Patents

Literature

50 results about "Crack closure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crack closure is a phenomenon in fatigue loading, where the opposing faces of a crack remain in contact even with an external load acting on the material. As the load is increased, a critical value will be reached at which time the crack becomes open. Crack closure occurs from the presence of material propping open the crack faces and can arise from many sources including plastic deformation or phase transformation during crack propagation, corrosion of crack surfaces, presence of fluids in the crack, or roughness at cracked surfaces..

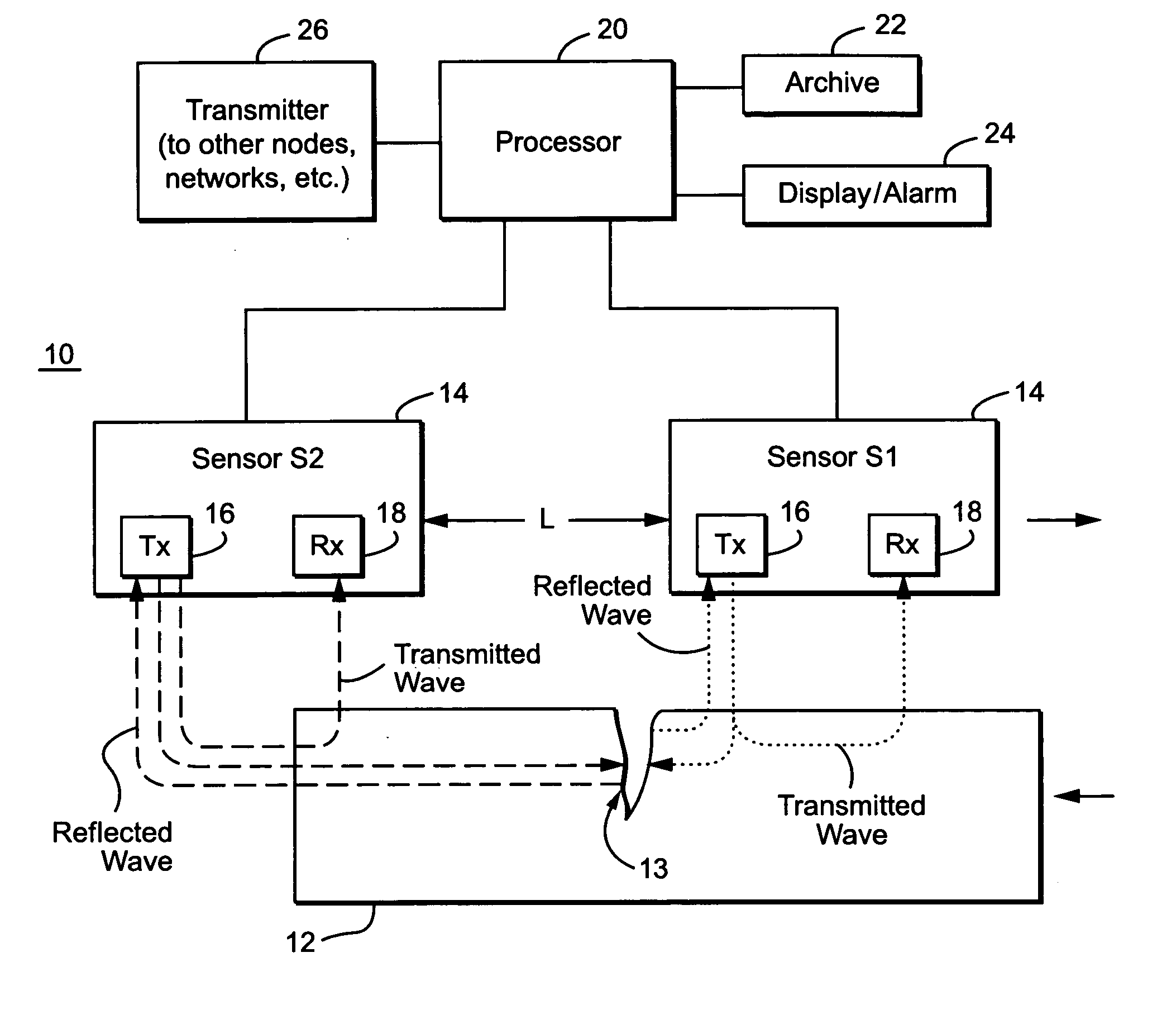

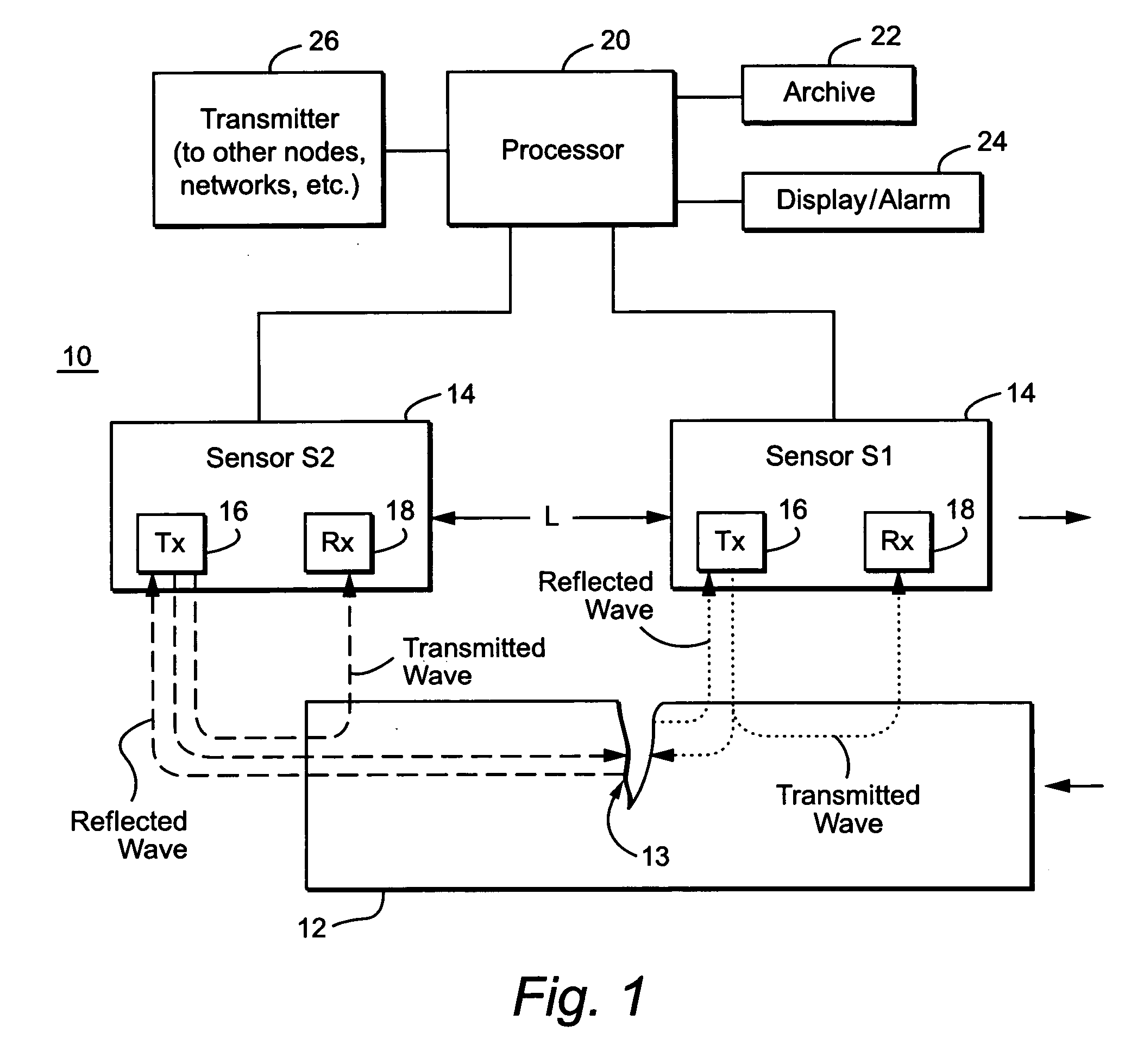

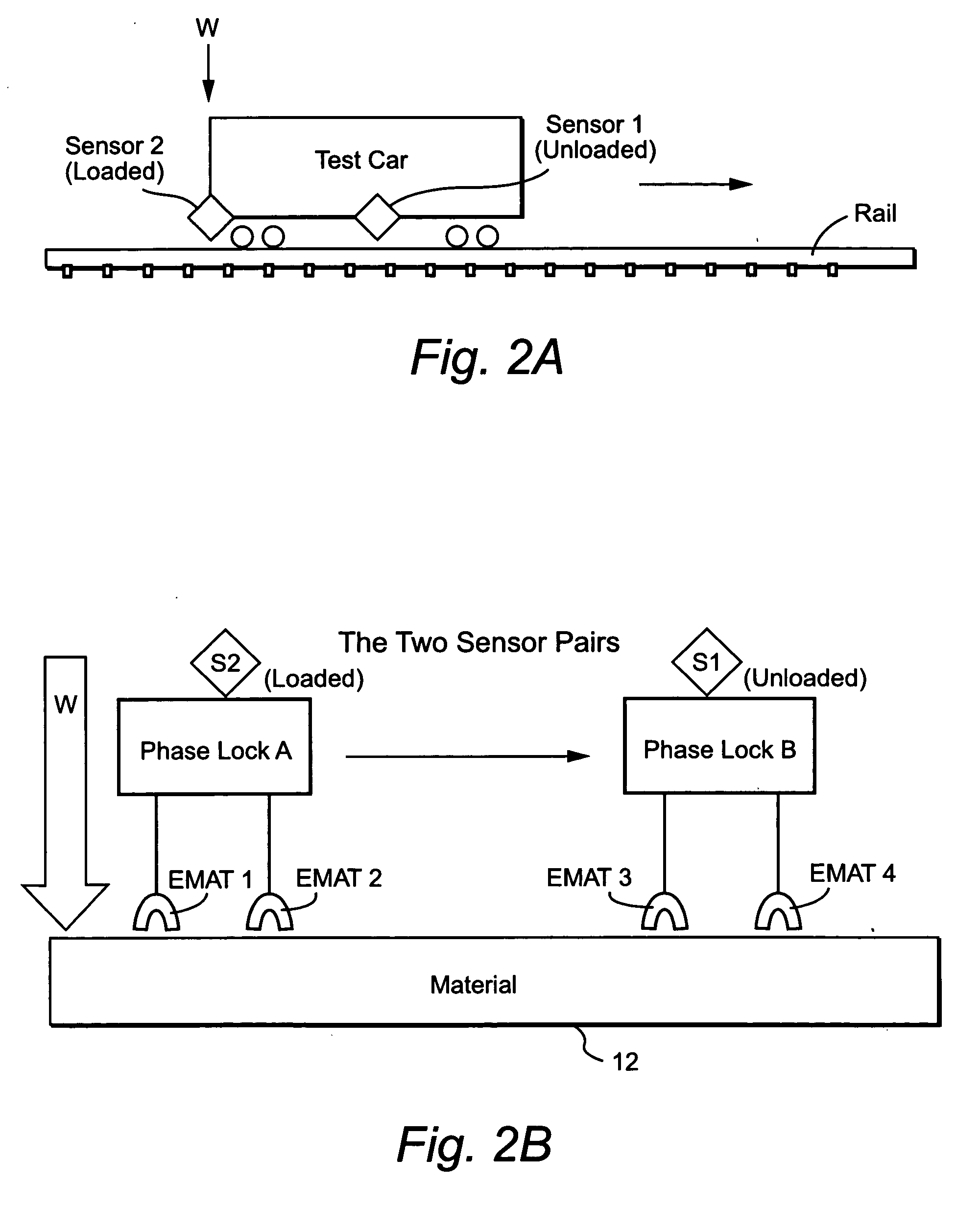

Method and apparatus for determining and assessing a characteristic of a material

InactiveUS20050072236A1Low costImprove accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesDifferential measurementCrazing

An acoustic energy-based, non-contact or contact testing approach provides low cost, highly accurate, and reliable information to (a) identify flaws and anomalies and (b) assess the integrity of a particular material. This approach is not hindered by surface conditions or impediments, and indeed, looks beneath the surface of the material by propagating an acoustic wave through the material using two differential transducers. A dynamic differential measurement is made of the material under a load condition and an unloaded condition that allows identification and assessment of various characteristics of the material. Multiple “windows” of information may be generated that permit (a) direct detection of flaws, defects, and anomalies using a scattering technique, (b) detection of crack closure and opening used to assess the stability of the material, (c) determination of strain on the material which relates to its performance, and (d) determination of defect dynamics linked to the defect size and stability.

Owner:LUNA INNOVATIONS

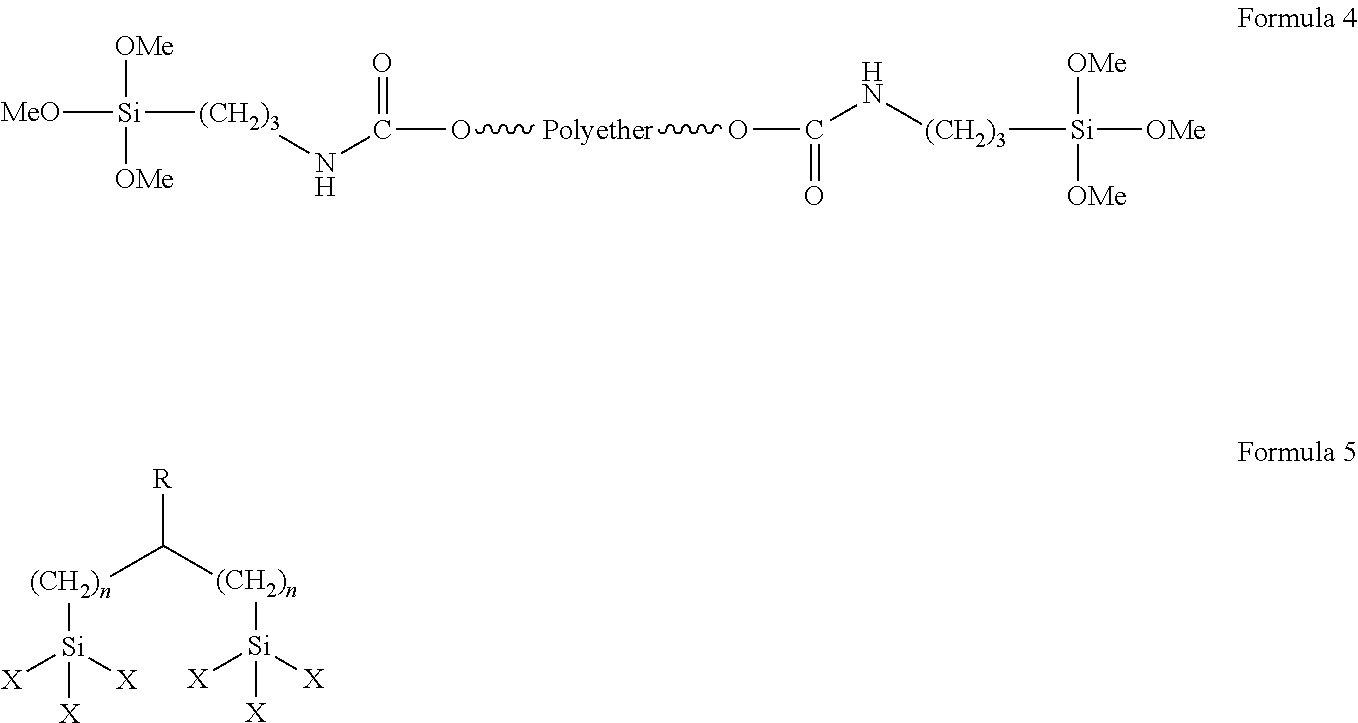

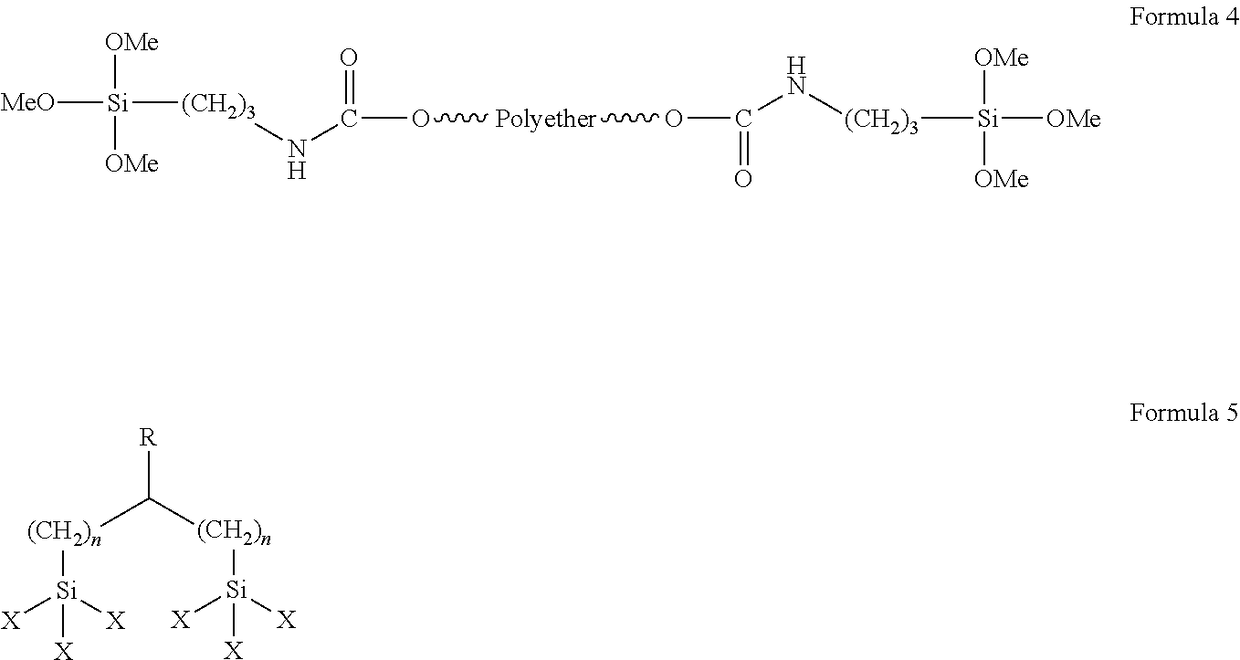

Proppant With Enhanced Interparticle Bonding

Polymer-coated proppants for hydraulic fracturing of oil and gas wells have an outer layer portion that comprises an organofunctional coupling agent, preferably an organofunctional silane coupling agent. The use of an organofunctional silane coupling agent in the outer layer portion of the proppant coating is preferably chosen to expose functionalities that will be reactive towards similar functionalities of adjacent and similarly coated proppants so that, when introduced downhole, these proppants form interparticle bonds at the temperatures and crack closure pressures found downhole in fractured strata. Such enhanced interparticle bonding helps keep the proppant in the fracture and maintains conductivity with reduced flowback. The invention also helps proppants designed for low temperature well to bond more firmly and allows proppants designed for high temperature wells to bond well even at lower downhole temperatures, thereby extending their useful range.

Owner:PREFERRED TECH

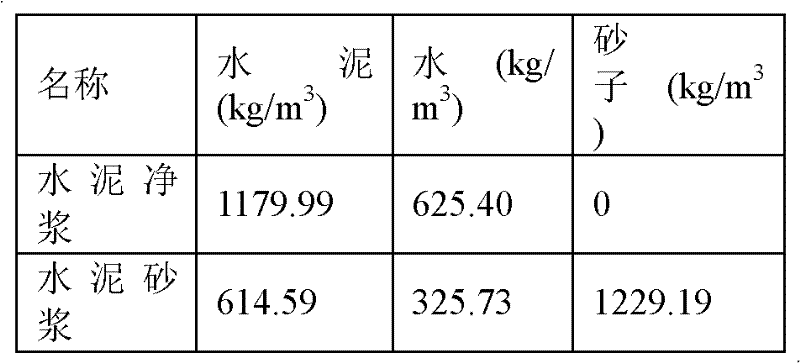

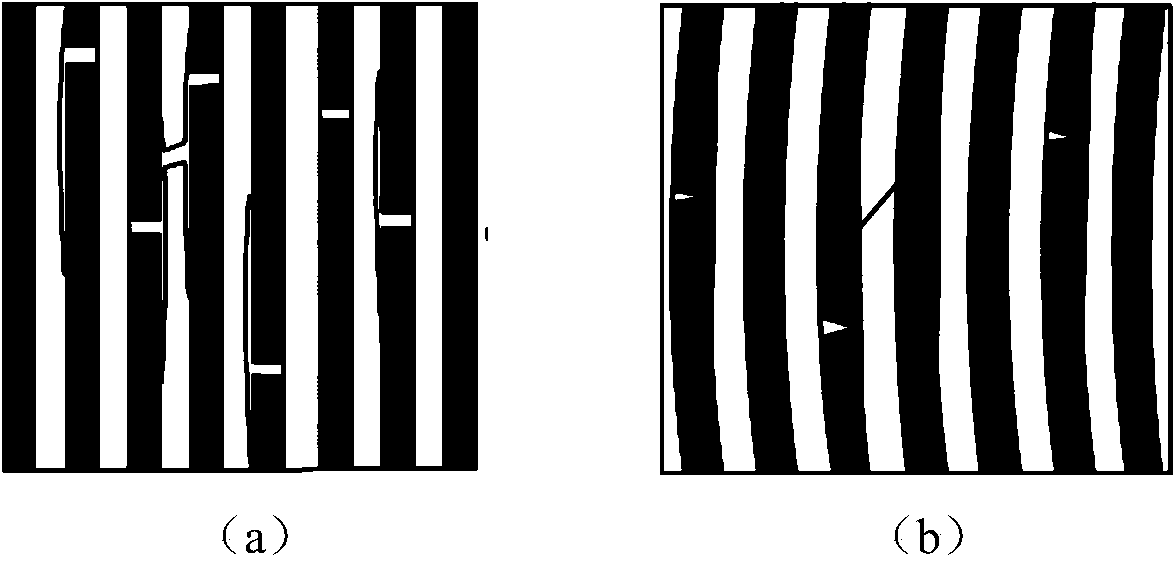

Method for performing non-destructive detection on evolution of three-dimensional carbonation depth of cement-based material through X-ray scanning

InactiveCN102590242AIntegrity guaranteedGuaranteed accuracyPreparing sample for investigationMaterial analysis by transmitting radiationPorosityObject based

The invention provides a method for performing non-destructive detection on evolution of the three-dimensional carbonation depth of a cement-based material through X-ray computerized tomography and relates to a novel detection method for the carbonation depth of a cement-based material. The main principle is that: an image is reconstructed by acquiring ray attenuation information of a rotary object based on an X-ray source; a carbonized region and a non-carbonized region of the cement-based material are distinguished according to difference of gray value; and the defects in the traditional pHmethod of phenolphthalein alcohol solution are overcome. Under the condition of not damaging a test piece, the evolution process of the three-dimensional carbonation depth of the cement-based material along with the time is detected. By the method, flaw space distribution in the carbonation process, the flaw volume, the flaw closing area, the evolution law of porosity and hole dimensional distribution and the topological properties, such as connectivity, sinuosity and the like, of the hole can be achieved.

