Bucket root platform double wedge shape blocks damping structure of turbine bucket

A damping structure and moving blade technology, applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problem of large frequency dispersion of blades, increase rigidity, ensure tightness, and overcome large frequency dispersion of blades Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

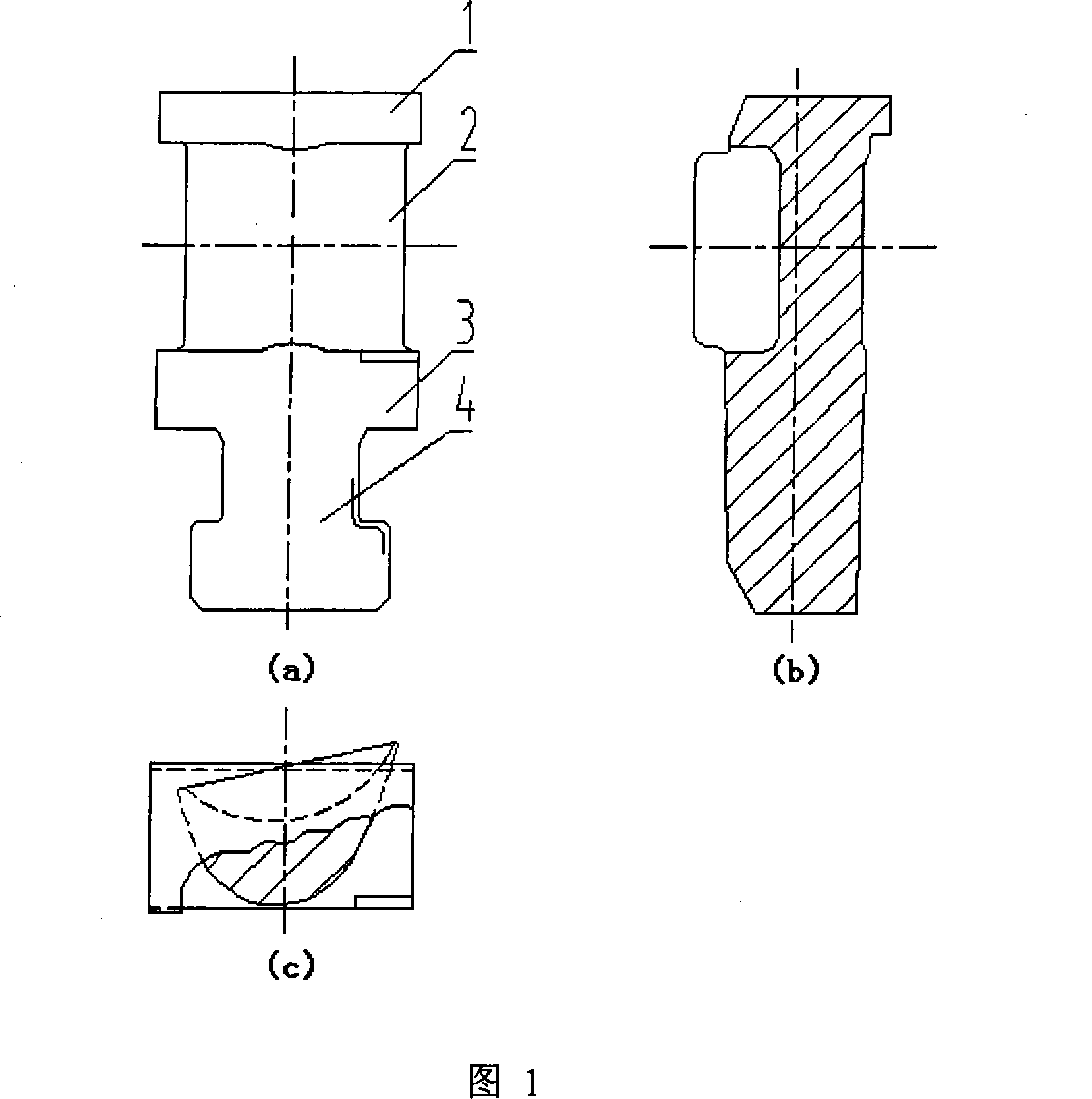

[0019] Referring to Figures 1 to 5, take the T-shaped blade root as an example for the following description:

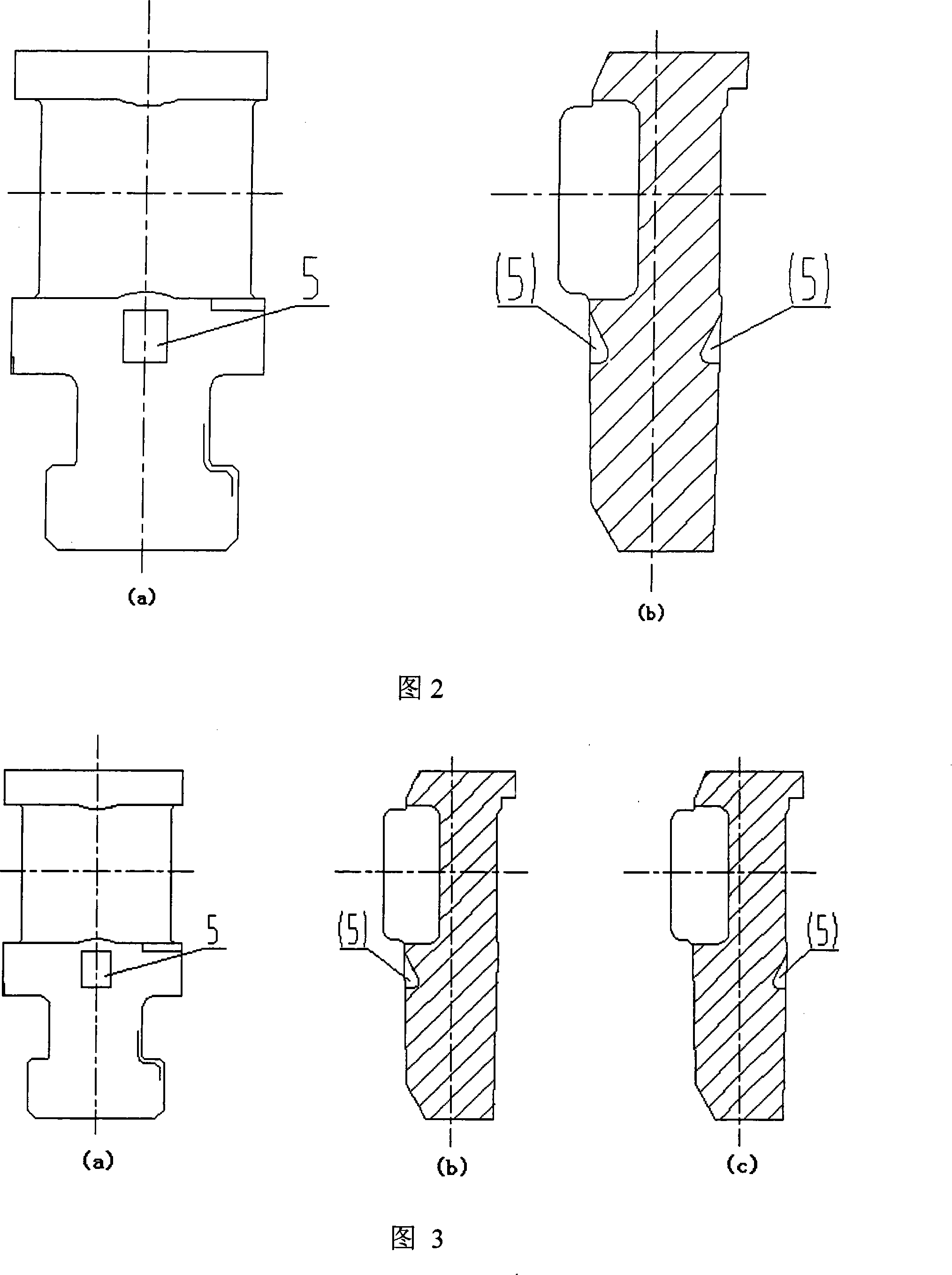

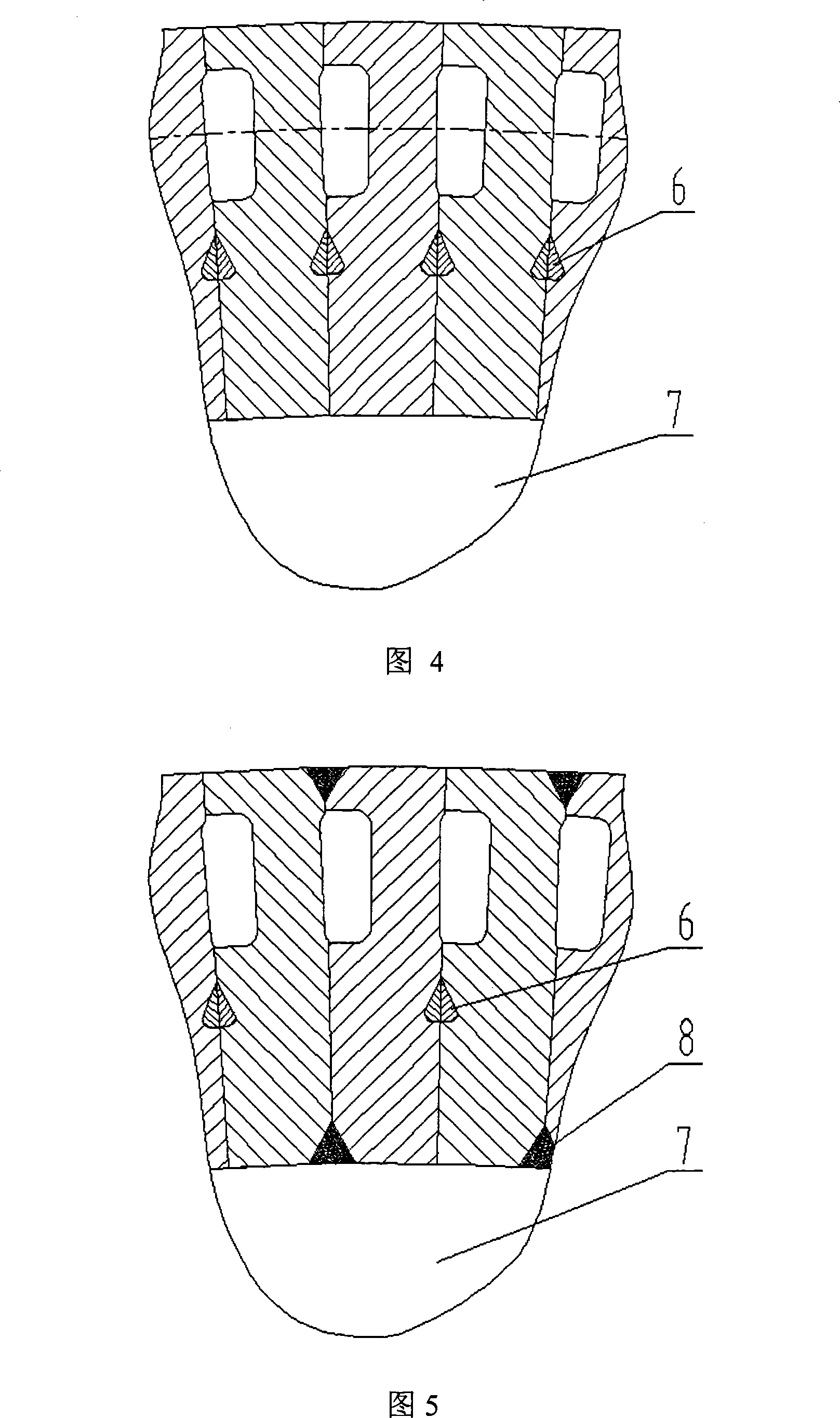

[0020] The blade root platform double-wedge block damping structure of the moving blade of the present invention comprises a shroud 1, a blade body 2, a blade root platform 3, a blade root 4, and a wedge-shaped damping block 6 installed in a gap 5 on the blade root platform 3. The moving blade, which is an important part of the turbine to realize energy conversion, is fixed on the impeller or rotor body 7 through the blade root 4 .

[0021] If the blade is a free blade, during processing, a notch 5 with a wedge-shaped cross-sectional shape is respectively processed on the two circumferential sides of each blade root platform 3, as shown in Figure 2; if the blade is a group of blades, during processing, A notch 5 with a wedge-shaped cross-section is respectively processed on the side of the blade root platform 3 matching the blade group and the adjacent blade group, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com