Patents

Literature

61results about How to "Improve load distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

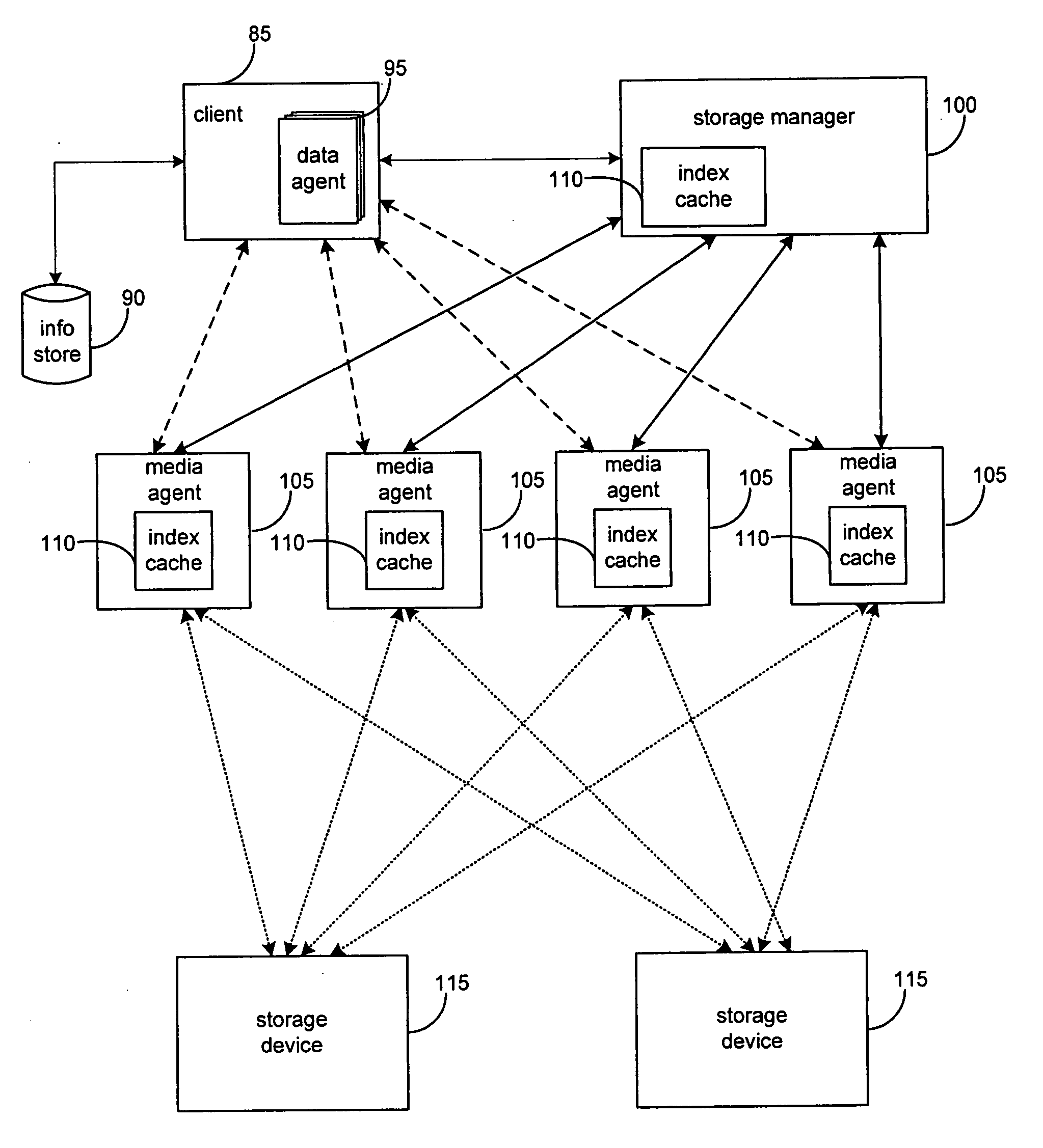

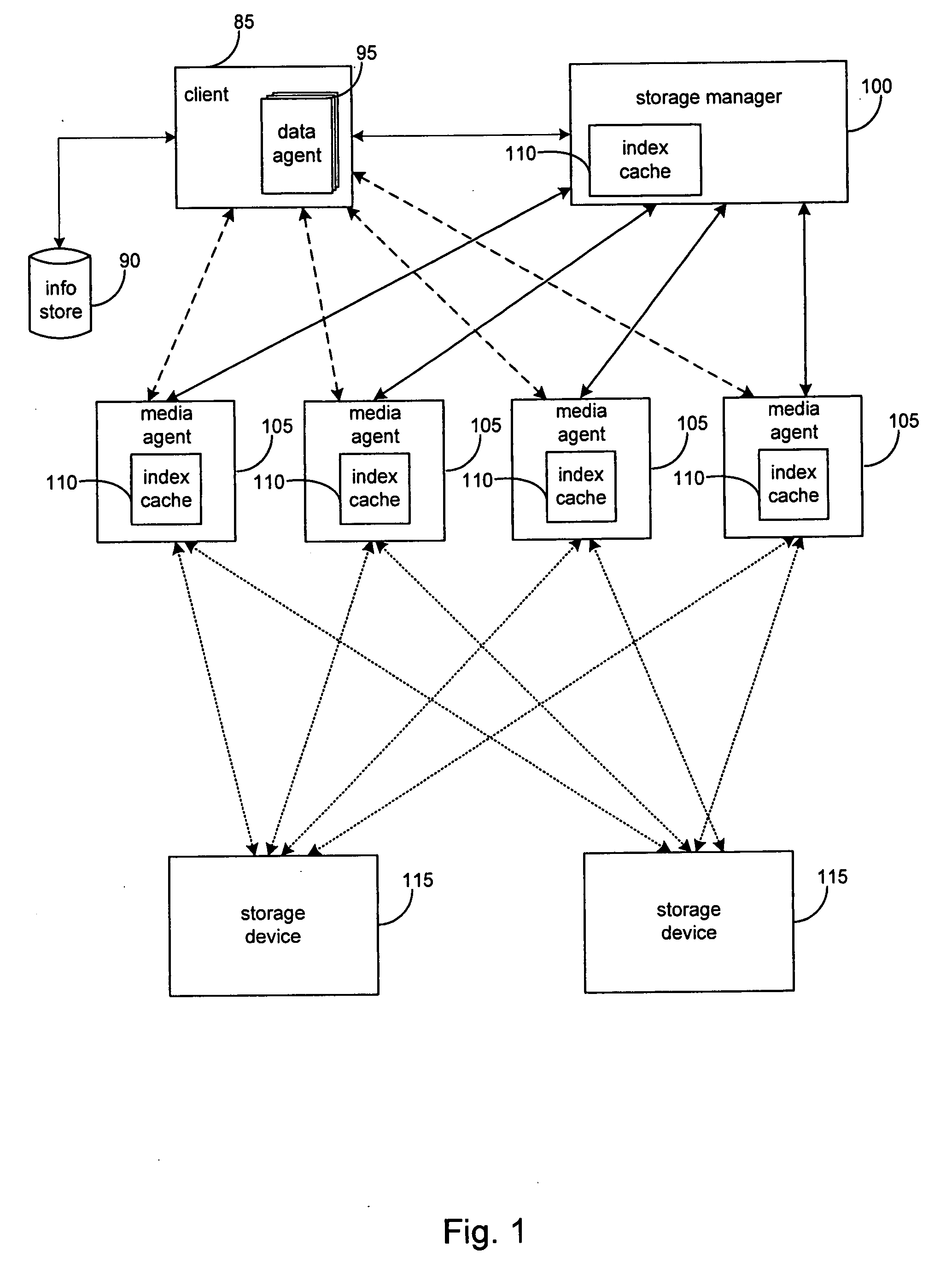

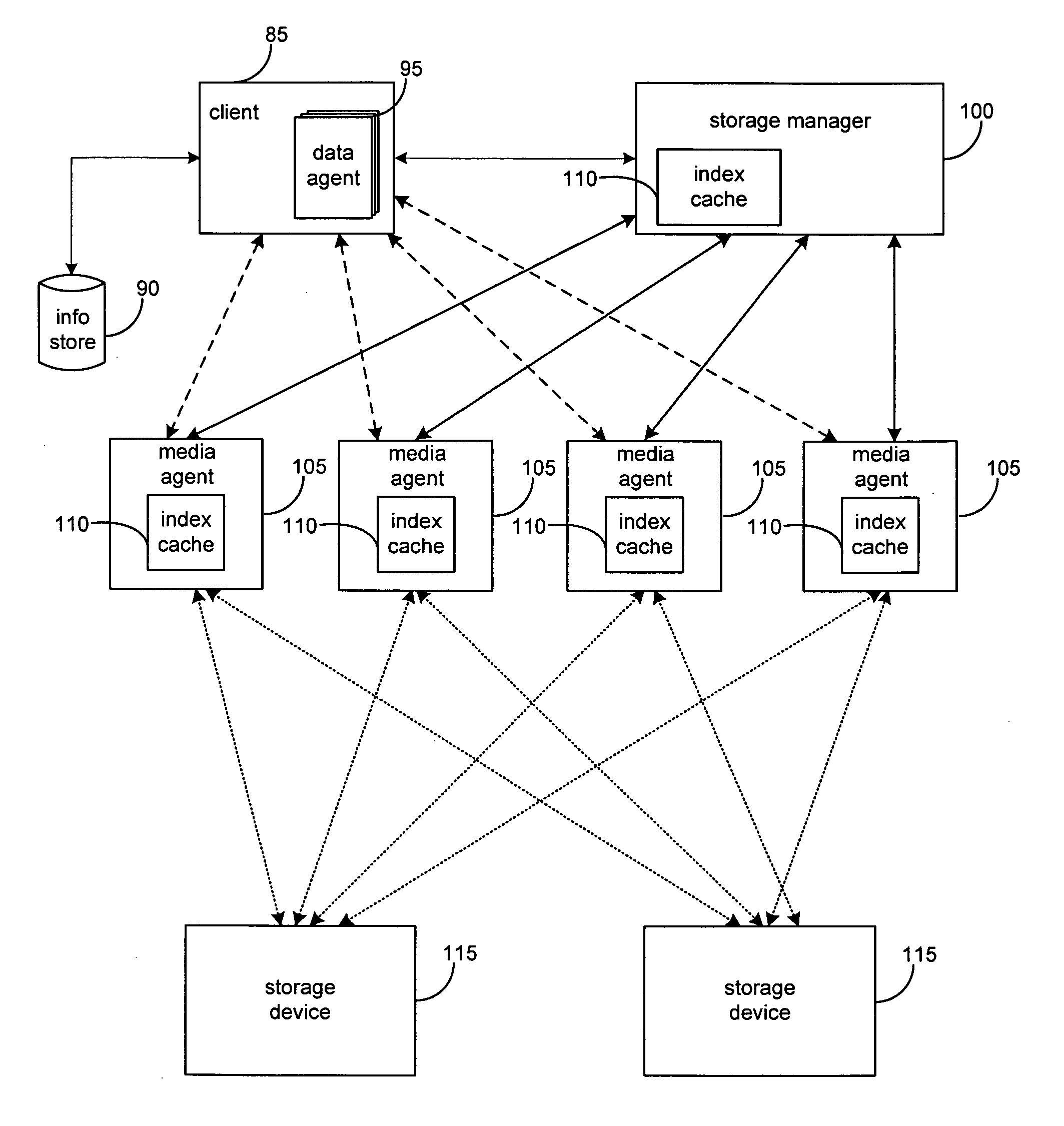

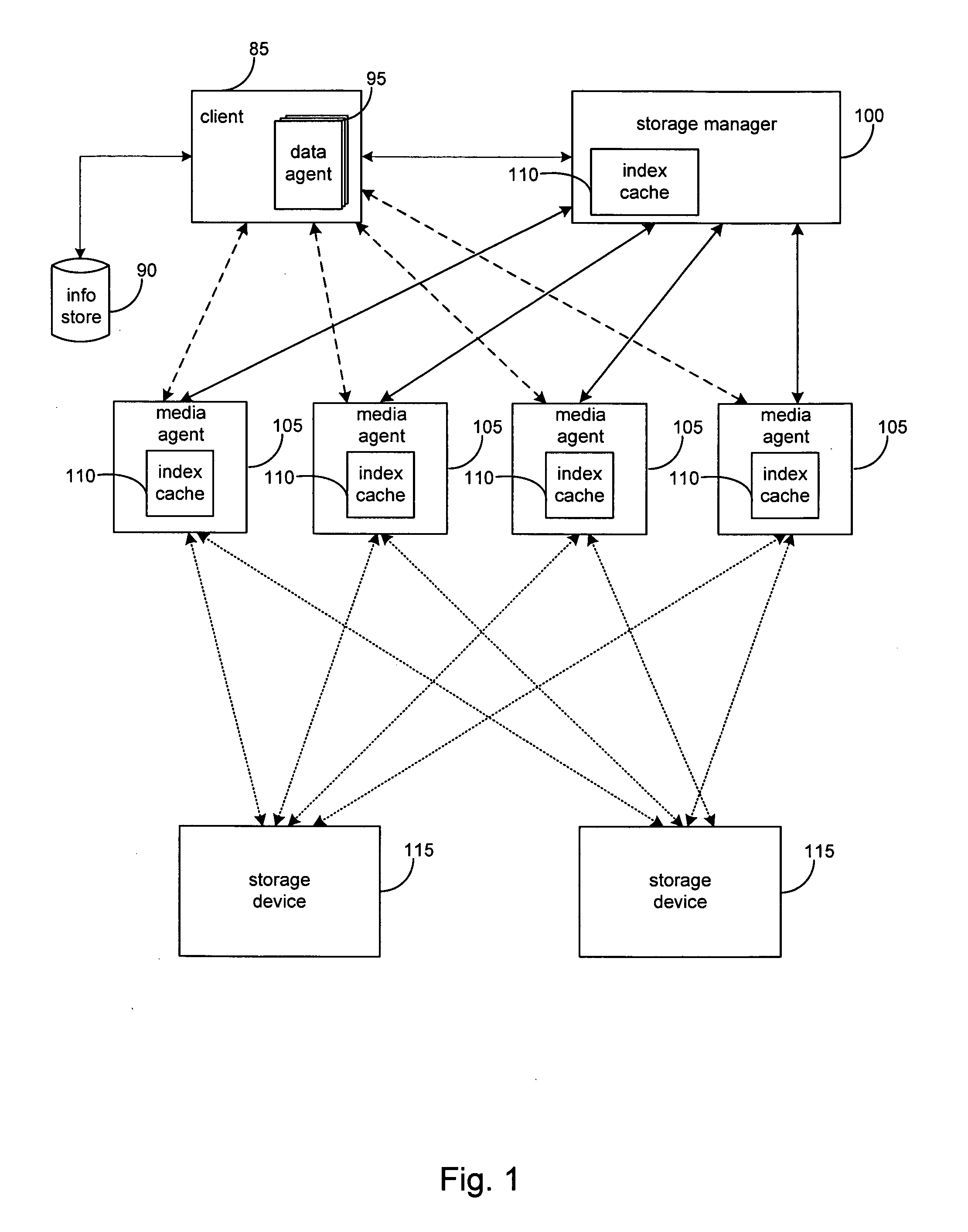

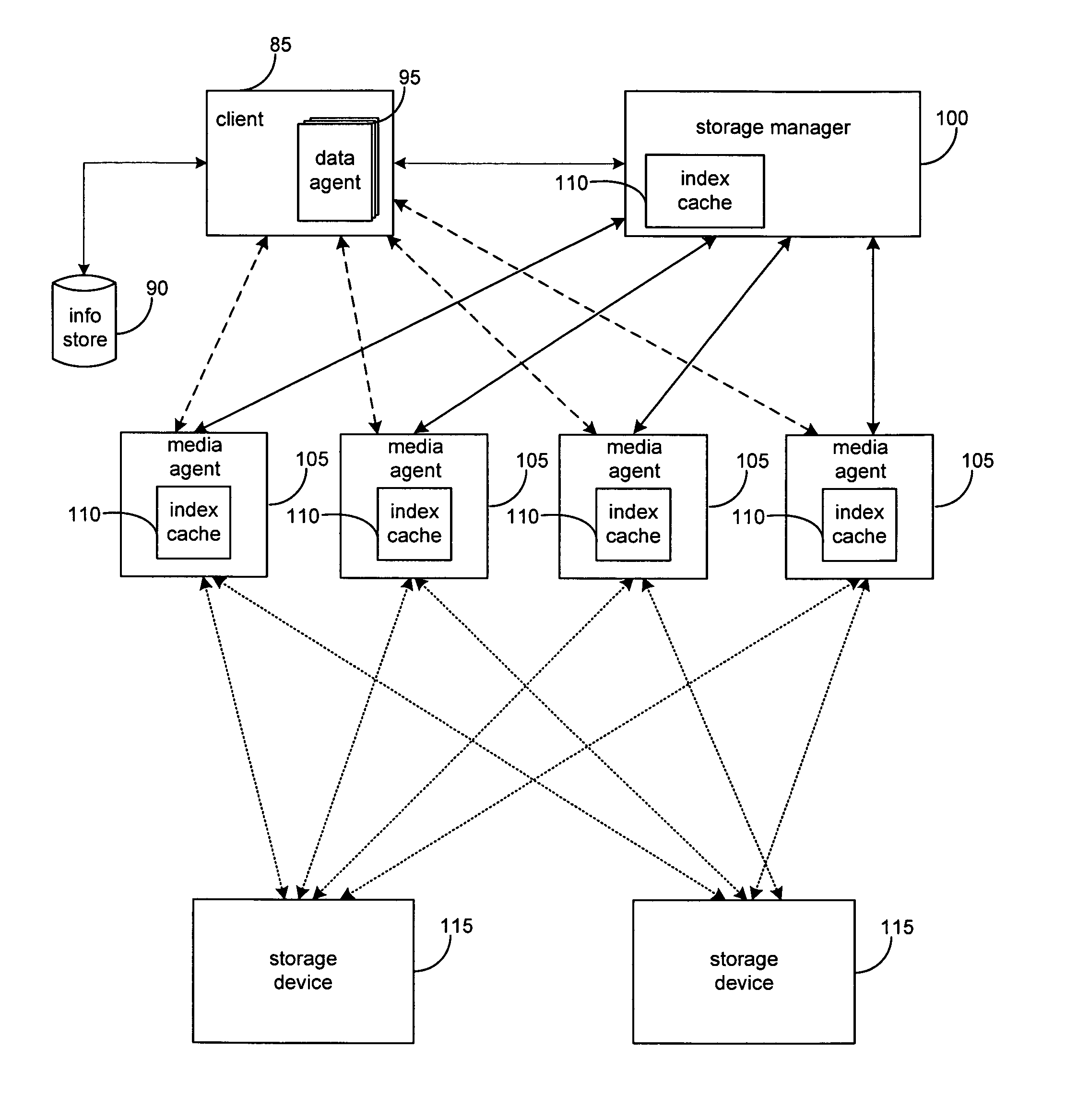

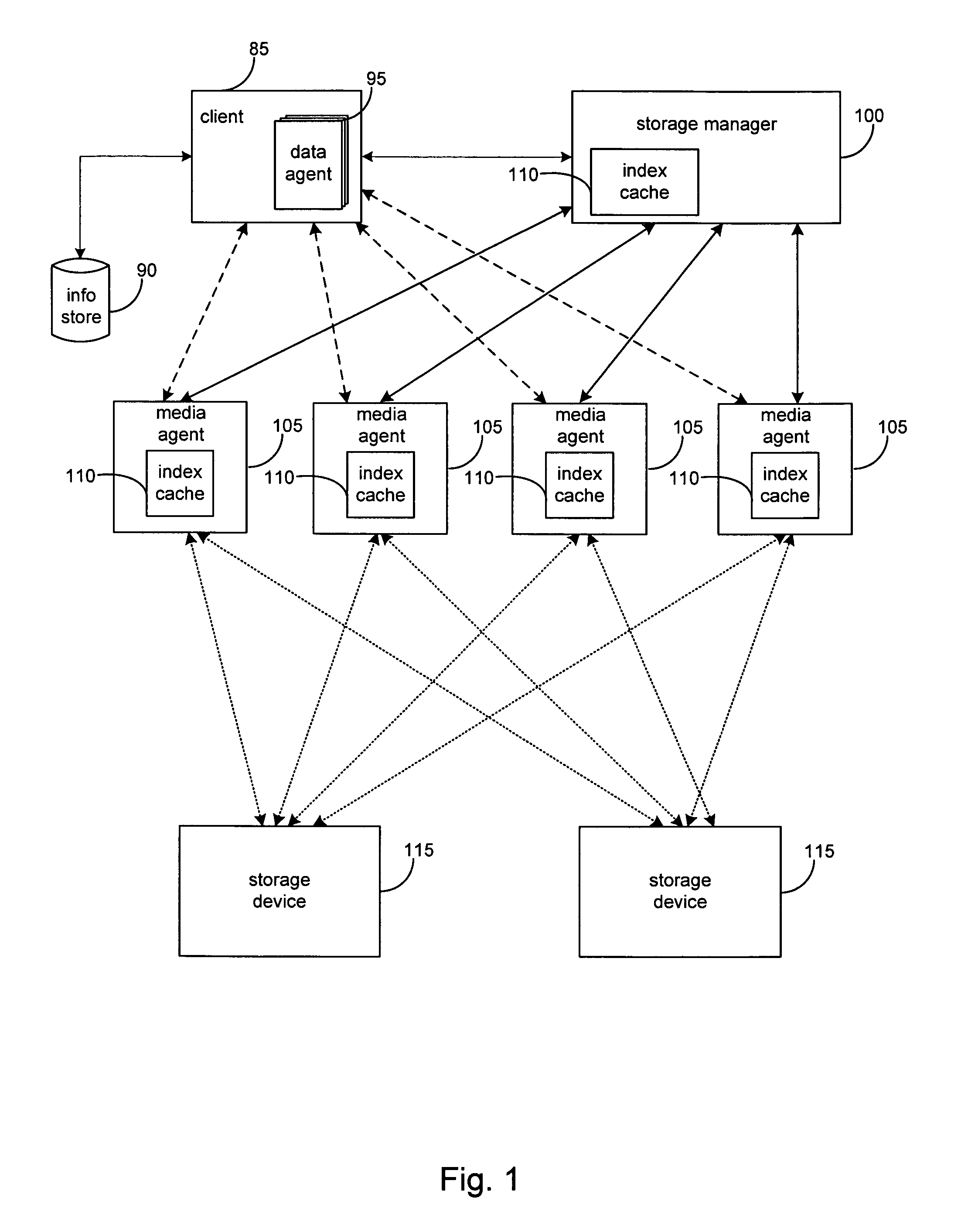

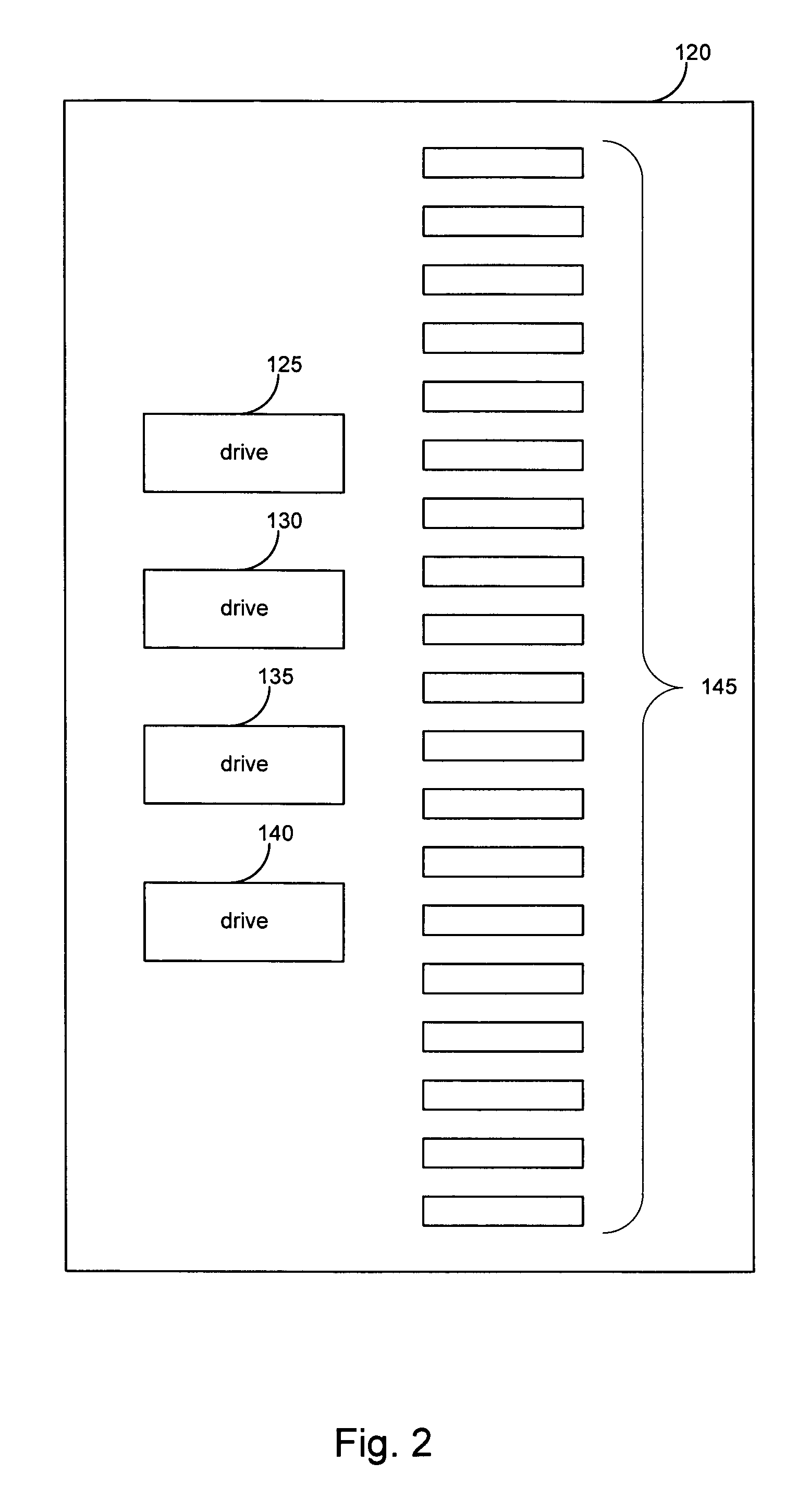

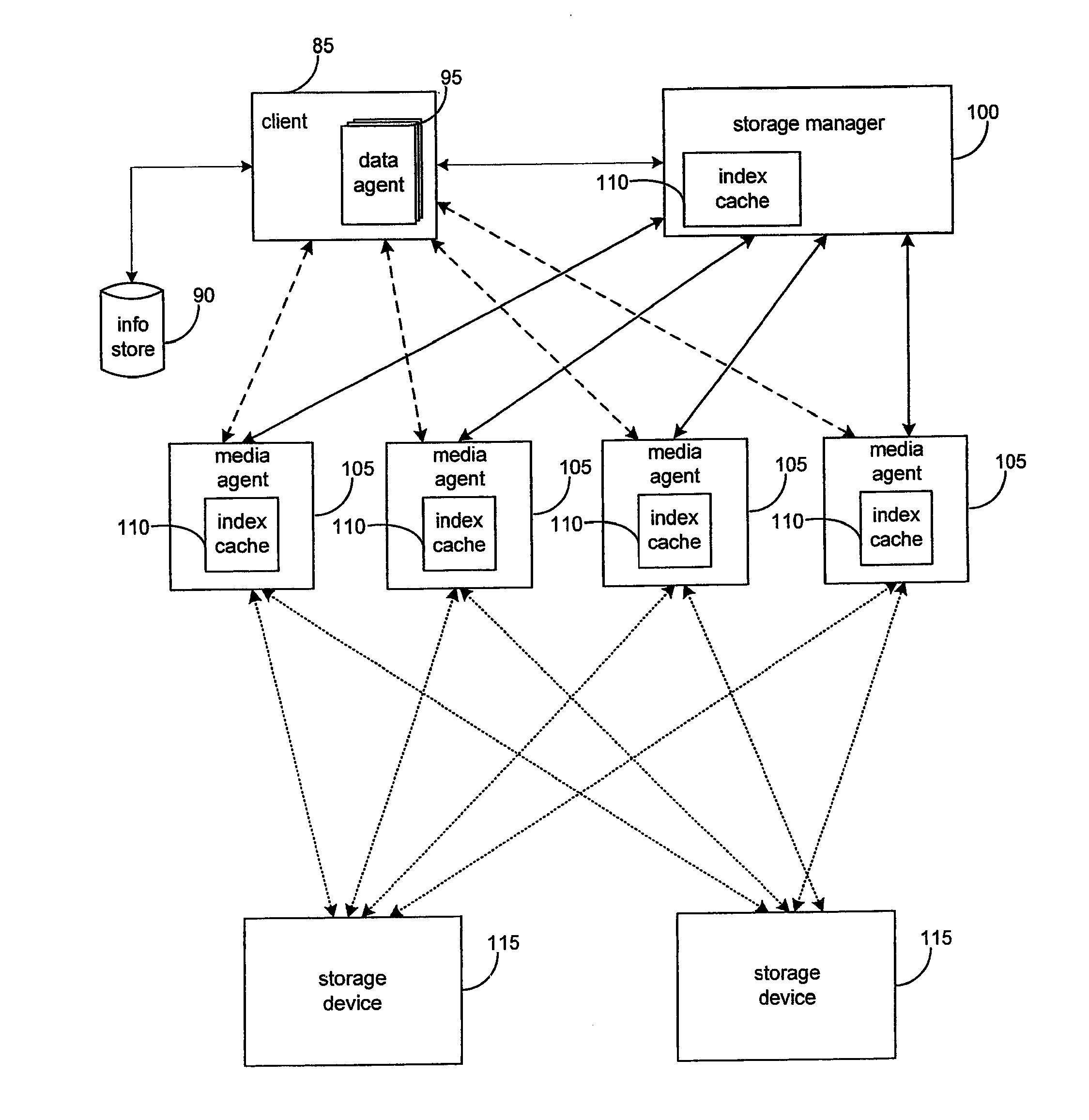

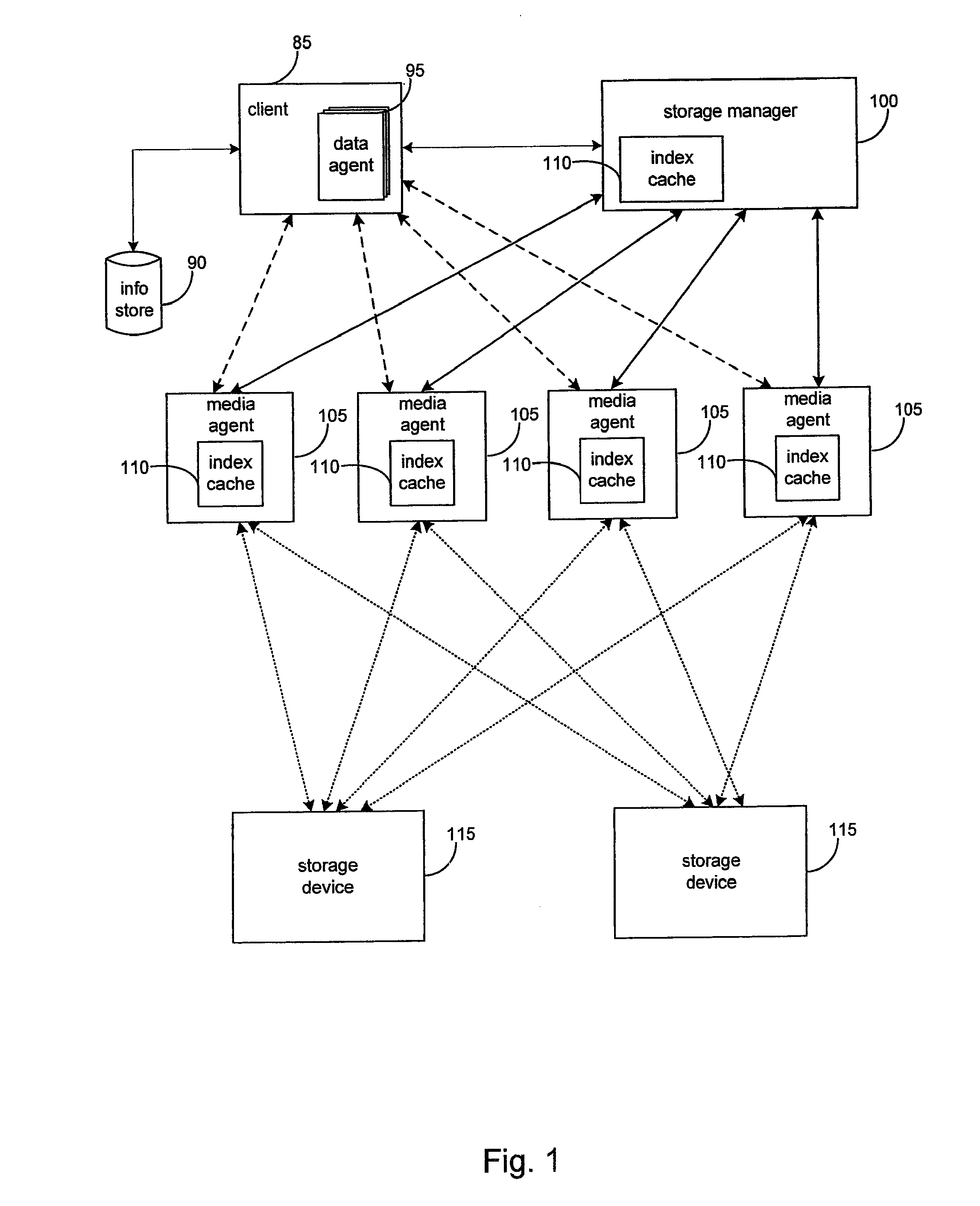

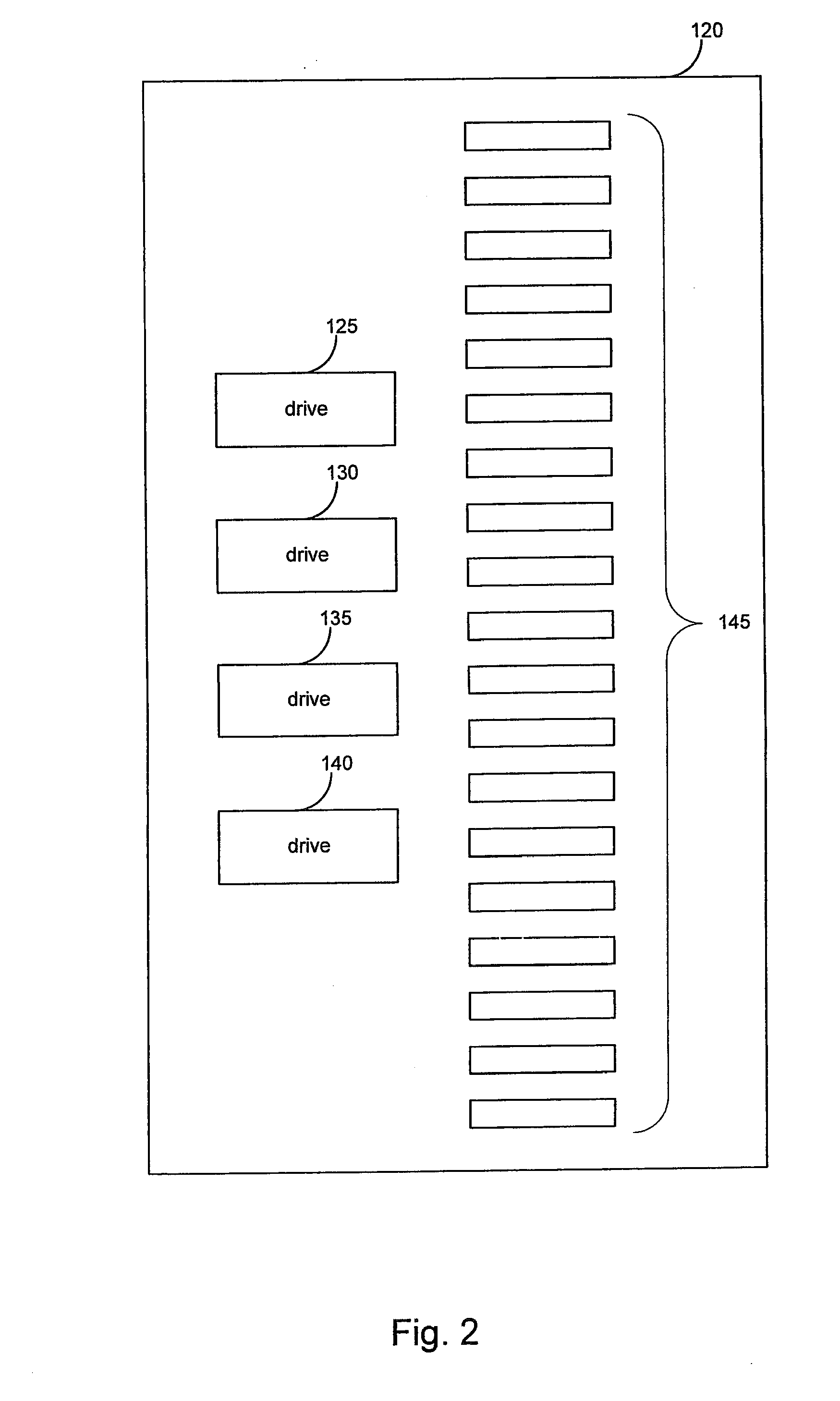

System and methods for granular resource management in a storage network

InactiveUS20080147878A1Improve performanceImprove system reliabilityDigital data information retrievalMultiple digital computer combinationsResource managementDatapath

In accordance with some aspects of the present invention, systems and methods are provided for dynamically and / or automatically selecting and / or modifying data path definitions that are used in performing storage operations on data. Alternate data paths may be specified or selected that use some or all resources that communicate with a particular destination to improve system reliability and performance. The system may also dynamically monitor and choose data path definitions to optimize system performance, conserve storage media and promote balanced load distribution.

Owner:KOTTOMTHARAYIL RAJIV +2

Systems and methods for granular resource management in a storage network

InactiveUS20070198722A1Improve performanceImprove reliabilityDigital computer detailsNetwork connectionsStorage area networkResource management

In accordance with some aspects of the present invention, systems and methods are provided for dynamically and / or automatically selecting and / or modifying data path definitions that are used in performing storage operations on data. Alternate data paths may be specified or selected that use some or all resources that communicate with a particular destination to improve system reliability and performance. The system may also dynamically monitor and choose data path definitions to optimize system performance, conserve storage media and promote balanced load distribution.

Owner:COMMVAULT SYST INC

Systems and methods for granular resource management in a storage network

InactiveUS8572330B2Improve performanceImprove reliabilityNetwork connectionsMemory systemsStorage area networkResource management

Owner:COMMVAULT SYST INC

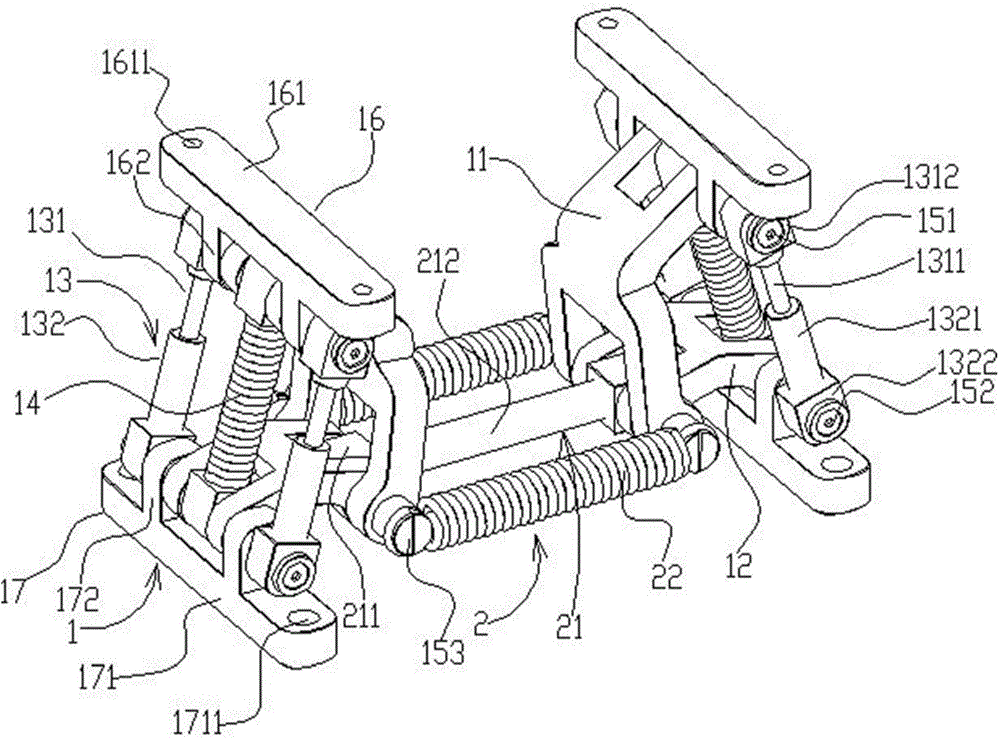

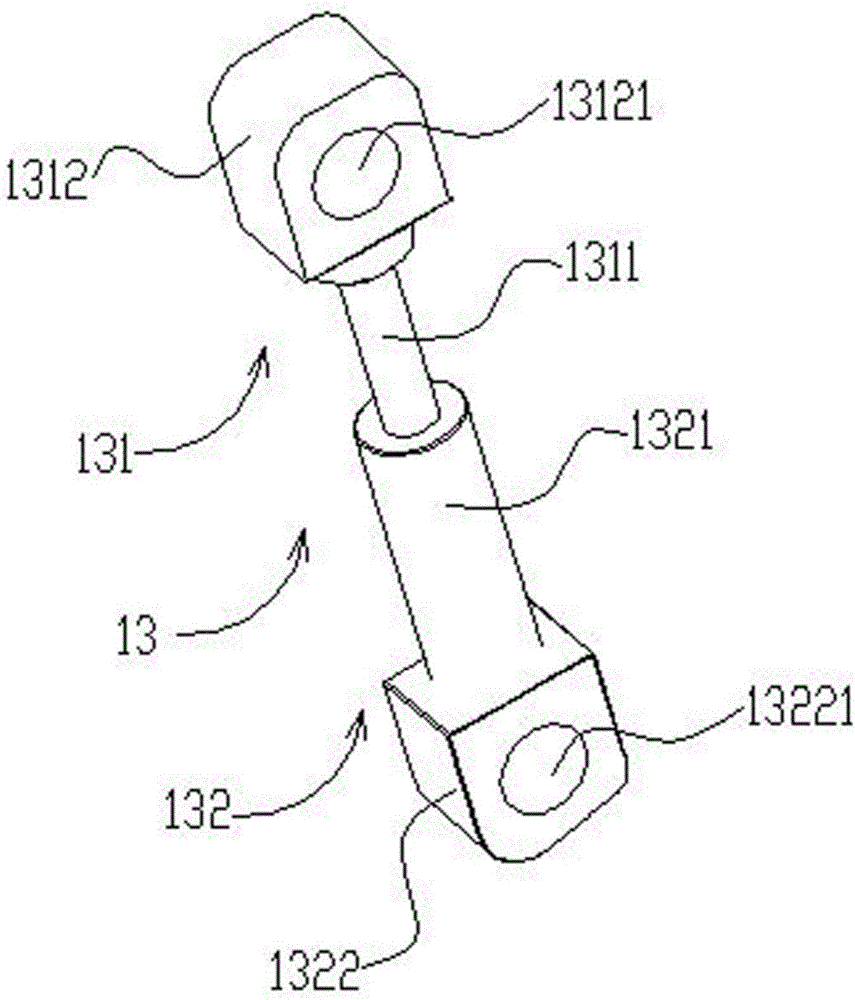

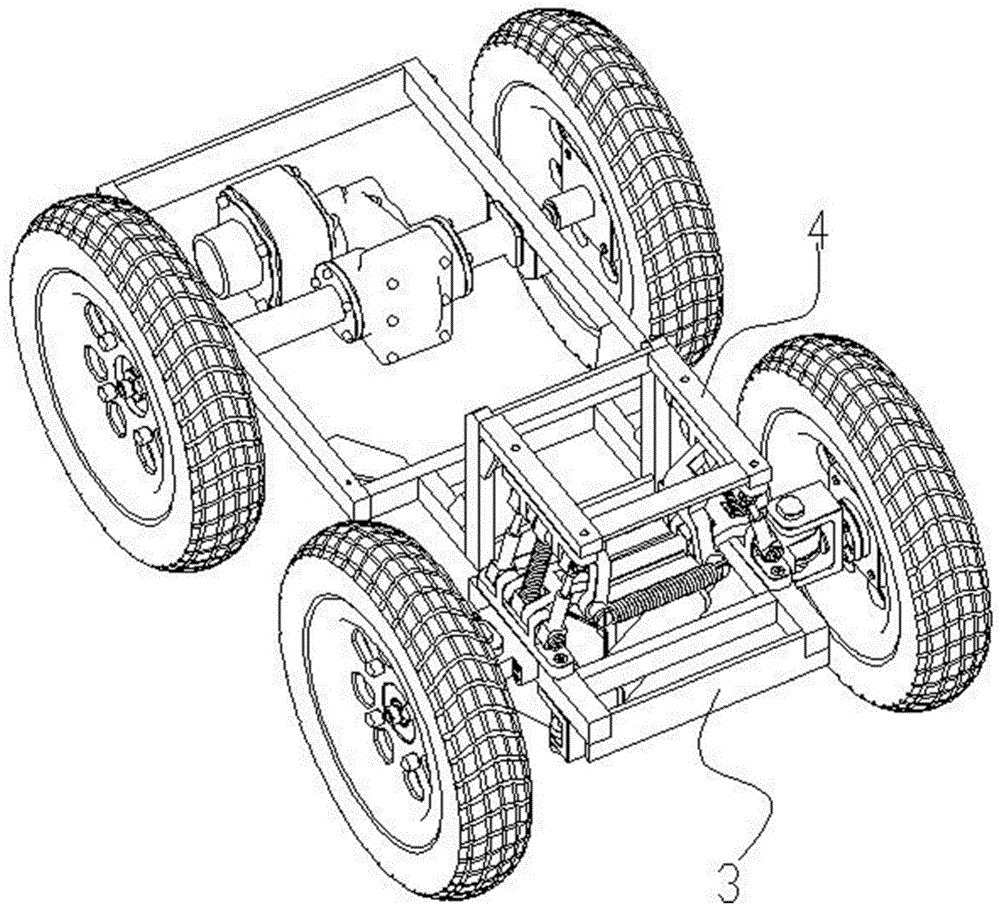

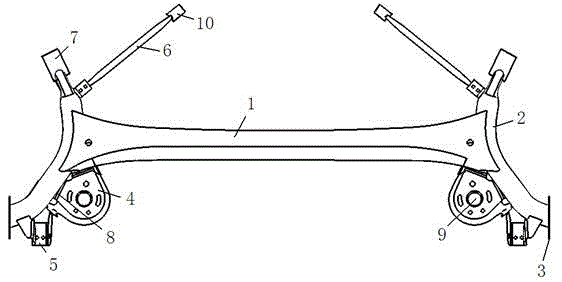

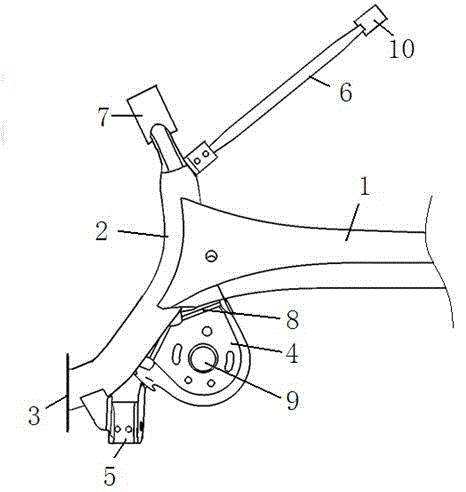

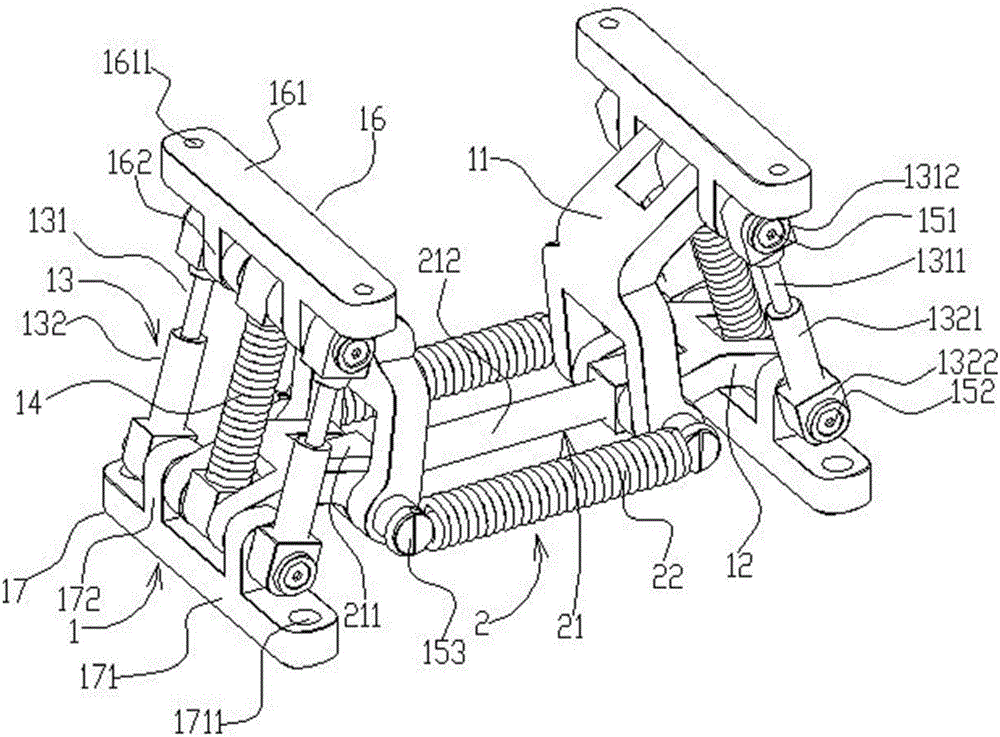

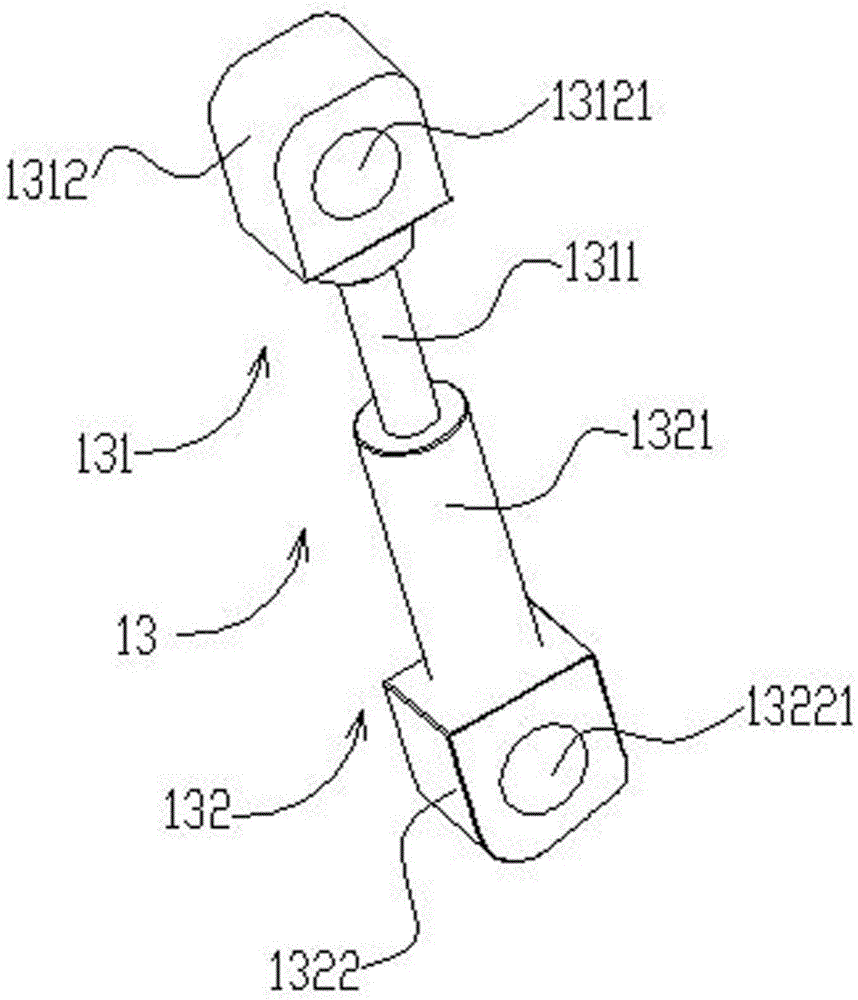

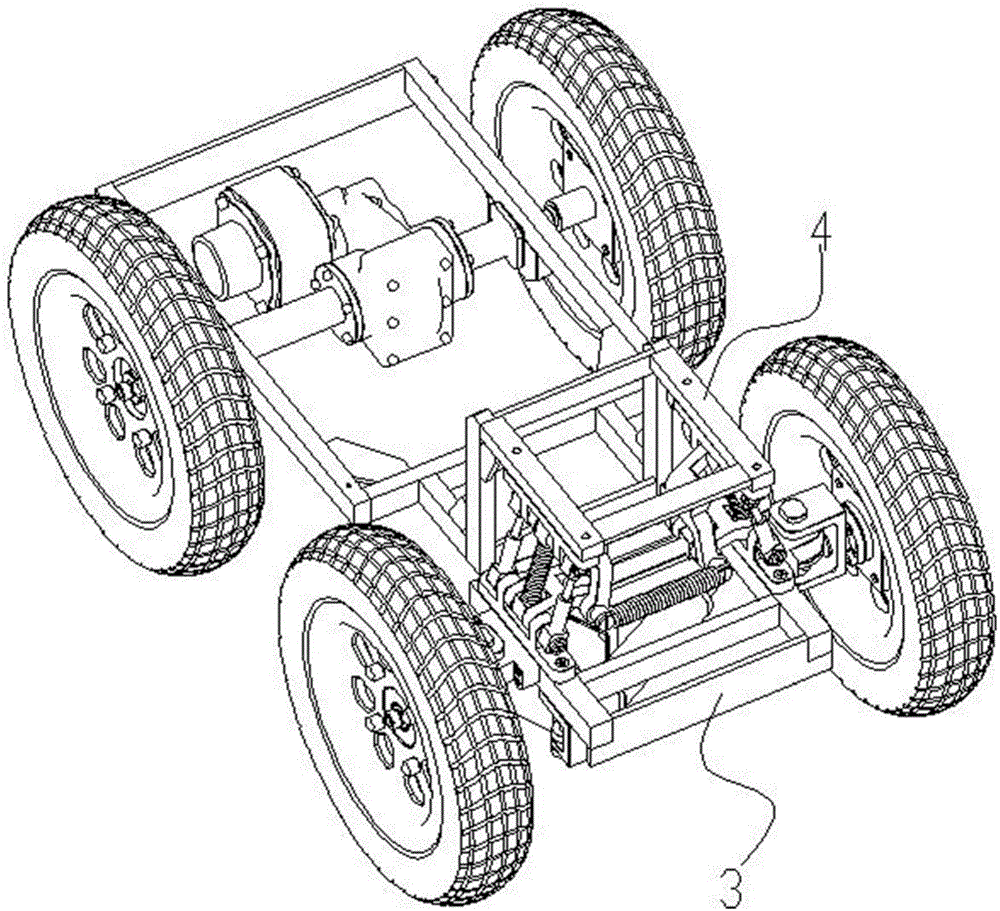

Suspension for chassis of four-wheel moving robot

ActiveCN104085266AImprove the installation effectEasy to installInterconnection systemsResilient suspensionsBody rollVehicle frame