Owner:SOUTHEAST UNIV

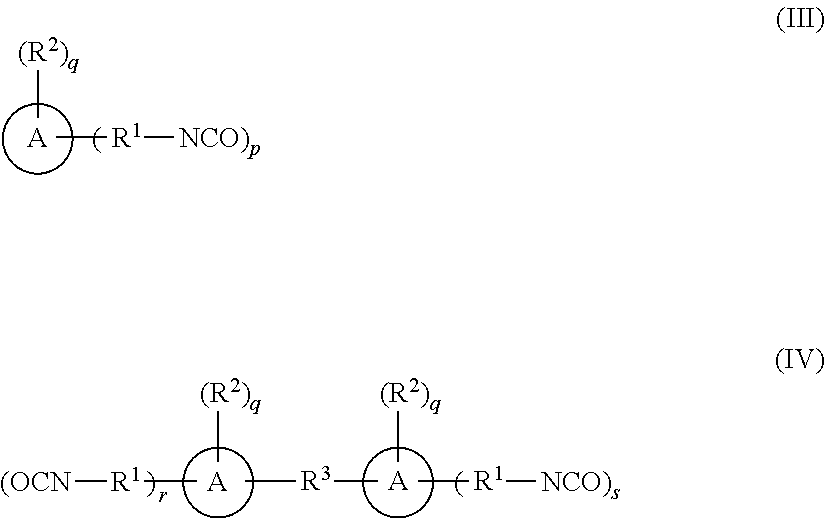

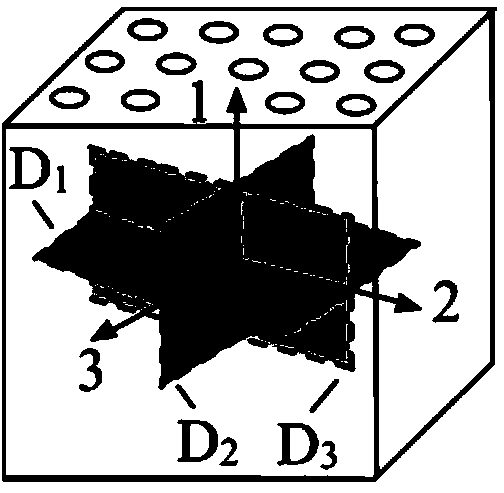

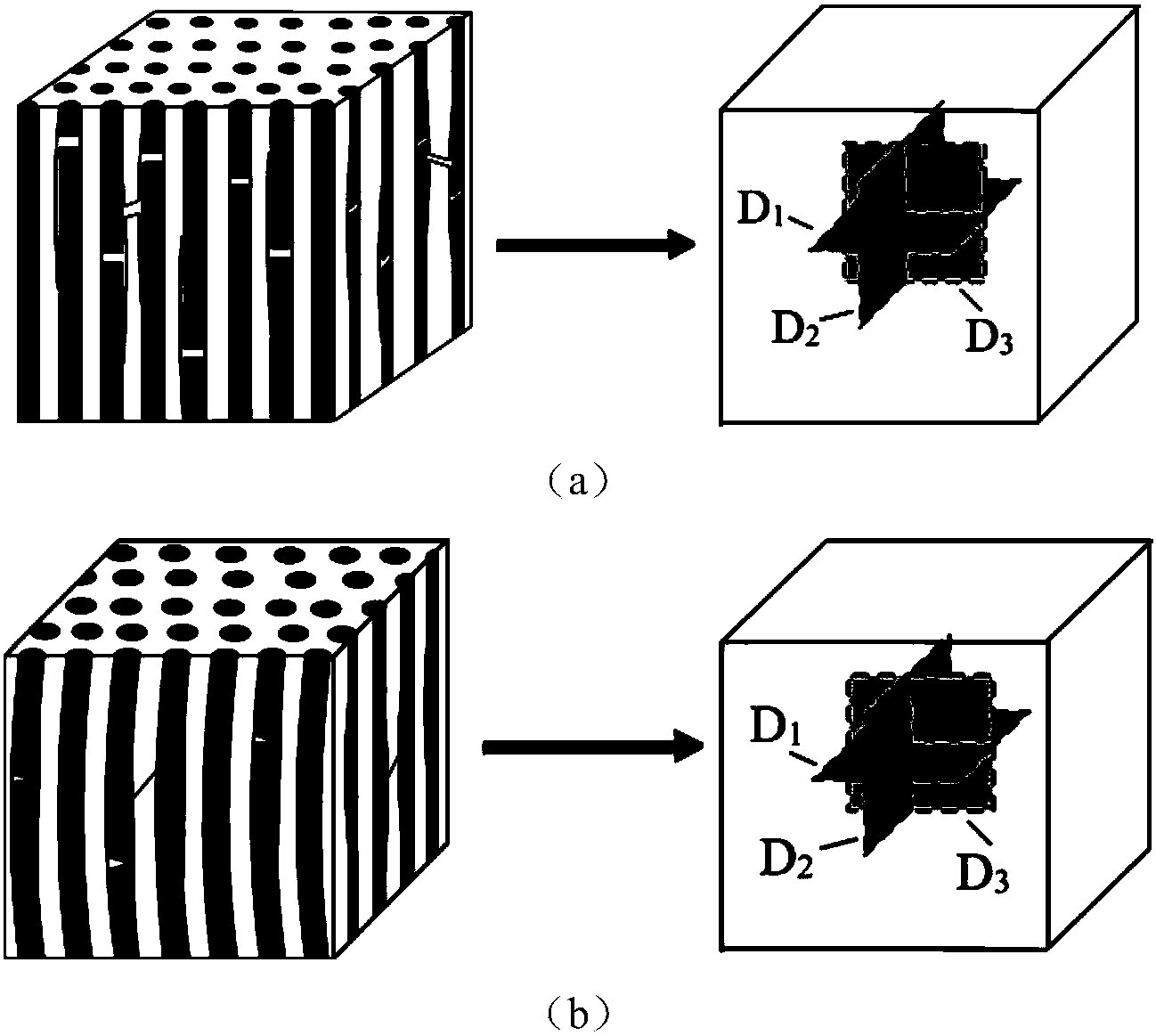

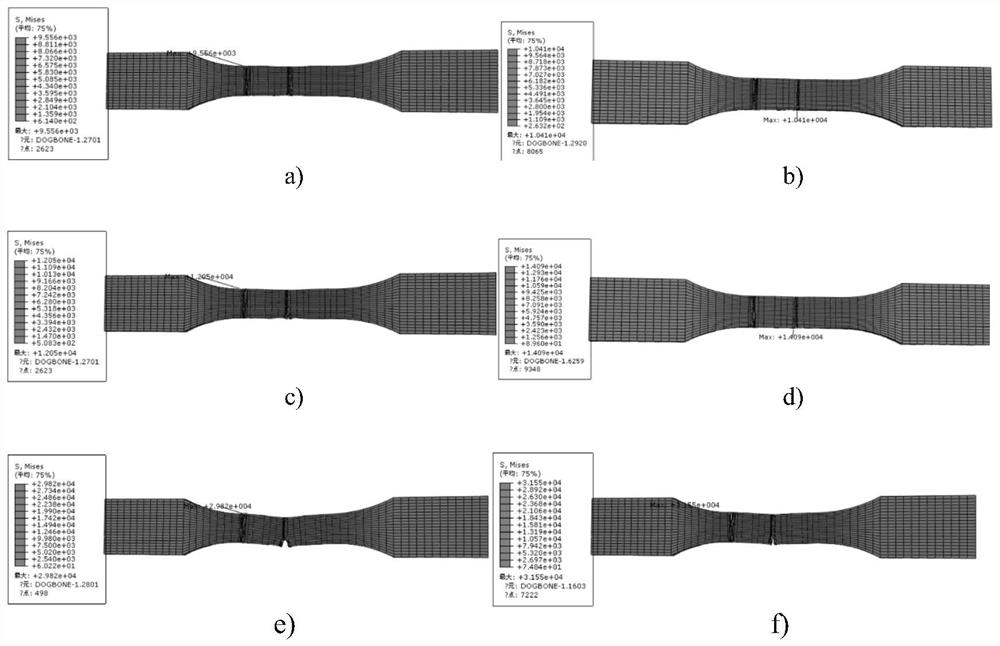

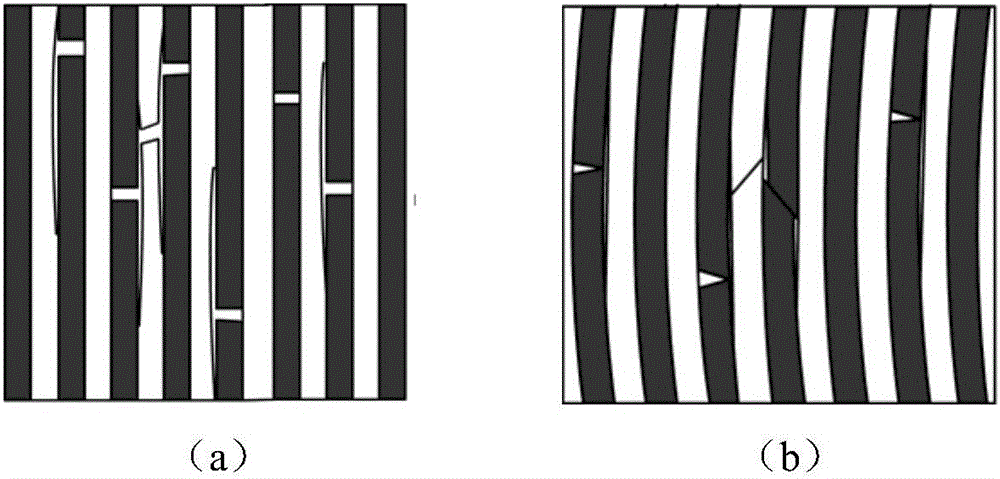

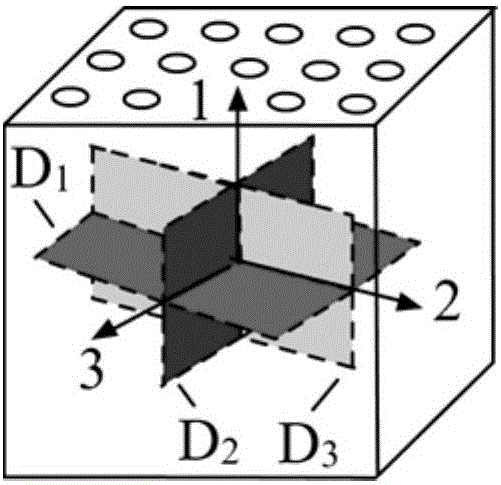

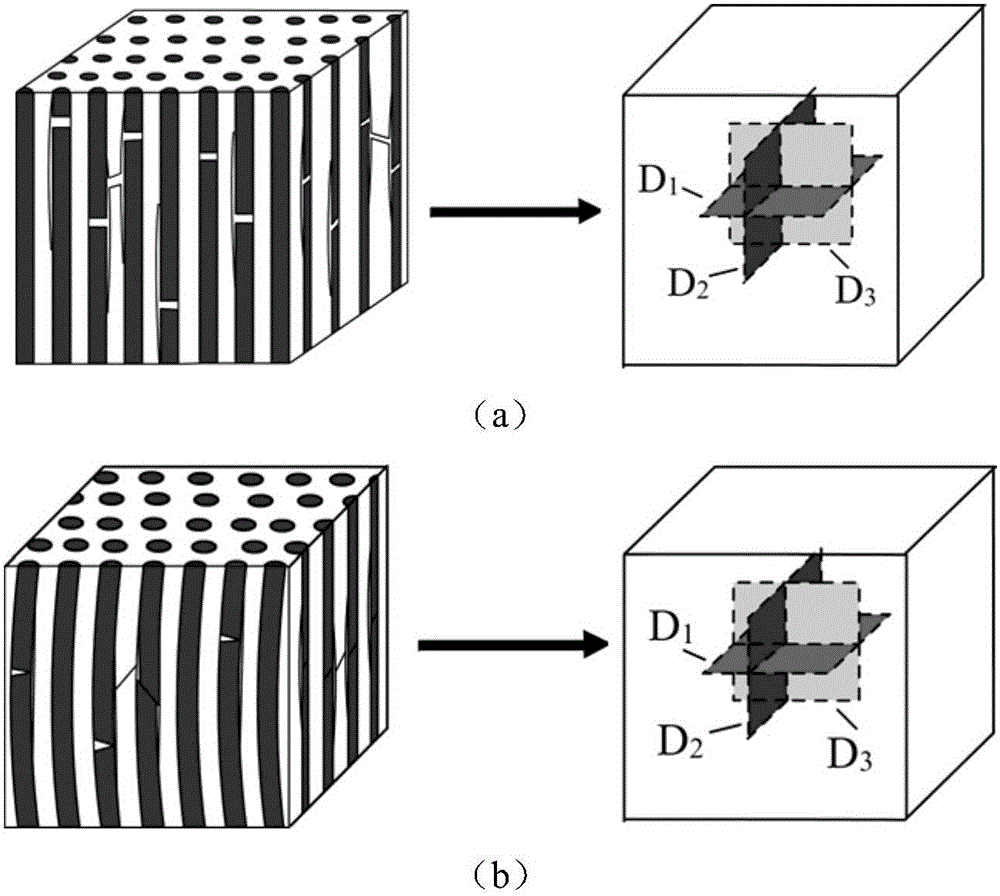

Composite material structure failure analysis method based on continuum damage mechanics degradation model

InactiveCN103592175AComputing performanceAccurate calculationStrength propertiesMatrix damageContinuum damage mechanics

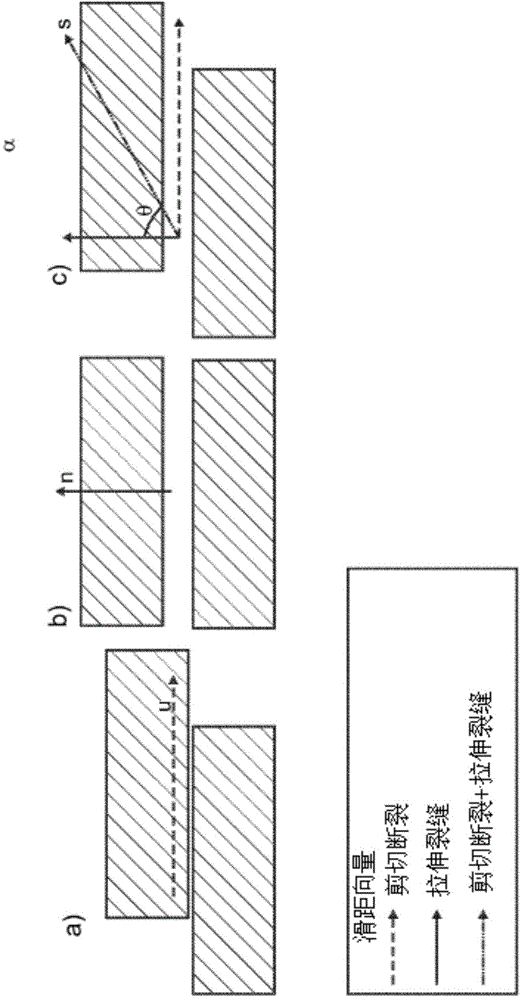

The invention relates to a composite material structure failure analysis method based on a continuum damage mechanics degradation model. According to the method, a three-dimensional continuum damage mechanics degradation model of a unidirectional fiber enhanced composite material is constructed, two types of damage forms such as fiber cracks and matrix cracks and the orientation of damages are considered, and meanwhile, the crack closure effect caused by coupling of the fiber damage and the matrix damage and reverse loading of load in a fiber stretching and compressing damage process is considered; three damage variables are respectively used for representing the fiber crack damage and two mutually-perpendicular matrix crack damages respectively, so that the continuum damage mechanics degradation model for failure analysis of a composite material structure is obtained. Compared with the conventional anti-climax degradation model, the continuum damage mechanics degradation model has the advantages that the behavior characteristics of the damaged composite material under different load states are considered, and the performance of the damaged material can be accurately represented; the composite material structure failure analysis method is suitable for simulation of a composite material structure damage process and forecasting of the intensity under a condition that the load state and a constraint situation are more complicated.

