Shaft part with surface local quenching transition area and machining process

A technology of local quenching and shaft parts, which is applied in the direction of metal material coating process, furnace type, manufacturing tools, etc., can solve the problems of broken shaft, stress concentration, strength drop, etc., and achieve the improvement of load distribution on the shaft and good application The effect of foreground, reliable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

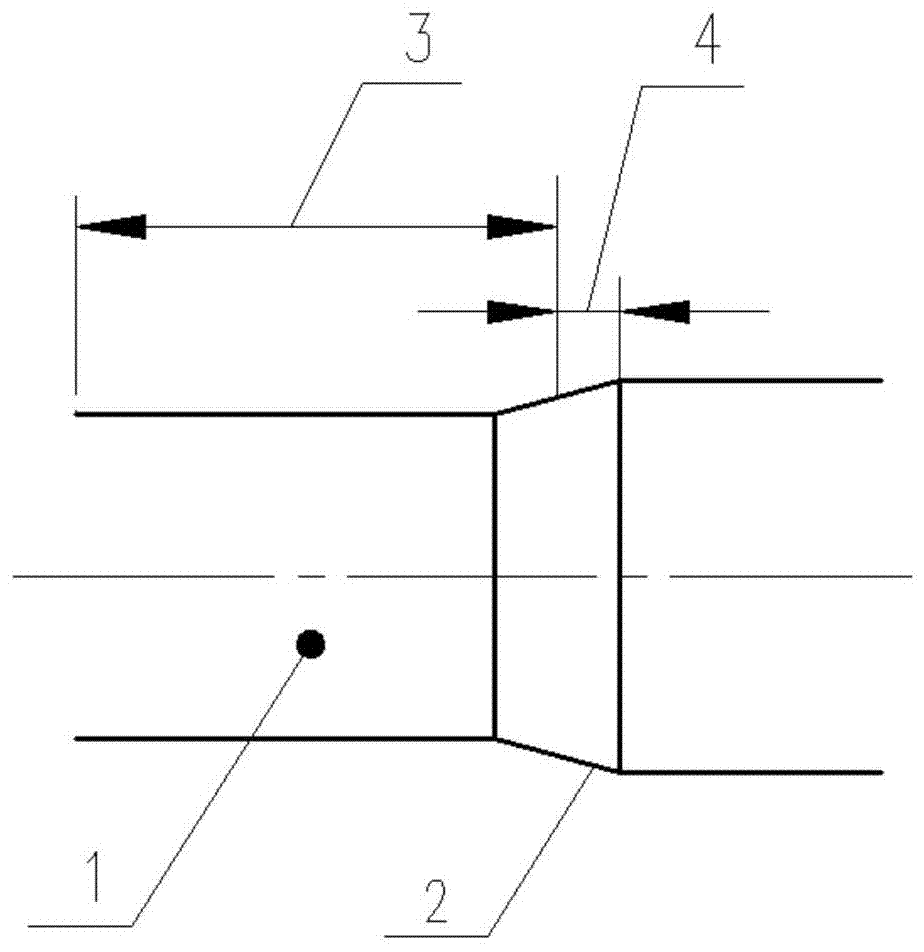

[0019] Such as figure 1 As shown, a shaft part with a partial surface quenching transition zone is a shaft part 1 including a conical cylindrical surface 2, and the partial quenching transition zone 4 on the surface of the shaft part is designed as a conical cylindrical surface 2; the surface partial quenching transition Zone 4 shaft diameter increases along the conical cylinder and the strength increases; the large head of the conical cylinder belongs to the surface partial quenching transition zone 4, the small head of the conical cylinder 2 belongs to the surface partial quenching zone 3, the surface partial quenching transition zone 4 and the surface local quenching zone 3 The junction is designed in the middle of the conical cylinder 2, and the shaft part 1 is a quenched and tempered steel shaft part or a carburized steel shaft part.