The invention provides a suspension for a chassis of a four-wheel moving robot. The suspension comprises at least one pair of elastic supporting devices and a connecting assembly used for connecting the elastic supporting devices. Each elastic supporting device comprises an upper connecting rod, a lower connecting rod, a first stroke limiting structure and a compressing spring. The connecting assembly comprises a second stroke limiting structure and at least one extension spring. The suspension is installed between a frame and an axle of the four-wheel moving robot and used for transmitting force and torque acted between wheels and the frame. According to the suspension, a three-freedom-degree elastic parallel mechanism can reduce side-sway of a robot body running on the uneven road surface, centralization of impact force on the frame from the wheels in the jolting or shaking state is dispersed, reversing loads of the robot body are reduced, load distribution of the four wheels is improved, and the adhesion between the wheels and the ground and the riding comfort are improved.

Owner:SHENZHEN SMART SECURITY & SURVEILLANCE SERVICE ROBOT CO LTD

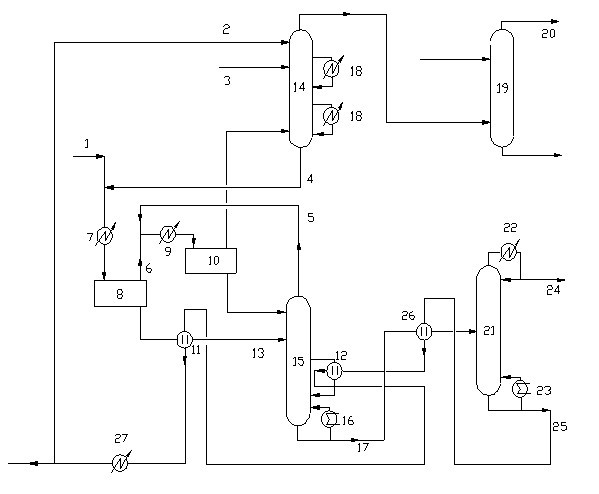

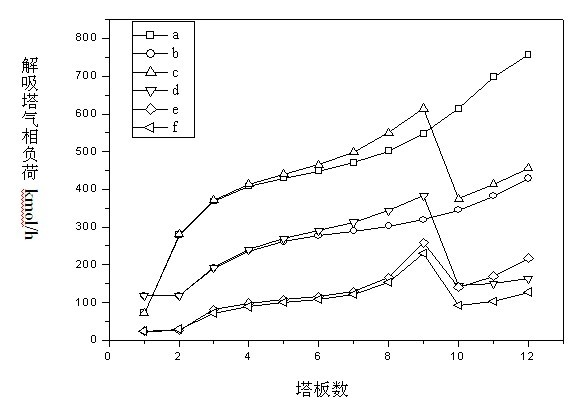

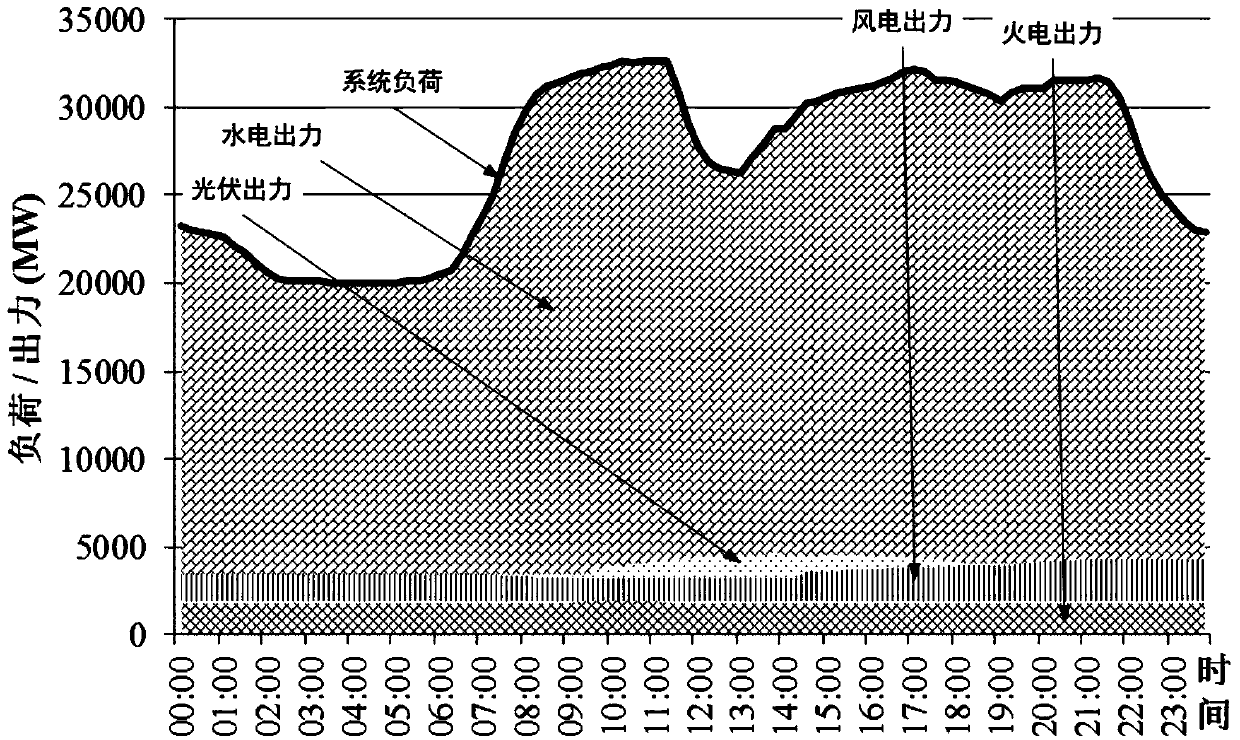

Reinforced mass transfer and efficient energy-saving type absorption stabilizing system

InactiveCN102021033AImprove mass transfer efficiencyReduce loadTreatment with hydrotreatment processesCondensation processThermodynamics

The invention provides a reinforced mass transfer and efficient energy-saving type absorption stabilizing system. The invention relates to absorption stabilizing system production technologies such as catalytic cracking, delay coking, hydrocracking and the like, in particular to a compound reinforced technology of secondary condensation and middle reboiler arrangement for the absorption stabilizing system. In the invention, a technology that adsorption tower bottom oil and compressed rich gas are mixed for primary condensation and the primarily condensed gas is mixed with desorption gas for secondary condensation is adopted, thereby avoiding the mix of the desorption gas with the adsorption tower bottom oil and the compressed rich gas, reducing primary condensation load and reinforcing the mass transfer of stepwise condensation processes while eliminating backmixing of a desorption tower. Primary condensation liquid is heated and then fed, and the middle reboiler is arranged in the desorption tower, so that the load of the reboiler in the desorption tower can be effectively reduced. Compared with a cold feeding technology, a hot feeding technology, a cold feeding-middle reboiler technology, a hot feeding-reboiler technology and secondary condensation-middle reboiler technology, energy consumption can be respectively reduced by 25-34%, 18-26%, 16-24%, 7-13% and 6-8% by using the reinforced compound technology in the invention. The novel technology has the advantages of reinforcing the mass transfer of the absorption stabilizing system, reducing the energy consumption of the system and relieving the load in the tower.

