Foamy carbon material preparation method based on principle of starch fermentation

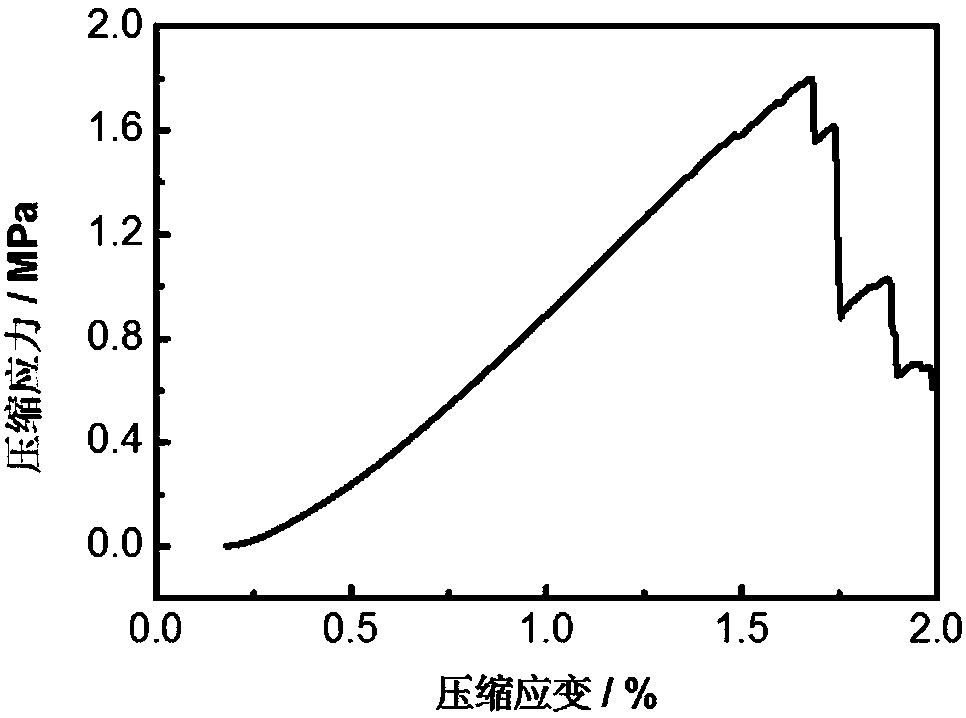

A technology of starch fermentation and carbon foam, applied in the field of porous materials, can solve the problems of high electrical conductivity, low thermal conductivity, and low density of three-dimensional porous materials, and achieve easy industrial production, low raw material cost, high electrical conductivity, and compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] The specific embodiment one, a kind of method of making foam carbon material based on the principle of starch fermentation in the present embodiment is carried out according to the following steps:

