Patents

Literature

361 results about "Stress strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress is something that occurs in a part, usually as a result of its being assembled into a machine and loaded. However, stresses may be built into a part by processing or handling. For example, shot peening produces a compressive stress in the outer surface of a part, and also improves the fatigue strength of the part. Strength.

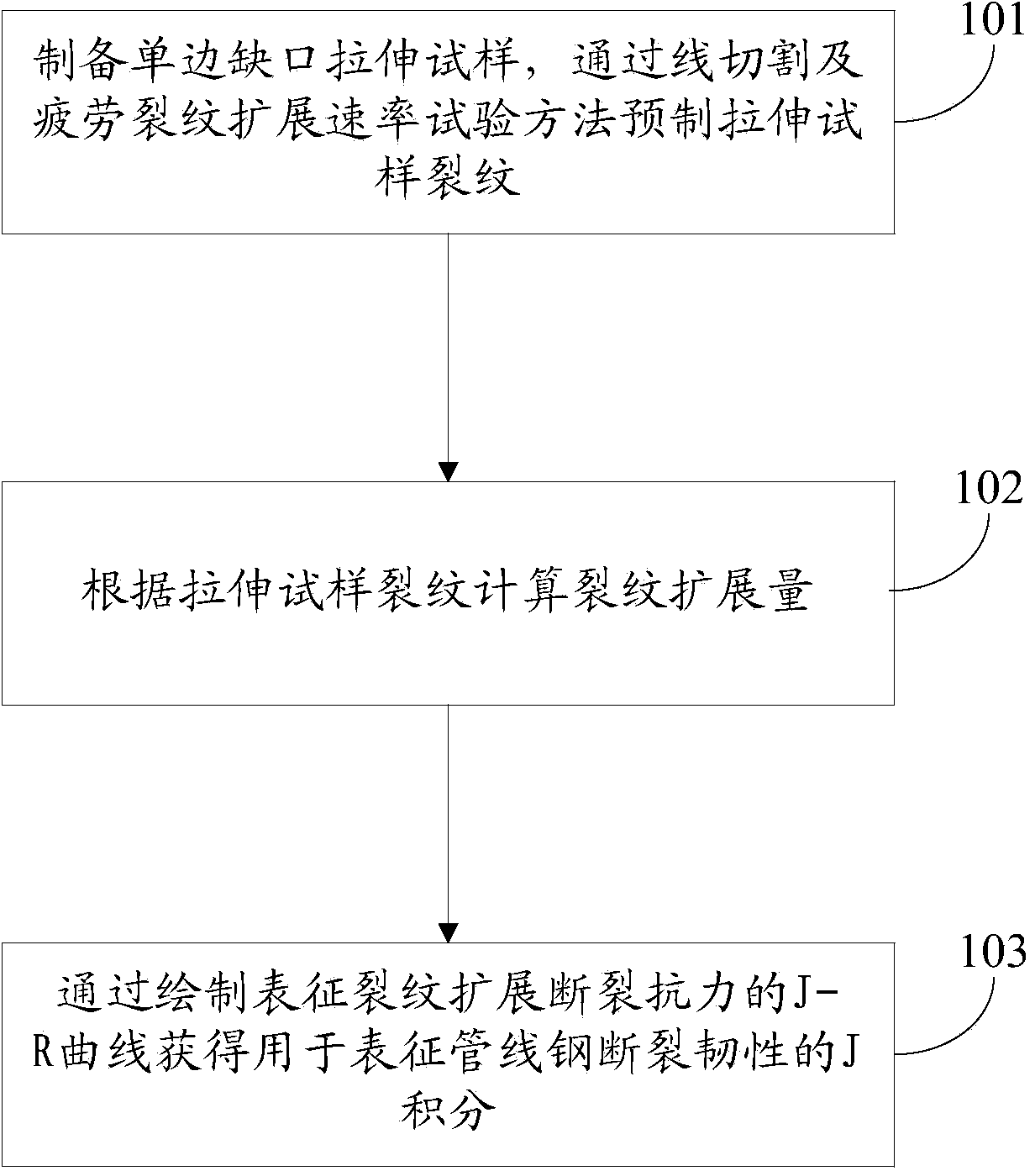

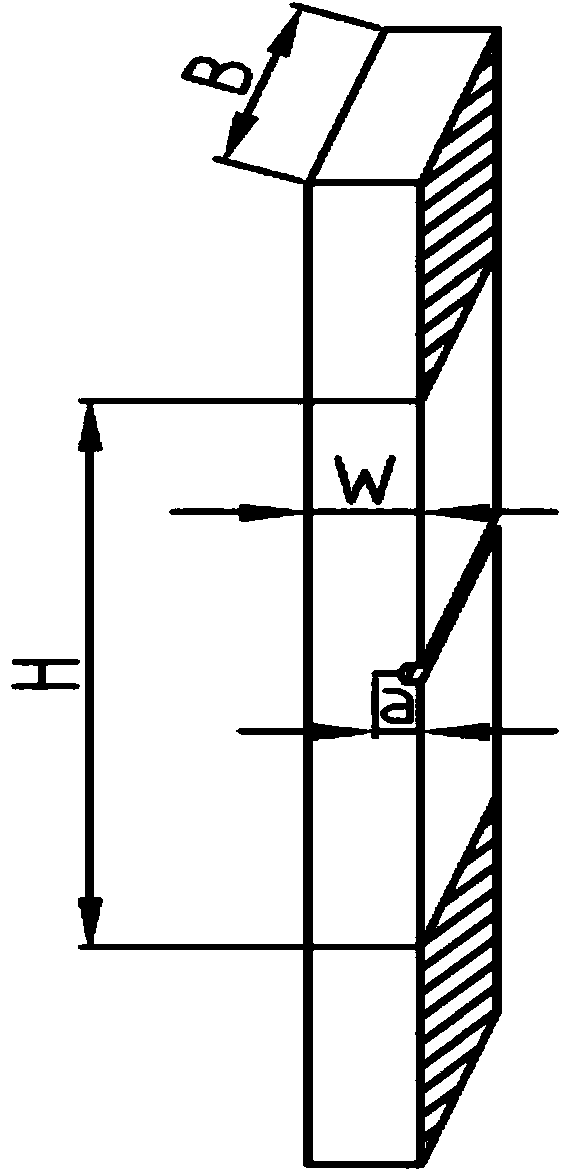

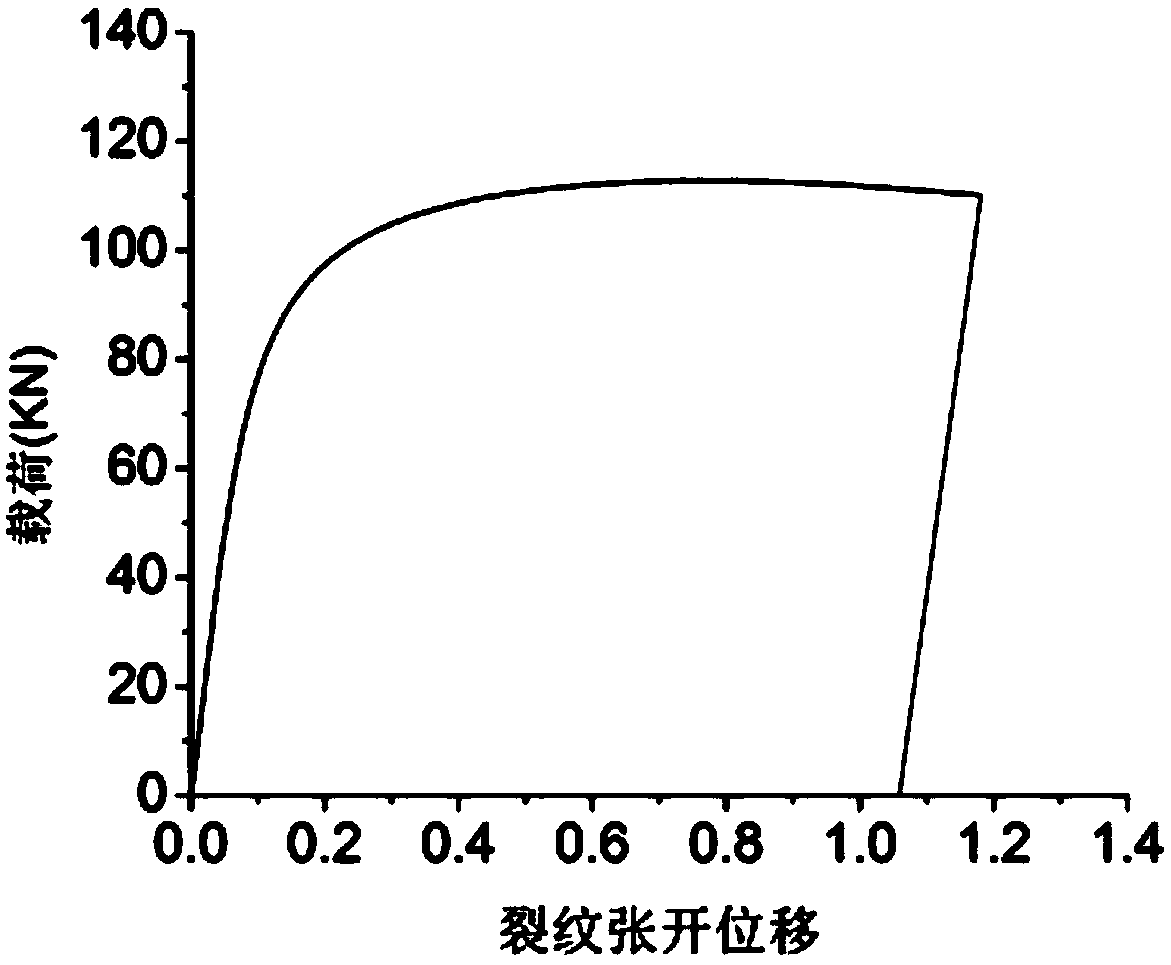

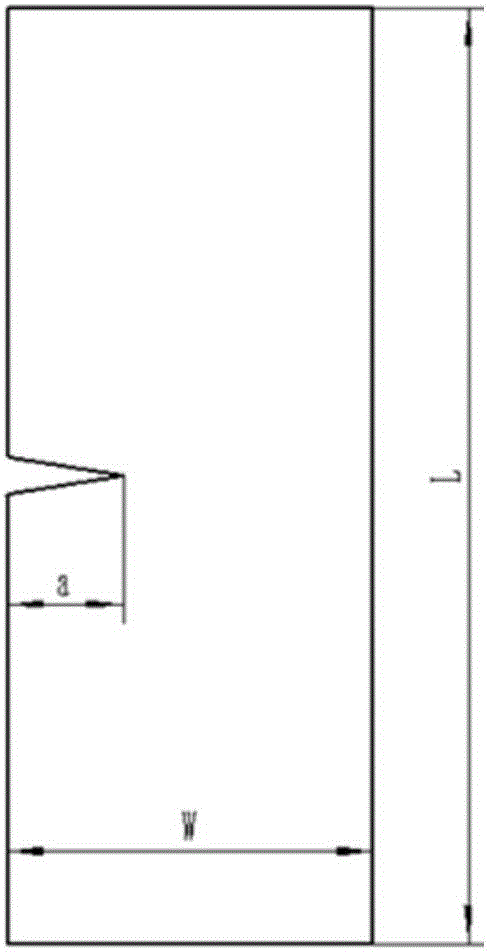

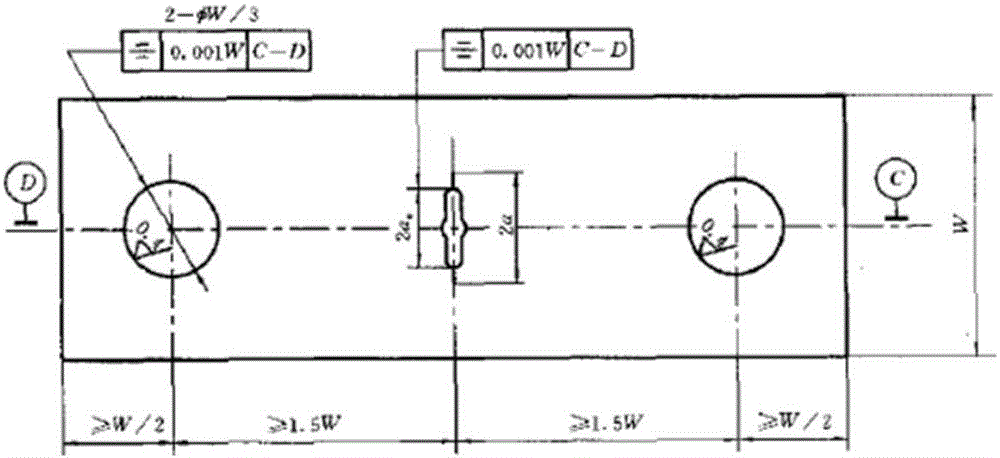

Method for measuring fracture toughness of pipeline steel by using unilateral notched tensile test

ActiveCN103604694AAvoid wastingReasonable fracture toughness valueMaterial strength using tensile/compressive forcesCrack resistanceStress intensity factor

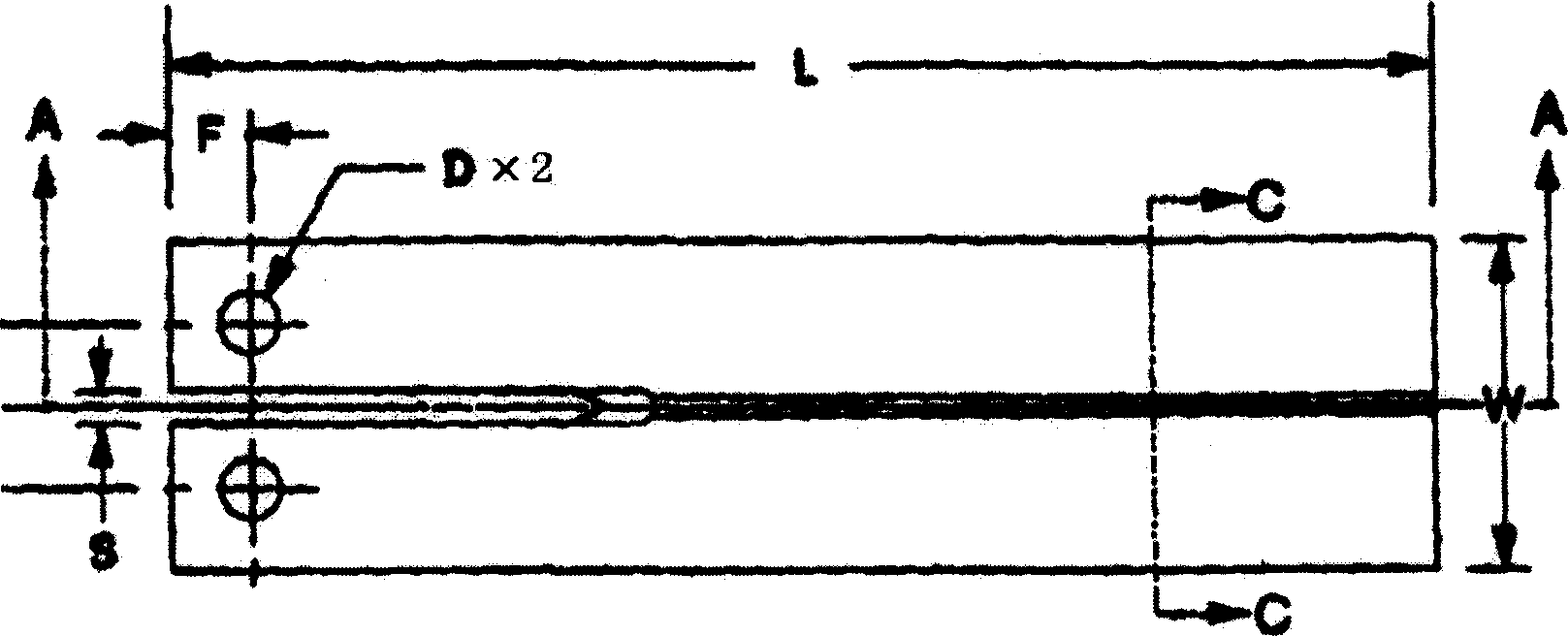

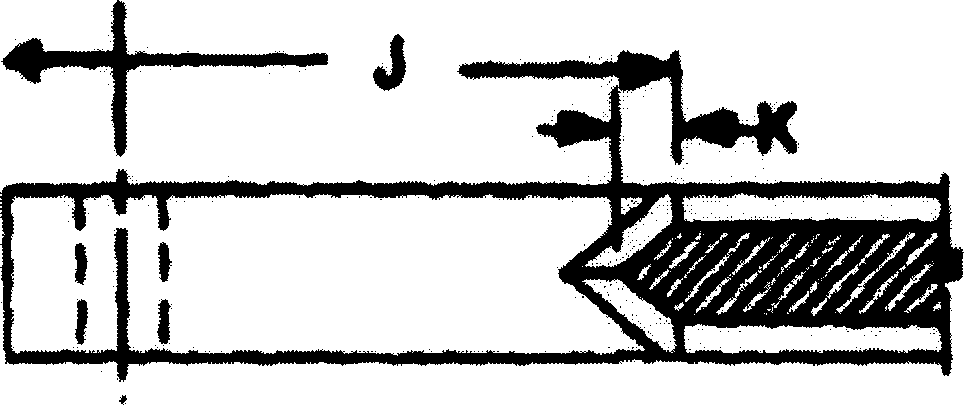

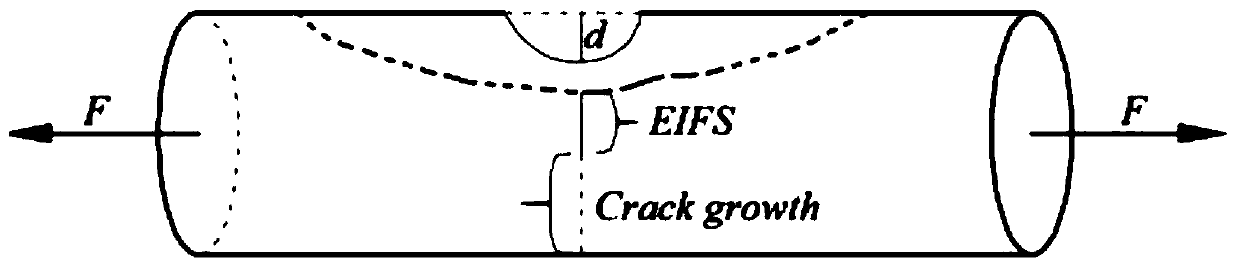

The invention discloses a method for measuring fracture toughness of pipeline steel by using a unilateral notched tensile test. The method is characterized by comprising the steps of preparing a unilateral notched tensile test sample; prefabricating a tensile sample crack by wire-electrode cutting and fatigue crack growth rate test method; calculating crack growth amount according to the tensile sample cracks; and acquiring J integration and stress intensity factor K for characterizing the fracture toughness of the pipeline steel by drawing a J-R curve for characterizing crack resistance of the crack growth. The method measures the fracture toughness of the pipeline steel by using tensile samples (SENT samples), overcomes the defects that the scope of measurement results of tensile samples (SENT samples) by a conventional technology is so small that the fracture toughness of the pipeline steel can not be evaluated; the crack toughness value of the tensile samples (SENT samples) can be more reasonable; waste of test for pipeline steel materials can be prevented; and the method has the advantages of high measurement accuracy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

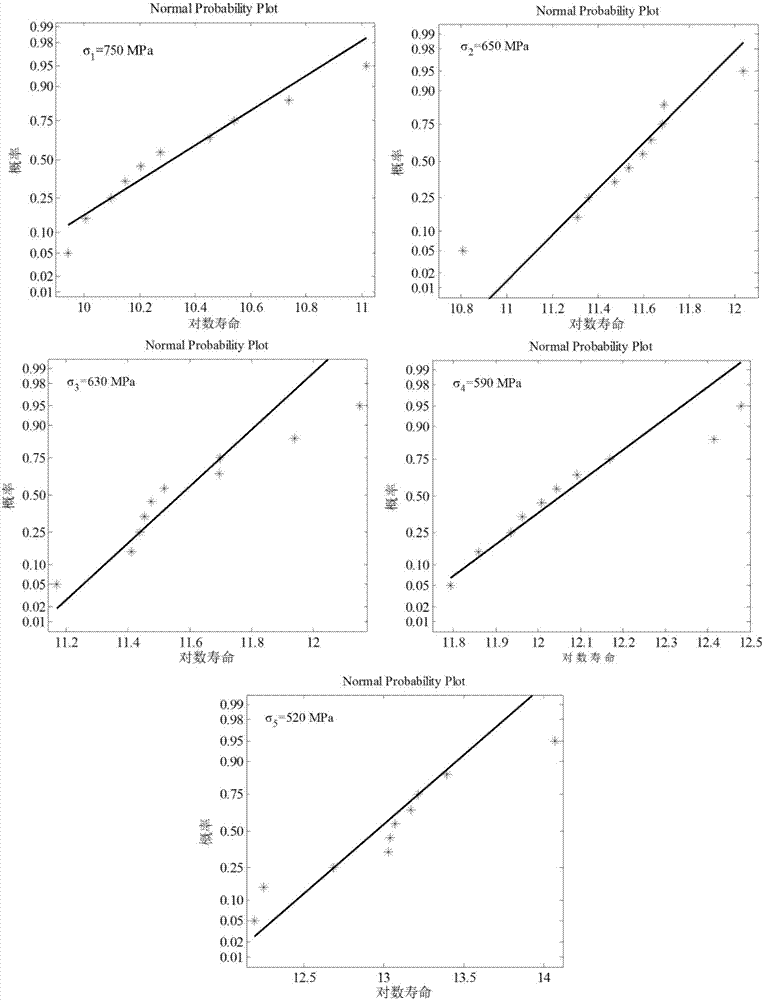

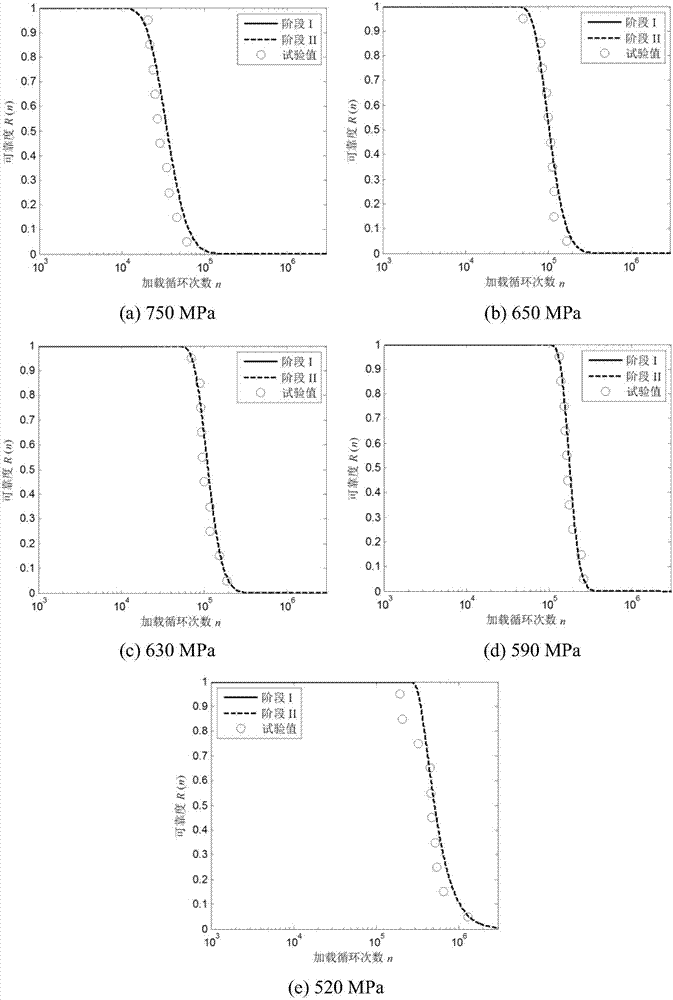

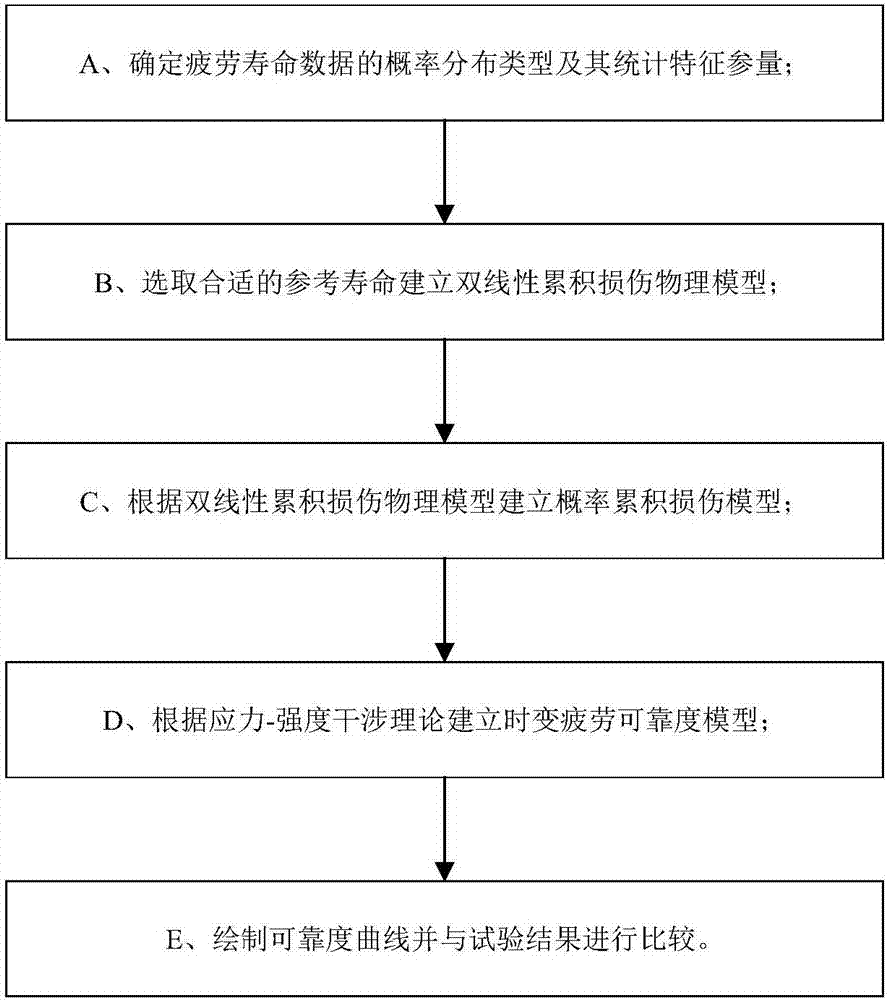

Time-dependent fatigue reliability analysis method based on bilinear cumulative damage