Owner:SUN YAT SEN UNIV

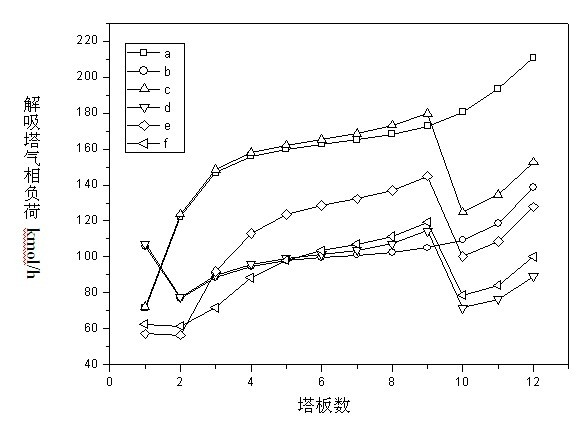

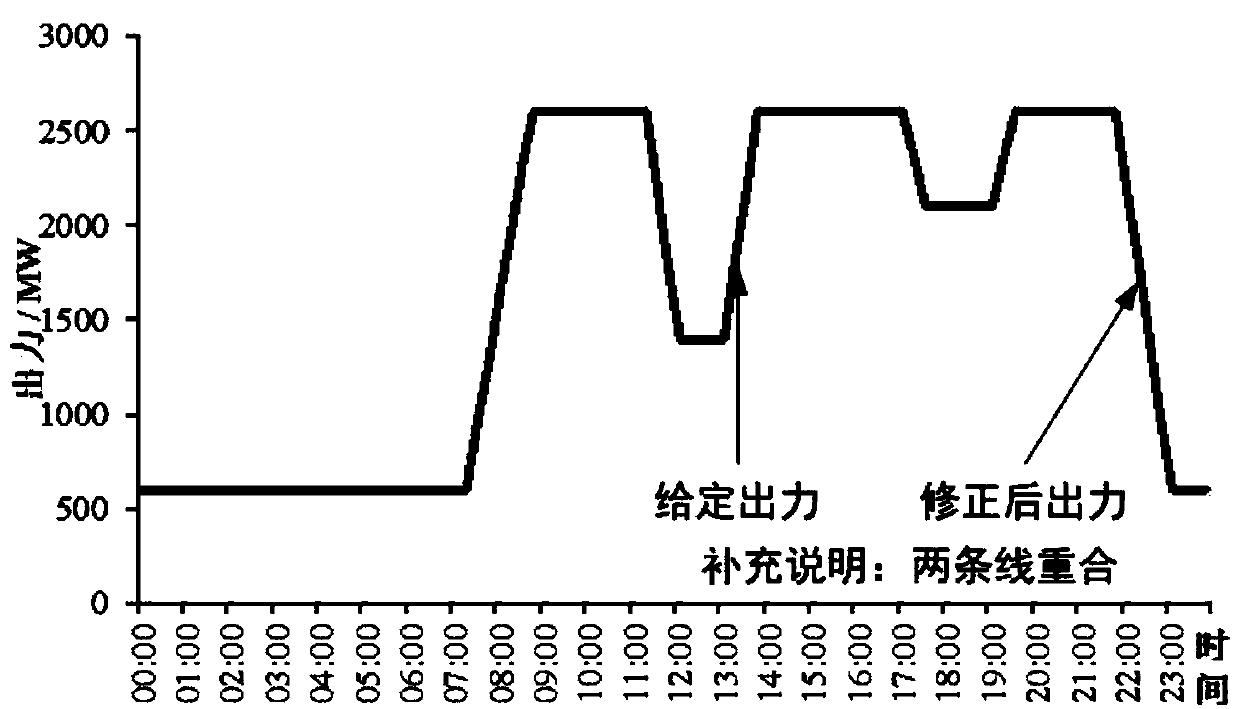

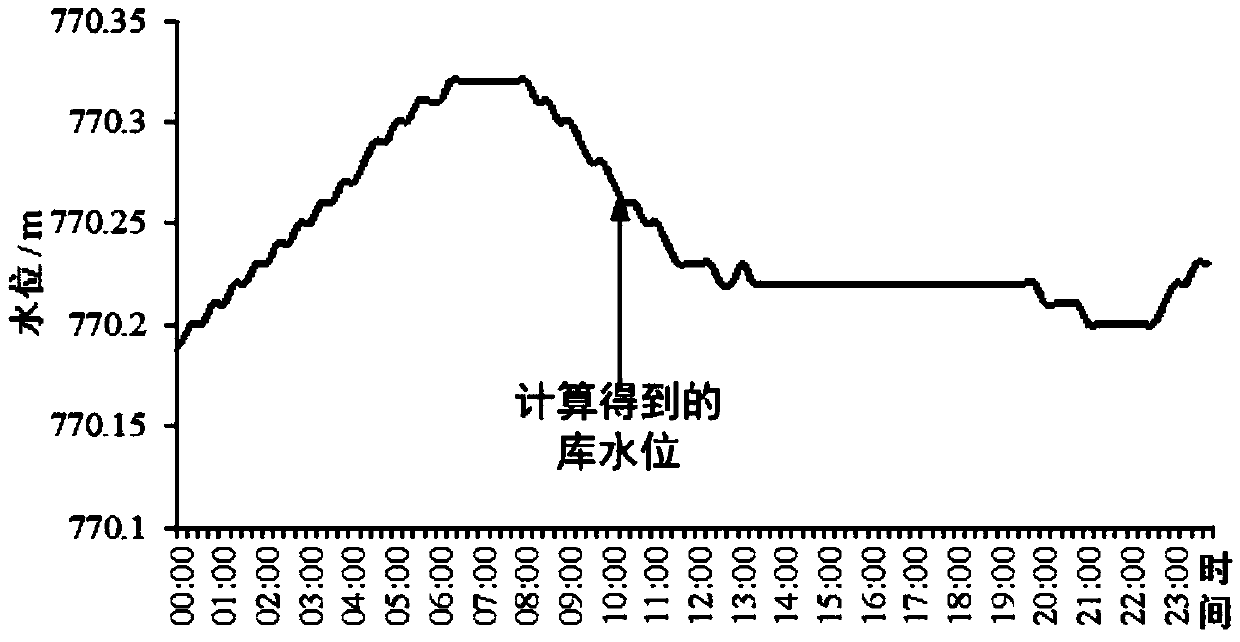

Super-large scale hydropower station group short period practical scheduling method

ActiveCN108320111AImprove load distributionReasonable hydropower scheduling resultsResourcesSystems intergating technologiesPower stationPower grid

The invention belongs to the water power scheduling operation field, and relates to a super-large scale hydropower station group short period practical scheduling method; the method divides all hydropower stations into three types according to scheduling characteristics including system hierarchy, space attributes, task requirements and plan particularity, and proposes an abandoned water correction strategy based on pitch peak response and a valley period load balancing reduction strategy, thus realizing checking analysis and output adjustment of power stations of a fixed scheduling mode; forcascade hydropower stations of middle and small rivers, the method takes the total output process as control conditions, uses the minimum total power consumption as an object, thus optimizing load distribution among the cascade hydropower stations; for large scale river cascade hydropower stations, the method builds a pitch peak scheduling model, proposes a balance power station equal load factorscheduling method, thus realizing system pitch peak response and all time load balance. The method can fast provide a reasonable water power scheduling result, thus satisfying power grid real operation timeliness and practicality requirements, and providing a new technical path for effectively solving super-large scale hydropower system scheduling problems.

Owner:DALIAN UNIV OF TECH

Systems and Methods for Granular Resource Management in a Storage Network

InactiveUS20110004683A1Improve performanceImprove reliabilityDigital data information retrievalMultiple digital computer combinationsStorage area networkResource management

In accordance with some aspects of the present invention, systems and methods are provided for dynamically and / or automatically selecting and / or modifying data path definitions that are used in performing storage operations on data. Alternate data paths may be specified or selected that use some or all resources that communicate with a particular destination to improve system reliability and performance. The system may also dynamically monitor and choose data path definitions to optimize system performance, conserve storage media and promote balanced load distribution.

Owner:KOTTOMTHARAYIL RAJIV +2

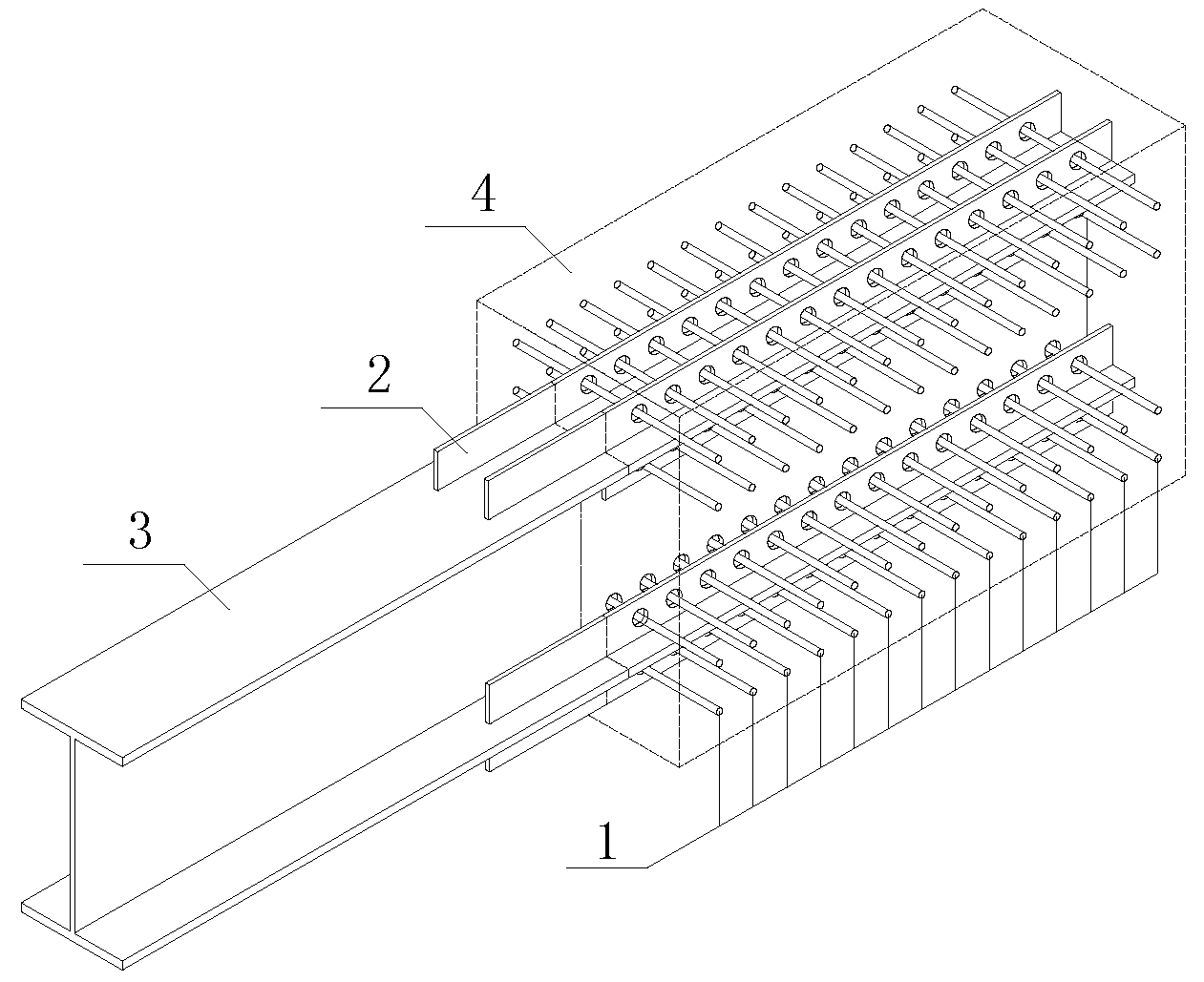

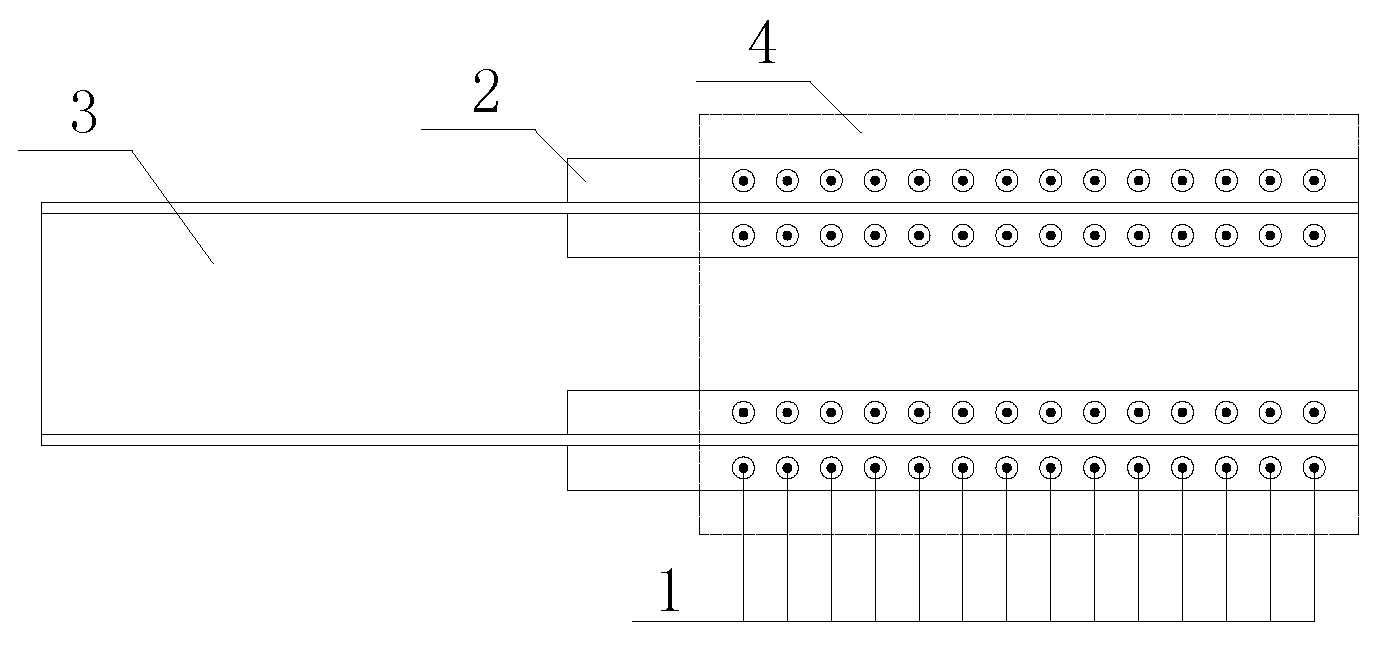

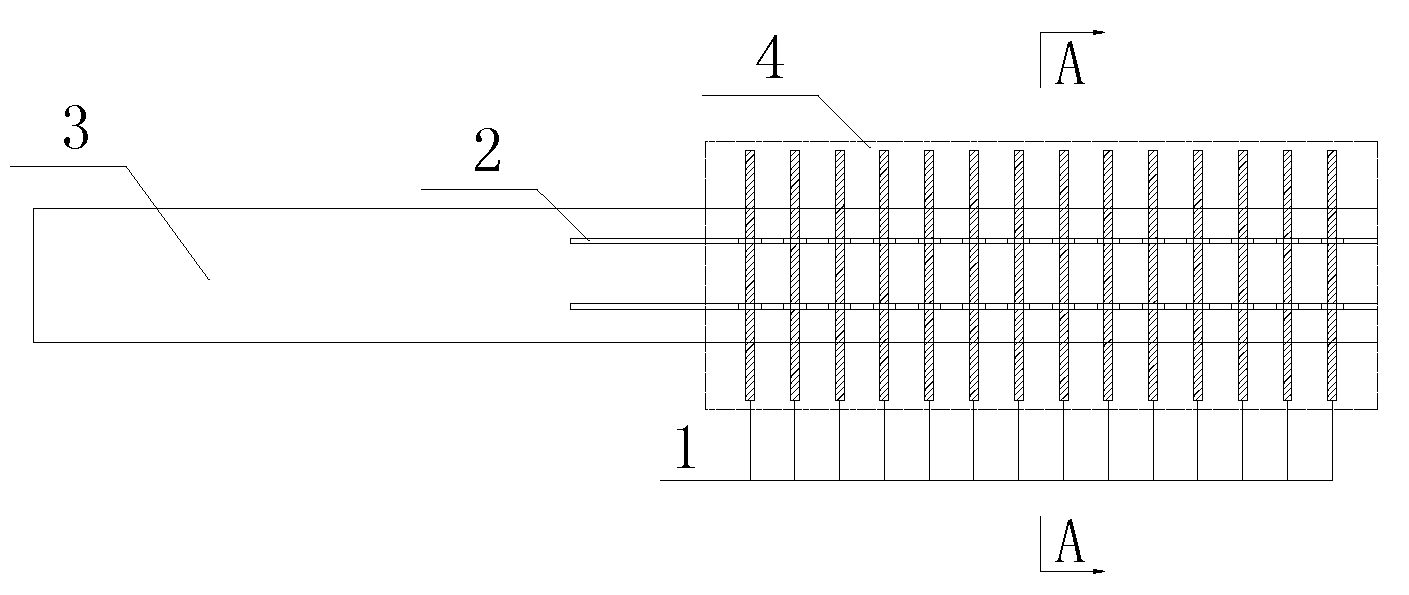

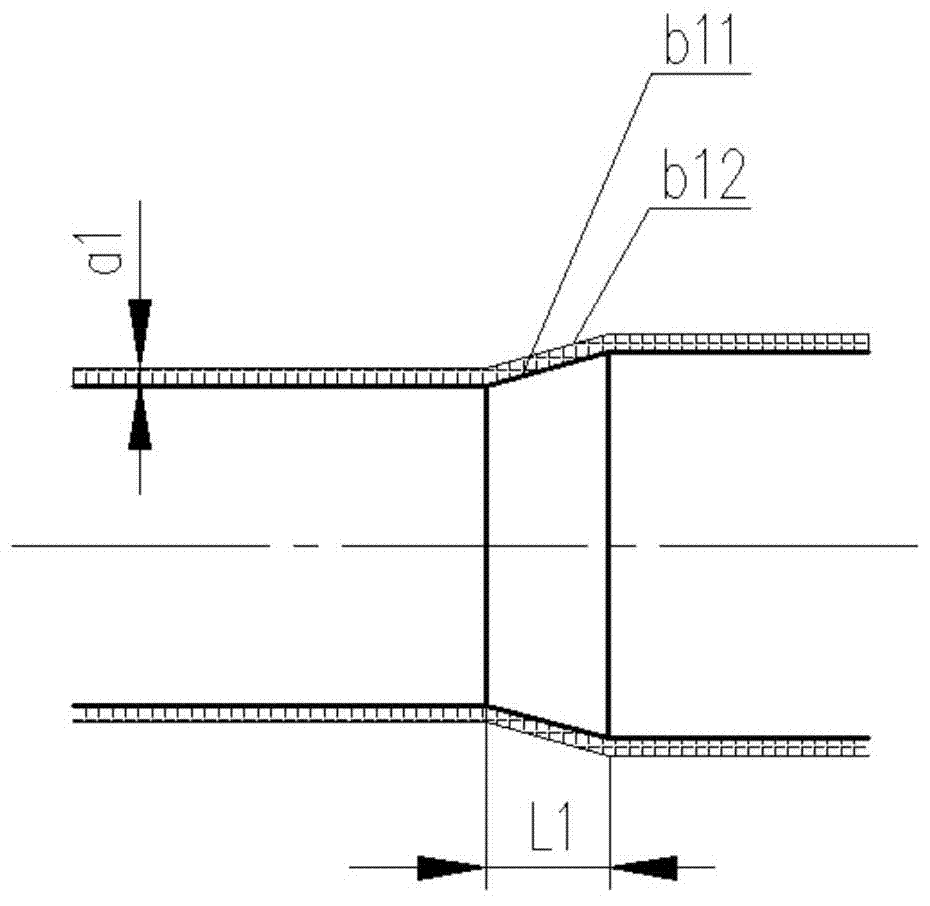

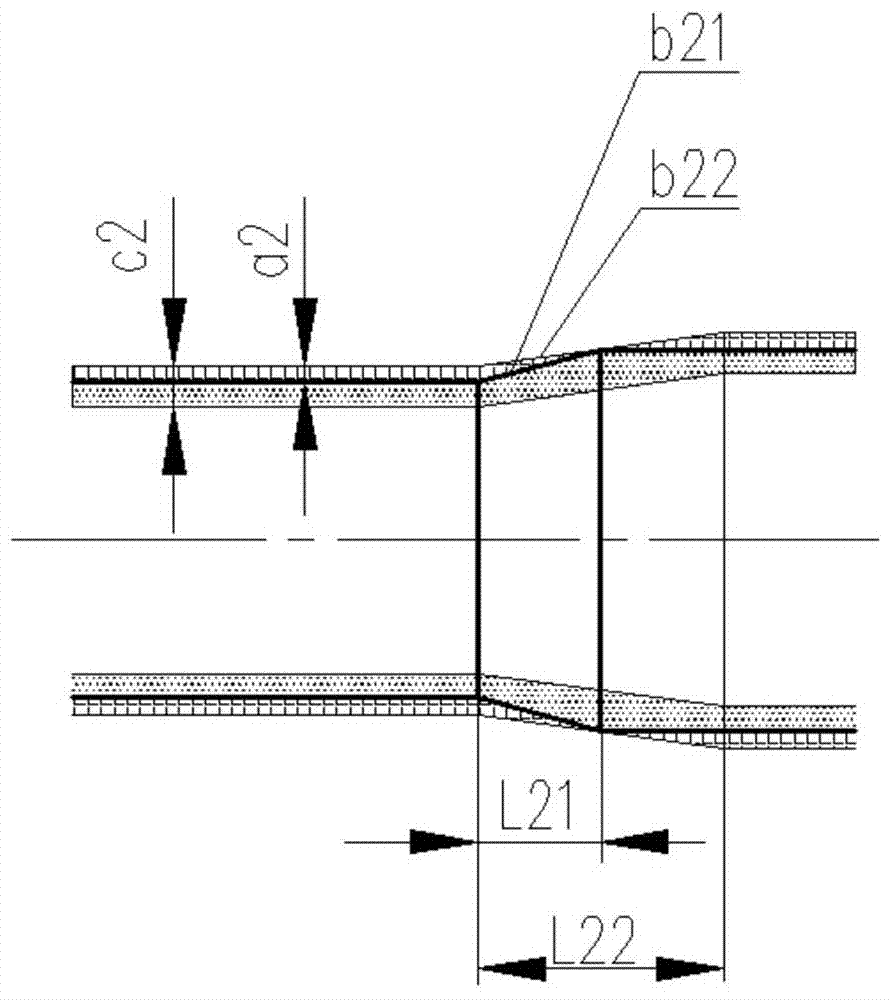

Continuous variable-stiffness shear key type steel-concrete joint section

InactiveCN103061418AImprove load distributionImprove stress distributionLoad-supporting elementsBridge structural detailsSteel platesRebar

The invention belongs to the technical field of civil engineering and particularly relates to a steel-concrete joint section used for steel-concrete composite structures. The continuous variable-stiffness shear key type steel-concrete joint section comprises a steel beam, a concrete beam, perforated steel plates and through reinforcing steel bars with ribs, the perforated steel plates are welded on the surfaces of the flanges of the steel beam, round holes corresponding to the perforated steel plates are arranged on a web plate, the through reinforcing steel bars with the ribs penetrate through the round hole centers on the perforated steel plates and the web plate of the steel beam, and the concrete beam is poured on the periphery of the steel beam and wraps the perforated steel plates and the through reinforcing steel bars with the ribs. The load distribution state of shear keys in the steel-concrete joint section and the stress distribution state of the steel-concrete joint section are improved, security coefficient of the steel-concrete joint section can be increased, and the steel-concrete joint section is convenient to construct and high in construction efficiency and does not need complex construction equipment.

Owner:SOUTHWEST JIAOTONG UNIV

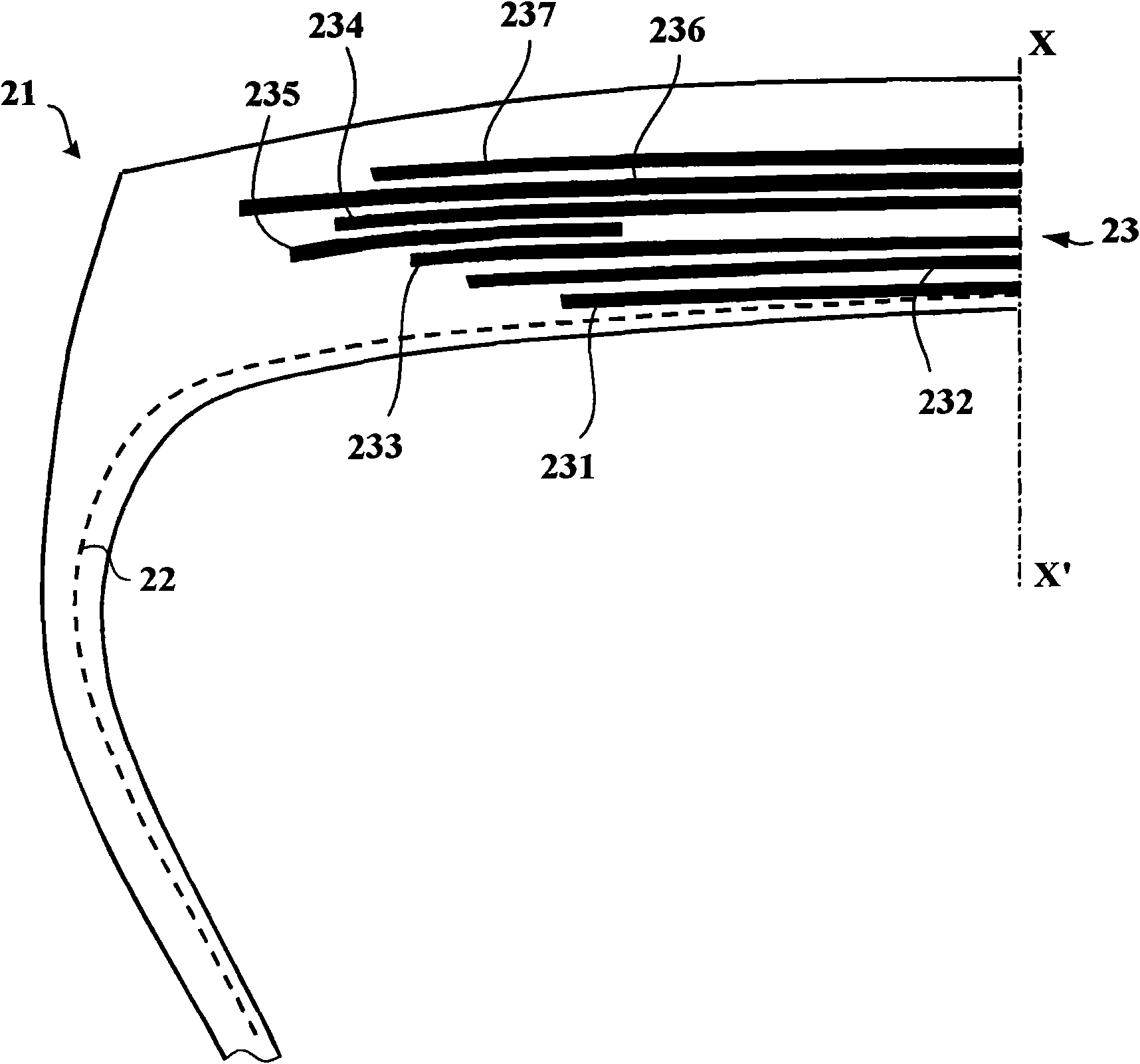

Reinforced bearing for a wind-power generator blade

ActiveCN101617120AImprove load distributionRolling contact bearingsWind motor controlWind forceElectric generator

