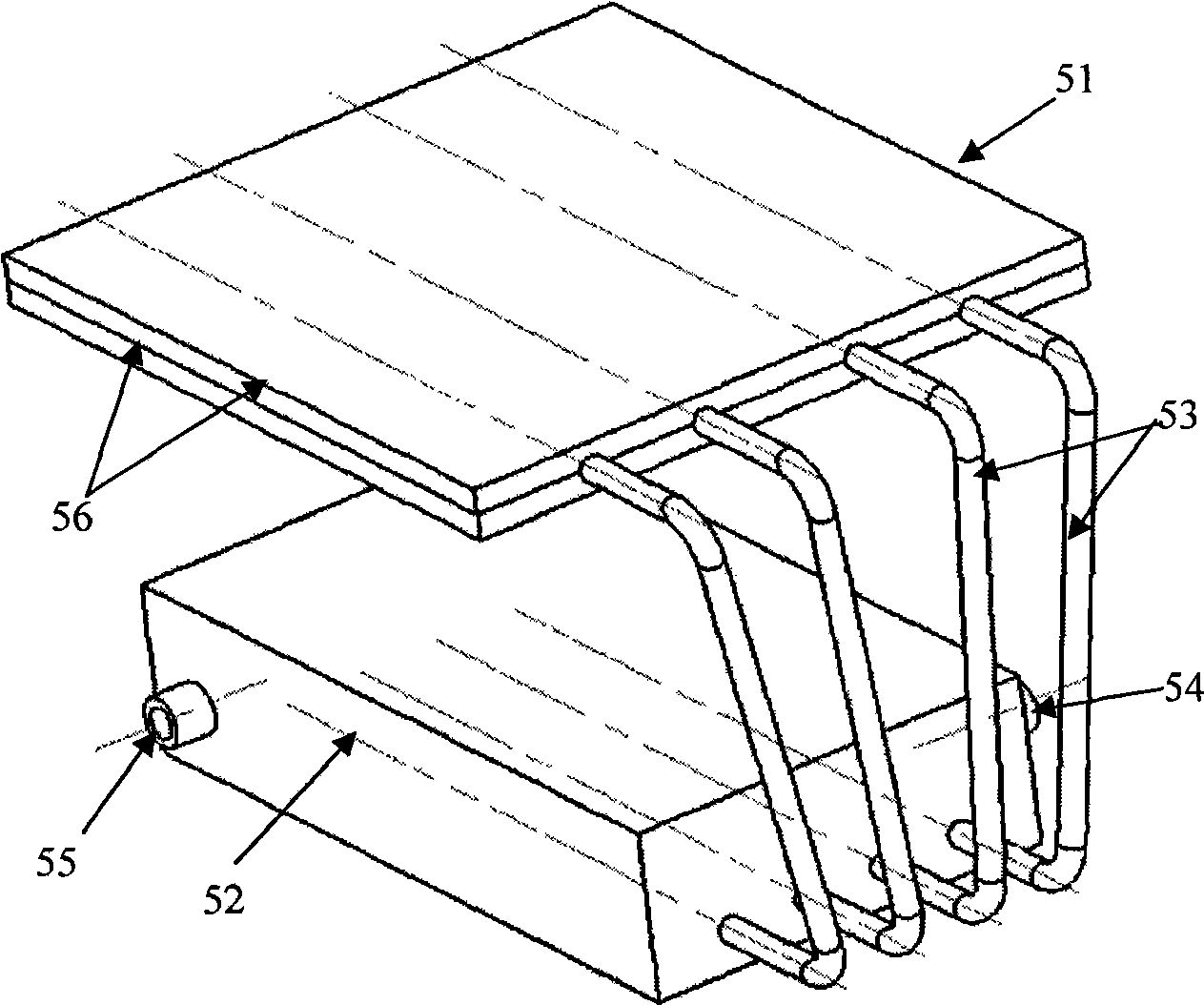

High-effective integral spray cooling system

InactiveCN101534627AReduce heat transfer areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention relates to a high-effective integral spray cooling system, which solves heat dissipation problem in field such as high power electron or laser system. The spray cooling system includes a spray cavity, a heat exchanger, a cooler, a circulating pump and a system working medium circulation pipeline, wherein the heat exchanger is a heat pipe heat exchanger; one end of the heat pipe of the heat pipe heat exchanger is a condensation end, and the other end is an evaporation end; the evaporation end is arranged in the spray cavity and is a steam condenser, and the condensation end is arranged in a water cooling shell-and-tube heat exchanger outside the spray cavity. The invention separates steam cooling and liquid cooling, which is beneficial to respectively increase heat transfer effect in condensation and cooling process; employs the heat pipe condenser to further increase heat transfer performance in condensation process and reduce heat exchange area of the condenser; and arranges the condenser in the spray cavity for making spray cooling structure more compact and reducing flow resistance of working medium steam, thereby reducing operating pressure of the spray cavity and being beneficial to increase general heat dispersion performance of spray cooling.

Owner:UNIV OF SCI & TECH OF CHINA +1

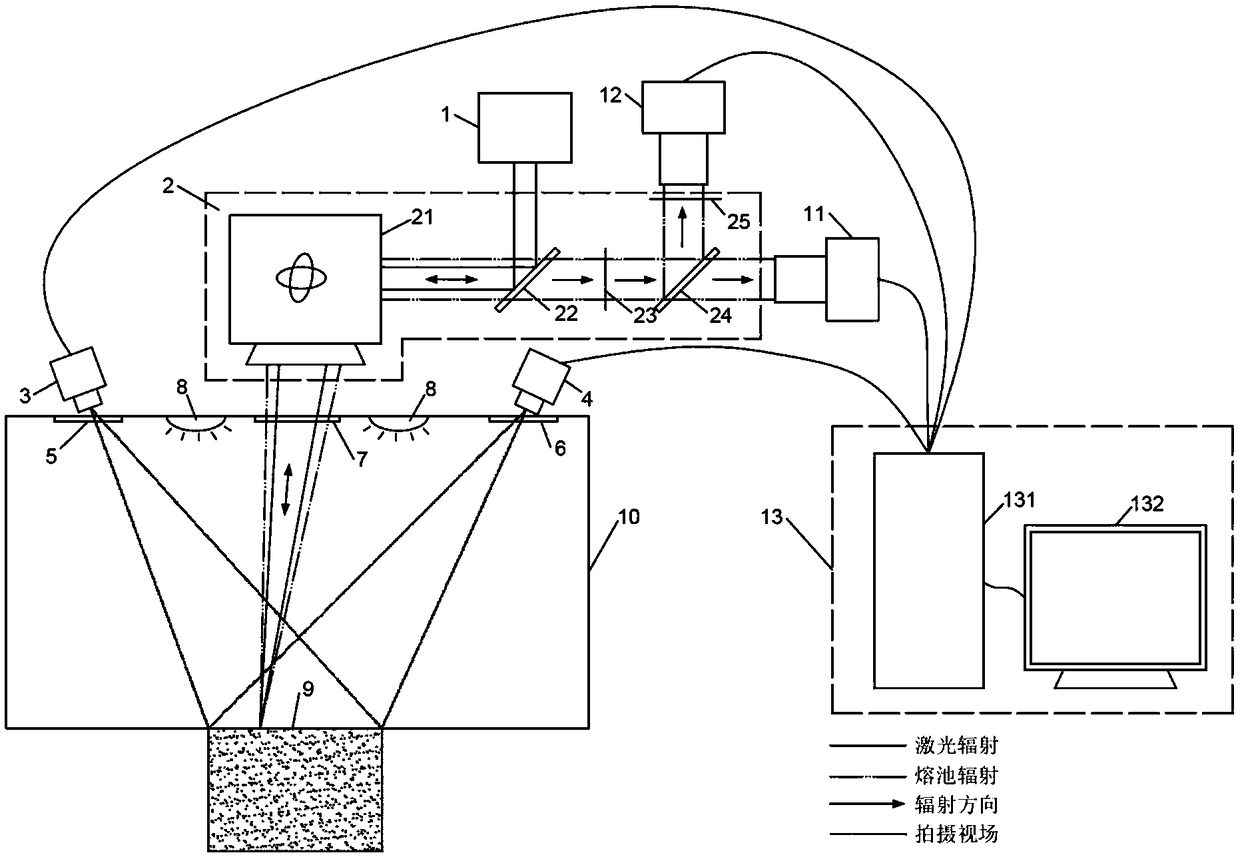

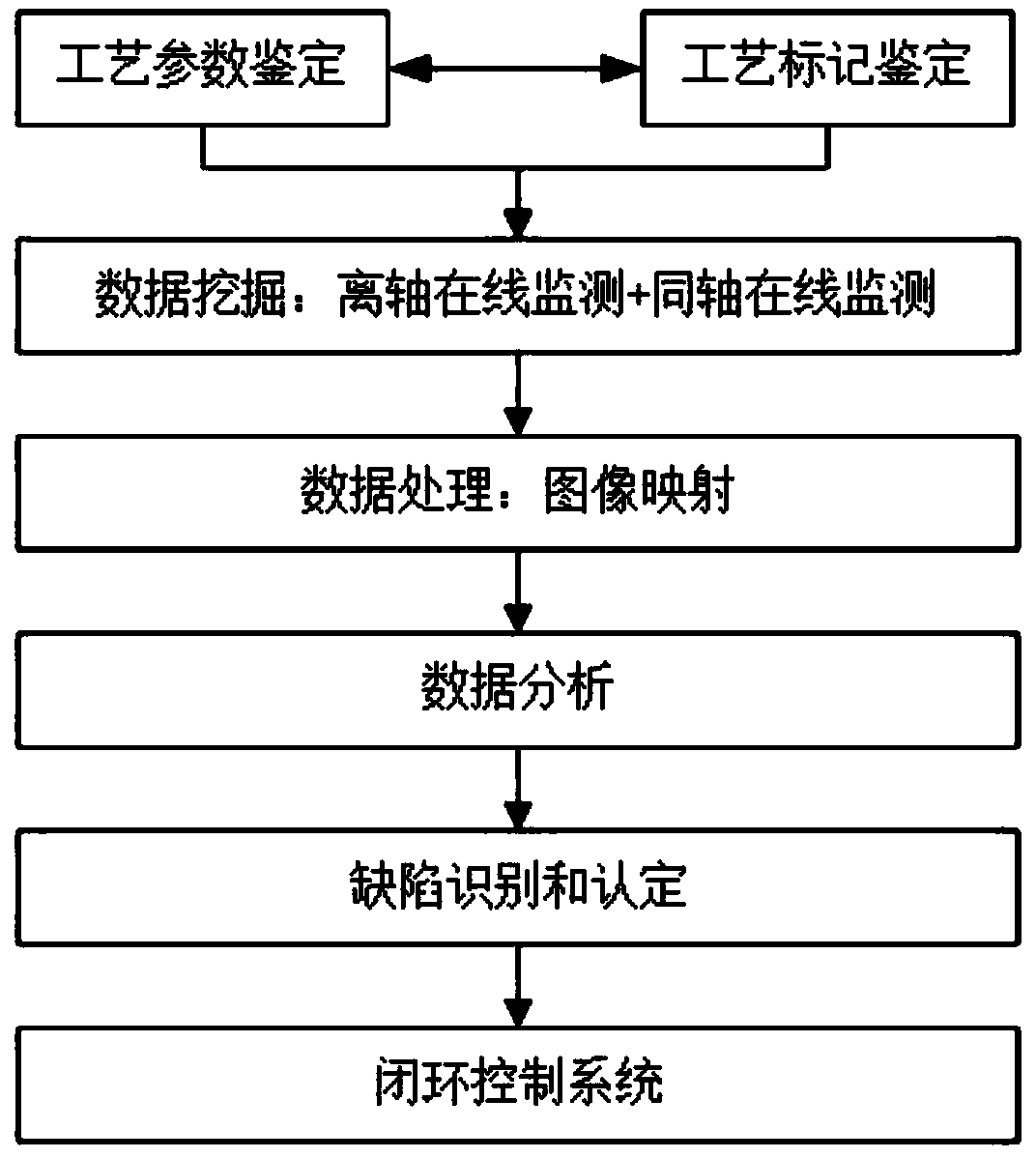

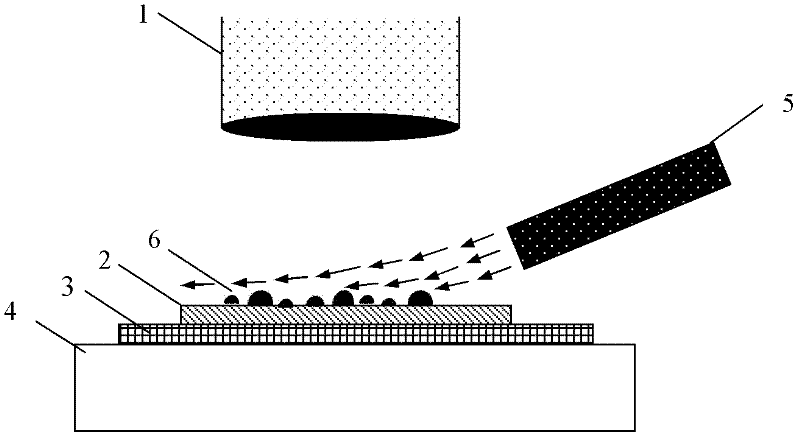

Real-time quality monitoring device and method for selective laser melting processing process

InactiveCN108788153ARealize online monitoringAvoid interferenceAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a real-time quality monitoring device and method for a selective laser melting processing process. Advantages of non-contact measurement means such as an industrial camera, aninfrared thermal imager, a high-speed camera and a photodiode are comprehensively utilized, and a set of complete monitoring method is formed. Through the on-line monitoring method combining an off-axis on-line monitoring device with a coaxial on-line monitoring device, the working condition of a printing work plane can be captured, and real-time molten pool data can also be collected. The meltingand condensation processes of metal powder can be monitored in a microcosmic manner, and a printer system and a workpiece layer-by-layer quality can also be monitored in a macroscopic manner. The industrial camera is adopted to monitor powder bed defects and printing defects, and the infrared thermal imager tracks the scanning path and captures the thermal stress; and the high-speed camera observes the geometrical morphology of a molten pool, and the photodiode captures the radiation strength of the molten pool. The process marks are made to correspond to printing process parameters, and on-line monitoring of the selective laser melting processing process can be realized more effectively.

