Bucket root platform double wedge shape blocks damping structure of turbine blades

A damping structure and moving blade technology, applied in the directions of blade support elements, engine elements, machines/engines, etc., can solve the problems of large frequency dispersion of blades, increase rigidity, overcome large frequency dispersion of blades, and reduce blade roots. The effect of the possibility of fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

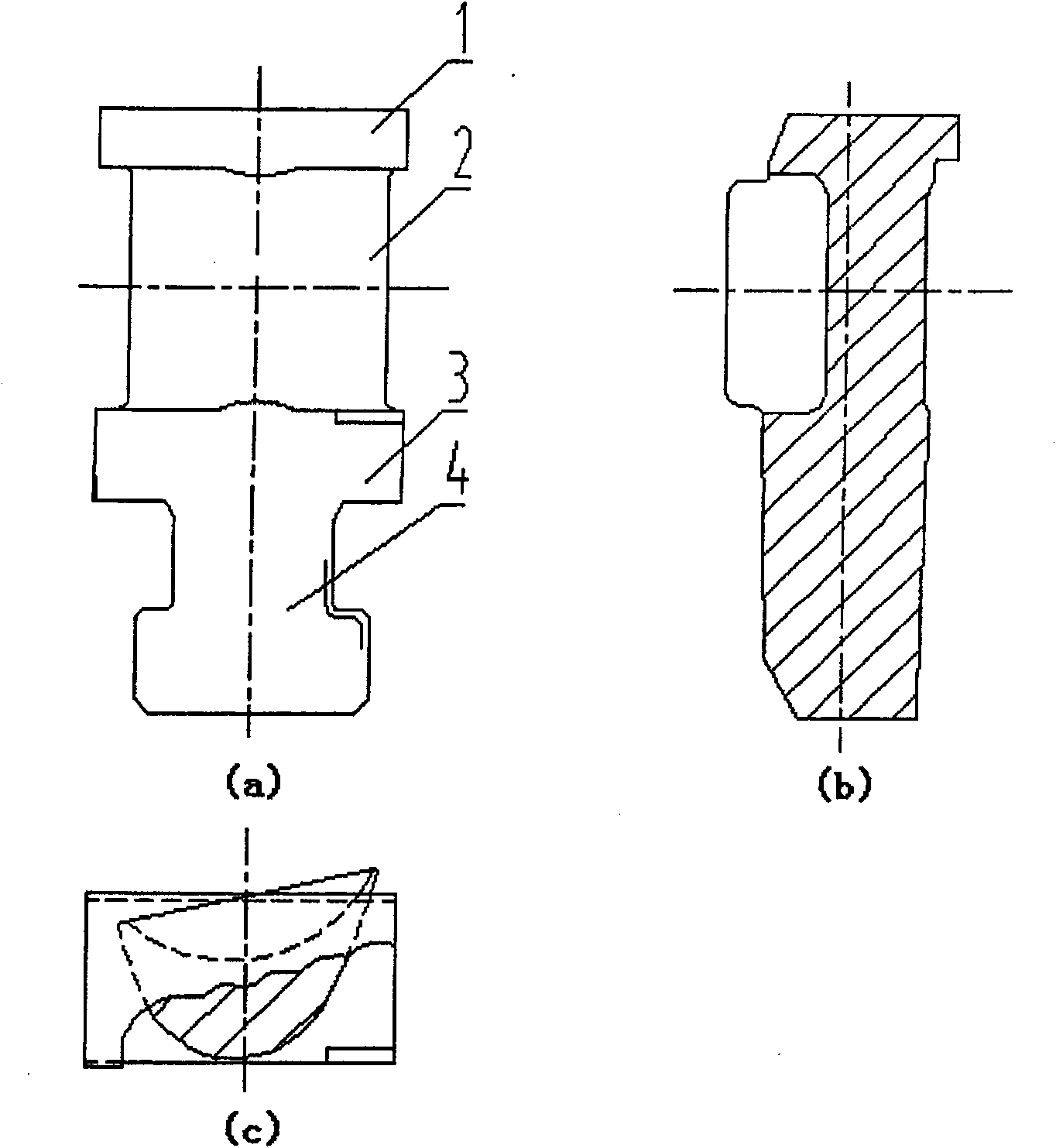

[0019] see Figure 1 to Figure 5 , taking the T-shaped blade root as an example for the following description:

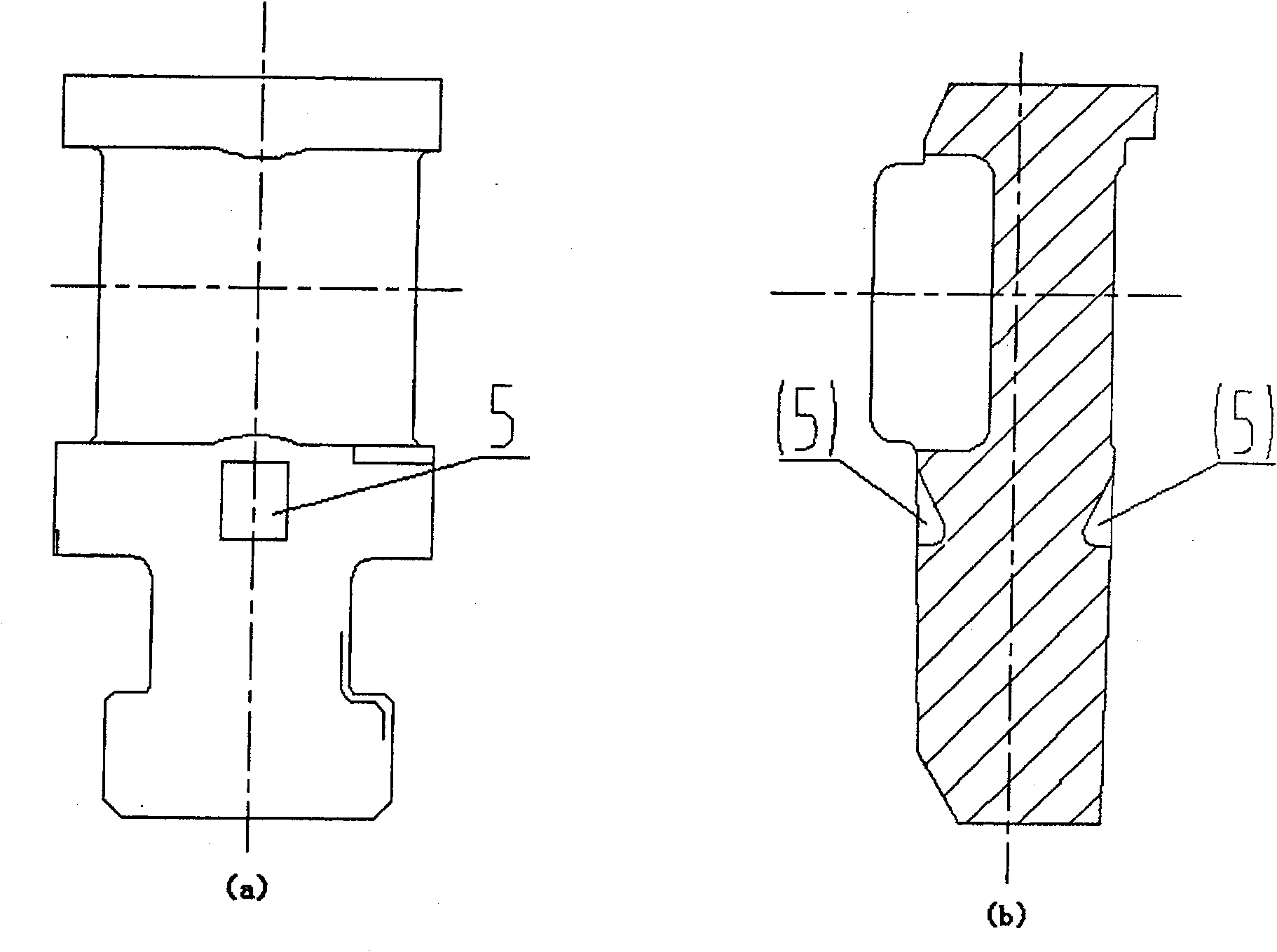

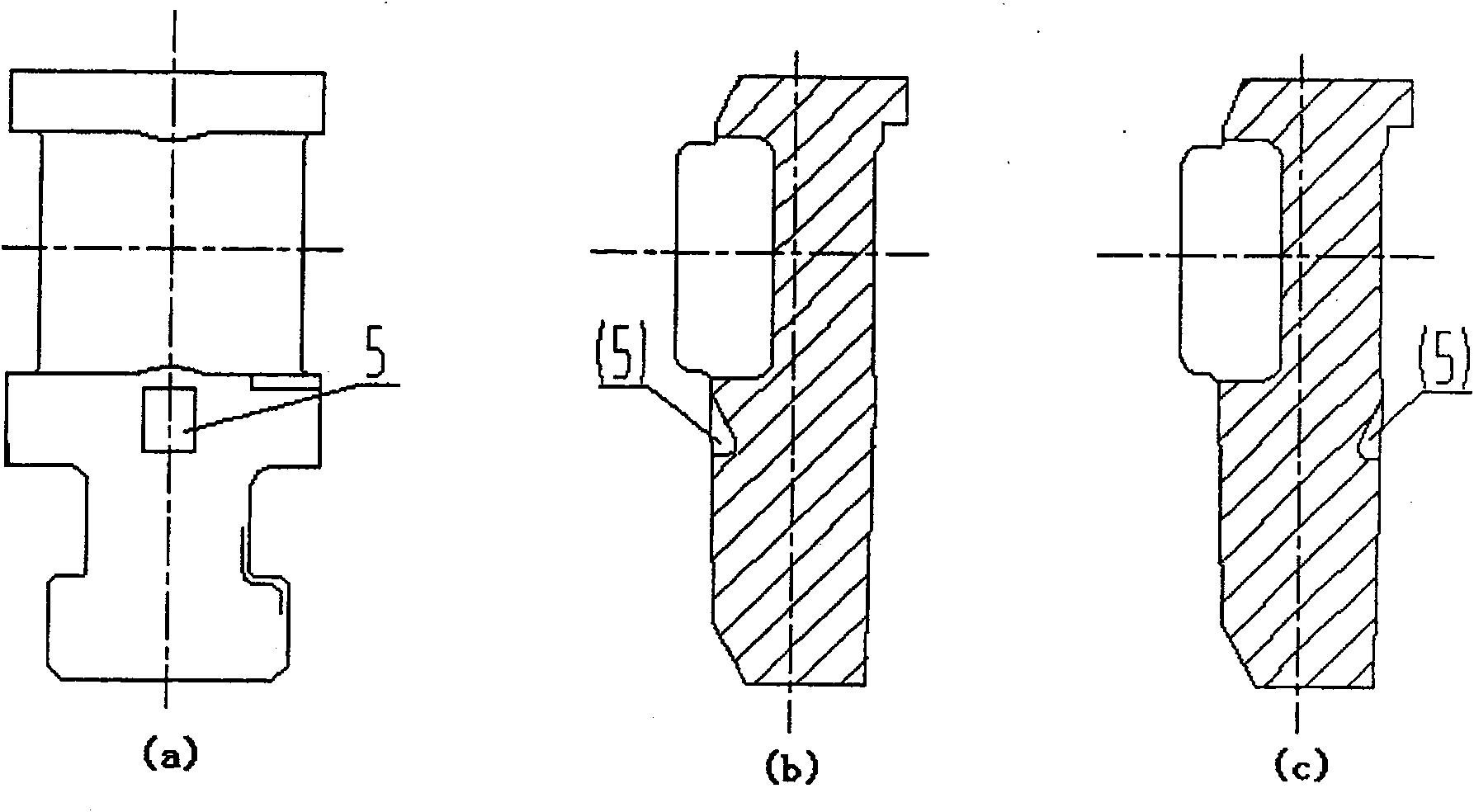

[0020] The blade root platform double-wedge block damping structure of the moving blade of the present invention comprises a shroud 1, a blade body 2, a blade root platform 3, a blade root 4, and a wedge-shaped damping block 6 installed in a gap 5 on the blade root platform 3. The moving blade, which is an important part of the turbine to realize energy conversion, is fixed on the impeller or rotor body 7 through the blade root 4 .

[0021] If the blade is a free blade, during processing, a notch 5 with a wedge-shaped cross-sectional shape is respectively processed on the two circumferential sides of each blade root platform 3, see figure 2 As shown; if the blade is a group of blades, during processing, a notch 5 with a wedge-shaped cross-sectional shape is respectively processed on the side of the blade root platform 3 matching the blade group and the adjacent bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com