Owner:GAMESA INNOVATION & TECH SA

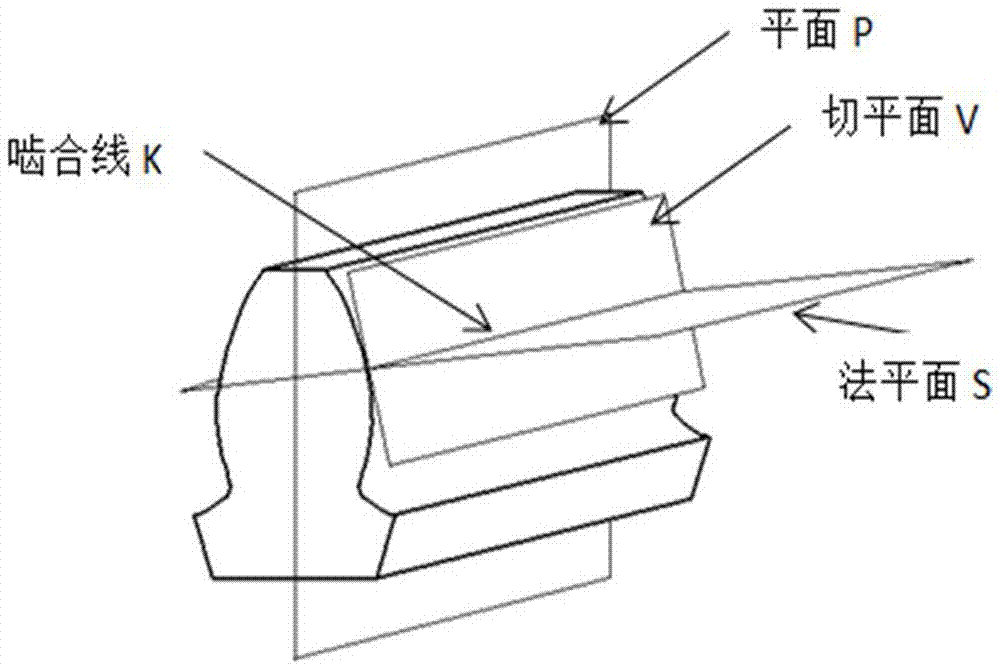

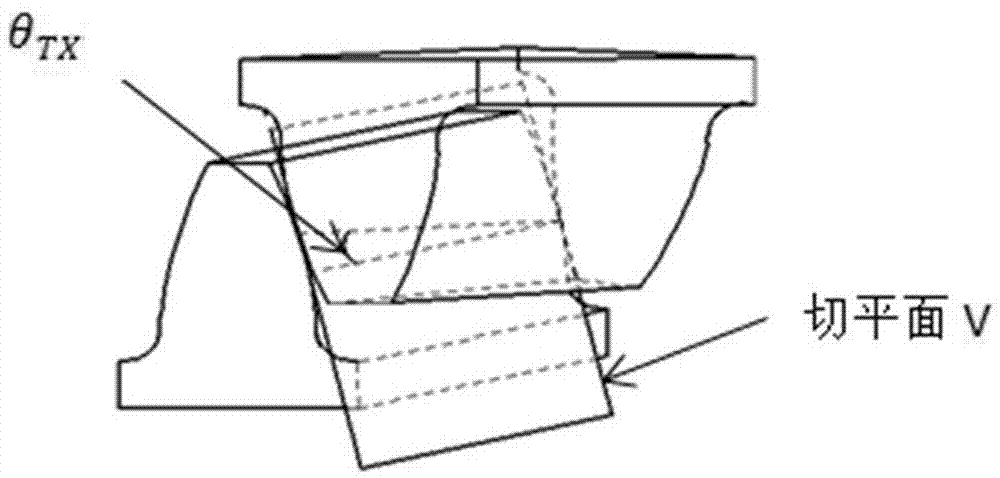

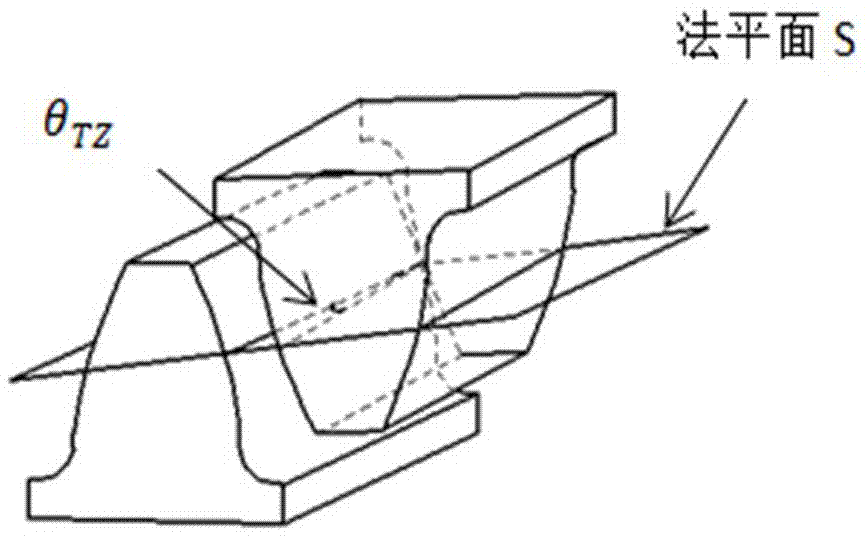

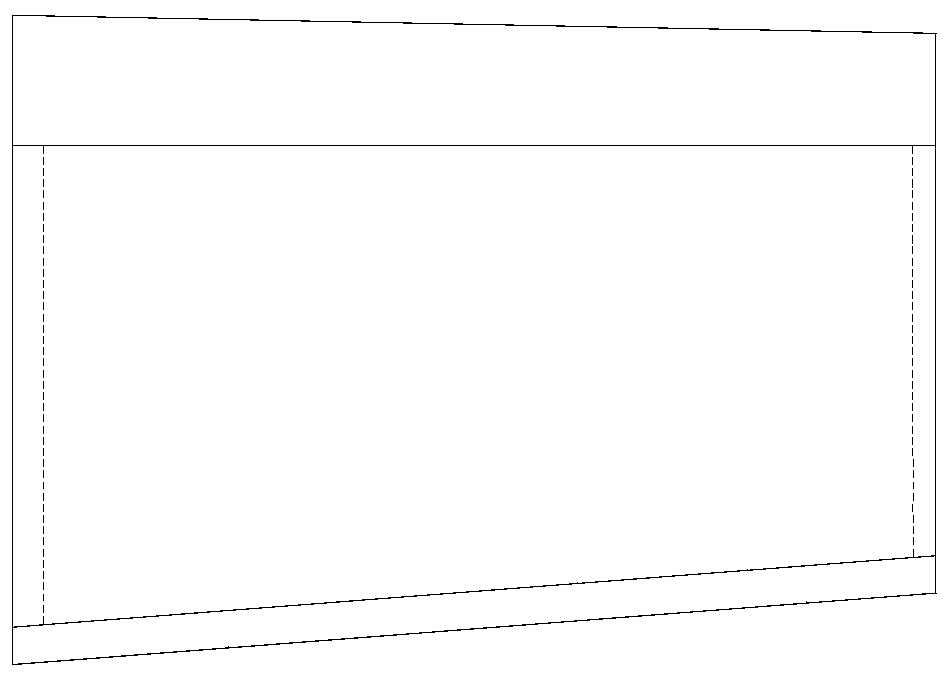

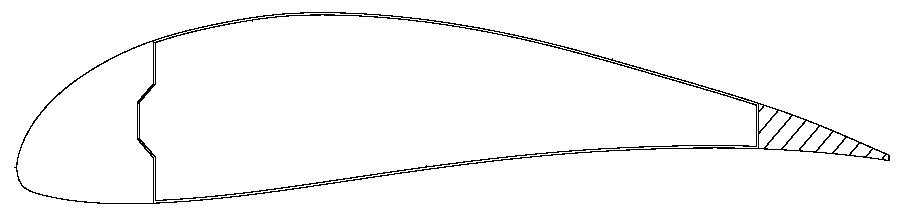

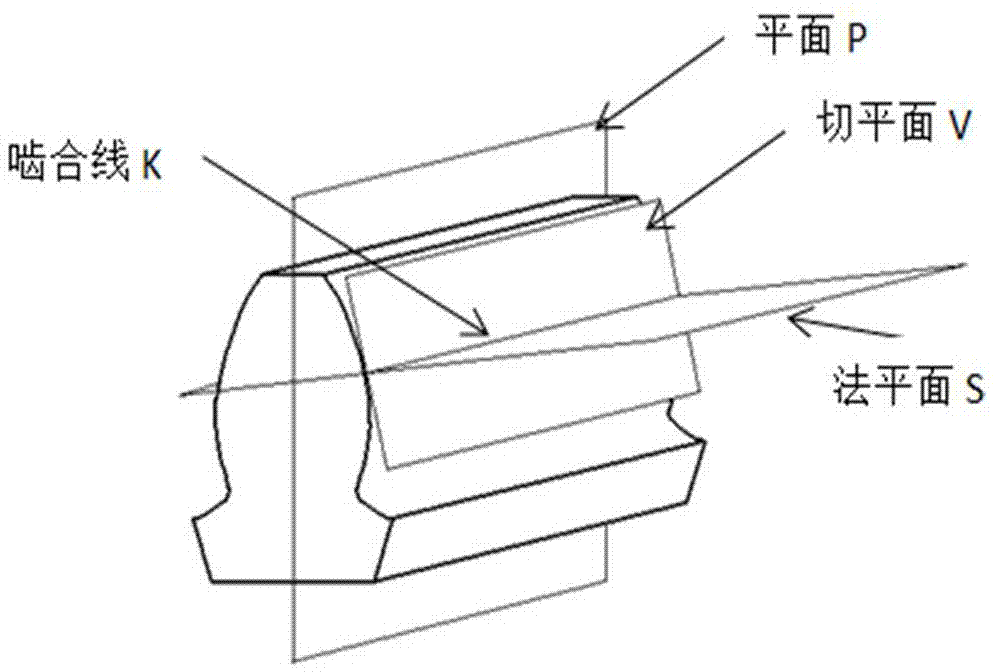

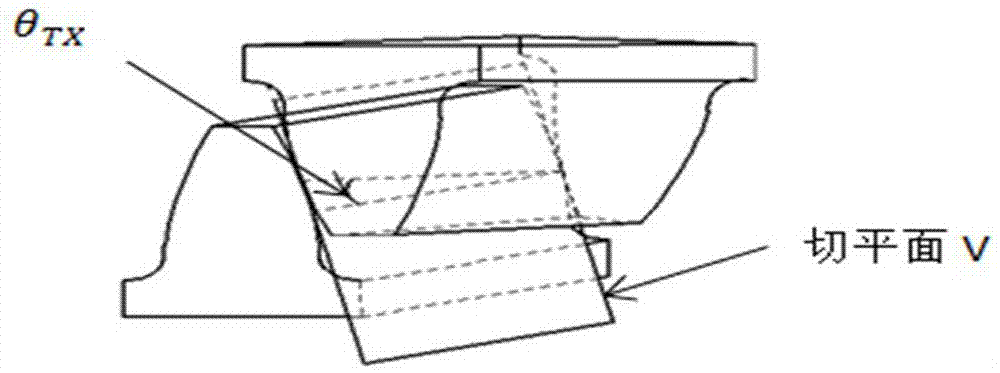

Spur gear profile modification method based on thermal elastic deformation of gear teeth and deflection deformation of gear

ActiveCN107025367AHigh shape accuracyExtended service lifeGeometric CADPortable liftingCouplingEngineering

The invention discloses a spur gear profile modification method based on thermal elastic deformation of gear teeth and deflection deformation of a gear. The spur gear profile modification method comprises the following steps: 1, establishing a three-dimensional model of a gear based on UG; 2, introducing the gear three-dimensional model into finite element software, and analyzing thermal elastic coupling deformation of the gear under a working condition; 3, establishing an overall three-dimensional model of a gearbox based on UG; 4, introducing the three-dimensional model of the gearbox into the finite element software, and analyzing stress deformation of the gearbox under a working condition; 5, analyzing deformation of a tooth surface in different directions because of comprehensive deformation of the gearbox, and analyzing deformation characteristics; 6, taking influence characteristics of the thermal elastic deformation and deflection deformation inside different planes of the gear to tooth surface stress into profile modification; and 7, taking the thermal elastic deformation and the deflection deformation of the tooth surface inside a tangent plane into account, acquiring a profile modification curved surface equation, and performing profile modification. By adopting the method, the modification precision of a spur gear working under a high-speed heavy load working condition is improved, the uniform distribution situation of a tooth surface load is effectively improved, and the service life of the gear is prolonged.

Owner:SHANXI PINGYAO REDUCER

Technology forming method of small and medium-sized unmanned aerial vehicle composite material outer wing

ActiveCN110193955AImprove shock absorptionImprove resistance to damageInternal combustion piston enginesSilicon rubberFront edge

The invention relates to a technology forming method of a small and medium-sized unmanned aerial vehicle composite material outer wing. The method comprises the following steps of forming mold manufacturing, front edge silicon rubber core mold manufacturing, film bag body manufacturing, outer wing front edge manufacturing, and outer wing main body manufacturing; after surface treatment is correspondingly carried out on bonding areas corresponding to the outer wing front edge and a main body front beam surface, and structure double-sided adhesive tapes with the same shape as that of the bondingareas are tore to remove isolation paper on one sides, the adhesive surfaces are adhered to the bonding areas of the outer wing front edge, then solating films on the other sides of the structural adhesive tapes are tore, and the outer wing front edge is horizontally embedded into a boss of the corresponding position of the outer wing main body through a positioning groove at the left end of theouter wing front edge so as to obtain a composite material integral structure outer wing product. According to the technology forming method, the problem of limitation of multiple curing forming, andthe uniformity of the product quality and the thickness are improved.

Owner:XIAN AISHENG TECH GRP +1

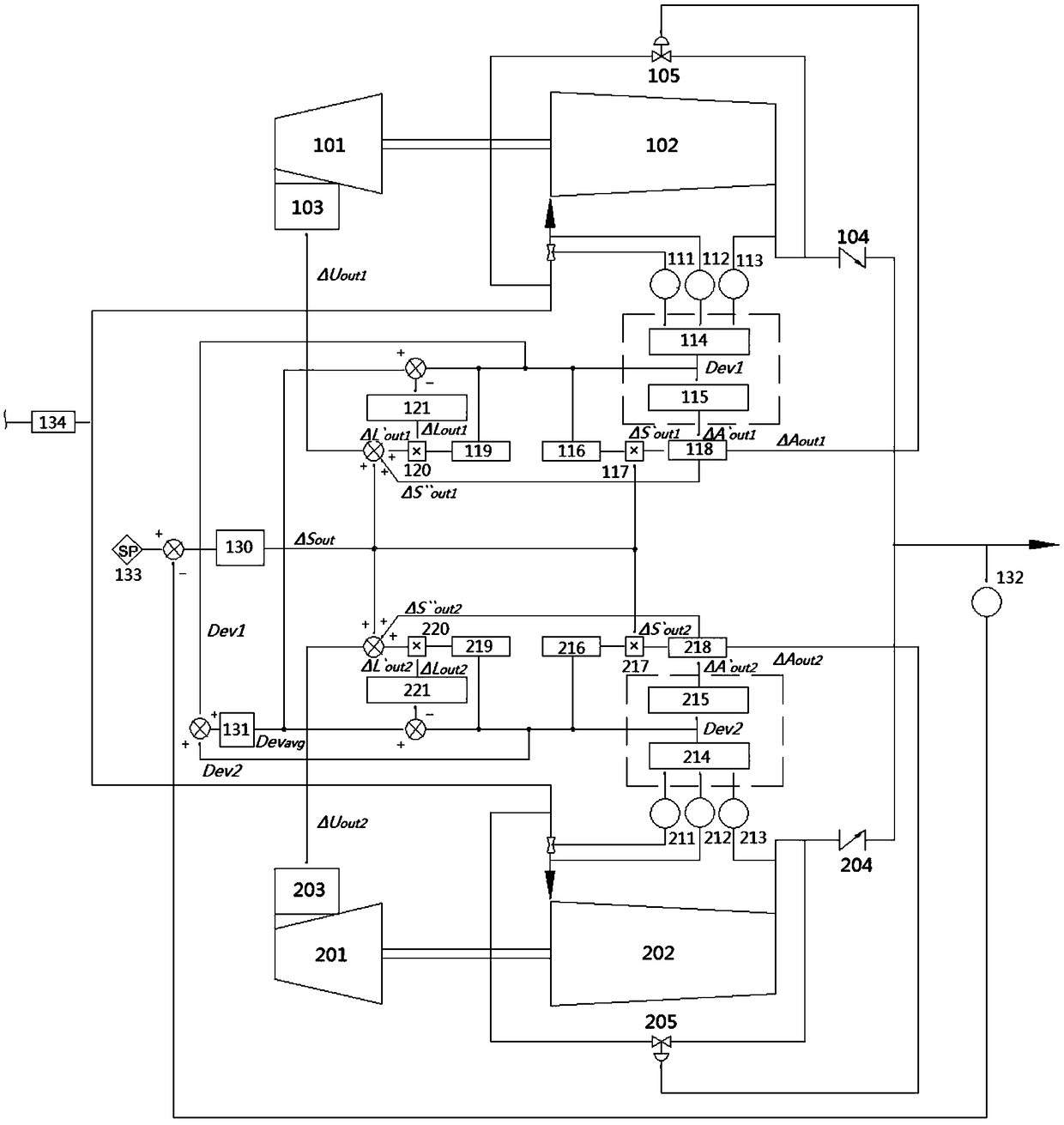

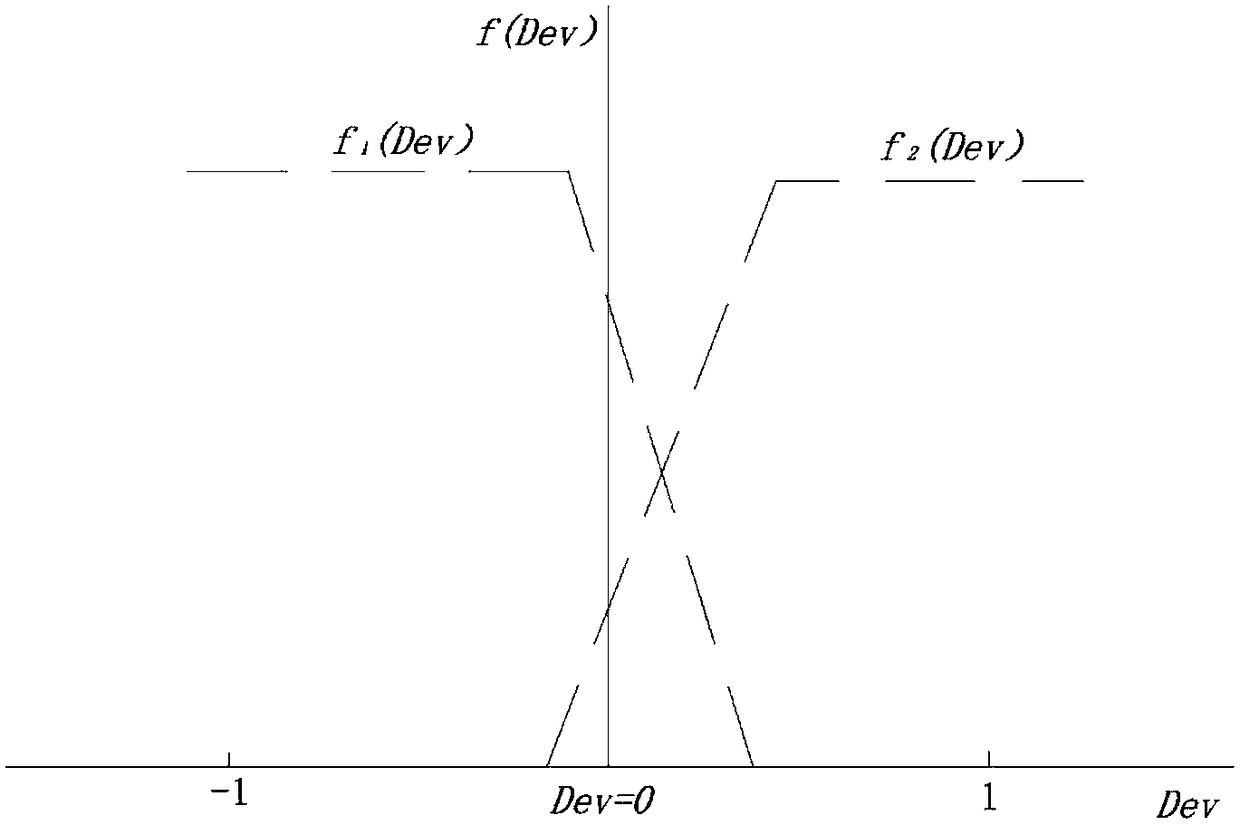

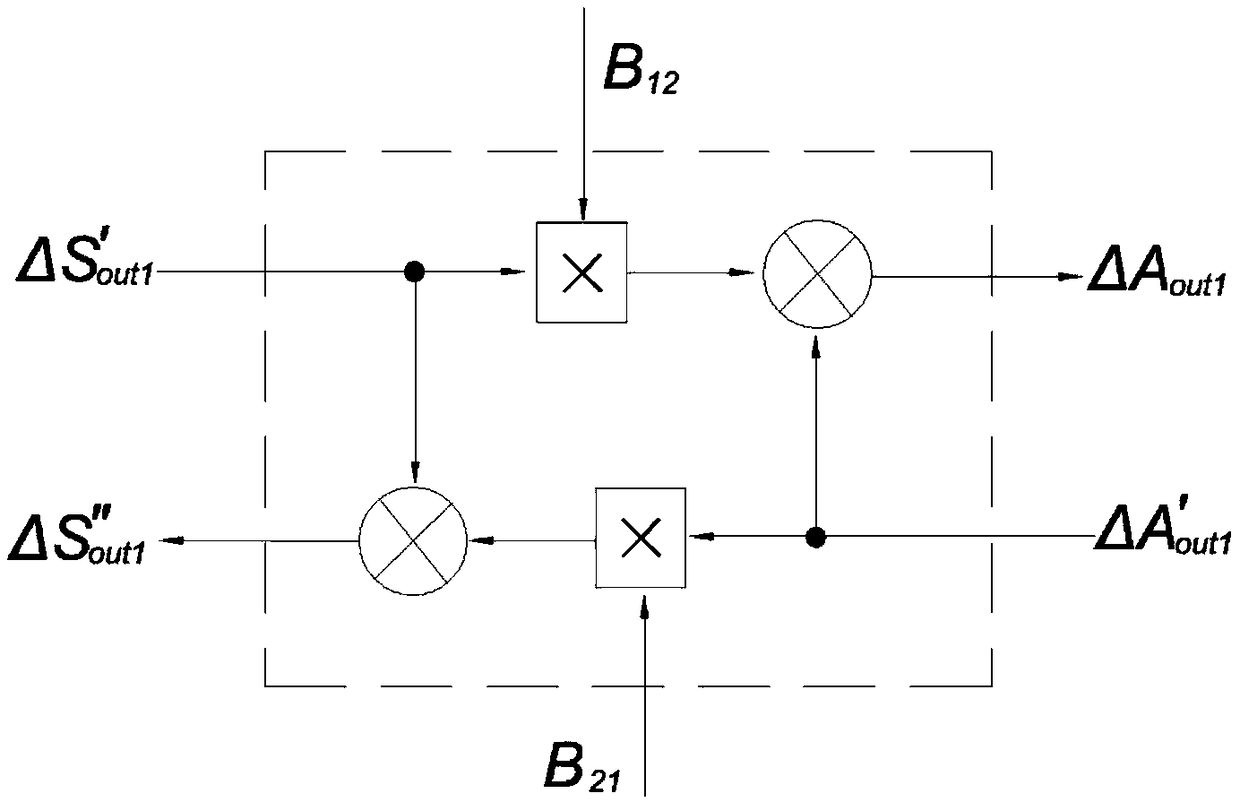

Control method and control system for turbine compressors operated in parallel

ActiveCN108708872AProtect safe operationMaximize operating efficiencyPump controlNon-positive displacement fluid enginesControl systemLoad distribution

The invention discloses a control method and a control system for turbine compressors operated in parallel. The system comprises a load balance control part, a performance control part and an anti-surge control part. The method comprises the steps that the surge control deviation is calculated, according to the surge control deviation of all the units in a compression station and the average surgecontrol deviation, automatic load distribution of the units is achieved, the performance control and the load balance control are adopted and combined to control the rotating speed of turbines and the main performance parameters of the units, and the coupling relation between the performance control and the anti-surge control is eliminated. According to the method and the system, through the combined coordination control, the load distribution of the compression station units operated in parallel is optimized, the safety operation of the units is better protected, and the operation efficiencyof the units is maximized.

Owner:XI AN JIAOTONG UNIV +1

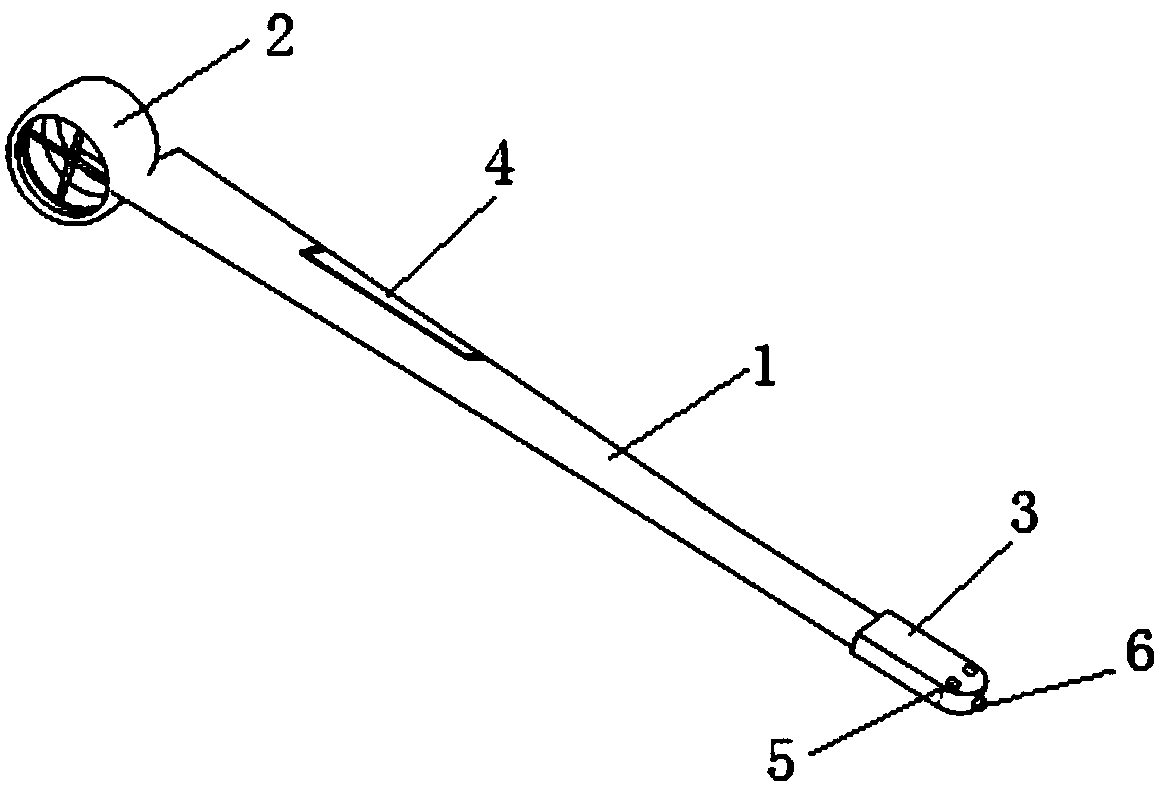

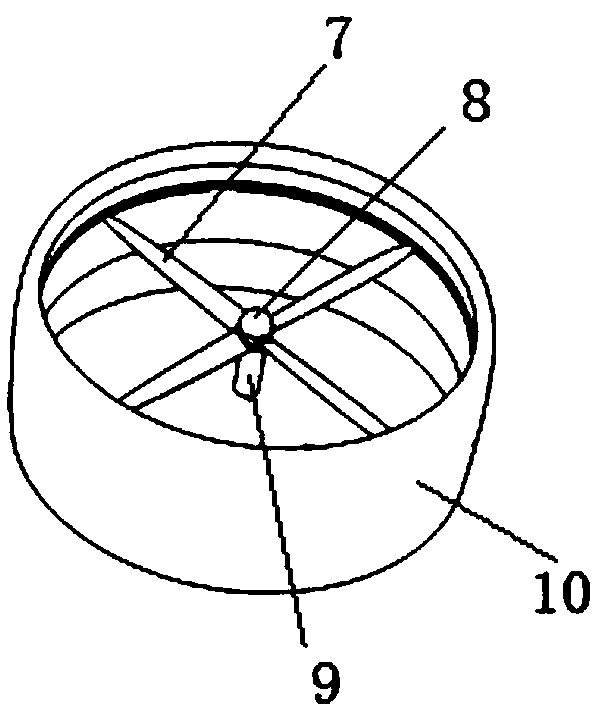

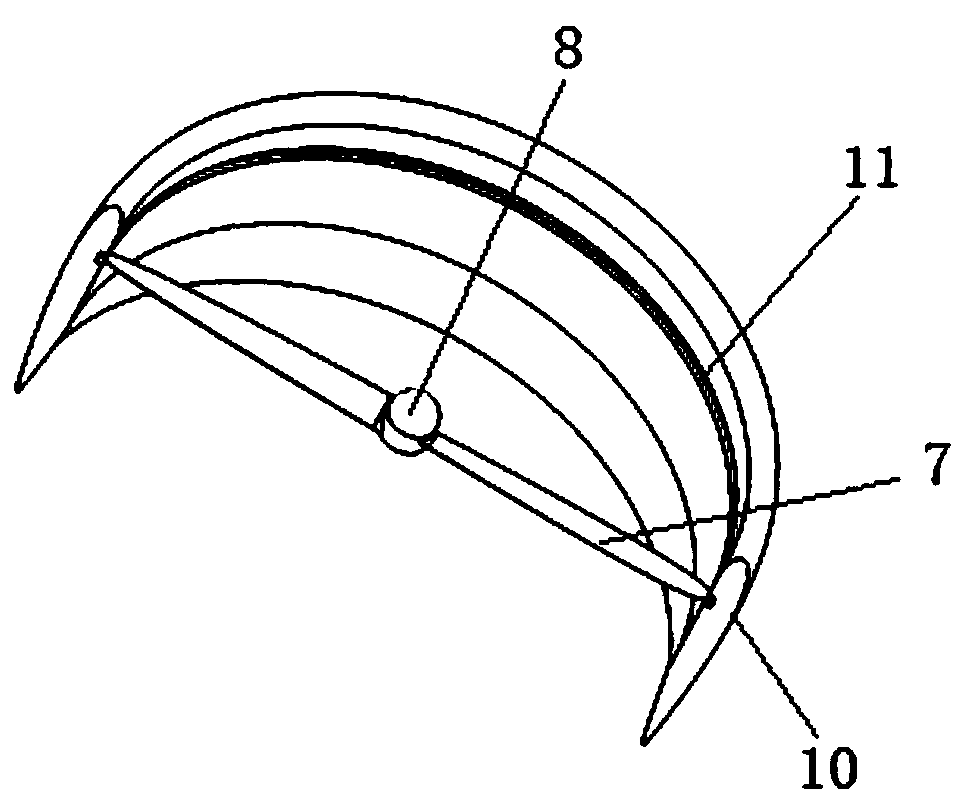

Novel embedded ducted propeller driven blade

PendingCN109334952AImprove weighing efficiencyReduce complexityPropellersRotary wingDucted propeller

The invention discloses a novel embedded ducted propeller driven blade which comprises a blade part, an embedded ducted propeller and a blade root connector, wherein the embedded ducted propeller is arranged at a blade tip of the blade part; the blade root connector is arranged at a blade root of the blade part; the blade root connector is connected with a main rotor shaft; the embedded ducted propeller comprises vanes, a fairing, a hub and an embedded duct; the hub is arranged in the center of the embedded duct; the fairing is arranged at the top end of the hub; the vanes are distributed in an annular space formed by the embedded duct and the hub; one end of each vane is connected with the hub; the other ends of the vanes are slidingly connected with a slide rail circumferentially arranged on an inner wall of the embedded duct; the hub is internally provided with a driving device; and the vanes are driven by the driving device to rotate. According to the novel embedded ducted propeller driven blade, a complicated and cumbersome mechanical transmission system and a reactive torque system can be cancelled; the weight efficiency of a helicopter is improved; the rotor performance is improved at the same time; and vibration and noise are inhibited.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