Owner:西安智造人企业管理合伙企业(有限合伙)

Process for production of biaxially oriented films based on crystallizable thermoplastics, using recycled material whose molecular weight has been increased by condensation processes

ActiveUS7700015B2Not impair property of filmGood orientationOther chemical processesPlastic recyclingThermoplasticCondensation process

Owner:MITSUBISHI POLYESTER FILM

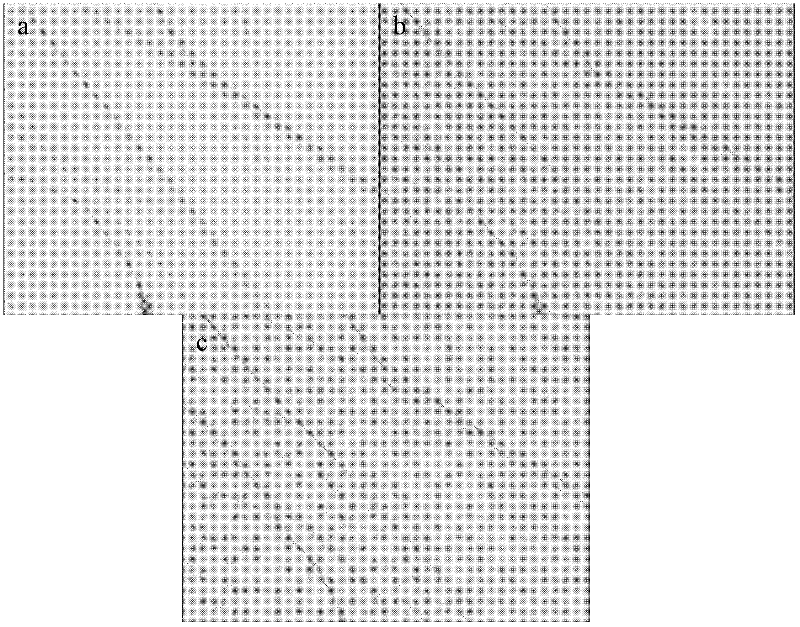

Method for detecting two dimensional nanostructured material film surface detect

InactiveCN102495065ADetermining the distribution of defectsEasy to coverOptically investigating flaws/contaminationMaterial analysis by measuring secondary emissionCondensation processThermodynamics

The invention discloses a detection method of two dimensional nanostructured material film surface detect distribution and relates to the field of material surface defect and its distribution detection. The method comprises the following steps of: firstly drying a sample beforehand, removing water molecules on the surface of the sample, allowing a gas mixture of steam and other gases to flow on the surface of the sample by a steam injection device, carrying out condensation operation, acquiring morphological, distribution and quantitative features of droplets on the surface of the film material under single and multiple condensation conditions, and determining distribution law of the sample surface defect. As the absorption and condensation process of the water molecules on the surface ofthe two dimensional film material is usually completed in milliseconds, the defect detection is very rapid; in addition, deionized water vapor which is mild is used on the surface of the material, and the sample can be restored to the original state just by a subsequent drying step. Therefore, the method is lossless for the sample to be detected.

Owner:PEKING UNIV

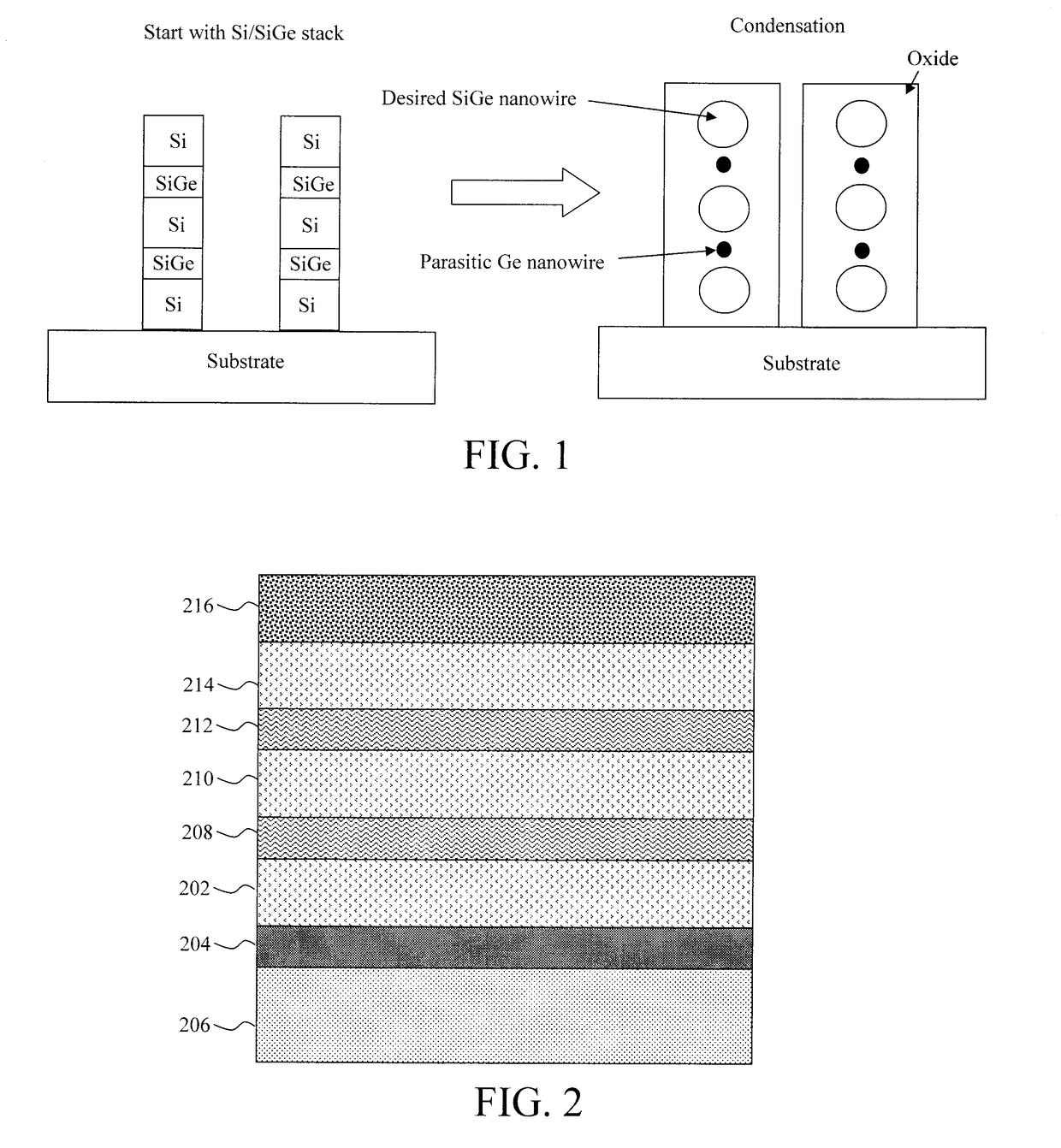

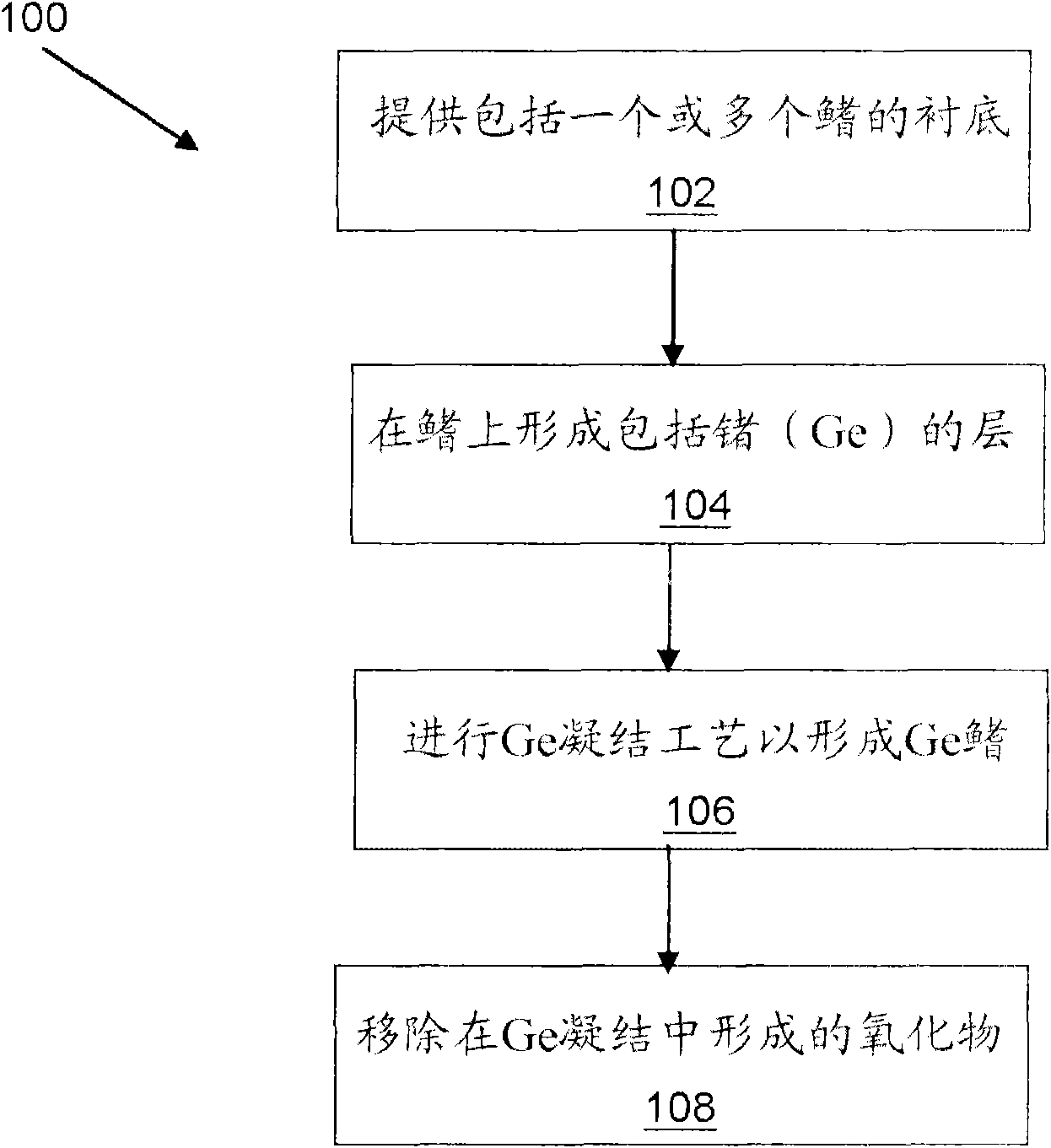

Method of fabrication of a FINFET element

The present disclosure provides a FinFET element and a method of fabricating a FinFET element. The FinFET element includes a germanium-FinFET element (e.g., a multi-gate device including a Ge-fin). In one embodiment, the method of fabrication the Ge-FinFET element includes forming silicon fins on a substrate and selectively growing an epitaxial layer including germanium on the silicon fins. A Ge-condensation process may then be used to selectively oxidize the silicon of the Si-fin and transform the Si-fin to a Ge-fin. The method of fabrication provided may allow use of SOI substrate or bulk silicon substrates, and CMOS-compatible processes to form the Ge-FinFET element.

Owner:TAIWAN SEMICON MFG CO LTD

Method for processing instant tea powder

ActiveCN101189990AAvoid lostInhibit deteriorationPre-extraction tea treatmentTea extractionInstant teaFlavor

The invention provides a method that takes fresh tea leaves as raw materials to process instant tea powder, which can prevent loss and deterioration of nutrition substance when in the tea manufacturing process. The technique is that: when the raw material is extracted, pectinase is added to enhance extraction rate of the tea leaves and to extract solid substance from solution after the processes of extracting, enzymatic hydrolysis, filtration, condensation and drying, etc. of the raw materials; then tannase is added for enzymatic hydrolysis, so as to resolve the deposition problem of the tea soup and to reduce the bitterness of the instant tea powder and improve the dissolution ability of the tea powder in cold water. The technologies of membrane separation and condensation are adopted in filtration and condensation process; and spray drying or vacuum freeze drying is adopted in drying process; therefore, the whole production process is carried out at relatively low temperature, which maximally preserves the nutrition substances and flavor substances, and the produced instant tea powder is abundant in nutrition and has fresh and soft taste.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Method of preparing long chain alkane for jet fuel by virtue of sugar platform compound

ActiveCN104650947AReduce usageAchieve phase separationLiquid hydrocarbon mixture productionBio-feedstockAlkaneIsomerization

The invention discloses a method of preparing long chain alkane for a jet fuel by virtue of a sugar platform compound. The method comprises the following steps: carrying out aldol condensation on the sugar platform compound in an aqueous solution under catalysis of alkali to generate a long chain oxygenated compound with ten to seventeen carbons; and then carrying out hydrogenation under the action of a metal catalyst, and finally carrying out hydrogenation, deoxidation, isomerization, cracking and cyclization under the action of the metal catalyst to generate a long chain n-alkane / isoparaffin with eight to fifteen carbons. According to the method disclosed by the invention, other organic solvents are prevented from being used, and in the condensation process, condensation products are separated from one another, a solid condensation product is directly separated from the aqueous solution, and the energy consumption is lowered; a solid product is dissolved by an alcohol solvent, the subsequent hydrogenation and deoxidation processes are carried out on the solid product, and the alcohol solvent can be provided by sugar / sugar alcohol hydrogenolysis; meanwhile, hydrogen needed by the technological process can be directly provided by the reforming process of a sugar alcohol solution, and the C component and the H component in a biological jet fuel and the solvent used in the process can be from biomass materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Production process of 5-acetyl acetamino benzimidazolone

The invention relates to a technology for producing 5-acetyl amido benzimidazolone. The condensation process is as follows: o-phenylendiamine, carbamide, water and concentrated sulfuric acid are added into a condensation reaction kettle step by step, the pH value is controlled to between 6 and 7, and benzimidazolone is obtained by drying the mixture; the nitration process is as follows: the benzimidazolone, chlorinated benzene and concentrated sulfuric acid are added into a nitration reaction kettle, the chlorinated benzene is reclaimed and purified by reduced pressure distillation and water boiling, and 5-nitryl benzimidazolone is obtained by drying the mixture; the reduction process is as follows: the 5-nitryl benzimidazolone, iron powder, hydrochloric acid and water are added into a reduction reaction kettle, the mixture is subject to suction filtering, cooling, crystallization and drying after the reaction for producing the 5-amino benzimidazolone; and the acetylization process is as follows: the 5- amino benzimidazolone, Diketene, phosphoric acid, caustic soda liquid and water are added into an acetylization kettle, the pressure inside the kettle is discharged in the temperature rising process, and the mixture is subject to suction filtering and drying to produce the 5-acetyl amido benzimidazolone. The process has the total yield coefficient up to 75 percent, purity quotient more than 99 percent and the product quality which meets the international standards of the same products at home and abroad.

