Lubricating bearing applied to multi-freedom-degree spherical moving device

A technology for spherical motion and lubricating bearings, applied in the direction of pivot connection, etc., can solve the problems of poor adaptability of multi-degree-of-freedom spherical motion, affecting running performance, and failing to operate normally, so as to improve transmission efficiency, improve load distribution and lubrication performance, The effect of increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

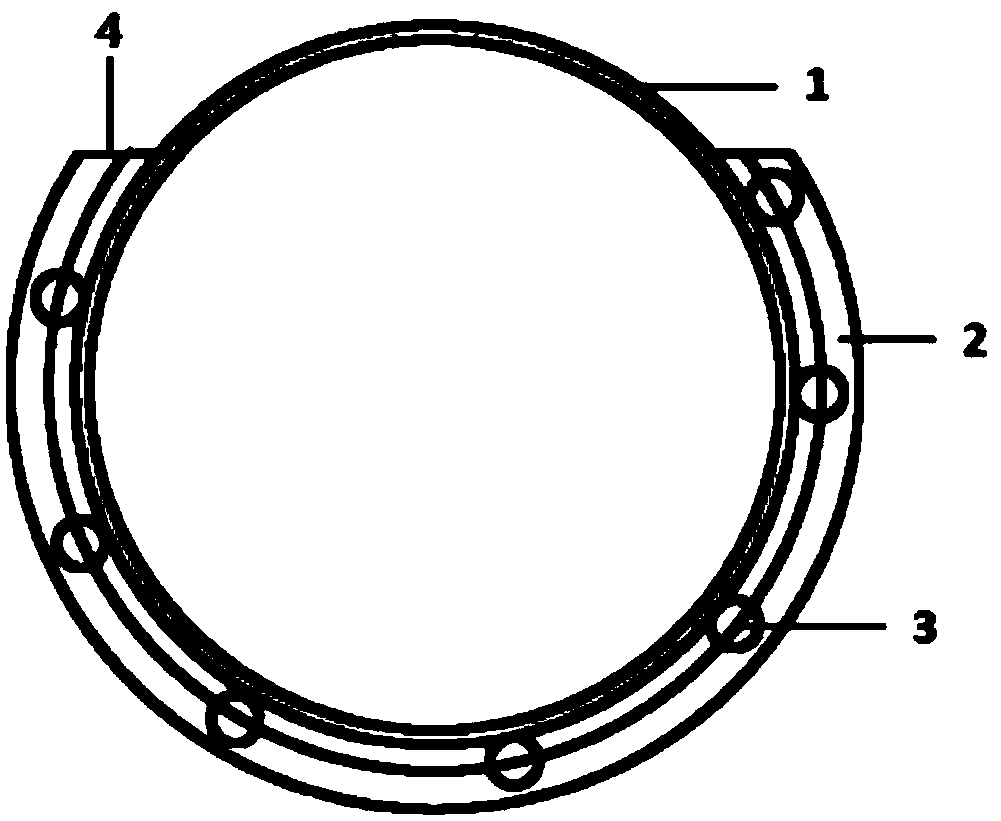

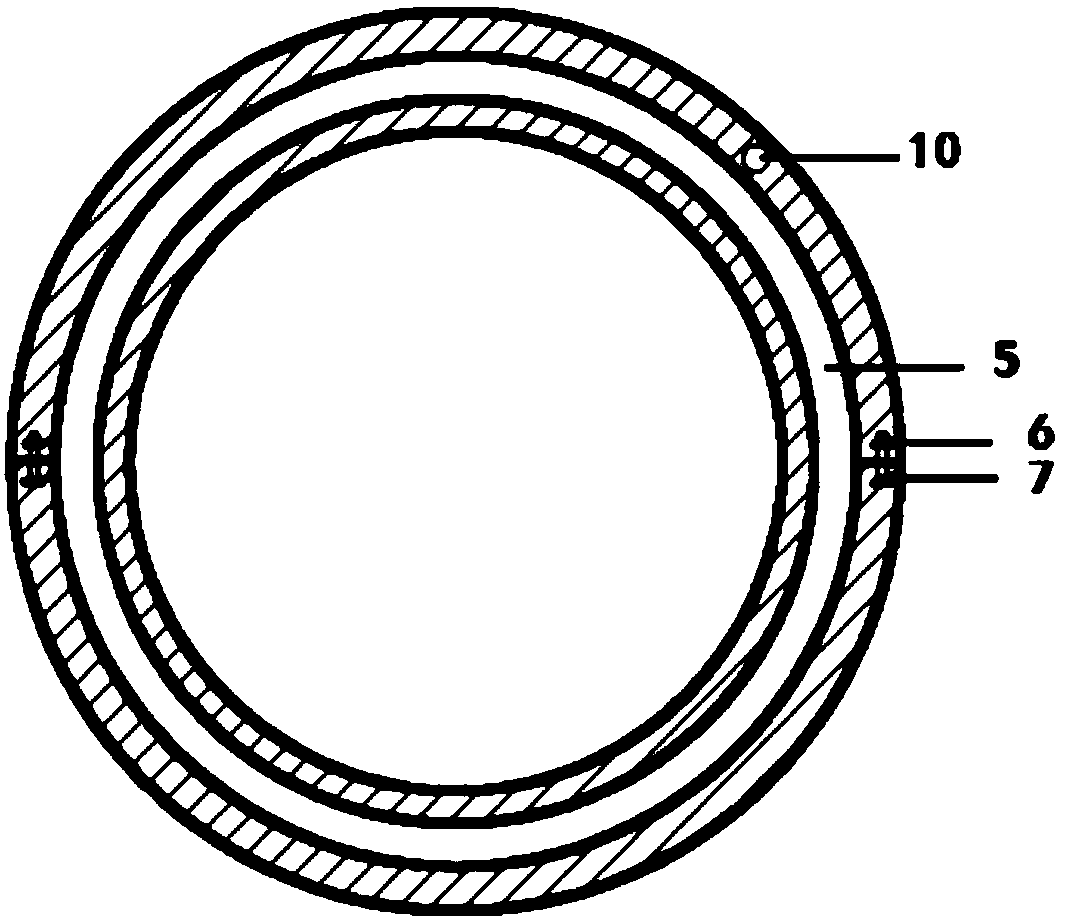

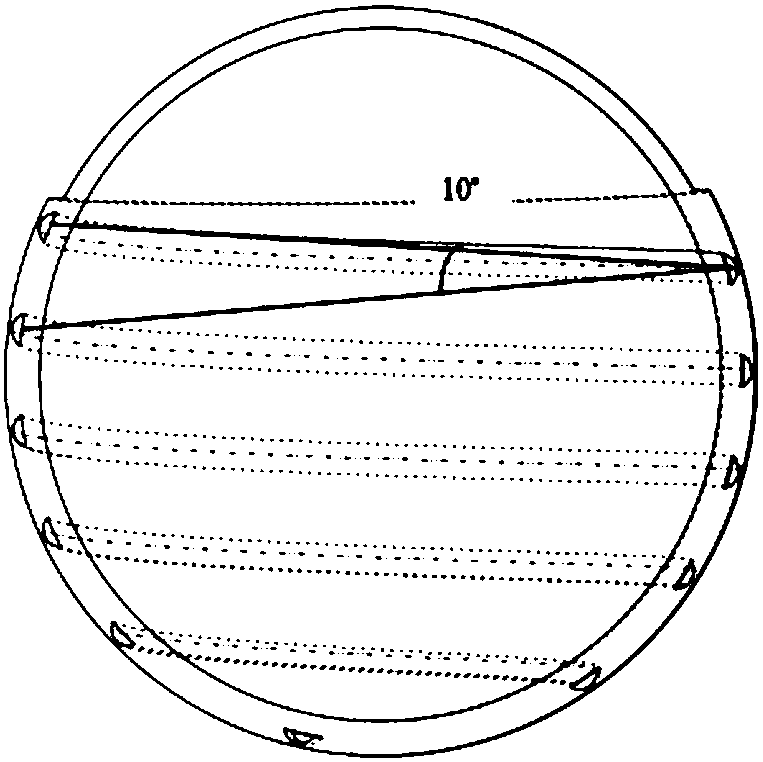

[0025] Such as figure 1 , 2 As shown, a lubricated bearing suitable for a multi-degree-of-freedom spherical motion device includes a complete spherical inner shell 1 and a non-complete spherical outer shell 2, the inner shell 1 is installed in the outer shell 2, and the The outer surface of the inner shell 1 and the inner surface of the outer shell 2 are spherical surfaces with overlapping spheres, which can complete multi-degree-of-freedom movements and have a strong bearing capacity; when the opening of the outer shell 2 is closed, it is connected and fixed by two bolt assemblies. The bolt assembly includes nuts 6 and bolts 7 , the two incomplete hemispherical shells of the casing 2 are aligned, and then the bolts 7 pass through the connecting holes on the casing 2 and are screwed and fixed by the nuts 6 . The design of the split shell makes the installation of the inner shell more convenient, without heating, it can be directly installed inside the shell, the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com