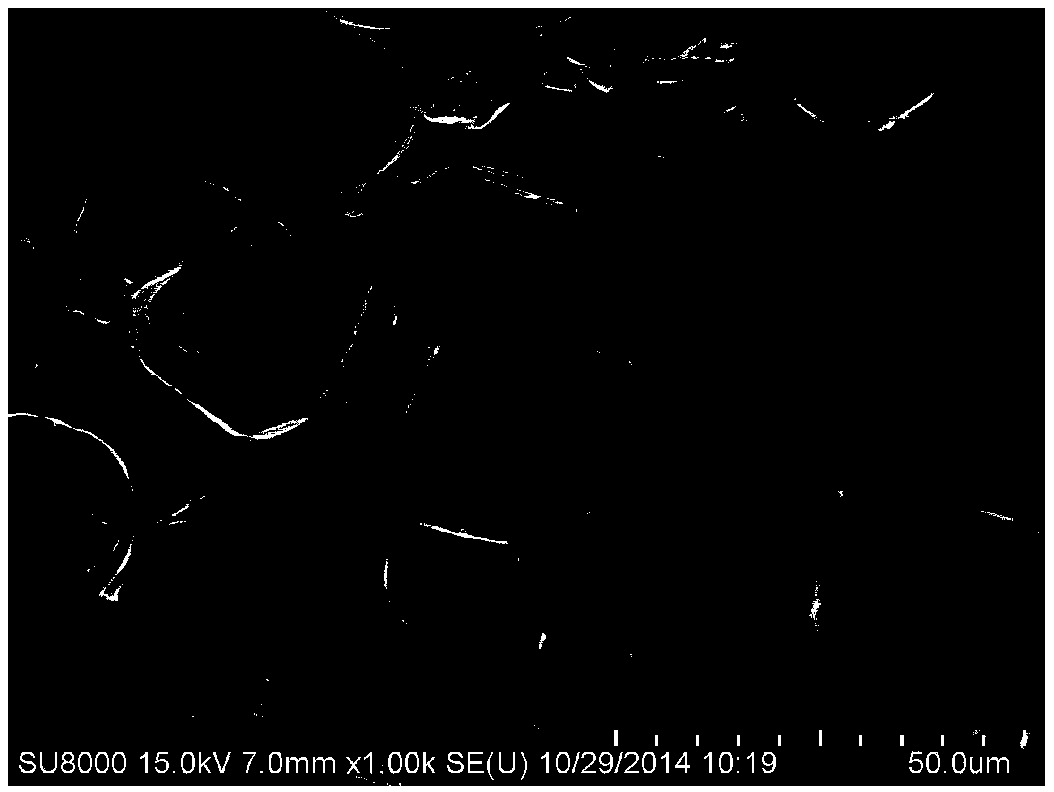

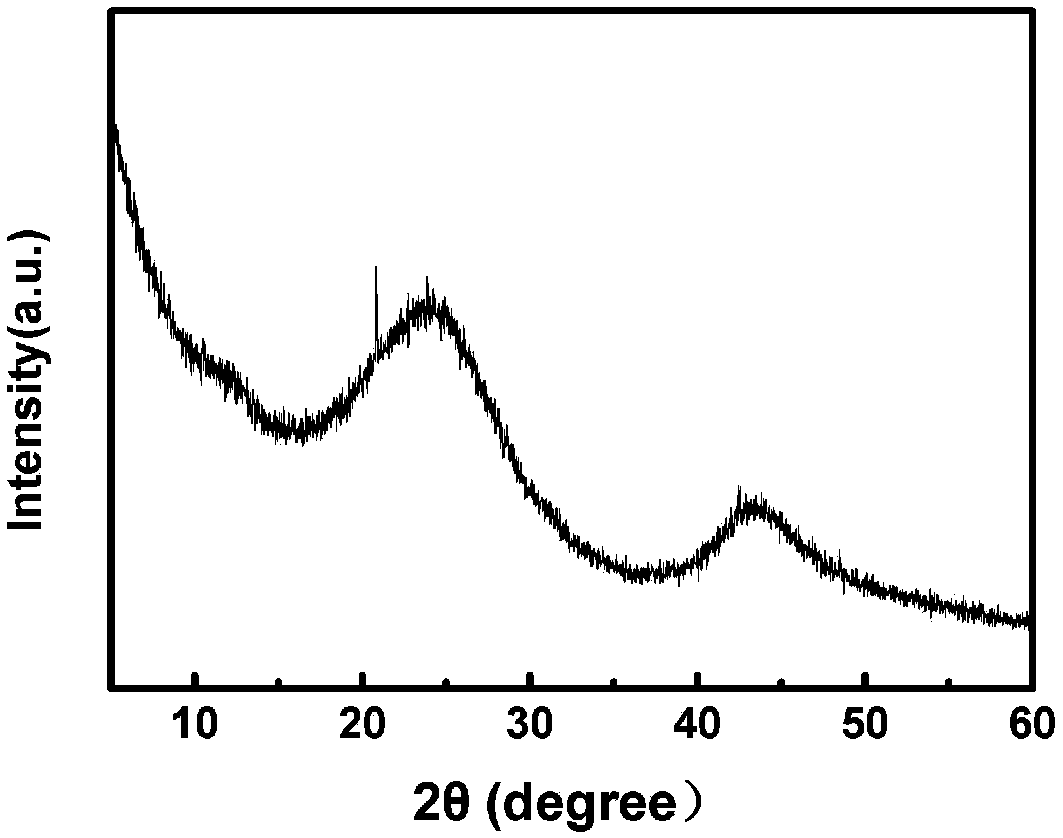

[0028] Weigh 200g of starch and 3.5g of dry yeast, add 100ml of deionized water, stir for 10min and shape. After fermenting at a humidity of 75% and a temperature of 30°C, press it with your fingers without elasticity (the fermentation time generally takes 60 minutes), knead it into a set shape, and continue to ferment for the second time at a humidity of 80% and a temperature of 35°C until After pressing with fingers, there is no elasticity (secondary fermentation generally takes 60 minutes). The precursor obtained by the above fermentation was put into a drying oven and heated for 30 minutes to obtain a solidified starch porous structure. The porous material was placed in a vacuum drying oven, and dried for 12 hours at a vacuum degree of 20 Pa and a temperature of 50°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com