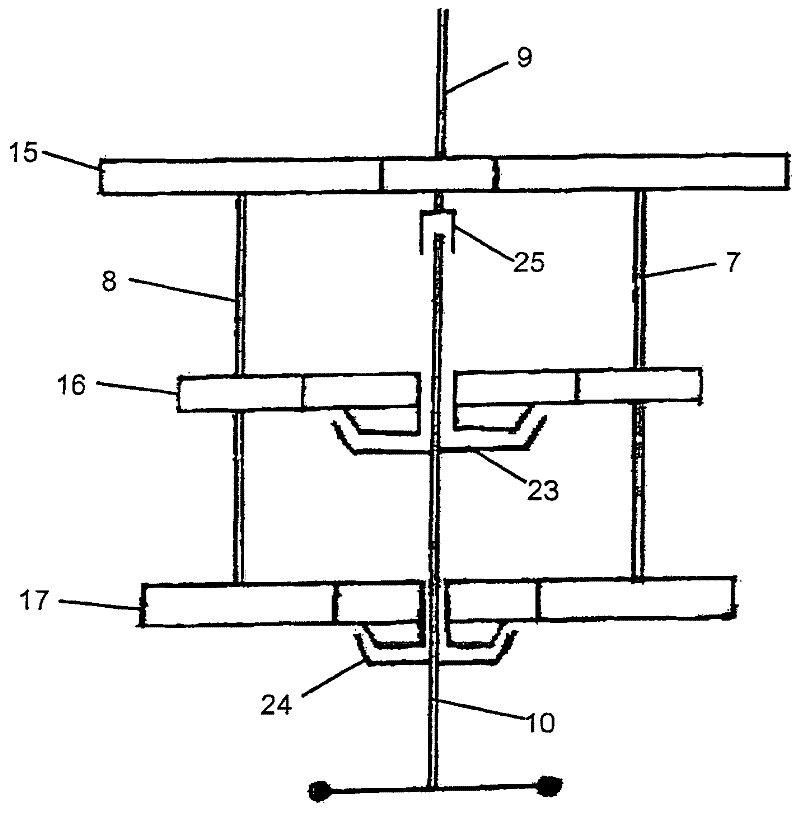

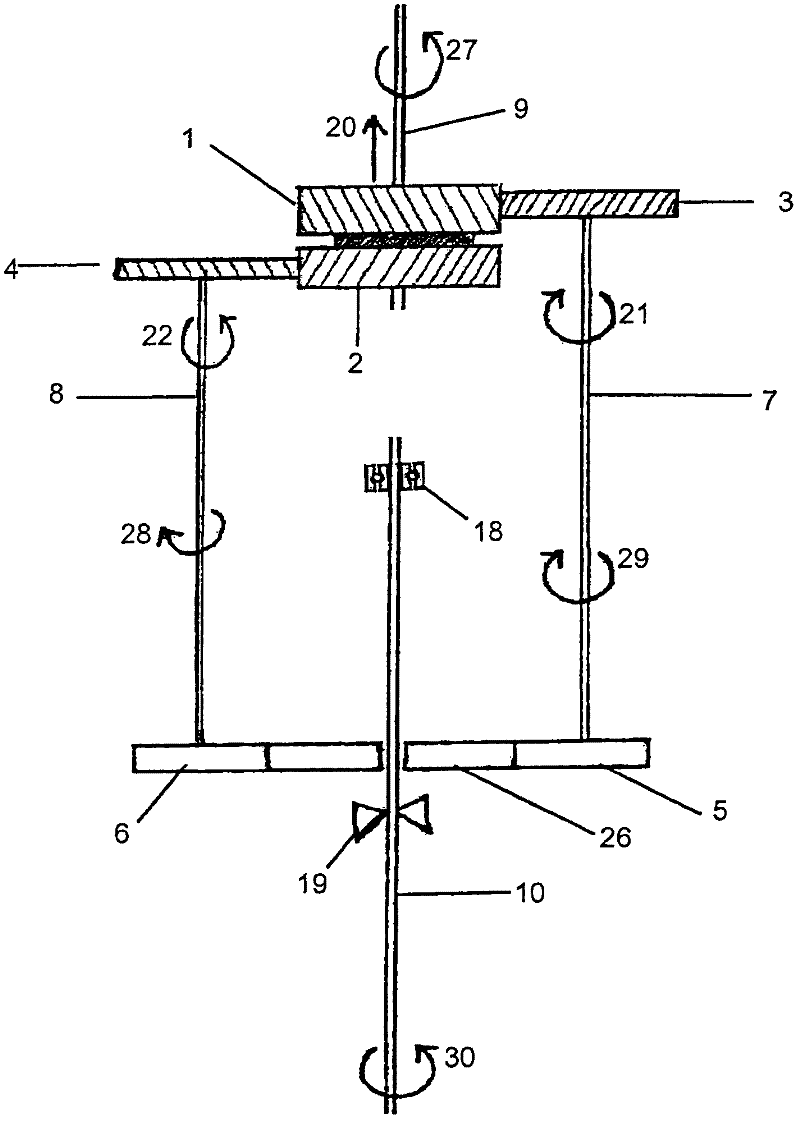

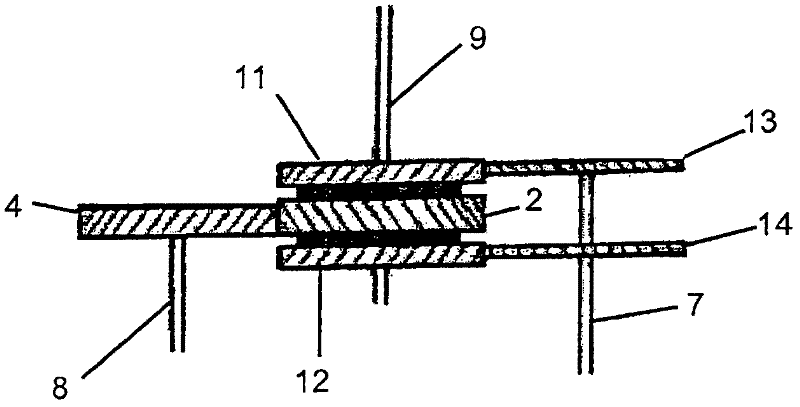

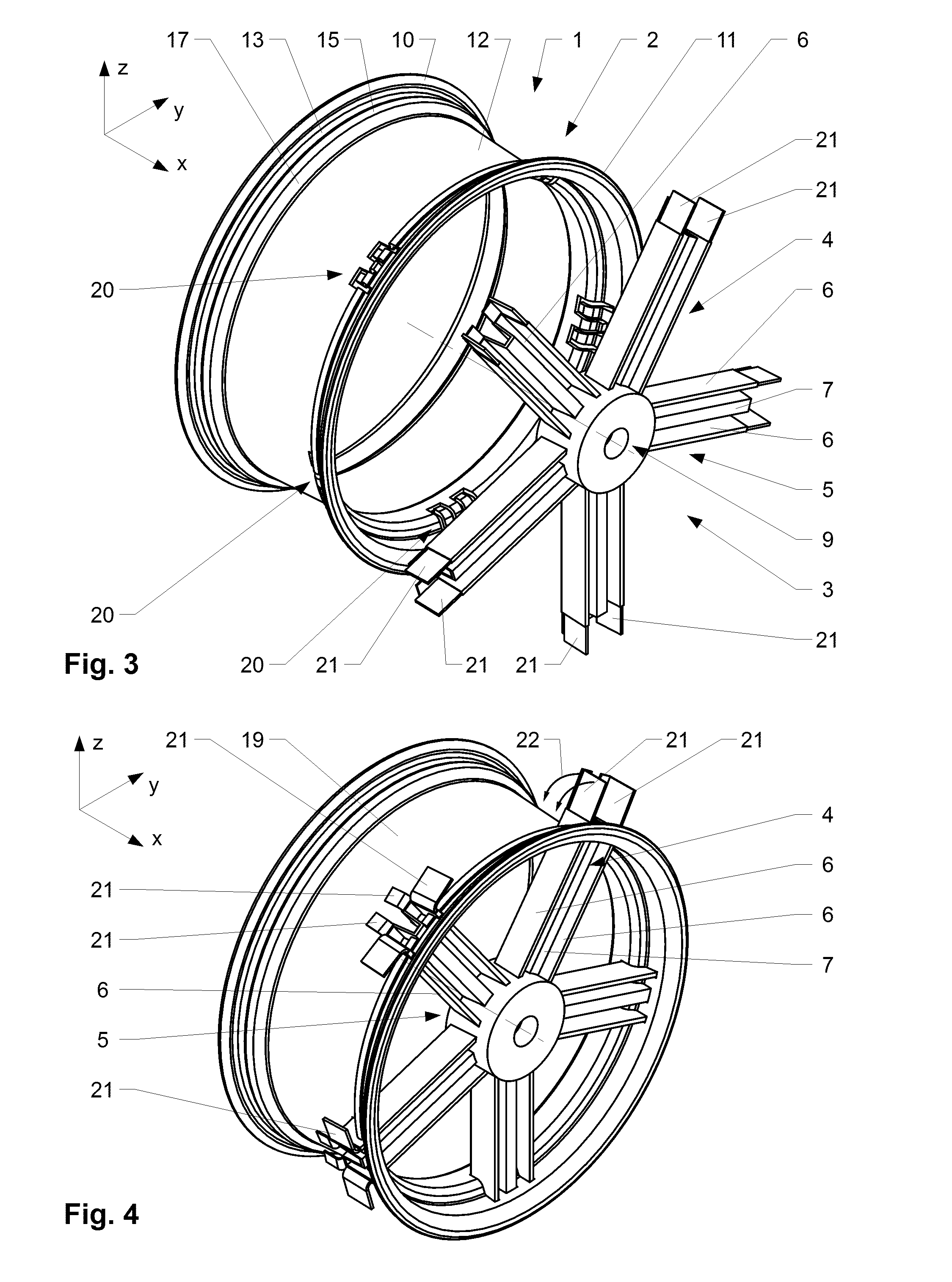

Gearbox with load distribution system

A gearbox comprising: an input shaft (9) having first and second helical input gears (1, 2) of opposite hand fixed axially relative to each other and axially moveable in tandem; an output shaft (10); first and second lay shafts (7, 8) offset from the axis of the input shaft (9, 10) and configured to engage with the input and output shafts (9, 10) for transmitting rotational movement from the input shaft (9) to the output shaft (10), each lay shaft (7, 8) comprising an input gear (3, 4) such that the first lay shaft (7) engages with the first input gear (1) but not the second input gear (2) and the second lay shaft (8) engages with the second input gear (2) but not the first input gear (1 ),- and two or more output gears (26) rotatably mounted on, and selectively engageable with, the output shaft (10), the output gears being in continuous mesh with corresponding output gears (5, 6); on the first and second lay shafts (7, 8), wherein the gearbox is configured such that an imbalance in load sharing between the input shaft (9) and the first and second lay shafts (7, 8) when the output shaft (10) is engaged with the first and second lay shafts (7,8) results in axial movement of the first and second input gears (1, 2) tending to reduce the imbalance.

Owner:SMART MFG TECH

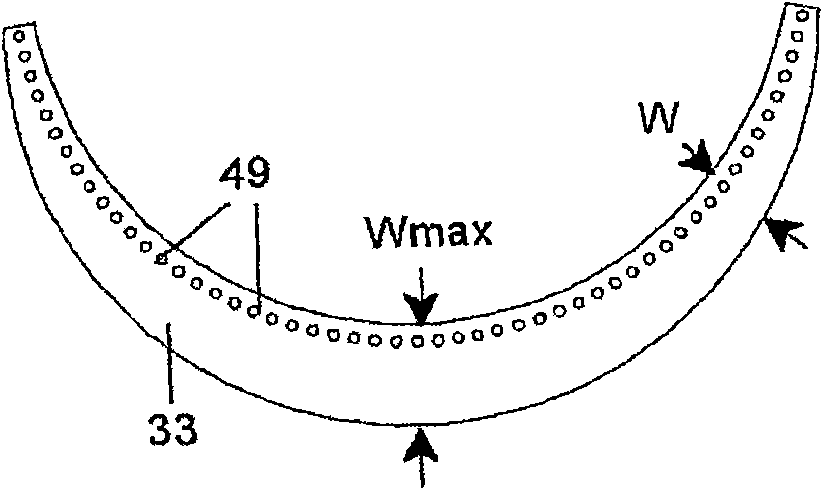

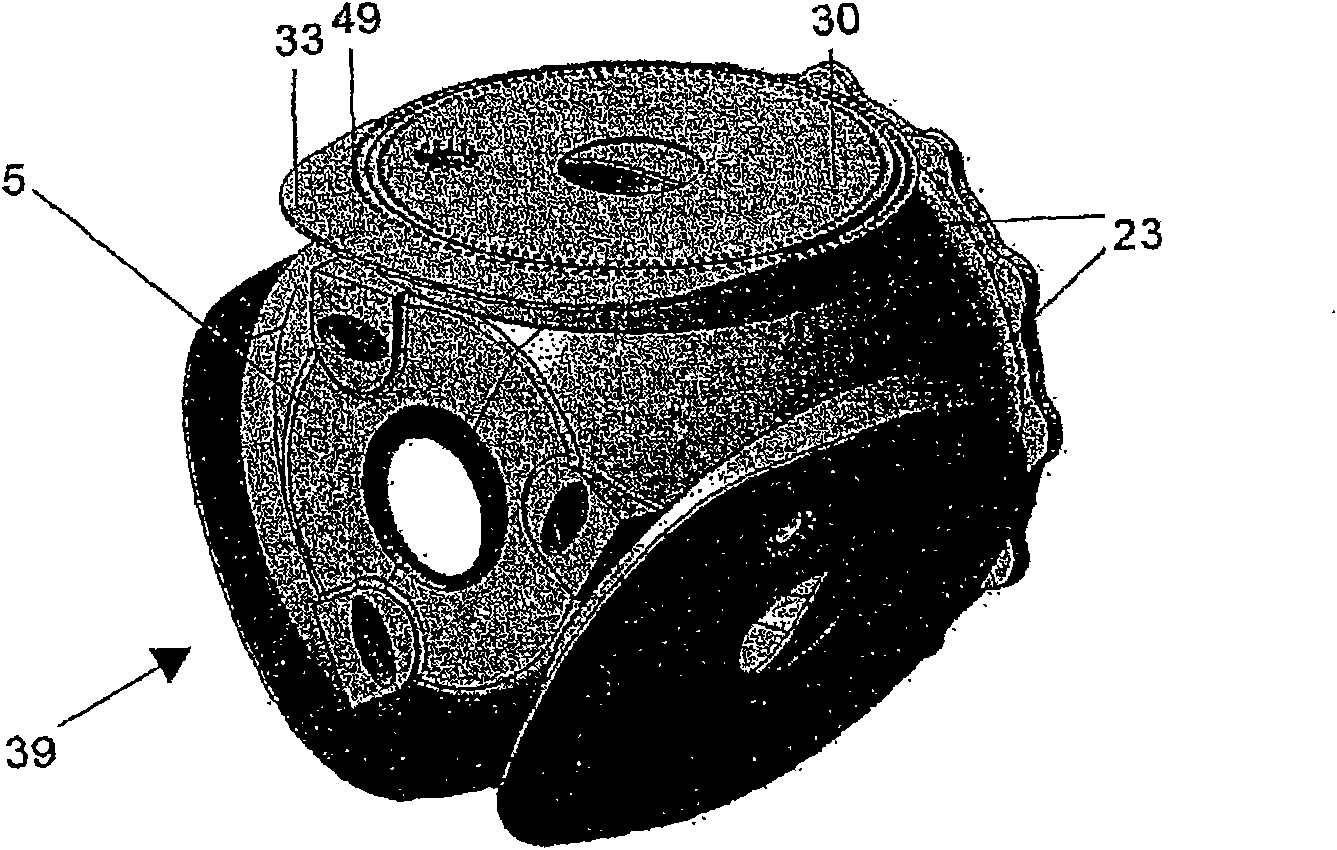

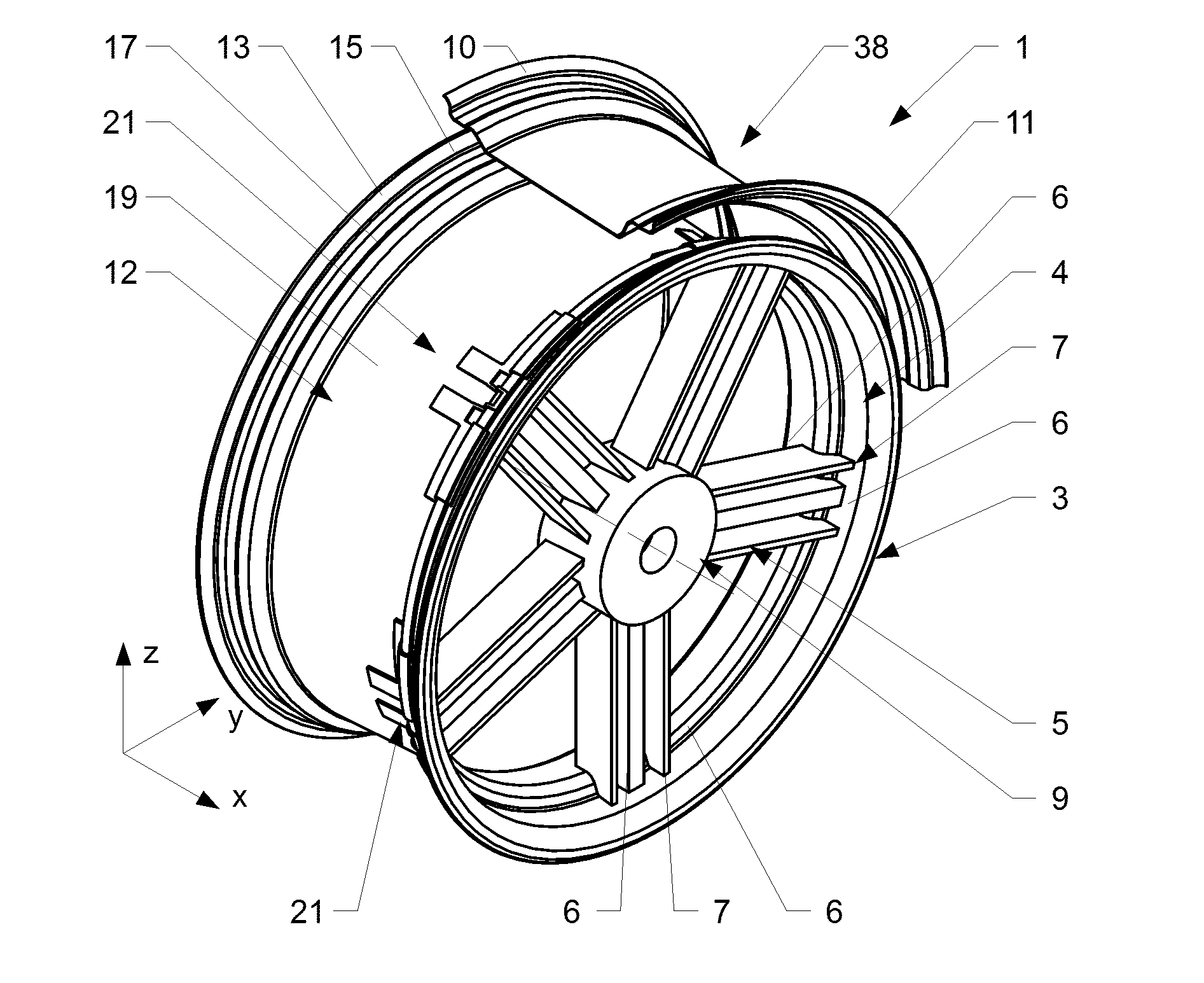

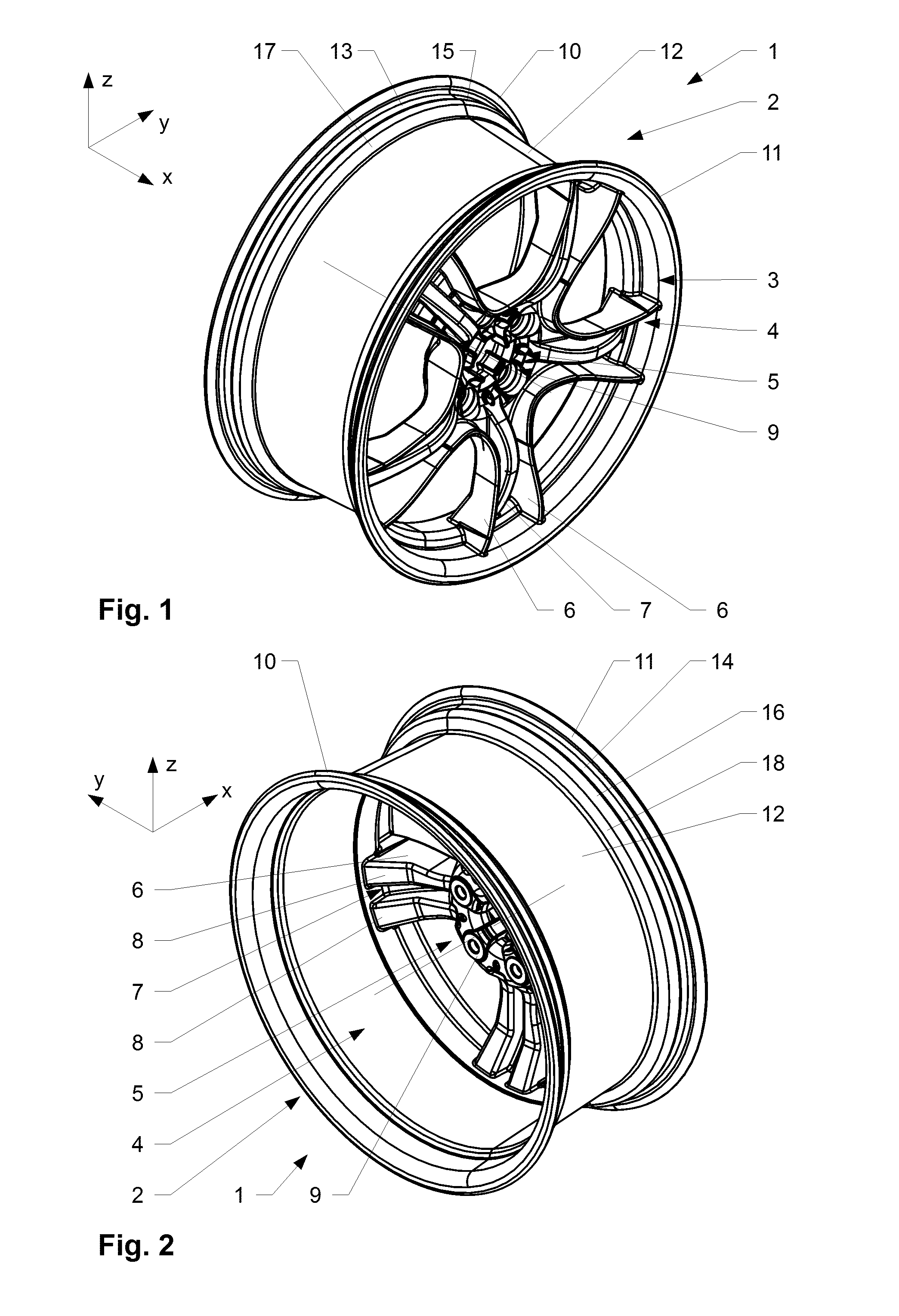

Wheel made out of a fiber reinforced plastic material

ActiveUS20160193869A1Increase load capacityImprove load distributionRimsNon-metallic wheel bodyPlastic materialsSpoke

Owner:MUBEA CARBO TECH GMBH

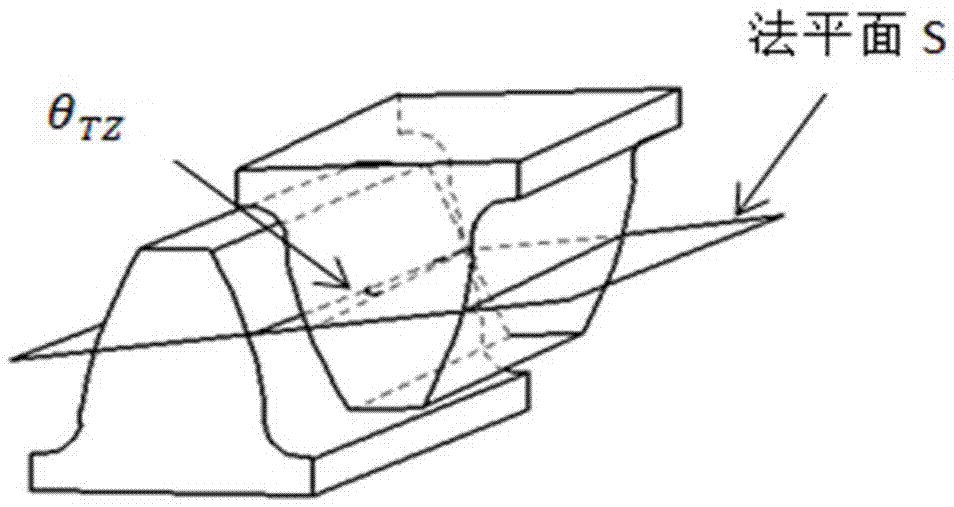

Cylindrical spur gear tooth trace modification method based on tooth surface stress edge action and gear skew deformation

ActiveCN107256300AHigh shape accuracyImprove fatigue strengthGeometric CADSpecial data processing applicationsBox modelEngineering

The present invention discloses a cylindrical spur gear tooth trace modification method based on tooth surface stress edge action and gear skew deformation. The method comprises the steps of: 1. establishing a three-dimensional gear model based on UG; 2. analyzing gear tooth elastic deformation and tooth surface stress "edge action" of the three-dimensional gear model under a certain working condition; 3. establishing an overall three-dimensional gear box model based on the UG; 4. analyzing gear box stressed deformation of the three-dimensional gear box model under a certain working condition; 5. analyzing deformation amounts and deformation characteristics of a tooth surface in different directions caused by comprehensive deformation of a gear box; 6. for the "edge action" and characteristics of influence of skew deformation in different planes of a gear on tooth surface stress, classifying all deformations, and considering all the deformations into tooth trace modification; and 7. considering the "edge action" during elastic deformation and skew deformation of a tooth surface in a normal plane to deduce a tooth trace modification curved line formula for tooth trace modification. The method provided by the present invention increases modification precision of the cylindrical spur gear that is operated under a high-speed heavy-load working condition, effectively improves the tooth surface load distribution condition, and prolongs the service life of gears.

Owner:SHANXI PINGYAO REDUCER

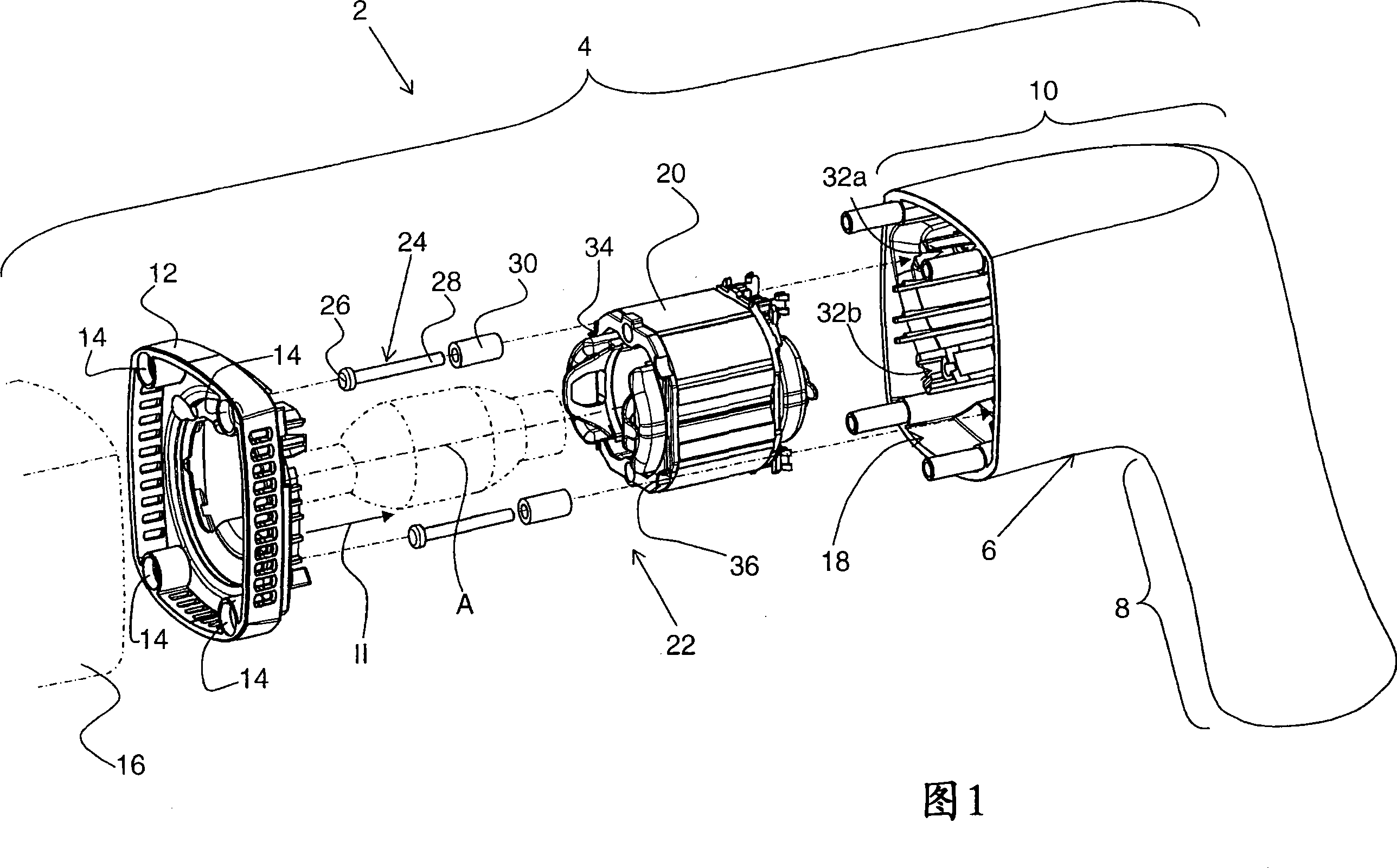

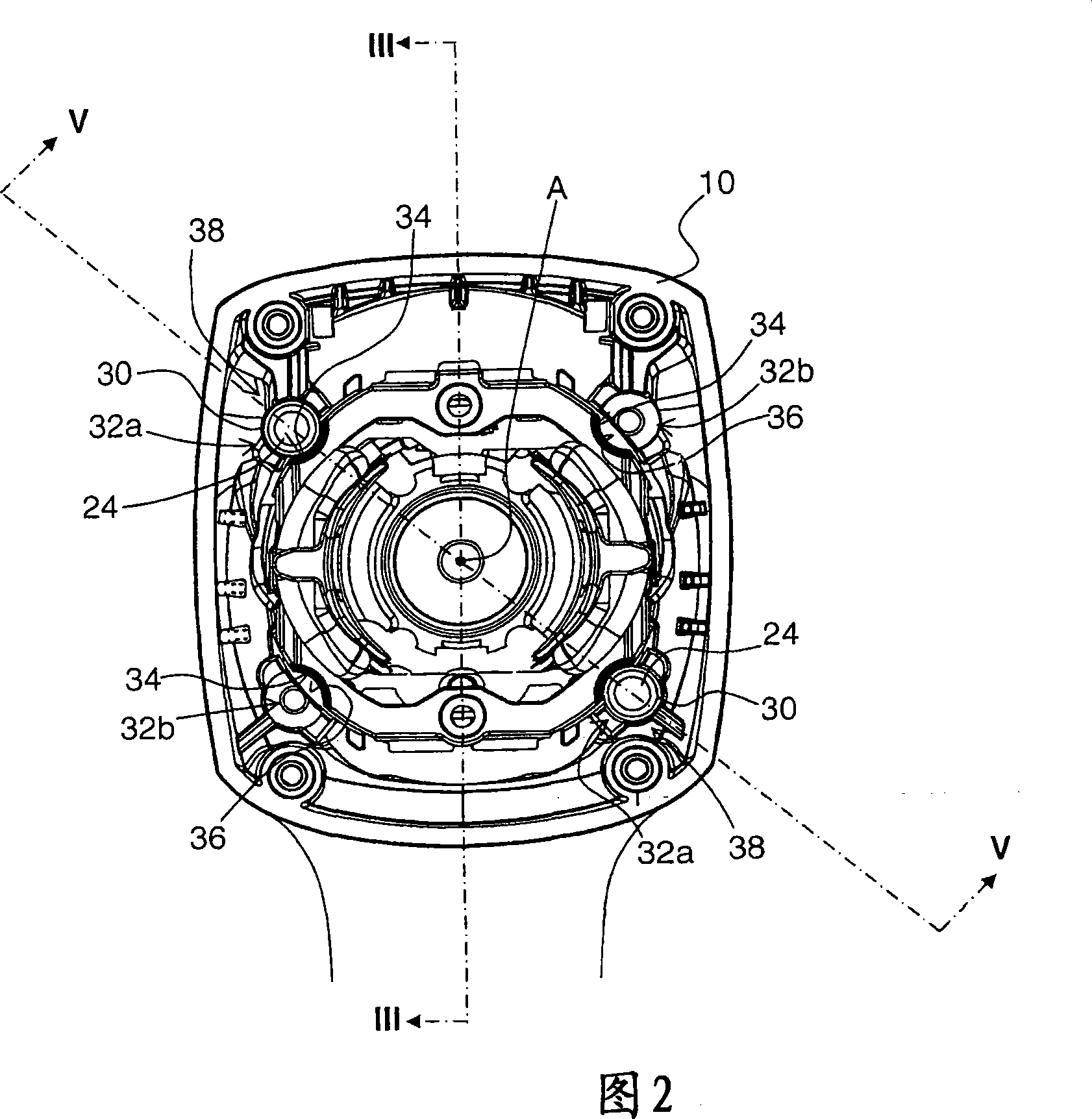

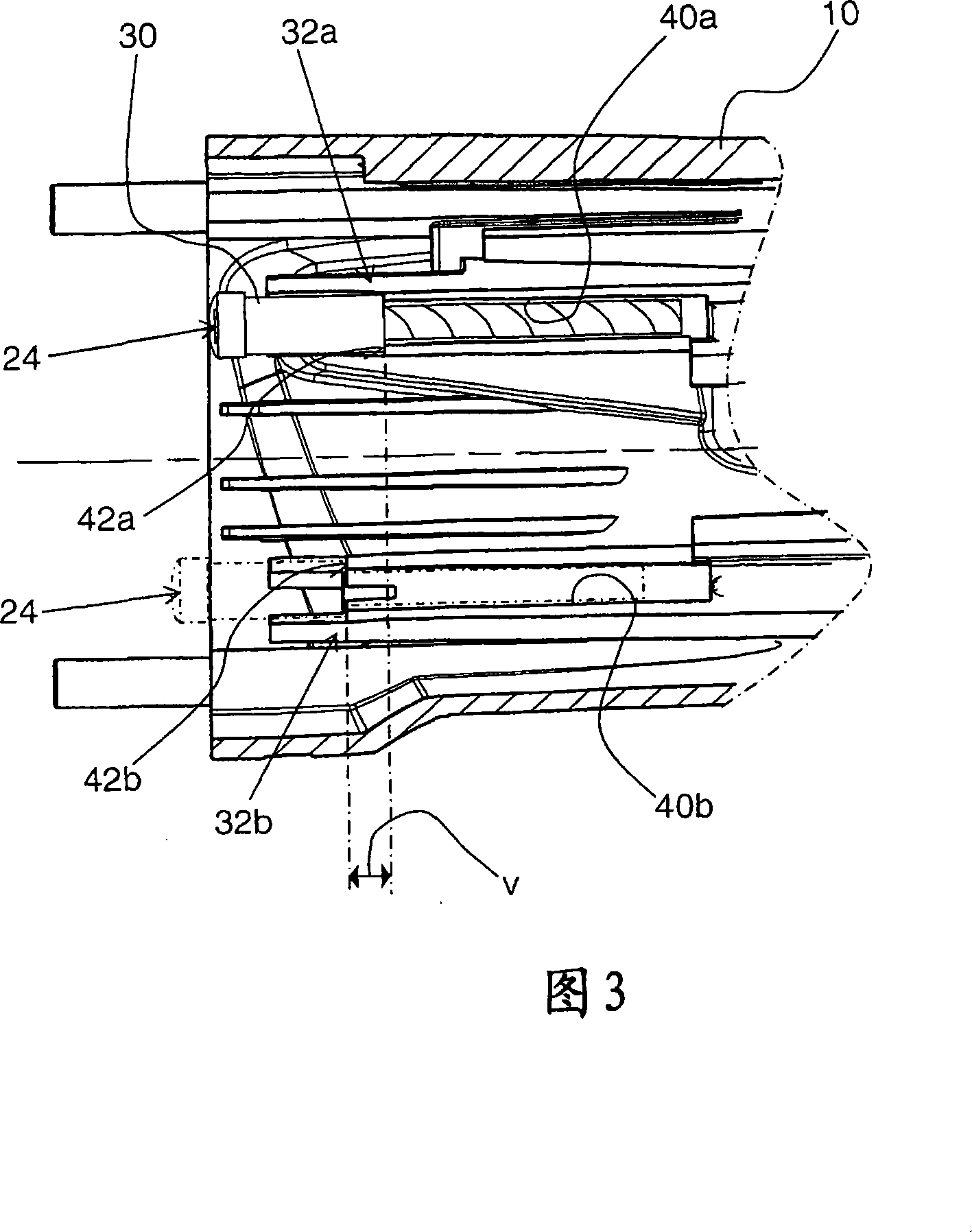

Hand tool device has multipart housing

InactiveCN101207311AAvoid deformationIncrease stiffnessPortable power-driven toolsMechanical energy handlingHand heldHand tool

