Method for evaluating critical stress intensity and sensitive factor of stress corrosion cracking for oil well pipe

A technology of stress corrosion cracking and critical stress, applied in the direction of measuring devices, testing material hardness, instruments, etc., can solve problems such as differences in processing requirements and influences, and achieve strong practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

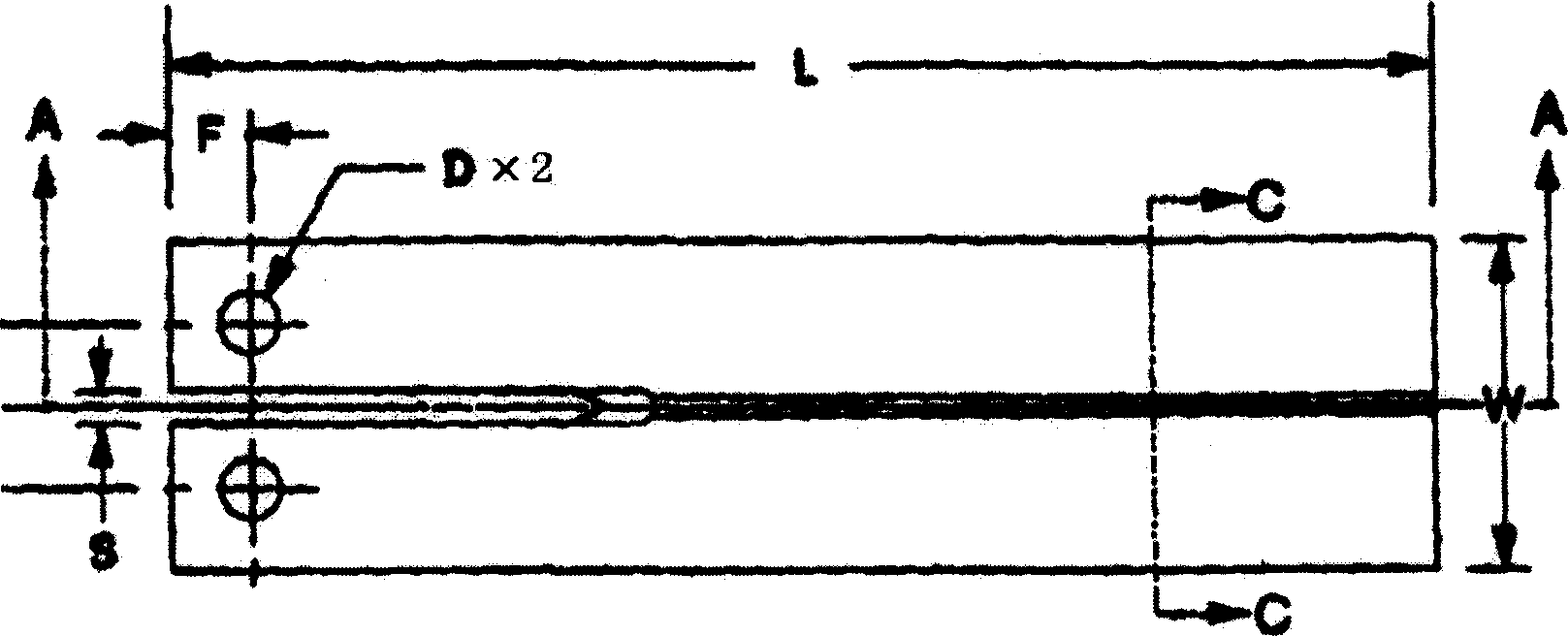

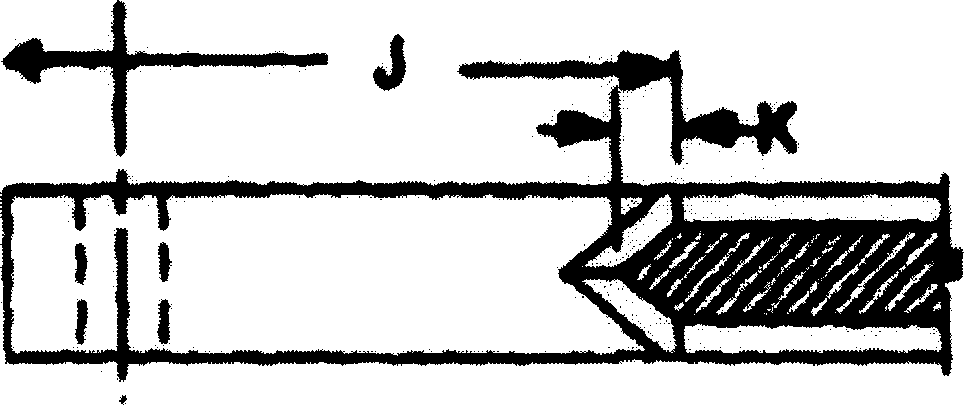

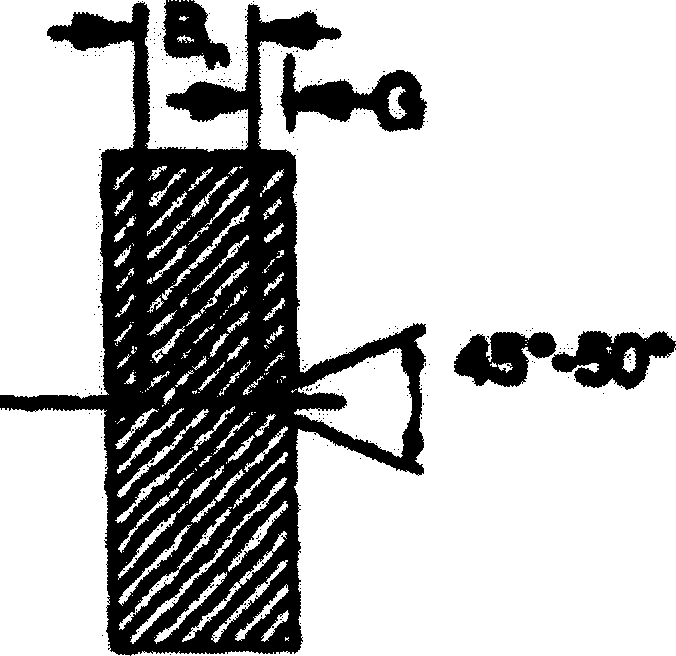

[0049] Take an example of anti-sulfur oil well pipe K 1SCC The index evaluation is taken as an example to illustrate the implementation effect of the present invention. The NACE TM0177-96 Method D standard DCB sample is used (machined mountain-shaped notch cracks are used, no fatigue cracks are prefabricated), and the actual measured dimensions of the DCB sample are listed in Table 1:

[0050] Bn

[0051] Carry out wedge splitting loading on the sample, soak in H according to IRP requirements 2 The S corrosion solution was taken out after 14 days, and the wedge was removed to measure the critical balance load, and the effect of the secondary fatigue crack growth on the H 2 S Stress corrosion crack front coloring, determination of crack length a f Then calculate K 1SCC value. Two sets of "quasi-static loading-unloading flexibility closed-loop curves" before and after the test obtained by applying the inventive method, see Figure 12 , Figure 13 shown.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com