Owner:DONGYING TIANZHENG CHEM

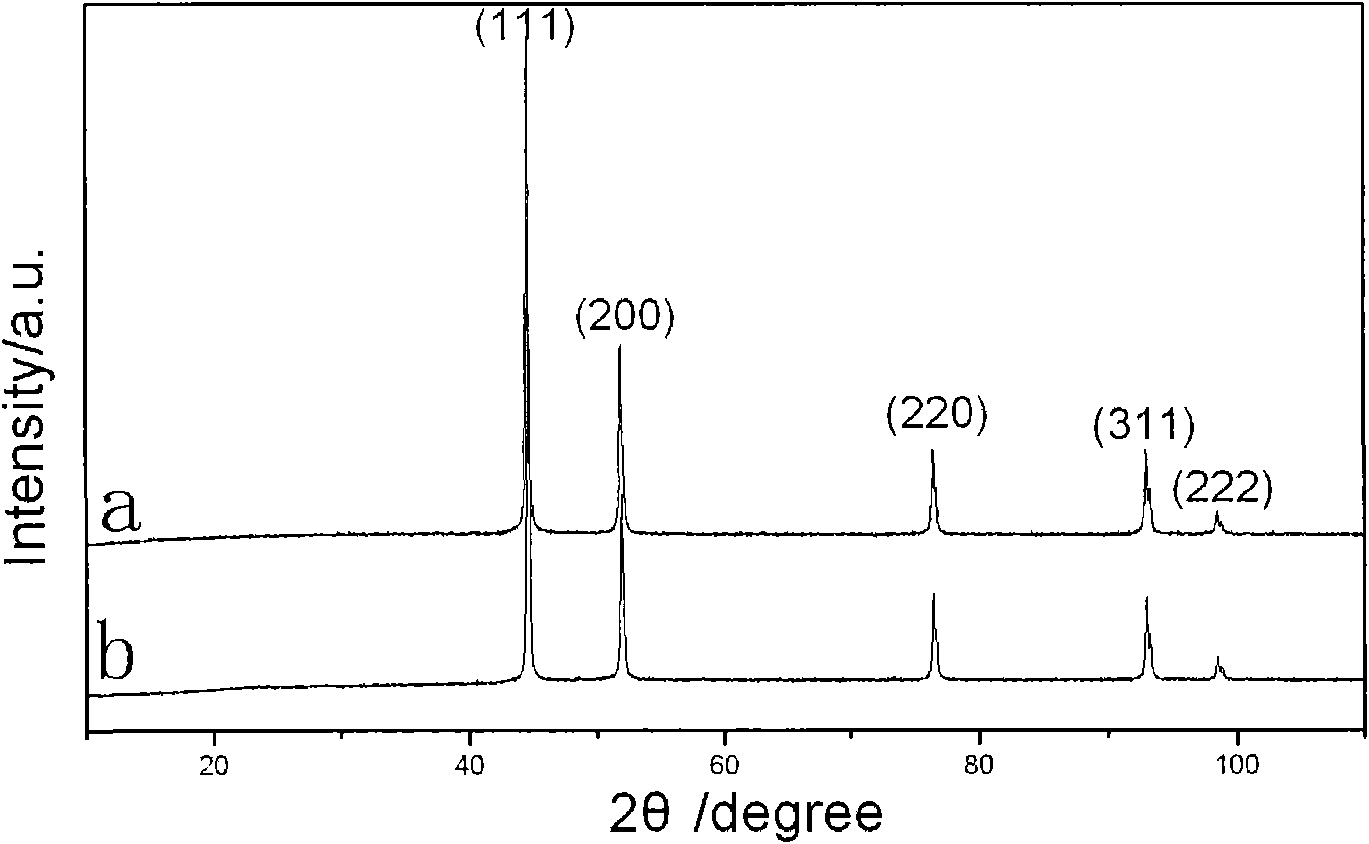

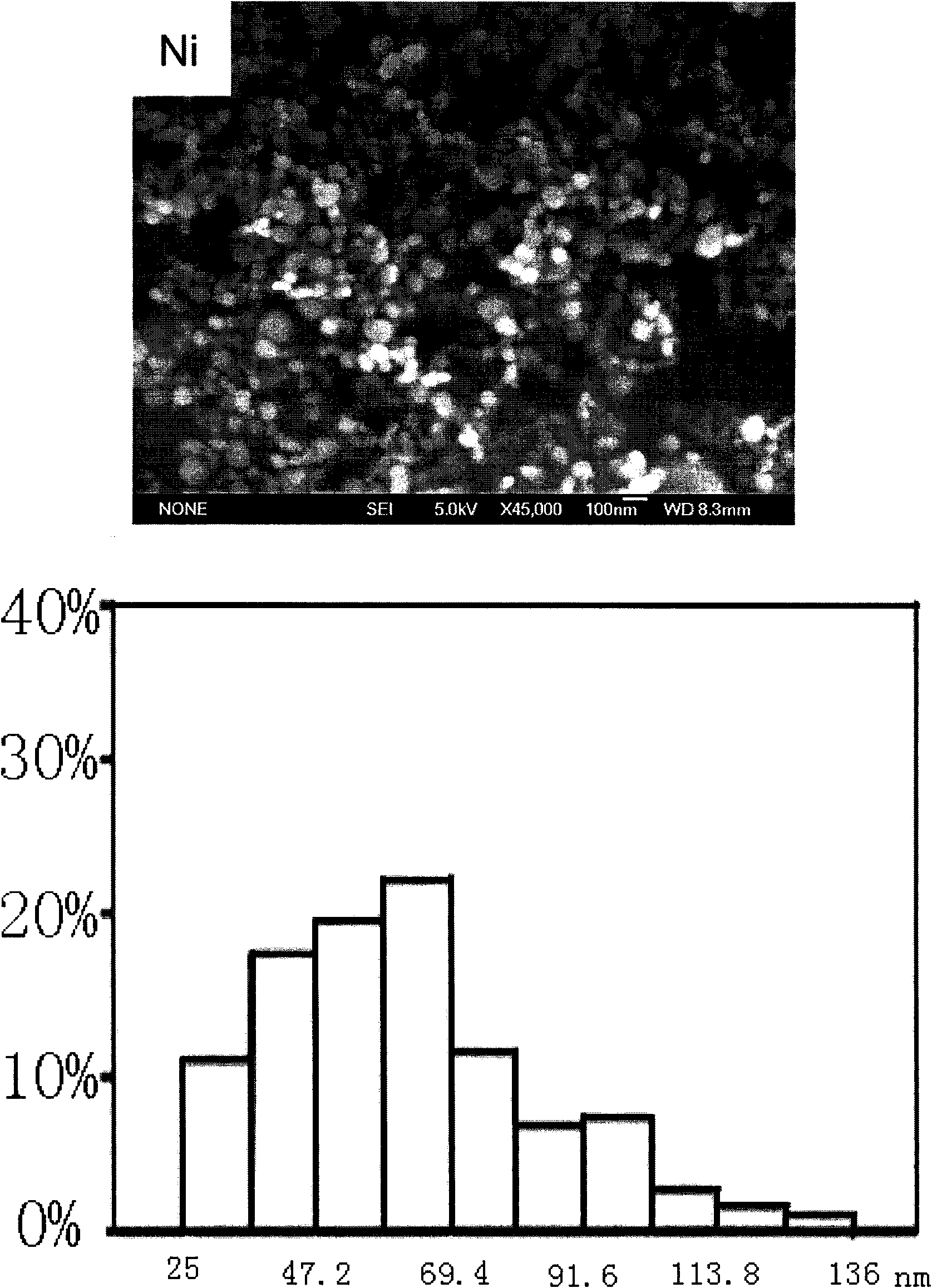

Method preparing superfine metallic nickel powder with high frequency plasma

The invention relates to a method preparing spherical metallic nickel powder with high frequency plasma. The method takes the hydrate of metallic nickel or subcarbonate as raw material and carries out hydrogen reduction through the high frequency plasma technology to prepare the superfine spherical nickel powder. Plasma arc is added to the raw material. The plasma is heated in high temperature through high frequency induction and generates reduction reaction with high-activity hydrogen plasma. The superfine spherical nickel powder can be obtained through a shape controller in the condensation process. The utility model is characterized in that the nickel hydroxide or the subcarbonate are used as the raw material, in the reduction process of the plasma, the particle size and the shape of the nickel powder can be controlled easily, the process flow is short and the production process is environment-friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

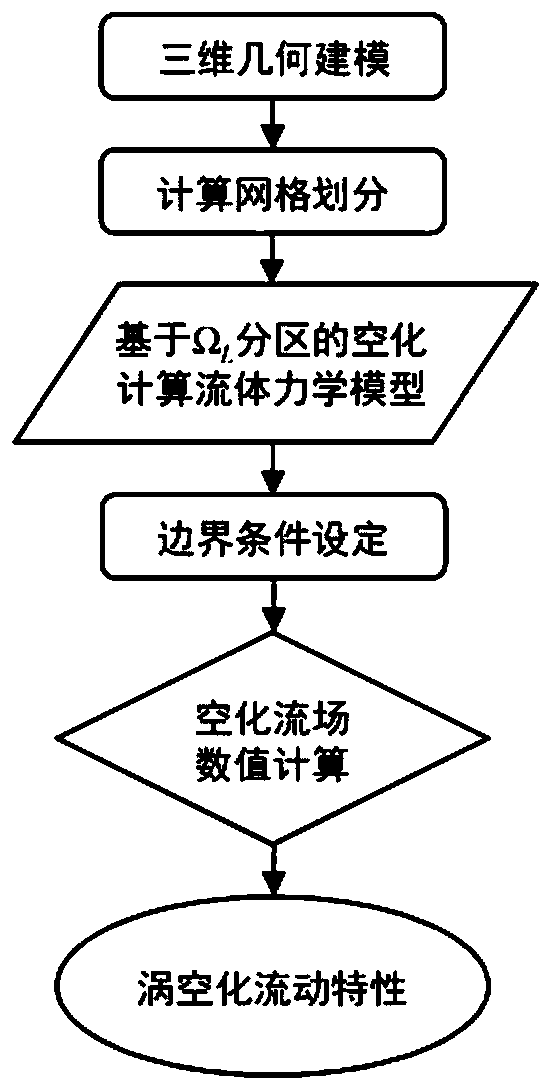

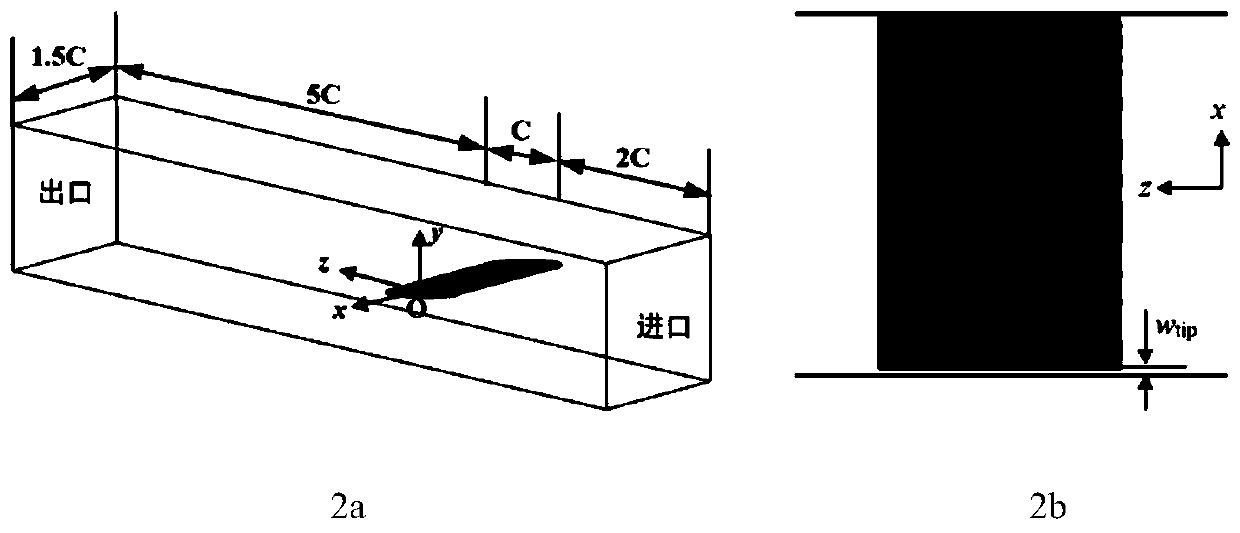

Cavitation flow numerical simulation method based on Liutex-Omega vortex recognition theory

ActiveCN109859311AImprove forecast accuracySpecial data processing applications3D modellingVapor liquidCondensation process

The invention discloses a cavitation flow numerical simulation method based on a Liutex-Omega vortex recognition theory. The method specifically comprises the following steps of: judging a vortex region in a cavitation flow field by adopting a standardized Liutex-Omega vortex recognition coefficient L; effectively identifying a strong vortex region with rotating dominance, establishing a cavitation flow calculation fluid mechanics model based on a Liutex-Omega vortex identification coefficient omegaL partition according to a delay action mechanism of a strong vortex on a vapor-liquid condensation process in cavitation, and carrying out numerical calculation on a three-dimensional cavitation flow field to obtain vortex cavitation flow characteristics. Comparative analysis is carried out onan actual measurement result and an existing classical cavitation model calculation result; it is verified that the method can effectively reflect the vortex cavitation flow characteristics and the space-time evolution law of the vortex cavitation flow, the prediction precision of the vortex cavitation flow is remarkably improved, and the method can be popularized and applied to numerical simulation research of the vortex cavitation flow characteristics of three-dimensional hydrofoils, water pumps, water turbines, propellers and the like.