InactiveCN107103140AReflect time-varying characteristicsAchieving Reliability PredictionGeometric CADDesign optimisation/simulationFatigue loadingPhysical model

The invention discloses a time-dependent fatigue reliability analysis method based on bilinear cumulative damage. The method includes the steps that 1, the probability distribution type and statistical characteristic parameter of fatigue life data are determined; 2, the appropriate reference life is selected, and a bilinear cumulative damage physical model is built; 3, according to the bilinear cumulative damage physical model, a probability cumulative damage model is built; 4, according to the stress-strength interference theory, a time-dependent fatigue reliability model is built; 5, a reliability curve is drawn and compared with an experimental result; the characteristics of a crack initiation stage and a crack propagation stage in the fatigue failure process and the randomness in the damage accumulation process are comprehensively considered, the bilinear damage theory serves as a modeling base, the probability cumulative damage model is built, through the combination with the stress-strength interference theory, the time-dependent fatigue reliability model based on cumulative damage and critical damage is built, the time-varying characteristics of fatigue loading and the dynamic behavior of the damage accumulation process are reflected, and the reliability prediction in the whole fatigue life cycle is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

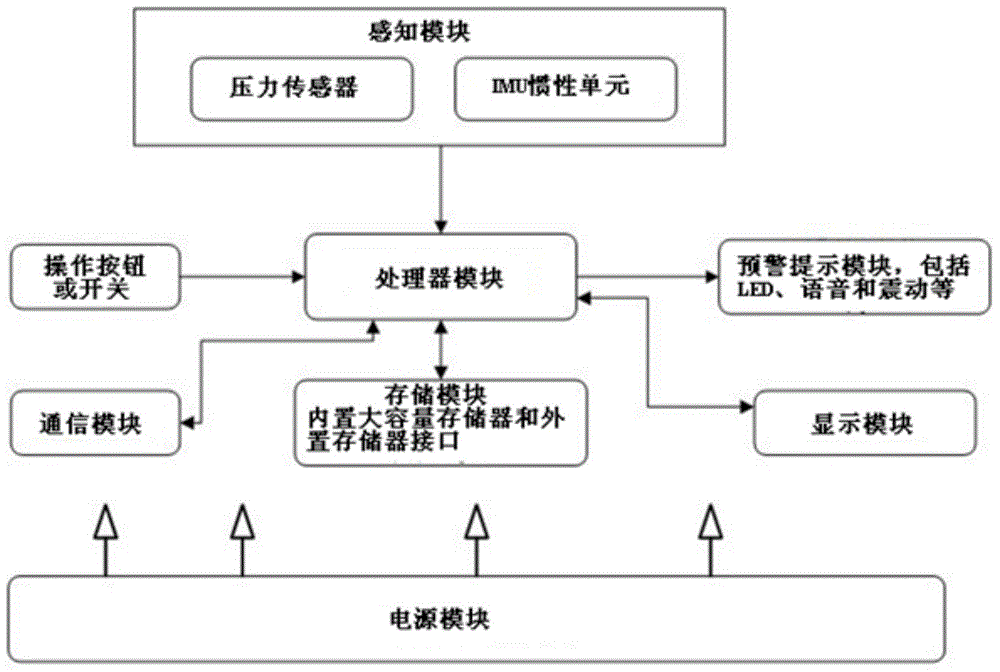

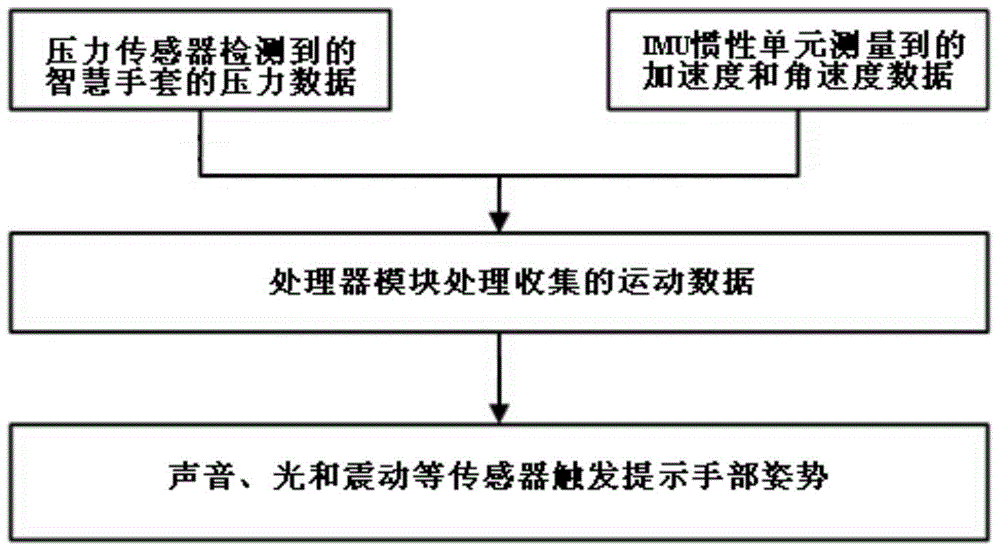

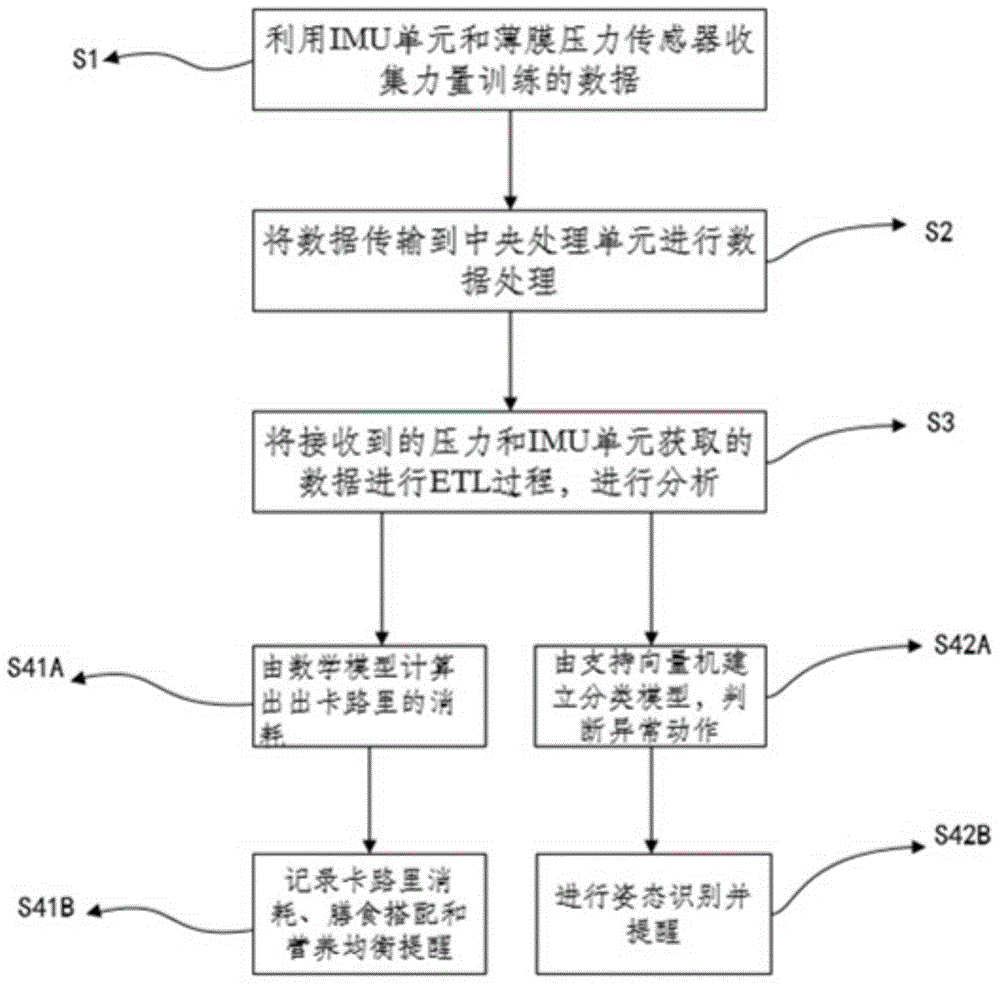

Intelligent gloves, method and system for calorie consumption and hand posture recognition

ActiveCN104888444ALow detection accuracyReduce false alarm rateGlovesSport apparatusStress strengthLarge Calorie

The invention provides a pair of intelligent gloves, method and system for calorie consumption and hand posture recognition. The pair of intelligent gloves comprises a processor module, a memory module, a communication module, an induction module, an early warning prompt module, a display module, a power module, a switch module and a cloud server. The memory module, the communication module, the induction module, the early warning prompt module, the display module, the power module, the switch module and the cloud server are respectively connected with the processor module. The induction module comprises a pressure sensor and an IMU. The pressure sensor and the IMU are respectively used for being responsible for sensing hand stress strength and IMU data in users' fitness process, collecting source data according to user strength training and sending the source data to the processor module. The processor module is responsible for preprocessing of the source data. According to the pair of intelligent gloves, in the strength training process, the detection accuracy rate of detected motions is high, the rate of false alarm is low, and alarm signals can be sent when the hand posture is deviated.

Owner:SHENZHEN UNIV

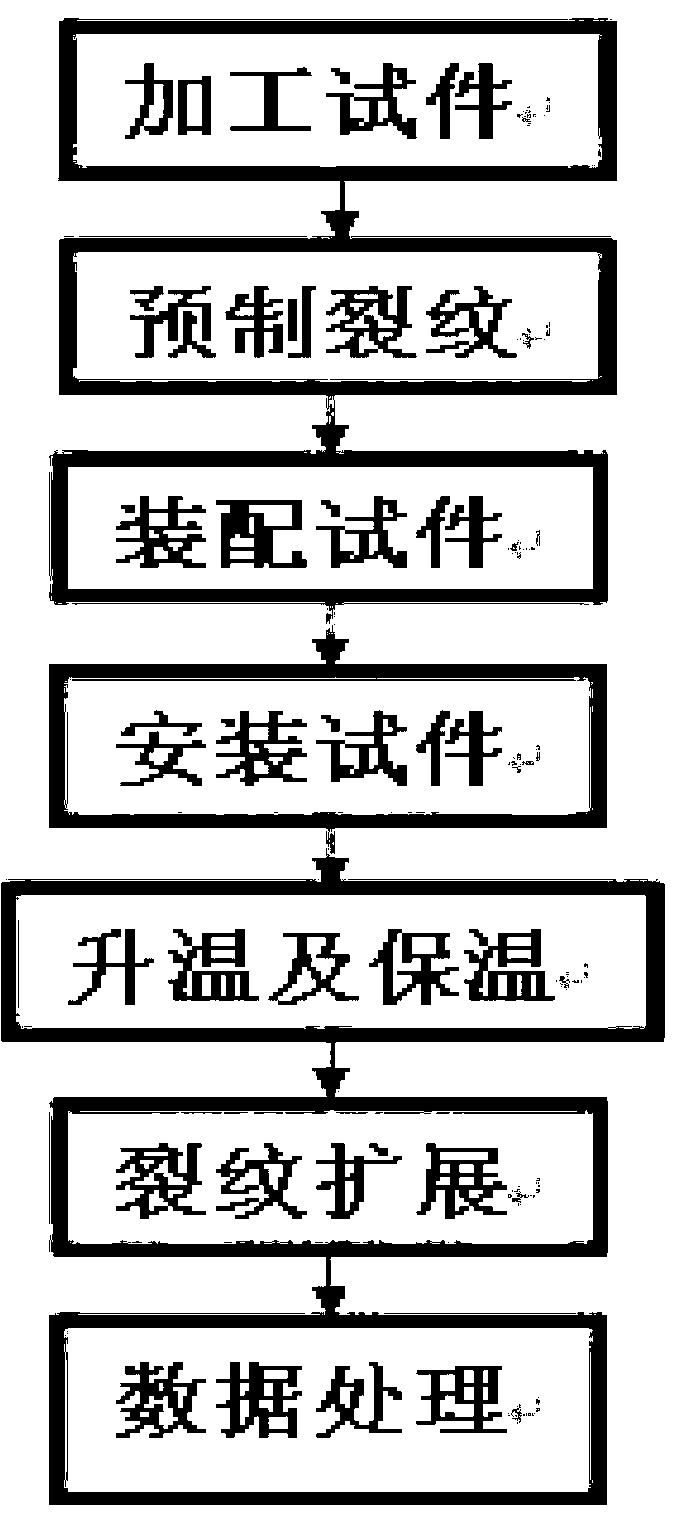

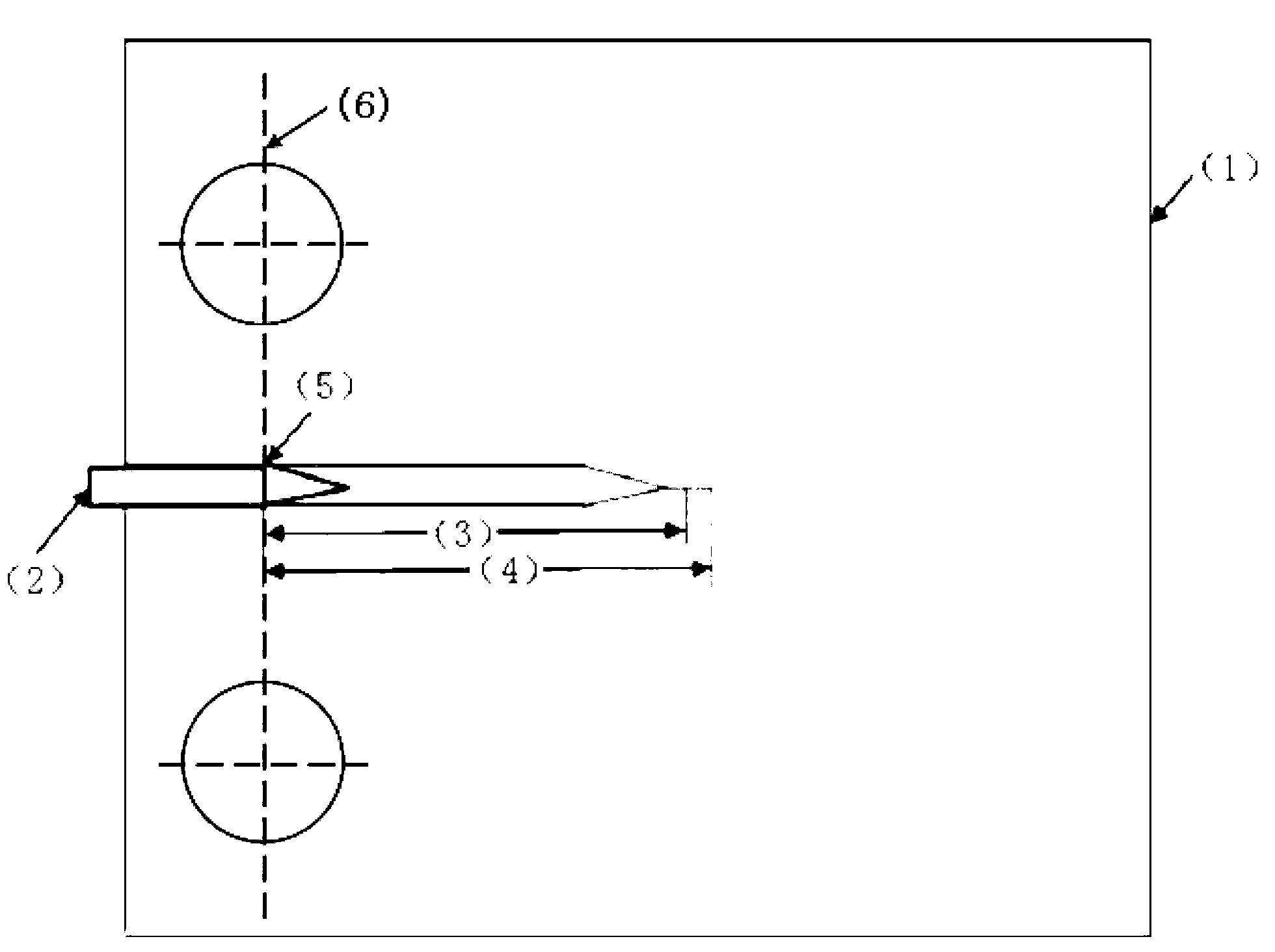

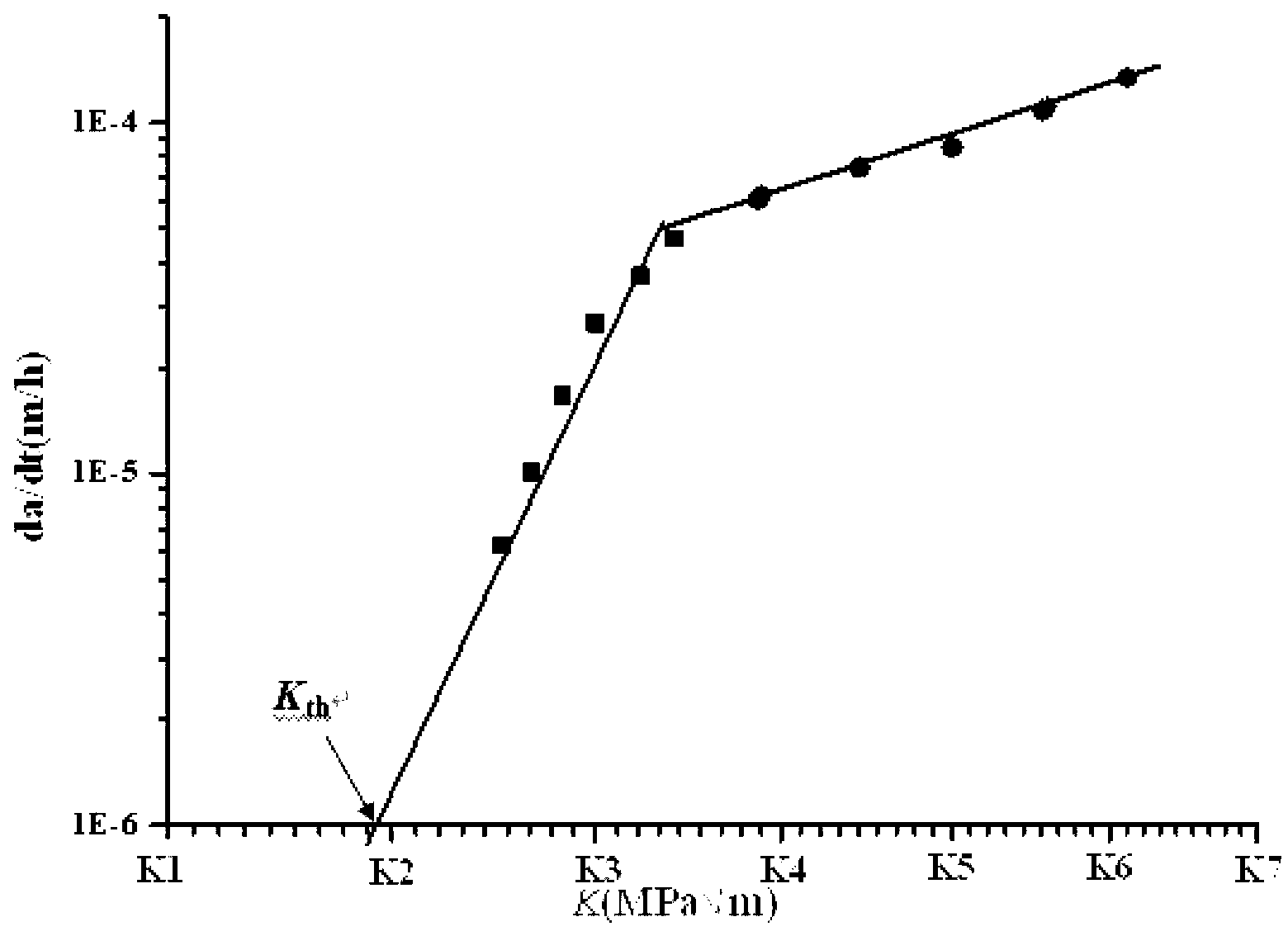

Method for measuring high-temperature creep crack growth threshold value of material

ActiveCN103217346AImprove scalabilityIncrease costInvestigating material ductilityStress intensity factorTest requirements

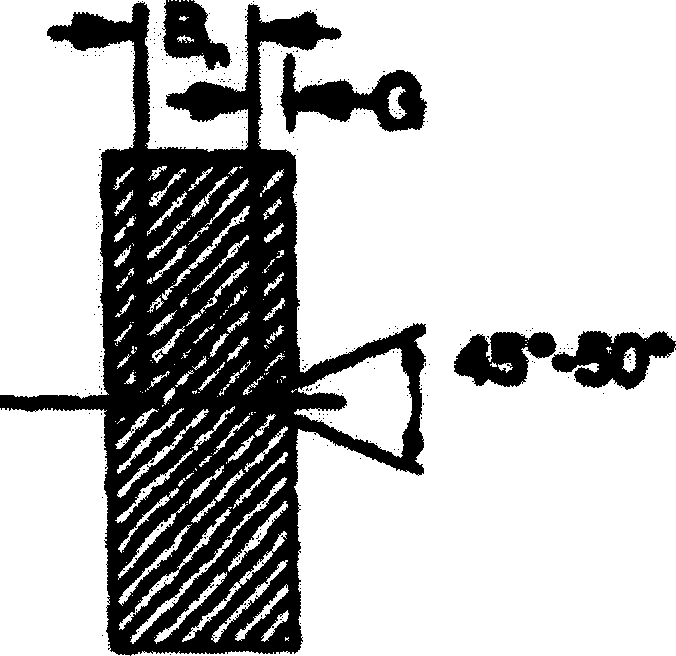

The invention discloses a method for measuring high-temperature creep crack growth threshold value of material. The method comprises the following steps of: for a specific material, according to the creep crack growth test requirement, processing at least 6 standard compact tension specimens, performing crack prefabrication for the well processed at least 6 specimens on a fatigue performance tester, wherein the prefabricated crack length is 0.5 times of the width of each specimen; wedging a wedge-shaped block into an initial notch of each specimen, placing the headmost end of the straight part of the wedge-shaped block at the position of a loading line, providing displacement for the loading line, forming a stress-strain field characterized by a stress strength factor at the tip of the specimen crack, and providing a driving force for the creep crack growth, wherein the specimens with different initial stress strength factors grow after certain time under creep effect in high-temperature environment, and in the same time interval, the crack growth lengths are different; drawing for the different stress strength factors and the corresponding crack growth rates, and solving the creep crack growth threshold value of the material through an extrapolation method. According to the method provided by the invention, multiple specimens can be tested for one time, and thus, the test cost is greatly reduced and the test time is greatly shortened.