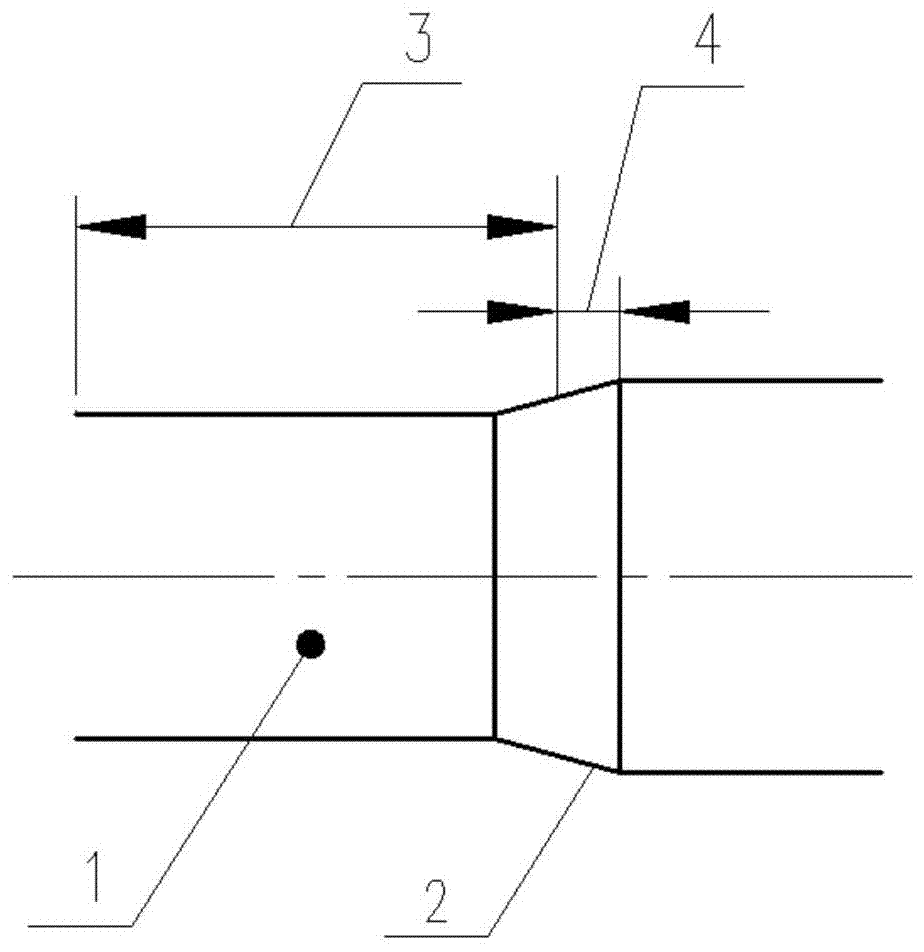

The invention relates to a handheld machine tool (2) which is provided with a multi shell (4), comprising an electric motor shell (10). The electric motor shell forms an installation opening (18). An electric motor (22) stator (20) to determine an axle (A) can be embedded into the electric motor shell (10) via the opening, wherein, the stator (20) for forming an axial arresting device can be fixed on embedded position. The axial arresting device can cling to the stator (20) on the opening side and can be axial fixed via two clamping and connecting devices (38). The clamping and connecting device is provided with at least two clamping elements (24). The clamping elements are kept on two first clamping grooves (32a) which are arranged on the electric motor shell (10). For this provision, at least two second-clamping grooves (32b) are additionally arranged on the electric motor shell (10). Relative to the first clamping grooves (32a), the second clamping grooves have an axial offset (v).

Owner:HILTI AG

Shaft part with surface local quenching transition area and machining process

ActiveCN107955874AHigh strengthStrong enough to be reliableSolid state diffusion coatingFurnace typesMachining processUltimate tensile strength

The invention discloses a shaft part with a surface local quenching transition area. The shaft part comprises a conical cylinder surface; the surface local quenching transition area is designed as a conical cylinder surface; the strength of the shaft diameter of the surface local quenching transition area is improved along with enlargement of the conical cylinder surface; a large head of the conical cylinder surface belongs to the surface local quenching transition area; a small head of the conical cylinder surface belongs to a surface local quenching area; and the joint between the surface local quenching transition area and the surface local quenching area is designed at the middle part of the conical cylinder surface. The machining process enables all positions of a whole shaft of the shaft part with locally quenched surface to reach enough reliable strength, so that heat treatment cracks are not easy to generate, sudden drop of the strength cannot occur, and cracking and shaft breakage due to fatigue failure of the surface local quenching transition area are prevented.

Owner:ZHUZHOU JIUZHOU TRANSMISSION MACHINERY

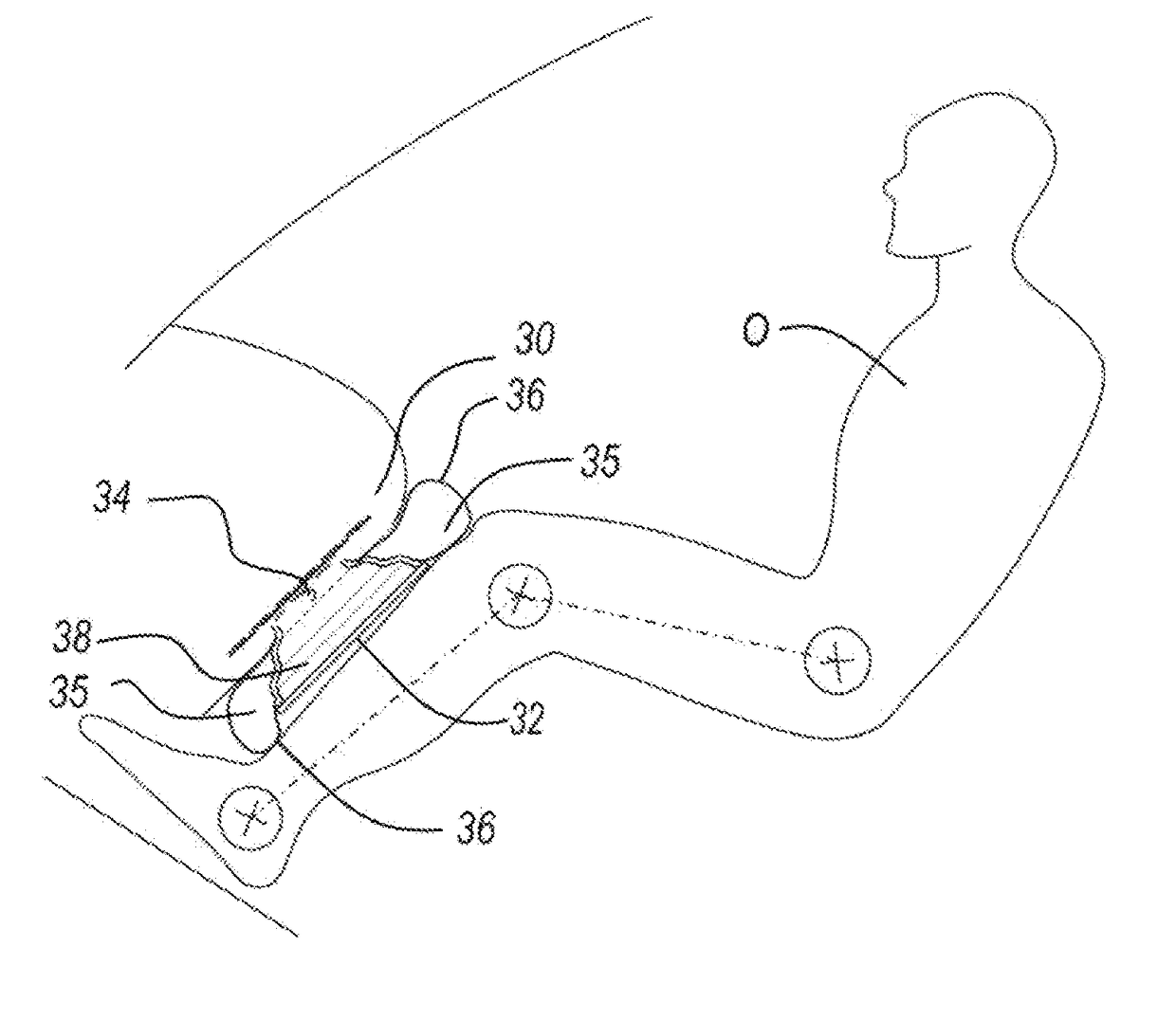

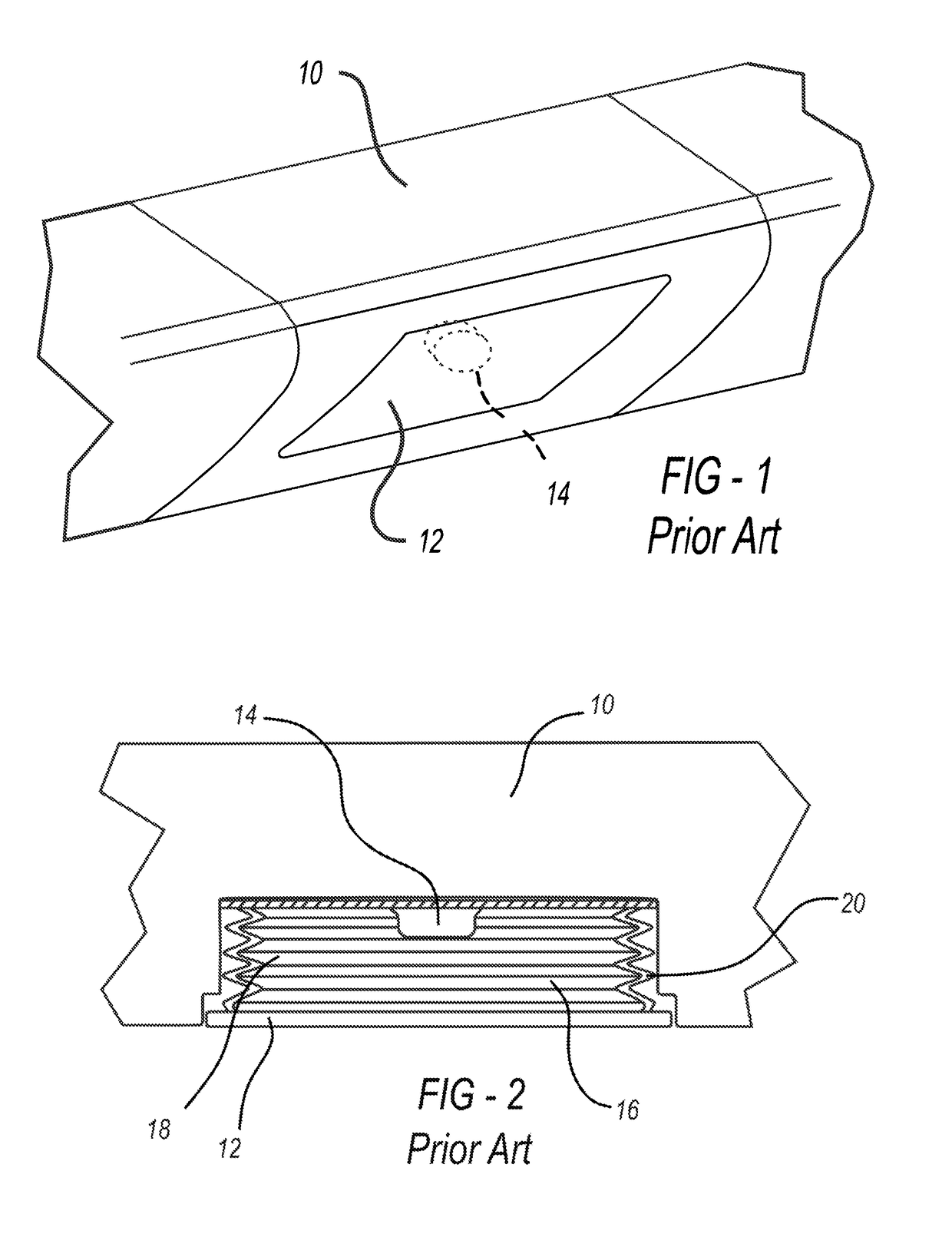

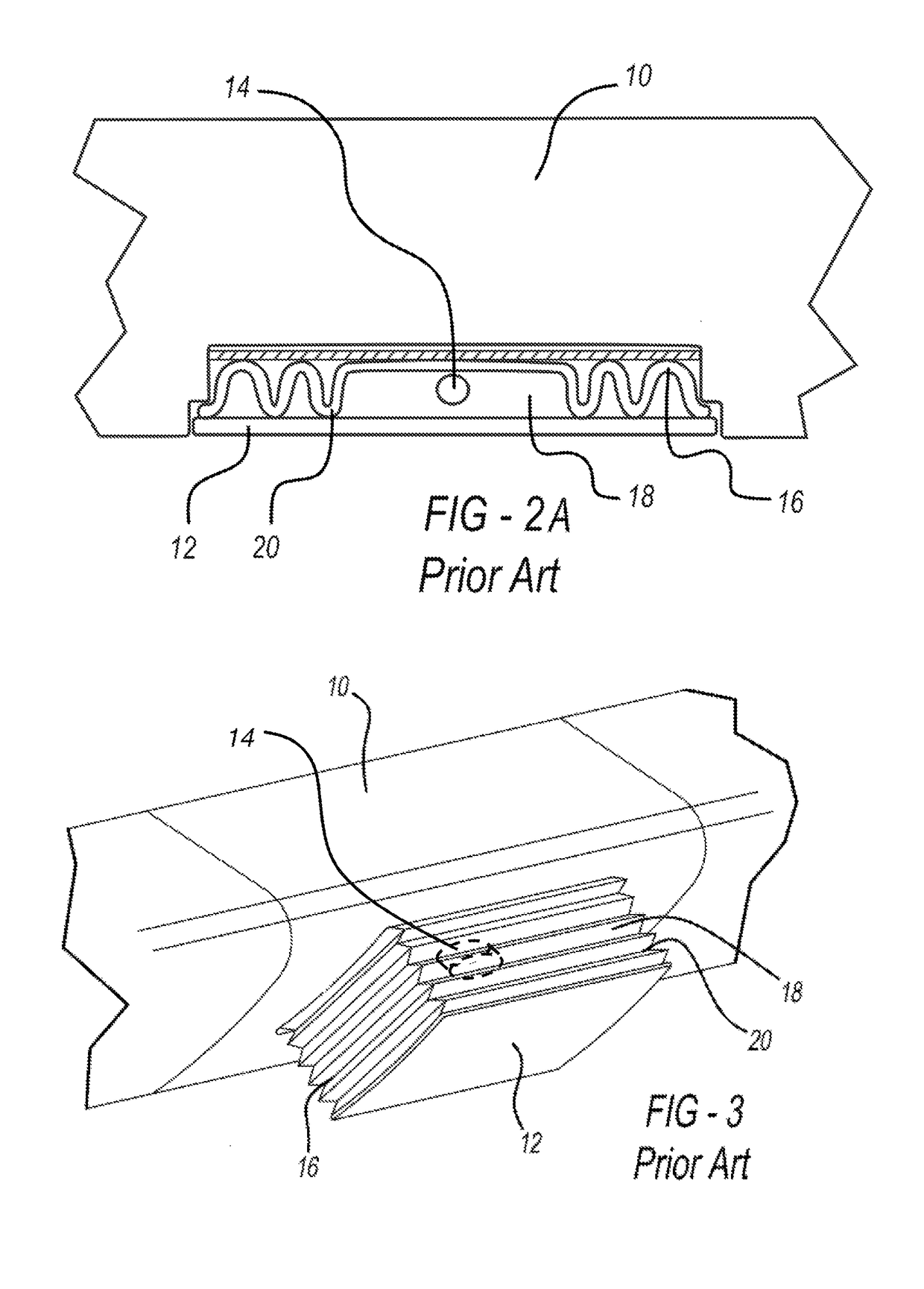

Deployable semi-rigid body contact restraint member with integral flexible expansion member

ActiveUS9637080B2Reduce stiffnessReduce physical injuryPedestrian/occupant safety arrangementEnergy absorptionShell molding

A hybrid expandable restraint volume enclosure system incorporating at least one deployable semi-rigid human body reaction surface is provided. One or more walls of the expanding volume are substantially pliable, attaching at one end to a mounting base that is attachable to a structural member of a vehicle and another end attached to a semi-rigid deployable reaction surface. The energy absorbing expansion member may be thin walled or membrane-like and comprised of pliable rubber, plastic or a woven fabric. Methods of attaching a flexible expansion member to either a semi-rigid contact surface or a semi-rigid expansion wall of the enclosure include providing a mechanical attachment by capturing an expansion member edge between a frame and semi-rigid member. Material from a molded semi-rigid member may flow over or into geometries provided in a flexible expansion member for joining. An interface may be defined by blend-molding to transition different material stiffness.

Owner:FORD GLOBAL TECH LLC

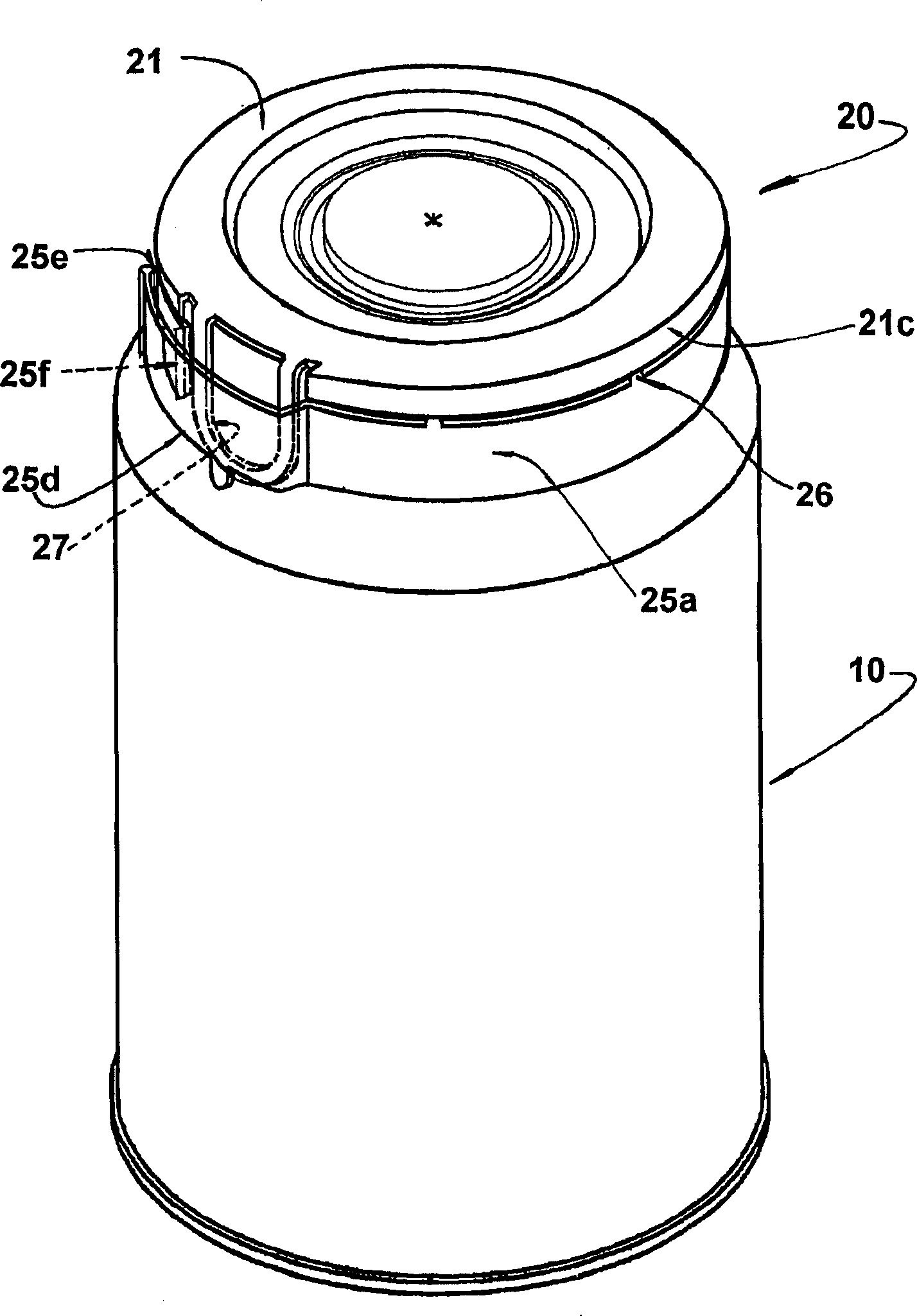

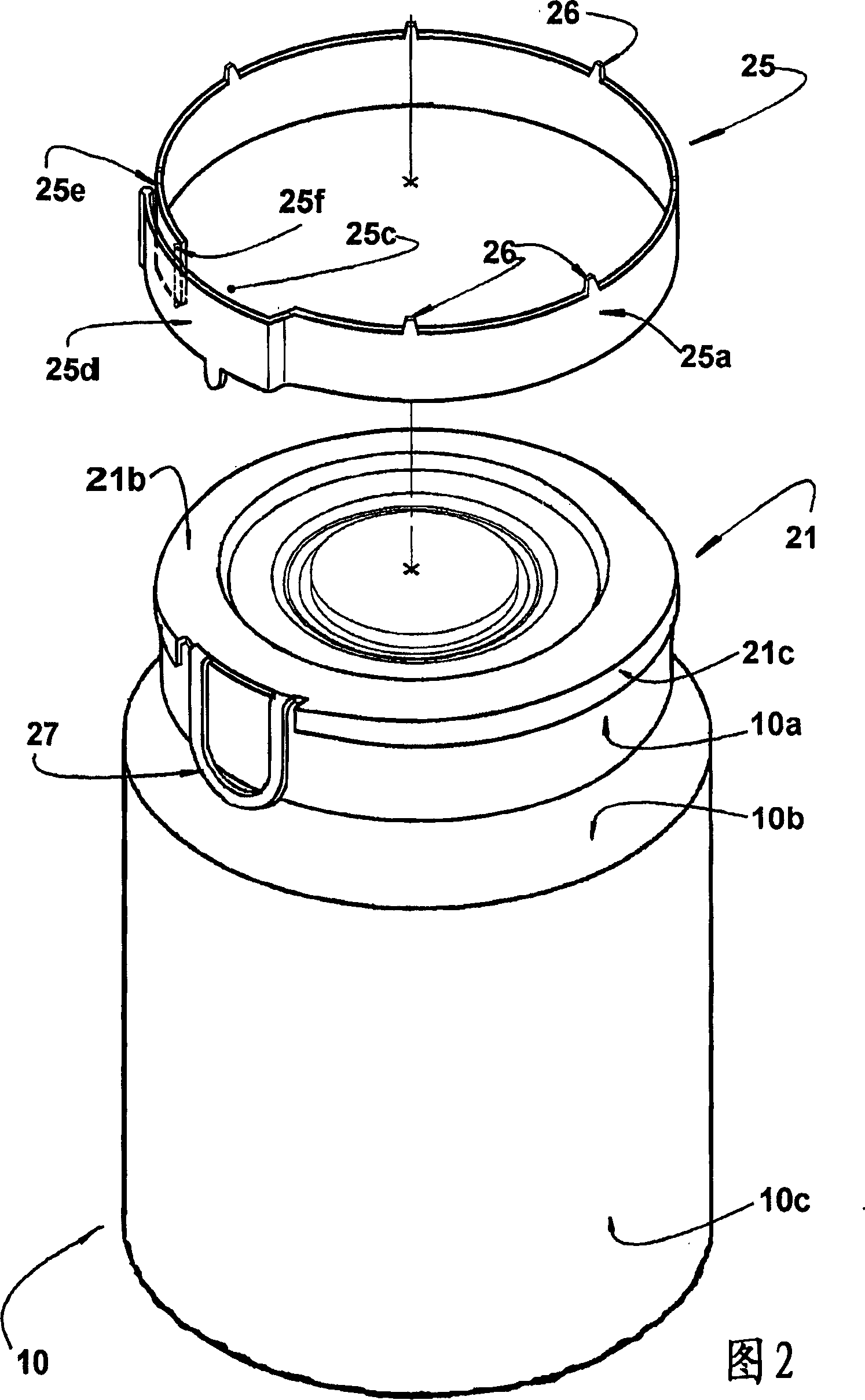

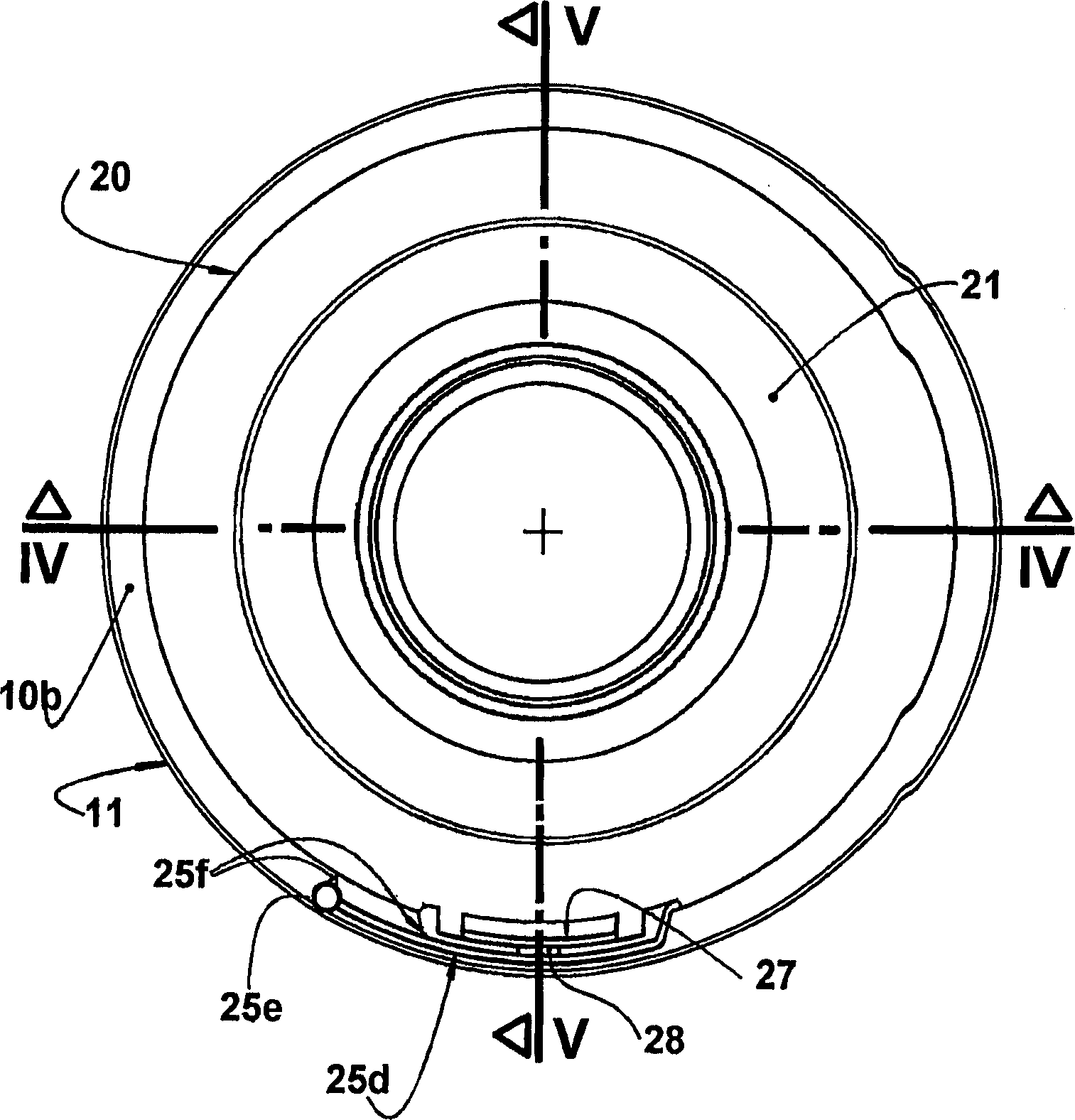

Closure arrangement for cans

InactiveCN1849244AAvoid mutual contactImprove load distributionRemovable lids/coversLidsEngineeringMechanical engineering