Owner:BEIHANG UNIV

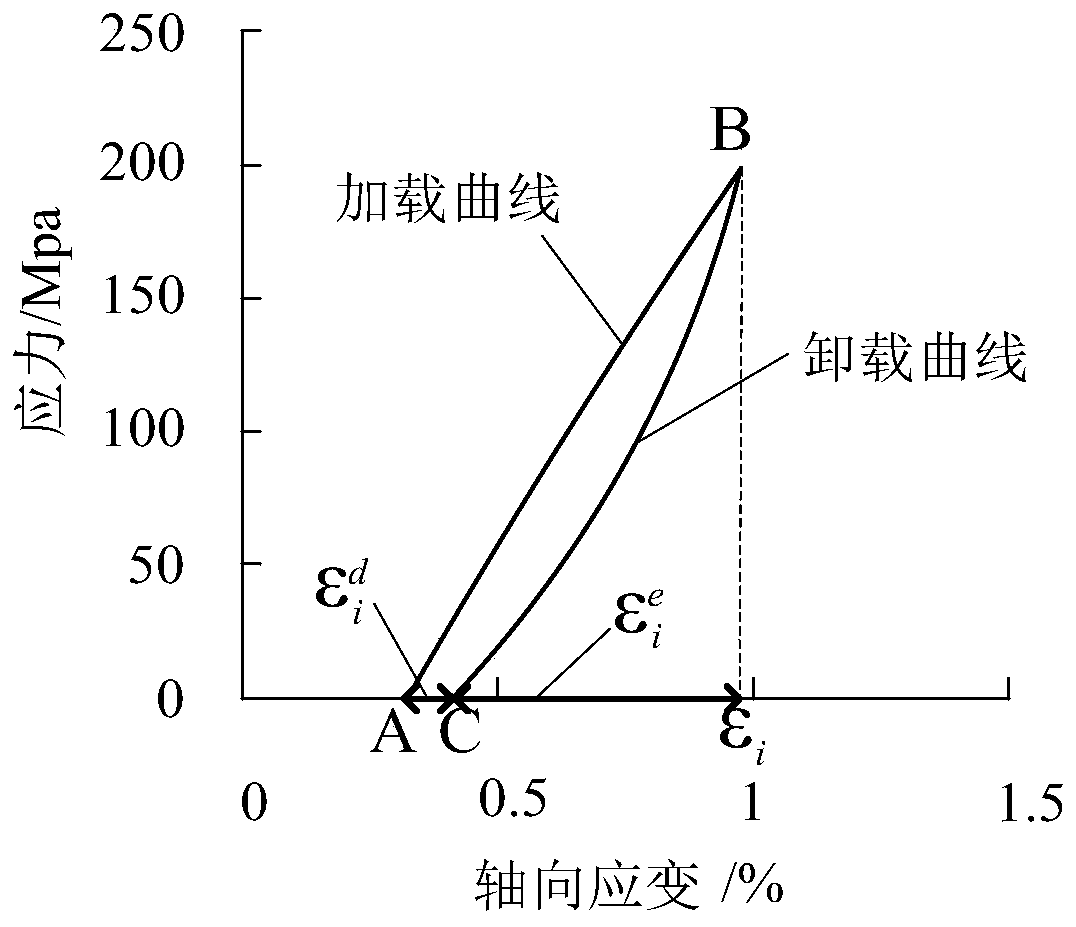

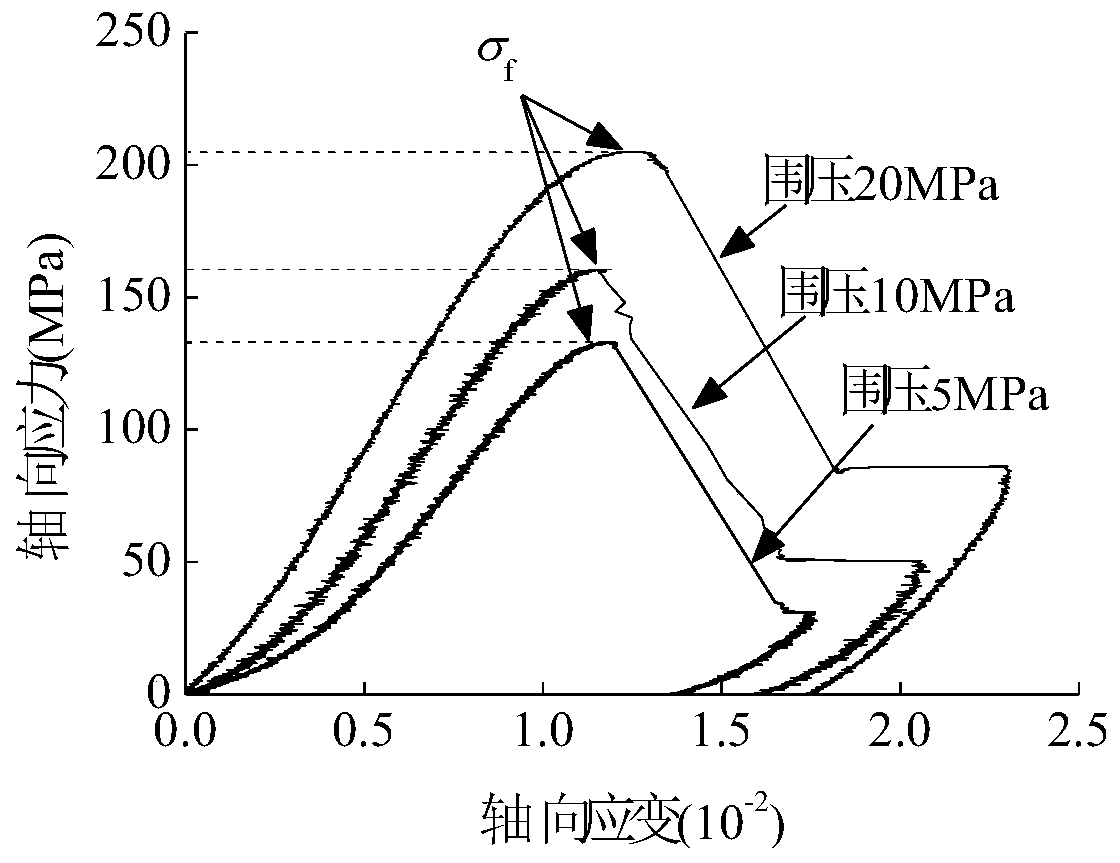

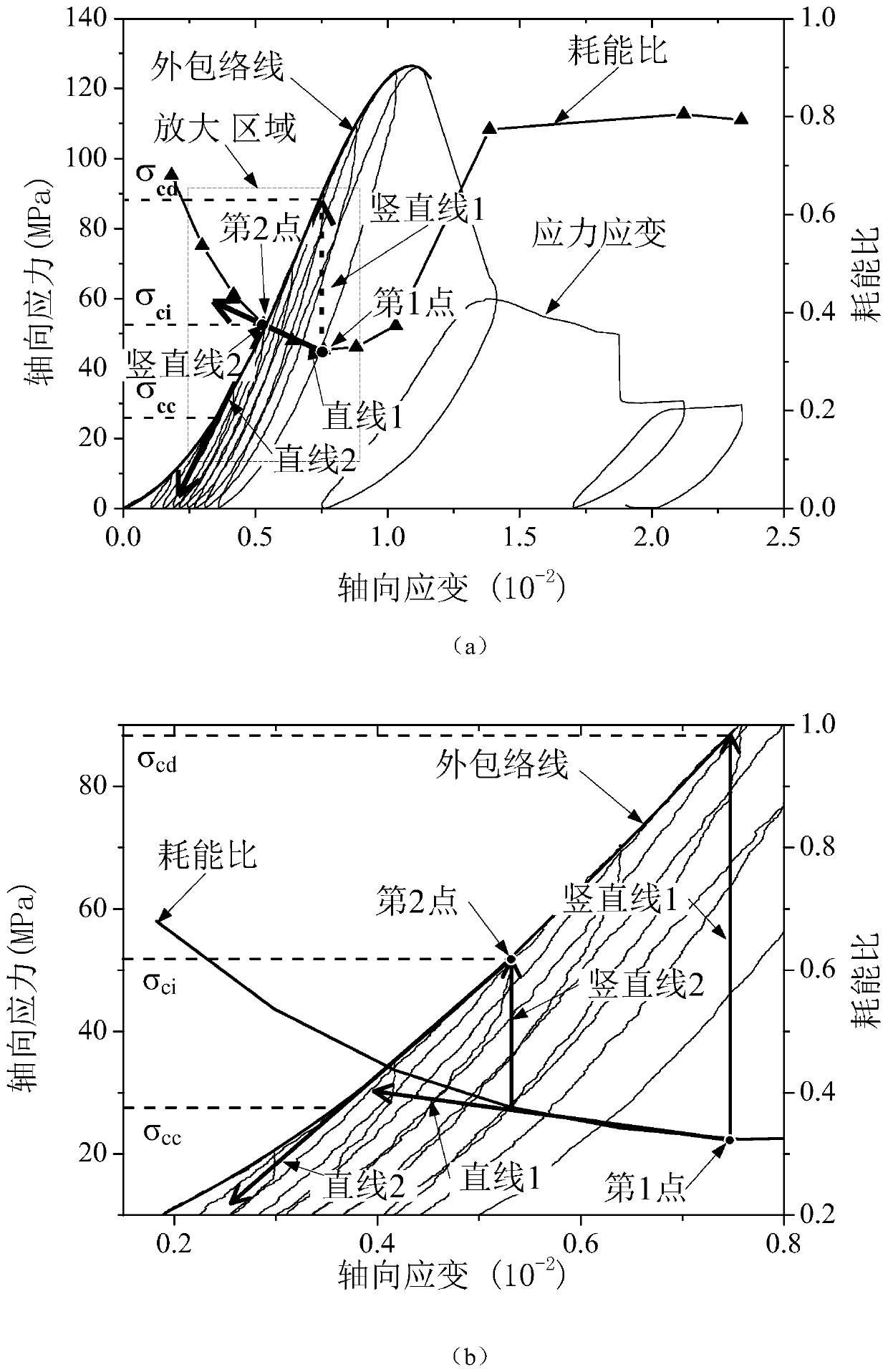

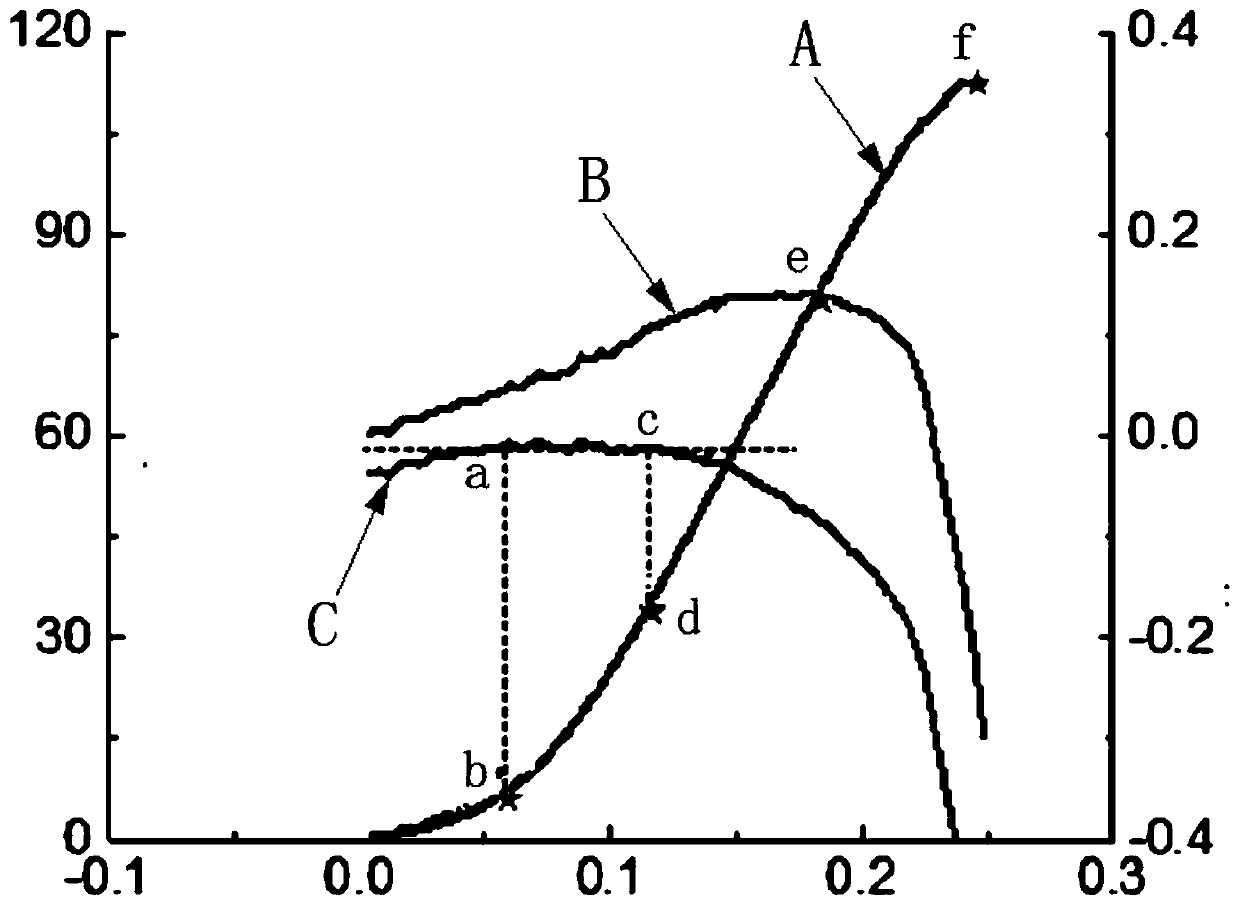

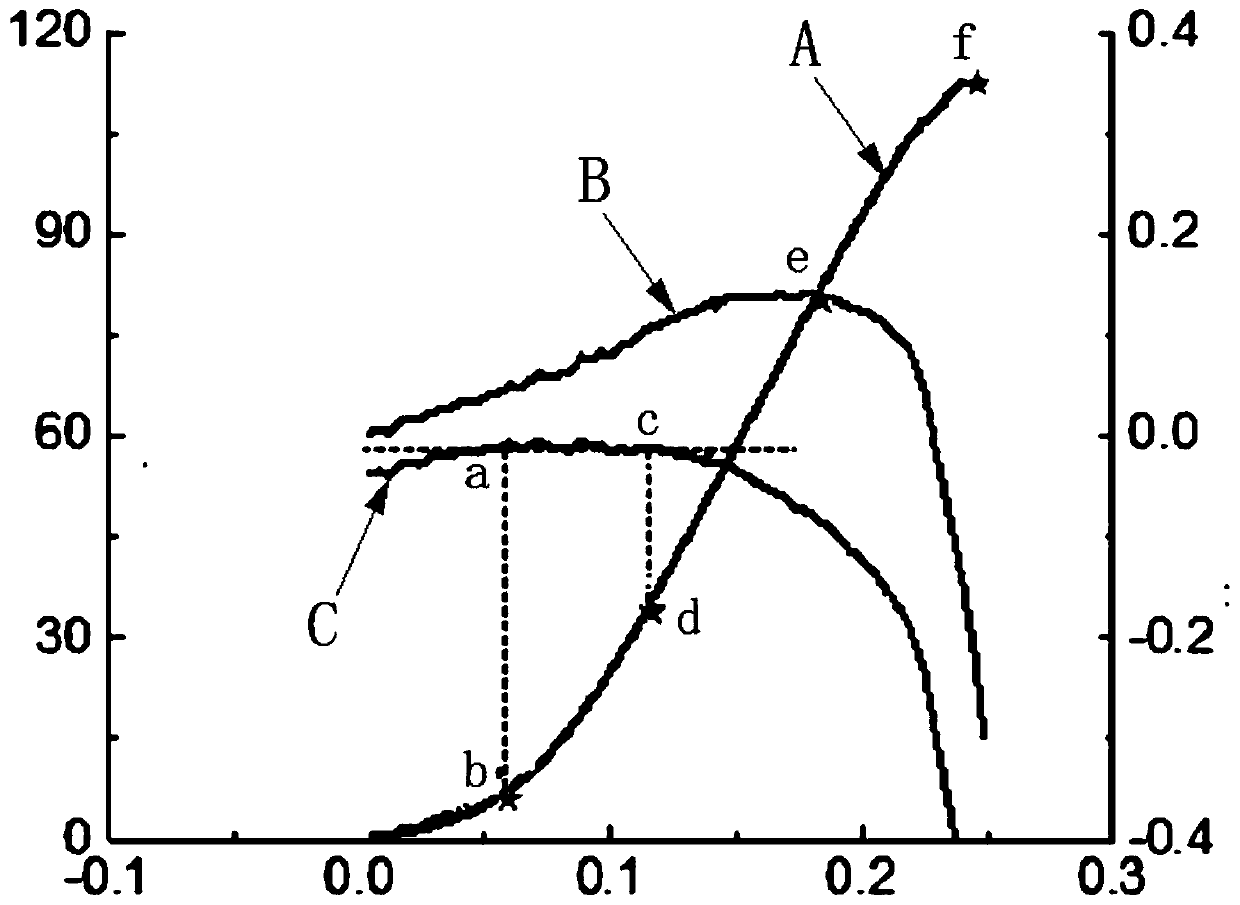

Method for determining characteristic stress in rock material damage evolution process based on energy analysis

InactiveCN110296892ACalculations are reliableEasy to operateWithdrawing sample devicesPreparing sample for investigationCrack closureStress–strain curve

The invention discloses a method for determining characteristic stress in a rock material damage evolution process based on energy analysis, and mainly relates to crack closure stress, initiation stress and damage stress in the rock material damage evolution. The minimum value of the energy consumption ratio on the energy consumption ratio-axial strain curve is taken as a first point to draw a vertical line 1, and the rock damage stress can be found on the outer envelope line of the axial stress-strain curve; a straight line 1 is drawn from the point to the upper left along the energy consumption ratio-axial strain curve, a vertical line 2 is drawn at the position where the straight line 1 deviates from the energy consumption ratio-axial strain curve, and the intersection point on the corresponding axial stress-strain curve outer envelope line is the rock initiation stress; and the rock initiation stress is taken as a second point along the axial stress-strain curve outer envelope lineto draw a straight line 2, the straight line 2 is drawn towards the origin of coordinates, the position which deviates from the axial stress- strain curve outer envelope line is the rock crack closure stress. The method for determining characteristic stress in the rock material damage evolution process based on energy analysis has strong operability, further reduces human subjectivity; and the method for determining characteristic stress in the rock material damage evolution process based on energy analysis is more advantageous in terms of operation process and determination of the amount ofcharacteristic stress.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

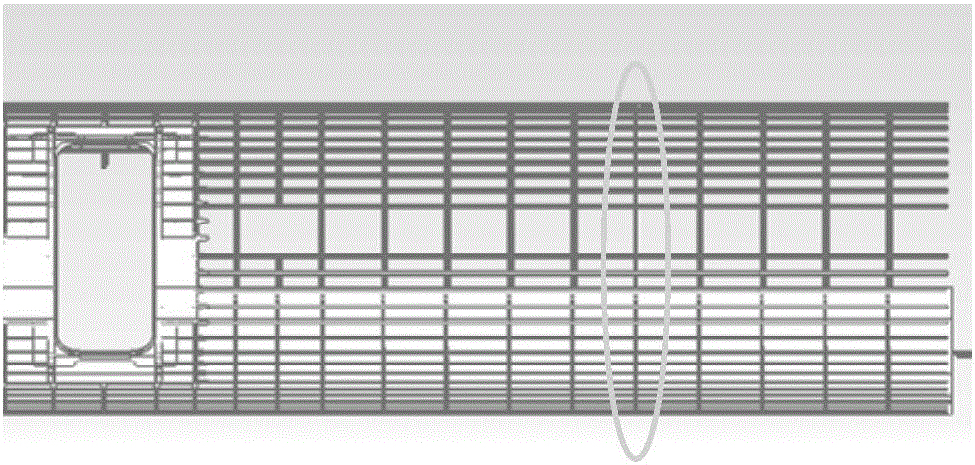

Stiffened wallboard damage tolerance analysis method based on finite element analysis solving

ActiveCN106354934ADesign optimisation/simulationSpecial data processing applicationsElement modelResidual strength

The invention relates to a stiffened wallboard damage tolerance analysis method based on finite element analysis solving, comprising the steps of first, determining a crack growth direction according to aircraft wallboard structural form and load-bearing condition; setting limit crack length to determine model scale; second, establishing a crack-free stiffened wallboard details finite element model; third, applying total load to the model to solve wallboard stress distribution; fourth, simulating cracks different in length in the finite element model, and extracting note balance force and displacement of a crack tip unit; fifth, solving stress strength factor K for tips with different crack lengths of a stiffened wallboard in fourth step by applying virtual crack closure technique VCCT; sixth, subjecting the stiffened wallboard to crack growth life and structural residual strength analysis. The method can provide real simulation for stiffened wallboard different-size cracks, crack tip stress and strain condition, stiffened wallboard different-size crack stiffener stress level, and fastener load; crack growth analysis is performed on stiffened wallboard skin based on analysis results.

Owner:AVIC SAC COMML AIRCRAFT

Thermal treatment method for simultaneously improving strength and fatigue resistance property of aluminum alloy

The invention relates to a thermal treatment method for simultaneously improving the strength and fatigue resistance property of aluminum alloy. The method comprises the following steps of: heating aluminum / zinc / magnesium / copper alloy subjected to solution treatment for 2 hours at the temperature of 460-495 DEG C to 70-120 DEG C, and carrying out heat preservation for 24-96 hours; then carrying out heat preservation for 2-120 minutes at the temperature of 150-170 DEG C, and cooling to room temperature; and subsequently, carrying out heat preservation for 24-96 hours at the temperature of 70-120 DEG C, and then discharging and performing air cooling, wherein the aluminum / zinc / magnesium / copper alloy comprises the following components: Zn, Mg, Cu, Mn, Zr and Al. The thermal treatment provided by the invention is simple and reasonable in technology; through three-stage aging thermal treatment technology, the grain boundary of the aluminum / zinc / magnesium / copper alloy is in an overaging state, and the structure in the grain mainly consists of eta ' phase and a G.P. zone; and the overaging structure of the grain boundary is good in corrosion resistance, and the G.P. zone particles in the grain are beneficial to reciprocating slippage and crack closing dislocated under the alternating stress action, so that the fatigue resistance property is improved, and the alloy is good in stress corrosion resistance property and exfoliation corrosion resistance property and is suitable for industrial application.

Owner:CENT SOUTH UNIV

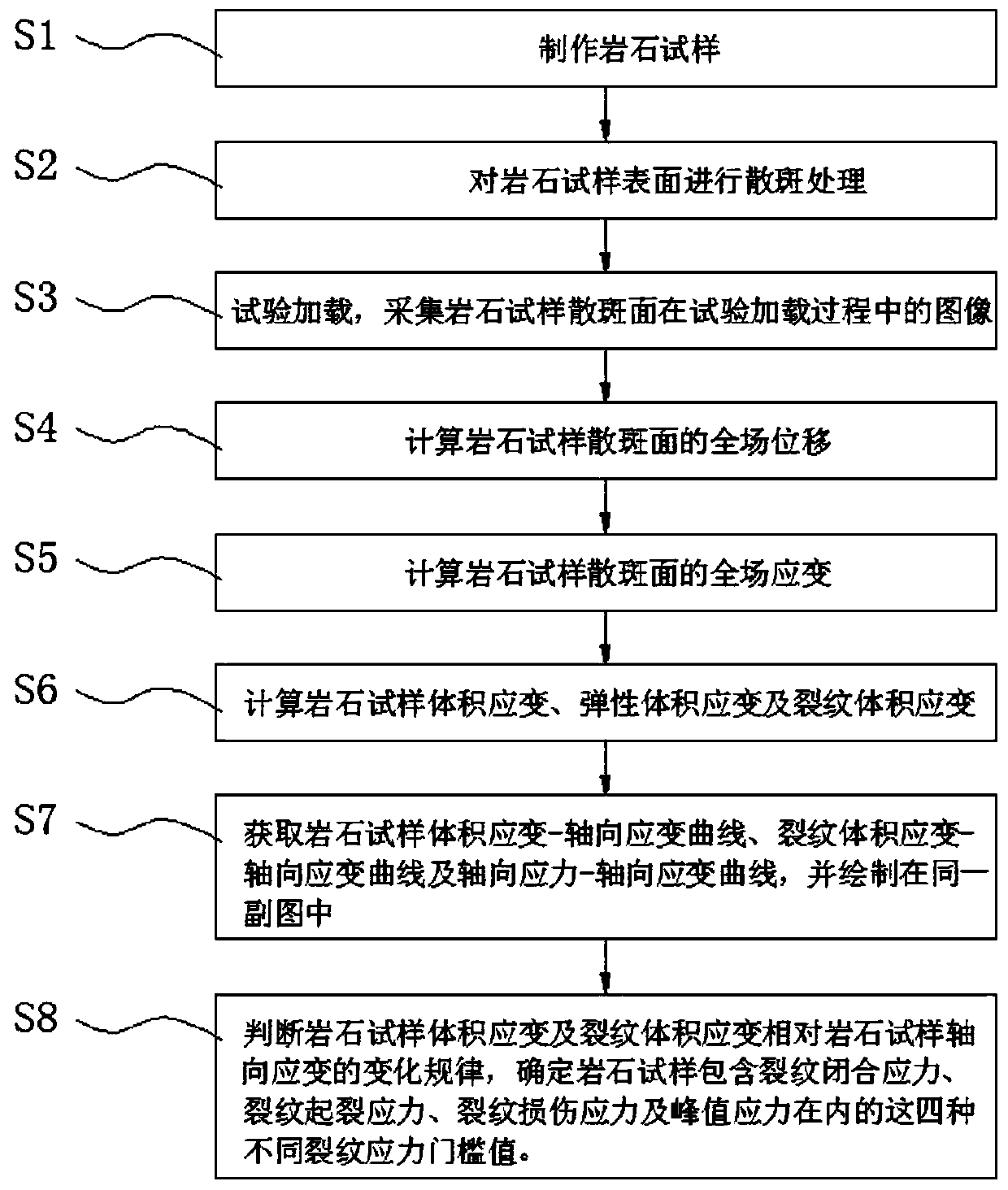

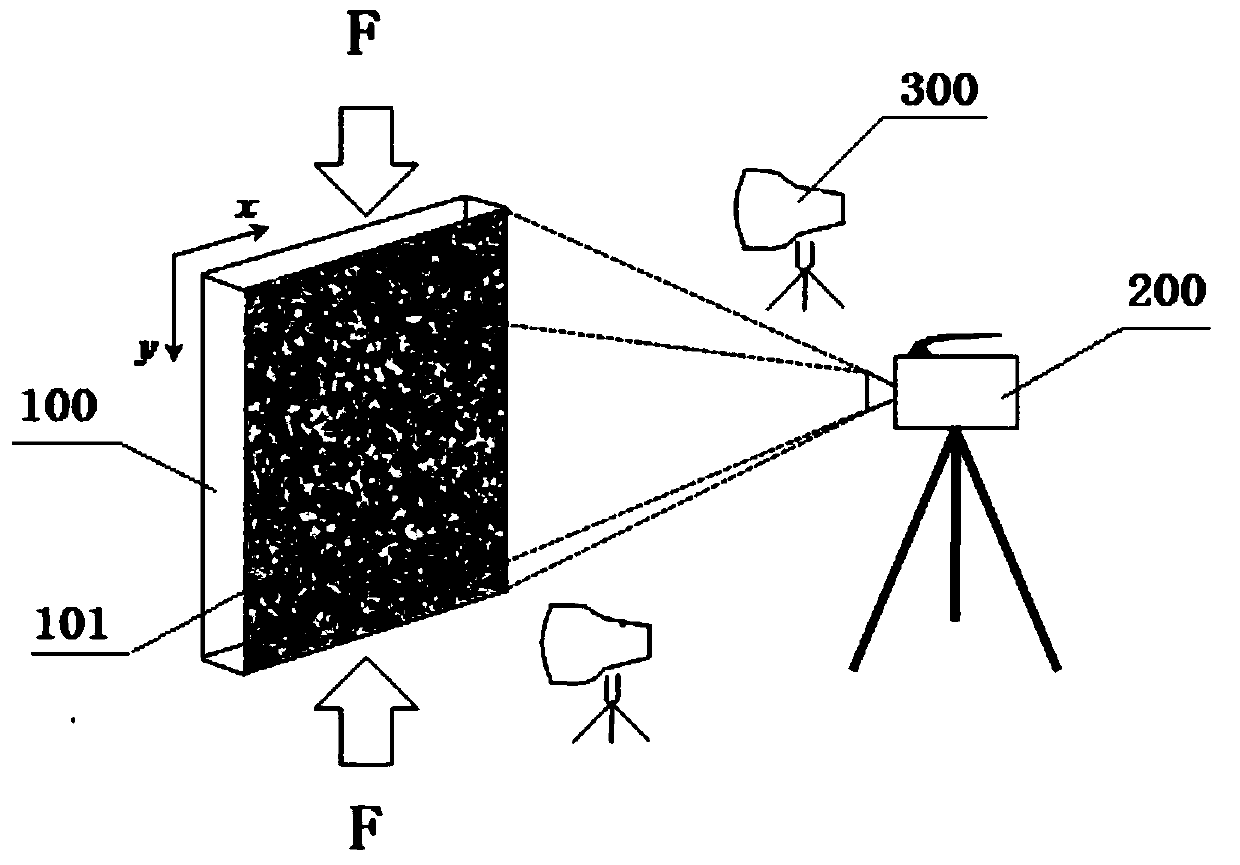

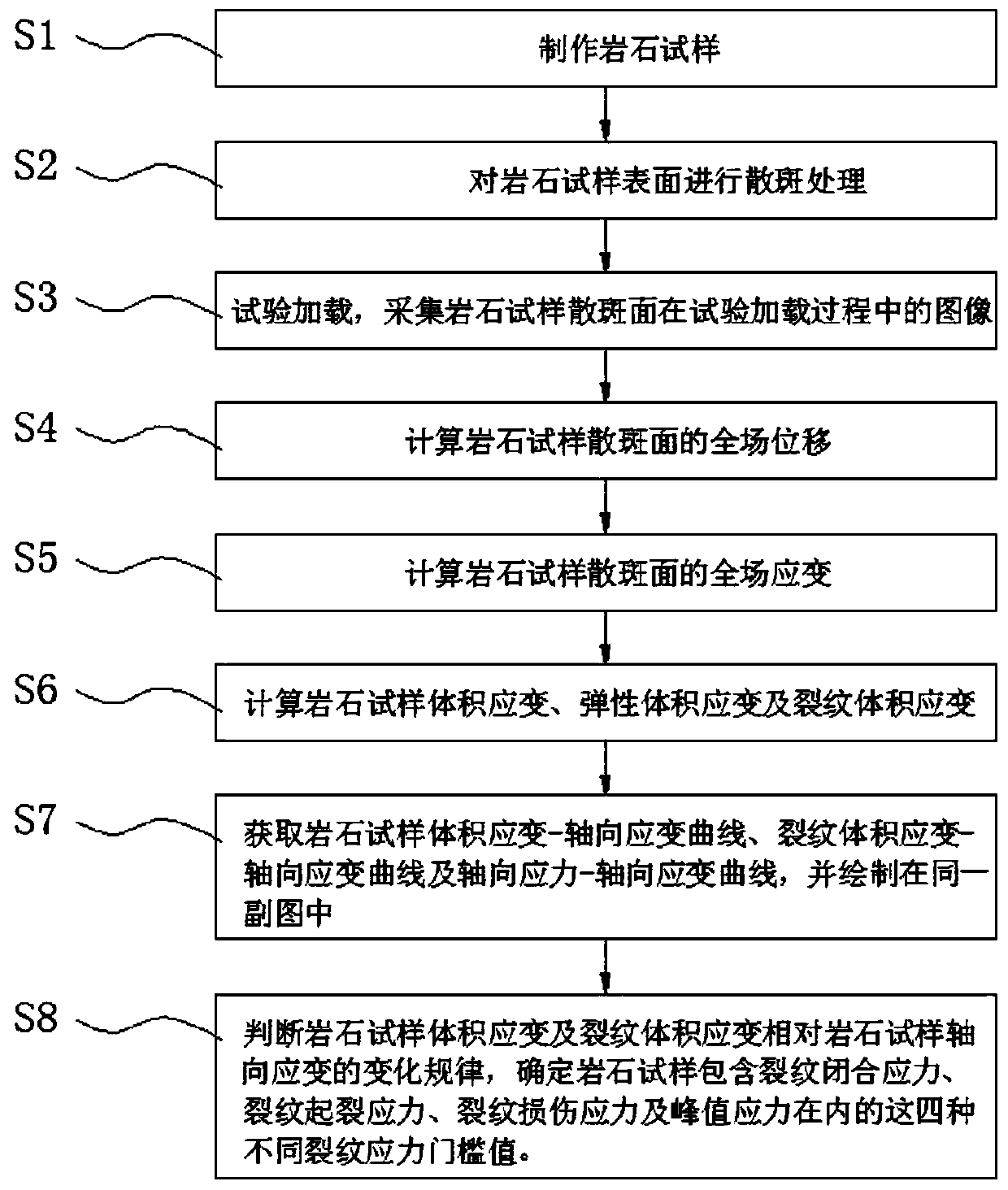

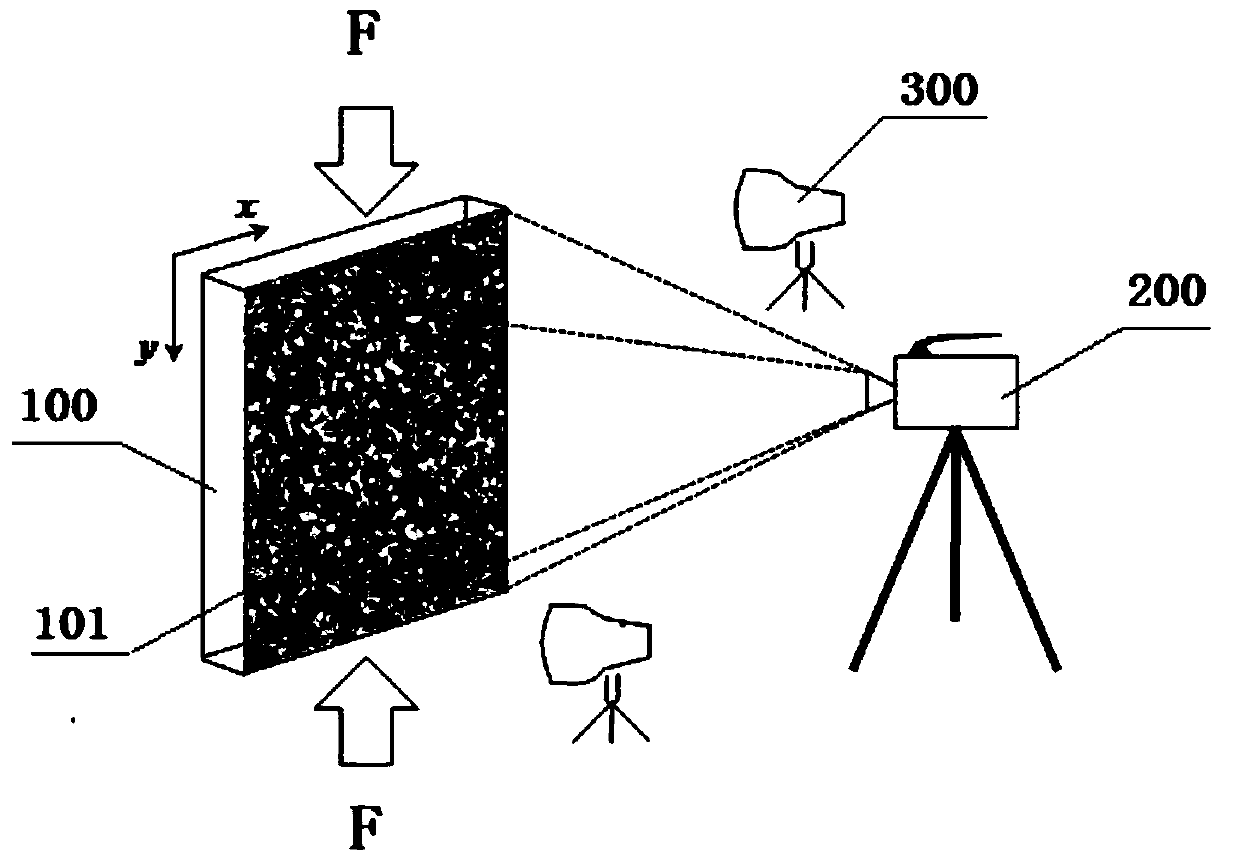

Method for determining rock crack stress threshold value based on full-field strain measurement

ActiveCN110658067ARepresentative and universalEasy to handlePreparing sample for investigationMaterial strength using tensile/compressive forcesFull field strainCrack closure

The invention discloses a method for determining a rock crack stress threshold value based on full-field strain measurement. The method comprises the following steps: manufacturing a rock sample; performing speckle treatment on the surface of the rock sample; carrying out test loading and collecting an image of a speckle surface of the rock sample in the test loading process; calculating the full-field displacement of the speckle surface of the rock sample; calculating the full-field strain of the speckle surface of the rock sample; calculating a volume strain, an elastic volume strain and a crack volume strain of the rock sample; acquiring a rock sample volume strain-axial strain curve, a crack volume strain-axial strain curve and an axial stress-axial strain curve, and drawing the curvesin the same subgraph; and determining changing rules of the volume strain of the rock sample and the crack volume strain and determining threshold values of the four crack stresses including the crack closing stress, the crack initiation stress, the crack damage stress and the peak stress of the rock sample. The method has the advantages of low requirement on test environment, more convenience inapplication, high result reliability, and higher representativeness and universality.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