Owner:HOHAI UNIV

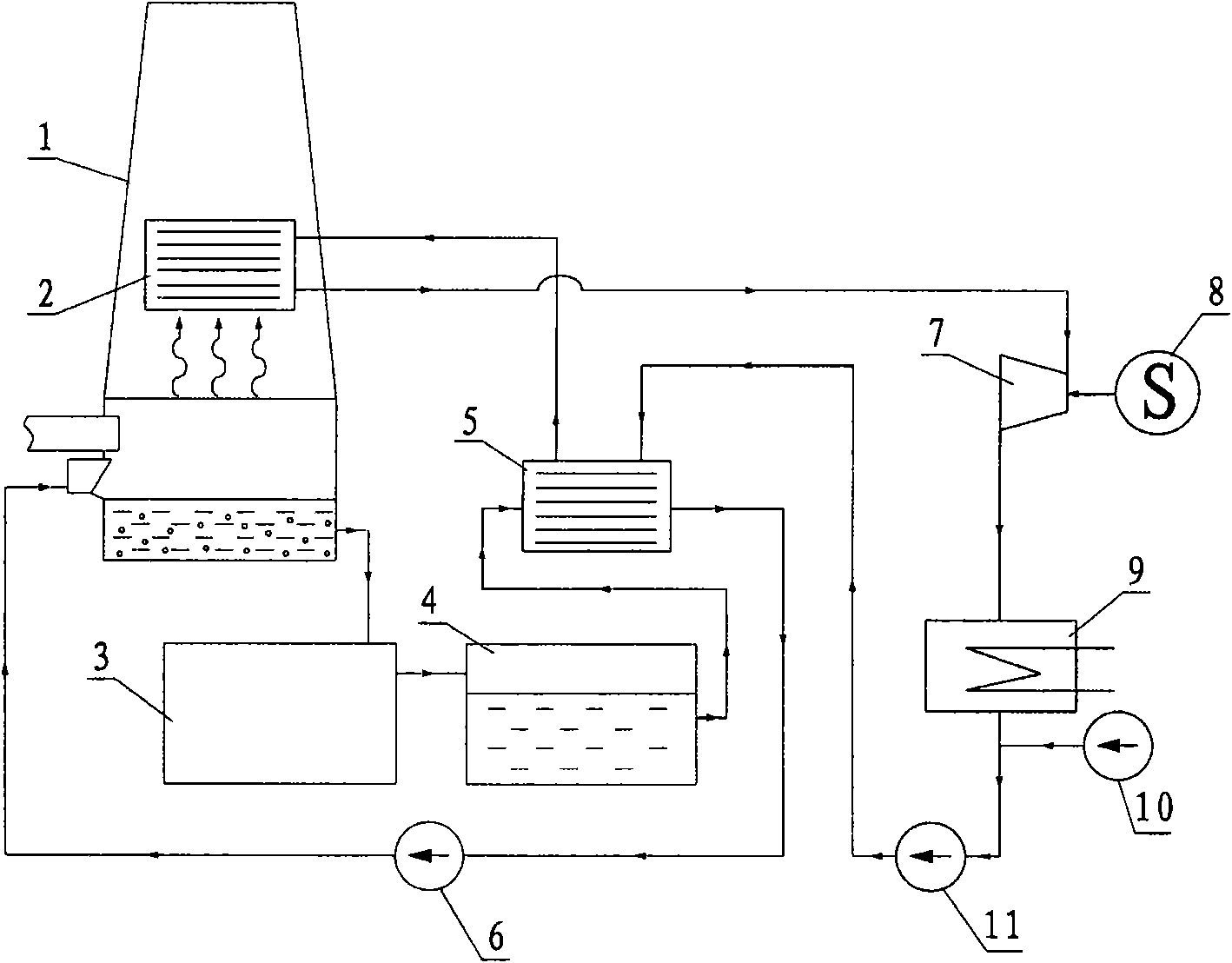

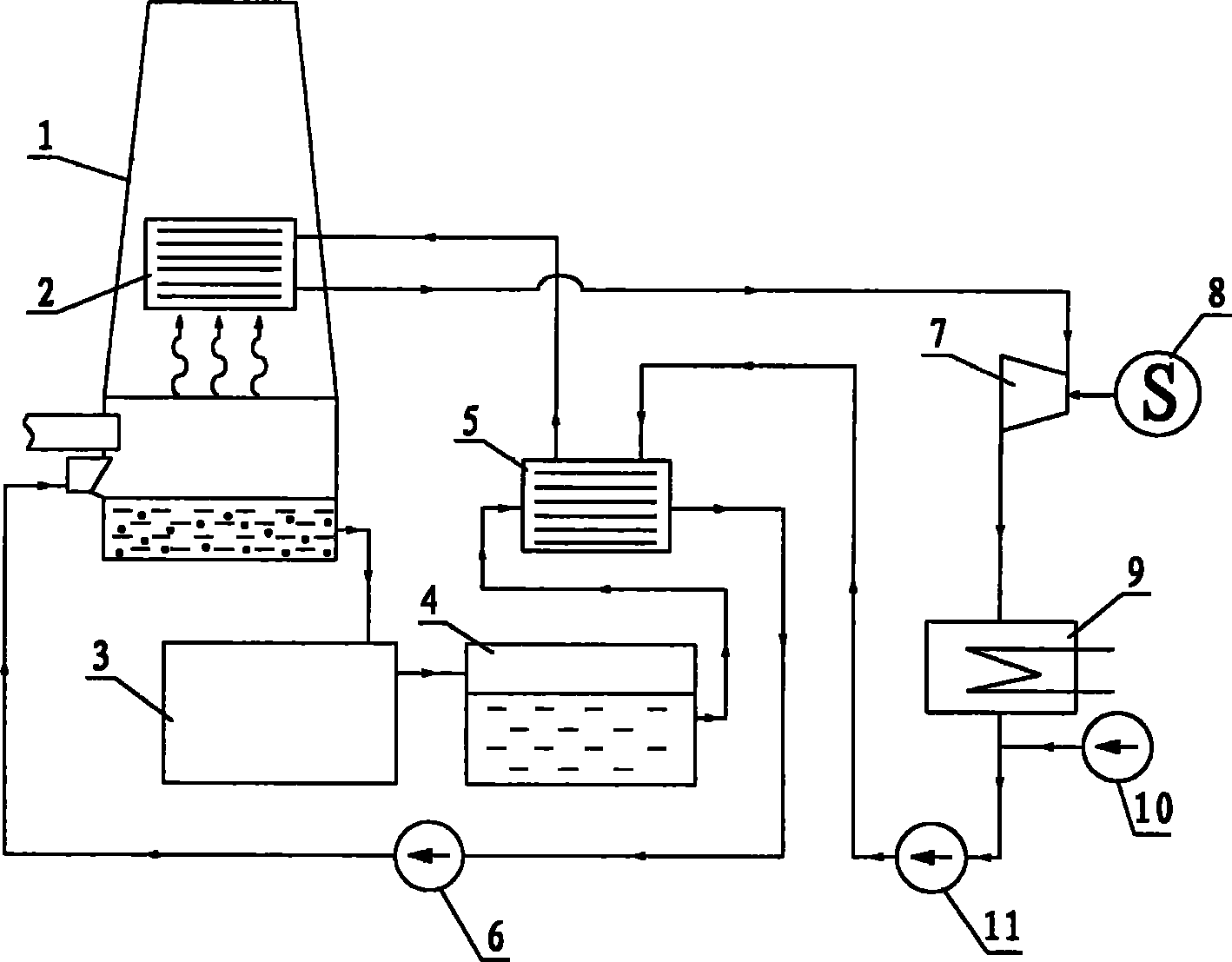

Method and device for collecting steam of flushing cinder and afterheat of hot water in iron-making blast furnace

ActiveCN101792830AAchieve recyclingReduce pollutionSteam generation heating methodsSteam superheatersWater sourceSlag

The invention provides a method and a device for collecting the steam of flushing cinder and the afterheat of hot water in an iron-making blast furnace, which belong to the technical field of afterheat recovery. The method comprises the following steps of: delivering the filtered slag quenching water from a conventional blast furnace slag processing system to a circulating pre-heater to heat a working medium, allowing the slag quenching water at a lower temperature from circulating pre-heater to return to the blast furnace to flush slag; introducing the working medium heated by the pre-heater into a circulating evaporator in which the working medium absorbs the heat released in the condensation process of the flushing cinder steam and evaporates and allowing the vaporized steam to drive a steam turbine so as to drive a generator to generate power; and condensing the working medium departing from the steam turbine into liquid, returning the liquid to the circulating pre-heater and evaporator and recycling the liquid by repeated heating and vaporization. The device comprises a flushing cinder steam heat-exchange loop, a slag quenching water heat-exchange circulation loop and a working medium circulation loop. The method and the device have the advantages of maximizing the cyclic utilization of the flushing quenching heat and the water source, reducing the pollution of the flushing cinder steam to the environment and recycling the energy sources and the natural resources.

Owner:BEIJING SHOUGANG INT ENG TECH

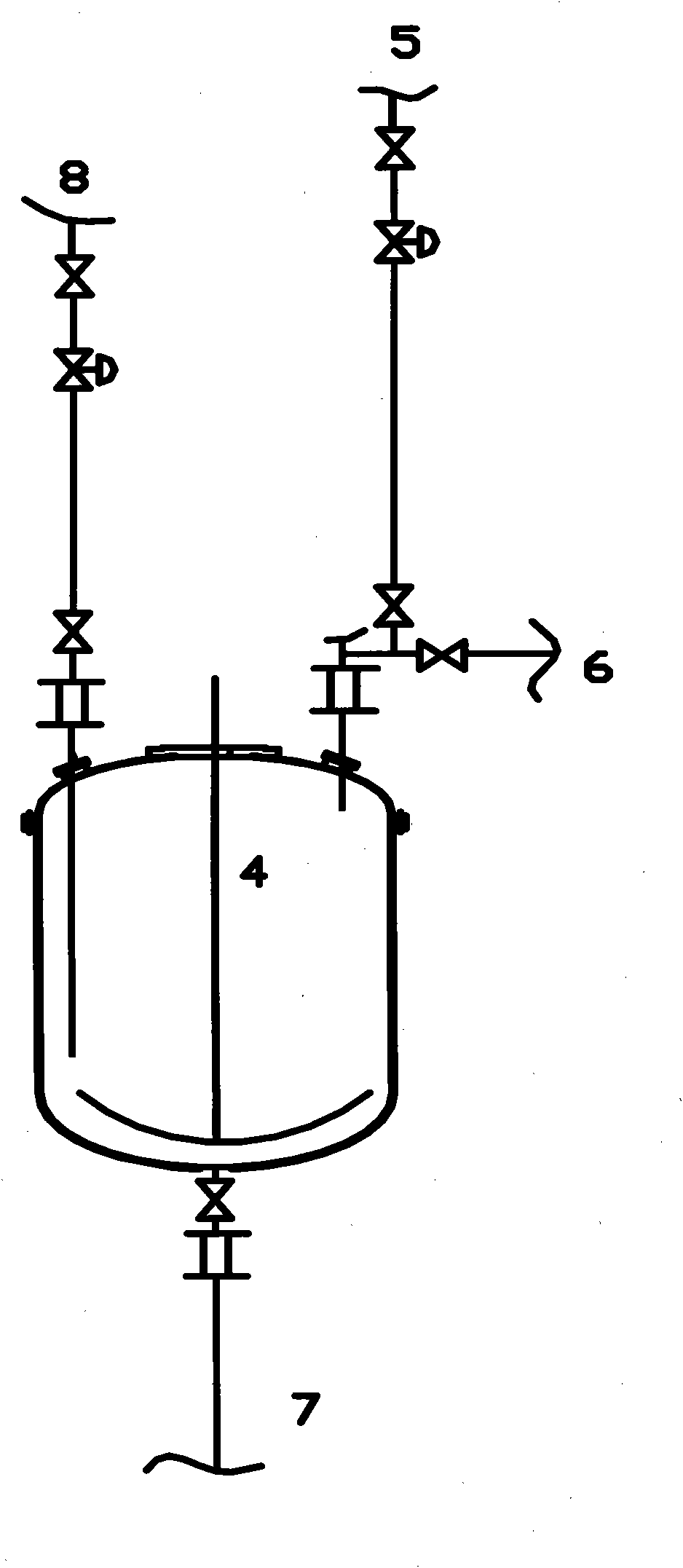

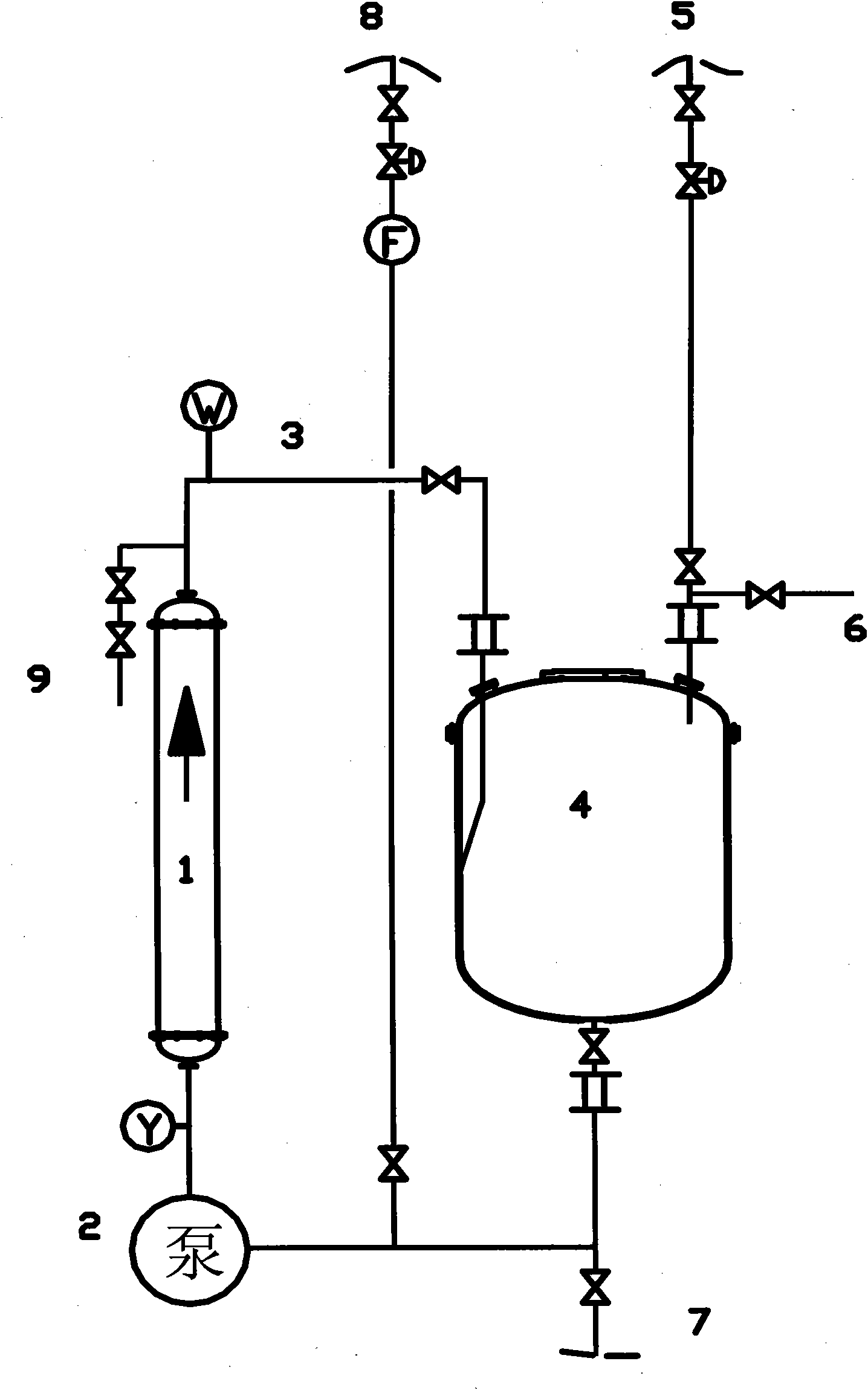

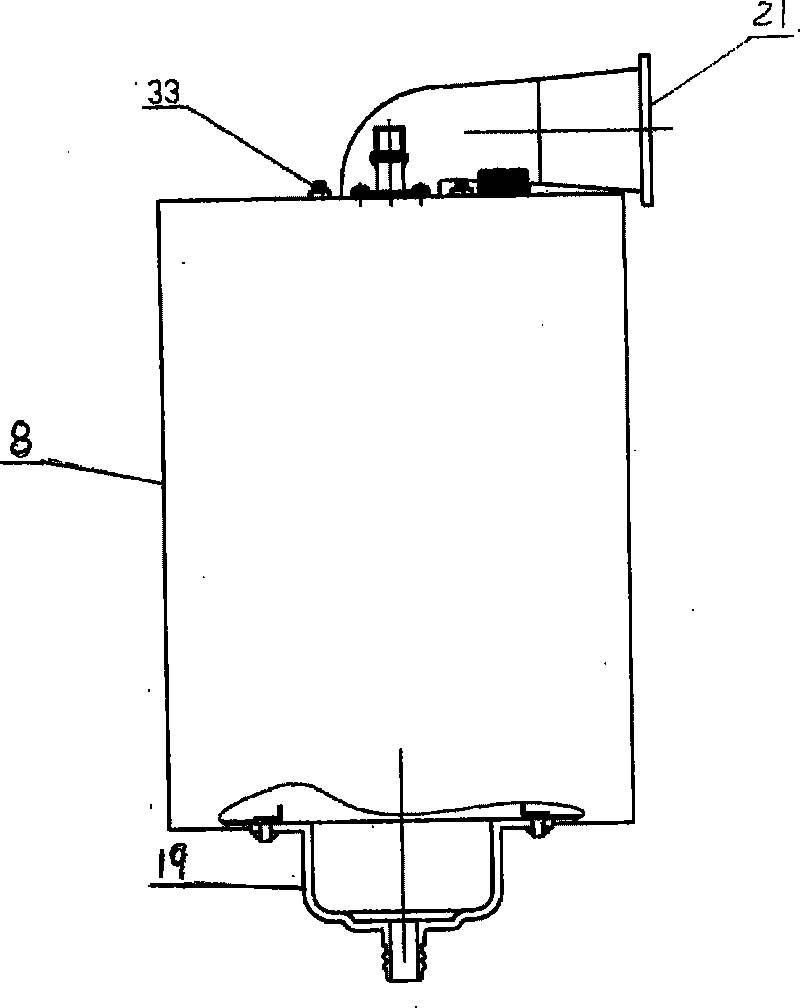

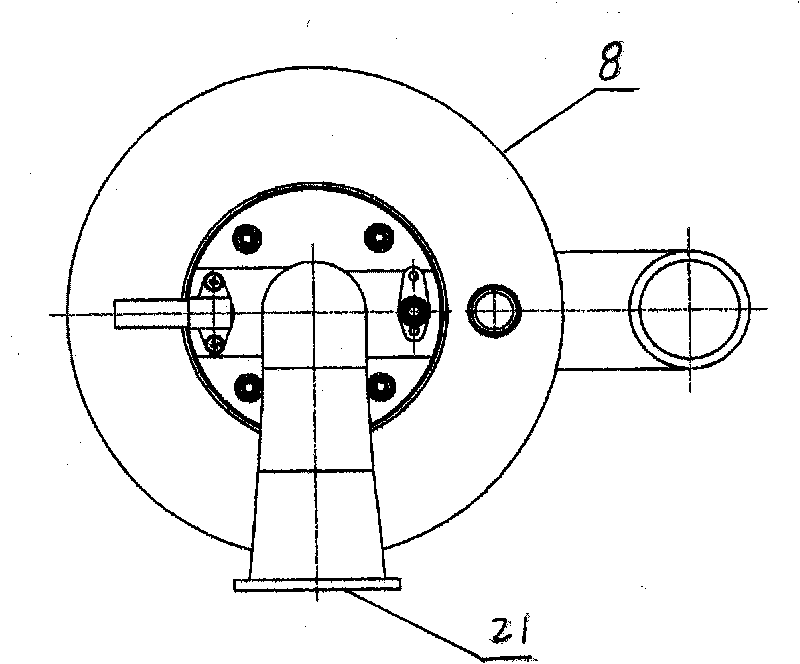

Condensation production process and special device of N-long-chain acyl amino acid salt

ActiveCN102126984AReduce contentSolve the inhibition problem of acid chloride hydrolysisOrganic compound preparationSulfonic acids salts preparationCondensation processN acylaminoacid

The invention relates to a production process and special device of the condensation process of N-long-chain acyl amino acid salt. By adopting the process and special device, the hydrolysis of acyl chloride can be inhibited and the content of the by-product fatty acid salt can be reduced in the condensation process of acyl amino acid type surfactant. Therefore, the weight of the surfactant can be increased, the content of fatty acid salt can be reduced by 50%-75% compared with the single-pot reaction, the conversion rate can be increased to more than 99%, the feeding ratio can be reduced, the condensation time can be shortened and the production efficiency can be increased.

