Reinforced bearing for a wind-power generator blade

A wind turbine and blade shaft technology is applied in the field of the installation structure of the blade on the wind turbine hub, which can solve the problems of large deformation and bad load distribution, and achieve the effect of improving the load distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

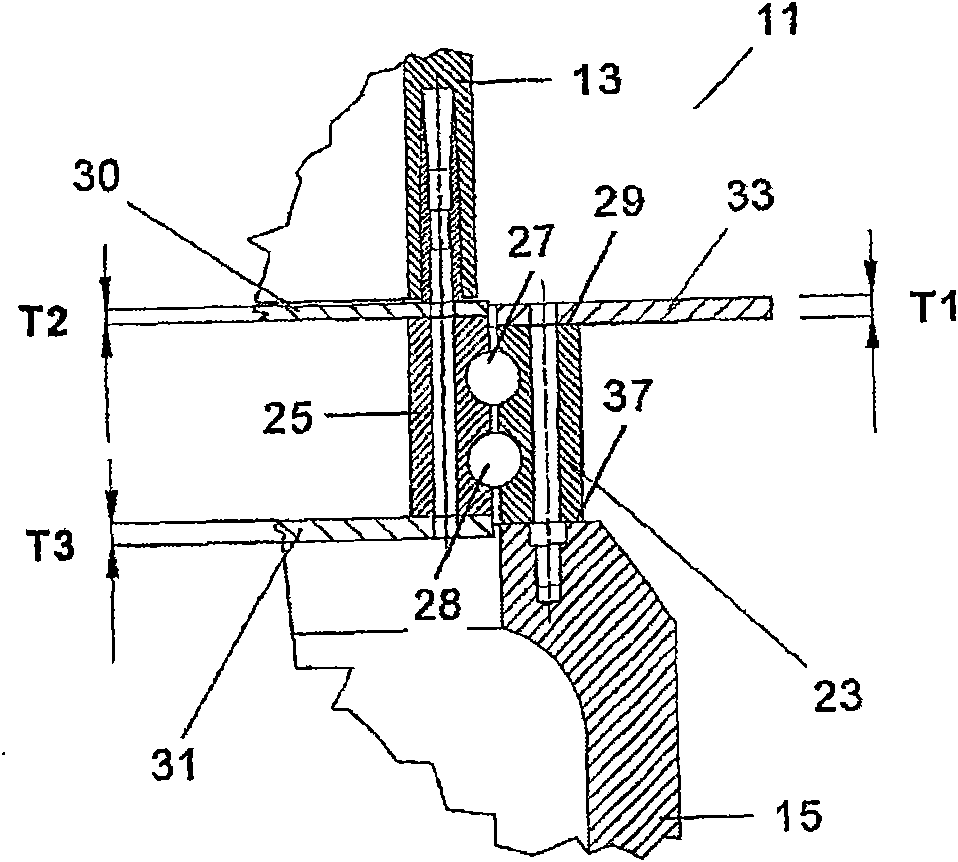

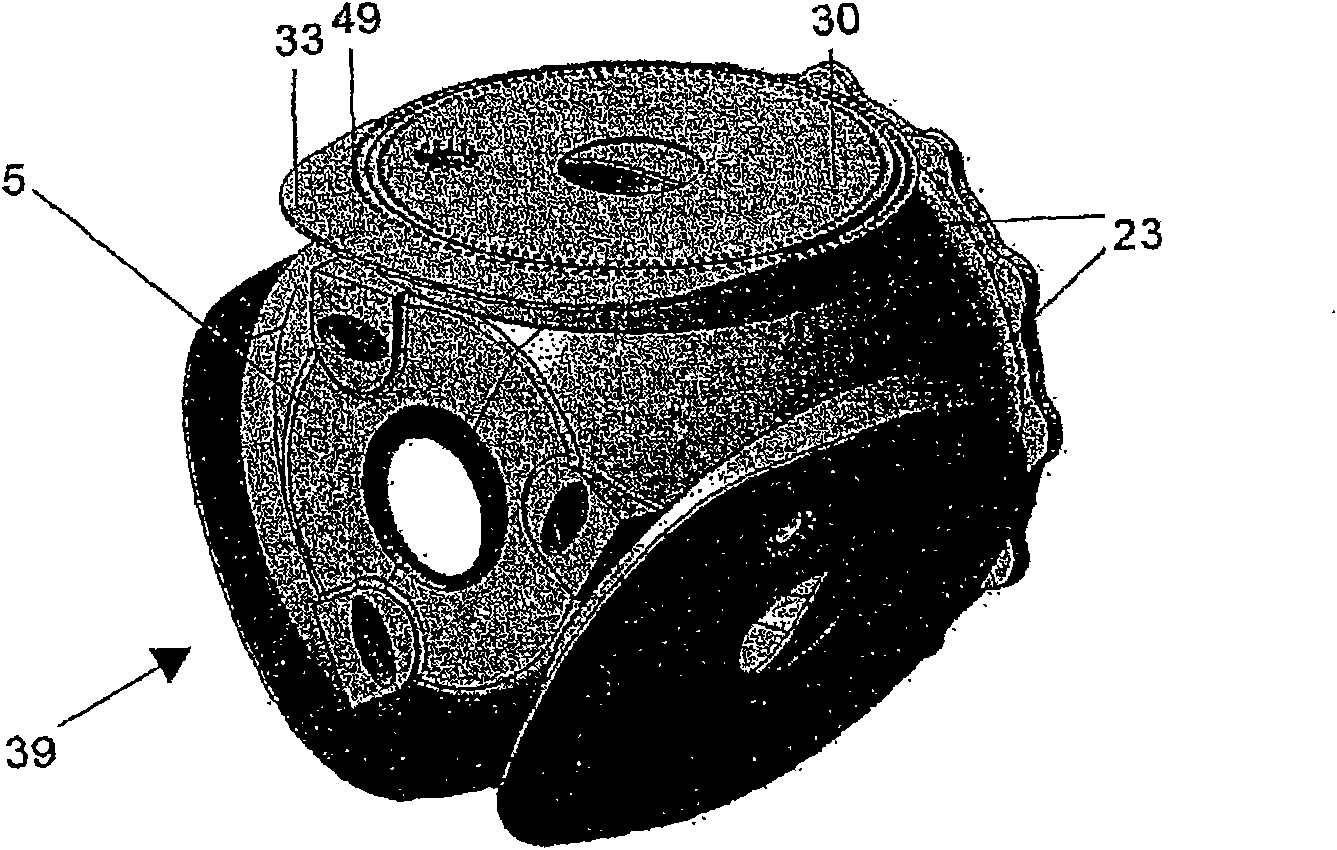

[0017] In a wind turbine with a pitch control system using a linear actuator for each blade, the known mounting structure of the blades on the hub 5 uses a bearing 11 between each blade root 13 and the corresponding hub connection 15, the bearing 11 Comprising an outer ring 23 connected to the hub connection 15, an