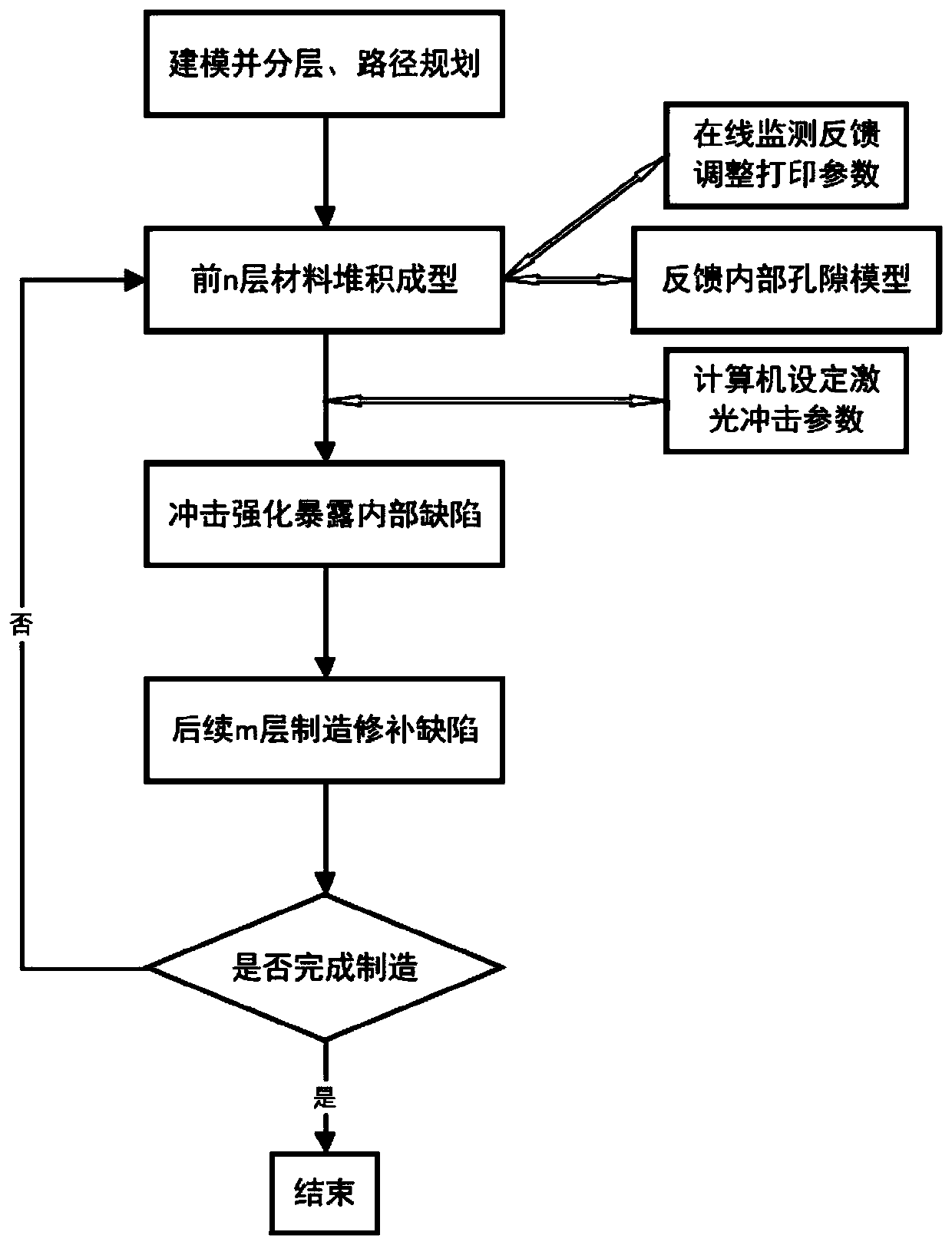

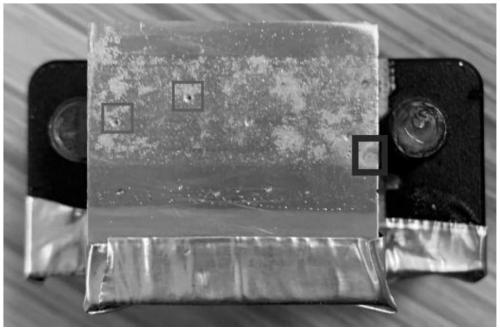

Pore defect removing method for metal additive manufacturing component based on online monitoring

ActiveCN111036911AGet poresAcquisitionAdditive manufacturing apparatusIncreasing energy efficiencyPore distributionHigh energy

The invention discloses a pore defect removing method for a metal additive manufacturing component based on online monitoring. A DED metal additive manufacturing system, an on-line monitoring system for monitoring pore defect positions in real time in the additive manufacturing process, a laser shock peening system for repairing defects, and a central control system used for coordinating and matching the additive manufacturing process, the online monitoring process and the laser shock peening process are included. The central control system obtains a pore distribution model according to the on-line monitoring system; the laser shock peening system is controlled to conduct interlayer 3D shock peening on the additive manufacturing sample through high-energy pulse laser, for air hole defects,thin-layer metal above the defects is broken, and then feeding in the follow-up forming process is controlled through the DED metal additive manufacturing system to eliminate the air hole defects; and for cracks in the length direction parallel to the manufacturing direction, the central control system enables the cracks to be closed by applying residual pressure stress, and the cracks can be removed after defects are detected.