Owner:SHANGHAI OLI ENTERPRISES CO LTD

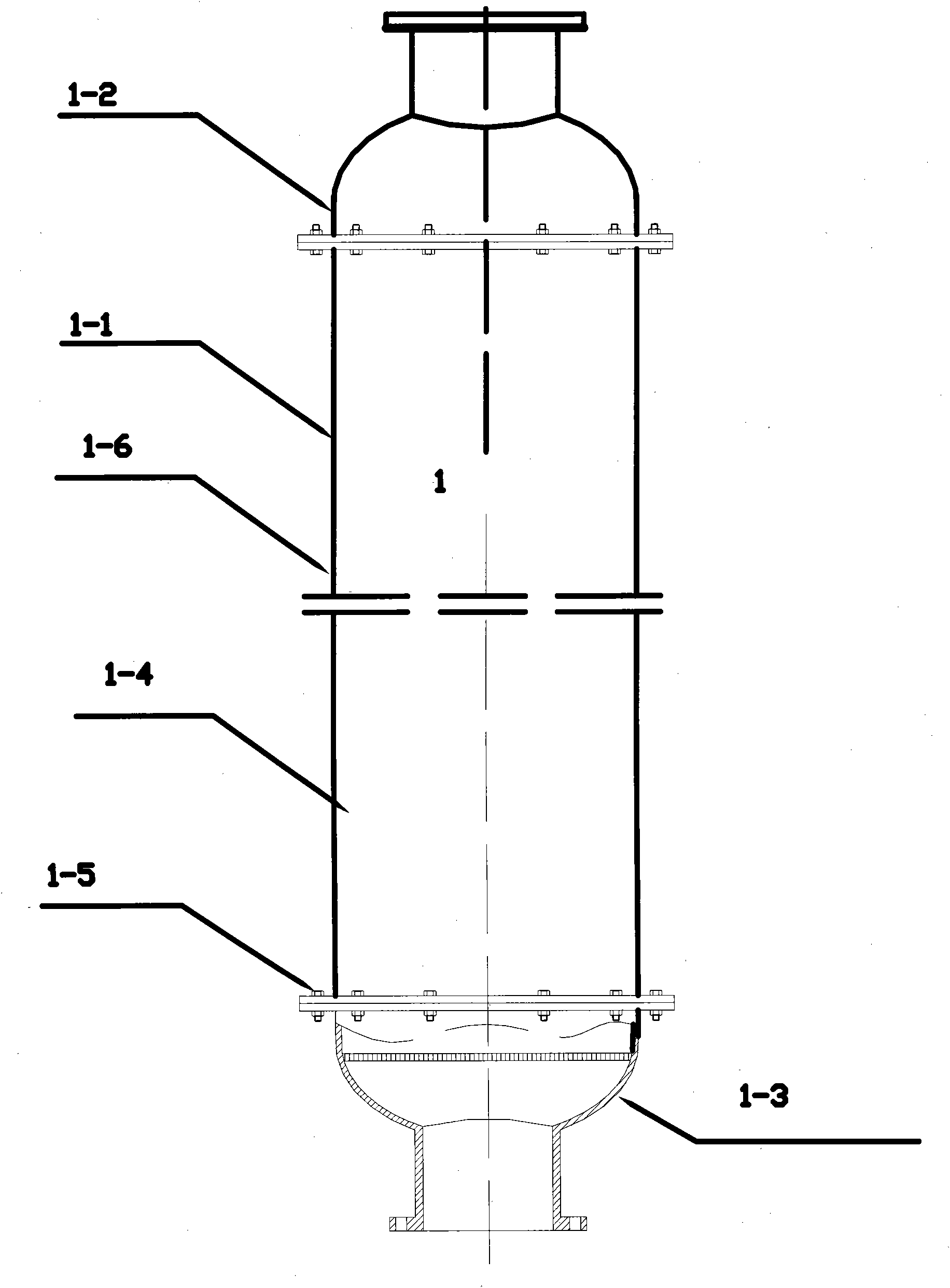

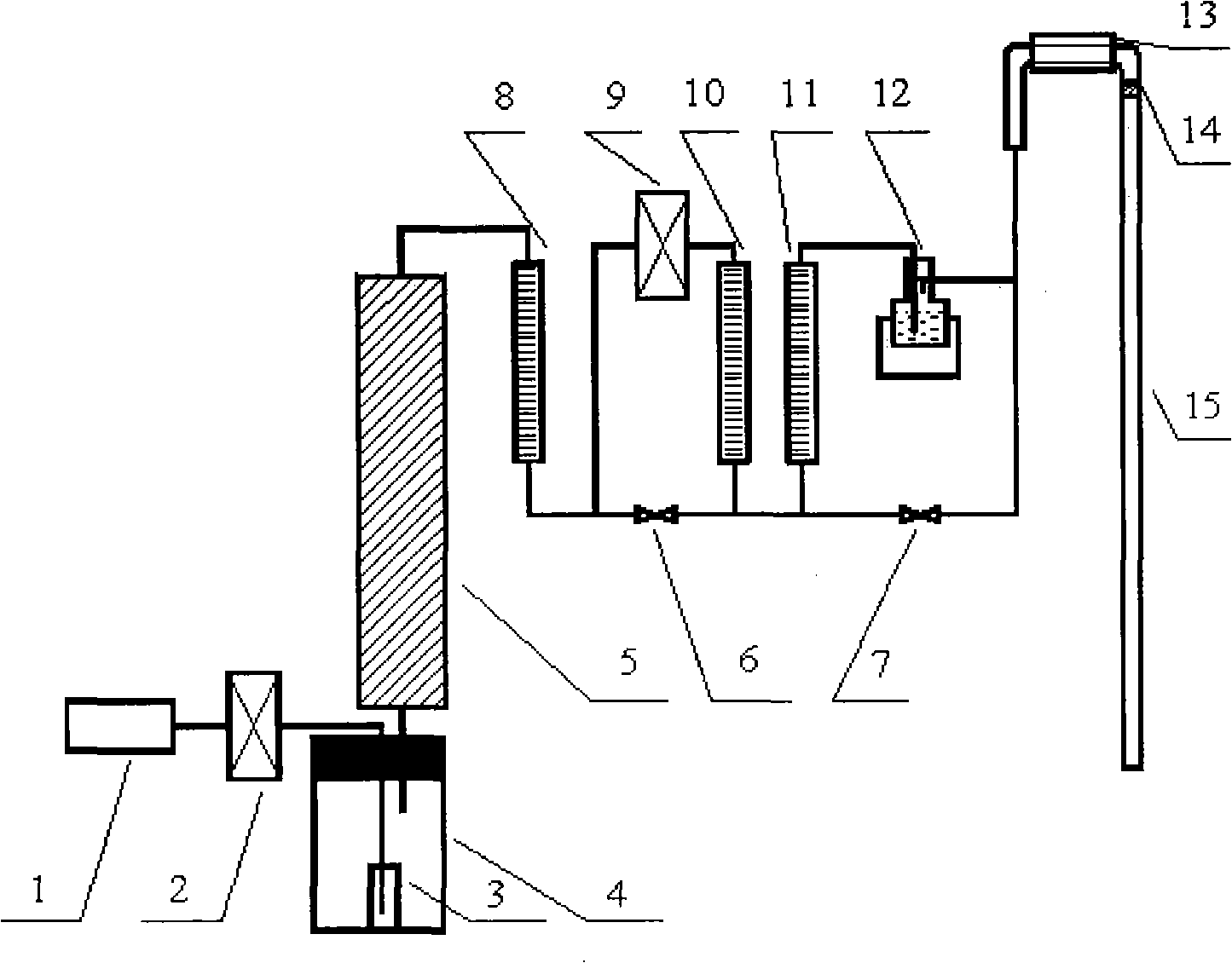

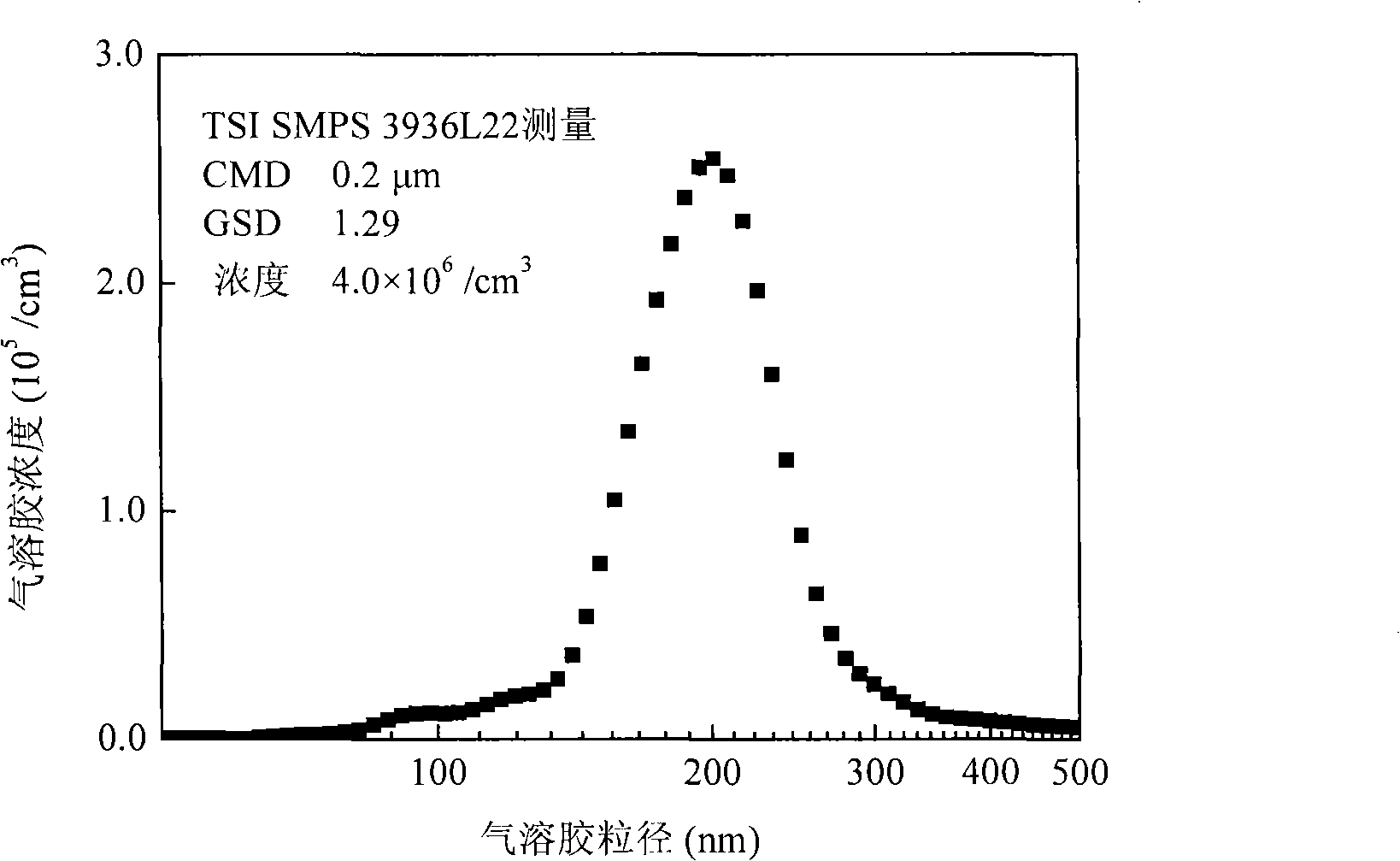

Quasi-monodispersed submicron aerosol generating device using vaporization condensation process

InactiveCN101284220AGood monodispersityMonodisperse and cheapColloidal chemistry detailsMaterial analysisSprayerEngineering

The invention relates to a generating device of quasi-monodispersed submicron aerosol by using an evaporation condensation method. The generating device comprises a high-pressure gas source, a first filter, a sprayer, a diffusion desiccator, a second filter, a saturator, a reheater, a condenser tube, and a first valve as well as a second valve, wherein, the first valve and the second valve are respectively used for adjusting the flow capacity of the second filter and the saturator; the high-pressure gas source adopts a high-pressure air source; the reheater and the condenser tube adopt metallic conduits; a baffle plate is arranged at a jet exit of the sprayer; a screen mesh or a closing ring is arranged at the inlet of the condenser tube. The generating device is convenient and durable, the running cost is low, the median diameter in aerosol generating counting ranges from 0.08 micrometres to 0.5 micrometres, the geometric standard deviation is less than 1.3, the counting concentration ranges from 1*10<4> to 1*10<8> / cm<3>, the stability and the repeatability are good when in generation, and the requirements of various equipment inspections and experimental researches can be satisfied.

Owner:TSINGHUA UNIV

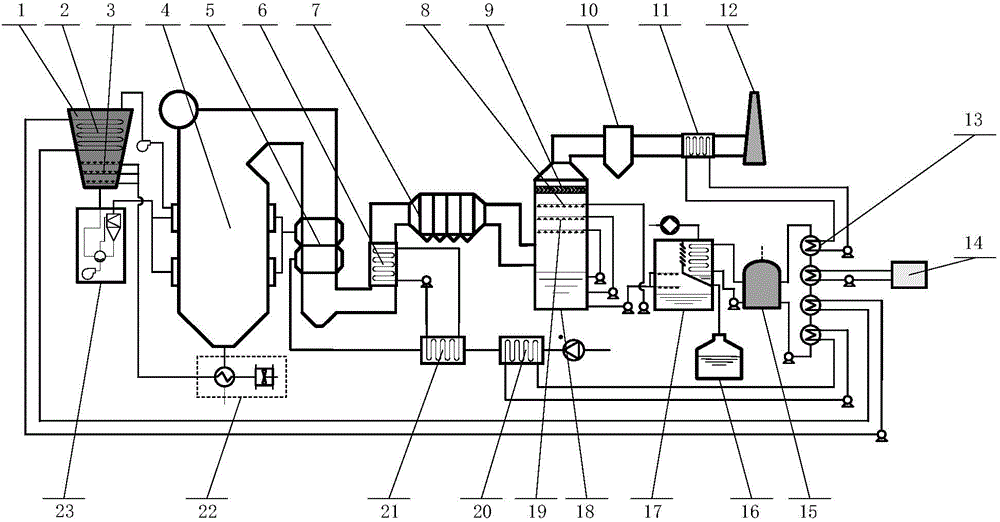

Coal-fired power plant flue gas heat regenerative system and energy-saving water-saving ultra-clean discharging method

ActiveCN104930539AImprove solubilityImprove desulfurization efficiencyIndirect carbon-dioxide mitigationLump/pulverulent fuel preparationSlurryWater vapor condensation

The invention discloses a coal-fired power plant flue gas heat regenerative system and an energy-saving water-saving ultra-clean discharging method. The temperature of the flue gas is reduced to about 90-110 DEG.C through a low-temperature coal economizer, and the recycled flue gas heat heats primary and secondary wind entering a boiler through a steam air heaters, so that the first stage of heat regenerative cycles is achieved. The temperature of the flue gas at the outlet of a desulfurization tower is reduced to 30-40 DEG.C through a vacuum flash evaporation and solidification device and a low-temperature heat pump heat exchange device, and a part of water vapor of the flue gas is condensed and collected, so that water is saved. The low-temperature heat pump heat exchange device absorbs the latent heat released in flue gas sensible heat and condensation processes, and dry as-fired coal and air are heated, so that the second stage of heat regenerative cycles is achieved. A boiler slag discharge system recycles the waste heat of heat slag, and the as-fired coal is heated, so that the third stage of heat regenerative cycles is achieved. When the waste heat is not used up, the remained waste heat can be utilized, so that energy is saved. Low-temperature desulphurization slurry led out from the vacuum flash evaporation and solidification device is injected into the desulfurization tower, so that the desulphurization efficiency is improved, and an ultra-clean discharging objective is achieved.