Owner:BEIHANG UNIV

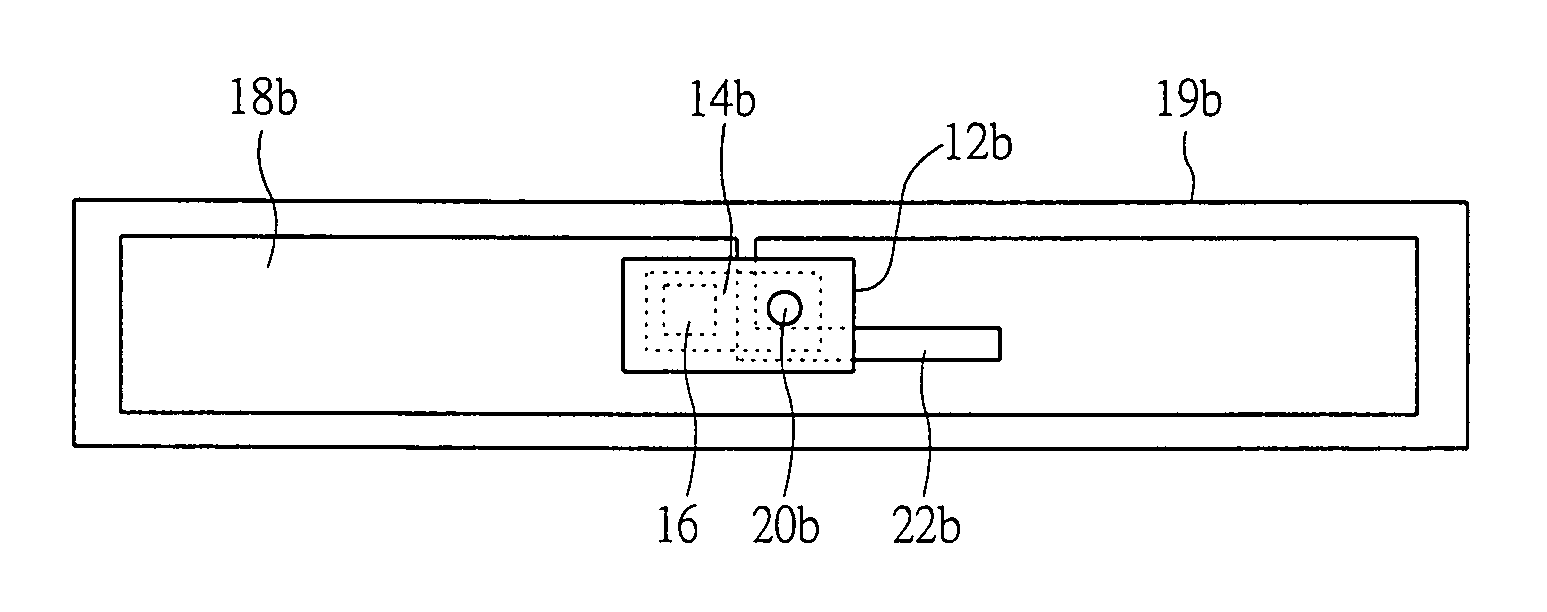

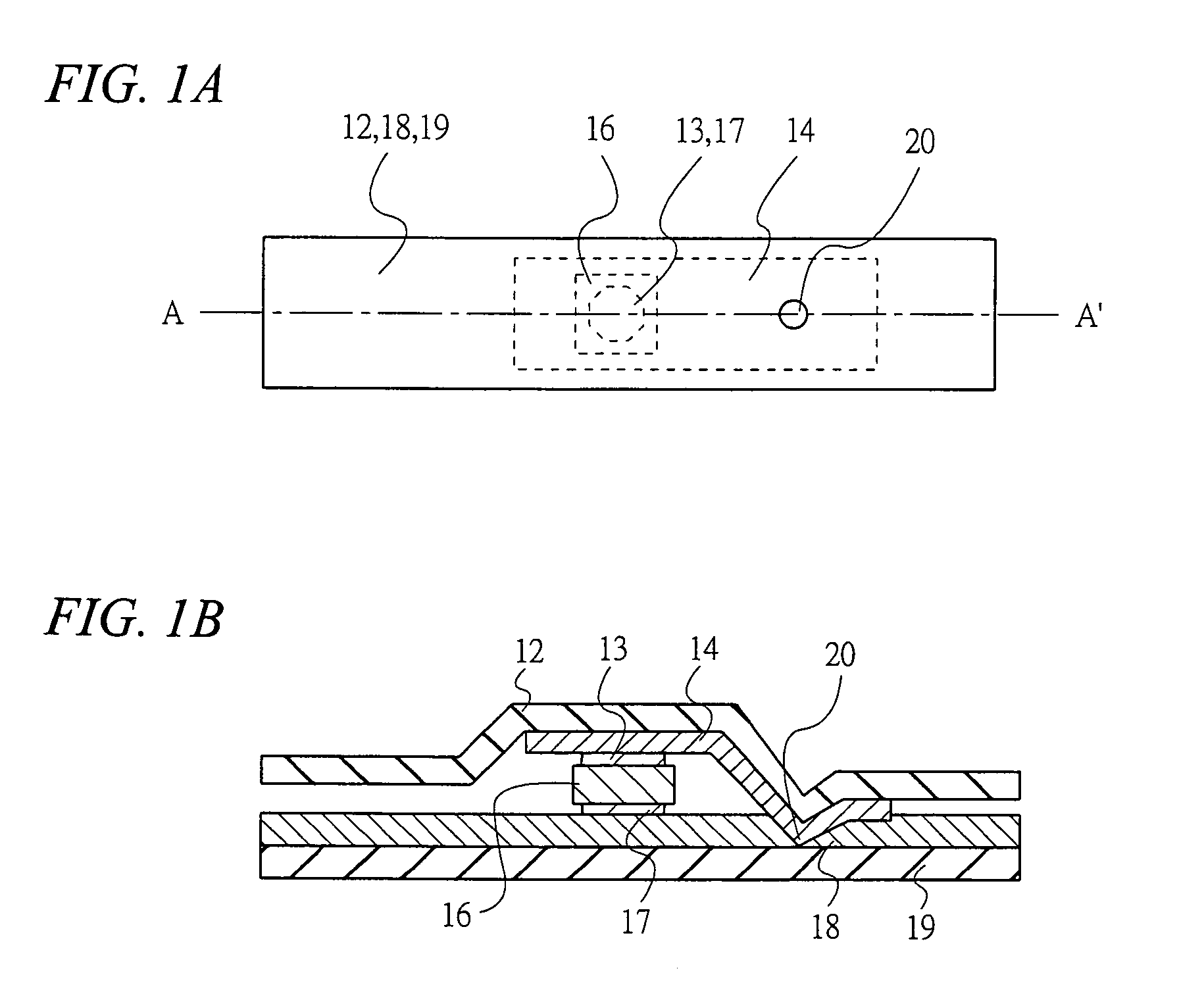

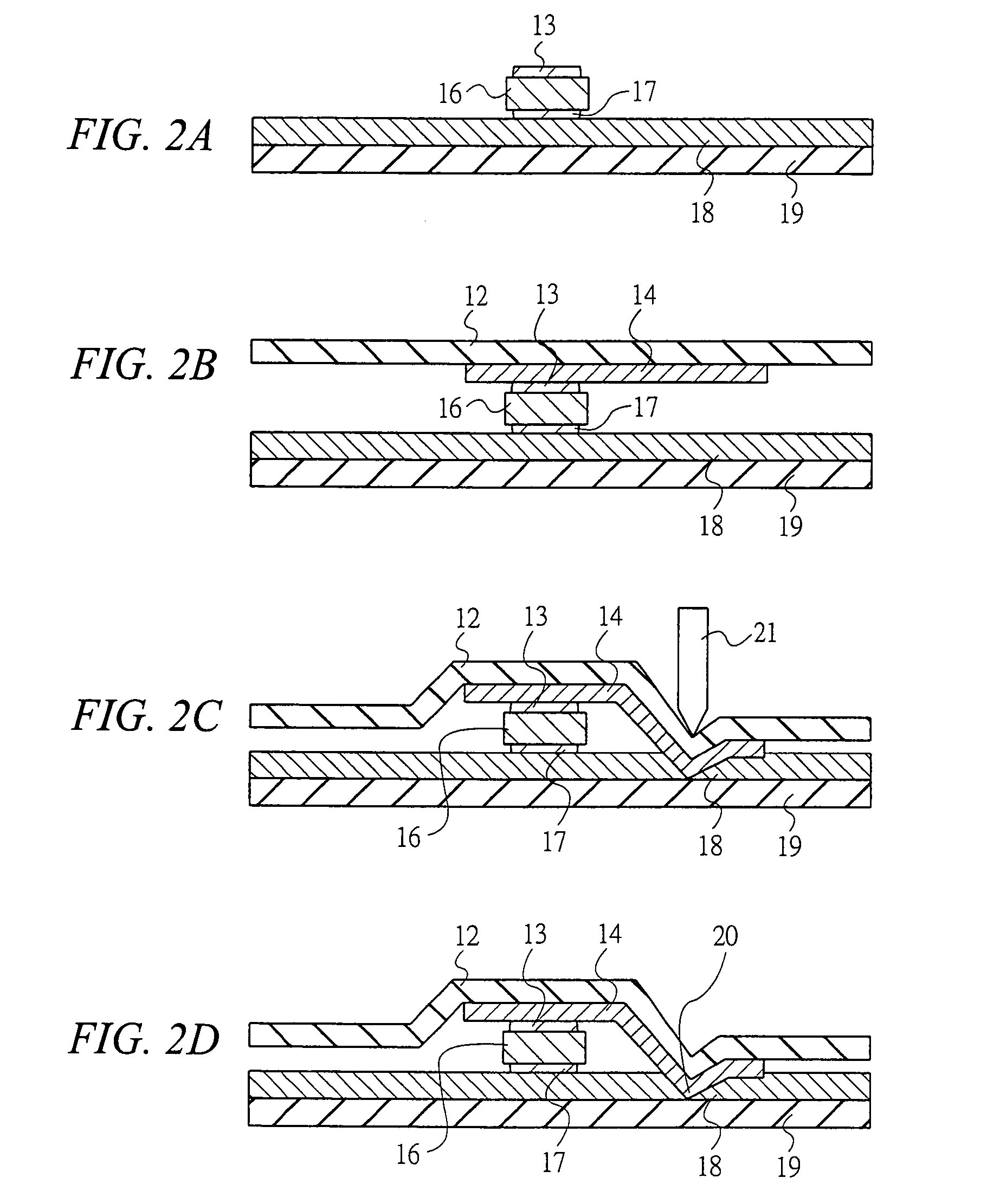

Semiconductor devices and manufacturing method therefor and electronic commerce method and transponder reader

InactiveUS7036741B2Improve accuracyImprove efficiencySimultaneous aerial operationsSolid-state devicesElectrical conductorEngineering

In a wireless IC tag utilizing a wireless IC chip, the wireless IC tag having sufficient stress strength is manufactured economically. There is adopted a structure in which an upper electrode and a lower electrode are respectively formed on a front surface and a rear surface of a wireless IC chip, and the upper electrode is connected to a first conductor and a lower electrode is connected to a second conductor, and the first conductor and the second conductor are connected outside the wireless IC chip. Thereby, it is possible to fabricate the wireless IC tag economically and to ensure the stress strength.

Owner:HITACHI LTD

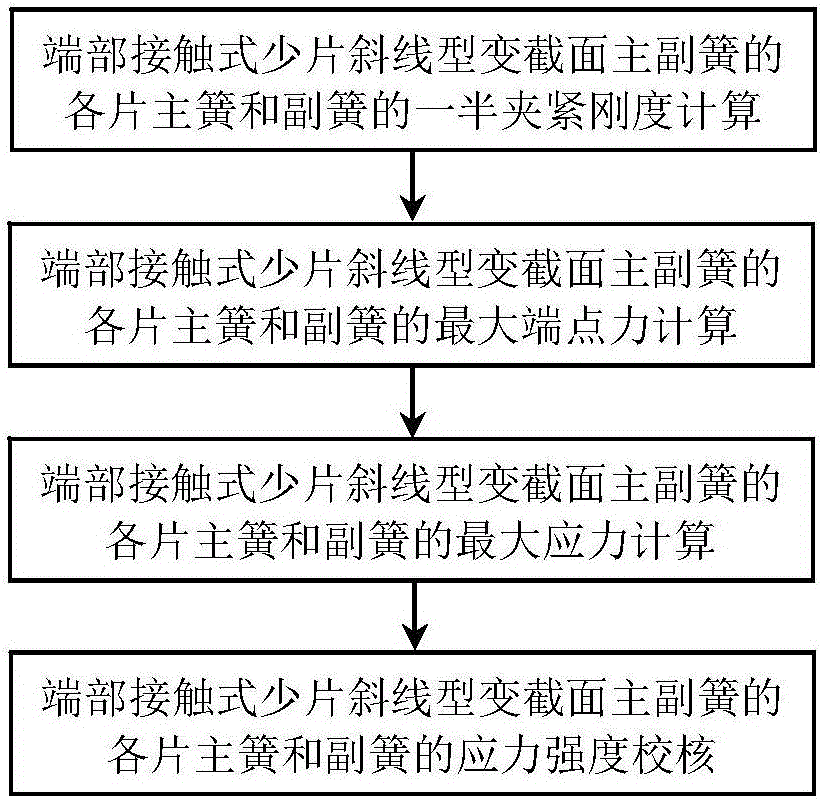

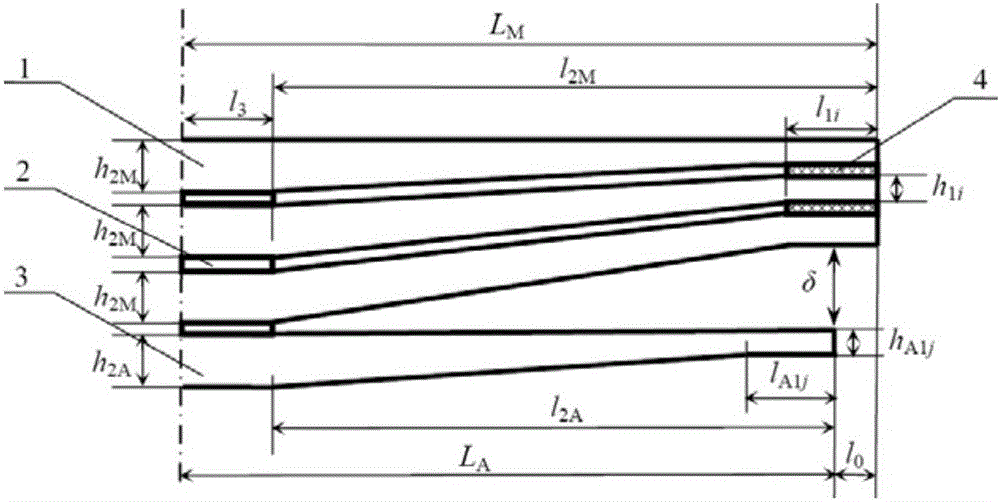

Method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs

InactiveCN105740591AThe calculation value of the maximum stress check is accurate and reliableImprove the design levelDesign optimisation/simulationSpecial data processing applicationsEngineeringStress strength

The invention relates to a method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs and belongs to the technical field of suspension leaf springs. It is possible to verify and calculate stress strength of each of main and auxiliary leaves according to structural parameters, elastic model and allowable stress of all main and auxiliary leaves of the end contact type few-leaf oblique variable-section main and auxiliary springs, acting load of each auxiliary spring and maximum load bearable by a main spring. Experiments and simulation tests show that this method is correct, maximum stress verification calculations of all main and auxiliary leaves are accurate and reliable, the design level, product quality and life of the end contact type few-leaf oblique variable-section main and auxiliary leaf springs as well as vehicle driving smoothness may be improved; meanwhile, it is also possible to reduce designing and testing cost and increase product development speed.

Owner:王炳超

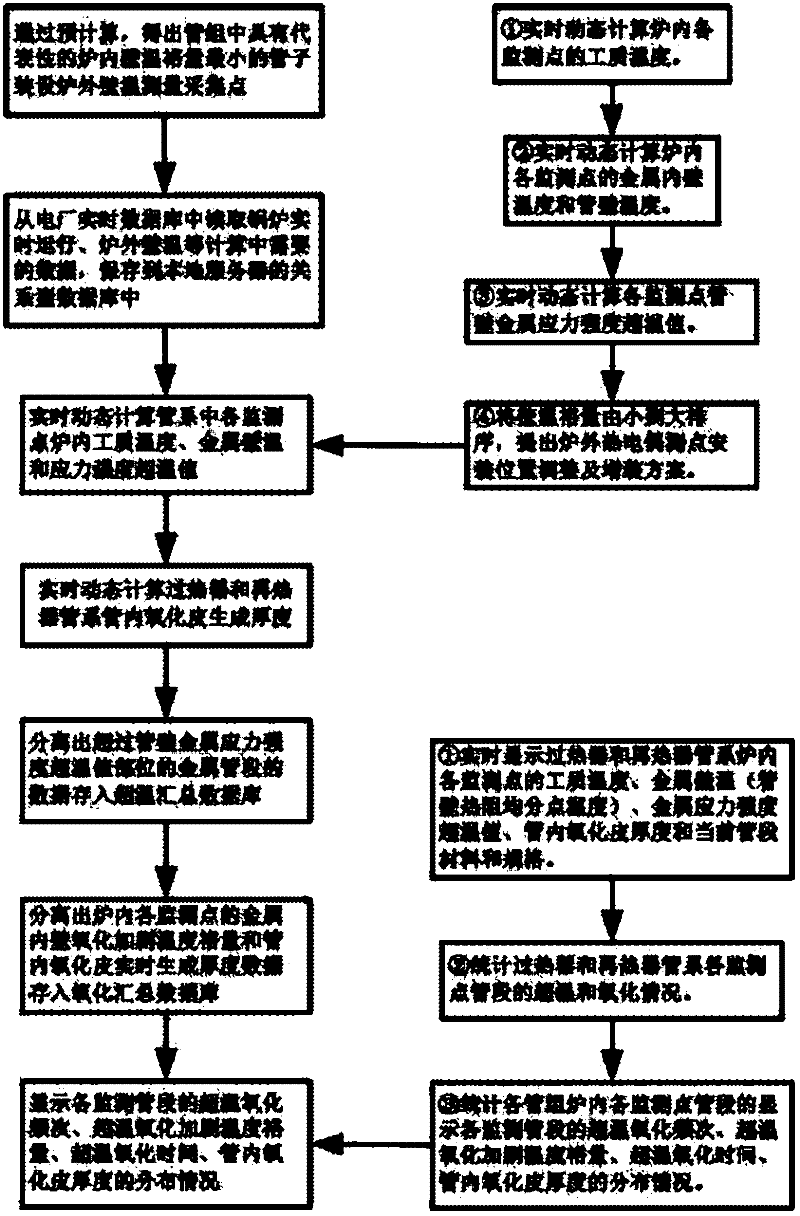

Method for avoiding overheat tube burst in tubular boiler of power station boiler

ActiveCN102444885AExtended service lifeEliminate squibBoiler indication operationsBoiler controlPower stationRelational database

The invention relates to a method for avoiding overheat tube burst in a tubular boiler of a power station boiler, belonging to the technical field of power station boilers. The method comprises the following steps: selecting representative tubes from a nest of tubes to install measurement acquisition points of temperature of an outer wall of the boiler; reading data from a power plant real-time database, and storing the data in a relational database of a local server; dynamically calculating the generation thicknesses of scale cinder in tubes of overheater and reheater in real time; separating out data of metal tube sections of parts exceeding metal stress strength overtemperature values of tube walls from calculated results and storing the data in an overtemperature summarizing database; and according to calculated inner wall working medium boundary layer temperature, metal inner wall oxidation aggravation temperature margin and real-time generation thickness of scale cinder in the tubes, automatically generating a visual distribution graph according to sequence. The method provided by the invention can accurately give out a tube burst early warning of the power station boiler, and preset measurements can be taken to avoid great direct financial losses to enterprises and nation caused by tube burst of the power station boiler.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

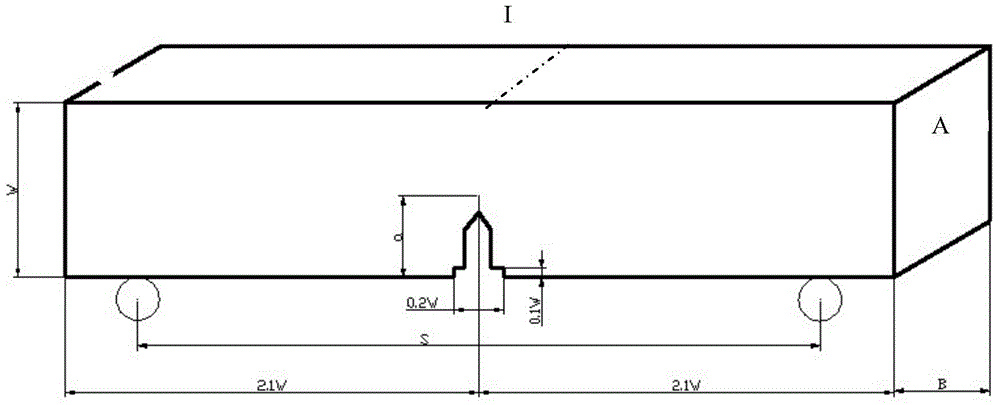

Method for testing fracture toughness of rattan canes based on three-point bending mode

InactiveCN104568605AImprove test accuracyImprove accuracyMaterial strength using steady bending forcesCritical loadStress strength

The invention provides a method for testing the fracture toughness of rattan canes based on a three-point bending mode. The method comprises the following steps: preparing a sample, and regulating a water content rate so as to obtain a sample of which the water content rate is 10-12%; recording a load-crack opening displacement (PV) curve, measuring actual crack depths, and calculating critical loads PQ and critical stress intensity factors KQ. According to the method provided by the invention, the crack opening displacement is measured by a C.O.D Gauge, and the test precision is improved. Aiming at the characteristics of the rattan materials, the sampling method for testing the fracture toughness of rattan canes is ensured, and the measured results having high accuracy and good reproducibility are obtained. The calculation method for testing the fracture toughness of rattan cane, provided by the invention, provides qualitative and quantitative bases for the utilization of the rattan canes.

Owner:INT CENT FOR BAMBOO & RATTAN

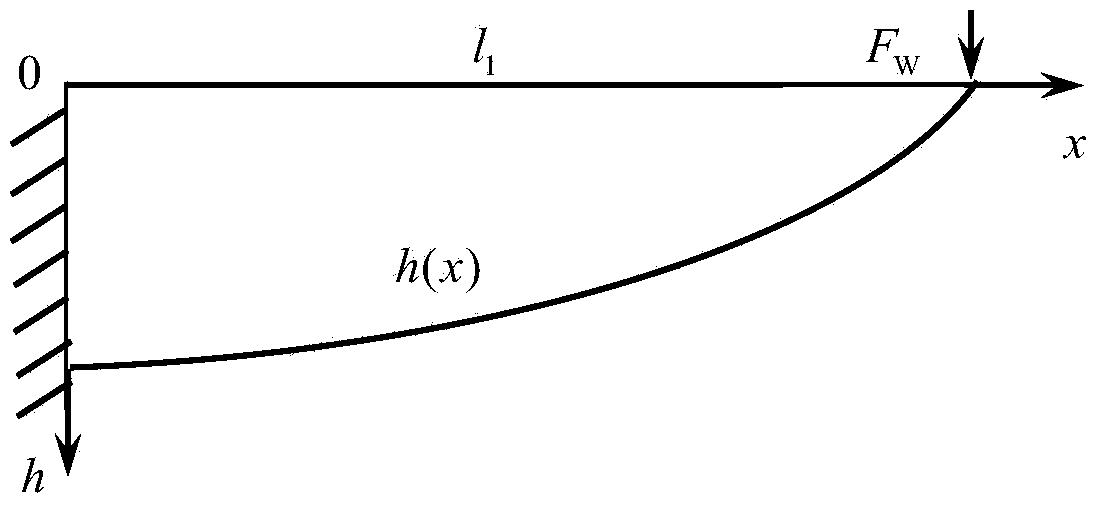

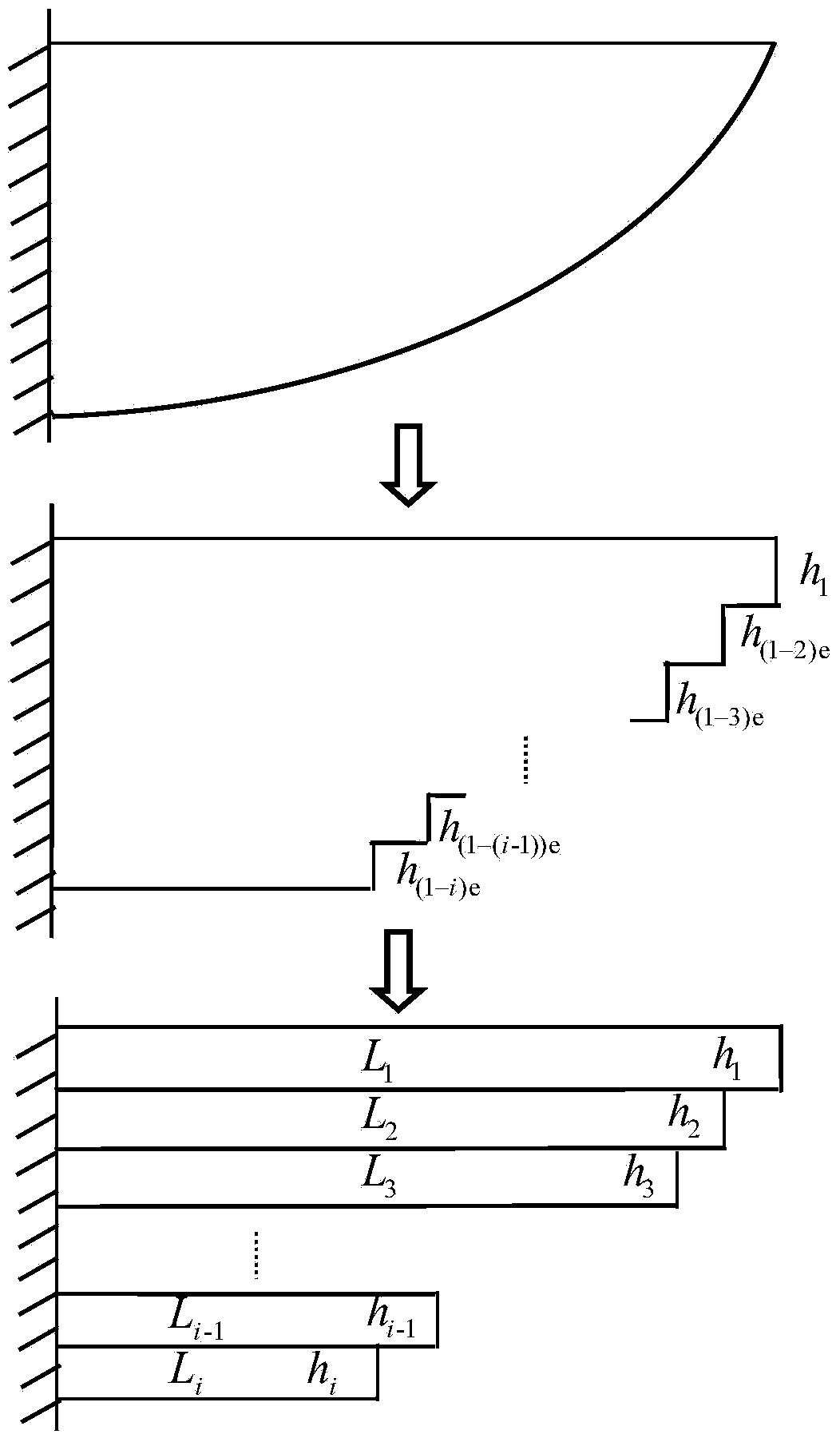

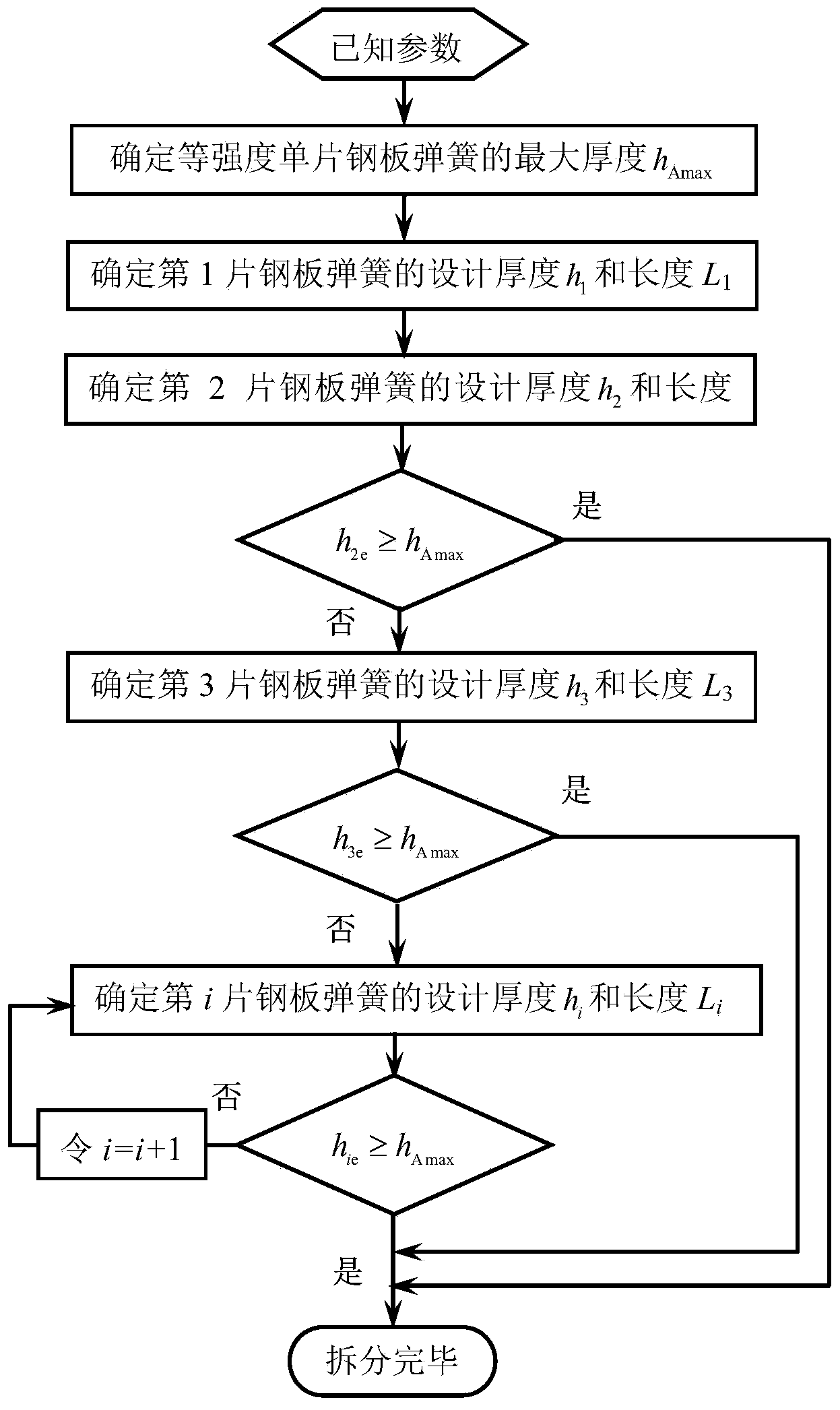

Dismounting design method of automobile equal-strength superposition steel plate spring

InactiveCN104239618AAnalysis split design method is accurateAnalytical split design approach is reliableLeaf springsSpecial data processing applicationsVariable thicknessSheet steel

The invention relates to a dismounting design method of an automobile equal-strength superposition steel plate spring, and belongs to the technical field of a vehicle suspension steel plate spring. Most steel plate springs in the prior art adopt a graphic method or an ANSYS simulation verification method, and the CAD design requirement of the automobile equal-strength superposition steel plate spring cannot be met. The dismounting design method provided by the invention is characterized in that according to a load borne by one end of a vehicle one-wheel steel plate spring, the maximum thickness of the automobile equal-strength single-piece variable-thickness curve surface steel plate spring is designed, and then, the automobile equal-strength superposition steel plate spring is subjected to dismounting design by utilizing the equivalent principle and the equal stress intensity condition design requirements, so the thickness and the length of each piece of the automobile equal-strength superposition steel plate spring can be obtained through the design. The dismounting design method provided by the invention can be used for accurately and reliably carrying out dismounting design on the automobile equal-strength superposition steel plate spring, in addition, the design cost and the test cost can also be reduced, and the important design technology and method can be provided for the design of the steel plate spring.