Owner:XI AN JIAOTONG UNIV

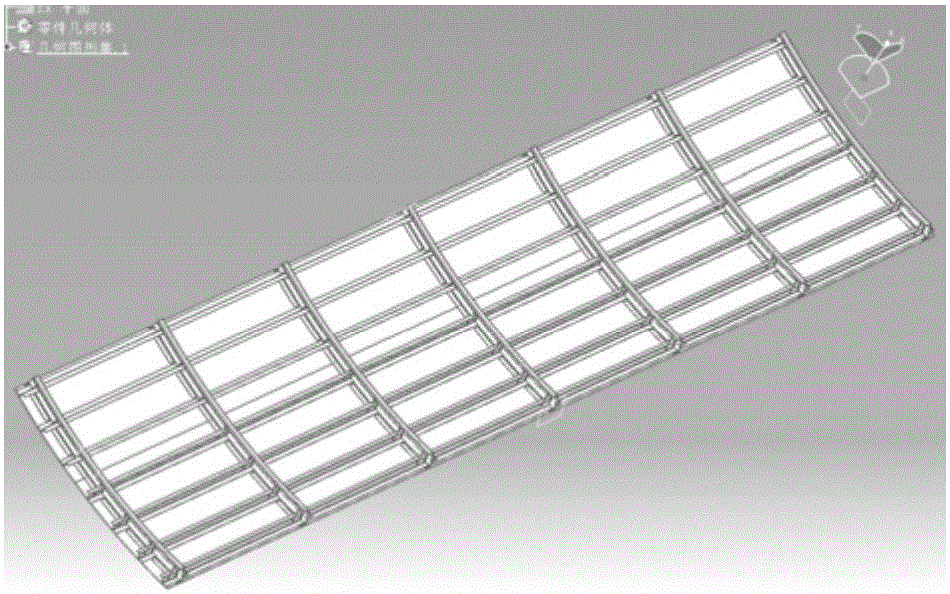

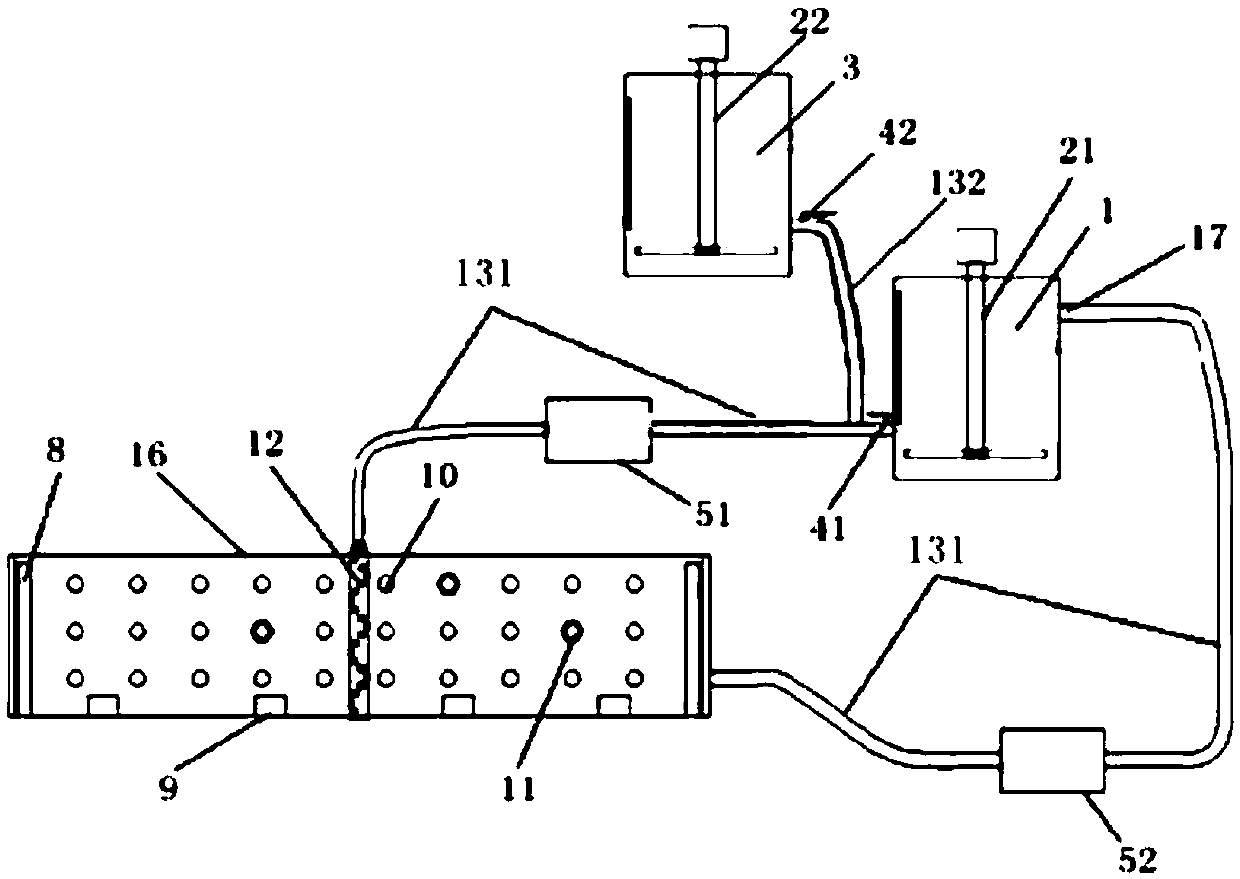

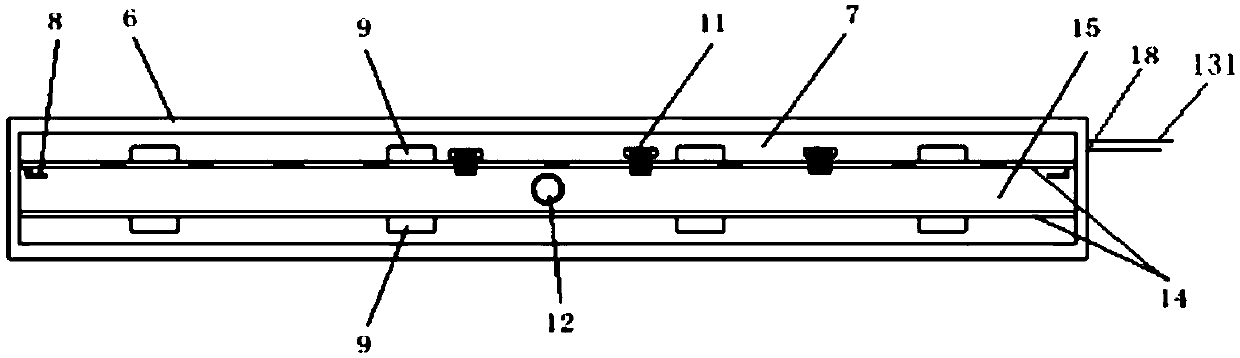

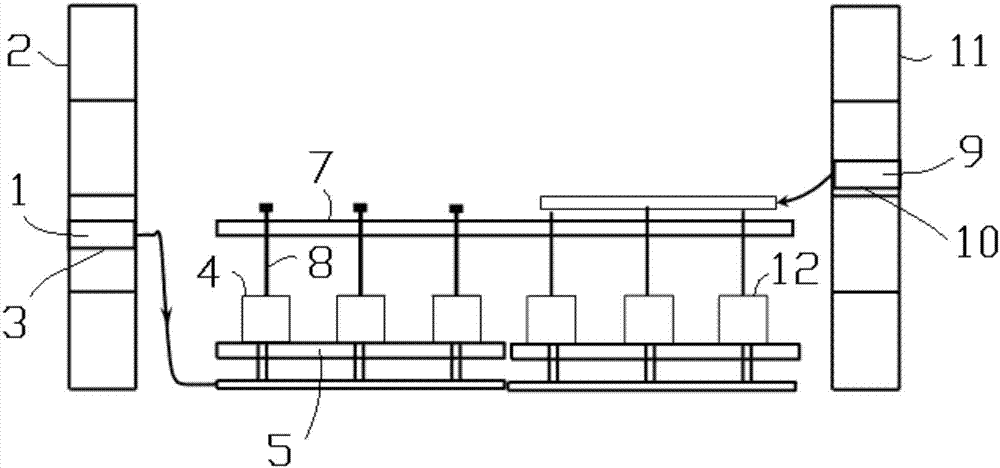

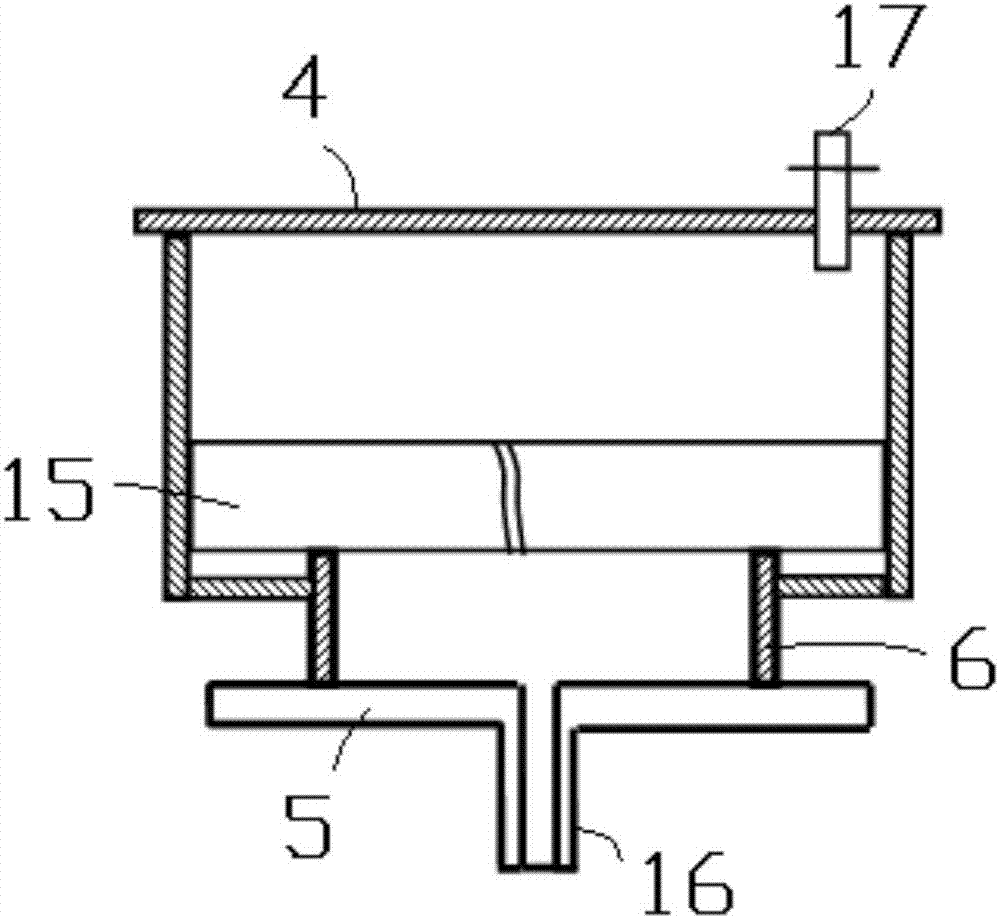

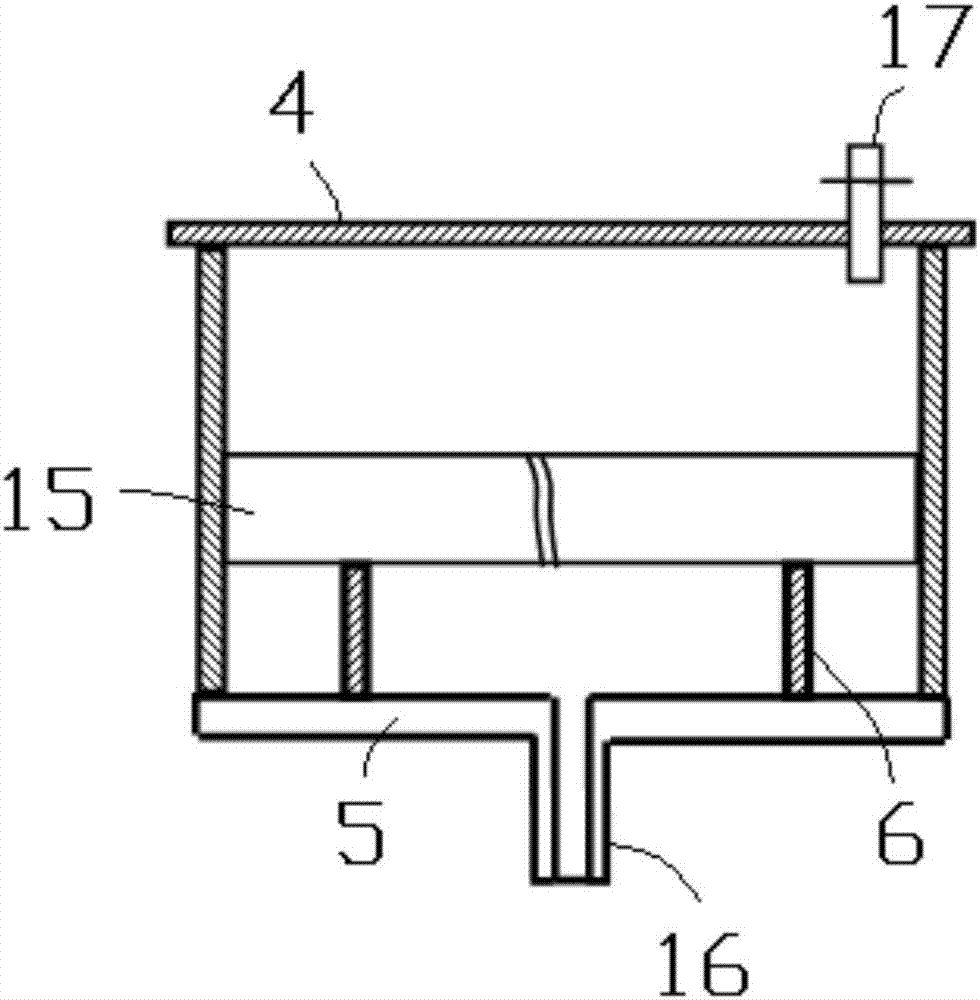

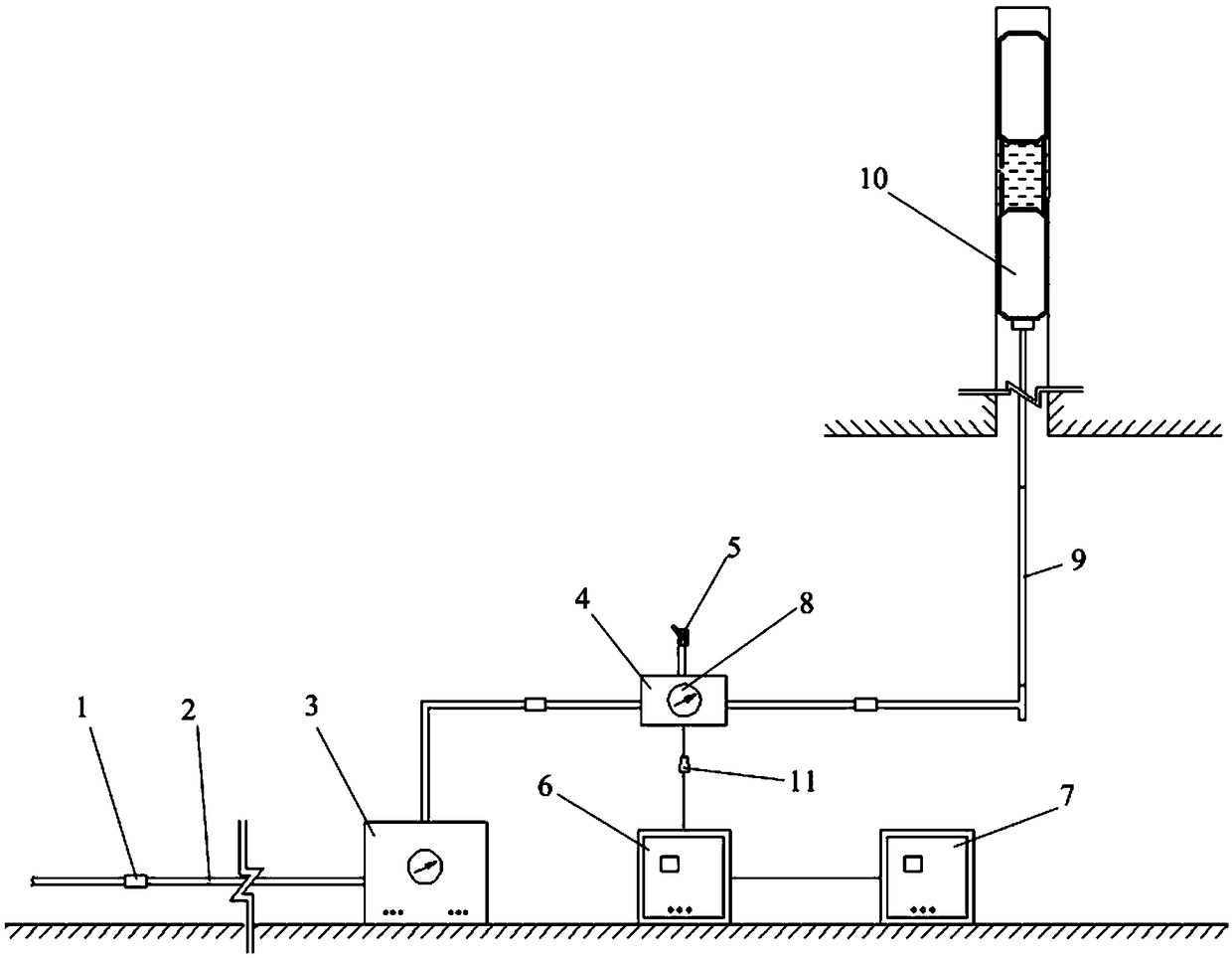

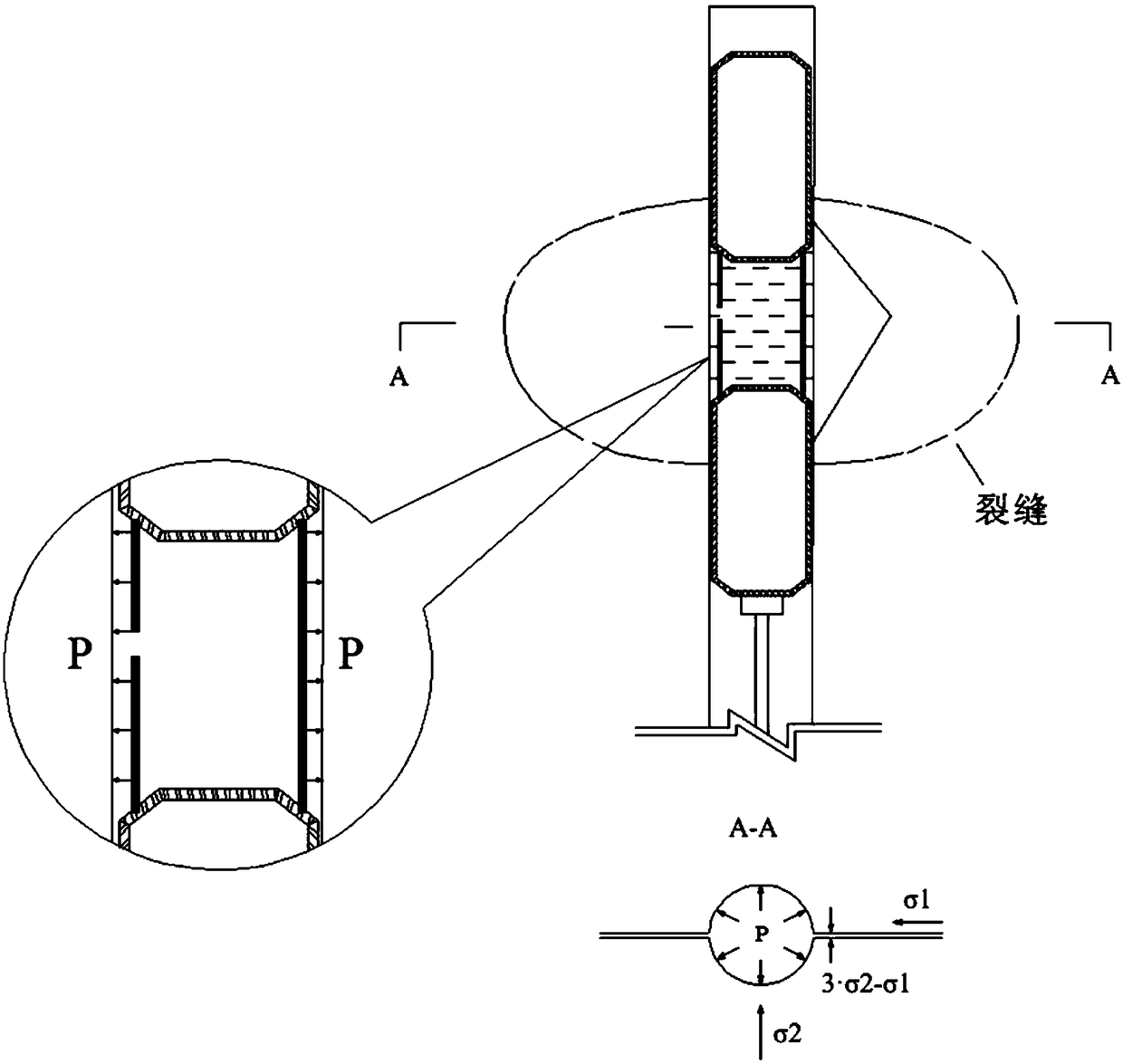

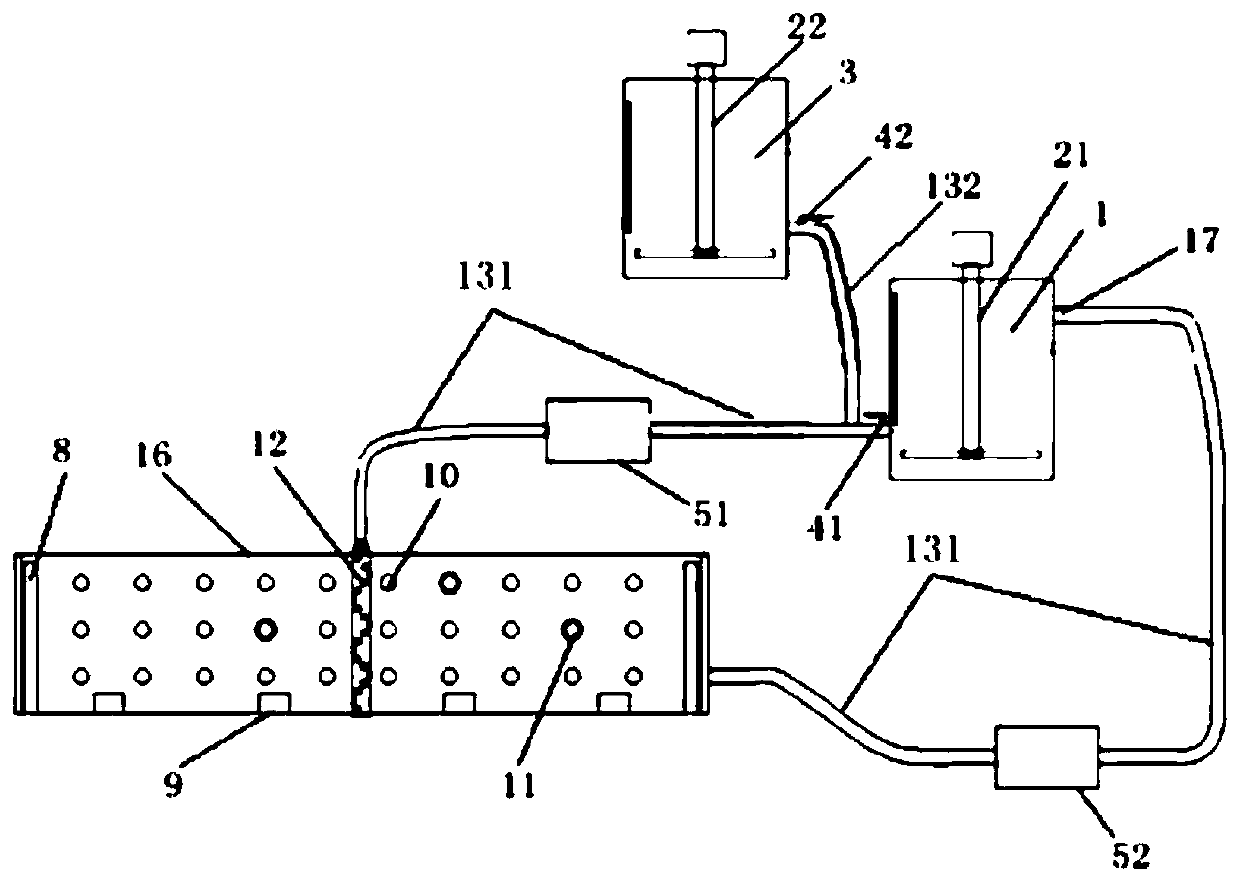

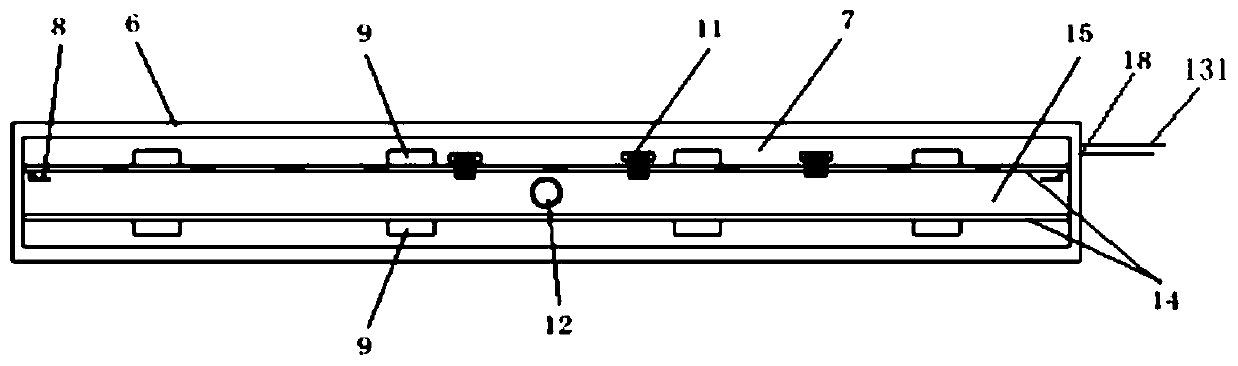

Visual crack device for simulating crack closure and leak-off and working method thereof

InactiveCN108680339AGood for evaluating performanceImprove accuracyHydrodynamic testingCrack closureFracturing fluid

A visual crack device for simulating crack closure and leak-off and a working method thereof are disclosed. The visual crack device includes: a visual crack simulation plate, a fracturing fluid pump,and a fracturing fluid tank which are connected to from a circulation loop through a fracturing main pipeline; and a sand mixing liquid tank which is connected to the fracturing main pipeline betweena discharging opening of the fracturing fluid tank and the fracturing fluid pump through a branch pipeline; the exterior of the crack simulation plate is a rectangular container, and the interior of the crack simulation plate is divided into three layers by two flat plates; a simulation fracturing crack is arranged between the flat plates; a reservoir simulation space is formed between one flat plate and the rectangular container; stress simulation driving devices are arranged on outer surfaces of the flat plates; leak-off holes are formed in the flat plates; a fluid outlet of the rectangularcontainer is positioned on the bottom of the reservoir simulation space, and is connected to a circulating inlet of the fracturing fluid tank; one end of a shaft is connected to the fracturing main pipeline, and the other end of the shaft is positioned in the fracturing crack; and perforation holes are distributed in the surface of the shaft. The visual crack device completes the leak-off function, can achieve crack closure and re-opening, and can improve the accuracy of the experimental results.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

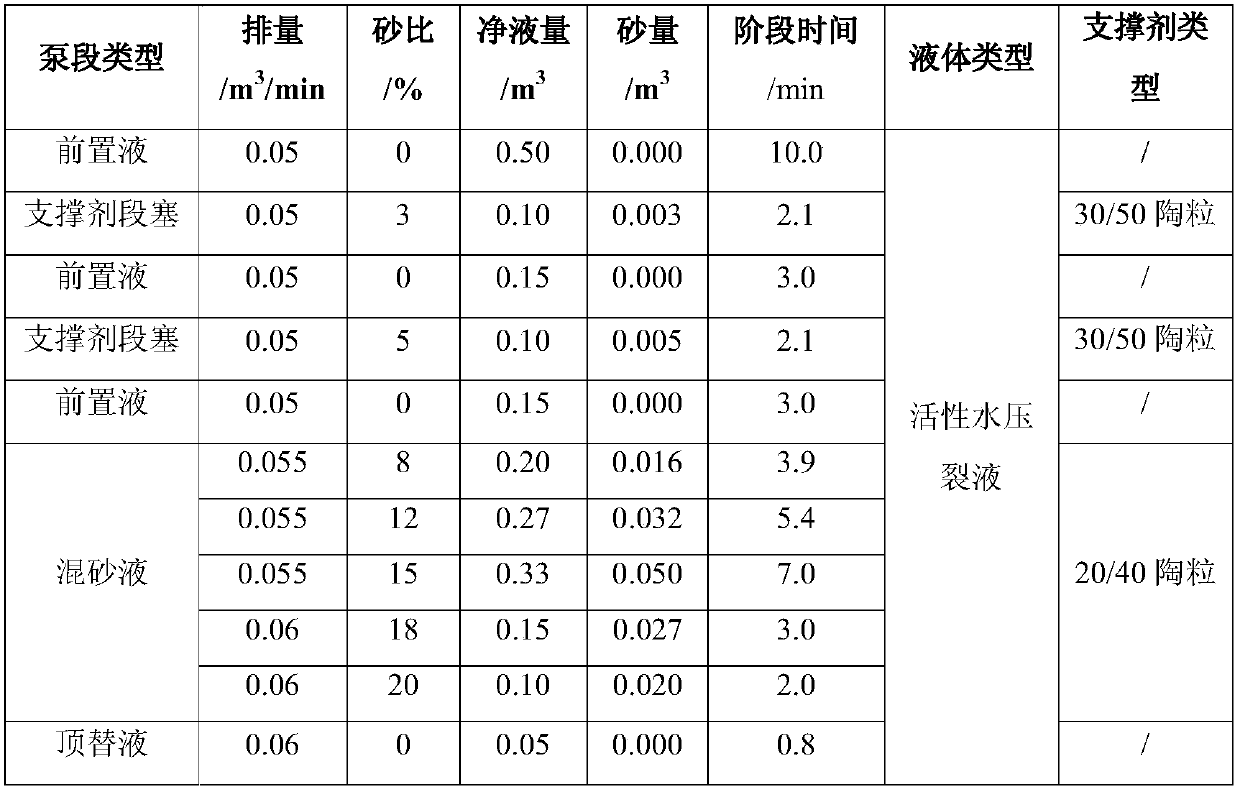

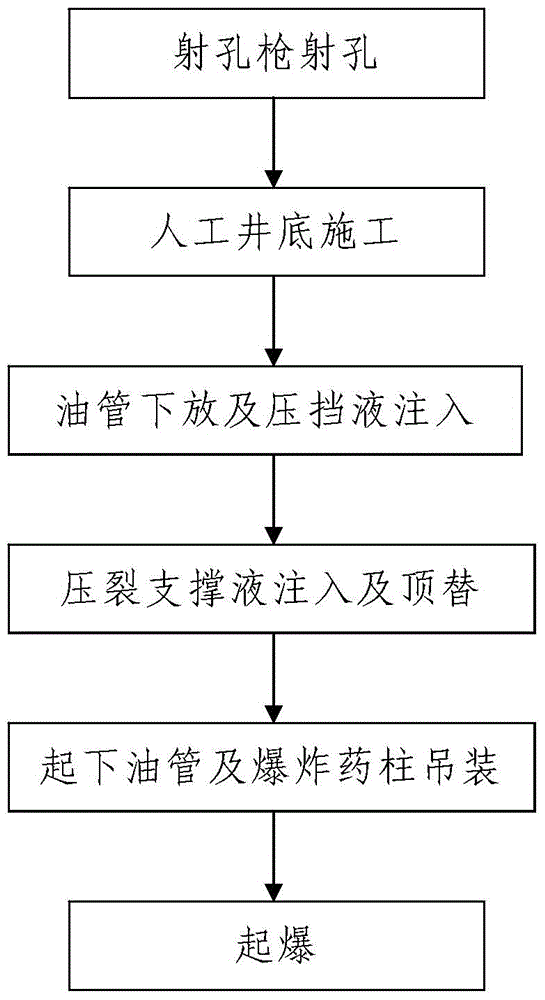

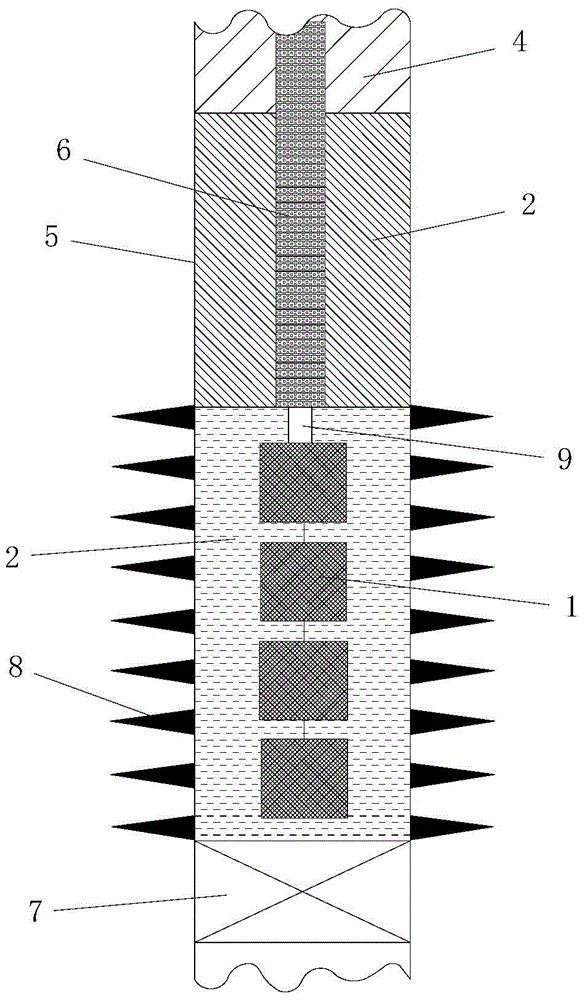

Method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture

The invention discloses a method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture. The method comprises following steps: 1, perforation by a perforating gun: adopting the perforating gun put lower into a well bore of an oil-gas well for perforation and forming multiple perforation tunnels in a target interval; 2, construction of an artificial bottom of the well: constructing the artificial bottom of the well at the bottom of the well bore of the oil-gas well; 3, downward placement of an oil pipe and injection of pressure baffle liquid: downwardly placing the oil pipe to the position where the target interval is located, injecting pressure baffle liquid into wellbores of the oil-gas well by means of the oil pipe till a sleeve pipe and the oil pipe are poured with pressure baffle liquid; 4, injection and displacement of fracturing propping liquid with the process as follows: primary injection of separation liquid, injection of fracturing propping liquid, secondary injection of separation liquid and displacement of fracturing propping liquid till the fracturing propping liquid is displaced to the target interval; 5, tripping of the oil pipe, hoisting and displacement of explosive columns; 6, initiation of explosion. The method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture has following beneficial effects: the method has simple steps and a reasonable design and is conveniently realized and has fine usage effect; and a crack closure problem during the process of high-energy gas fracture is effectively solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

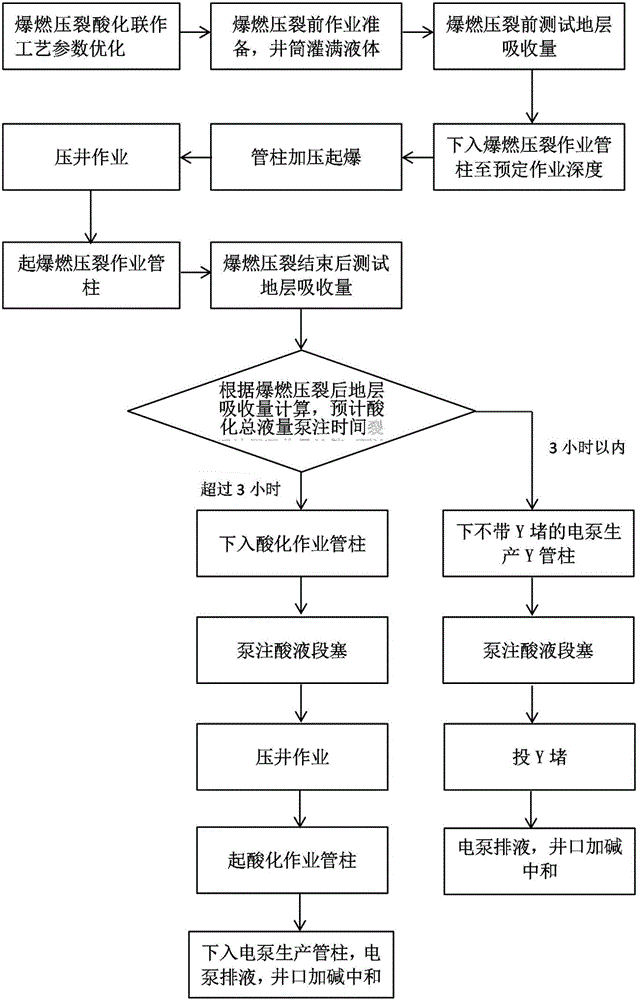

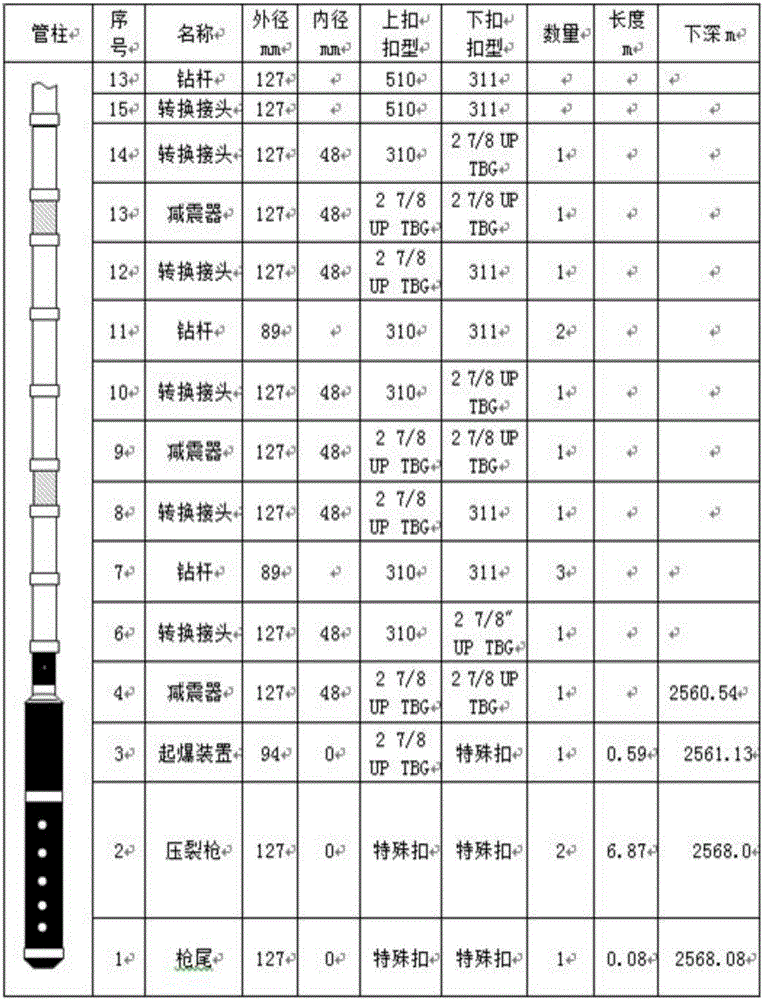

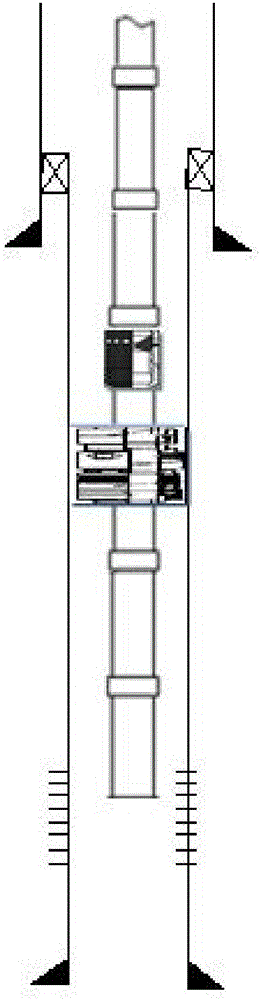

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

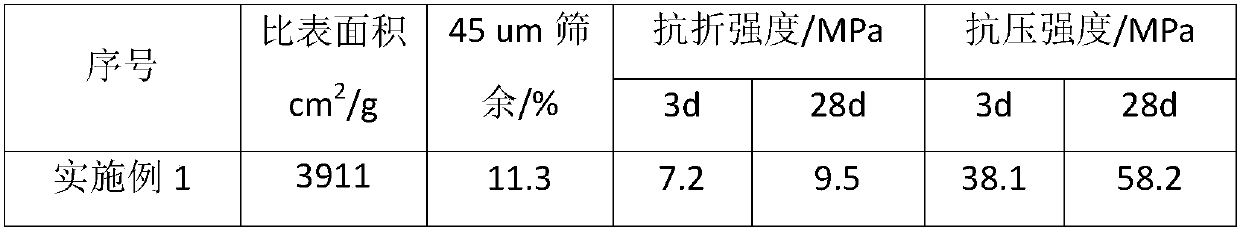

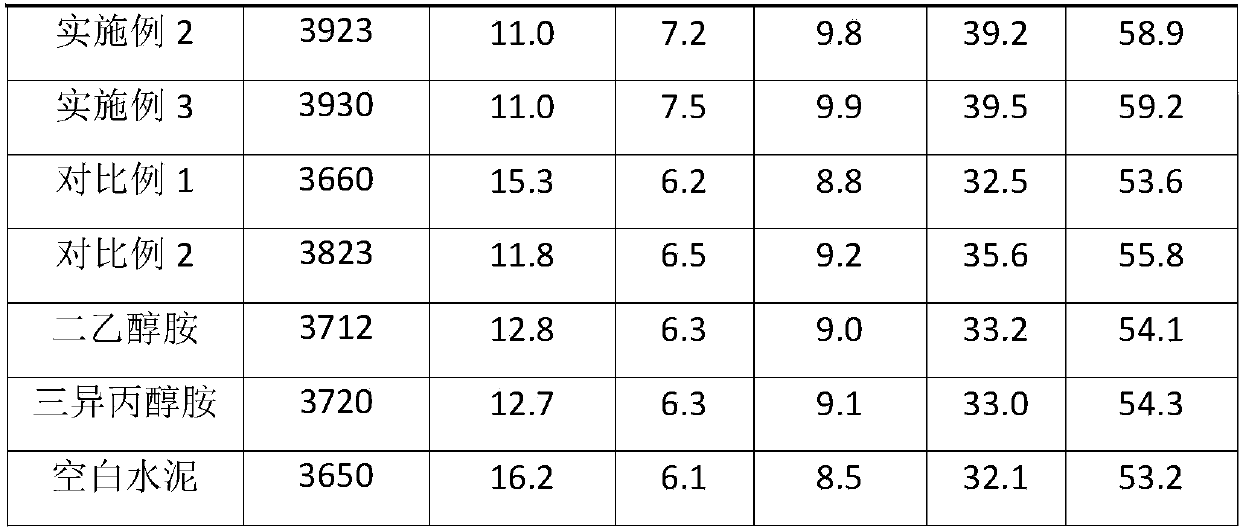

Cement grinding aid and preparation method thereof

The invention discloses a cement grinding aid and a preparation method thereof, and belongs to the technical field of building materials. The grinding aid is prepared from a modified alcohol amine type grinding aid component, isooctanol phosphate, a thickening dispersant, a surfactant, a defoaming agent and water. According to the invention, maleic anhydride and diethanolamine are polymerized, andthen are fully modified by isopentenyl alcohol polyoxyethylene ether and acrylic acid under the condition of an aqueous solution to obtain the modified alcohol amine type grinding aid component. Themolecules of the alcohol amine type grinding aid component modified under assistance of the isooctanol phosphate in a grinding aid formula are spread to the surfaces of more high-energy particles, theisooctanol phosphate and the modified alcohol amine type grinding aid component act cooperatively, crack closure of materials is stopped, the crack propagation is accelerated, a synergistic effect isachieved, and a grinding aid effect is achieved jointly. The grinding aid formula is simple, raw materials are easily obtained, and the cement grinding aid is small in mixing amount and remarkable ineffect, and is suitable for being popularized and used.