Owner:SHANDONG UNIV +2

Apparatus for enhancing condensation and boiling of a fluid

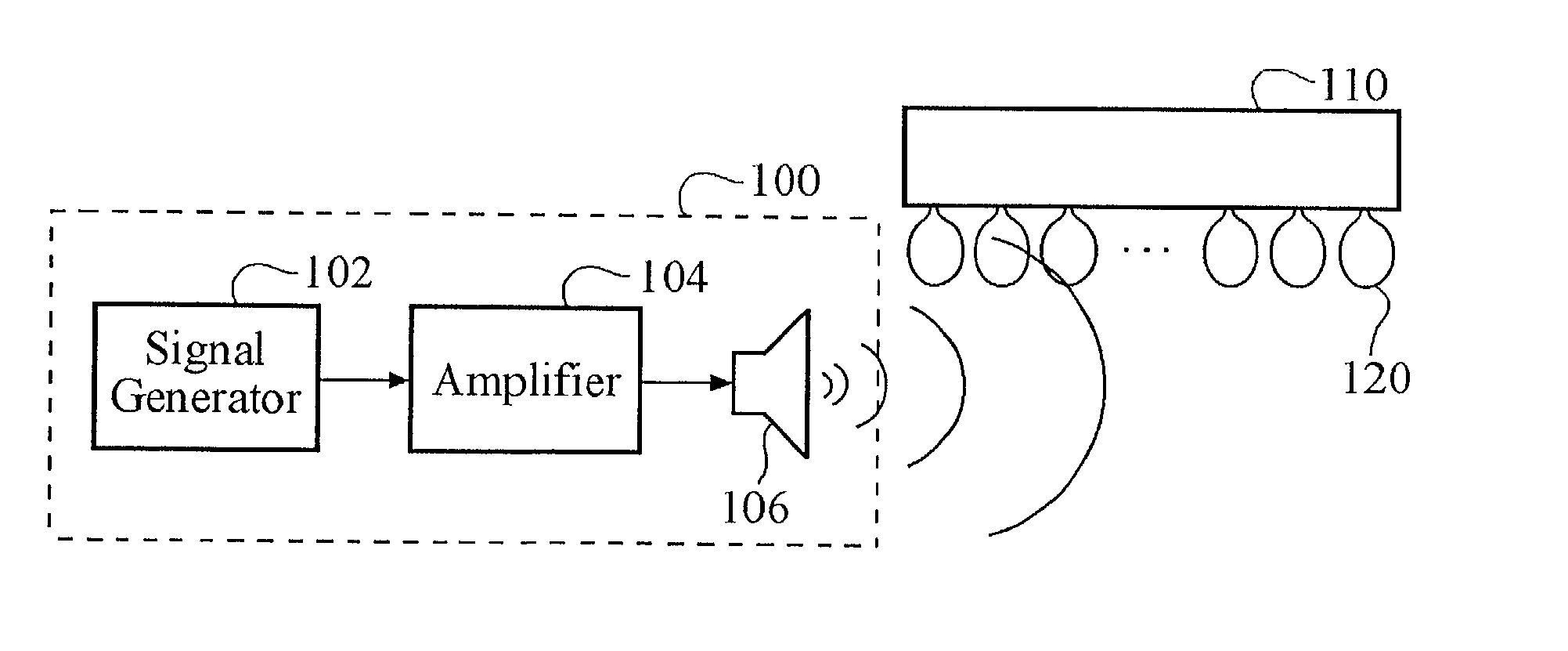

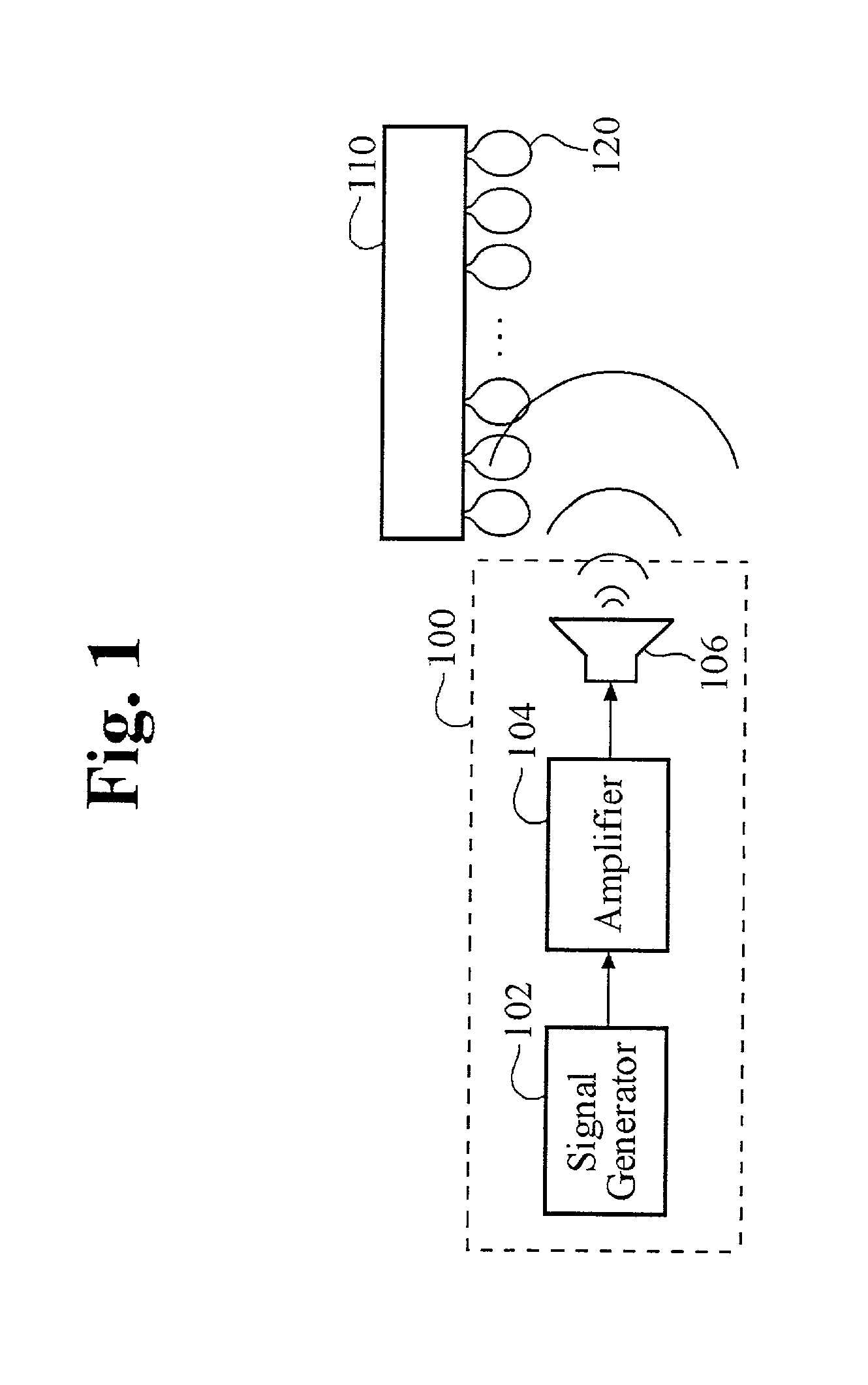

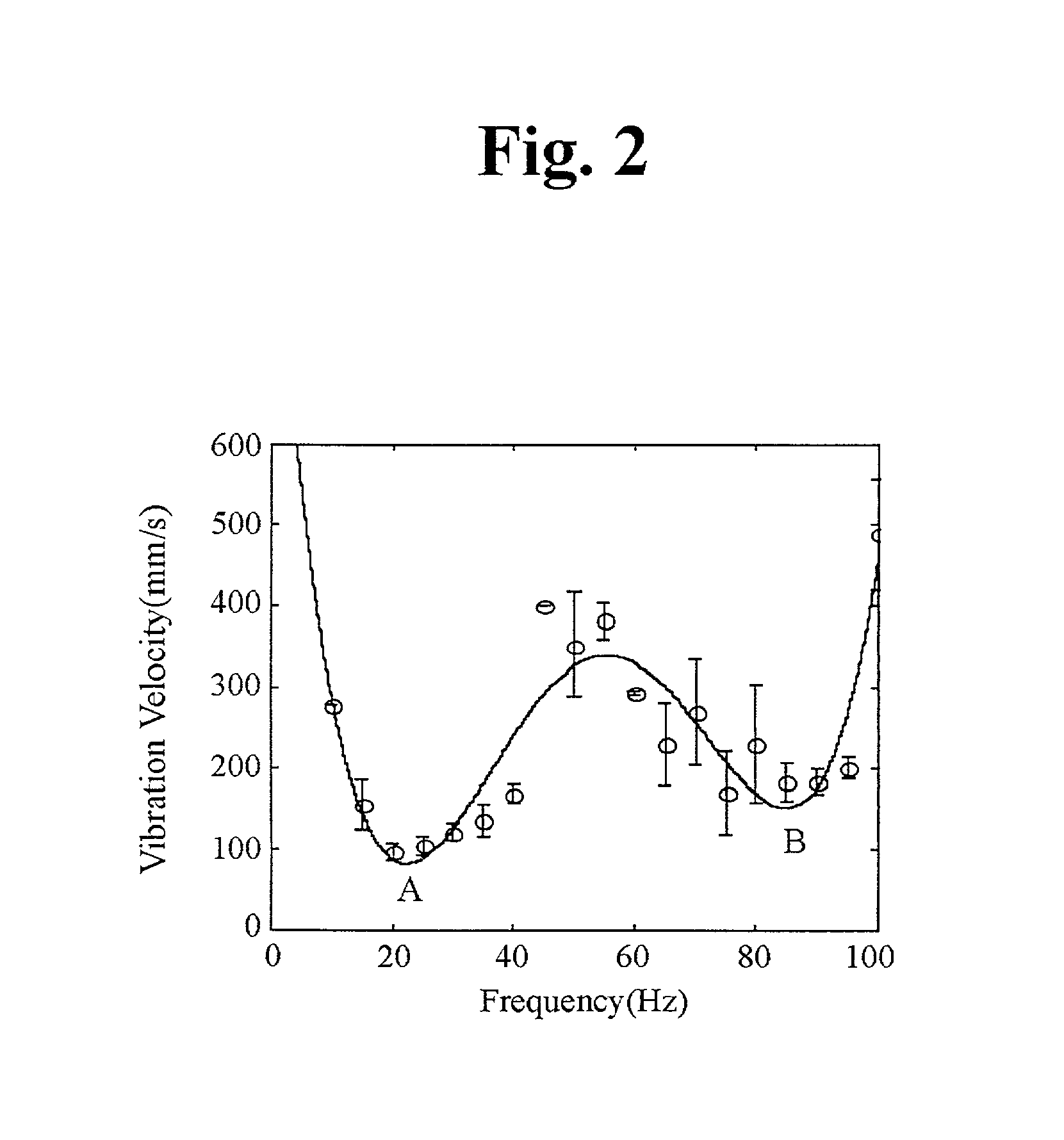

InactiveUS20020079089A1Promote generationVibration cleaningHeat transfer modificationCondensation processResonance oscillation

An apparatus enhances the condensation and boiling of a fluid in heat exchange machines, by directly applying time-periodic acoustic waves with a resonance oscillation frequency to liquid drops and / or bubbles formed on a solid surface, when the fluid is in the process of condensation or boiling, thereby effectively removing them therefrom. The apparatus comprises a signal generator for generating a driving signal based on a resonant oscillation frequency of at least one of the liquid drops and the bubbles; and a vibrator, in response to the driving signal, for providing an acoustic pressure wave to said at least one of the liquid drops and the bubbles, to thereby detach them from the solid surface.