Owner:BRASILATA S A EMBALAGENS METALICAS

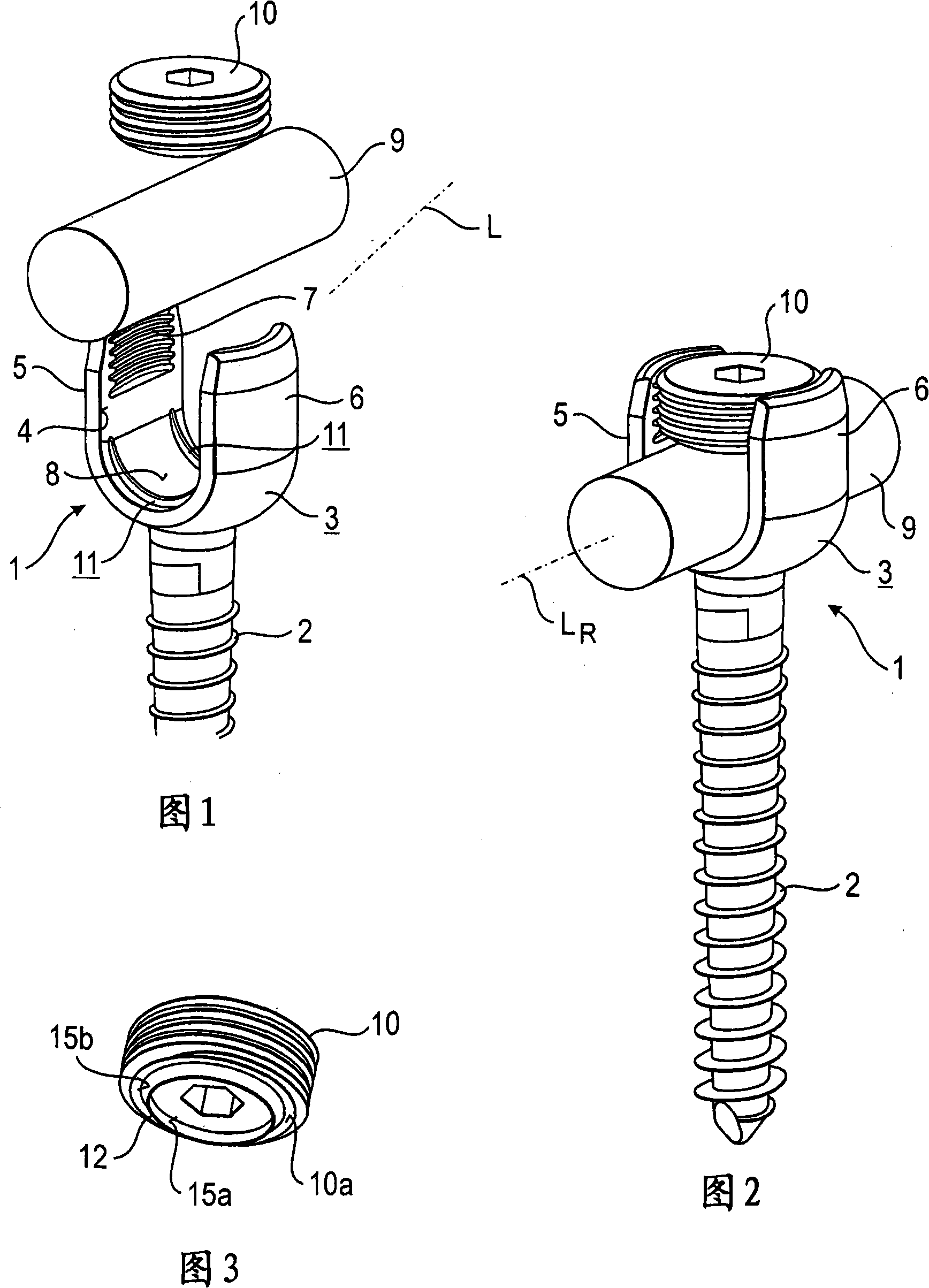

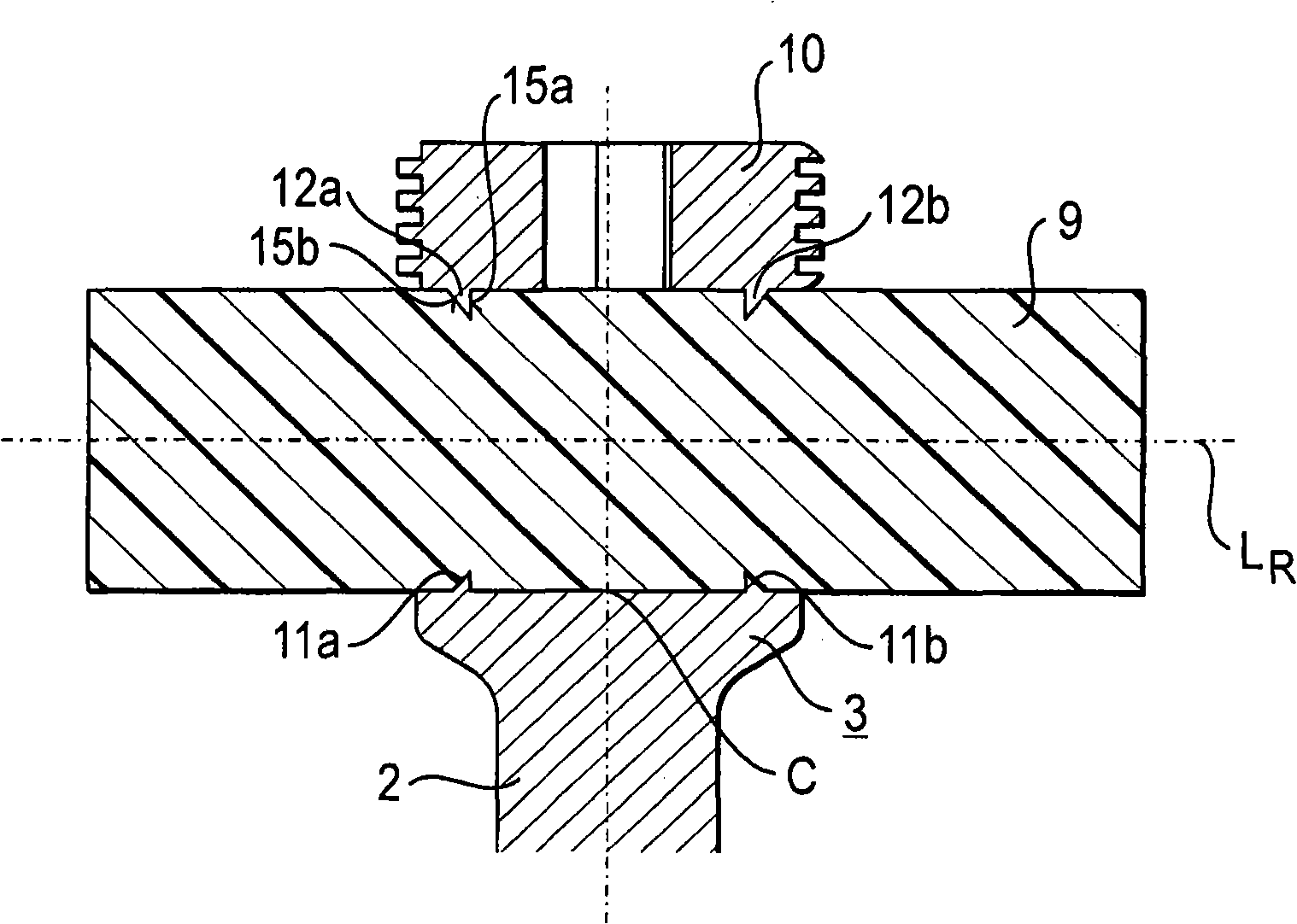

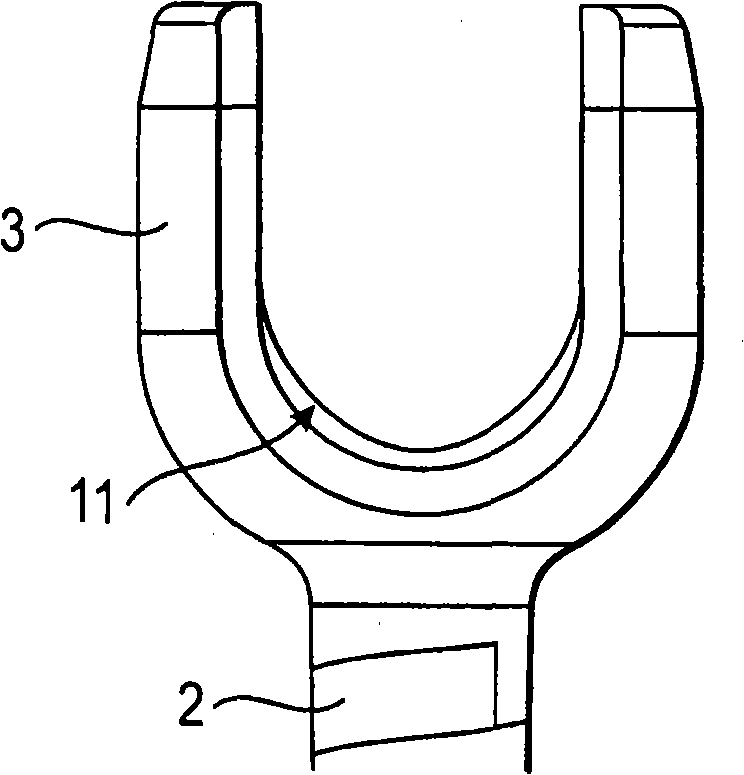

Bone anchoring device

InactiveCN101347351AAvoid wear and tearReduce riskInternal osteosythesisBiomedical engineeringVertebra

A bone anchoring device is provided comprising an anchoring element having a shank (2) to be anchored in a bone or a vertebra, a rod (9) for connecting at least two anchoring elements, the rod being made of an elastic material, a receiving part (3) being connected to the shank (2) for receiving the rod, a seat (8) for the rod being provided in the receiving part the seat having a rod contacting surface, a locking device (10) cooperating with the receiving part for fixation of the rod in the seat, the locking device comprising a rod contacting surface, wherein the rod contacting surface of the seat and / or the rod contacting surface of the locking device comprises an engagement structure (11,12) for engaging the rod, the engagement structure having an asymmetric cross section.

Owner:BIEDERMANN TECH GMBH & CO KG

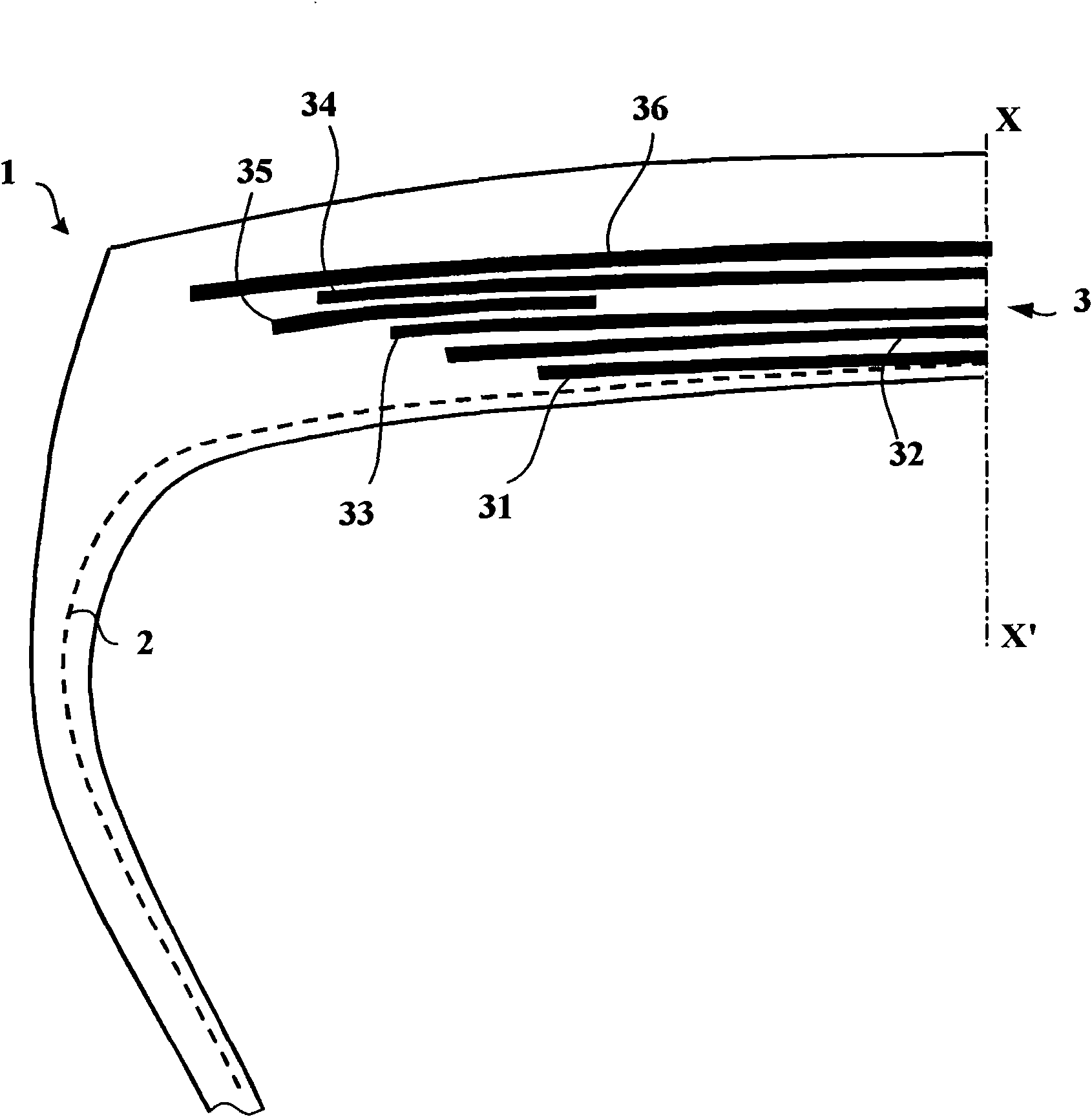

Tire for heavy vehicle

InactiveCN101583500AIncreased durabilityLimit the risk of degradationPneumatic tyre reinforcementsWheelsEngineeringMechanical engineering

Owner:OCIETE DE TECH MICHELIN

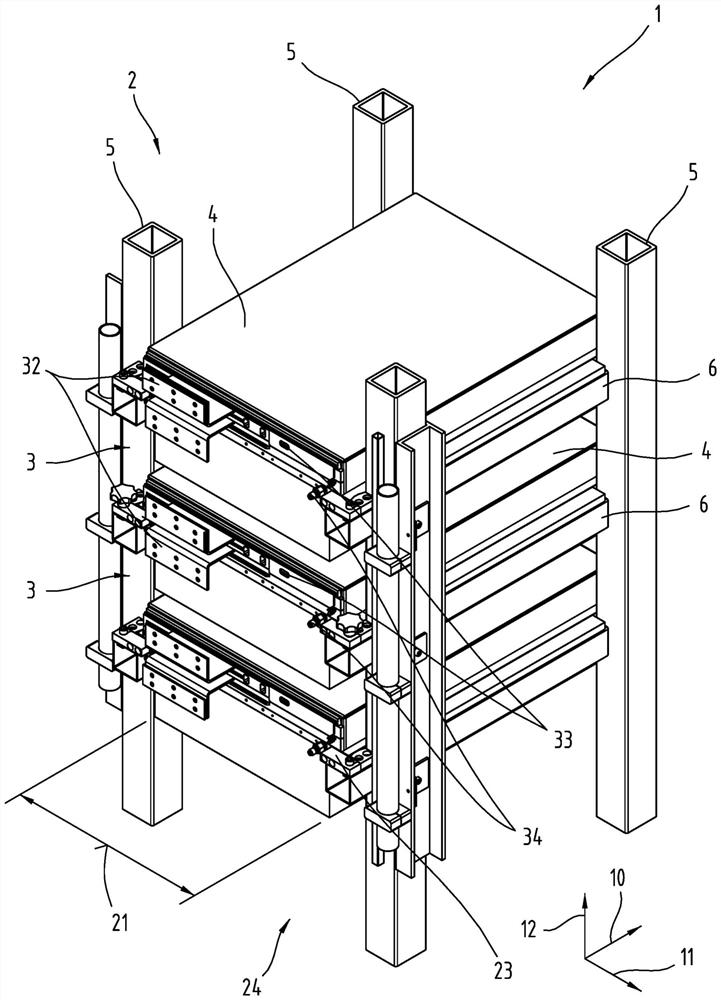

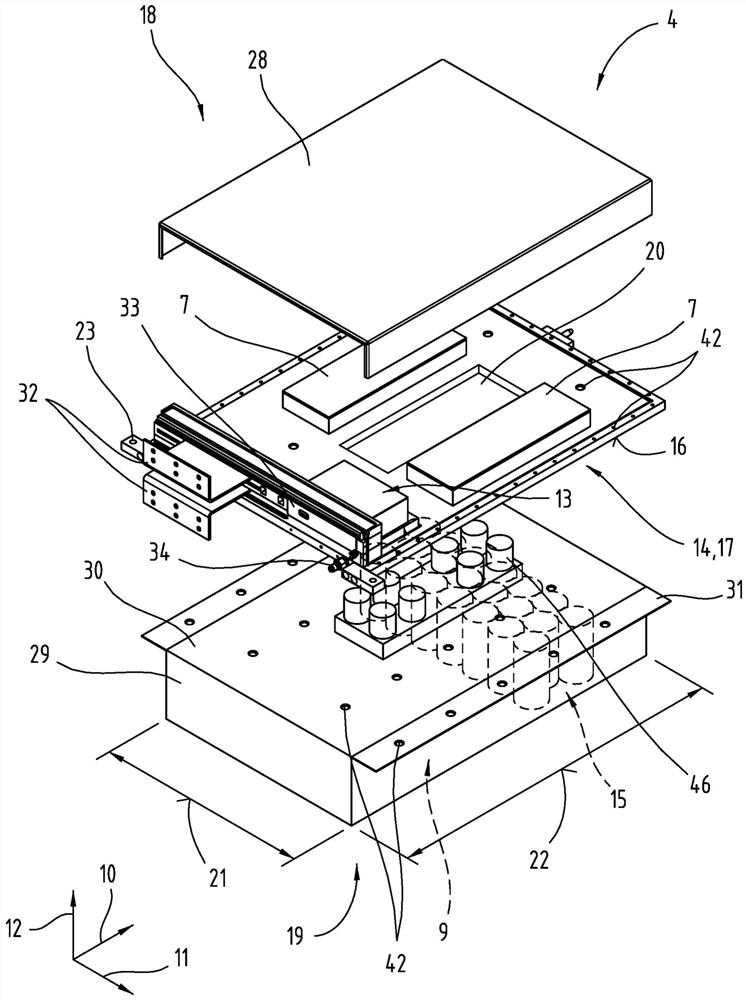

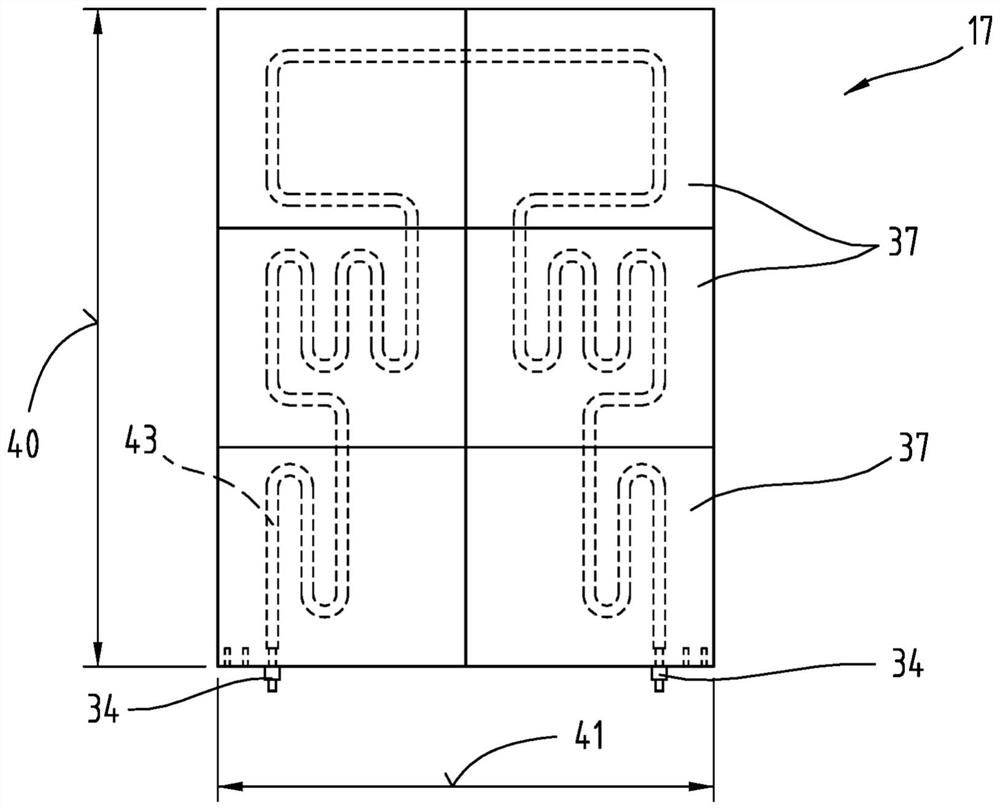

Power assembly having a load-bearing cooling body

PendingCN112237056AEffective exportSmall sizeSubstation/switching arrangement detailsPrinted circuit board receptaclesVoltage converterLevel converter

The invention relates to a power assembly (4) for a medium- or high-voltage converter (1), preferably a modular multi-level converter, comprising at least one power semiconductor assembly (7), preferably an IGBT assembly, at least one energy accumulator assembly (9), preferably a capacitor assembly, at least one cooling device (14), wherein the cooling device (14) is designed as a cooling plate (17) through which a coolant can flow, in particular a cooling fluid, and the at least one power semiconductor assembly (7) and / or the at least one energy accumulator assembly (9) are arranged on an upper (18) and / or underside (19) of the cooling plate (17), and wherein at least the power semiconductor assembly (7) is thermally conductively connected to the cooling plate (17), and wherein the cooling plate (17) is provided for load-bearing support on a frame (2) of an associated receiving space (3) of the medium- or high-voltage converter (1), and has protruding support surfaces (16) laterally in the transverse direction (11) in relation to at least one energy accumulator width (21) of the energy accumulator assembly (9).

Owner:MIBA ENERGY HLDG GMBH

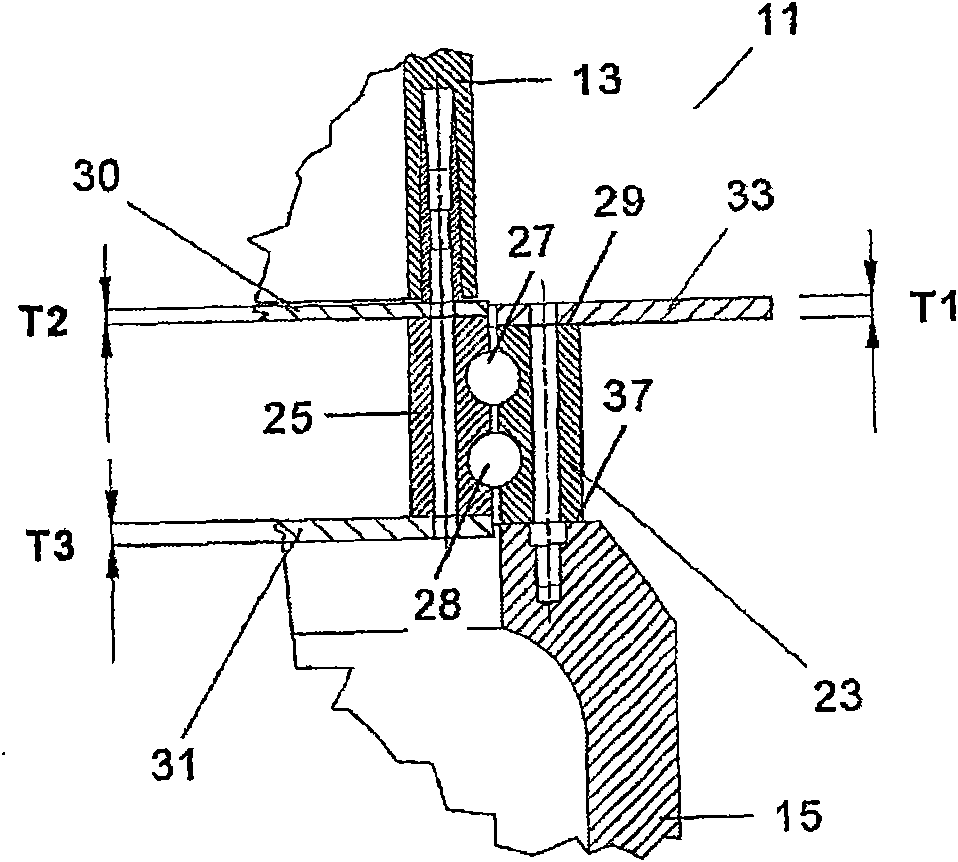

Twist beam suspension

InactiveCN104999878AReduced risk of crackingImprove load distributionResilient suspensionsShock absorberChassis

The invention discloses a twist beam suspension. The twist beam suspension comprises a cross beam, wherein longitudinal beams are symmetrically arranged at the two ends of the cross beam; the lower ends of the longitudinal beams are connected with longitudinal hub plates for mounting wheels; spring seats are fixedly mounted at the lower ends of the longitudinal beams connected with the cross beam; shock absorber mounting brackets are mounted on the longitudinal beams on the lower sides of the spring seats; the lower sides of the outer walls of the spring seats are also fixed together with the upper sides of the outer walls of the shock absorber mounting brackets through welding; and reinforcing rods are mounted on the inner side walls of the upper ends of the longitudinal beams. Through the adoption of the reinforcing rod structures, partial loads on bushings at the front ends of the longitudinal beams are shared by the reinforcing rods under conditions that a vehicle is turning, passing a pit and so on when the load is born on the suspension; therefore, the load of the suspension are shared at a plurality of points so that structural cracking risks at the mounting points of the bushings at the front sections of the longitudinal beams of the twist beam suspension are reduced. As the cross beam, the longitudinal beams, the spring seats, the shock absorber mounting brackets, the reinforcing rods, the hub plates and so on are reasonably assembled together, the maneuvering performance of the whole vehicle is effectively improved and the reliability and maneuverability of a chassis are enhanced.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

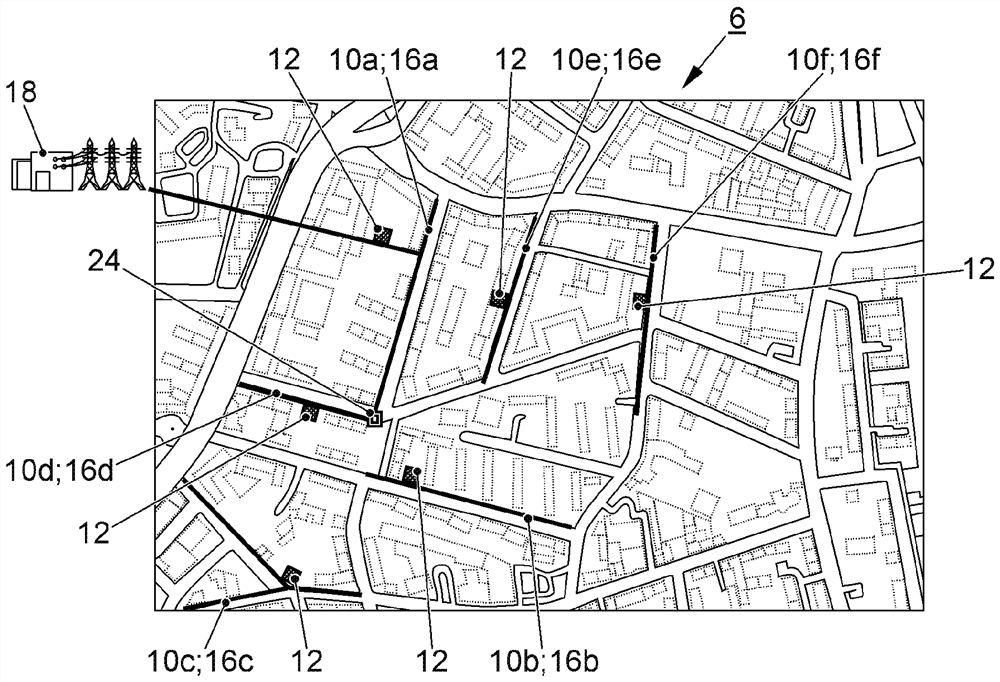

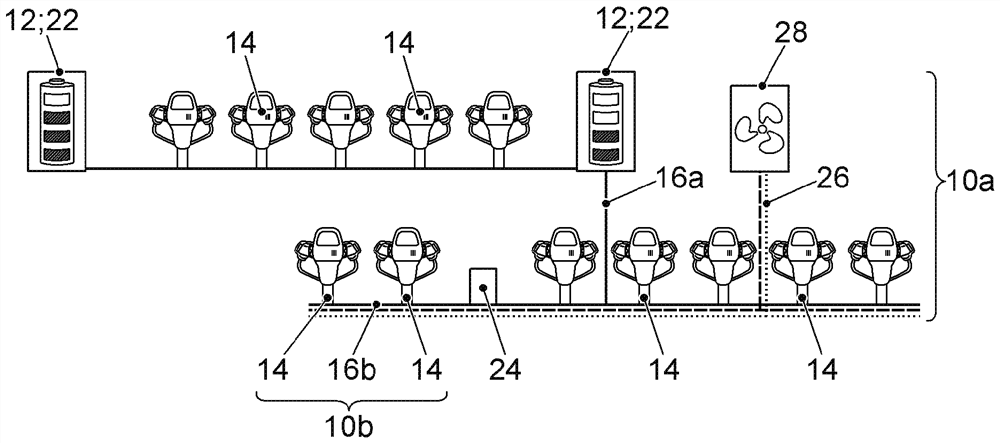

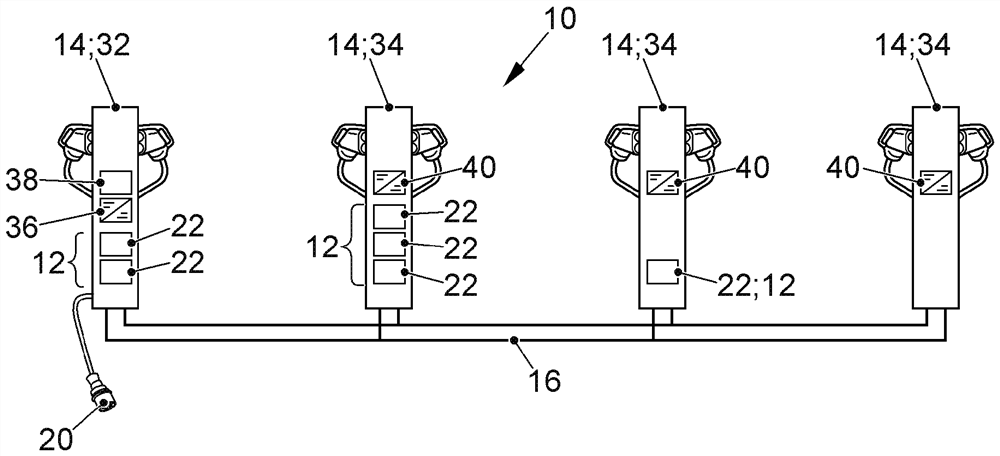

Charging infrastructure for charging motor vehicle

PendingCN112895958AImprove efficiencyAdaptable and scalableCharging stationsElectric vehicle charging technologyPower gridElectric drive

The invention relates to a charging infrastructure for charging a motor vehicle. The invention relates to a charging infrastructure (6) for charging at least one electrically driven or electrically drivable motor vehicle (8). The charging infrastructure is provided with at least one charging complex (10, 10a, 10b, 10c, 10d, 10e, 10f) having a plurality of charging piles (14) as charging points, the charging piles (14) is coupled to one another by means of an island network (16, 16a, 16b, 16c, 16d, 16e, 16f), wherein the island network (16, 16a, 16b, 16c, 16d, 16e, 16f) is coupled or can be coupled to an external supply network (18) and / or an energy generator (30), and wherein the charging assembly (10, 10a, 10b, 10c, 10d, 10e, 10f) has at least one battery energy store (12) as an electrical buffer energy store.