Owner:RIZHAO FEM NEW MATERIAL TECH

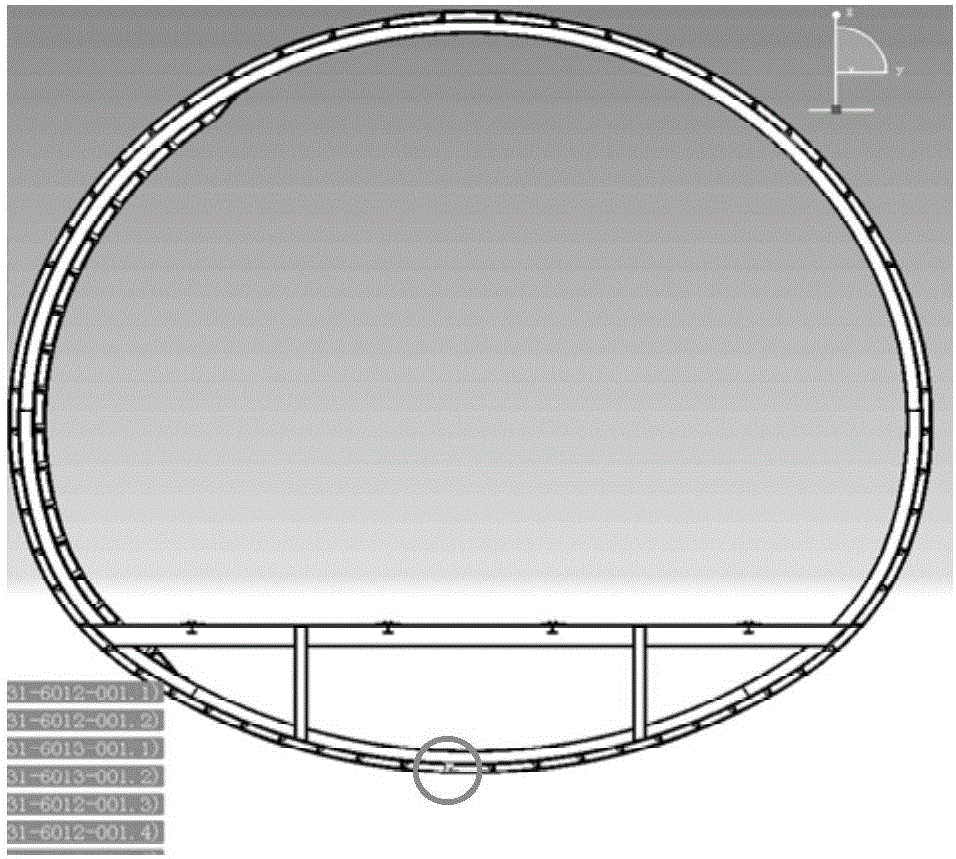

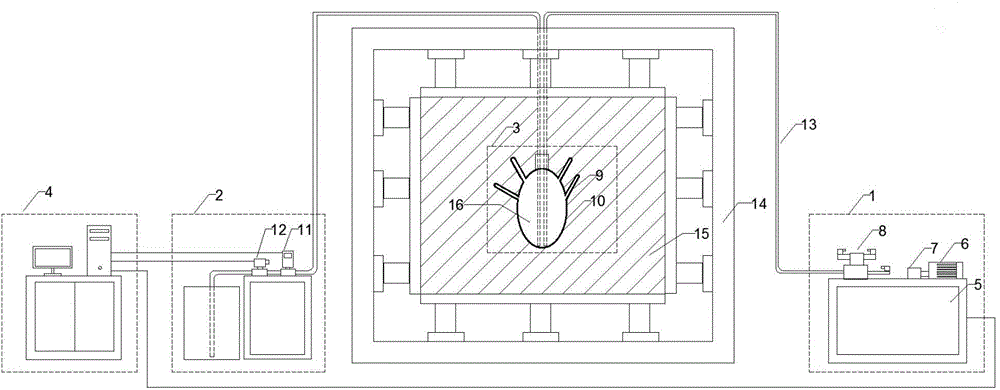

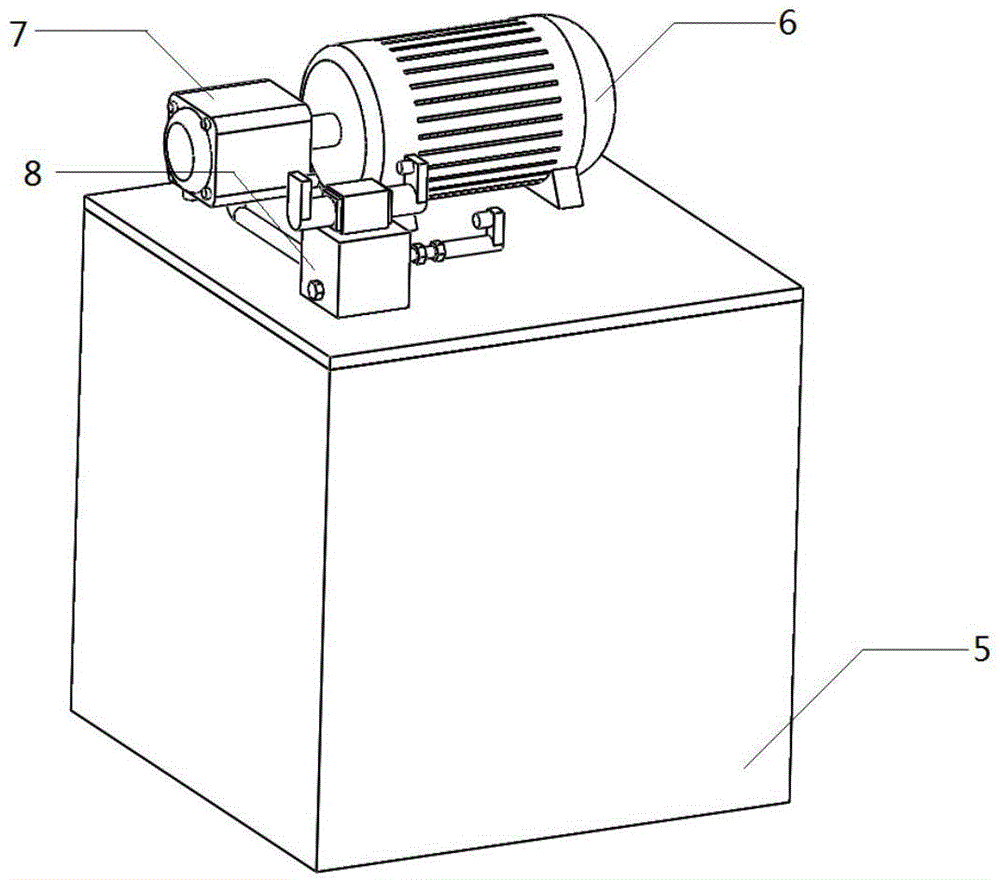

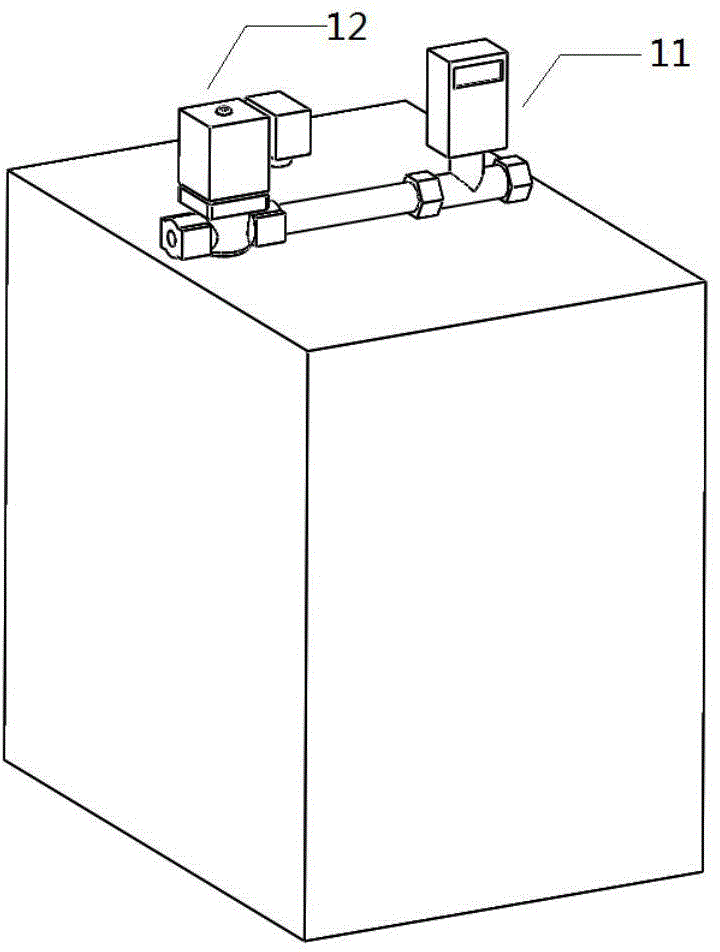

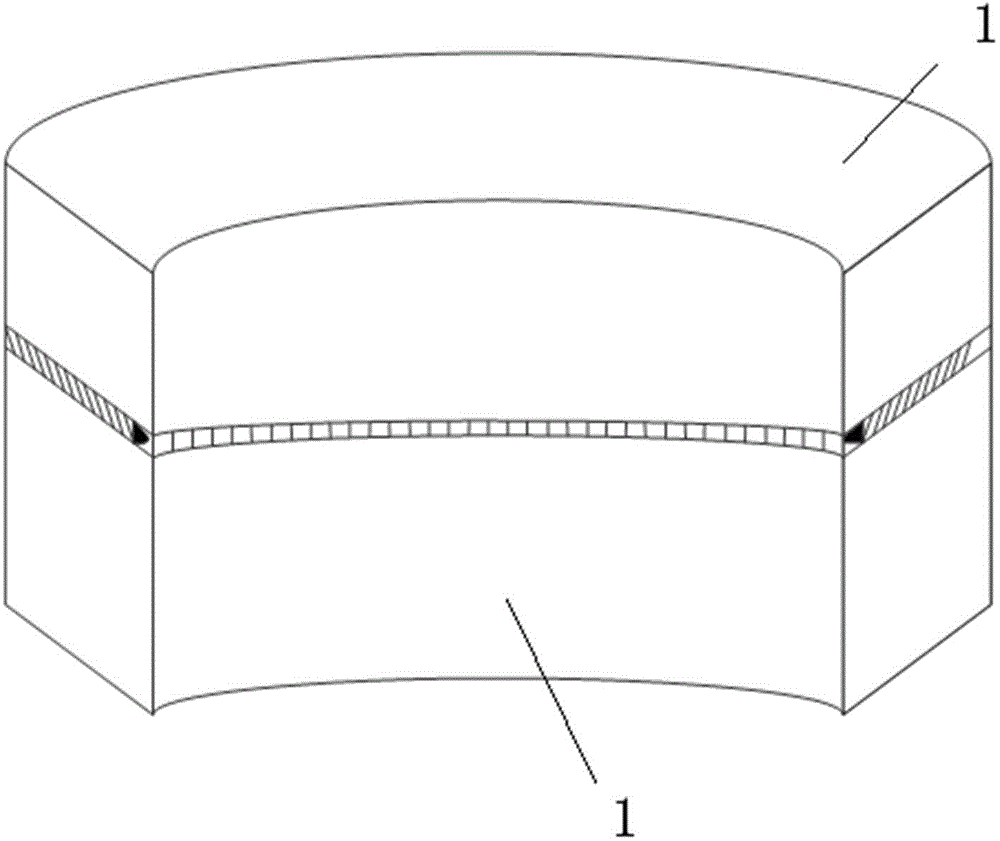

Physical modeling experiment system and method for oil deposit karst cave collapse and crack closure

ActiveCN104818983AEfficient deliveryReveal collapse damageBorehole/well accessoriesSolenoid valveKarst

The invention discloses a physical modeling experiment system and method for oil deposit karst cave collapse and crack closure. The physical model experiment system comprises three-dimensional geomechanics modeling experiment bed. A three-dimensional geological model is made through bedded-earth rolling in the three-dimensional geomechanics modeling experiment bed by adoption of materials similar to the model. A karst cave and a crack which are reserved for the model and fits with the dimension of a cave-crack internal pressure force-transmitting device are reserved in the three-dimensional geological model. The cave-crack internal pressure force-transmitting device is arranged in the karst cave and the crack reserved for the model and tightly close to the walls of the karst cave and the crack reserved for the model. The cave-crack internal pressure force-transmitting device is respectively connected with an oil-extraction decompression device and an oil-injection pressure device which are arranged outside the three-dimensional geomechanics modeling experiment bed through a high-pressure oil pipe. A man-machine interaction control system is respectively connected with a solenoid valve set, an intelligent sensor and a servo motor which are arranged in the oil-injection pressure device and a high-precision pressure sensor and a normally closed type solenoid valve which are arranged in the oil-extraction decompression device through a shielded wire. The invention further discloses an experiment method for the physical modeling experiment system.

Owner:SHANDONG UNIV

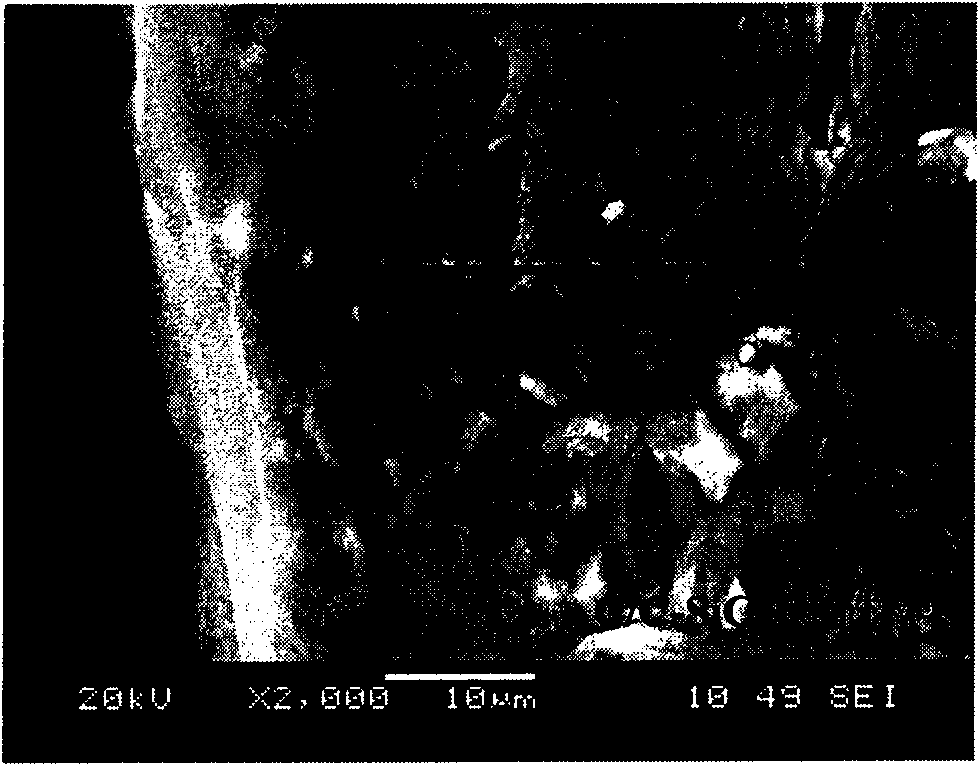

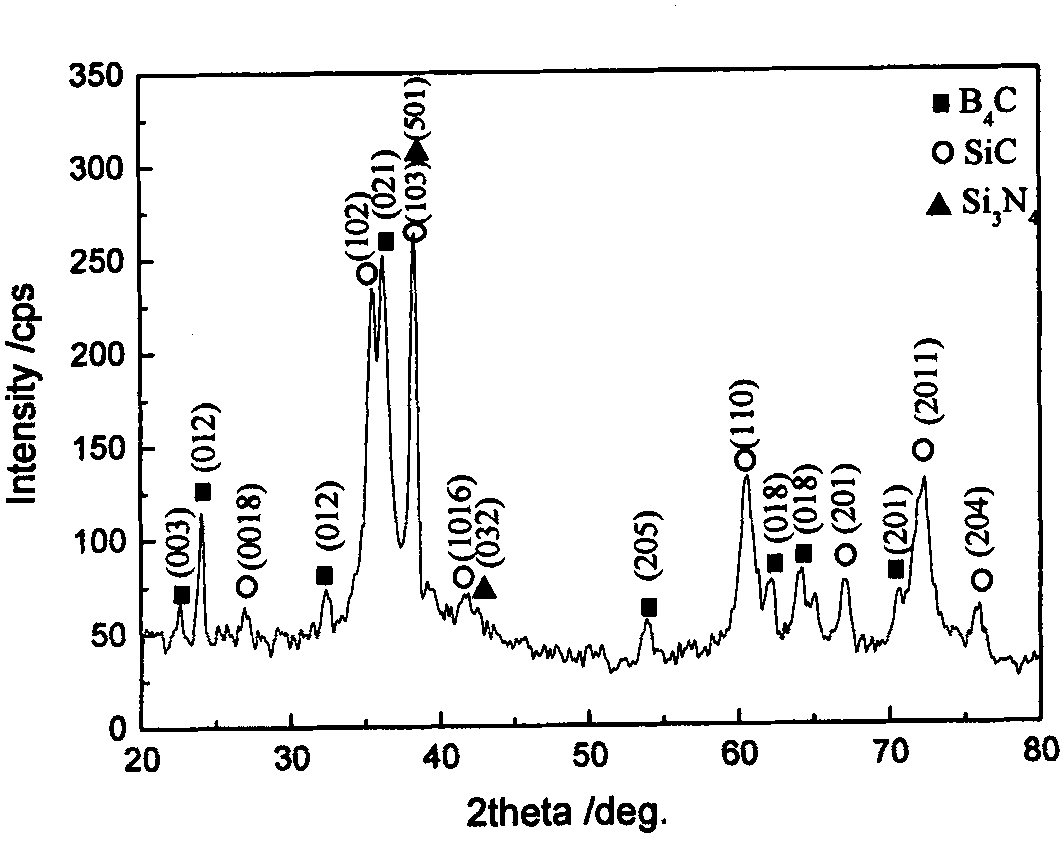

Method for preparing carbon/carbon-silicon carbide (C/C-SiC) composite self-sealing and anti-oxidation coating

InactiveCN101905979AOvercome the disadvantage of large difference in thermal expansion coefficientHigh bonding strengthCrack closureRoom temperature

The invention discloses an effective method for preparing a C / C-SiC composite self-sealing and anti-oxidation coating by conversion of a precursor, which belongs to the field of carbon material protection. A Si3N4 / SiC / B4C anti-oxidation coating with a certain self-sealing capability is prepared by taking active group-containing polysilazane precursor polymer as a raw material and adding a proper amount of B4C packing and by a coating-sintering process. The process comprises the following steps of: firstly, mixing polysilazane and the B4C powder in a certain proportion uniformly to prepare slurry, and coating the slurry on the surface of a C / C-SiC composite subjected to surface treatment; secondly, placing the C / C-SiC composite in a nitrogen furnace to perform crosslinking and curing at the temperature of between 200 and 300 DEG C for 1 to 2h; thirdly, heating at a speed of 5 DEG C / min till the temperature is 1,200 to 1,300 DEG C, keeping the temperature for 1 to 2h and then slowly cooling to room temperature; and finally, performing reinforcement treatment for 1 to 2 times to obtain the Si3N4 / SiC / B4C ceramic anti-oxidation coating with a uniform and compact surface. The method has the advantages of low preparation temperature, controllable product ingredient and structure, high performance and the like, has obvious advantages in aspects of crack closure, preparation cost reduction and the like and is an anti-oxidation coating preparation method with a great prospect.

Owner:JIAMUSI UNIVERSITY

Experimental device system for testing concrete crack self-healing ability

PendingCN107389906AHeight adjustableFlexible adjustment of experimental water pressure valueMaterial testing goodsSelf-healingCrack closure

The invention relates to an experimental device system for testing concrete crack self-healing ability, belonging to the field of water conservancy and civil engineering. The system can be used in the test fields of natural healing ability study of concrete, bionic self-healing study and self-healing ability study realized by adulterating special materials in a cement base. According to the experimental device system, the height of a water tank can be adjusted, and then the experimental water pressure value can be flexibly adjusted; the healing tests of multiple sets of test-pieces can be simultaneously conducted; the application of water pressure not only can be conducted from top to bottom but also can be conducted from bottom to top; the shapes of concrete test-pieces are not limited, and can be either square or cylindrical; by an observation window formed by a transparent material, the crack closure situation in the experimental process can be tracked and recorded in the whole course. According to the experimental device system, the crack self-healing ability of the concrete test-pieces can be studied from multiple angles, the structure is simple, and the operation is convenient.

Owner:POWERCHINA CHENGDU ENG

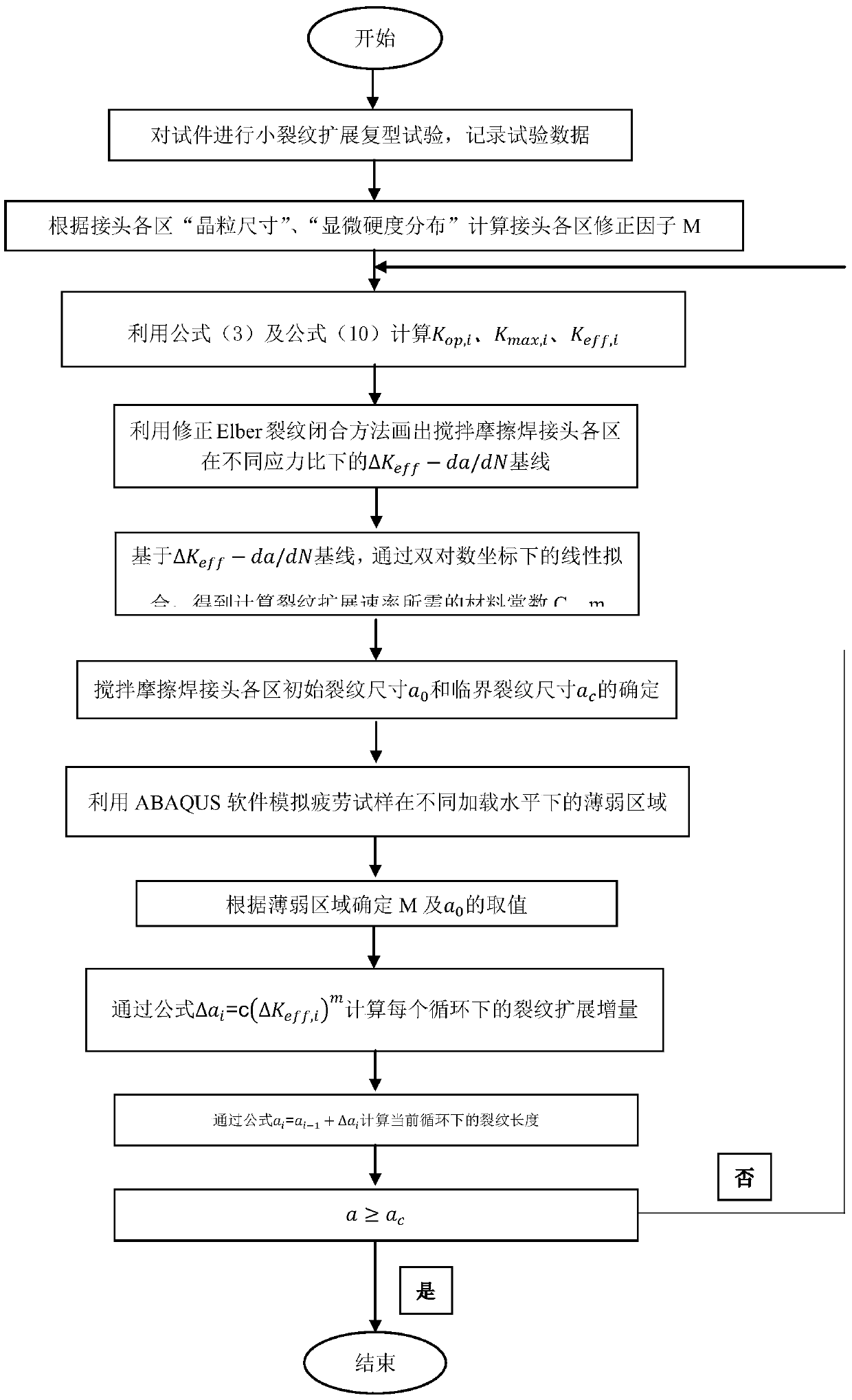

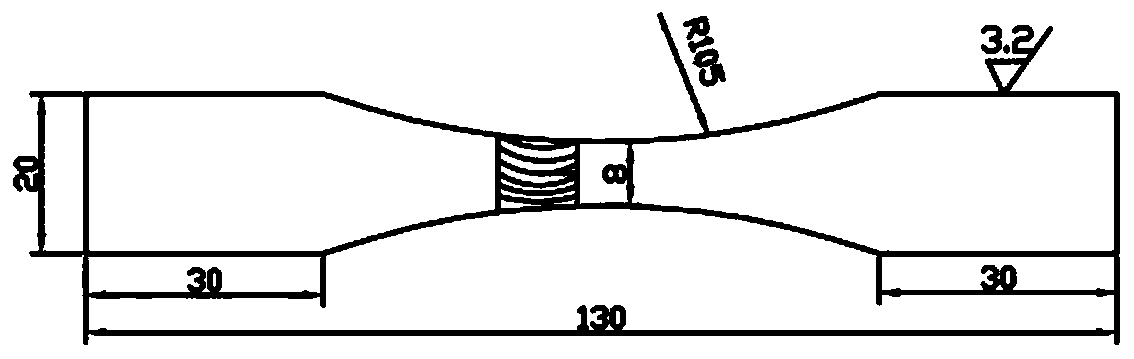

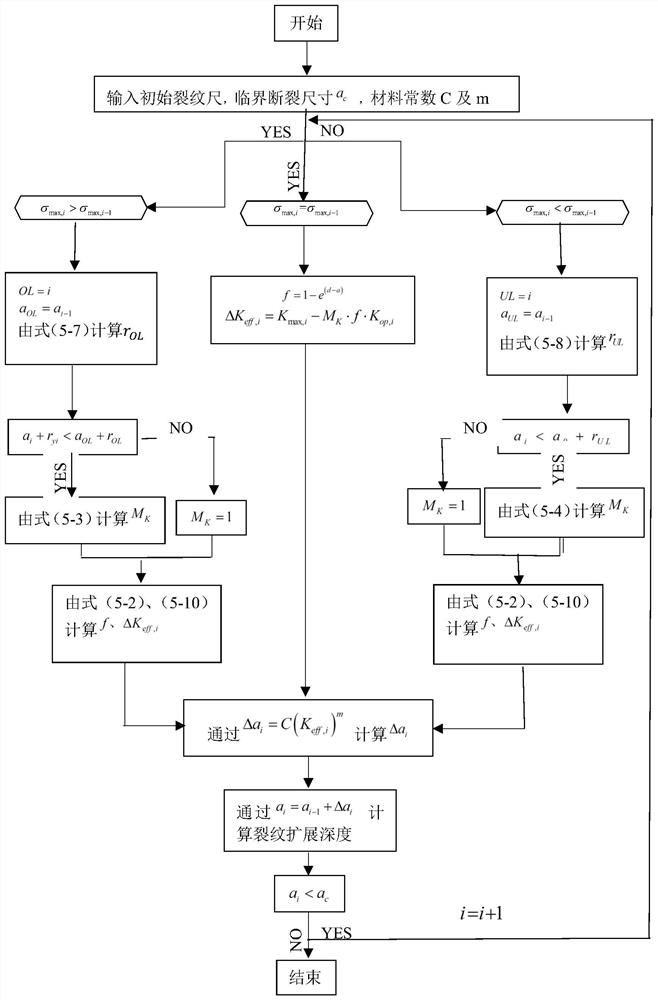

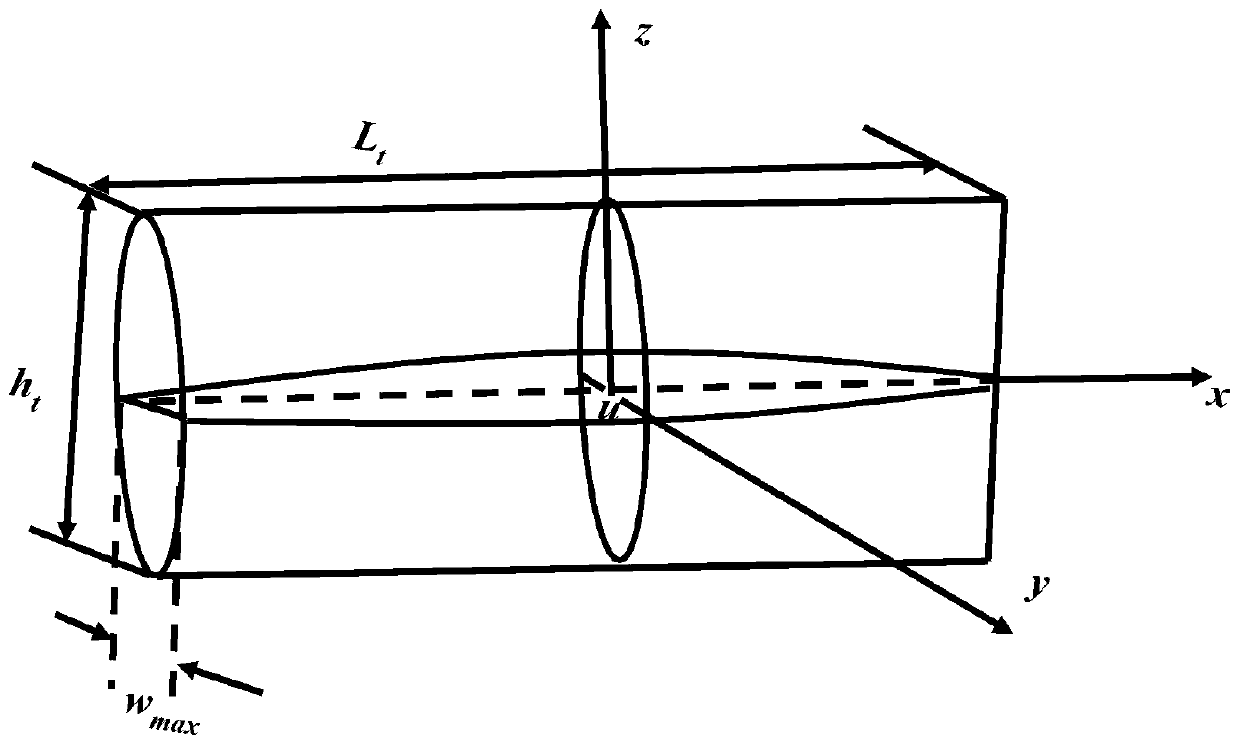

Method for predicting fatigue life of friction stir welding joint based on grain size and microhardness

The invention discloses a method for predicting the fatigue life of a friction stir welding joint based on grain size and microhardness, and belongs to the field of fatigue diagnosis and analysis. Themethod comprises the following steps: carrying out fatigue small crack propagation replication experiments on a sample under different loading levels to obtain crack propagation data of fractures indifferent areas of the friction stir welding joint; correcting an Elber crack closing method through the microcosmic performance of each area of the friction stir welding joint, further obtaining delta Keff-da / dN crack propagation rate baselines of fractures in different areas of the joint under different stress ratio conditions, and fitting correlation coefficients C and m; determining an initialcrack size a0 and a critical crack size ac; and simulating weak areas of the friction stir welding joint under different loading levels by utilizing ABAQUS, and selecting a correction factor M and aninitial crack size a0 according to the weak areas. Through continuous cyclic calculation, when the crack size reaches the critical crack size ac, it is regarded that the crack is broken, and the fatigue life of the friction stir welding joint under different loading levels is obtained.