Owner:SHANDONG UNIV OF TECH

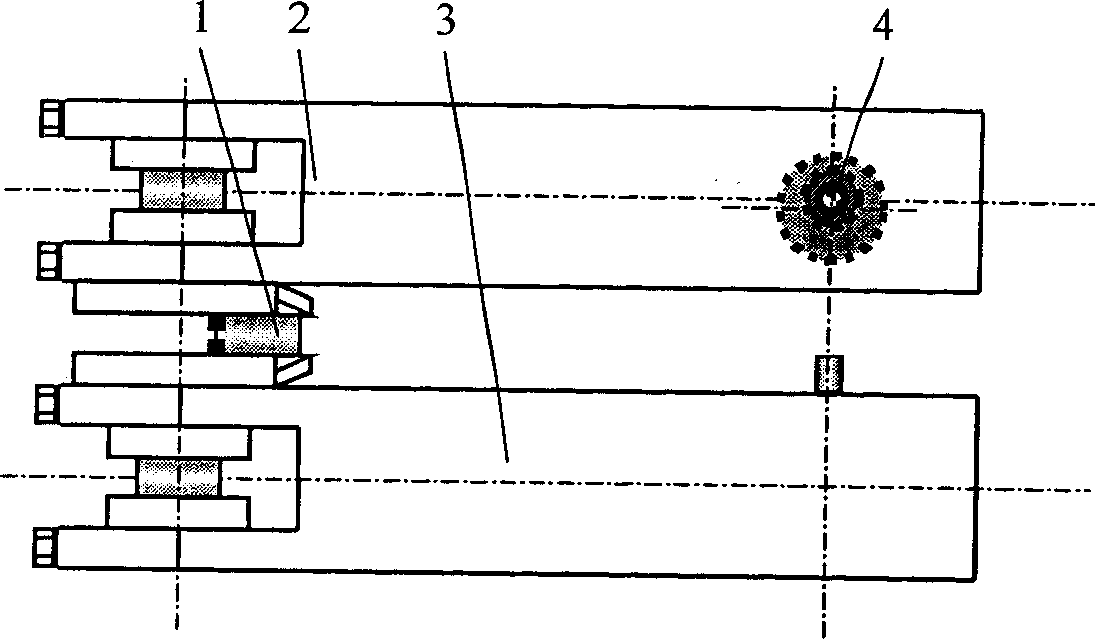

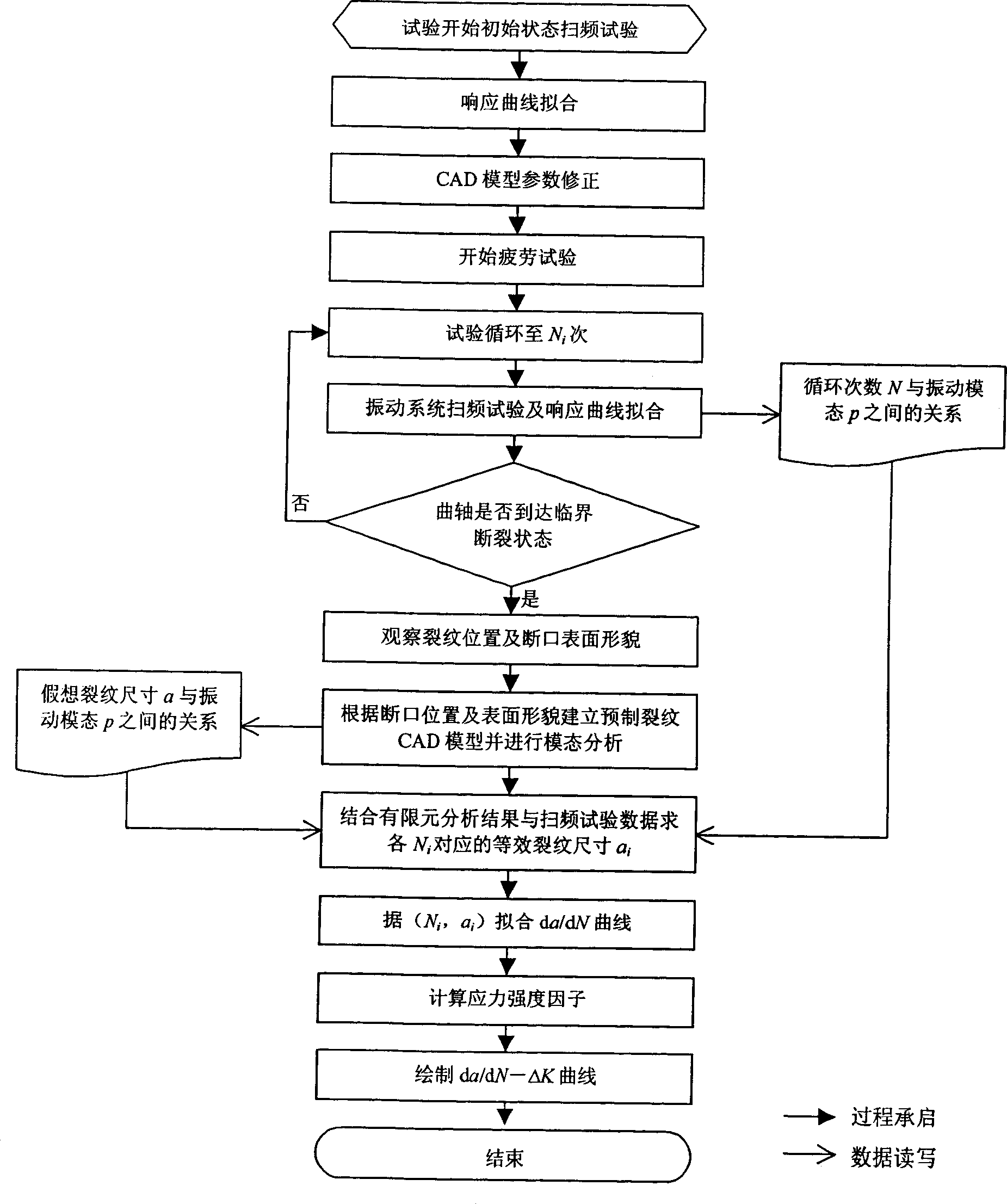

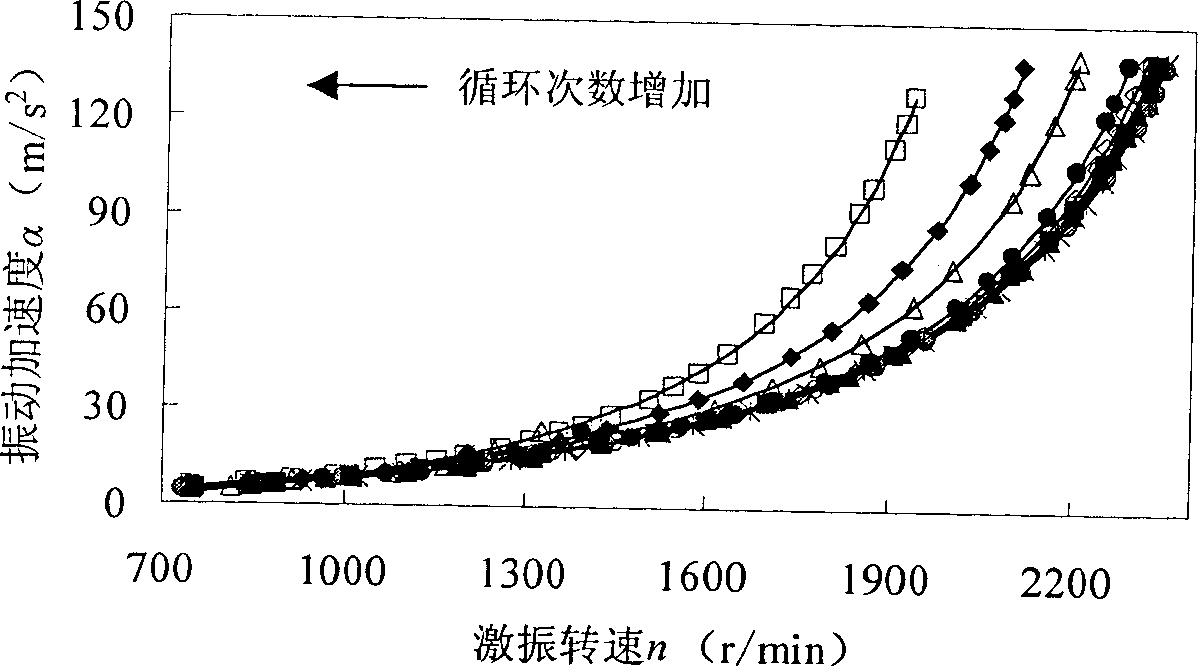

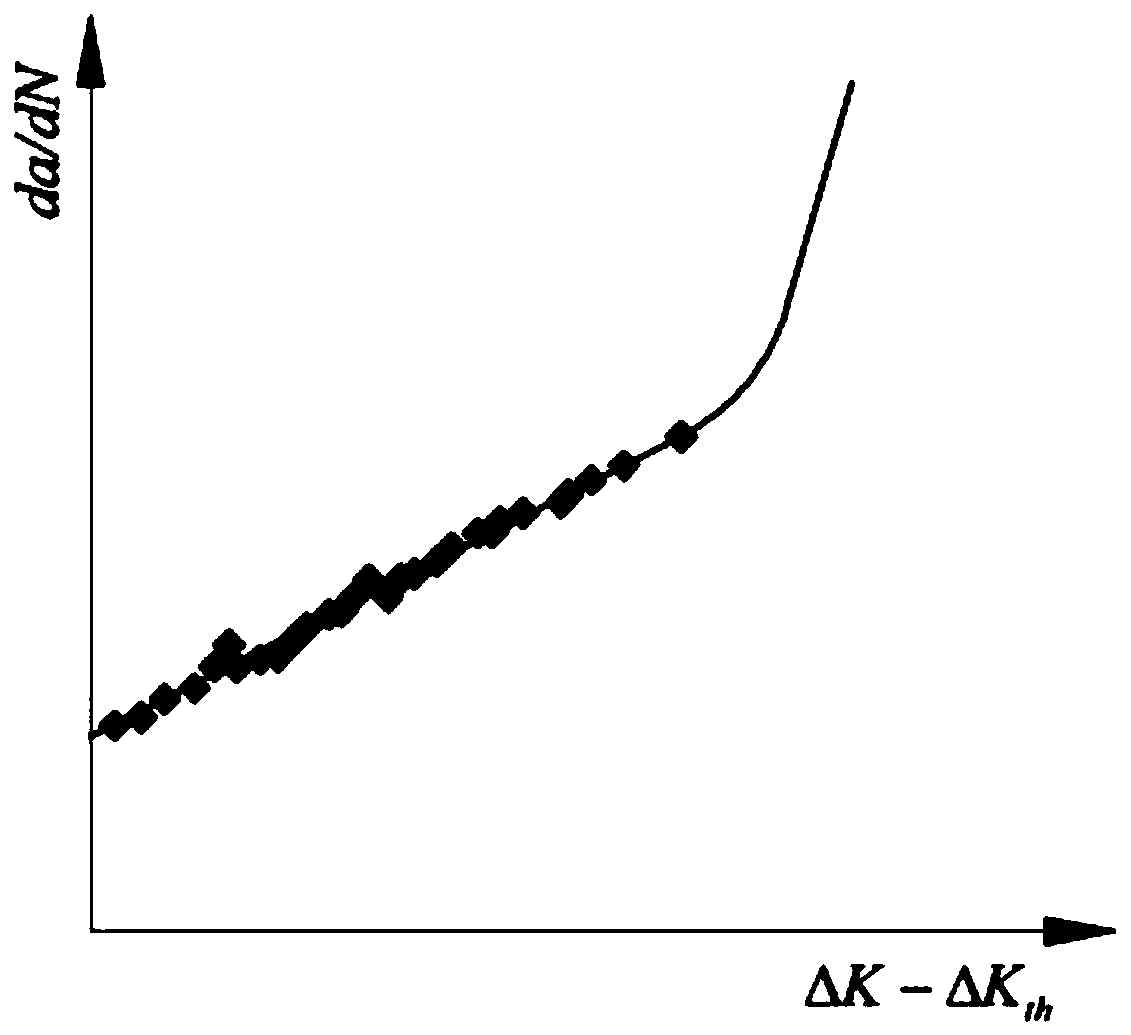

Method for investigating fatigue crack expansion

The invention discloses a fatigue crack extension testing method, making a sweeping test in the fatigue test course and obtaining the variation condition of vibration response of the test system varies with test piece crack extension on the forced vibration condition; using a numeric method to make sweeping data fitting and obtaining variation curve of resonant frequency with number of circulating times; after the test piece is broken, according to actually observed crack size and shape, prefabricating crack of a CAD model and making finite model analysis and obtaining a curve of resonant angular frequency of the system against test piece size, using the curve and able to obtain dynamic extension rule of test piece crack and then obtaining its curve of variation rate; and finally combining with calculation of stress strength factor range Delta K, and able to obtain a curve of crack extension rate.

Owner:ZHEJIANG UNIV

Aeroengine case seam allowance size repairing method

The invention relates to an aeroengine case seam allowance size repairing method. The porosity and hardness of a coating and the content of oxides in the coating can be effectively adjusted by controlling the plasma spraying power and the heating process of spraying powder during flying, and heat stress of the coating is reduced. The hardness and thermal expansion coefficient of the prepared nickel-aluminum coating are equivalent with those of a case, the bonding strength of the coating is far higher than the stress strength of a case seam allowance under the given working condition, and the use working condition of the aeroengine case can be met.

Owner:HARBIN DONGAN ENGINE GRP

Method for evaluating critical stress intensity and sensitive factor of stress corrosion cracking for oil well pipe

ActiveCN1766550APracticalUsing mechanical meansInvestigating material hardnessStress strengthCritical stress

The invention discloses a method for measuring the oil well pipe corrosion cracking critical stress intensity and sensitive factor. It adopts U-type loading hook to do static loading-unloading closed loop movement to the pin-and-hole of the twin cantilever (DCB) sample before and after the sulfide stress corrosion cracking test, makes the firmer chisel, loads the DCB perpetuity shift sample and obtains the loading and the relate curve of the shift at the same time; it quantity measures the DCB sample firmer chisel initial level loading, firmer chisel loading DCB actual cantilever shift and the critical level loading value after the test.

Owner:BAOSHAN IRON & STEEL CO LTD

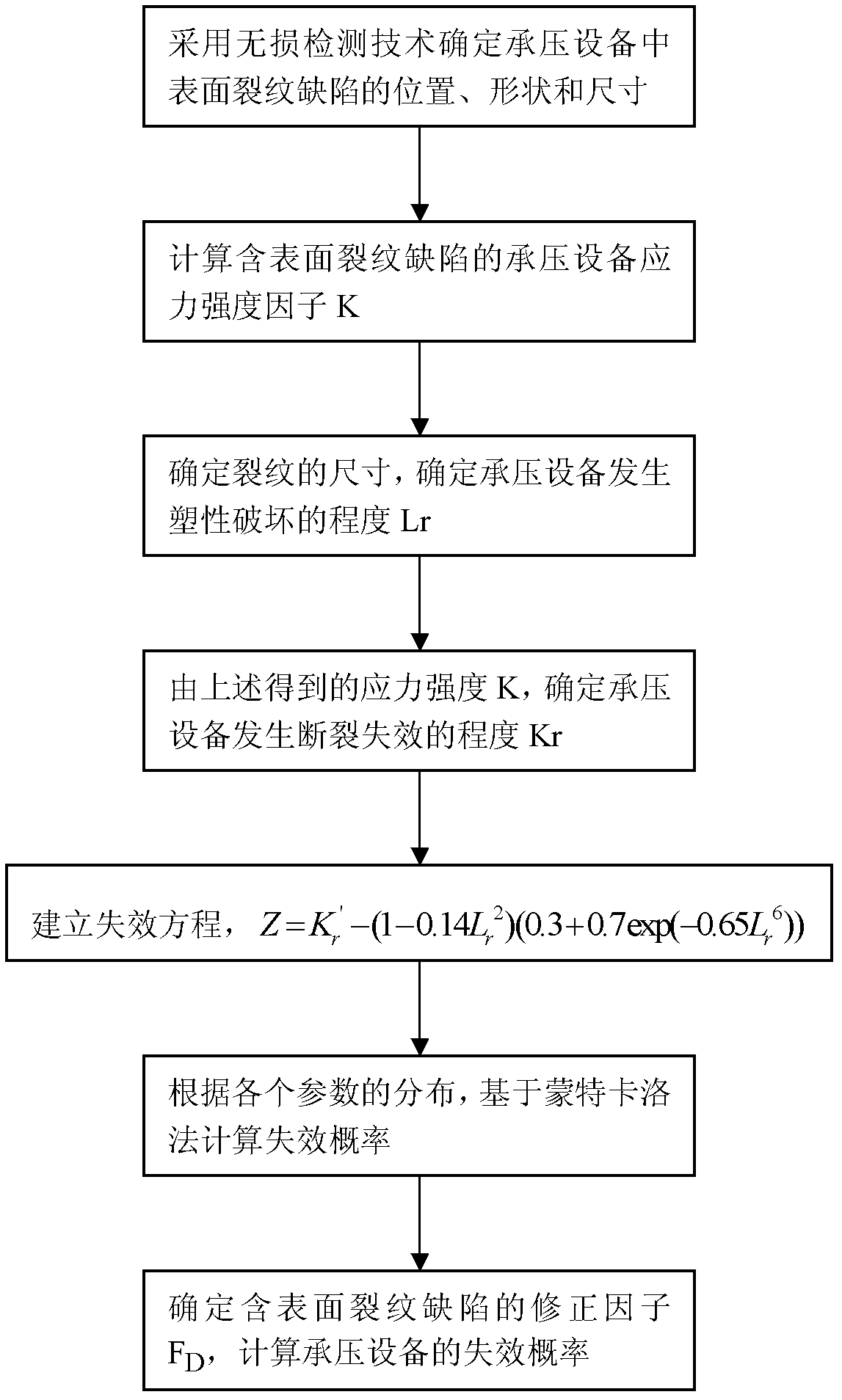

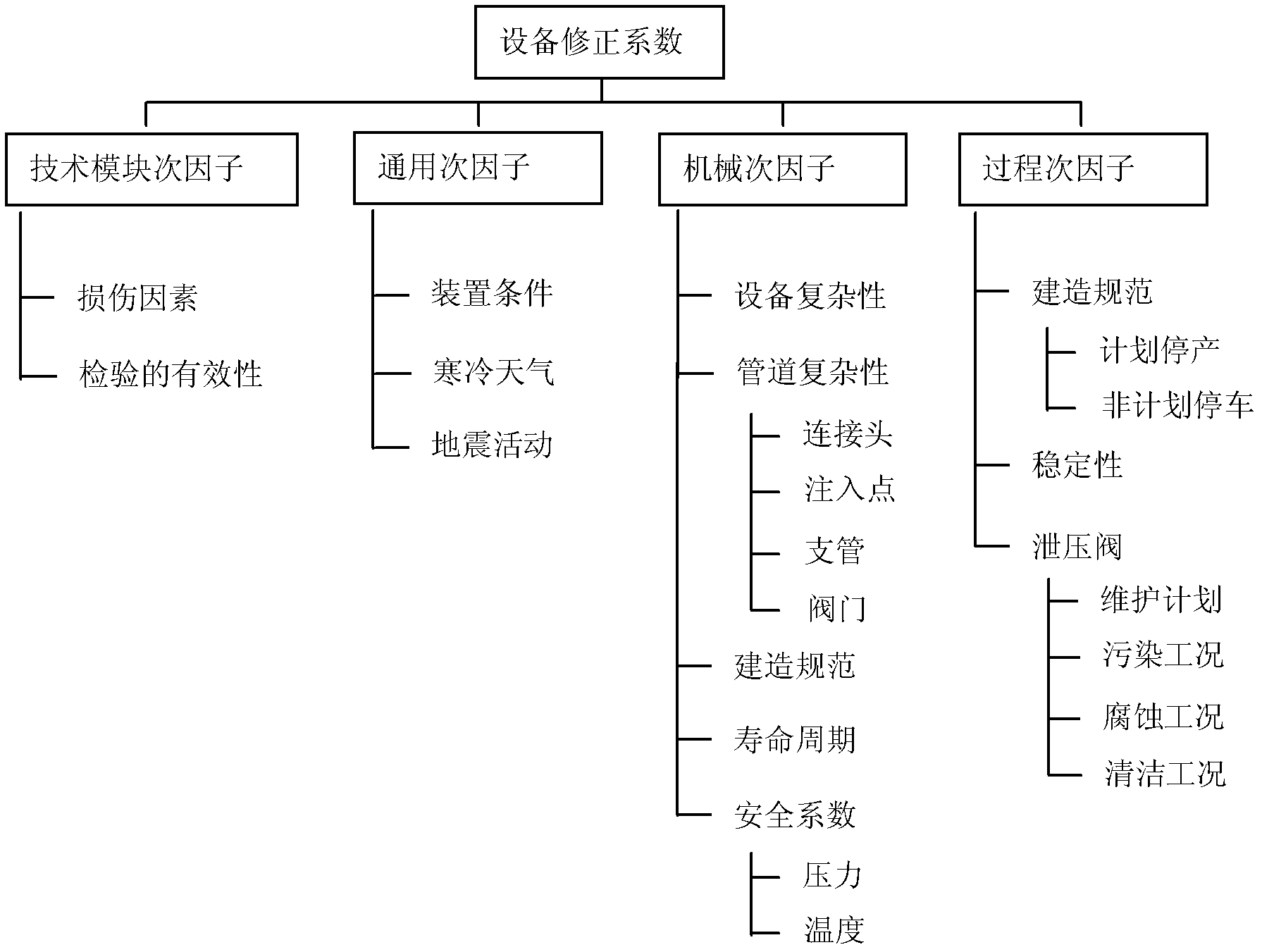

Quantitative risk analysis method of pressure bearing equipment containing surface crack defects

InactiveCN102628769AThe calculation result is accurateEasy to getSpecial data processing applicationsStrength propertiesNon destructiveStress strength