Owner:VOLKSWAGEN AG

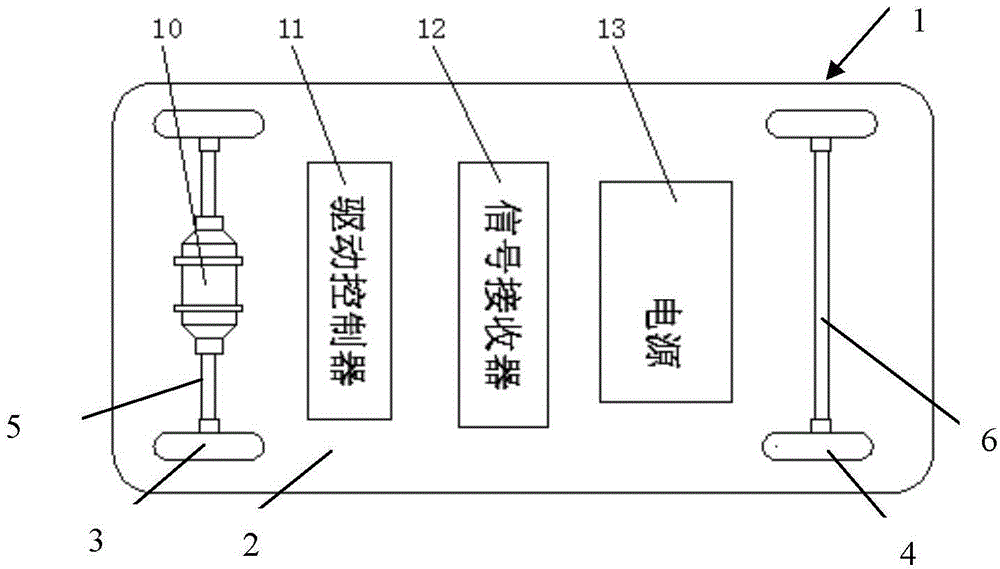

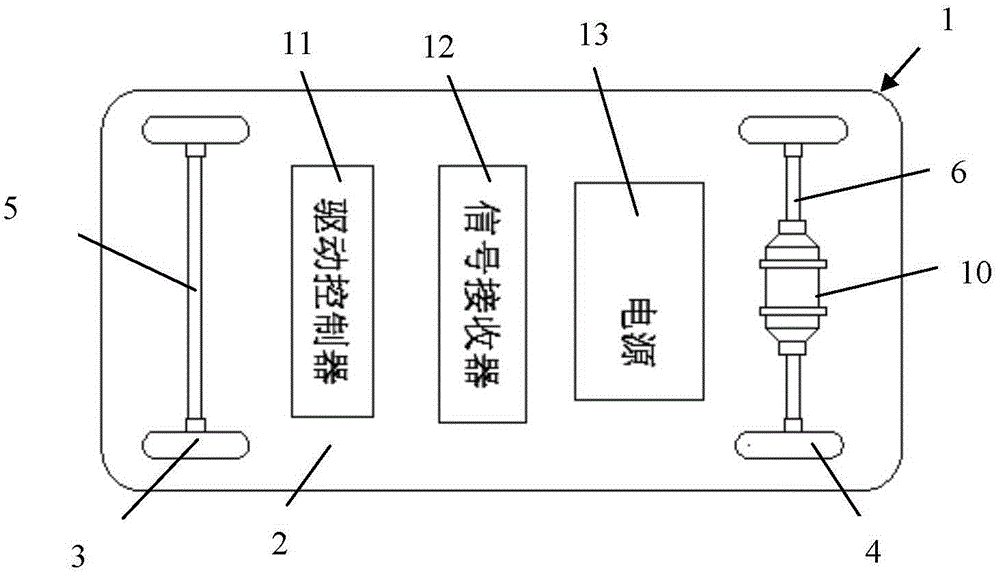

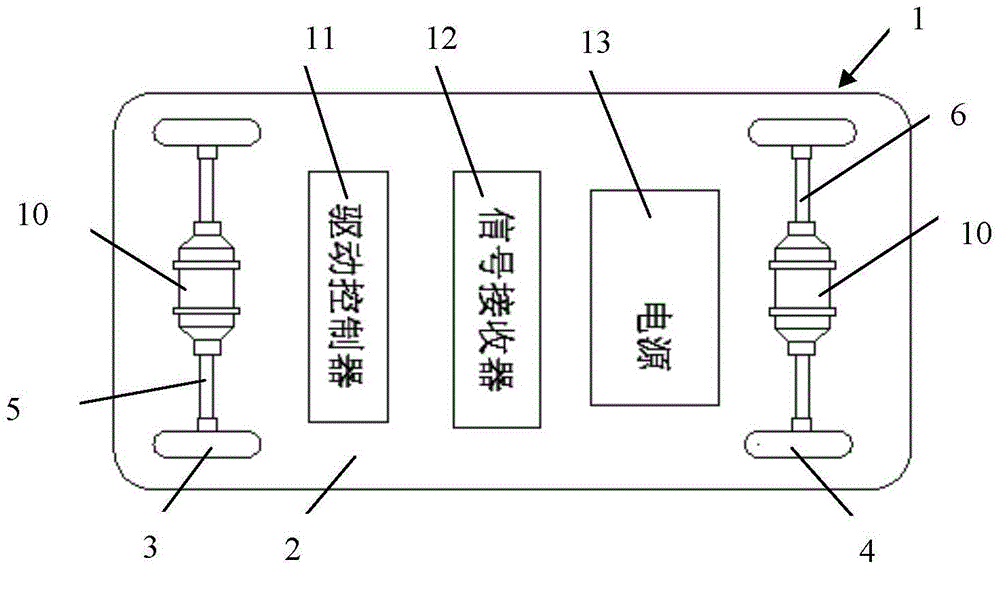

Auxiliary drive electric trailer flat car used for goods and luggage transportation

InactiveCN104816617AImprove performanceImprove load distributionElectric propulsion mountingElectricityElectric drive

An auxiliary drive electric trailer flat car used for goods and luggage transportation comprises an electric trailer flat car body, at least one electric motor, a drive controller, a signal receiver and a power supply, wherein the electric trailer flat car body mainly comprises a supporting plate, and two front wheels and two rear wheels arranged at the front and back of the bottom surface of the supporting plate; the two front wheels are connected by a front axle; the two rear wheels are connected by a rear axle; the electric motor is installed at the axle; the drive controller is connected with the electric motor and a central controller arranged on a trailer truck; the signal receiver is connected with the drive controller and the central controller; the power supply is electrically connected with each electric component. According to the invention, on the basis of the electric drive characteristics of goods and luggage transportation at the civil aviation airport, under the condition that total power of the whole system is constant, power arrangement is dispersed, the whole is broken into parts, mutual cooperation is realized, and under the principles of optimizing power and lowering the operation difficulty and manufacturing costs, the overall performance of a transport vehicle system is improved and the load distribution of energy medium is improved.

Owner:CIVIL AVIATION UNIV OF CHINA

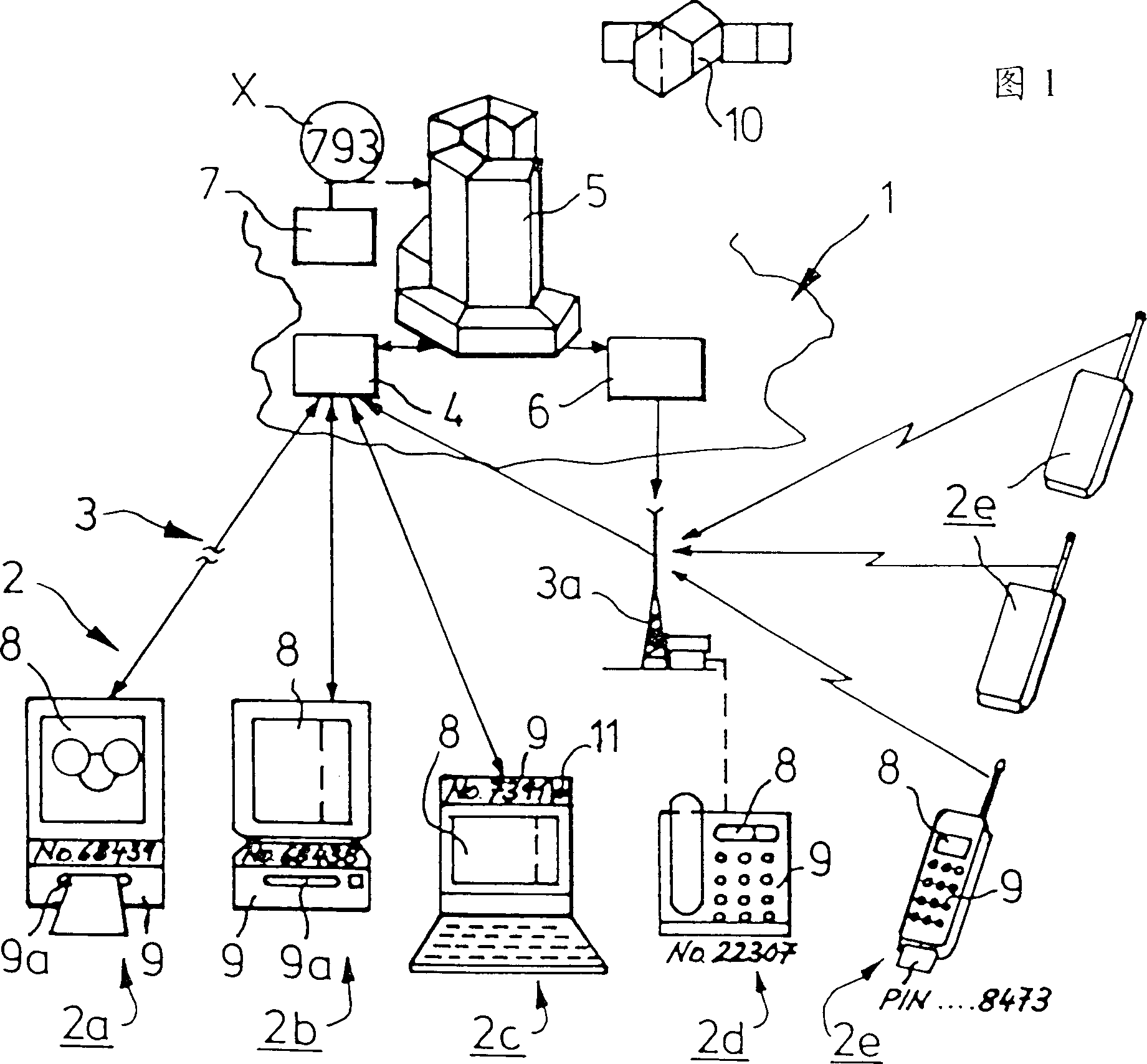

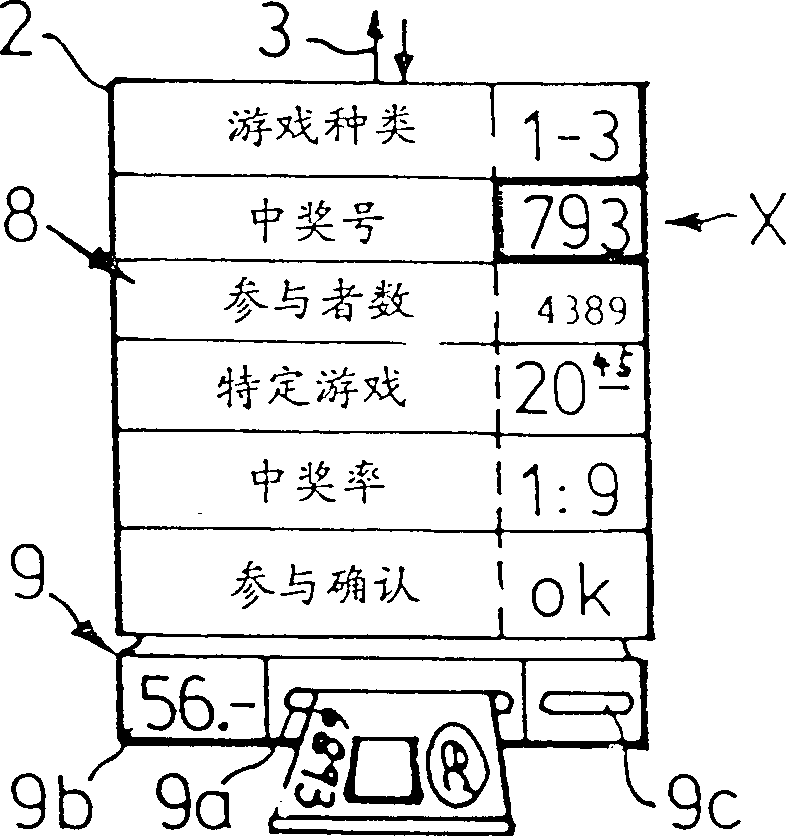

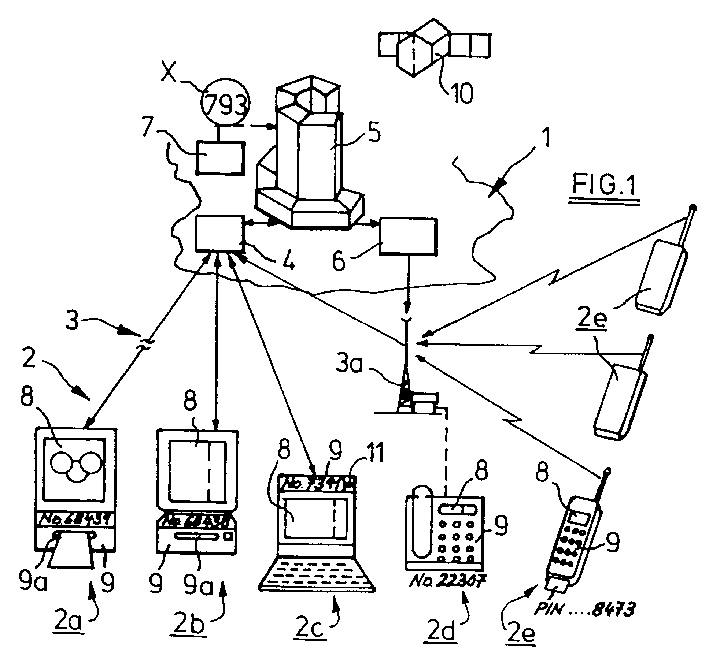

Playing device system

InactiveCN1098510CReduce management costsHigh win rateData processing applicationsApparatus for meter-controlled dispensingTelecommunications linkRemote data transmission

A playing device system (1) can be used by a number of players with various playing devices (2) at a distance from each other. Each of these devices can be connected to a common host computer (5) via a remote data transmission system (3) and they are controlled by a random symbol generator (7) which determines a winning combination of symbols (X). In order to simplify the system, it is proposed that the random symbol generator (7) be assigned to the host computer (5), with the playing devices (2) constituting a display (8) indicating the winning combination (X) generated by the random symbol generator (7) and connected with an input device (9) to participate in the continuous determination of the winnings.

Owner:彼得埃巴

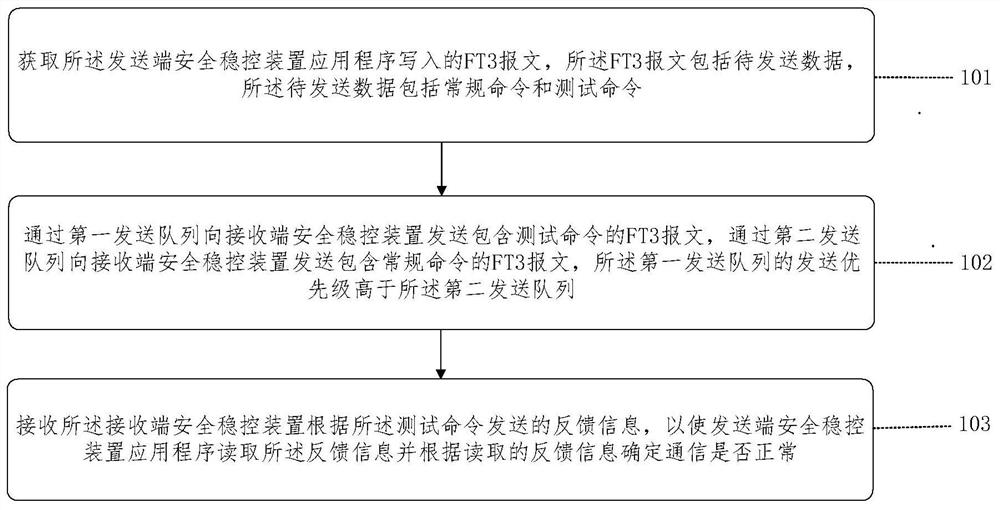

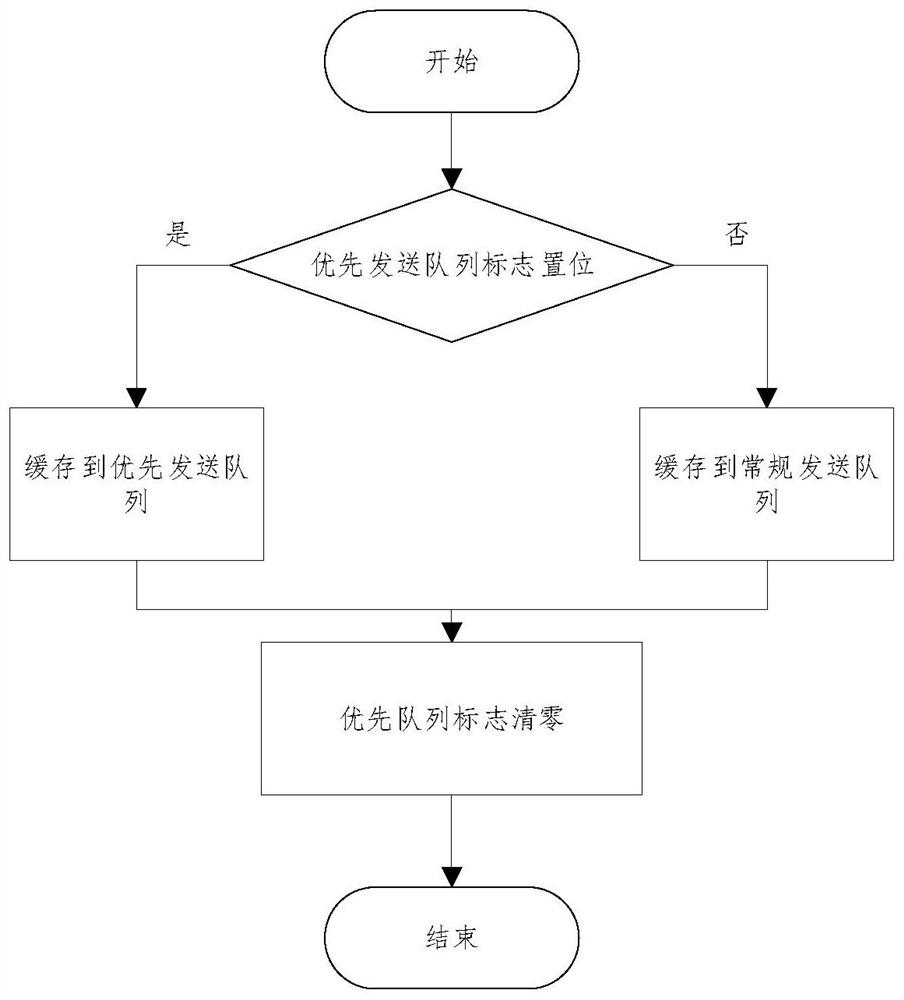

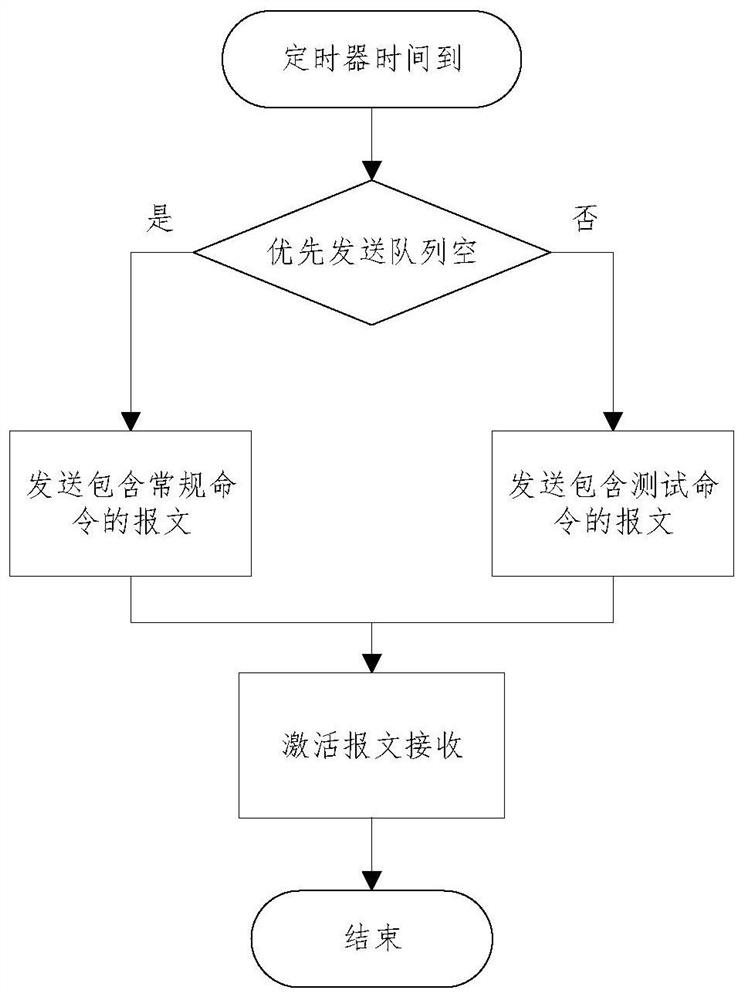

Communication method, device and system between security and stability control devices based on Ft3 protocol

PendingCN114079639AGuaranteed uptimeAvoid lostTransmissionTotal factory controlData packControl system

Disclosed is a communication method, device and system between security and stability control devices based on an FT3 protocol. The method comprises the step of: acquiring FT3 messages written by an application program of the sending end security and stability control device, wherein the FT3 messages comprise data to be sent, and the data to be sent comprises a conventional command and a test command; sending the FT3 message containing the test command to the receiving end security and stability control device through a first sending queue, sending the FT3 message containing the conventional command to the receiving end security and stability control device through a second sending queue, wherein the sending priority of the first sending queue is higher than that of the second sending queue; and receiving feedback information sent by the receiving end security and stability control device according to the test command, so that the application program of the sending end security and stability control device reads the feedback information and determines whether communication is normal or not according to the read feedback information. Therefore, normal operation of the security and stability control system can be ensured, and loss caused by failure of the security and stability control system is avoided.

Owner:XUJI GRP

A suspension for four-wheel mobile robot chassis

ActiveCN104085266BImprove the installation effectEasy to installInterconnection systemsResilient suspensionsBody rollVehicle frame

The invention provides a suspension for a chassis of a four-wheel moving robot. The suspension comprises at least one pair of elastic supporting devices and a connecting assembly used for connecting the elastic supporting devices. Each elastic supporting device comprises an upper connecting rod, a lower connecting rod, a first stroke limiting structure and a compressing spring. The connecting assembly comprises a second stroke limiting structure and at least one extension spring. The suspension is installed between a frame and an axle of the four-wheel moving robot and used for transmitting force and torque acted between wheels and the frame. According to the suspension, a three-freedom-degree elastic parallel mechanism can reduce side-sway of a robot body running on the uneven road surface, centralization of impact force on the frame from the wheels in the jolting or shaking state is dispersed, reversing loads of the robot body are reduced, load distribution of the four wheels is improved, and the adhesion between the wheels and the ground and the riding comfort are improved.

Owner:SHENZHEN SMART SECURITY & SURVEILLANCE SERVICE ROBOT CO LTD

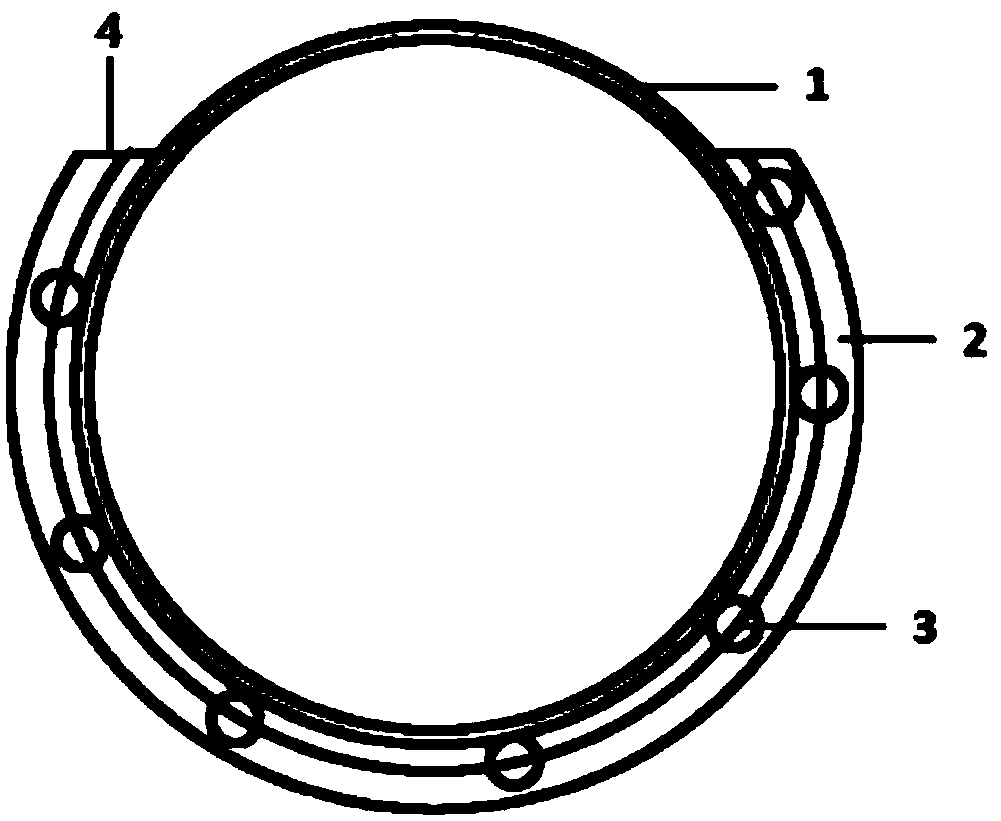

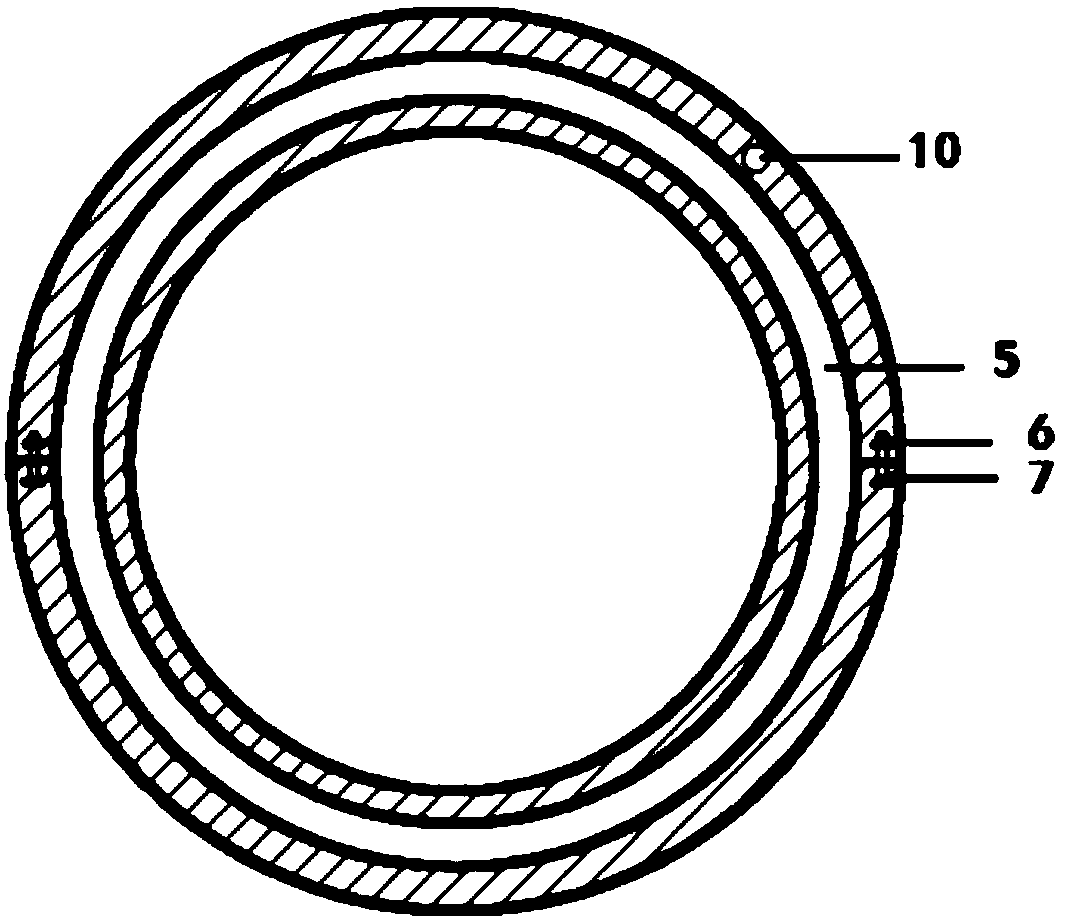

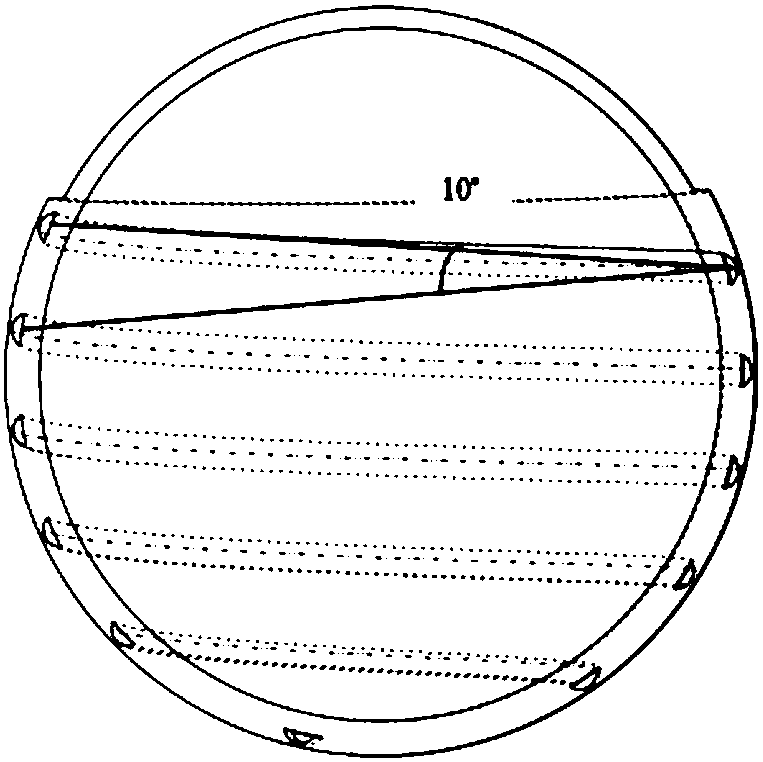

Lubricating bearing applied to multi-freedom-degree spherical moving device

ActiveCN108317159AReduces the possibility of fatigue damageReduce the cushioning forcePivotal connectionsRolling resistanceEngineering

The invention provides a lubricating bearing applied to a multi-freedom-degree spherical moving device which comprises a complete spherical inner shell and a non-complete spherical outer shell, wherein the outer surface of the inner shell and the inner surface of the outer shell are spherical surfaces with the coincident sphere center, the outer shell is connected and fixed by two bolts, a spiralarc groove with a spiral angle in a 10 to 15-degree range is arranged on the inner surface of the outer shell, a holder on which rolling balls are arranged is arranged in the groove, an oil inlet is arranged in the outer surface of the casing, injected lubricating oil can enter a spiral rolling way to fill a layer of lubricating oil between the inner shell and the outer shell, and a layer of sealing ring is arranged between the inner shell and the outer shell to prevent the lubricating oil from leaking. The lubricating bearing disclosed by the invention has the advantages of compact and reasonable structure and convenience in installation; the rolling balls in the spiral arc groove can bear larger radial load, axial load and radial-axial combined load and can change sliding friction into rolling friction, so that a friction type is changed, and a friction coefficient is reduced; the lubricating bearing has the advantages of very good wear resistance, and the service life of the lubricating bearing is prolonged.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com