Owner:BEIJING UNIV OF TECH

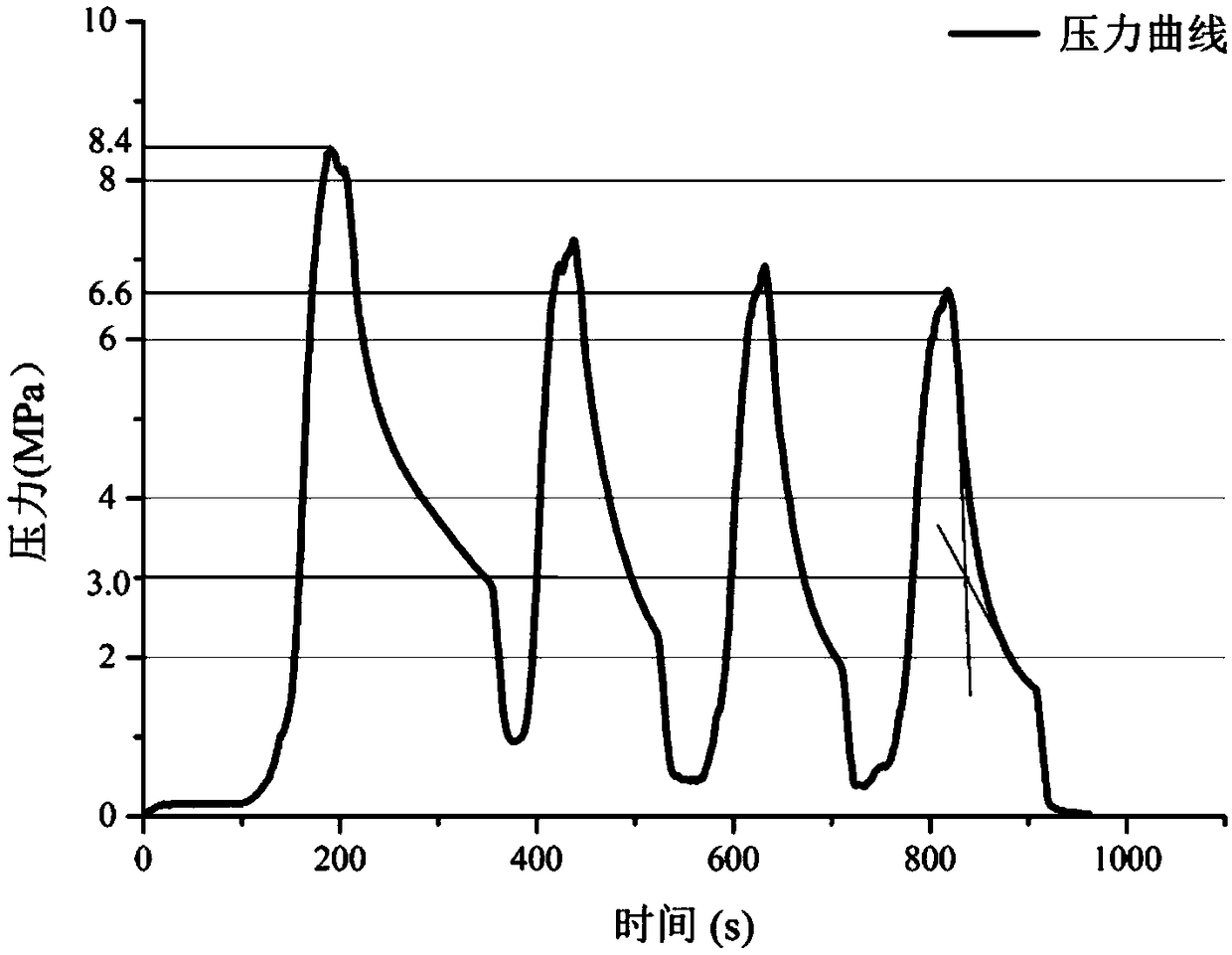

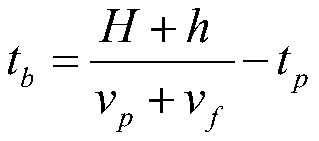

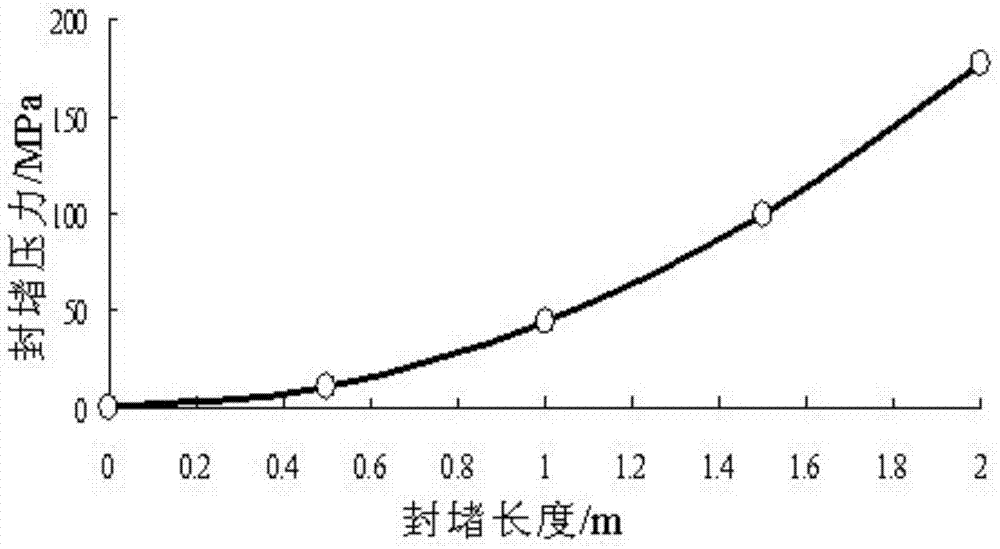

Method for testing crustal stress of coal rock mass by hydraulic fracturing

InactiveCN109357794ASimple structureFirmly connectedHydraulic/pneumatic force measurementCrack closureHydraulic fracturing

The invention relates to a method for testing a crustal stress of a coal rock mass by hydraulic fracturing, and belongs to the technical field of crustal stress measurement. The method solves the problems that an existing method for measuring the crustal stress is inconvenient in measurement and transportation, and the device is too complex. The method comprises the following steps: selecting a testing section of a core to be tested; connecting with a testing device, and performing leak detection testing on the testing device; sending a packer of the testing device to the testing section, connecting with a power source and a hydraulic medium of the testing device; pressurizing the packer to expand the packer; starting a pressure sensor to start monitoring the pressure in real time, and recording an initial water pressure of the testing section; pumping high-pressure liquid into the testing section to fracture the testing section; stopping pumping the high-pressure liquid until the crack generated by the fracturing of the testing section is closed; repeating S5 and S6 for at least three times, and recording the pressure of each testing section detected by the pressure sensor when fracturing; and calculating a crustal stress according to a stress relationship and a force relation when the crack is generated.

Owner:CHINA UNIV OF MINING & TECH

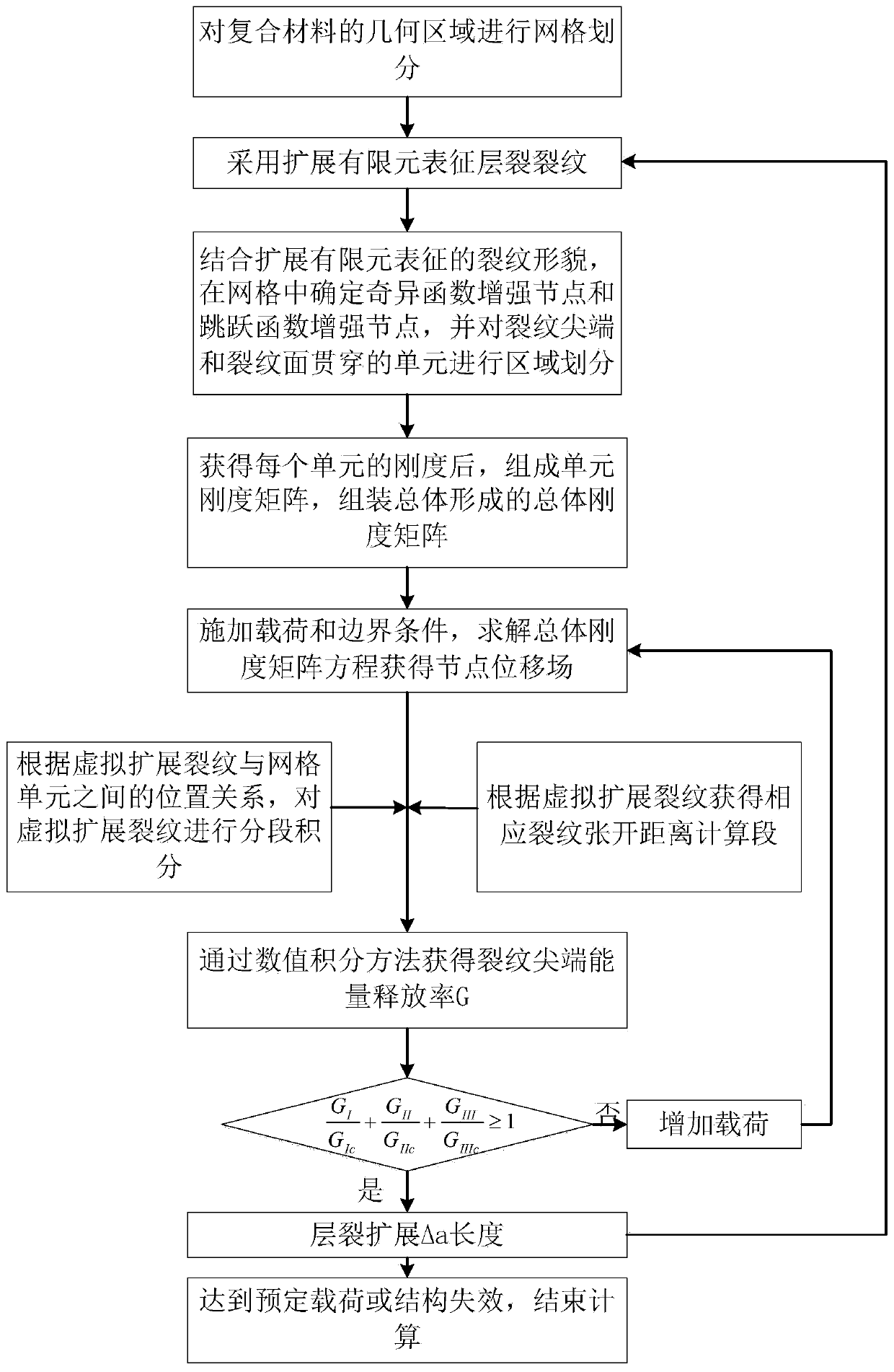

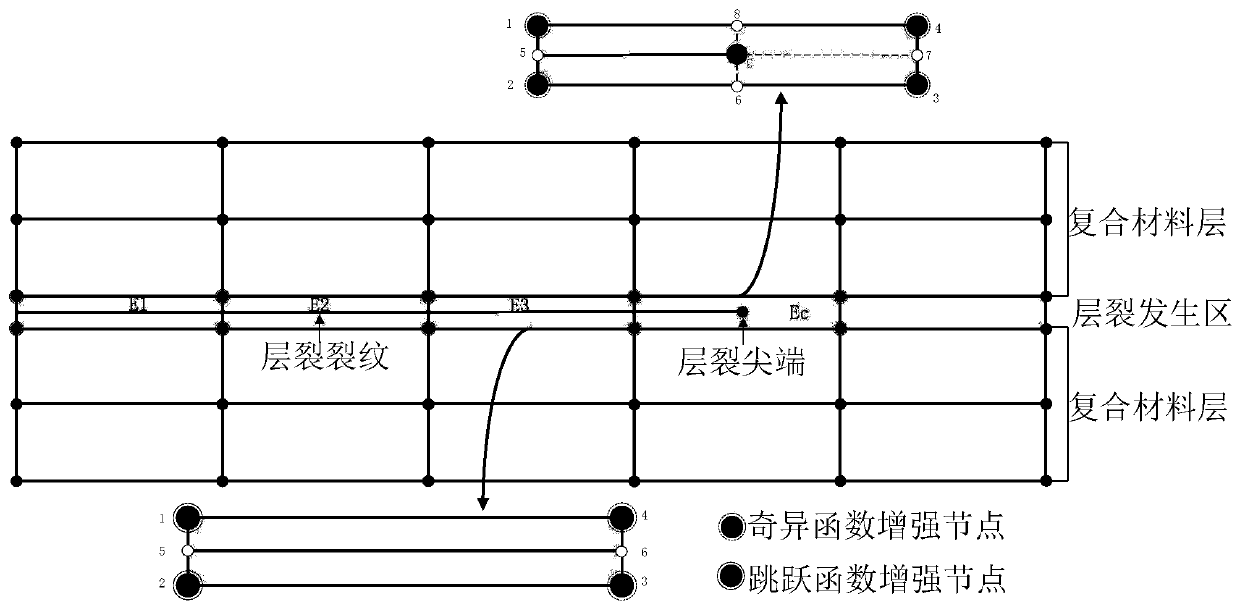

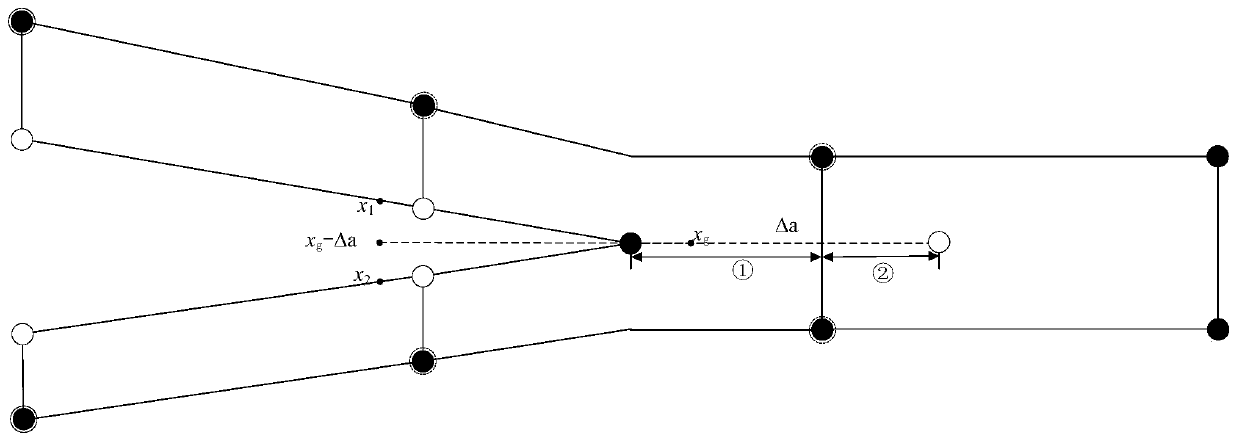

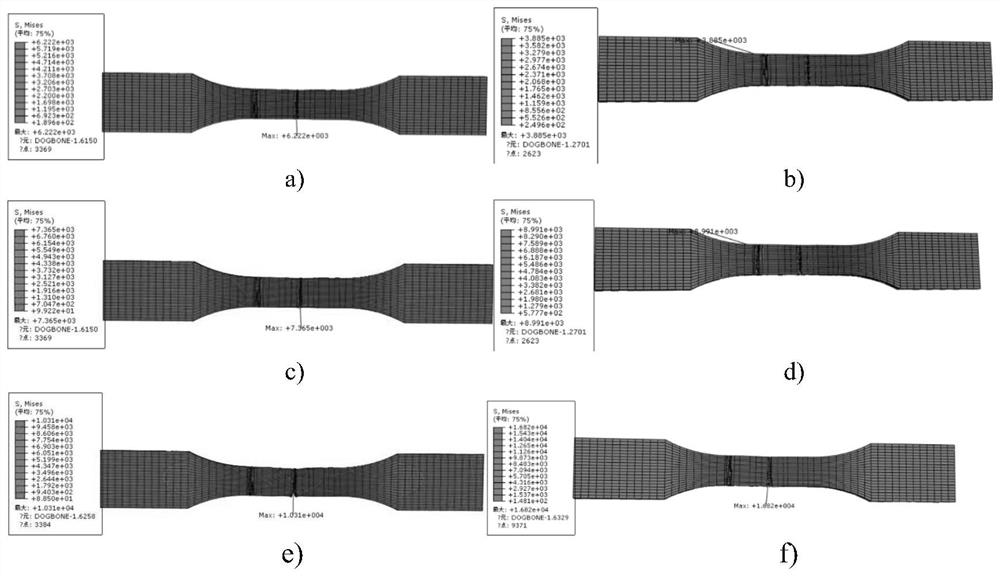

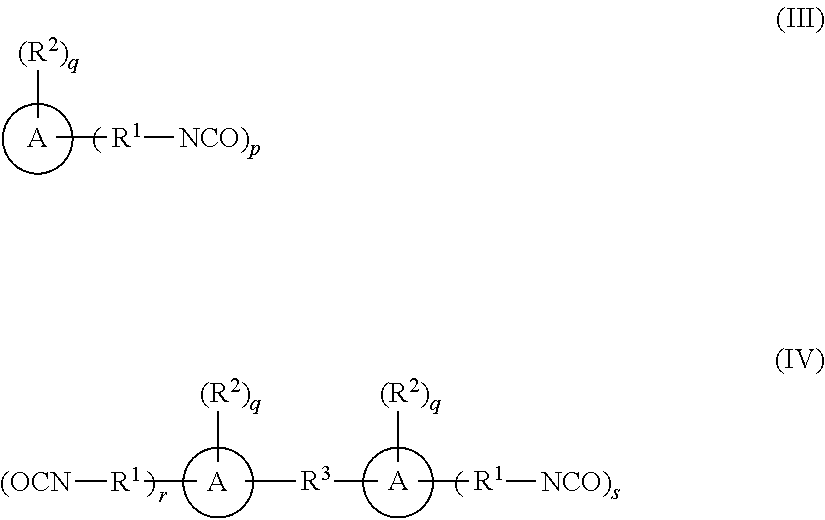

Two-dimensional calculation method for composite material layer cracking

ActiveCN110245376ASolve the problem of difficult calculation of release rateSolve computational difficultiesSustainable transportationDesign optimisation/simulationUnit sizeExtended finite element method

The invention discloses a two-dimensional calculation method for composite material layer cracking. The method comprises the following steps: S1, solving node displacement by adopting an extended finite element method; S2, based on the virtual crack closing technology, the energy release rate of the tip of the layer crack is obtained; S3, judging whether the layer cracks are expanded or not; and S4, when a predetermined load is reached or the structure fails, ending the calculation. The method has the advantages that the virtual crack closing technology and the expansion finite element method are combined, the expansion finite element is adopted for representing the layer crack, the unit boundary does not need to be matched with the crack shape when the grid is divided, and the grid does not need to be divided again when layer crack expansion is simulated; the requirement of layer cracking simulation on the unit size is reduced, and the calculation result is more accurate than that of a cohesion unit method; and when layer splitting expansion analysis is carried out, iteration is not needed, and the calculation efficiency is improved.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Method for predicting variable-amplitude fatigue life of friction stir welding component

The invention discloses a method for predicting variable-amplitude fatigue life of a friction stir welding component, and belongs to the technical field of fatigue diagnosis and analysis of mechanical components. The method includes: prefabricating micro-cracks in the weak area according to the loading sequence under the simulated variable-amplitude load, determining the change of the weak area through the variable-amplitude load, and simulating the crack propagation rule of the component under variable amplitude; carrying out different load fatigue small crack propagation interruption fatigue experiments, calculating the small crack propagation rate, and obtaining a crack propagation rule under variable amplitude; calculating corresponding correction factors MK and f, adding the correction factors MK and f on the basis of an effective stress intensity factor in an Elber crack closing method to obtain delta Keff-da / dN crack growth rate base lines of different areas under different stress ratios, and fitting material constants C and m; determining an initial crack size a0 and a critical crack size ac; and determining a weak area under the current load level, and selecting a correction factor MK, f and an initial crack size a0 according to the weak area. Through cyclic calculation, fatigue life under different loading levels is obtained.

Owner:BEIJING UNIV OF TECH

Proppant with enhanced interparticle bonding

ActiveUS10100247B2Improve bindingMaintain conductivityLayered productsFluid removalCrack closureCoupling

Polymer-coated proppants for hydraulic fracturing of oil and gas wells have an outer layer portion that comprises an organofunctional coupling agent, preferably an organofunctional silane coupling agent. The use of an organofunctional silane coupling agent in the outer layer portion of the proppant coating is preferably chosen to expose functionalities that will be reactive towards similar functionalities of adjacent and similarly coated proppants so that, when introduced downhole, these proppants form interparticle bonds at the temperatures and crack closure pressures found downhole in fractured strata. Such enhanced interparticle bonding helps keep the proppant in the fracture and maintains conductivity with reduced flowback. The invention also helps proppants designed for low temperature well to bond more firmly and allows proppants designed for high temperature wells to bond well even at lower downhole temperatures, thereby extending their useful range.