Owner:NANJING UNIV OF TECH

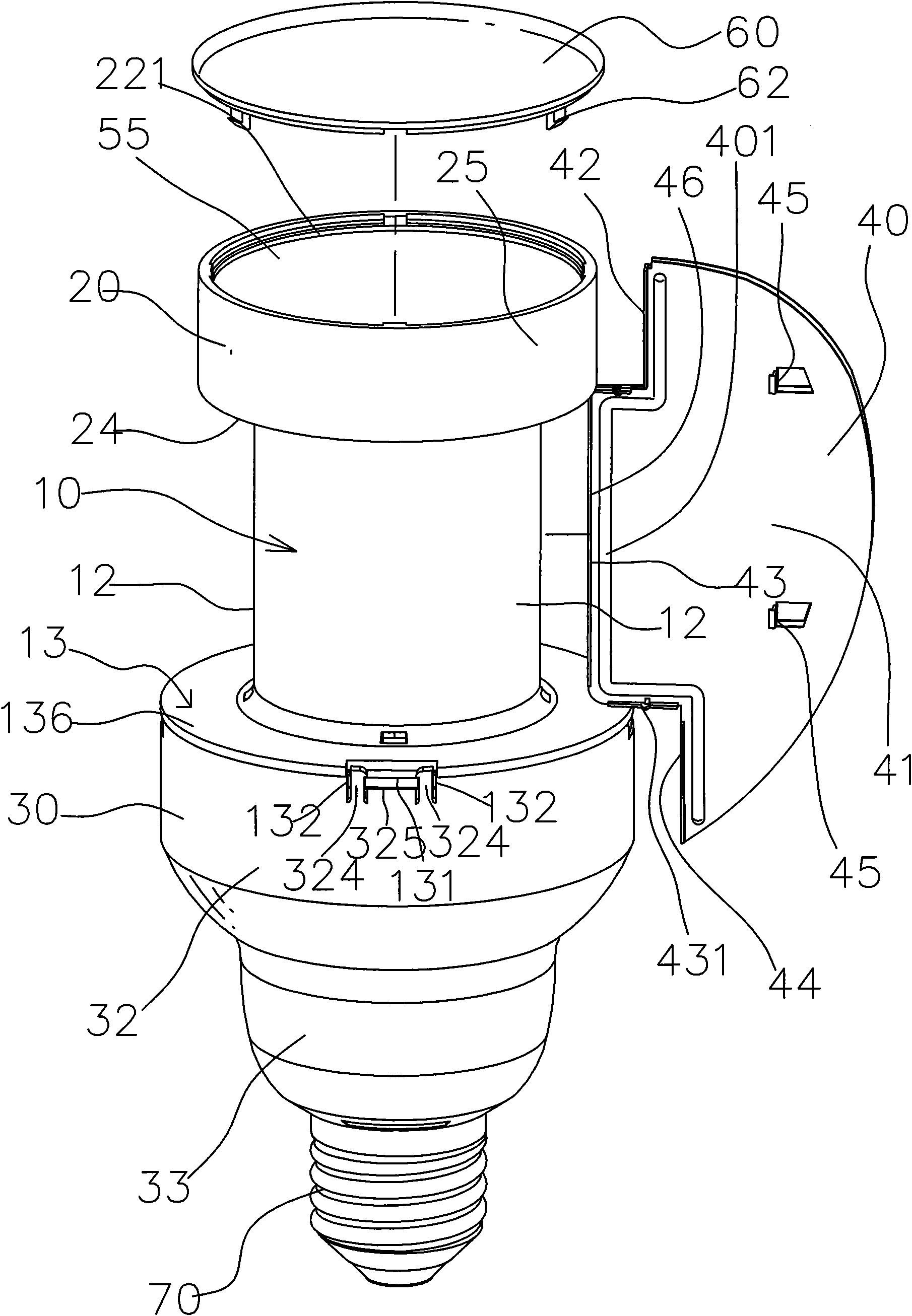

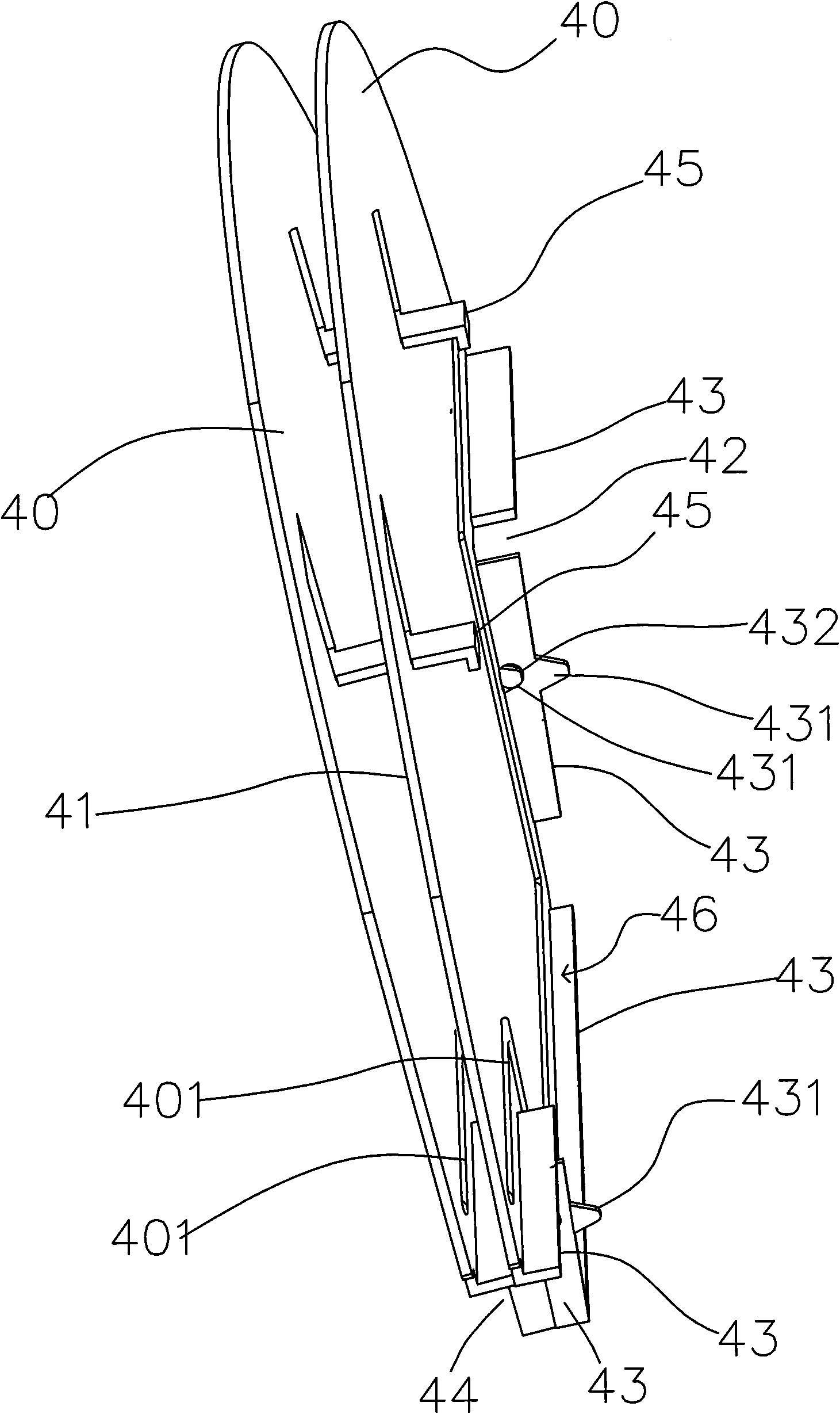

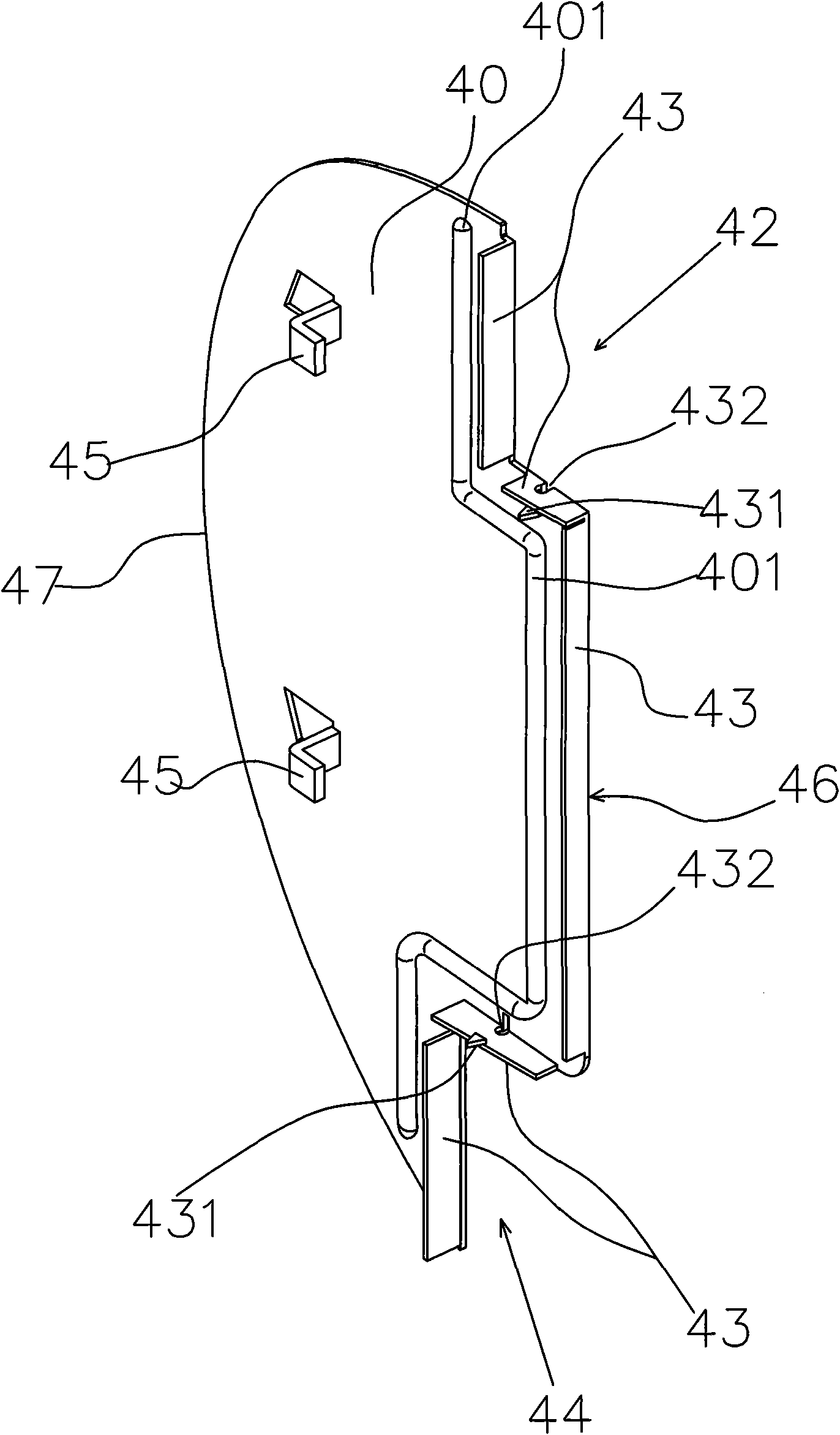

Connection device for LED lamp and radiating fins

InactiveCN101514808AEffective control of separation distanceSeparation distance controlPoint-like light sourceSemiconductor/solid-state device detailsStress strengthEngineering

The invention discloses a connection device for an LED lamp and radiating fins, which comprises a central tube and a plurality of the radiating fins, wherein the central tube takes the central tube as a center; the upper part of the central tube is connected with an annular lamp holder, while the lower end is connected with a lower shell; the plurality of the radiating fins are connected to the surfaces of the lamp holder, the central tube and lower circular pieces of the central tube; the fin body of each radiating fin is at least punched with more than one convex body; each convex body is pressed against one surface of the adjacent radiating fin; and the adjacent radiating fins contact by means of support of the convex body to enhance the stability, the stress strength and the thermal conductivity of all radiating fins and ensure that the adjacent radiating fins keep constant space.

Owner:ABLECOM TECH

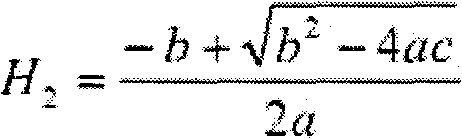

Triaxial stress strength designing method for vertical well casing string

The invention discloses a triaxial stress strength designing method for a vertical well casing string. The triaxial stress strength designing method for the vertical well casing string comprises the following steps of: determining the steel grade, the wall thickness and the setting lengths of a first-section casing; performing internal pressure strength check and tensile strength check on the top of the first-section casing; calculating the setting lengths Lon and Lan of the first-section casing; and performing internal strength and extrusion strength check on the first-section casing till the designed well depth is met. By simultaneously considering the influence of coactions of an axial force, an external extrusion force and an internal pressure on the strength of the casing, the magnitude of the triaxial stress is calculated, an equivalent stress is calculated and supposed to be equal to the yield strength of the casing, and the strength of the casing is designed, so that the design is more reasonable and the designed vertical well casing string is more durable.

Owner:常萍

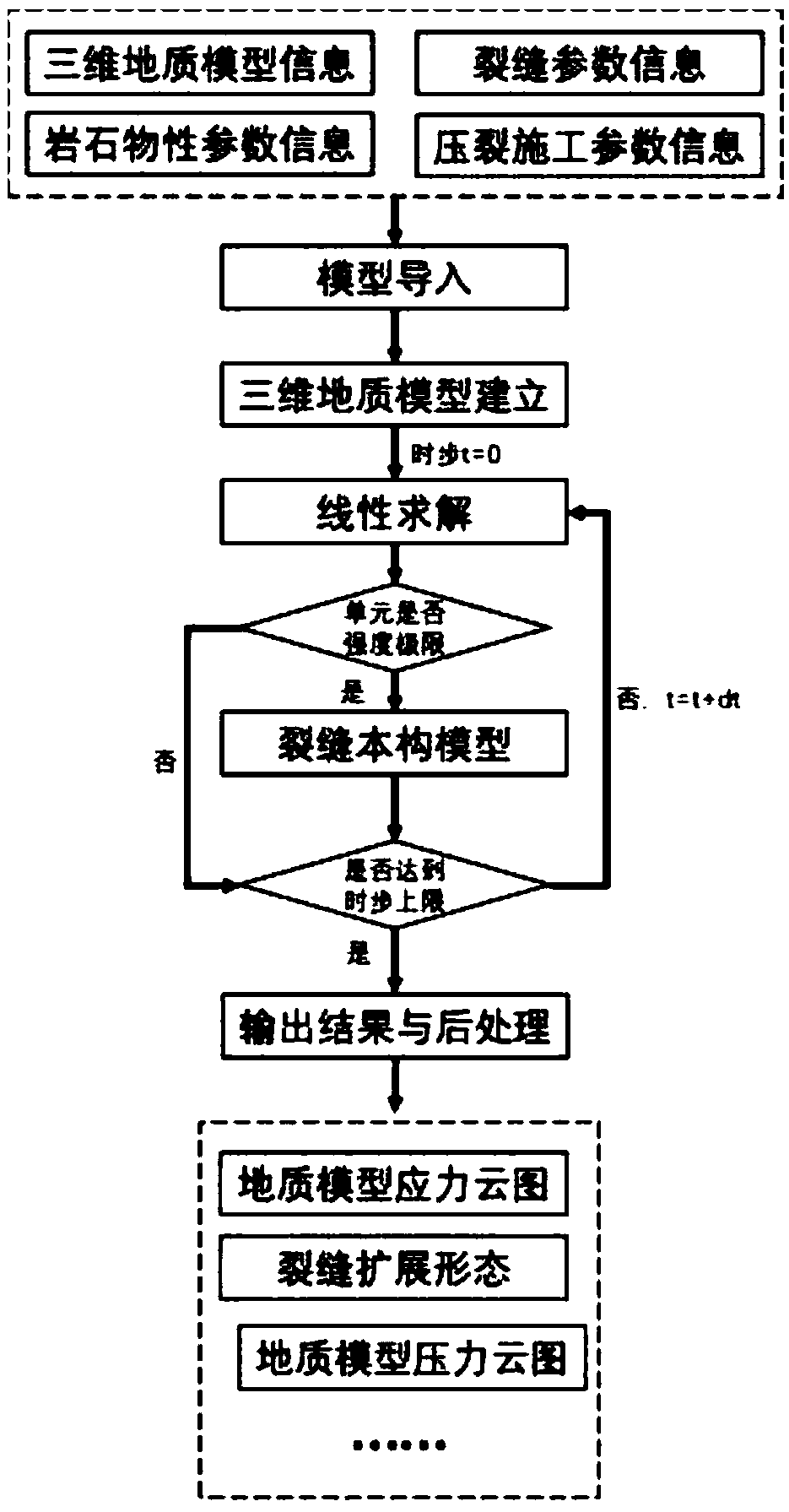

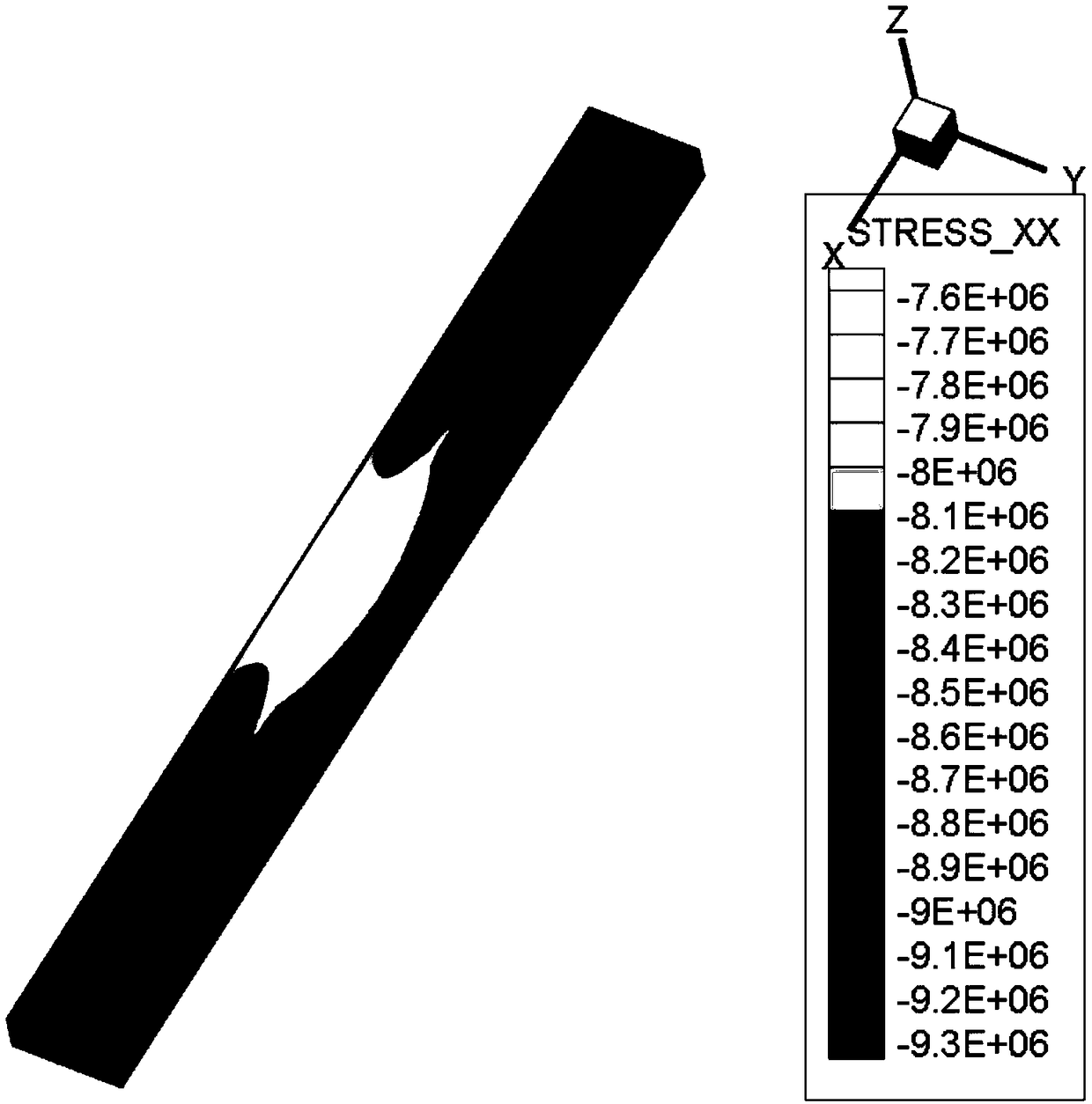

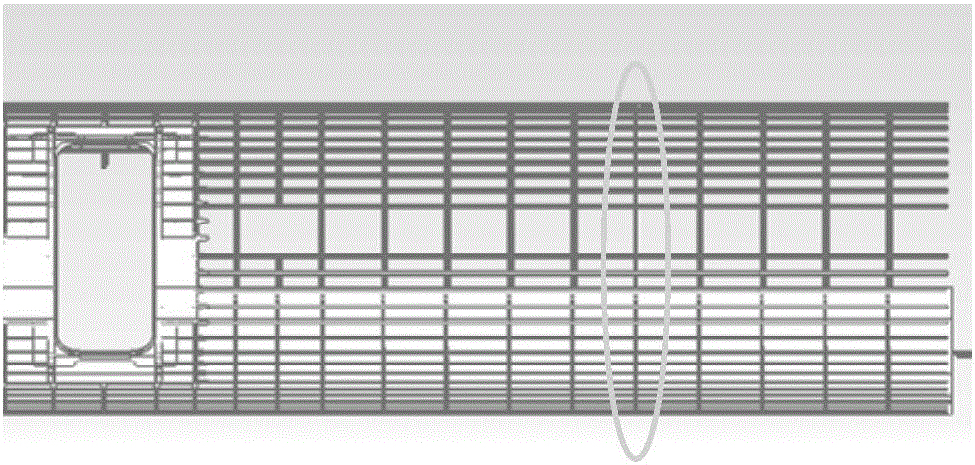

A simulation method of single fracture propagation based on quasi-continuous geomechanical model

ActiveCN109241588AImprove reliabilityEasy to set upDesign optimisation/simulationSpecial data processing applicationsStress strengthHydraulic fracturing

The invention discloses a simulation method of single propagation expansion based on a quasi-continuous geomechanical model, which comprises the following steps: acquiring geological parameters, including three-dimensional geological information and rock physical property information; Correcting petrophysical information; Establishing three-dimensional geological model of stratum; establishing FEMfluid-solid coupling model; obtaining the pressure field, displacement field, stress field and strain field of the three-dimensional geological model by solving the fluid-solid coupling equations ofthe finite element method; judging whether cracks are produced or not according to the stress strength criterion; obtaining The fracture width, permeability matrix and flexibility matrix, and then calculating the influence of fracture on pressure field and displacement field. The simulation of single fracture propagation based on quasi-continuous geomechanical model is realized. The invention hasthe advantages of quick solution, high accuracy and good reliability, and effectively solves the problem of dynamic display of fractures in the process of hydraulic fracturing simulation.

Owner:PEKING UNIV

Stiffened wallboard damage tolerance analysis method based on finite element analysis solving

ActiveCN106354934ADesign optimisation/simulationSpecial data processing applicationsElement modelResidual strength

The invention relates to a stiffened wallboard damage tolerance analysis method based on finite element analysis solving, comprising the steps of first, determining a crack growth direction according to aircraft wallboard structural form and load-bearing condition; setting limit crack length to determine model scale; second, establishing a crack-free stiffened wallboard details finite element model; third, applying total load to the model to solve wallboard stress distribution; fourth, simulating cracks different in length in the finite element model, and extracting note balance force and displacement of a crack tip unit; fifth, solving stress strength factor K for tips with different crack lengths of a stiffened wallboard in fourth step by applying virtual crack closure technique VCCT; sixth, subjecting the stiffened wallboard to crack growth life and structural residual strength analysis. The method can provide real simulation for stiffened wallboard different-size cracks, crack tip stress and strain condition, stiffened wallboard different-size crack stiffener stress level, and fastener load; crack growth analysis is performed on stiffened wallboard skin based on analysis results.