Owner:KOREA INST OF SCI & TECH

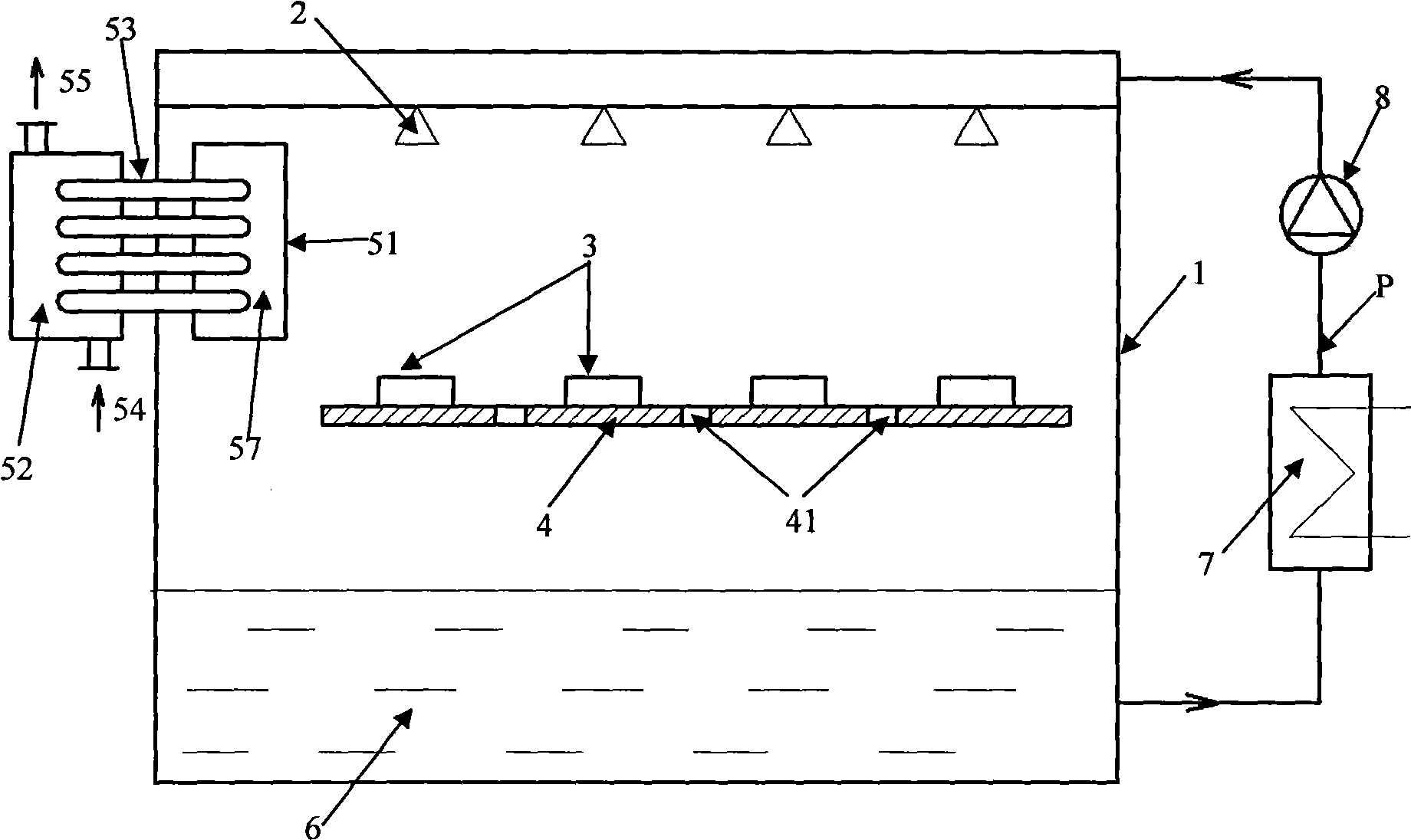

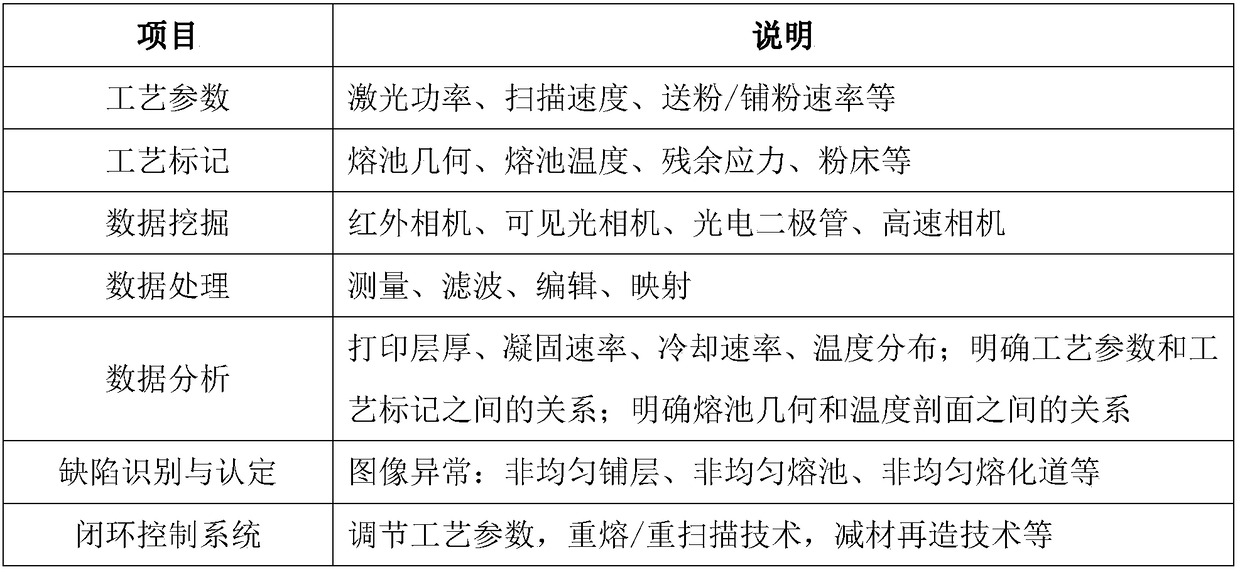

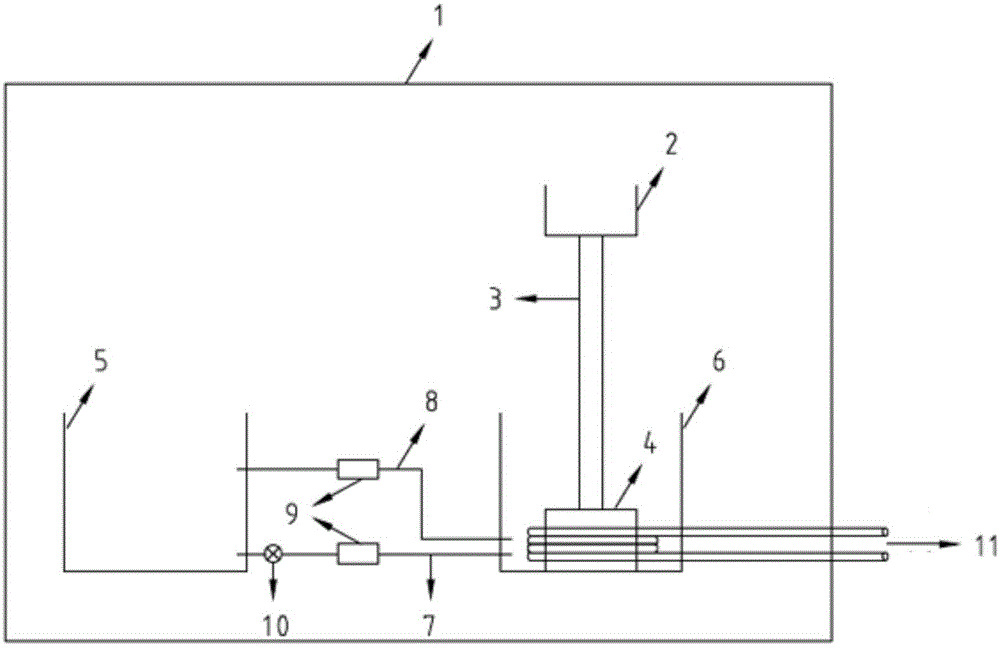

Cooling system for amorphous metal member formed in laser 3D printed manner and cooling method of cooling system

InactiveCN105081321AFast flowPrevent crystallizationAdditive manufacturing apparatusMelting tank3d print

The invention discloses a cooling system for an amorphous metal member formed in a laser 3D printed manner. The cooling system is characterized by comprising a cooling fluid storing tank and a cooling fluid working tank; the cooling fluid storing tank is communicated with the cooling fluid working tank through a cooling fluid conveying pipe and a cooling fluid returning pipe; and a work bench is arranged in the cooling fluid working tank, and the periphery of the work bench is surrounded by a plurality of layers of circulating cooling water pipes. The invention further discloses a cooling method of the cooling system. The liquid level of cooling fluid is always lower than a laser printing layer and kept at the preset height by controlling the rising speed of the liquid level of the cooling fluid, so that the molten pool heat of the metal member can quickly flow to the cooling fluid through the a metal base body. The circulating cooling water pipes can take the heat of the cooling fluid away in time, and the temperature of the cooling fluid is reduced. By means of the cooling system, the manufactured metal member can be always kept in the specified temperature, the molten pool heat can be quickly and efficiently radiated, and melt is prevented from crystallizing. Thus, the amorphous metal member can be obtained.

Owner:DALIAN JIAOTONG UNIVERSITY

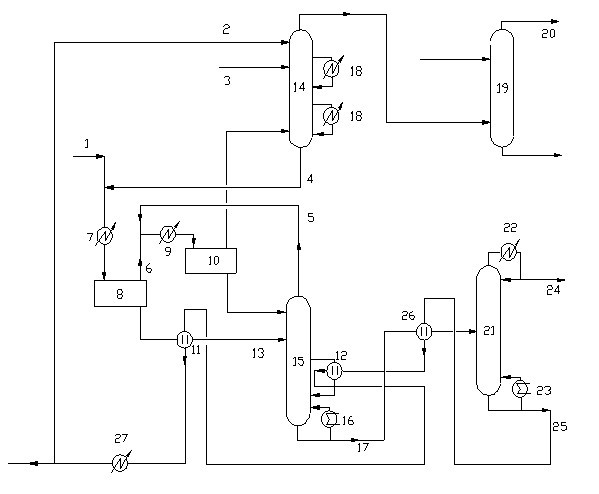

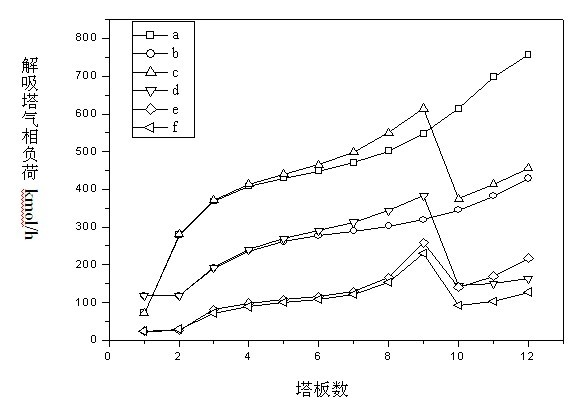

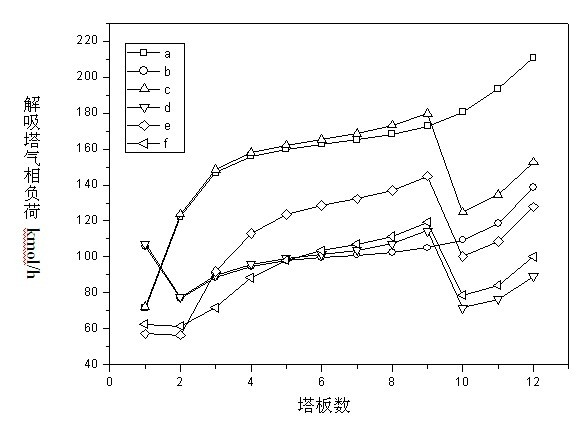

Reinforced mass transfer and efficient energy-saving type absorption stabilizing system

InactiveCN102021033AImprove mass transfer efficiencyReduce loadTreatment with hydrotreatment processesCondensation processThermodynamics

The invention provides a reinforced mass transfer and efficient energy-saving type absorption stabilizing system. The invention relates to absorption stabilizing system production technologies such as catalytic cracking, delay coking, hydrocracking and the like, in particular to a compound reinforced technology of secondary condensation and middle reboiler arrangement for the absorption stabilizing system. In the invention, a technology that adsorption tower bottom oil and compressed rich gas are mixed for primary condensation and the primarily condensed gas is mixed with desorption gas for secondary condensation is adopted, thereby avoiding the mix of the desorption gas with the adsorption tower bottom oil and the compressed rich gas, reducing primary condensation load and reinforcing the mass transfer of stepwise condensation processes while eliminating backmixing of a desorption tower. Primary condensation liquid is heated and then fed, and the middle reboiler is arranged in the desorption tower, so that the load of the reboiler in the desorption tower can be effectively reduced. Compared with a cold feeding technology, a hot feeding technology, a cold feeding-middle reboiler technology, a hot feeding-reboiler technology and secondary condensation-middle reboiler technology, energy consumption can be respectively reduced by 25-34%, 18-26%, 16-24%, 7-13% and 6-8% by using the reinforced compound technology in the invention. The novel technology has the advantages of reinforcing the mass transfer of the absorption stabilizing system, reducing the energy consumption of the system and relieving the load in the tower.

Owner:SUN YAT SEN UNIV

Condensation washing method for fluorinated ethylene-propylene resin

The invention relates to a condensation washing method for fluorinated ethylene-propylene resin. An emulsion polymerization method is adopted for preparing luorinated ethylene-propylene resin polymerization emulsion, then, the fluorinated ethylene-propylene resin is obtained through still standing, dilution, stirring condensation and washing, and a chemical condensation mode can also be used as an auxiliary mode in the stirring condensation process. The mechanical condensation and the chemical condensation are combined in the condensation washing method provided by the invention, the condensation effect is excellent and is obviously superior to that of the traditional condensation method, the obtained fluorinated ethylene-propylene resin has large grain diameter and high volume density, fluorinated ethylene propylene (FEP) plastics can be favorably and further processed, and in addition, the method has the advantages that the operation is simple and convenient, the condition is mild, and the method is suitable for industrial large-scale application.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

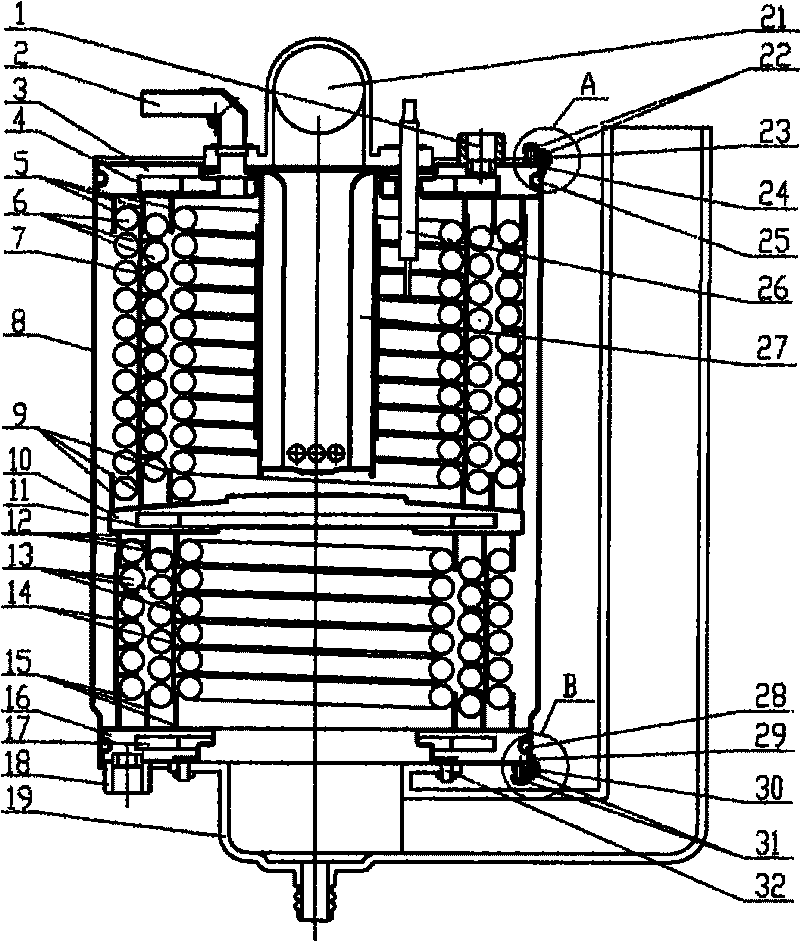

High-efficiency condensing type heat exchanger

InactiveCN101726109AImprove heat transfer efficiencySafety devices for heat exchange apparatusEnergy efficient heating/coolingEngineeringWater vapor condensation

The invention relates to a high-efficiency condensing type heat exchanger which comprises a tubular shell, an upper-layer water tank, an upper spiral sleeve pipe, a middle-layer water tank, a lower spiral sleeve pipe, a lower-layer water tank and a U-shaped condensed water collection smoke exhauster. The heat energy generated in the combustion process of water exchange is used for lowering the temperature of the smoke generated in the combustion process, and the water vapor in the smoke is condensed into the liquid state from the gaseous state to generate condensed water, thereby absorbing the latent heat emitted in the condensation process and improving the heat exchange efficiency of the heat exchanger. In the invention, the shell has a dismountable internal structure, can be cleared and maintained easily, improves the heat exchange efficiency of the heat exchanger, is suitable for various products of gas-fired hot water, and is suitable for domestic gas-fired hot water heating equipment and the like.