inner ring 25 and upper and lower rows of rolling elements 27, 28, the inner ring 25 has reinforcement plates 30, 31 of thickness T2 and T3 for minimizing its deformation .

[0018] According to the invention, a reinforcing plate 33 of thickness T1 is attached to the outer ring 23 on the upper surface 29 opposite the lower surface 37 connected to the hub connection 15 . In the upper surface 29, the bearing 11 operates under tension and the outer ring 23 tends to have a large amount of deformation, thus having a poor load distribution.

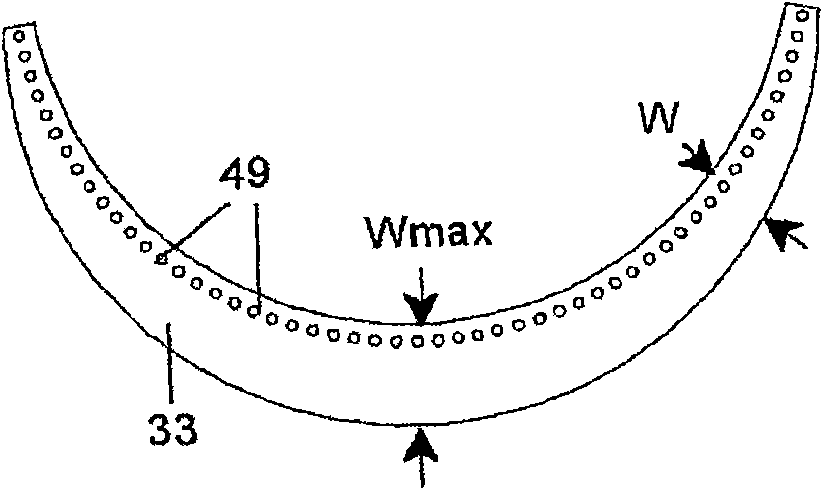

[0019] In a preferred embodiment of the invention, the stiffener plate 33 in the vertical plane of the blade shaft reinforces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com