Owner:PREFERRED TECH

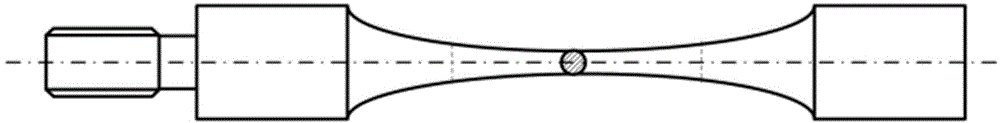

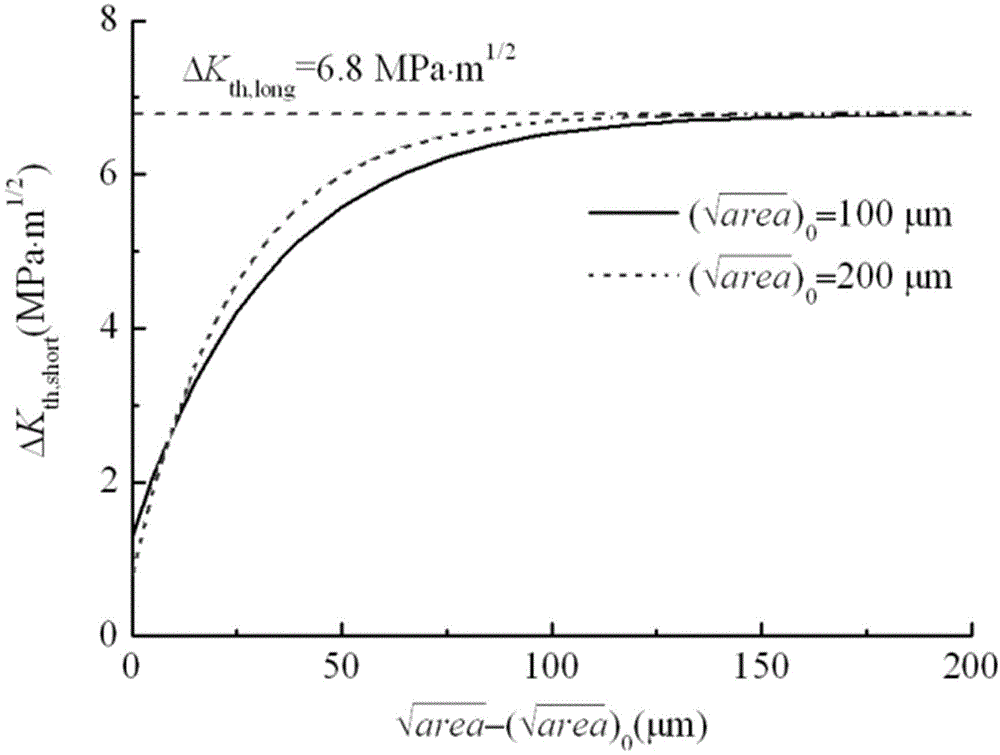

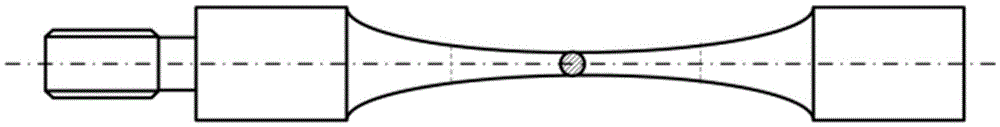

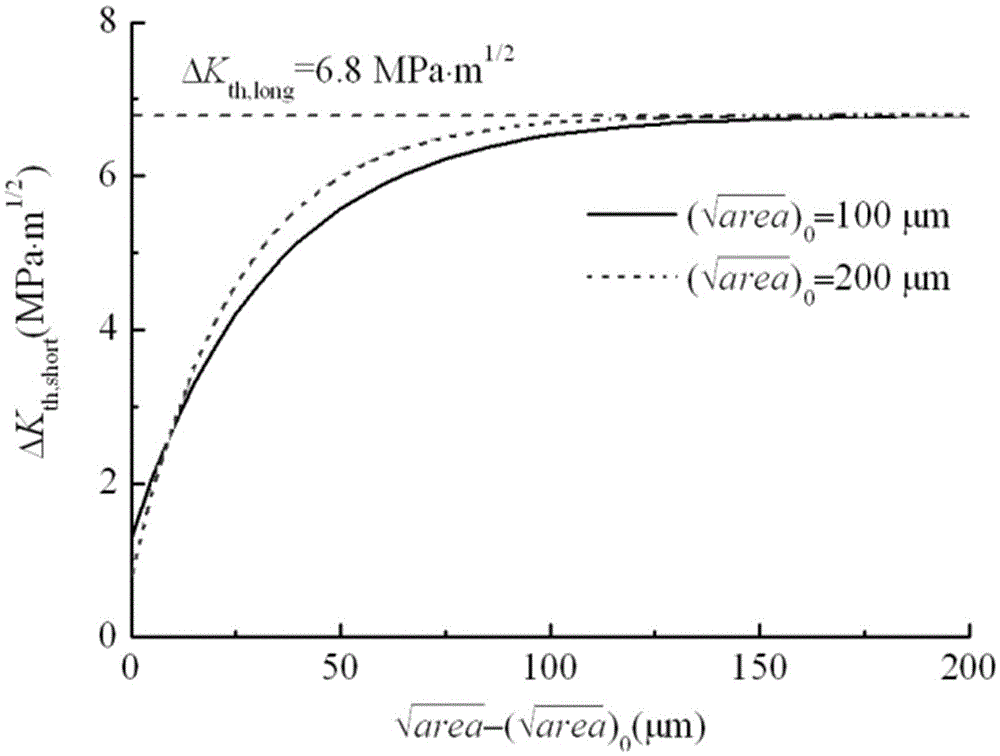

Welding defect evaluation method of steam turbine rotor

ActiveCN103954688AThe method is clearCalculation is simple and fastAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDefect sizeCrack closure

The invention belongs to the field of steam turbine rotor welding manufacturing and discloses a welding defect evaluation method of a steam turbine rotor. The welding defect evaluation method comprises the following steps: the first step, adopting ultrasound accelerated fatigue tests on rotors of different batches with different welding processes to respectively obtain the maximum defect size of the structures of the rotors of different batches to be used as the initial defect size; the second step, respectively measuring a fatigue threshold value and estimating material intrinsic threshold value of the rotor of each batch under conditions of a plurality of stress ratios; the third step, obtaining a computational formula of the fatigue threshold value of the rotor of each batch; the fourth step, expanding two batches of welding initial defect sizes to certain specific sizes and determining merits of the welding process by virtue of comparison of the fatigue threshold value. By utilizing the welding defect evaluation method, welding defect type and distributed information are obtained by adopting very high cycle fatigue tests, defects are treated as cracks, and the welding defect is evaluated and the welding process is optimized by applying the relationship of short crack closure, fatigue threshold value and crack length.

Owner:EAST CHINA UNIV OF SCI & TECH +1

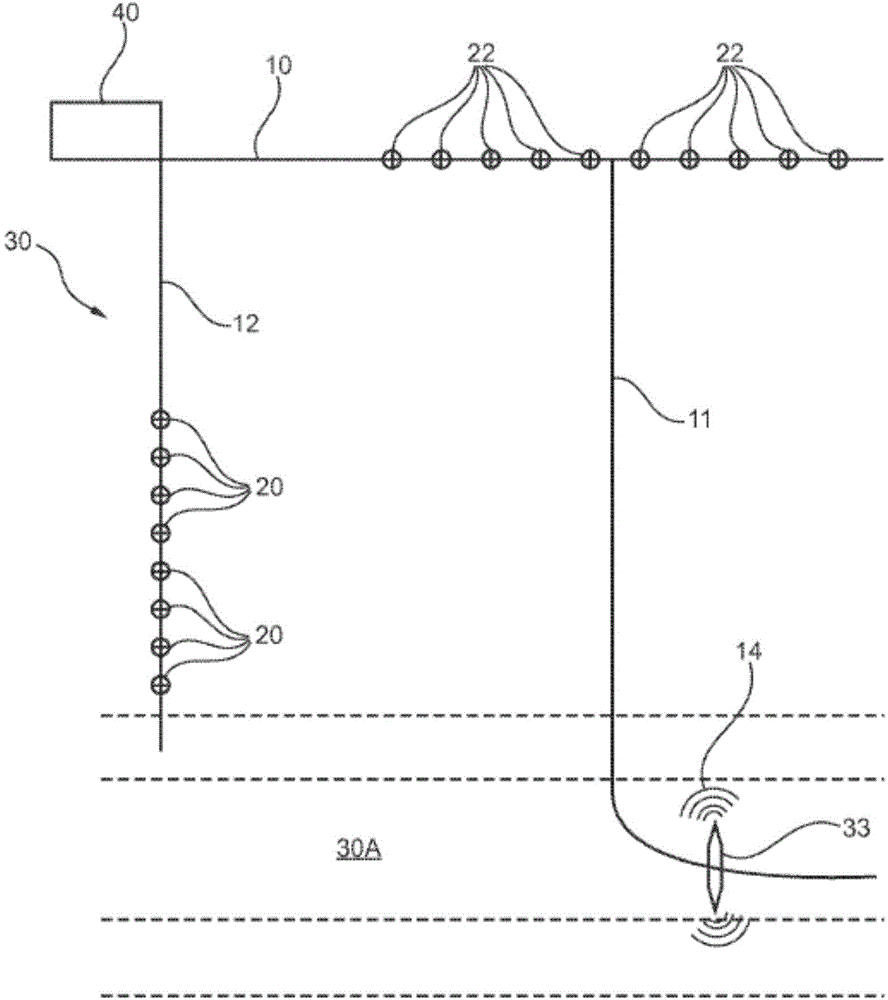

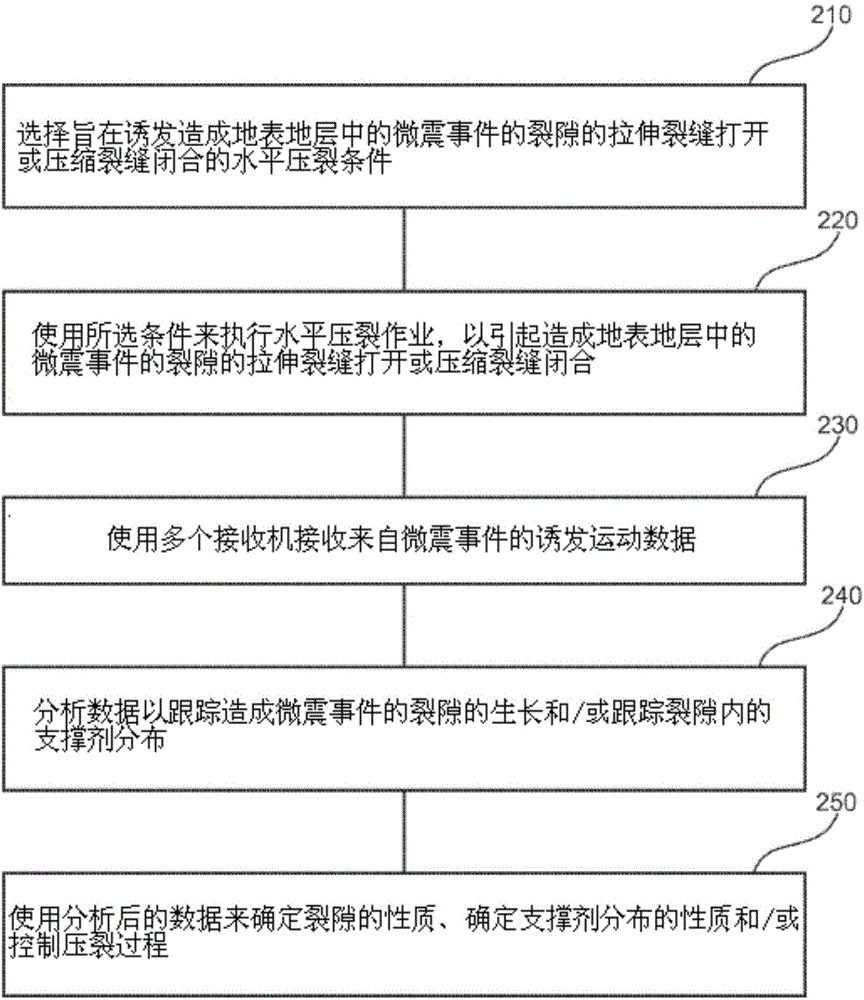

Fracture monitoring and characterisation

Hydraulic fracturing conditions intended to induce tensile crack opening or compressional crack closure of a fracture responsible for a microseismic event in the Earth formation are selected 210 and a hydraulic fracturing operation is performed using the selected conditions to cause tensile crack opening or compressional crack closure of the fracture responsible for a microseismic event in the Earth formation 220. Induced motion data from the microseismic event is received 230 using a plurality of receivers, and the received data is analysed 250 to track the development of the fracture responsible for the microseismic event and / or to track a proppant distribution within the fracture. Another aspect relates to characterising fracture networks wherein the microseismic event is represented in the model that relates induced motion to the event by a moment tensor that only has two types of component and wherein the two types of component are double couple components and tensile or compressional crack components.

Owner:PRAD RES & DEV LTD

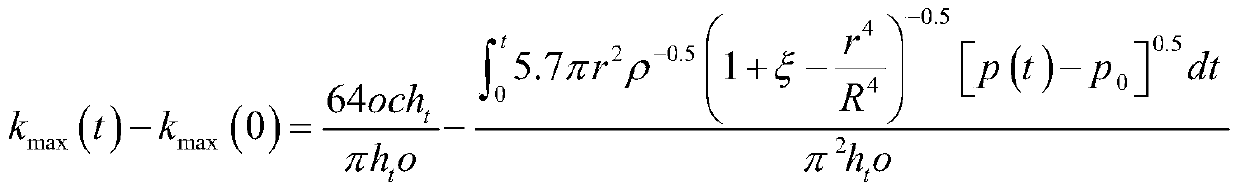

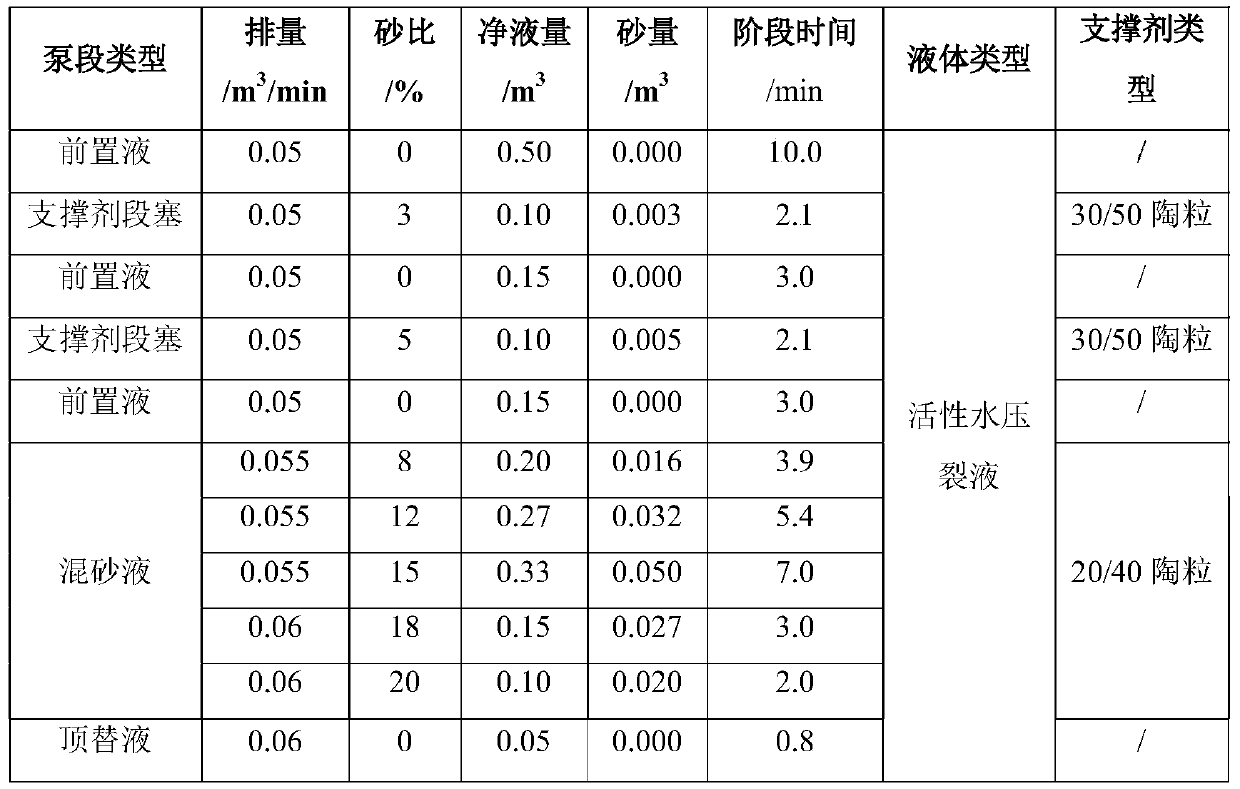

Precise proppant placing method aiming at natural fracture development gas pool hydrofracture

ActiveCN110984947ALarge particle sizeImprove laying efficiencyFluid removalFluid migrationWell logging

The invention discloses a precise proppant placing method aiming at natural fracture development gas pool hydrofracture. Geological parameters and physical property parameters of a reservoir stratum are obtained according to certain single well logging interpretation, and the density of a proppant and the density of fracturing fluid are determined according to the stratum crack closure pressure ofthe reservoir stratum; the resistance to the proppant in the fluid migration process is determined according to the Reynolds number; the sedimentation height of the proppant in a crack is calculatedaccording to the crack closing time obtained after pumping is stopped and the migration speed of the proppant during flowing back; the weight of the crack formed by fracturing this time is calculatedaccording to the sedimentation height of the proppant in the crack; the sand-carrying fluid pumping time is calculated according to the target well perforation thickness and the sedimentation height of the proppant in the crack in combination with the crack closing time obtained after pumping is stopped; and finally, the proppant is laid according to the obtained fracturing construction parameters. According to the precise proppant placing method, the proppant is precisely conveyed to a fracturing transforming layer section developed by the natural fracture, the laying efficiency of the proppant is effectively improved, and the capacity increasing revamping effect is improved.

Owner:SOUTHWEST PETROLEUM UNIV

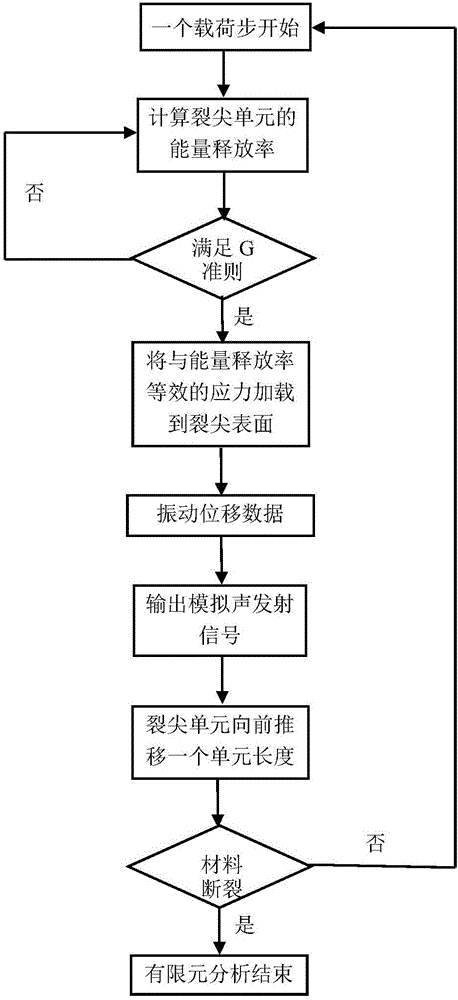

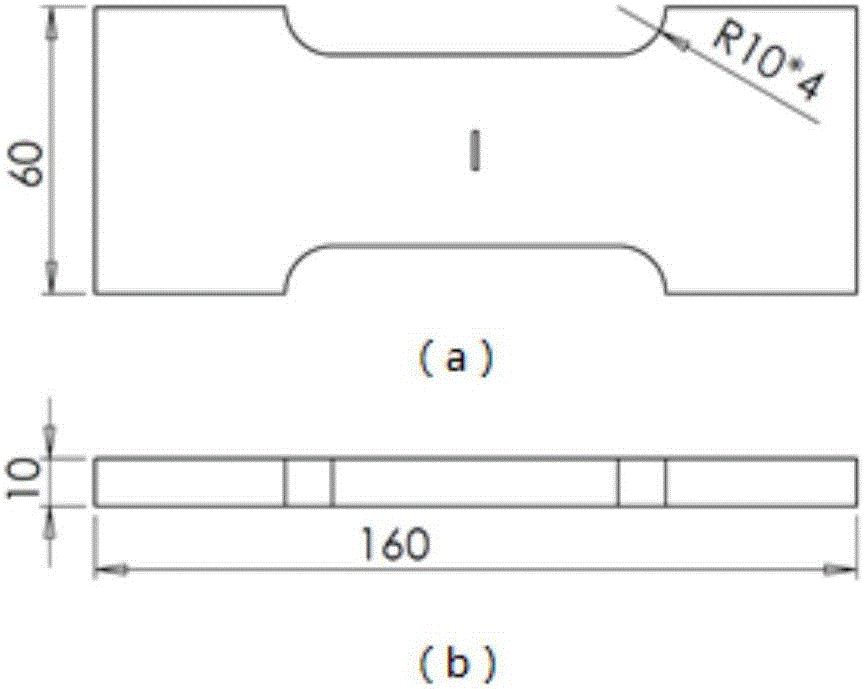

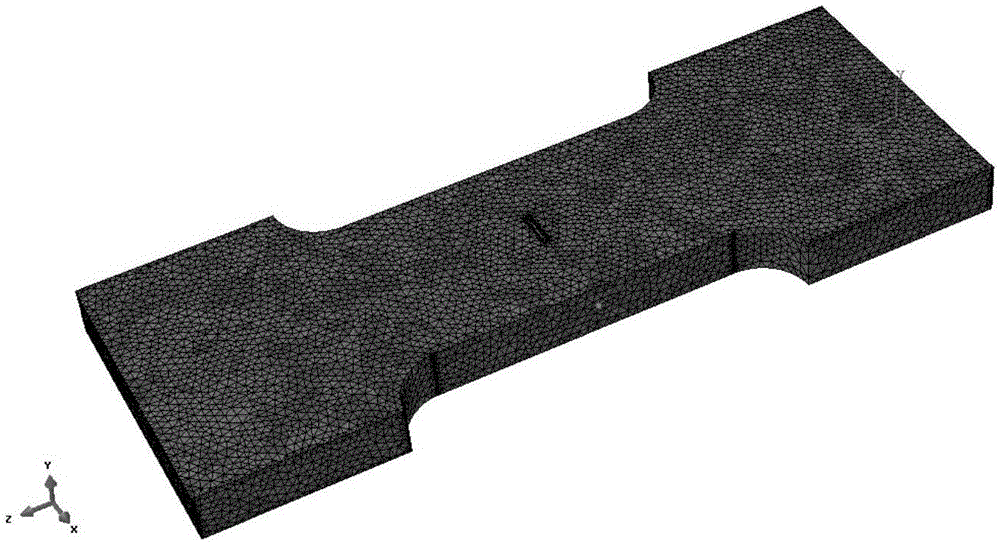

Virtual crack close method based analog acoustic emission signal acquisition method

InactiveCN106844941APrevent discreteHas a degree of integrationDesign optimisation/simulationSpecial data processing applicationsElement modelCrack closure

The invention discloses a virtual crack close method based analog acoustic emission signal acquisition method. The method includes: analyzing a transfer function and a basic detection principle of an acoustic emission detection system to obtain a finite element analysis based metal component fatigue crack acoustic emission signal amplitude expression on the basis of an elastic wave propagation theory; on the basis of a virtual crack close method theory, a user unit subprogram function of ABAQUS software is adopted for developing an acoustic emission fatigue unit which can be used for acquiring fatigue crack analog acoustic emission signals of metal components; establishing a finite element model of the metal components in ABAQUS, and adopting the virtual crack close method based acoustic emission fatigue unit for acquiring the fatigue crack analog acoustic emission signals of the metal components under specific load action. The method has advantages that problems of long period, complex test steps and high cost in acquisition of the fatigue crack acoustic emission signals of the metal components through fatigue acoustic emission detection test are solved, and influences caused by different operation environment temperatures and impact loads are avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A visual fracture device and working method for simulating fracture closure and fluid loss

InactiveCN108680339BPerfect filtration functionSimple structureHydrodynamic testingFiltrationCrack closure

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A method for judging the threshold value of rock crack stress based on full-field strain measurement

ActiveCN110658067BEasy to handleThe surrounding test environment requirements are lowPreparing sample for investigationMaterial strength using tensile/compressive forcesFull field strainCrack closure

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

A Failure Analysis Method for Composite Structures Based on Continuum Damage Mechanics Degradation Model

InactiveCN103592175BComputing performanceAccurate calculationStrength propertiesMatrix damageFiber-reinforced composite

The invention relates to a composite material structure failure analysis method based on a continuum damage mechanics degradation model. According to the method, a three-dimensional continuum damage mechanics degradation model of a unidirectional fiber enhanced composite material is constructed, two types of damage forms such as fiber cracks and matrix cracks and the orientation of damages are considered, and meanwhile, the crack closure effect caused by coupling of the fiber damage and the matrix damage and reverse loading of load in a fiber stretching and compressing damage process is considered; three damage variables are respectively used for representing the fiber crack damage and two mutually-perpendicular matrix crack damages respectively, so that the continuum damage mechanics degradation model for failure analysis of a composite material structure is obtained. Compared with the conventional anti-climax degradation model, the continuum damage mechanics degradation model has the advantages that the behavior characteristics of the damaged composite material under different load states are considered, and the performance of the damaged material can be accurately represented; the composite material structure failure analysis method is suitable for simulation of a composite material structure damage process and forecasting of the intensity under a condition that the load state and a constraint situation are more complicated.

Owner:BEIHANG UNIV

Evaluation Method for Welding Defects of Steam Turbine Rotor

ActiveCN103954688BThe method is clearCalculation is simple and fastAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDefect sizeCrack closure

The invention belongs to the field of steam turbine rotor welding manufacturing and discloses a welding defect evaluation method of a steam turbine rotor. The welding defect evaluation method comprises the following steps: the first step, adopting ultrasound accelerated fatigue tests on rotors of different batches with different welding processes to respectively obtain the maximum defect size of the structures of the rotors of different batches to be used as the initial defect size; the second step, respectively measuring a fatigue threshold value and estimating material intrinsic threshold value of the rotor of each batch under conditions of a plurality of stress ratios; the third step, obtaining a computational formula of the fatigue threshold value of the rotor of each batch; the fourth step, expanding two batches of welding initial defect sizes to certain specific sizes and determining merits of the welding process by virtue of comparison of the fatigue threshold value. By utilizing the welding defect evaluation method, welding defect type and distributed information are obtained by adopting very high cycle fatigue tests, defects are treated as cracks, and the welding defect is evaluated and the welding process is optimized by applying the relationship of short crack closure, fatigue threshold value and crack length.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com