Owner:GUANGDONG ROC COOLING & HEATING EQUIP

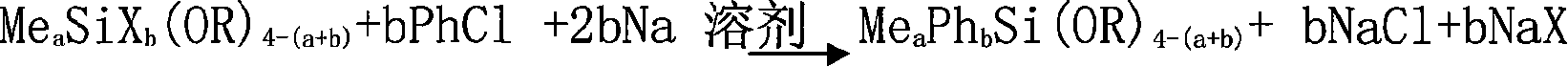

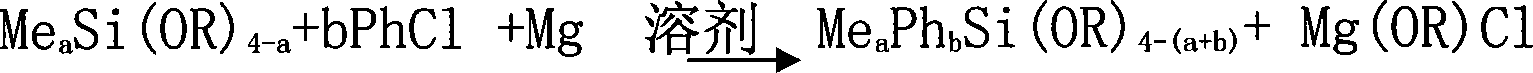

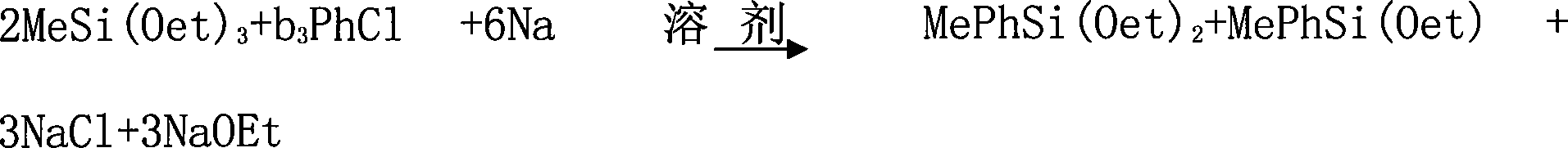

Phenyl alkoxy silane prepared by sodium condensation method

InactiveCN101077877AReasonable designThorough responseGroup 4/14 element organic compoundsCondensation processChlorobenzene

The present invention relates to sodium condensation process for synthesizing phenyl alkoxyl silane. Chlorobenzene and MeaSiXb(OR)4-(a+b), where, X is Cl or Br, R is Me or Et, a is 0 or1 and b is 1, 2, 3 or 4, are made to produce sodium condensation reaction in solvent at 98-130 deg.c for 0.5-8 hr. The process has complete reaction of metal sodium, simple operation, short reaction period, benzene converting rate up to 70-80 %, and MePhSi(OR)2 selectivity up to 50 %.

Owner:盐城市华业医药化工有限公司

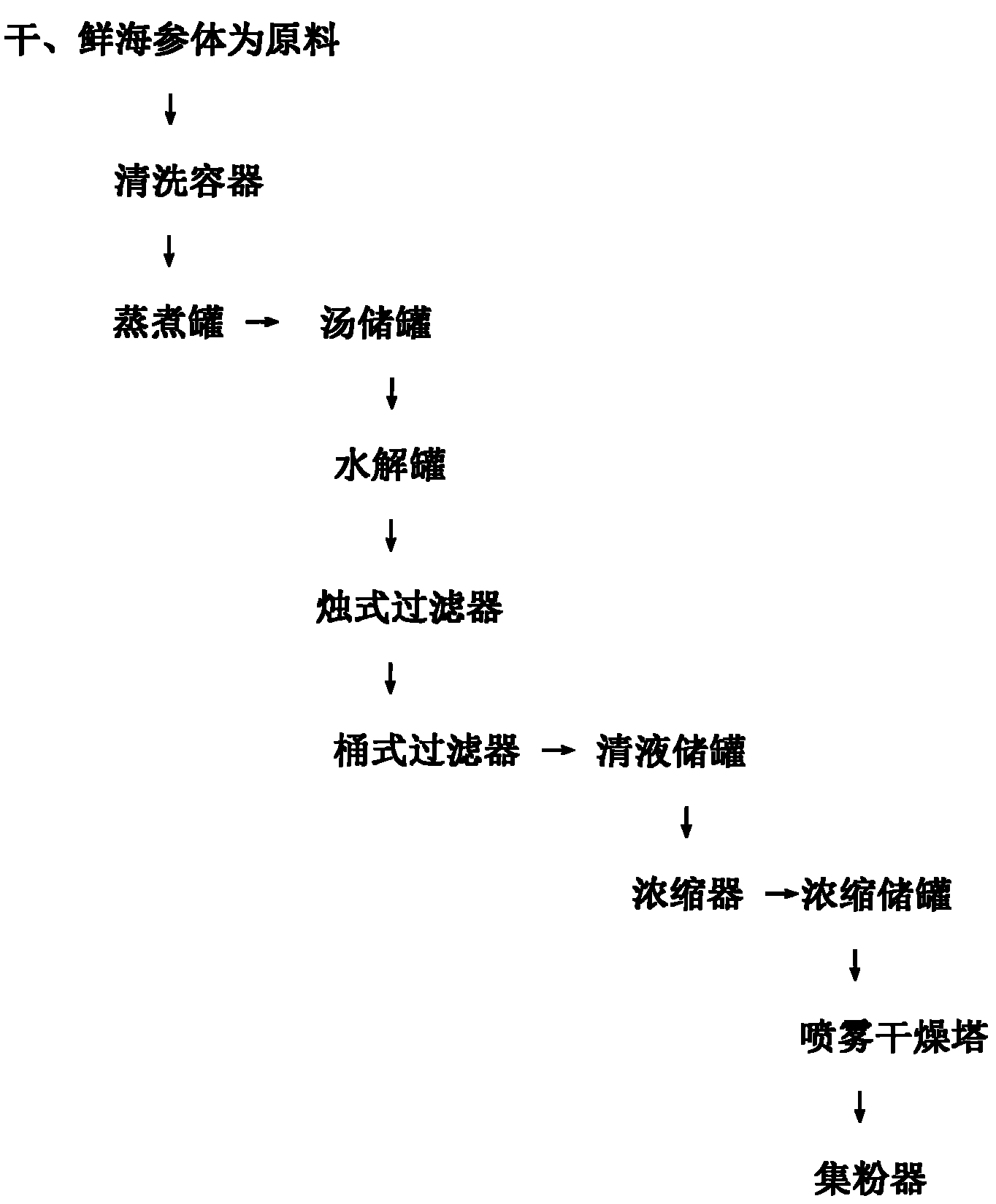

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

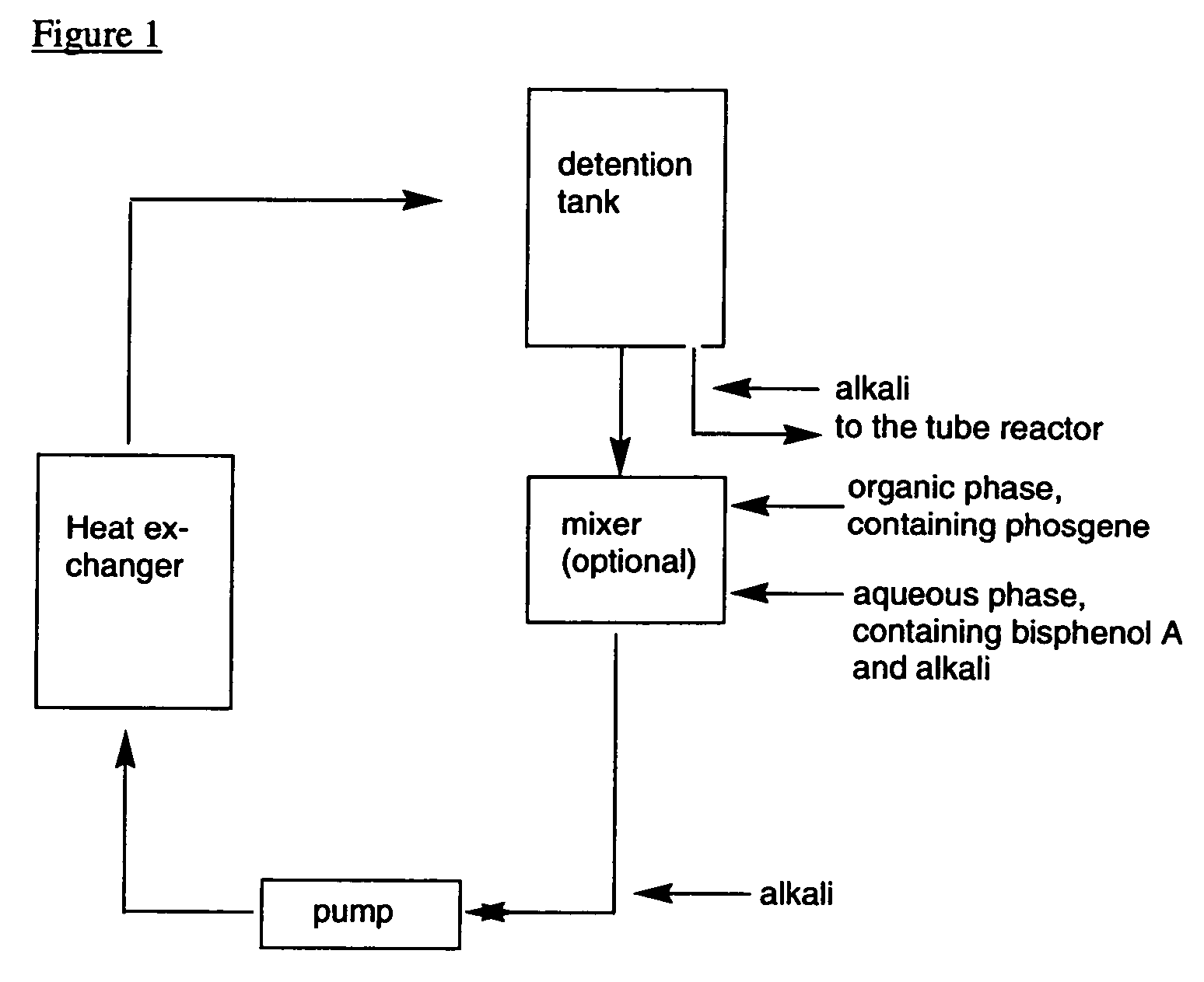

Process for the preparation of polycarbonates

An improvement in the continuous two-phase interfacial condensation process for preparing polycarbonate is disclosed. In the process that entails at least one diphenol, phosgene, at least one chain terminator, and optionally branching agents and is carried out in the presence of a catalyst the improvement comprising maintaining the concentration of the catalyst at a level of at least 0.012 mol per mol of diphenol.

Owner:COVESTRO DEUTSCHLAND AG

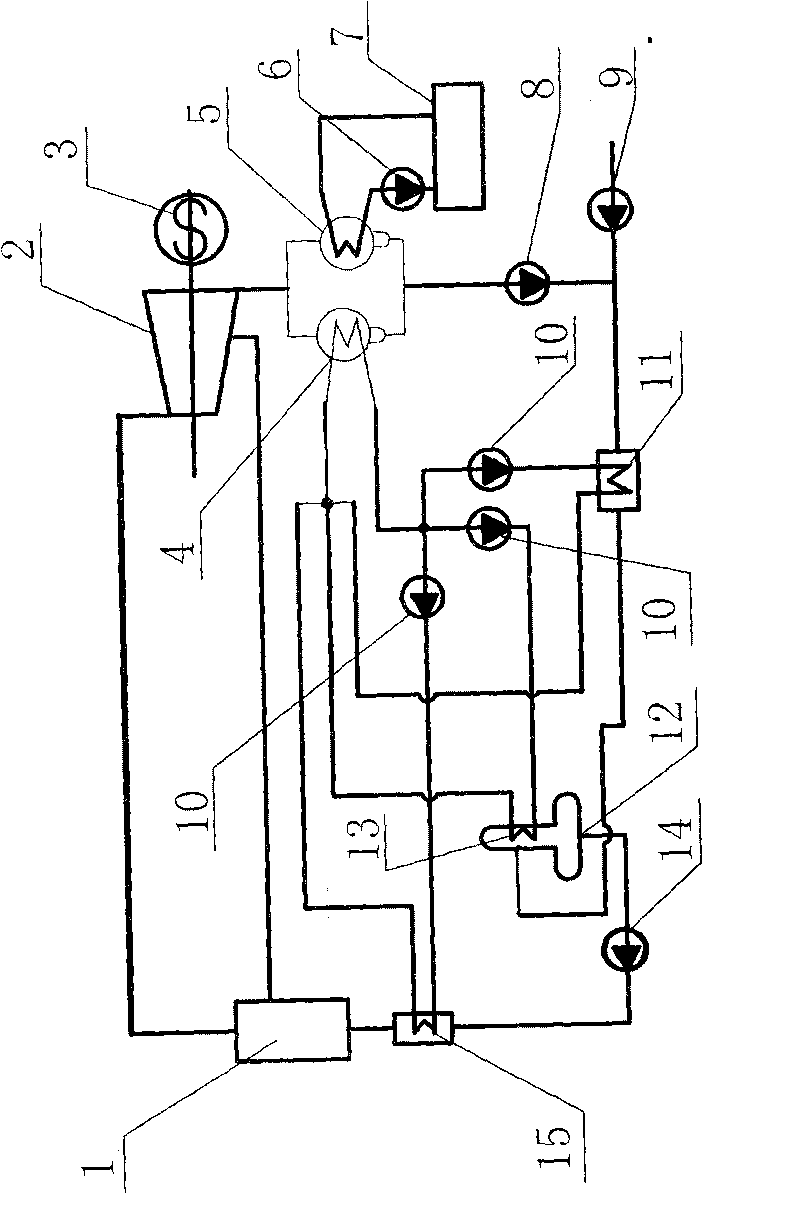

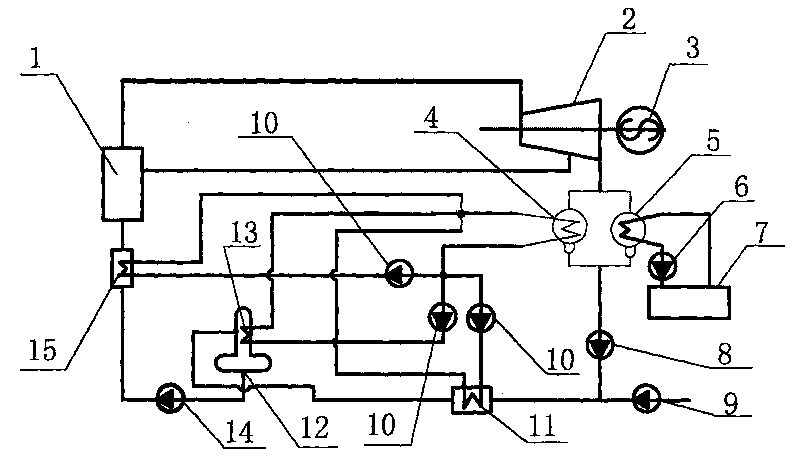

Self-coupling cold source heat pump circulating device of low-temperature exhaust heat power generating system in low temperature exhaust steam condensation process

ActiveCN101705849AReduce lossesReduce power consumptionSteam engine plantsSteam condensationDeaerator

The invention relates to the technical field of low-temperature exhaust heat power generation at low temperature, in particular to a self-coupling cold source heat pump circulating device of a low-temperature exhaust heat power generating system in the low temperature exhaust steam condensation process. The self-coupling cold source heat pump circulating device comprises a conventional low-temperature exhaust heat power generating heat circulation system, a heat pump type condenser which is arranged parallel with a water-cooled condenser is arranged at an exhaust steam outlet of a lower pressure cylinder of a steam turbine; a gaseous state working medium outlet of the heat pump type condenser is divided into three paths which respectively pass through a heat pump system compressor, wherein a first path passes through a heat pump condensed water heater, a second path passes through a heat pump deoxidized heater and a third path passes through a heat pump water feeding heater and then returns to a liquid state working medium input of the heat pump type condenser; the heat pump water feeding heater is arranged between a condensing water pump and a deaerator; the heat pump deoxidized heater is arranged on the deaerator; and the heat pump water feeding heater is arranged at a water feeding inlet of a water feeding pump and an exhaust heat boiler. The invention substantially improves the exhaust heat utilization efficiency of the low-temperature exhaust heat power generating system and enables the system to produce more power energy under the condition that exhaust heat sources are the same.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com