Owner:AVIC SAC COMML AIRCRAFT

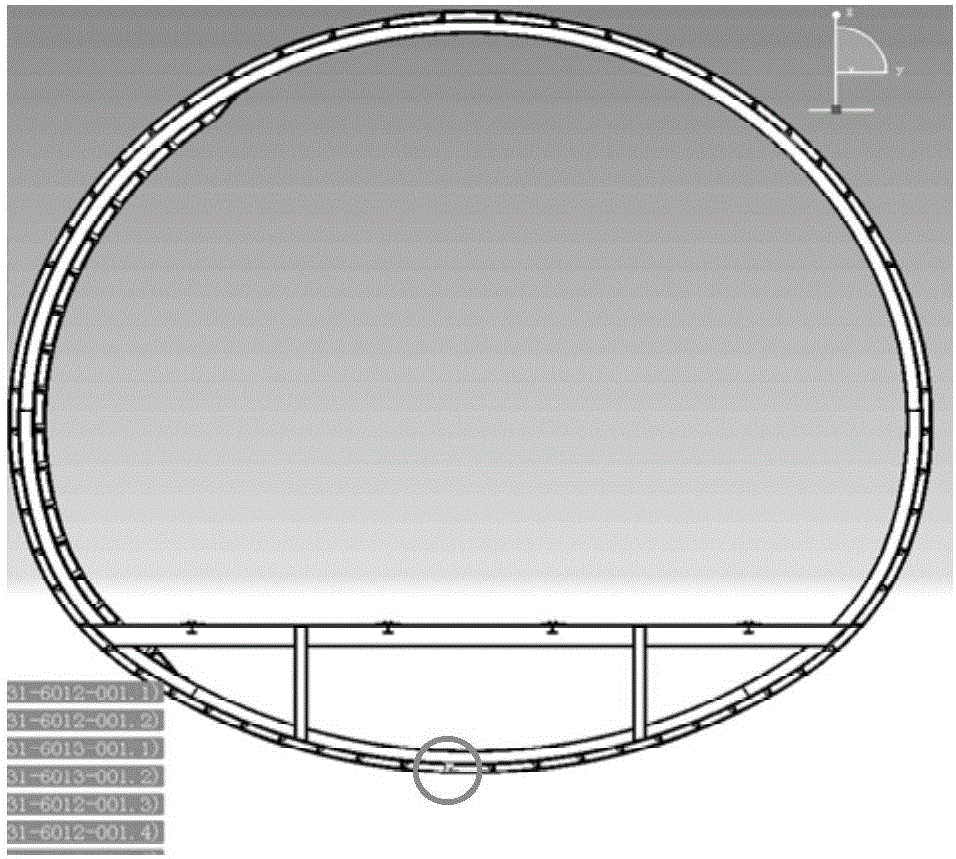

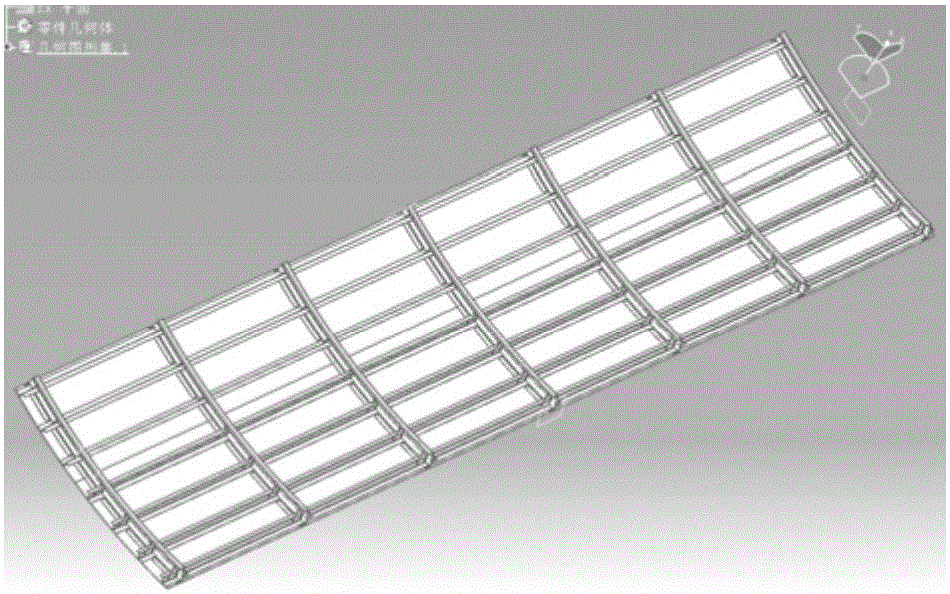

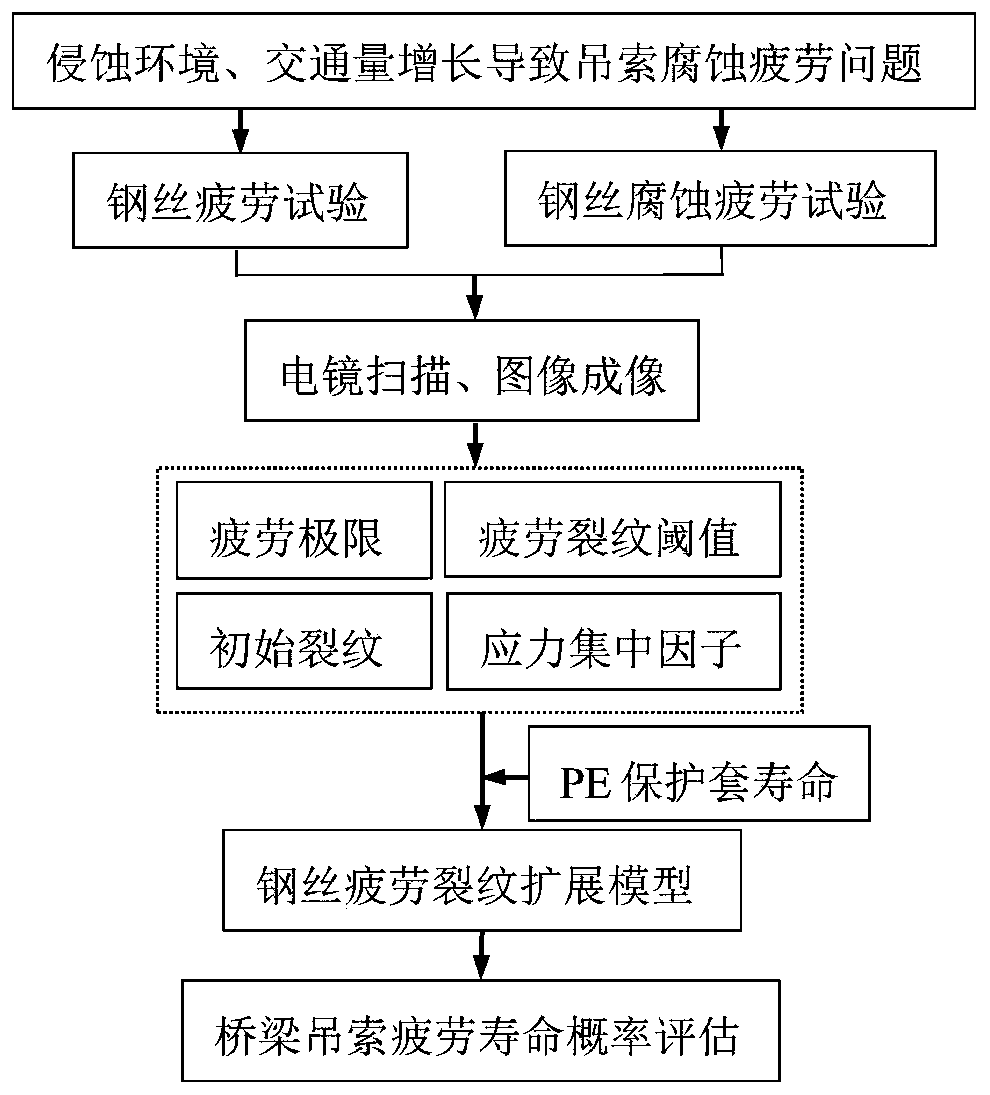

Service bridge sling fatigue life probability assessment method

PendingCN110020497AThe prediction method is reasonableGeometric CADSpecial data processing applicationsLife evaluationStress strength

According to the service bridge sling fatigue life probability assessment method disclosed by the invention, fatigue test data are fitted by implementing fatigue crack propagation tests of a bridge sling high-strength steel wire under different stress ratios, and a relational expression of fatigue crack growth analysis model parameters and stress ratios is obtained; a stress concentration effect caused by a corrosion pit is fused into the stress strength factor model, and a sling high-strength steel wire fatigue crack propagation analysis model is established by adopting small crack growth andnear-threshold crack growth analysis; an initial crack is obtained on the basis of an equivalent initial crack principle, the fatigue life of a single steel wire is obtained by integrating a steel wire crack propagation model, a correlation coefficient is introduced, the influence of stress redistribution of a sling after wire breakage is considered, and life evaluation of the bridge sling underthe corresponding wire breakage rate condition can be achieved. The prediction method is reasonable and high in generalization performance, and can be used for predicting the fatigue life of the long-span bridge sling.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

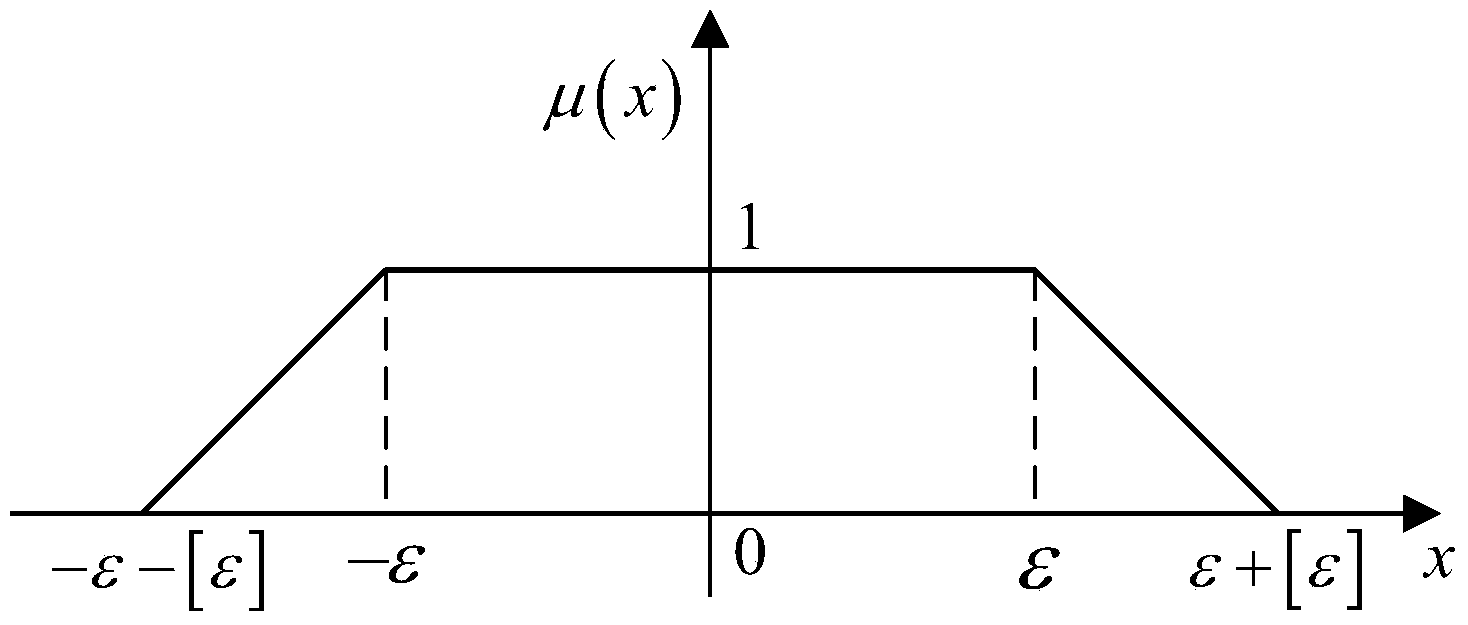

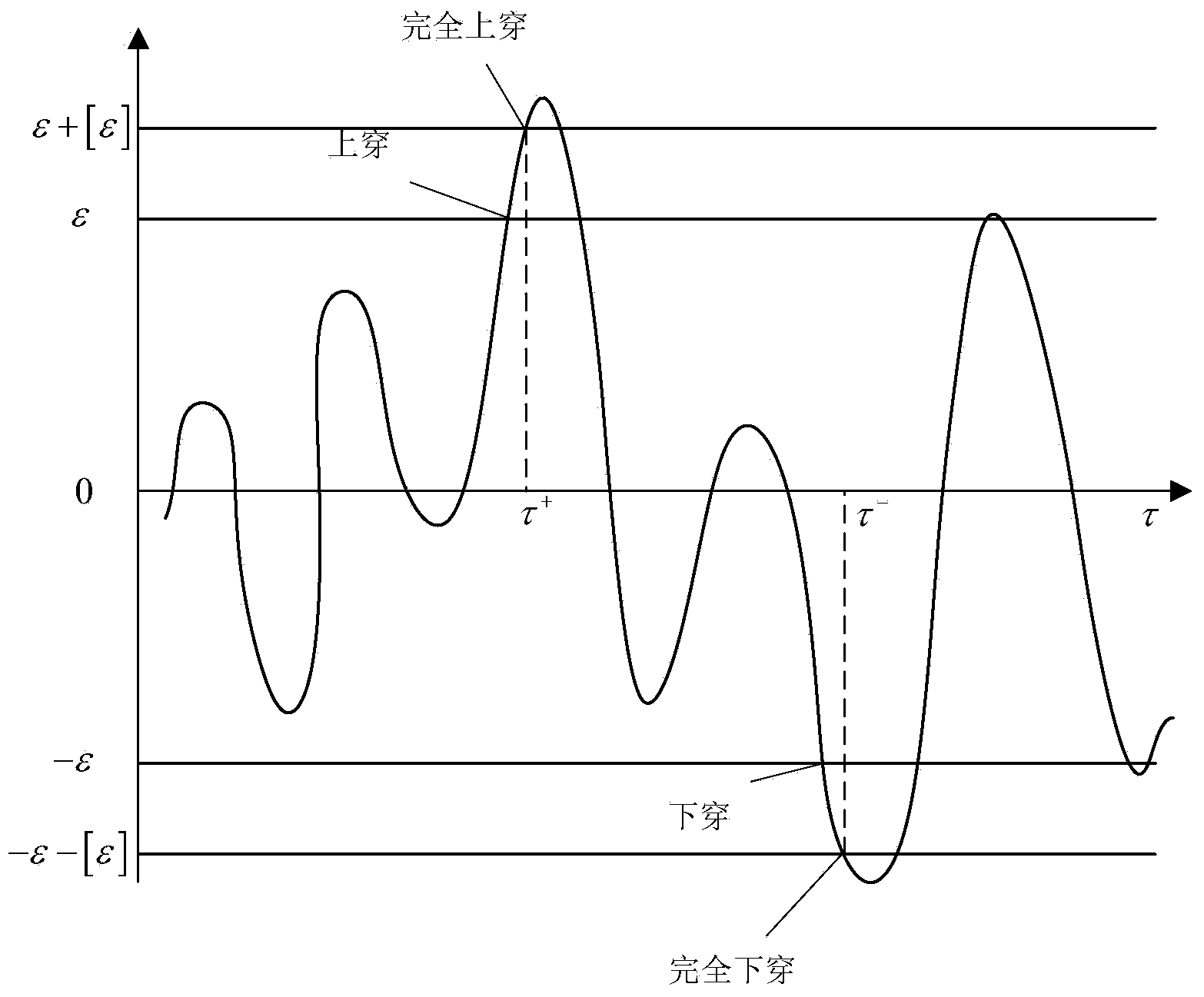

Mechanism movement accuracy reliability analysis method based on fuzzy out-crossing model

InactiveCN104008238AHigh engineering application valueSpecial data processing applicationsCross modelAlgorithm

The invention discloses a mechanism movement accuracy reliability analysis method based on a fuzzy out-crossing model. The mechanism movement accuracy reliability analysis method includes the steps of (1) building a generalized fuzzy random stress-strength interference model (please see the specifications for the model) according to task characteristics, (2) determining a subordinating degree function mu(x) of movement errors, (3) determining the reliability R(tau0) at the moment tau0, and calculating the complete up-crossing rate v+(tau) and the complete down-crossing rate v-(tau), and (4) calculating the fuzzy time-variation reliability R in the mechanism task executing process. By means of the mechanism movement accuracy reliability analysis method, influences of the errors and tolerances of mechanism movement on the mechanism accuracy reliability are considered, a time-variation reliability calculation method-PHI2 and a state fuzzy analysis method are combined, and the mechanism fuzzy time-variation reliability problem can be effectively solved; the aim that in a classical mechanism movement reliability theory, when the time-variation performance and the fuzzy performance are considered at the same time, the failure probability is calculated by properly changing the out-crossing model is achieved.

Owner:BEIHANG UNIV

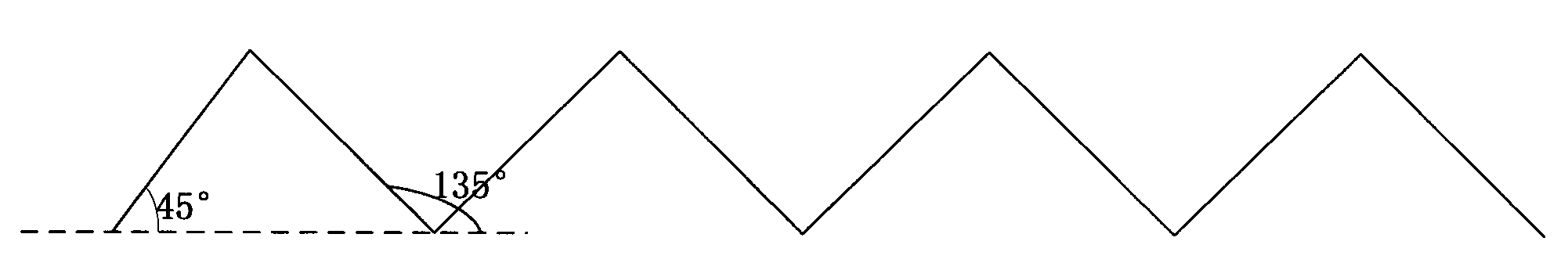

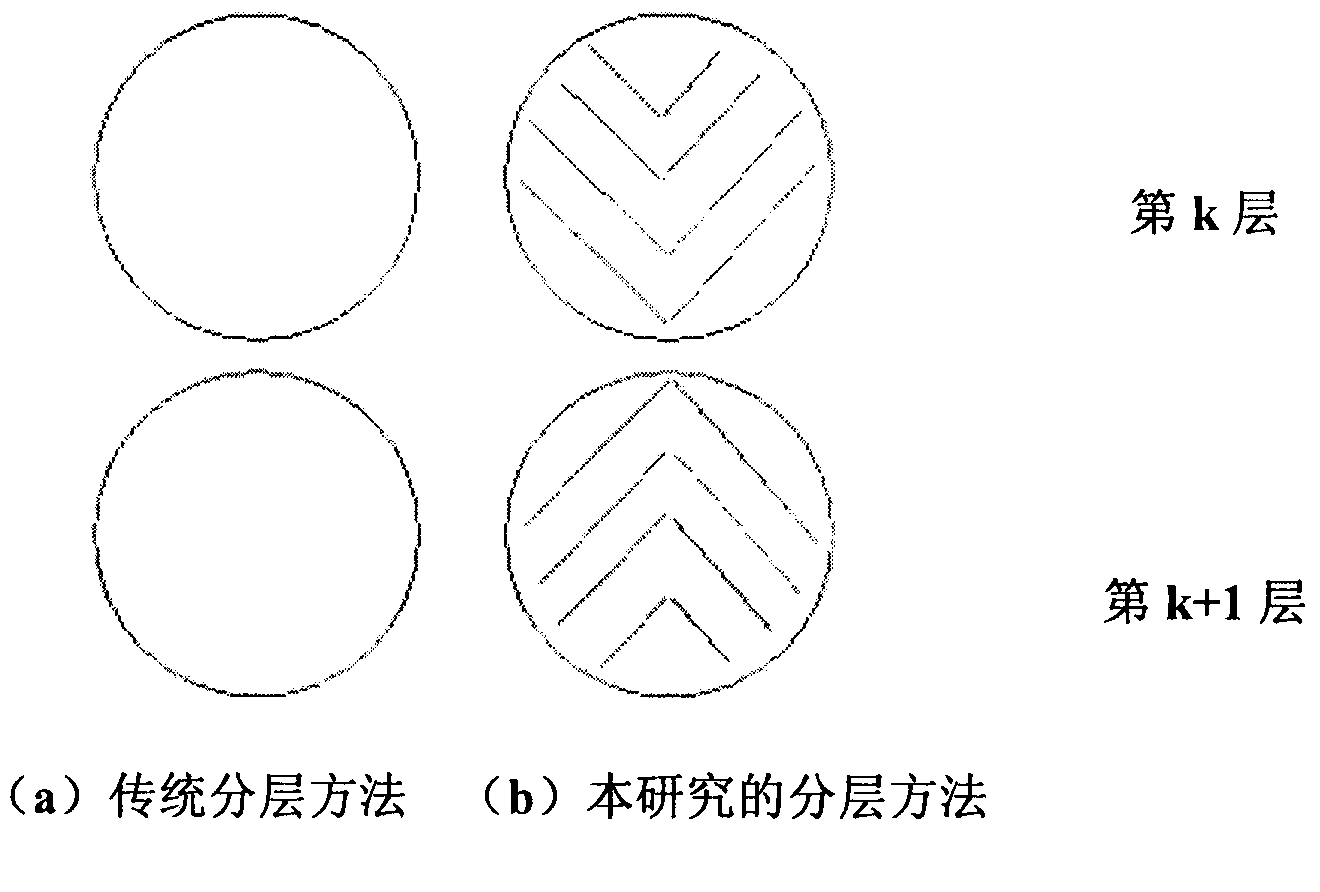

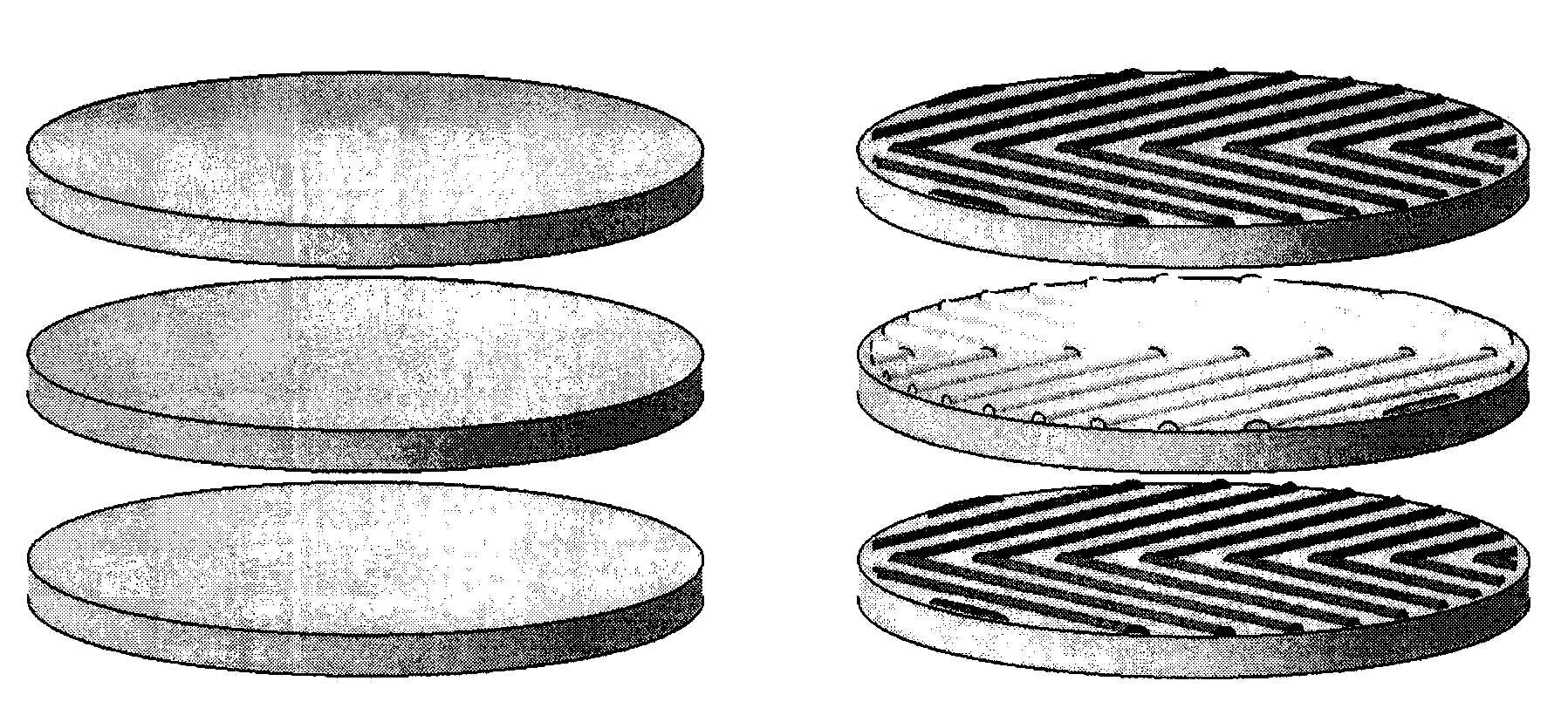

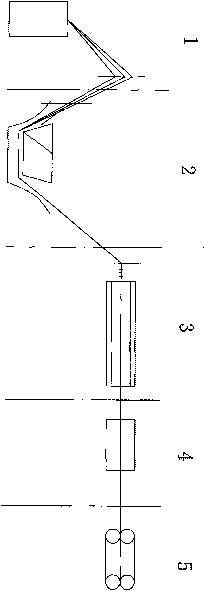

Three-dimensional (3D) printing method based on three-dimensional braiding

InactiveCN103353830ASolve the problem of insufficient strengthSolving Challenges in Innovative DesignDigital output to print unitsEngineeringStress strength

The invention belongs to the field of 3D printing and relates to a three-dimensional (3D) printing method based on three-dimensional braiding. The method is a TDBP three-dimensional braiding printing method capable of effectively fusing a three-dimensional braiding method and a three-dimensional printing method in the textile industry. According to the TDBP three-dimensional braiding printing method, the stress strength of a 3D printed product can be improved. According to the 3D printing method, the problem that a molded product is insufficient in stress strength in the three-dimensional printing industry can be solved, the application defects of the 3D printed product in a main bearing structural member and high functional parts are overcome, and the application field of the 3D printed product is widened.

Owner:TIANJIN POLYTECHNIC UNIV

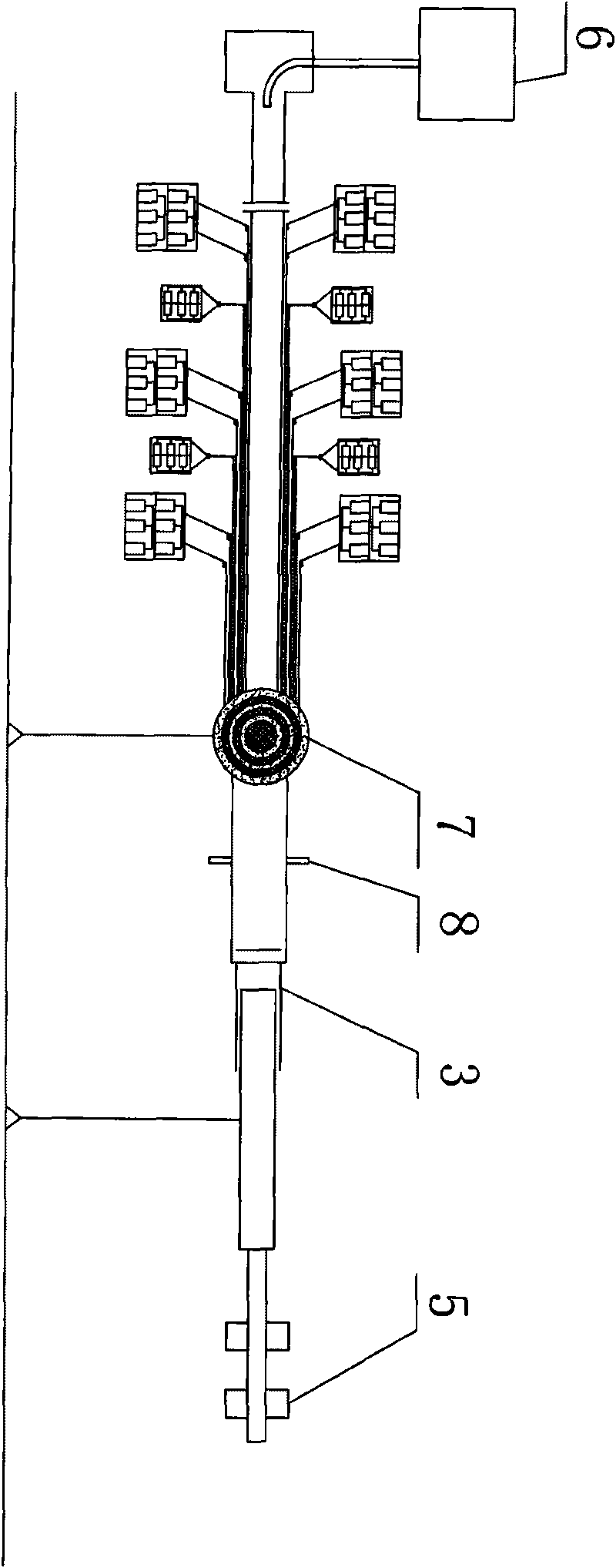

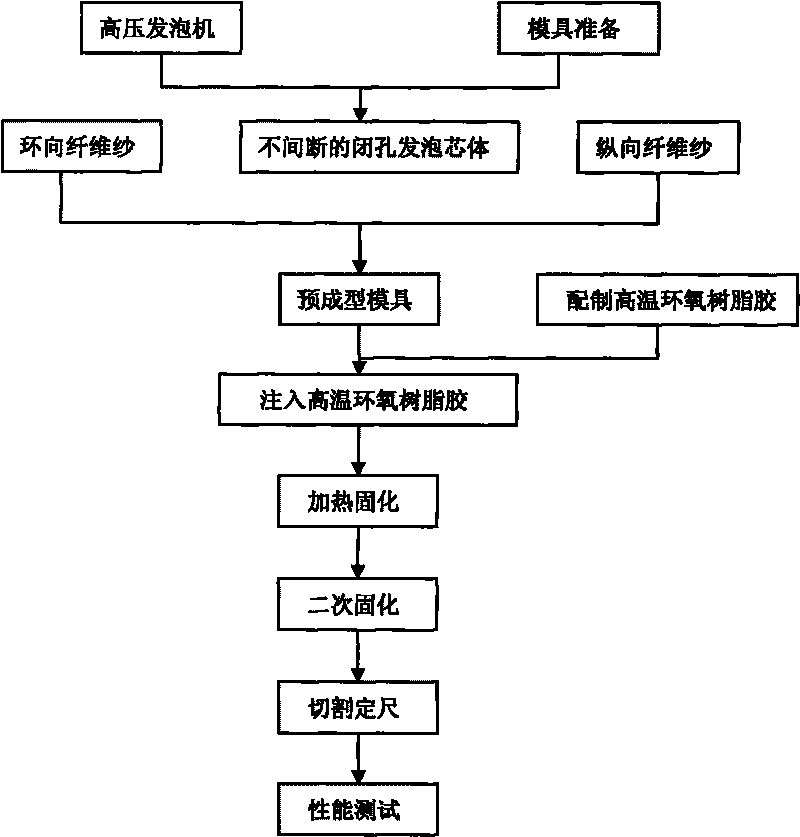

Method for preparing solid core rod of one-step molded high-voltage composite insulator

The invention relates to a method for preparing a solid core rod of a one-step molded high-voltage composite insulator. At present, a large-diameter epoxy glass fiber core rod in particular a large-diameter solid core rod which is used for a high-voltage strut composite insulator and has the diameter of more than 130 millimeters does not exist domestically. The method for preparing the solid core rod comprises the following steps of: selecting an internal mold high pressure foaming system to make an uninterrupted closed cell foamed insulation core body; adopting the combination of a circumferential yarn and a longitudinal yarn to ensure that the circumferential yarn, the longitudinal yarn and the closed cell foamed core body enter a pre-forming mold at the same time; according to different stress strength grades, enwinding the yarn circumferentially for 1 to 3 layers; adopting a vacuum gum injecting method in a gum dipping process; adding the pre-forming mold and a gum injecting hole to a mold part; and putting the closed cell foamed core body, the longitudinal yarn and the circumferential yarn into the mold at the same time to soak an epoxy resin adhesive for solidification molding so as to ensure that the closed cell foamed core body is adhered to a fiber resin layer more firmly. A product produced by the preparation method can replace the large-diameter solid core rod and meet the operating requirements on the core body of the composite insulator.

