Virtual crack close method based analog acoustic emission signal acquisition method

A technology of transmitting signals and simulating sound, which is applied in the field of obtaining simulated acoustic emission signals of fatigue crack propagation of metal components, which can solve the problems of cumbersome test steps, high cost, and long cycle of fatigue crack acoustic emission signals, and achieve the effect of highly integrated characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

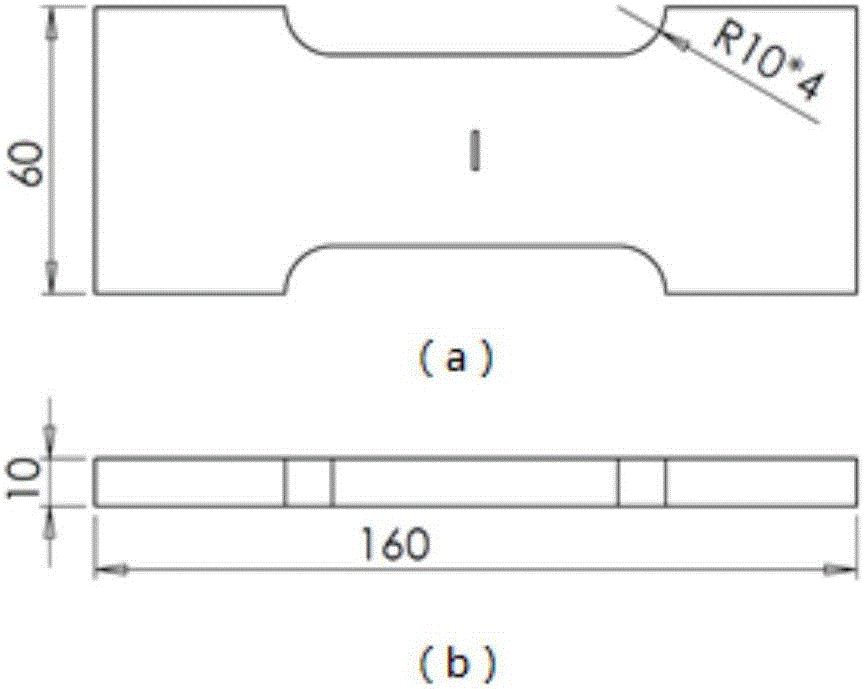

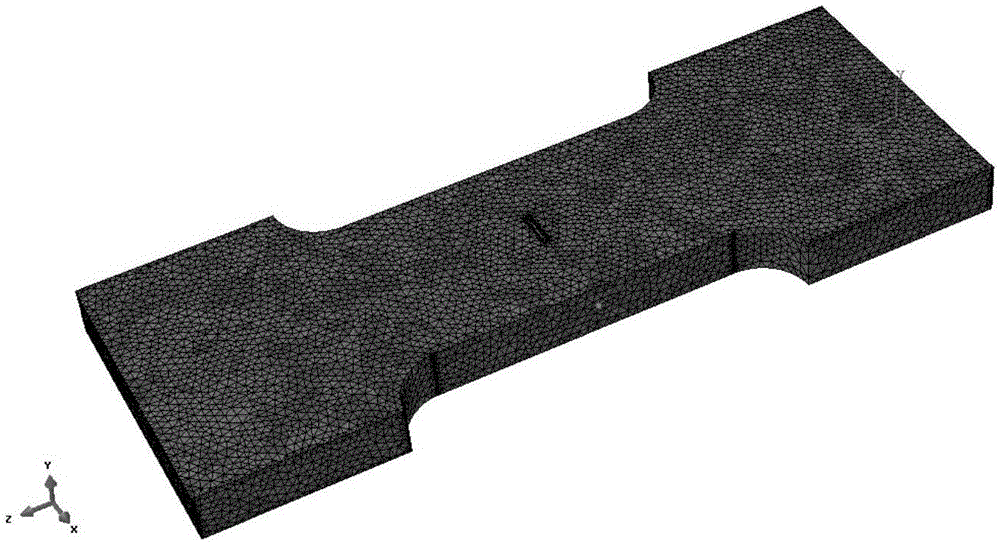

[0041] The present invention will be described in detail below with reference to the drawings and specific implementation examples.

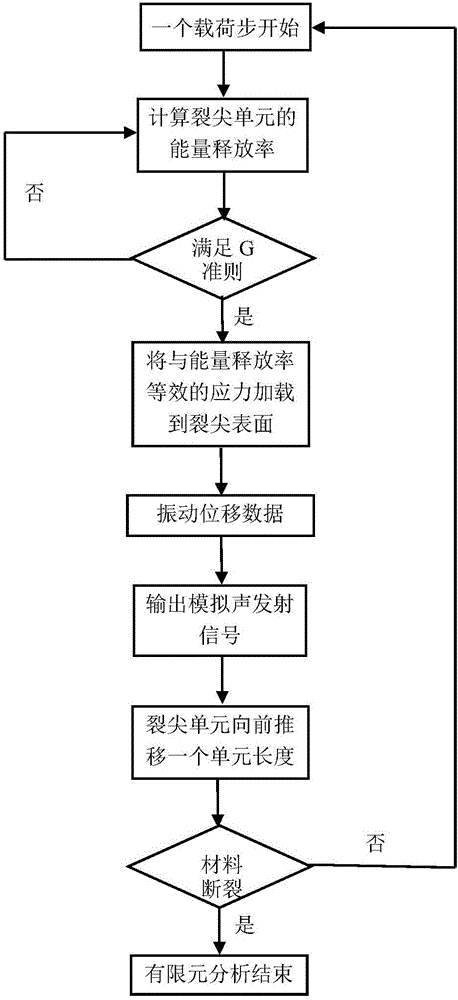

[0042] A method for obtaining simulated acoustic emission signals based on the virtual crack closure method, including the following steps:

[0043] (1) Establish the amplitude expression of acoustic emission signal based on finite element analysis

[0044] The transfer function of the acoustic emission detection system and its basic detection principles are analyzed. Based on the transfer function theory, the output voltage amplitude of the acoustic emission sensor can be obtained after Laplace transform of the output signal:

[0045]

[0046] In the formula: s is the contact area between the acoustic emission sensor and the detected structure, in m 2 ; U (x, y, z) is the displacement of the detected contact surface, in m; K is the acoustic emission sensor gain; g (x, y) is the surface sensitivity of the acoustic emission sensor.

[0047] Acoustic emissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com