Reinforced mass transfer and efficient energy-saving type absorption stabilizing system

An absorption stabilization system, energy-saving technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., can solve the problem of reducing the energy consumption of the absorption stabilization system, and achieve the goal of reducing energy consumption, heat load, and load reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

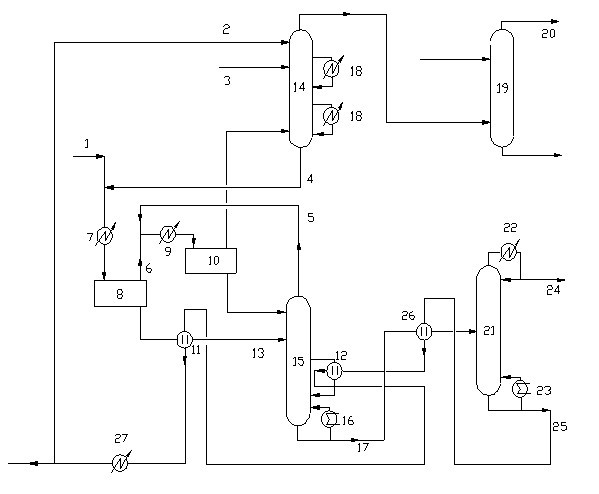

[0029] In this example, the absorption stabilization system of a 1.4Mt / a catalytic cracking unit in a petrochemical enterprise is used for calculation. The process flow is as follows figure 1 Shown: the flow rate of compressed rich gas is 46.2t / h, and the flow rate of naphtha is 65.8t / h. The compressed rich gas 1 is mixed with the absorption tower bottom oil 4 and then enters the circulating water cooler 7 with an outlet temperature of 60°C, and then enters the liquid separation tank 8 for gas-liquid separation. The liquid phase of the liquid separation tank is heated to 80°C by the heat exchanger 11 and enters the upper middle part of the desorption tower 15 as a hot feed. The heat exchanger 11 uses stable gasoline as a heat source. After the gas phase 6 of the liquid separation tank is mixed with the desorption gas 5, the temperature drops to 35°C through the circulating water cooler 9, and then enters the liquid separation tank 10 for gas-liquid separation, and the liquid p...

Embodiment 2

[0038] The absorption and stabilization system of a 1.0Mt / a delayed coking unit in a petrochemical enterprise is used for accounting. The process flow is as follows figure 1 As shown, the specific process flow of this example is the same as that of Example 1, and the operating conditions are: the flow rate of compressed rich gas is 11.3t / h, the flow rate of naphtha is 20.7t / h, the outlet temperature of the circulating water cooler 7 is 60°C, and the circulating water cooler 9 The outlet temperature is 40°C, and the outlet temperature of the feed heat exchanger 11 of the desorption tower is 80°C. Same as Example 1, the process quality control index is C in deethanized gasoline 2 4 3 + Content<1.5%(v).

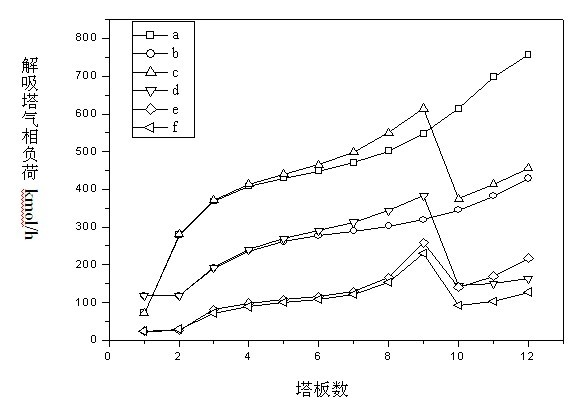

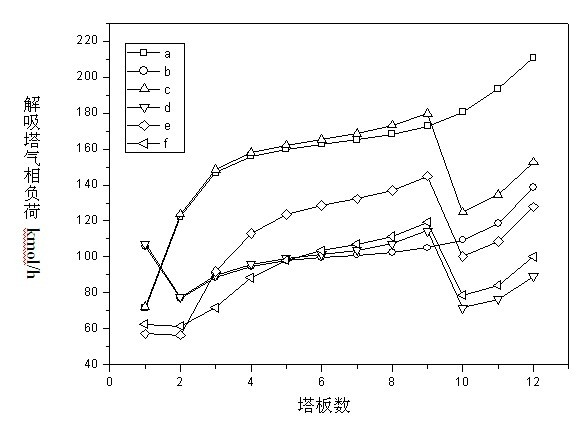

[0039] Under the same feed and product quality, the combined process of this example is combined with cold feed, hot feed, cold feed-intermediate reboiler, hot feed-intermediate reboiler, two-stage condensation-intermediate reboiler The five processes were compared and analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com