Owner:陕西泰普瑞电工技术有限公司

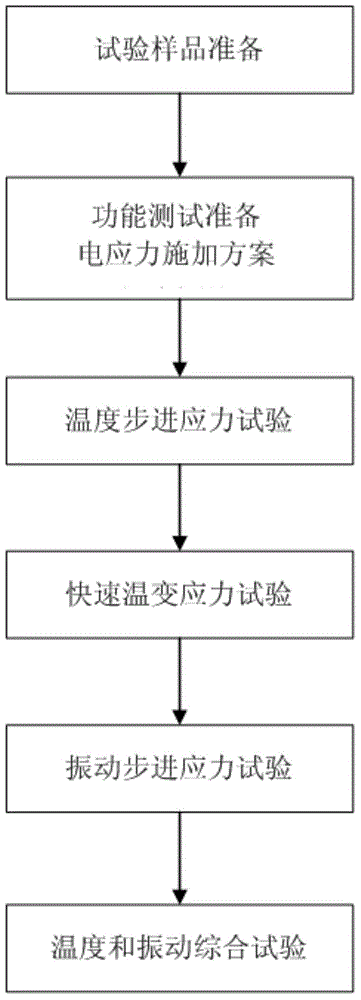

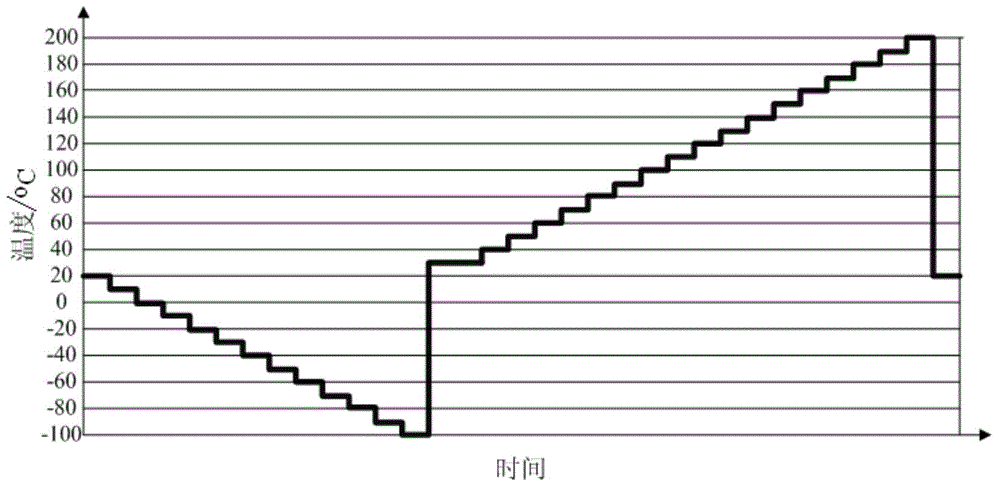

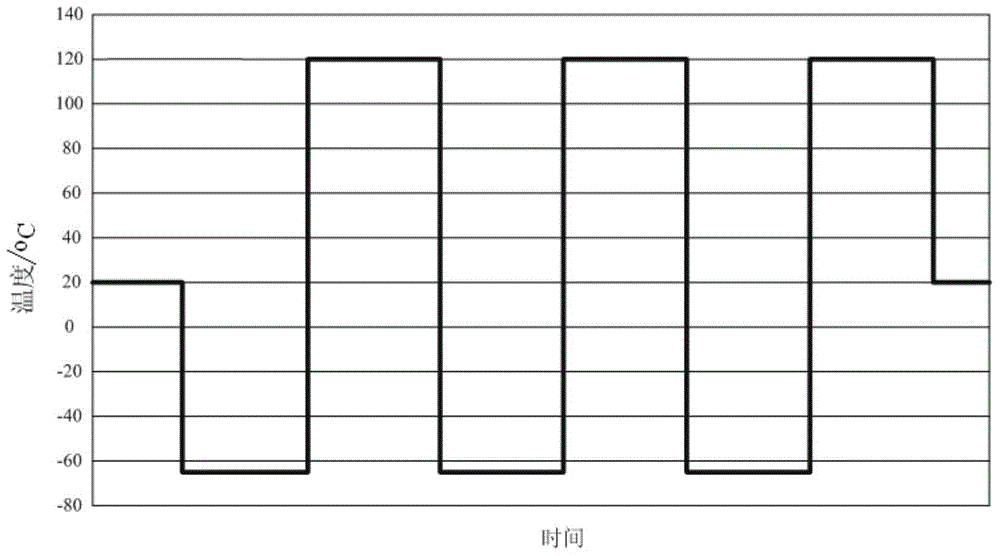

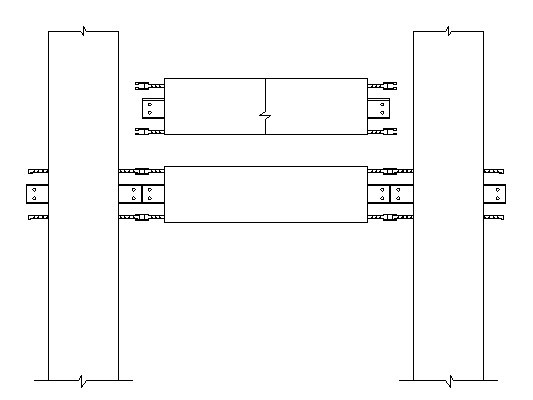

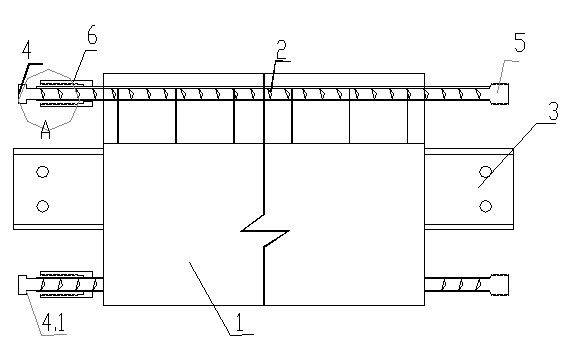

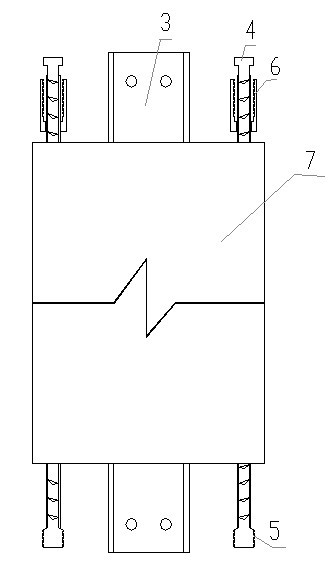

Quick evaluation method for ultimate stress strength of integrated circuit for spaceflight

InactiveCN104596719AQuickly determine damage limitsQuickly identify jobsVibration testingStrength propertiesCombined testUltimate stress

The invention discloses a quick evaluation method for ultimate stress strength of an integrated circuit for spaceflight. The quick evaluation method includes temperature stepping stress test, quick temperature change stress test, vibration stepping stress test, and temperature and vibration comprehensive stress test. The whole process of each test tests the functions of a sample to be evaluated and records fault phenomenons. The other special stress can be exerted to the sample to be evaluated when exerting temperature or vibration stress, such as electric stress. According to the quick evaluation method for the ultimate stress strength of the integrated circuit for the spaceflight, through exerting a series of combined tests, the failure time of the product is reduced, and the evaluation test finishing time is reduced to one week from the original six months to one year; through the heat, power and electric stress combined test, a superimposed or coordination effect is formed, and the evaluation test completeness and precision are greatly improved. Multiple verification results prove that the product fault mode coverage rate discovered in the test evaluation can arrive at more than 98%.

Owner:北京自动测试技术研究所有限公司

Assembled constructional reinforced concrete structural member

InactiveCN102677779AImprove assembly connection construction speedSolve the large amount of on-site assembly and constructionBuilding reinforcementsReinforced concreteStress strength

The invention relates to an improved assembled constructional reinforced concrete structural member which is characterized in that the connecting end of the concrete structural member extends to form a concrete structure or connecting reinforcement; and the head of the concrete structural member is a cylindrical bolt head and / or a cylindrical thread head which is thickened in the radial direction and has the peripheral thickness of more than or equal to 4mm; the inner side of a bolt head at the cylindrical bolt head end is preliminarily sleeved with a connecting sleeve, of which the outer end is an internal thread and the inner end is a neck. During structural member assembly and reinforcement connection, only the connecting sleeve is needed to be moved outwards along the axial direction and rotated to be screwed together with the cylindrical thread head connected to the other end of the connecting sleeve, so that sleeve connection can be used for locating the reinforcement connection of the assembled concrete structural member, stress strength is achieved after the connection is finished, the construction speed for assembling and connecting the concrete structural member is greatly increased, the strength of a joint is greater than that of reinforcement base metal, the joint is stable in reliability and is not influenced by personal factors, only one connecting sleeve is needed, and therefore, smaller length of only 60-100mm is needed, materials are saved, the connection cost is low, and the defects of large construction workload for assembling an assembled reinforced concrete building in situ, labor waste for in-situ assembly construction, low speed and instable quality are overcome.

Owner:江苏金砼预制装配建筑发展有限公司

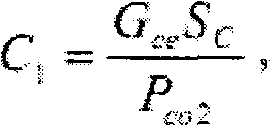

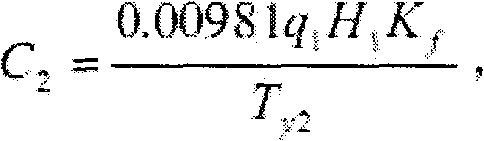

Sealing life prediction method for flexible-packaging lithium-ion batteries

ActiveCN107292025AImprove engineering applicabilityIn line with the actual useDesign optimisation/simulationSpecial data processing applicationsBond interfaceEngineering

The invention relates to a sealing life prediction method for flexible-packaging lithium-ion batteries and belongs to the technical field of sealing life prediction. The sealing life prediction method includes the steps of determining key degradation mechanism and building a bonding interface cohesive zone model based on consideration of degradation effect; determining a degradation trend that environmental degradation factor changes along with stress by building a degradation accelerating model; calculating to obtain a bonding interface strength time model on condition of different stress according to the initial bonding strength; determining a stress time model based on the function relationship between air pressure and time by a simulation method; and finally, predicting the sealing life of the flexible-packaging lithium-ion battery according to the generalized stress strength theory. According to the sealing life prediction method, the influence to the degradation process within the whole life circle of the outer packaging sealing material from the internal pressure of the lithium-ion battery is taken into consideration, variation trend of the sealing performance of the lithium-ion battery in actual use is simulated, the sealing life of the flexible-packaging lithium-ion battery on different environmental conditions can be calculated in theory, and the method has high engineering applicability.

Owner:BEIHANG UNIV

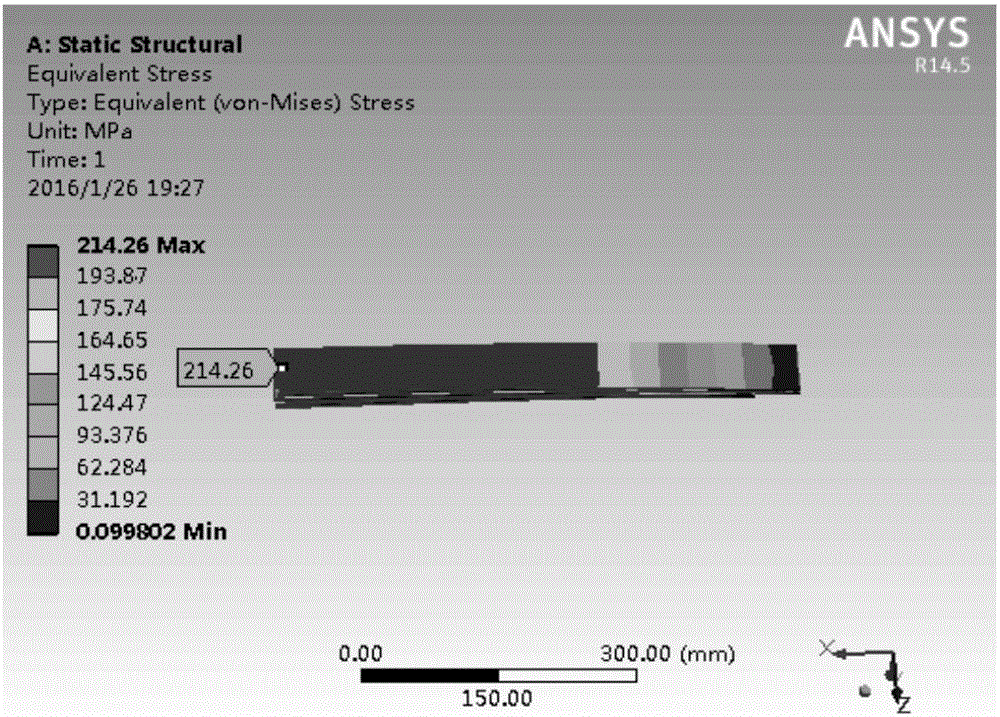

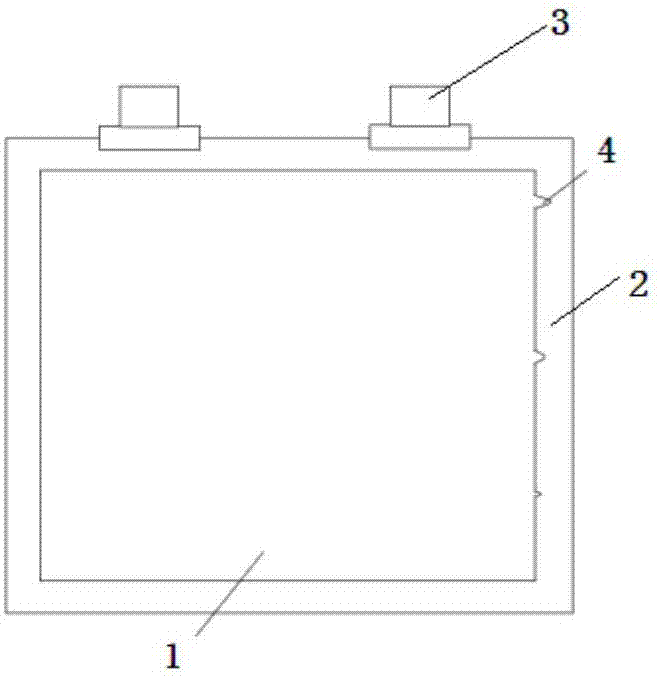

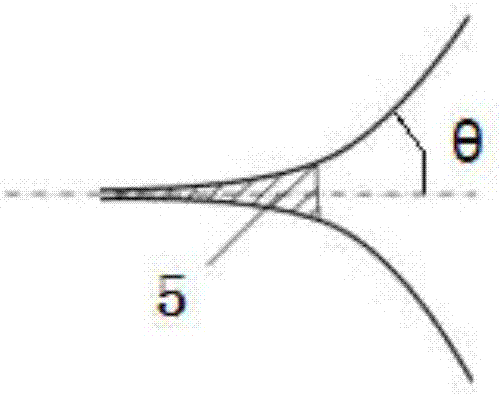

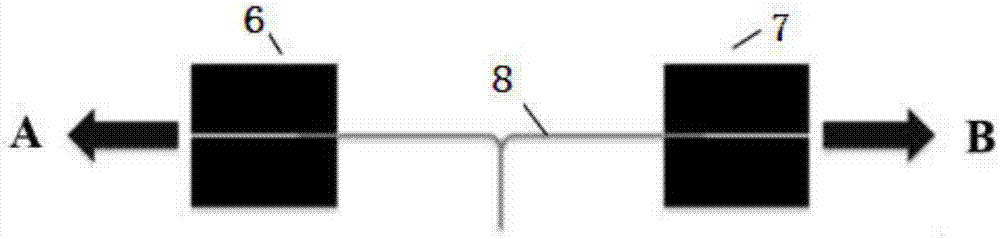

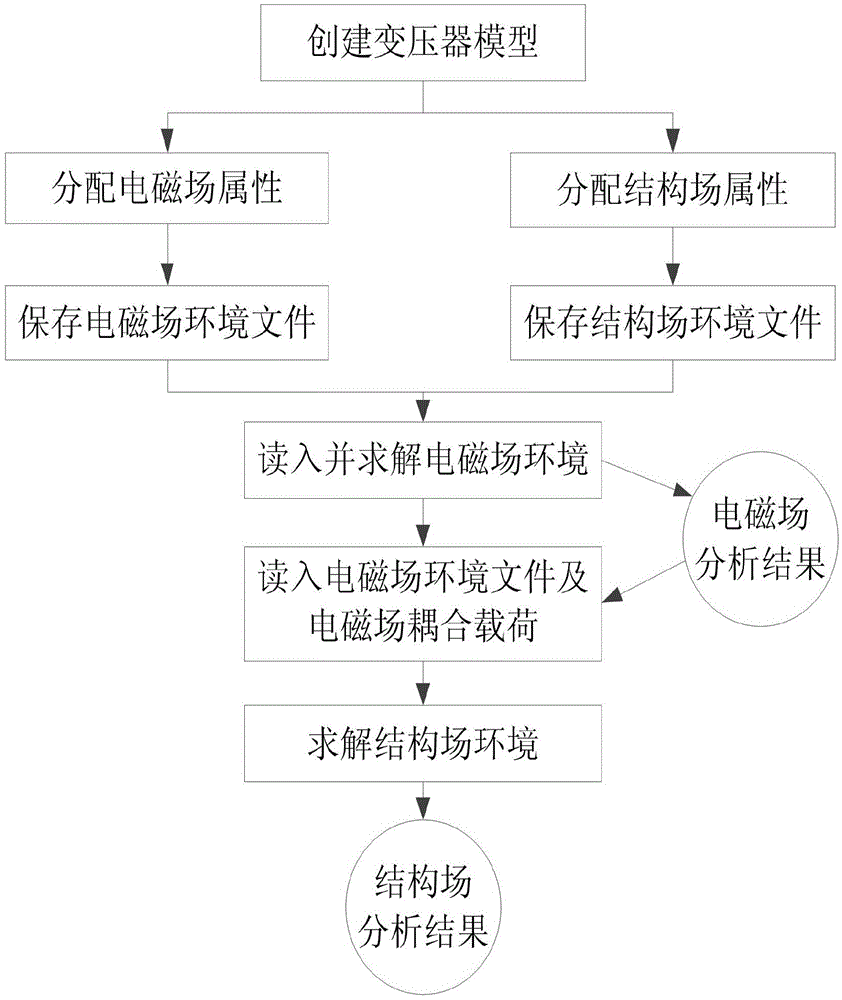

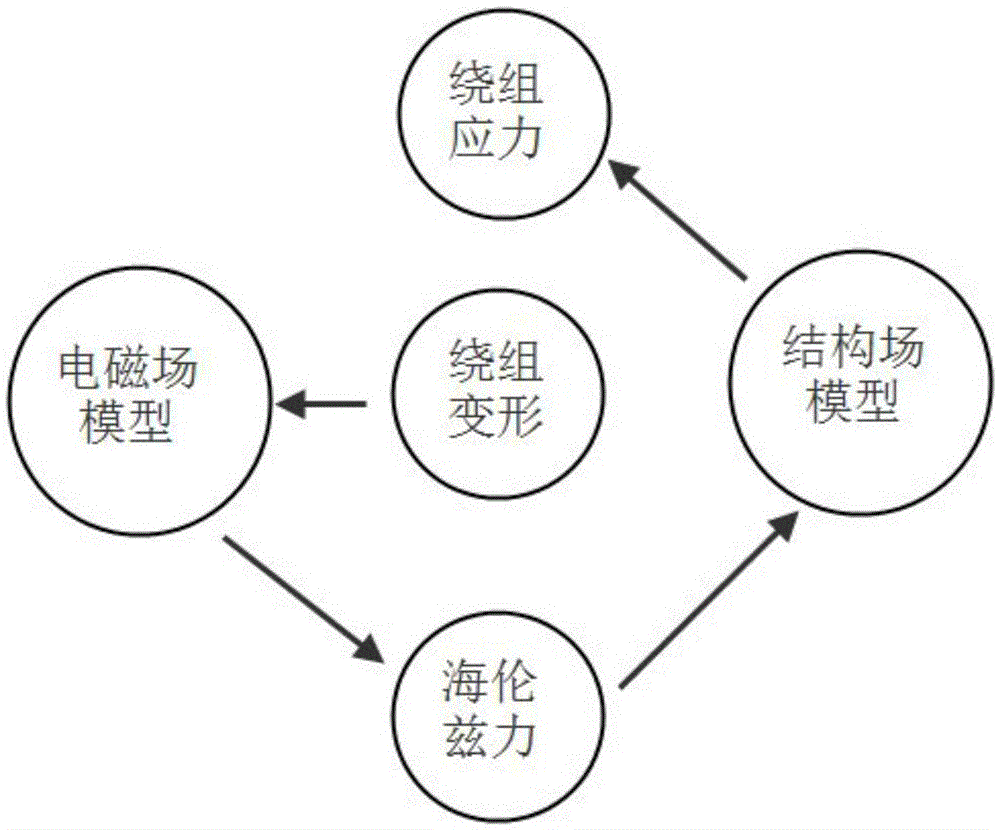

Magnetic-structural-coupling-field-based transformer winding deformation analysis method

InactiveCN105046036AUnderstand the deformationGuaranteed analytical accuracyTransformers/inductances coils/windings/connectionsSpecial data processing applicationsElement analysisComputational physics

The invention relates to a magnetic-structural-coupling-field-based transformer winding deformation analysis method. According to the technical scheme, the method comprises the following steps: a transformer magnetic-structural coupling model containing an electromagnetic field model and a structural field model is established and attributes and constraint conditions of the electromagnetic field model and the structural field model are set; a current is loaded on the electromagnetic field model to obtain an analysis result of an electromagnetic field Lorentz force; the analysis result of the electromagnetic field Lorentz force is extracted and is loaded on the structural model as an electromagnetic field load, and deformation of the transformer winding and the stress strength are observed, thereby realizing the analysis of the transformer deformation. According to the invention, a magnetic-structural-coupling finite element analysis method is applied to the transformer winding deformation analysis and thus the analysis on the transformer winding deformation state is realized under the circumstances that no power failure occurs and no cover suspending needs to be carried out, so that work of field testing and cover suspension examination and the like can be avoided. On the premise that the analysis accuracy is guaranteed, the work load is reduced and the operation and maintenance costs are saved.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