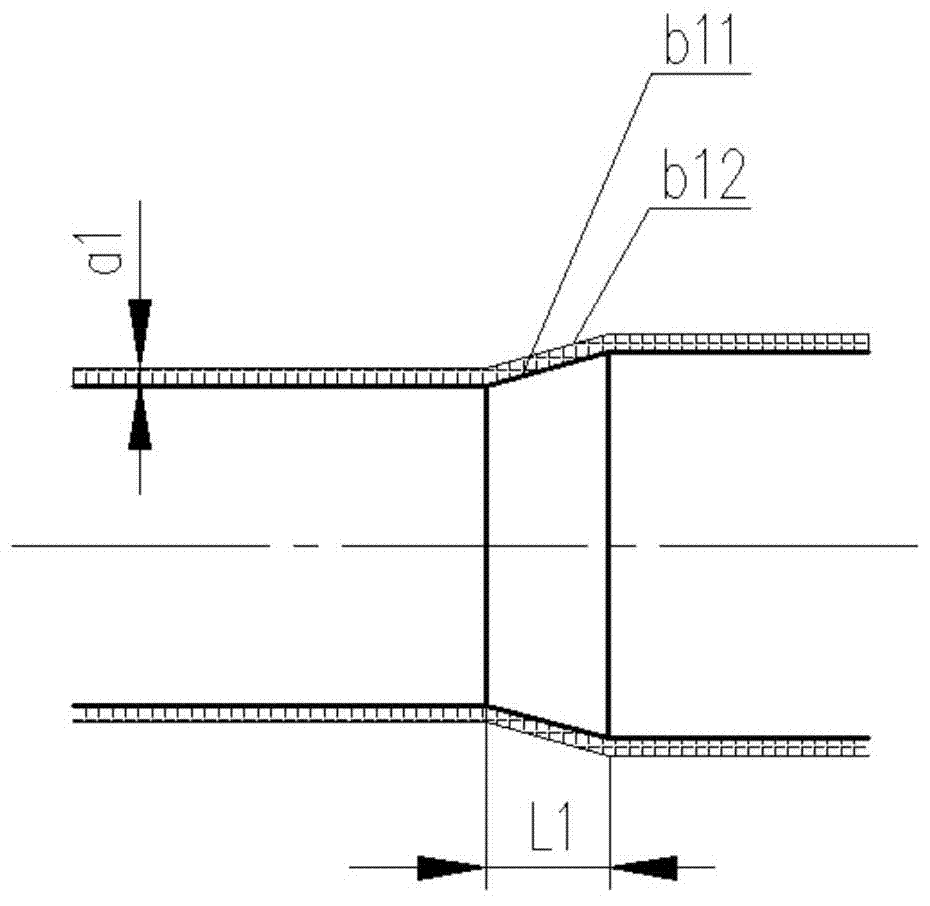

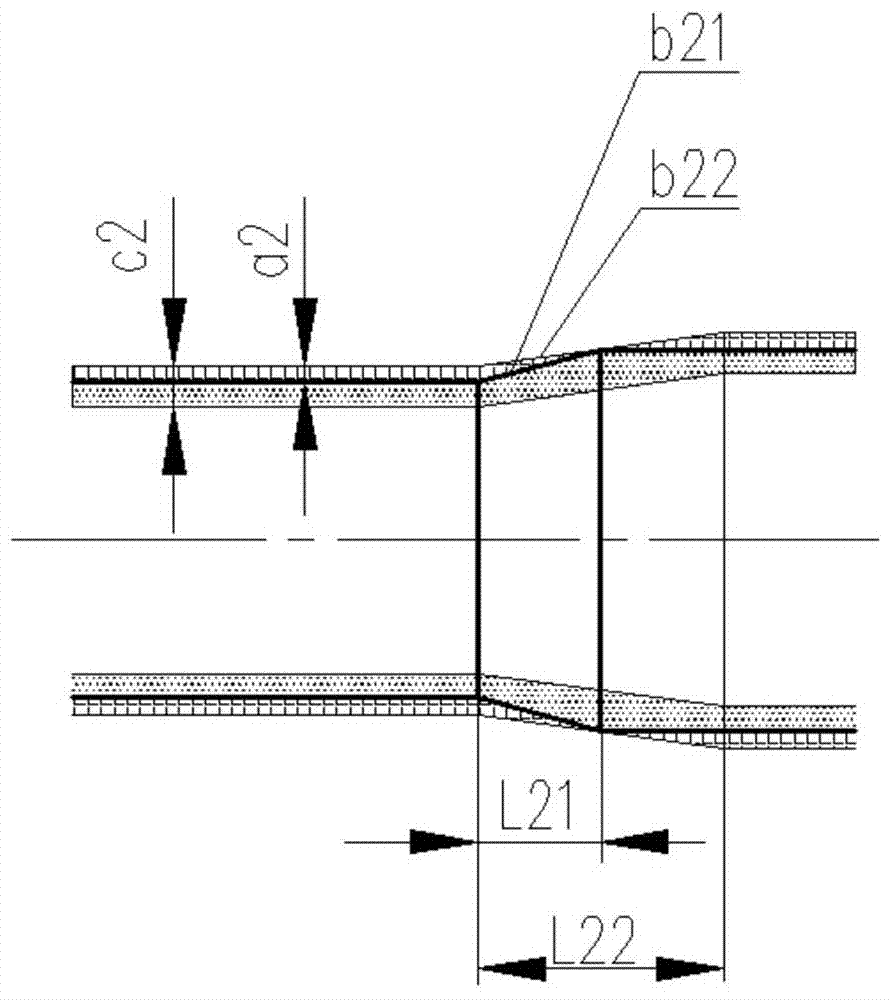

[0020] A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com