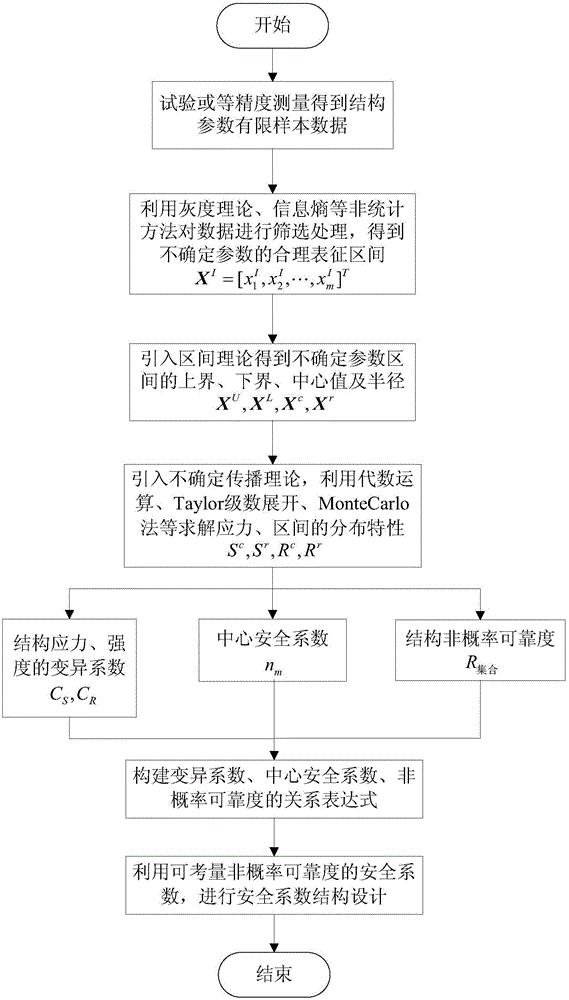

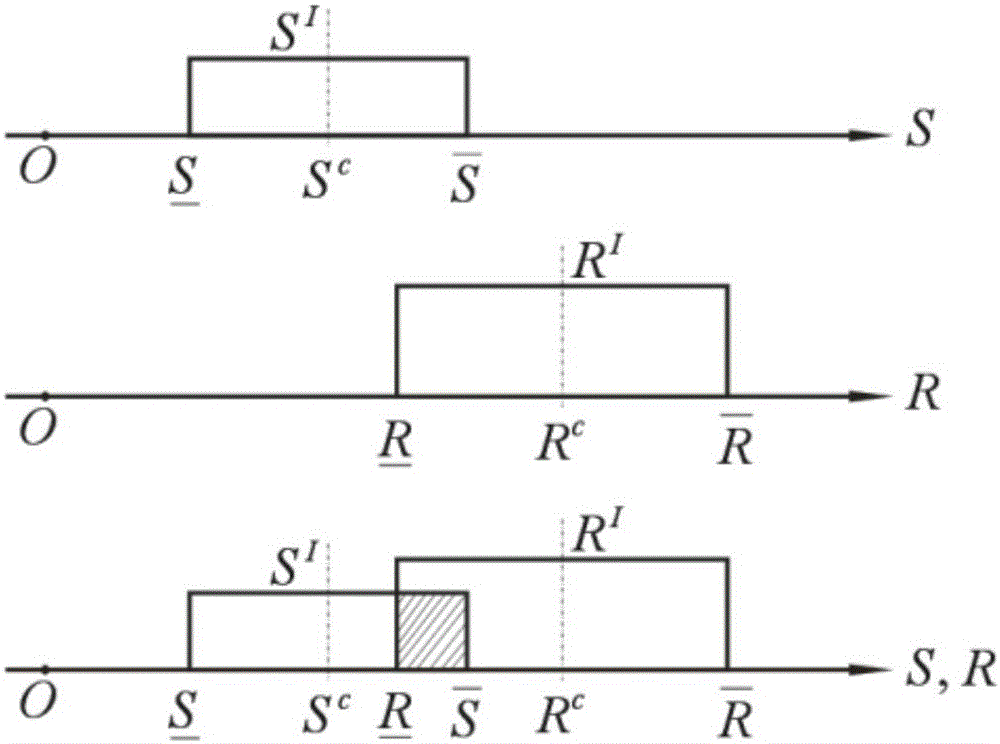

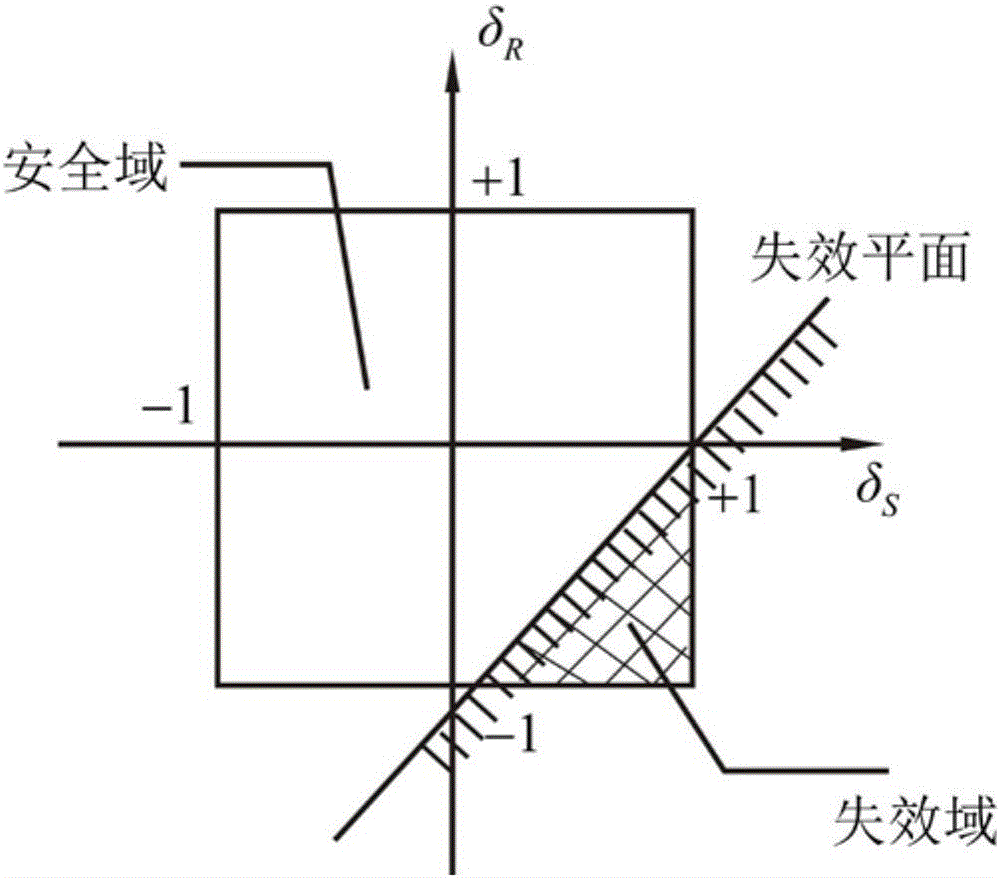

Safety coefficient design method capable of evaluating non-probability reliability of structure

ActiveCN105844060AReduce structural weightShorten the design cycleGeometric CADSpecial data processing applicationsStress strengthEngineering structures

The invention discloses a safety coefficient design method capable of evaluating non-probability reliability of a structure. Firstly, non-probability characteristics of uncertain parameters are reasonably represented with a non-statistical measurement method by the aid of finite sample data of structure parameters; uncertain distribution characteristics of structural stress and strength are determined through approximation solution, Monte Carlo simulation method and the like; a stress-strength non-probability set interference model of the structure is established, and a corresponding non-probability set theory reliability evaluation formula is proposed; an analytical expression of safety coefficients related to the non-probability set theory reliability, strength variation coefficient, stress variation coefficient and the like is established in combination with the non-probability set theory reliability evaluation formula; according to the engineering structure, corresponding safety coefficients are calculated according to corresponding reliability requirements, safety coefficient structure design is conducted, and the optimal structure design scheme meeting certain reliability is obtained. The method considers safety and economy of the design and reserves characteristics that traditional safety coefficient design methods are simple in concept and easy to implement.

Owner:BEIHANG UNIV

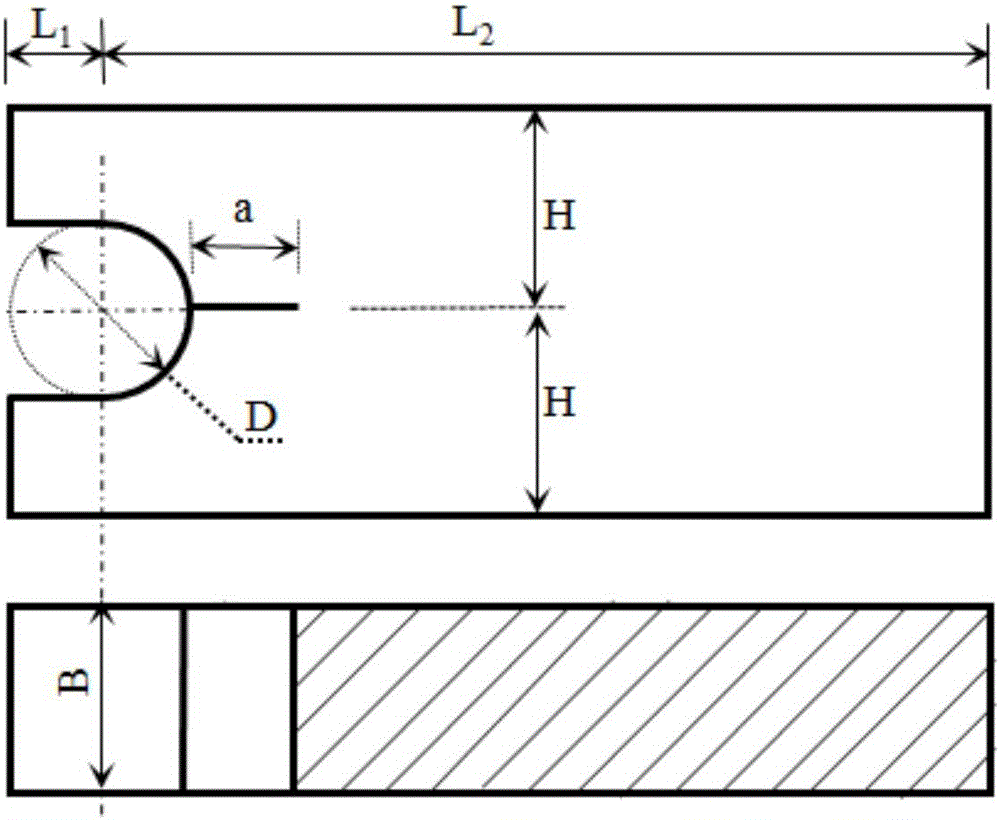

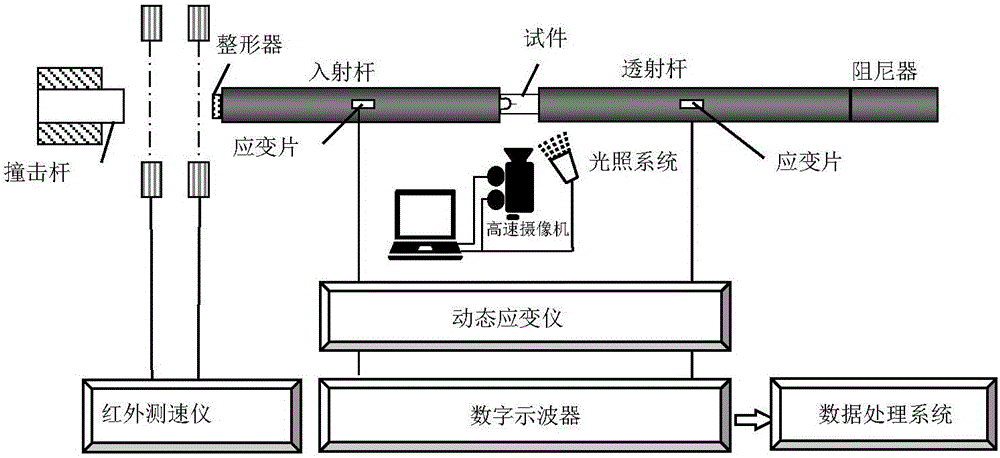

Testing method for dynamic crack arrest toughness of I-type crack under impact load

InactiveCN106290012ASimple methodEasy to operateMaterial strength using single impulsive forceConfiguration designStress intensity factor

The invention discloses a testing method for the dynamic crack arrest toughness of an I-type crack under the impact load, and belongs to the technical field of geotechnical engineering. The method includes the steps of conducting impact test research through a large-diameter separated type Hopkinson pressing rod and a test configuration designed by an inventor, determining the dynamic crack toughness of a sample through an experiment-numerical value method, calculating the load borne by the sample and the moment of crack arrest through strain signals obtained through a test, inputting an obtained time travel curve to a finite element program Ansys, calculating the near-field displacement of a crack tip through a 1 / 4 node unit, obtaining the time travel curve of the I-type dynamic rupture stress strength factor of the sample through a displacement extrapolation method, obtaining the strain strength factor value corresponding to the crack arrest moment as the dynamic crack arrest toughness of the material, and then obtaining the pure I-type crack dynamic crack arrest toughness under the effect of the impact load. The method is simple and convenient to operate and should have more practical application meaning in research of the dynamic crack arrest characteristic of rock under the impact dynamic load.

Owner:SICHUAN UNIV

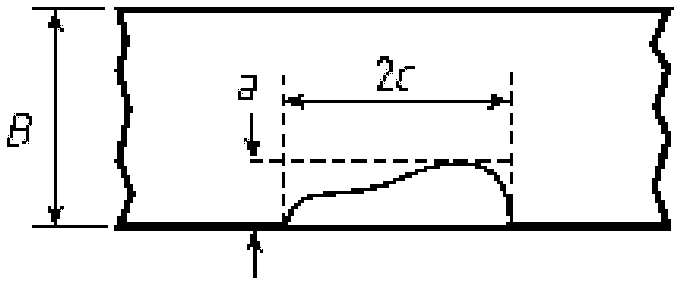

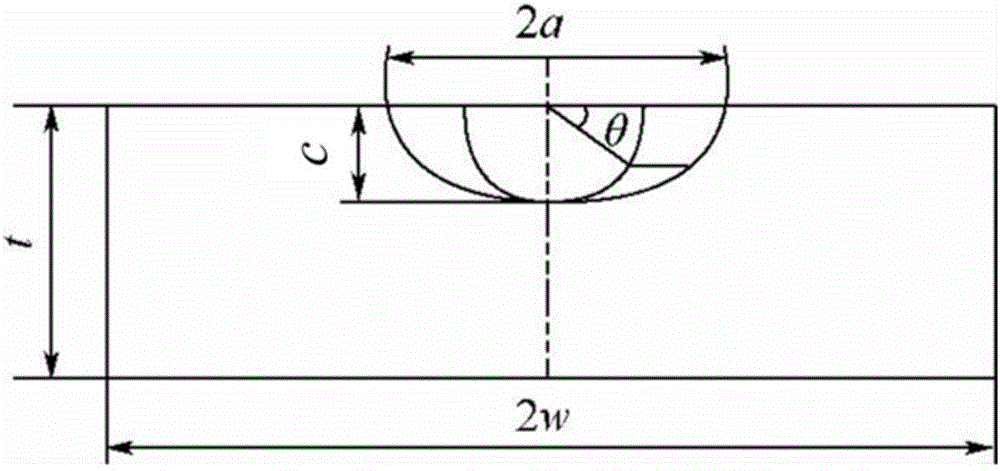

Bidirectional fatigue crack expansion rate testing method and testing system

ActiveCN106568662AThe result is accurateSimple methodMaterial strength using repeated/pulsating forcesStress intensity factorStress strength

The invention relates to a fatigue crack expansion testing technology, and specifically relates to a bidirectional fatigue crack expansion rate testing method and testing system. The testing method comprises the following steps: prefabricating a semicircular gap in the center of a test piece; clamping the test piece in a fatigue testing machine; applying an alternating load to prefabricate fatigue cracks; adopting a constant equivalent amplitude circulating load to carry out a fatigue crack expansion experiment, during the experiment, applying a labeling load so as to leave a label line for reading, reading the fracture under a tool microscope to obtain the semi-length (a) of the label line along the width direction of the test piece, the depth (c) of the label line along the thickness direction of the test piece, and corresponding circulation number (N) of the alternating load; calculating the stress strength factors of the surface cracks under the clamping boundary conditions; according to a, c, and N, evaluating the crack expansion rate so as to determine the bidirectional fatigue crack expansion rate parameters: nA, CA, nB, and CB. The method can directly read the crack forms and sizes from the fracture, the result is precise, no extra facility is needed, and one experiment can obtain the fatigue crack expansion rate parameters in two directions.

Owner:BEIHANG UNIV

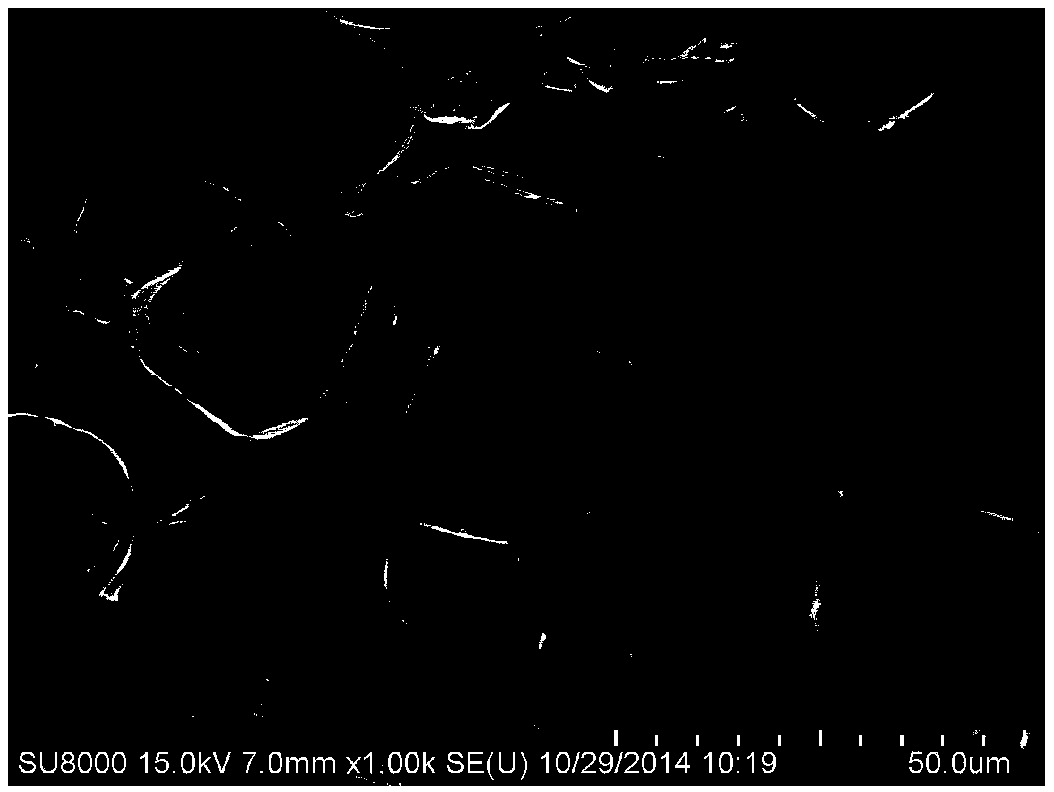

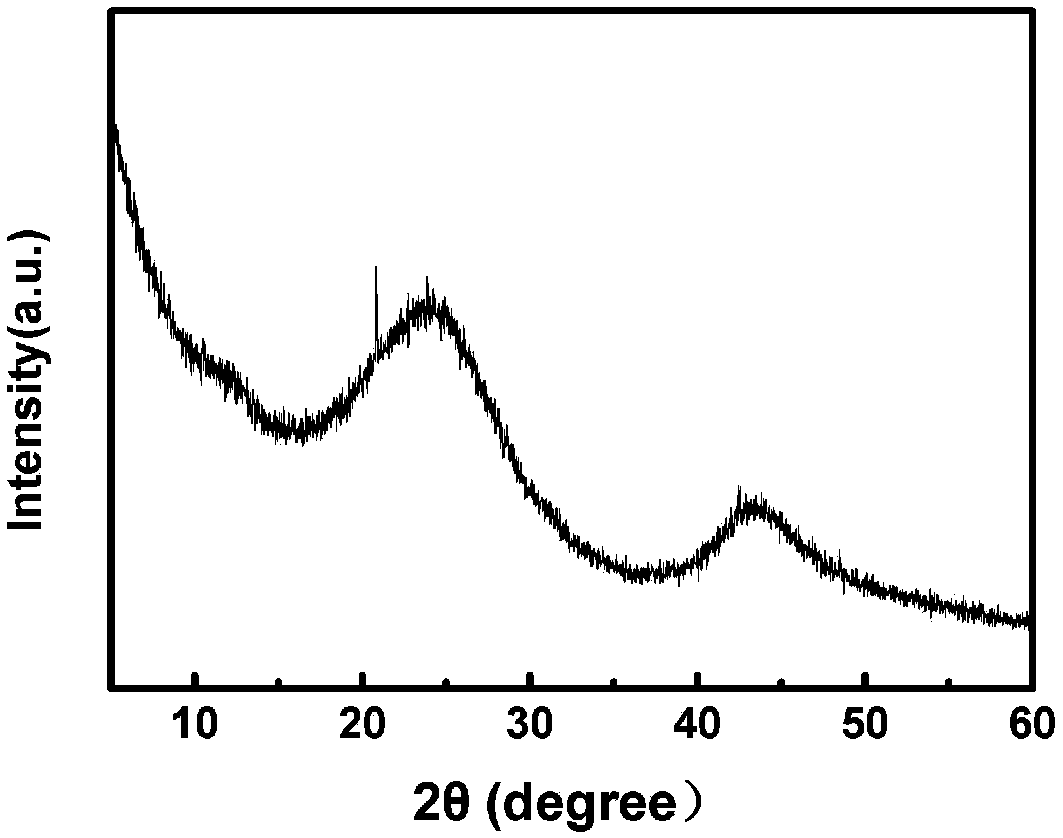

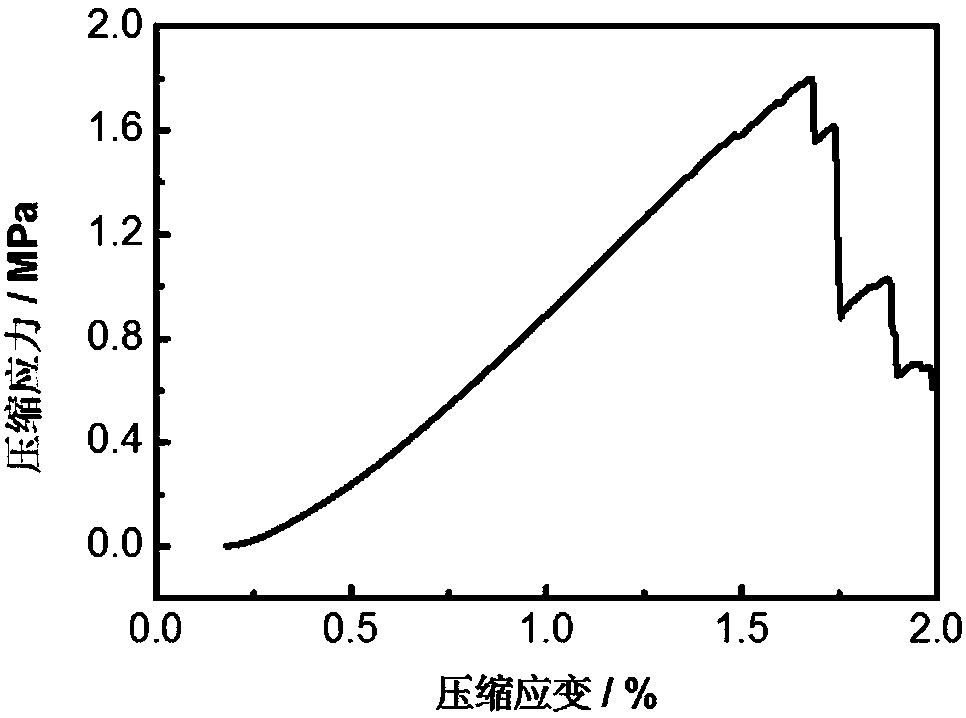

Foamy carbon material preparation method based on principle of starch fermentation

The invention discloses a foamy carbon material prepared on the basis of the principle of starch fermentation, and belongs to the field of porous materials. Starch, yeast and water are used as raw materials to prepare the foamy carbon material through curing, baking and forming; and a three-dimensional porous carbon material can be obtained after carbonization under the protection of high-temperature inert gas, natural cooling and drying. Scanning electron microscope and X-ray diffraction representation shows that the material is of a porous and ordered graphite structure; and mechanical testsindicate that the material has relatively strong stress strength under low density and is an ideal environmentally-friendly foamy carbon material with low cost and high strength.

Owner:HARBIN INST OF TECH

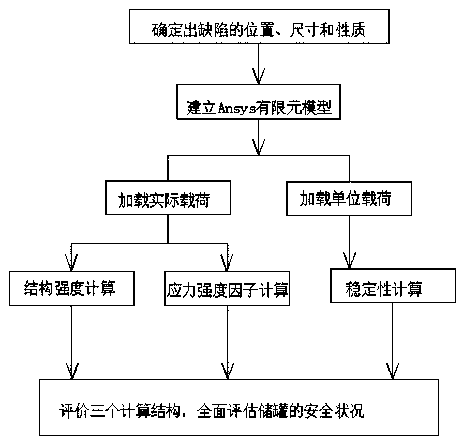

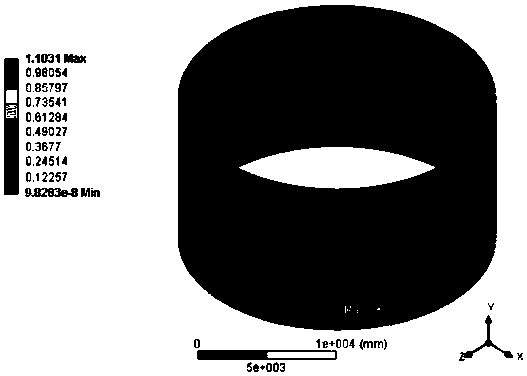

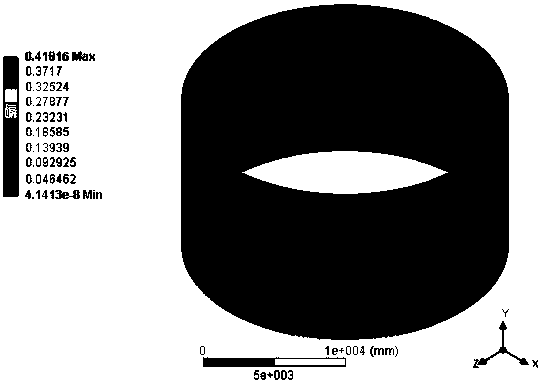

Overall evaluation method for normal-pressure storage tank containing defect

InactiveCN108363859AComprehensive and accurate security situationInhibit expansionSpecial data processing applicationsNon destructiveStress intensity factor

The invention discloses an overall evaluation method for a normal-pressure storage tank containing a defect. The method is characterized by including the following steps: measuring a property, a sizeand a position of the defect on the storage tank; establishing a storage tank model of the defect in Ansys software according to a storage tank structure and the defect position, size and property; using the Ansys software for loading actual loads to calculate storage tank structure strength and a storage tank stress strength factor, and loading unit loads for stability calculation; and evaluatingcalculated and obtained storage tank structure strength, the storage tank stress strength factor and a stability result to comprehensively evaluate safety status of the storage tank. According to themethod, deficiencies and shortcomings on the aspect of current domestic storage tank safety evaluation standards are solved, the safety status of the storage tank is evaluated from multiple angles ofstructural mechanics, fracture mechanics and the like through a method of combining non-destructive earlier-stage detection and calculation of the finite-element software Ansys, and a calculation result has higher reliability.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com